Supplied By www.heating spares.co Tel. 0161 620 6677

Format C

Installation and

servicing instructions

GB

PLEASE LEAVE THIS INSTRUCTION

WITH THE USER

Supplied By www.heating spares.co Tel. 0161 620 6677

Format 80 C:

Gas Council number 47-719-12

Format 100 C:

Gas Council number 47-719-13

Format 110 C:

Gas Council number 47-719-21

These appliances comply with the S.E.D.B.U.K. scheme, band “D”

SIME COMBINATION BOILERS

Installer checklist

Please remember to carry out the following checks after installation. This will achieve complete customer satis-

faction, and avoid unnecessary service calls. A charge will be made for a service visit where the fault is not due to

a manufacturing defect.

– Has a correct by-pass been fitted and adjusted?

– Has the system been flushed in accordance with the guidelines given in BS7593 “Treatment of water in domes-

tic hot water central heating systems”?

– Is the system and boiler full of water, and the correct pressure showing on the pressure gauge?

– Is the Auto Air Vent open?

– Has the pump been rotated manually?

– Is the gas supply working pressure correct?

– Is the boiler wired correctly? (See installation manual).

– Has the D.H.W. flow rate been set to the customer requirements?

– Has the customer been fully advised on the correct use of the boiler, system and controls?

– Has the log book provided been completed?

Please refer to commissioning instructions for filling in the log book

Note: All CORGI registered installers carry a CORGI ID Card.

You can check your installer is CORGI Registered by calling 01256 372300

IPX4D

Supplied By www.heating spares.co Tel. 0161 620 6677

1 TECHNICAL FEATURES AND DIMENSIONS

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 DIMENSIONAL DETAILS

1.3 GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 HYDRAULIC CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 INTERNAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 GENERAL REQUIREMENTS FOR INSTALLATION

2.1 STATUTORY REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 BOILER POSITION

2.3 FLUE TERMINAL POSITION

2.4 VENTILATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 GAS SUPPLY

2.6 ELECTRICITY SUPPLY

2.7 EXTERNAL CONTROLS

2.8 WATER SYSTEMS - GENERAL

2.9 REQUIREMENTS FOR SEALED WATER SYSTEMS

2.10 D.H.W. SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 INSTALLING THE BOILER

3.1 FIXING THE WALL MOUNTING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 HANGING THE BOILER

3.3 FLUE DUCTS PREPARATION

3.4 FLUE AND TERMINAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 SEPARATE DUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 WATER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 GAS CONNECTIONS

3.8 SAFETY VALVE CONNECTION

3.9 WIRING INSTRUCTIONS

4 COMMISSIONING AND TESTING

4.1 FILLING THE WATER SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 COMMISSIONING THE BOILER

4.3 SETTING THE C.H. INPUT

4.4 SETTING THE D.H.W. FLOWRATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 FINAL CHECKS

4.6 USER’S INSTRUCTIONS

5 ROUTINE SERVICING INSTRUCTIONS

5.1 MAIN BURNER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 FAN ASSEMBLY

5.3 HEAT EXCHANGER

5.4 WATER FLOW SWITCH

5.5 CHIMNEY SWEEP FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 RE-ASSEMBLY

5.7 RE-COMMISSIONING

5.8 CLEANING THE C.H. WATER FILTER

CONTENTS

Supplied By www.heating spares.co Tel. 0161 620 6677

6 FAULT FINDING

6.1 EARTH CONTINUITY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 SHORT CIRCUIT CHECK

6.3 POLARITY CHECK

6.4 RESISTANCE TO EARTH CHECK

6.5 FAULT FINDING LEDS

6.6 C.H. MODE - FAULT FINDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.7 D.H.W. MODE - FAULT FINDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 WIRING & FUNCTIONAL DIAGRAM

7.1 ILLUSTRATED FLOW WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 REPLACEMENT OF PARTS

8.1 HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 COMBUSTION CHAMBER INSULATION

8.3 FAN ASSEMBLY

8.4 MAIN BURNER

8.5 IGNITION/DETECTION ELECTRODE

8.6 GAS VALVE

8.7 AIR PRESSURE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.8 OVERHEAT THERMOSTAT

8.9 THERMISTOR

8.10 DRIVER PCB

8.11 PUMP MOTOR

8.12 D.H.W. HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.13 DIVERTOR VALVE - COMPLETE

8.14 DIVERTOR VALVE - MICROSWITCH ASSEMBLY

8.15 C.H. EXPANSION VESSEL

8.16 PRESSURE/TEMPERATURE GAUGE

8.17 SAFETY VALVE

8.18 AUTOMATIC AIR VENT

8.19 TIME CLOCK

9 EXPLODED VIEWS

9.1 HYDRAULIC CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.2 DIVERTOR VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.3 COMBUSTION CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.4 STRUCTURAL COMPONENTS AND CONTROL & REGULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Supplied By www.heating spares.co Tel. 0161 620 6677

718

55

165

335

125 60

ø 60/100

700

K

110

L

55

70 70 70 70 ==

AB

D

E

C

22

1.1 INTRODUCTION

The Sime “FORMAT C” are wall mounted, fan assisted bal-

anced flue combination boilers.

