Remove the “Testing Certificate” from inside the combustion chamber and

keep together with the instructions manual.

The package of the “2R GT” boiler contains instructions for installation, operation and maintenance of the diesel burner.

CONTENTS

1 BOILER DESCRIPTION

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.2 DIMENSIONAL DETAILS

1.3 TECHNICAL FEATURES

1.4 LOSS OF HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.5 COMBUSTION CHAMBER DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.6 SOME BURNER BRANDS COMPATIBLE WITH “1R/2R” BOILERS

2INSTALLATION

2.1 BOILER ROOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 BOILER ROOM DIMENSIONS

2.3 CONNECTING UP SYSTEM

2.4 CONNECTING UP FLUE

2.5 BOILER BODY ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.6 FITTING THE CASING

2.7 ELECTRICAL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.8 ASSEMBLY OF “RVA 43.222” CLIMATE CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3 USE AND MAINTENANCE

3.1 COMMISSIONING THE BOILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 LIGHTING AND OPERATION

3.3 CLEANING THE BOILER

3.4 USER WARNINGS

3.5 HOW TO USE THE “RVA 43.222” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1R - 2R - 2R GT

ENGLISH

24

1.1 INTRODUCTION

The cast iron boilers “1R/2R freestanding” for gas-oil or gas has been desi-

gned in compliance with the European

Directives 90/396/CEE, 89/336/CEE,

73/23/CEE, 92/42/CEE.

The cast iron boilers “2R GT” for gas-oil

has been designed in compliance with

the European Directive 92/42/CEE.

The components for “1R/2R free-

standing” installation are supplied in

three separate packages: boiler body,

casing with enclosed documents and

control panel.

“2R GT” boilers are supplied in four

separate packages: boiler body, casing

with enclosed documents, control

panel and burner with instructions.

1BOILERDESCRIPTION

1R6 1R7 1R8 1R9

Output kW 64.8 74.0 84.0 93.3

kcal/h 55,700 63,600 72,200 80,200

Input kW 73.4 83.1 93.8 103.4

kcal/h 63,100 71,500 80,700 88,900

P (depth) mm 595 670 750 825

Sections n° 6 7 8 9

Maximum water head bar 4 4 4 4

Water content l37.542.046.551.0

Loss of head

Smoke mbar 0.20 0.16* 0.22* 0.30*

Water (Δt 10°C) mbar 30.0 34.0 40.0 45.5

Comb. chamber pressure mbar – 0.01 0.06 0.08 0.08

Suggested chimney depression

mbar 0.21 0.22 0.30 0.38

Smokes temperature °C 225 217 209 201

Smokes flow m

3

n/h 68.0 77.7 88.0 97.6

Adjustment range

Heating °C 30÷85 30÷85 30÷85 30÷85

Smokes volume dm

3

42 46 50 55

Weight kg 261 293 325 357

1.3 T EC HN IC AL F EAT UR ES

1.3.1 “1R” boiler

560 (1R) - 700 (2R)

P

125 (1R)

135 (2R)

ø 150 (1R)

ø 200 (2R)

270 (1R)

330 (2R)

925 (1R) - 1130 (2R)

70 (1R)

85 (2R)

695 (1R) - 875 (2R)

865 (1R) - 1075 (2R)

R

S

M

1.2 D IM EN SI ON AL DE TAI LS

Fig. 1

1R 2R/2R GT

MC.H. flow 1

1

/

2

”2”

R C.H. return 1

1

/

2

”2”

S Boiler/filling drain 3/4” 3/4”

