MURELLE

GREEN PLANET

I-HE 35 MF

& E-HE35 MF

CONDENSING BOILER

AUS

User, Service and

Installation Instructions

CONTENTS

1.0 USERS INSTRUCTIONS

. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page 3

2.0 USERS PRE-SERVICE CHECK LIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page 6

3.0 BOILER REGISTRATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page 7

4.0 COMMISSIONING BOILER CHECK LIST

5.0 SERVICE RECORDS

6.0 INSTALLERS INSTUCTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page 8

page 9

page 12

FONDERIE SIME S.p.A.

of Via Garbo 27 - Legnago (VR) - Italy declares that its hot water boilers, which bear the CE

mark under Gas Directive 90/396/CEE and are fitted with a safety thermostat calibrated to a maximum of 110°C,

are not subject to application of PED Directive 97/23/CEE as they meet the requirements of article 1 paragraph

3.6 of the Directive.

All descriptions and illustrations provided in this manual have been carefully prepared but we reserve the right to make change

and improvements in our products that may affect the accuracy of the information contained in this manual.

This Warranty is granted to you by Hunt Heating ABN 50 354

796 935, in respect of your acquisition of a Sime Central

Heating Boiler within the Commonwealth of Australia. This

Warranty does not in any way affect your rights under any

Trade Practices Act, and is in addition to your implied legal

rights.

Provided that the installation of the boiler is in accordance

with the specifications provided to you or your licensed instal-

ler, the boiler is warranted by Hunt Heating against defects

caused by the manufacturer’s faulty materials and/or work-

manship, in respect to parts and labour, for a period of twelve

months commencing from the date of commissioning of the

boiler. or a maximum of 18 months from the date of delivery

from Hunt Heating which ever is the earlier

The Licensed Installer must complete the information at the

in section 3.0 of this manual. Failure to do so may cause the

Warranty to beco me null and void.

SIME CENTRAL HEATING BOILERS - WARRANTY

This document issued 091201 - HE-35 1st December 2009

Page 2 of 40

IMPORTANT

When carrying out the commissioning of the boilers, it is highly recommended that you perform the following checks:

– Make sure that there are no flammable liquids and or materials in the immediate vicinity of the boiler.

– Make sure that the electrical connections have been made correctly and that the earth wire is connected to a good

earthing system.

– Open the gas tap and check the soundness of the connections, including that of the burner.

– Make sure that the boiler is set for operation for the type of gas supplied.

– Check that the flue for the outlet of the products of the combustion is unobstructed.

– Make sure that any shutoff valves are open.

– Make sure that the system is charged with water and is thoroughly vented.

1.0 USER INSTRUCTIONS

WARNINGS

– In case of fault and/or incorrect equipment operation, deactivate it, without making any repairs or taking any direct

action. Apply only to qualified technical personnel.

– Boiler installation and any other assistance and/or maintenance activity must be carried out by qualified personnel

registered as a licenced gas technician. Under no circumstances, the devices sealed by the manufacturer can be

tampered with.

– It is absolutely prohibited to block the intake grilles and the aeration opening of the room where the equipment is

installed.

– The manufacturer shall not be held liable for any damage caused by improper use of the appliance.

LIGHTING AND OPERATION

BOILER IGNITION (fig. 24)

The first ignition of the boiler must be carried out by qualified technical personnel.

Successively, if it is necessary to start up

the boiler again, adhere strictly to the following instructions: open the gas tap to

allow the flow of the fuel.

Move t he main switch of t he sys tem to

“O N”. W hen fuel is fed to the b oiler, a

sequence of checks will be carried out and

the display shows the normal condition of

the functioning, always indicating the pressure of the system. If the blue luminous bar

is on, this indicates the presence of voltage.

N.B.: To the first pressure the keys of the

controls (2) the display is illuminated, to

the successive pressure the operation

modality is active.

Winter

Press the key of the controls (pos. 2)

to activate the wint er mode functi oning

(heating and D.H.W.). The display will be as

shown in the figure.

Summer

Press the key of the controls (pos. 2) to

activate the summer mode f unctioning

(only the production D.H.W.). The display will

be as shown in the figure.

APRE

2

Fig. 24

OPEN

Page 3 of 40

REGULATION OF THE WATER

TEMPERATURE FOR HEATING (fig. 25)

To se t t he temper ature of the water for

heating, press the key of the controls

(2).

