UK

Dewy 30/130

HE FS

Installation and

servicing instructions

PLEASE LEAVE THIS INSTRUCTION

WITH THE USER

All descriptions and illustrations provided in this manual have been carefully prepared but we reserve the right to make changes

and improvements in our products that may affect the accuracy of the information contained in this manual.

This boiler may require 2 or more operatives to move it into its installation site, remove it from its packaging and during

movement into its installation location. Manoeuvring the boiler may include the use of a sack truck and involve lif ting pushing

and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques when performing these tasks and the following precautions

should be considered:

– Grip the boiler at the base

– Be physically capable

– Use personal protective equipment as appropriate e.g. gloves, safety footwear.

During all manoeuvres and handling actions, every attempt should be made to ensure the following unless unavoidable

and/or the weight is light.

– Keep back straight

– Avoid twisting at the waist

– Always grip with the palm of the hand

– Keep load as close to the body as possible

– Always use assistance

WARNING

Caution should be exercised when performing any work on this appliance.

Protective gloves and safety glasses are recommended.

– Avoid direct contact with sharp edges.

– Avoid contact with any hot surfaces.

NOTICE

Please be aware that due to the wet testing of the appliance, there may some residual water in the hydraulic circuit.

– Protect any surfaces, carpets or floorings.

– Use a suitable container to catch any water that escape when removing the protective caps from the connections.

SAFE HANDLING

The Benchmark Scheme

Sime Ltd is a licensed member of the Benchmark Scheme which aims to improve the standards of installation and

commissioning of domestic heating and hot water systems in the UK and to encourage regular servicing to optimise safety, efficiency and performance.

Benchmark is managed and promoted by the Heating and Hotwater Industry Council.

For more information visit www

.centralheating.co.uk

CONTENTS

1 DESCRIPTION OF THE BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 6

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 10

3 CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 19

4 USE COMMISSIONING, AND MAINTENANCE

(including BENCHMARK/Mains Pressure Hot Water Storage Checklist & Service Record) . . . . . . pag. 23

5 EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 32

IMPORTANT

When carrying out commissioning of the boiler, you are highly recommended to perform the following checks:

–

Make sure that there are no liquids or inflammable materials in the immediate vicinity of the boiler.

– Make sure that the electrical connections have been made correctly and that the earth wire is connected to a

good earthing system.

– Open the gas tap and check the soundness of the connections, including that of the burner.

– Make sure that the boiler is set for operation for the type of gas supplied.

– Check that the flue pipe for the outlet of the products of the combustion is unobstructed and has been properly

installed.

– Make sure that any shutoff valves are open.

– Make sure that the system is charged with water and is thoroughly vented.

– Check that the circulating pump is not locked (CAUTION: Remember to release the pump coupled with the control

panel, if necessary, to protect the electronic control card).

– Purge the system, bleeding off the air present in the gas pipe by operating the pressure relief valve on the gas

valve inlet.

– Check that the syphened drip is fully filled with water. If necessary, fill it via the special opening.

– Ensure that the Benchmark checklist in the use and maintenance section of this manual is completed.

Please refer to commissioning instructions for filling in the checklist of this installation guide.

Note: All Gas Safe registered installers carry a ID Card.

You can check your installer is Gas Safe Registered by calling 0800 408 5577

Important Information

IT IS A STATUTORY REQUIREMENT THAT ALL GAS APPLIANCES ARE INSTALLED BY COMPETENT PERSONS,

IN ACCORDANCE WITH THE GAS SAFETY (INSTALLATION AND USE) REGULATIONS (CURRENT EDITION). The

manufacturer’s instructions must not be taken as overriding any statutory requirements, and failure to comply with these regulations may lead to prosecution.

No modifications to the appliance should be made unless they are fully approved by the manufacturer.

GAS LEAKS: DO NOT OPERATE ANY ELECTRICAL SWITCH, OR USE A NAKED FLAME. TURN OFF THE GAS

SUPPLY AND VENTILATE THE AREA BY OPENING DOORS AND WINDOWS CONTACT THE GAS EMERGENCY

SERVICE ON 0800111999.

Dewy 30/130 HE FS:

Gas Council number 47-283-05

These appliances comply with the S.E.D.B.U.K. scheme, band “A”

IPX4D

6

1.1 INTRODUCTION

“DEWY 30/130 HE FS” boilers are premix

condensation thermal appliances which use

microprocessor technology for function

control and management. They comply with

the european directives 90/396/CEE,

2004/108/CE, 2006/95/CE,

92/42/CEE and with the european specifications EN 483 - EN 625.

These appliances can be fired by natural

gas (methane) and propane gas (G31).

The instructions given in this manual are

provided to ensure proper installation and

perfect operation of the appliance.

1 DESCRIPTION OF THE BOILER

1.2 DIMENSIONS

600

65

1620

610

315

252

76

M2

R2

M1

R1

M

R

S1

C1

S3

G

117

62

S2

U

C

E

10 9

349

712

946

70

110 9

1229

70

1349 140

300

300

828

846

Fig. 1

SERVICE CLEARANCES

ABOVE THE APPLIANCE CASING 300 mm

AT THE R.H.S. 300 mm

AT THE L.H.S. 300 mm

IN FRONT OF THE APPLIANCE 700 mm

ACCESS TO THE CONNECTIONS AT THE REAR OF THE BOILER MUST

BE PROVIDED.

CONNECTIONS

R Zone 1 system return 3/4” (UNI-ISO 228/1)

R1 Zone 2 system return (optional) 3/4” (UNI-ISO 228/1)

R2 Zone 3 system return (optional) 3/4” (UNI-ISO 228/1)

M2 Zone 3 system delivery (optional) 3/4” (UNI-ISO 228/1)

M1 Zone 2 system delivery (optional) 3/4” (UNI-ISO 228/1)

M Zone 1 system delivery 3/4” (UNI-ISO 228/1)

G Gas connection 3/4” (UNI-ISO 228/1)

E D.H.W. inlet 3/4” (UNI-ISO 228/1)

U D.H.W. outlet 3/4” (UNI-ISO 228/1)

S1/S2 C.H. safety relief valve/tank

S3 Condensation outlet ø 25

E

SUPPLIED WITH THE BOILER:

- Pressure reducing valve

- Single check valve

- Expansion relief valve and

associated tundish

1.3 TECHNICAL FEATURES

DEWY 30/130 HE FS

Heat output

Nominal (80-60°C) kW (kcal/h) 29,3 (25.200)

Minimum (80-60°C) kW (kcal/h) 10,4 (9.000)

Nominal (50-30°C) kW (kcal/h) 32,0 (27.600)

Minimum (50-30°C) kW (kcal/h) 11,4 (9.800)

Nominal D.H.W. heat output kW 29,3

Heat input

Nominal/Minimum kW 30,0 / 10,8

Efficiency (80-60°C)

Nominal/Minimum output % 97,7 / 96,7

Efficiency (50-30°C)

Nominal/Minimum output % 106,8 / 105,8

Water content l 10,9

Electrical supply 230V 50 Hz Fuse et 1.6AT

Adsorbed power consumption W175

Electrical protection grade

IP X4D

C.H. pressure relief valve setting bar 3

Maximum C.H. working pressure bar 2.5

Maximum temperature °C 85

Expansion vessel

Capacity l 10

Preloading pressure bar 1

C.H. setting range °C 20 - 80

D.H.W. setting range °C 10 - 60

D.H.W. production

Maximum D.H.W. supply pressure bar 10

D.H.W. flow rate (EN 625) l/min 21,0

Continuous D.H.W. flow rate ∆t 30°C l/min 14

D.H.W. operating pressure bar 3.5

Maximum D.H.W. pressure bar 6

D.H.W. tank capacity l 120

D.H.W. expansion vessel l 4

D.H.W. expansion vessel charge pressure bar 3.5

D.H.W. tank heating time between 15 and 60°C min 18’ 7”

Recuperation time between 25 and 55°C min 9’ 40”

Recuperation time to raise 70% of volume to 60°C min 14’ 49”

D.H.W. expansion relief valve setting bar 6

Combined temperature & pressure relief valve setting bar 7

Combined temperature & pressure relief valve setting °C 90

Smokes temperature

Maximum/ Minimum (80-60°C) °C 70 / 69

Maximum/ Minimum (50-30°C) °C 48 / 45

Smokes flow kg/h 49

Category II2H3P

Type B23/C13-33-43-53

Weight kg 190

Weight (full) kg 321.1

Main burner nozzles

Quantity n° 1

G20 ø mm 6,0

G25 ø mm 7,7

G31 ø mm 4,3

Gas consumption

Nominal / Minimum (G20) m3st/h 3,17 / 1,14

Nominal / Minimum (G25) m3st/h 3,69 / 1,32

Nominal / Minimum (G31) kg/h 1,22 / 0,44

Gas supply pressure

G20 mbar 20

G25 mbar 25

G31 (Propan) mbar 37

CO2 % methane (G20) min/max 9,2 / 9,3

CO2 % methane (G25) min/max 9,5 / 9,6

CO2 % propan (G31) min/max 10,1 / 10,3

CO emission ppm 27

NOx emission (Class 5) ppm 35

(1)

