Page 1

Instruction Manual

FORKLIFT JACK

HFJ-700A

CAPACITY: 7000kgs

NOTE: Owner / Operator must read and

understand this instruction manual

before using the forklift jack.

Page 2

1

contents

1. SPECIFICATIONS-----------------------------------2

2. IMPORTANT------------------------------------------2

3. FEATURES--------------------------------------------3

4. OPERATING INSTRUCTIONS------------------4

5. SAFETY TIPS-----------------------------------------7

6. MAINTENANCE INSTRUCTIONS--------------10

7. PUMP PRRMING INSTRUCTIONS-----------10

8. PLACARD PARTS LIST--------------------------11

9. PARTS LIST ﹠ EXPLODED FIGURE-------12

Page 3

2

SPECIFICATIONS

Rated capacity ……………………………. 7000kg/15400lbs

Starting pad height (notch) ……………... 65mm/2-1/2inches

Raised height—maximum……………..420mm/16-1/2inches

Width………………………………………250mm/9-4/5inches

Weight…………………………………………...48kg/105.6lbs

IMPORTANT:

Owner and/or Operator Responsibilities:

1. The use of this jack is subject to certain hazards that can only

precluded by the exercise of intelligence, care and common sense. It

is therefore essential to have competent and careful personnel

involved in the use and operation of this equipment.

Before using the jack, you must read and understand all the

instructions, warnings and precautions contained in this manual as

well those affixed to the jack in the form of decals.

2. Warning symbol:

This symbol is used to warn you of

specific situations which may

occur and must be avoided when

using the HFJ-700A jack. Failure to

observe these warnings may result

in personal injury and/or property

damage.

WARNING

Page 4

3

3. You must refer this manual to all operators, using the HFJ-700A

jack. They must read and understand the contents of this manual.

This manual is written in English. If the equipment is to be used by

operators who cannot read or understand English, it is the

responsibility of the owner (or his designated representative) to

instruct these people in the use of the jack. To avoid unnecessary risk

of bodily injury or property damage, the operator MUST understand

and observe these instructions and warnings.

4. The owner must inspect, or appoint a knowledgeable person, to

inspect the jack at regular intervals.

Each jack must be inspected immediately if subjected to an abnormal

load or shock. Regular inspection should be made weekly for daily

use and monthly for intermittent use.

Damaged jacks-any jack which appears to be damaged in any way or

deemed badly worm or operates abnormally-MUST BE REMOVED

FROM SERVICE UNTIL NECESSARY REPAIRS ARE MADE.

5. You must retain this manual and make it available to all persons

in need of the information contained herein.

6. For additional copies, please contact our dealer.

FEATURES:

Here is an abbreviated list of features:

1.Low starting height 2. Easy portability

3.Two-position lift pad 4. Simple, rugged design

5.Lift pad swivels with load as jack is raised and lowered.

6.Safety valve

Page 5

4

OPERATING

INSTRUCTIONS:

1. To raise: close the release valve(turn the knob clockwise) then pump

the handle.

2. To lower: turn the release valve SLOWLY counter-clockwise. When

lowering the jack lift truck. It is important to keep the rate of lowering

under your control. Do not lower the fork lift until the area is free of

personnel, tools and equipment. Keep all body parts away from the

area wheels of the jack because they move backwards when

lowering.

