CONTENTS

1 DESCRIPTION OF THE BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3 CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4 USE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

IMPORTANT

When carrying out commissioning of the boiler, you are highly recommended to perform the following checks:

– Make sure that there are no liquids or inflammable materials in the immediate vicinity of the boiler.

– Make sure that the electrical connections have been made correctly and that the earth wire is connected to a good

earthing system.

– Check that the flue pipe for the outlet of the products of the combustion is unobstructed.

– Make sure that any shutoff valves are open.

– Make sure that the system is charged with water and is thoroughly vented.

– Check that the circulator is not blocked.

INSTALLER INSTRUCTIONS

AQUA OF/BF

ENGLISH

1.1 INTRODUCTION

One of the features of the cast iron

thermal group with the integrated gasoil burner is its functional silence and it

has been designed in accordance with

the european directives CEE 92/42.

The perfectly balanced combustion

and the high yield allows it to

economise considerably the operating

costs. The instructions relative to the

following models are indicated in the

present manual:

–

“AQUA 30-40 OF” for heating and

hot water production with accumulative tank.

–

“AQUA 30-40 BF” for heating and

hot water production with accumulative tank and airtight combustion

burner.

The instructions given in this manual

are provided to ensure proper installation and perfect operation of the appliance and should be strictly followed.

66

1 DESCRIPTION OF THE BOILER

1.2 DIMENSIONS

550

1430

A

850

70

215

1230

340825

515

12 5

200

90

107 5

1230

825

515

12 5

200

90

107 5

215

70

340

U

C

E

U

C

E

75

75

S1

M

R

S2

S1

M

R

S2

ø80/125

ø130

Versione “BF”

Versione “OF”

=

=

=

=

Fig. 1

KEY

M C.H. flow G 1” (UNI-ISO 228/1)

R C.H. return G 1” (UNI-ISO 228/1)

U D.H.W. outlet G 3/4” (UNI-ISO 228/1)

E D.H.W. inlet G 3/4” (UNI-ISO 228/1)

C Recirculation G 3/4” (UNI-ISO 228/1)

S Boiler drain

S1 System safety valve drain

S2 Boiler safety valve drain

550

ø80/125

ø130

Versione “BF”

Versione “OF”

850

A

1430

69 231,5

65

65

879

288

239

14 5

16 5

14 516 5

65

65

879

239

288

512,5

512,5

69

231,5

S2

U

C

E

S1

M

R

S

S2

U

C

E

S1

M

R

S

AQUA 30 BF AQUA 40 BF

Amm 75 175

AQUA 30 - 40 OF/BF

AQUA 30 - 40 OF/BF INOX

“BF” version “OF” version

“BF” version “OF” version

67

1.3 TECHNICAL FEATURES

AQUA 30 OF/BF AQUA 40 OF/BF AQUA 30 OF/BF INOX AQUA 40 OF/BF INOX

Heat output * kW 31.3 (27.5) 40.0 (35.2) 31.3 (27.5) 40.0 (35.2)

kcal/h 26,900 (23,700) 34,400 (30,300) 26,900 (23,700) 34,400 (30,300)

Heat input * kW 34.8 (30.6) 44.3 (39.0) 34.8 (30.6) 44.3 (39.0)

kcal/h 29,900 (26,300) 38,100 (33,500) 29,900 (26,300) 38,100 (33,500)

Type B

23 B23 B23 B23

Elements n° 4 5 4 5

Maximum water head bar 4 4 4 4

Water content l 28 33 24.5 30.5

Expansion vessel

Water content/Preloading pressure l/bar 10/1 12/1 10/1 12/1

Loss of head smoke mbar 0.16 0.21 0.16 0.21

Combustion chamber pressure ** mbar – 0.02 – 0.05 – 0.02 – 0.05

Suggested chimney depression ** mbar 0.18 0.23 0.18 0.23

Smoke temperature ° C 185 18 5 18 5 185

Smoke flow * m

3

n/h 41.4 (35.9) 52.8 (46.3) 41.4 (35.9) 52.8 (46.3)

CO

2 % 12.5 12.5 12.5 12.5

Maximum temperature °C 95 95 95 95

Power consumption “OF/BF” W 200/230 180/210 200/230 180/210

Adjustment range heating °C 45÷85 45÷85 45÷85 45÷85

Adjustment range D.H.W. °C 30÷60 30÷60 30÷60 30÷60

D.H.W. production

Tank capacity l 120 120 110 110

D.H.W. flow rate EN 625 l/min 20.9 20.9 20.9 20.9

Contin. D.H.W. flow rate ∆t 30°C * l/h 840 (790) 840 830 (780) 830

D.H.W. expansion vessel l 4 4 4 4

D.H.W. tank maximum water head bar 7 7 7 7

Gas-oil burner ***

Burner nozzle * 0.75 60°W 0.85 60°W 0.75 60°W 0.85 60°W

(0.65 60°W) (0.85 60°W) (0.65 60°W) (0.85 60°W)

Pump pressure * bar 14 (14) 14 (12) 14 (14) 14 (12)

Shutter regulator position for “OF” version * 5.2 (4.1) 6.2 (5.3) 5.2 (4.1) 6.2 (5.3)

Shutter regulator position for “BF” version * 4.1 (4.0) 3.6 (2.4) 4.1 (4.0) 3.6 (2.4)

Diaphragm position for “BF” version * G (D)

_

G (D)

