Sime Open Hybrid MEM 30-009, Open Hybrid MEM 25-009, Open Hybrid MEM 35-006, Open Hybrid MEM 30-006, Open Hybrid MEM 35-009 Installation And Maintenance Manual

...

Fonderie SIME S.p.A.

6322912 - 03/2016 - R3

INSTALLATION AND MAINTENANCE MANUAL

OPEN HYBRID MEM ErP

Dear Customer,

Thank you for purchasing an

Open Hybrid MEM ErP

system, a last generation appliance, with all the technical and performance

features to satisfy your needs for heating and the supply of domestic hot water, in maximum safety and with low running costs.

We recommend that your new appliance is started up within 30 days from the date of installation by qualified technicians,

so that you can benefit from both the legal warranty and the conventional warranty provided by

Sime

which is to be found

at the end of this manual.

EN

2

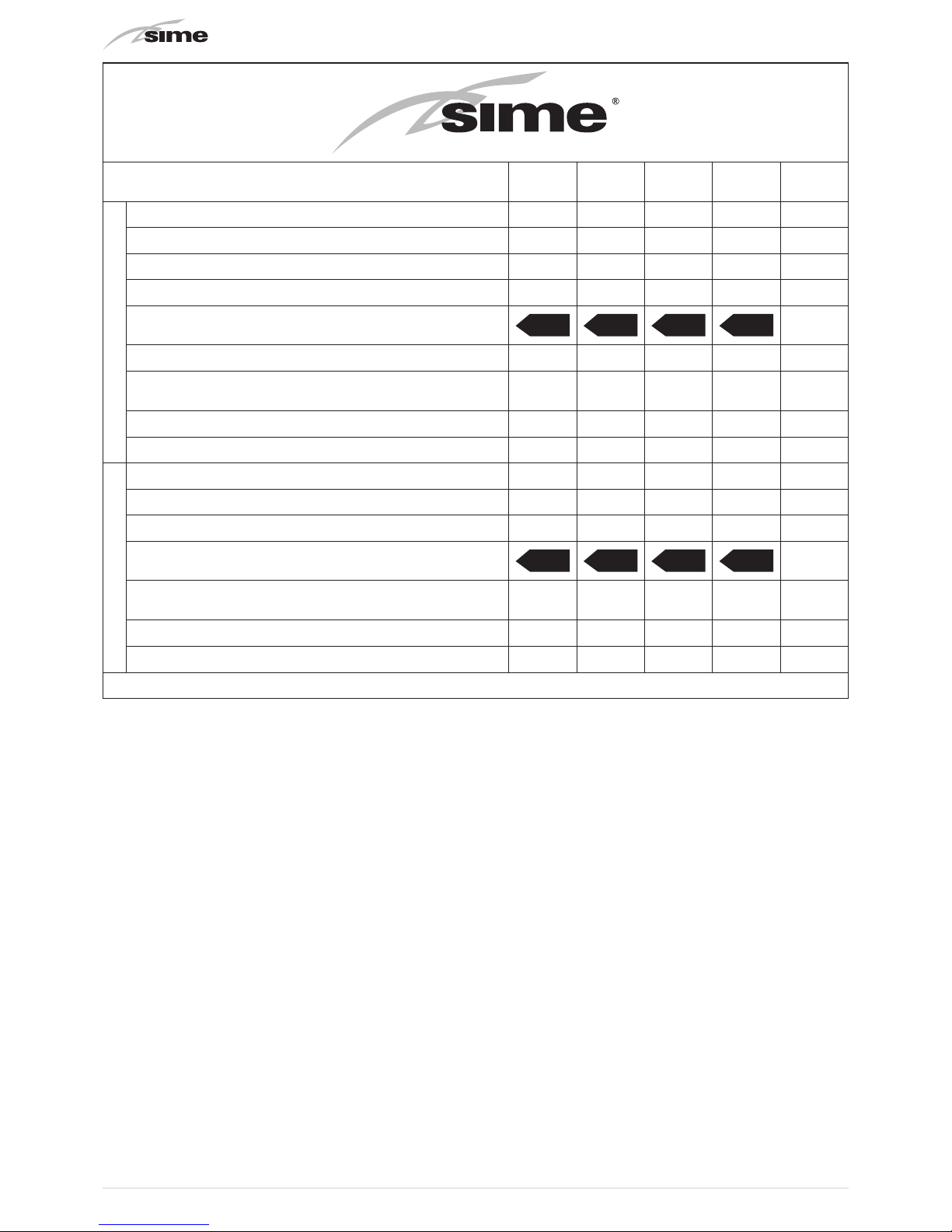

RANGE

MODEL CODE

Open Hybrid MEM 25-006 8114400

Open Hybrid MEM 25-009 8114401

Open Hybrid MEM 25-012 8114402

Open Hybrid MEM 30-006 8114403

Open Hybrid MEM 30-009 8114404

Open Hybrid MEM 30-012 8114405

Open Hybrid MEM 35-006 8114406

Open Hybrid MEM 35-009 8114407

Open Hybrid MEM 35-012 8114408

Open Hybrid MEM 25-006 S 8114409

Open Hybrid MEM 25-009 S 8114410

Open Hybrid MEM 25-012 S 8114411

Open Hybrid MEM 30-006 S 8114412

Open Hybrid MEM 30-009 S 8114413

Open Hybrid MEM 30-012 S 8114414

Open Hybrid MEM 35-006 S 8114415

Open Hybrid MEM 35-009 S 8114416

Open Hybrid MEM 35-012 S 8114417

COMPLIANCE

Our company declares that

OPEN HYBRID MEM ErP

systems

comply with the following directives:

– Gas Appliances Directive 2009/142/EC

– Low Voltage Directive 2006/95/EC

– Electromagnetic Compatibility Directive 2004/108/EC

– Ecodesign Directive 2009/125/EC

– Regulation (UE) N. 811/2013 - 813/2013

SYMBOLS

a

DANGER

To indicate actions which, if not carried out correctly,

can result in injury of a general nature or may damage or cause the appliance to malfunction; these

actions therefore require particular caution and adequate preparation.

f

DANGER

To indicate actions which, if not carried out correctly, could lead to injury of an electrical nature; these

actions therefore require particular caution and adequate preparation.

d

IT IS FORBIDDEN

To indicate actions which MUST NOT BE carried out.

m

WARNING

To indicate particularly important and useful information.

TABLE OF CONTENTS

1 SYSTEM DESCRIPTION 4

1.1 Operation ......................................5

1.1.1 Domestic hot water . . . . . . . . . . . . . . . . . . . . 5

1.1.2 Heating .............................. 5

1.1.3 Cooling .............................. 6

1.1.4 Anti-freeze function .................... 6

1.1.5 Anti-blocking function .................. 6

1.1.6 Photovoltaic function ................... 6

1.1.7 Automatic filling function ............... 6

1.1.8 Automatic degassing function ........... 6

1.2 Structure ......................................7

1.3 Technical data ..................................8

1.3.1 Boiler ................................ 8

1.3.2 Heat pump............................ 9

1.4 Main water circuits .............................10

1.4.1 Open Hybrid MEM ErP base............. 10

1.4.2 Open Hybrid MEM ErP base - High

Temperature kit....................... 10

1.4.3 Open Hybrid MEM ErP base - High

Temperature Kit - Solar Kit ............. 11

1.5 Sensors.......................................12

1.6 Expansion vessels ..............................12

1.7 Circulation pump ..............................12

1.7.1 High temperature system pump ......... 12

1.7.2 Low temperature system pump.......... 12

1.7.3 Pump equipped with LED............... 12

1.8 Mem Remote Control ...........................13

1.9 Electrical panel ................................13

1.10 Wiring diagram ................................14

2 INSTALLATION 16

2.1 Receiving the product ...........................16

2.2 Dimensions ...................................16

2.3 Handling ......................................16

2.4 Installation of the Open Hybrid Mem ErP System ....16

2.4.1 Heat pump installation................. 20

2.5 Smoke outlet and combustion air inlet .............21

2.5.1 Openings in the frame to allow the passage

of the smoke outlet.................... 21

2.5.2 Separate ducts (Ø 60/100mm) ........... 22

2.5.3 Separate ducts (Ø 60mm and Ø 80mm) ... 22

2.6 Mem Remote Control Installation .................23

2.7 Solar thermal storage tank connections............23

2.8 Position of the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.9 Electrical connections...........................25

2.9.1 Connection to the mains ............... 25

2.9.2 Component connections................ 25

2.9.3 Boiler connections .................... 25

2.10 Filling operations...............................26

2.10.1 Automatic degassing function ........... 27

2.10.2 Setting boiler parameters .............. 27

2.11 Emptying operations ............................28

3 COMMISSIONING 29

3.1 Preliminary operations ..........................29

3.2 Commissioning ................................29

3.3 Parameter setting and display ....................30

3.4 Complete list of parameters......................31

3.5 Parameter functions ............................34

3.5.1 General settings ...................... 34

3.5.2 Generation System Settings............. 35

3.5.3 Input and Output Configuration .......... 37

3.5.4 Heating ............................. 38

3.5.5 Cooling.............................. 40

3.5.6 DHW................................ 41

3.5.7 Energy Settings....................... 42

3.5.8 Communication....................... 43

4 MAINTENANCE 44

4.1 Adjustments...................................44

4.2 Alarms .......................................44

4.3 Any pump faults and possible solutions ............46

4.4 Alarm log .....................................46

5 APPLICATION DIAGRAMS 47

6 PRODUCT DATA SHEET 55

3

SAFETY WARNINGS AND REGULATIONS

m

WARNINGS

– After having removed the packaging make sure

that the product supplied is integral and complete

in all its parts. If this is not the case, please contact the Dealer who sold the appliance.

– The appliance must be used as intended by

Sime

who is not responsible for any damage caused to

persons, animals or things, improper installation,

adjustment, maintenance and improper use of the

appliance.

– In the event of water leaks, disconnect the appli-

ance from the mains power supply, close the water

mains and promptly inform professionally qualified personnel.

– Periodically check that the operating pressure of

the water heating system when cold is

1,0-1,2 bar

.

If this is not the case, increase the pressure or

contact professionally qualified personnel.

– If the appliance is not used for a long period of

time,

ONLY WHEN THERE IS THE RISK OF FREEZING

,

at least one of the following operations must be

carried out:

-

set the main system switch to "OFF";

-

close the gas and water valves for the water

heating system.

