This book is an integral and essen-

After un packing, make sure the

CAUTION: RISK OF POLLUTION.

Before connecting the appliance

system. For the electrical safety of the

appliance, it is necessary to equip the

system with the proper grounding. This must

be carried out by a qualified electrician who

must ensure that the electric power of the

system is sufficient to absorb the maximum

power input stated on the plate.

In particular that the size of the wiring cables

is sufficient to absorb power input.

The use of adapters, multiple sockets or

extensions is strictly forbidden. If they prove

necessary, call a fully qualified electrician.

The machine must be installed

according to the local standards in force with

regard to plumbing systems. For this reason, the plumbing connections must be carried out by a qualified technician.

This appliance must only be used

as described in this handbook. The manufacturer shall not be liable for any damage

caused due to improper, incorrect and

unreasonable use.

The following basic rules must be

observed when using any electric appliance:

- do not touch the appliance when hands or

feet are wet;

CAUTION: RISK OF ELECTRIC SHOCK.

- do not use the appliance when barefoot;

- do not use extensions in bath or shower

rooms

- do not pull the supply cord out of the

socket to disconnect it from the mains

- do not leave the appliance exposed to

atmospheric agents (rain, sun, etc.) unless

expressly provided for rain;

- do not let the appliance be used by children, unauthorised staff or staff who have

not read and fully understood the contents

of this handbook.

E N G L I S H

Before servicing the appliance, the

To clean the appliance, set the

If the appliance breaks down or

For installation, the qualified electri-

To avoid dangerous overheating,

Do not obstruct the extraction

The user must not replace the

appliance supply cord. If the cord is damaged, switch off the appliance and have a

qualified technician change the cord.

If no longer using the appliance, we

recommend making it inoperative, after

removing the plug from the mains electricity,

cut the power supply cable.

CAUTION: RISK OF POLLUTION.

Do not dispose of the machine in the environment. To dispose of the machine, use an

authorised centre, or contact the manufacturer for relative information.

To ensure that the machine is properly

ventilated, place it with the ventilation side at a

distance of 15 cm from walls or other.

Once a machine wash cycle has been

started, do not interrupt it, as detergent residues

may then be left inside the delivery group.

CAUTION: RISK OF INTOXICATION.

Use the steam nozzle with care and never

place hands below the jet of steam. Do not touch

the nozzle immediately after use.

CAUTION: RISK OF BURNS OR SCALDING.

We remind you that before carrying out

any installation, maintenance, unloading or adjustment operations, the qualified operator must put on

work gloves and protective footwear.

When adding coffee beans, the machine

operator must not place his/her hands inside the

container.

CAUTION: RISK OF CUTTING.

Congratulations,

upon the wise choice you have made by purchasing the MASTER model.

In fact, you are now the owner of not just a simple coffee dispenser, but a true espresso coffee-making machine which is fully automatic and

completely controlled by a microprocessor. This means absolute reliability and simple to use.

We are certain that our MASTER model will increase your confidence in Nuova Simonelli and that you will undoubtedly recommend others to

purchase the MASTER model, since the MASTER model has been chosen to increase the profitability of the coffee shop, thus fully optimising running costs.

This machine has been manufactured in compliance with the EEC directives 89/392, 89/336, 73/23, 89/109 and subsequent modifications.

With best wishes

Nuova Simonelli s.r.l.