_

Weight kg 226 254 220 247

* The date shown between the brackets refer to the factory settings

** For “OF” versions only

*** Calibration values with the coaxial drain terminal code 8096220 installed

68

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

5

17

18

19

20

Fig. 2

1.4 MAIN COMPONENTS

1.4.1 “AQUA 30-40 OF/BF” version

KEY

1 Boiler drainer cock

2 Tank drainer cock

3 120 litre tank

4 Tank pump

5 Control valve

6 Gas-oil burner

7 Hublot

8 Bulb housing sheath

9 Control panel

10 Expansion vessel

11 System safety valve 3 BAR

12 Water switch

13 Air intake for airtight burner

(“BF” versions)

14 Hydrometer

15 System pump

17 Filling

18 Tank safety valve 7 BAR

19 Tank expansion vessel

20 Magnesium anode

69

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

5

Fig. 2/a

1.4.2 “AQUA 30-40 OF/BF INOX” version

16

KEY

1 Gas-oil burner

2 Hublot

3 Filling

4 Tank pump

5 Control valve

6 Tank expansion vessel

7 Control panel

8 Expansion vessel

9 110 litre tank in inox

10 Bulb housing sheath

11 Water switch

12 System safety valve 3 BAR

13 Air intake for airtight burner

(“BF” versions)

14 Hydrometer

15 System pump

16 Magnesium anode

70

1

2

34

5

6

7

8

9

8

14

10

11

12

19

18

17

16

15

Fig. 3

1.5 FUNCTIONAL DIAGRAM

1.5.1 “AQUA 30-40 OF/Bf” version

Fig. 3/a

1.5.2 “AQUA 30-40 OF/BF INOX” version

KEY

1 System safety valve

2 System expansion vessel

3 Boiler body

4 Air relief valve

5 Water switch

6 Hydrometer

7 System pump

8 Control valve

9 Gas-oil burner

10 Filling

11 Tank safety valve

12 Tank expansion vessel

14 Tank pump

15 Tank drainer cock

16 Boiler drainer cock

17 Magnesium anode

18 D.H.W. probe

19 120 litre tank

KEY

1 Boiler body

2 Hydrometer

3 Air relief valve

4 System pump

5 Tank pump

6 Control valve

7 Tank expansion vessel

8 Tank safety valve

9 Magnesium anode

10 Tank drainer cock

11 System expansion vessel

12 Boiler drainer cock

13 Filling

14 System safety valve

15 Gas-oil burner

16 110 litre tank

17 Water switch

2.1 BOILER ROOM

The boilers with a rating of more than

35 kW must be equipped with a technical room whose dimensions and

requirements correspond to the current standards and regulations.

The minimum distance between the

walls of the room and the boiler must

not be less than 0.60 m., while the minimum height between the top of the

boiler and the ceiling must be at least 1

m. which can be reduced to 0.50 m.

for boilers with incorporated heaters

(however the minimum height of the

boiler room must not be less than 2,5

m). The boilers with a rating of less

than 35 kW can be installed only in

perfectly air-vented rooms.

To circulate air in the room, air vents

must be made on the outside walls

which satisfy the following requirements:

– Have a total surface area of at least

6 cm

2

for each installed Kw of thermal capacity and however not less

than 100 cm

2

.

– To be situated as close as possible

to the floor, unobstructable and protected by a grate which does not

reduce the air passage area.

2.2 CONNECTING UP SYSTEM

Before proceeding to connect up the

boiler, you are recommended to make

the water circulate in the piping in

order to eliminate any foreign bodies

that might be detrimental to the operating efficiency of the appliance.

For connecting up the pipes, make

sure to follow the indications illustrated in fig. 1.

The connections should be easy to disconnect using pipe unions with orientable connections.

The shutoff valve must be connected

to a suitable flow system and return

pipes.

2.2.1 System filling

The boiler and the relative system

must be filled operating on the bearing

tap and the pressure of cold charging

the system must be included between

1 - 1.2 bar. During filling the main

switch should be left open.

Filling must be done slowly so as to

allow any air bubbles to be bled off

through the provided air vents.

This operation can be made easy by

positioning horizontally the incision of

the block screw of the shutoff valve.

Upon completing the filling, put the

screw back to its original position. At

the end of the operation make sure

that the tap is closed (fig. 4).

2.2.2 D.H.W. production

In order that the boiler be capable of

supplying treated water, all the air in

the boiler’s serpentine must be bled

off at the first ignition. This operation

is made easy by positioning horizontally the incision of the block screw of

the shutoff valve (5 fig. 2-2/a). After

all the air has been bled off, put the

screw back to its original position.

2.2.3 Characteristics of feedwater

To prevent lime scale and damage to

the tap water exchanger, the water

supplied should have a hardness of no

more than 20°F.

In all cases the water used should be

tested and adequate treatment devices should be installed.

To prevent lime scale or deposits on

the primary exchanger, the water used

to supply the heating circuit should

must be treated in accordance with

UNI-CTI 8065 standards. It is absolutely essential that the water is to be

treated in the following cases:

– Very extensive systems (with high

contents of feedwater).

– Frequent addition of makeup water

into the system.

– In case it is necessary to empty the

system either partially or totally.

2.3 SMOKE EXHAUST

2.3.1 Connecting up flue

The flue is of fundamental importance

for the proper operation of the boiler;

if not installed in compliance with the

standards, starting the boiler will be

difficult and there will be a consequent

formation of soot, condensation and

encrustation.

