Format B

Installation and

servicing instructions

UK

Please read the Important Notice within

this guide regarding your boiler warranty

199838

ENSURE THAT THESE INSTRUCTIONS ARE LEFT

FOR THE USER AFTER COMPLETION OF THE

BENCHMARK SECTION

All descriptions and illustrations provided in this manual have been carefully prepared but we reserve the right to make changes

and improvements in our products that may affect the accuracy of the information contained in this manual.

IMPORTANT NOTICE

For the first year all of our appliances are protected by our manufacturer’s guarantee which covers both parts and

labour.

As you would expect from Sime Ltd, it is our aim to provide our valued customers with the best in after sales and

service.

To take advantage of any extended warranty offered, all you have to do is to adhere to these 3 simple conditions:

• The installation must be carried out to Manufacturers/Benchmark Standards by a Gas Safe Registered

Engineer, and recorded in the installation manual.

• The appliance must be registered with both Sime Ltd and Gas Safe within 30 days of installation.

• The appliance must be serviced annually, by either Sime Ltd or a Gas Safe registered engineer- ensuring that the

Benchmark service record in the installation manual is completed.

Failure to comply with the above will result in only the 12 month warranty being offered.

In the absence of any proof of purchase, the 12 month warranty period will commence from the date of manufacture

of the boiler as shown on the appliance data plate.

The Benchmark Scheme

Sime Ltd is a licensed member of the Benchmark Scheme which aims to improve the standards of installation and

commissioning of domestic heating and hot water systems in the UK and to encourage regular servicing to optimise safety, efficiency and performance.

Benchmark is managed and promoted by the Heating and Hotwater Industry Council.

For more information visit www

.centralheating.co.uk

Format 80 B:

Gas Council number 47-283-07

Format 100 B:

Gas Council number 47-283-08

These appliances comply with the S.E.D.B.U.K. scheme, band “D”

SIME COMBINATION BOILERS

Installer checklist

Please remember to carry out the following checks after installation. This will achieve complete customer satis-

faction, and avoid unnecessary service calls. A charge will be made for a service visit where the fault is not due to

a manufacturing defect.

– Has a correct by-pass been fitted and adjusted?

– Has the system been flushed in accordance with the guidelines given in BS7593 “Treatment of water in domes-

tic hot water central heating systems”?

– Is the system and boiler full of water, and the correct pressure showing on the pressure gauge?

– Is the Auto Air Vent open?

– Has the pump been rotated manually?

– Is the gas supply working pressure correct?

– Is the boiler wired correctly? (See installation manual).

– Has the D.H.W. flow rate been set to the customer requirements?

– Has the customer been fully advised on the correct use of the boiler, system and controls?

– Has the log book provided been completed?

IPX4D

Important Information

IT IS A STATUTORY REQUIREMENT THAT ALL GAS APPLIANCES ARE INSTALLED BY COMPETENT PERSONS, IN

ACCORDANCE WITH THE GAS SAFETY (INSTALLATION AND USE) REGULATIONS (CURRENT EDITION). The manufacturer’s instructions must not be taken as overriding any statutory requirements, and failure to comply with these

regulations may lead to prosecution.

No modifications to the appliance should be made unless they are fully approved by the manufacturer.

GAS LEAKS: DO NOT OPERATE ANY ELECTRICAL SWITCH, OR USE A NAKED FLAME. TURN OFF THE GAS SUPPLY

AND VENTILATE THE AREA BY OPENING DOORS AND WINDOWS CONTACT THE GAS EMERGENCY SERVICE ON

0800111999.

Please refer to commissioning instructions for filling in the checklist of this installation guide.

Note: All Gas Safe registered installers carry a ID Card.

You can check your installer is Gas Safe Registered by calling 0800 408 5577

6

1.1 INTRODUCTION

The Sime “FORMAT B” are wall mounted, fan assisted

balanced flue combination boilers.

The appliance is supplied suitable for use with natural gas,

L.P.G. and provide central heating and instantaneous

production of D.H.W. Heat output is varied according to

demand by the modulating gas control on both D.H.W. and C.H.

The appliance is supplied with a telescopic air/flue duct

suitable for wall thicknesses up to 635 mm (25 in) although

extension duct kits are available (see details in section 3.4).

The combined flue and air duct can exit the boiler from either

side or from the rear of the appliance. A vertical extension

and additional flue elbow may be fitted. If required, the boilers

can also be fitted with a separate flues kit (see section 3 for

details).

The boiler is designed for use with sealed primary water

systems and is supplied fully assembled and equipped with

complete valve packs.

The boiler can be used with a 24V room thermostat (class II

according to EN 60730.1).

This booklet provides instructions for the boiler models:

“FORMAT 80 B - FORMAT 100 B” with following features:

– electronic ignition,

– fully modulating.

1 TECHNICAL FEATURES AND DIMENSIONS

TABLE 2 - Minimum clearances

For ventilation For servicing

ABOVE THE APPLIANCE CASING 200 mm 300 mm

AT THE R.H.S. 15 m m 15 m m

AT THE L.H.S. 15 m m 15 m m

BELOW THE APPLIANCE CASING 200 mm 200 mm

IN FRONT OF THE APPLIANCE 350 mm 500 mm

TABLE 1 - Connections

R C.H. return 22 mm Compression

M C.H. flow 22 mm Compression

G Gas connection 15 mm Compression

E Cold water 15 mm Compression

U Hot water 15 mm Compression

1.2 DIMENSIONAL DETAILS

80 B 100 B

L mm 400 450

K mm 215 240

Fig. 1

7

1.3 GENERAL DATA

80 B 100 B

Heat output

Nominal kW 23.8 30.8

Minimum kW 8.9 11.8

Heat input

Nominal kW 25.5 33.0

Minimum kW 10.2 13.5

Termal efficiency (CEE 92/42 directive) ★★★ ★★★

Class NOx 33

Water content l 2.2 2.4

Adsorbed power consumption W120 165

Electrical protection grade

IPX4D IPX4D

Maximum water head bar 3 3

Maximum temperature °C 85 85

Expansion vessel

Water content/Preloading pressure l/bar 7/1 8/1

C.H. setting range °C 30÷80 30÷80

D.H.W. setting range °C 30÷60 30÷60

D.H.W. flow rate (EN 625) l/min 11.3 14.5

Continuous D.H.W. flow rate ∆t 30°C l/min 11.4 14.7

Minimum D.H.W. flow rate l/min 2.2 2.2

D.H.W pressure

Minimum/Maximum bar 0.1/7 0.2/7

Smokes temperature °C 90/102 105/129

Smokes flow gr/s 15.6/16.9 20.2/22.0

Losses after shutdown to 50°C W/h 78 79

Category II

2H3+ II2H3+

Typ e B22-52/C12-32-42-52-82 B22-52/C12-32-42-52-82

Electrical supply 230V - 50 hz, fused at 3 A 230V - 50 hz, fused at 3 A

Internal fuse Line: F1.6A Line: F1.6A

Weight kg 38 40

Main burner nozzle

Quantity n° 12 14

Natural gas (G20) ø mm 1.30 1.30

LPG (G30 - G31) ø mm 0.77 0.80

Gas consumption *

Natural gas (G20) m

3

/h 2.70 3.49

Butane (G30) kg/h 2.01 2.60

Propane (G31) kg/h 1.98 2.56

Burner gas pressure

Natural gas (G20) mbar 2.0÷11.8 2.5÷14.5

Butane (G30) mbar 4.8÷28.5 4.7÷28.2

Propane (G31) mbar 6.3÷36.5 6.0÷36.2

Gas supply pressure

Natural gas (G20) mbar 20 20

Butane (G30) mbar 28 - 30 28 - 30

Propane (G31) mbar 37 37

* Gas consumption f igures express the lowest calorif ic power of pure gas under standard conditions at 15°C – 1013 mbar; this figure may differ from the actual

figure, which is dependent on gas composition and environmental conditions.

8

1

3

5

7

9

8

15

17

21

16

20

13

18

19

11

10

4

6

2

12

23

22

G

U

EMR

1.4 HYDRAULIC CIRCUIT

Fig. 2

GAS D.H.W. M.C.W. FLOW RETURN

KEY

1Fan

2 Bithermal exchanger

3 D.H.W. probe (SS)

4 100°C safety stat

5 Combustion chamber

6 C.H. sensor (SM)

7 Gas valve

8 Water pressure switch

9 Temperature and pressure gauge

10 Circulation pump

11 Air relief valve

12 Expansion vessel

13 Automatic by-pass

15 Water flow switch

16 Drain plug

17 D.H.W. filter

18 Safety valve

19 C.H. return cock

20 C.H. flow cock

21 D.H.W. cock

22 Gas cock

9

1.6 BOILER OPERATION

The boiler operating mode is controlled by the selector switch

on the control panel. When set to winter ( ) it will operate in

the Domestic Hot Water and Central Heating modes. For

Domestic Hot Water only the selector switch should be set to

summer ( ). Domestic hot water supply always takes

priority over central heating. If a demand for hot water is

required during a central heating period, the boiler will

automatically switch to hot water mode until the demand is

satisfied.

1.6.1 Central Heating mode

If there is a call for central heating the pump will start to

circulate the primary heating water and the fan will run at full

speed; once the air pressure switch has been proved the

burner will light. The burner output then automatically adjusts

to suit the system demand; as the temperature of the heating

water in the boiler approaches that set by the adjustable

central heating control knob the burner output is reduced.

