Page 1

SAI Global

SRM 9000 Series

FM VHF/UHF Mobile

Radio Transceiver

Revision 9 Hardware

SERVICE MANUAL

TNM-M-E-0002

ISSUE 1.0

May 2006

ISO9001 Lic.QEC20848

Page 2

SRM9000 Series Mobile Radio Transceiver Rev 9 Hardware TNM-M-E-0002 ~ Iss 1.0

Page 3

SRM9000 SERIES SERVICE MANUAL

TABLE OF CONTENTS

APPENDICES........................................................................................................................................ III

DECLARATION.....................................................................................................................................IV

COPYRIGHT .........................................................................................................................................IV

ERRORS AND OMISSIONS ..................................................................................................................IV

DOCUMENT HISTORY ..........................................................................................................................V

LIST OF ASSOCIATED PUBLICATIONS ..............................................................................................V

WARNINGS AND CAUTIONS............................................................................................................... VI

1. INTRODUCTION .......................................................................................................................... 1

1.1 GENERAL................................................................................................................................... 1

1.2 SCOPE ...................................................................................................................................... 1

1.3 DESCRIPTION ............................................................................................................................. 1

1.4 PRODUCT VARIANTS AND FACILITIES............................................................................................ 2

1.5 SOFTWARE VERSIONS AND NAMING ..............................................................................................5

1.5.1 Filename Structure........................................................................................................... 5

1.5.2 Application Code.............................................................................................................. 5

1.5.3 Software Type Code......................................................................................................... 5

1.5.4 Version Number............................................................................................................... 7

1.5.5 Exclusions........................................................................................................................ 7

1.5.6 Displaying Software Versions........................................................................................... 7

1.5.7 Automatic Version Upgrade Prompting............................................................................. 8

1.5.8 Transceiver SW Description, Start-up and Backup-Software............................................ 9

1.5.9 Wailing Siren (Boot-up Software Corrupted) ..................................................................... 9

1.6 ADJUSTMENT AND ALIGNMENT ..................................................................................................... 9

1.7 CHASSIS ASSEMBLY ................................................................................................................. 10

1.7.1 Torque Settings.............................................................................................................. 10

1.7.2 Thermal Compound Application ..................................................................................... 10

1.7.3 Assembly....................................................................................................................... 10

1.8 SPECIFICATION......................................................................................................................... 10

1.8.1 General.......................................................................................................................... 10

1.8.2 Transmitter..................................................................................................................... 12

1.8.3 Receiver ........................................................................................................................ 13

1.8.4 Signalling....................................................................................................................... 14

1.8.4.1 CTCSS............................................................................................................... 14

1.8.4.2 FFSK.................................................................................................................. 15

1.8.4.3 Selcall ................................................................................................................ 15

1.8.4.4 DTMF................................................................................................................. 17

1.8.4.5 DCS ................................................................................................................... 18

1.8.4.6 C4FM ................................................................................................................. 18

1.8.5 Environmental................................................................................................................ 19

2. SERVICE PHILOSOPHY............................................................................................................ 20

2.1 SERVICE CONCEPT ................................................................................................................... 20

2.2 WARRANTY.............................................................................................................................. 20

2.2.1 Service Within and Out Of Warranty.............................................................................. 20

2.2.2 Ancillary Items............................................................................................................... 20

2.3 SOFTWARE POLICY................................................................................................................... 20

© TMC Radio 2006 page i TNM-U-E-0002 Issue 1

Page 4

SRM9000 SERIES SERVICE MANUAL

3. TECHNICAL DESCRIPTION...................................................................................................... 22

3.1 RECEIVER................................................................................................................................ 22

3.1.1 Front End Filters and RF Amplifier................................................................................. 22

3.1.2 First Mixer and IF Section.............................................................................................. 22

3.1.3 Quadrature Demodulator................................................................................................ 22

3.1.4 Receiver Audio Processing ............................................................................................ 24

3.2 TRANSMITTER .......................................................................................................................... 25

3.2.1 Drivers and PA Stages................................................................................................... 25

3.2.2 Power Control ................................................................................................................ 25

3.2.3 Antenna Changeover and Harmonic Filter...................................................................... 25

3.2.4 Transmitter Audio Processing......................................................................................... 25

3.3 FREQUENCY SYNTHESISER........................................................................................................ 26

3.3.1 General.......................................................................................................................... 26

3.3.2 PLL................................................................................................................................ 27

3.3.3 VCO’s............................................................................................................................ 27

3.3.4 Negative Bias Generator and Loop Filter........................................................................ 27

3.3.5 Phase Modulator............................................................................................................ 27

3.3.6 Reference Oscillator....................................................................................................... 28

3.4 CONTROL ................................................................................................................................ 28

3.4.1 DSP and PLA ................................................................................................................. 28

3.4.2 DSP Clock Oscillator...................................................................................................... 29

3.4.3 PLA PWM ...................................................................................................................... 29

3.5 MEMORY ................................................................................................................................. 29

3.6 POWER SUPPLIES..................................................................................................................... 31

3.6.1 Power On Function ........................................................................................................ 31

3.6.2 Power Supplies.............................................................................................................. 31

3.6.2.1 8V Regulator U900............................................................................................. 31

3.6.2.2 5V Regulator U901............................................................................................. 31

3.6.2.3 3.3V Regulator U912 .......................................................................................... 32

3.6.2.4 2.5V Regulator U903.......................................................................................... 32

3.6.2.5 Negative Power Supply U904E/F........................................................................ 32

3.6.2.6 Unswitched Battery (13V8_UNSW_F)................................................................. 32

4. ALIGNMENT (LEVEL 3 SERVICE ONLY).................................................................................. 33

4.1 TEST EQUIPMENT ..................................................................................................................... 33

4.2 TEST SET-UP ........................................................................................................................... 35

4.2.1 COMMS Set up .............................................................................................................. 36

4.2.2 Radio Preparation.......................................................................................................... 37

4.2.3 Alignment Procedure...................................................................................................... 38

4.2.3.1 VCO DAC Alignment .......................................................................................... 38

4.2.3.2 TCXO (Radio Netting Adjustment)...................................................................... 39

4.2.3.3 Rx Front End...................................................................................................... 40

4.2.3.4 Mute Adjustment................................................................................................. 41

4.2.3.5 RSSI................................................................................................................... 42

4.2.3.6 Tx Power............................................................................................................ 43

4.2.3.7 Modulation.......................................................................................................... 44

4.2.3.8 Programming...................................................................................................... 45

4.2.3.9 Customers Radio Personality Data ..................................................................... 45

5. REPLACEABLE PARTS............................................................................................................. 46

5.1 COMMON PARTS ...................................................................................................................... 46

5.2 BAND-SPECIFIC PARTS ............................................................................................................. 47

6. CIRCUIT DIAGRAMS ................................................................................................................. 47

© TMC Radio 2006 page ii TNM-U-E-0002 Issue 1

Page 5

SRM9000 SERIES SERVICE MANUAL

6.1 ISSUE 9 CIRCUIT DIAGRAMS ...................................................................................................... 47

APPENDICES

APPENDIX A ~ GLOSSARY

APPENDIX B ~ TRANSCEIVER CONNECTIONS

APPENDIX C ~ SRM9010 MICROPHONE

APPENDIX D ~ SRM9020 MICROPHONE

APPENDIX E ~ SRM9022 MICROPHONE

APPENDIX F ~ SRM9030 CONTROL HEAD

APPENDIX G ~ ANCILLARIES

© TMC Radio 2006 page iii TNM-U-E-0002 Issue 1

Page 6

SRM9000 SERIES SERVICE MANUAL

Declaration

The performance figures quoted are subject to normal manufacturing and service tolerances. The right is

reserved to alter the equipment described in this manual in the light of future technical development.

Copyright

All rights reserved. No part of this publication may be reproduced in any form or by any means without the

prior permission of TMC Radio.

Errors and Omissions

The usefulness of this publication depends upon the accuracy and completeness of the information

contained within it. Whilst every endeavour has been made to eliminate any errors, some may still exist. It

is requested that any errors or omissions noted should be reported to:

TMC Radio Pty Ltd.

1270 Ferntree Gully Road

Scoresby Vic

3179 Australia

Ph: +61 3-9730-3800 (Direct: -3914)

