INSTALLER INSTRUCTIONS

CONTENTS

1 DESCRIPTION OF THE BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 94

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 98

3 CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 108

4 USE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pag. 111

IMPORTANT

When carrying out commissioning of the boiler, you are highly recommended to perform the following checks:

–

Make sure that there are no liquids or inflammable materials in the immediate vicinity of the boiler.

– Make sure that the electrical connections have been made correctly and that the earth wire is connected to a

good earthing system.

– Open the gas tap and check the soundness of the connections, including that of the burner.

– Make sure that the boiler is set for operation for the type of gas supplied.

– Check that the flue pipe for the outlet of the products of the combustion is unobstructed and has been properly

installed.

– Make sure that any shutoff valves are open.

– Make sure that the system is charged with water and is thoroughly vented.

– Check that the circulating pump is not locked (CAUTION: Remember to release the pump coupled with the control

panel, if necessary, to protect the electronic control card).

– Purge the system, bleeding off the air present in the gas pipe by operating the pressure relief valve on the gas

valve inlet.

– Check that the syphened drip is fully filled with water. If necessary, fill it via the special opening.

FONDERIE SIME S.p.A. of Via Garbo 27 - Legnago (VR) - Italy declares that its hot water boilers, which bear the CE

mark under Gas Directive 90/396/CEE and are fitted with a safety thermostat calibrated to a maximum of 110°C,

are not subject to application of PED Directive 97/23/CEE as they meet the requirements of article 1 paragraph

3.6 of the Directive.

DEWY - ENGLISH

IT

ES

PT

GB

94

1.1 INTRODUCTION

“DEWY” boilers are premix condensation

thermal appliances which use microprocessor technology for function control and

management. They comply with the european directives 90/396/CEE,

89/336/CEE, 73/23/CEE, 92/42/CEE

and with the european specifications EN

483 - EN 625.

These appliances can be fired by natural

gas (methane) and propane gas (G31).

The instructions given in this manual are

provided to ensure proper installation and

perfect operation of the appliance.

1 DESCRIPTION OF THE BOILER

1.2 DIMENSIONS

1.2.1 “30/80” model

330

G

240

310

M

R

55

S2

C

U

S1

E

70

490

390

13 0

S3

230

230

74 5

Ø 60/100

230

65

1290

460

215

Fig. 1

CONNECTIONS

R C.H. return 3/4” (UNI-ISO 228/1)

M C.H. flow 3/4” (UNI-ISO 228/1)

G Gas connection 3/4” (UNI-ISO 228/1)

E D.H.W. inlet 3/4” (UNI-ISO 228/1)

U D.H.W. outlet 3/4” (UNI-ISO 228/1)

C Recirculation 3/4” (UNI-ISO 228/1)

S1 C.H. safety relief valve

S2 Tank unit safety relief valve

S3 Condensation outlet ø 25

600

65

1620

610

315

252

76

M2

R2

M1

R1

M

R

S1

C1

S3

G

S2

117

62

U

C

E

10 9

349

712

946

70

110 9

1229

70

1349 140

300

300

828

846

1.2.2 “30/130” model

CONNECTIONS

R Zone 1 system return 3/4” (UNI-ISO 228/1)

R1 Zone 2 system return (optional) 3/4” (UNI-ISO 228/1)

R2 Zone 3 system return / Low

temperature return (optional) 3/4” (UNI-ISO 228/1)

M2 Zone 3 system delivery / Low

temperature delivery (optional) 3/4” (UNI-ISO 228/1)

M1 Zone 2 system delivery (optional) 3/4” (UNI-ISO 228/1)

M Zone 1 system delivery 3/4” (UNI-ISO 228/1)

G Gas connection 3/4” (UNI-ISO 228/1)

E D.H.W. inlet 3/4” (UNI-ISO 228/1)

U D.H.W. outlet 3/4” (UNI-ISO 228/1)

C Recirculation 3/4” (UNI-ISO 228/1)

C1 Recirculation pump kit (optional) 1/2” (UNI-ISO 228/1)

S1/S2 C.H. safety relief valve/tank

S3 Condensation outlet ø 25

Fig. 1/a

IT

ES

PT

GB

95

1.3 TECHNICAL FEATURES

DEWY 30/80 DEWY 30/130

Heat output

Nominal (80-60°C) kW (kcal/h) 29,3 (25.200) 29,3 (25.200)

Minimum (80-60°C) kW (kcal/h) 10,4 (9.000) 10,4 (9.000)

Nominal (50-30°C) kW (kcal/h) 32,0 (27.600) 32,0 (27.600)

Minimum (50-30°C) kW (kcal/h) 11,4 (9.800) 11,4 (9.800)

Nominal D.H.W. heat output kW 29,3 29,3

Heat input

Nominal/Minimum kW 30,0 / 10,8 30,0 / 10,8

Efficiency (80-60°C)

Nominal/Minimum output % 97,7 / 96,7 97,7 / 96,7

Efficiency (50-30°C)

Nominal/Minimum output % 106,8 / 105,8 106,8 / 105,8

Water content l 9,5 10,9

Adsorbed power consumption W175 175

Electrical protection grade

IP X4D IP X4D

Maximum water head bar 3 3

Maximum temperature °C 85 85

Expansion vessel

Capacity l 8 10

Preloading pressure bar 1 1

C.H. setting range °C 20 - 80 20 - 80

D.H.W. setting range °C 10 - 60 10 - 60

D.H.W. production

D.H.W. flow rate (EN 625) l/min 19,9 21,0

Continuous D.H.W. flow rate ∆t 30°C l/min 14 14

Maximum D.H.W. pressure bar 7 7

D.H.W. tank capacity l 80 130

D.H.W. expansion vessel l 4 4

Recuperation time between 25 and 55°C min 9’ 9’40”

Smokes temperature

Maximum/ Minimum (80-60°C) °C 70 / 69 70 / 69

Maximum/ Minimum (50-30°C) °C 48 / 45 48 / 45

Smokes flow kg/h 49 49

Category II

2H3P II2H3P

Type B23, C13-33-43-53 B23, C13-33-43-53

Weight kg 127 191

Main burner nozzles

Quantity n° 1 1

G20 ø mm 6,0 6,0

G25 ø mm 7,7 7,7

G31 ø mm 4,3 4,3

Gas consumption

Nominal / Minimum (G20) m

3

st/h 3,17 / 1,14 3,17 / 1,14

Nominal / Minimum (G25) m

3

st/h 3,69 / 1,32 3,69 / 1,32

Nominal / Minimum (G31) kg/h 1,22 / 0,44 1,22 / 0,44

Gas supply pressure

G20 mbar 20 20

G25 mbar 25 25

G31 (Propan) mbar 37 37

CO

2 % methane (G20) min/max 9,2 / 9,3 9,2 / 9,3

CO

2 % methane (G25) min/max 9,5 / 9,6 9,5 / 9,6

CO

2 % propan (G31) min/max 10,1 / 10,3 10,1 / 10,3

CO emission ppm 27 27

NOx emission (Class 5) ppm 35 35

(1)

Flow calculated with a fixed temperature on the hot-water service potentiometer of 60° C for a maximum period of 10 minutes

IT

ES

PT

GB

96

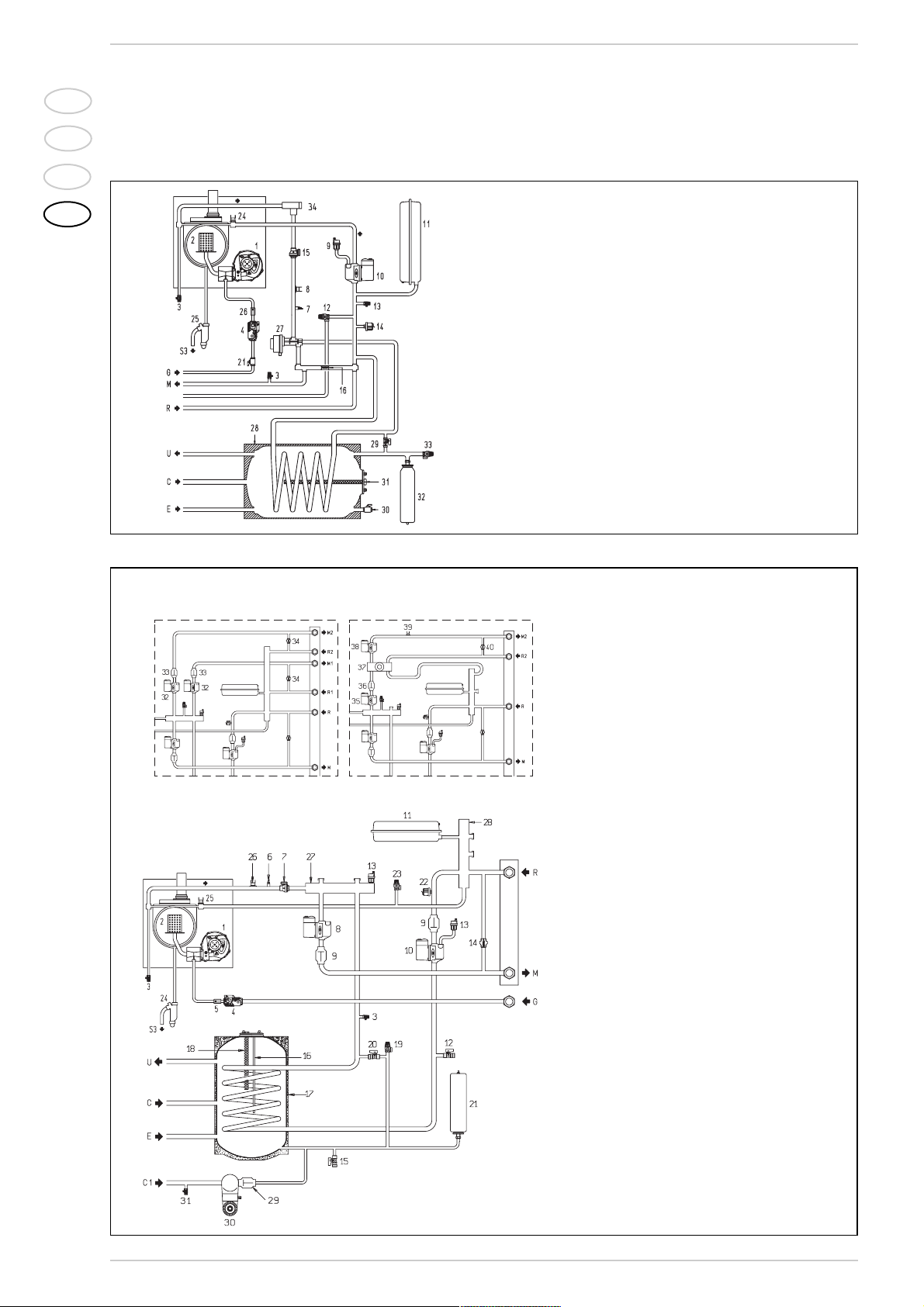

1.4 FUNCTIONAL DIAGRAM

1.4.1 “30/80” model

Fig. 2

KEY

1Fan

2 Water-gas exchanger

3 Breather valve

4 Gas valve

7 C.H. sensor (SM)

8 100°C safety stat

9 Air relief valve

10 Circulation pump

11 Expansion vessel

12 Safety valve

13 Boiler discharge

14 Water pressure transducer

15 Flowmeter

16 Automatic by-pass

21 Gas cock

24 Limit stat

25 Condensation water trap

26 Gas rate adjuster

27 Motor-operated diverter valve

28 Storage tank 80 liter

29 Filling cock

30 D.H.W. discharge cock

31 Magnesium anode

32 D.H.W. expansion vessel

33 D.H.W. safety valve 7 bar

34 Aqua Guard Filter System

CONFIGURAZIONE

KIT BASSA TEMPERATURA

CONFIGURAZIONE

KIT POMPA 2/3 ZONA

1.4.2 “30/130” model

Fig. 2/a

KEY

1Fan

2 Water-gas exchanger

3 Breather valve

4 Gas valve

5 Gas rate adjuster

6 C.H. sensor (SM)

7 Flowmeter

8 Zone 1 system pump

9 Single-acting valve

10 Hot water tank pump

11 Expansion vessel

12 Boiler discharge

13 Air relief valve

14 Automatic by-pass

15 D.H.W. discharge cock

16 Tap water probe (SB)

17 Storage tank 130 liter

18 Magnesium anode

19 D.H.W. safety valve 7 bar

20 Filling cock

21 D.H.W. expansion vessel

22 Water pressure transducer

23 Safety valve

24 Condensation water trap

25 Limit stat 85°C

26 100°C safety st at

27 System delivery manifold

28 System return manifold

RECIRCULATION KIT CONFIGURATION (code 8102600)

29 Single-acting valve

30 Recirculation pump with programmer timer

31 Pressure relief valve

PUMP KIT 2/3 ZONE CONFIGURATION

(code 8100700/8100710)

32 Zone 2 and 3 system pump

33 Zone 2 and 3 single-acting valve

34 Zone 2 and 3 system bypass

LOW TEMPERATURE KIT CONFIGURATION

(code 8100760)

