ENGLISH

DAKAR

DAKAR400

E-2

1

ENGLISH

2

“EC” DECLARATION OF CONFORMITY

SIMA, S.A.

Polígono Industrial Juncaril, C/ Albuñol, Parcela 250 C. P. 18220 Albolote, Granada (SPAIN)

Company responsible for manufacturing and commercialising the below specified machine:

MATERIALS TABLE SAW

ENGLISH

DECLARES:

That the above mentioned machine designed for maso nry cutting of stone and other

construction materials is in conformity with all applicable provisions of the Directive of

Machines

(2006/42/CE) and the national applicable regulations.

The machine is also in conformity with EC applicable provisions:

2006/95/CE; 2004/108/CE; 2000/14/CE; 2002/44/CE; 2002/95/CE; 2002/96/CE

The machine is also in conformity with the provisions of the following applicable norms

UNE-EN 292-1; UNE-EN 292 -2; UNE-EN 294; UNE-EN 349; UNE-EN 60204-1; UNE-EN 12418;

UNE-EN 1050 ; UNE-EN 953.

Details of the authorized person to elaborate the technical file

Eugenio Fernández Martín

Technical Department Manager

SIMA S.A.

Polígo no Industrial Junc aril, C/ Albuñol, Parcela 250 - 18220 Albolote, Gra nada (SP AI N)

Albolote 01.01.2010

Signed:

Javier García Marina

Managing Director

3

ENGLISH

ÍNDICE

“EC” DECLARATION OF CONFORMITY ............................................................ 3

1. GENERAL INFORM A TI ON ............................................................................ 5

2. GENERAL DESCRIPTION OF THE MACHINE ................................................. 5

2.1 PICTOGRAMAS ................................................................................................................. 6

3. TRANSPORTATION ..................................................................................... 6

4. ELECTRICAL PLUGGING AND AD JUSTING THE DISK ROTATION SENSE ...... 7

5. ELECTRICAL EQUI PMENT ........................................................................... 7

6. SEGURITY RECOMENDATIONS. .................................................................. 8

7. DESCRIPTION .......................................................................................... 10

8. MOUNTING AND DISMOUNTING THE CUTTING DISK ............................... 11

8.1 MOUNTING/REPLACING THE CUTTING DISK ...................................................................... 11

9. MACHINE STARTING-UP AND USING INSTRUCTIONS .............................. 12

9.1 ASSEMBLY INSTRUCIONS ................................................................................................ 12

9.2 FILLING THE TRAY WITH WATER

9.3 POSITION OF THE MACHINE AND THE OPERATOR, CONNECTION AND DISCONNECTION

9.4 DJUSTABLE CUTTING RUL E

9.5 CHANGING POSITION FROM 300 TO 350MM OR 350 TO 400MM BLADE

9.6 CUTTING LENGHT SWITCH

...................................................................................... 13

........ 13

............................................................................................. 14

................................ 14

.............................................................................................. 15

10. MAINTENANCE ....................................................................................... 15

10.1 SETTING THE ANGLE OF THE BLADE ............................................................................... 16

10.2 GUIDEWAY ALIGNMENT BLADE

11. SOLUTIONS TO MOST FREQUENT ANOMALIES ....................................... 18

12. TECNICA L CHARACTERISTICS ................................................................ 19

13. WARRANTY ............................................................................................ 20

14. SPARE PARTS ......................................................................................... 20

15. ENVIROMENT PROTECTION. ................................................................... 20

16. DECLARATION OF NOISES. ..................................................................... 20

17. DECLARATION ON MECHANICAL VIBRATIONS ....................................... 20

18. ELECTRICAL SCHEMES . .......................................................................... 21

...................................................................................... 17

4

ENGLISH

1. GENERAL INFORMATION

WARNING: Please read and understand perf e c tly the pr e se nt in struction before using the machine.

SIMA S.A. thanks you for your trust in our products and for purchasing the TABLE SAW DAKAR MEKANO or

DAKAR400 MEKANO model

This manual provides you w ith the necessary instructions to star t, use, maintain and in your cas e, repair of

the present machine. All aspects as far as the safety and health of the users is concerned have been stated.