Fax: +61 3-9730-3968

Mob: +61 408-160-661

E-mail: jkuhrt@tmcradio.com

www.tmcradio.com/

© TMC Radio 2006 page iv TNM-U-E-0002 Issue 1

Page 7

SRM9000 SERIES SERVICE MANUAL

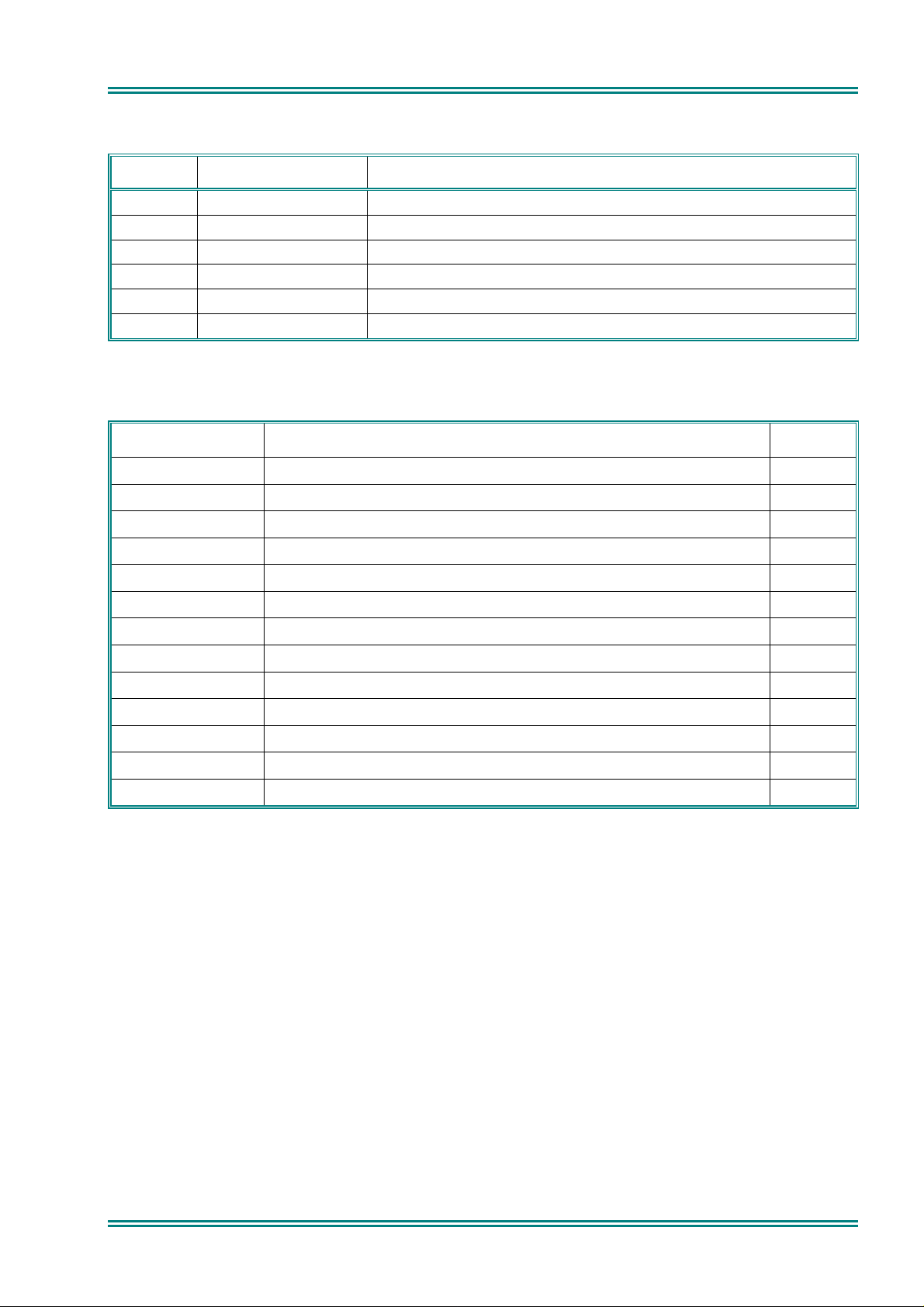

Document History

Issue Date Comments

1 January 2006 Initial issue

List of Associated Publications

Document No. Description Issue

TNM-I-E-0005 SRM9000 Series Installation Instructions 5

TNM-P-E-004 Selcall Product Manual 2.56

TNM-U-E-0012 SRM9020 Trunk Operating Instructions 2

TNM-U-E-0013 SRM9020 PMR Operating Instructions 2

TNM-U-E-0063 SRM9022 PMR Operating Instructions 1

TNM-U-E-0014 SRM9025 PMR Operating Instructions 2

TNM-U-E-0015 SRM9025 Trunk Operating Instructions 2

TNM-U-E-0003 SRM9030 PMR Operating Instructions 2

TNM-U-E-0004 SRM9030 Trunk Operating Instructions 2

TNM-U-E-0020 SRM9030 Brief User Guide 2

TNM-U-E-0042 SRM9010 Brief User Guide 2

TNM-U-E-0043 SRM9020 Brief User Guide 2

TNM-U-E-0044 SRM9025 Brief User Guide 2

© TMC Radio 2006 page v TNM-U-E-0002 Issue 1

Page 8

SRM9000 SERIES SERVICE MANUAL

In vehicles

Warnings and Cautions

Compliance with RF Energy Exposure Standards: To minimise exposure to RF fields during

equipment service and repair, the antenna terminal of the SRM9000 radio should be connected

to a suitable non-radiating RF load when the transmitter is in use.

SRM9000 radio equipment is to be connected only to 12-volt negative earth systems.

with a 24-volt supply, an approved 24V/12V converter must be used. The supply must not be

taken from a 12V tap on the battery.

To avoid RF injury, do not touch the Antenna when the Transmitter is in use.

Double-fused 12V Supply Leads, Antenna cables and Speaker wiring is to be routed as far

away as possible from gas or fuel lines or any electronic control device. The radio transceiver

and antenna are to be mounted as far away as possible from these devices and their cabling.

Equipment is to be installed, by a competent person, in accordance with the requirements of

local radio communications authorities and/or Health and Safety regulations.

WARNING

WARNING

WARNING

WARNING

Post installation checks should be performed to ensure that there is no effect on the operation

of the vehicle’s electronics.

WARNING

Do not operate your radio, without a handsfree kit, whilst driving a vehicle.

WARNING

Do not operate your radio in an explosive atmosphere. Obey the “Turn Off Two-way Radios”

signs where these are posted, e.g. on a petrol station forecourt.

Caution

During disassembly and assembly, refer to Torque Settings in Section 1.7

Caution

Customer configuration files should be saved prior to any alignment adjustments.

Preparing the radio for alignment will erase from the radio all customer PMR and Trunking

configuration data (channel, signalling information etc). The only data retained by the

Alignment Tool is the factory alignment data for the radio (DAC settings for Tx power, front-end

© TMC Radio 2006 page vi TNM-U-E-0002 Issue 1

Page 9

SRM9000 SERIES SERVICE MANUAL

1. INTRODUCTION

1.1 GENERAL

The SRM9000 series of FM mobile radio transceivers is designed for PMR and Trunked operation in VHF

and UHF radio systems.

The system is available in a number of functional variants. Each variant uses the standard SRM9000

mobile transceiver, which is software configured for different control ancillaries. The software configuration

together with the type of controller (Basic or Enhanced microphone, Handset, or Alphanumeric Control

Head) determines the radio features for the different variants as follows.

PMR/Trunked

Basic Telemetry Transceiver No Display or Control Head. SRM9005

Low Range Version with Basic Fist Microphone. SRM9010

Mid Range Version with Enhanced Alphanumeric Fist Microphone. SRM9020

High-end Version with Graphics Display Handset. SRM9022

High-end Version with Alpha Display Handset. SRM9025

System Level Remote Control Head with Alpha capability and Handset /

Fist Microphone / Desk Microphone options.

SRM9030

1.2 SCOPE

This manual provides technical specifications, description and servicing details for the SRM9000 series of

mobile radio transceivers together with the related microphones and control heads.

Unless specifically stated otherwise, the text and illustrations refer to all versions in the series.

1.3 DESCRIPTION

The design concept utilises wide band analogue techniques for RF transmit and receive circuitry with digital

signal processing of analogue or digital modulation and demodulation. Electronic tuning is used throughout

the mobile to eliminate manual tuning and level adjustment.

A Digital Signal Processor (DSP) and a Programmable Gate Array (PLA) are used with other dedicated

devices in the SRM9000 to perform the following functions under software control:

• Frequency Synthesis of all operating frequencies.

• Modulation and demodulation of 10/12.5/20/25kHz FM signals on a per channel basis.

• Modem functionality for specified data modulation schemes.

• Filtering, pre-emphasis, de-emphasis, limiting, compression, muting, CTCSS, Selcall or any other

frequency or level dependent signal modification.

• Serial communications with the Control Ancillaries and Alignment Tool.

• Tuning Control data for Tx and Rx.

The SRM9000 Transceiver comprises a rugged extruded aluminium sleeve, which houses a single printed

circuit board assembly and provides all heatsink requirements. The sleeve housing is closed at each end

by high-impact plastic end caps; all cable ports and mechanical interfaces are sealed against moisture and

dust ingress.

The PCB assembly comprises a single, multi-layer PCB containing all the RF and control circuitry. The

PCB seats on an extruded aluminium tray that slides into the outer aluminium sleeve where it is secured

with screws accessed from the outside of the case. Provision is made under the main PCB tray assembly

for additional hardware options as well as optional accessories plugged directly into the main PCB.

There are two installation methods available for the SRM9000. The outer aluminium extrusion has side

flanges that allow the mobile to be bolted directly to any flat surface in the vehicle. A quick release cradle is

also available.

© TMC Radio 2006 page 1 TNM-U-E-0002 Issue 1

Page 10

SRM9000 SERIES SERVICE MANUAL

Control Unit

Microphone

1.4 PRODUCT VARIANTS AND FACILITIES

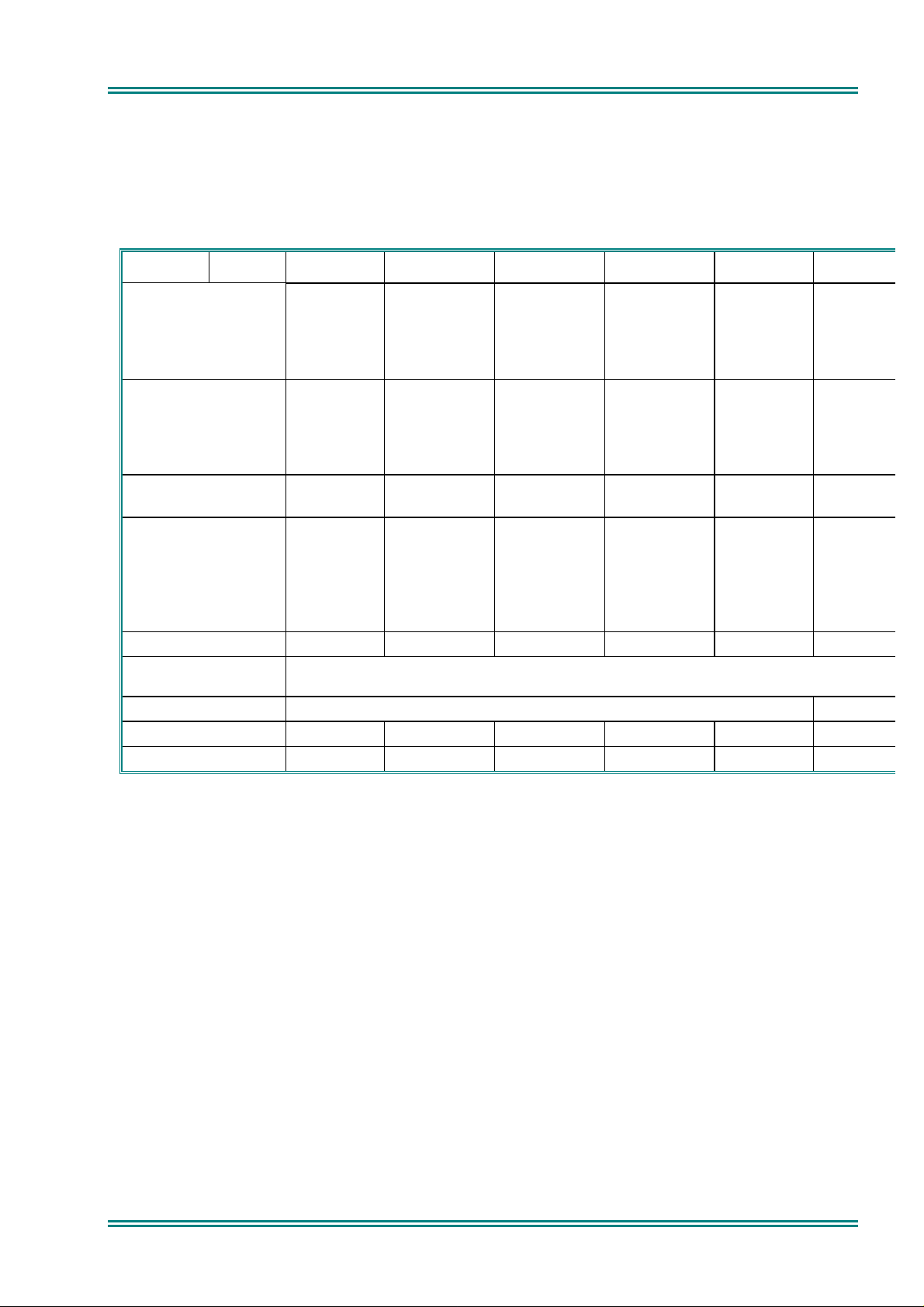

Product variants and facilities are detailed in Table 1-1, Table 1-2 and Table 1-3.

Table 0-1 Common Features for All Variants

Feature: Model: 9005 9010 9020 9022 9025 9030

Control None or

Serial or

Parallel if

Option

Board

Display

Adjustable Display

- 1 digit LED 6 char LCD 8x14 char

- - Yes Yes Yes Yes

Illumination

Buttons and Keys

Speaker

- Vol Up/Down

- Yes Yes Yes* Yes* Yes

Frequency Bands

Channel Spacing

Menu driven

Customisable Menus

- - Yes Yes Yes Yes

- - Yes Yes Yes Yes

Display

Microphone

Select

1 Function

66-88MHz, 136-174MHz, 174-208MHz, 208-245MHz, 335-375MHz,

Display

Microphone

Vol Up/Down

4 Function

Scroll

Up/Down

400-480MHz, 440-520MHz

10/12.5/20/25kHz

Controller

Microphone

LCD

Graphics

102x64

pixels

Vol Up/Down

6 Function

12 Keypad

Send/End

Menu + Scroll

Display

Handset

2x12 char

LCD

Vol Up/Down

6 Function

12 Keypad

Send/End

Menu +

Scroll

with

8x14 char

LCD

Graphics

102x64

pixels

6 Function

12 Keypad

Send/End

Menu +

Scroll

* Note: Handsets have a built-in earpiece, therefore an external speaker is optional.