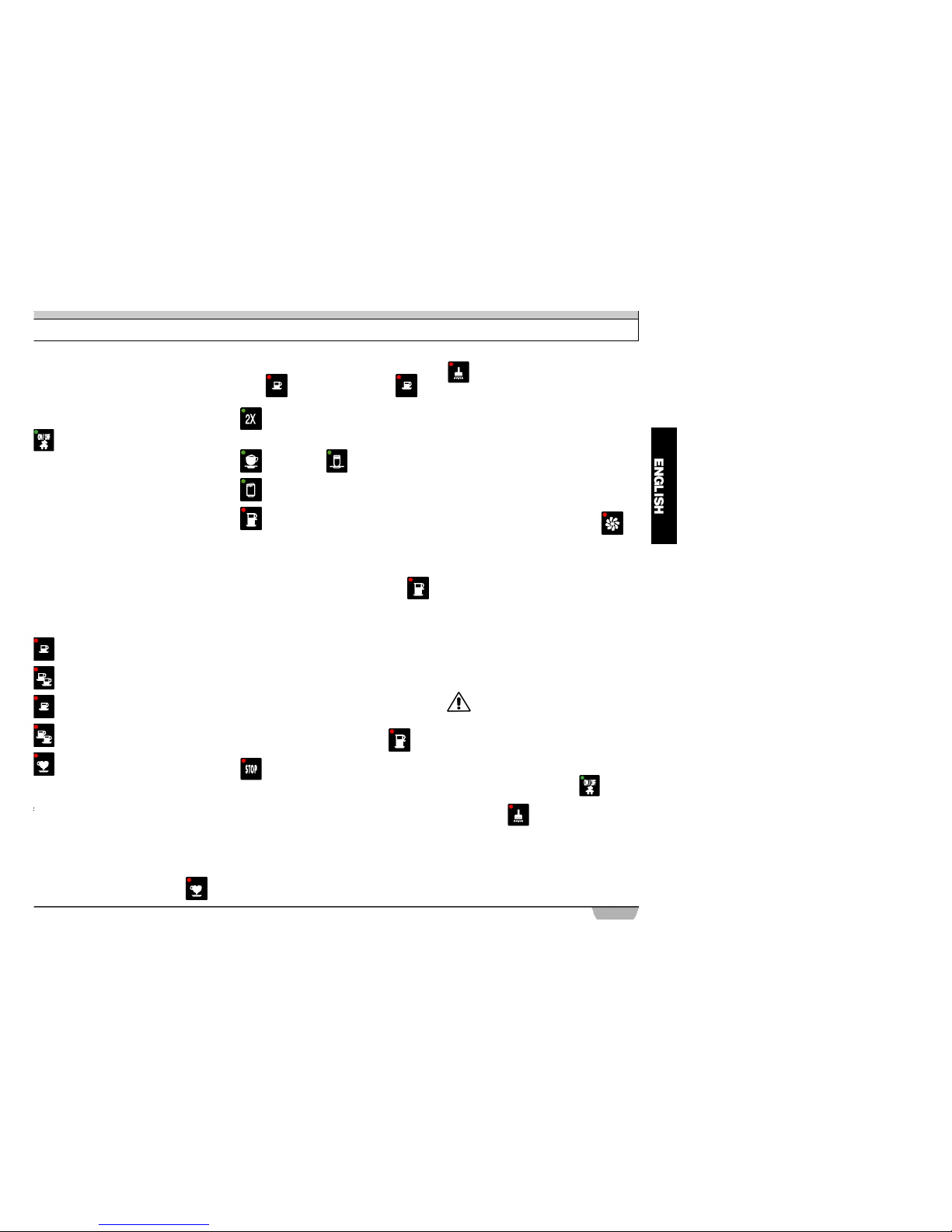

SERIE

SERIES

MASTER COFFEE

CUP WARMER

MASTER CAPPUCCINO

MASTER COFFEE SERVICE

MASTER CAPPUCCINO SERVICE

PESO LORDO

GROSS WEIGHT

PESO NETTO

NET WEIGHT

55 Kg. 120 Lb.

75 Kg. 165 Lb.

55 Kg. 120 Lb.

75 Kg. 165 Lb.

20 Kg. 44 Lb.

60 Kg. 132 Lb.

90 Kg. 198 Lb.

60 Kg. 132 Lb.

90 Kg. 198 Lb.

22 Kg. 48 Lb.

2400 W.

2600 W.

2400 W.

2600 W.

230 W.

Lt. 3,5 1 GA L.

Lt. 3,5 1 GA L.

Lt. 3,5 1 GA L.

Lt. 3,5 1 GA L.

420 16,5”

680 26,8”

420 16,5”

680 26,8”

300 11 , 8 ”

320 12,6”

575 22,6”

320 12,6”

575 22,6”

200 7,9”

700 27,5”

700 27,5”

700 27,5”

700 27,5”

640 25,2”

400 15,8”

400 15,8”

400 15,8”

400 15,8”

400 15,8”

510 20,0”

510 20,0”

510 20,0”

510 20,0”

510 20,0”

P O T. TERMICA

EL. POWER

CAP. CALDAIA

BOILER CAP.

A B C D E

DIMENSIONI / DIMENSION mm

TRANSPORT AND HANDLING

The machine is transported on pallets

which also contain other machines - all

boxed and secured to the pallet with supports.