– If there is the risk of freezing, leave the gas valves

open and ensure the appliance is connected to the

mains power. This way the anti-freeze function will

remain active if set appropriately.

– In order to ensure optimal appliance operations

Sime

recommends that maintenance and checks

are carried out

ONCE A YEAR.

m

WARNINGS

–

It is recommended that all operators

read this manual carefully in order to use the appliance in a safe

and rational manner.

–

This manual

is an integral part of the appliance. It

must therefore be kept for future reference and

must always accompany the appliance in the event

the appliance is transferred or sold to another

Owner or User or is installed on another system.

–

Installation and maintenance

of this appliance must

be carried out by a qualified company or by a professionally qualified technician in accordance with

the instructions contained in the manual. The

company or technician will, at the end of installation operations, issue a statement of compliance

with national and local Technical Standards and

Legislation in force

RESTRICTIONS

d

IT IS FORBIDDEN

– The appliance is not to be used by children or un-

assisted disabled persons.

– Do not use electrical devices or appliances such as

switches, electrical appliances etc if you can smell

fuel. If this should happen:

-

open the doors and windows to air the room;

-

close the gas isolation device;

-

promptly call for professional assistance.

– Do not touch the appliance with bare feet or with

any wet part of the body.

– Do not carry out any technical intervention or

cleaning operation before having disconnected

the appliance from the mains power by setting the

main switch to "OFF", and closing the gas supply.

– Do not modify the safety or adjustment devices

without authorization and instructions from the

manufacturer.

– Do not block the condensate drain (if present).

– Do not pull, detach or twist the electrical cables

coming out of the appliance even if the appliance is

disconnected from the mains power supply.

– Do not block or reduce the size of the ventilation

openings of the room where the appliance is in-

stalled, if present.

– Remove the mains power and gas supply from the

appliance if the external temperature could fall

below ZERO (risk of freezing).

– Do not leave containers with flammable substanc-

es in the room where the appliance is installed.

– Do not leave packaging material around since it

could be dangerous. Therefore dispose of it as pre-

scribed by legislation in force.

4

1 SYSTEM DESCRIPTION

OPEN HYBRID MEM ErP systems are built-in, “modular” systems for heating and cooling rooms and for the production of

domestic hot water. They can be "assembled" on the basis of

the system needs requested by the customer.

The basic OPEN HYBRID MEM ErP structure consists of:

– Enclosure frame, fully recessed for outdoors, or in cabinet

for indoors. This must be ordered and installed before the

"components" are requested.

– Basic appliances/components (to be installed inside the

built-in housing structure):

– Hot water storage tank in stainless steel with a capacity

of 150 litres.

– 25, 30 or 35 kW hot water on-demand condensing boiler

– Main electrical panel.

– 8 litre hot water expansion vessel

– Relief valve and pump.

– Pipes for connecting all the appliances which make up

the system.

– A bag containing nuts, bolts and screws, the technical

data plate and the assembly instructions.

– Single column solar panel assembly complete with all the

water circuit elements needed for operating a solar ther-

mal circuit if installed (optional).

– Thermostatic mixer (optional)

– 12 litre solar thermal expansion vessel (optional)

Additional appliances/devices to complete the basic/minimum structure:

– Sime SHP M ErP heat pump to be selected on the basis of

system requirements

– MRM Remote Control to manage the entire system.

In the basic configuration, OPEN HYBRID MEM ErP systems

provide hot water at a maximum delivery temperature of 60°C

and return temperature of 50°C, but they can also be integrated with the following optional kits:

– High temperature kit: to manage system terminals such as

radiators, fan convectors.

– Solar kit: to use the SIMESOL 182 solar panel to produce

domestic hot water maximising the use of alternative energy and limiting boiler usage.

m

WARNING

– With this appliance the USE OF THE EXTERNAL

SENSOR IS COMPULSORY for the boiler to work

with a sliding temperature (delivery temperature

varies automatically on the basis of the external

temperature detected), for the activation of the an

ti-freeze function and to calculate the convenience

of the ener

gy sour

ces.

– Commissioning of the OPEN HYBRID MEM

ErP system must be carried out by qualified

technicians.

Fig. 1

5

1.1 Operation

1.1.1 Domestic hot water

The 150 litre hot water storage tank in STAINLESS STEEL is

made exclusively from renewable sources with the following

priorities:

1

Solar Thermal Energy (if present);

2

Heat pump.

The domestic hot water prepared in the storage tank always

remains in the boiler before being used. The boiler burner is

activated by the MEM only if the inlet temperature does not

reach the setpoint set by the user.

– Weekly programming from the MEM display for the prepa-

ration of the domestic hot water and therefore of the storage tank.

– The solar thermal system (if present) can prepare the 150

litres of hot water in the storage tank at the maximum temperature of 90°C. The actual energy ratio depends on the

solar rays which the solar collector is subject to. The solar

thermal pump is managed by the MEM on the basis of the

storage tank-collector and implements the ANTI-FREEZE

COLLECTOR, COOLING COLLECTOR).

– The heat pump can prepare 150 litres of hot water in the

storage tank up to the maximum temperature of 50°C.

Preparation by the heat pump only occurs in periods in

COMFORT mode. To allow for preparation when also in REDUCED mode, act on the specific parameter.

– The amply dimensioned plate heat exchanger allows the

heat pump to operate with high COP values also for the

preparation of domestic hot water in addition to reduced

restore times. Management by the MEM includes activation

of the heat pump only when the storage tank is almost completely depleted of hot water in order to reduce the number

of start-ups to a minimum and to allow the heat pump to

operate at low temperatures (high COP).

– The actual preparation temperature of the storage tank by

the heat pump is calculated dynamically by the MEM on the

basis of the efficiency conditions (external temperature +

delivery temperature).

– The MEM manages the heat pump domestic hot water pri-

ority on the basis of some modifiable parameters:

– Priority in the summer (COOLING or DOMESTIC HOT WATER

with maximum time to be set). Default priority COOLING

– Priority in the winter (HEATING or DOMESTIC HOT WATER

with maximum time to be set). Default priority DOMESTIC

HOT WATER for no more than 30 minutes.

– The ANTI-LEGIONELLA function, if enabled, includes prepa-

ration of the storage tank at a temperature of 55°C (maintained for approximately 2 hours) once a week for bacteria

sanitisation.

1.1.2 Heating

– The heating request is made by means of the dry contact

(for example, a safety limit microswitch, etc..).

– The medium-low temperature heating circuit can reach a

maximum delivery temperature of 55°C with only the heat

pump operating. It is possible to reach a temperature of

60°C (return 50°C) with the combined heat pump - boiler

operation.

– The 30 litre inertial storage tank acts as a thermal flywheel

(needed by the heat pump) and hydraulic separator allowing operation with any flow rate processed by the system.

Thanks to the specific design, the inertial tank always guarantees the best possible working conditions for the heat

pump making it work at the minimum temperature made

available by the system (no mixing of the return water inside

the inertial storage tank).

– The delivery setpoint can be set by the user at a fixed value

or it can be calculated dynamically by the MEM on the basis

of the external temperature and the selected climatic curve.

– System safety thermostat (50°C fixed calibration with the

option of deactivating the parameter) to protect the radiating system at low temperatures.

– In every operating condition, the MEM control unit calcu-

lates the heat pump COP (external temperature + delivery

temperature) and therefore whether the boiler or the heat

pump is most appropriate and it controls the subsequent

activation. If the most appropriate source is not sufficient to

cover the system needs, the other source can be activated

at the same time for the minimum energy needed to reach

the setpoint (this function can be set by the specific parameters). This way AND (simultaneous) operation is possible of

the sources allowing the heat pump to be activated even in

conditions in which it would normally be switched off as the

power output is less than the system requirements.

– The power modulation of the heat pump and the boiler is

always controlled by the MEM at the minimum level necessary to meet the set system setpoint (there is no increase in

the generator setpoint in relation to the system if not necessary).

– The defrost function of the heat pump is controlled by the MEM

eliminating almost all temporary comfort loss and compensating the energy withdrawn from the system or the boiler.

– Using the MEM parameters, it is possible to set gas and

electrical energy costs to allow the dynamic calculation of

the financial advantage of using each individual source. If

this data is not available, the energy convenience will still

be calculated (primary energy equivalence).

– The high efficiency and high flow-head modulating pump

is able to guarantee the necessary flow rate to the system

adjusting the number of revolutions (and therefore the consumption) on the basis of the instantaneous absorbed power of the system.

– Option of installing a HIGH TEMPERATURE KIT for an addi-

tional heating circuit with delivery temperature up to 80°C.

This circuit is used exclusively by the boiler as the temperatures are too high for the heat pump to operate. If the request is made for the boiler to operate together with the

high and low temperature circuits, the boiler generates with

a high temperature setpoint while the low-temperature circuit is adjusted by means of a distribution valve before mixing inside the puffer to obtain the set temperature.

6

1.1.3 Cooling

– Setting the summer mode (cooling) from the remote display

or remote contact (option of installing a summer/winter selector for the user's convenience - not supplied).

– The cooling request is made by means of the dry contact (for

example, a safety limit microswitch, etc..).

– Heat pump operation only in cool mode.

– Fixed system setpoint set by the user.

– Humidistat input (dry contact) for a second setpoint which

can be set by the installer for dehumidification (reduction)

or to prevent the formation of condensate in the radiating

system (increase).

– The power modulation of the heat pump is always controlled

by the MEM at the minimum level necessary to meet the set

system setpoint (there is no reduction in the heat pump setpoint in relation to the system if not necessary).

– 30 litre puffer and pipes with insulation present. The install-

er must complete the insulation of the connection points as

indicated in the installation manual.

1.1.4 Anti-freeze function

– Protection activated by the MEM with activation of the pumps,

valves and generators on the basis of the temperatures detected by the sensors (electrical power is required). It is essential that there is a correctly installed external sensor.

1.1.5 Anti-blocking function

– Function controlled by the MEM with the activation of all the

active organs after a period of inactivity to prevent blocking

(electrical power is required).

1.1.6 Photovoltaic function

– Function managed by the MEM to increase the amount of

auto-consumption of the electrical energy produced by a

photovoltaic system if installed.

1.1.7 Automatic filling function

– If system pressure drops with the subsequent intervention

of the low pressure alarm, it is possible to refill simply be

pressing a button on the display.

1.1.8 Automatic degassing function

– Function to be activated by the installer or technical per-

sonnel to allow rapid degassing of the air inside the system

during commissioning

– In any case, the system must be made according to the di-

agrams present in the installation manual and goose-neck

fittings are to be avoided.