© TMC Radio 2006 page 2 TNM-U-E-0002 Issue 1

Page 11

SRM9000 SERIES SERVICE MANUAL

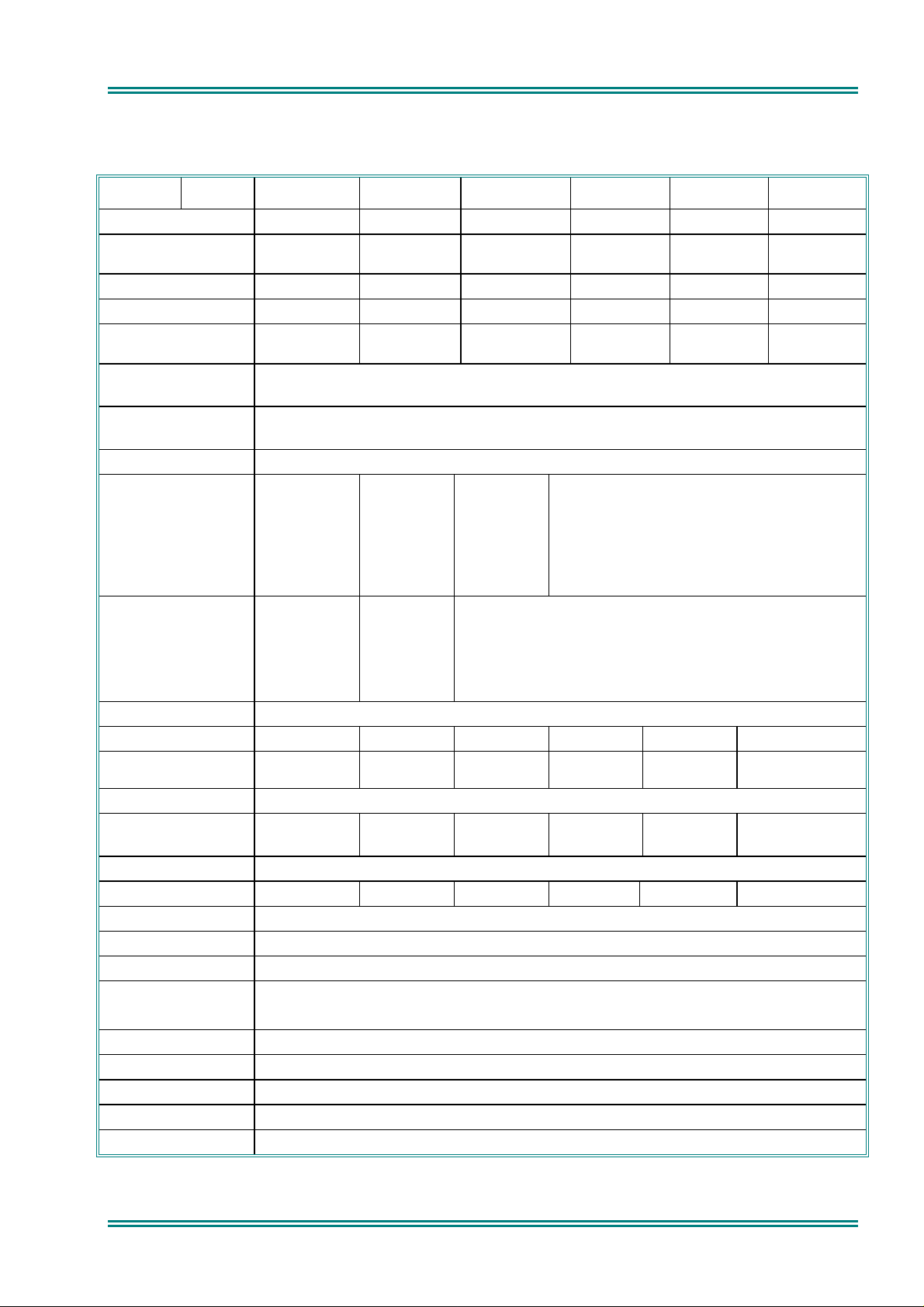

Table 0-2 Conventional-PMR Variants

Feature: Model: 9005 9010 9020 9022 9025 9030

Channels

Signalling

Attack Operation

DTMF Encode

MPT1327 Trunking

PTT Limit Timer

with warning beeps

Busy Channel

Lockout

PTT Inhibit on Busy

Scanning

Voting

Priority Scanning

Nuisance Delete

Phonebook

1000 10 100 + 1000 1000 1000

CTCSS/DCS CTCSS/DCS

ANI

- Yes Yes Yes Yes Yes

- 2 Fixed Seq 2 Fixed Seq Yes Yes Yes

Yes Program-

mable

Yes 10 groups

of up to 16

channels

per group.

Yes 10 fixed

groups

consisting

of up to 16

channels

per group.

- - Yes Yes Yes Yes

- - 250 entries 250 entries 250 entries 250 entries

CTCSS/DCS

Selcall

User

selectable

10 groups

of up to 16

channels

per group, 4

user defined

scan

groups.

Up to 200 groups consisting of up to 16 channels per group.

CTCSS/DCS

Selcall

User

selectable

Yes

Yes

Yes

124 groups of up to 16 channels per group, 4

user defined scan groups.

Yes

CTCSS/DCS

Selcall

User

selectable

CTCSS/DCS

Selcall

User

selectable

Multiax

Mod/Demod

Option - - - - -

Yes

Function

Ignition Sense Input

VOX Handsfree

600 Ohm Interface

SIB

DMAP

ASI Standard

Option Option Option Option Yes Option

Yes

Option

Option

Option

ASI with GPS

Direct GPS

RSM with GPS

P25

Audio Discriminator

Option

Option

Option

Option

Option

© TMC Radio 2006 page 3 TNM-U-E-0002 Issue 1

Page 12

SRM9000 SERIES SERVICE MANUAL

Table 0-3 Trunked Variants

Feature: Model: 9005 9010 9020 9022 9025 9030

Channels

Frequency Bands

Background Hunt

and Vote-Now

MPT1343 dial strings

1024 channels in 50 sub-bands

Specifically: 136-174MHz, 400-450MHz (and possible in all other bands)

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

ANN Numbering

Phonebook

- - - Yes Yes Yes

250 10 100+ 250 250 250

Memories

User Phonebook

Alpha Status List

SDM/EDMs

NPDs

Mod/Demod

Recall

entries

configured

by FPP only

- - Yes Yes Yes Yes

Yes - - Yes Yes Yes

Yes - - TBA TBA TBA

Option - - - - -

Recall

entries

configured

by FPP only.

Recall

entries

configured

by FPP only

Function

Attack Operation

Ignition Sense Input

VOX Handsfree

General External IO

600 Ohm Interface

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Option Option Option Yes* Yes* Yes*

Option Option Option Option Option Option

Option Option Option Option Option Option

* Note: Requires external microphone for optimum performance.

Recall and

edit.

Recall and

edit.

Recall and

edit.

© TMC Radio 2006 page 4 TNM-U-E-0002 Issue 1

Page 13

SRM9000 SERIES SERVICE MANUAL

1.5 SOFTWARE VERSIONS AND NAMING

There are various associated items of Software (SW) required for the SRM9000 radio and programmer to

operate. This section simply defines the naming rules of the SW files to allow identification and conformity.

This allows different versions of SW to be distributed and co-exist without confusion.

The SRM9000 Transceiver has three items of SW for digital and analogue PMR, Trunking and Alignment.

The 9022/9025 Controller Mic/Handsets have one SW file for their PIC’s and 9030 Control Head has two

SW files for its Flash and EEPROM.

1.5.1 Filename Structure

Basically the Filename Structure is defined as follows:

• 2 character Application code

• 2 or 3 character SW Type code

• 3 character version number

• File Extension as required.

eg. 99tm533.bin

99p_533.bin

99s_533.bin

99cf101.hex

99ce101.hex

1.5.2 Application Code

This identifies the application the SW was initially designed for:

9k Standard SRM9000 Pre-Rev 9 Software

99 Standard SRM9000 Rev 9 Software

ak SRM9000 Pre-Rev 9 Software applicable for SRP9022

a9 SRM9000 Rev 9 Software applicable for SRP9022

rw Specific SW for Raywood Taxi Applications

1.5.3 Software Type Code

This identifies different types of SW within an application.

s_ Startup

p_ Standard PMR. DMAP or No option board

p_s PMR with Scrambler/Discriminator option board

p_g PMR with Direct GPS

p_a PMR with ASI Map27option board

p_u PMR with ASI SUP option board

p_q PMR with ASI-G Map27option board

a__ 9022 Standard PMR. DMAP or No option board

a_s 9022 PMR with Scrambler/Discriminator option board

a_g 9022 PMR with Direct GPS

© TMC Radio 2006 page 5 TNM-U-E-0002 Issue 1

Page 14

SRM9000 SERIES SERVICE MANUAL

a_a 9022 PMR with ASI Map27option board

a_u 9022 PMR with ASI SUP option board

a_q 9022 PMR with ASI-G Map27option board

tm Standard MPT1343 Trunking. DMAP or No option board

ta Standard ANN Trunking. DMAP or No option board

tb Basic (9010/9020) MPT1343 Trunking. DMAP or No option board

tmg Standard MPT1343 Trunking. Direct GPS option board

tag Standard ANN Trunking. Direct GPS option board

tbg Basic (9010/9020) MPT1343 Trunking. Direct GPS option board

tma Standard MPT1343 Trunking. ASI Map27 option board

taa Standard ANN Trunking. ASI Map27 option board

tba Basic (9010/9020) MPT1343 Trunking. ASI Map27 option board

tmu Standard MPT1343 Trunking. ASI SUP option board

tau Standard ANN Trunking. ASI SUP option board

tbu Basic (9010/9020) MPT1343 Trunking. ASI SUP option board

tmq Standard MPT1343 Trunking. ASI-G option board

taq Standard ANN Trunking. ASI-G option board

tbq Basic (9010/9020) MPT1343 Trunking. ASI-G option board

TBD 9022 Trunking

bo Transceiver Boot-code

bc Transceiver Boot-Backup-code

bf Transceiver PLA-code

ba Transceiver PLA-Backup-code

Note. The above file names are not stored within the code. As a consequence, when the radio is read by the

FPP, the FPP will display version numbers and release dates for the Backup, Startup, PMR, TMR and

DMAP codes. The Bootloader, PLA Backup and PLA codes show release dates only.

© TMC Radio 2006 page 6 TNM-U-E-0002 Issue 1

Page 15

SRM9000 SERIES SERVICE MANUAL

1.5.4 Version Number

This is a 3-digit number allocated by Engineering to identify the SW version.

e.g. 103 = Version 1.03

1.5.5 Exclusions

The Programmer SW does not follow the above rules as it is a PC based Program and its version number

can be easily identified by starting the SW. Later releases of SW will be backward compatible, unless

deliberately not so, in which case a different directory structure/path may be implemented.