Prior to carrying out any transport or

handling operation, the operator must:

- put on work gloves and protective

f o o t w e a r, as well as a set of overalls

which must be elasticated at the wrists

and ankles.

The pallet must be transported using a

suitable means for lifting (e.g., forklift).

CAUTION: RISK OF IMPACT

OR CRASHING.

During all handling operations, the operator must ensure that there are no persons,

objects or property in the handling area.

The pallet must be slowly raised to a height of 30 cm and moved to the loading

area. After first ensuring that there are no

persons, objects or property, loading operations can be carried out.

Upon arrival at the destination and after

ensuring that there are no persons,

objects or property in the unloading area,

the proper lifting equipment (e.g. forklift)

shoud be used to lower the pallet to the

ground and then to move it (at approx. 30

cm from ground level), to the storage

area.

CAUTION: RISK OF IMPACT

OR CRASHING.

Before carrying out the following operation, the load must be checked to ensure

that it is in the correct position and that,

when the supports are cut, it will not fall.

The operator, who must first put on work

gloves and protective footwear, will proceed to cut the supports and to storing the

product. To carry out this operation, the

technical characteristics of the product

must be consulted in order to know the

weight of the machine and to store it

accordingly.

CAUTION: RISK OF POLLUTION.

Once the machine has been removed

from the pallet or container, these latter

items must not be disposed of in the environment, due to the risks of pollution.

CAUTION: RISK OF POLLUTION.

At this point, the qualified member of staff

shall carry out the connection to the plum-

bing and electrical system, as shown in

Figures 4 - 5.

The qualified member of staff must, if the

electric cable supplied is not suff i c i e n t ,

always use another of the same section.

Check that the mains power supply has an

efficient grounding system, which should be

connected to the machine using the green

and yellow wire.

CAUTION: RISK

OF SHORT CIRCUITS.

We would like to remind the qualified electrician that THE MACHINE MUST A LWAY S

BE PROTECTED WITH AN A U TO M AT I C

SWITCH WITH SUFFICIENT P O W E R

(220 - 240V/12A).

The company cannot be held responsible for damage to things or injury to persons caused by failure to comply with

the safety instructions and installation

and maintenance instructions contained

in this handbook (we remind you that

the above operations must only be carried out by qualified staff).

For the correct functioning and long life

of your machine, we recommend that

you install a water softener and filter (no

wider than 150 microns) to the inlet tube.

Make sure that there are at least 2 bars

of pressure and if this is not so, adjust

the hot water mixer accordingly. To gain

access to the mixer, remove the right

hand side panel of the machine.

Mixer adjustment: when releasing hot

water, use the central knob over the boiler, moving it slightly to vary the temperature of the water as it leaves the

machine.

Furthermore, water supply pressure

should not exceed 4 bars. If this is not

the case, fit a pressure reducer

upstream of the water softner.

CAUTION: RISK

OF SHORT CIRCUITS.

Before connecting the machine to the

mains power supply, please check that the

supply voltage corresponds to the machine

voltage (see the technical characteristics on

page 26).

Connect the machine to the power supply.

In the Master/Cappuccino version, the refrigerator will start up automatically.

The machine is now on “standby” and the

key which starts the machine will begin to

flash.

S TA R T-UP: Start the machine by pressing

the machine start key ; the machine

will begin to carry out a self-diagnostic

check and unit positioning cycle and, if

necessary, it will fill the boiler by means of

the automatic water filling system.

NOTE: The maximum automatic refill time

for the machine ranges from 60 to 90

seconds. After this time, refilling will be

INSTALLATION AND ADJUSTMENT

nterrupted and the display will read:

for at least 1 second), and then re-

.

ADJUSTMENTS TO BE MADE BYA QUALIFIED TECHNICIAN

Pressostat adjustment

(boiler temperature)

To increase or reduce pressure (therefore

the corresponding temperature), the qualified technician must:

- remove the top cup-holder plate

- turn the adjusting screw (Fig. 8) clockwise to decrease and counter-clockwise to

increase.

recommended value 0,8-1,4 bars

pressostat (fig.8)

Grinding adjustment

- switch off the machine using the P L U G

key .

The following operation must be carried

out with dry hands.

- Open the control door to gain access to

the grinding adjusting ring nut (Fig. 9).