Respecting all instructio ns and recommendations assures safe ty and low maintenance. As such, re ading this manual

carefully is compulsory for any person responsi b le for the use, mainte nanc e or rep air of this mac hine .

As such, reading this manual carefully is compulsory for any person responsible for the use, maintenance or

repair of this machine.

It is recommended to have always this manual in an easily accessible place where the machine is being

used.

2. GENERAL DESCRIPTION OF THE MACHINE

SIMA Cutting Table Saws, DAKAR MEKANO or DAKAR400 MEKANO models, are designed and manufactured to

be used at masonry building sites, in particular to cut until 20 cm high concrete blocks and other construction

materials, mineral and co mpounds with at least one bearing side (tile , terrazzo, brick, marble, granite , concrete or

ceramics shingle, stoneware... T he cutting tool is a d iamond disk powered by an electric mo tor and water cooled by a

closed-circuit pump. The progress of the disk is done manually by moving the cutting head in the direction of the

material to be cut. The DAKAR MEKANO or DAKAR400 MEKANO models ar e manuf ac tured of high q ua lity materials.

Any use other than the machine has been designed for is considered inappropriate and can be

dangerous; therefore, it is expressly prohibited.

• DAKAR MEKANO or DAKAR400 MEKANO models are very reliable table saw on work sir, capable to

performance mitring and 90º cutting.

• Enable to move the head up and down directions easily and manually way , thro ugh turning and blocking the

head using the handle proportionate for the pur po se

• The head of the motor keep the right balance even when the block is cancel due a spring.

• Its steel chassis avoid vibrations d ur ing c utting . The re fo re we get a better eff ic ie ncy of the diamond blade.

• The sliding cart is supported by four wheels which roll over two rolling tracks build with a “U” frame. A rubber

protection is dispose on the sliding cart in its upper sid e to avoid the s lid i ng of the material being cut.

• The machine has four demountable legs to facilitate its tr ansport and handles for its displacement.

• It has been furnished with a graduated ruler to cut pieces in angle s . It carrie s o ut mitre -cuts up to 45º.

• The machine is protected with an anti-splatter scr een to avoid the water splashing towards the back part of

the machine where the cutting is being performed.

• The frame of the machine is painted with a highly resistant anti-corrosion epoxy polyester paint.

• This machine has been designed and manufactured to cut with a water cooled diam o nd d isk. T he cooli ng is

carried out by a closed-circuit electric pump with a cons tant wate r f low .

• The electric pump with a high impedance windi ng avoids its burning in normal conditions of use and certainly

that it is always covered with water.

• Bearings´ electric motors are mounted with a high waterproof grade in order to guarante e long liv e to its

elements.

5

2.1 PICTOGRAMAS

Pictograms included in the machine entail the follo wing:

• USE SAFETY BOO T S

• USE HELMET AND EYE AND AUDITIVE PROTECTION

• READ INSTRUCTIONS MANUAL

• USE SAFETY GLO VES.

• SOUND POWER LEVEL ISSUED BY THE MACHIN E.

ENGLISH

Machine connected to 110V.

Machine connected to 230V.

Machine connected to 400V.

Hot surfaces.

Entry not allowed to persons outside the labor. Warning cutting tool.

Minimum cutting unit distance DAKAR MEKANO.

Minimum cutting unit distance DAKAR400 MEKANO.

Height of the cutting unit to 300 and 350 blade.

Height of the cutting unit to 350 and 400 blade.

Cutting length adjustment.

3. TRANSPORTATION

After unpacking the machine, it can be move it into the work place manually by two people.

6

ENGLISH

It is recommended to empty the water from the tray before moving the machine to avoid splashing or

spillage. It is also necessary to block the car to avoid unexpected slip during transport. Check also that they are fully

tightened the screws holding the legs to the tray to avoid dislodging the raising machine.