The first time the key is pressed, the SET of

heating circuit 1 is selected. The second

time it is pressed, the SET of heating circuit

2 is selected. The display will be as shown

in the figure.

Change the values with the key and

.

Standar d visualisation will return to the

display by pressing the key

again, or

after 10 seconds if no key is pressed.

Regulation of the external sensor

If an external sensor is installed, the value

of the output temperature is automatically

chosen by the system, which quickly adjusts

th e e nvi ron men tal t empera tur e on the

basis of the external temperature.

If you wish to change the value of the temperature, increasing or decreasing that calculated aut oma ticall y b y the electronic

card, proceed as indicated in the preceding

paragraph. The level of various correction

of a value of temperature proportional calculated. The display will be as shown in fig.

26/a.

REGULATION OF THE D.H.W.

TEMPERATURE (fig. 26)

To set the desir ed temperature D.H.W.,

press the key of the controls (pos. 2).

The display will be as shown in the figure.

Change the values with the key and

.

The display will r etu rn to the st and ard

visualisation by pressing the key again,

or after 10 seconds if no key is pressed.

TO SWITCH OFF THE BOILER (fig. 24)

In the case of a short absence, press the

key of the controls (pos. 2). The display

will be as shown in the fig. 24. In this way,

leaving t he electricity and the fuel supply

connected, the boil er is protect ed from

fro st an d fr om t he pum p be comi ng

blocked.

If the boiler is not used for a pr olonged

per iod, it is a dvis able to disconnect the

electricity supply, by switching of f the main

switch of the system, and to close the gas

tap and, if low temperatures are expected,

to completely empty the hydraulic circuits

to avoid pipes being broken by the formation of ice in the pipes.

2

Fig. 25

2

Fig. 26

Fig. 25/a

Page 4 of 40

ANOMALIES AND SOLUTIONS

When there is a functioning anomaly, the

display shows an alarm and the blue luminous bar becomes red.

Descriptions of the anomalies with the relative alarms and solutions are given below:

– ALARM 02 (fig. 27/a)

If the water pressure detected is lower

than 0.5 bar, the boiler will stop and the

display will show “ALL 02”.

Bring t he pressure back to normal by

means of the charge system (C) until the

pressure indicated by the transducer is

between 1 and 1.5 bars.

ON COMPLETION OF THE OPERATION,

MAKE SURE THE LOAD VALVES IS CLOSED.

If it is necessary to repeat the system

loading procedure, it is advisable to

contact qualified technical personnel

to check the seal of the heating system

(to check whether there are any leaks).

– ALL 03

Request ass ist ance fro m q ual ifie d

technical personnel.

– ALL 04

Request ass ist ance fro m q ual ifie d

technical personnel.

– ALL 05

Request ass ist ance fro m q ual ifie d

technical personnel.

– ALL 06 (fig. 27/c)

Press the key on the controls (2) to

re-start the boiler.

If the anomaly persists, request assi-

stance from qualified technical personnel.

– ALL 07 (fig. 27/d)

Press the key of the controls (2) to

re-start the boiler.

If the anomaly persists, request assistance from qualified technical personnel.

– ALL 08

Request ass ist ance fro m q ual ifie d

technical personnel.

– ALL 09

Request ass ist ance fro m q ual ifie d

technical personnel.

– ALL 10

Request ass ist ance fro m q ual ifie d

technical personnel.

– ALL 13

(fig. 27/e)

Press the key of the controls (2) to

re-start the boiler.

If the anomaly persists, request assi-

stance from qualified technical personnel.

– ALL 14

Re quest ass istance fro m qua li fied

technical personnel.

– ALL 15

Re quest ass istance fro m qua li fied

technical personnel.

– From “ALL 20” to “ALL 29”

Re quest ass istance fro m qua li fied

technical personnel.

GAS CONVERSION

If it is necessary to change to a different

type of gas, request assistance only from

authorised technical personnel.

MAINTENANCE

2

Fig. 27/c

2

Fig. 27/a

Fig. 27/d

2

Fig. 27/e

175

125

60

Please refer to the maintenance schedule in Section 5

of this manual.

The boiler is supplied is supplied with an electrical

supply cable. If this is damaged in any way it should

be replaced only by a new cable from Hunt Heating

and installed by a qualifies technician.