The appliance is supplied suitable for use with natural gas,

LPG and provide central heating and instantaneous production of D.H.W. Heat output is varied according to demand by

the modulating gas control on both D.H.W. and C.H.

The appliance is supplied with a telescopic air/flue duct suitable for wall thicknesses up to 635 mm (25 in) although

extension duct kits are available (see details in section 3.4).

The combined flue and air duct can exit the boiler from either

side or from the rear of the appliance. A vertical extension and

additional flue elbow may be fitted. If required, the boilers can

also be fitted with a separate flues kit (see section 3 for details).

The boiler is designed for use with sealed primary water systems and is supplied fully assembled and equipped with complete valve packs.

The boiler can be used with a 24V room thermostat (class II

according to EN 60730.1). This booklet provides instructions

for the boiler models: “FORMAT 80 C” - “FORMAT 100 C” “FORMAT 110 C” with following features:

– electronic ignition,

– fully modulating,

– built in mechanical time clock.

1

1 TECHNICAL FEATURES AND DIMENSIONS

TABLE 2 - Minimum clearances

For ventilation For servicing

ABOVE THE APPLIANCE CASING 200 mm 300 mm

AT THE R.H.S. 15 mm 15 m m

AT THE L.H.S. 15 mm 15 m m

BELOW THE APPLIANCE CASING 200 mm 200 mm

IN FRONT OF THE APPLIANCE 350 mm 500 mm

TABLE 1 - Connections

A C.H. return 22 mm Compression

B C.H. flow 22 mm Compression

C Gas connection 1/2 in Bsp

D Cold water 15 mm Compression

E Hot water 15 mm Compression

1.2 DIMENSIONAL DETAILS

80 C 100 C 110 C

L mm 400 450 450

K mm 180 205 205

Fig. 1

Supplied By www.heating spares.co Tel. 0161 620 6677

2

1.3 GENERAL DATA

MODE OUTPUT INPUT (G.C.V.)

BURNER PRESS. (Nat. gas)

BURNER PRESS. (Butane/Propane)

kW Btu/h kW Btu/h mbar inwg mbar inwg

CENTRAL HEATING RANGE 9.0 31,000 12.0 42,000 2.4 0.9 5.9/7.7 2.4/3.1

10.6 36,000 14.1 48,000 3.2 1.3 7.9/10.3 3.2/4.1

12.3 42,000 16.2 55,000 4.1 1.7 10.2/13.2 4.1/5.3

14.1 48,000 18.2 62,000 5.2 2.1 12.7/16.3 5.1/6.5

X* (G20-G31) 15.9 54,000 20.3 69,000 6.3 2.5 15.4/19.6 6.2/7.9

X* (G30) 17.7 60,000 22.4 76,000 7.5 3.0 18.4/23.2 7.4/9.3

19.6 67,000 24.5 84,000 8.9 3.6 21.5/26.9 8.6/10.8

21.5 73,000 26.6 90,000 10.3 4.1 24.8/30.8 10.0/12.4

23.4 80,000 28.7 98,000 11.8 4.7 28.5/36.5 11.4/14.7

DOMESTIC HOT WATER Max. 23.4 80,000 28.7 98,000 11.8 4.7 28.5/36.5 11.4/14.7

Min. 9.0 31,000 12.0 42,000 2.4 0.9 5.9/7.7 2.4/3.1

* Factory setting

TABLE 3a - Nominal boiler ratings (5 minutes after lighting) for “FORMAT 80 C”

MODE OUTPUT INPUT (G.C.V.)

BURNER PRESS. (Nat. gas)

BURNER PRESS. (Butane/Propane)

kW Btu/h kW Btu/h mbar inwg mbar inwg

CENTRAL HEATING RANGE 11.4 39,000 15.0 51,000 2.6 1.0 5.5/7.1 2.2/2.9

13.5 46,000 17.5 60,000 3.5 1.4 7.4/9.4 3.0/3.8

15.6 53,000 20.0 68,000 4.5 1.8 9.7/12.1 3.9/4.8

17.7 60,000 22.5 77,000 5.6 2.3 12.2/14.9 4.9/6.0

X* (G20-G31) 19.8 68,000 25.0 86,000 6.8 2.7 14.9/18.0 6.0/7.2

X* (G30) 22.0 75,000 27.6 94,000 8.2 3.3 17.9/21.3 7.2/8.6

24.2 83,000 30.1 103,000 9.6 3.8 21.2/24.8 8.5/10.0

26.5 90,000 32.6 111,000 11.1 4.5 24.7/28.5 9.9/11.4

28.8 98,000 35.1 120,000 12.7 5.1 28.5/36.5 11.4/14.7

DOMESTIC HOT WATER Max. 28.8 98,000 35.1 120,000 12.7 5.1 28.5/36.5 11.4/14.7

Min. 11.4 39,000 15.0 51,000 2.6 1.0 5.5/7.1 2.2/2.9

* Factory setting

TABLE 3b - Nominal boiler ratings (5 minutes after lighting) for “FORMAT 100 C”

MODE OUTPUT INPUT (G.C.V.)