35 Mixer valve delivery pump

36 Unidirectional low temperature valve

37 Mixer valve

38 Low temperature delivery pump

39 Low temperature safety thermostat

40 Low temperature bypass

PUMP KIT 2/3 ZONE

CONFIGURATION

LOW TEMPERATURE KIT

CONFIGURATION

IT

ES

PT

GB

97

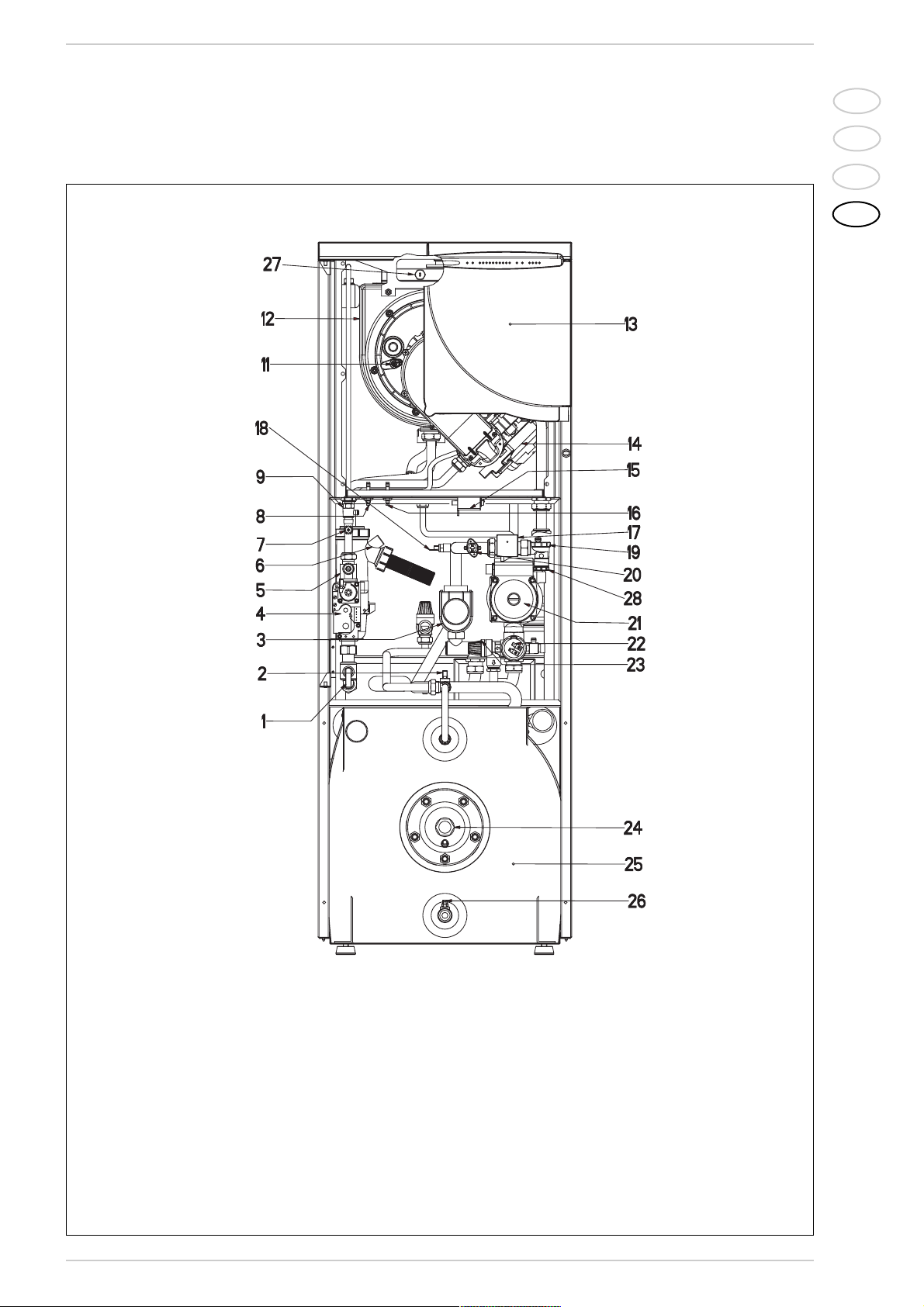

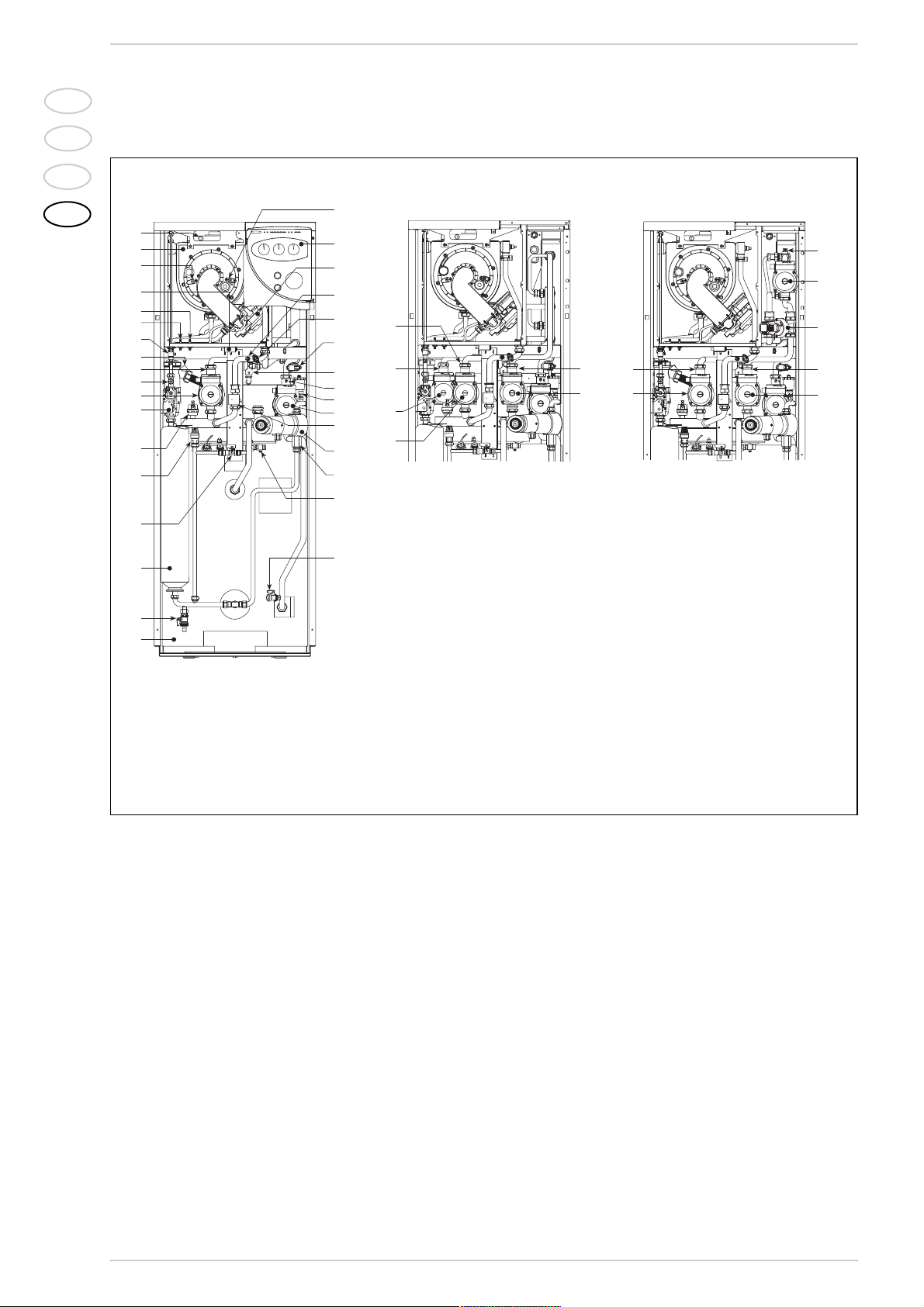

1.5 MAIN COMPONENTS

1.5.1 “30/80” model

Fig. 3

KEY

1 Gas cock

2 Manual filling

3 Motor -operated diverter valve

4 Gas valve

5 Gas rate adjuster

6 Condensation water trap

7 Gas pressure take-off

8 Positive pressure take-off

9 Breather valve

11 Sensing electrode

12 Water-gas exchanger

13 Control panel

14 F an

15 Ignition transformer

16 Negative pressure take-off

17 Flowmeter

18 C.H. sensor (SM)

19 Automatic breather

20 100°C safety stat

21 Circulating pump

22 Water pressure transducer

23 Safety valve

24 Magnesium anode

25 Storage tank 80 liter

26 D.H.W. discharge cock

27 Smoke stat

28 Aqua Guard Filter System

IT

ES

PT

GB

98

38

37

39

40

41

8

10

CONFIGURAZIONE

KIT BASSA TEMPERATURA

CONFIGURAZIONE

KIT POMPA 2/3 ZONA

35

36

34

33

8

10

19

20

21

22

24

23

25

26

27

28

29

30

31

18

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

42

1.5.2 “30/130” model

Fig. 3/a

The boiler must be installed in a fixed location and only by specialized and qualified

firms in compliance with all instructions

contained in this manual. Furthermore, the

installation must be in accordance with current standards and regulations.

2.1 BOILER ROOM

The

“DEWY”

version boilers can be installed in any domestic environment without

any location restrictions or comburent air

requirements.

2.2 CONNECTING UP SYSTEM

To protect the heat system from damaging

corrosion, incrustation or deposits, af ter

installation it is extremely important to

clean the system using suitable products

such as, for example, Sentinel X300 or

X400. Complete instructions are provided

with the products but, for further information, you may directly contact GE Betz.

For long-term protection agains corrosion

and deposits, the use of inhibitors such as

Sentinel X100 is recommended after cleaning the system. It is important to check

the concentration of the inhibitor after

each system modification and during maintenance following the manufacturer’s

instructions (specific tests are available at

your dealer). The safety valve drain must be

connected to a collection funnel to collect

any discharge during interventions.

WARNING: Failure to clean the heat

system or add an adequate inhibitor invalidates the device’s warranty.

Gas connections must be made in accordance with current standards and regula-

tions. When dimensioning gas pipes from

the meter to the module, both capacity

volume (consumption) in m3/h and gas

density must be taken into account.

The sections of the piping making up the

system must be such as to guarantee a

supply of gas sufficient to cover the maximum demand, limiting pressure loss

between the gas meter and any apparatus

being used to not greater than:

– 1.0 mbar for family II gases (natural gas);

– 2.0 mbar for family III gases (butane or

propane).

A sticker inside the module includes identification and gas type data specific to the

module.

2.2.1 Connection of condensation

water trap

The drip board and its water trap must be

2 INSTALLATION

LEGEND

1 130 litre hot water tank

2 Hot water tank drain cock

3 Hot water tank expansion tank

4 Manual filling unit

5 Hot water tank safety valve

6 Automatic bleed

7 Gas valve

8 Zone 1 heating system pump

9 Gas flow control

10 Zone 1 single-acting valve

11 Condensation drain trap

12 Manual pressure relief valve

13 Positive pressure intake

14 Negative pressure intake

15 Ignition transformer

16 Measurement electrode

17 Primary exchanger

18 Ignition electrode

19 Control panel

20 Ventilator

21 Heating probe (SM)

22 100°C safety thermometer

23 Heating system safety valve

24 Water pressure transducer

25 Single-acting valve

26 Manual recirculation kit bleed (optional)

27 Hot water tank pump

28 Flow switch

29 Tap water recirculation pump with timer

(optional)

30 Single-acting valve (optional)

31 Manual pressure relief valve

32 Boiler drain cock

33 Zone 2 heat pump (optional)

34 Zone 2 single-acting valve (optional)

35 Zone 3 single-acting valve (optional)

36 Zone 3 heat pump (optional)

37 Low temperature safety thermostat

(optional)

38 Low temperature delivery pump (optional)

39 Mixer valve (optional)

40 Low temperature single-acting valve

(optional)

41 Mixer valve delivery pump (optional)

42 Smoke stat

PUMP KIT 2/3 ZONE

CONFIGURATION

LOW TEMPERATURE KIT CONFIGURATION

IT

ES

PT

GB

99

connected to a civil drain through a pipe

with a slope of at least 5 mm per metre to

ensure drainage of condensation water.

The plastic pipes normally used for civil

drains are the only type of pipe which is

appropriate for conveying condensation

to the building’s sewer pipes.

2.2.2 Filter on the gas pipe

The gas valve is supplied ex factory with an

inlet filter, which, however, is not adequate to

entrap all the impurities in the gas or in gas

main pipes.

To prevent malfunctioning of the valve, or in

certain cases even to cut out the safety device with which the valve is equipped, install an

adequate filter on the gas pipe.

2.4 SYSTEM FILLING

Filling of the boiler and the system is done

by the charge cock

(2 fig. 3 - 4 fig. 3/a).

The charge pressure, with the system

cold, must be 1 bar.

Filling must be done slowly so as to allow

any air bubbles to be bled off through the

air valves.

Once the filling has been completed, close

the filling tap.

2.5 COAXIAL DUCT ø 60/100

The air inlet-smoke outlet assembly, code

8096250, is included in the standard supply of the appliance complete with mounting

instructions.

2.5.1 Coaxial duct

accessories

The accessories to be used for this type of

installation and some of the connecting

systems that may be adopted are illustred

in fig. 4.

With the pipe bend included in the kit, the

maximum length of the piping should not

exceed 2.8 meter.

When the vertical extension code

8086950 is used, the terminal par t of the

pipe must always come out horizontally.

2.5.2 Positioning the

outlet terminals

The outlet terminals for forced-draught

appliances may be located in the external

perimeter walls of the building.

To provide some indications of possible solutions, Table 1 gives the minimum distances

to be observed, with reference to the type

of building shown in fig. 5.

