Page 1

SIM7000G_User Manual_V1.01

Document Title

SIM7000G_User Manual

Page 2

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Version

1.00

Date

2018-10-10

Status

Released

Document Control ID

SIM7000G_User Manual_V1.01

General Notes

SIMCom offers this information as a service to its customers to support the application and

engineering efforts that use the products designed by SIMCom. The information provided is based

on the requirements specifically from the customers. SIMCom has not undertaken any independent

search for additional relevant information, including any information that may be in the customer’s

possession. Furthermore, the system validation of the product designed by SIMCom within a larger

electronic system remains the responsibility of the customer or the customer’s system integrator.

All specifications supplied herein are subject to change without notice.

Copyright

This document contains the proprietary technical information which is the property of SIMCom

Limited, copying of this document, giving it to others, the using or communication of the contents

thereof are forbidden without the official authority by SIMCom. Offenders are liable to the

payment of the damages. All rights are reserved in the event of grant of a patent or the registration

of a utility model or design. All specifications supplied herein are subject to change without notice

Copyright © SIMCom Wireless Solutions Co., Ltd. 2017

Page 3

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Compliance Information

FCC Compliance Statement: This device complies the FCC Rules . Operation is subject to the

following two conditions: 1. This device may not cause harmful interference, and 2. This device

must accept any interference received, including interference that may cause undesired operation.

This device must accept any interference received, including interference that may cause undesired

operation. Product that is a radio transmitter is labeled with FCC ID.

FCC Caution:

(1)Exposure to Radio Frequency Radiation. This equipment must be installed and operated in

accordance with provided instructions and the antenna(s) used for this transmitter must be installed

to provide a separation distance of at least 20 cm from all persons and must not be collocated or

operating in conjunction with any other antenna or transmitter. End-users and installers must be

provided with antenna installation instructions and transmitter operating conditions for satisfying

RF exposure compliance.

(2) Any changes or modifications not expressly approved by the grantee of this device could void

the user's authority to operate the equipment.

(3) This Transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

(4) Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user authority to operate the equipment.

(5) the modules FCC ID is not visible when installed in the host, or

(6) if the host is marketed so that end users do not have straight forward commonly used methods

for access to remove the module so that the FCC ID of the module is visible; then an additional

permanent label referring to the enclosed module: Contains Transmitter Module FCC ID: 2AJYU-

SIM7000G or Contains FCC ID: 2AJYU-SIM7000G must be used.

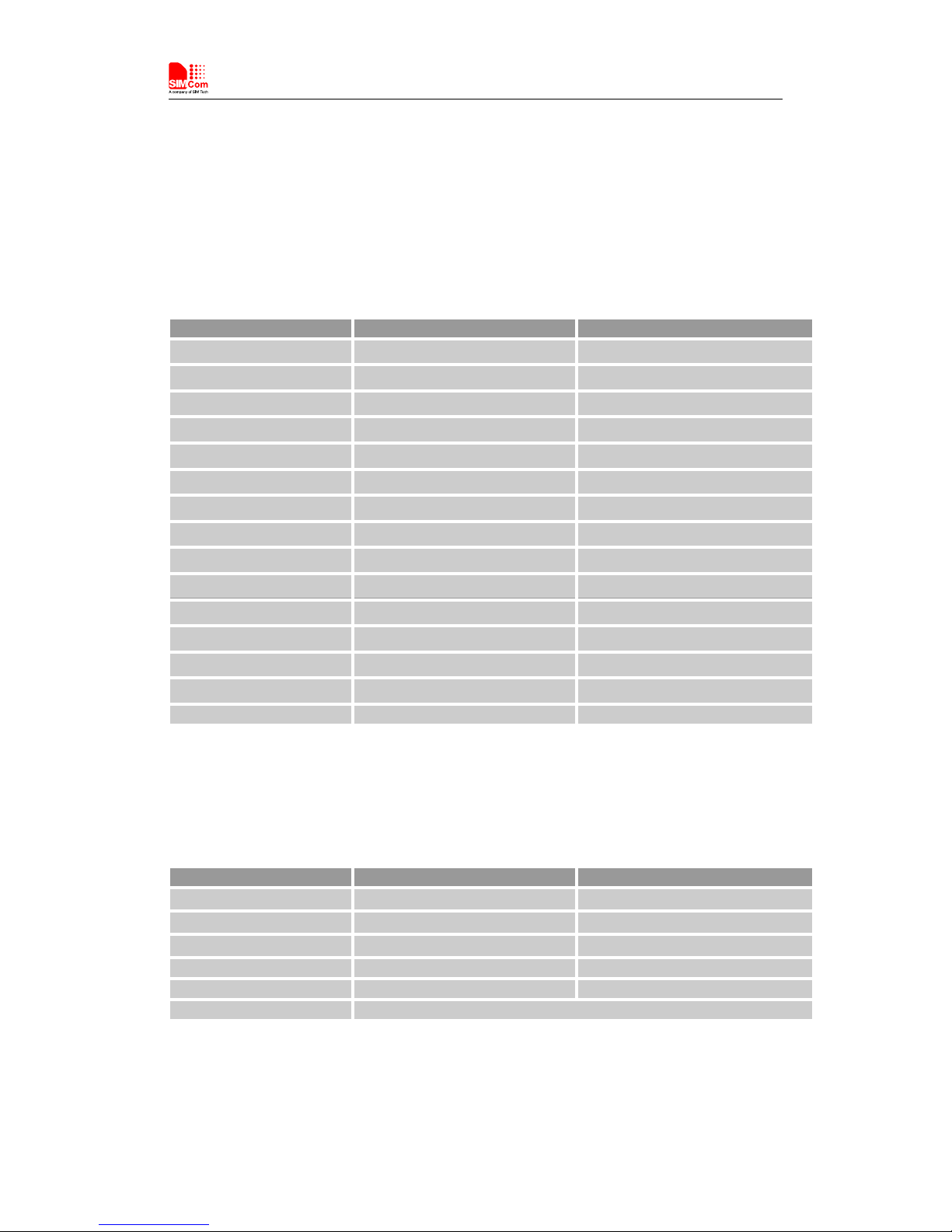

This product is suitable for collocation internal and external antenna.Gain the scope of the

reference is as follows:

Frequency Band Antenna Gain reference (dBi)

GSM 850 ≤6.0

GSM 1900 ≤10.0

NB-IOT Band2 ≤10.0

NB-IOT Band5 ≤6.0

NB-IOT Band12 ≤6.0

NB-IOT Band13 ≤6.0

NB-IOT Band17 ≤6.0

NB-IOT Band26 ≤6.0

CAT-M1 Band2 ≤10.0

CAT-M1 Band4 ≤10.0

CAT-M1 Band5 ≤6.0

CAT-M1 Band12 ≤6.0

CAT-M1 Band13 ≤6.0

CAT-M1 Band26 ≤6.0

Page 4

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

hereby, declare that the essential requirements set out in the Radio Equipment Directive

2014/53/EU Serviceshave been fully fulfilled on our product with indication below:

Product Name: LTE CAT-M1(eMTC) and NB-IoT Module

Model Name: SIM7000G

Brand Name: SIMCom

Hardware Version: SIM7000G_V1.03

Software Version: SIM7000G R1529

The following standards have been applied for the investigation of compliance:

EN 60950-1:2006+A11:2009+A1:2010+A12:2011+A2:2013

EN 62311-2008

EN 301 489-1 V2.2.0

EN 301 489-3 V2.1.1

EN 301 489-19 V2.1.0

EN 301 489-52 V1.1.0

EN 55032:2015

EN 301 511 V12.5.1

EN 301 908-1 V11.1.1

EN 301 908-13 V11.1.