A flue therefore must satisfy the following requirements:

– be constructed with waterproof

materials and resistant to smoke

temperature and condensate;

– be of adequate mechanical resilience

and of low heat conductivity;

– be perfectly sealed to prevent cool-

ing of the flue itself:

– be as vertical as possible; the termi-

nal section of the flue must be fitted

with a static exhaust device that

ensures constant and efficient

extraction of products generated by

combustion;

–

to prevent the wind from creating

pressure zones around the chimney top greater than the uplift

force of combustion gases, the

exhaust outlet should be at least

0.4 m higher than structures adjacent to the stack (including the roof

top) within 8 m;

– have a diameter that is not inferior

to that of the boiler union: square or

rectangular-section flues should

have an internal section 10%

greater than that of the boiler union;

– the useful section of the flue must

conform to the following formula:

71

2 INSTALLATION

Fig. 4

OPEN

S resulting section in cm

2

K reduction coefficient for liquid

fuels: 0.024

P boiler input in Kcal/h

H

height of the flue in meters mea-

sured from the flame axis to the

flue outlet into the atmosphere.

When dimensioning the flue, the

effective height of the flue in

meters must be considered,

measured from the flame axis to

the top of the flue, reduced by:

– 0.50 m for each change of

direction of the connection

union between boiler and flue;

– 1.00 for each horizontal

metre of the union itself.

Our boilers are the B

23 type and do

not need any particular connections

other than the one to the flue as

described above.

2.3.2 Smoke exhaust with

ø 80/125 coaxial flue

“BF” version boilers are set to be

connected to ø 80/125 stainless

steel coaxial flues that can be adjusted to the most suitable direction

for room requirements (fig. 6).

The maximum acceptable length of

the flue must not be over 7.0 equivalent meters.

Load losses in meters for each single accessory to be used in the

exhaust configuration are indicated

in Table A.

Only use original SIME accessories

and make sure that connections are

correct as indicated in the instructions supplied with the accessories.

2.4 FUEL ADDUCTION

The fuel can be fed into the thermal

group sideways, the ducts must be

passed through the aperture on the

72

P

S=K

√H

1

2

3

4

2

5

6

7

7

3

3

ø 80/125

min. 715

KEY

1 Stainless steel coaxial flue L. 886 code 8096220

2a Stainless steel extension L. 1000 code 8096121

2b Stainless steel extension L. 500 code 8096120

3a 90° stainless steel curve MF code 8095820

3b 45° stainless steel curve MF code 8095920

4 Stainless steel vertical condensation recovery L. 135 code 8092820

5 Tile with hinge code 8091300

6 Roof outlet terminal L. 1063 code 8091203

7 Kit code 8098810

Fig. 6

TABLE A

Load loss (mt)

90° stainless steel curve MF 1,80

45° stainless steel curve MF 0,90

Stainless steel extension L. 1000 1,00

Stainless steel extension L. 500 0,50

Roof outlet terminal L. 1063 1,00

Stainless steel coaxial flue L. 886 0,70

Stainless steel vertical condensation recovery L. 135 0,70

WARNING:

The maximum acceptable length of the flue must not be over 7.0 equivalent meters.

Always use the condensation recovery (4) in outlets with vertical exhaust.

right or left hand side of the shell for

connection to the pump (fig. 7 - 7/a).

Important

– Make sure, before turning on the

boiler, that the return tube is free.

An excessive counter-pressure

would break the pump seal.

– Make sure that the tubes are

sealed.

– The maximum depression of 0.4 bar

(300 mmHg) (see

Table 1

) must not

be exceeded. Gas is freed from the

fuel above that value and can cause

cavitation of the pump.

– It’s advisable to bring the return

tube in the depression systems up

to the same height of the intake

tube. In this case the foot valve is

unnecessary.

If instead the return tube arrives

above the fuel level, the foot valve is

indispensable.

Starting the pump

Turn on the burner to start the pump

and check the flame ignition.

If a “lock out” occurs before fuel

arrival, wait for at least 20 seconds

then press the burner release button

“RESET” and wait for the whole startup operation to repeat until the flame

lights up.

2.5 BURNER ADJUSTMENTS

Each unit is shipped with a burner unit

equipped with a nozzle and calibrated

at the factory; it is recommended,

however, that the settings listed under

point 1.3 be checked, with reference

to atmospheric pressure at sea level.

If it is necessary to adjust the burner

differently from the factory settings,

this should be done by authorised personnel following the instructions provided below.

Remove the shell door to access the

burner unit’s controls.