– If they cannot be avoided, the installer must ensure that

there are bleed devices in the top sections.

7

1.2 Structure

1

2

6

5

4

3

8

7

9

18

15

20

21

19

16

14

13

12

11

10

17

Fig. 2

KEY

1

150 litre domestic hot water storage tank

2

Plate heat exchanger (Sp)

3

Sensor socket

B1

4

Sensor

B5

5

Diverter valve (VD)

6

Domestic hot water pump (PS)

7

Domestic hot water expansion vessel (Ve)

8

Sensor socket

B2

9

Domestic hot water storage tank drain valve

(

Rs

)

10

Domestic hot water relief valve (Vs)

11

Sensor

B3

12

System safety thermostat (TS)

13

Check valve (Vr)

14

Low temperature system pump

(PI)

15

Inertial puffer

16

Automatic filling

(EV)

17

Electrical panel

18

Condensation boiler

19

Mem Remote control

20

External sensor (SE)

21

Sime SHP M ErP heat pump

8

1.3 Technical data

1.3.1 Boiler

DESCRIPTION

Brava Slim HE ErP

25 30 35

CERTIFICATIONS

Country of intended installation

IT – ES – PT – GR – SI

Fuel

G20 / G31

PIN number

1312CP5936

Category

II2H3P

Appliance classification

B23P - B33P - B53P - C13 - C33 - C43 - C53 - C63 - C83

Class NOx

5 (< 70 mg/kWh)

HEATING PERFORMANCE

HEAT INPUT (*)

Nominal flow (Q

n max)

kW 20 24 30

Minimum flow (Qnw min)

kW 4 4,8 6

HEAT OUTPUT

Nominal (80-60°C) (P

n max)

kW 19,7 23,6 29,5

Nominal (50-30°C) (Pn max)

kW 21,4 25,7 32,2

Minimum G20 (80-60°C) (Pn min)

kW 3,9 4,7 5,9

Minimum G20 (50-30°C) (Pn min)

kW 4,3 5,1 6,5

Minimum G31 (80-60°C) (Pn min)

kW 3,9 4,7 5,9

Minimum G31 (50-30°C) (Pn min)

kW 4,3 5,1 6,5

EFFICIENCY

Max useful efficiency (80-60°C)

% 98,5 98,3 98,3

Min useful efficiency (80-60°C)

% 97,5 97,9 98,3

Max useful efficiency (50-30°C)

% 107 107,1 107,3

Min useful efficiency (50-30°C)

% 107,5 106,3 108,3

Useful efficiency at 30% of load (40-30°C)

% 107,0 107,0 107,0

Thermal efficiency (EEC 92/42)

Losses after shutdown at 50°C

W 84 88 88

DOMESTIC HOT WATER PERFORMANCE

Nominal heat input (Q

nw max)

kW 24 28 34,8

Minimum heat input (Qnw min)

kW 4 4,8 6

Specific D.H.W. flow rate ∆t 30°C (EN 13203)

l/min 11,2 12,9 16,5

Continuous D.H.W. flow rate (∆t 25°C / ∆t 35°C)

l/min 13,6 / 9,7 16,1 / 11,5 20 / 14,3

Minimum D.H.W. flow rate

l/min 2 2 2

Max (PMW) / Min Pressure

bar 7 / 0,5 7 / 0,5 7 / 0,5

kpa 700 / 50 700 / 50 700 / 50

ENERGY PERFORMANCE

HEATING

Heating seasonal energy efficiency class

A A A

Heating seasonal energy efficiency

% 91 91 91

Sound power

db(A) 54 56 53

DOMESTIC HOT WATER

Domestic hot water energy efficiency class

A A A

Domestic hot water energy efficiency

% 82 80 80

Stated domestic hot water profile load

XL XL XL

ELECTRICAL SPECIFICATIONS

Power supply voltage

V 230

Frequency

Hz 50

Absorbed electrical power (Qn max)

W 70 85 92

Absorbed electrical power at (Qn min)

W 52 52 57

Absorbed electrical power in stand-by

W 3,6 3,6 3,6

Electrical protection degree

IP X5D

COMBUSTION DATA

Smoke temperature at Max/Min flow (80-60°C)

°C 82 / 66 89 / 71 77 / 67

Smoke temperature at Max/Min flow (50-30°C)

°C 59 / 45 71 / 51 58 / 49

Maximum smoke flow Min/Max

g/s 11,2 / 1,9 13,1 / 2,2 16,3 / 2,8

CO2 at Max/Min flow rate (G20)

% 9,0 / 9,0 9,0 / 9,0 9,0 / 9,0

CO2 at Max/Min flow rate (G31)

% 10,0 /10,0 10,0 /10,0 10,0 / 10,0

NOx measured

mg/kWh 39 41 37

NOZZLES GAS

Number of nozzles

No. 1 1 1

Nozzle diameter (G20-G31)

mm 5,3 5,3 5,3

Gas consumption at Max/Min flow rate (G20)

m3/h 2,53 / 0,42 2,96 / 0,50 3,70 / 0,63

Gas consumption at Max/Min flow rate (G31)

Kg/h 1,86 / 0,31 2,17 / 0,37 2,71 / 0,46

Gas supply pressure (G20/G31)

mbar 20 / 37 20 / 37 20 / 37

kpa 2 / 3,7 2 / 3,7 2 / 3,7

TEMPERATURE PRESSURE

Max operating temperature (T max)

°C 85

Heating adjustment range

°C 20÷80

Domestic hot water adjustment range

°C 10÷60

9

DESCRIPTION

Brava Slim HE ErP

25 30 35

Max operating pressure (PMS)

bar 3

kpa 300

Water content in boiler

l 4,65 4,75 4,95

Lower Heat Output (Hi)

G20 Hi.

9,45 kW/m3 (15°C, 1013 mbar) -

G31 Hi.

12,87 kW/kg (15°C, 1013 mbar)

1.3.2 Heat pump

DESCRIPTION

SHP M ErP

006 009 012

ELECTRICAL SPECIFICATIONS

Power supply 230V/1/50Hz 230V/1/50Hz 230V/1/50Hz

Maximum absorbed power kW 2,81 4,61 5,78

Maximum inrush current A 7,9 13,0 16,4

Maximum absorbed current A 12,3 20,2 25,4

COOLING

Cooling capacity (1) kW

3,88

6,10 7,71

Absorbed power (1) kW 1,34 2,10 2,65

E.E.R. (1) W/W 2,90 2,91 2,91

Cooling capacity (2) kW

5,46

8,52 11,8

Absorbed power (2) kW 1,51 2,36 3,11

E.E.R. (2) W/W 3,62 3,61 3,80

HEATING

Heat Output (3) kW

5,40

8,30 11,63

Absorbed power (3) kW 1,69 2,59 3,64

C.O.P. (3) W/W 3,20 3,20 3,20

Heat Output (4) kW

5,65

8,88 12,28

Absorbed power (4) kW 1,40 2,19 3,02

C.O.P. (4) W/W 4,05 4,05 4,06

COMPRESSOR

Type Rotary DC Inverter Rotary DC Inverter Twin Rotary DC Inverter

Number 1 1 2

Absorbed power while cooling (1) kW 1,25 2,16 2,59

Absorbed power while cooling (2) kW 1,21 2,10 2,73

Absorbed power while heating (3) kW 1,36 2,26 2,44

Absorbed power while heating (4) kW 1,18 2,00 2,90

Coolant oil (type, quantity) mL ESTER OIL VG74, 480 ESTER OIL VG74, 820 FV50S, 1070

FAN MOTOR

Type DC Brushless Motor DC Brushless Motor DC Brushless Motor

Number 1 1 2

Nominal absorbed power kW 0,156 0,188 2 x 0,18

Nominal absorbed current A 0,48 0,57 2 x 0,55

Speed r/min 900 900 1000

Maximum air flow rate m

3

/s 1,08 1,63 2,42

COOLANT

Type R410A R410A R410A

Coolant quantity kg 1,55 2,10 3,65

Project pressure (high / low) MPa 4,2 / 1,5 4,2 / 1,5 4,2 / 1,5

WATER CIRCUIT

Water flow rate (4) L/s 0,29 0,45 0,59

Useful flow-head (4) kPa 43 29 51

Pump nominal power (4) kW 0,094 0,102 0,125

Pump maximum power kW 0,124 0,124 0,165

Pump maximum absorbed current A 0,55 0,55 0,75

Expansion vessel L 2 2 2

Plumbing connections inch 1”M 1”M 1”M

Minimum water volume L 18 25 25

NOISE LEVEL

Sound pressure (5) dB(A) 44-50 45-53 46-54

DIMENSIONS AND WEIGHTS

Dimensions (WxHxD) mm 1134x719x373 1229x861x368 1260x1400x448

Max dimensions of package (WxHxD) mm 1310x850x430 1310x1000x430 1260x1400x448

Operating weight kg 73 92 135

Net/gross weight kg 69/77 87/96 140/153

Performance with the following conditions:

(1) Cooling: external air temperature 35°C; water temperature in/out 12/7°C.

(2) Cooling: external air temperature 35°C; water temperature in/out 23/18°C.

(3) Heating: external air temperature 7°C b.s. 6°C b.u.; water temperature in/out 40/45°C.

(4) Heating: external air temperature 7°C b.s. 6°C b.u.; water temperature in/out 30/35°C.

