Page 1

0

Instruction Manual

Hydraulic Jack

Note: The Owner/Operator must read carefully and understand

all the information presented here before operation.

Page 2

1

1

Warning in advance………………………………

2 2 Description………………………………………..

2 3 Transporting & Storing…………………………...

3

3.1

Storing……………………………………

3

3.2

Transporting…………………………….

3 4 Installing…………………………………………...

3 5 Operating………………………………………….

4 5.1

Scope of use…………………………….

4

5.2

Method of operating…………………….

4

5.3

Safety standard…………………………

5 6 Maintaining………………………………………..

7 7 Add oil……………………………………………..

8

8

Trouble shooting guide…………………………..

8 9 List of parts………………………………………..

9

10

Constructional detail of part……………………..

10

Contents

Page 3

2

THANK YOU VERY MUCH FOR CHOOSING OUR HYDRAULIC

JACK. FOR YOUR SAFETY AND CORRECT OPERATION,

PLEASE CAREFULLY READ THE MANUAL BEFORE USE.

NOTE: All of the information reported herein is based on data

available at the time of printing. The factory reserves the right to

modify its own products at any time without notice or incurring in any

sanction. Please verify with the factory for possible updates.

1. WARNING IN ADVANCE

1.1 This jack shall be operated only by those peoples of

profession, with skills, and of educated.

1.2 The use of this jack should follow every important points

described in this manual, otherwise the injure of operators or

damage of articles during use of this jack might be happened

because of negligence.

1.3 Before jack-operating, operator should check and confirm that

the jack is in good state.

1.4 The original manufacturer has no responsibility to the change

of jack's mechanical property caused by maintaining of the

third party without any written permission from manufacturer

except repairing by the manufacturer or his agency.

2. DESCRIPTION

This package includes one jack, one spare parts bag and one this

manual.

Page 4

3

Model

HM50

HM100

Loading (ton)

5ton

10ton

Lifting height (mm)

205

230

Min.height / tooth (mm)

25

30

Min. height / head (mm)

368

420

Load on the operating

handle (N)

380

400

Net weight (kg)

25

35

Reduced speed

adjustable

adjustable

Temperature of use

-20C°∽+50 C°

-20C°∽+50 C°

Packing size (mm)

360x190x430

380x220x510

3. TRANSPORTING & STORING

3.1 Storing

Keeping the folded jack in dry place.

3.2 Transporting

The operating handle (02) is just for operating the jack. When

transporting the jack, it can not be dropped or be thrown

because it may cause the piston of it damaged, and the pump

of it might be spoiled. Therefore, the jack should be fixed

before transporting to avoid it being shocked by other objects.

4. INSTALLMENT

The installing of jack is very simple .The only thing you should follow

is to insert the operating handle (02) to the socket (04) and screw it

tightly in clockwise direction.

Page 5

4

5. OPERATING

5.1 Scope of use

When use this jack it shall be put on the fixed and solid place, such

as reinforced concrete floor to lift or to move weight articles vertically

or horizontally. In order to lift articles in such limited area of jack,

some auxiliary pad can be placed under the base of it. The tooth

plate (43) of jack should be put on the base, so that it can be folded

inside when compacting the jack.

5.2 Method of operating

5.2.1 Lifting

Put a weight on the tooth plate of jack stable.

Attention: Can not use the front end of tooth plate to lift the weight.

Important point: When lifting the weight by the tooth plate, the

weight should be closed to the head of jack to avoid the pillar (47) of

jack being bent.

Please screw in the unload handle (16) tightly in clockwise direction

before lifting.

Then press and lift the operating handle up and down repeatedly to

pump the pressure to lift the weight. The lifting movement can be

stopped immediately by stopping the lifting operation.

Page 6

5

5.2.2 Reducing

Please screw out the unload handle slowly in anti-clockwise

direction to reduce the weight step by step. But when screw up the

round unload handle again, the reducing movement can be stopped

instantly.

Note: When the jack is in unload condition, the head of it should be

pressed to reduce its height.

Attention: If the jack is not in the state of maintaining, each part of it

can not be dismantled except the operating handle.

5.3 Safety standard

5.3.1 The lifting of weight is dangerous operation, the appointed

operators should be professional, be trained and be experienced.

5.3.2 Those extra weights can not be added on the lifted weight to

avoid dropping accident happening.

5.3.3 Never exceed the recommended maximum limitation of lifting

weight.

5.3.4 Please keep a safety distance with the lifted weight.

5.3.5 Never use the jack , or being changed or spoilt, or in bad

condition itself.