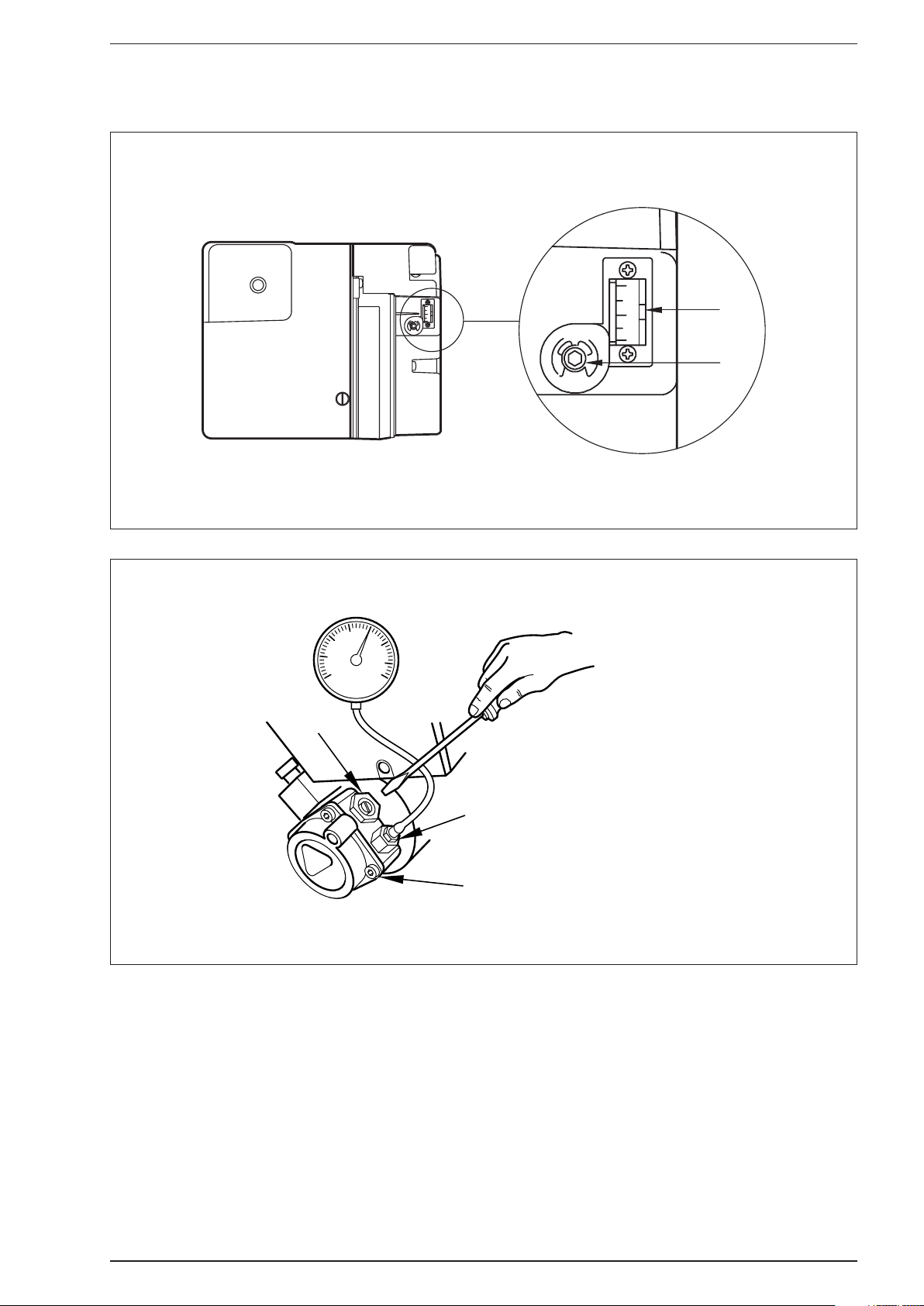

2.5.1 Air lock adjustment

To adjust the air lock, loosen the screw

(1 fig. 8) and slide the graduated scale

(2 fig. 8) indicating the position air lock

position.

The values for adjustment of each unit

are given in point 1.3.

2.5.2 Pump pressure adjustment

To adjust gas-oil pressure, turn the

screw (3 fig. 8/a) and check pressure

with a pressure gauche connected to

the intake (2 fig. 8/a), making sure

pressure corresponds to the value

given under point 1.3.

73

H max 4 mH

H

1

2

3

4

5

6

7

8

10 99

Fig. 7

Fig. 7/a

H L (meters)

meters øi tube øi tube

8 mm 10 mm

035100

0,5 30 100

125100

1, 5 2 0 9 0

215 70

38 30

3,5 6 20

CONNECTIONS

1 Vacuometer attachment

2 Pressure regulator

3 Manometer attachment

4 By-pass screw

5 Back-flow flexible pipe

(included in supply)

6 Suction flexible pipe

(included in supply)

7 Auxiliary pressure intake

8Valve

9 Racor 3/8” (included in supply)

10 Fuel feed line filter

(included in supply)

ATTENTION:

- loosen the pump joints (5-6) before pointing the flexible pipes for

bringing them out from the prefixed opening on the right/left hand

side of the shell. Afterwards tighten the joints to the pump.

- The pump is prearranged for the double-tube function. Remove the

by-pass screw (4) for single tube function.

H = Difference in level

L = Maximum length

of the intake tube

TABLE 1

2.6 HEATER UNIT

In “AQUA 30 OF/BF” and “AQUA 30

OF/BF INOX” models, the heater unit

comes on with the consensus of the

burner, after a delay of a maximum of

90 seconds required to bring fuel in

the nozzle holder area up to a temperature of 65°C.

Once this temperature has been

reached, the thermostat, which is

located above the preheater (1 fig.

14/b), will give consensus for the

burner to start. The heater will remain

on for as long as the burner stays on

and go off when the burne goes off.

NOTE:

“AQUA 40 OF/BF” and “AQUA

40 OF/BF INOX” model have no

heater unit, as it is not required.

2.7 ELECTRICAL CONNECTION

The boiler is supplied with an electric

cable and the electric power supply to

the boiler must be 230V-50Hz singlephase through a fused main switch.

The stat cable, whose installation is

compulsory for obtaining a better

adjustment of the room temperature,

must be connected as shown in fig. 99/a.

NOTE:

Device must be connected to an efficient earthing system.

SIME declines all responsibility for

injury or damage to persons

resulting from the failure to provide for proper earthing of the

appliance.

Always turn off the power supply

before doing any work on the electrical panel.