Following the direction of the arrows,

grinding of the coffee beans can be adjusted to more coarse (counter-clockwise)

or finer (clockwise).

Close the door again.

Freezer’s temperature adjustment

(Master Cappuccino version)

To reach the adjustment’s thermostat remo-

ve the drip tray and the container. Turn the

grip clockwise to lower the temperature, anticlockwise to increase it. A t e m p e r a t u r e

between 4 and 7 °C is advisable.

The temperature is shown by the thermometer on the frontal part of the machine.

Pump adjustment

To adjust the pump the qualified technician must:

- pull out the coffee-grounds box

- loosen the adjusting screw until the screw lock nut is

freed (Fig. 7)

- increase (turn clockwise) or decrease (turn counterclockwise) the pump pressure; recommended values 7-9

bars

- tighten the lock nut.

(fig. 7)

gauge (fig. 6)

pump (fig.7)

grinding (fig.9)

S TA R T-UP: By pressing the key, the

. In the event that mal-

unctions or breakdowns are shown after the

1 Short Espresso

2 Short Espressos

1 Long Espresso

2 Long Espressos

1 Decaffeinated Coffee (not avaible in

coffee beans jar on the upper cup storage

surface and insert the dose of decaffeinated coffee (Fig. 1, n. 11).

- press the key for either 1 SHORT ESPRES-

SO or 1 LONG ESPRESSO .

This key doubles the dose of a short

or long espresso.

Cappuccino. Caffè latte.

Hot Milk.

Continuous Delivery:

This key makes it possible to deliver automatically a programmed number of cups of coff e e

and to vary the amount set (min. 1, max. 99)

Press the Continuous Delivery key

and the display will show the number of cups

to be delivered. It is possible to vary the programmed amount using the arrow keys ▼▲.

NOTE: By pressing the key ENTER a f t e r

varying the programmed amount, the new

number of cups to be delivered is stored in

the machine’s memory.

Press one of the flashing keys.

NOTE: To interrupt the programmed cycle,

press the Continuous Delivery key .

allows you to interrupt the delivery of

coffee, cappuccino, white coffee and milk in

advance.

NOTE: in the self-service versions, if you

want to interrupt the delivery of coffee and

cappuccino in advance you have to press a

second time the key of the delivery choosed.

HOT WATER: This allows the timed

delivery of hot water and, if pressed a

second time, its interruption. (Please see

Dose Programming, p. 33).

NOTE, KEY FUNCTIONS: Key U, abilitation

full programmable settings; key T, only reading functions, it does not allow any setting’s

modification.

WASHING CYCLE (Master/Coffee Version):

Press the WASHING CYCLE key o r

press the arrow key ▼followed by E N T E R .

The machine will begin the washing cycle (15

deliveries of 10 seconds each, with a 10second interval plus a final delivery lasting 20

seconds). If you wish to wash the machine

with specific detergent tablets, place one of

these tablets inside the decaffeinated coff e e

compartment and then press the washing key.

Once the washing phase has been started,

DO NOT INTERRUPT, otherwise detergent

residues may remain inside the delivery group.

CAUTION: RISK OF INTO X I C AT I O N .

When the washing phase is finished, deliver

a cup of coffee in order to eliminate possible

detergent residues.

During the washing phase, all keys are disa-

bled, except for the on/off key and the

hot water key .

We recommend that you carry out a

“WASHING CYCLE” at least once a day to

keep the delivery section clean. A

“ WASHING CYCLE” should also be carried out at least once a week, using spe-

USE AND PROGRAMMING

▼

followed by the

E N T E R, key.

C O M P L E T E

. Using the arrow key ▼, it is pos-

ENTER

COMPLETE WASHING

MILK WASHING

are selected, the line

▼

, until the

display reads D E L I V E RY C O U N T. Select the

key for the delivery you wish to check and, if

you wish to reset, press the R E S E T k e y.

To display and reset the number of cups of

d e c a ffeinated coffee delivered, once the

display reads D E L I V E RY C O U N T, press

the decaffeinated key and select the

key for the delivery you wish to check and,

if you wish to reset, press the RESET key.

To exit the delivery counter/reset phase,

press to return to the M A C H I N E

READY setting or the arrow key ▼to pass

on to the next programming stage.

In self-service versions press twice the arrow key

▼

to return to the

MACHINE READY

s e t t i n g .