2

EN 303 413 V1.1.1

Page 5

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Contents

Contents............................................................................................................................................... 5

Table Index.......................................................................................................................................... 7

Figure Index........................................................................................................................................ 8

Revision History..................................................................................................................................9

1 Introduction................................................................................................................................10

1.1 Product Outline.....................................................................................................................10

1.2 Hardware Interface Overview...............................................................................................11

1.3 Hardware Block Diagram..................................................................................................... 12

1.4 Functional Overview.............................................................................................................13

2 Package Information................................................................................................................. 15

2.1 Pin Assignment Overview.................................................................................................... 15

2.2 Pin Description......................................................................................................................17

2.3 Mechanical Information........................................................................................................20

2.4 Footprint Recommendation.................................................................................................. 21

3 Interface Application.................................................................................................................22

3.1 Power Supply........................................................................................................................22

3.1.1 Power Supply Design Guide..........................................................................................23

3.1.2 Recommended Power Supply Circuit............................................................................23

3.1.3 Voltage Monitor............................................................................................................. 24

3.2 Power on/Power off/Reset Function.....................................................................................25

3.2.1 Power on........................................................................................................................ 25

3.2.2 Power off........................................................................................................................26

3.2.3 Reset Function................................................................................................................27

3.3 UART Interface.....................................................................................................................28

3.3.1 UART Design Guide......................................................................................................28

3.3.2 RI and DTR Behavior....................................................................................................29

3.4 USB Interface........................................................................................................................30

3.5 SIM Interface........................................................................................................................ 31

3.5.1 SIM Application Guide..................................................................................................31

3.5.2 Recommended SIM Card Holder.................................................................................. 32

3.6 PCM Interface.......................................................................................................................33

3.6.1 PCM timing....................................................................................................................33

3.6.2 PCM Application Guide.................................................................................................35

3.7 I2C Interface......................................................................................................................... 35

3.8 Network status...................................................................................................................... 35

3.9 Other interface...................................................................................................................... 36

3.9.1 ADC............................................................................................................................... 36

3.9.2 LDO................................................................................................................................37

4 RF Specifications........................................................................................................................38

4.1 LTE CAT-M1RF Specifications............................................................................................38

Page 6

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

4.2 LTE CAT-M1Antenna Design Guide....................................................................................41

4.3 GNSS.................................................................................................................................... 42

4.3.1 GNSS Technical specification....................................................................................... 42

4.3.2 GNSS Application Guide...............................................................................................43

5 Electrical Specifications............................................................................................................ 45

5.1 Absolute maximum ratings...................................................................................................45

5.2 Operating conditions.............................................................................................................45

5.3 Operating Mode.................................................................................................................... 46

5.3.1 Operating Mode Definition............................................................................................46

5.3.2 Sleep mode.....................................................................................................................47

5.3.3 Minimum functionality mode and Flight mode.............................................................47

5.4 Current Consumption............................................................................................................48

5.5 ESD Notes.............................................................................................................................49

6 SMT Production Guide............................................................................................................. 50

6.1 Top and Bottom View of SIM7000.......................................................................................50

6.2 Label Information................................................................................................................. 51

6.3 Typical SMT Reflow Profile.................................................................................................52

6.4 Moisture Sensitivity Level (MSL)........................................................................................52

6.5 Stencil Foil Design Recommendation..................................................................................53

7 Packaging....................................................................................................................................54

7.1 tray packaging.......................................................................................................................54

Appendix............................................................................................................................................57

A. Reference Design....................................................................................................................... 57

B. Coding Schemes and Maximum Net Data Rates over Air Interface.............................................

C. Related Documents.....................................................................................................................58

D. Terms and Abbreviations........................................................................................................... 60

E. Safety Caution.............................................................................................................................62

Page 7

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table Index

Table 1: SIM7000 frequency bands and air interface.......................................................................................... 10

Table 2: General features..................................................................................................................................... 13

Table 3: Pin definition..........................................................................................................................................16

Table 4: IO parameters definition........................................................................................................................ 17

Table 5: Pin description........................................................................................................................................17

Table 6: VBAT pins electronic characteristic.......................................................................................................22

Table 7: Recommended Zener diode list..............................................................................................................23

Table 8: Power on timing and electronic characteristic....................................................................................... 26

Table 9: Power off timing and electronic characteristic.......................................................................................27

Table 10: RESET pin electronic characteristic.................................................................................................... 28

Table 11: SIM electronic characteristic in 1.8V mode (SIM_VDD=1.8V)......................................................... 31

Table 12: SIM electronic characteristic 3.0V mode (SIM_VDD=2.95V)........................................................... 31

Table 13: Amphenol SIM socket pin description................................................................................................. 32

Table 14: PCM format..........................................................................................................................................33

Table 15: PCM timing parameters....................................................................................................................... 34

Table 16: NETLIGHT pin status.......................................................................................................................... 36

Table 17: ADC electronic characteristics............................................................................................................. 36

Table 18: Electronic characteristic....................................................................................................................... 37

Table 19: Conducted transmission power............................................................................................................ 38

Table 20: Operating frequencies.......................................................................................................................... 38

Table 21: E-UTRA operating bands..................................................................................................................... 39

Table 22: Conducted receive sensitivity.............................................................................................................. 39

Table 23: CAT-M1 Reference sensitivity (QPSK)............................................................................................... 40

Table 24: Trace loss........................................................................................................................................... 39

Table 25: Trace loss..............................................................................................................................................41

Table 26: Recommended TVS............................................................................................................................. 41

Table 27: Absolute maximum ratings.................................................................................................................. 45

Table 28: Recommended operating ratings..........................................................................................................45

Table 29: 1.8V Digital I/O characteristics*..........................................................................................................45

Table 30: Operating temperature..........................................................................................................................46

Table 31: Operating mode Definition.................................................................................................................. 46

Table 32: Current consumption on VBAT Pins (VBAT=3.8V)........................................................................... 48

Table 34: The ESD performance measurement table (Temperature: 25℃, Humidity: 45%).............................. 49

Table 35: The description of label information.................................................................................................... 51

Table 36: Moisture Sensitivity Level and Floor Life........................................................................................... 52

Table 37: Tray size............................................................................................................................................... 55

Table 38: Small Carton size................................................................................................................................. 55

Table 39: Big Carton size..................................................................................................................................... 56

Table 39: Coding Schemes and Maximum Net Data Rates over Air Interface....................................................56

Table 40: Related Documents.............................................................................................................................. 58

Table 41: Terms and Abbreviations......................................................................................................................60

Table 42: Safety Caution......................................................................................................................................62

Page 8

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Figure Index

Figure 1: SIM7000 block diagram....................................................................................................................... 12

Figure 2: Pin assignment overview...................................................................................................................... 15

Figure 3: Dimensions (Unit: mm)........................................................................................................................ 20

Figure 4: Footprint recommendation (Unit: mm)................................................................................................ 21

Figure 5: VBAT voltage drop during burst emission (GSM/GPRS)....................................................................22

Figure 6: Power supply application circuit.......................................................................................................... 23

Figure 7: Linear regulator reference circuit......................................................................................................... 24

Figure 8: Switching mode power supply reference circuit.................................................................................. 24

Figure 9: Reference power on/off circuit............................................................................................................. 25

Figure 10: Power on timing sequence..................................................................................................................25

Figure 11: Power off timing sequence................................................................................................................. 26