74

1

2

5

6

7

RESET

TWICE

ONLY

12

1

2

3

bar

KEY

1 Gas-oil pump

2 Pressure gauche intake

3 Pressure adjustment screw

Fig. 8

Fig. 8/a

75

2.7.1 “AQUA OF/BF - AQUA OF/BF INOX” wiring diagram

Fig. 9

KEY

IG Main switch

TB Tank stat

R Relay

TL Limit stat

TS Safety stat

EI Summer/Winter switch

TC Boiler stat

SPA Water pressure gauge triggered light

SA Power on light

SB Burner “lock out” warning light

PA Water switch

PI C.H. pump

PB Tank pump

B Gas-oil burner

TA Room stat

OP Timer programmer (optional)

TI Anti thermal inertia thermostat

NOTE:

When connecting the room stat (TA) remove the

bridge between terminals 20-21

When connecting the Timer Programmer (OP)

remove the bridge between terminals 30-31.

76

2.7.2 “AQUA OF/BF - AQUA OF/BF INOX” wiring diagram with optional RVA 43.222 unit

Fig. 9/a

KEY

IG Main switch

TB Tank stat

R Relay

TL Limit stat

TS Safety stat

EI Summer/Winter switch

TC Boiler stat

SPA Water pressure gauge triggered light

SA Power on light

SB Burner “lock out” warning light

PA Water switch

PI C.H. pump

PB Tank pump

B Gas-oil burner

TA Room stat

C RVA 43.222 control unit connectors (optional)

SS Type QAZ21 boiler immersion probe (optional)

SC Type QAZ21 boiler immersion probe (optional)

SE Outdoor temperature probe QAC31 (optional)

UA Type QAA70 room thermometer (optional)

TI Anti thermal inertia thermostat

NOTE: When connecting the RV 43 222 unit remove the

bridge between terminals 20-21 and remove the relay (R).

77

~

5 s

~

12 s

~

12 s0÷150 s 0÷150 s

2.7.3 “AQUA 30 OF/BF - AQUA 30 OF/BF INOX” functional diagram

Consensus for start-up

Heater stat

Heater

Motor

Ignition transform.

Gas-oil valve

Flame

Stop light

Normal Stopped due to failure to ignite

~

5 s

~

12 s

~

12 s

Consensus for start-up

Motor

Ignition transform.

Gas-oil valve

Flame

Stop light

2.7.4 “AQUA 40 OF/BF - AQUA 40 OF/BF INOX” functional diagram

Normal Stopped due to failure to ignite

78

3.1 COMBUSTION CHAMBER

DIMENSIONS

The combustion chamber is a direct

passage type and is conform to the EN

303-3 standard annex E. The dimensions are shown in fig. 10. An adequate protection panel is mounted on

the inside wall of the rear head of all

the models.

3.2 SYSTEM AVAILABLE HEAD

The head available for the heating

plant is shown as a function of the

flow in graph in fig. 11.

3.3 ANTI THERMAL

INERTIA THERMOSTAT

The purpose of the anti thermal inertia

thermostat (TI) is to restart the boiling

unit pump when the boiler reaches the

temperature of 90°C, discharging the

excess heat due to the thermal inertia

of the cast iron body towards the boiling unit. The circulator will automatically stop working as soon as the boiler

temperature falls below 90°C.

4.1 RVA 43.222 UNIT

(optional)

The control panel allows the use della

centralina RVA 43.222 supplied in kit

form upon request, complete with

mounting instructions (fig. 12).

Make the electric connection as

shown in point 2.7.

4.2 TANK MAINTENANCE

The preparation of hot treated water

is guaranteed by a heater in INOX AISI

316L, complete with magnesium

anode for protecting the heater and

inspection flange for control and

cleaning.

The magnesium anode (20 fig. 2 - 16

fig. 2/a) should be periodically controlled and substituted whenever

worn out.

3 CHARACTERISTICS

4 USE AND MAINTENANCE

L Volume

mm dm

3

AQUA 30 405 24,0

AQUA 40 505 30,5

Fig. 12

L

270

280

Fig. 10

0

200

1600

140012001000800600400

P OR TATA (l/h)

PREVALENZA RESIDUA (mbar)

500

400

10 0

200

300

AQUA - AQUA INOX - ESTELLE B INOX

1800

Fig. 11

FLOW RATE (l/h)

RESIDUAL HEAD (mbar)

REMOVE

79

4.4 DISASSEMBLY

OF OUTER CASING

The shell can be completely disassembled for an easy maintenance of the

boiler by following the numeric steps

shown in fig. 13.

4.5 DISASSEMBLY

OF EXPANSION VESSEL

The heating expansion tank is disassembled in the following manner:

– Make sure that the boiler has been

emptied of water.

– Unscrew the union which connects

the expansion tank.

– Remove the expansion tank.

Before filling up the system make sure

that the expansion tank is reloaded at

the pressure of 0.8 ÷ 1 bar.

3

8

4

1

2

7

5

6

7

8

3

9

4

1

6

5

2

Fig. 13

AQUA 30 - 40 OF/BF

AQUA 30 - 40 OF/BF INOX

4.6 BURNER MAINTENANCE

To dismantle the burner from the boiler

door, remove the nut (fig. 14).

–

To access the internal part of the

burner, remove the air lock unit

held in place by two screws to the

sides and remove the right hand

shell, which is held in place by four

screws, taking care not to damage

the O-ring seal. OR.

– To dismantle the nozzle holder and

heater unit, proceed as follows:

– open the cover, which is held in

place by a screw, and remove the

heater cables (1 fig. 14/a) protected by a heat resistant sheath;

remove the fairlead and pass the

cables through the hole.

– remove the two cables from the

ignition electrodes fastened in

place with a faston.

–

loosen the union (2 fig. 14/a) and

remove the four screws which fasten the collar (3 fig. 14/a) to the

burner.

– To dismantle the eater or thermo-

stat, refer to figure 14/b.