* Without baf fles

25

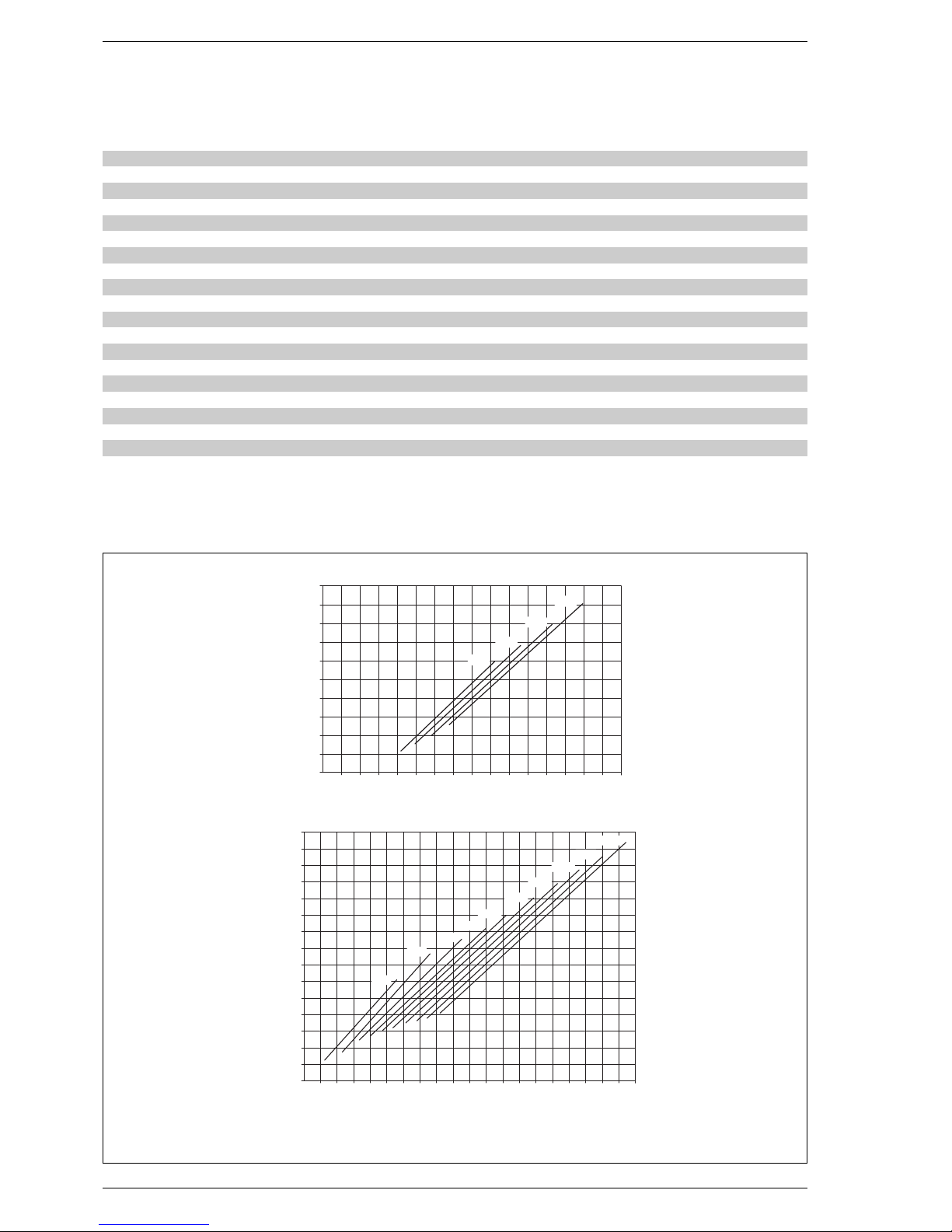

1.4 LOS S OF H EA D

1.3. 2 “2 R/ 2R G T” b oi le r

Fig. 2

NOTE: The losses of head shown in the diagram were obtained with a Δt of 10°C

“1R” boiler

“2R/2R GT” boilers

6789101112131415

Output kW 100.6 123.8 147.1 165.1 179.7 197.7 213.4 230.2 248.8 266.9

kcal/h 86,500 106,500 126,500 142,000 154,500 170,000 183,500 198,000 214,000 229,500

Input kW 113.5 139.1 164.7 184.1 199.7 219.7 237.1 255.8 276.4 296.7

kcal/h 97,600 119,700 141,600 158,300 171,700 188,900 203,900 220,000 237,700 255,200

P (depth) mm 735 835 935 1,035 1,135 1,235 1,335 1,435 1,535 1,635

Sections n° 6 7 8 9 10 11 12 13 14 15

Max. water head bar 5 5 5 5 5 5 5 5 5 5

Wate r content l92107122136151165180194209223

Loss of head

Smoke mbar 0.10 0.15 0.22 0.29 0.24* 0.37* 0.39* 0.42* 0.49* 0.50*

Water (Δt 10°C) mbar 61.0 76.0 85.0 92.0 100.0 1,120 118.0 121.0 125.0 130.0

Comb. chamb. press. mbar – 0.02 – 0.02 – 0.01 – 0.02 – 0.02 – 0.01 – 0.02 0.31 0.35 0.50

Suggested chimney depress.

mbar 0,12 0,17 0,23 0,31 0,26 0,38 0,41 0,73 0,84 1,00

Smokes temperature °C 238 236 234 232 229 224 219 215 211 207

Smokes flow m

3

n/h 105.2 129.2 153.3 171.9 186.9 205.4 221.6 238.9 257.9 276.6

Adjustment range

Heating °C 30÷85 30÷85 30÷85 30÷85 30÷85 30÷85 30÷85 30÷85 30÷85 30÷85

Smoke volume dm

3

83 92 101 110 119 128 138 147 157 167

Weight kg 462 520 578 636 676 734 792 850 908 966

12345678

0

10

20

30

40

50

Portata m3/h

Δp mbar

1R 8

1R 7

1R 6

1R 9

4 5 6 7 8 9 10 11 121314 15 16 17 18 19

0

20

40

60

80

100

Portata m3/h

Δp mbar

2R 6

2R 7

2R 9

2R 8

120

20 21 22 23

140

2R 10

2R 11

2R 12

2R 13

2R 14

2R 15

* Without baf fles

Flow m3/h

Flow m3/h

26

1.5 COMBUSTION CHAMBER

DIMENSIONS

The dimensions of this direct passage

combustion chamber are reported in

fig. 3.

Fig. 3

“1R” 6789

A mm 310 310 310 310

B mm 310 310 310 310

L mm 448 524 600 676

Volume m

3

0,038510 0,045129 0,051748 0,058367

“2R - 2R GT” 6789101112131415

A mm 390 390 390 390 390 390 390 390 390 390

B mm 430 430 430 430 430 430 430 430 430 430

L mm 570 670 770 870 97 0 1.070 1.170 1.27 0 1.370 1.470

Volume m

3

0,081690 0,096314 0,110938 0,125562 0,140186 0,154810 0,169434 0,184058 0,198682 0,213306

1.6 SOME BURNER BRANDS COMPATIBLE WITH “1R/2R” BOILERS

In general, the oil burner that is compatible with the boiler should use full spray nozzles.