(5) Sound pressure level measured in free field at 1 m from the unit according to ISO 3744

10

1.4 Main water circuits

1.4.1 Open Hybrid MEM ErP base

LOW

TEMPERATURE

SYSTEM

PUFFER

PI

Vr

Vr

PSVsSp

Water mains

Water mains

DOMESTIC HOT WATER

STORAGE HEATER

VD

F

HEAT

PUMP

MU E R

SE

Vr

B2

B5

B3

TS

B1

Ve

VM

Fig. 3

1.4.2 Open Hybrid MEM ErP base - High Temperature kit

1

LOW

TEMPERATURE

SYSTEM

PI

PS

Water mains

Water mains

Radiator

VD

F

HEAT

PUMP

MU E R

SE

B2

B5

B3

TS

B1

Ve

VM

VAT

PUFFER

DOMESTIC HOT WATER

STORAGE HEATER

Vr

Vr

Vs

Sp

Vr

Fig. 4

11

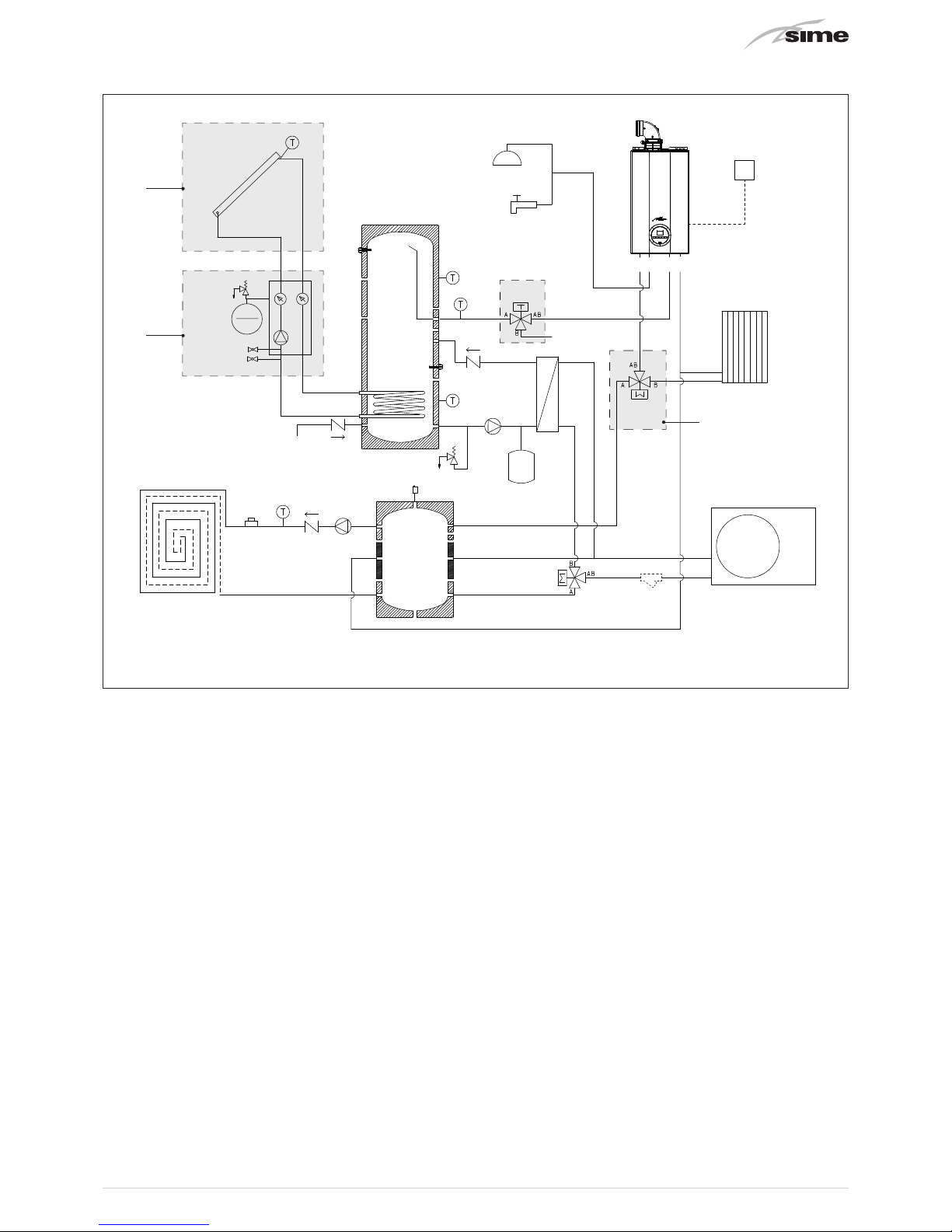

1.4.3 Open Hybrid MEM ErP base - High Temperature Kit - Solar Kit

3

2

1

LOW

TEMPERATURE

SYSTEM

PI

Vr

Vr

PS

Vs

Sp

Water

Mains

Water mains

Solar

unit

VeS

Radiator

VD

F

HEAT

PUMP

SOLAR

COLLECTOR

MU E R

SE

Vr

B2

B5

B4

B3

TS

B1

Ve

VM

VAT

PUFFER

DOMESTIC HOT WATER

STORAGE HEATER

Fig. 5

KEY

Vr

Check valve

VD

Diverter valve

Vs

Relief valve

TS

Safety thermostat (low temperature system)

PS

Domestic hot water pump

PI

System pump (low temperature)

Sp

Plate heat exchanger

Ve

Domestic hot water expansion vessel

VeS

Solar expansion vessel (optional)

VM

Domestic hot water valve (optional)

VAT

High temperature valve (optional)

B1

Domestic Hot Water High Sensor

B2

Domestic Hot Water Low Sensor

B3

Low Temperature system delivery sensor

B4

Solar Collector Sensor (supplied with the Solar Kit)

B5

DHW Inlet O-ring sensor (in boiler)

SE

External sensor

F

Y Filter (not supplied, the responsibility of the installer)

M

Delivery

R

Return

U

DHW Output

E

DHW Inlet

1

HIGH TEMPERATURE KIT

2

SOLAR KIT

3

SOLAR PANEL

12

1.5 Sensors

The sensors installed have the following characteristics:

– B1 - Domestic Hot Water Storage Tank High Sensor NTC

R25°C; 10kΩ

– B2 - Domestic Hot Water Storage Tank Low Sensor NTC

R25°C; 10kΩ

– B3 - Low Temperature system delivery sensor NTC R25°C;

10kΩ

– B4 - Solar Collector Sensor (supplied with the Solar Kit)

PT1000

– B5 -DHW Inlet O-ring sensor (in boiler) NTC R25°C; 10kΩ

– SE - External sensor NTC R25°C; 10kΩ

Correspondence of Temperature Detected/Resistance

Examples of reading:

TR=75°C → R=1925Ω

TR=80°C → R=1669Ω

TR

0°C 1°C 2°C 3°C 4°C 5°C 6°C 7°C 8°C 9°C

Resistenza R (

Ω)

0°C

27279

17959

12090

8313

5828

4161

3021

2229

1669

1266

973

26135

17245

11634

8016

5630

4026

2928

2164

1622

1232

25044

16563

11199

7731

5440

3897

2839

2101

1577

1199

24004

15912

10781

7458

5258

3773

2753

2040

1534

1168

23014

15289

10382

7196

5082

3653

2669

1982

1491

1137

22069

14694

9999

6944

4913

3538

2589

1925

1451

1108

21168

14126

9633

6702

4751

3426

2512

1870

1411

1079

20309

13582

9281

6470

4595

3319

2437

1817

1373

1051

19489

13062

8945

6247

4444

3216

2365

1766

1336

1024

18706

12565

8622

6033

4300

3116

2296

1717

1300

998

10°C

20°C

30°C

40°C

50°C

60°C

70°C

80°C

90°C

100°C

1.6 Expansion vessels

The expansion vessel installed on the boilers has the following

characteristics:

Expansion vessel

Capacity (l)

Prefilling

(kpa) (bar)

in boiler

9 100 1

domestic hot water

8 300 3

solar

12 250 2.5

(*) Conditions of:

Average maximum temperature of the system 85°C

Start temperature at system filling 10°C.

m

WARNING

– The difference in height between the relief valve

and the highest point of the system cannot exceed

6 metres. If the difference is greater than 6 metres,

increase the prefilling pressure of the expansion

vessel and the system when cold by 0.1 bar for each

meter increase.

1.7 Circulation pump

The flow-head performance curve for the pumps used in the Open

Hybrid MEM ErP Systems are indicated in the following graphs:

1.7.1 High temperature system pump

RESIDUAL HEAD (mbar)

0

0 800 1000 1200600400200

100

200

300

400

500

600

30

25

35

FLOW (l/h)

Fig. 5

1.7.2 Low temperature system pump

Flow-head-Performance Diagram (Pump at max speed and

∆p constant).

0

0 800 1000 1200 1400 1600

1800

600400200

100

200

300

400

500

RESIDUAL HEAD (mbar)

FLOW (l/h)

600

700

800

Fig. 6

1.7.3 Pump equipped with LED

LED

Fig. 7

13

Brava Slim HE 35 ErP

boilers use the pump equipped with LED

warning lights which indicate:

LED colour Status Trouble-shooting

LED off No electrical power

Green

Permanently

on

Normal operation

Red/Green Flashing

"Transient safety shutdown"

Anomaly in progress

Red Flashing Permanent safety shutdown

For the “Any pump faults and possible solutions“ see the rel-

evant section at the end of the manual.

1.8 Mem Remote Control

The MEM Remote Control manages the entire system

OPEN HYBRID MEM ErP.

Prg

Esc

156

Backlit display

82

31

Button Function

Alarm display (if present)

Red flashing light = alarm present

Access to parameters menu

(press and hold)

Return to previous menu or the Main screen

Scroll forwards

Confirm the selection of an item in the menu or

modification of value/data

Scroll backwards

Fig. 8

1.9 Electrical panel

To facilitate the electrical connections,it is recommended that

the panel is hooked to a clip on the domestic hot water storage tank. The panel is equipped with the following pre-cabled

components which require connection.