4.7 CLEANING

AND MAINTENANCE

Preventive maintenance and checking

of the efficient operation of the equipment and safety devices must be carried out at the end of each heating

season exclusively by the authorised

technical staff.

4.7.1 Cleaning smoke ducts

Use an adequate swab for cleaning

the smoke ducts of the boiler. After

cleaning, position the circulators in

their original position (fig. 15).

4.7.2 Cleaning combustion head

The combustion head is cleaned in the

following manner (fig. 16):

– Disconnect the high tension cables

from the electrodes.

– Unscrew the fixture screws of the

circulator support and remove it.

– Brush the propeller delicately (tur-

bulence disc).

– Carefully clean the photo-resistance

of eventual deposits of dirt deposited on its surface.

– Clean the remaining components of

the combustion head of eventual

deposits.

80

Fig. 14

2

1

3

Fig. 14/a

2

1

3

Fig. 14/b

RONDO' 3/4 OF

ESTELLE 3/4 OF

RONDO' 5/6 OF

ESTELLE 5/6 OF

Fig. 15

KEY

1 Control bow cables

2 Connection

3 Collar

KEY

1 Heater stat

2 Cap

3 Heater

81

– Upon completion re-assemble the

unit in the opposite way as

described above taking care to

respect the indicated measurements.

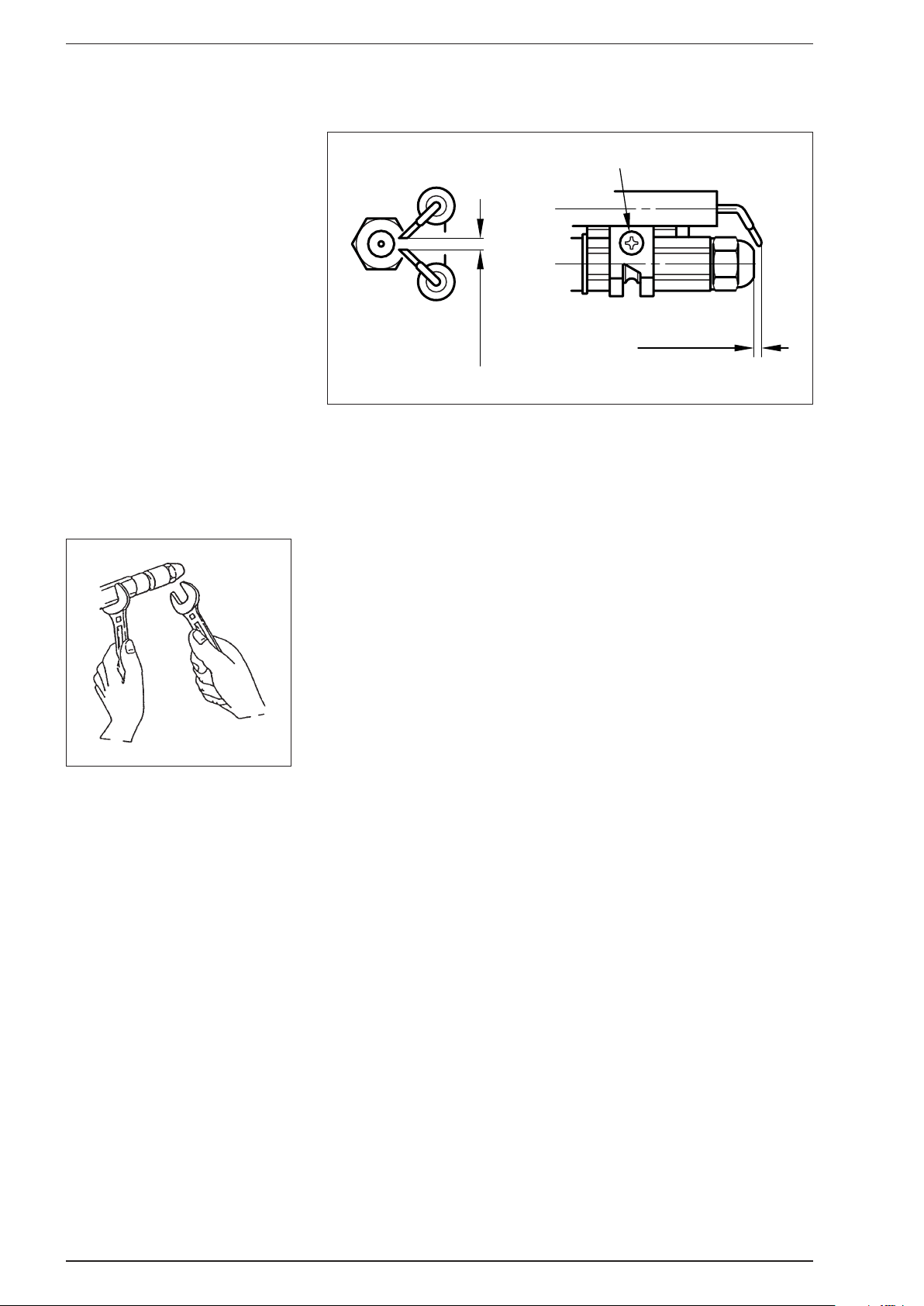

4.7.3 Substitution of nozzle

The nozzle should be substituted at

the beginning of every heating system

for guaranteeing the correct fuel flow

and a good spray efficiency.

The nozzle is substituted in the following manner:

– Disconnect the high tension cables

from the electrodes.

– Loosen the fixture screw (A fig. 16)

of the electrodes support and

remove it.

– Block the spray door using a n°19

spanner and unscrew the nozzle

with a n°16 spanner (fig. 17).