Fig. 5

TABLE 1

Siting of terminal Appliances from 7 to 35 kW

(distances in mm)

A - below openable window 600

B - below ventilation opening 600

C - below eaves 300

D - below balcony (1) 300

E - from adjacent window 400

F - from adjacent ventilation opening 600

G - from horizontal or vertical soil or drain pipes (2) 300

H - from corner of building 300

I - from recess in building 300

L - from ground level or other treadable surface 2500

M - between two terminals set ver tically 1500

N - between two terminals set horizontally 1000

O - from a surface facing without openings or terminals 2000

P - as above but with openings and terminals 3000

1)

Terminals below a practicable balcony must be located in such a way that the total path of the smoke

from its outlet point from the terminal to its outlet point from the external perimeter of the balcony, including the height of possible railings, is not less than 2000 mm.

2) When siting terminals, where materials that may be subject to the action of the combustion products

are present in the vicinity, e.g., eaves, gutters and downspouts painted or made of plastic material,

projecting timberwork, etc., distances of not less than 1500 mm must be adopted, unless adequate

shielding is provided to guard these materials.

IMPORTANT:

Each additional 90° curve installed reduces

the available length by 0.90 metres.

Each additional 45° curve installed reduces

the available length by 0.45 metres.

Fig. 4

KEY

1a-b Coaxial duct kit code 8096250

2a Extension L. 1000 code 8096150

2b Extension L. 500 code 8096151

3 Vertical extension L. 140 with take-off point code 8086950

4a 90° additional bend code 8095850

4b 45° additional bend code 8095950

NOTE

Before connecting

accessories, it is

always advisable to

lubricate the internal

part of the gaskets

with silicon products.

Avoid using oils and

greases.

IT

ES

PT

GB

2.5.3 Coaxial duct outlet on the roof

The accessories to be used for this type of

installation and some of the connecting

systems that may be adopted are illustrated in fig. 7.

It is possible to insert up to a maximum of

three extensions and reach a maximum

rectilinear distance of 3.7 meter.

Should it be necessary to make two changes of direction in the pipe development,

the maximum length of the pipe must not

exceed 2 meter.

2.6 SEPARATE PIPES ø 80

A special kit may be used to separate the

flue gas outlet from the fresh air intake.

The intake may be installed to the right or

left of the flue gas outlet.

Both ducts may be oriented in any direction.

Refer to fig. 8 for positioning.

The maximum overall length of the intake

and exhaust ducts depends on the head

losses of the single fittings installed

(excluding the doublers) and must not be

greater than 15,5 mm H2O.

For head losses in the fittings, refer to

Table 2.

2.6.1 Separate pipe accessories

Kit code 8089911 is supplied for this purpose (fig. 9).

The sectored diaphragm is to be used

according to the maximum head loss

allowed in both pipes, as given in fig. 10.

KEY

1 Blind flange

2 Flue gas duct flange

3 Fixing screw

4 Gasket ø 125/95

5 Intake duct collar

Fig. 9

100

Fig. 7

15 5

Ø 80

Ø 80

10 5

P

L

CA

K

Z

CS

KEY

CA Inlet

CS Outlet

Example of allowable installation calculation in that the sum of the head losses of the

single fittings is less than 15,5 mm H2O:

Inlet Outlet

7 m horizontal pipe ø 80 x 0,20 1,40 –

7 m horizontal pipe ø 80 x 0,40 – 2,80

n° 2 90° elbows ø 80 x 0,30 0,60 –

n° 2 90° elbows ø 80 x 0,50 – 1,00

n° 1 terminal ø 80 0,10 0,40

Total head loss 2,10 + 4,20 = 6,3 mm H2O

TABLE 2

Accessories ø 80 Total head loss (mm H2O)

DEWY

Inlet Outlet Roof outlet

90° elbow MF 0,30 0,50 –

45° elbow MF 0,20 0,40 –

Extension L. 1000 (horizontal) 0,20 0,40 –

Extension L. 1000 (vertical)) 0,30 0,30 –

Outlet terminal – 0,40 –

Inlet terminal 0,10 – –

Doubler fitting 0,30 – –

Roof outlet terminal L.1381 – – 0,60

Fig. 8

30/80 30/130

Kmm 215 348

L mm 130 263

P mm 245 230

Z mm 330 315

KEY

1 Vertical extension L. 140 with take-off points code 8086950

2a Extension L. 1000 code 8096150

2b Extension L. 500 code 8096151

3 Tile with ar ticulation joint code 8091300

4 Roof outlet terminal L. 1285 code 8091205

5 Supplementary 90° elbow code 8095850

6 Supplementary 45° elbow code 8095950

NOTE

Before connecting accessories, it is

always advisable to lubricate the

internal part of the gaskets with

silicon products. Avoid using oils

and greases.

3

4

2

5 3

1

IT

ES

PT

GB

101

2.6.2 Connection with existing flues

The ø 80 flue gas pipe may be connected to

an existing flue. When the “DEWY” boiler is

running at a low temperature, a regular flue

may be used under the following conditions:

– No other boiler must be using the flue.

–

The flue interior must be shielded

from direct contact with condensation

from the boiler.

The products of combustion must be

conveyed through a flexible or rigid plastic pipe around 100 to 150 mm in diameter, and condensation must be sipho-

ned off at the foot of the pipe.

The usable height of the water trap must

be at least 150 mm.

2.6.3 Separate-pipes roof outlet

The accessories to be used for this type of

installation and some of the connecting

systems that may be adopted are illustrated in fig. 12.

There is the possibility of doubling the airintake and smoke-outlet pipes and then bringing them back together again so as to

obtain a concentric discharge by using the

doubler fitting (9 fig. 12).

In these cases, when assembling, recover

the silicone gasket used on the terminal

adapter (5 fig. 11), which is to be replaced

by the doubler, and insert it into the seat

made in the doubler.

For this type of discharge the sum of the

maximum rectilinear development

allowed for the pipes must not exceed

15,5 mm H2O.

When calculating the lengths of pipe, take

into account the parameters given in the

Table 2.

Fig. 10

KEY

1 Separate pipes kit code 8089911

2 90° elbow MF code 8077450 (6 pz.)

3 90° elbow MF with take-off points code 8077452

4a Extension L. 1000 code 8077351 (6 pz.)

4b Extension L. 500 code 8077350 (6 pz.)

5 Outlet terminal code 8089501

6 Int.-est. ring kit code 8091500

7 Inlet terminal code 8089500

8 45° elbow MF code 8077451 (6 pz.)

NOTE

Before connecting accessories, it is always

advisable to lubricate the internal part of the

gaskets with silicon products. Avoid using oils

and greases.

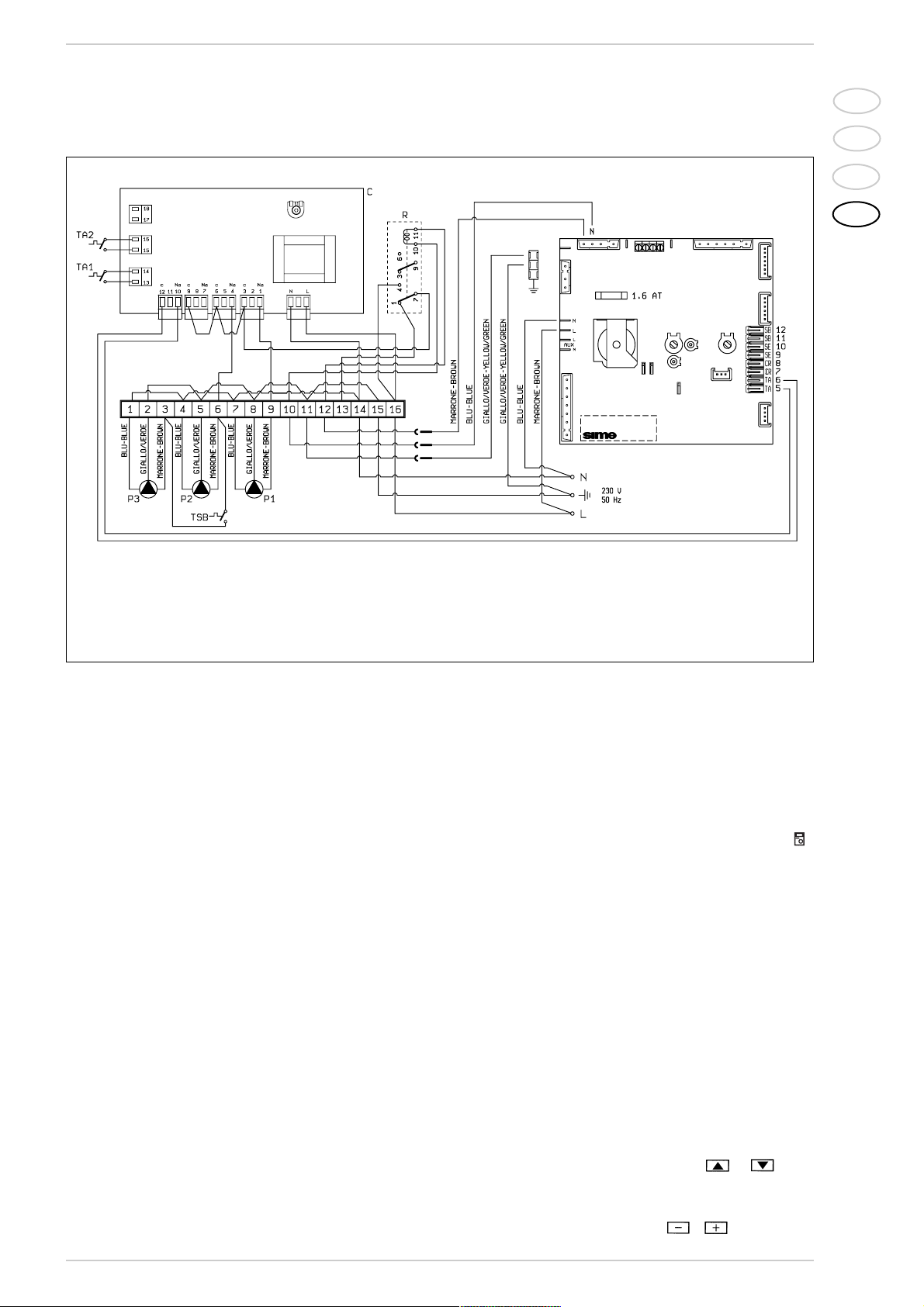

2.8 ELECTRICAL CONNECTION

The boiler is supplied with an electric cable.

Should this require replacement, it must be

purchased exclusively from SIME. The electric power supply to the boiler must be

230V - 50Hz single-phase through a fused

main switch, with at least 3 mm spacing

between contacts. Respect the L and N

polarities and the earth connection.

NOTE: Device must be connected to an

efficient earthing system. SIME declines

all responsibility for injury or damage to

persons, animals or things, resulting from

the failure to provide for proper earthing

of the appliance. Always turn off the

power supply before doing any work on

the electrical panel.

2.8.1 Room stat connection

(fig. 13 pos. A)

To gain access to the electronic board connector (3), remove the control panel cover

and connect the room stat to the terminals

TA (5-6) after having removed the jumper.

The thermostat or timer-thermostat,

recommended for better room temperature control, must be class II as specified by

standard EN 60730.1 (clean contact).

WARNING: Applying mains voltage to the

terminals of conector (3) will irreparably

damage the control board. Make sure

that any connections to be made are not

carrying mains voltage.

2.8.2 “Logica Remote Control”

connection (fig. 13 pos. B)

The electrical plant must comply with local

standards and all cables must comply with

low safety voltage requirements of EN

60730. For lengths up to 25 m, use cables

of section 0.25 mm2, for longer lengths up

to 50 m use cables of section 0.5 mm2.

First of all, assemble and wire the socket

(2), then insert the equipment which will

start-up as soon as it receives current.

To gain access to connector (3) remove the

control panel cover and connect the climate

regulator to terminals CR (6-7).

WARNING: External voltage must not be

connected to terminals 1-2-3-4 of the

"Logica Remote Control". A telephone remote switch with a zero potential contact or a

window contact can be connected to terminals 3-4. Equipment for the checking of civil

plants via a telephone line includes the

model TEL 30.4 LANDIS & STAEFA.

2.8.3 External temperature sensor

connection (fig. 13 pos. C)

The cables must comply with low safety voltage requirements of EN 60730. For lengths

up to 25 m, use cables of section 0.25 mm2,

for longer lengths up to 50 m use cables of

section 0.5 mm2.

To gain access to boiler connector (3) remove the control panel cover and connect the

external temperature sensor to terminals

SE (8-9).

102

IT

ES

PT

GB

Fig. 12

KEY

1 Separate pipes kit code 8089911

2 90° elbow MF

code 8077450 (6 pz.)

3

90° elbow

MF with take-off points code 8077452

4 a Extension L. 1000 code 8077351 (6 pz.)

4 b Extension L. 500 code 8077350 (6 pz.)

6 Int.-est. ring kit code 8091500

7 Inlet terminal code 8089500

9 Doubler fitting code 8091400

10 Tile with articulated joint code 8091300

11

Roof outlet terminal L. 1381

code 8091204

NOTE

Before connecting accessories, it is always

advisable to lubricate the internal part of the

gaskets with silicon products. Avoid using oils

and greases.