1

3

6

2

4

5

7

KEY

1

Control unit

2

Communication bus converter

3

Transformer

4

Power supply terminals

5

Low voltage terminals

6

High voltage terminals

7

Fuses

Fig. 9

14

1.10 Wiring diagram

BOILER

Y2

Y1

B -

A +

GNX

MOD-BUS

CONVERTOR

230V - 24V

TRANSFORMER

30VA

SP1

230V

0

230

GND

A

B

24

0

F2

T 2A

CABLE

SUPPLIED 6m

Extendable up to 50m

(RJ12 telephone cable)

24V

B4

B1

B2

B3

B5

B6

B8

ID1

GND

ID2

PE

L

N

N06

N07

N01

NA

LA

TS

MO3

MO1

12 3

LV system protection

(present in electrical panel)

CONTROL UNIT

EARTH

NODE

ELECTRICAL PANEL

FUI

T 6.3A

GND

Y2

C2

N02

N03

C3

G

G0

SYNC

SYNC

B1

B2

B3

B4

B5

B6

GND

+5Vref

+VDC

IDI

GND

CI

NCI

NOI

N04

N05

N06

N07

C3

GND

ID2

B7

B8

GND

TLAN

Y1

GNX

+

-

GND

+

-

N03

C3

N04

N05

N06

N07

C3

GND

ID2

B7

B8

OT

SE

MO2

N L N L

PE

N L

PE

M

2

3

6

M

DOMESTIC HOT WATER PUMP

LOW TEMPERATURE SYSTEM PUMP

AUTOMATIC FILLING VALVE

HEAT PUMP DIVERTER VALVE

KEY

1 Control unit

2 Mod-bus converter

3 Transformer

MO1/3

Electrical panel terminal board

OT OpenTherm Connection

B1 Domestic Hot Water High Sensor

B2 Domestic Hot Water Low Sensor

B3 Low Temperature system delivery sensor

B4 Solar Collector Sensor

B5 DHW Inlet O-ring sensor in boiler

15

Electrical wiring diagram

NANO1

NALA

NALA

LA

NA

L

N

NANO6

PE

PE

PE PE

GND

GND

GND

GND

GND

NANO7

ELECTRICAL PANEL TERMINAL BOARD (Open Hybrid Mem)

MO1

GNX

2

6

3

GND

GND

BLUE

BLACK

BROWN

123456

T

BOILER TERMINAL BOARD

ID2

ID1

B6

B4

B8

24 V

Y2

Y1

B -

FU2

FU1

A +

GND

HEAT PUMP TERMINAL BOARD

N1

L1

R+

R-

GNDR

ELECTRICAL PANEL CONTROL UNIT

MEM REMOTE CONTROL

M

EXTERNAL SENSOR - OPTIONAL KIT

(cable not supplied 2x0.5mm²)

RJ12 TELEPHONE CABLE supplied as

standard L=6m extendable up to 50m

HEAT PUMP - MODBUS

(cable not supplied shielded 3x0.5mm²)

BOILER - POWER SUPPLY

(boiler output cable supplied as standard)

SOLAR PUMP - OPTIONAL KIT

(cable supplied in optional kit)

COLD MODE

(230Vac 1A max - cable not supplied 2x1.5mm²)

HIGH TEMPERATURE CIRCUIT VALVE - OPTIONAL KIT

(cable supplied in optional kit)

HIGH TEMPERATURE CIRCUIT REQUEST (*)

LOW TEMPERATURE CIRCUIT REQUEST (*)

HUMIDISTAT REQUEST (*)

MULTIFUNCTION DIGITAL INPUT (*)

SOLAR COLLECTOR SENSOR - OPTIONAL KIT (*)

L

N

PE

IG1

PE

POWER SUPPLY

230 V - 50 Hz

OT (Cable from electrical panel supplied as standard)

T

(*) cable not supplied 2x0.5mm²

ANTI-FREEZE RESISTOR - OPTIONAL KIT

(cable supplied in optional kit)

L

N

L

N

KA

MO3

MO2

N

L

PE

IG2

HEAT PUMP

POWER SUPPLY

230 V - 50 Hz

16

2 INSTALLATION

2.1 Receiving the product

The OPEN HYBRID MEM ErP systems are supplied with the

following packages:

1

2

4

3

Fig. 10

m

WARNING

Package 2 contains the Pipe Kit, the Mem Remote Control, the sensors and the insulation parts to be used after

lling.

2.2 Dimensions

Description

W

(mm)

D (mm) H (mm)

1 - Domestic Hot Water Storage Tank 370 375 2100

2 - Plumbing system kit 500 380 1235

3 - Boiler 450 280 780

4- SHP M 006 ErP heat pump

1140 375 720

4- SHP M 009 ErP heat pump

1230 370 865

4- SHP M 012 ErP heat pump 1260 450 1400

2.3 Handling

Handling of the Sime OPEN HYBRID MEM ErP system is to be

carried out with equipment which is suitable for the dimensions and weights of the parts using suitable accident prevention protection.

When handling is not carried out manually, operators must ensure

that the maximum weight per person is not exceeded.

a

DANGER

Use suitable tools and accident prevention protection when removing the packaging and when handling the appliance.

d

IT IS FORBIDDEN

Do not leave packaging material around or near

children since it could be dangerous. Dispose of it as

prescribed by legislation in force.

2.4 Installation of the Open Hybrid Mem ErP

System

The OPEN HYBRID MEM ErP system is to be assembled in the

following sequence:

– Domestic hot water storage tank

– Boiler

– Plumbing system kit

INSTALLATION OF THE DOMESTIC HOT WATER STORAGE TANK

Lift the domestic hot water storage tank and hook onto the frame

bracket (A), place the upper slot on the storage tank onto the prearranged pun (B) and secure using the nut and washer supplied.

The storage tank can only be made secure when it is hooked

to the frame bracket.

A

B

C

Fig. 11

– Mount the 3/8”-3/4” reducer (supplied) on the water mains con-

nection fitting (C) using sealant or teflon to ensure tightness.

17

BOILER INSTALLATION

Position the boiler inside the built-in frame hanging it by placing the slots on the two prearranged pins. Secure using the

nuts and washers supplied.

Fig. 12

m

WARNING

The installer must ensure that a condensate outlet

pipe is fitted. The pipe must not have any siphons

or horizontal sections to prevent ice from forming if

there is condensate inside.

WATER SYSTEM KIT INSTALLATION

m

WARNING

Always place a seal on every joint and tighten the

swivel joints only when all operations have been

completed.

Premise

Check that the connections have already been fitted on the

fitting template

– Connect the pipe (1) code 6277844 (cold water inlet from

mains) to the connection (E- mains inlet) of the fitting template

and to the domestic hot water storage tank

– Connect the pipe (2) code 6277821 to the plate heat exchanger

(Sp) and rest it on the shelf (M) in the built-in frame. Connect the

pipe (2) to the domestic hot water storage tank

2

M

Sp

1

E

Fig. 13

– Mount the assembly consisting of: pipe (3) code 6277822, do-

mestic hot water pump (PS), pipe (4) code 6277823, relief valve

(Vs) and cock (Rs)

m

WARNING

– To facilitate the installation/tightening operations,

it is recommended that the assembly is connected

after having fitted the pipes.

– Fit the domestic hot water pump (PS) with the arrow

facing upwards.

3

Sp

4

Rs

Vs

PS

Fig. 14

18

– Connect the pipe (5) code 6277824 to the connection (U-Do-

mestic hot water output) of the fitting template and to the boiler connection (U-DHW output)

– Connect the pipe (6) code 6226973 to the connection (G-Gas) of

the fitting template and to the boiler connection (G-gas)

– Connect the pipe (7) code 6277832 to the connection (E-ACS

inlet) of the boiler and the domestic hot water storage tank

5

U G

7 6

Fig. 15

– Connect the pipe (8) code 6277828 to the plate heat exchanger

(Sp)

– Connect pipe (9) code 6277830 to the pipe (8) connection and

to the connection (MP- Heat Pump Delivery) of the fitting template

– Connect the pipe (10) code 6277825 to the plate heat exchang-

er (Sp) and to the diverter valve (VD)

m

WARNING

Respect the direction of the diverter valve as shown

in the figure below

VD

11

12

B A

AB

10

Fig. 16

– Connect the pipe (11) code 6277827 to the

diverter valve (VD)

– Connect the pipe (12) code 6277826 to the diverter valve (VD)

and to the connection (RP-Heat Pump Return)

Rp

Mp

8

10

12

11

VD

9

Fig. 17

19

Fit the puffer by placing the slot onto the prearranged pin, inside

the frame and secure it using the washer and nut supplied

– Connect the pipes (11) and (8) to the puffer

– Connect the pipe (13) code 6277834 to the connection (R- sys-

tem return) of the boiler and to the puffer

– Connect the pipe (14) code 6277829 to the connection (R- sys-

tem return) of the fitting template and to the puffer

R

R-caldaia

8

14

13

11

Fig. 18

– Create the assembly consisting of the pipe (15) code 6277831,

the check valve (Vr) with the arrow facing downwards, the low

temperature system pump (PI) and the pipe (16) code 6277835;

connect the assembly to the puffer and to the connection

(M-System delivery) of the fitting template

M

16

PI

Vr

15

Fig. 19

20

– Connect the pipe (17) code 6277833 to the connection (M-de-

livery) of the boiler and to the puffer

– Connect the pipe (18) code 6277848 to the connection on the

pipe (7) and to the solenoid valve (EV)

– Connect the solenoid valve (EV) to the small automatic system

filling pipe (19)

– Make sure that the check valve and the mesh filter are correctly

installed in the solenoid valve seat

18

19

7

M-caldaia

EV

17

Fig. 20

– Fit the domestic hot water expansion valve code 6245108 to the

prearranged bracket in the built-in frame and secure it using

the counternut supplied

– Connect the flexible tube code 6017401 to the domestic hot

water expansion vessel and to the connection (Z) of the pipe (3)

ensuring that the vessel, when undergoing maintenance, can

be moved without needing to be even partially drained.

– Before filling the system, close all the unused connections of the

storage tank and the pipes using the bronze plugs supplied

Z

Ve

Fig. 21

2.4.1 Heat pump installation

All models of the SHP M ErP series have been designed and

built to be installed externally and therefore the following precautions are recommended:

– observe and respect all the minimum service gaps indicated

below as this will prevent recirculation between intake and delivery which can cause the unit to perform poorly or even interrupt normal operation.

– create a floor (raised support base) suitably sized for the unit.

When the unit is operating in heating mode, the floor prevents

the formation of ice which, if allowed to accumulate, can interfere with machine operation.

– place anti-vibration supports between the base and the contact

surface even if the units are only transmitting minor vibrations

to the ground

Model

Dimensions

A B* C D E*

SHP M 006 ErP 1500 500 400 400 500

SHP M 009 ErP 1500 500 400 400 500

SHP M 012 ErP 1500 500 400 400 500

*

Recommended gaps for installation, technical assistance and

maintenance

A

D

C

B

E

Fig. 22

Plumbing connections

The plumbing connections must be carried out in compliance

with National or Local Regulations in force. The pipes must

be made in steel, galvanised steel or PVC and they must be

appropriately dimensioned on the basis of the nominal water

flow of the unit and the load losses of the water circuit. All

plumbing connections must be isolated using closed cell material which is of a suitable thickness. The Heat Pump must

be connected to the pipes using flexible joints. The following

components must be installed in the water circuit:

– Socket thermometers to detect the circuit temperature.

– Manual shutter valves to isolate the Heat Pump from the water

circuit.

– Y filter with metal link not exceeding 1 mm positioned on the

Heat Pump inlet pipe.

– Filling assembly and discharge valve where necessary.

m

WARNING

For additional and more detailed information, refer

to the manual supplied with the Heat Pump.