NOTE: When the words D R AWER FULL

appear on the display, it means that the

drawer has reached the full limit for coffee

grounds. Therefore, it is necessary to remove and clean the drawer. The machine

does, in any case, permit a further 10 delivery cycles to be performed, after which,

the display will read D I S C H A R G E

DRAWER and it will no longer be possible

to use the delivery keys. To release the

keys, you must first remove the coff e e

grounds drawer, which you should the clean

and put back into its original position.

Using Steam

CAUTION: RISK OF BURNS OR

SCALDING.

During steam delivery, never touch the

steam jet with any part of the body or place

your hands underneath it.

To use steam, it is sufficient to pull the steam

lever towards you (Fig. 1, no. 4). This lever

makes it possible to regulate the steam gradually as it leaves the tube (Fig. 1, no. 5) as

well as allowing locking the maximum output

position. The steam tube is movable.

To obtain froth when heating the milk, place

the nozzle in a container which is 3/4 full

(and preferably shaped like a cut-off cone).

Once the milk has boiled, lower the container and bring the surface of the milk into

contact with the steam nozzle. By making

small, circular movements with the container,

the desired froth will be formed.

At the end of every steam delivery, carefully

clean the tube with a damp cloth.

PROGRAMMING

COFFEE DOSE PROGRAMMING: T h i s

function allows to programme the quantity

of water for coffee, as well as to programme

the time for hot water. Insert the U-key to

enable programming and move the arrow

key ▼until the display reads P R O G R A M

COFFEE DOSES. Select the dose to be

programmed and, when this operation has

been completed, press (follow the

same procedure for other doses). In the

SELF SERVICE version press the selected

key a second time once the desired dose

has been delivered.

NOTE: To programme the dose for hot

water, press the key and the machine

will begin to deliver hot water. Once the desired dose has been delivered, press the

key again. The maximum hot water

delivery time is 2 minutes.

RESET

the display will read

MACHI-

).

o enable programming and move the arrow

▼

until the display reads MILK DOSE

he other doses). In the SELF SERVICE ver-

unction allows you to programme grinding

imes for the different selections possible.

▼

until the display reads

. Select the key for the

ime you wish to set (programmed grinding

imes are shown on the top line of the

he arrow keys

▼ ▲

and press the E N T E R

function, press

R E S E T

MACHINE READY

).

whether to deliver coffe first and then milk or

vice versa.

DOUBLE CYCLE: This function allows you

to select the delivery of 2 cups of coffee in

one cycle (SINGLE CYCLE) or in 2 cycles

(DOUBLE CYCLE).

DATE-TIME: To set or change the day of the

week or the time.

PROGRAM ON-OFF: To set the times for

the machine to switch on - off automatically

as well as to set the weekly day off.

DISCHARGE TIME: This function allows you

to programme the drying time for the coffee

grounds after delivery.

DISCHARGE OPTION: This function allows

you to programme the machine according to

the type of container which will be used to

hold the discharged tablets of coff e e

grounds (standard internal container or

external container). In the first case (standard internal container), it is also possible to

programme the maximum number of

grounds (min. 20, max. 40), while in the

second case (external container), the number is fixed at 200.

CHOOSE LANGUAGE: This function allows

you to choose the language used on the

LCD display.

MANUAL STOP: In the SELF SERVICE version, this function enables to stop delivery of

coffee by pushing the same button.

STANDARD PROG.: This page contains the

following functions:

COFFEE DOSES: To set the standard

quantity of water for coffee delivery and the

hot water delivery times.

MILK TIMES: To set the standard delivery

times for cappuccino, white coffee and

warm milk.

DISCHARGE AND GRINDING TIMES: To set

the standard discharge and grinding times.

VARIOUS SETTINGS: To program the

standard number of continuous deliveries,

milk washing times, washing times, single

and double cycle settings, English language option and the number of coff e e

grounds for discharge drawer management

Insert the U-key to enable programming and

move the arrow key ▼until the display reads

INSTALLATION

. Press ENTER and use the

arrow keys ▼▲to choose from the options:

A U TO WA S H I N G

, CAPPUCCINO PRO-

DUCTION,

DOUBLE CYCLE,DATE-TIME

,

PROGRAMM. ON-OFF

, DISCHARGE

TIME, DISCHARGE OPTION,

C H O O S E

L A N G U A G E

, MANUAL S TO P,

P R O G .