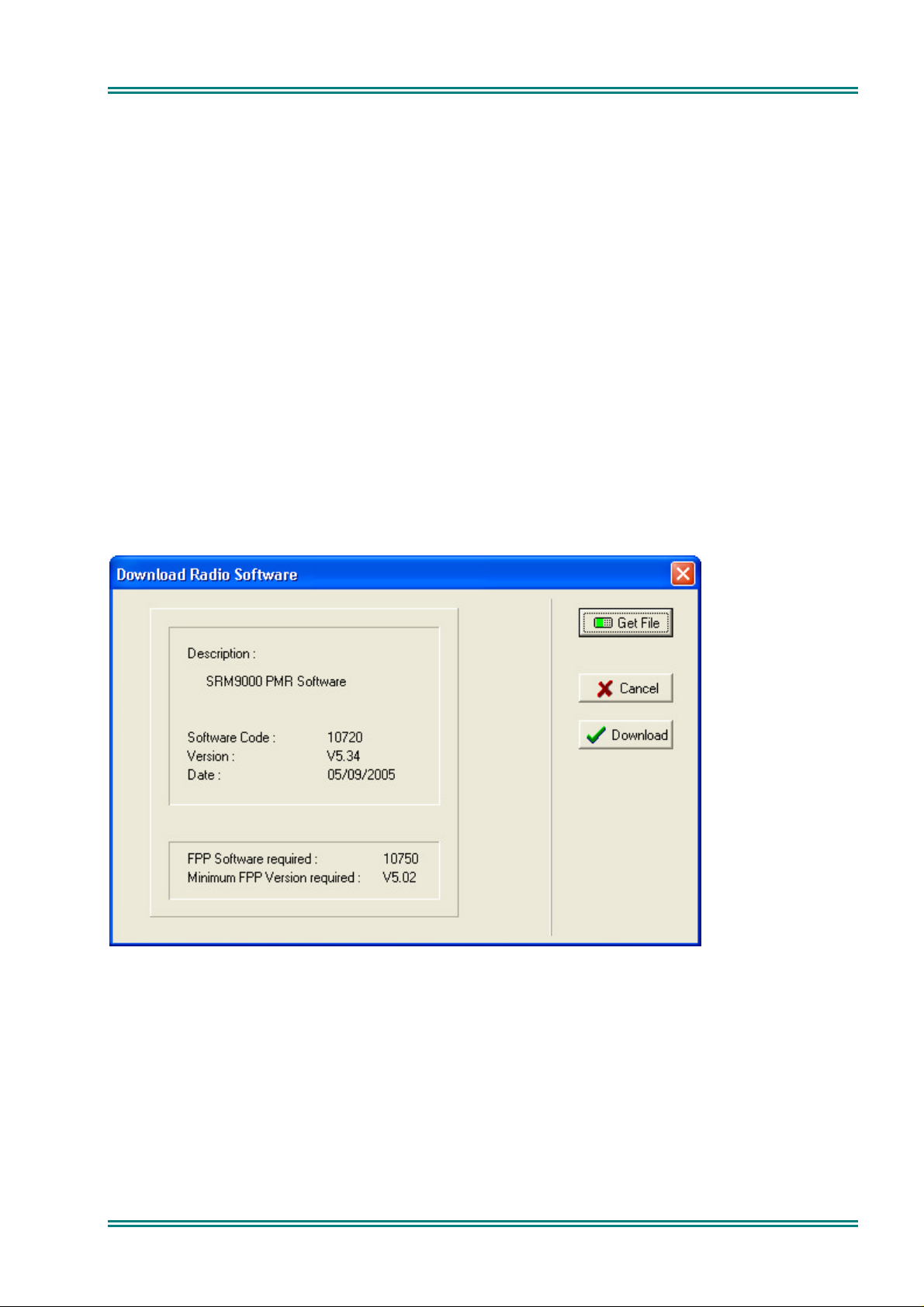

1.5.6 Displaying Software Versions

Each Transceiver SW code file (e.g. 99tm533.bin, etc.) contains version information about itself and

possibly compatible Programming SW.

For Radio SW saved on Disk, this information can be displayed via the Programmer function:

Options : Upgrade_Software : Get_File

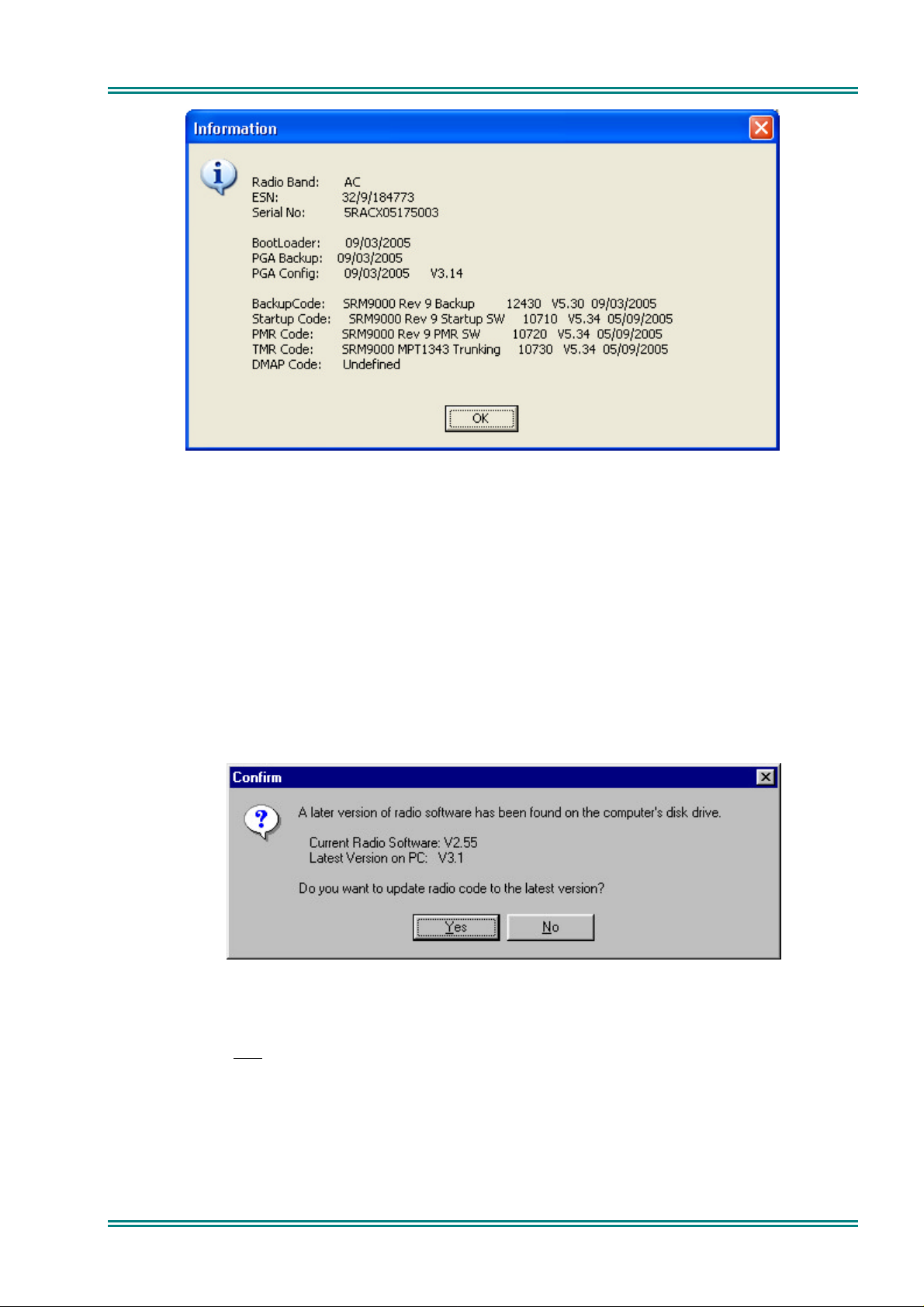

For Software loaded in the radio, information can be read from the Transceiver and displayed via the

Programmer function:

Options : Radio_Information

© TMC Radio 2006 page 7 TNM-U-E-0002 Issue 1

Page 16

SRM9000 SERIES SERVICE MANUAL

SRM9030 Control Head SW can be displayed on the Control Head by holding the ‘3’ button down when the

radio is switched on. This is only implemented in CH V1.06 SW (Oct/2000) and later.

SRM9025 Handset SW has a similar method of Version identification.

SRM9020 Microphone SW has a similar method of Version identification.

SRM9022 Handset SW can be displayed by pressing the top side button when the radio is switched on.

SRM9010 Microphone does not have any method of determining loaded SW. There is only one version of

this SW in the field.

1.5.7 Automatic Version Upgrade Prompting

When a configuration is downloaded to the Transceiver, the Programmer performs a brief check on the SW

currently installed in the radio. If a later version of SW exists (on PC hard-disk) then the Programmer will

prompt the user with the following message:

NOTE. As early versions of FPP cannot recognise a more recent revision of the radio, it is important that

the latest FPP version is downloaded from http://www.tmcradio.com.

If YES is selected, the Transceiver Radio code is updated before the new configuration is downloaded.

If NO is selected, only the configuration is downloaded.

This process also updates the Startup code to ensure it is compatible with the loaded PMR or Trunk code.

Note : If the …\SRM9000\FPP\RadioSW folder contains no files, then the above check will not be

performed.

© TMC Radio 2006 page 8 TNM-U-E-0002 Issue 1

Page 17

SRM9000 SERIES SERVICE MANUAL

1.5.8 Transceiver SW Description, Start-up and Backup-Software

The SRM9000 Transceiver software is split into the following separate modules:

• Bootloader and Backup Software

• Start-Up Software

• PLA and PLA-Backup Software

• Mainline PMR Software

• Mainline Trunk Software

When the Transceiver starts, it basically performs the following steps:

• Initial execution starts with the Bootloader code, which attempts to load the Start-Up Software (if

Start-Up checksum is bad, then the Backup Software is loaded.)

• Start-Up Software then downloads the PLA code (or PLA-Backup code if PLA checksum is bad)

to the PLA device. If both PLA and PLA-Backup checksums are bad then the radio is not

operational and serial communication is not possible.

• Start-Up Software then reads the On/Off switch plus Ignition-Sense lines and compares these

with saved parameters to determine if the radio should be continue to power-up or switch itself off

again.

• Start-Up software then attempts to load either PMR or Trunk Mainline Software (dependent on

saved parameter) and switches execution to complete the power-up process and start normal

operation.

If the Mainline Software cannot be loaded, or a Job file configuration has not been loaded (e.g. nonexistent or checksum fail) then execution switches to Backup Software until the error is corrected (e.g. by

FPPing the radio).

There are three states that the radio can configure after switch-on:

• Mainline Trunk Software or Mainline PMR Software (normal power-up)

If the radio does not have a valid Job file configuration loaded, then it will display a “No PMR Cfg”

or “No TMR Cfg” message.

• Start-Up Software (characterised by “Alignment Mode” shown on the display). This is also the

code that is running when the radio is being aligned using the Alignment Tool.

• Backup Software (via various paths from above.)

1.5.9 Wailing Siren (Boot-up Software Corrupted)

A “WAILING SIREN” sound is emitted from the Loudspeaker while the radio is running in Boot Backup

Software. In this mode the FPP can be used to re-load a Jobfile, or re-load Start-Up or Mainline Operating

Software.