Figure 12: Reference reset circuit........................................................................................................................ 27

Figure 13: UART full modem.............................................................................................................................. 28

Figure 14: UART null modem............................................................................................................................. 28

Figure 15: Reference circuit of level shift............................................................................................................29

Figure 16: RI behaviour(SMS and URC report).............................................................................................29

Figure 17: RI behaviour(voice call)................................................................................................................30

Figure 18: USB reference circuit......................................................................................................................... 30

Figure 19: SIM interface reference circuit........................................................................................................... 31

Figure 20: Amphenol SIM card socket................................................................................................................ 32

Figure 21: PCM_SYNC timing............................................................................................................................33

Figure 22: External codec to module timing........................................................................................................ 33

Figure 23: Module to external codec timing........................................................................................................ 34

Figure 24: Audio codec reference circuit............................................................................................................. 35

Figure 25: I2C reference circuit........................................................................................................................... 35

Figure 26: NETLIGHT reference circuit............................................................................................................. 36

Figure 27:Power on sequence of the VDD_EXT.............................................................................................. 37

Figure 28: Antenna matching circuit (MAIN_ANT)........................................................................................... 42

Figure 29: Active antenna circuit.........................................................................................................................43

Figure 30: Passive antenna circuit (Default)........................................................................................................43

Figure 31: Top and bottom view of SIM7000......................................................................................................50

Figure 32: Label information............................................................................................................................... 51

Figure 33: The ramp-soak-spike reflow profile of SIM7000............................................................................... 52

Figure 34: packaging diagram..............................................................................................................................54

Figure 35: Tray drawing.......................................................................................................................................55

Figure 36: Small carton drawing..........................................................................................................................55

Figure 37: Big carton drawing............................................................................................................................. 55

Figure 38: Reference design.................................................................................................................................57

Page 9

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Revision History

Data

Version

Description of change

Author

2018-08-22

1.00

Original

Tu Hongjun

Li Ya

Page 10

1 Introduction

This document describes the electronic specifications, RF specifications, interfaces, mechanical

characteristics and testing results of the SIMCom SIM7000G module. With the help of this

document and SIM7000G software application notes/user guides, users can understand and use

SIM7000G module to design and develop applications quickly.

1.1 Product Outline

The SIM7000 series modules support LTE CAT-M1、NB-IoT and GPRS/EDGE;

The physical dimension of SIM7000G is 24 × 24 × 2.6mm mm. And the physical dimension is

compatible with the packaging of SIM900, SIM800 and SIM800F.

Table 1: SIM7000G frequency bands and air interface

Standard

Frequency

SIM7000G

GSM

EGSM900MHz

DCS1800MHz

LTE-FDD

*

HD-FDD

LTE-FDD B1

LTE-FDD B2

LTE-FDD B3

LTE-FDD B4

LTE-FDD B5

LTE-FDD B6

LTE-FDD B8

LTE-FDD B12

LTE-FDD B13

LTE-FDD B18

LTE-FDD B19

LTE-FDD B20

LTE-FDD B28

LTE-TDD

*

LTE CAT-M1TDD

B39

Category

LTE-M1 and

NB-IoT

GNSS

Page 11

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

1.2 Hardware Interface Overview

The interfaces are described in detail in the next chapters include:

● Power Supply

● USB Interface

● UART Interface

● SIM Interface

● ADC

● LDO Power Output

● PCM Interface

● I2C Interface

● GPIOs

● Antenna Interface

Page 12

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

1.3 Hardware Block Diagram

The block diagram of the SIM7000G module is shown in the figure below.

Figure 1: SIM7000 block diagram

Page 13

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

1.4 Functional Overview

Table 2: General features

Feature

Implementation

Power supply

Power supply voltage 3.0~4.3V

Power saving

Current in sleep mode: 1mA

Current in PSM mode: 9uA

Radio frequency bands

Please refer to the table 1

Transmitting power

LTE CAT-M1power class: 3 (0.25W)

Data Transmission

Throughput

LTE CAT-M1CAT M1: 300Kbps (DL)

LTE CAT-M1CAT M1: 375Kbps (UL)

Antenna

LTE CAT-M1main antenna.

GNSS antenna

GNSS

GNSS engine (GPS,GLONASS and BD)

Protocol: NMEA

SMS

MT, MO, CB, Text and PDU mode

SMS storage: SIM card or ME(default)

SIM interface

Support identity card: 1.8V/ 3V

SIM application toolkit

Support SAT class 3, GSM 11.14 Release 98

Support USAT

Audio feature

Support PCM interface

Only support PCM master mode and short frame sync, 16-bit linear data

formats

UART interface

A full modem serial port by default

Baud rate: 300bps to 4Mbps(default:115200bps)

Can be used as the AT commands or data stream channel

Support RTS/CTS hardware handshake

Multiplex ability according to GSM 07.10 Multiplexer Protocol

USB

USB 2.0 high speed interface

Firmware upgrade

Firmware upgrade over USB interface

Physical characteristics

Size:24 × 24 × 2.6mm

Weight:3g

Temperature range

Normal operation temperature: -30°C to + 80°C

Extended operation temperature: -40°C to + 85°C*

Storage temperature -45°C to + 90°C

*Note: Module is able to make and receive voice calls, data calls, SMS and make GPRS/LTE

CAT-M1traffic in -40℃ ~ +85℃. The performance will be reduced slightly from the 3GPP

Page 14

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

specifications if the temperature is outside the normal operating temperature range and still

within the extreme operating temperature range.

Page 15

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

2 Package Information

2.1 Pin Assignment Overview

All functions of the SIM7000G will be provided through 68 pads that will be connected to the

customers’ platform. The following Figure is a high-level view of the pin assignment of the

SIM7000.

Figure 2: Pin assignment overview

Page 16

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table 3: Pin definition

Pin No.

Pin Name

Pin No.

Pin Name

1

PWRKEY

2

GND

3

DTR4RI

5

DCD

6

BOOT_CFG

7

CTS8RTS

9

TXD

10

RXD

11

PCM_CLK

12

PCM_SYNC

13

PCM_DIN

14

PCM_DOUT

15

VDD_EXT

16

NRESET

17

GND

18

GND

19NC20

NC

21NC22

NC

23

MDM_LOG_TX

24

USB_VBUS

25

ADC

26

NC

27

USB_DP

28

USB_DM

29

GND

30

SIM_VDD

31

SIM_DATA

32

SIM_CLK

33

SIM_RST

34

SIM_DET

35NC36

NC

37

I2C_SDA

38

I2C_SCL

39

GND

40

NC

41NC42

NC

43NC44

NC

45

GND

46

GND

47NC48

GPIO4

49

GPIO1/UART3_RXD

50

GPIO0/UART3_TXD

51NC52

NETLIGHT

53

GNSS_ANT

54

GND

55

VBAT

56

VBAT

57

VBAT

58

GND

59

GND

60

RF_ANT

61

GND

62

GND

63

GND

64

GND

65

GND

66

STATUS

67

GPIO2

68

GPIO3

NOTE: Before the normal power up, BOOT_CFG cannot be pulled up.

Page 17

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

2.2 Pin Description

Table 4: IO parameters definition

Pin type

Description

PI

Power input

PO

Power output

AI

Analog input

AIO

Analog input/output

I/O

Bidirectional input /output

DI

Digital input

DO

Digital output

DOH

Digital output with high level

DOL

Digital output with low level

PU

Pull up

PD

Pull down

Table 5: Pin description

Pin name

Pin No.

Default

status

Description

Comment

Power supply

VBAT

55、56、

57

PI

Power supply, voltage range:

3.0~4.3V.