IT

ES

PT

GB

103

TA

CR

CR

SE

2

A

B

C

3

1

SB

SB

SB

KEY

1 Control panel

2 “Logica Remote Control” socket

3 Conector (J2)

TA Room stat

(not supplied)

CR Logica Remote Control

(optional)

SE External temperature sensor

(optional)

SB D.H.W. sensor

KEY

EV1 Gas valve coil

EV2 Gas valve coil

EA Ignition electrode

ER Sensing electrode

TS 100°C safety stat

VFan

TPA Water pressure transducer

VD Motor-operated diverter valve

PI Pump

SE External sensor (optional)

TA Room stat

SM C.H. sensor (blue)

TL Limit stat

TRA Ignition transformer

TR Transformer 230 - 24V

FL Flowmeter

SS D.H.W. sensor (red)

CR Logica Remote Control (optional)

SV Ventilator board

OP Time programmer

TF Smoke stat

Note: The room stat must (TA) be connected to the terminals 5-6

CONNECTOR SPARE PART CODES:

J2 code 6278613

J3 code 6278660

J4 code 6278659

J5 code 6278658

J7 code 6278636

Fig. 14

2.8.4 Wiring diagram “30/80” model

Fig. 13

IT

ES

PT

GB

104

KEY

EV1 Gas valve coil

EV2 Gas valve coil

EA Ignition electrode

ER Sensing electrode

TS 100°C safety stat

VFan

TPA Water pressure transducer

PI Pump

SE External sensor (optional)

TA Room stat

SM C.H. sensor (blue)

TL Limit stat

TRA Ignition transformer

TR Transformer 230 - 24V

FL Flowmeter

SS D.H.W. sensor (red)

CR Logica Remote Control (optional)

SV Ventilator board

OP Time programmer

TF Smoke stat

PB Hot water tank pump

PR Recirculation pump (optional)

Note: The room stat must (TA) be connected to the terminals 5-6

CONNECTOR SPARE PART CODES:

J2 code 6278613

J3 code 6278660

J4 code 6278659

J5 code 6278658

J7 code 6278636

Fig. 14/a

2.8.5 Wiring diagram “30/130” model

Fig. 14/b

2.8.6 “30/130” wiring diagram with zone pump kit (code 8100700) and third zone pump kit (8100710)

LEGEND

C Zone control unit

R Relay

P1 Zone 1 system pump

P2 Zone 2 system pump

P3 Zone 3 system pump

TA1 Zone 1 room thermostat

TA2 Zone 2 room thermostat

TA3 Zone 3 room thermostat

IT

ES

PT

GB

105

2.9 LOGICA REMOTE CONTROL

All the boiler's functions can be managed

by a optional digital multifunctional device

code 8092204 for the remote of the boiler itself and for regulating room climatic

conditions with an operational reserve of

12 hours.

The heating circuit is controlled by the room

temperature sensor built-in the equipment

or by the atmospheric conditions, with or

without environmental inflow, if the boiler is

connected to an external sensor.

Characteristics:

– Ergonomic control unit divided according

to function (control levels)).

– Clear division of basic functions:

• operating regime, correction of set

value and presence button are directly

accessible;

• Different real current values are

accessible through the "info" button;

• other functions can be programmed

after the cover has been opened;

• special service level with protected

access;

– Each setting or modification is displayed

and confirmed.

– Tome setting (special line for changing

BST/CET).

– Heating programme with max. 3 heating

periods per day, individually selectable.

–

Copy function for easy transfer of heating programme to the next or pre-

vious day.

–

Holiday programme: the programme is

interrupted for the holiday period and automatically restar ted on returning home.

– Option to return the heating program to

default values.

– Programming lock (child safety).

Functions:

– Delivery temperature control guided by

the atmospheric conditions, taking into

account the dynamics of the building.

– Delivery temperature control guided by

atmospheric conditions with influence of

ambient temperature.

– Ambient temperature control only.

– Adjustable influence of ambient tempera-

ture shift .

– Switch-on and switch-off optimisation.

– Rapid lowering.

– ECO functions (daily heating limiter, auto-

matic summer/winter switch-over).

– Controllable maximum delivery tempera-

ture limit (specifically for floor plants).

– Limitation of increase in pre-set delivery

temperature.

– Anti-freeze protection for buildings.

– Hourly programming of the tank unit

temperature on two levels: comfort and

reduced.

– Domestic hot water control with nominal

value requirement and enable.

– Connection to room sensor or switching

of operating regime through the telepho-

ne system with external contact or

through a window contact.

– Anti-bacterial.

2.9.1 Installation

The unit must be installed in the main living

room. For installation, follow the assembly

instructions inserted in the package.

At this point, with the selector knob on ( ),

the installer can adjust the basic parameters settings according to the individual

needs (point 2.8.2).

If there is a thermostatic radiator valve

fitted, this must be set to maximum.

2.9.2 Installation settings

The settings for the basic operating parameters for individual needs are reported in

the instruction leaflet supplied with the

"Logica Remote Control" and in the section

reserved for the user in this manual.

For further adjustments which can be carried out by the installer, the "Logica Remote

Control" offers a level of service and parameterising which can only be accessed

through a special combination of buttons.

To activate this level of service or parameterising press buttons and least 5

seconds. This will activate the parameterising level. Then use the same arrow buttons

to select the individual input lines and adjust

the values with or .

Fig. 14/c

2.8.7 “30/130” wiring diagram with low temperature kit code 8100760

LEGEND

C Zone control unit

R Relay

P1 Zone 1 system pump

P2-P3 Low temperature zone pump

TA1 Zone 1 room thermostat

TA2 Low temperature zone room thermostat

TAB Low temperature safety thermostat

IT

ES

PT

GB

106

Maximum limit of delivery

temperature

Variation of the maximum speed of the

delivery temperature

Activation of adaptation

Optimisation of

switch-on time

Heating gradient

Presetting switch-off

time (00 = off)

The delivery temperature is limited to the maximum set value.

The increase per minute of the prescribed delivery temperature value sent

in °C is limited to the imposed value.

With the activation of the adaptation, the pre-set value transmitted to the

boiler regulator is adapted to the effective heat need.

The adaptation functions with both the atmospheric guide with ambient

influence and with pure ambient control.

If the "Logica Remote Control" is set as a remote control only, the adaptation

must be is deactivated.

If the switch-on time optimisation is active, the "Logica Remote Control" modifies the heating gradient until it finds the optimum heating point

0 = off 1 = on

The "Logica Remote Control" selects the switch-on time such that the set

value has more or less been reached at the start of the usage time.

The more severe the night-time cooling, the earlier the heating time starts.

Example: Current ambient temperature 18.5°C

Nominal ambient temperature 20°C

Heating gradient 30 min/K

Presetting of switch-on time:

1.5 K x 30 min/K = 45 minutes

00 means that the switch-o time has not been pre-set (function disabled).

If the switch-off time optimisation is active (value > 0), the "Logica Remote

Control" modifies the pre-set time until it finds the optimum switch-off time..

55

56

57

58

59

60

Antifreeze protection

"Pre-set ambient

temperature value"

Summer/Winter switch-over

temperature

Type of control:

0 = with ambient influence

1 = without ambient influence

Influence of ambient temperature

Heating takes place up to this pre-set value if the plant is activated in standby

(e.g. holidays).

In this way, the building antifreeze function is active, preventing an excessive

lowering of the ambient.

This parameter regulates the temperature of the automatic summer/winter switch-over.

This parameter de-activates the ambient influence and as a result all the

optimisations and adaptations.

If a valid external temperature is not transmitted , the controller switches to

the pure ambient control guide variable.

If the ambient controller is used only as a remote control (placed in the reference room and without an external sensor connected), the value must be

set at 0 (zero).

If the change in ambient temperature from the pre-set value remains high

during the entire day, the influence must be increased. If the ambient temperature is around the pre-set value (control oscillation), the influence must

be reduced.

Note: If the ambient temperature influence constant is set at 0, the adaptation of the heating curve is deactivated. In this case, parameter 57 will

have no effect at all.

54

HEATING CIRCUIT SETTINGS

52

53

51

IT

ES

PT

GB

107

Final user level 2

programming block

Input function terminal 3-4

This block (1) can be activated to display all the parameters without

modifying them. Pressing buttons or displays “OFF”.

WARNING:

The activation block can be deactivated temporarily by pressing buttons

and simultaneously; a confirmation sign appears on the display.

At this point press simultaneously the buttons and for at least 5

seconds.

To permanently remove the activation block, set parameter 63 on 0.

The freely programmable input (terminals 3-4) allows three different functions

to be activated. The parameter has the following significance:

1 =

If an external sensor is connected, the display will show the temperature

of the external sensor ( _ _ = no sensor connected, function disabled).

2 = With an external contact, it is possible to switch-over to "reduced pre-

set value of the ambient temperature".

3 = With an external contact, it is possible to switch-over to "reduced pre-

set value of the antifreeze ambient temperature" (short circuit 0 0 0 or

interruption _ _ _ ). The display shows the current status of the external

contact.

64

63

SERVICE VALUES

DOMESTIC HOT WATER SETTINGS

Reduced domestic hot

water pre-set value

Domestic hot water load

The reduced pre-set value of the temperature of the domestic hot water allow

the required water temperature to be obtained outside the programmed

usage times (daily programme 8).

0 = 24 hours/ day - Hot water is always available at the temperature set

with user parameter n°3.

1 = standard - Hot water according to the daily heating programme.

In the comfort areas of heating the temperature of the boiler unit is regulated to the value set with user parameter n° 3.

In the reduced areas of heating the temperature of the boiler unit is

regulated to the value set with parameter n° 61 of the ser vice level.

2 = service disconnected

3 = second daily programme (8) - Every day of the week the temperature of

the hot water is set according to programme 8. In this case there is a

single programming for all the days of the week and three time zones are

available. In the time spans set the temperature of the boiler unit is regulated according to that set in parameter n°3. In the remaining hours the

boiler unit is controlled to the temperature set with parameter n° 61 the

of service level.

62

61

Modo de acção do contacto externo

Influxo das sondas

ambiente + externa

Anti-bacterial function

Se a entrada (bornes 3 e 4 do ropadé) está ligada a um contacto externo de

potencial zero (parâmetro 64 = 2 ou 3), pode ser determinado o modo de

acção do contacto (tele-interruptor do telefone ou contacto janela). O modo de

acção especifica o estado de contacto no qual a função desejada está activa.

Display: modo de acção fechado (curto-circuito) 0 0 0

modo de acção aber to (interrupção) _ _ _

Determina o coeficiente de mistura entre a sonda ambiente interna e externa, quando o parâmetro 64 = 1.

0 % = activa só a sonda interna (0% externa - 100% interna)

50 % = valor médio da sonda externa + interna

100 % = activa só a sonda externa

Para a regulação ambiente e a visualização, é utilizada a mistura programada. Se a sonda externa apresenta um curto-circuito ou uma interrupção

prossegue-se com a sonda interna.

This function allows the hot water to be brought to a high temperature once

a week in order to eliminate eventual pathogenic agents.

It is active every Monday for a maximum duration of 2.5 hours at a delivery

temperature of 65°C.

0 = not active 1 = active

65

66

69

IT

ES

PT

GB

108

3.1 ELECTRONIC BOARD

The electronic boards are manufactured in

compliance with the EEC 73/23 low-voltage

directives.

They are supplied with 230V and, through a

built-in transformer, send a voltage of 24V

to the following components: gas valve,

safety stat, C.H. and D.H.W. sensor, external

temperature sensor (optional), modulator,

micro divertor valve, flow switch safety

valve, water pressure transducer, room

stat or “Logica Remote Control”.

An automatic and continuous modulation

system enables the boiler to adjust the heat

output to the various system requirements

or the User’s needs.

The electronic components are guaranteed

against a temperature range of 0 to

+60°C.

3.1.1 Fault finding

The indicator leds signalling irregular

and/or incorrect operation of the equipment are indicated in fig. 16.

3.1.2 Devices

The electronic board is equipped with the

following devices:

– “POT. RISC.” trimmer (10 fig. 17)

Sets the maximum heating power value.

To increase the value turn the trimmer

clockwise; to reduce the value turn the

trimmer anticlockwise.

– “POT. ACC.” trimmer (6 fig. 17)

Trimmer to vary the pressure level upon

ignition (STEP), of the gas valve.

According to the type of gas for which

the boiler is equipped, the trimmer must

be regulated so as to obtain a pressure

of approx. 3 mbar at the burner for

methane gas and 7 mbar for propane

gas (G31).

To increase pressure, turn the trimmer

clockwise; to reduce pressure, turn the

trimmer counterclockwise.

The slow ignition pressure level can be

set during the first 3 seconds following

burner ignition.

After setting the pressure level upon

ignition (STEP) according to the type of

gas, check that the pressure for heating is still at the value previously set.