Page 5 of 40

1 General.

Has the system worked before? if it did why did it stop?

Check that the power, gas, valves or thermostat are turned ON

Does it work? - If NO go to Q2

2 Power

With power to the boiler. Are there indicator lights on or any error messages? If the indicator lights are on

which ones? Check with boiler manual to understand what lights or error message mean and correct if

Does it work? - If NO go to Q3

3 Gas

Is the gas isolation valve on? At the boiler, at the meter. Do other gas appliances work?

Check the gas isolation valve is on at the boiler and at the meter. If OFF do not turn on

unless safe to do so. Check why it was turned OFF. Do the other gas appliances work?

Does it work? - If NO go to Q4

4 Room Thermostat.

Is the display very dim or not showing at all? Is the room thermostat calling for heat? Turn it off, turn on,

does it click and show the correct symbol?

If nothing happens – the batteries may need replacing, the room thermostat may be

faulty. Bridging out the switch can be used to test this. Check voltage before re-moving

cover.

Does it work? - If NO go to Q5

5 Boiler.

Does the boiler start to work and then shut down? Fan, Pump, Ignition. Is there an usual noise coming from

the boiler? Is there water running from the pressure relief valve?

Try turning knob on the pressure relief valve and releasing it. If it is still faulty turn OFF

IMMEDIATELY and call Hunt Heating or your service technician.

Does it work? - If NO go to Q6

6 Radiators.

Are some radiators hot and others cold?

Check that the radiator valves are turned on, that the thermostatic heads are operating

correctly and the lockshield valves are open. Is the system balanced properly?

Is the top of the radiator cold but the bottom hot – Bleed air from the radiator.

2.0 USER’S PRE-SERVICE CHECK LIST

Before calling for Hunt Heating Boiler Service please check the following.

I’m Cold ! – The Heaters not Working.

FOR WARRANTY AND SERVICE: Ring: 1300 001800

Please have Product Details, Serial Number and Installer Information Ready before ringing refer to next page