VDD_EXT

15

PO

LDO power output 1.8V for

other external circuits with Max

50mA current output, such as

level shift circuit.

If unused, keep it

open.

GND

2、 17、

18、29、

39、45、

46、54、

58、59、

61、62、

63、64、

65

Ground

System Control

PWRKEY

1

DI,PU

System power on/off control

input, active low. The efficient

input level must be below 0.5V.

The level is 0.8V when

this PIN is floating;

NRESET

16

DI, PU

System reset control input,

active low.

NRESET has been

pulled up to 1.8V via

40Kohm resistor

internally.

Page 18

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

SIM interface

SIM_DATA

31

I/O,PU

SIM Card data I/O, which has

been pulled up via a 10KR

resistor to SIM_VDD

internally. Do not pull it up or

down externally.

All lines of SIM

interface should be

protected against ESD.

SIM_RST

33DOSIM Reset

SIM_CLK

32DOSIM clock

SIM_VDD

30

PO

Power output for SIM card, its

output Voltage depends on SIM

card type automatically. Its

output current is up to 50mA.

SIM_DET

34DISIM card detecting input

If used, keep a 10k Ω

resistor pulling up to

the VDD_EXT

USB

USB_VBUS

24

DI,PD

Valid USB detection input with

3.5~5.25V detection voltage

USB_DP

27

I/O

Positive line of the differential,

bi-directional USB signal.

USB_DM

28

I/O

Negative line of the differential,

bi-directional USB signal.

UART interface

DTR3DI,PU

DTE get ready

If unused, keep them

open.

RI4DOH

Ring Indicator

DCD

5

DOH

Carrier detects

CTS7DOH

Clear to Send

RTS8DI,PU

Request to send

TXD

9

DOH

Transmit Data

RXD

10

DI,PU

Receive Data

I2C interface

I2C_SDA

37

I/O

I2C clock output

If unused, keep open,

or else pull them up

via 2.2KΩ resistors to

the VDD_EXT.

I2C_SCL

38DOI2C data input/output

PCM interface

PCM_CLK

11DOPCM data bit clock.

If unused, please keep

them open.

PCM_SYNC

12DOPCM data frame sync signal.

PCM_DIN

13DIPCM data input.

PCM_DOUT

14DOPCM data output.

Page 19

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

GPIO

NETLIGHT

52

DO

LED control output as network

status indication.

If unused, keep them

open.

STATUS

66

DO

Operating status output.

High level: Power on and

firmware ready

Low level: Power off

GPIO0

50

IO

Default: GPIO

Optional: UART3_TXD

GPIO1

49

IO

Default: GPIO

Optional: UART3_RXD

GPIO2

67IOGPIO

GPIO3

68IOGPIO

GPIO4

48IOGPIO

RF interface

GNSS_ANT

53AIGNSS antenna soldering pad

RF_ANT

60

AIO

MAIN antenna soldering pad

Other interface

BOOT_CFG

6

DI,PD

Boot configuration input.

Module will be forced into

USB download mode by

connect this pin to VDD_EXT

during power up.

Reserve two test points

for BOOT_CFG and

VDD_EXT.

DO NOT PULL UP

BOOT_CFG

DURING NORMAL

POWER UP!

MDM_LOG_T

X

23

DO

Module log output for SW

debug. (only used for platform)

Reserve a test point for

this pin.

ADC

25

AI

Analog-digital converter input.

voltage range: 0.1~1.7V.

If unused, keep them

open.

NC

19、20、

21、 22、

26、35、

36、40、

41、 42、

43、 44、

47、 51、

No connection.

Keep it open

Page 20

2.3 Mechanical Information

The following figure shows the package outline drawing of SIM7000.

Figure 3: Dimensions (Unit: mm)

Page 21

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

2.4 Footprint Recommendation

Figure 4: Footprint recommendation (Unit: mm)

Page 22

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

3 Interface Application

3.1 Power Supply

Pin 55, pin 56 and pin 57 are VBAT power input.

On VBAT pads, the ripple current up to 0.6A typically due to LTE CAT-M1emission burst and up

to 2A typically due to GSM/GPRS emission burst (every 4.615ms). It may cause voltage drop. So

the power supply for these pads must be able to provide sufficient current up to more than 2A in

order to avoid the voltage drop is more than 300mV.

The following figure shows the VBAT voltage ripple wave at the maximum power transmit phase

in GSM emission mode.

Figure 5: VBAT voltage drop during burst emission (GSM/GPRS)

Note: The test condition: The voltage of power supply for VBAT is 3.8V, Cd=100 µF tantalum

capacitor (ESR=0.7Ω) and Cf =100nF (Please refer to Figure 6—Application circuit).

Table 6: VBAT pins electronic characteristic

Symbol

Description

Min.

Typ.

Max.

Unit

VBAT

Module power voltage

3.0

3.8

4.3

V

I

VBAT(peak)

Module power peak current in GSM emission mode.

-2-

A

Module power peak current in LTE CAT-M1emission

mode.

-

0.6-A

I

VBAT(average)

Module power average current in normal mode

Please refer to the table 32

I

VBAT(sleep)

Power supply current in sleep mode

I

VBAT(power-off)

Module power current in power off mode.

--7

uA

Page 23

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

3.1.1 Power Supply Design Guide

Make sure that the voltage on the VBAT pins will never drop below 3.0V, even during a transmit

burst, when current consumption may rise up to 2A. If the voltage drops below 3.0V, module will

be work abnormally.

Note: If the power supply for VBAT pins can support up to 2A, using a total of more than 300uF

capacitors is recommended, or else users must using a total of 1000uF capacitors typically, in

order to avoid the voltage drop is more than 300mV.

Some multi-layer ceramic chip (MLCC) capacitors (0.1uF, 1uF) with low ESR in high frequency

band can be used for EMC.

These capacitors should be put as close as possible to VBAT pads. Also, users should keep VBAT

trace on circuit board wider than 2 mm to minimize PCB trace impedance. The following figure

shows the recommended circuit.

Figure 6: Power supply application circuit

In addition, for over voltage protection, it is suggested to use a zener diode with 5.1V reverse

voltage and more than 500mW power dissipation.

Table 7: Recommended Zener diode list

No.

Manufacturer

Part Number

Power dissipation

Package

1

On semi

MMSZ5231BT1G

500mW

SOD123

2

Prisemi

PZ3D4V2H

500mW

SOD323

3

Vishay

MMSZ4689-V

500mW

SOD123

4

Crownpo

CDZ55C5V1SM

500mW

0805

3.1.2 Recommended Power Supply Circuit

It is recommended that a switching mode power supply or a linear regulator power supply is used.

It is important to make sure that all the components used in the power supply circuit can resist a

peak current up to 2A.

Page 24

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

The following figure shows the linear regulator reference circuit with 5V input and 3.8V output.

Figure 7: Linear regulator reference circuit

If there is a big voltage difference between input and output for VBAT power supply, or the

efficiency is extremely important, then a switching mode power supply will be preferable. The

following figure shows the switching mode power supply reference circuit.

Figure 8: Switching mode power supply reference circuit

Note: The Switching Mode power supply solution for VBAT must be chosen carefully against

Electro Magnetic Interference and ripple current from depraving RF performance.

3.1.3 Voltage Monitor

To monitor the VBAT voltage, the AT command “AT+CBC” can be used.

To monitor whether the VBAT voltage is inside a special range, the AT command

“AT+CBATCHK” can be used to enable the overvoltage warning function and the under-voltage

warning function. The default value of the overvoltage warning function in the software is 4.3V,

and the default value of the under-voltage warning function is 3.1V.