When this set temperature is reached, the burner

extinguishes and the fan stops. The pump continues to run for

30 seconds to prevent residual heat build up in the boiler. The

burner will not relight for 3 minutes unless there is a demand

for domestic hot water during this period.

1.6.2 Domestic Hot Water mode

The pump does not operate on a DHW demand, the fan runs

and once the air pressure switch has proved the boiler will

light.

The burner output then automatically adjusts to suit the

demand required to raise the temperature set by the

adjustable domestic hot water control knob.

When the hot water demand has been satisfied, it passes to

the operation in C.H., if the selector is set to winter ( ) and

there is a C.H. demand, otherwise the burner will extinguish.

1.5 INTERNAL VIEW

Fig. 3

KEY

1 Control panel

2 Burner

3 100°C safety stat

4 C.H. sensor (SM)

5Fan

6 Air pressure switch

7 Bithermal exchanger

8 Combustion chamber

9 D.H.W. sensor (SS)

10 Gas valve

11

Manifold with intakes

10

2.1 STATUTORY REQUIREMENTS

GAS SAFETY (INSTALLATION AND USE) REGULATIONS (as

amended). It is the law that all gas appliances are installed by

a registered person, in accordance with the above

regulations. Failure to install appliances correctly could lead

to prosecution. It is in your own interest, and that of safety, to

ensure that the law is complied with.

In addition to the above regulations, this appliance must be

installed in accordance with the current IEE Wiring

Regulations (BS 7671), Local Building Regulations, the

Building Standards (Scotland) (Consolidation) Regulations,

Byelaws of the local water undertaking, and Health and Safety

Document No 635 “The Electricity at Work Regulations

1989”. It should also be in accordance with the relevant

recommendations in the current editions of the following

British Standards and Codes of Practice: BS5449, BS5546,

BS5440:1, BS5440:2, BS6798, BS6891, and BG.DM2,

BS7074, and BS5482 for propane installations.

Manufacturer’s instructions must NOT be taken in any way

as over-riding statutory obligations.

2.2 BOILER POSITION

In siting the combination boiler, the following limitations MUST

be observed:

– The boiler is not suitable for external installation. The

position selected for installation should be within the

building, unless otherwise protected by a suitable

enclosure, and MUST allow adequate space for

installation, servicing, and operation of the appliance, and

for air circulation around it (section 2.4).

– This position MUST allow for a suitable flue termination to

be made. The combination boiler must be installed on a flat

vertical wall which is capable of supporting the weight of

the appliance, and any ancillary equipment.

– If the combination boiler is to be fitted in a timber framed

building it should be fitted in accordance with the Institute

of Gas Engineers document for Gas Installations In Timber

Frame Housing, Reference 16E/UP/7: 1998. If in doubt,

advice must be sought from the gas supplier.

– If the appliance is installed in a room containing a bath or

shower, any electrical switch or control utilising mains

electricity must be so situated that it cannot be touched by

a person using the bath or shower. Attention is drawn to

the requirements of the current I.E.E. Wiring Regulations

(BS 7671), and in Scotland the electrical provisions of the

Building Regulations applicable in Scotland.

– A compartment used to enclose the appliance MUST be

designed and constructed specifically for this purpose. An

existing cupboard, or compartment, may be used provided

it is modified accordingly.

– Where installation will be in an unusual location, special

procedures may be necessary. BS6798 gives detailed

guidance on this aspect.

2.3 FLUE TERMINAL POSITION

Detailed recommendations for flue installation are given in

BS5440:1. The following notes are for general guidance:

– The boiler MUST be installed so that the terminal is

exposed to the external air.

– It is important that the position of the terminal allows free

passage of air across it at all times.

– It is ESSENTIAL TO ENSURE, in practice that products of

combustion discharging from the terminal cannot reenter the building, or any other adjacent building, through

ventilators, windows, doors, other sources of natural air

infiltration, or forced ventilation/air conditioning. If this

does occur, the appliance MUST be turned OFF

IMMEDIATELY and the gas supplier consulted.

– The minimum acceptable dimensions from the terminal

to obstructions and ventilation openings are specified in

fig. 4.

– If the terminal discharges into a pathway or passageway

check that combustion products will not cause nuisance

and that the terminal will not obstruct the passageway.

– Where the lowest part of the terminal is fitted less than 2

m (78 in) above ground, above a balcony or above a flat

roof to which people have access, the terminal MUST be

protected by a purpose designed guard.

– Where the terminal is fitted within 850 mm (34 in) of a

plastic or painted gutter, or 450 mm (18 in) of painted

eaves, an aluminium shield at least 1,500 mm (59 in) long

must be fitted to the underside of the painted surface.

– The air inlet/outlet flue duct MUST NOT be closer than 25

mm (1 in) to combustible material.

– In certain weather conditions the terminal may emit a

plume of steam. This is normal but positions where this

would cause a nuisance should be avoided.

2 GENERAL REQUIREMENTS FOR INSTALLATION

Fig. 4

TABLE 5

Terminal position Minimum spacing in mm

A Directly below an openable window, 300

air vent or any other ventilation opening

B Below guttering, drain pipes or soil pipes 25*

C/D Below eaves, balconies or carport roof 25*

E From vertical drain pipes or soil pipes 75

F From internal or external corners 25

G Above adjacent ground, 300

roof or balcony level

H From a surface facing the terminal 600

I From a terminal facing the terminal 1,200

J From an opening in the carport 1,200

(e.g. door, window into dwelling)

K

Vertically from a terminal on the same wall

1,500

L

Horizontally from a terminal on the same wall

300

M

Horizontally from a ver tical terminal to a wall

300

N Horizontally from an openable 300

window or other opening

P Above an openable window or other opening 300

* With “heat shield” installed in accordance to BS 5440 Pt1.

11

2.4 VENTILATION REQUIREMENTS

Detailled recommendations for air supply are given in

BS5440:2. The following notes are for general guidance:

–

It is not necessary to have a purpose provided air vent in the

room or compartment in which the appliance is installed.

2.5 GAS SUPPLY

– The gas installation should be in accordance with BS6891.

The gas required for the boiler is specified in section 1.3.

– Ensure that the pipework from the meter to the appliance

is of adequate size.

– The governor at the meter must give a constant outlet

pressure of 20 mbar (8 inwg) for natural gas and 30 - 37

mbar (12 - 15 inwg) for LPG, when the appliance is running.

– The gas supply line should be purged.

NOTE: Before purging open all doors and windows, also

extinguish any cigarettes, pipes, and any other naked

flames.

– The complete installation must be tested for gas

soundness.

2.6 ELECTRICITY SUPPLY

The appliance MUST be earthed. A mains supply of 230 V 50 Hz single phase is required. All external controls and

wiring MUST be suitable for mains voltage.

Wiring should be in 3 core PVC insulated cable NOT LESS

than 0.75 mm

2

(24 x 0.2 mm) to BS6500, Table 16. Wiring

external to the boiler MUST be in accordance with current

l.E.E. Wiring Regulations (BS 7671) and local regulations. The

supply connection to the flying lead provided MUST be made

to a fused double pole switch, having a 3 mm (1/8 in) contact

separation in both poles, serving only the boiler and system

controls; the fuse rating should be 3 amp. This connection

should be readily accessible and be made adjacent to the

boiler (except in the case of bathroom installations for

domestic boilers where the point of connection to the mains

MUST be outside of the bathroom).

2.7 EXTERNAL CONTROLS (Refer to section 3.9)

The boiler is intended for use with a 24 V room thermostat.

The connection is made inside the control box as described in

section 3.9.

2.8 WATER SYSTEMS - GENERAL

– This appliance is designed for connection to sealed central

heating water systems.

– Check that the mains water pressure is sufficient to

produce the required D.H.W. flow rate, but does not

exceed the maximum D.H.W. pressure (1.3 point).

Where mains pressure exceed 6 bar a pressure

reducing valve must be fitted in the D.H.W. inlet.

2.8.1 Treatment of water circulating systems

–

All recirculatory systems will be subject to corrosion unless

an appropriate water treatment is applied. This means that

the efficiency of the system will deteriorate as corrosion

sludge accumulates within the system, risking damage to

pump and valves, boiler noise and circulation problems.

–

For optimum performance af ter installation this boiler and

its associated central heating system must be flushed in

accordance with the guidelines given in BS 7593 “Treatment

of water in domestic hot water central heating systems”.

–

This must involve the use of a proprietary cleanser, such as

Sentinel X300 or X400, or Fernox Superfloc. Full instructions

are supplied with the products, but for immediate

information please contact GE Betz (0151 420 9563) or

Fernox (01799 550 811) directly.

– For long term protection against corrosion and scale,

after flushing it is recommended that an inhibitor such as

Sentinel X100, or Fernox MB-1 or Copal is dosed in

accordance with the guidelines given in BS 7593.

Failure to flush and add inhibitor to the system may

invalidate the appliance warranty.

– It is important to check the inhibitor concentration after

installation, system modification and at every service in

accordance with the manufacturer’s instructions. (Test

kits are available from inhibitor stockists).