4. ELECTRICAL PLUGGING AND ADJUSTING THE DISK ROTATION SENSE

Upon receipt of the machine, make sure the network elec trical tension is adeq uate before plug ging the machine. The

electrical tension is to be found on the voltage indi c ation next to the switch of the machine.

WARNING: Never plug the machine to electricity, in case the ne twork power tension is no t the adequate

as the engine would undergo irreparable damages .

Once you have realised the previous steps and before placing the disk and manipulate the motor, it is

necessary to check and adj ust the rotation o f the motor ax is correctly, yo u have to plug the machine to the e lectricity

and start it up, watching the rotation directio n that mus t be clo ckw i se.

If necessary and with thr ee-phase mo tors, yo u can change the ro tation dir ection s wapping the two phas e wires in the

aerial or in the peg of the feeding extension cord.

WARNING: Never manipulate power supply cables or any other electrical

equipment on the machine before you unplug the machine from ele c tricity.

WARNING: Unplug the machine from the network before procee ding to change the

position of the bridge plates on the engines. Yo u should also proceed to change the

stickers indicating the supply voltage, so there will always be indicated on the

machine rated voltage.

5. ELECTRICAL EQUIPMENT

The electrical equipm ent of the DAKAR MEKANO or DAKAR400 MEKANO cutting tables manufacture d by SIMA,

S.A. has an IP54 protectio n degree. The power supply on this machine has a low minima l tension coil to avoid any

unexpected starting-up of the mac hi ne . Whe n there is a power cut or a f a ll o f tension that causes the machine to s to p,

7

ENGLISH

and once the normal power cond itions have been re-established, the m otor does not start until the green button is

pressed.

ATENCIÓN: The three-phase DAKAR MEKANO or DAKAR40 0 MEKANO models leave the factory prepared to work at

400V.

ATENCIÓN: When necessary to use a three-phase power tension at 230V , we need to swap the pos itions of

the bridge plates in the motor terminals box, as indicate d in the fo ll o w i ng figure:

ATENCIÓN: The extension cable used to feed the machine

needs to have a minimum section on the table as shown below

6. SEGURITY RECOMENDATIONS.

The machines with electric motor should always be

connected to a standard electrical box that has a circuit

breaker and a Residual-current device in accordance with

the characteristics of the engine ( see table).

8

WARNING: Always use earth p lug b ef or e star ti ng -up the machine.

• Use normalised cables

• Make sure the feeding voltage is in accordance with the voltage indicated in the adhesive label on the

machine.

• Make sure that the extension cords are not in contact with points of high temperature, oil, water, sharp

edges.

• Do not use high pressure water to clean circuits or electrical elements.

• The damaged electrical cables should be urgently replaced.

• Mantengan en su posición los elementos y protecc io ne s de seguridad.

• Always use approved protective items (glov es, he lm e t, goggles , boots ... ..)

• Turn the machine on the netw o rk and do not handle or operate on the m e c hanic al a nd e le c trical machine with

the engine running.

• Cutting table machines should be used by people who are familiar with its operation.

• It´s not allow to acc ess and manipulation of the machine to people who are not familiar with the mac hine

before.

• Work clothes should not include loose c lothing that c o uld get c aug ht in moving parts of the machine.

• Before starting the machine, read the instructions carefully and observe compliance with safety standar ds.

Learn well how to stop the machine quickly and safely.