21

2.5 Smoke outlet and combustion air inlet

Brava Slim HE

boilers must be equipped with appropriate smoke flue ducts and combustion air inlet ducts. These ducts are consid-

ered an integral part of the boiler and are provided by

Sime

as an accessory kit, to be ordered separately from the appliance on the

basis of the type permitted and the system requirements Also refer to the manual supplied with the boiler.

2.5.1 Openings in the frame to allow the passage of the smoke outlet

The drawing indicates the positions and prearranged dimensions in the built-in frame for the outlets for the smoke outlet and

combustion air inlet pipes

280

Ø120

Ø140

Ø140

Ø140

Ø140

135

85

280

Top view

Front view Rear viewRight side view

135

85

135

85

Fig. 23

m

WARNINGS

– The smoke flue and the connection to the flue pipe must be in compliance with the national and local Standards and

Legislation in force.

– The use of rigid ducts which are resistant to temperature, condensate, mechanical stress and are air-tight is compul-

sory.

– Outlet ducts which are not isolated are a risk of danger.

22

2.5.2 Separate ducts (Ø 60/100mm)

Constructing outlets for coaxial ducts indicates the use of the

"extension" code 8093107. This is to be ordered separately and

when connected to the other accessories, from those listed in

the table below, completes the smoke-outlet/ combustion air

inlet assembly.

Extension

1

2

3

4

Fig. 24

KEY:

1

Extension

2

Air inlet

3

Smoke outlet

4

Take-off point for smoke analysis

Coaxial accessories

Description

Code

Ø 60/100 mm

Coaxial duct kit 8096250

Extension W. 1000 mm 8096150

Extension W. 500 mm 8096151

Vertical extension W. 140 mm with

smoke analysis take-off point

8086950

Adapter for Ø 80/125 mm Additional 90° curve 8095850

Additional 45° curve 8095950

Tile with joint 8091300

Roof outlet terminal W. 1284 mm 8091205

2.5.3 Separate ducts (Ø 60mm and Ø 80mm)

Constructing outlets for separate ducts indicates the use of

the "air-smoke split pipe system". This is to be ordered separately from the boiler and when connected to the other accessories, from those listed in the table below, completes the

smoke-outlet/ combustion air inlet assembly.

Split pipe system

4

2

1

3

Fig. 25

KEY:

1

Split pipe system with take-off point

2

Air inlet

3

Smoke outlet

4

Take-off point for smoke analysis

Separate accessories

Description

Code

Diameter Ø

60 (mm)

Diameter Ø

80 (mm)

Air-smoke split pipe system (without

take-off point)

8093060 -

Air-smoke split pipe system (with takeoff point)

- 8093050

90° curve M-F (6 pieces) 8089921 8077450

90° curve M-F (with take-off point) 8089924 M-F 80/60 reduction 8089923 Extension W. 1000 mm (6 pieces) 8089920 8077351

Extension W. 500 mm (6 pieces) - 8077350

Extension W. 135 mm (with take-off

point)

- 8077304

Wall outlet terminal 8089541 8089501

Internal and external ring nut kit 8091510 8091500

Inlet terminal 8089540 8089500

45° curve M-F (6 pieces) 8089922 8077451

Manifold 8091400

Tile with joint 8091300

Roof outlet terminal W. 1390 mm 8091204

Inlet/outlet fitting Ø 80/125 mm - 8091210

m

WARNING

–

The maximum total length of the ducts,

obtained by

adding the lengths of the inlet and outlet pipes,

is determined by the load losses of the individual

accessories used and

must not exceed 15 mm H2O

.

23

m

WARNING

–

For all boiler versions,

the total extension must not

in any case exceed 25 m (inlet) + 25 m (outlet) for

ducts Ø 80 mm The total extension must not exceed 6 m (inlet) + 6 m (outlet) for ducts Ø 60 mm,

even if the total load loss is less than the maximum which can be applied

2.6 Mem Remote Control Installation

Wall mounting of the Mem Remote Control requires the initial

fitting of the rear holder (A) either directly onto the wall using two expansion plugs (not supplied) or a standard 3 module

case for switches using the dome headed screws to be found

inside the packaging.

– Connect the telephone line from the electrical panel of the Pen

Hybrid Mem

– Rest the front section (B) to the rear holder and secure

everything using the countersunk screws to be found inside

the packaging

– Apply the push-on rim (C)

A

B

C

Fig. 26

m

NB.

The cable supplied with the appliance is 6 m long

and can be extended to up to 50 m with an RJ12 telephone cable.

2.7 Solar thermal storage tank connections

1

- From the plate heat exchanger

2

- Magnesium anode

3

- Socket for Sensor B2 (Domestic Hot Water Storage Tank Low)

4

- Connection for fitting 3/8”-3/4”

5

- Socket for Sensor B1 (Domestic Hot Water Storage Tank High)

6

- DHW boiler inlet

7

- Solar Delivery Kit (to Solar Assembly)

8

- Solar Return Kit (to Solar Assembly)

9

- Water mains connection

1

5

6

7

8

9

2

3

4

Fig. 27

24

2

1

3

F

Fig. 29

– Using a pointed instrument, make a hole (F) in the cable gland

suitably dimensioned for the bipolar connection cable. The cable gland must prevent any moisture from penetrating.

– Insert the bipolar connection cable into the cable gland hole (F)

which must be at the bottom of the cable gland.

– Secure the sensor (2) to the wall using the screws supplied.

– Connect the bipolar cable to the terminals (3) inside the sensor.

– Refit the cover (1) on the sensor base.

m

WARNING

– The bipolar connection cable to the sensor is not

supplied.

– It can have a maximum cross section of 1 mm,a

maximum length of 30 metres and does not need

to respect the polarity.

– It is recommended that joints are avoided, if they are

necessary, they must be watertight and suitably protected.

– Any connection cable ducts must be separated from

live cables (230V a.c.)

2.8 Position of the sensors

The sensors

B1 (Domestic Hot Water Storage Tank High

and

B2

(Domestic Hot Water Storage Tank Low)

are connected in the

factory and must only be put into the sockets prearranged on

the domestic hot water storage tank. Gently tighten the socket

safety screw without crushing the cable to prevent the sensors from detaching.

The sensors

B5 (DHW boiler inlet), B3 (Low temperature system

delivery)

and

TS (Low Temperature system Safety Thermostat)

are

supplied with the appliance and must be positioned by the installer as indicated in the figures below and be connected to

the electrical panel (see “1.10 Wiring diagram”). Make sure

that no mistake is made regarding the fast-ons of the B5 and

B3 sensors as they are similar.

TS

B3

B5

Fig. 28

The

external sensor (SE)

, supplied as standard, must be positioned on a wall of the building to be heated. This wall must be

the one which is most exposed to the wind and is NORTH or

NORTH-WEST FACING. It must be placed at 2/3 of the height

of the wall.

The socket must be secured on a

smooth

section of the wall

and where there is open brickwork or irregular walls it is be

made in an area which is as smooth as possible.

d

IT IS FORBIDDEN

To position the external sensor near doors, windows

or flue pipes or any other heat source (for example,

direct sunlight).

INSTALLATION

After having identified the installation position:

– Drill the hole for the expansion plug (5x25) supplied with the

sensor and insert the plug.

– Remove the cover (1) using a small screwdriver or by twisting

the cover but without exerting excess force.

25

2.9 Electrical connections

2.9.1 Connection to the mains

The

Open Hybrid Mem ErP

appliance and the

Heat Pump

must be

connected to the mains network

independently

in compliance

with the applicable technical Regulations and national and local legislation in force.

m

WARNING

Each connection to the mains network must:

– Use an omnipolar cut-off switch

– Disconnect switch, in compliance with EN Stand-

ards

– Respect the connections L (Live) - N (Neutral)

– Connect the earth wire to an effective earthing sys-

tem. The manufacturer is not responsible for any

damage caused by failure to earth the appliance or

failure to observe the information provided in the

wiring diagrams.

d

IT IS FORBIDDEN

To use water pipes for earthing the appliance.

2.9.2 Component connections

The

Open Hybrid Mem ErP

appliance is equipped with an electrical panel to which the following cables have been wired in

the factory:

– Low Temperature System Pump Cable (PI)

– Domestic Hot Water Pump Cable (PS)

– Heat Pump Diverter Valve Cable (VD)

– Automatic Filing Valve Cable (CA)

– Connection Cable to Mem Remote Control (RJ12)

– Low Temperature System Safety Thermostat Cable (TS)

– OpenTherm Cable (OT) to be connected to the boiler terminal

board (terminals 5 and 6)

Inputs for the electrical

connection cables

Side

Rear

Fig. 30

m

WARNING

To facilitate the electrical connections, hook the panel

to a clip on the domestic hot water storage tank.

To make the connection cables enter the inside of

the built-in frame, use the designated openings prearranged in the lower part of the frame (see

“Fig. 30”

on page 25

)

To make the connection cables enter the inside of

the panel, use the prearranged openings (1) (see

“Fig. 31” on page 25)

.

The main power cable and the boiler power cable must pass

through the PG type restricting cable glands.

The other cables must pass through the prearranged openings

which are to be appropriately drilled and must be secured using

the free cable-lock at the bottom of the electrical panel.

1

Fig. 31

2.9.3 Boiler connections

The connections to be made are:

– the electrical power connection, already connected t the

boiler, to the Open Hybrid Mem ErP electrical panel.

– the external sensor (optional) and the communication cable

(OT) to the boiler terminal board.

SE

OT

SAUX

6

5

4

3

2

1

Fig. 32

All connectors pre-cabled to the electrical panel are marked with

the symbol to identify the device which is to be connected (see

water circuit diagram).

26

2.10 Filling operations

Filling the domestic hot water storage tank

To fill the storage tank:

– Open one or more than one hot water tap

– Open the water system isolation valve

– Wait until clean water comes out and then close them

Filling the systems

To fill the systems:

– Provide electrical power to the OPEN HYBRID MEM ErP and

the Heat Pump by setting the Main Switches IG1 and IG2 to

"ON"

ON

– The following screens will appear on the Mem Remote Con-

trol display and on the boiler display:

13:17:08 THUR 09/10/14

OPEN HYBRID MEM

– Open all the automatic bleed devices on the boiler, on the

heat pump and on the puffer

– Where possible, select the maximum pump speed (low tem-

perature system, domestic hot water system)

– Set all devices on the system to heat request (TA, etc.)

– Manually open the automatic filling valve, setting the screw

(A) to the “OPEN” position (screwdriver size 45° approximately preferably with rotation to the left and the right.)