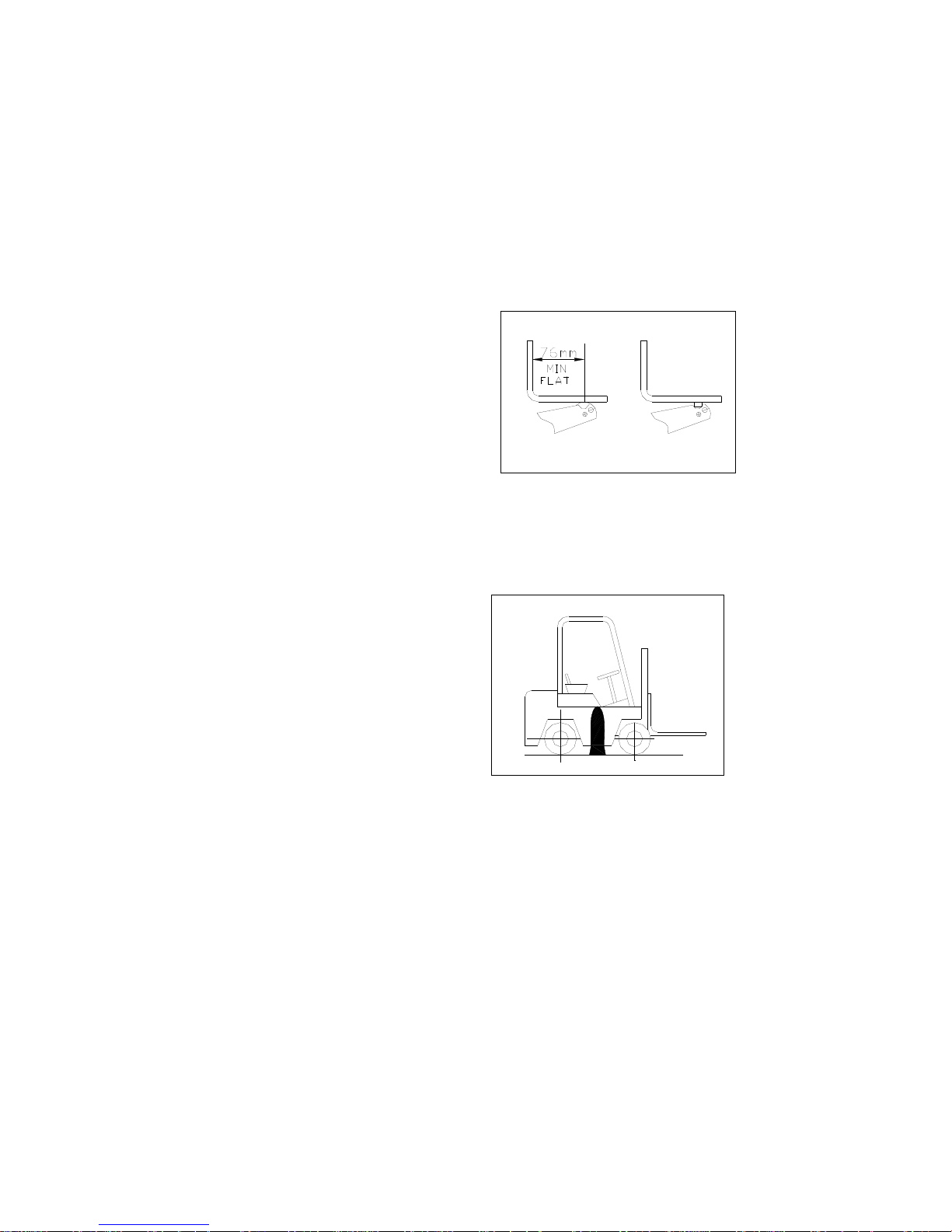

3. We recommend that a vehicle be

raised by cradling a support

point in the notch at the end of

the lift arm. (Fig. 1-B) To

accomplish this , it is advisable

to attach a steel bar to the lower

surface capable of supporting

the load. The serrated pad can

be used to raise a vehicle with

flat underside. See Fig. 1-A (flat

surface must be parallel to the

floor before lifting)

4. Always position lift pad least 76mm inward toward the centre of

vehicle from the beginning of the flat surface (See Fig. 1-A). Never

push jack under the fork lift beyond the “red line” marked on decal

located on top of the lift arm (see NOTICE ② in PLACARD).

a. When lifting from the

side the jack should be

located nearer to the rear

wheels than the front. If

the fork lift seems to be

heavier at one end, lower

the jack and move it closer

to the heavy end to obtain

suitable balance.

AB

Fig.1

Fig.2

Page 6

5

b. When lifting from the end

place the HFJ-700A at the

centre of the fork lift truck.

Always chock the wheels at the

opposite end of the fork lift.

When lifting 3 wheeled lift trucks,

never lift the 2 wheeled end.