2.9 REQUIREMENTS FOR SEALED WATER SYSTEMS

The heating system design should be based on the following

information:

a) The available pump head is given in fig. 5.

b) The burner starts when the C.H. flow reaches 400÷450

l/h. This safety condition is ensured by the flow switch.

c) The appliance is equipped with an internal by-pass that

operates with system heads (H) greater than 3 m. The

maximum flow through the by-pass is about 300 l/h. If

thermostatic radiator valves are to be installed, at least

one radiator should be without a thermostatic valve

(usually the bathroom radiator).

d) A sealed system must only be filled by a competent person

using one of the approved methods shown in fig. 7. The

system design should incorporate the connections

appropriate to one of these methods.

e) The following paragraphs outline the specifications of the

items fitted to the boiler.

0

200

1600

140012001000800600400

PO RTATA ( l/ h)

PREVALENZA RESIDUA (mbar)

500

400

100

200

300

30-28

25-23

Open BF TS2 - Metropolis - GG M

600

30-28

25-23

By-pass inserito

By-pass escluso

KEY

1 Available Head for “80 B” models

2 Available Head for “100 B” model

Flow rate (l/sec)

Available head (mbar)

Fig. 5

1

1

2

2

By-pass ON

By-pass OFF

12

TYPICAL SYSTEM DESIGN

NOTE: A drain cock should be installed at the lowest point of the heating circuit and beneath the appliance.

Fig. 6

Fig. 7

ALTERNATIVE METHODS OF FILLING A SEALED SYSTEM

13

2.9.1 Pump

The available head shown in fig. 5 is that in excess of the

appliance hydraulic resistance, i.e. that available for the

system at any given heating load up to the maximum output in

C.H. mode. Never reduce the pump speed below maximum as

this will reduce D.H.W. output. The pump speed is indicated on

the side of the pump speed selector switch (if fitted).

2.9.2 System volume (total water content)

The following Table gives the maximum system volume that

the integral expansion vessel can sustain under different

charge pressure conditions.

If the system volume exceeds that shown, an additional

expansion vessel must be fitted and connected to the heating

system primary return pipe as close as possible to the

appliance.

If an extra vessel is required, ensure that the total capacity of

both vessels is adequate. Further details are available in the

current issues of BS5449 and BS6798.

NOTE: If the pressure gauge indicates 2.65 bar or greater

when the appliance is at maximum temperature with all

radiators in circulation an extra expansion vessel is

required.

2.9.3 Pressure gauge

A pressure gauge is mounted on the appliance facia panel.

2.9.4 Safety valve

A safety valve set at 3 bar (43.5 psi) is fitted to the appliance

and a discharge pipe is routed to outside of the appliance.

This discharge pipe should be extended to terminate safely

away from the appliance and where a discharge would not

cause damage to persons or property but would be detected.

The pipe should be able to withstand boiling water, be a

minimum of 15 mm in diameter, and installed with a

continuous fall.

2.10 D.H.W. SYSTEMS

– Check that the mains supply pressure is within the

prescribed limits (1.3 point).

If necessary, a pressure reducing valve should be fitted to

the mains supply before the D.H.W. inlet connection.

– A maximum D.H.W. flow rate of:

11.4 l/m (3.0 gpm) for “FORMAT 80 B” and 14.7 l/m (3.9

gpm) for “FORMAT 100 B” is recommended.

Higher flow rates will not damage the appliance but may

lower the water temperature below an acceptable level.

– If the appliance is installed in an area where the temporary

hardness of the water supply is high, say over 150 ppm,

the fitting of an in line scale inhibitor may be an advantage.

Consult the Local Water Undertaking if in doubt.

– Devices capable of preventing the flow of expansion water:

e.g. non return valves and/or loose-jumpered stop cocks

should not be fitted unless separate arrangements are

made for expansion water.

– For specific information relating to fittings (eg. Showers,

washing machines etc.) suitable for connection in the

D.H.W. circuit, consult the Local Water Undertaking,

however the following information is given for guidance.

2.10.1 Domestic hot/cold water supply

taps and mixing taps

All equipment designed for use at mains water pressure is

suitable.

2.10.2 Showers

Any WRAS approved shower suitable for the mains water

pressure available may be used.

A loose or flexible shower head type may require the fitting of

an anti-syphon device to comply wth water by-laws.

2.10.3 Bidets

Providing that the appliance is of the over-rim flushing type,

the outlets are shrouded and it is impossible to attach a

temporary hand held spray, no anti syphonage device is

necessary.

Vessel charge and initial system

pressure

Total water content of system

using 8 l (1.76 gal) capacity expan-

sion vessel supplied with appliance

For systems having a larger capaci-

ty multiply the total system capacity

in litres (gal) by the factor to obtain

the total minimum expansion vessel

capacity required litres (gal)

bar

psi

l

gal

0.5

7. 3

96

21.1

.0833

1. 5

21.8

51

11. 2

.15 6

1. 0

14.5

74

16.2

.10 9

TABLE 6

14

Appliance package:

– combination boiler (assembled);

– installation and servicing instructions;

– users instructions;

– wall mounting templates (paper);

– wall mounting bracket;

– fixing screws with wall plugs;

– plastic bags containing:

– gas service cock;

– C.H. F/R isolation valves;

– D.H.W. isolation valve;

– D.H.W. elbow connection;

– associated fixing screws;

– associated gaskets;

– safety valve discharge pipe.

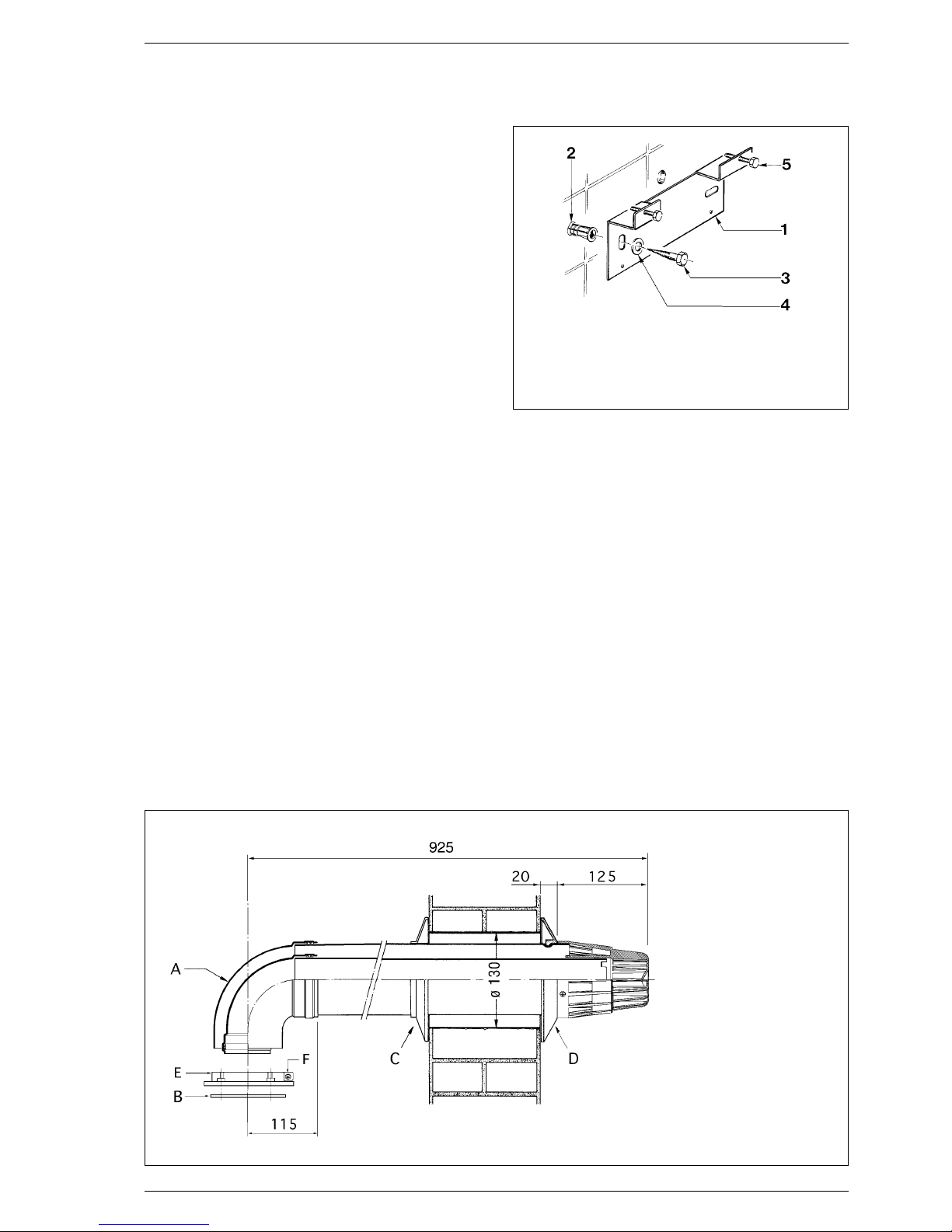

3.1 FIXING THE WALL MOUNTING BRACKET

Before installing the appliance ensure that the chosen

location is suitable (section 2.2) and that the requirements

for flue position, (section 2.3), and minimum clearances,

(

Table 2

) are satisfied. These minimum clearances are

essential to provide access for servicing, and are included on

the wall mounting templates.