1.6.1 ECOFLAM gas-oil burners

1.6.2 RIELLO gas-oil burners

Boiler Model Atomising

Gulliver R. 40 REG R2000 angle

1R6 RG2 - RG2D G10 – G120 60°

1R7 RG2 - RG2D G10 – G120 60°

1R8 RG2 - RG2D G10 – G120 60°

1R9 RG2 - RG2D - RG3 - RG3D G10 - G20 – G214 - G230D 60°

2R6 RG3 - RG3D G20 – G214 - G230D 60°

2R7 RG3 - RG3D G20 – G214 - G230D 60°

2R8 RG3 - RG3D G20 – G214 - G230D 60°

2R9 RG3 - RG3D G20 - G20D – G214 - G230D 60°

2R10 RG4S - RG4D - RG5D G20 - G20D – – 60°

2R11 RG4S - RG4D - RG5D G20 - G20D – – 60°

2R12 RL28/1 - RL28/2 - RG5D – – – 60°

2R13 RL28/1 - RL28/2 - RG5D – – – 60°

2R14 RL28/1 - RL28/2 - RG5D – – – 60°

2R15 RL28/1 - RL28/2 - RG5D – – – 60°

Boiler Model Atomising

1 flame 2 flames angle

1R6 MINOR 8 – 60°

1R7 MINOR 8 – 60°

1R8 MINOR 12 – 60°

1R9 MINOR 12 – 60°

Boiler Model Atomising

1 flame 2 flames angle

2R6÷8 MAIOR P 15 MAIOR P 15 AB 60°

2R9÷12 MAIOR P 25 MAIOR P 25 AB 60°

2R13-14 MAIOR P 35 MAIOR P 35 AB 60°

2R15 –MAIOR P 45 AB60°

1.6.3 F.B.R. gas-oil burners

Boiler Model Atomising

angle

1R6÷8 G2 2001 60°

1R9 - 2R6 G2 MAXI 60°

2R7 FG 14 TC 60°

Boiler Model Atomising

angle

2R8 FG 14 TC 60°

2R9÷13 G 20 TC 60°

2R14-15 G 30/2 TC 60° - 45°

27

2.1 BOILER ROOM

The boiler room should feature all the

characteristics required by standards

governing liquid fuel heating systems.

2.2

BOILER ROOM DIMENSIONS

Position the boiler body on the foundation bed, which should be at least 10

cm high. The body should rest on a

surface allowing shifting, possibly by

means of sheet metal.

Leave a clearance between the boiler

and the wall of at least 0.60 m, and

between the top of the casing and the

ceiling of 1 m (0.50 m in the case of

boilers with incorporated D.H.W. tank).

The ceiling height of the boiler room

should be less than 2.5 m.

2.3 CONNECTING UP SYSTEM

When connecting up the water supply

to the boiler, make sure that the specifications given in fig. 1 are observed.

All connecting unions should be easy

to disconnect by means of tightening

rings.

A closed expansion tank system

must be used.

2.3.1 Filling the water system

Before connecting the boiler, thoroughly flush the system to eliminate

scale which could damage the

appliance.

Filling must be done slowly so as to allow

any air bubbles to be bled off through the

air valves. In closed-circuit heating

systems, the cold water filling pressure

and the pre-charging pressure of the

expansion vessel should be no less than

or equal to the height of the water head

of the installation (e.g. for water head of

5 metres, the vessel pre-charging pressure and installation filling pressure

should be at least 0.5 bar).

2.3.2

Water system

characteristics

Water supplying the heating circuit

must be treated in accordance with

UNI-CTI 8065 standards.

It is absolutely essential to treat water

in the heating system in the following

cases:

–for extensive systems (with high

contents of water);

–frequent addition of water into the

system;

– should it be necessary to empty the

system either partially or totally.

2.4 CONNECTING UP FLUE

The flue is of fundamental importance

for the proper operation of the boiler;

if not installed in compliance with the

standards, starting the boiler will be

difficult and there will be a consequent

formation of soot, condensate and

encrustation.

The flue used to expel combustion products into the atmosphere must meet

the following requirements:

–

be constructed with waterproof

materials, and resistant to smoke

temperature and condensate;

–be of adequate mechanical resilien-

ce and of low heat conductivity;

–be perfectly sealed to prevent coo-

ling of the flue itself;

–be as vertical as possible; the termi-

1.6. 5 Bu rn er f la nge

The dimensions of the diesel burner

anchorage flange are given in fig. 4.

2INSTALLATION

A

B

C

Fig. 4

ABC

mm mm ø

1R 6 110 15 0 M 8

1R 7÷9 13 0 17 0 M 8

2R 6-7 13 0 17 0 M 8

2R 8÷15 16 0 19 0 M 10

2R GT 6-7 13 0 17 0 M 8

2R GT 8÷15 16 0 19 0 M 10

1.6. 4 RI EL LO gas b ur ne rs

Boiler Model Output (kW) Electrical Gas

1°stage 2°stage data type

1R 6÷9 GS10 42÷116 – 230V

±

10% ~50Hz G20/25 - G30/31

2R 6 GS10 42÷116 – 230V

±

10% ~50Hz G20/25 - G30/31

2R 7÷8 BS 3 65÷189 – 230V

±

10% ~50Hz G20/25 - G30/31

2R 9÷11 BS 4 110÷246 – 230V

±

10% ~50Hz G20/25 - G30/31

2R 8÷15 RS 28 81 163-325 230V

±

10% ~50Hz G20/25 - G30/31

2R 8÷15 RS 28/1 163÷349 – 230V

±

10% ~50Hz G20/25 - G30/31

nal section of the flue must be fitted

with a static exhaust device that

ensures constant and efficient

extraction of products generated by

combustion;

–to prevent the wind from creating

pressure zones around the chimney

top greater than the uplift force of

combustion gases, the exhaust

outlet should be at least 0.4 m

higher than structures adjacent to

the stack (including the roof top)

within 8 m;

–have a diameter that is not inferior

to that of the boiler union: square or

rectangular-section flues should

have an internal section 10% greater than that of the boiler union;

–the useful section of the flue must

conform to the following formula:

S resulting section in cm

2

Kreduction coefficient for liquid

fuels:

–0.045 for firewood

– 0.030 for coal

– 0.024 for light oil

– 0.016 for gas

Pboiler input in kcal/h

H height of flue in metres, measu-

red from the flame axis to the

top of the flue reduced by:

–0.50 m for each change of

direction of the connection

union between boiler and flue;

–1.00 m for each metre of

union itself.