Flow calculated with a fixed temperature on t he hot-water service pot entiometer of 60°C for a maximum period of 10 minutes

7

8

1.4 FUNCTIONAL DIAGRAM

PUMP KIT 2/3 ZONE

CONFIGURATION

Fig. 2

KEY

1Fan

2 Main heat exchanger

3 Main heat exchanger air vent

4 Gas valve

5 Gas rate adjuster

6 C.H. sensor (SM)

7 Flow switch assembly

8 Zone 1 system pump

9 Non return valve

10 Hot water cylinder pump

11 Expansion vessel

12 Drain vent

13 Air relief valve

14 Automatic by-pass

15 D.H.W. Cylinder drain cock

16 Cylinder sensor pocket (SB)

17 Cylinder

18 Sacrificial Anode

19 D.H.W. temperature/pressure relief.

20 Filling loop (optional cod. 8091810)

21 D.H.W. expansion vessel

22 Water pressure transducer

23 System pressure relief valve

24 Condensation trap

25 Limit stat 85° C

26 100°C safety stat

27 System deliver y manifold

28 System return manifold

29 Tundish

30 Pressure reducing valve

31 Single check valve

32 Expansion relief valve

33 Tundish expansion relief valve

PUMP KIT 2/3 ZONE CONFIGURATION

(code 8100700/8100710)

34 Zone 2 and 3 system pump

35 Zone 2 and 3 single-acting valve

36 Zone 2 and 3 system bypass

1.5 MAIN COMPONENTS

Fig. 3

LEGEND

1 Cylinder

2 Cylinder drain cock

3 Cylinder expansion vessel.

4 Tun dish

5 Cylinder temperature/pres-

sure relief

6 Air relief valve

7 Gas valve

8 Zone 1 heating system

pump

9 Gas rate adjuster

10 Zone 1 non return valve

11 Condensation trap

12 Heat exchanger air vent

13 Positive pressure intake

14 Negative pressure intake

15 Ignition transformer

16 Ionisation electrode

17 Main exchanger

18 Ignition electrode

19 Control panel

20 Fan

21 Heating sensor (SM)

22 100°C safety thermometer

23 System pressure

relief valve

24 Water pressure transducer

25 Non return valve

27 Hot water cylinder pump

28 Flow switch assembly

31 Drain vent

32 Drain vent

33 Zone 2 heat pump

(optional)

34 Zone 2 single-acting valve

(optional)

35 Zone 3 single-acting valve

(optional)

36 Zone 3 heat pump

(optional)

37 Smoke stat

38 Filling loop (optional)

PUMP KIT 2/3 ZONE CONFIGURATION

(Cod. 8100700/8100710)

FILLING LOOP CONFIGURATION

(Cod. 8091810)

9

10

Where no specific instructions are given,

the installation should be in accordance

with the relevant recommendations in the

current editions of the following British

Standards and Codes of Practice: BS

5440-1, BS 5440-2, BS 5449, BS 5482

(propane installations), BS 5546, BS 6700,

BS 6798, BS 6891, Institute of Gas Engineer document IGE/UP-7, BS 7074 (expansion vessel), and to other relevant British

Standards or code of Practice as necessary. It is a Statutory Requirement that

the installation conforms to the appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building Regulations (Northern Ireland), the Water Fitting Regulations or

Water Byelaws in Scotland, and the current I.E.E Wiring Regulations. When handling, due consideration should be given to

the appliance weight. If the appliance is not

to be installed immediately it should be stored in a clean dry place.

2.1 BOILER ROOM

The

“DEWY 30/130 HE FS”

version boilers

can be installed in any domestic environment

without any location restrictions

,

other than the load bearing capacity of the

floor where the appliance is to be sited,

(consult section 1.3 for weight), or“Combustion”

air requirements

. However, suitable

clearances for maintenance and servicing

should be provided, see fig. 1.

2.2 CONNECTING UP SYSTEM

Before connecting the boiler it is recommended that the system is flushed in

accordance with BS7593.

When making

the hydraulic connections, make sure that

the dimensions indicated in fig. 1 are

respected. Fit the supplied; pressure reducing valve (30 fig. 2), check valve (31 fig. 2)

and expansion relief valve assembly (32 fig.

2) with its associated tundish (33 fig. 2), in

the D.H.W. supply to the appliance, see fig.

2 and fig. 4 for details. It is important that

no isolating valve is fitted between the

expansion relief valve and the inlet to the

D.H.W. tank. Any additional D.H.W. drain

down cock fitted should be positioned as low

as possible to ensure that at least 80% of

the D.H.W. tank’s capacity can be drained.

If installed in a Hard Water area, then a suitable device should be fitted to treat the

mains supply to the appliance (Contact your

Water Distribution Company for advice on

suitable devices). The pressure relief

discharge pipes must be connected to

ensure safe discharge.

The gas connection must be made using seamless steel

pipe (Mannesmann type), galvanized and

with threaded joints provided with

gaskets, excluding three-piece connections, except for initial and end connections. Where the piping has to pass through walls, a suitable insulating sleeve must

be provided. When sizing gas piping, from

the meter to the boiler, take into account

both the volume flow rates (consumption)

in m3/h and the relative density of the gas

in question.

The sections of the piping

making up the system must be such as to

guarantee a supply of gas sufficient to cover

the maximum demand, limiting pressure

loss between the gas meter and any apparatus being used to not greater than 1.0

mbar for family II gases (natural gas). An

adhesive data plate is stuck inside the front

panel; it contains all the technical data identifying the boiler and the type of gas for

which the boiler is arranged.

2.2.1 Connection of condensation water trap

To ensure safe disposal of the condensate

produced by the flue gases, reference

should be made to BS6798:2009. The boiler incorporates a condensate trap which

has a seal of 75 mm, therefore no additional trap is required. The condensate should

ideally be discharged internally into an internal waste pipe(washing machine/sink

waste) or a soil pipe to avoid the risk of freezing. External pipe runs should be avoided,

but if it is necessary, the pipework should be

at least 32 mm and protected from the risk

of freezing with a waterproof insulation and

the length kept to a minimum and not

exceeding 3 m termination should be into

an external gully or purpose made

soakaway. We recommend that the condensate drain at the boiler is in 20 mm solvent weld pipe with a socket covering the

connection to the trap. Alternatively a suitable hose can be secured to the trap and terminated as required.

NOTE: All pipework must have a continuous

fall from the boiler and must be resistant to

corrosion by condensate, copper or steel is

NOT suitable. It should be noted that the

connection of a condensate pipe to a drain

may be subject to local building control

requirements.

2.2.2 Filter on the gas pipe

The gas valve is supplied with an inlet filter,

however, this may not be adequate to entrap

all the impurities in the gas or in gas main

pipes. To prevent malfunctioning of the valve

it may be necessary toinstall an adequate filter on the gas pipe.

2.2.3 Filling the Condensate Trap

The condensate trap can be filled, prior to fitting the flue by carefully pouring approximately 1 litre of water into the centre of the

exhaust terminal of the main heat exchanger.

2.2.4 Discharge Pipes and fittings

The position of any tundish must be visible to

the occupants and any tundish, drain valve

and discharge pipe and must be sited away

from any electrical components. The connections to the expansion relief valve and

temperature and pressure relief valve

should not be used for any other purpose.

See fig. 4 for example of the discharge

pipe(s) for the temperature and pressure

relief valve, and expansion relief valve terminations.

NOTE: it is permitted to connect discharge

pipes together provided that the joint pipe is

sized to accommodate the combined flow.

2.2.5 Expansion Vessel (C.H. only)

C.H. EXPANSION VESSEL – The integral

expansion vessel is pre-charged to a pressure of 1.0 bar, which should be checked

before the C.H. water system is filled.

This vessel is suitable for correct operation

of system capacities up to 82 litre capacity.

If the actual C.H. system volume is greater,

then an additional vessel must be fitted to

the system.

For systems where the volume is greater,

the additional expansion vessel volume can

be determined by multiplying the volume in

excess of that which can be accommodated by the appliance by the factor 0.901.

BS 7074 gives further details regarding

C.H. expansion vessel sizing.

2.3 CHARACTERISTICS

OF C.H. FEEDWATER

– All recirculatory systems will be subject

to corrosion unless an appropriate

water treatment is applied. This means

that the efficiency of the system will

deteriorate as corrosion sludge accumulates within the system, risking damage to pump and valves, boiler noise

and circulation problems.

– For optimum per formance after instal-

lation this boiler and its associated central heating system must be flushed in

accordance with the guidelines given in

BS 7593 “Treatment of water in

domestic hot water central heating systems”.

– Sime Ltd recommend only the use of

FERNOX products for the flushing and

final treatment of the system water.

This is particularly important in hard

water areas. Failure to flush and add

inhibitor to the system may invalidate

the appliance warranty. Artificially sof tened water must not be used to fill the

heating system.