– Open the paper wall mounting templates. If a rear flue is to

be used, discard the side templates and secure the rear

template in the desired position. For a side flue application,

secure both the rear and appropriate side template in

position.

– Mark the position of the two wall mounting bracket fixing

holes and the flue/air duct hole on the appropriate wall(s).

– Remove the template(s) and drill the two fixing holes using

a 10 mm masonry drill. Fit the plastic plugs provided.

– Cut the hole in the wall for the flue/air duct. The diameter

should not be less than 100 mm (4 in) and must be

horizontal. Refer to fig. 12-14.

– Accurately measure the wall thickness, and note this

dimension for later use.

– Secure the wall mounting bracket in position using the

screws provided. Ensure that it is the correct way up, as

indicated in fig. 8.

3.2 HANGING THE BOILER

– Lift the appliance into position. The upper cross member

locates onto the wall mounting bracket.

– Screw in the wall mounting bracket adjusting screws until

the appliance is secure and vertical.

3.3 COAXIAL DUCT ø 60/100

The air inlet-smoke outlet assembly ø 60/100 is supplied in a

kit code 8084811. For the assembly follow what is indicated

in figure 9:

– Make a hole in the wall sufficiently large to allow an inser-

tion of a PVC pipe 130 mm ø of the same length as the

thickness of the wall it has to pass through. Then fix the

PVC pipe in place using cement mortar.

– Before to inser t the duct in the wall hole fit in position the

3 INSTALLING THE BOILER

Fig. 8

KEY

1 Wall mounting bracket

2 Plastic wall plug (2 Off)

3 Woodscrew (2 Off)

4 Washer (2 Off)

5 Adjustment screw (2 Off)

KEY

A Elbow 90°

B Sponge-rubber

gasket ø 125/95

C White inner duct

D Grey outer duct

E Junction collar

F Screw

NOTE: The kit can be extended

to a maximum measure of

800 mm horizontal.

Fig. 9

15

outer wall seal (D).

– Push the tube outwards until the gasket comes out. Pull the

pipe inwards bringing the ring to rest on the wall.

– Slide the inner ring (C).

– Insert the inner/outer duct into the elbow (A) until the

ducts touch the inner part of the elbow where the diameter

becomes smaller.

– Fit the sponge-rubber gasket (B) to the collar (E).

– Secure the collar (E) to the sealed chamber using the four

screws provided.

– Insert the elbow (A) into the collar (E) tightening the screw

(F).

With the curve supplied in the kit the maximum horizontal

length of the flue must not exceed 3,6 metres.

The diagrams in fig. 10 illustrate a number of examples of different coaxial outlets.

NOTE: The air intake-flue outlet assembly must slope slightly

downwards to prevent rain water getting into the boiler.

3.3.1 Coaxial flue diaphragm ø 60/100

The boiler is supplied as standard with a ø 86 diaphragm.

With outlet type C12, install diaphragm ø 86 only if the

coaxial flue is less than 1 metres long.

For C32 discharge options, it is necessary to order the optional diaphragm separately ø 87,5 (cod. 6028624) and use it

in accordance with the instructions provided in figure 11.

C12

C32

C42

3

1

2

7

6

4

3

2

min 1,3 m - max 5 m

8

x

y

x + y = max 3,5 m "25"

x + y = max 3,0 m "30-35"

max 3,5 m "25"

max 3,0 m "30-35"

KEY

1 Coaxial flue kit L. 810

code 8084811

2 a Extension L. 1000 code 8096103

2 b Extension L. 500 code 8096102

3 Vertical extension

L. 200 code 8086908

4 Additional 90° curve code 8095801

6 Ar ticulated tile code 8091300

7 Roof outlet terminal

L. 1284 code 8091200

8 Vertical condensation collector

L. 200 cód. 8092803

IMPORTANT:

– Each additional 90° curve installed

reduces the available length by 1

metre.

– Each additional 45° curve installed

reduces the available length by 0.50

metres.

– It is advisable to assemble the conden-

sation collector (8) on vertical segments exceeding 2.5 metres in length

and to limit maximum length to 4

metres.

Fig. 10

x + y = max 3,6 m

max 3,6 m

16

With outlet type C12, install diaphragm ø 86 only if

the coaxial flue is less than 1 metres long.

With outlet type C32, use the following diaphragms, depending on flue length and without

any additional curves:

Installations with vetrical Installations with vertical condensation

extension L. 200 code 8086908 collector code 8092803

Diaphragm Diaphragm Without Diaphragm None

ø 86

optional ø 87,5

diaphragm optional

ø 87,5

diaphragm

(cod. 6028623) (cod. 6028624) (cod. 6028624)

L min = 1,3 m L min = 2,5 m L min = 4 m L max = 2,5 m L min = 2,5 m

L max = 2,5 m L max = 4 m L max = 5 m L max = 4 m

Fig. 11

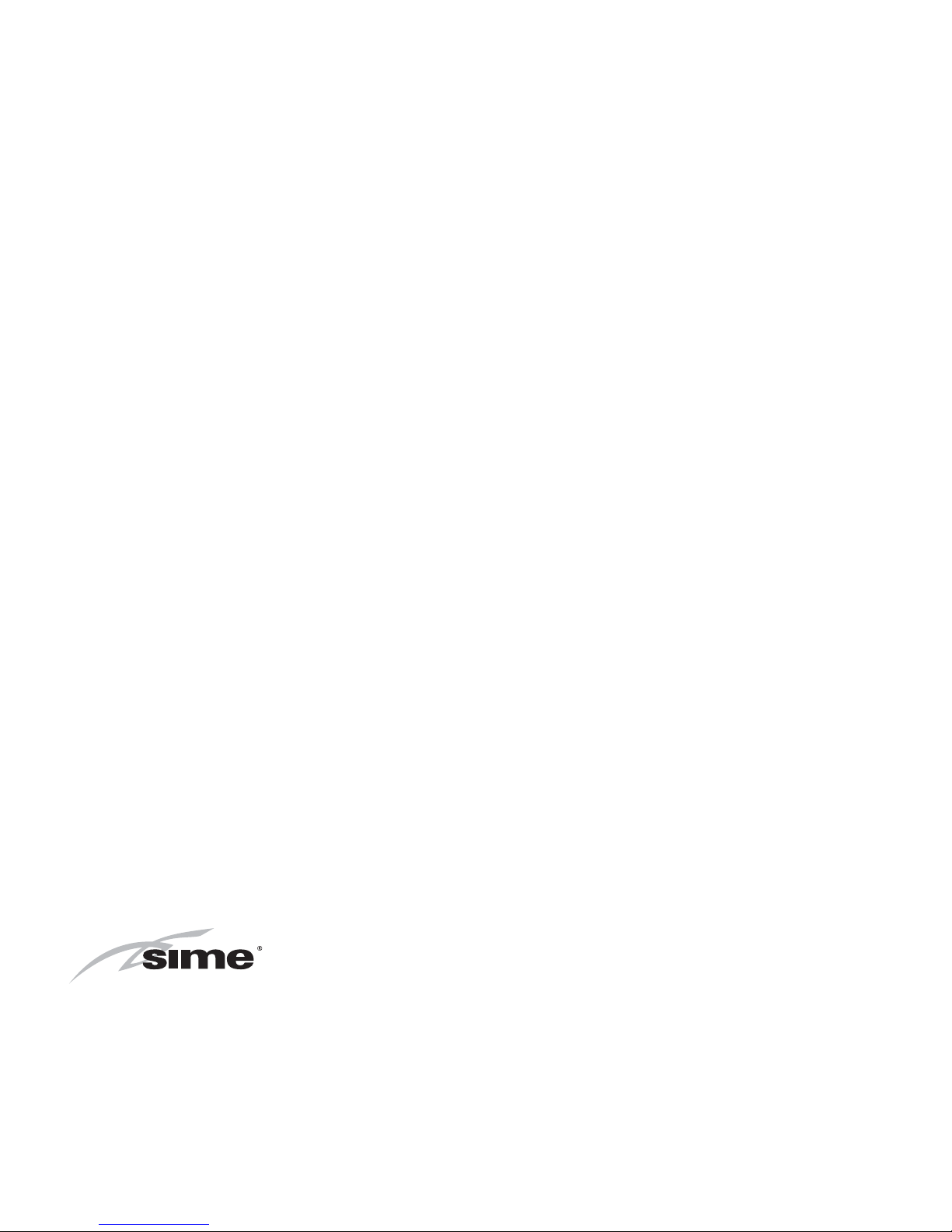

3.4 COAXIAL DUCT ø 80/125

The air inlet-smoke outlet assembly ø 80/125 is supplied in a

kit code 8084830. For the assembly follow what is indicated

in figure 12:

–Make a hole in the wall sufficiently large to allow an insertion

of a pipe ø 125 mm.

–Before to insert the duct in the wall hole fit in position the

outer wall seal (D).

–Push the tube outwards until the gasket comes out. Pull the

pipe inwards bringing the ring to rest on the wall.

–Slide the inner ring (C).

–Insert the adapter (G) to the coaxial duct.

–Insert the adapter to the elbow (A).

–Fit the sponge-rubber gasket (B) to the collar (E).

–Secure the collar (E) to the sealed chamber using the four

screws provided.