– “MET-GPL” connector (7 fig. 17)

With the connector switched-off, the

3 CHARACTERISTICS

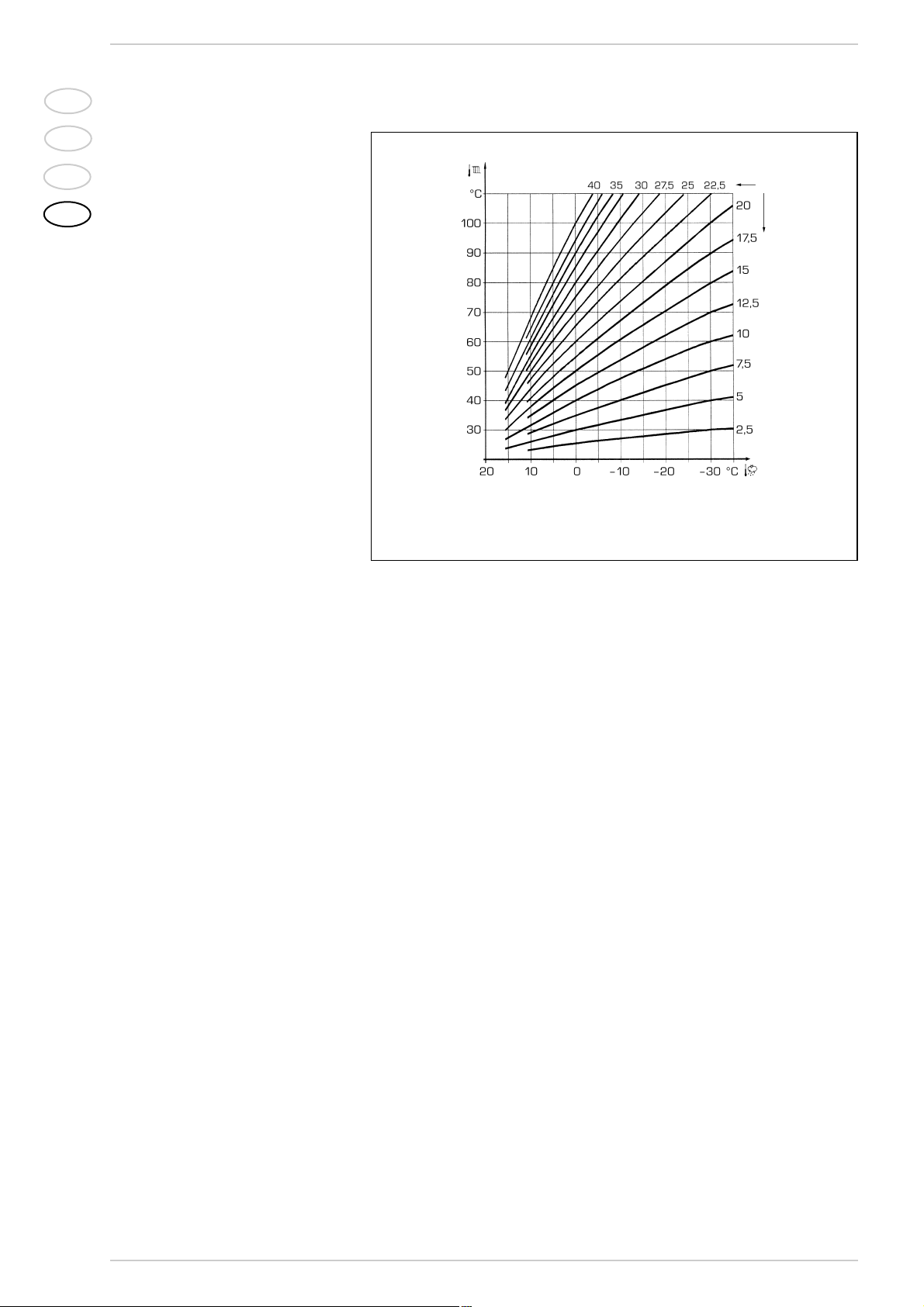

2.9.3 Gradient of

the characteristic

heating curve

The gradient of the characteristic heating

curve is imposed on the current value “15”

of Logica. Increasing the gradient as shown

in the drawing of fig. 15, the delivery temperature increases in correspondence to the

outside temperature.

2.10 EXTERNAL TEMPERATURE

SENSOR

The "Logica Remote Control" can be connected to an external temperature sensor

available a an optional extra (code

8094100).

This configuration ensures and maintains

the required temperature constant in the

room.

The ambient temperature is, in fact, indicted and evaluated as the calculated mean

of the value measured inside and outside

the dwelling.

For installation, follow the assembly instructions inserted in the package.

Fig. 15

Example: Choosing a gradient of 15 with an outside temperature

of –10°C we shall have a delivery temperature of 60°C.

IT

ES

PT

GB

109

boiler is set-up for NATURAL GAS; with

the connector switched-on, the boiler is

ready for LPG.

– “ANN. RIT.” connector (5 fig. 17)

In the heating phase, the electronic board

is programmed to include a burner technical delay interval of approx. 90 seconds,

which occurs both at system cold starting and at subsequent re-ignitions. The

aim is to overcome the problem of repeated ignitions and turning of f with very

short time intervals between. This could

occur in particular in systems presenting

high head losses.

At each restart after the period of slow

ignition, the boiler will set itself for about

1 minute at the minimum modulation

pressure, and will then move to the heating pressure value set.

When the connecting link is inserted,

both the programmed technical pause

and the period of operation at minimum

pressure in the startup phase will be cancelled. In this case, the times elapsing

between turning off and subsequent re-

ignition will depend on a temperature difference of 5°C detected by the SM sensor (heating flow sensor).

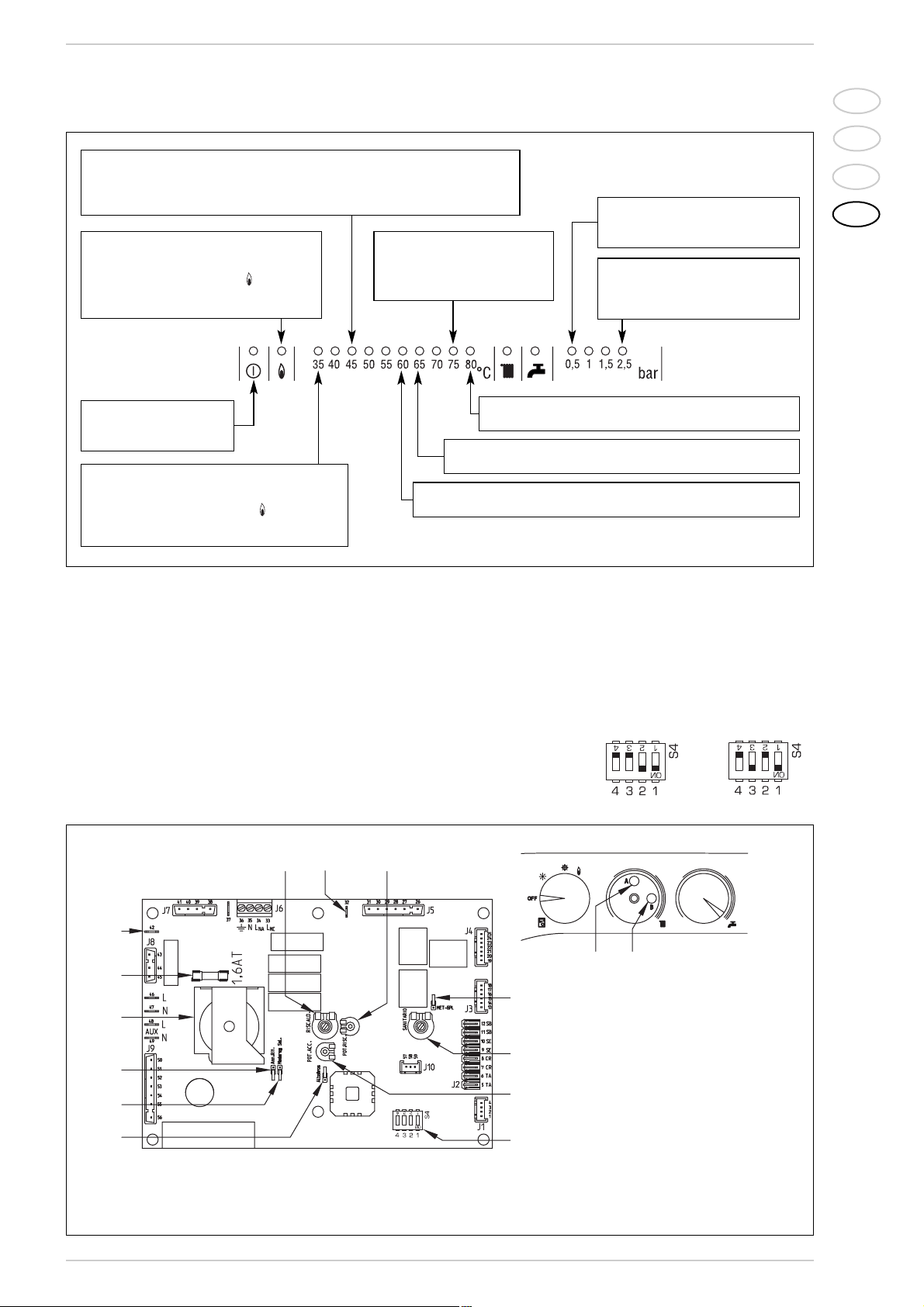

– DIP SWITCH (13 fig. 17)

Check that the cordless plugs are inserted in the position indicated:

Flashing red led,

communication fault

with “Logica Remote Control”

Green led of f if

power is cut-off

Flashing red led, water

pressure is too low (*)

Flashing red led, heating sensor fault

(SM)

Flashing red led,

plant safety

valve tripped (*)

Red led on, ignition blocked:

rotate selector CR/OFF/EST/INV/RESET

to release position

()

to restore operation

Flashing red led, safety stat tripped.

Rotate selector CR/OFF/EST/INV/RESET

to release position

()

to restore operation

Flashing red led, fan fault.

30 minutes af ter the fan has switched off,

the board will attempt a restart

(*)

When all 0.5 to 2.5 bar leds are off, check the

water pressure transducer connection.

Fig. 16

Flashing red led, D.H.W. sensor fault (SB)

Flashing red led, flame detection circuit fault

15

13

1

3

5

7

8

9

10

11

12

14

6

6

10

KEY

1 Ignition electrode earth faston

2 Ignition electrode faston

3 Fuse (1,6 AT)

4 Fuse(0,16 AT)

5 “ANN. RIT.” connector

6 “POT. ACC.” trimmer

7 Conector “MET-GPL”

8 D.H.W. potentiometer

9 Detector electrode faston

10 “POT. RISC.” trimmer

11 C.H. potentiometer

12 Selector CR/OFF/EST/INV/RESET

13 DIP SWITCH

14 Connector “Modureg Sel.”

15 Connector “Albatros”

NOTE: To gain access to trimmers (6) and (10), unscrew the central heating potentiometer knob

Fig. 17

Dewy 30/80 Dewy 30/130

IT

ES

PT

GB

110

– “Modureg Sel.” connector (14 fig. 17)

With the bridge disconnected the boiler

is predisposed to function with the SIT

gas valve, and with the bridge connected

it is predisposed to function with the

HONEYWELL gas valve.

– “Albatros” connector (15 fig. 17)

The bridge must always be disconnected.

It is connected only when multiple boilers

are installed in a sequence/cascade.

ATTENTION: It is essential that the operations described above be carried out by

authorized technical staff.

3.2 TEMPERATURE SENSOR

AND WATER PRESSURE

TRANSDUCER

Tables 3 - 3/a show the resistance values

(Ω) that are obtained on the sensor as the

temperature varies and the transducer

values obtained as the pressure varies.

When sensor (SM) is interrupted,

neither of the boiler's heating services

will function. With D.H.W. sensor (SB)

interrupted, the boiler will only work in

heating mode.

3.3 ELECTRONIC IGNITION

Ignition and flame detection is controlled by

two electrodes located on the burner.

These guarantee maximum safety with

intervention times, for accidental switching

off or gas failure, of within one second.

3.3.1 Operating cycle

Rotate the selector knob to summer or winter, and verify that green led ( ) lights up to

confirm the presence of voltage.

The burner must be ignited within 10

seconds.

However, it is possible for ignition

failures to occur, with consequent activation of signal indicating that the control box

has “locked out”.

– Gas failure

The control box runs through the cycle

normally sending electric power to the

ignition electrode. The electrode continues spark discharge for a maximum of

10 sec.If the burner does not light, the

lock-out indicator will light up.

This may occur upon first ignition or

after long periods of boiler lay-off when

there is air in the pipes. It may be caused

by the gas cock being closed or by one of

the valve coils having a break in the winding, so that the valve cannot open.

– Ignition electrode fails to spark

In the boiler, only the gas to the burner

is seen to open. After 10 sec. the warning light indicating equipment “lockout” lights up.

This may be due to a break in the wire of

the electrode or to the wire not properly

fastened to the electric terminal of the

control box;

– No detection of flame

The continuous spark discharge of the

electrode is noted starting from ignition

even though the burner is lit.

After 10 seconds have elapsed, the

sparks cease, the burner goes out, and

the warning light indicating equipment

“lock-out” lights up.

There could have a break in the wire of

the sensing electrode or the electrode

itself is touching earth: the electrode is

worn out and needs replacing. The control box is defective.

When there is a sudden voltage failure, the

burner shuts out immediately; when power

supply returns, the boiler will start up again

automatically.

3.4 FLOW SWITCH SAFETY VALVE

A flow switch safety valve (17 fig. 3) intervenes, blocking the operation of the burner if

the boiler is without water due to the formation of an air lock in the heat exchanger

or if the circulator is not working, or, model

“30/80”, because the “Aqua Guard Filter

System” is obstructed with impurities.

NOTE: If replacing the flow switch valve,

make sure that the arrow stamped on the

valve points in the same direction as the

flow of water.

3.5 SYSTEM AVAILABLE HEAD

For boilers with the standard fittings, the

residual head for the heating system on

the basis of rate of flow is represented in

the diagram in figure 18.

TABLE 3 (Sensors)

Temperature (°C) Resistance (Ω)

20 12.090

30 8.313

40 5.828

50 4.161

60 3.021

70 2.229

80 1.669

TABLE 3/a (Transducer)

Pressure Resistance (Ω)

(bar) min max

0 297 320

0,5 260 269

1 222 228

1,5 195 200

2167173

2,5 137 143

3108113

3,5 90 94

Fig. 18

1 HIGH TEMPERATURE ZONE

FLOW RATE (l/h)

RESIDUAL HEAD (mbar)

600

500

400

300

200

PREVALENZA RESIDUA (mbar)

10 0

0

200

vers. 30/80

vers. 30/130

140012001000800600400

PORTATA (l/h)

Dewy

1600

3.5.1 Head with total rate of flow

to other zones

In “30/130” versions using the second

and third zone kit, determine the head available to the zones as shown in the following

example:

Rate of flow calculated for zone 1 = 350 l/h

Rate of flow calculated for zone 2 = 400 l/h

Rate of flow calculated for zone 3 = 400 l/h

To obtain head available to zone 1, add the

total rate of flow to the other zones (in this

case zones 2 and 3): 400 l/h + 400 l/h =

800 l/h.