Failure to flush and add inhibitor to

the system may invalidate the appliance warranty.

– It is important to check the inhibitor

concentration after installation, system

modification and at every service in

accordance with the manufacturer’s

instructions (Test kits are available from

inhibitor stockists).

2 INSTALLATION

2.4. FILLING AND COMMISSIONING

2.4.1 D.H.W. circuit

Before filling the D.H.W. system, ensure

appliance selector knob is in the “Off” position, then open the hot water tap nearest

the appliance.

Open the D.H.W. supply isolating valve to

the appliance, once water star ts to flow

from the tap close it, and then open and

close each hot water tap in turn to ensure

that all the air is removed from the

pipework. Open the hot water tap furthest

away from the appliance and let water flow

for about 10 minutes, or for sufficient time

to flush out the system. Check for leaks.

2.4.2 C.H. circuit

Once the D.H.W. circuit is commissioned

the C.H. circuit can be filled via the internal

filling loop (if fitted), or via any external

arrangement. Ensure both the D.H.W. and

C.H. temperature controls are set to minimum, and that there is no room thermostat demand. Turn on the electrical supply

to the appliance (see Section 2.8), and turn

the selector knob to the summer position.

To use the internal filling loop, ensure that

the flexible hose is attached to both valves,

then open the C.H. isolating valve and then

open the D.H.W. double check isolating

valve, (See fig. 2).

Once the green “1 bar” led lights up close

both isolating valvesensure that all the

radiators are vented, continue opening the

filling loop to maintain the 1 bar pressure.

When all the radiators are vented ensure

the pressure is at 1 bar. then disconnect

the flexible hose from the D.H.W. double

check isolating valve. Check for leaks and

free rotation of the circulating pumps.

2.5 COAXIAL DUCT ø 60/100

Prior to fitting the flue system the conden-

sate trap can be filled see 2.2.3. The coaxial

suction and discharge pipes are supplied in

a special kit (that can be purchased separately) along with assembly instructions. The

diagrams of fig. 5 illustrate some examples

of different types of discharge options

allowed and the maximum lengths that can

be reached. It is essential that a flue gas

analysis test point is made available directly

above the boiler.

2.5.1 Coaxial duct accessories

The maximum flue length using 60/100

ducts and accessories must not exceed 2.8

metres.

2.5.2 Positioning the outlet terminals

The outlet terminals for forced-draught

appliances may be located in the external

perimeter walls of the building.

To provide some indications of possible solu-

Fig. 4

11

12

NOTE: Place the duct horizontally.

IMPORTANT:

Each additional 90° curve installed reduces the

available length by 0.90 metres.

Each additional 45° curve installed reduces the

available length by 0.45 metres.

KEY

1a-b Coaxial duct kit code 8096250

2a Extension L. 1000 code 8096150

2b Extension L. 500 code 8096151

3 Vertical extension L. 140 with

take-off point code 8086950

4a 90° additional bend code 8095850

4b 45° additional bend code 8095950

Fig. 5

NOTE: Before installing accessories, lubricate the internal

part of gaskets with silicon-based products. Avoid using

oils and greases.

Fig. 5/a

Terminal position Minimum spacing

A Directly below an openable window, air vent

or any other ventilation opening 300 mm 12 in

B Below guttering, drain pipes or soil pipes 75 mm 3 in

C/D Below eaves, balconies or carpor t roof (*) 200 mm 8 in

E From vertical drain pipes or soil pipes 75 mm 3 in

F From internal or external corners 300 mm 12 in

G Above adjacent ground, roof or balcony level 300 mm 12 in

H From a boundar y or surface facing the boiler 600 mm 24 in

I From a terminal facing the terminal 1,200 mm 48 in

J From an opening in the carport

(eg door, window into dwelling) 1,200 mm 48 in

K Vertically from a terminal on the same wall 1,500 mm 60 in

L Horizontally from a terminal on the same wall 300 mm 12 in

M Horizontally from a ver tical terminal to a wall 300 mm 12 in

N Horizontally from an openable window or o ther opening 300 mm 12 in

P Above an openable window or other opening 300 mm 12 in

Q From an adjacent ver tical terminal 600 mm 24 in

TABLE 1

(*) Note : this can be reduced to 25 mm, but it would be necessary to protect the

surfaces from the ef fects of condensate.

– If the terminal discharges into a pathway or passageway

check that combustion products will not cause nuisance

and that the terminal will not obstr uct the passageway.

– Where the lowest part of the terminal is fitted less than 2

m (78 in) above ground, above a balcony or above a flat roof

to which people have access, the terminal MUST be protected by a purpose designed guard.

– Where the terminal is fitted wit hin 850 mm (34 in) of a

plastic or painted gutter, or 450 mm (18 in) of painted

eaves, an aluminium shield at least 1,500 mm (59 in) long

must be fitted to the under side of the painted surface.

– The air inlet/outlet flue duct MUST NOT be closer than 25

mm (1 in) to combustible material.

– In cer tain weather conditions the terminal may emit a

plume of steam. This is normal but positions where this

would cause a nuisance should be avoided.

tions, Table 1 gives the minimum distances

to be observed, with reference to the type

of building shown in fig. 5/a.

2.6 SEPARATE PIPES ø 80

A special kit may be used to separate the

flue gas outlet from the air intake. The

intake may be installed to the right or left of

the flue gas outlet. It is essential that a flue

gas analysis test point is made available

directly above the boiler. Refer to fig. 8 for

positioning. The maximum overall length of

the intake and exhaust ducts depends on

the head losses of the single fittings

installed (excluding the doublers) and

must not be greater than 15,5 mm H2O.

For head losses in the fittings, refer to Table

2.

2.6.1 Separate pipe accessories

Kit code 8089911 is supplied for this purpose (fig. 9).

2.8 ELECTRICAL CONNECTION

Wiring external to the appliance must be in

accordance with the current I.E.E Wiring

regulations (BS 7671) for electrical installation and any local regulations, which apply.

Connection to the mains supply must facilitate complete electrical isolation of the

appliance. A 3A fused double pole switch

having a 3 mm contact separation in both

poles and serving only the appliance (and its

external controls) may be used.

The boiler is supplied with an electric cable.

15 5

Ø 80

Ø 80

10 5

P

L

CA

K

Z

CS

KEY

CA Inlet

CS Outlet

Fig. 8

DEWY 30/130 HE FS

Kmm 348

Lmm 263

Pmm 230

Zmm 315

1

2

3

4

5

3

KEY

1 Blind flange

2 Flue gas duct flange

3 Fixing screw

4 Gasket ø 125/95

5 Intake duct collar

Fig. 9

TABLE 2

Accessories ø 80 Head loss (mm H2O)

Inlet Outlet Roof outlet

90° elbow MF 0.30 0.50 –

45° elbow MF 0.20 0.40 –

Extension L. 1000 (horizontal) 0.20 0.40 –

Extension L. 1000 (vertical) 0.30 0.30 –

Outlet terminal – 0.40 –

Inlet terminal 0.10 – –

Doubler fitting 0.30 – –

Roof outlet terminal L. 1381 – – 0.60

13

14

Should this require replacement, it must be

purchased exclusively from SIME.

The electric power supply to the boiler must

be 230V - 50Hz single-phase.

Respect the L and N polarities and the

earth connection.

NOTE: Device must be connected to an

efficient earthing system. SIME declines

all responsibility for injury or damage to

persons, animals or things, resulting from

the failure to provide for property

earthing of the appliance. Always turn off

the power supply before doing any work

on the electrical panel.

2.8.1 Room thermostat

connection

(fig. 12 pos. A)

To gain access to the electronic board connector (3), remove the control panel cover

and connect the room stat to the terminals

TA (5-6) after having removed the jumper.

The thermostat or timer-thermostat, must

be class II as specified by standard EN

60730.1 (clean contact).

WARNING: Applying mains voltage to the

terminals of conector (3) will irreparably

damage the control board. Make sure

that any connections to be made are not

carrying mains voltage.

2.8.2 “Logica Remote Control”

connection (fig. 12 pos. B)

The electrical plant must comply with local

standards and all cables must comply with

low voltage safety requirements of EN

60730. For lengths up to 25 m, use cables

TA

CR

CR

SE

2

A

B

C

3

1

SB

SB

SB

KEY

1 Control panel

2 “Logica Remote Control” socket

3 Conector (J2)

TA Room stat (not supplied)

CR Logica Remote Control (optional)

SE External temperature sensor (optional)

SB D.H.W. sensor

Fig. 12

of section 0.25 mm2, for longer lengths up

to 50 m use cables of section 0.5 mm2.

Connect as shown (2). To gain access to

connector (3) remove the control panel

cover and connect the climate regulator to

terminals CR (7-8).

WARNING: External voltage must not be

connected to terminals 1-2-3-4 of the

"Logica Remote Control".

2.8.3 External temperature sensor

connection (fig. 12 pos. C)

The cables must comply with low safety vol-

tage requirements of EN 60730. For lengths

up to 25 m, use cables of section 0.25 mm2,

for longer lengths up to 50 m use cables of

section 0.5 mm2.