Simply writing a Jobfile to the radio should allow the FPP to determine and update the offending software –

however there may be instances where the FPP cannot determine this and the Start-Up and Mainline

Software should be updated manually. This can be done using the FPP : Upgrade_Software : Get_File …

then Download. Both Start-Up Software (filename = 99s_xxx.bin) and Mainline PMR (99p_xxx.bin) or

Trunk (99txxxx.bin) should be loaded if the FPP cannot automatically fix the problem. The wailing siren

should stop once the problem is fixed.

Note: Should these steps fail to restore the set and the Wailing Siren cease, the radio will need to be

returned to a Level 3 Service Centre for FLASH replacement.

1.6 ADJUSTMENT AND ALIGNMENT

There are no manual internal adjustments in the SRM9000. Re-programming and alignment is done using

software tools with the PCB installed in its chassis. For servicing, the radio PCB can be operated as a

stand alone unit provided a temporary heatsink is fitted under the transmitter PA module for transmitter

© TMC Radio 2006 page 9 TNM-U-E-0002 Issue 1

Page 18

SRM9000 SERIES SERVICE MANUAL

servicing and that the receiver audio output be kept below 100mW for receiver servicing. Radio

performance is not adversely affected by operating without the outer sleeve but there will be some change

to performance when the metal cans are removed from the RF sections of the board.

On re-assembly, the PA module should be checked for a thin layer of heat-conducting paste. If this is

missing or dried-out, it should be replaced prior to re-assembly.

1.7 CHASSIS ASSEMBLY

Important - Take Note!

1.7.1 Torque Settings

Assembly of 'Chassis' (Inner Extrusion) to 'Outer Extrusion' 1.4 Nm (PA x 2), 1.25Nm (Others x 3)

Assembly of 'Front' and 'Rear' end-caps to 'Outer Extrusion' 1.4 Nm.

1.7.2 Thermal Compound Application

For radios using a PA tray without full bottom surface with no cut-out, no thermal compound is necessary.

However, on later radios that have a tray containing a cut-out section in the bottom, just enough thermal

compound should be applied to provide good thermal contact with the chassis.

Note. If thermal compound is old and difficult to spread, it should be discarded.

1.7.3 Assembly

The Inner extrusion should initially be fitted to the PCB and the assembly then slid into place within the

chassis.

Then by holding the inner extrusion upwards by hand, it is then important to insert all screws by hand and

ensure they have been fully inserted through the PCB, thereby locating the assembly correctly.

Still holding the inner extrusion upwards to ensure the assembly does not twist, lightly torque up the centre

screw of the row of three followed by the PA module mounting screw towards the middle of the chassis.

The remaining screws can then be screwed up to full torque followed by re-torque of the first two screws

again.

1.8 SPECIFICATION

1.8.1 General

Operation

Single or two frequency simplex (half-duplex).

Modulation

Frequency modulation (phase) F3E, F1D, F1E.

Operational Temperature Range

-30°C to 60°C

Supply Voltage Requirements

10.8V to 16.3V DC negative earth (13.8V nom.)

Current Consumption

Radio off

Standby (squelched):

Mobile With Control Mic Mobile With Alpha Mic Mobile With Alpha

Head

≤ 5mA ≤ 5mA ≤ 5mA

≤ 200mA ≤ 210mA ≤ 210mA*

© TMC Radio 2006 page 10 TNM-U-E-0002 Issue 1

Page 19

SRM9000 SERIES SERVICE MANUAL

Rx Audio O/P:

300mW (not bridged)

4.0W

Transmit:

25W

1W

*Add 250mA to current consumption for Control Head with backlight on.

Frequency Bands Frequency Range Band Frequency Range

E0 66 - 88 MHz R1 335 - 375MHz

AC 136 - 174MHz TU 400 - 480MHz

K1 174 - 208MHz UW 440 - 520MHz

KM 208 -245MHz

Switching Bandwidth

Radio covers the complete band without retuning

Channel Spacing

10/ 12.5 / 20 / 25kHz

Frequency Stability (-30°C to

60°C)

Less than ±2.0ppm

Dimensions (mm) Height Width Depth

Transceiver

9010/30 Microphone

9020 Alpha Display Microphone

9022 Graphics Display Controller

Mic

9025 Alpha Display Handset

9030 Graphics Display Control

Head

9030 Desk Microphone

9030 Handset

* Does not include cable or strain relief

Weight

Transceiver 1.8kg

Conformance Approvals

* Pending in some cases

≤ 450mA ≤ 470mA ≤ 500mA *

≤ 1200mA ≤ 1220mA ≤ 1250mA*

VHF UHF

≤ 6.5A ≤ 6.5A

≤ 1.5A ≤ 1.5A

56

91*

96*

145*

165*

65

300

200

ETS EN 300 086 *

EN 300 113 *

EN 300 489 *

170

62

70

68

52

188

120

50

165

38

42

30

30

46

130

40

EN 300 219 *

Australia AS4295 *

USA FCC (AC, UW)

© TMC Radio 2006 page 11 TNM-U-E-0002 Issue 1

Page 20

SRM9000 SERIES SERVICE MANUAL

1.8.2 Transmitter

Power Output

Transmitter Rise Time

Duty Cycle

Spurious Emissions

Residual Noise

Audio Frequency Distortion

Audio Frequency Response

Audio Sensitivity (1kHz)

(User programmable via FPP)

Any two levels programmable from

High Power: 25W Adjustable down to 1W

Low Power: 1W Adjustable up to 25W

Less than 40 ms

1 minute transmit: 4 minutes receive

< 0.25uW (9kHz to 1GHz)

< 1.0uW (1GHz to 4GHz)

60% deviation. CCITT Weighted

25kHz Channel Spacing >45dB

12.5kHz Channel Spacing >40dB

≤ 3% (at 60% deviation)

300 to 3000Hz* +1dB -3dB

Figures apply for a flat audio response or a 6dB/octave pre-

emphasis curve

(*2550Hz for 12.5kHz channel spacing)

RJ8 Connector: 40mV±2dB

Option Audio: 40mV±2dB

© TMC Radio 2006 page 12 TNM-U-E-0002 Issue 1

Page 21

SRM9000 SERIES SERVICE MANUAL

1.8.3 Receiver

Sensitivity

Adjacent Channel

Selectivity

Intermodulation Rejection

Spurious Response

Rejection

Blocking

Conducted Spurious

Emissions

FM Residual Noise

(CCITT weighted)

Mute Range

ETS AS4295

≤0.5µV PD (-113dBm) for 20dB

SINAD

25kHz Channel Spacing: >73dB

12.5kHz Channel Spacing: >60dB

>65dB >70dB

>70dB >73dB

>95dB >95dB

<2nW (-57dBm) - 9kHz to 1GHz

<20nW (-47dBm) - 1GHz to 4GHz

GENERAL

25kHz Channel Spacing: >45dB

12.5kHz Channel Spacing: >40dB

Typically 6dB to 25dB SINAD

Typical setting 10dB to 12dB SINAD

≤0.3µV PD (-117.5dBm) for 12dB

SINAD

≤0.5µV PD (-113dBm) for 20 dB

Quieting.

25kHz Channel Spacing: >73dB

12.5kHz Channel Spacing: >65dB

<20nW (-47dBm) - 9kHz to 4GHz

Mute Response Time

Voting Response Time

Audio Distortion

Audio Frequency

Response

Deviation Sensitivity

(for rated audio at 1kHz)

Option Audio Output at

60% MSD (P1-23)

Option Audio Output at

60% MSD (P2-15)

Handset Audio (S1-6)

<30mS (no CTCSS)

Add 200mS for CTCSS

Searches at 50ms/channel

4W into 4Ω at <5% distortion

300 to 3000Hz*: +1dB to -3dB

Figures apply for a flat audio response or a 6dB/octave de-emphasis curve

(*2550Hz for 12.5kHz channel spacing)

Speaker: 20% MSD±3dB

Standard build: Flat Unsquelched Audio: 200mV±1dB RMS-O/C (R871=NF,

R872=0R, R82=NF on Rev 9C or 0R/1k on Rev 9B), Flat Squelched Audio:

450mV±2dB RMS-O/C at Rated Speaker Audio (R871=1k or 0R, R872=NF,

R82=NF).

Standard build: Flat Unsquelched Audio: 160mV±1dB RMS (600 ohms) R871=1k,

R82=1k, C857=NF: Flat Squelched Audio: 88mV±2dB RMS (600 ohms) at Rated

Speaker Audio.

230mV±2dB RMS (600 ohms) at Rated Speaker Audio.

© TMC Radio 2006 page 13 TNM-U-E-0002 Issue 1

Page 22

SRM9000 SERIES SERVICE MANUAL

1.8.4 Signalling

1.8.4.1 CTCSS

All 38 standard CTCSS Tones are supported as per the table below.

Identifier Frequency Identifier Frequency Identifier Frequency

Q 67.0 C 107.2 0 167.9

R 71.9 L 110.9 1 173.8

S 74.4 D 114.8 2 179.9

T 77.0 M 118.8 3 186.2

U 79.7 E 123.0 4 192.8

I 82.5 N 127.3 5 203.5

V 85.4 F 131.8 6 210.7

A 88.5 O 136.5 7 218.1

W 91.5 G 141.3 8 885.7

J 94.8 P 146.2 9 223.6

= 97.4 H 151.4 * 241.8

B 100 X 156.7 # 250.3

K 103.5 Y 162.2 ‘ ‘ NONE

Encoder

Tone Deviation:

25kHz channel spacing 500 to 750Hz

20kHz channel spacing 400 to 600Hz

12.5kHz channel spacing 250 to 375Hz

Tone Distortion Less than 5.0%

Frequency Error Less than ±0.5%

© TMC Radio 2006 page 14 TNM-U-E-0002 Issue 1

Page 23

SRM9000 SERIES SERVICE MANUAL

Decoder

Bandwidth Not greater than ±3.0%

Deviation Sensitivity Less than 6.0% of system deviation (for decode with full RF quieting)

Noise Immunity Less than 500ms dropout per minute at 10dB SINAD

(CTCSS tone deviation 10% of system deviation. RF deviation 60% at

1000Hz).

False Decode Rate Less than 5 false decodes per minute (no carrier input)

Talk-off For no dropouts in one minute, interfering tone at 90% of system deviation

(CTCSS tone at 10% of system deviation).