When the VBAT voltage is out of the range, the module will be power off. If users need to power

off SIM7000 when the VBAT voltage is out of the range, the AT command “AT+CBATCHK” can

be used to enable the overvoltage power-off function and the under-voltage power-off function. The

default value of the overvoltage power-off function in the software is 4.4V, and the default value of

the under-voltage power-off function is 2.9V.

Note: Under-voltage warning function and under-voltage power-off function are disabled by

default. For more information about these AT commands, please refer to Document [1].

Page 25

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

3.2 Power on/Power off/Reset Function

3.2.1 Power on

SIM7000 can be powered on by pulling the PWRKEY pin to ground.

The PWRKEY pin has been pulled up with a diode to 1.8V internally, so it does not need to be

pulled up externally. It is strongly recommended to put a 100nF capacitor and an ESD protection

diode close to the PWRKEY pin, as it would strongly enhance the ESD performance of PWRKEY

pin. Please refer to the following figure for the recommended reference circuit.

Figure 9: Reference power on/off circuit

The power-on scenarios are illustrated in the following figure.

Figure 10: Power on timing sequence

Page 26

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table 8: Power on timing and electronic characteristic

Symbol

Parameter

Min.

Typ.

Max.

Unit

T

on

The time of active low level impulse of PWRKEY

pin to power on module

72--

ms

T

on(status)

The time from power-on issue to STATUS pin

output high level(indicating power up ready )

4.2--

s

T

on(uart)

The time from power-on issue to UART port ready

3.5--

s

T

on(usb)

The time from power-on issue to USB port ready

3.5--

s

VIHInput high level voltage on PWRKEY pin

0.6

0.8

1.8

V

VILInput low level voltage on PWRKEY pin

-0.300.5

V

3.2.2 Power off

The following methods can be used to power off SIM7000.

● Method 1: Power off SIM7000 by pulling the PWRKEY pin to ground.

● Method 2: Power off SIM7000 by AT command “AT+CPOWD”.

● Method 3: over-voltage or under-voltage automatic power off. The voltage range can be set by

AT command “AT+CBATCHK”.

● Method 4: over-temperature or under-temperature automatic power off.

Note: If the temperature is outside the range of -30~+80℃, some warning will be reported via

AT port. If the temperature is outside the range of -40~+85℃, SIM7000 will be powered off

automatically.

For details about “AT+CPOWD” and “AT+CBATCHK”, please refer to Document [1].

These procedures will make modules disconnect from the network and allow the software to enter a

safe state, and save data before module be powered off completely.

The power off scenario by pulling down the PWRKEY pin is illustrated in the following figure.

Figure 11: Power off timing sequence

Page 27

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table 9: Power off timing and electronic characteristic

Symbol

Parameter

Time value

Unit

Min.

Typ.

Max.

T

off

The active low level time pulse on PWRKEY pin to

power off module

1.2--

s

T

off(status)

The time from power-off issue to STATUS pin output low

level(indicating power off )*

1.3--

s

T

off(uart)

The time from power-off issue to UART port off

1.3--

s

T

off(usb)

The time from power-off issue to USB port off

1.3--

s

T

off-on

The buffer time from power-off issue to power-on issue

1--

s

*Note: The STATUS pin can be used to detect whether module is powered on or not. When

module has been powered on and firmware goes ready, STATUS will be high level, or else

STATUS will still low level.

3.2.3 Reset Function

SIM7000 can be reset by pulling the RESET pin to ground.

Note: This function is only used as an emergency reset. The RESET pin will be ineffectiveness

in the power off mode.

The RESET pin has been pulled up to 1.8V with a 40KΩ resistor internally. So it does not need to

be pulled up externally. It is strongly recommended to put a100nF capacitor and an ESD protection

diode close to the RESET pin. Please refer to the following figure for the recommended reference

circuit.

Figure 12: Reference reset circuit

Page 28

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table 10: RESET pin electronic characteristic

Symbol

Description

Min.

Typ.

Max.

Unit

T

reset

The active low level time impulse on RESET pin

to reset module

50

100

500

ms

VIHInput high level voltage

1.2

1.8

2.1

V

VILInput low level voltage

-0.300.8

V

3.3 UART Interface

SIM7000 provides a 7-wire UART (universal asynchronous serial transmission) interface as DCE

(Data Communication Equipment). AT commands and data transmission can be performed through

UART interface.

Moreover, if users need to use two UART simultaneously, SIM7000 also provides a 2-wire UART

interface multiplex from GPIO. The GPIO0 multiplex as TXD of the 2-wire UART, and the GPIO1

multiplex as RXD of the 2-wire UART. Standard version cannot support this function

3.3.1 UART Design Guide

The following figures show the reference design.

Figure 13: UART full modem

Figure 14: UART null modem

Page 29

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

The SIM7000 UART is 1.8V voltage interface. If user’s UART application circuit is 3.3V voltage

interface, the level shifter circuits should be used for voltage matching. The TXB0108RGYR

provided by Texas Instruments is recommended. The following figure shows the voltage matching

reference design.

Figure 15: Reference circuit of level shift

To comply with RS-232-C protocol, the RS-232-C level shifter chip should be used to connect

SIM7000 to the RS-232-C interface, for example SP3238ECA, etc.

Note: SIM7000 supports the following baud rates: 300, 600, 1200, 2400, 4800, 9600, 19200,

38400, 57600, 115200, 230400, 460800, 921600, 3200000, 3686400, 4000000bps. The default

band rate is 115200bps.

3.3.2 RI and DTR Behavior

The RI pin description:

The RI pin can be used to interrupt output signal to inform the host controller such as application

CPU.

Normally RI will keep high level until certain conditions such as receiving SMS, or a URC report

coming, and then it will change to low level. It will stay low until the host controller clears the

interrupted event with “AT+CRIRS” AT command.

Figure 16: RI behaviour(SMS and URC report)

Page 30

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Normally RI will be kept at a high level until a voice call, then it will output periodic rectangular

wave with 5900ms low level and 100ms high level. It will output this kind of periodic rectangular

wave until the call is answered or hung up.

Figure 17: RI behaviour(voice call)

Note: For more details of AT commands about UART, please refer to document [1] and [22].

The DTR pin description:

After setting the AT command “AT+CSCLK=1”, SIM7000 will enter sleep mode by pulling up the

DTR pin when module is in the idle mode. In sleep mode, the UART is unavailable. When

SIM7000 enters sleep mode, pulling down DTR can wake up module.

3.4 USB Interface

The SIM7000 contains a USB interface compliant with the USB2.0 specification as a peripheral,

but the USB charging function is not supported.

SIM7000 supports the USB suspend and resume mechanism which can reduce power consumption.

If there is no data transmission on the USB bus, SIM7000 will enter suspend mode automatically,

and will be resumed by some events such as voice call, receiving SMS, etc.

Figure 18: USB reference circuit

Because of the high speed on USB bus, more attention should be paid to the influence of the

junction capacitance of the ESD component on USB data lines. Typically, the capacitance of the D1

and D2 should be less than 1pF.

D3 is suggested to select the diode with anti-ESD and voltage surge function, or customer could

add a ZENER diode for surge clamping.

Note:The USB_DM and USB_DP nets must be traced by 90Ohm+/-10% differential impedance.

Page 31

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

3.5 SIM Interface

SIM7000 supports both 1.8V and 3.0V SIM Cards.

Table 11: SIM electronic characteristic in 1.8V mode (SIM_VDD=1.8V)

Symbol

Parameter

Min.