BURNER PRESS. (Nat. gas)

BURNER PRESS. (Butane/Propane)

kW Btu/h kW Btu/h mbar inwg mbar inwg

CENTRAL HEATING RANGE 11.2 38,000 15.0 51,000 2.2 0.9 4.5/5.8 1.8/2.3

13.6 46,000 17.9 61,000 3.1 1.3 6.4/8.2 2.6/3.3

16.0 55,000 20.9 72,000 4.2 1.7 8.5/11.0 3.4/4.4

18.5 63,000 23.9 81,000 5.4 2.2 11.0/14.1 4.4/5.7

X* (G20-G31) 21.0 72,000 26.8 92,000 6.8 2.7 13.7/17.6 5.5/7.1

X* (G30) 23.6 80,000 29.8 101,000 8.3 3.3 16.7/21.4 6.7/8.6

26.2 89,000 32.7 111,000 10.0 4.0 20.0/25.6 8.0/10.3

28.9 99,000 35.7 122,000 11.8 4.7 23.5/30.0 9.4/12.0

31.6 108,000 38.6 132,000 13.7 5.5 28.2/36.2 11.3/14.5

DOMESTIC HOT WATER Max. 31.6 108,000 38.6 132,000 13.7 5.5 28.2/36.2 11.3/14.5

Min. 11.2 38,000 15.0 51,000 2.2 0.9 4.5/5.8 1.8/2.3

* Factory setting

TABLE 3c - Nominal boiler ratings (5 minutes after lighting) for “FORMAT 110 C”

Supplied By www.heating spares.co Tel. 0161 620 6677

3

1

2

3

4

22

5

7

8

11

14

10

9

6

16

12

18

15

13

19

21

20

17

U

E

G

M R

27

1.4 HYDRAULIC CIRCUIT

KEY

1Fan

2 Water-gas exchanger

3 Combustion chamber

4 Gas valve

5 D.H.W. exchanger

6 Divertor valve

7 NTC sensor

8 100°C safety thermostat

9 Air relief valve

10 Circulation pump

11 Expansion vessel

12 Safety valve

13 Drain plug

14 Water flow switch

16 Automatic by-pass

17 D.H.W. filter

18 C.H. return cock

19 C.H. flow cock

20 D.H.W. cock

21 Gas cock

27 Temperature gauge phial

28 Pressure gauge

29 C.H. water filter

80 C 100 C 110 C

Main burner injectors No off 12 14 15

Dia for Natural gas

m m 1. 3 1. 3 1.3

Dia for LPG mm 0.77 0.78 0.80

Water capacity l (gal) 3.4 (0.75) 4.7 (1.00) 4.7 (1.00)

Minimum water flow D.H.W. l/min (gal/min) 2 (0.5) 2 (0.5) 2 (0.5)

D.H.W. flow rate

at a temperature rise of 30°C l/min (gal/min) 11.2 (2.5) 13.8 (3.0) 15.1 (3.3)

35°C l/min (gal/min) 9.6 (2.1) 11.9 (2.6) 12.9 (2.8)

Static head Minimum bar (psi) 0.5 (7.3) 0.5 (7.3) 0.5 (7.3)

Maximum bar (psi) 3.0 (43.5) 3.0 (43.5) 3.0 (43.5)

D.H.W. pressure Minimum bar (psi) 1.0 (14.6) 1.0 (14.6) 1.0 (14.6)

Maximum bar (psi) 6.0* (87) 6.0* (87) 6.0* (87)

Weight Empty kg (lb) 38 (84) 40 (88) 40 (88)

Total (full) kg (lb) 41.4 (91) 44.7 (98) 44.7 (98)

Electrical supply 230 V - 50 Hz, Fused at 3 A

Internal fuse Line: F 1.6 A

Maximum power consumption Watt 150 160 160

Maximum gas consumpt. (Natural gas) m3/h (ft3/h) 2.73 (96) 3.34 (118) 3.68 (130)

Maximum gas consumpt. (Butane - Propane) kg/h (lb/h)

2.02 - 1.99 (4.45 - 4.39) 2.48 - 2.44 (5.47 - 5.38) 2.74 - 2.70 (6.04 - 5.95 )

Max. working temperature °C (F) 95 (203) 95 (203) 95 (203)

Integral exp. vessel capacity l (gal) 8 (1.76) 8 (1.76) 8 (1.76)

* For greater pr essures it is necessar y to install a pressure reducer in the inlet of D.H.W.