To gain access to boiler connector (3) remove the control panel cover and connect the

external temperature sensor to terminals

SE (9-10).

J7

J6

J5

J4

J3

J2

J1

J10

J9

J8

J1

J2

2.8.4 Wiring diagram

Fig. 13

KEY

EV1 Gas valve coil

EV2 Gas valve coil

EA Ignition electrode

ER Ionisation electrode

TS 100°C safety stat

VFan

TPA Water pressure transducer

PI Pump

SE External sensor (optional)

TA Room thermostat

SM C.H. sensor

TL Limit stat

TRA Ignition transformer

TR Transformer 230 - 24V

FL Flow switch

SB D.H.W. sensor

CR Logica Remote Control (optional)

SV Fan board

OP Time programmer

TF Smoke stat

PB Hot water cylinder pump

PR Recirculation pump (optional)

Note: Room thermostats (TA), with voltage free(clean

contacts) are connected to terminals 5-6.

CONNECTOR SPARE PART CODES (Main PCB):

J1 code 6316215

J2 code 6278613

J3 code 6299961

J4 code 6293564

J5 code 6299921

J6 code 6278699

J7 code 6278636

J8 code 6098305

CONNECTOR SPARE PART CODES (Fan driver PCB):

J1 code 6260996

J2 code 6278661

15

16

2.10 LOGICA REMOTE CONTROL

The boilers functions can be remotely controlled with the use of a optional programmer 8092204.

Climatic influence can also

be achieved with the further additional

external sensor 8094100.

Characteristics:

– Ergonomic control unit divided according

to function (control levels)).

– Clear division of basic functions:

• operating regime, correction of set

value and presence button are directly

accessible;

• Different real current values are

accessible through the "info" button;

• other functions can be programmed

after the cover has been opened;

• special service level with protected

access;

– Each setting or modification is displayed

and confirmed.

– Tome setting (special line for changing

BST/CET).

– Heating programme with max. 3 heating

periods per day, individually selectable.

–

Copy function for easy transfer of heating programme to the next or previous day.

–

Holiday programme: the programme is

interrupted for the holiday period and automatically restar ted on returning home.

– Option to return the heating program to

default values.

– Programming lock (child safety).

Functions:

– Delivery temperature control guided by

the atmospheric conditions, taking into

account the dynamics of the building.

– Delivery temperature control guided by

atmospheric conditions with influence of

ambient temperature.

– Ambient temperature control only.

– Adjustable influence of ambient tempera-

ture shift .

– Switch-on and switch-of f optimisation.

– Rapid lowering.

– ECO functions (daily heating limiter, auto-

matic summer/winter switch-over).

– Controllable maximum delivery tempera-

ture limit (specifically for floor plants).

– Limitation of increase in pre-set delivery

temperature.

– Anti-freeze protection for buildings.

– Hourly programming of the tank unit

temperature on two levels: comfort and

reduced.

– Domestic hot water control with nominal

value requirement and enable.

– Connection to room sensor or switching

of operating regime through the telepho-

ne system with external contact or

through a window contact.

– Anti-bacterial.

2.10.1 Installation

The unit must be installed in the main living

room. For installation, follow the assembly

instructions inserted in the package.

At this point, with the selector knob on ( ),

the installer can adjust the basic parameters settings according to the individual

needs (point 2.8.2).

If there is a thermostatic radiator valve

fitted, this must be set to maximum.

2.10.2 Installation settings

The settings for the basic operating parameters for individual needs are reported in

the instruction leaflet supplied with the

"Logica Remote Control" and in the section

reserved for the user in this manual.

For further adjustments which can be carried out by the installer, the "Logica Remote

Control" offers a level of service and parameterising which can only be accessed

through a special combination of buttons.

To activate this level of service or parameterising press buttons and least 5

seconds.

This will activate the parameterising level.

Then use the same arrow buttons to select

the individual input lines and adjust the

values with or .

2.9 TIME PROGRAMMER

The boiler is supplied with a programmer

clock (fig. 14).

For instructions on how to use this clock,

see the user's manual.

Fig. 14

Maximum limit of delivery

temperature

Variation of the maximum speed of the

delivery temperature

Activation of adaptation

Optimisation of

switch-on time

Heating gradient

Presetting switch-off

time (00 = off)

The delivery temperature is limited to the maximum set value.

The increase per minute of the prescribed deliver y temperature value sent

in °C is limited to the imposed value.

With the activation of the adaptation, the pre-set value transmitted to the

boiler regulator is adapted to the effective heat need.

The adaptation functions with both the atmospheric guide with ambient

influence and with pure ambient control.

If the "Logica Remote Control" is set as a remote control only, the adaptation

must be is deactivated.

If the switch-on time optimisation is active, the "Logica Remote Control" modifies the heating gradient until it finds the optimum heating point

0 = off 1 = on

The "Logica Remote Control" selects the switch-on time such that the set

value has more or less been reached at the start of the usage time.

The more severe the night-time cooling, the earlier the heating time starts.

Example: Current ambient temperature 18.5°C

Nominal ambient temperature 20°C

Heating gradient 30 min/K

Presetting of switch-on time:

1.5 K x 30 min/K = 45 minutes

00 means that the switch-o time has not been pre-set (function disabled).

If the switch-off time optimisation is active (value > 0), the "Logica Remote

Control" modifies the pre-set time until it finds the optimum switch-off time..

55

56

57

58

59

60

Antifreeze protection

"Pre-set ambient

temperature value"

Summer/Winter switch-over

temperature

Type of control:

0 = with ambient influence

1 = without ambient influence

Influence of ambient temperature

Heating takes place up to this pre-set value if the plant is activated in standby

(e.g. holidays).

In this way, the building antifreeze function is active, preventing an excessive

lowering of the ambient.

This parameter regulates the temperature of the automatic summer/winter switch-over.

This parameter de-activates the ambient influence and as a result all the

optimisations and adaptations.

If a valid external temperature is not transmitted , the controller switches to

the pure ambient control guide variable.

If the ambient controller is used only as a remote control (placed in the reference room and without an external sensor connected), the value must be

set at 0 (zero).

If the change in ambient temperature from the pre-set value remains high

during the entire day, the influence must be increased. If the ambient temperature is around the pre-set value (control oscillation), the influence must

be reduced.

Note: If the ambient temperature influence constant is set at 0, the adaptation of the heating curve is deactivated. In this case, parameter 57 will

have no effect at all.

54

HEATING CIRCUIT SETTINGS

52

53

51

17

18

Final user level 2

programming block

Input function terminal 3-4

This block (1) can be activated to display all the parameters without

modifying them. Pressing buttons or displays “OFF”.

WARNING:

The activation block can be deactivated temporarily by pressing buttons

and simultaneously; a confirmation sign appears on the display.

At this point press simultaneously the buttons and for at least 5

seconds.

To permanently remove the activation block, set parameter 63 on 0.

The freely programmable input (terminals 3-4) allows three different functions

to be activated. The parameter has the following significance:

1 =

If an external sensor is connected, the display will show the temperature

of the external sensor ( _ _ = no sensor connected, function disabled).

2 = With an external contact, it is possible to switch-over to "reduced pre-

set value of the ambient temperature".

3 = With an external contact, it is possible to switch-over to "reduced pre-

set value of the antifreeze ambient temperature" (short circuit 0 0 0 or

interruption _ _ _ ). The display shows the current status of the external

contact.

64

63

SERVICE VALUES

DOMESTIC HOT WATER SETTINGS

Reduced domestic hot

water pre-set value

Domestic hot water load

The reduced pre-set value of the temperature of the domestic hot water allow

the required water temperature to be obtained outside the programmed

usage times (daily programme 8).

0 = 24 hours/ day - Hot water is always available at the temperature set

with user parameter n°3.

1 = standard - Hot water according to the daily heating programme.

In the comfort areas of heating the temperature of the boiler unit is regulated to the value set with user parameter n° 3.

In the reduced areas of heating the temperature of the boiler unit is

regulated to the value set with parameter n° 61 of the service level.

2 = service disconnected

3 = second daily programme (8) - Every day of the week the temperature of

the hot water is set according to programme 8. In this case there is a

single programming for all the days of the week and three time zones are

available. In the time spans set the temperature of the boiler unit is regulated according to that set in parameter n°3. In the remaining hours the

boiler unit is controlled to the temperature set with parameter n° 61 the

of service level.

62

61

Operating mode of external contact

External and ambient

sensor influence

Anti-bacterial function

(with storage capacity boiler unit)

If the entrance (terminals 3 and 4 of the base) is connected to a zero potential

external contact (parameter 64 = 2 or 3), the operating mode of the contact

can be determined (remote telephone switch or window contact). The operating

mode specifies the status of the contact in which the required function is active.

Display: Operating mode closed (short circuit) 0 0 0

Operating mode open (interruption) _ _ _

Determines the mix ratio between the internal and external ambient sensor

when parameter 64 = 1.

0 % = internal sensor only active (0% external - 100% internal)

50 % = mean value of external + internal sensor

100 % = external sensor only active

The set mix is used for ambient control and display.