Full quieting signal: 310Hz to 3000Hz

20dB SINAD RF signal: 320Hz to 3000Hz

12dB SINAD RF signal: 350Hz to 3000Hz

Response Time Less than 250ms (full quieting/tone >100Hz)

Less than 350ms (full quieting/tone <100Hz)

De-Response Time Less than 250ms

Reverse Tone Burst none

1.8.4.2 FFSK

1200 Baud : 1200 / 1800 Hz MPT1317 based

2400 Baud : 1200 / 2400 Hz MPT1317 based

1.8.4.3 Selcall

The following tone sets are supported as per tables below:

• ST-500: CCIR, EEA, ZVEI, DZVEI, EIA

• ST500/CML: ZVEI_3, DZVEI

• CML: CCIR, EEA, ZVEI

• SIGTEC: CCIR, CCIRH, EEA, ZVEI_1, XVEI_2, ZVEI_3, NATEL, EIA

• SEPAC: CCIR, EEA, ZVEI_1, ZVEI_2, ZVEI_3, EIA

© TMC Radio 2006 page 15 TNM-U-E-0002 Issue 1

Page 24

SRM9000 SERIES SERVICE MANUAL

Selcall Tone Frequency Table

Tone CML ST500 SIGTEC SIGTEC SEPAC CML ST500 SIGTEC

CCIR CCIR CCIR CCIRH CCIR EEA EEA EEA

0 1981 1981 1981 1981 1981 1981 1981 1981

1 1124 1124 1124 1124 1124 1124 1124 1124

2 1197 1197 1197 1197 1197 1197 1197 1197

3 1275 1275 1275 1275 1275 1275 1275 1275

4 1358 1358 1358 1358 1358 1358 1358 1358

5 1446 1446 1446 1446 1446 1446 1446 1446

6 1540 1540 1540 1540 1540 1540 1540 1540

7 1640 1640 1640 1640 1640 1640 1640 1640

8 1747 1747 1747 1747 1747 1747 1747 1747

9 1860 1860 1860 1860 1860 1860 1860 1860

A 2400 1055 2110 2400 2400 1055 1055 2110

B 930 .... 2400 930 1055 930 .... 1055

C 2247 2400 1055 2247 2247 2247 2400 2400

D 991 .... 2247 991 991 991 .... 2247

E 2110 2110 930 2110 2110 2110 2110 930

F .... .... 991 1055 .... .... .... 991

Tone SEPAC CML ST500 SIGTEC SEPAC SIGTEC SEPAC SIGTEC

EEA ZVEI ZVEI ZVEI-1 ZVEI-1 ZVEI-2 ZVEI-2 ZVEI-3

0 1981 2400 2400 2400 2400 2400 2400 2200

1 1124 1060 1060 1060 1060 1060 1060 970

2 1197 1160 1160 1160 1160 1160 1160 1060

3 1275 1270 1270 1270 1270 1270 1270 1160

4 1358 1400 1400 1400 1400 1400 1400 1270

5 1446 1530 1446 1446 1446 1446 1446 1400

6 1540 1670 1670 1670 1670 1670 1670 1530

7 1640 1830 1830 1830 1830 1830 1830 1670

8 1747 2000 2000 2000 2000 2000 2000 1830

9 1860 2200 2200 2200 2200 2200 2200 2000

A 1055 2800 970 2600 2800 970 885 2400

B 970 810 .... 2800 970 885 741 885

C 2247 970 2800 741 885 741 2600 741

D 2400 886 .... 970 .... 2600 .... 2600

E 2110 2600 2600 810 2600 2800 970 2800

F .... .... .... 886 .... 600 .... 600

© TMC Radio 2006 page 16 TNM-U-E-0002 Issue 1

Page 25

SRM9000 SERIES SERVICE MANUAL

Tone SEPAC ST500/CML ST500 SIGTEC SIGTEC SEPAC ST500

ZVEI-3 ZVEI-3 DZVEI DZVEI NATEL EIA EIA EIA

0 2200 2400 2200 2200 1633 600 600 600

1 970 1060 970 970 631 741 741 741

2 1060 1160 1060 1060 697 882 882 882

3 1160 1270 1160 1160 770 1023 1023 1023

4 1270 1400 1270 1270 852 1164 1164 1164

5 1400 1530 1400 1400 941 1305 1305 1305

6 1530 1670 1530 1530 1040 1446 1446 1446

7 1670 1830 1670 1670 1209 1587 1587 1587

8 1830 2000 1830 1830 1336 1728 1728 1728

9 2000 2200 2000 2000 1477 1869 1869 1869

A 885 885 2600 825 1805 459 2151 2151

B 741 .... .... .... 1995 2151 1091 ....

C 2600 810 886 2600 1300 2600 2400 2010

D .... .... 810 .... 1700 2010 .... ....

E 2400 970 2400 2400 2175 2433 459 459

F .... .... .... .... 2937 2292 .... ....

Selcall Tone Periods

The Selcall tone period:

4 preset lengths selectable: 20ms and 30 seconds in 1ms increments.

1.8.4.4 DTMF

DTMF Encode supported via keypad:

TONES 1209Hz 1336Hz 1477Hz

697Hz 1 2 3

770Hz 4 5 6

852Hz 7 8 9

941Hz * 0 #

Tone Period, programmable: 0 – 2.55s in 10ms steps.

Inter-Tone Period, programmable: 0 – 2.55s in 10ms steps.

Link Establishment Time, programmable: 0 - 10s in 10ms steps.

Tx Hang Time, programmable: 0 – 9.99s in 10ms steps.

Side-Tone in Loudspeaker: selectable via programmer

© TMC Radio 2006 page 17 TNM-U-E-0002 Issue 1

Page 26

SRM9000 SERIES SERVICE MANUAL

1.8.4.5 DCS

Data rate 134 bits per second, frequency modulated

7.46ms/bit

171.6ms per codeword continuously repeating

Deviation 0.5kHz for 12.5kHz systems

1kHz for 25kHz systems

Codeword size 23 bits comprising:

8 bits - DCS code (3 octal digits 000-777)

3 bits - Fixed octal code 4

11 bits - CRC (error detection) code

Available Codes 104 codes from 512 theoretically possible codes – see below

Turn off code 200ms 134Hz tone at PTT release

DCS Codes can be Transmitted “Normal” or “Inverted” (programmable).

The radio can Receive DCS codes in either Transmitted “Normal” or “Inverted” or both (selectable via

programmer).

Valid DCS Codes

023 132 255 413 612

025 134 261 423 624

026 143 263 431 627

031 145 265 432 631

032 152 266 445 632

036 155 271 446 654

043 156 274 452 662

047 162 306 454 664

051 165 311 455 703

053 172 315 462 712

054 174 325 464 723

065 205 331 465 731

071 212 332 466 732

072 223 343 503 734

073 225 346 506 743

074 226 351 516 754

114 243 356 523

115 244 364 526

116 245 365 532

122 246 371 546

125 251 411 565

131 252 412 606

1.8.4.6 C4FM

Digital speech format in accordance with TIA/EIA 102 requirements.

© TMC Radio 2006 page 18 TNM-U-E-0002 Issue 1

Page 27

SRM9000 SERIES SERVICE MANUAL

1.8.5 Environmental

Note: Operation of the equipment is possible beyond the limits stated but is not guaranteed.

Operational Temperature

-30°C to +60°C

Storage Temperature

-40°C to +80°C

Vibration Specification

IEC 68-2-6 with additional frequency acceleration from 60 – 150Hz

Check

Cold

IEC 68-2-1 Test 5 hours at -10°C –30°C

Dry Heat

IEC 68-2-2 Test 5 hours at +55°C +60°C

Damp Heat Cycle

IEC 68-2-30 Test 2 cycles at +40°C

Product Sealing

Main Radio Unit: IEC529 rating IP54

Microphones: IEC529 rating IP54

Remote Control Head IEC529 rating IP54

MIL STD810

Low Pressure 500.4 Procedure II

High Temperature Storage 501.4 Procedure I

High Temperature Operation 501.4 Procedure II

Low Temperature Storage 502.4 Procedure I

Low Temperature Operation 502.4 Procedure II

Temperature Shock 503.4 Procedure I

Humidity 507.4 Figure 507.4-1

Sand and Dust 510.4 Procedure I – Blowing Dust

Random Vibration 514.5 Figure 514.5C-1

Transit Drop 516.5 Table 516.5-V1

Functional Shock of severity 25g

Acceleration, 6ms pulse duration,

500 shocks in 6 directions.

© TMC Radio 2006 page 19 TNM-U-E-0002 Issue 1

Page 28

SRM9000 SERIES SERVICE MANUAL

2. SERVICE PHILOSOPHY

2.1 SERVICE CONCEPT

The SRM9000 series has been designed to provide low cost trunked, non-trunked analogue and digital

speech mobile transceivers, using common core electronics, software and interfacing. It is a requirement

that once the customer has purchased equipment, TMC Radio can follow this by providing an ongoing, high

level of customer support together with a competitive and professional servicing activity.

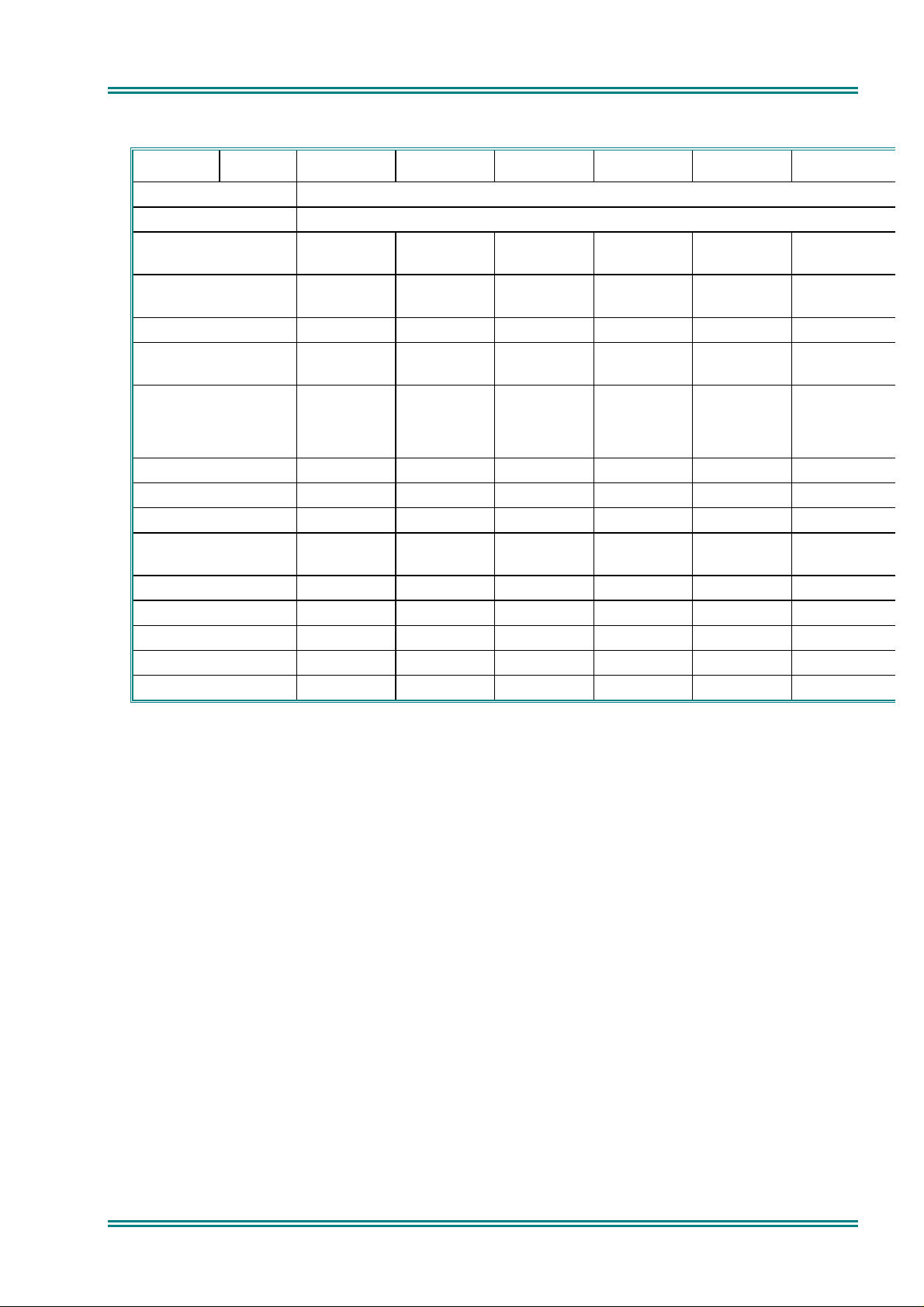

There are three levels of service available:

Level Activity Recommended Spares Recommended Test

Equipment

1 Replacement of complete

transceiver/antenna/fuses

Reprogramming

2 Replacement of PCB or

mechanical component

replacement, Cosmetic repair

3 Repair by PCB or mechanical

component replacement,

Cosmetic repair.