–Insert the elbow (A) into the collar (E) tightening the screw

(F).

With the curve supplied in the kit the maximum horizontal

length of the flue must not exceed 6 metres (vers. “Format

80 B”) - 7 metres (vers. “Format 100 B”).

The diagrams in fig. 13 illustrate a number of examples of different coaxial outlets.

NOTE: The air intake-flue outlet assembly must slope slightly

downwards to prevent rain water getting into the boiler.

1055

295

115

ø 125

B

F

E

A

G

C

D

95

KEY

A Elbow 90°

B Sponge-rubber

gasket ø 125/95

C White inner duct

D Grey outer duct

E Junction collar

F Screw

G Adapter

Fig. 12

17

C12

C32

C42

2

7

6

4

1

2

min. 4 m - max 6 m "25"/7 m "30"

8

x

y

x + y = min. 3,6 m/max 6 m "25"

x + y = min. 3,6 m/max 7 m "30"

5

5

3

8

2

1

1

min. 3,6 m - max 6 m "25"/7 m "30"

Fig. 17

IMPORTANT:

– Each additional 90° curve installed reduces the available length by 1 metre.

– Each additional 45° curve installed reduces the available length by 0.50 metres.

– The insertion of the recovery condenses (8) is obligatory in the tipologia of C32 download.

– The insertion of the recovery condenses (8) is obligatory in the tipologia of C42 download

when the section “y” is advanced to 2,5 metres.

KEY

1 Coaxial flue kit code 8084830

2 Extension L. 1000 code 8096130

3 Vertical extension L. 200 ø 60/100 code 8086908

4 a Additional 90° curve code 8095820

4 a Additional 45° curve code 8095920

5 Adapter from ø 80/125 code 8093120

6 Ar ticulated tile code 8091300

7 Roof outlet terminal L. 1284 code 8091200

8 Vertical condensation collector L. 200 ø 60/100 cód. 8092803

18

3.5 SEPARATE DUCTS

(Optional alternative twin pipe system)

When installing the separate ducts, comply with the

requirements of the current standards, as well as the

following practical pointers:

– With direct intake from outside, when the pipe is longer

than 1 m, you are recommended to insulate the piping so

as to prevent the formation of condensation on the outside

of the piping during particularly cold periods of the year.

– With the outlet pipe outside the building or in cold indoor

environments, insulation is necessary to prevent burner

ignition failure. In such cases, provide for condensate

drainage.

– If a segment of the flue passes through a flammable wall,

this segment must be insulated with a glass wool pipe

insulator 30 mm thick, with a density of 50 kg/m

3

.

The maximum overall length of the intake and exhaust

ducts depends on the head losses of the single fittings

installed and can reach approximately the following

horizontal measures:

– 15 m for “Format 80 B” model,

– 21 m for “Format 100 B” model.

For head losses in the fittings, refer to

Table 7.

1

2

3

4

6

165

110

165

K

ø 80

ø 80

100

92

Fig. 18

KEY

1 Sponge-rubber gasket

ø 125/95

2 Fixing screw

3 Smoke outlet flange

4 Air intake diaphragm

6 Manifold with intakes

80 B 100 B

Kmm 185 210

Fig. 18/a

N° segments Total load loss mm H2O

to remove 25 BF 30 BF

none 0 ÷ 3,0 0 ÷ 3,0

n° 1 3,0 ÷ 4,0 3,0 ÷ 4,0

n° 2 4,0 ÷ 5,0 4,0 ÷ 5,0

n° 3 5,0 ÷ 6,0 5,0 ÷ 6,0

n° 4 6,0 ÷ 7,0 6,0 ÷ 7,0

n° 5 6,0 ÷ 7,0 7,0 ÷ 8,0

n° 6 7,0 ÷ 8,0 8,0 ÷ 9,0

n° 7 7,0 ÷ 8,0 9,0 ÷ 10,0

n° 8 8,0 ÷ 9,0 10,0 ÷ 11,0

n° 9 8,0 ÷ 9,0 11,0 ÷ 12,0

n° 10 - 12,0 ÷ 13,0

without diaphragm 9,0 ÷ 10,5 13,0 ÷ 14,0

19

3.5.1 Separate flue accessories

Part No 8089904 is supplied for this purpose. The sectored

diaphragm is to be used according to the maximum head loss

allowed in both pipes, as given in fig. 18/a.

3.5.2 Use of air intake (fig. 19)

To use the air intake in this type of outlet you must perform

the following operations:

–

Remove the base of the air intake, using a tool to cut it off (a);

–Overturn the air intake (b) and replace the seal (5) with the

seal supplied in the kit code 8089904;

–Insert the intake diaphragm supplied in the kit code

8089904, pushing it in until it is in contact with the seat;

You can now insert the extension or curve in its housing to

complete the intake (you need not use any seat or sealant).

3.6 WATER CONNECTIONS

3.6.1 Central heating connections

–

Fit the two C.H. isolation valves using the gaskets supplied to

the flow and return connections as shown in fig. 2. The pipe

connections are labelled on the lower part of the boiler.

– Connect the C.H. pipework as required.

3.6.2 D.H.W. connections

– Fit the D.H.W. isolation valve to the cold water inlet

connection as shown in fig. 2.

– Fit the union connection to the D.H.W. outlet.

– Connect the D.H.W. pipework as required.

3.7 GAS CONNECTIONS

– Screw the gas cock into the internal thread in the gas inlet

connection using a suitable jointing compound.

– Connect the gas supply pipe.

3.8 SAFETY VALVE CONNECTION

– The appliance safety valve is located towards the R.H.S. of

the boiler and the discharge pipe is supplied loose. Remove

the two selftapping screws and lower the control box to

improve access.

– Connect the discharge pipe to the valve outlet, and extend

the pipe to ensure that any discharge from the safety valve

is safely routed to a drain. The discharge pipe should be a

minimum of 15 mm copper, and must avoid sharp corners

or upward pipe runs where water may be retained.

3.9 WIRING INSTRUCTIONS

(Refer to sections 2.6 - 2.7 and fig. 20)

– Support the valve whilst tightening the nut and olive to

avoid damage to the technil assembly.

– Disconnect the electric power supply before performing

any work.

– Remove the three screws (9) locking the control panel in place

and pull the panel forward until it can be tilted downward.

– To access the components of the electrical panel, unscrew

the four screws holding the protective guard in place (6).

Fig. 19

a

b

5

IMPORTANT: The three housings on the

diaphragm permit assembly of the air

intake in one position only (with numbers

toward inside the boiler).

TABLE 7

Accessories ø 80 Load loss (mm H2O)

“80 B/100 B”

Intake Outlet Roof out. Intake

90° curve MF 0.30/0.30 0.40/0.50 –

45° curve MF 0.20/0.20 0.30/0.40 –

Extension L. 1000 (horizontal) 0.20/0.20 0.30/0.40 –

Extension L. 1000 (vertical) 0.30/0.30 0.20/0.30 –

Outlet terminal – 0.30/0.40 –

Intake terminal 0.10/0.10 – –

Manifold 0.20/0.30 – –

Roof outlet terminal L.1390 – – 0,50/0.60

Condensation collection T – 1.00/1.10 –

20

– To gain access to connector “TA”, remove the control

panel cover (7) and connect the room stat to the

terminals 10-11 after having removed the jumper.

The thermostat or timer-thermostat, recommended for

better room temperature control, must be class II as

specified by standard EN 60730.1 (clean contact).

– Carry out electrical system checks through a suitable test

meter: earth continuity, polarity, resistance to earth and

short circuit.

– Re-secure control box.

– Ensure sufficient length of cable to allow access to control

panel.

8

1

25

4

7

6

Fig. 20

KEY

1 Temperature and pressure gauge

2 Easy-Stat Receiver housing (8092221)

4 Main PCB

5 Ear th faston

6 Control panel protection

7 Cover (TA)

8 Connector (TA)

ATTENTION: After having removed the three fixing

screws, tilt the panel downward to gain access

.

21

SIME SUPPORT THE BENCHMARK INITIATIVE

All relevant sections of the logbook must be filled in at the

time of installation and thereaf ter service information on the

back page of the logbook. Commissioning of the boiler is not

complete until the logbook is filled in.

Before commissioning the appliance, the whole gas

installation including the meter MUST be purged and tested

for gas soundness in accordance with BS6891.

IMPORTANT: open all doors and windows, extinguish naked

lights, and DO NOT SMOKE whilst purging the gas line.

Before commencing the commissioning procedure, ensure

that the gas service cock is turned on, the electricity supply

is isolated, and that the D.H.W. and C.H. isolation valves are

in the closed position.

4.1 FILLING THE WATER SYSTEM

– Open the C.H. flow and C.H. return valves (20 - 19 fig. 2).

– Loosen the automatic air vent cap (11 fig. 2).

– Open all radiator valves and system air vents. Fill the

system with water using one of the approved methods

described in section 2.9 to about 0.5 bar greater than the

system design pressure. Close all air vents. Do not close

the A.A.V. the one near the pump!

– Check the system for water soundness.

– Completely drain the appliance and heating system,

thoroughly flush the system, and refill the system design

pressure to BS 7593.

– Open the D.H.W. inlet valve, open any hot tap, clear of air

bubbles. Close hot tap.