If the external sensor is short circuited or interrupted, the operation continues with the internal sensor.

This function allows the hot water to be brought to a high temperature once

a week in order to eliminate eventual pathogenic agents.

It is active every Monday for a maximum duration of 2.5 hours at a delivery

temperature of 65°C.

0 = not active 1 = active

65

66

69

3.1 ELECTRONIC BOARD

The electronic boards are manufactured in

compliance with the EEC 73/23 low-voltage

directives.

They are supplied with 230V and, through a

built-in transformer, send a voltage of 24V

to the following components: gas valve,

safety stat, C.H. and D.H.W. sensor, external

temperature sensor (optional), modulator,

micro divertor valve, flow switch safety

valve, water pressure transducer, room

stat or “Logica Remote Control”.

An automatic and continuous modulation

system enables the boiler to adjust the heat

output to the various system requirements

or the User’s needs.

The electronic components are guaranteed

against a temperature range of 0 to

+60°C.

3.1.1 Fault finding

The indicator leds signalling irregular

and/or incorrect operation of the equipment are indicated in fig. 16.

3.1.2 Devices

The electronic board is equipped with the

following devices:

– “POT. RISC.” trimmer (10 fig. 17)

Sets the maximum heating power value.

To increase the value turn the trimmer

clockwise; to reduce the value turn the

trimmer anticlockwise.

– “POT. ACC.” trimmer (6 fig. 17)

Trimmer to vary the pressure level upon

ignition (STEP), of the gas valve.

According to the type of gas for which

the boiler is equipped, the trimmer must

be regulated so as to obtain a pressure

of approx. 3 mbar at the burner for

methane gas and 7 mbar for propane

gas (G31).

To increase pressure, turn the trimmer

clockwise; to reduce pressure, turn the

trimmer counterclockwise.

The slow ignition pressure level can be

set during the first 3 seconds following

burner ignition.

After setting the pressure level upon

ignition (STEP) according to the type of

gas, check that the pressure for heating is still at the value previously set.

– “MET-GPL” connector (7 fig. 17)

With the connector linked-off, the boiler

3 CHARACTERISTICS

2.10.3 Gradient of the characteristic

heating curve

The gradient of the characteristic heating

curve is imposed on the current value “15”

of Logica. Increasing the gradient as shown

in the drawing of fig. 15, the delivery temperature increases in correspondence to the

outside temperature.

2.11 EXTERNAL TEMPERATURE

SENSOR

The "Logica Remote Control" can be connected to an external temperature sensor

available a an optional extra (code

8094100).

This configuration ensures and

maintains the required temperature constant in the room. The ambient temperature is, in fact, indicted and evaluated as

the calculated mean of the value measured inside and outside the dwelling.

For installation, follow the assembly instructions inserted in the package.

Fig. 15

Example: Choosing a gradient of 15 with an outside temperature

of –10°C we shall have a delivery temperature of 60°C.

19

20

is set-up for NATURAL GAS; with the connector linked-on, the boiler is ready for

LPG.

– “ANN. RIT.” connector (5 fig. 17)

In the heating phase, the electronic board

is programmed to include a burner technical delay interval of approx. 90 seconds,

which occurs both at system cold starting and at subsequent re-ignitions. The

aim is to overcome the problem of repeated ignitions and turning off with very

short time intervals between. This could

occur in particular in systems presenting

high head losses.

At each restart after the period of slow

ignition, the boiler will set itself for about

1 minute at the minimum modulation

pressure, and will then move to the heating pressure value set.

When the connecting link is inserted,

both the programmed technical pause

and the period of operation at minimum

pressure in the startup phase will be cancelled. In this case, the times elapsing

between turning off and subsequent re-

ignition will depend on a temperature difference of 5°C detected by the SM sensor (heating flow sensor).

– DIP SWITCH (13 fig. 17)

Check that the switches are positioned

as shown.

Flashing red led,

communication fault

with “Logica Remote Control”

Green led off if

power is cut-off

Flashing red led, water

pressure is too low (*)

Flashing red led, heating sensor fault

(SM)

Flashing red led,

plant safety

valve tripped (*)

Red led on, ignition blocked:

rotate selector CR/OFF/SUM/WIN/RESET

to release position

()

to restore operation

Flashing red led, safety/smoke stat tripped.

Rotate selector CR/OFF/SUM/WIN/RESET

to release position

()

to restore operation

Flashing red led, fan fault.

30 minutes after the fan has switched off,

the board will attempt a restart

(*)

When all 0.5 to 2.5 bar leds are off, check the water

pressure transducer connection.

WARNING: the operation of plants with open vessels is

guaranteed only for static pressures above 0.7 bar.

Fig. 16

Flashing red led, flame detection circuit fault

15

13

1

3

5

7

8

9

10

11

12

14

6

6

10

KEY

1 Ignition electrode earth faston

3 Fuse (1,6 AT)

5 “ANN. RIT.” connector

6 “POT. ACC.” trimmer

7 Conector “MET-GPL”

8 D.H.W. potentiometer

9 Ionisation electrode faston

10 “POT. RISC.” trimmer

11 C.H. potentiometer

12 Selector CR/OFF/SUM/WIN/RESET

13 DIP SWITCH

14 Connector “Modureg Sel.”

15 Connector “Albatros”

NOTE: To gain access to trimmers (6) and (10), unscrew the central heating potentiometer knob

Fig. 17

Flashing red led, flowmeter fault

– “Modureg Sel.” connector (14 fig. 17)

The bridge must always be

connected.

– “Albatros” connector (15 fig. 17)

The bridge must always be disconnected.

It is connected only when multiple boilers

are installed in a sequence/cascade.

ATTENTION: It is essential that the operations described above be carried out by

authorized technical staff.

3.2 TEMPERATURE SENSOR

AND WATER PRESSURE

TRANSDUCER

Boiler frost protection is achieved via the

NTC heating sensor that activates when

the water temperature reaches 6°C.

Tables 3 - 3/a show the resistance values

(Ω) that are obtained on the sensor as the

temperature varies and the transducer

values obtained as the pressure varies.

When sensor (SM) is interrupted,

neither of the boiler's heating services

will function. With D.H.W. sensor (SB)

interrupted, the boiler will only work in

heating mode.

3.3 ELECTRONIC IGNITION

Ignition and flame detection is controlled by

two electrodes located on the burner.

These guarantee maximum safety with

intervention times, for accidental switching

off or gas failure, of within one second.

3.3.1 Operating cycle

Rotate the selector knob to summer or winter, and verify that green led ( ) lights up to

confirm the presence of voltage.

The burner must be ignited within 10

seconds.

However, it is possible for ignition

failures to occur, with consequent activation of signal indicating that the control box

has “locked out”.

– Gas failure

The control box runs through the cycle

normally sending electric power to the

ignition electrode. The electrode continues spark discharge for a maximum of

10 sec.If the burner does not light, the

lock-out indicator will light up.

This may occur upon first ignition or

after long periods of boiler lay-off when

there is air in the pipes. It may be caused

by the gas cock being closed or by one of

the valve coils having a break in the winding, so that the valve cannot open.

– Ignition electrode fails to spark

In the boiler, only the gas to the burner

is seen to open. After 10 sec. the warning light indicating equipment “lockout” lights up.

This may be due to a break in the wire of

the electrode or to the wire not properly

fastened to the electric terminal of the

control box;

– No detection of flame

The continuous spark discharge of the

electrode is noted starting from ignition

even though the burner is lit.

After 10 seconds have elapsed, the

sparks cease, the burner goes out, and

the warning light indicating equipment

“lock-out” lights up.

There could have a break in the wire of

the sensing electrode or the electrode

itself is touching earth: the electrode is

worn out and needs replacing. The control box is defective.

When there is a sudden voltage failure, the

burner shuts down immediately; when the

power supply returns, the boiler will start

up again automatically.

3.4 FLOW SWITCH

A flow switch (28 fig. 3) intervenes, blocking

the operation of the burner if the boiler is

without water due to the formation of an air

lock in the heat exchanger or if the pump is

not working.

NOTE: the flow switch assembly is replacede, make sure that the arrow stamped

on the valve points in the same direction

as the flow of water.

3.5 SYSTEM AVAILABLE HEAD

For boilers with the standard fittings, the

residual head for the heating system on

the basis of rate of flow is represented in

the diagram in figure 18.