TABLE 4 - General specifications

Fig. 2

DHW MCW GAS FLOW RETURN

Supplied By www.heating spares.co Tel. 0161 620 6677

4

6

12

11

10

9

8

7

5

4

3

2

1

13

14

19

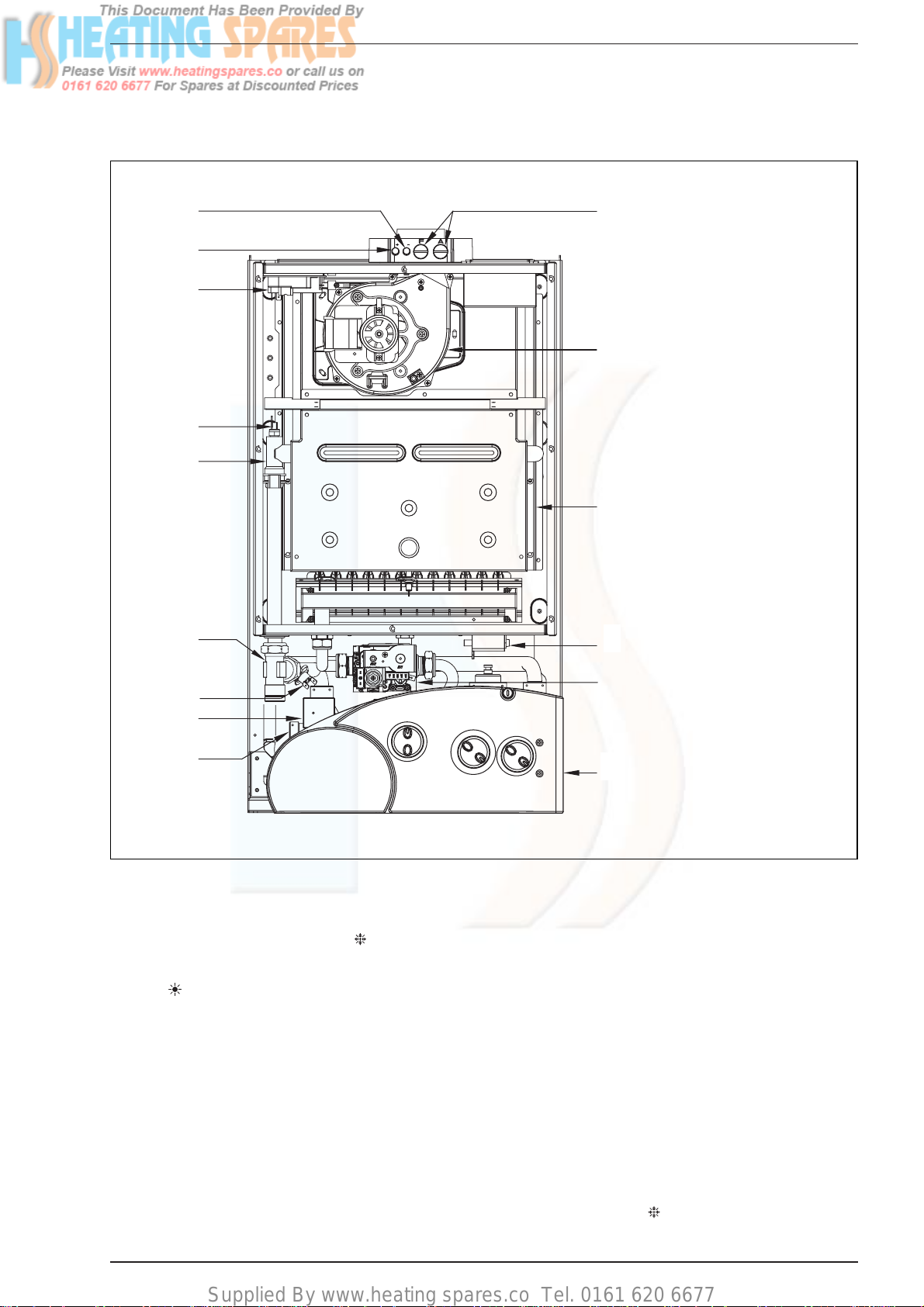

1.5 INTERNAL VIEW

KEY

1 Control panel

2 Ignition transformer

3 Combustion chamber

4Fan

5 Combustion analysis intakes

6 Negative pressure intake

7 Positive pressure intake

8 Air pressure switch

9 C.H. sensor (SM)

10 Main exchanger

11

100°C safety stat

12 Gas valve

13 Flow water switch

14 Diver tor valve

19 C.H. water filter

Fig. 3

1.6 BOILER OPERATION

The boiler operating mode is controlled by the selector switch

on the control panel. When set to winter ( ) it will operate in

the Domestic Hot Water and Central Heating modes. For

Domestic Hot Water only the selector switch should be set to

summer ( ).