WARNING: Do not lift from the

end of the fork lift if the contact

surface is sloped or rounded(See

Fig.4)

WARNING: This is a lifting device

only!After lifting, load must be

immediately supported by

adequate stands. Failure to do so

may result in personal injury

and/or property damage.

WARNING: Care must be taken

not to tilt the vehicle more than

15°when using the serrated pad.

Excessive tilting can cause the

jack to kick out suddenly and

Fig.3

WARNING

Fig.4

WARNING

WARNING

WARNING

Page 7

6

drop the load. See instruction 3 page 7.

5. Select the lifting point on the fork lift with care. It must be strong

enough to resist the lifting force without damaging the fork lift. It is

desirable to cradle the lifting point in the arm notch when

possible(See Fig.1-B).

6. Use only the serrated lifting

pad, or the notch at the end of

the lifting arm as the lifting

contact. Do not attempt to use

any other part of the HFJ-

700A lack as a lifting contact

point.

7. Raise a fork lift with the HFJ-700A only when:

a. The forks are in a lowered position

b. There is no load of any kind on the forks

c. There are no personnel on the jacks

8. If the fork lift truck is to be lifted, lowered and relifted, the following

procedure is to be followed.

a. Lift and lower in accordance with the instructions in this manual

b. Before using a second jack, make certain that the jack is

replaced in full accordance with the initial instructions in this

manual. (See Paragraph 4 of Operating Instructions)

Fig.5

Page 8

7

SAFETY TIPS

WARNING: The warnings and

instructions listed and described

hereafter must be followed at all

times. If there is any uncertainty

regarding an intended use of the

HFJ-700A, contact your

supervisor. Failure to observe these warnings and instructions may

result in injury and/or property damage.

1. Both the HFJ-700A jack and the fork lift must be on a firm lever

surface capable of supporting the load. Do not attempt to lift from a

polished or greasy floor.

2. The HFJ-700A may be used to lift from either side or end of the fork

lift truck. However, 2 wheels of the lift truck must remain firmly on the

floor.

3. Use extreme caution when lifting narrow fork lift trucks (less than

1016mm Wide) from the sides. Always make sure that the height

between the floor and the bottom of the raised tyre is never more than

one fourth (1/4

th

) of the vehicle’s tread width. See Fig.6.(Tread width

is measured from centre line to centre line of the tyre treads.) If the

one forth figure is exceeded, the fork lift truck could reach the point of

instability and tip over or the angularity of the forklift truck frame could

cause the jack to kick out and drop the load.

Example: If treadwith=914.40mm,then never lift the bottom of the

vehicle tyre more than 228.60mm off the floor.

WARNING

ht

TREAD WIDTH

Fig.6

Page 9

8

4. Never use more than one jack to lift the fork lift truck. Failure to

observe this instruction may lead to unstable conditions and could

cause failure of one of the jacks.

5. Do not use the HFJ-700A to raise all for 4 wheels of the fork lift from

the floor. Two wheels of the lift truck must remain in contact with the

floor at all times.

6. Do not push the jack under the

fork lift beyond the red line

marked on the decal on the top

of the lift arm. This will maintain

at least one inch clearance

between the body of the jack

and the fork lift in its raise

position. Failure to observe

these instructions could result in

damage to the HFJ-700A and/or

loss of load.

7. Do not use any kind of “cribbing”

under the HFJ-700A, or on top

of the lift pad area. The jack

must always remain in direct

contact with the floor, and the

lifting pad or notch must be in

direct contact with the fork lift.

Fig.7

Fig.8

Page 10

9

8. Keep hands, feet and all other body parts out of the area of the

scissors mechanism at all times. This instruction applies to handling

and carrying as well as lifting and lowering the jack. The scissors

action of the lifting mechanism can cause serious injury.

9. Do not drop, throw, drive over or otherwise abuse the HFJ-700A. The

jack must be treated with the same care as any other precision tool

upon which your safety and the safety of your co-workers depends.

10.Do not drive the lift truck off the jack or attempt to move the fork lift

at any time when it is supported by the HFJ-700A.

11.Do not work on the fork lift, or

get under it for any reason until

it is properly supported by

means of adequate stands.