As shown in the graph (fig. 18/a) at the

800 l/h curve, head at 350 l/h for zone 1

= 180 mbar.

The same procedure may be applied to

other zones to obtain:

Zone 2 = 350 l/h + 400 l/h = 750 l/h.

As shown in the graph at the 800 l/h

curve, head at 400 l/h = 160 mbar.

Zone 3 = 350 l/h + 400 l/h = 750 l/h.

As shown in the graph at the 800 l/y

curve (curve E), head at 400 l/h = 160

mbar.

3.5.2 Head available with the low

temperature kit

In “30/130” versions using the low temperature kit, residual available head on the

basis of rate of flow is represented in the

graph in fig. 18/b.

111

IT

ES

PT

GB

Fig. 18/a

Fig. 18/b

1 HIGH AND 1 LOW TEMPERATURE ZONE

3 HIGH TEMPERATURE ZONES

FLOW RATE (l/h)

RESIDUAL HEAD (mbar)

FLOW RATE (l/h)

RESIDUAL HEAD (mbar)

A High temperature zone

B Low temperature zone with

mixer valve at 40°C

500

400

300

200

A= 0 l/h D= 600 l/h

B= 200 l/h E= 800 l/h

C= 400 l/h

DEWY 30/130

10 0

PREVALENZA RESIDUA (mbar)

0

500

400

300

200

10 0

PREVALENZA RESIDUA (mbar)

B

C

D

E

200

PORTATA (l/h)

A Zona alta temperatura

B Zona bassa temperatura con

valvola miscelatrice a 40°C

A

140012001000800600400

1600

DEWY 30/130

A

B

0

200

140012001000800600400

PORTATA (l/h)

1600

IT

ES

PT

GB

112

4.1 D.H.W. PRODUCTION

The preparation of hot water is guaranteed

by the glass storage tank unit with magnesium anode for the protection of the boiler

unit and inspection flange for its control and

cleaning.

The magnesium anode must be checked

annually and substituted when it is worn.

It is advisable to place a sluice gate at the

entrance of the D.H.W. tank unit which,

apart from the total closure, allows the regulation of the supply capacity.

If the boiler does not produce hot water,

make sure that the air has been released

by pressing on the manual vents after having switched off the main switch.

4.2 GAS VALVE

The boiler, is equipped standard with the

HONEYWELL VK 8115M gas valve (fig. 20).

4 USE AND MAINTENANCE

Fig. 20

KEY

1 Regulation intake

2 EV1-EV2 coils

3 Pressure inlet upstream

4 Pressure inlet downstream

5 OFF-SET

CR1

CR

TA

(5)

SONDA

SANITARIO

CONNETTORE J2

COPERTURA

TA

(6)

SB

(11)

SB

(12)

CIRCUITO CON VALVOLE DI ZONA

NOTA: I relé vengono impiegati solo nel caso

le valvole di zona siano prive di micro.

L

N

TA

TA1

VZ

R

VZ1

R1

CIRCUITO CON POMPE DI ZONA

L

N

TA

TA

P

R

P1

R1

KEY

TA-TA1 Zone room stat

VZ-VZ1 Zone gas valve

R-R1 Zone relay

CR-CR1 Zone microvalve or relay contact

P-P1 Zone pump

Fig. 19

COVER

CONNECTOR J2

CIRCUIT WITH ZONE VALVE

CIRCUIT WITH ZONE PUMP

NOTE: Relays are used only if the area valves have

no microswitches.

D.H.W.

SENSOR

3.6 SMOKE STAT

To protect the polypropylene conduit from

smoke the appliance is provided with an

exhaust thermostat (27 fig. 3 - 42 fig. 3/a).

3.7

MAINS ELECTRICITY

CONNECTION

Use a separate electricity supply to connect

the room stats and relative zone valves or

pumps.

The micro or relay contact connection is

made to TA-CR-SE (J2) connector of the circuit board after having removed the jumper

(fig. 19).

1

5

4

3

2

IT

ES

PT

GB

113

4.3 ADJUSTMENT

OF HEAT OUTPUT

FOR HEATING

To adjust boiler heat output for heating

purposes, i.e., modifying the setting made

at the factory which is approximately 17

kW, use a screwdriver to adjust the heating heat output trimmer (10 fig. 17).

To increase working pressure, turn the

trimmer clockwise; to reduce pressure,

turn the trimmer counterclockwise.

To determine boiler heat output setting,

check energy consumption by observing

the meter and then compare with the

values shown in Tables 4 - 4/a - 4/b; or

measure “air ∆p” with a digital pressure

gauge connected up as shown in fig. 21.

Compare values with those shown in

Tables 4 - 4/a - 4/b.

Fig. 21

91 2

3

4

76

5

KEY

1 Gas pressure intake

2 Gas valve

3 Mixer intake (–)

4 Ventilator intake (+)

5 Nozzle

6Fan

7 Air/gas mixer

9 Digital pressure gauge

0302010

∆p aria mm H

2

O

Potenza termica kW

25

20

10

15

50

40

60

5

30

50-30

°C

35

70

80-60

°C

0302010

∆p aria mm H

2

O

Potenza termica kW

25

20

10

15

504060

5

30

50-30

°C

35

70

80-60

°C

G20 G31

4.3.1 Diagram illustrating heat output in relation to “air ∆p”

TABLE 4/a - G20

* Air ∆p is measured during boiler operation using a differential pressure gauge connected to the ventilator intake.

** The gas consumptions refer to the calorific value at standard conditions at 15°C - 1013 mbar.

Variable heat output Air ∆p*

Gas consum.

**

(80-60°C) (50-30°C) (80-60°C) (50-30°C) G20

kW kW mm H

2

O mm H2Om3/h st

29,3 32,0 63,8 66,4 3,17

22,9 25,0 45,0 45,0 2,48

16,1 17,6 25,0 25,0 1,75

10,4 11,4 8,4 9,2 1,14

TABLE 4/b - G31

Variable heat output Air ∆p*

Gas consum.

**

(80-60°C) (50-30°C) (80-60°C) (50-30°C) G31

kW kW mm H

2

O mm H2O kg/h

29,3 32,0 68,4 70,4 1,52

21,8 23,4 45,0 45,0 1,19

15,4 16,6 25,0 25,0 0,84

10,4 11,4 9,2 9,5 0,55

Fig. 22

Heat outout (kW)

Air ∆p mm H

2

O

Heat outout (kW)

∆p de aire mm H

2

O

IT

ES

PT

GB

114

“∆p air” ADJUSTMENT

To measure “∆p air” simply con-

nect a dif ferential pressure

gauge with a decimal or Pascal

scale to the positive and negative tap, observing the symbols

(

Drawing 1

).

Sequence of operations:

1) Turn the heating power con-

trol trimmer clockwise as

far as it will go (

B – Drawing

2

) with the fan at its top

speed.

2) Attempt to achieve the “∆p

air” values given in the table

by adjusting the MAX trimmer on the fan board

(

Drawing 3

):

∆p air max.

3) Turn the heating power con-

trol trimmer anti-clockwise

as far as it will go (

B –

Drawing 2

) with the fan at

its top speed.

4) Attempt to achieve the “∆p

air” values shown in the

table using the “MIN” trimmer on the fan board

(

Drawing 3

):

∆p air min.

“∆p air-gas” ADJUSTMENT

To measure “∆p air-gas”, simply

connect the positive tap of the

differential pressure gauge to

the gas tap and the negative

tap to the corresponding tap on

the boiler (

Drawing 4

)

Always adjust gas pressure

with the fan at its top speed.

Sequence of operations:

1) Turn the heating power con-

trol trimmer anti-clockwise

as far as it will go (

B –

Drawing 5

) with the fan at

its top speed.

2) Open the gas capacity step

(

1 – Drawing 6

) all the way

so that the notch is in a horizontal position.

The boiler must always be calibrated while set on heating.

ATTENTION:

– On PROPANE – G31 boilers

it is a good idea to check

that the position of the GPL

bridge on the control board

is correct.

–

Diaphragm code 6028640

(

Drawing 7

) is assembled

on the “Dewy 25” model

functioning on PROPANE –

G31 only.

–

If the fan control board code

8260501 is replaced on

“Dewy” models running on

PROPANE – G31 it is very

important to remember to

cut the specified resistance

(

Drawing 8

).

Upon completion of the calibration procedure, check CO2values using a combustion analyser. If a difference which is more than 0.2 above

or below the values indicated in the table is found, it will be necessary to correct it:

– Use the OFFSET screw (

2 – Drawing 6

) to correct CO2at “MIN” output.

– Use the capacity step to correct CO

2

at “MAX” output (

1 – Drawing 6

).

Drawing 1

Drawing 2

Drawing 4

Drawing 6

Drawing 7

Drawing 8

Dewy 25 30

Natural gas (G20)

49,5 63,8

Propane (G31) 49,5 68,4

Dewy 25 30

Natural gas (G20)

7,1 8,4

Propane (G31) 7,1 9,2

Drawing 5

3) Adjust the gas valve OFFSET regulation (

2 – Drawing 6

), aiming

to achieve the “∆p air- gas” shown in the table:

Capacity step open

4) Using the capacity step (

1 – Drawing 6

), attempt to achieve the

“∆p air-gas” shown in the table:

Capacity step regulated

Dewy 25 30

Natural gas (G20) 7,3 7,0

Propane (G31) 8,1 10,1

Dewy 25 30

Natural gas (G20) 5,3 6,3

Propane (G31) 4,4 9,0

“Dewy 25” “Dewy 30”

CO

2

(Natural gas) CO2(Propane) CO2(Natural gas) CO2(Propane)

“MIN” output 9,3 10,2 9,0 10,1

“MAX” output 8,9 10,0 9,1 10,3

Drawing 3

MIN. MAX

“∆p air”

adjustment

4.4 BOILER CALIBRATION

Fig. 23

B

1

B

2

IT

ES

PT

GB

115

4.5 DISASSEMBLY OF

EXPANSION VESSEL

To disassemble the expansion vessel, proceed as follows:

– Make sure that the water has been emp-

tied out of the boiler.

– Unscrew the connection and the locknut.

– Remove the expansion vessel.

Before refilling the system, using a pressure gauge attached to the valve make sure

that the expansion vessel is preloaded at a

pressure of 0.8 to 1 bar.

4.6 CLEANING AND

MAINTENANCE

Preventive maintenance and checking of

efficient operation of equipment and safety

devices must be carried out exclusively by

authorized technical personnel.

During maintenance operations the

authorised technician must check that

the syphened drip is full of water (this

check is of importance particularly when

the generator has been out of use for a long

period of time). Filling is done via the special

opening (fig. 24).

4.6.1 Disassembly the control panel

and skirt cover lid (fig. 25)

To remove the cover, take out the screws

(1 – 2) that hold it in place on the instrument panel. Position side “A” of the bracket on the skirt side so that the instrument

panel is hooked on the side in order to

facilitate this operation.

4.6.2 Chimney sweep function

To carry out the verification of combustion

in the boiler, turn the selector and stop on

the position ( ) until the orange led ( )

starts to flash intermittently (fig. 29).

From that moment the boiler will start functioning in heating mode at the maximum

power, with switching off at 80°C and

restarting at 70°C.

Before activating the chimney sweep function make sure that the radiator valves or

eventual zone valves are open.

The test may be carried out also during hot

water functioning. To do so it is enough,

after having activated the chimney sweep

function, to take some hot water from one

or more taps; after a few minutes the

request of the hot-water service feeler is

activated and it automatically switches on

the led ( ). Even in this condition the boiler functions at the maximum temperature

always with the primary controlled between

80°C and 70°C. During the entire duration

of the testing the hot water taps must

remain open. After verifying the combustion

the boiler should be switched off by placing

the selector on the (OFF) position; then

return the selector to the desired function.

ATTENTION: After about 15 minutes the

chimney sweep function automatically

deactivates.

4.6.3 Cleaning the “Aqua Guard

Filter System” (fig. 27)

Model “30/80”, to clean the filter, close

the delivery/return on/off taps, turn off

the power to the control panel, remove the

casing and empty the boiler using the drain

provided. Place a container for collection

underneath the filter and proceed to clean

the filter, removing impurities and limestone deposits. Check the seal o-ring before

reassembling the cap with the filter.