Domestic hot water supply always takes priority over central

heating. If a demand for hot water is required during a central

heating period, the boiler will automatically switch to hot water

mode until the demand is satisfied.

1.6.1 Central Heating mode

If there is a call for central heating the pump will start to circulate the primary heating water and the fan will run at full speed;

once the air pressure switch has been proved the burner will

light. The burner output then automatically adjusts to suit the

system demand; as the temperature of the heating water in the

boiler approaches that set by the adjustable central heating

control knob the burner output is reduced. When this set temperature is reached, the burner extinguishes and the fan stops.

The pump continues to run for 30 seconds to prevent residual

heat build up in the boiler. The burner will not relight for 3 minutes unless there is a demand for domestic hot water during

this period.

1.6.2 Domestic hot water mode

When there is a demand for hot water, the diverter valve operates and the pump circulates the primary heating water. The

fan will run at full speed; once the air pressure switch has been

proved the burner will light.

The burner output then automatically adjusts to suit the

demand required to raise the temperature set by the

adjustable domestic hot water control knob. When the hot

water demand has been satisfied, the diverter valve operates

to divert the primary heating water to the central heating, if the

selector is set to winter ( ) and there is a C.H. demand, otherwise the burner will extinguish.

Supplied By www.heating spares.co Tel. 0161 620 6677

5

2.1 STATUTORY REQUIREMENTS

GAS SAFETY (INSTALLATION AND USE) REGULATIONS (as

amended). It is the law that all gas appliances are installed by

a registered person, in accordance with the above regulations. Failure to install appliances correctly could lead to prosecution. It is in your own interest, and that of safety, to ensure

that the law is complied with.

In addition to the above regulations, this appliance must be

installed in accordance with the current IEE Wiring

Regulations (BS 7671), Local Building Regulations, the

Building Standards (Scotland) (Consolidation) Regulations,

Byelaws of the local water undertaking, and Health and Safety

Document No 635 “The Electricity at Work Regulations

1989”. It should also be in accordance with the relevant recommendations in the current editions of the following British

Standards and Codes of Practice: BS5449, BS5546,

BS5440:1, BS5440:2, BS6798, BS6891, and BG.DM2,

BS7074, and BS5482 for propane installations.

Manufacturer’s instructions must NOT be taken in any way

as over-riding statutory obligations.

2.2 BOILER POSITION

In siting the combination boiler, the following limitations MUST

be observed:

– The boiler is not suitable for external installation. The posi-

tion selected for installation should be within the building,

unless otherwise protected by a suitable enclosure, and

MUST allow adequate space for installation, servicing, and

operation of the appliance, and for air circulation around it

(section 2.4).

– This position MUST allow for a suitable flue termination to

be made. The combination boiler must be installed on a

flat vertical wall which is capable of supporting the weight

of the appliance, and any ancillary equipment.

– If the combination boiler is to be fitted in a timber framed

building it should be fitted in accordance with the Institute

of Gas Engineers document for Gas Installations In Timber

Frame Housing, Reference 16E/UP/7: 1998. If in doubt,

advice must be sought from the gas supplier.

– If the appliance is installed in a room containing a bath or

shower, any electrical switch or control utilising mains

electricity must be so situated that it cannot be touched

by a person using the bath or shower. Attention is drawn

to the requirements of the current I.E.E. Wiring Regulations (BS 7671), and in Scotland the electrical provisions

of the Building Regulations applicable in Scotland.

– A compartment used to enclose the appliance MUST be

designed and constructed specifically for this purpose. An

existing cupboard, or compartment, may be used provided it is modified accordingly.

– Where installation will be in an unusual location, special

procedures may be necessary. BS6798 gives detailed

guidance on this aspect.

2.3 FLUE TERMINAL POSITION

Detailed recommendations for flue installation are given in

BS5440:1. The following notes are for general guidance:

– The boiler MUST be installed so that the terminal is

exposed to the external air.

– It is important that the position of the terminal allows free

passage of air across it at all times.

– It is ESSENTIAL TO ENSURE, in practice that products of

combustion discharging from the terminal cannot reenter the building, or any other adjacent building, through

ventilators, windows, doors, other sources of natural air

infiltration, or forced ventilation/air conditioning. If this

does occur, the appliance MUST be turned OFF IMMEDIATELY and the gas supplier consulted.

–

The minimum acceptable dimensions from the terminal to

obstructions and ventilation openings are specified in fig. 4.