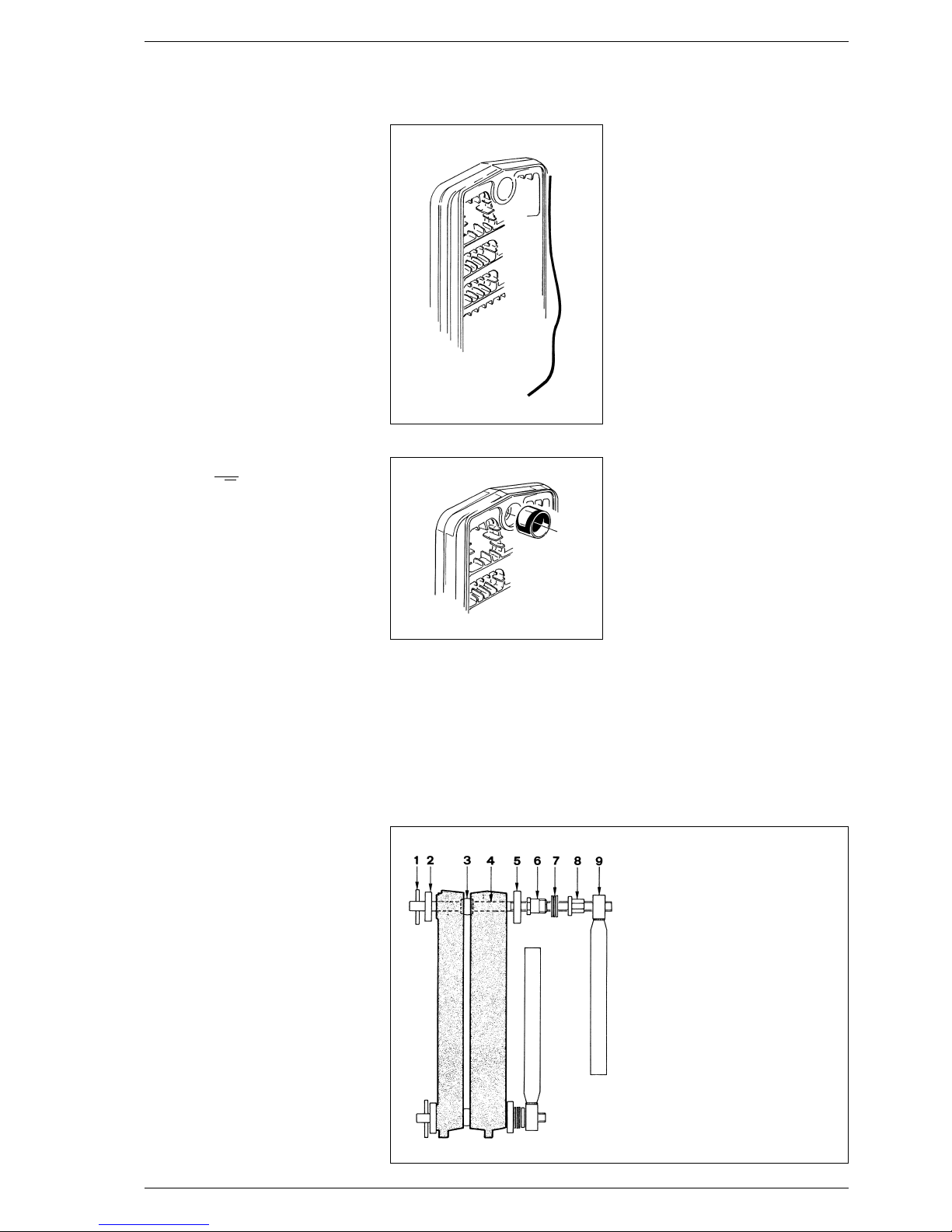

2.5 BOILER BODY ASSEMBLY

The boiler body comes supplied assembled. Where there is difficulty in gaining

access to the boiler room, the body can

be supplied in separate sections. For

assembly, proceed as follows:

–prepare the sections, cleaning the

seats of the tapered nipples with

solvent;

– insert the bead of putty (fig. 5) in the

groove provided for fume tightness,

pressing lightly;

– prepare one of the two intermediate

sections. After lubricating them with

boiled linseed oil, insert the tapered

nipples (fig. 6);

–prepare the head, proceeding as

above, and bring it up to the intermediate section. Add only one section at a time;

–

assemble the sections, using the

tools provided consisting of a pair of

staybolts for assembly with the corresponding accessories (code

6050900 - fig. 7), exerting pressure

simultaneously on the top hub and

on the bottom hub. If, during this operation, the sections were to slot

together in such a way as not to be

even and parallel, slide a chisel in the

tighter side and, by applying a little

force, bring the two pieces together

so that they are parallel.

The sections can be considered properly joined together when their

outer edges come into contact;

– insert the bead of putty in the groo-

ve of the section that has just been

assembled, and then proceed to joining up the other sections until the

body is completed.

NOTE: befo re proceeding to connect the system, test the boiler

block with a water pressure of 7.5

bar.