4.8 FAULT FINDING

There follow a list of some reasons

and the possible remedies for a series

of faults which could happen causing a

failure or an irregular function of the

appliance. A function fault, in most

cases, causes the “lock out” signal on

the control panel to turn on. When

this light turns on, the burner can only

function again after the reset button

has been pressed; once this has been

done and a regular ignition occurs, the

failure can be defined momentary and

not dangerous.

On the contrary, if the “lock out” persists, then the cause of the fault as

well as the remedy must be looked for

in the following faults:

The burner does not ignite

– Check the electric connections.

– Check the regular fuel flow, the

cleanness of the filters, of the nozzle

and air vent from the tube.

– Check the regular spark ignition and

the proper function of the burner.

The burner ignites regularly but the

flame goes out immediately

– Check the flame detection, the air

calibration and the function of the

appliance.

Difficulty in regulating the burner

and/or lack of yield

– Check: the regular flow of fuel, the

cleanness of the boiler, the non

obstruction of the smoke duct, the

real input supplied by the burner

and its cleanness (dust).

The boiler gets dirty easily

– Check the burner regulator (smoke

analysis), the fuel quantity, the flue

obstruction and the cleanness of

the air duct of the burner (dust).

The boiler does not heat up

– Control the cleanness of the shell,

the matching, the adjustment, the

burner performances, the preadjusted temperature, the correct

function and position of the regulation stat.

– Make sure that the boiler is suffi-

ciently powerful for the appliance.

Smell of unburnt products

– Control the cleanness of the boiler

shell and the flue, the airtightness of

the boiler and of the flue ducts (door,

combustion chamber, smoke ducts,

flue, washers).

– Control the quality of the fuel.

Frequent intervention of the boiler

shutoff valve

– Control the presence of air in the

system, the function of the circulation pumps.

– Check the load pressure of the appli-

ance, the efficiency of the expansion

tanks and the valve calibration.

Fig. 17

4 ± 0,3 mm

A

2 - 2,5 mm

Fig. 16

82

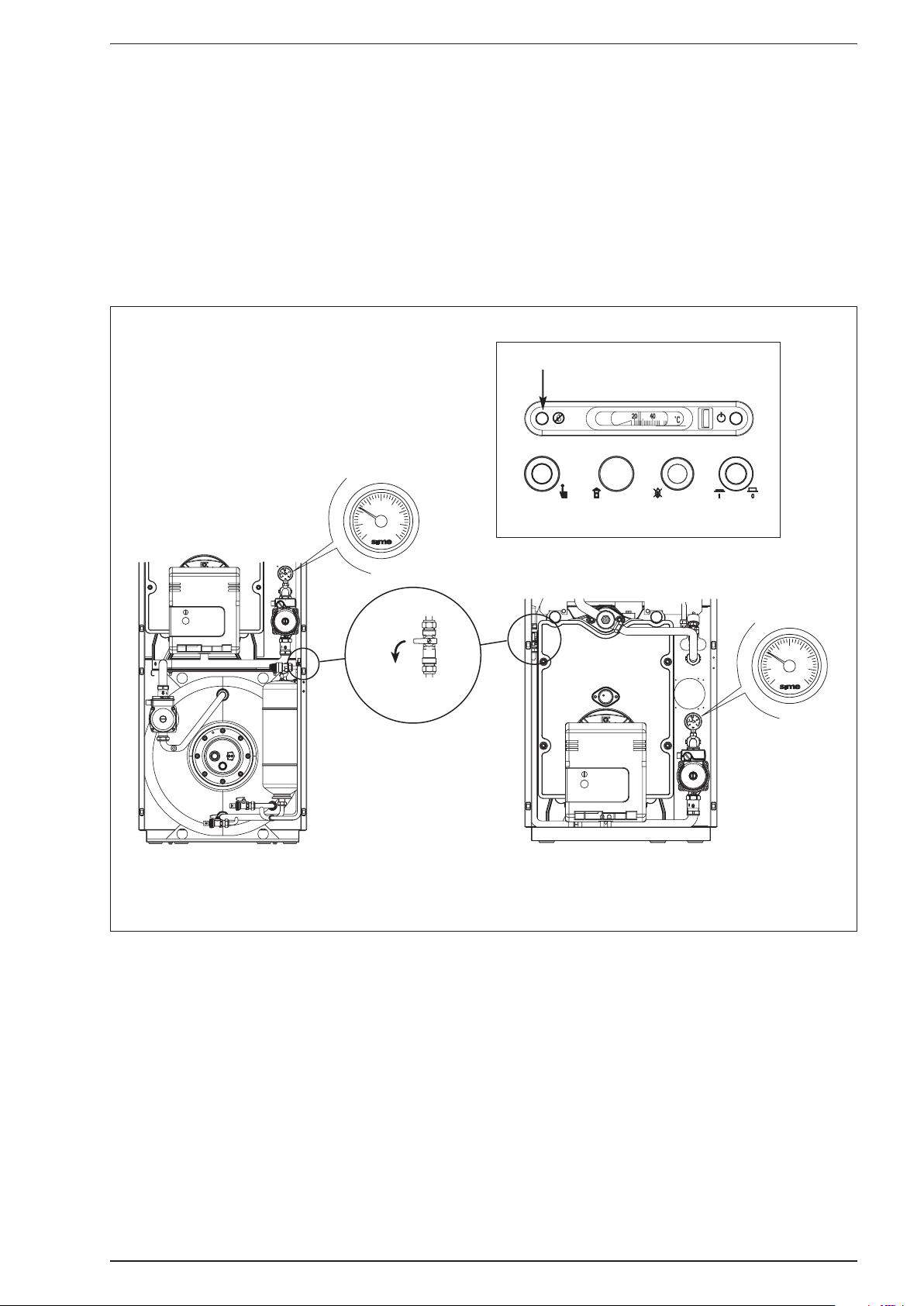

BOILER IGNITION

Press the main switch for lighting the

boiler. The green light turns on to indicate that the appliance is powered (fig.