– If the terminal discharges into a pathway or passageway

check that combustion products will not cause nuisance

and that the terminal will not obstruct the passageway.

– Where the lowest part of the terminal is fitted less than 2

m (78 in) above ground, above a balcony or above a flat

roof to which people have access, the terminal MUST be

protected by a purpose designed guard.

– Where the terminal is fitted within 850 mm (34 in) of a

plastic or painted gutter, or 450 mm (18 in) of painted

eaves, an aluminium shield at least 1,500 mm (59 in) long

must be fitted to the underside of the painted surface.

– The air inlet/outlet flue duct MUST NOT be closer than

25 mm (1 in) to combustible material.

– In certain weather conditions the terminal may emit a

plume of steam. This is normal but positions where this

would cause a nuisance should be avoided.

2 GENERAL REQUIREMENTS FOR INSTALLATION

Fig. 4

TABLE 5

Terminal position Minimum spacing in mm

A Directly below an openable window, 300

air vent or any other ventilation opening

B Below guttering, drain pipes or soil pipes 25*

C/D Below eaves, balconies or carport roof 25*

E From vertical drain pipes or soil pipes 75

F From internal or external corners 25

G Above adjacent ground, 300

roof or balcony level

H From a surface facing the terminal 600

I From a terminal facing the terminal 1,200

J From an opening in the carport 1,200

(e.g. door, window into dwelling)

K

Vertically from a terminal on the same wall

1,500

L

Horizontally from a terminal on the same wall

300

M

Horizontally from a vertical terminal to a wall

300

N Horizontally from an openable 300

window or other opening

P Above an openable window or other opening 300

* With “heat shield” installed in accordance to BS 5440 Pt1.

Supplied By www.heating spares.co Tel. 0161 620 6677

6

2.4 VENTILATION REQUIREMENTS

Detailled recommendations for air supply are given in

BS5440:2. The following notes are for general guidance:

–

It is not necessary to have a purpose provided air vent in the

room or compartment in which the appliance is installed.

2.5 GAS SUPPLY

– The gas installation should be in accordance with

BS6891. The gas required for the boiler is specified in

Table 4

.

– Ensure that the pipework from the meter to the appliance

is of adequate size.

–

The governor at the meter must give a constant outlet

pressure of 20 mbar (8 inwg) for natural gas and 30 - 37

mbar (12 - 15 inwg) for LPG, when the appliance is running.

– The gas supply line should be purged.

NOTE: Before purging open all doors and windows, also

extinguish any cigarettes, pipes, and any other naked

flames.

–

The complete installation must be tested for gas soundness.

2.6 ELECTRICITY SUPPLY

The appliance MUST be earthed. A mains supply of 230 V 50 Hz single phase is required. All external controls and

wiring MUST be suitable for mains voltage.

Wiring should be in 3 core PVC insulated cable NOT LESS

than 0.75 mm

2

(24 x 0.2 mm) to BS6500, Table 16. Wiring

external to the boiler MUST be in accordance with current

l.E.E. Wiring Regulations (BS 7671) and local regulations. The

supply connection to the flying lead provided MUST be made

to a fused double pole switch, having a 3 mm (1/8 in) contact

separation in both poles, serving only the boiler and system

controls; the fuse rating should be 3 amp. This connection

should be readily accessible and be made adjacent to the boiler (except in the case of bathroom installations for domestic

boilers where the point of connection to the mains MUST be

outside of the bathroom).

2.7 EXTERNAL CONTROLS (Refer to section 3.9)

The boiler is intended for use with a 24 V room thermostat.

The connection is made inside the control box as described in

section 3.9.

2.8 WATER SYSTEMS - GENERAL

– This appliance is designed for connection to sealed cen-

tral heating water systems.

– Check that the mains water pressure is suf ficient to pro-

duce the required D.H.W. flow rate, but does not exceed

the maximum D.H.W. pressure (

Table 4

). Where mains

pressure exceed 6 bar a pressure reducing valve must

be fitted in the D.H.W. inlet.

2.8.1 Treatment of Water Circulating Systems

– All recirculatory systems will be subject to corrosion

unless an appropriate water treatment is applied. This

means that the efficiency of the system will deteriorate as

corrosion sludge accumulates within the system, risking

damage to pump and valves, boiler noise and circulation

problems.

– For optimum performance after installation this boiler

and its associated central heating system must be

flushed in accordance with the guidelines given in BS

7593 “Treatment of water in domestic hot water central

heating systems”.

– This must involve the use of a proprietary cleanser, such

as BetzDearborn Sentinel X300 or X400, or Fernox

Superfloc. Full instructions are supplied with the products,

but for immediate information please contact BetzDearborn (0151 420 9563) or Fernox (01799 550 811)

directly.