OPEN

(45° rh or lh)

CLOSED

A

Fig. 33

NB.

The pressure in the system, visible on the boiler display for

filling purposes, should be

1.2 bar.

– Press the button on the Mem Remote Control for at-

least 5 s, until the screen appears

ENTER PASSWORD

1243

– Press to confirm and enter “password” settings. The

cursor will be on the first digit to be set.

– Press

and set (1)

– Press

to confirm and prearrange the setting for the 2nd

digit

– Press

and set (2)

– Press

to confirm

– Continue in the same way until the last digit has been con-

firmed (3).

– The

PARAMETERS MENU

screen will appear

PARAMETERS MENU

GENERAL SETTINGS

GENERATION

I/O CONFIGURATION

HEATING

COOLING

DOMESTIC HOT WATER

ENERGY SETTINGS

– Activating the Automatic Degassing Function

27

2.10.1 Automatic degassing function

To activate the Automatic Degassing Function

– Press

to select GENERATION

PARAMETERS MENU

GENERAL SETTINGS

GENERATION

I/O CONFIGURATION

HEATING

COOLING

DOMESTIC HOT WATER

ENERGY SETTINGS

– Press to confirm and enter GENERATION S202 and

to

display the screen GENERATION S203

GENERATION S203

AUTOMATIC

DEGASSING FUNCTION:

NOT ACTIVE

– Press to confirm and go into the modifiable area

– Press or and select “ACTIVE”

– Press

to confirm the modification made, start Automat-

ic Degassing.

NB.

Automatic degassing lasts 30 minutes and deactivates automatically. It can be interrupted at any moment, if necessary

by pressing the buttons

or and once again selecting

“NOT ACTIVE”. This function can be repeated a number of

times.

– Before finishing the degassing function, open the available

manual bleed valves (radiators, fan convectors, etc.)

Once the degassing function has finished

– Check on the boiler display that the system pressure is at

1.2 bar and adjust if necessary.

– Remove the heat request (TA, etc.) set previously.

2.10.2 Setting boiler parameters

To go into the parameters menu:

– from the stand-by screen press the button

y

– select the operating mode WINTER

n

– press the buttons r and t (for approximately 5 seconds)

at the same time until

“PAR 01”

(parameter number) and the

value set (0-4) appears on the display

– press the button t to scroll up through the list of parame-

ters until reaching

PAR 17

.

NB.:

pressing and holding the buttons r or t lets the user

scroll quickly.

– on reaching

PAR 17

, press the button < and set the value to

“0”

. The modifications are stored automatically.

– press the button

t

and move to

PAR 18

.

– press the button

<

and set the value to

“2”

.

– press the button t and move to

PAR 40

.

– press the button

<

and set the value to

“--”

.

–

simultaneously

, press and hold the buttons r and t for a

few seconds until the initial screen appears.

28

m

IMPORTANT

When these operations have been completed

IT IS

MANDATORY TO

:

– CHECK THE TIGHTNESS of all the joints.

– COMPLETE THE INSULATION of the pipes and

ALL the devices involved (for example, PI pump, Vr

valve, puffer bleed device, etc) using the insulation

parts supplied with the Water System Kit and spe-

cific insulation tape.

It is advisable that the pipes already supplied as insulated are completed.

2.11 Emptying operations

Emptying the domestic hot water storage tank

To empty the domestic hot water storage tank:

– Close the water system isolation valve

– Open at least one hot water tap

– Connect a pipe to the domestic hot water storage tank drain

valve (Rs) and duct it appropriately. Open the storage tank

drain valve.

– If further draining is necessary, the connection (A) of the

pipe which joins the plate heat exchanger and the water

heater can be loosened slightly.

m

WARNING

Suitably protect the devices below from any dripping

water.

Rs

A

A

Fig. 34

m

WARNING

Whenever the storage tank is drained, even partially,

the systems/circuits used by the appliance

MUST

be

refilled or reintegrated following the procedure described in the section

“2.10 Filling operations”

includ-

ing the Automatic Degassing Function.

29

3 COMMISSIONING

3.1 Preliminary operations

When the Sime

Open Hybrid Mem ErP

is commissioned, this

must be carried out by a professionally qualified technician

who, before starting the appliance, must check that:

– the type of gas used is the same as that for which the appli-

ance has been prearranged, the mains network pressure is

suitable and the duct is deaired

– the gas isolation valves for the heating system and the wa-

ter system are open

– the heat pump and boiler siphons are filled and the conden-

sate outlets are routed correctly

– the combustion air and smoke outlet ducts have been exe-

cuted correctly

– the expansion vessels are correctly prefilled

3.2 Commissioning

After having carried out the preliminary operations, perform

the following to start the Open Hybrid Mem ErP system:

– Set the main switches IG1 and IG2 to "ON"

ON

– The following screens will appear on the Mem Remote Con-

trol display and on the boiler display:

13:17:08 THUR 09/10/14

OPEN HYBRID MEM

– Check that the storage tank temperature is below 25°C.

Otherwise, open one or more than one hot water tap and

lower the temperature. Then close the taps again.

From the Mem Remote Control "Stand-by" screen:

– Press twice. The symbol n will be highlighted (flashing)

– Press twice. The symbol r will be highlighted (flashing)

13:17:08 THUR 09/10/14

COOL OFF REDUCED

n

t

r

7.3ºc

– Press to confirm the selection and go to MODIFY DHW

SETTINGS

– Press

or to select “YES”

– Press

to confirm “YES” and go to DHW OPERATING

MODE

– Press

or to select REDUCED

– Press

twice to confirm the selection and go back to the

“Stand-by” screen

13:17:08 THUR 09/10/14

OPEN HYBRID MEM

On the boiler Control Panel:

– press the button

y

once for at least 1 second to select

"SUMMER mode"

l

. the value of the delivery sensor de-

tected at that moment will appear on the display

Carry out the "Automatic self-calibrating procedure" as follows:

– press button r and set the DOMESTIC HOT WATER SET to

maximum using the button

>

30

– press and hold down the buttons < and > at the same time

for approximately 10 seconds until the flashing symbols

l

and

n

appear on the display

– as soon as the symbols begin to flash, release the buttons <

and

>

and press the button y,

within 3 seconds

– the "Automatic self-calibrating procedure" starts

–

open the hot water taps so that the ow rate is as high as possible

– the values flash on the display:

“100”

(maximum value), fol-

lowed by an "intermediate value" and finally

“00”

(minimum

value)

The operator must wait for approximately 15 minutes for the

"self-calibrating procedure" to end and the message "SUMMER mode"

l

to reappear on the display

Once this operation has been completed, close the taps

opened previously and check that the boiler shuts down.

– Press and hold the button y for at least 1 second and se-

lect "WINTER mode”

n

.

The

Open Hybrid Mem ErP

will start to operate normally.

m

WARNING

This procedure MUST ALWAYS BE CARRIED OUT

when:

– The type of gas used is changed.

– Replacing the boiler board or other components

(see the section

“4.5 Extraordinary maintenance”

in

the boiler manual).

From the Main screen, set the OPERATING MODE required by

the User.

3.3 Parameter setting and display

To go into the parameters menu from the

Main

screen on the

Mem Remote Control:

– Press and hold the button

for at least5 seconds until the

screen appears

ENTER PASSWORD

1243

– Press to confirm and enter “password” settings. The

cursor will be on the first digit to be set.

– Press

and set (1)

– Press

to confirm and prearrange the setting for the 2nd

digit

– Press

and set (2)

– Press

to confirm

– Continue in the same way until the last digit has been con-

firmed (3).

– The

PARAMETERS MENU

screen will appear

PARAMETERS MENU

GENERAL SETTINGS

GENERATION

I/O CONFIGURATION

HEATING

COOLING

DOMESTIC HOT WATER

ENERGY SETTINGS

– Press to confirm and go into the GENERAL SETTINGS

MENU

– Press

or to scroll through the screens until reach-

ing the screen required

– Press

to confirm and go into the modifiable area

– Press

or to modify the "data"

– Press

to confirm the modification

– Press

to go back to the

PARAMETERS MENU

– Press

or to select another

MENU

Continue as described above to set all the parameters listed in

the table on the following pages

NB.