Typ.

Max.

Unit

SIM_V

DD

LDO power output voltage

1.75

1.8

1.95

V

VIHHigh-level input voltage

0.65*SIM_VDD

-

SIM_VDD +0.3

V

VILLow-level input voltage

-0.300.35*SIM_VDD

V

VOHHigh-level output voltage

SIM_VDD -0.45

-

SIM_VDD

V

VOLLow-level output voltage

000.45

V

Table 12: SIM electronic characteristic 3.0V mode (SIM_VDD=2.95V)

Symbol

Parameter

Min.

Typ.

Max.

Unit

SIM_V

DD

LDO power output voltage

2.75

2.95

3.05

V

VIHHigh-level input voltage

0.65*SIM_VDD

-

SIM_VDD +0.3

V

VILLow-level input voltage

-0.300.25*SIM_VDD

V

VOHHigh-level output voltage

SIM_VDD -0.45

-

SIM_VDD

V

VOLLow-level output voltage

000.45

V

3.5.1 SIM Application Guide

It is recommended to use an ESD protection component such as ESDA6V1W5 produced by ST

(www.st.com ) or SMF15C produced by ON SEMI (www.onsemi.com ). Note that the SIM

peripheral circuit should be close to the SIM card socket. The following figure shows the 6-pin

SIM card holder reference circuit.

Figure 19: SIM interface reference circuit

Page 32

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Note: SIM_DATA has been pulled up with a 10KΩ resistor to SIM_VDD in module. A 100nF

capacitor on SIM_VDD is used to reduce interference. For more details of AT commands about

SIM, please refer to document [1].SIM_CLK is very important signal, the rise time and fall time

of SIM_CLK should be less than 40ns, otherwise the SIM card might not be initialized correctly.

If SIM_DET is used, a 10KΩ resistor is necessary to pulling up to the power VDD_EXT.

3.5.2 Recommended SIM Card Holder

It is recommended to use the 6-pin SIM socket such as C707 10M006 512 produced by Amphenol.

User can visit http://www.amphenol.com for more information about the holder.

Figure 20: Amphenol SIM card socket

Table 13: Amphenol SIM socket pin description

Pin

Signal

Description

C1

SIM_VDD

SIM Card Power supply.

C2

SIM_RST

SIM Card Reset.

C3

SIM_CLK

SIM Card Clock.

C5

GND

Connect to GND.

C6

VPP

C7

SIM_DATA

SIM Card data I/O.

Page 33

3.6 PCM Interface

SIM7000 provides a PCM interface for external codec, which can be used in master mode with

short sync and 16 bits linear format.

Table 14: PCM format

Note: For more details about PCM AT commands, please refer to document [1].

3.6.1 PCM timing

SIM7000 supports 2.048 MHz PCM data and sync timing for 16 bits linear format codec.

Figure 21: PCM_SYNC timing

Figure 22: External codec to module timing

Characteristics

Specification

Line Interface Format

Linear(Fixed)

Data length

16bits(Fixed)

PCM Clock/Sync Source

Master Mode(Fixed)

PCM Clock Rate

2048 KHz (Fixed)

PCM Sync Format

Short sync(Fixed)

Data Ordering

MSB

Page 34

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Figure 23: Module to external codec timing

Table 15: PCM timing parameters

Parameter

Description

Min.

Typ.

Max.

Unit

T(sync)

PCM_SYNC cycle time

–

125–μs

T(synch)

PCM_SYNC high level time

–

488–ns

T(syncl)

PCM_SYNC low level time

–

124.5

–

μs

T(clk)

PCM_CLK cycle time

–

488–ns

T(clkh)

PCM_CLK high level time

–

244–ns

T(clkl)

PCM_CLK low level time

–

244–ns

T(susync)

PCM_SYNC setup time high before falling edge

of PCM_CLK

–

122–ns

T(hsync)

PCM_SYNC hold time after falling edge of

PCM_CLK

–

366–ns

T(sudin)

PCM_IN setup time before falling edge of

PCM_CLK

60––

ns

T(hdin)

PCM_IN hold time after falling edge of

PCM_CLK

60––

ns

T(pdout)

Delay from PCM_CLK rising to PCM_OUT valid

––60

ns

T(zdout)

Delay from PCM_CLK falling to PCM_OUT

HIGH-Z

––60

ns

Page 35

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

3.6.2 PCM Application Guide

The following figure shows the external codec reference design.

Figure 24: Audio codec reference circuit

3.7 I2C Interface

SIM7000 provides a I2C interface compatible with I2C specification, version 5.0, with clock rate

up to 400 kbps. Its operation voltage is 1.8V.

The following figure shows the I2C bus reference design.

Figure 25: I2C reference circuit

Note:I2C_SDA and I2C_SCL do not have pull-up resistors in module. So the two external

pulling up resistors are needed in application circuit.

“AT+CRIIC and AT+CWIIC” AT commands could be used to read/write register values of the

I2C peripheral devices. For more details about AT commands please refer to document [1].

3.8 Network status

The NETLIGHT pin is used to control Network Status LED, its reference circuit is shown in the

Page 36

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

following figure.

Figure 26: NETLIGHT reference circuit

Note: The value of the resistor named “R” depends on the LED characteristic.

Table 16: NETLIGHT pin status

NETLIGHT pin status

Module status

64ms ON, 800ms OFF

No registered network

64ms ON, 3000ms OFF

Registered network

64ms ON, 300ms OFF

Data transmit

OFF

Power off or PSM mode

Note: NETLIGHT output low level as “OFF”, and high level as “ON”.

3.9 Other interface

3.9.1 ADC

SIM7000 has a dedicated ADC pin. It is available for digitizing analog signals such as battery

voltage and so on. The electronic specifications are shown in the following table.

Table 17: ADC electronic characteristics

Characteristics

Min.

Typ.

Max.

Unit

Resolution

–15–

Bits

Conversion time

–

442

–

ms

Page 37

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Input Range

0.1

1.7

V

Input serial resistance

1

–

–

MΩ

Note: “AT+CADC” can be used to read the voltage of the ADC pin, for more details, please refer

to document [1].

3.9.2 LDO

SIM7000 has a LDO power output named VDD_EXT. The output voltage is 1.8V.

Figure 27:Power on sequence of the VDD_EXT

Table 18: Electronic characteristic

Symbol

Description

Min.

Typ.

Max.

Unit

V

VDD_EXT

Output voltage

1.7

1.8

1.9

V

IOOutput current

--50

mA

Note:The VDD_EXT is used to the IO power in the module. The Output voltage is not supported

to set.

Page 38

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

4 RF Specifications

4.1 LTE CAT-M1 RF Specifications

Table 19: Conducted transmission power

Frequency BAND

Power

Min.

1

23dBm +/-2.7dB

<-40dBm

2

23dBm +/-2.7dB

<-40dBm

3

23dBm +/-2.7dB

<-40dBm

4

23dBm +/-2.7dB

<-40dBm

5

23dBm +/-2.7dB

<-40dBm

8

23dBm +/-2.7dB

<-40dBm

12

23dBm +/-2.7dB

<-40dBm

13

23dBm +/-2.7dB

<-40dBm

17

23dBm +/-2.7dB

<-40dBm

18

23dBm +/-2.7dB

<-40dBm

19

23dBm +/-2.7dB

<-40dBm

20

23dBm +/-2.7dB

<-40dBm

26

23dBm +/-2.7dB

<-40dBm

39

23dBm +/-2.7dB

<-40dBm

Table 20: Operating frequencies

Frequency

Receiving

Transmission

GPS L1 BAND

1574.4 ~1576.44 MHz

-

GLONASS

1598 ~1606 MHz

-

BD

1559 ~1563 MHz

LTE CAT-M1BAND

Refers to Table 21

Page 39

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table 21: E-UTRA operating bands

E-UTRA

UL Freq.