– For long term protection against corrosion and scale,

after flushing it is recommended that an inhibitor such as

BetzDearborn Sentinel X100, or Fernox MB-1 or Copal is

dosed in accordance with the guidelines given in BS

7593.

Failure to flush and add inhibitor to the system may

invalidate the appliance warranty.

– It is important to check the inhibitor concentration after

installation, system modification and at every service in

accordance with the manufacturer’s instructions. (Test

kits are available from inhibitor stockists).

2.9 REQUIREMENTS FOR SEALED WATER SYSTEMS

The heating system design should be based on the following

information:

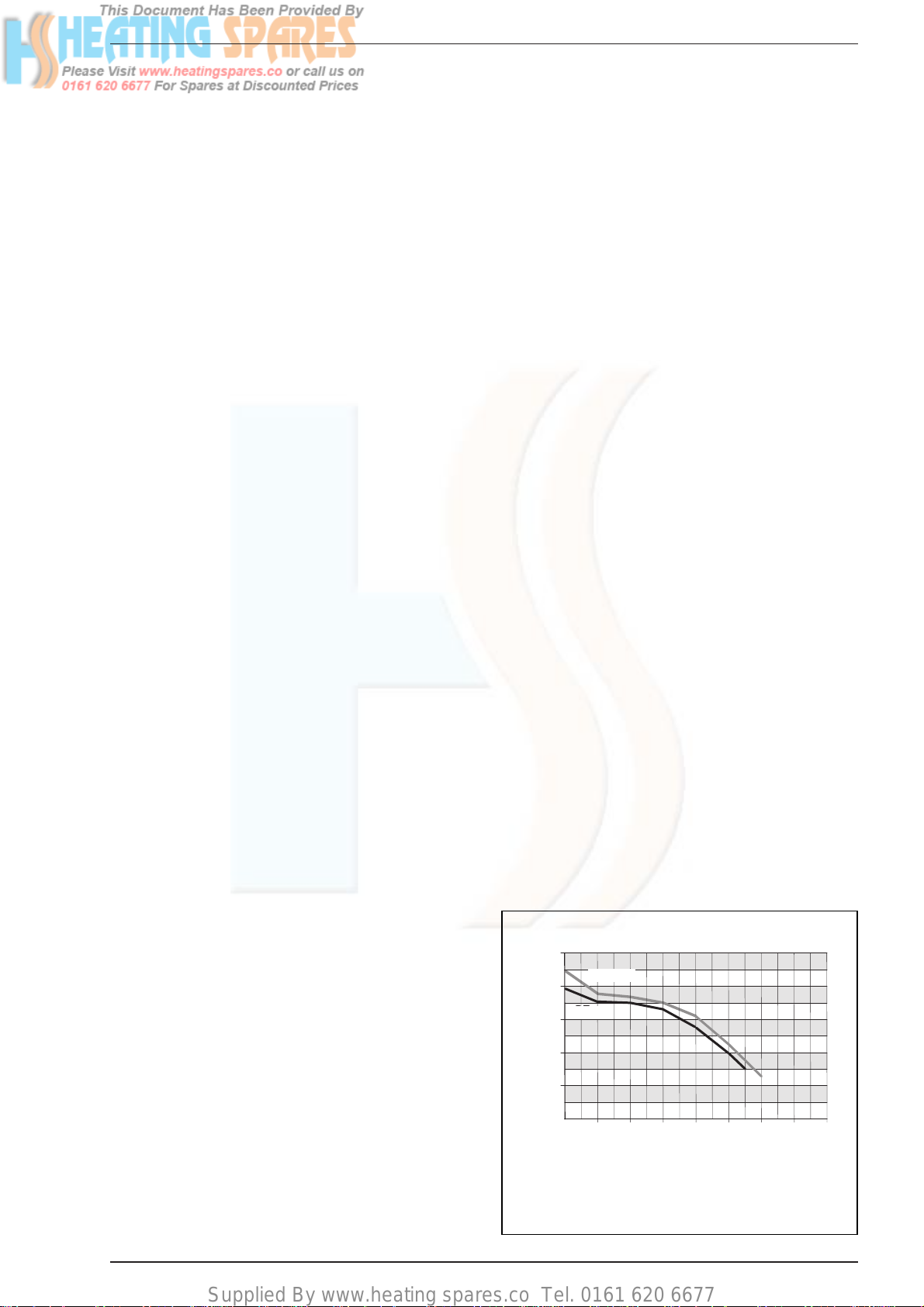

a) The available pump head is given in fig. 5.

b) The burner star ts when the C.H. flow reaches 400÷450

l/h. This safety condition is ensured by the flow switch.

c) The appliance is equipped with an internal by-pass that

operates with system heads (H) greater than 3 m. The

maximum flow through the by-pass is about 300 l/h. If

thermostatic radiator valves are to be installed, at least

one radiator should be without a thermostatic valve (usually the bathroom radiator).

