Page 1

1

Instruction Manual

BS Series

NOTE: Owner/Operator must read and understand this instruction manual

before using the lift table.

RevB: 02/2009

Page 2

2

Operation and Service Manual

BEFORE OPERATING THE LIFT TABLE, READ THIS MANUAL CAREFULLY AND UNDERSTAND

COMPLETELY. KEEP THIS MANUAL ON FILE FOR FUTURE REFERENCE. IF THIS IS LOST, PLEASE

CONTACT YOUR LOCAL SUPPLIER FOR A NEW COPY. ALSO, IF THE WARNING/CAUTION DECAL ON

THE UNIT IS LOST, PLEASE CONTACT YOUR LOCAL SUPPLIER FOR A NEW DECAL.

NOTE: On this manual, WARNING means the danger which can lead to death or serious injury. CAUTION

means the danger which can lead to slight injury or property damage.

1. WARNING

1.DO NOT put foot or hand in scissors mechanism.

2.DO NOT allow other person to stand in front of or behind lift table when it is moving.

3.DO NOT move lift table when table is in raised position. Load could fall down.

4.DO NOT enter under table.

5.DO NOT overload lift table.

6.DO NOT put foot in front of rolling wheels. Injury could result.

7.WATCH difference and hardness of floor level when moving lift table. Load could fall down.

8.DO NOT use lift table on slope or inclined surface, lift table may become uncontrollable and create danger.

9.DO NOT lift people. People could fall down and suffer severe injury.

2. CAUTION

1.Read this operation manual carefully and understand completely operating lift table. Improper operation

could create danger.

2.This lift table is a movable lifter designed to lift or lower rated load on table. NO NOT use lift table for other

purpose than its intended use.

3.DO NOT allow person to operate lift table who does not understand its operation.

4.DO NOT lower table too fast. Load could fall down and create danger.

5.KEEP watching the condition of load. Stop operating lift table if load becomes unstable.

6.Byake lift table when sliding load on of off table.

7.DO NOT side or end load. Load must be distributed on at least 80%of table area.

8.DO NOT use lift table with unstable, unbalanced loosely stacked load.

9.Practice maintenance work according to service instructions.

10. DO NOT modify lift table without manufacturer’s written consent.

11. REMOVE load from table and use safety stopper to prevent table from lowering when servicing lift table.

12. This lift table is not designed to be water resistant. Use lift table under dry condition.

3. DAILY INSPECTION

Daily inspection is effective to find the malfunction or fault on lift table. Check lift table on the following points

before operation.

Page 3

3

CAUTION

DO NOT use lift table if any malfunction or fault is found.

(1) Check for scratch, bending or cracking on the lift table.

(2) Check if there is any oil leakage from the cylinder.

(3) Check the vertical creep of the table.

(4) Check the smooth movement of the wheel.

(5) Check the function of brake.

(6) Check if all the bolt and nuts are tightened firmly.

4. OPERATING LIFTTABLE

4-1. How to use the brake.

CAUTION

Brake lift table when not moving it in order to prevent sudden movement.

The brake is equipped with the swivel caster on the right side.

(1) Braking the wheel, press the brake pedal.

(2) Releasing the brake, lift up the brake pedal.

4-2 Lifting the table

WARNING

1. DO NOT overload lift table, stay within its rated capacity.

2. DO NOT side end load must be distributed on at least 80% of table area.

Press the lifting pedal several times the until the table reaches the desired position.

The table does not elevate after reaching the highest position even if the lifting pedal is pressed.

The table lowers slightly after reaching the highest position.

MAXIMUM CAPACITY OF TABLE

BS15

BS25

BS50

BS75

BS100

BS30D

BS50D

BS80D

150KG

250KG

500KG

750KG

1000KG

300KG

500KG

800KG

Page 4

4

NOTE:

The hydraulic cylinder is designed to hold table. As is the nature of the hydraulic system, table lowers very

slowly over and extended period of time, Please note the table does not stay at the same position

ionindefiinitely.

4-3. Lowering table

WARNING

DO NOT put foot or hand in scissors mechanism.

Pull the lowering down and table lowers.