Page 6 of 40

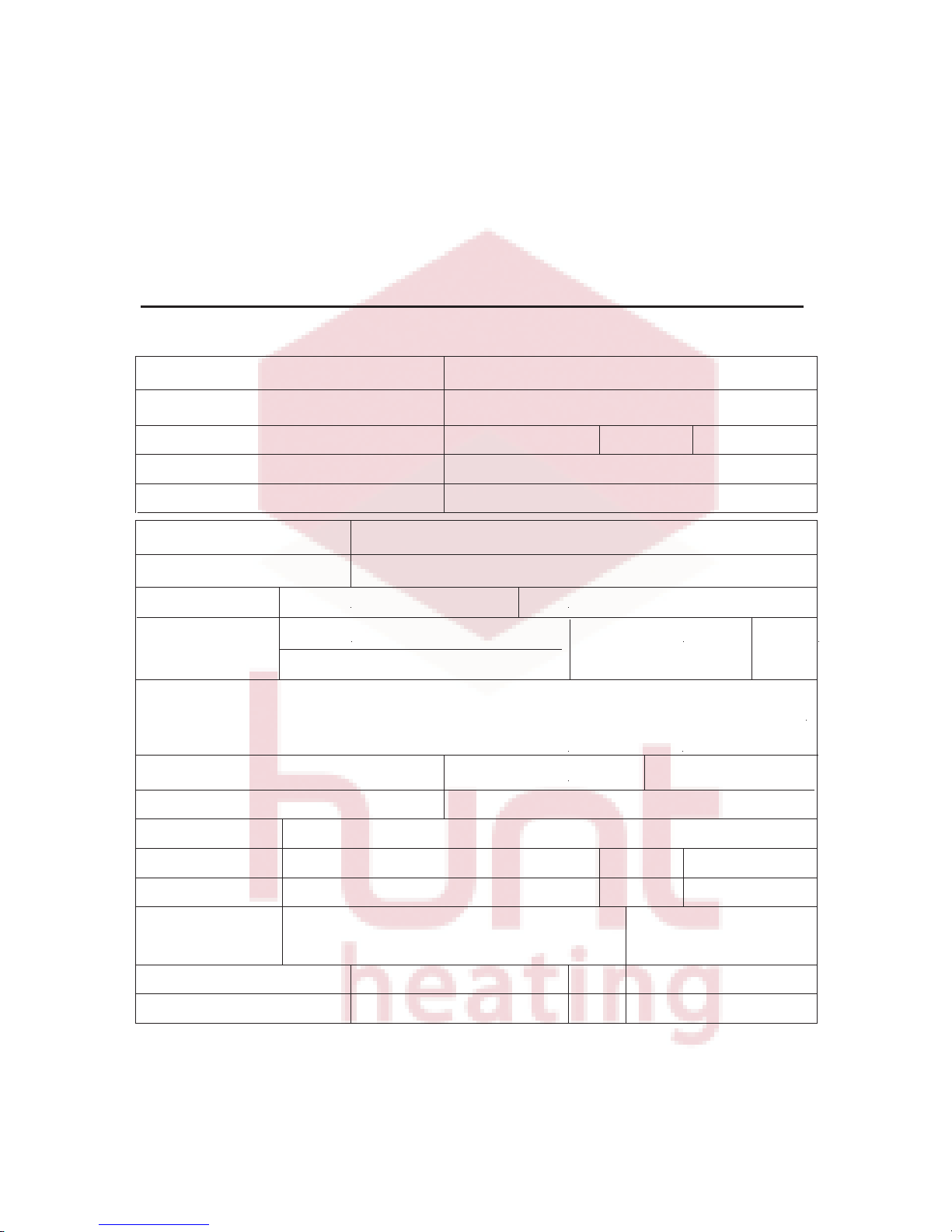

3.0 BOILER REGISTRATION

IMPORTANT INFORMATION

Please read before Inst allation fill in and retain for future use.

LOG BO OK -

Installation, C ommissioning an d S ervice

.

1. Installation Details

Owner - name

Installation A ddress - Street

City PC State

Installation Ph one N umber

Contact and Ph one Nu mber

Sime Product - Model

Serial Nu mber

Gas T ype

Natural G as

?

LPG

?

Internal

?

External

?

Gas p ressure

Settings

Max Pa

Adjusted output setting

kW

Central Heating

Water tre atment

System Volume Litres

No

?

Yes

Yes

?

?

?

Product Q ty Used Litres

Dilution rate Litres per 100 litres

System FLUSHED before installation of boiler

The System pipes MUST BE FLUSHED before the connecting this boiler

New

?

Existing

Installer Company

Company Address

City PC State

Installer

Name

PIC Licence No.

Commissioning completed Date;- / /20 _ _

Date;- / /20 _ _

by

to

Hand Ov er completed

?

?

Internal - I-HE 35 or External - E-HE 35

refer to data plate

Page 7 of 40

4.0 COMMISSIONING BO ILER CH ECK LIST

IF IN DOU BT AS K

A s uggested me thod of co mmissioning th e bo iler, ac tual me thod ca n v ary ac cording to th e bo iler

make type and the installation. The boiler must always be installed and commissioned by an approved

,

gas te chnician. The i nstaller ce rtifies th at this

Boiler has b een in stalled to ma nufacturer’s

instructions, has been filled, commissioned and is ready for use.

No. Description

ü

when done

1.

Read carefully th e in struction ma nuals s upplied wi th t his bo iler.

BEFORE INSTALLING T HIS B OILER FLUSH OUT THE PIPES UNTIL CLEAN WATER IS ACHIEVED.

2

–

.

3.

Turn on wa ter to fi ll s ystem, ch eck fo r le aks r egularly

an d b leed a ir fr om al l

points.

B leed

the

air fr om all th e p umps i n the system,

and r otate th e im peller sh aft

4

Check th at al l r adiators v alves ar e op en,

remove th e

thermostatic

valve

heads,

fully

open

all

lockshields

5

Turn ON g as, bl eed a ir ou t at th e i solation va lve u nion. Re seal an d ch eck fo r gas leaks.

Tu rn g as OF F.

6

Turn e lectricity on at th e po wer po int. At th e bo iler fr ont pa nel se t th e temperature setting

to th e lo west s etting, s witch b oiler to ON po sition.

The

“Power on ” In dicator sh ould lig ht. Tu rn th e bo iler of f at th e fr ont pa nel.