STANDARD

.

A U TO WA S H I N G

: Press E N T E R and use

the arrow keys

▼ ▲

to set the desired time

(min. 0.5 seconds, max. 5 seconds).

To confirm this setting, press E N T E R . To

return to the

INSTALLATION

function, press

RESET

and to exit the programming function

press

RESET

(the display will read

MACHI-

NE READY

).

CAPPUCCINO PRODUCTION: Press

E N T E R, then by means of

▼ ▲

you can

choose between the options C O F F E E

MILK or MILK COFFEE. Press ENTER to

confirm. To return to the I N S TA L L AT I O N

function, press RESET and to exit the programming function press RESET again (the

display will read MACHINE READY).

DOUBLE CYCLE

: Press E N T E R and use

the arrow keys

▼ ▲

to choose from the

options

2 COFFEE WITH DOUBLE CYCLE

or

2 COFFEES WITH SINGLE CYCLE

. To

confirm this setting, press E N T E R.

To return to the

I N S TA L L AT I O N

f u n c t i o n ,

press

R E S E T

and to exit the programming

function press

RESET again

(the display will

read

MACHINE READY

).

: press E N T E R to display the

▼ ▲

arrow keys, it is pos-

I N S TA L L AT I O N

R E S E T

and to quit the program-

R E S E T

again (the machi-

MACHINE READY

) .

: press E N T E R t o

R E S E T

and the

▼ ▲

arrow keys to change

▼ ▲

R E S E T

menu by pressing

. To return to the

I N S TA L L AT I O N

R E S E T

and to quit the program-

R E S E T

again (the machi-

MACHINE READY

) .

: Press ENTER, the pilot

arrow keys

▼ ▲

to set the desired time. To

confirm the setting, press E N T E R. Repeat

this operation for the remaining keys. To exit

the programming function, press

RESET.

To return to the

I N S TA L L AT I O N

f u n c t i o n ,

press

R E S E T

and to exit the programming

function press

RESET again

(the display will

read

MACHINE READY

).

DISCHARGE OPTION

: press the E N T E R

key once to display the set number. Use the

arrow keys ▼▲to choose from the options

FREE DISCHARGE

or

WITH DRAW E R

.

When choosing the function

W I T H

DRAWER

, press ENTER to programme the

DREGS NR.

. Use the arrow keys

▼ ▲

t o

change the number of coffee grounds (min.

20, max. 40), and press E N T E R to confirm

this selection. When choosing the

F R E E

D I S C H A R G E

function (grounds fixed at

200), press E N T E R to confirm. To exit the

programming function press

R E S E T

( t h e

display will read

MACHINE READY

).

CHOOSE LANGUAGE

: Press E N T E R a n d

use the arrow keys

▼ ▲

to choose from the

options

E N G L I S H

or

I TA L I A N

. To confirm this

setting, press E N T E R. To return to the

I N S TA L L AT I O N

function, press

R E S E T

a n d

to exit the programming function press

R E S E T

(the display will read

MACHINE READY

) .

M A N U A L S TO P

: Available only in the

S E L F S E RVICE version push ENTER a n d

through

▼▲

arrows, select “ENABLED”

(allowing manual stop through the same

botton) or “NOT ENABLED” (excluding

manual stop).

PROG. STANDARD

.: There are five ways to

input standard programming functions:

One: Hold down the E N T E R key for 5

seconds. The display will read COFFEE

DOSES and, after 5 seconds, the machine will

return to the

MACHINE READY

status, inserting all standard doses, times and settings.

Two: Press the E N T E R key once. T h e

display will read COFFEE DOSES. Press

the ENTER key once more to confirm, then

set coffee delivery times and the standard

hot water delivery times. The machine will

automatically return to the

PROG. STA N-

D A R D

function. To return to the

M A C H I N E

READY

status, press the

RESET

key twice.

Three: Press the E N T E R key once. T h e

display will read COFFEE DOSES. Press

the ▼key and the display will read MILK

TIMES. Press ENTER to confirm and to set

the standard times for cappuccino, white coffee and hot milk. The machine will automatically return to the

PROG. STANDARD

func-

tion. To return to the

MACHINE READY

status, press the

RESET

key twice.