5. Specifications

Model

Capacity

(kg)

Table

(mm)

Table

Height(mm)

Stroke

L×W×H

(mm)

Pedal to top.

(approx. times)

Wheel

(mm)

φ

Weight

(kg)

BS15

150

700×450

225-760

535

1000×450×950

16

100

41

BS25

250

830×500

335-915

580

1100×500×1010

25

125

78

BS50

500

1010×520

430-1000

570

1130×520×1185

44

150

118

BS75

750

1010×520

432-1000

568

1130×520×1260

55

150

120

BS100

1000

1010×520

440-960

520

1130×520×1260

68

150

137

BS30D

300

1010×520

435-1585

1150

1130×520×1260

53

150

150

BS50D

500

1010×520

435-1585

1150

1130×520×1260

68

150

168

BS80D

800

1010×520

490-1400

910

1130×520×1275

95

150

165

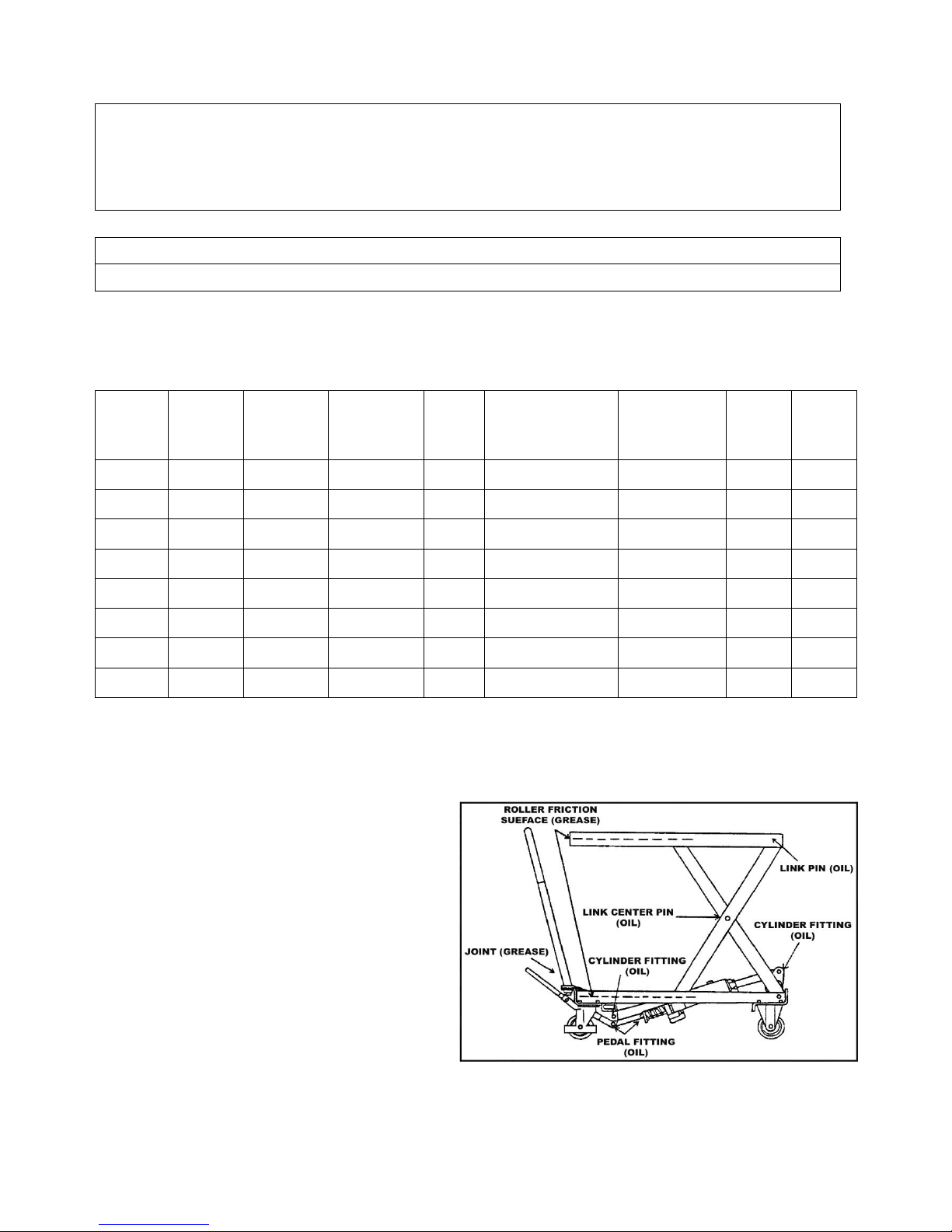

6. Service instruction

6.1-1. Lubricate each point described below every month:

6.2.Change hydraulic oil every 12 months.