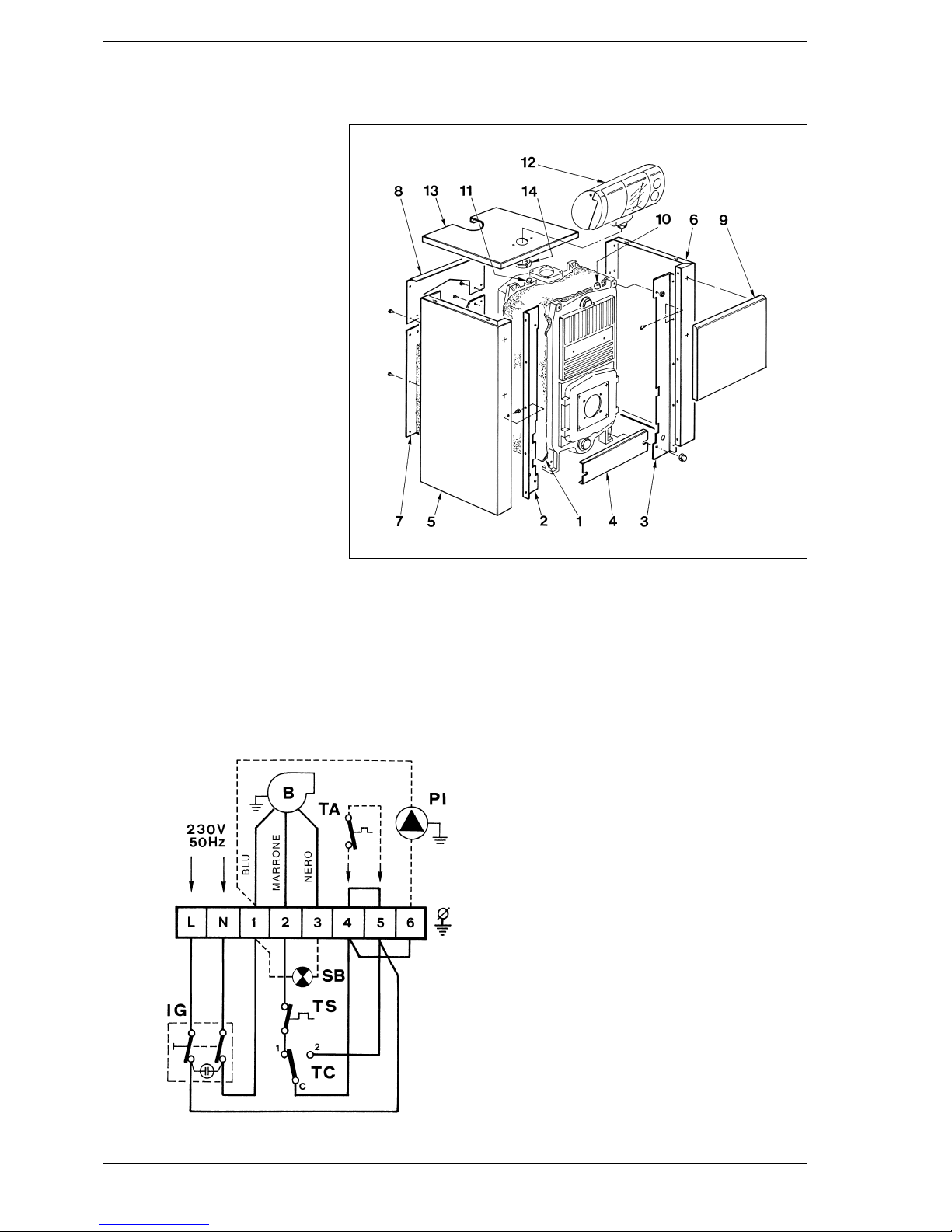

2.6 FITTING THE CASING

The casing and the control panel are

supplied in separate cardboard packages. The housing package also contains the boiler documents and the

glass wool for insulating the cast iron

body. To fit the casing, proceed as follows (fig. 8):

– fix the left front side angle bar (2)

and the right front side angle bar (3)

to the upper tie rods using the two

galvanized nuts provided;

– place the front cross bar (4) on the

lower tie rods before securing the

angle bars with the two cap nuts

provided;

– insulate the cast iron body with the

glass wool (1);

– fix the side parts (5) and (6) to the

angle bars using the ten self-tapping

screws provided, and secure them

at the back with the nuts placed on

the tie rods;

28

Fig. 5

Fig. 6

KEY

1 Pin

2Flange ø 35/87

3 Biconical nipples

4Staybolt L. 900 + staybolt L. 980

5Flange ø 50/87

6 Stub

7 Thrust bearing

8 Nut

9Tightening wrench

Fig. 7

P

S=K

√H

– assemble the lower rear panel (7)

with the eight self-tapping screws

provided;

–

assemble the upper rear panel (8)

with the six self-tapping screws provided;

– fix the control panel (12) to the cover

(13) using the check nut (14);

– unwind the capillary tubes of the two

thermostats and thermometer by

inserting their sensors inside the

sheath (11), securing the assembly

in position using the capillary tube

retaining spring provided;

– screw the water gauge to the check

valve (10);

– complete assembly by fixing the

cover (13) and the front panel (9) to

the side parts.

NOTE: Remove the “Testing Certificate” from inside the combustion

chamber and keep together with

the instructions manual.