4.2 COMMISSIONING THE BOILER

– Loosen the screw and connect a pressure gauge to the

burner pressure test point on the gas valve (fig. 21).

– Ensure that the rotary switch on the facia panel is set to

the summer position “ ” (D.H.W. Only), turn the D.H.W.

thermostat to maximum (fully clockwise), and turn on the

electrical supply. Fully open any D.H.W. tap and the burner

will light.

– Allow the boiler to run for at least 5 minutes and check

that the burner pressure is as stated in section 1.3. The

D.H.W. burner pressure is factory set and should not

require adjusting. If the burner pressure is low, check that

the appliance has not begun to modulate (this will occur if

the D.H.W. flow rate is low. If modulation is suspected,

open all D.H.W. taps to maximise flow and recheck burner

pressure). Check also the inlet pressure with the burner

alight; this should be 20 mbar +/– 1.0 mbar standing

pressure & the working inlet pressure limited to a loss no

greater than 1.0 mbar for natural gas. If it is necessary to

adjust the D.H.W. burner pressure the method is

described in section 8.6.

– Reduce the D.H.W. draw off rate to the minimum

necessary to maintain the burner alight by carefully

adjusting the D.H.W. inlet valve and check that the burner

pressure decreases in response to D.H.W. temperature

rise. Fully open the inlet valve.

– Close the D.H.W. tap and ensure that the burner is

extinguished and the pump stops.

4 COMMISSIONING AND TESTING

BURNER PRESSURE

TEST POINT

Fig. 21

22

4.5 FINAL CHECKS

– Re-light and test for gas soundness.

– Re-fit the casing front panel and securing brackets.

– Set the C.H. and D.H.W. potentiometers to the required

settings.

– Ensure that the time clock is set at the desired time

periods. Set the room thermostat (if fitted) to the required

setting.

4.6 USER’S INSTRUCTIONS

Upon completion of commissioning and testing the system,

the installer should:

– Give the “Users Instructions” to the householder and

emphasise their responsibilities under the “Gas Safety

(Installation and Use) Regulations 1996 (as amended)”.

– Explain and demonstrate the lighting and shutdown

procedures.

– Advise the householder on the efficient use of the system,

including the use and adjustment of all system controls for

both D.H.W. and C.H.

– Advise the user of the precautions necessary to prevent

damage to the system, and to the building, in the event of

the system remaining inoperative during frost conditions.

– Explain the function of the boiler overheat thermostat, and

how to reset it.

Emphasise that if cut-out persists, the boiler should be

turned off and the installer or service engineer consulted.

– Stress the importance of an annual service by a

registered heating engineer.

23

Failure to install and commission according to the manufacturer’s instructions and complete this Benchmark Commissioning Checklist will invalidate the warranty. This

does not affect the customer’s statutory rights.

If yes, and if required by the manufacturer, has a water scale reducer been fitted?

CONDENSING BOILERS ONLY

The condensate drain has been installed in accordance with the manufacturer’s instructions and/or BS5546/BS6798 Yes

If the condensate pipe terminates externally has the pipe diameter been increased and weatherproof insulation fitted? Yes

24

Service Record

It is recommended that your heating system is serviced regularly and that the appropriate Service Interval Record is completed. This is also a condition

of any extended warranty offered.

Service Provider

Before completing the appropriate Service Record below, please ensure you have carried out the service as described in the

manufacturer’s instructions.

Always use the manufacturer’s specified spare part when replacing controls.

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Operative ID No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Service 1 Service 2

Service 3 Service 4

Service 5 Service 6

Service 7 Service 8

Service 9 Service 10

To ensure continued efficient operation of the appliance, it is

recommended that it is checked and serviced as necessary

at regular intervals. The frequency of servicing will depend

upon the particular installation conditions and usage but in

general once a year should be adequate.

It is the law that any service work must be carried out by

registered personnel (C.O.R.G.I.). Before commencing any

service operation, ISOLATE the mains electrical supply, and

TURN OFF the gas supply at the main service cock. Service

the appliance by following the full procedure detailed below.

5.1 MAIN BURNER ASSEMBLY

– Remove the casing as showed in fig. 23.

– Remove the 8 fixing screws securing the sealed chamber

front panel then remove the panel.

– Unscrew the 7 screws securing the combustion chamber

front panel and remove the panel, taking care not to

damage the insulation.

– Remove the electrode by unscrewing it from the burner

manifold.

– Unscrew the burner manifold union and locking nut. Lift

the front of the burner to disengage manifold thread and

then lift the burner clear.

– Remove the burner manifold by disconnecting the four

screws.

– Inspect and if necessary, clean the injectors, electrodes,

and the main burner bars.

5.2 FAN ASSEMBLY

– Disconnect the electrical connections to the fan. Note the

position of the earth conductor.

– Remove the three screws securing the fan.

– Tilt the fan forwards and remove in a downwards direction.

– Inspect the fan assembly and clean if necessary.

5.3 BITHERMAL EXCHANGER

– Inspect the bithermal exchanger, and clean if necessary.

5.5 CHIMNEY SWEEP FUNCTION

(combustion analysis)

To carry out the verification of combustion in the boiler turn

the selector and stop on the position ( ) until the

green/orange led starts to flash intermittently.

From that moment the boiler will start functioning in heating

mode at the maximum power, with switching off at 80°C and

restarting at 70°C.

Before activating the chimney sweep function make sure

that the radiator valves or eventual zone valves are open.

The test may be carried out also during D.H.W. mode.

To do so it is enough, after having activated the chimney

sweep function, to take some hot water from one or more

outlets.

Even in this condition the boiler functions at the maximum

temperature always with the primary controlled between

80°C and 70°C. During the entire duration of the testing the

hot water taps must remain open.

After verifying the combustion the boiler should be switched

off by placing the selector on the OFF position; then return the

selector to the desired function.

5 ROUTINE SERVICING INSTRUCTIONS

8 SEALED CHAMBER SCREWS

3 FAN FIXING SCREWS

MAIN EXCHANGER

7 COMBUSTION CHAMBER

FRONT PANEL SCREWS

BURNER MANIFOLD UNION

Fig. 24

1

2

Fig. 23

SCREWS

25

26

ATTENTION: After about 15 minutes, or once the hot water

request has been fulfilled, the chimney sweep function

automatically deactivates.

5.6 RE-ASSEMBLY

– Re-assemble all the components in reverse order and

replace all the gaskets fitted in the gas line.

Ensure that all seals are correctly fitted and that the

pressure sensing line is correctly fitted.

Check that the fan earth connection is correctly re-fitted.

Note that the fan polarity (Line and Neutral) is immaterial.

– Check for gas soundness before fitting the casing.

5.7 RE-COMMISSIONING

– Turn on the gas supply, and check for gas soundness whilst

the appliance is running.

– Check the operation of the appliance in both C.H. and

D.H.W. mode and ensure in both cases that the burner

pressure after at least 5 minutes running is as stated on

the data plate or in

Table 3

.

Adjust if necessary as described in section 8.

When any service or replacement of electrical components

which has required the breaking and re-making of electrical

connections has taken place, the following tests must be

repeated:

– earth continuity;

– short circuit;

– polarity;

– resistance to earth.

27

6.1 EARTH CONTINUITY CHECK

Appliances must be electrically disconnected, meter set on Ω

(ohm) x 1 scale and adjust zero if necessary. Tests leads from

any appliance earth point (e.g. inside control box) see wiring

diagrams (section 7) to earth pin on plug. Resistance should

be less than 1Ω (ohm). If the resistance is greater than 1Ω

(ohm) check all earth wires for continuity and all contacts are

clean and tight. If the resistance to earth is still greater than

1Ω (ohm) then this should be investigated futher.

6.2 SHORT CIRCUIT CHECK

Switches turned FULL ON - meter set on Ω (ohms) x 1 scale.

Test leads from L to N on appliance terminal block, if meter

reads 0 then there is a short circuit.

Meter set on Ω (ohm) x 100 scale. Repeat it with leads from

L to E. If meter reads less than infinity (∞) there is a fault.

NOTE: Should it be found that the fuse has failed but no

fault is indicated, a detailed continuity check (i.e. by

disconnecting and checking each component) is required to

trace the faulty component.

It is possible that a fault could occur as a result of local

burning/arcing but no fault could be found under test.

However, a detailed visual inspection should reveal

evidence of burning around the fault.

6.3 POLARITY CHECK

Appliance reconnected to mains supply and meter set on

300 V ac scale. Test at appliance terminal block.

– Test leads from L to N meter reads approx.: 240 V ac.

– Test leads from L to E “ ” meter reads approx. 240 V ac.

– Test leads from N to E “ ” meter reads from 0 to 15 V ac.

6.4 RESISTANCE TO EARTH CHECK

Appliance must be disconnected from main supply and meter

on Ω (ohm) x 100 scale.

All switches including thermostat on test leads from L to E - if

meter reads other than infinity (∞) there is a fault which

should be isolated. A detailed continuity check is required to

trace the faulty component.

IMPORTANT:

These series of checks are the first electrical checks to be

carried out during a fault finding procedure. On completion

of the service/fault finding task which has required the

breaking and remaking of electrical connections then the

checks 6.1 Earth continuity, 6.3 Polarity and 6.4

Resistance to earth must be repeated.