5.3.6 When lifting the weight by tooth plate, please keep the weight

closing to the head of jack to avoid the pillar of jack being bent.

Please check the drawing again.

5.3.7 Please confirm that each support point of ground should be

solid and stable including floor area and loading etc, then any type

of operating should be handled on the plane surface only.

5.3.8 Please guarantee the lifted weight being stable during the

whole lifting period to avoid it being turn over or being slipped. Each

device shall be fixed before lifting.

5.3.9 Never operating the jack when people standing on the lifting

Page 7

6

objects

brace plate

objects

weight.

5.3.10 Never use the front end of the tooth plate to lift weight. The

tooth plate should be located in its base totally, the pushing point to

the weight should close to the back end of tooth plate as far as

possible.

5.3.11Never screw the adjustable screw (18),under any

circumstance, otherwise a typical accident of jack-dropping might be

happened. These parts (10,11,18,19,20,21) are the device of

overloading protection.

5.3.12Never use the side of jack's head to lift weight. The weight

should be contacted with the black shadow surface of the following

pictures.

5.4.3 Operators should be very careful to use different jacks to lift a

heavy-duty weight. It attention to the shifting of center of gravity

during reducing or lifting the weight. The total lifting weight of all

jacks should be larger than load of lifted weights.

5.4.4 The owner of jack should guarantee all of the stick labels

concerning safety standards keeping on its relative locations, which

should be replaced when they can not be read clearly.

5.4.5 This operation manual can not cover all situations, please

follow each step of it cautiously.

Page 8

7

6.MAINTAINING

6.1 Routine inspecting

6.1.1 Before each operating, please inspect and confirm that:

(1) All of the stoppers and screws of jack have been screwed up

tightly.

(2) The jack's pump without any oil-leaking.

(3) The pump body, tooth plate and its base without any cracking or

form deformation happening-changing.

(4) The pump should be operated normally without loading.

6.1.2 Under the frequent use of the jack, the time of checking shall

be shortened as well, and following checking points shall be

emphasized:

(1) All of the jack stoppers, screws, and nuts should be screwed up

sufficiently and should be adjusted when it necessary.

(2) When the jack is in loading state, please pump it totally until the

release valve opening and without any oil-leaking (but the oil spot on

the surface of pillar or valve stem is in normal).Please release the

pressure of pump and check the pillar to confirm the pillar being flat

and vertical without any shocking and scraping. If any damage of it

being found the pillar should be changed in time.

(3) When the jack is reducing, operator should check whether the

reducing movement is stable or not and it should be wedged (but

some slight vibration is in normal).

(4) Please, carefully check all of the exterior parts of jack including,

Pump body: no deformation, cracking and impacting on it;

Operating handle of pump: no deformation no over space in each

plug, otherwise the old plug shall be replaced by a new one;

Tooth plate: no deformation & cracking;

Base: no deformation &cracking.

Page 9

8

Items

Symptom

Possible cause

Aliments

1

Jack can not

be pumped

up properly.

The release valve

is not closed.

1.Screw in the unload

handle (16) tightly in

clockwise direction.

2.Loose the screw

(37) to release the air

from the pump, then

screw in it tightly.

2

Jack can not

be released

down at the

top position

The release valve

is not opened

enough.

Screw out the unload

handle (16) in counter

- clockwise direction

3

Jack can not

be pumped

up to its

rated

high-test

position

Oil is not enough.

Screw out the screw

(10),add hydraulic oil.

4

The oil has

leaked,

around the

plunger.

Seals are worn

out.

Replace worn seals

with new seals (8)

and (9) (in the spare

parts bag .

7.ADD OIL

If the jack can not be pumped up to its rated high-test position, you

may have to add hydraulic oil into the oil tank. The hydraulic fluid to

be used must have a quality of ISO VG22 or equivalence. Mixing of

difference fluids is prohibited!