Lubricating Points

(1) Fitting of cylinder……Oil

(2) Roller friction surface……Grease

(3) Link Pin ……Oil

(4) Pedal fitting point……Oil

(5) Link center pin……Oil

(6) Joint……Grease

(7) Grease nipple……Grease

(8) Hydraulic circuit

Page 5

5

7. Hydraulic Circuit

Page 6

6

Page 7

7

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1

Table pair

1

48

Spring washer

1

2

Guide roller

4

49

Washer

1

3

Scissors

1

50

Bushing

1

4

Snap ring

6

51

Steel ball

1

5

Link pin

4

52

Steel ball holder

1

6

Safety pin

1

53

Relief spring

1

7

Hex bolt

16

54

Regulating pressure plug

1

8

Washer

18

55

O ring 1 9

Frame pair

1

56

Relief plug

1

10

Front wheel

2

57

O ring 1 11

Spring washer

19

58

Plug

1

12

Hex. nut

18

59

Rear wheel

2

13

Piston rod

1

60

Handle pin

4

14

Dust seal

1

61

Handle lock spring L

1

15

O ring 2 61A

Handle lock spring R

1

16

Back up ring

1

62

Bushing

2

17

Cylinder pair

1

63

Snap ring

4

18

Spring seat

1

64

Pedal holder

1

19

Spring 1 65

Snap ring

2

20

Seal ring

1

66

Pressure roller

1

21

Joint 1 67

Pressure roller pin

1

22

Flow control joint

1

68

Pedal Pivot Pin

1

23

O ring 1 69

Hex. bolt

2

24

Adjust casing

1

70

Elbow 2 25

Spring seat

1

71

Oil retum hose

1

26

Valve spring

1

72

Rubber bushing

1

27

Conical valve

1

73

High pressure hose

1

28

Valve seat

1

74

Seal ring

6

29

O ring 1 75

Adaptor

2

30

Steel ball φ7

1

76

Pedal Pair

1

31

Dust seal

1

77

Pedal rubber

1

32

Y ring 1 78

Hex bolt

1

33

Plunger

1

79

Lock bar

1

34

Pump spring B

1

80

Hex. bolt

1

35

Pump spring A

1

81

Cylinder pivot pin

1

36

Pump bass

1

82

Grease fitting

2

37

Net 1 83

Piston head pin

1

38

Washer

1

84

Roller chain

1

39

Back valve spring

2

85

Valve rod Ⅱ

1

40

O-ring 1 86

Nut M6

1

41

Plug 1 87

Handle pair

1

Page 8

8

42

O ring 1 88

Valve rodⅠ

1

43

Steering bush

1

89

Control link

1

44

O ring 1 90

Roll pin

1

45

Discharge lever

1

91

Roll pin

1

46

Valve arm

1

92

Check ring

2

47

Socket head screw

1

A

Cylinder Assembly

13-21

B

Pump Unit Assembly

64-78

C

Pump Unit Sub Assembly

22-58

D

Handle Assembly

84-91

E

Pedal Assembly

76-77

F

Seal kit ass'y

14,15,20,23,29,31,32,40,42,44,55,57,74

Page 9

9

Page 10

10

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1.

Seal cover d30×D42×7

1

53.

Lever bushing

1

2.

Cylinder cover

1

54.

Washer 6

2

3.

O-ring d63×2.65

2

55.

Spring washer 6

1

4.

O-ring d30×3.55

1

56.

Hex soch screw M6×16

1

5.

Piston rod

1

57.

Put pressure assembly line

1

6.

Spacing casing

1

59.

Nut M8

17

7.