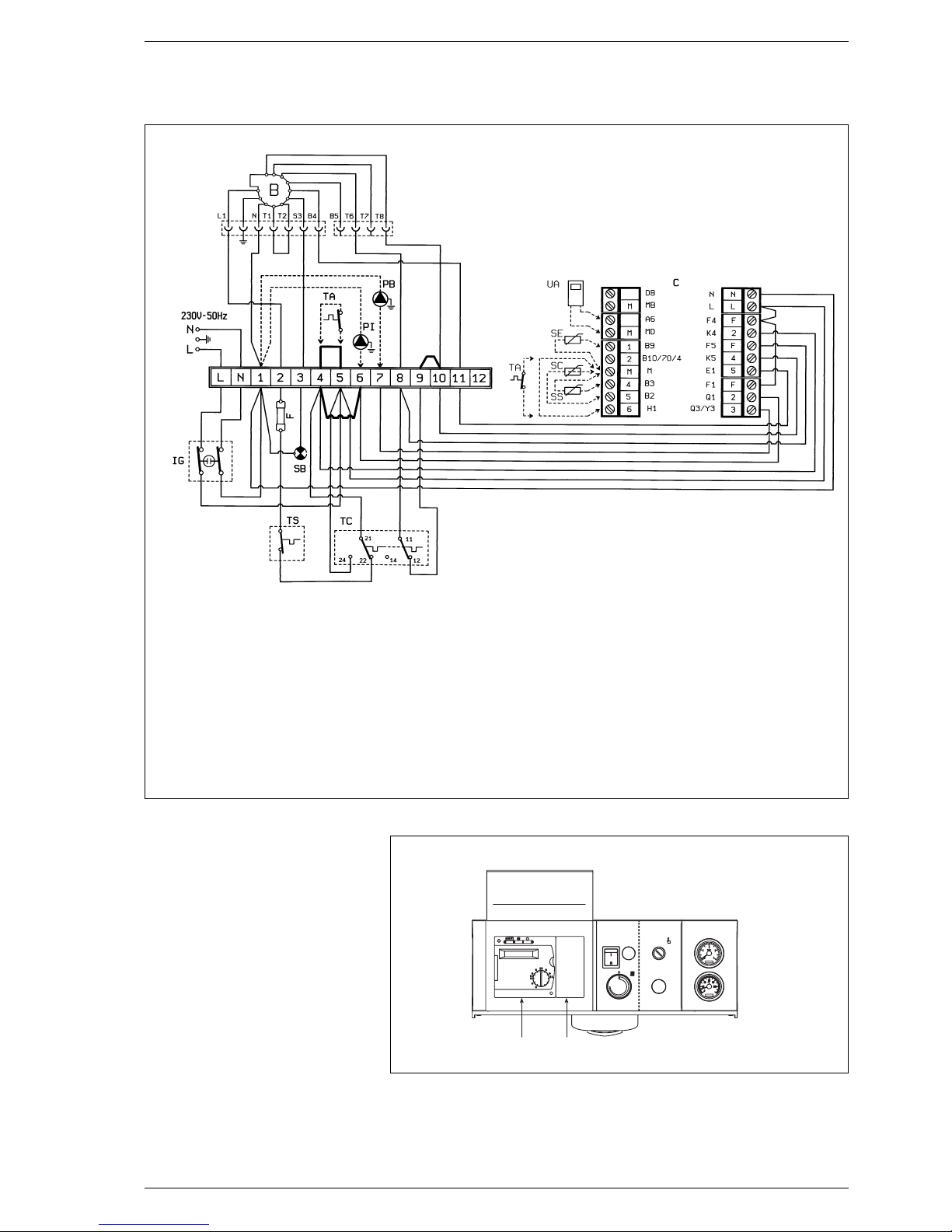

2.7 ELECTRICAL CONNECTION

(figg. 9 - 9/a)

The boiler is fitted with an electricity

cable, and requires a a single-phase

power supply of 230V - 50Hz through the main switch protected by

fuses. The room thermostat (required for enhanced room temperatu-

re control) must be connected to

the terminals 4-5 after removing

the link. Connect the burner cable

supplied.

NOTE: Device must be connected to

an efficient earthing system. SIME

declines all responsibility for injury

caused to persons due to failure to

earth the boiler.

Always turn off the power supply

before doing any work on the electrical panel.

29

Fig. 8

KEY

IG Main switch

TA Room stat (not supplied)

PI C.H. pump (not supplied)

TC Boiler stat

TS Safety stat

B Burner (not supplied)

SB Burner lock-out lamp

NOTA: The room stat must be connected to the terminals 4-5 after

removing the link.

Fig. 9

“1R/2R” boilers

2.8 ASSEMBLING

THE RVA 43.222 CLIMAT

CONTROLLER (fig. 10)

All functions of the “2R GT” boiler may

be controlled using the controller, code

8096303, which is supplied with an

outdoor temperature probe (SE) and a

boiler immersion probe (SC).

The controller is to be connected to an

additional series of low voltage connectors for connection of the room temperature control unit (the connectors are

supplied in a bag inside the control

panel).

The probe bulb of the external hot

water tank, if any, (SS) code 6277110,

must be inserted in the hot water tank

sheath, while the bulb of the boiler

probe (SC) must be inserted in the boiler sheath.

When assembling the outdoor temperature probe, follow the instructions

provided in the probe package. Refer to

fig. 9/a for wiring instructions.

IMPORTANT:

To make sure that the unit works properly, set the boiler control thermostat as high as it will go.

30

Fig. 9/a

“2R GT” boiler

KEY

F Fuse (T 6A)

IG Main switch

SB Burner shutdown emergency light

TC Two-stage control thermostat

TS Safety thermostat

BBurner

PI System pump

PB Boiler pump

C Connectors for RVA 43.222 controller

(black - red - brown)

TA Environment thermostat

UA Type QAA70 room temperature control unit

(optional)

SE Outdoor temperature probe (optional)

SC Type QAZ21 boiler probe (optional)

SS Type QAZ21 hot water probe (optional)

NOTE: Connect the TA by removing the jumper

from terminals 4-5. Connect up the RVA43.222

control device and remove the jumpers from terminal boards 4-5, 4-6, 9-10

12

Fig. 10

KEY

1 Cover

2 RVA 43.222 controller

3.1 COMMISSIONING

THE BOILER

When commissioning the boiler it is

recommended:

–to make sure that the system has

been filled with water and adequately vented;

–to make sure that the flow and

return valves are fully open;

–to make sure that flue and chimney

are free from obstructions;

– to make sure that the electrical con-

nections to the mains and the

earthing are correct;

–

to make sure that no flammable

liquids or materials are near the

boiler.