Repair of Radio PCB to

component level in CRU.

Antennas, Fuses

Ancillaries

Listed in Level 2 Spares

Schedule

Listed in Level 2 Spares

Schedule

Radio PCB components

only available to CRU.

Multimeter P.C.

Radio software

Programmer

As above + service aids and

test equipment

As above + service aids and

test equipment

2.2 WARRANTY

Initially, the normal 12-month warranty will apply to all radios and ancillaries.

2.2.1 Service Within and Out Of Warranty

The field Service Level for the SRM9000 mobile is LEVEL 2, PCB replacement.

LEVEL 2 Service, PCB (only) and case part replacement, will be carried out in field repair workshops, or the

Central Repair Unit (CRU) if required.

LEVEL 3 Service (Radio PCB component level repair) will ONLY be carried out in the Central Repair Unit.

For this, the complete radio must be returned to the CRU.

A PCB replacement program may be offered by the CRU in some countries.

2.2.2 Ancillary Items

All ancillary items (except remote alphanumeric control head) are Level 1 service.

These items should be replaced if faulty; they are non-repairable, and non-returnable to the CRU.

2.3 SOFTWARE POLICY

Software provided by TMC Radio shall remain the Company's property, or that of its licensors and the

customer recognises the confidential nature of the rights owned by the Company.

The customer is granted a personal, non-exclusive, non-transferable limited right of use of such software in

machine-readable form in direct connection with the equipment for which it was supplied only.

In certain circumstances the customer may be required to enter into a separate licence agreement and pay

a licence fee, which will be negotiated at the time of the contract.

© TMC Radio 2006 page 20 TNM-U-E-0002 Issue 1

Page 29

SRM9000 SERIES SERVICE MANUAL

The customer undertakes not to disclose any part of the software to third parties without the Company's

written consent, nor to copy or modify any software. The Company may, at its discretion, carry out minor

modifications to software. Major modifications may be undertaken under a separate agreement, and will be

charged separately.

All software is covered by a warranty of 3 months from delivery, and within this warranty period the

Company will correct errors or defects, or at its option, arrange free-of-charge replacement against return of

defective material.

Other than in the clause above, the Company makes no representations or warranties, expressed or implied

such, by way of example, but not of limitation regarding merchantable quality or fitness for any particular

purpose, or that the software is error free, the Company does not accept liability with respect to any claims

for loss of profits or of contracts, or of any other loss of any kind whatsoever on account of use of software

and copies thereof.

© TMC Radio 2006 page 21 TNM-U-E-0002 Issue 1

Page 30

SRM9000 SERIES SERVICE MANUAL

3. TECHNICAL DESCRIPTION

3.1 RECEIVER

Refer to Figure 3-1.

3.1.1 Front End Filters and RF Amplifier

The receiver input signal from the antenna passes through the harmonic filter and antenna switch. With the

mobile in receive mode, diodes D580, D540a and D541a in the antenna switch are reverse biased allowing

the receiver input signal to be coupled through to the receiver front-end with minimal loss. The overall

insertion loss of the harmonic filter and switch is approximately 0.8dB.

A noise blanker is also fitted to E0 band radios. The noise blanker samples the received signal and gates

the 45MHz signal in the IF stage in the event that high level noise transients are received. Due to inherent

time delays in the bandpass filters prior to the blanking gate, gating synchronisation occurs before the

transients can adversely affect the following stages.

Varactor-tuned bandpass filters at the input and output of the RF amplifier provide receiver front-end

selectivity. Varactor tuning voltages are derived from the alignment data stored in the radio. The DSP

processes this data to optimise front end tuning relative to the programmed channel frequencies, which may

be changed at any time without re-aligning the radio.

To achieve the required varactor tuning range an arrangement of positive and negative bias power supplies

is used to provide a total bias across the varactors of up to 14.0VDC. A fixed 2.5V positive bias derived

from the 5.0V supply and voltage divider R425/R426 is applied to the cathodes of the varactor diodes. The

negative bias supply originates at the DSP/PLA as a PWM signal (FE TUNE) for the four front-end tuning

voltages TUNE1 to 4, for the particular channel frequency selected. The PWM signal is dependent on

channel frequency and tuning and passes through level shifting transistors Q404 to Q411 where it is

converted to a negative voltage in the range -0.5V to -11.5V. The -12.0V rail of the level translators is

generated by U904E/F with D903 to D906 providing the required voltage multiplication.

The RF amplifier stage comprises a low noise transistor amplifier Q400 that is compensated to maintain

good linearity and low noise matching. This provides excellent intermodulation and blocking performance

across the full operating range. The overall gain of the front-end is typically 14dB for all bands.

3.1.2 First Mixer and IF Section

The output of the last front-end bandpass filter is coupled into single balanced mixer T400/D413 which

converts the RF signal to an IF frequency of 45MHz. The local oscillator injection level is typically +8dBm at

T400 pin 1 with low side injection used for UHF bands and high side for VHF bands.

Following the mixer is IF amplifier Q401 that provides approximately 15dB of gain and in association with

its output circuitry, presents the required load conditions to the 4 pole 45MHz crystal filters Z401A/Z401B.

The crystal filters provide part the required selectivity for adjacent channel operation with the remaining

selectivity provided by a DSP bandpass filter algorithm.

3.1.3 Quadrature Demodulator

Additional IF gain of approximately 44dB occurs in U401, which is a dedicated IF AGC amplifier/Quadrature

Demodulator. The AGC voltage for U401 is derived from the RSSI function of the DSP. The onset of AGC

operation occurs when RF input signal level at the antenna connector exceeds -90dBm and can reduce the

gain by approximately 100dB for strong signals.

Conversion of the 45MHz IF signal to I and Q baseband signals is carried out by the demodulator section of

U401. The 90MHz local oscillator signal is generated by VCO Q402 which is phase locked by the auxiliary

PLL output of U701 via feedback signal AUX_LO2.

© TMC Radio 2006 page 22 TNM-U-E-0002 Issue 1

Page 31

SRM9000 SERIES SERVICE MANUAL

to U701

from U701

from

PLA

U300

from

PLA

U300

Tx Audio

TX_PSU

AUX_CP

ACK_LO2

VCO

Q412

90 MHz

SWITCH

Q607

Buffer

Synthesiser

VCO Buffer

Q604/Q605

VCO

Q402

90 MHz

To TX Buffer

TX/RX

Switch

D610/D611

AGC

IQ

U401

Demodulator

Filters

4-Pole

45 MHz

Q401

IF Amp

T400

Mixer

Q I

Z401A/B

Noise Blanker E0

Differential

Amp U402

band only

N

I

Aux Gain

A

G

Switch U806A

(Rev9C+only)

TX_MODE

Switch

U801C

TX/TX AF

Q

Switch

Tx/Disc AF

I

U800

CODEC

DATA_EN

U801B

U803B

AF Amp

TX_MOD

From PLA/DSP

TX Mod Out

To TX VCO

RX_PSU

CPP

U701

Synthesiser

Q600

RX VCO

VCO Control Volts

Q601

Switch

RX VCO

TUNE_1, 2, 3 & 4

.

Filter

Bandpass

U803A

AF Amp

Q400

RF Amp

EN 2

U302C

Mode 2

Rx Audio

Filter

Bandpass

.

U802A

AF Amp

.

Rx Audio

De-emphasis

EN 4

Gate

U302B

Network

SPKR_ON

Q810/

Switch

Speaker

Q811/Q813

.

RX_PSU

From PLA

D580/

Switch

Antenna

D540/D541

To TX PA

Filter

L585

L582,

L584 &

Antenna

Rx Audio Mode1

( H/S Audio)

AUDIO_OUT 2

AUDIO_OUT 1

EN 1

U806C

(Rev9C+ only)

(Option Audio)

Rx Audio Mode3

AUDIO_OUT 3

EN 3

Amp

U806B

(Rev9C+ only)

(Option Audio)

U805

Speaker

SPKR_OUT 1

SPKR_OUT 2

Figure 3-1 VHF/UHF Receiver Block Diagram

© TMC Radio 2006 page 23 TNM-U-E-0002 Issue 1

Page 32

SRM9000 SERIES SERVICE MANUAL

3.1.4 Receiver Audio Processing

The base band audio from the IQ Demodulator is applied to a differential amplifier that cancels out DC

offsets and converts the balanced demodulator I/Q output signals to unbalanced inputs for the CODEC

U800.

All receiver audio processing and filtering functions are performed by the CODEC under the control of the

DSP. The receiver I and Q analogue baseband signals are converted to digital signals by the CODEC ADC

before being applied to a series of digital filters which provide the final stage of adjacent channel filtering,

high pass and low pass filtering, mute noise processing and volume control for narrow and wideband

operation. The fully processed signal is then converted to an analogue audio signal by the CODEC DAC

and then applied to conventional audio amplifiers U803A/B and the speaker amplifier U805.

In addition, Discriminator Audio is derived from the other CODEC output channel and then amplified by

U802A after which it is applied to one of the radio I/O connectors for option purposes. Discriminator Audio is

a preset level set by the FPP and is independent of squelch operation.

There are two speaker options available. A half bridged configuration using a speaker across balanced

output SPKR OUT1 and 2, which provides an audio output level of up to 4 watts into 4 ohms. The other

option is a full bridge configuration using a high power speaker across SPKR OUT1 and 2 and providing an

audio output level of up to 10 watts into 8 ohms. The carrier and signalling mute functions are performed

by Q810/811/813 under DSP control. De-emphasis to the audio PA U805 is performed by R861 and

capacitors C866 to C871. Flat audio is provided to S1-6 via amplifier U803A.

© TMC Radio 2006 page 24 TNM-U-E-0002 Issue 1

Page 33

SRM9000 SERIES SERVICE MANUAL

3.2 TRANSMITTER

Refer to Figure 3-2.

3.2.1 Drivers and PA Stages

The RF output level from the VCO T/R switch D611a is typically +5dBm (UHF) and +8dBm (VHF). Tx

buffers Q606/Q612 increase this level to provide approximately 10dBm of drive power to the Tx driver

Q571. The Tx driver stage provides a maximum of 17dBm of drive to the PA module and provides part of

the power control function in conjunction with the first stage of the PA module. The buffer/driver circuits in

conjunction with their attenuator circuits also provide a high degree of VCO isolation from the Tx output.

The gains of PA driver Q571 and PA module are controlled by the power control loop to ensure that

transmitter output power remains within defined limits.

PA module U500 utilises three MOSFET stages (UHF) and two MOSFET stages (VHF) to achieve the

required maximum RF output power level of +44dBm (25 watts).

Note. Care should be taken during servicing since if for any reason the drive power is lost, while the power

control voltage is high, the current into the PA may exceed its specification. Therefore, the power supply

current should be monitored at all times and preset to as low as required. The radio has additional inbuilt

safeguards, but these should not be relied on.

Power output settings are derived from alignment data stored in flash memory during the initial factory

alignment. The DSP processes this data to optimise the power output level relative to the programmed

channel frequencies that may be changed at any time without retuning the radio.

PA current is monitored via comparator U520B, the output of which is passed via a temperature

compensation network R541 to R543 to ADC U301C. U301C samples the applied voltage after which it is

passed to the PLA and then processed by the DSP.