When the stands are in place

and are supporting the fork lift

truck, remove the HFJ-700A

from the working area before

beginning work.Fig.9

12.The HFJ-700A jack is designed solely for the lifting of fork lift trucks.

Use of the jack for any other purpose constitutes misuse of the jack.

Users of the jack hereby warned of this misuse, which can result in

physical injury and/or property damage.

13.Damaged jacks-Any jack which appears to be damaged in any way,

is found to be badly worn, or operates abnormally MUST BE

REMOVED FROM SERVICE until necessary repairs are made.

14.Do not modify the HFJ-700A jack in any manner.

15.Do not exceed the rated capacity of the HFJ-700A,which is 7000kg.

Fig.9

Page 11

10

MAINTENANCE

INSTRUCTIONS:

1. Apply several drops of a grade machine oil to the stem of the pump

plunger.

2. Oil the handle joints while operating the pump handle to work the oil

in.

3. Although the hydraulic unit on the HFJ-700A is a sealed unit and will

probably never need fluid adding to the reservoir, the following

instructions shall be followed in the event fluid is needed:

To refill the reservoir, place the jack in normal upright position, and

completely lower jack by opening release knob. Carefully clean dirt

and contaminants form around the fill plug and the remove the plug.

Add Mobile DTE#13 hydraulic oil to reservoir until fluid runs out the fill

plug hole. Do not use brake fluid. (Extreme care should be taken to fill

plug the fluid contaminant free and keep dirt and contaminants out of

the reservoir of the jack.) Reinstall fill plug.

PUMP PRIMING

INSTRUCTIONS:

To prime the model HFJ-700A actuator, in the event that it

inadvertently becomes unprimed, proceed as follows:

1. Open release valve (large red knob on top) approximately 2 full tuns.

2. Stroke handle through 2 full turns, slowly.

3. Raise handle fully up, turnover jack on left side, as viewed from rear.

Push handle “down”.

4. Stand jack upright again, raise handle to up, lay over on left side

and push handle “down” again.

5. Stand jack upright, stroke handle while closing release valve and

jack should operate satisfactorily.

Page 12

11

HFJ-700A PLACARD

PARTS LIST

ITEM

NO.

DESCRIPTION NO.

REQ’D

1 Warning Label (Use Stands to Support Vehicle) 1

2 Jack Position Plate 1

3 Lift Pad Instructions 1

4 Identification Piacard,HFJ-700A 1

5 Warning Label(Do Not Adjust) 1

1

WARNING

4

5

WARNING

TWO

POSITION

LIFT PAD

2

NOTICE

3

HFJ-700A

Page 13

12

NO

DESCRIPTION QTY

NO

DESCRIPTION QTY

01 Screw 2 34 Back-Up Ring 1

02 Lock Washer 4 36 Plunger 1

03 Trunnion 2 37 Retaining Ring 8

04 Frame 1 1 38 Pin 3

05 Screw 2 39 Pin 1

06 Washer 2 40 Link Rod 1

07 Axle 1 41 O-Ring 2

08 Snap Ring 2 42 Back-Up Ring 1

09 Washer 2 43 O-Ring 2

10 Wheel 2 44 Oil Tank 1

11 Frame 2 1 45 O-Ring 2

12 Screw 2 46 Port Ring 1

13 Lock Washer 2 47 Cylinder 1

14 Nut 2 49 Piston 1

15 Spacer 2 50 Valve Seat 1

16 Pin 1 51 O-Ring 1

17 Saddle 1 52 Release Rod 1

18 Pin 1 53 Release Knob 1

20 Screw 2 54 Pin 1

21 Seal Ring 2 55 Chain Hook 1

22 Screw 1 56 Chain 1

23 Spring 1 57 Handle Base 1

24 Ball Seat 1 58 Screw 2

25 Ball 1 59 Handle 1 1

26 Valve Block 1 60 Handle 2 1

27 Magnet Steel 1 61 Grip 1

28 Ball 3 62 Seal Ring 1

29 Spring 1 67 Screw 1

30 Screw 1 70 Piston Rod 1

31 Seal Ring 1 71 Wiper 1

32 Pump 1 72 Y-Ring 1

33 O-Ring 1

Page 14

13

Loading...

Loading...