6.5 FAULT FINDING LEDS

The indicator leds signalling irregular and/or incorrect

operation of the equipment are indicated in fig. 26.

Before commencing any service operation, ISOLATE the

mains electrical supply, and TURN OFF the gas supply at the

main service cock. It is the law that any service work must be

carried out by registered personnel (Gas Safe Register).

6 FAULT FINDING

Fig. 26

Bi-colour green led off if power is cut-off.

Bi-colour orange led: C.H. sensor (SM) fault.

Green led flashing: fan/smoke pressure switch failure.

Orange led flashes if water pressure is insuf ficient.

Flashing red led indicates a problem in the tap water probe (SS).

Red led on, ignition lock-out/safety and smokes stats

tripped: turn the selector switch briefly to the position

marked ( ) to restore functioning

28

6.6 C.H. MODE - FAULT FINDING

Start from cold Rotary switch set to WINTER position.

Room thermostat (if fitted) calling for heat and all D.H.W. taps off.

C.H. thermostat set to maximum position.

Clock in the on position.

NOTE:

After completing fault finding reset the room thermostat (if fitted) to the required setting. If the appliance will not function

check the wiring to the clock and if necessary, replace the clock.

Is there power

at the external

socket?

Make

power

available

Does

the pump

start?

Does

the fan

start?

Turn the clock

in the right

position

Is fuse

at mains

plug OK?

Is the clock in

the correct

band time?

Is there voltage

available

to the fan?

Replace

the clock

Replace fuse in

mains plug

Check the

time clock does

his contacts

open and close

when the clock

turns?

Replace

the fan

Make it free to

rotate

Put a jumper

on the room

thermostat

connection

Check the

power supply

cable

Is pump shaft

free to rotate?

Is there voltage

available

to the pump?

Replace

the pump

Check pump

connection

Does the boiler

lock-out without

starting the

burner?

The boiler

lock-out

starting

the burner

Is there a spark

at the ignition

electrode?

Is the ionization

probe connected

to the main PCB

and the ground?

Check the

gas supply

Check for continuity between ignition

electrode and igni-

tion transformer

The gap between

ignition electrode

and hood

is correct?

Fit correctly the

ignition electrode

Is the gas

available?

Check the

connection of

the gas valve on

the control board

PCB

Is there voltage at

the gas valve?

Replace the

gas valve

Yes

No

Is there a jumper

on the room

thermostat

connection?

No

Yes

No

Yes

No

Yes

Yes

Yes

Yes

No

Yes

No

Yes

Yes

Yes

No

No

Yes

YesYes

No

No

Yes

No

No

No

No

Yes

No

Verify that the

safety

thermostat

is working

correctly?

Replace the

thermostats

No

Is the

connection of

the safety

thermostats

correct?

Reset the

connection

No

Yes

Restore the

connection

Verify that the

safety

thermostat

is working

correctly?

No

Yes

Yes

Check the

connection of

the thermostat

Replace the

thermostat

No

Yes

29

6.7 D.H.W. MODE - FAULT FINDING

Start from cold - rotary switch set to SUMMER position, D.H.W. thermostat set to maximum, and all D.H.W. taps OFF.

Is there power

at the external

socket?

Make

power

available

Open any tap.

Is there an

adequate flow

rate of D.H.W.

available?

Does

the fan

start?

Is fuses

at mains

plug OK?

Clean or replace

the water flow

switch

Is there voltage

available

to the fan?

Replace fuses in

mains plug

Replace

the fan

Check the

power supply

cable

Does the boiler

lock-out without

starting the

burner?

The boiler

lock-out

starting

the burner

Is there a spark

at the ignition

electrode?

Is the ionization

probe connected

to the main PCB

and the ground?

Check the

gas supply

Check for continu-

ity between ignition

electrode and igni-

tion transformer

The gap between

ignition electrode

and hood

is correct?

Fit correctly the

ignition electrode

Is the gas

available?

Restore the

connection

Check the

connection of

gas valve on

the control board

PCB

Is there voltage at

the gas valve?

Replace the

gas valve

Yes

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

No

No

Yes

Yes

No

Yes

No

No

No

Yes

No

Yes

Verify that the

safety

thermostat

is working

correctly?

Replace the

thermostats

No

Is the

connection of

the safety

thermostat

correct?

Reset the

connection

No

Yes

Yes

No

Verify that the

safety

thermostat

is working

correctly?

Yes

Check the

connection of

the thermostat

Replace the

thermostat

No

30

7 WIRING & FUNCTIONAL DIAGRAMS

7.1 ILLUSTRATED FLOW WIRING DIAGRAM

CN2 (code 6299977)

CN6 (code 6299974)

CN7 (code 6299973)

CN1

JUMPERS

JP4

WHITE

100 °C SAFETY STAT

C.H. SENSOR (SM)

D.H.W. SENSOR (SS)

GAS VALVE

PRESSURE

SWITCH

ROOM

THERMOSTAT

PUMP

FAN

IGNITION/

IONISATION

ELECTRODE

WATER FLOW

SWITCH ASSEMBLY

TIME

CLOCK

Fig. 27

NOTE:

– The room thermostat may be connected to the terminals 15-16 (CN1) of the “TA” connector after having removed the link.

– To remote control the boiler connect an external clock to the terminals 1-2 (24 V) of the “TA” connector and set the built-

in clock to “constant” mode (see user instructions for details).

JUMPERS POSITION AND FEATURES

JUMPER POSITION AND FEATURE SUPPLY POSITION

CLOSED OPEN

JP4 - METANO/GPL Ready to function with LPG Ready to function with natural gas Open

8.1 BITHERMAL EXCHANGER

– Remove the fan as described in section 8.3.

–

Disconnect the pressure sensing pipe from the flue box, lift the

collector hood assembly, tilt forwards, and remove the hood.

– Isolate the C.H. flow and return valves.

– Drain the bithermal exchanger using the drain cock (at the

bottom RHS of the appliance)

– Unclip the bithermal exchanger securing clips and

unscrew completely the expansion vessel nut.

– Disconnect the pipes from the exchanger and lift out the

heat exchanger.

– Re-assemble in reverse order, ensuring that the bithermal

exchanger seals and clips are correctly located and that

the pressure sensing pipe is correctly re-fitted. The fan

polarity is not important except the earth conductor (G/Y

which is marked on the appliance).

– Refill, and re-commission the system as described in

section 4.

8.2 COMBUSTION CHAMBER INSULATION

The design of this appliance is such that the rear and side

insulation should not require replacement unless

mechanically damaged.

IMPORTANT: When handling insulation panels, take care to

avoid producing or inhaling dust particles. When removing

old or damaged insulation panels, dampen with water to

minimise dust.

To replace the insulation front panel, proceed as follows:

– remove the combustion chamber front panel as described

in section 5.1;

– replace the front insulation panel and glue it into position

on the front panel using the glue supplied. Re-assemble in

reverse order.

Should the rear or side panels become damaged, replace

them as follows.

– remove the heat exchanger as described in section 8.1;

–

remove the side insulation panels followed by the rear panel;

– re-assemble in reverse order, refill, and recommission the

system as described in section 4.

8.3 FAN ASSEMBLY

– Remove the casing front panel and sealed chamber front

panel as described in section 5.1.

– Disconnect the electrical connections and the pressure

sensing pipes to the fan. Note the position of the earth

conductor.

– Unscrew the three screws securing the fan.

– Drop and tilt the fan forwards and remove in a downwards

direction.

– Re-assemble in reverse order. Ensure that the earth

connection is correctly refitted. Note that the polarity (Line

and Neutral) is immaterial.

8.4 MAIN BURNER

– Remove the main burner by following section 5.1.

– Transfer the ignition electrode onto the new burner

assembly.

– Re-assemble in reverse order. Check the electrode gaps

(fig. 28) and test for gas soundness.

– Re-commission the appliance as described in section 4.

8.5 IGNITION/DETECTION ELECTRODE

– Remove the casing front panel and sealed chamber front

panel as described in section 5.1.

– Unscrew the single screw securing the electrode in

position, and release the electrode from the burner.

– Remove the electrode and disconnect its cable from the

ignition transformer.

– Replace the electrode and re-assemble in reverse order.

8.6 GAS VALVE

– Remove the casing front panel as described in section 5.1.

– Disconnect the two leads from the modulating solenoid

and disconnect the valve connector (one screw).

– Unscrew the nut between the inlet pipe and the valve.

– Unscrew the burner manifold nut underneath the sealed

chamber, and withdraw the gas valve complete with outlet

pipe.

– Transfer the outlet pipe onto the new gas valve, using a

new gasket (supplied with the valve).

– Fit the new gas valve assembly into the appliance using the

other new gasket supplied on the valve inlet, and re-

assemble in reverse order.

– Re-light the appliance, check for gas soundness, and re-

commission in accordance with section 4.

In addition it will be necessary to set the D.H.W. and C.H. heat

inputs, with reference to fig. 29, as follows:

Note that it is necessary to set the MAXIMUM PRESSURE

FIRST.

– Connect a pressure gauge to the burner pressure test

point.

– Remove the sealing cap of the proportioning unit (C) by

rotating it ⁄ turn anticlockwise.

– Adjust DHW potentiometer to maximum, then fully open

any DHW tap to light the boiler.

– Using a 10 mm spanner, turn nut (B) to attain the

maximum pressure in

Table 3

.