Fig. 25

Side A

Side A

Fig. 26

Fig. 24

Fig. 27

FLASHING YELLOW LED

Lato A

Lato A

1

2

SPIA GIALLA INTERMITTENTE

IT

ES

PT

GB

116

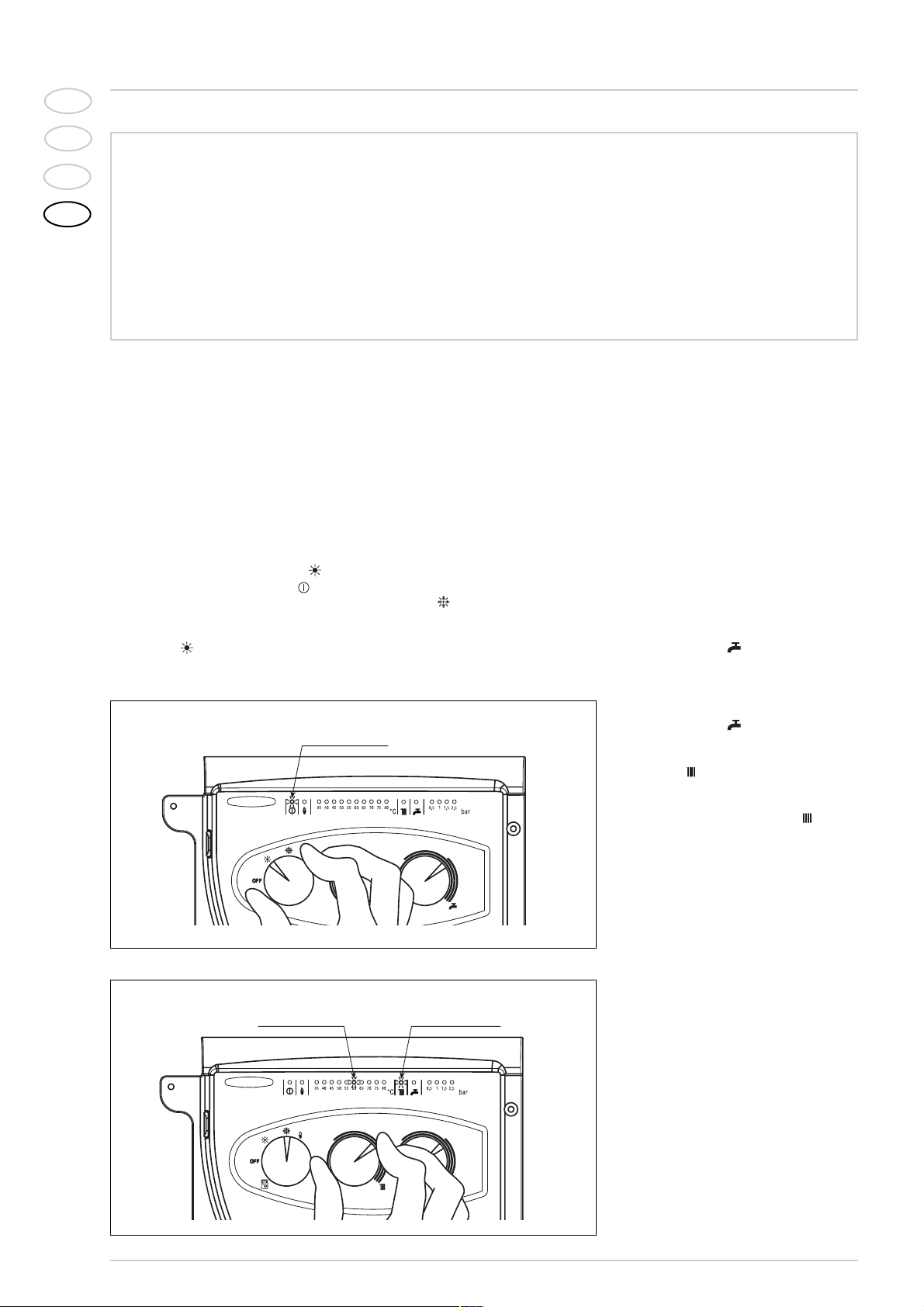

BOILER IGNITION (fig. 1)

Open the gas valve, lower the control panel

cover and activate the boiler by rotating the

selector knob to the summer positio ( ).

The lighting-up of the green led ( ) will

indicate that the apparatus is switched-on

and ready.

–

With the rotary switch in the summer

position ( ) the boiler will start-up

upon demand for domestic hot water,

and run at full power to reach the selected temperature.

The gas feeding pressure will then automatically vary to ensure that the required temperature is kept constant.

– With the rotary switch in the winter

position ( ) once the boiler has reached the value set on the heating potentiometer, it will start to modulate in automatically in order to supply the required

power output to the system. The opera-

tion of the boiler will be stopped through

the intervention of the thermostat or

“Logica Remote Control”.

TEMPERATURES ADJUSTMENT (fig. 2)

– The D.H.W. temperature can be adju-

sted by turning the knob of the D.H.W.

potentiometer ( ).

When there is a demand for hot water,

the set temperature is displayed on the

red led scale from 35÷80°C and the yellow domestic hot water led lights-up at

the same time ( ).

–

The C.H. temperature can be adjusted

by turning the knob of the C.H. potentiometer

( ).

The set temperature is indicated on the red led scale from

35÷80°C and the yellow heating led

lights up at the same time

().

If the

temperature of the blackflow water is

lower than around 55° C, condensation

of the combustion by-products is obtained, further increasing the efficency of

thew thermal exchange.

TURNING THE BOILER OFF (fig. 1)

To turn the boiler of f place the selector

knob on the OFF position. If the boiler is

not going to be used for a lengthy

period it is advised to turn of f the electricity supply, close the gas tap, and if

the temperatures foreseen are low,

empty the boiler and the hydraulic

system to avoid breakage in the tubes

due to the freezing of the water.

GAS CONVERSION

Should it be necessary to conver t the

appliance to a different gas from the one

for which the boiler has been equipped,

approach the technical staff.

WARNINGS

– In case of fault and/or incorrect equipment operation, deactivate it, without making any repairs or taking any direct

action. Contact an authorised technical staff.

– The installation of the boiler and any servicing or maintenance job must be carried out by qualified personnel. Under

no circumstances, the devices sealed by the manufacturer can be tampered with.

– It is absolutely prohibited to block the intake grilles and the aeration opening of the room where the equipment is

installed.

LIGHTING AND OPERATION

Fig. 1

Fig. 2

GREEN LED

RED LED YELLOW LED

USER INSTRUCTIONS

SPIA VERDE

SPIA GIALLASPIA ROSSA

IT

ES

PT

GB

117

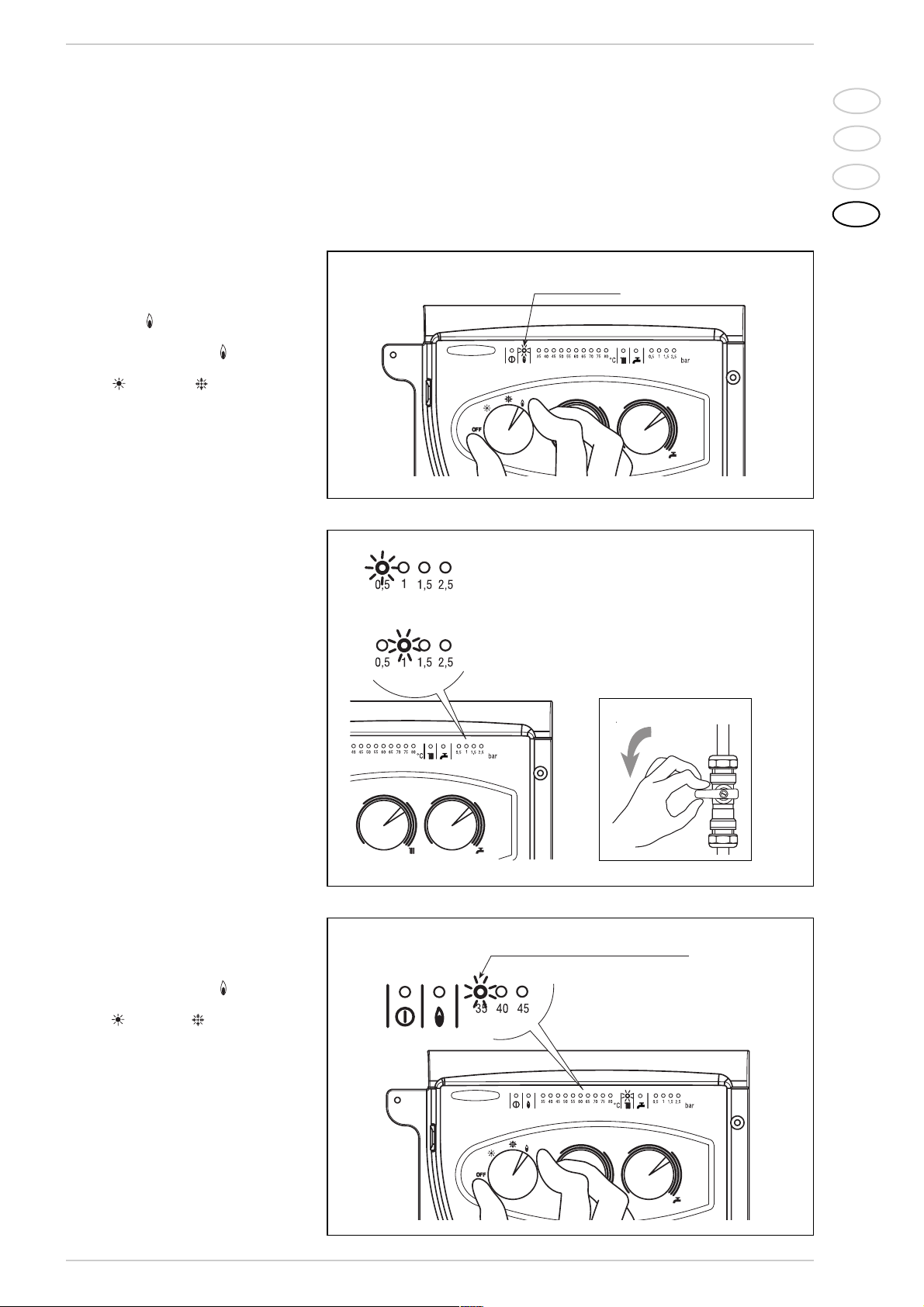

FAULT FINDING

–

Ignition lock-out

(fig. 3)

If the burners do not ignite, the red led

will light-up

( ).

To attempt a boiler restart, rotate the

selector knob to position

()

and release it immediately, placing it in the summer

()

or winter

()

operation posi-

tion

.

If the boiler lock-out re-occurs, contact

an authorised Service Centre.

–

Insufficient water pressure

(fig. 4)

If the red "0.5" bar led star ts flashing,

the boiler will not function.

To restart operation, rotate the charge

valve anticlockwise until the green "1

bar" led lights up.

ONCE THE FILLING HAS BEEN COMPLETED, CLOSE THE FILLING TAP.

If all the leds are off, call the local authorised Service Centre for technical assistance.

–

Safety stat trip

(fig. 5)

If the safety thermostat trips, the red

"35°C" led will start flashing. In order to

attempt a boiler restart, rotate the

selector knob to position ( ) and release immediately, returning it to the summer ( ) or winter ( ) position.

If the boiler lock-out occurs again, call

local authorised Service Centre for

technical assistance.

CLEANING

AND MAINTENANCE

Preventive maintenance and checking

of the efficient operation of the equipment and safety devices must be carried out exclusively by the authorized

technical staff.

The boiler is supplied with an electric

cable. Should this require replacement,

contact exclusively with the authorized

technical staff.

Fig. 3

Fig. 4

SPIA ROSSA INTERMITTENTE

IN CONDIZIONE DI SICUREZZA

SPIA VERDE IN CONDIZIONE

DI FUNZIONAMENTO

APRE

Fig. 5

RED LED

FLASHING RED LED

FLASHING RED LED

IN SAFETY CONDITION

GREEN LED IN OPERATING

CONDITION

OPEN

SPIA ROSSA

SPIA ROSSA INTERMITTENTE

IT

ES

PT

GB

118

–

Other anomalies

(fig. 6)

When one of the red

“40÷80°C”

leds

start flashing, switch-off the boiler and

then try to ignite again.

After 2 or 3 unsuccessful attempts, do

not try again but call authorised technical staff.

When “DEWY” is connected to the “Logica

Remote Control” regulator, the selector

CR/OFF/SUM/WIN/UNBLOCK must be

placed in the position ( ); the knobs of the

hot-water service heating potentiometers

do not have any ef fect and all of the functions will be managed by the regulator (fig.

7).

If the “Logica Remote Control” breaks

down, the boiler will function by placing the

selector on the ( o ), position, obviously without consequent control of the room

temperature.

No interior da tampa estão indicadas as

instruções de funcionamento (fig. 8). Cada

programação ou modificação é visualizada

e confirmada no display (fig. 9).