7

Turn th e r oom th ermostat to th e ma nual O N po sition s et th e t emperature to a high level so that it does

no t s witch of f du ring th e co mmissioning ph ase. Th e thermostat will unusually click and show an

a n in dicator in th e wi ndow,

8

Switch th e bo iler ON a t th e bo iler fr ont pa nel co ntrol.

9

Boiler sh ould s tart fa n, pu mp an d ig nite g as. If it fa ils fi rst f ew t imes th is m ay be just residual air

In th e gas line. A noisy water pump indicates there is air in the water pipes.

10.

Boiler lights a nd heats the water.

11.

Check g as flame is th e co rrect co lour an d fo r gas an d wa ter le aks

as the system heats up .

12.

Check th at h eat i s go ing t o a ll r adiators th rough th e m anual or th ermostatic first

and r eturn via the lo ckshield v alve. If no t S TOP fi x NO W and any leaks.

13

Allow th e bo iler to hea t u p to th e se t te mperature an d sw itch of f. Re-adjust the boiler temperature

14

to a mi d t emperature po int. CA UTION, If t his is connected to a floor heating system. The boiler

sh ould re li ght a nd in crease th e water temperature to the new setting.

15

Check th at a ll r adiators a re hot al l th e wa y u p. If t he r adiator is co ld at th e to p,

then th ere is u sually a ir in th e r adiator Bleed the radiator. Balance the system so that all.

16.

Set th e r oom th ermostat to th e co rrect t imes a nd t emperatures ac cording to

the ma nufacture’s

On completion of the commissioning phase, complete the information sheet at the front of this manual.

Hand over the installation to the owner and demonstrate how the system works plus basic fault

resolution and safety procedures. Make sure that this important document is kept in a safe accessible

place.

Turn off all services to this boiler - water, gas and power. Install the boiler as shown in the

instructions following and connect all services.

radiators are hot as according to the radiator installation manual. Adjust the boiler water temperature.

instructions

Page 8 of 40

Handover Ins tructions

when d one

1. Fill in al l th e de tails on t his Bo ile

r manua.l

2. Instruct th e o wner /u sers on th e co rrect op eration of th e h eating s ystem, th is

includes ho w t o tu rn th e sy stems o n a nd of f, ad just th e t ime an d t emperature

settings .

3. How t o tu rn th e h eating s ystem of f i n s ummer an d on fo r w inter.

4. Where al l th e ma jor it ems ar e, th eir fu nctions an d how t o ch eck an d tu rn th em on or

off. Simple fault resolution i.e. power on.

5. How t o ch eck an d r emove ai r in th e r adiators. Gi ve t hem a bl eed ke y.

6.. The im portance of th is SERVICE RECORDS, ke eping s afe &

accessible

when r equired.

7. Recommend th at th e bo iler sh ould be s erviced at / before th e st art of wi nter ne xt

year th en ev ery t wo ye ars.

5.0 SERVICE REC ORDS

Service – 1 – Year 1 Date

Service te chnician Name PIC Li cence No .

Service Co mpany

Contact ph one nu mber

Work Co mpleted

Notes

ü

Page 8 of 20

Page 9 of 20

4 of 7

Service –2– year 3 Date

Service te chnician Name PIC Licence No .

Service Co mpany

Contact ph one nu mber

Work Co mpleted

Service

Service––34––

year 5

year 7

Date :

Date :

Service te chnician

Service te chnician

Name: PIC Licence No .

Name: PIC Licence No .

Service Co mpany

Service Co mpany

Contact ph one nu mber

Contact ph one nu mber

Work Co mpleted

Work Co mpleted

Notes

Notes

Notes

Page 10 of 40

Service –5–

year 9

Date

Service te chnician Name PIC Licence No .

Service Co mpany

Contact ph one nu mber

Work Co mpleted

Service

Service––78––

year 11

year 13

Date :

Date :

Service te chnician

Service te chnician

Name: PIC Licence No .

Name: PIC Licence No .

Service Co mpany

Service Co mpany

Contact ph one nu mber

Contact ph one nu mber

Work Co mpleted

Work Co mpleted

Notes

Notes

Notes

Please contact Hunt Heating for more service sheets

Page 10 of 20

Page 11 of 40

6.0 INSTALLER INSTRUCTIONS

CONTENTS

1 DESCRIPTION OF THE BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

3 CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

4 USE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Page 12 of 40

Loading...

Loading...