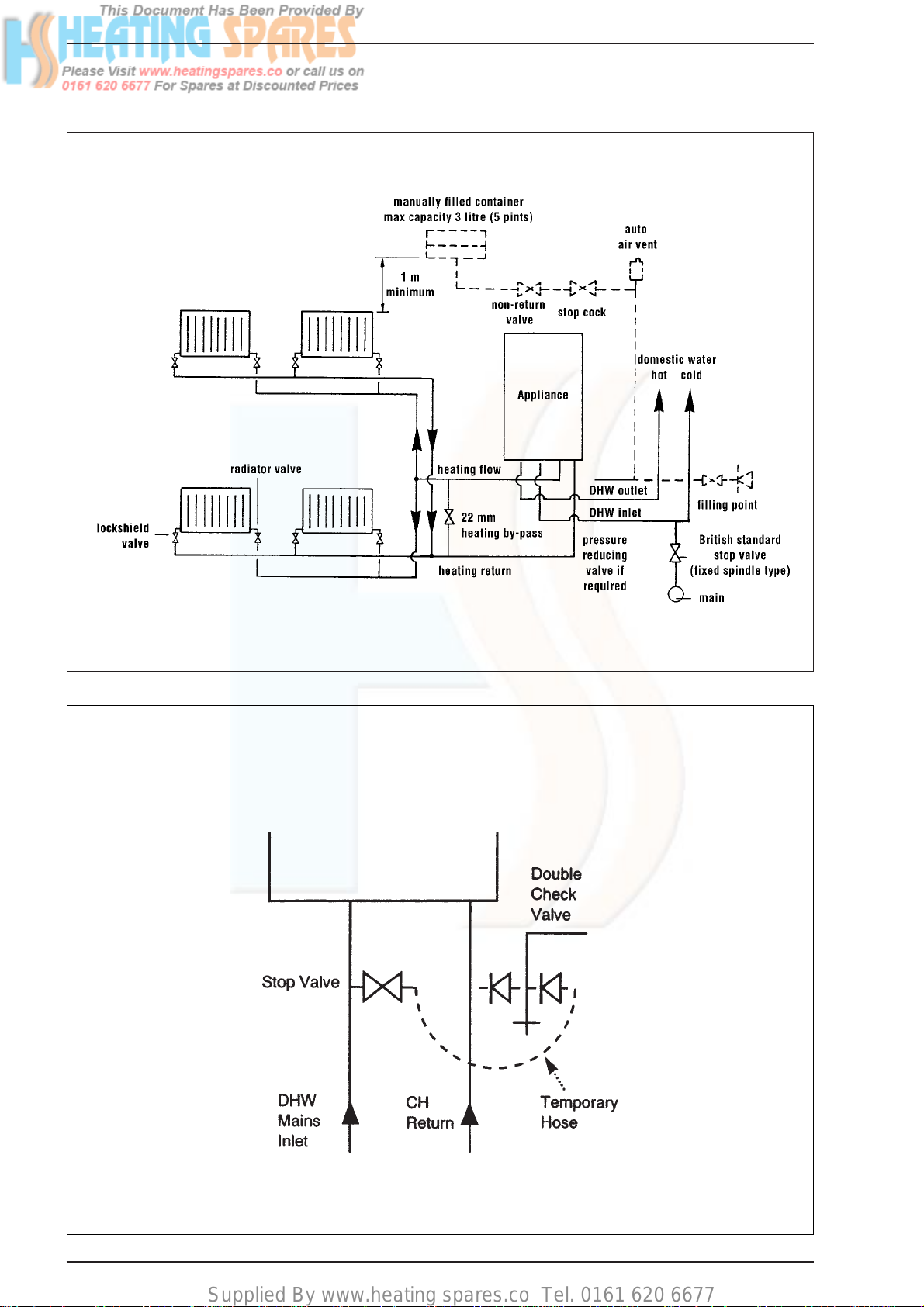

d) A sealed system must only be filled by a competent per-

son using one of the approved methods shown in fig. 7.

0

200

1600

140012001000800600400

PORTATA (l/h)

PREVALENZA RESIDUA (mbar)

500

400

10 0

200

300

30 - 35

25

Format.zip

KEY

1 Available Head for “80 C - 100 C” models

2 Available Head for “110 C” model

Flow rate (l/sec)

Available head (mbar)

Fig. 5

1

2

Supplied By www.heating spares.co Tel. 0161 620 6677

7

TYPICAL SYSTEM DESIGN

ALTERNATIVE METHODS OF FILLING A SEALED SYSTEM

NOTE: A drain cock should be installed at the lowest point of the heating circuit and beneath the appliance.

Fig. 6

Fig. 7

Loading...

Loading...