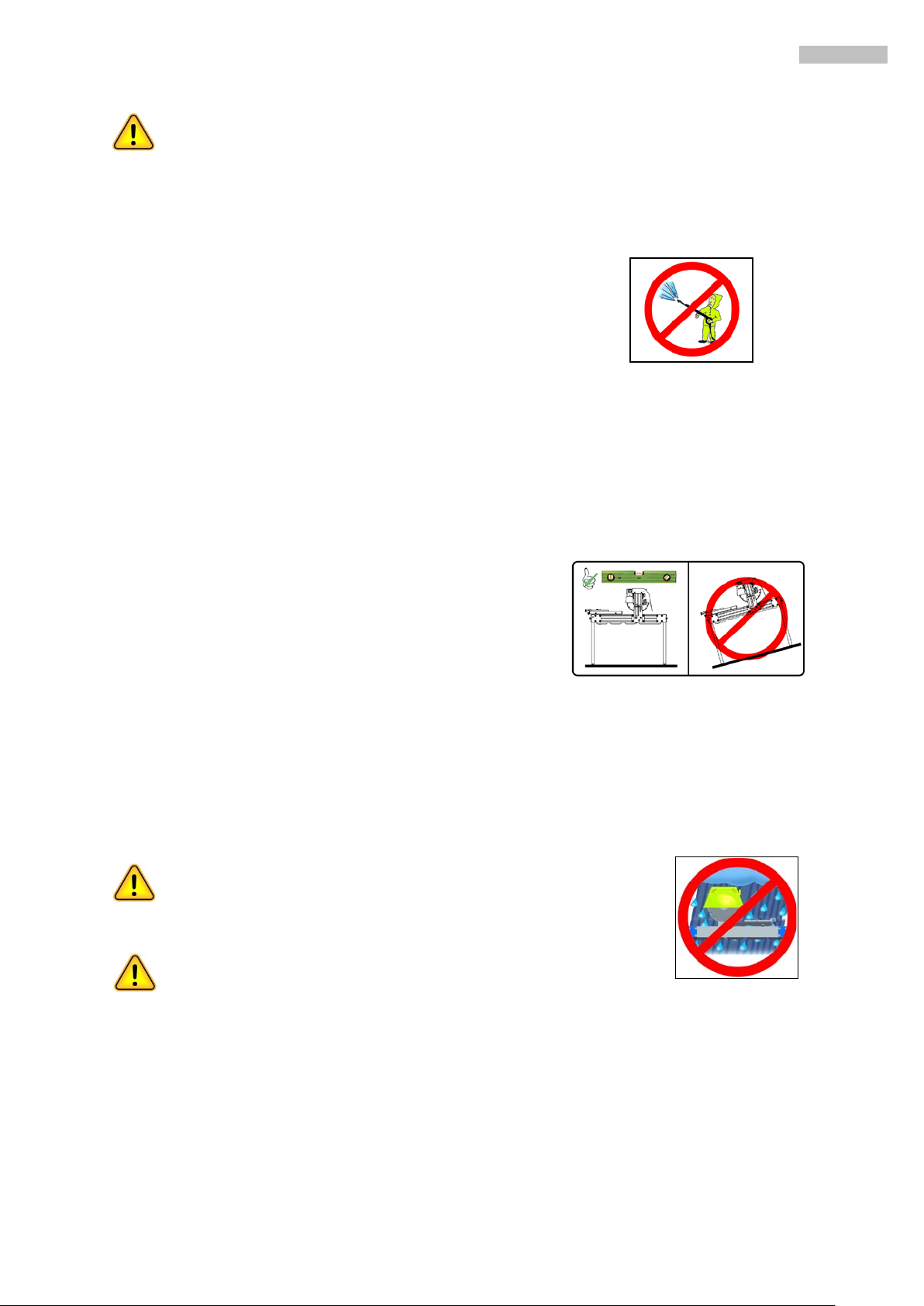

• Place the machine on a flat and well lit and you do not switch the machine on until it´s got a balance

position.

• Make sure the machine is in perfect technical condition and fully oper ational.

• Do not operate the machine if all the prote ctions and safeguards are assembled which have been designed

for that purpose.

• When moving the machine, always verify that eng ine and moving parts are blocked.

• Use only diamond blades specifie d in this manual.

This machine M UST NOT BE U SED IN THE RAIN. Cover with waterproof

materials. If the machine has been exposed in the rain check before

connecting the electrical parts are not wet. Always work with good

lighting conditions.

ENGLISH

WARNING: You must follow all safety recommendations outlined in this

manual and comply with regulations for the pr evention of occupational hazards of each place

SIMA, S.A. is not responsible for the consequences possibly generated but the inadequate use of the

materials cutting machine DAKAR MEKANO or DAKAR400 MEKANO model.

9

Loading...

Loading...