DL Freq.

Duplex Mode

1

1920 ~1980 MHz

2110 ~2170 MHz

HD-FDD

2

1850 ~1980 MHz

1930~1990 MHz

HD-FDD

3

1710 ~1785 MHz

1805 ~1880 MHz

HD-FDD

4

1710~1755 MHz

2110 ~2155 MHz

HD-FDD

5

824 ~849 MHz

869 ~894 MHz

HD-FDD

8

880 ~915 MHz

925 ~960 MHz

HD-FDD

12

699 ~716 MHz

729 ~746 MHz

HD-FDD

13

777 ~787 MHz

746 ~756 MHz

HD-FDD

17

704 ~716 MHz

734 ~746 MHz

HD-FDD

18

815 ~830 MHz

860 ~875 MHz

HD-FDD

19

830 ~845 MHz

875 ~890 MHz

HD-FDD

20

832 ~862 MHz

791 ~821 MHz

HD-FDD

26

814 ~849 MHz

859 ~894 MHz

HD-FDD

28

703 ~748 MHz

758 ~803 MHz

HD-FDD

39

1880 ~1920 MHz

1880 ~1920 MHz

TDD

Table 22: Conducted receive sensitivity

Frequency

Receive sensitivity(Typical)

Receive sensitivity(MAX)

LTE CAT-M1FDD/TDD

Refers to Table 23

Page 40

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Table 23: CAT-M1 Reference sensitivity (QPSK)

E-UTRA Band

REFSENS (dBm)

Duplex Mode

1

-103

HD-FDD

2

-101

HD-FDD

3

-100

HD-FDD

4

-103

HD-FDD

5

-101.5

HD-FDD

7

-101

HD-FDD

8

-100.5

HD-FDD

11

-103

HD-FDD

12

-100

HD-FDD

13

-100

HD-FDD

18

-103

HD-FDD

19

-103

HD-FDD

20

-100.5

HD-FDD

21

-103

HD-FDD

26

-101

HD-FDD

27

-101.5

HD-FDD

28

-101.5

HD-FDD

31

-97.3

HD-FDD

39

-103.7

TDD

41

-101.7

TDD

Maximum Power Reduction (MPR)

Modulation

Channel bandwidth / Transmission bandwidth (NRB)

MPR

(dB)

1.4

MHz

3.0

MHz

5

MHz10MHz15MHz20MHz

QPSK

>2>2>1>4--≤ 1

QPSK

>5>5----≤ 2

16 QAM

≤ 2

≤ 2>1>3--

≤ 1

16QAM

>2>2>3>5--≤ 2

Page 41

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

4.2 LTE CAT-M1 Antenna Design Guide

Users should connect antennas to SIM7000’s antenna pads through micro-strip line or other types

of RF trace and the trace impedance must be controlled in 50Ω. SIMCom recommends that the

total insertion loss between the antenna pads and antennas should meet the following requirements:

Table 24: Trace loss

Frequency

Loss

700MHz-960MHz

<0.5dB

1710MHz-2170MHz

<0.9dB

2300MHz-2650MHz

<1.2dB

To facilitate the antenna tuning and certification test, a RF connector and an antenna matching

circuit should be added. The following figure is the recommended circuit.

Page 42

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Figure 28: Antenna matching circuit (MAIN_ANT)

In figure 28, the components L101,C106,C107 and R101 or R102 are used for antenna matching,

the values of components can only be achieved after the antenna tuning and usually provided by

antenna vendor. By default, the L101,R101or R102 are 0 Ω resistors, and the C106, C107 are

reserved for tuning. The RF test connector is used for the conducted RF performance test, and

should be placed as close as to the module’s MAIN_ANT pin. The traces impedance between

SIM7000 and antenna must be controlled in 50Ω.

4.3 GNSS

SIM7000 merges GNSS (GPS/GLONASS/BD) satellite and network information to provide a

high-availability solution that offers industry-leading accuracy and performance. This solution

performs well, even in very challenging environmental conditions where conventional GNSS

receivers fail, and provides a platform to enable wireless operators to address both location-based

services and emergency mandates.

4.3.1 GNSS Technical specification

Tracking sensitivity: -162 dBm(GPS)/-158 dBm(GLONASS)/TBD (BD)

Cold-start sensitivity: -148 dBm

Page 43

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

Accuracy (Open Sky): 2.5m (CEP50)

TTFF (Open Sky) : Hot start <1s, Cold start<35s

Receiver Type: 16-channel, C/A Code

GPS L1 Frequency: 1575.42±1.023MHz

GLONASS: 1597.5~1605.8 MHz

BD: 1559.05~1563.14 MHz

Update rate: Default 1 Hz

GNSS data format: NMEA-0183

GNSS Current consumption : 100mA (GSM/LTE CAT-M1Sleep ,in total on VBAT pins)

GNSS antenna: Passive/Active antenna

Note: If the antenna is active type, the power should be given by main board because there is no

power supply on the GPS antenna pad. If the antenna is passive, it is suggested that the external

LNA should be used.

4.3.2 GNSS Application Guide

Users can adopt an active antenna or a passive antenna to SIM7000. If using a passive antenna, an

external LNA is a must to get better performance. The following figures are the reference circuits.

Figure 29: Active antenna circuit

Figure 30: Passive antenna circuit (Default)

Page 44

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

In above figures, the components C1, L1 and L2 are used for antenna matching. Usually, the values

of the components can only be achieved after antenna tuning and usually provided by antenna

vendor. C2 is used for DC blocking. L3 is the matching component of the external LNA, and the

value of L3 is determined by the LNA characteristic and PCB layout. Both VDD of active antenna

and V_LNA need external power supplies which should be considered according to active antenna

and LNA characteristic. LDO/DCDC is recommended to get lower current consuming by shutting

down active antennas and LNA when GNSS is not working.

GNSS can be tested by NMEA port. NMEA sentences can be obtained through UART or USB

automatically. NMEA sentences include GSV, GGA, RMC, GSA, and VTG. Before using GNSS,

user should configure SIM7000 in proper operating mode by AT command. Please refer to related

documents for details. SIM7000 can also get position location information through AT directly.

Note:

1. GNSS is closed by default and can be started by “AT+CGNSPWR=1”. The AT command has

two parameters, the first is on/off, and the second is GNSS mode. Default mode is standalone

mode.

AGPS mode needs more support from the mobile telecommunication network. Please refer to

document [24] for more details.

2. If the passive antenna is used, put the LNA close to the antenna.

3. Make sure there are no noise signals around GNSS antenna.

Page 45

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

5 Electrical Specifications

5.1 Absolute maximum ratings

Absolute maximum rating for digital and analog pins of SIM7000 are listed in the following table:

Table 26: Absolute maximum ratings

Parameter

Min.

Typ.

Max.

Unit

Voltage at VBAT

-0.5-6.0

V

Voltage at USB_VBUS

-0.5-5.85

V

Voltage at digital pins

(RESET,GPIO,I2C,UART,PCM)

-0.3-2.1

V

Voltage at digital pins (SIM)

-0.3-3.05

V

Voltage at PWRKEY

-0.3-1.8

5.2 Operating conditions

Table 27: Recommended operating ratings

Parameter

Min.