3.2 LIGHTING AND

OPERATION

3.2.1 Lighting the boiler

To lig h t t h e b oil e r p r oc e ed a s f ol l ow s

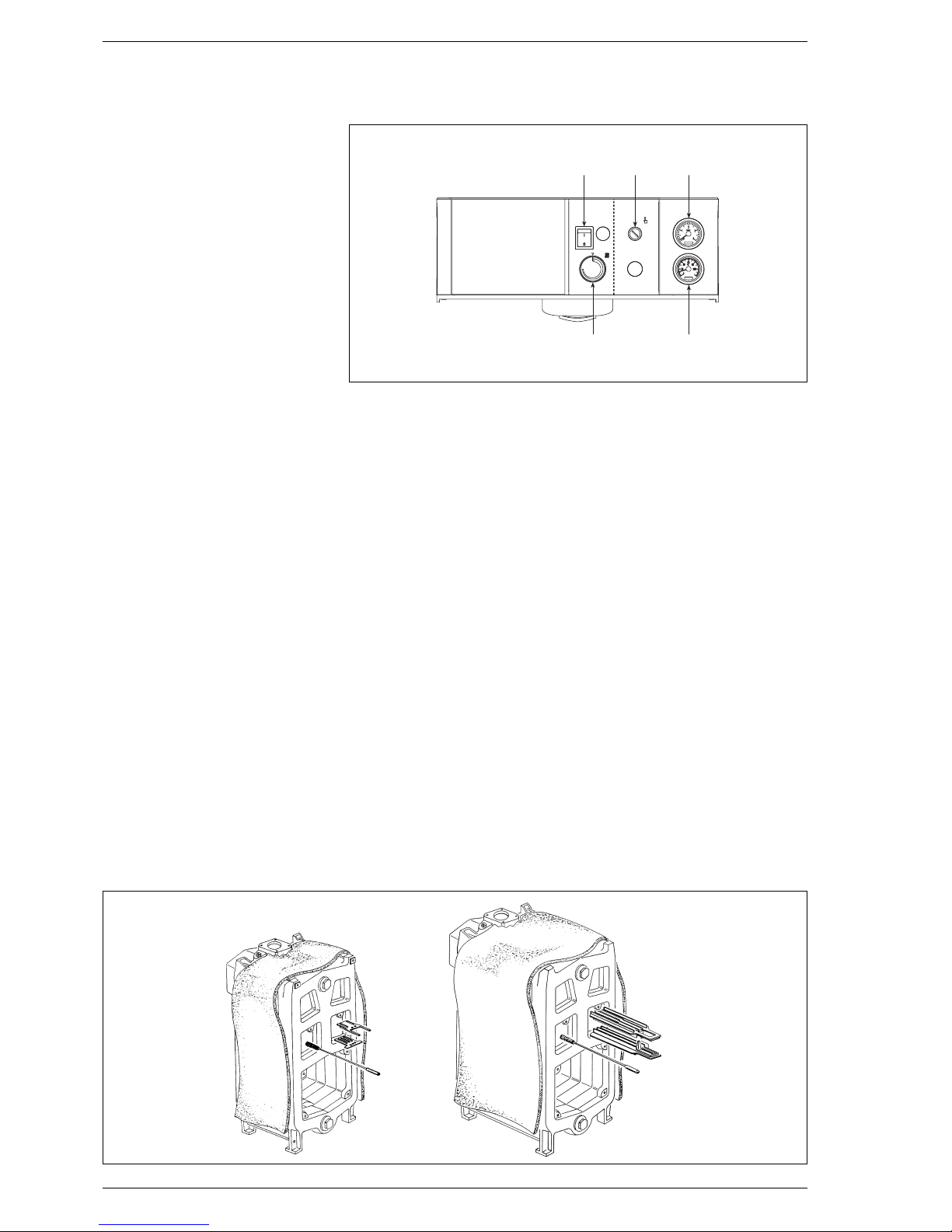

(fig. 11):

–check that the “Testing Certificate”

has been removed from inside the

combustion chamber;

–switch on the main switch (1); the

burner will start ;

–turn the boiler stat knob (5) to the

desidered setting.

For best results, set the boiler stat

knob to a temperature no lower

than 60°C to prevent the formation

of condensate.

The set temperature value can be

checked on the thermometer (4).

3.2.2 Safety stat

The safety stat with automatic reset

calibration set at 100°C (2 fig. 11)

trips, immediately turning off the burner when the boiler accidentally

overheats. To restore normal operations, wait until the temperature

drops below the thermostat calibration setting.

3.2.3 System filling

Periodically check the pressure values

of the hydrometer (3 fig. 11) which,

when the system is cold, should range

between 1 and 1.2 bar. If the pressure

is less than 1 bar, reset the system.

3.2.4 Turning OFF boiler

To turn off the boiler, cut off the voltage by pressing the mains switch (1

fig. 11).