TABLE 3/a (Transducer)

Pressure Resistance (Ω)

(bar) min max

0 297 320

0,5 260 269

1 222 228

1,5 195 200

2167173

2,5 137 143

3108113

3,5 90 94

0

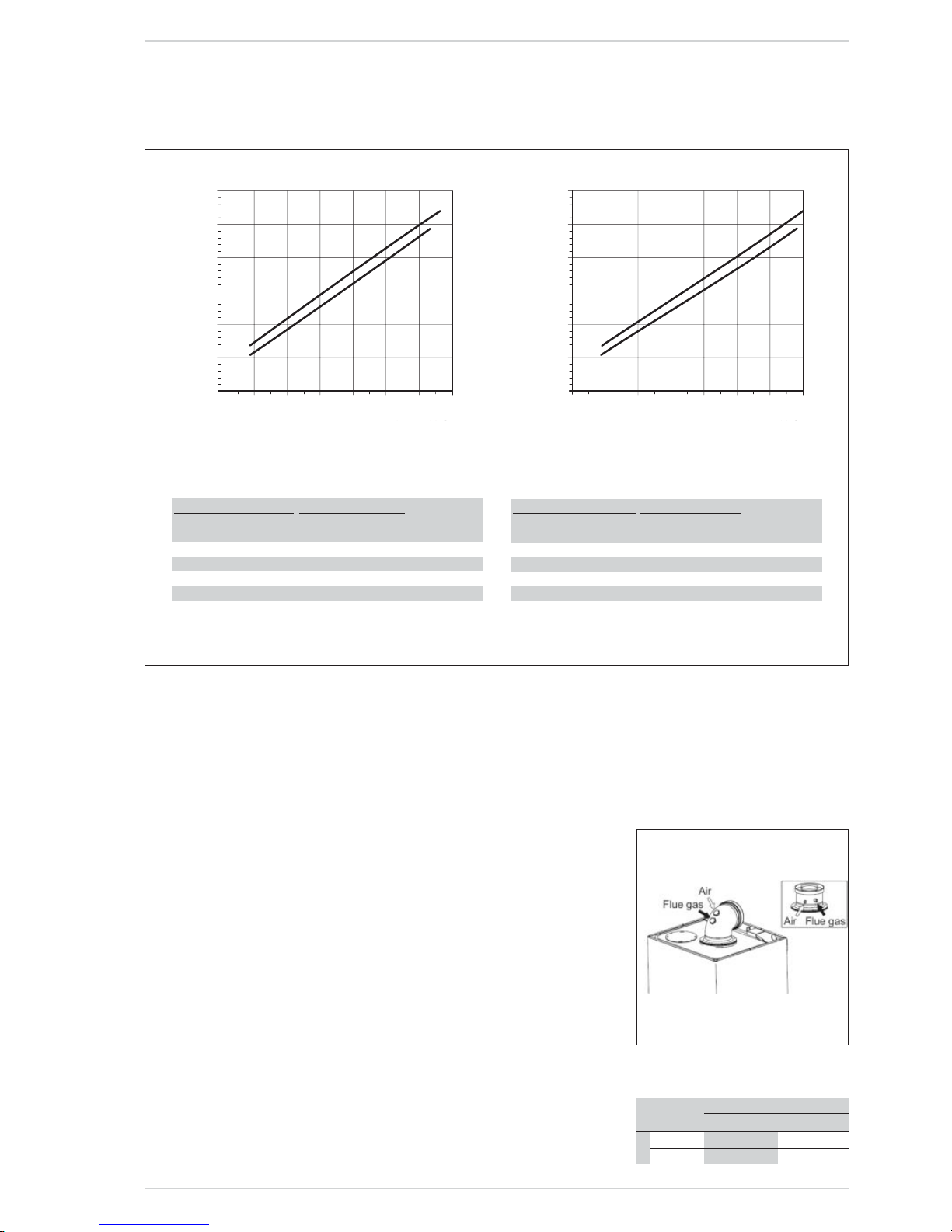

600

200

1600

140012001000800600400

P OR TATA (l/h)

PREVALENZA RESIDUA (mbar)

500

400

10 0

200

300

vers. 30/80

vers. 30/130

Dewy

Fig. 18

1 HIGH TEMPERATURE ZONE

FLOW RATE (l/h)

RESIDUAL HEAD (mbar)

TABLE 3 (Sensors)

Temperature (°C) Resistance (Ω)

20 12.090

30 8.313

40 5.828

50 4.161

60 3.021

70 2.229

80 1.669

21

22

3.5.1 Head with total rate of flow

to other zones

In “DEWY 30/130 HE FS” versions using

the second and third zone kit, determine

the head available to the zones as shown in

the following example:

Rate of flow calculated for zone 1 = 350 l/h

Rate of flow calculated for zone 2 = 400 l/h

Rate of flow calculated for zone 3 = 400 l/h

To obtain head available to zone 1, add the

total rate of flow to the other zones (in this

case zones 2 and 3): 400 l/h + 400 l/h =

800 l/h.

As shown in the graph (fig. 18/a) at the

800 l/h curve, head at 350 l/h for zone 1

= 180 mbar.

The same procedure may be applied to

other zones to obtain:

Zone 2 = 350 l/h + 400 l/h = 750 l/h.

As shown in the graph at the 800 l/h

curve, head at 400 l/h = 160 mbar.

Zone 3 = 350 l/h + 400 l/h = 750 l/h.

As shown in the graph at the 800 l/y

curve (curve E), head at 400 l/h = 160

mbar.

3.6 SMOKE

STAT

To ensure an effective protection of the flue

from becoming damaged from excessive

heat, the boiler is supplied with a standard

smoke thermostat (37 Fig. 3).

0

200

1600

140012001000800600400

P OR TATA (l/h)

PREVALENZA RESIDUA (mbar)

500

400

10 0

200

300

A

DEWY 30/130

B

C

D

E

A= 0 l/h D= 600 l/h

B= 200 l/h E= 800 l/h

C= 400 l/h

Fig. 18/a

3 HIGH TEMPERATURE ZONES

FLOW RATE (l/h)

RESIDUAL HEAD (mbar)

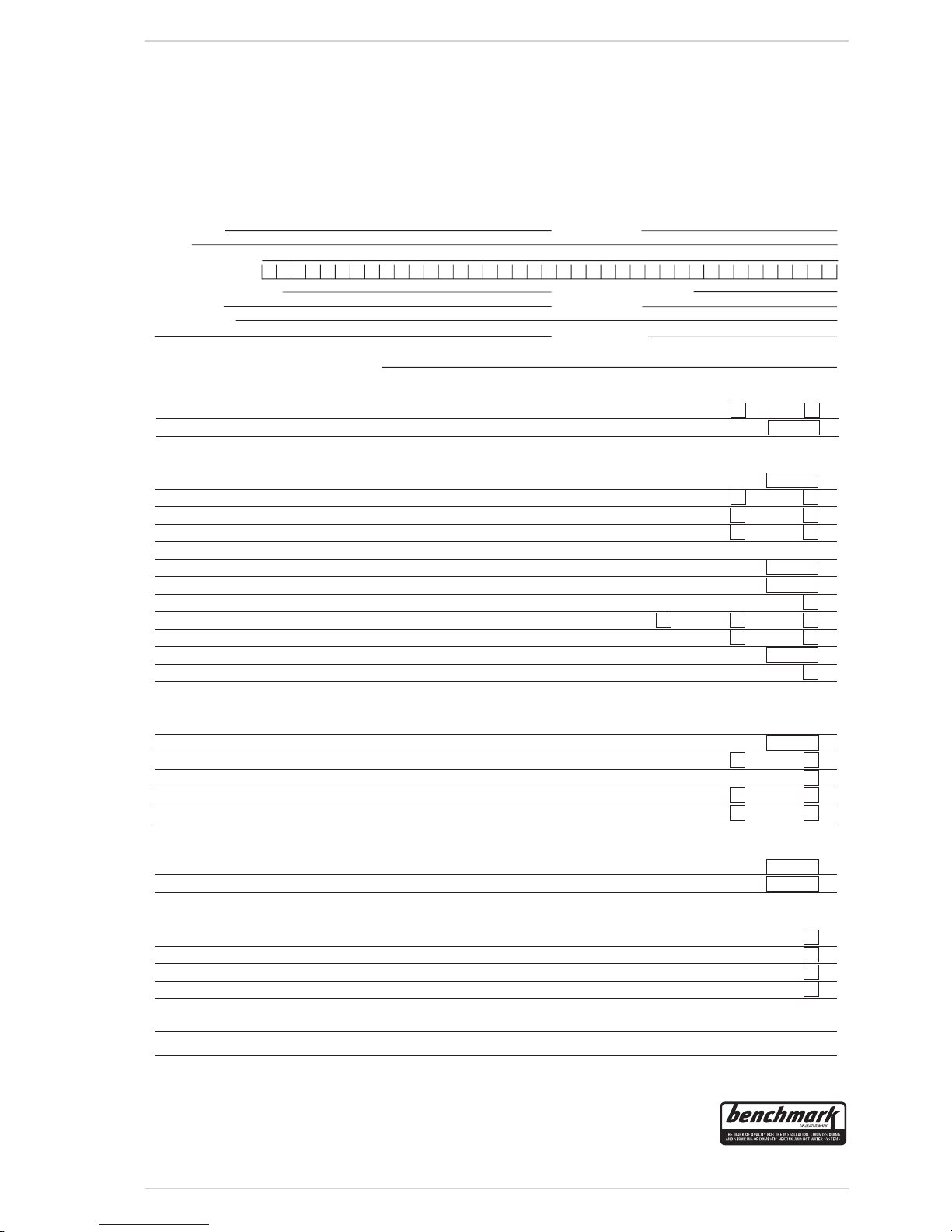

Fig. 21

91 2

3

4

76

5

KEY

1 Gas pressure intake

2 Gas valve

3 Mixer intake (–)

4 Ventilator intake (+)

5 Nozzle

6Fan

7 Air/gas mixer

9 Digital manometer

To ensure correct operation and efficiency it is important that the boiler is

serviced at regular intervals, at least

once a year.