3.2.2 Power Control

Output power is stabilised by a power control feedback loop. A printed circuit transmission line, L580, R580,

D510 and associated components comprise the power detector. Comparator U520A and associated

components provide the power setting and control functions. Forward and reverse power is sampled by the

power detector and applied as a DC voltage to the inverting input of the comparator. The TX_PWR set

voltage is a DC voltage proportional to the programmed Tx power setting and is applied to the non-inverting

input of the comparator.

The TX_PWR voltage originates from the PLA as a PWM signal and is integrated for application to the

comparator.

PA module output level changes due to supply voltage, load or temperature variations are detected and

applied to the comparator that proportionally adjusts the PA module bias supply and the PA driver (Q571)

supply, and therefore the PA drive level. High temperature protection is provided by thermistor R552 that

progressively reduces the power level if the PA module temperature becomes excessive.

3.2.3 Antenna Changeover and Harmonic Filter

The antenna changeover circuit consisting of pin diodes D580/D540a/D541a, is switched by

Q541/Q542/Q543 and associated circuitry allowing the transmitter output to be coupled to the antenna while

providing isolation for the receiver input. With the transmitter switched on, the diodes are forward biased

allowing power to be coupled through to the antenna and isolating the receiver by grounding its input at

C588. The short circuit at the receiver input is transformed to an effective open circuit at D580 by L583,

which minimises transmitter loading. With the transmitter switched off the diodes are reverse biased

allowing the receiver input signal to reach the receiver front end with minimal loss. The harmonic rejection

low pass filter comprises L582/L584/L585 and associated capacitors.

3.2.4 Transmitter Audio Processing

The microphone audio input signal is applied to the microphone input (AUDIO_IN1) and is derived from an

external microphone unit with an applied nominal level of 40mV RMS. U801A is a control gate that switches

between AUDIO_IN1 and OPTION_AUDIO1 to provide external audio options and data input.

© TMC Radio 2006 page 25 TNM-U-E-0002 Issue 1

Page 34

SRM9000 SERIES SERVICE MANUAL

U801C provides CODEC input switching which selects either the receiver I signal or transmitter audio/data

signals depending on the Tx/Rx mode. All pre-emphasis, filtering, compression and limiting processes for

narrow and wideband operation are carried out in the DSP after A-D conversion by CODEC U800. The

processed transmitter audio/data from the CODEC output at VOUTR is applied to the VCO as a modulation

signal with a level of approximately 200mV P/P via AF Switch U801B.

from PLA

Set from PLA

PWM TX Power

Integrator

R308/C307

TX_PWR

R552

Thermal

Shut Back

PA_ON

Q542

Q541/

Switch

Control

Antenna

D510

Power

Control

Detector

Power

U520A

Control

Comparator

LO1_RX

To RX Mixer

Filter

L582/

Antenna

L584/L585

TX Current Sense to PLA

D541

D580/

D540/

Switch

Antenna

Coupler

Directional

TX PA U500

Q571

TX Driver

Amp

Q612

Q606/

TX Buffer

Q611

D610/

TX/RX

Switch

VCO

Q605

Buffer

Q604/

TX_CURRENT

Current

13V8_UNSW From L8

Sense

U520B

Standard Microphone

External Accessory Audio

MOD_SW

Switch

U801A

Internal MIC/ External

Audio Control From PLA

I

Q

TX_MODE

Switch

U801C

RX/TX AF

From PLA

TX/RX AF Control

Q602

TX VCO

TX_MOD

Q603

Switch

TX VCO

From PLA/DSP

Gate

Audio

U801B

ADC/DAC/

CODEC U800

DATA_EN

Figure 3-2 VHF/UHF Transmitter Block Diagram

3.3 FREQUENCY SYNTHESISER

3.3.1 General

Refer to Figure 3-3.

© TMC Radio 2006 page 26 TNM-U-E-0002 Issue 1

Page 35

SRM9000 SERIES SERVICE MANUAL

The frequency synthesiser consists of one transmitter and two receiver voltage controlled oscillators, loop

filters, varactor negative bias generator, reference oscillator and an integrated dual phase locked loop

device U701.

3.3.2 PLL

The PLL device contains two prescalers, programmable dividers and phase comparators to provide a main

and auxiliary PLL. The main PLL of U701 controls the frequency of the Tx/Rx VCOs via Control Voltage

outputs at pins 2 and 3 and VCO feedback to pin 6. The auxiliary PLL is used to control the receiver 90MHz

second local oscillator via the Control Voltage output at pin 17 and VCO feedback to pin 15. The PLL

operation involves the division of the 14.4MHz reference oscillator frequency to 225kHz (VHF) or 450kHz

(UHF) by divider U710. It is then divided by the internal divider of U701 down to a low frequency that

corresponds to a sub-multiple of the radio channel spacing, ie. 6.25kHz for 12.5/25kHz channel spacing,

5kHz for 10/20kHz channel spacing or 7.5kHz if required. The VCO frequency is sampled and divided down

to the same frequency after which it is phase compared to the reference. Any error produces an offset to the

Control Voltage output that is used to correct the VCO frequency. A valid lock detect output is derived from

pin 20 and is sampled by the PLA. During transmit, if an unlocked signal is detected the radio will switch

back to receive mode. An unlocked signal in receive mode will cause the radio to beep.

3.3.3 VCO’s

The transmitter and receiver VCO’s use low noise JFET transistors Q600 (Rx), Q602 (Tx) and associated

parts to generate the signals for the required band coverage. Electronic tuning is provided by varactor

diodes D600 to D608 with their control voltages derived from the Loop Filter, PLL and Negative Bias

Generator. VCO selection and timing is controlled by the DSP/PLA via the Rx and Tx power supplies and

applied through switches Q601 (Rx) and Q603 (Tx). VCO buffer Q604/Q605 isolates the VCO from load

variations in following circuits and active power supply filter Q615 minimises supply related noise. A PLL

feedback signal is sampled from the VCO buffer output via buffer Q607.

The 90MHz receiver VCO comprises Q402 and associated parts. Automatic tuning is achieved by applying

a control voltage to D414/D415 via Loop Filter R445, R446, R701, C486, C701 and C702.

3.3.4 Negative Bias Generator and Loop Filter

A positive and negative varactor bias supply similar to the front-end varactor arrangement has been used to

achieve the required broadband tuning range of the VCO’s. PLL device U701 is programmed to deliver a

nominal +2.5V output from phase detector/charge pump CPPF or CPP regardless of the channel frequency

selected. This voltage is filtered to remove synthesiser noise and reference products by the Loop Filter

comprising C671 to C681 and R653/R654/R655. The resulting low noise voltage is applied to the cathode

side of the VCO varactor tuning diodes as a positive bias voltage. The negative bias supply originates as a

positive DC voltage (0.1V to 3.0V) at the DAC output of U701 (DOUT) with a level relative to the

programmed state of the radio (eg. channel frequency and Tx/Rx state). The voltage is translated to a

negative voltage between 0V and –16V by the circuit comprising Q700 to Q703. The -16V rail of this supply

is generated by U904E/F with D903 to D906 providing the voltage multiplying effect needed to achieve 16V. The output of the negative supply is applied directly to the VCO varactor anodes as the negative

tuning voltage VCAP BIAS.

3.3.5 Phase Modulator

The modulation path for audio, data and higher frequency CTCSS signals is via varactor D609 and its

associated components in the Tx VCO. The reference input to the PLL (REF) provides the low frequency

modulation path via the Phase Modulator.

The phase modulator comprises the following sections:

- Integrator U711A is a low pass filter providing 6dB per octave attenuation to frequencies above

approximately 10Hz.

- Divider U710 divides the 14.4MHz reference frequency down to 225kHz (VHF) or 450kHz (UHF).

- Ramp generator Q711/Q712 provides a saw tooth output, the slope of which is adjustable

via the MOD_BAL line. This adjustment is set via a DAC output controlled from the Alignment

Tool. Adjustment of the ramp slope effectively changes the Phase Modulator gain by

modification of the Schmitt Trigger switching points after modulation from the Integrator is

combined to the saw tooth ramp.

© TMC Radio 2006 page 27 TNM-U-E-0002 Issue 1

Page 36

SRM9000 SERIES SERVICE MANUAL

To RX Mixer

The divided reference signal is differentiated and discharges C744 via Q711 after which Q711 is turned

off allowing C744 to recharge via constant current source Q712/Q713.

- Schmitt Trigger comprising Q714 to Q716 converts the modulation combined with the saw tooth ramp

to a square wave output, the duty cycle of which is controlled by the ramp slope and modulation.

Modulation balance adjustment is carried out using a CODEC generated 100Hz square wave applied to

the TX_MOD input and set to give an optimum demodulated square wave output.

3.3.6 Reference Oscillator

TCXO U700 determines the overall frequency stability and frequency setting of the radio. The frequency

setting is achieved by adjusting its ADJ voltage with the Alignment Tool. In addition, the ADJ input is used in a

frequency control loop with the receiver I and Q signals to provide receiver AFC. U700 operates at 14.4MHz

and is specified at ±2.0ppm frequency stability over the temperature range -30° to +75°C.

Data From

DSP

RX_PSU TX_PSU

RX_PSU

To IQ

Demodulator

U400

TX_MOD

MOD_BAL

Integrator

U711A

Buffer

U711B

LO2

Ramp

Generator

Q711Q713

3.4 CONTROL

Refer to Figure 3-4.

SYNTH

Buffer

Q710

CPP

CPPF

DOUT

PLL Loop

Filter

VCO Neg

Bias

Supply

Q700Q703

14.4MHz

Reference

Oscillator

U700

VCAP_BIAS

AFC

from

PLA

RX/TX VCO

Q600/ Q602

TX_MOD

90MHz

VCO Q402

Phase

Modulator

Q714-

Q716

Divide 32 (UHF)

Divide 64 (VHF)

AUX_LO2

AUX_CP

Prog.

Divider

U710

REF

Synthesiser

U701

Figure 3-3 VHF/UHF Synthesiser, Block Diagram

VCO

Buffer

Q604/

Q605

Synth

Buffer

Q607

TX/RX

Switch

D601/

D611

To TX Buffer

LO1_RX

3.4.1 DSP and PLA

The SRM9000 transceiver operates under the control of a DSP (U201) and PLA (U300) combination that

together with a number of other dedicated devices perform all the operational and processing functions

required by the radio. The PLA is configured by the DSP under software control to provide the following

functions:

• Channel set-up of all operating frequencies

• Modulation processing and filtering

• De-modulation processing and filtering

• Tx power output reference

© TMC Radio 2006 page 28 TNM-U-E-0002 Issue 1

Page 37

SRM9000 SERIES SERVICE MANUAL

• Modulation Balance adjustment

• Receiver front-end tuning

• Serial communications with alignment tool, microphone and control head

• Modem functionality for data modulation

• All signalling / CTCSS generation and decoding

• DSP Crystal Oscillator control

• Receiver muting control

• RSSI / AGC control

• AFC

• Tx / Rx switching and PTT control

• PLL lock detect

• Audio switching

• Power On/Off control

• Interface functionality with Option Boards and External Devices

• Battery voltage and Tx current monitor

3.4.2 DSP Clock Oscillator

The DSP is clocked by a 15.360MHz oscillator that consists of crystal X200 and an internal DSP oscillator.

Q200 forms a crystal switching circuit with C205 which, when activated by a command from the PLA, steers