Turn the nut clockwise to increase or anti-clockwise to

decrease the burner pressure.

31

8 REPLACEMENT OF PARTS

Fig. 28

4

± 0.5

IGNITION/DETECTION

ELECTRODE

– Turn the main selector switch on and off a few times (with

the hot tap still open) and check that the pressure returns

to the correct (set) maximum value (as in

Table 3

).

– Set the minimum burner pressure by first isolating the

electricity supply and disconnecting one of the modulating

solenoid leads, then restore the electricity supply and fully

open a DHW tap to light the appliance at minimum gas

rate.

– Set the minimum pressure with reference to

Tables 3

by

holding nut (B) in position with a 10 mm spanner and

rotating the plastic screw (A) with a screwdriver until the

correct pressure is obtained. Turn the screw clockwise to

increase the pressure or anti-clockwise to decrease it. It is

essential that the max pressure has been set prior to

adjusting the minimum pressure. Check that the minimum

pressure is correctly set by turning on and off the D.H.W.

inlet valve several times and ensuring that the pressure

returns to that previously adjusted;

– Isolate the power supply, re-connect the modulation lead,

restore the power and re-check the maximum pressure,

then re-fit the plastic cover (1).

– Reduce the D.H.W. draw off rate to the minimum nec-

essary to maintain the burner alight by carefully adjusting

the D.H.W. Inlet valve and check that the burner pressure

decreases in response to D.H.W. temperature rise. Fully

open the inlet valve;

– Close the D.H.W. tap and ensure that the burner is

extinguished and the pump stops.

– Adjust the Central Heating maximum pressure as

described in section 4.3, then complete the recommissioning as described in 4.4 and 4.5.

8.7 AIR PRESSURE SWITCH

– Remove the casing front panel and sealed chamber front

panel as described in section 5.1.

– Disconnect the pressure sensing pipe from the switch.

– Remove the switch (two screws) and fit the new one.

– Transfer the electrical connections one at a time (to

ensure that they are not incorrectly re-fitted) to the new

switch.

– Re-assemble in reverse order referring to the wiring

diagrams (section 7) if necessary. Ensure that the

pressure sensing lead is correctly connected to the low

pressure connection on the pressure switch (marked P2).

8.8 SAFETY THERMOSTAT

The safety thermostat is situated on the flow pipe (3 fig. 3).

– Remove the casing front panel as described in section 5.1.

– Disconnect the two limit thermostat wires.

– Unscrew the two limit thermostat fixing screws and

remove the thermostat.

– Replace the thermostat and spread heat sink compound

(supplied) over the base of the new one.

– Re-assemble in reverse order (Polarity is immaterial).

8.9 THERMISTOR

The thermistor is placed over the main exchanger.

– Remove the casing front panel as described in section 5.1.

– Isolate the C.H. flow and return valves (20 - 19 fig. 2), and

drain the appliance through the drain plug (16 fig. 2).

– Pull off the electric connection, and unscrew the

thermistor from the exchanger.

– Replace the thermistor and re-assemble in reverse order.

Table 8

shows the resistance values (Ω) that are obtained on

the sensor as the temperature varies.

8.10 DRIVER PCB

– Remove the casing front panel as described in section 5.1.

– Open the control panel protecting cover by removing the

four fixing screw.

– Pull off the potentiometer knobs.

– Release the PCB (6 screws), transfer all connections onto

the new PCB, and re-assemble in reverse order.

8.11 PUMP MOTOR

– Remove the casing front panel as described in section 5.1.

– Unplug the electrical connection plug.

– Isolate the C.H. flow and return valves (20 - 16 fig. 2), and

drain the appliance through the drain plug (16 fig 2).

– Unscrew the four fixing screws on the motor.

– Replace the pump motor and re-assemble in reverse

order. If the new pump is fitted with a speed adjuster,

ensure that the speed is set to maximum.

–

Refill and commission the system as described in section 4.1.

8.15 C.H. EXPANSION VESSEL

Replacement is not recommended if a rear flue outlet is used

or if the clearance above the casing is less than 300 mm.

– Remove the casing front panel as described in section 5.1.

32

Temperature (°C) Resistance (Ω)

20 12,090

30 8,313

40 5,828

50 4,161

60 3,021

70 2,229

80 1,669

TABLE 8

KEY

A Plastic screw

BNut

C Sealing cap

Fig. 29

33

– Isolate the C.H. flow and return valves (20 - 19 fig. 2), and

drain the appliance through the drain plug (16 fig. 2).

– Unscrew the expansion vessel union on the C.H. return

pipe.

– If a rear flue outlet is used it is necessary to disengage the

flue and air duct temporarily. Refer to section 3.5.

– Remove the adjusting screws on the wall mounting

bracket thereby allowing the appliance to move slightly

forwards at the top.

– Lift the expansion vessel out of the appliance through the

top.

– Replace the expansion vessel and re-assemble in reverse

order. Re-pressurise and re-commission the system as

described in section 4.1.

8.16 PRESSURE/TEMPERATURE GAUGE

– Remove the casing front panel as described in section 5.1.

– Isolate the C.H. flow and return valves (20 - 19 fig. 2).

– Drain the appliance through the drain point (16 fig. 2).

– Remove the circlip securing the pressure sensor to the

hydraulic group and pull out the sensor.

– Remove the fixing spring of the thermometer bulb from

the C.H. flow pipe.

– Squeeze the gauge to depress the retaining clips, then

ease the gauge forwards.

– Reassemble in reverse order.

Refill and re-commission the system as described in

section 4.1.

8.17 SAFETY VALVE

– Remove the casing front panel as described in section 5.1.

– Isolate the C.H. flow and return valves (20 - 19 fig. 2).

– Drain the appliance through the drain point (16 fig. 2)

– Remove the circlip securing the valve to the hydraulic

group and remove the valve.

– Fit the new safety valve and re-assemble in reverse order.

Refill and re-commission the system as described in

section 4.1.

8.18 AUTOMATIC AIR VENT

– Remove the casing front panel as described in section 5.1.

– Isolate the C.H. flow and return valves (20 - 19 fig. 2).

– Drain the appliance through the drain point (16 fig. 2).

– Remove the circlip securing the automatic air vent to the

hydraulic group.

– Fit the new automatic air vent and re-assemble in reverse

order. Refill and re-commission the system as described in

section 4.1.

8.19 TIME CLOCK

– Pull off the electrical connections at the back of the clock.

– Remove the two screws securing the plastic frame of the

time clock to the facia panel.

– Remove the plastic frame and pull out the time clock.

– Re-assemble in reverse order and test the operation of

the new clock.

– Set it to the desired settings as described in section 4.3.

COD. TYPE DATE PAGE

3820086/318 FORMAT 80B - 100B 26.04.2007 1/4

34

9 EXPLODED VIEWS

35

POSITION CODE DESCRIPTION MODEL NOTE

COD. TYPE DATE PAGE

• Recommended stock par ts - Com ponenti da tenere a scorta

POSITION CODE DESCRIPTION MODEL NOTE

1 6138570 Side frame part

2 6138770 Frame assembly upper support 80

2 A 6138771 Frame assembly upper support 100

3 6255430 Expansion vessel lower support 80

3 A 6255431 Expansion vessel lower support 100

4 • 5139140 Expansion vessel l.7 - 3/8” M 80

4 A • 5139130 Expansion vessel l.8 - 3/8” M 100

5 6146305 Brass Nut 3/8”

6 6288105 Sealed chamber rear panel 80

6 A 6288115 Sealed chamber rear panel 100

7 6119313 Plastic cap

8 6287900 Air/smoke manifold

9 6147406 Air/smoke manifold plug M14x1.5

10 • 6226417 O-ring 3043

11 6242602 Air/smoke manifold screw

12 6248803 Lip seal for Ø 60 pipe

13 6028706 Air/smoke manifold gasket

14 2000716 Screw T.C.B. M4x8

15 5190700 Main burner assembly 80

15 A 5190752 Main burner assembly 100

16 • 6235931 Ignition-ionisation electrode

17 6146301 Brass nut 1/2”

18 6288415 Combustion chamber rear panel 80

18 A 6288416 Combustion chamber rear panel 100

19 6288500 Combust. chamber right hand side panel 80

19 A 6288510 Combust. chamber right hand side panel 100

20 6288600 Combust. chamber left hand side panel 80

20 A 6288610 Combust. chamber left hand side panel 100

21 6139789 Combustion chamber rear insulation 80

21 A 6139790 Combustion chamber rear insulation 100

22 6139774 Combustion chamber side insulation 80

22 A 6139792 Combustion chamber side insulation 100

23 6028707 Air intake gasket

24 6288000 Air intake

25 6257512 Air deflector for separate ducts

26 6174249 Gas/Water heat exchanger 80

26 A 6174250 Gas/Water heat exchanger 100

27 6231356 Temperature sensor

28 6272504 Temperature sensor fixing spring

29 5190601 Smoke chamber assembly 80

29 A 5190611 Smoke chamber assembly 100

30 2016020 Locked nut M4

31 • 6225632 Fan 80

31 A • 6225624 Fan 100

32 2000715 Screw TCB M4x10 AISI 304

33 6288701 Combustion chamber front panel 80

33 A 6288711 Combustion chamber front panel 100