Four: Press the E N T E R key once. T h e

display will read COFFEE DOSES. Press

the ▼key twice and the display will read

DISCHARGE TIMES AND GRINDING.

Press ENTER to confirm and to set the standard times for coffee grounds discharge and

for coffee grinding. The machine will automatically return to the

PROG. STA N D A R D

function. To return to the

M A C H I N E

READY

status, press the

RESET

key twice.

Five: Press the E N T E R key once. T h e

display will read COFFEE DOSES. Press

the ▼key three times and the display will

read VARIOUS SETTINGS. Press E N T E R

to confirm and to set the standard variables

for all other functions. The machine will

automatically return to the

PROG. STA N-

DARD

function. To return to the

MACHINE

READY

status, press the

RESET

key twice.

(with single cycle)

(with double cycle)

(with single cycle)

(with double cycle)

5 cycles

LIST OF DISPLAYMESSAGES

-

NOT A L L O W E D

: The functions are not

enabled. Insert the “U” key

-

GROUP HEATING

: The unit is being hea-

ted

-

MACHINE READY

: The machine is ready

for dose selection

-

MANUAL STOP

: The manual stop control

has been used before the programmed

dose has been effected

-

DECAF. SELECTED

: Decaffeinated coffee

delivery selected

-

PROG. CONTINUE

: Continues program in

function

-

PROGRAM DOSES

: Delivery dose pro-

gramming phase

-

GRINDING TIME

: Grinding times program-

ming phase

-

DELIVERY COUNT

: Display of dose coun-

ters selected

-

DISCHARGE OPTION

: Grounds dischar-

ge programming phase

-

UNIT CLEANING

: Unit cleaning and repo-

sitioning phase

-

DRAWER FULL

: Grounds drawer full prealarm

-

DISCHARGE DRAW E R

: The Machine is

locked because the grounds drawer is full

-

D R AWER OPEN

: The grounds drawer is

missing or badly positioned

-

DOUBLE CYCLE

: Double cycle selected

-

DOOR OPEN

: Front door open

MALFUNCTIONS LIST

CAUTION: GENERAL RISK.

It is strictly forbidden for the operator to

intervene on the machine in the event that

one of the following malfunctions occurs.

Always use a qualified technician.

-

FLOWMETER ERROR

: The control unit

has detected a malfunction in the flowmeter

-

D E L I V E RY E R R O R

: The machine has

reached the delivery time limit of 2 minutes

-

G R O U PE R R O R

: The control unit has detec-

ted a malfunction in the mechanical unit

-

R E F I L L E R R O R

: The machine has reached the maximum time of the automatic

boiler water filling

-

MILK DOSE ERROR

: The milk dose has

not been programmed

-

DOSE NOT ALLOWED

: The water dose

for the coffee has not been programmed

CUP WARMER MODULE

INSTALLATION AND USE

Place the Cup Warmer Module next to the

coffee machine.

Check to see that the module is level and

if necessary, level it.

Ensure that your hands are dry and then

plug in the module.

Turn the On/Off switch to the On position.

The machine is now working.

Leave the cups to heat well for half one

hour and then use as necessary.

With clean hands, place the previously

washed coffee cups into the baskets.

During cleaning and maintenance operations, the Master Cup Warmer Module is

turned to the “0” energy level in the following manner:

- Turn the On/Off switch to the Off position.

op, lifting it up from the front and sliding it

▼

followed by the

ries alternated with pauses. The whole cycle

lasts approximately 4 minutes.

We recommend that you carry out a

GROUP WASHING CYCLE at least once a

day in order to keep the delivery point

clean.

Group washing should be carried out at

least ONCE A WEEK, using the proper

tablets of detergent.

CAUTION: RISK OF INTO X I C AT I O N .

We remind you not to interrupt a washing

cycle using detergent tablets once started,

otherwise detergent residues may remain

inside the machine.

Proceed as follows:

- Insert the tablet of detergent into the door

situated alongside the bell-jar of coff e e

beans on the top cup storage surface

(Fig.1, no.11).

- Press the WASHING CYCLE key or the

arrow key ▼, followed by the ENTER key:

the machine will automatically start its

wash cycle.

Repeat the washing operation, this time

without inserting the detergent tablet, in

order to eliminate any detergent residues completely.