Typ.

Max.

Unit

Voltage at VBAT

3.0

3.8

4.3

V

Voltage at USB_VBUS

3.5

5.0

5.25

V

Table 28: 1.8V Digital I/O characteristics*

Parameter

Description

Min.

Typ.

Max.

Unit

VIHHigh-level input voltage

1.17

1.8

2.1

V

VILLow-level input voltage

-0.300.63

V

VOHHigh-level output voltage

1.35-1.8

V

VOLLow-level output voltage

0-0.45

V

I

OH

High-level output current(no

pull down resistor)

-2-

mA

I

OL

Low-level output current(no pull

up resistor)

--2-

mA

I

IH

Input high leakage current (no

pull down resistor)

--1

uA

I

IL

Input low leakage current(no

pull up resistor)

-1--

uA

Page 46

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

*Note: These parameters are for digital interface pins, such as GPIOs (including

NETLIGHT,STATUS,SIM_DET), I2C, UART, PCM, MDM_LOG_TX and BOOT_CFG.

The operating temperature of SIM7000 is listed in the following table.

Table 29: Operating temperature

Parameter

Min.

Typ.

Max.

Unit

Normal operation temperature

-302580

℃

Extended operation temperature*

-402585

℃

Storage temperature

-4525+90

℃

*Note: Module is able to make and receive voice calls, data calls, SMS and make GSM/LTE

CAT-M1traffic in -40 ℃ ~ +85 ℃ . The performance will be reduced slightly from the 3GPP

specifications if the temperature is outside the normal operating temperature range and still

within the extreme operating temperature range.

5.3 Operating Mode

5.3.1 Operating Mode Definition

The table below summarizes the various operating modes of SIM7000 product.

Table 30: Operating mode Definition

Mode

Function

Normal operation

LTE CAT-M1Sleep

In this case, the current consumption of module will be reduced to the

minimal level and the module can still receive paging message and

SMS.

/LTE CAT-M1Idle

Software is active. Module is registered to the network, and the

module is ready to communicate.

LTE CAT-M1Talk

Connection between two subscribers is in progress. In this case, the

power consumption depends on network settings such as DTX off/on,

FR/EFR/HR, hopping sequences, and antenna.

LTE CAT-M1Standby

Module is ready for data transmission, but no data is currently sent or

received. In this case, power consumption depends on network

settings.

LTEData transmission

There is data transmission in progress. In this case, power

consumption is related to network settings (e.g. power control level);

uplink/downlink data rates, etc.

Minimum functionality

mode

AT command “AT+CFUN=0” AT+CSCLK=1 can be used to set the

module to a minimum functionality mode without removing the

power supply. In this mode, the RF part of the module will not work

and the SIM card will not be accessible, but the serial port and USB

port are still accessible. The power consumption in this mode is lower

Page 47

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

than normal mode.

Flight mode

AT command “AT+CFUN=4” can be used to set the module to flight

mode without removing the power supply. In this mode, the RF part

of the module will not work, but the serial port and USB port are still

accessible. The power consumption in this mode is lower than normal

mode.

PSM mode

Setting the timer of the software can be entered PSM mode. In this

mode, the module will be the least current consumption. Meanwhile,

all the output of the LDO and DCDC in the module will be closed

except the RTC power. And also all of the functions will be

unavailable except the RTC function. RTC timer can wake up the

module.

Power off mode

Module will go into power off mode by sending the AT command

“AT+CPOWD” or pull down the PWRKEY pin, normally. In this

mode the power management unit shuts down the power supply, and

software is not active. The serial port and USB are is not accessible.

5.3.2 Sleep mode

In sleep mode, the current consumption of module will be reduced to the minimal level, and

module can still receive paging message and SMS.

Several hardware and software conditions must be satisfied together in order to let SIM7000 enter

sleep mode:

1. UART condition

2. USB condition

3. Software condition

Note: Before designing, pay attention to how to realize sleeping/waking function and refer to

Document [26] for more details.

5.3.3 Minimum functionality mode and Flight mode

Minimum functionality mode ceases a majority function of the module, thus minimizing the power

consumption. This mode is set by the AT command which provides a choice of the functionality

levels.

● AT+CFUN=0: Minimum functionality

● AT+CFUN=1: Full functionality (Default)

● AT+CFUN=4: Flight mode

If SIM7000 has been set to minimum functionality mode, the RF function and SIM card function

will be closed. In this case, the serial port and USB are still accessible, but RF function and SIM

card will be unavailable.

If SIM7000 has been set to flight mode, the RF function will be closed. In this case, the serial port

and USB are still accessible, but RF function will be unavailable.

Page 48

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

When SIM7000 is in minimum functionality or flight mode, it can return to full functionality by the

AT command “AT+CFUN=1”.

5.4 Current Consumption

The current consumption is listed in the table below.

Table 31: Current consumption on VBAT Pins (VBAT=3.8V)

GNSS

GNSS supply current

(AT+CFUN=0,with USB connection)

Tracking Typical: 34mA

LTE CAT-M1sleep/idle mode

LTE CAT-M1supply current

(GNSS off,without USB connection)

Sleep mode Typical: 1mA

Idle mode Typical: 11mA

LTE CAT-M1Talk

TBD

TBD

TBD

TBD

LTE CAT-M1data

LTE-FDD B2

@23dbm Typical: 160mA

@10dbm Typical: 116mA

@0dbm Typical: 102mA

LTE-FDD B4

@23dbm Typical: 168mA

@10dbm Typical: 117mA

@0dbm Typical: 113mA

LTE-FDD B12

@23dbm Typical: 167mA

@10dbm Typical: 109mA

@0dbm Typical: 96mA

LTE-FDD B13

@23dbm Typical: 167mA

@10dbm Typical: 109mA

@0dbm Typical: 98mA

Page 49

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

5.5 ESD Notes

SIM7000 is sensitive to ESD in the process of storage, transporting, and assembling. When

SIM7000 is mounted on the users’ mother board, the ESD components should be placed beside the

connectors which human body may touch, such as SIM card holder, audio jacks, switches, keys, etc.

The following table shows the SIM7000 ESD measurement performance without any external ESD

component.

Table 32: The ESD performance measurement table (Temperature: 25℃, Humidity: 45%)

Part

Contact discharge

Air discharge

VBAT,GND

+/-6K

+/-12K

Antenna port

+/-5K

+/-10K

USB

+/-4K

+/-8K

UART

+/-4K

+/-8K

Other PADs

+/-3K

+/-6K

Page 50

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

6 SMT Production Guide

6.1 Top and Bottom View of SIM7000

Figure 31: Top and bottom view of SIM7000

Page 51

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

6.2 Label Information

Figure 32: Label information

Table 33: The description of label information

No.

Description

A

LOGO

B

No.1 Pin

C

Project name

D

Product code

E

Serial number

F

International mobile equipment identity

G

QR code

Page 52

Smart Machine Smart Decision

SIM7000 _Hardware Design _V1.00 2017-05-23

6.3 Typical SMT Reflow Profile

SIMCom provides a typical soldering profile. Therefore the soldering profile shown below is only

a generic recommendation and should be adjusted to the specific application and manufacturing

constraints.

Figure 33: The ramp-soak-spike reflow profile of SIM7000

Note: For more details about secondary SMT, please refer to the document [21].

6.4 Moisture Sensitivity Level (MSL)

SIM7000 is qualified to Moisture Sensitivity Level (MSL) 3 in accordance with JEDEC J-STD-033.

If the prescribed time limit is exceeded, users should bake modules for 192 hours in drying