This must be done only by a qualified technician.

During the routine service the condensate drain can be checked. It is important

should the boiler not be used for some

time that the trap is checked and filled if

required.

4.1 D.H.W. PRODUCTION

The cylinder is equipped with a sacrificial

magnesium anode, and inspection flange.

The magnesium anode must be checked

annually and substituted when it is worn.

It is advisable to incorporate a isolation

valve in the domestic supply to the boiler. It

must be positioned upstream of the combined pressure/backflow valves.

Adjustment of the flow rate through the boiler can be achieved by adjustment of the isolation valve.

The temperature and pressure relief valve

and expansion relief valves should not be

used for venting or draining the system.

To drain the D.H.W. circuit, turn off the gas

and electricity supplies and close the

D.H.W. supply isolating valve to the appliance. Connect a hose to the D.H.W. discharge

cock (See item 2, fig 3) and feed to a suitable drain. Open a hot water tap, and then

open the D.H.W. discharge cock, to drain

the tank.

4.2 GAS VALVE

The boiler, is equipped standard with the

HONEYWELL VK 8115M gas valve (fig. 20).

4.3 ADJUSTMENT OF HEAT OUTPUT

FOR HEATING

To adjust boiler heat output for heating

purposes, i.e., modifying the setting made

at the factory which is approximately 17

kW. Remove the heating control knob to

access the trimmer "B". To increase the

heating output, turn the trimmer clockwi-

se; to reduce the heating output, turn the

trimmer counterclockwise. To establish

the output of the boiler conduct a gas rate

test and compare with the values shown

in fig. 21 Tables 4 - 4/a - 4/b; or measu-

re “air ∆p” with a digital pressure gauge

connected up as shown in fig. 21.

Compare values with those shown in

Tables 4 - 4/a - 4/b.

4 USE COMMISSIONING, AND MAINTENANCE

1

2

3

4

5

Fig. 20

KEY

1 Regulation intake

2 EV1-EV2 coils

3 Pressure inlet upstream

4 Pressure inlet downstream

5 OFF-SET

23

24

0302010

∆p aria mm H

2

O

Potenza termica kW

25

20

10

15

50

40

60

5

30

50-30°C

35

70

80-60

°C

0302010

∆p aria mm H

2

O

Potenza termica kW

25

20

10

15

504060

5

30

50-30°C

35

70

80-60°C

G20 G31

4.3.1 Diagram illustrating heat output in relation to “air ∆p”

TABLE 4/a - G20

* Air ∆p is measured during boiler operation using a differential pressure gauge connected to the ventilator intake.

** The gas consumptions refer to the calorific value at standard conditions at 15°C - 1013 mbar.

Variable heat output Air ∆p*

Gas consum.

**

(80-60°C) (50-30°C) (80-60°C) (50-30°C) G20

kW kW mm H

2

O mm H2Om3/h st

29,3 32,0 63,8 66,4 3,17

22,9 25,0 45,0 45,0 2,48

16,1 17,6 25,0 25,0 1,75

10,4 11,4 8,4 9,2 1,14

TABLE 4/b - G31

Variable heat output Air ∆p*

Gas consum.

**

(80-60°C) (50-30°C) (80-60°C) (50-30°C) G31

kW kW mm H

2

O mm H2O kg/h

29,3 32,0 68,4 70,4 1,52

21,8 23,4 45,0 45,0 1,19

15,4 16,6 25,0 25,0 0,84

10,4 11,4 9,2 9,5 0,55

Fig. 22

Heat outout (kW)

Air ∆p mm H

2

O

Heat outout (kW)

∆p de aire mm H

2

O

4.4 COMMISSIONING

The gas valve is factory set and should

require no adjustment.

PLEASE NOTE: The combustion for this

appliance has been checked, adjusted and

preset at the factory for operation on the

gas type specified on the appliance data

plate. However it is advisable to check for

correct combustion having first checked:

– That the boiler has been installed in

accordance with these instructions.

– The integrity of the flue system and the

flue seals

– The integrity of the boiler combustion cir-

cuit and the relevant seals.

Proceed to put the boiler into operation as

follows, after installation a gas purge and

tightness/drop test have been made.

Ensure that the pump has been manually

rotated. Switch the boiler to the SUMMER

position. Open the gas cock, Ensure that any

timers or room thermostats are in the on

position.

The boiler will attempt to light.

4.5 CHECK THE OPERATIONAL

(WORKING) GAS INLET PRESSURE

Set up the boiler to operate at maximum

rate condition (chimney sweep) as

described in 4.6.2.

With the boiler operating in the maximum

rate condition, check that the operational

(working) gas pressure at the inlet test

point (see fig. 20 item 3), complies with the

requirements of 1.3.

Ensure that this inlet pressure can be maintained with all other appliances in the property working.

4.5.1 Combustion Check

Competence to carry out the check of the

combustion performance.

PLEASE NOTE: BS 6798: 2009 Specification

for installation and maintenance of gas-fired

boilers of rated input not exceeding 70 kw

net advises that:

– The person carrying out a combustion

measurement should have been

assessed as competent in the use of a

flue gas analyser and the interpretation

of the results;

– The flue gas analyser should be one

meeting the requirements of BS7927 or

BS-EN50379-3 and be calibrated in

accordance with the analyser manufacturers requirements, and competence

can be demonstrated by satisfactor y

completion of the CPA1 ACS assessment

which covers the use of electronic

portable combustion gas analysers in

accordance with BS7967, parts 1 to 4.

Connect the flue gas analyser to the flue

gas sampling point as shown in fig 23 and

check the combustion following the

sequence described in 4.4.

CO / CO2 RATIO

Fig. 23

CO ppm

1

00 400

CO2 %

NG 9% 0,0011 0,0044

LPG 10% 0,0010 0,0040

“∆p air” ADJUSTMENT

To measure “∆p air” simply con-

nect a differential pressure

gauge with a decimal or Pascal

scale to the positive and negative tap, observing the symbols

(

Drawing 1

).

Sequence of operations:

1) Turn the heating power con-

trol trimmer clockwise as

far as it will go (

B – Drawing

2

) with the fan at its top

speed.

2) Attempt to achieve the “∆p

air” values given in the table

by adjusting the MAX trimmer on the fan board

(

Drawing 3

):

∆p air max.

3) Turn the heating power con-

trol trimmer anti-clockwise

as far as it will go (

B –

Drawing 2

) with the fan at

its top speed.

4) Attempt to achieve the “∆p

air” values shown in the

table using the “MIN” trimmer on the fan board

(

Drawing 3

):

∆p air min.

“∆p air-gas” ADJUSTMENT

To measure “∆p air-gas”, simply

connect the positive tap of the

differential pressure gauge to

the gas tap and the negative

tap to the corresponding t ap on

the boiler (

Drawing 4

)

Always adjust gas pressure

with the fan at its top speed.

Sequence of operations:

1) Turn the heating power con-

trol trimmer anti-clockwise

as far as it will go (

B –

Drawing 5

) with the fan at

its top speed.

2) Open the gas capacity step

(

1 – Drawing 6

) all the way

so that the notch is in a horizontal position.

The boiler must always be calibrated while set on heating.

ATTENTION:

– On PROPANE – G31 boilers

it is a good idea to check

that the position of the GPL

bridge on the control board

is correct.

–

Diaphragm code 6028640

(

Drawing 7

) is assembled

on the “Dewy 25” model

functioning on PROPANE –

G31 only.

–

If the fan control board code

8260501 is replaced on

“Dewy” models running on

PROPANE – G31 it is very

important to remember to

cut the specified resistance

(

Drawing 8

).

B

2

1

Upon completion of the calibration procedure, check CO2values using a combustion analyser. If a difference which is more than 0.2 above

or below the values indicated in the table is found, it will be necessar y to correct it:

– Use the OFFSET screw (

2 – Drawing 6

) to correct CO2at “MIN” output.

– Use the capacity step to correct CO

2

at “MAX” output (

1 – Drawing 6

).