18).

Choose the position Summer/Winter

on the switch (fig. 19):

–

The boiler operates in treated

phase with the switch in the

position (SUMMER)

–

The boiler operates both in treated

phase as well as for heating with

the switch in the position (WINTER). The room stat or the chronostat will stop the operation of the

boiler.

TEMPERATURE ADJUSTMENT

–

The heating temperature can be

adjusted by turning the knob of the

thermostat (fig. 20).

–

The heating temperature can be

adjusted by turning the knob of the

thermostat which has a range of

between 45 and 85°C.

The temperature setting can be

checked on the thermometer.

To ensure optimal boiler efficiency at

all times, we recommend not to

drop below a minimum working temperature of 60°C (fig. 21).

USER INSTRUCTIONS

WARNINGS

– In case of fault and/or incorrect operation, deactivate it without making any repairs or taking any direct action. If fuel or

combustion is smelt, air the room and close the fuel interception device. Contact the authorised technical staff.

–

The installation of the boiler and any servicing or maintenance job must be carried out by qualified personnel.

–

It is absolutely prohibited to block the intake grilles and the aeration opening of the room where the equipment is

installed. The intake grilles are indispensable for a correct combustion.

IGNITION AND OPERATION

Fig. 18

Fig. 19

Fig. 20

60°C

Fig. 21

GREEN LIGHT ON

SAFETY STAT

The safety stat is of the manually

resetting type and opens, causing the

main burner to turn off immediately,

whenever the temperature of 110°C is

exceeded in the boiler. To restore boiler operation, unscrew the black cap

and reset the button (fig. 22).

Should the appliance “lock out” again,

please approach the authorised technical staff.

BURNER RESTART

In case that ignition or operation faults

occur, the main burner “locks out” and

the red lamp lights up on the control

panel. Press the “RESET” button to

restart the ignition conditions until the

flame lights up (fig. 23).

This operation can be repeated 2-3

times at maximum and in case of failure contact the authorised technical

staff.

ATTENTION: Make sure that there is

fuel in the tank and that the taps are

open. After each fill up of the tank it

is advisable to interrupt the operation of the burner for about one hour.

TURNING OFF BOILER

It is sufficient to press the main switch

to turn off the boiler (fig. 18).

Close both the gas-feed pipe tap and

the water tap if the boiler remains

inoperative for a long period.

SYSTEM FILLING

Check periodically that the hydrometer

83

RESET

TWICE

ONLY

Fig. 23

Fig. 22

RESET

BUTTON

RED WARNING LIGHT ON

has pressure values at a switched-off

system of 1 - 1.2 bar.

If the orange water pressure gauge

light turns on inhibiting boiler operations, restore operations by turning

the supply tap counter-clockwise.

After the operation check that the tap

is properly closed (fig. 24).

Should the pressure exceed the fore-

seen limit, discharge the superfluous

amount by operating on the vent knob

of any radiator.

CLEANING AND MAINTENANCE

At the end of each heating season, it is

essential to have the boiler thoroughly

checked and cleaned out.

Preventive maintenance and checking

of the efficient operation of the equipment and safety devices must be carried out exclusively by the authorised

technical staff.

84

04

13

2

bar

04

13

2

bar

Fig. 24

OPEN

AQUA 30-40 OF/BF AQUA 30-40 OF/BF INOX

ORANGE LIGHT ON

DICHIARAZIONE DI CONFORMITA’

CALDAIE A COMBUSTIBILE LIQUIDO

La FONDERIE SIME SpA, con riferimento all’art. 5 DPR n°447 del 6/12/1991

“Regolamento di attuazione della legge 5 marzo 1990 n°46”, dichiara che le proprie caldaie a com-

bustibile liquido serie:

AR SOLO RONDO’ B

ARB DUETTO ESTELLE B

1R OF AQUA ESTELLE

2R OF/OF S/GT OF RONDO’

sono complete di tutti gli organi di sicurezza e di controllo previsti dalle norme vigenti in materia e rispondono, per caratteristiche tecniche e funzionali, alle prescrizioni delle norme:

UNI 7936 (dicembre 1979), FA130-84, FA168-87

EN 303-1994.

Le caldaie a gasolio sono inoltre conformi alla DIRETTIVA RENDIMENTI 92/42 CEE.

La ghisa grigia utilizzata è del tipo EN-GJL 150 secondo la norma europea UNI EN 1561.

Il sistema qualità aziendale è certificato secondo la norma UNI EN ISO 9001: 2000.

Legnago, 5 settembre 2006

Il Direttore Generale

ing. Aldo Gava

Fonderie Sime S.p.A. - Via Garbo, 27 - 37045 Legnago (Vr) - Tel. 0442 631111 - Fax Servizio Tecnico 0442 631292 - www.sime.it

TAGLIARE LUNGO LA LINEA TRATTEGGIATA

Cod. 6276007C - 04/09 - Documentation Dpt.

Fonderie Sime S.p.A

Via Garbo, 27 - 37045 Legnago (Vr)

Tel. + 39 0442 631111 - Fax +39 0442 631292

www.sime.it

Loading...

Loading...