8.TROBLE SHOOTING GUIDE

Page 10

9

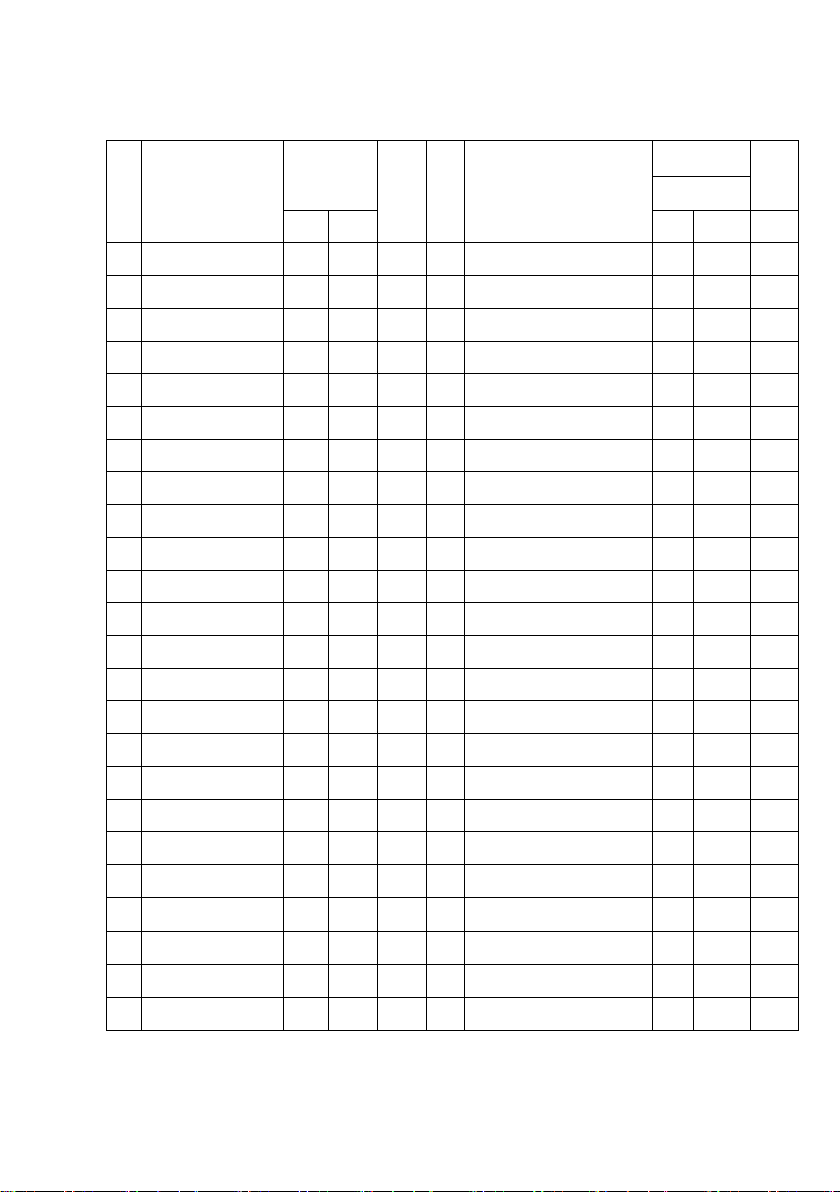

NO

NAME

CODE OF

NUM

NO

NAME

CODE OF

NUM

PART

PART

5t

10t

5t

10t

1

Handle Grip

501

501 1 25

Ball

525

525 3 2

Handle

502

502 1 26

Spring

526

526 2 3

Snap Ring

503

503 6 27

Screw

527

527 2 4

Socket

504

504 1 28

Pump Body

528

528

1

5

Pin

505

505 2 29

O-Ring

529

529

2

6

Plunger

506

506 1 30

Y-Ring

530

530 1 7

Wiper

507

507 1 31

O-Ring

531

531 1 8

Back-Up Ring

508

508 2 32

Valve Stem Bush

532

532 1 9

O-Ring

509

509 2 33

Oil Pipe

533

533

1

10

Screw

510

510 1 34

Retaining Ring

534

534 1 11

Gasket

511

511 3 35

Filter

535

535

1

12

Ball

512

512 1 36

Flexible Bag

536

1036

1

13

O-Ring

513

513 1 37

Screw

537

537

1

14

Release Rod

514

514 1 38

Assemble Of Cylinder

538

1038

1

15

Snap Ring

515

515 1 39

Steel Wire

539

1039

1

16

Unload Handle

516

516 1 40

O-Ring

540

1040

1

17

Screw

517

517 1 41

Retaining Ring

541

1041

2

18

Adjusting Screw

518

518 1 42

Bush

542

1042

2

19

Spring

519

519 1 43

Forked Mounting

543

1043

1

20

Ball Seat

520

520 1 44

Y-Ring

544

1044

1

21

Ball

521

521 1 45

Snap Ring

545

1045

1

22

Linkage

522

522 1 46

Limit Block

546

1046

1

23

Screw

523

523 4 47

Pillar

547

1047

1

24

Pin

524

524 1

9 .LIST OF PARTS

Page 11

10

10.CONSTRUCTIONAL DETAIL OF PARTY

Loading...

Loading...