Drawing 1

Drawing 2

Drawing 4

Drawing 6

Drawing 7

Drawing 8

Dewy 25 30

Natural gas (G20)

49,5 63,8

Propane (G31) 49,5 68,4

Dewy 25 30

Natural gas (G20)

7,1 8,4

Propane (G31) 7,1 9,2

B

Drawing 5

3) Adjust the gas valve OFFSET regulation (

2 – Drawing 6

), aiming

to achieve the “∆p air- gas” shown in the table:

Capacity step open

4) Using the capacity step (

1 – Drawing 6

), attempt to achieve the

“∆p air-gas” shown in the table:

Capacity step regulated

Dewy 25 30

Natural gas (G20) 7,3 7,0

Propane (G31) 8,1 10,1

Dewy 25 30

Natural gas (G20) 5,3 6,3

Propane (G31) 4,4 9,0

“Dewy 25” “Dewy 30”

CO

2

(Natural gas) CO2(Propane) CO2(Natural gas) CO2(Propane)

“MIN” output 9,3 10,2 9,0 10,1

“MAX” output 8,9 10,0 9,1 10,3

Drawing 3

MIN. MAX

“∆p air”

adjustment

4.6 BOILER CALIBRATION

Fig. 24

25

26

4.7 DISASSEMBLY OF

EXPANSION VESSEL

To disassemble the expansion vessel, proceed as follows:

– Make sure that the water has been emp-

tied out of the boiler.

– Unscrew the connection and the locknut.

– Remove the expansion vessel.

Before refilling the system, using a pressure gauge attached to the valve make sure

that the expansion vessel is preloaded at a

pressure of 0.8 to 1 bar.

4.8 CLEANING AND

MAINTENANCE

Preventive maintenance and checking of

efficient operation of equipment and safety

devices must be carried out exclusively by

authorized technical personnel.

During maintenance operations the

authorised technician must check that

the condensate trap is full of water (this

check is of importance particularly when

the generator has been out of use for a long

period of time).

Filling is done via the special opening (fig.

25).

4.8.1 Disassembly the control panel

and skirt cover lid (fig. 26)

To remove the cover, take out the screws

(1 – 2) that hold it in place on the instrument panel. Position side “A” of the bracket on the skirt side so that the instrument

panel is hooked on the side in order to

facilitate this operation.

4.8.2 Chimney sweep function

To carry out the verification of combustion

in the boiler, turn the selector and stop on

the position ( ) until the orange led ( )

starts to flash intermittently (fig. 27).

From that moment the boiler will star t

ignite in heating mode at the maximum

power, switching off at 80°C and restarting

at 70°C.

Before activating the chimney sweep function make sure that the radiator valves

and any zone valves are open.

The test may be carried out using the hot

water function.

It may be necessary to draw off domestic

water until the cylinder temperature

reduces and the switches on the led ( ).

In this condition the boiler ignites at the

maximum output with the primary circuit

controlled between 80°C and 70°C.

During the duration of the testing the hot

water taps must remain open. Af ter verifying the combustion the boiler should be

switched off by placing the selector on the

Fig. 25

Lato A

Lato A

Fig. 26

1

2

Side A

Side A

(OFF) position; then return the selector to

the desired function.

ATTENTION: After about 15 minutes the

chimney sweep function automatically

deactivates.

SPIA GIALLA INTERMITTENTE

Fig. 27

FLASHING YELLOW LED

27

28

Failure to install and commission according to the manufacturer’s instructions and complete this Benchmark Commissioning Checklist will invalidate the warranty. This

does not affect the customer’s statutory rights.

If yes, and if required by the manufacturer, has a water scale reducer been fitted?

CONDENSING BOILERS ONLY

The condensate drain has been installed in accordance with the manufacturer’s instructions and/or BS5546/BS6798 Yes

If the condensate pipe terminates externally has the pipe diameter been increased and weatherproof insulation fitted? Yes

29

Service Record

It is recommended that your heating system is serviced regularly and that the appropriate Service Interval Record is completed.

Service Provider

Before completing the appropriate Service Record below, please ensure you have carried out the service as described in the

manufacturer’s instructions.

Always use the manufacturer’s specified spare part when replacing controls.

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Operative ID No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Date:

Engineer Name:

Company Name:

Telephone No.

Gas Safe Register No.

Comments:

Signature:

Service 1 Service 2

Service 3 Service 4

Service 5 Service 6

Service 7 Service 8

Service 9 Service 10

30

MAINS PRESSURE HOT WATER STORAGE SYSTEM COMMISSIONING CHECKLIST

*

llA installations in England and Wales must be notified to Local Authority Building Control (LABC) either directly or through a Competent Persons Scheme.

A Building Regulations Compliance Certificate will then be issued to the customer.

www.centralheating.co.uk

ALL SYSTEMS PRIMARY SETTINGS (indirect heating only)

Is the primary circuit a sealed or open vented system? Sealed

Open

What is the maximum primary flow temperature?

°C

ALL SYSTEMS

What is the incoming static cold water pressure at the inlet to the system? bar

Has a strainer been cleaned of installation debris (if fitted)? Yes N o

Is the installation in a hard water area (above 200ppm)? Yes

No

If yes, has a water scale reducer been fitted? Yes

No

What type of scale reducer has been fitted?

What is the hot water thermostat set temperature?

°C

What is the maximum hot water flow rate at set thermostat temperature (measured at high flow outlet)?

l/min

Time and temperature controls have been fitted in compliance with Part L of the Building Regulations? Yes

Type of control system (if applicable) Y Plan

S Plan Other

Is the cylinder solar (or other renewable) compatible? Yes

No

What is the hot water temperature at the nearest outlet? °C

All appropriate pipes have been insulated up to 1 metre or the point where they become concealed Yes

UNVENTED SYSTEMS ONLY

Where is the pressure reducing valve situated (if fitted)?

What is the pressure reducing valve setting?

bar

Has a combined temperature and pressure relief valve and expansion valve been fitted and discharge tested? Yes No

The tundish and discharge pipework have been connected and terminated to Part G of the Building Regulations Yes

Are all energy sources fitted with a cut out device? Yes

No

Has the expansion vessel or internal air space been checked? Yes

No

THERMAL STORES ONLY

What store temperature is achievable? °C

What is the maximum hot water temperature?

°C

ALL INSTALLATIONS

The hot water system complies with the appropriate Building Regulations Yes

The system has been installed and commissioned in accordance with the manufacturer’s instructions Yes

The system controls have been demonstrated to and understood by the customer Yes

The manufacturer’s literature, including Benchmark Checklist and Service Record, has been explained and left with the customer Yes

Commissioning Engineer’s Signature

Customer’s Signature

(To confirm satisfactory demonstration and receipt of manufacturer’s literature)

This Commissioning Checklist is to be completed in full by the competent person who commissioned the storage system as a means of

demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference.

Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights.

Customer Name Telephone Number

Address

Cylinder Make and Model

Cylinder Serial Number

Commissioned by

(print name) Registered Operative ID Number

Company Name Telephone Number

Company Address

Commissioning Date

To be completed by the customer on receipt of a Building Regulations Compliance Certificate

*

:

Building Regulations Notification Number (if applicable)

31

SERVICE RECORD

It is recommended that your hot water system is serviced regularly and that the appropriate Service Record is completed.

Service Provider

Before completing the appropriate Service Record below, please ensure you have carried out the service as described in the manufacturer’s

instructions.

SERVICE 1 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 2 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 3 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 4 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 5 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 6 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 7 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 8 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 9 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

SERVICE 10 Date

Engineer Name

Company Name

Telephone Number

Comments

Signature

32

5 EXPLODED VIEWS

COD. TYPE DATE PAGE

3810009/505 DEWY 30/130 HE FS 31.10.2007 1/6

COD. TYPE DATE PAGE

3810009/505 DEWY 30/130 HE FS 31.10.2007 2/6

33

34

COD. TYPE DATE PAGE

3810009/505 DEWY 30/130 HE FS 31.10.2007 3/6

Fonderie Sime S.p.A. - Via Garbo, 27 - 37045 Legnago (Verona) - Tel. +39-0442-631111 - Fa x +39-0442-631292 - www.sime.it

POSITION CODE DESCRIPTION MODEL NOTE

COD. TYPE DATE PAGE

• Recommended stock par ts - Componenti da t enere a scorta

POSITION CODE DESCRIPTION MODEL NOTE

1 6266034 Sealed chamber rear panel

2 6266121 Sealed chamber side panel

3 • 6231331 D.H.W. tank sensor

4 6119343 Cap for stat hole

5 6179200 Holder complete with locking nut

6 • 6277201 Water trap

7 2013302 Fastener for self tapping screw

8 6280500 3-ways junct. with press. test nipple

9 6146303 Brass Nut 1/8”

10 5003105 Glass-lined H.W. cylinder l. 130

11 6179102 Drain cock 1/2”

12 6277301 Condensate drainage pipe

13 6274303 Upstream side mixer part

14 6226427 O-ring 156

15 6274304 Downstream side mixer part

16 6274105 Burner nozzle ø 6,00 natural gas

16 A 6274104 Burner nozzle ø 4,30 LPG

17 6226428 O-ring 115

18 6174804 Gasket for fan flange

19 6174807 Gasket for downstream side mixer part

20 • 6261401 Fan RG130/0800-3612

21 6146713 Limit stat

22 6278303 Premix burner

23 6028703 Gasket for duct flange

24 6083052 Duct flange

25 2030240 Teflon gasket Ø 17x24x2

26 6277401 Pipe connecting gas valve-mixer

27 2030227 Gasket Ø 12x18x2