- The Master Cappuccino Version is equipped

to wash the milk foamer, delivery group and

the tube which takes the milk from the inside

of the cooler. To carry out a complete

washing cycle, proceed as follows:

Remove the milk suction tube from the

container and position it in another container along with the proper detergent solution. Insert the U-key for programming, and

press the arrow key ▼once, followed by

the E N T E R k e y. The display will read

“COMPLETE WASH” and, when ENTER is

pressed, the machine will begin to suck up

detergent to clean the tubes and the milk

f o a m e r. At the same time, the delivery

group wash cycle will begin. When the suction and detergent wash cycle have fini-

shed, repeat the washing operation, this

time replacing the detergent with hot water,

in order to eliminate any possible residues

from the tubes. We recommend that you

to carry out this washing operation at

the end of every day and in any case,

every time that you switch off the

machine for any period of time.

The group washing cycle should be car-

ried out using the proper detergent

tablets at least once a week.

CAUTION: RISK OF INTO X I C AT I O N .

We remind you not to interrupt a washing

cycle using detergent tablets once started.

Proceed as follows:

- Insert the tablet of detergent into the door

situated alongside the bell-jar of coff e e

beans on the top cup storage surface

(Fig.1, no.11).

- Carry out the complete washing cycle as

described above.

- Repeat the washing operation, this time

without inserting the detergent tablet, in

order to eliminate any detergent residues

completely.

CLEANING AND MAINTENANCE

CAUTION: RISK OF BURNS

the delivery unit sides.

R e g e n e r a t i o n

Once the regeneration times have been

established, proceed as follows:

- Set the machine to the “0” energy level

(that is, machine switched off and the

plug removed from the mains) and place

a container with a capacity of at least 2

litres under pipe “E” (Fig. 11 / A )

- turn levers “C” and “D” to the right (Fig.

11/B).

- unscrew knob “G” and remove the plug.

- put in normal cooking salt (1 Kg for the

KD/8 model; 1.5 Kg for the KD/12).

- replace the plug and turn just lever “C” to the

left (Fig. 11/C) letting water drain out of pipe

“F” until it is no longer salty (about 1/2 hour).

- turn lever “D” to the left (Fig. 11 / D ) .

Installation and regulation of

the cappuccino maker

(fig. 12)

The MASTER/COFFEE model may be supplied with an optional cappuccino maker for

the instant cappuccino; it can be inserted

directly on to the coffee outlet nozzle.

The following operations must be carried

out by a qualified technician.

I n s t a l l a t i o n :

- turn off the machine with the PLUG k e y

- open the front door;

- draw out and remove the standard steam

nozzle by loosening the screw fixing it to

the tap.

- mount the new steam fitting supplied in

the kit and tighten the screw after having

re-inserted the conical spring, being careful not to damage the "O"-ring;

- connect the steam fitting to the cappuccino

maker (detail 2 point A) by the silicon tube;

- insert the other tube (for suction of the

milk) into the connection of part 5;

- fit the cappuccino maker into the space

made on the coffee output nozzle.

Setting:

- fit the cappuccino maker, keeping the ring

nut (4) fully screwed down on the nozzle

body (3);

- put the tube (8) inside the milk container

so that it can draw up the liquid;

- partially unscrew the ring nut (4) which

regulates the density of the froth in order

to obtain the density required;

- check that the boiler is at 0.8 bars pressu-

DAYS / REGENERATION

CUPS

DAY

*Coarse sea salt

Grobes Meersalz

Gros sel de cuisine

Sal grueso de cocina

re min. (fig. 5), otherwise reclose the door

and switch the machine on again;

milk will start to flow out of the cappuccino

maker;

again.

sure, check the density of the froth at this

setting.

repeat the above operations, loosening

and tightening the ring nut (4), being careful to check that holes C of part (6) are

clean.

Cleaning: Before proceeding to disassembly and cleaning, we remind you to set the

machine to “0” energy level (that is, machine switched off and the plug removed from

the mains).

Wash the cappuccino maker thoroughly,

dismantling it piece by piece at least once

a day.

Should more than one hour pass between

one cappuccino and another, it is advisable to clean the cappuccino maker by putting tube (8) into the hot water instead of

in the milk.

Disposal

Do not dispose of the machine in the environment. To dispose of the machine, use

an authorised centre, or contact the

manufacturer for relative information.

CAUTION: RISK OF POLLUTION.

(fig. 12)

Loading...

Loading...