Always refer to the title and number of the screen (for example,

GENERAL S100) as the number of the parameter is not always

displayed. It is data which is only used by the Mem program

31

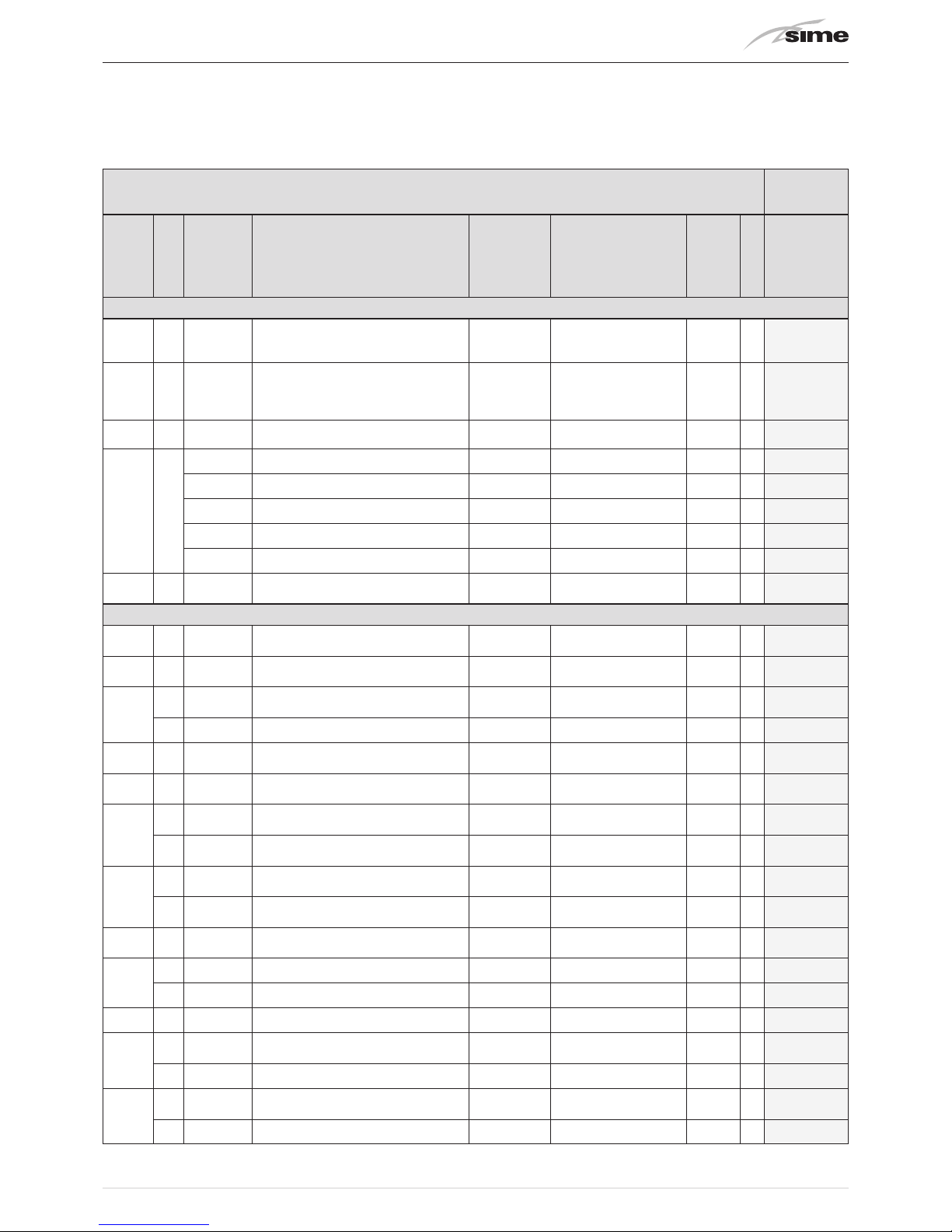

3.4 Complete list of parameters

The parameters are divided into levels:

– U = USER

– I = INSTALLER

Use a pencil to note down the value of each modified parameter in the "Set Value" column in relation to the default value.

✎

➡

SCREEN

LEVEL

PARAMETER

DESCRIPTION DEFAULT RANGE

UNIT OF

MEASURE-

MENT

DATA TYPE

SET VALUE

1 – General Settings

S100

U 1000 Climate Control Operating Mode OFF

• OFF

• HEAT

• COOL

- I

S102

U 1010 Domestic Hot Water Operating Mode OFF

• OFF

• TIME

• COMFORT

• REDUCED

- I

S110

I 1100 Language English English - I

S112

U

- Setting Current Hour -- 00 ÷ 23 hh I

- Setting Current Minute -- 00 ÷ 59 mm I

- Setting Current Day -- 01 ÷ 31 DD I

- Setting Current Month -- 01 ÷ 12 MM I

- Setting Current Year ---- 2010 ÷ 2199 YYYY I

S114

I -

Enabling automatic switch to daylight

saving time

ENABLED

• DISABLED

• ENABLED

- D

2 – Generation System Settings

S202

I 2020 Anti-blocking function for devices ACTIVE

• NOT ACTIVE

• ACTIVE

- D

S203

I 2030 Automatic Degassing Function NOT ACTIVE

• NOT ACTIVE

• ACTIVE

- D

S207

I 2070 Automatic System Filling Function ACTIVE

• NOT ACTIVE

• ACTIVE

- D

I 2072 Filling time 5 1 ÷ 999 s I

S220

I 2200 Boiler Type

BRAVA HE

ErP

• Not included

• BRAVA HE ErP

- I

S240

I 2400 Heat Pump Type

SHP M ErP

• Not included

• SHP M ErP

- I

S248

I 2480 Priority Heat Pump Heating-DHW DHW

• HEATING

• DHW

-

I 2482

Maximum time for Heat Pump DHW

priority over heating

30 0 ÷ 500 min.

S249

I 2485 Priority Heat Pump Cooling-DHW COOLING

• COOLING

• DHW

-

I 2487

Maximum time for Heat Pump DHW

priority over cooling

30 0 ÷ 500 min.

S250

I 2500 Solar Thermal System Type Not included

• Not included

• 1-SING.COLL..

- I

S252

I 2520 ∆T ON Solar Pumps 8.0 0.0 ÷ 99.9 °C A

I 2522 ∆T OFF Solar Pumps 4.0 0.0 ÷ 99.9 °C A

S253

I 2530 Solar Pump Minimum Operating Time 20 0 ÷ 600 s I

S254

I 2540 Solar Collector Anti-freeze Function ACTIVE

• NOT ACTIVE

• ACTIVE

- D

I 2541 Solar Collector Minimum Temperature -10.0 -40.0 ÷ 10.0 °C A

S256

I 2560 Solar Collector Cooling Function ACTIVE

• NOT ACTIVE

• ACTIVE

- D

I 2561 Solar Collector Maximum Temperature 120.0 80.0 ÷ 350.0 °C A

32

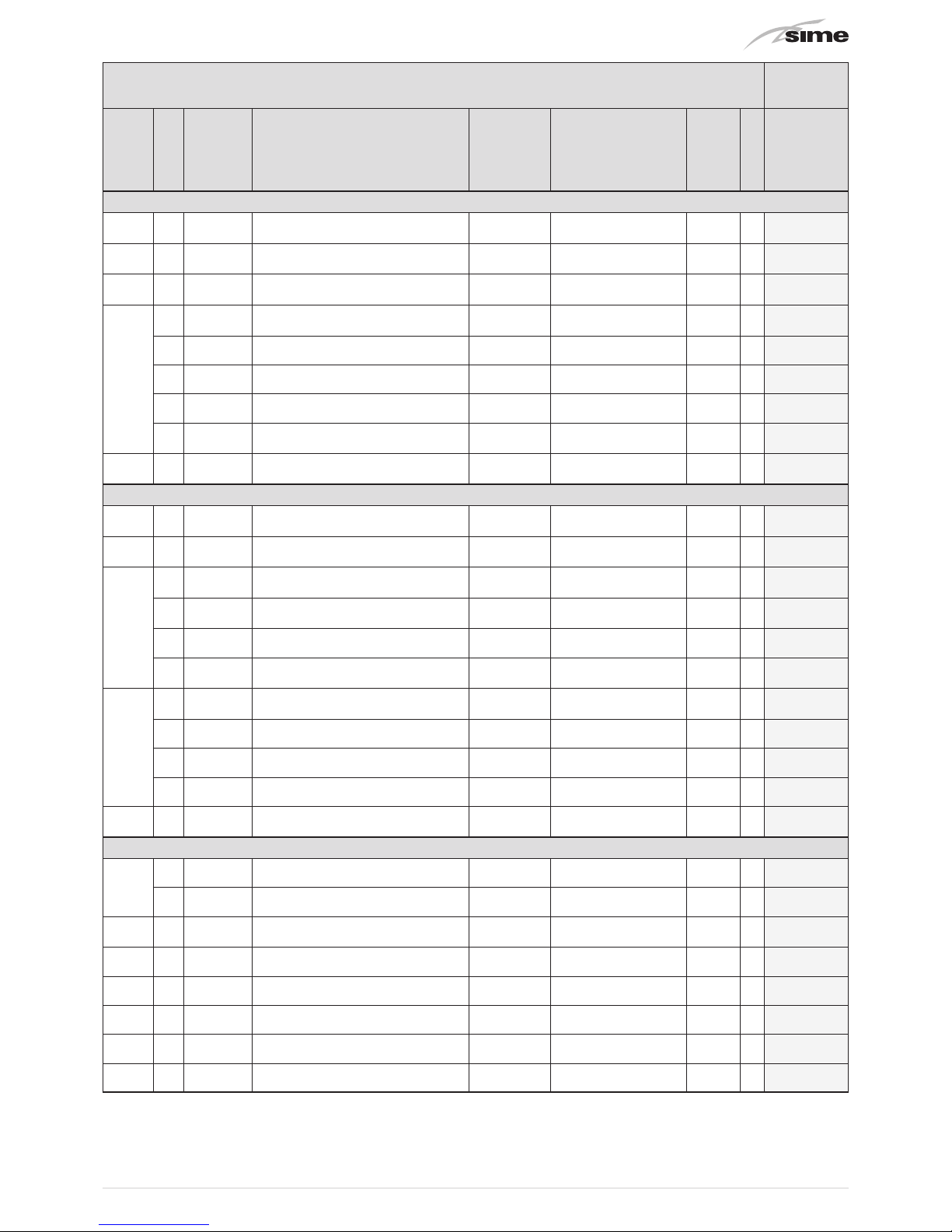

Use a pencil to note down the value of each modified parameter in the "Set Value" column in relation to the default value.

✎

➡

SCREEN

LEVEL

PARAMETER

DESCRIPTION DEFAULT RANGE

UNIT OF

MEASURE-

MENT

DATA TYPE

SET VALUE

3 – Input and Output Configuration

S300

I - Analogue Input Value Display - - -

S301

I - Digital Input Status Display - - -

S302

I - Analogue Output Value Display - - -

S303

I - Digital Output Status Display - - -

S310

I 3100 External Sensor Connection

FROM

BOILER

• NOT INCLUDED

• FROM BOILER

• From Heat Pump

- I

S350

I 3500 B6 Digital input function

COOL

MODE

• NONE

• COOL MODE

• ELECTRICAL CONVENIENCE

- I

S370

I 3700 NO6 Digital output function

COOL

MODE

• NONE

• COOL MODE

• ALARM SIGNALLING

- I

4 – Heating

S400

I 4001

Low Temperature Circuit Adjustment

Type

CLIMATIC

CURVE

• FIXED SETPOINT

• CLIMATIC CURVE

-

S402

U 4020 Low Temperature Circuit Fixed setpoint 40.0 20.0 ÷ 80.0 °C A

S404

U 4040

Setpoint for Low Temperature Circuit

Nominal Ambient Temperature

20.0 5.0 - 30.0 °C A

I 4043 Low Temperature Circuit Heating Curve 1.0 0.2 - 2.2 - A

I 4044

Low Temperature Circuit Heating Curve

Transfer

0.0 -15.0 - 15.0 °C A

I 4045

Low Temperature Circuit Heating Curve

Rotation

0.0 -15.0 - 15.0 °C A

S406

I 4060

Minimum Setpoint for Low Temperature

Circuit Heating System

20.0 10.0 - 60.0 °C A

I 4062

Maximum Setpoint for Low Temperature

Circuit Heating System

45.0 10.0 - 60.0 °C A

I 4066

50°C Low Temperature Circuit Safety

Thermostat

ENABLED

• DISABLED

• ENABLED

-

S409

I 4090 Building cladding Inertia-Delay 4

• 0

• 4