LOGICA REMOTE CONTROL

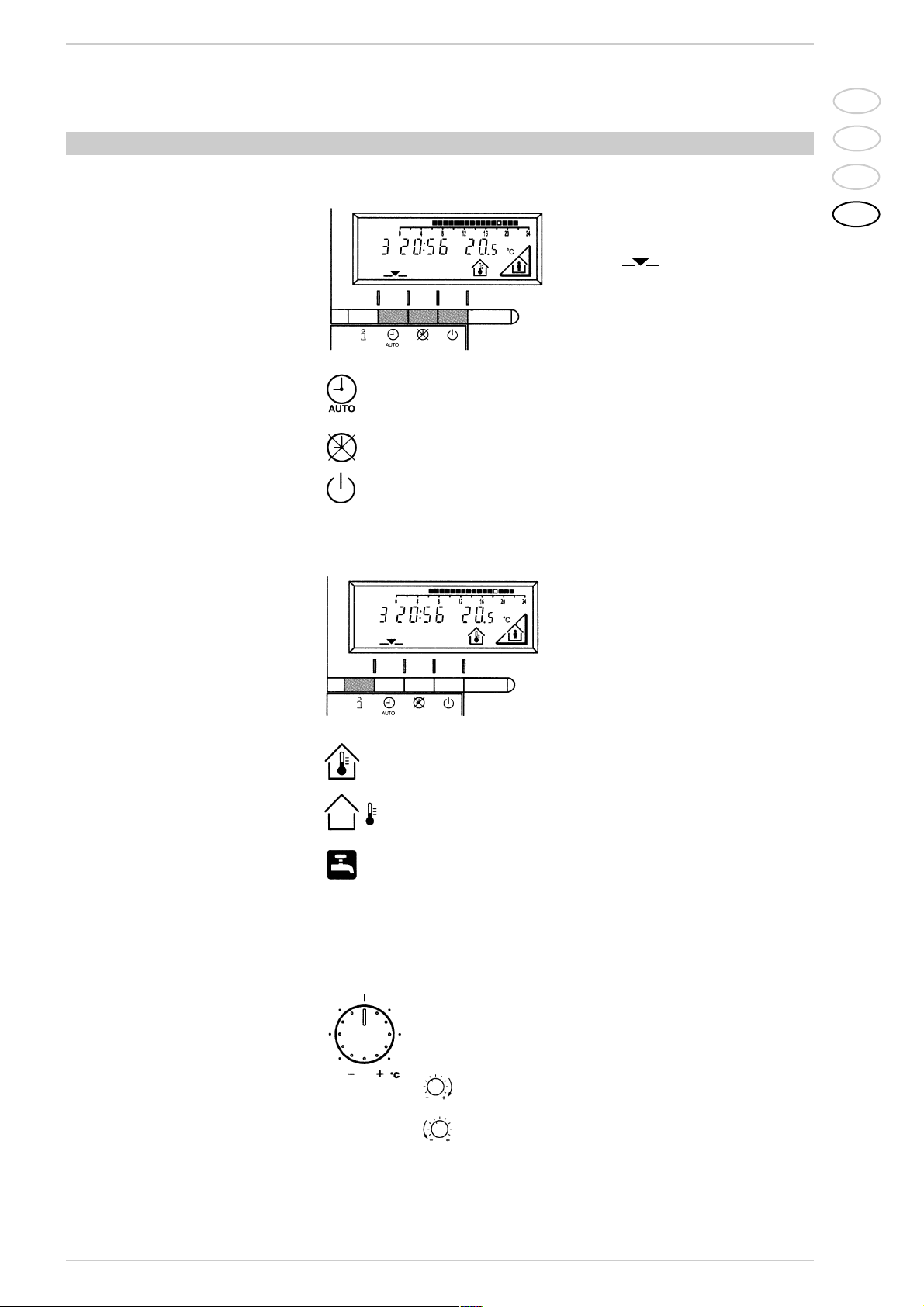

KEY

1 Display

2 Info button

3 Operating mode button: automatic operation

4 Operating mode button: manual operation

5 Operating mode button: availability

6 Cover with instruction compartment

7 Temperature knob

8 Presence button

Fig. 8

KEY

1 Display, time

2 Heating programme

3 Unit (%/C°)

4 Presence button display

5 External temperature

6 Ambient temperature

7 Holiday function

8 Operating mode

9 Line number/day

10 Burner on

11 Heating function

12 Domestic hot water/temperature/D.H.W. load

Fig. 9

Fig. 7

Fig. 6

FLASHING RED LED

SPIA ROSSA INTERMITTENTE

1

2

3

4

5

6

7

8

IT

ES

PT

GB

119

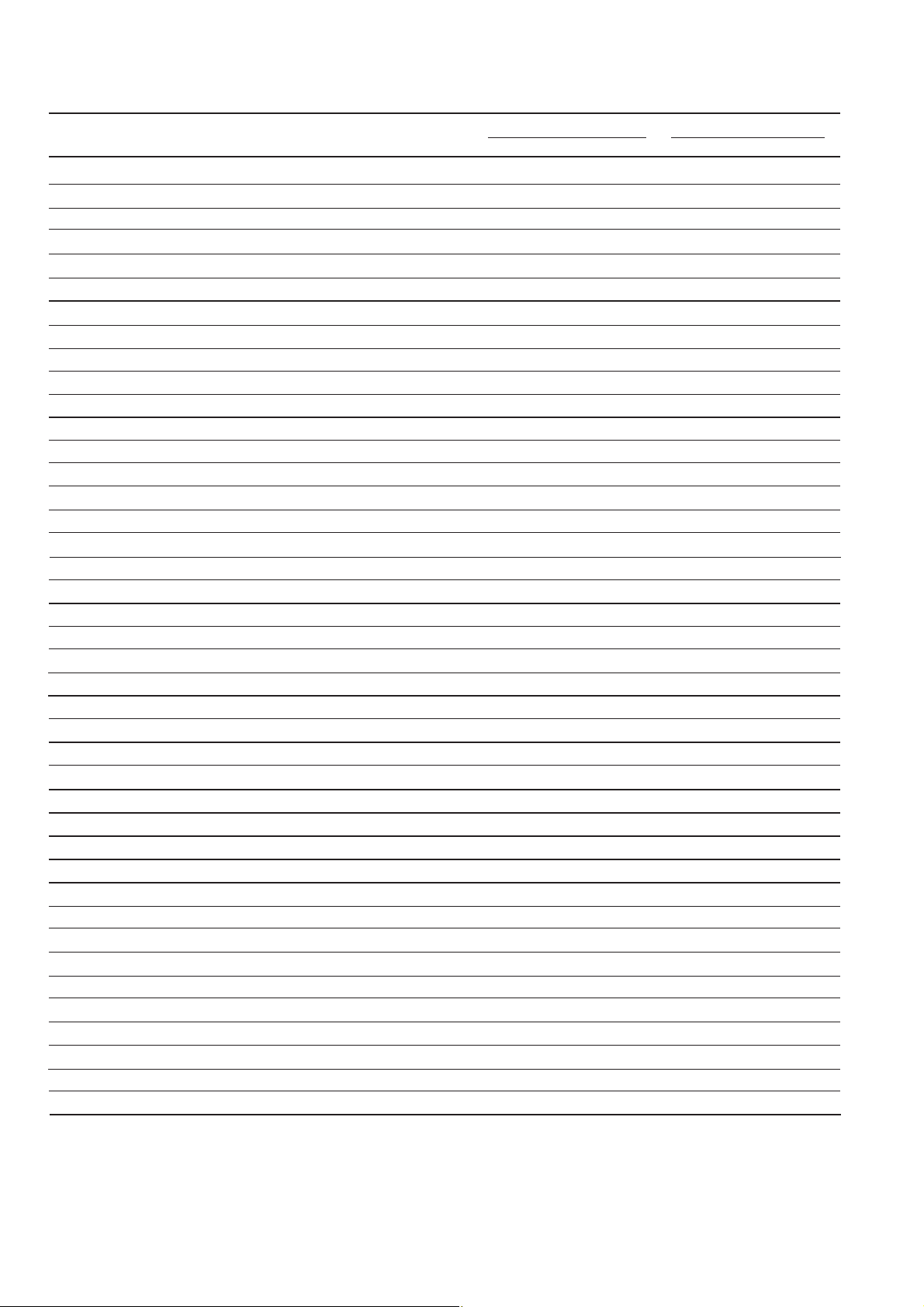

If it is too hot or too cold in your apartment, you can easily adjust the fixed

temperature with the temperature knob.

Before adjusting it again, however, allow the temperature to stabilise first.

Note: With the temperature knob you can only adjust the fixed temperature, whilst the redu-

ced temperature remains the same.

– Adjusting the temperature

If you turn the knob towards the + sign, the fixed temperature is

increased by about 1 °C for every notch.

If you turn the knob towards the - sign, the fixed temperature is

decreased by about 1 °C for every notch.

Before adjusting the temperature of the regulator, the thermostatic valves, which may be

present, have to be regulated to the desired temperature.

For every operation of the Info key the following list of items, one af ter the other, are

displayed. The thermo-feeler continues to

function independently of the display.

Day, hour, room temperature

External temperature*

Hot-water service temperature*

* This data appear only if the relative feeler is

connected or if they are transmitted by the

regulator of the boiler.

– Info key

(reference key grey colour)

The operating mode desired is selected by

pressing the relative key with the corresponding symbol. The choice is displayed with the

symbol

Automatic functioning: the heating functions automatically according to the heating programme entered. The programme may be excluded for brief periods with

the on-line key.

Manual functioning: the heating functions manually according to the choice made

with the on-line key.

Availability: the heating is deactivated.

– Selection of the operating mode

(reference keys grey colour)

ACTIVATING

During functioning the lid of the regulator must be closed.

IT

ES

PT

GB

120

– Setting the time

To set the current day of the week

(1 = Monday/7 = Sunday)

To set the current hour

To set the current minute

Once the hour is completed, the setting of the hour changes.

12

13

14

With and keys the current hour is regulated. Pressing these keys together, the

regulation is speeded up in an increasing sense.

If the rooms remain unused for a long period of time, the temperature can be reduced with the on-line key, in this way saving energy. When

the rooms are occupied again, press the on-line key to re-heat them.

The current choice is displayed on the display:

– On-line key

Fixed temperature heating

Reduced temperature heating

NOTA:

In automatic mode, the apparatus switches from the fixed temperature to the reduced temperature according to the temporal programme. The manual switching of the temperature is

done manually with the on-line key.

– Temperature regulation

Fixed temperature:

temperature when the rooms are occupied

(basic setting)

Reduced temperature:

temperature during periods of absence or night

Hot-water service temperature:

– desired temperature of hot-water service

– comfort temperature of the hot-water service

(with storage capacity boiler unit)

Reduced temperature of hot-water service (with storage capacity boiler unit):

temperature desired for hot-water service at reduced level.

To have access to the “reduced hot-water service temperature” parameter, press

the and keys at the same time for at least 5 seconds and then go along

the entered lines with the key until parameter 61 is reached. Regulate the value

with and

.

Before proceeding with the adjustment in the temperature on the regulator, the thermostatic valves, which may be present, have to be regulated to the desired temperature.

1

2

3

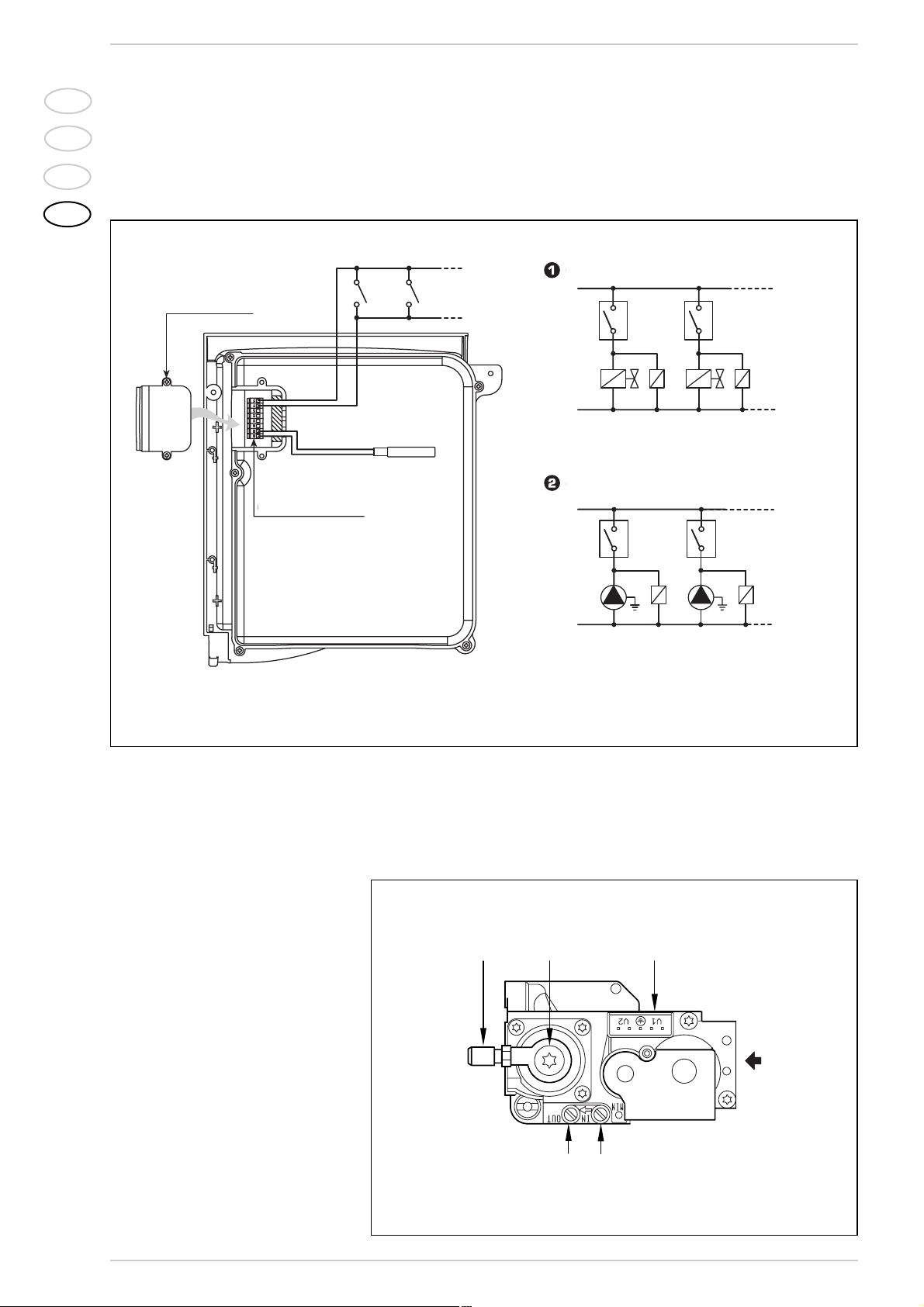

61