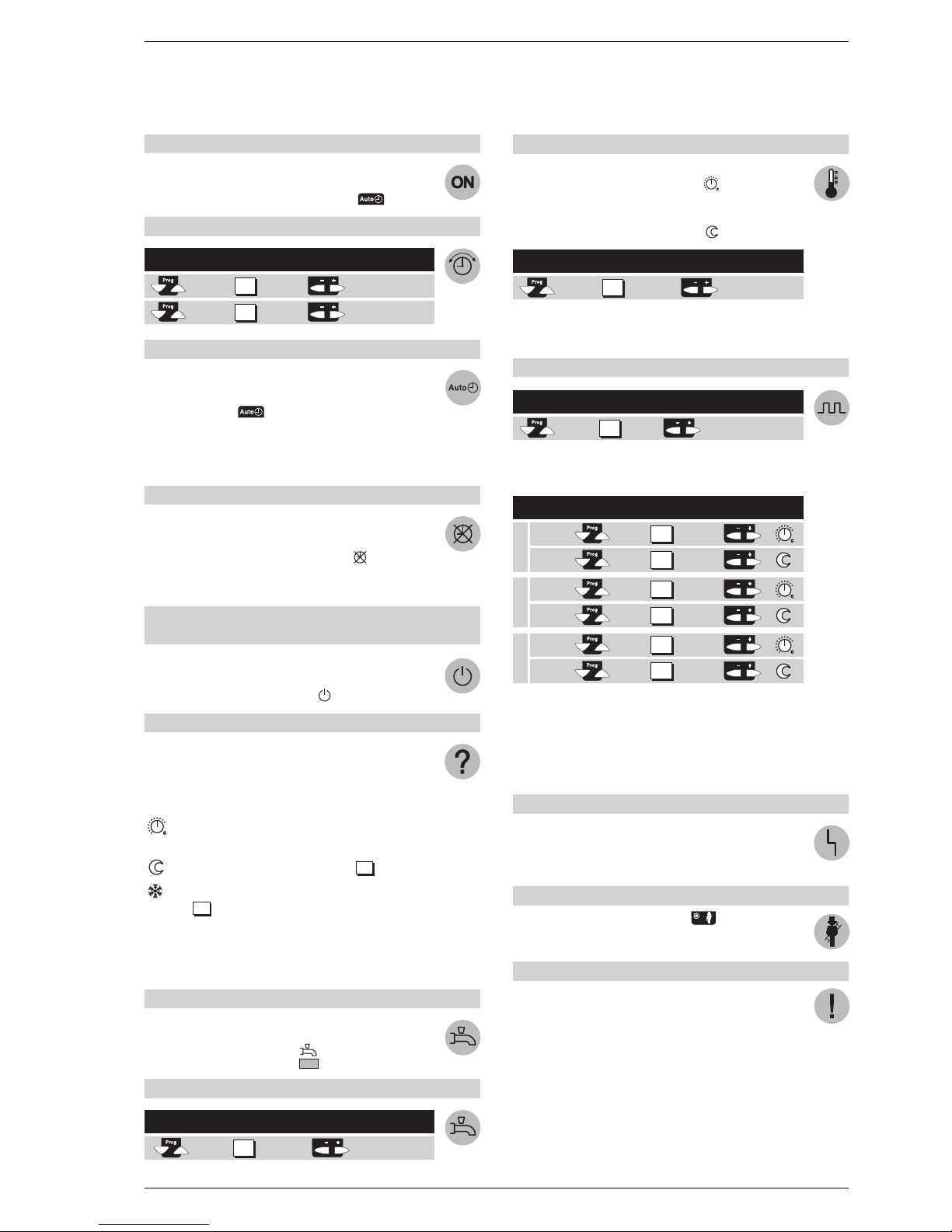

3.3 CLEANING THE BOILER

(fig. 12)

The boiler body and flue should be

cleaned at the end of each season.

To clean the boiler, simply remove the

burner-holding plate and the cleaning

plate with their insulation and protection panels; this operation gives easy

access to the three front pockets and

the combustion chamber.

Before proceeding to clean the and

“1R 6 - 2R/2R GT 6 ÷ 9” models, the

baffles must be removed.

Once maintenance has been completed, reposition the baffles.

Use the pig to clean the smoke pipes.

NOTE: Preventive maintenance must

be carried out by authorized technical staff.

3.4 USER WARNINGS

When faults occur and/or the equipment does not operate correctly, turn

it off, without attempting to make any

repairs or take direct action.

For any operation only contact the

authorised technical personnel in your

area.

31

3 USE AND MAINTENANCE

Fig. 12

1 23

45

Fig. 11

“1R” boiler “2R/2R GT” boilers

TO TURN ON THE HEATING

–Turn on the main switch.

– Set the correct hour of the day and the day of the week.

– Place in automatic mode with the button .

TO SET THE HOUR

HOW TO USE THE AUTOMATIC MODE

In the automatic mode the temperature of the room is regulated on the basis of the periods of heating chosen.

– Push the button .

NOTE: Select the heating periods according to one’s daily

requirements; in this way it is possible to significantly

save on energy.

TO ACTIVATE CONTINUOUS HEATING

The continuous heating mode keeps the temperature of the

room at the set level via the regulating knob.

– Push the “Continuous Operation” button .

–Regulate the room temperature with the

regulating knob.

TO SET THE STANDBY MODE

(when the user is away for a long period of time)

The standby mode keeps the temperature of the room at

the level of antifreeze protection.

– Push the “Standby mode” button .

MEANING OF THE SYMBOLS

On the display a few of the symbols indicate the current operating state. The appearance of a line under one of these

symbols signals that the corresponding operating state is

“active”.

Heating at the nominal temperature

(regulating knob)

Heating at reduced temperature (line ).

Heating at antifrost protection temperature

(line ).

NOTE: For further information on the symbols and the

operating state refer to the detailed description of the

heating plant.

TO VARY THE HOT WATER PRODUCTION

The production of hot water can be activated or deactivated

by the push of a button.

–Push the button “Hot water” .

IF THE HOT WATER IS TOO HOT OR TOO COLD

IF THE ROOMS ARE TOO HOT OR TOO COLD

–Check that current operating state on the display.

– In the case of nominal temperature .

Increase or reduce the temperature of the room with the

regulating knob.

– In the case of reduced temperature .

NOTE: After each regulation wait at least two hours for

the new temperature to expand through the room.

TO CHANGE THE HEATING PERIODS

With reference to the day chosen set the changes

as following:

NOTE: The heating periods automatically repeat on a

weekly basis.

To this end select the automatic mode.

It is possible to reset the standard programme on line 23

by pushing the buttons + and – at the same time.

IF THE HEATING DOES NOT WORK PROPERLY

– Refer to the detailed documentation

on the heating system, following the fault finding

instructions.

TO MEASURE GAS COMBUSTION

–Push the “chimneysweep” button .

The heating will work according to the level requested.

HOW TO SAVE ENERGY WITHOUT FOREGOING ON COMFORT

– A temperature of around 21°C is advised in the rooms

that are used. Every degree above this will increase heating costs by 6–7%.

–Aerate the rooms only for a brief period, opening the win-

dows completely.

–In the rooms that are not used place the regulating valve

in the antifreeze position.

–Leave the space in front of the radiators free from

obstructions (remove furniture, curtains...).

– Close windows and blinds to reduce

dispersion of heat.

Select the Display Set the regulation

line with the buttons

hour of the day

day of the week

1

2

14

15

Select the Display Pre-select the weekly block

line or the single day

1-7 = week

1 = Lu/7 = Do

5

Period Push Display Set For

requested button hour °C

Start

End

Start

End

Start

End

6

7

8

9

10

11

Select the Display Change the temperature

line with the buttons

°C

14

Period 1

Period 2

Period 3

13

Select the Display Set the desired

line temperature

°C

32

3.5 HOW TO USE THE “RVA 43.222”

To make the most of your “RVA 43.222” controller, follow the instructions provided below:

Loading...

Loading...