Guide ringδ1.5×15

1

60.

Washer 8

30

8.

O-ring D20×2.4

1

62.

Spring pin

1

9.

Seal ring d34×D40×4.5

1

63.

Control link

1

10.

Piston rod retainer

1

64.

Handle

1

11.

Retaining ring 18

1

65.

Spacing casing

2

12.

Piston

1

66.

Spring washer 12

2

13.

Cylinder

1

67.

Hexagon head stud M12×30

2

14.

Cylinder washer

1

68.

Split pin

1

15.

Reservior

1

69.

Pin 1 16.

O-ring d10×2.65

1

73.

Pedal bent pipe

1

17.

Filler screw

1

74.

Pedal rubber

1

18.

Washer for reservior

1

75.

Shake link

1

19.

Steel ball 5

1

76.

Spring washer 8

17

20.

Spring base

1

77.

Hex soch screw

1

21.

Regulating pressure spring

1

78.

Buffer mat

1

22.

Regulating pressure screw

1

79.

Partition set

1

23.

O-ring d7.1×1.8

1

80.

Pin axle

1

24.

End cover

1

81.

Retainer 10

2

25.

O-ring d15×2.65

2

82.

Pin axle

1

26.

Regulating speed spring

1

83.

Retainer 20

1

27.

Regulating speed slide valve

1

84.

Washer

1

28.

Regulating speed spring casing

1

85.

Pin axle

1

29.

Regulating speed valve casing

1

86.

Link 2 30.

Steel ball 7

1

87.

Hex soch screw M8×25

16

31.

O-ring d6.9×1.8

1

88.

Wheel

2

32.

Conical valve

1

89.

Wheel

2

33.

Check valve spring

1

90.

Chassis

1

34.

Check valve casing

1

91.

Pin axle

1

35.

O-ring d10×1.8

1

92.

Bolt M6×8

1

36.

Check valve screw

1

93.

Bushing

2

37.

Spring base

1

94.

Scissors lever

1

38.

Spring 1 95.

Retainer 16

9

39.

Seal cover d18×D25×4.5

1

96.

Roller for chassis

2

40.

O-ring d18×2.65

1

97.

Bushing

2

41.

Pump plunger

1

98.

Nut M10

2

Page 11

11

42.

Y-ring 1 100.

Washer 10

4

43.

Pump body for plunger

1

101.

Satety rod

2

44.

O-ring d28×3.1

1

102.

Screw bolt M10×40

2

45.

Pump body

1

103.

Spring pin 8×30

2

46.

O-ring d10.6×2.65

1

104.

Roller for table

2

47.

Spring

1

105.

Table 1 48.

Reflux rod

1

106.

Pin axle

1

49.

O-ring d4×1.8

1

107.

Pin axle

2

50.

Guide casing

1

108.

Screw M6×30

1

51.

Protect casing

1

109.

Cover-type nut M6

1

52.

Lever 1

A

Pump ass’y

1~51

B

Swivel wheel ass’y

88 C Front wheel ass’y

89 D Sealkit ass’y

1,3,4,7,8,9,16,23,25,31,35,39,40,42,44,46,49

E

Handle ass’y

54,55,57,62,63,64,68,69,108,109

Page 12

12

Page 13

13

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1.

Seal cover d30×D42×7

1

54.

Hex soch screw M6×16

1

2.

Cylinder cover

1

55.

Put pressure assembly line

1

3.

O-ring d63×2.65

2

58.

Washer 8

2

4.

O-ring d30×3.55

1

60.

Spring pin 5×14

1

5.

Piston Rod

1

61.

Control link

1

6.

Spacing casing

1

62.

Handle

1

7.

Guidering δ1.5×15

1

63.

Spacing casing

2

8.

O-ring D20×2.4

1

64.

Spring washer 12

2

9.

Seal ring d34×D40×4.5

1

65.

Hex screw M12×30

2

10.

Retainer for piston rod

1

66.

Split pin 2×15

1

11.

Spacing retainer 18

1

67.

Pin

1

12.

Piston

1

71.

Pedal bent pipe

1

13.

Cylinder

1

72.

Hex soch screw M8×20

2

14.

Washer for cylinder

1

73.

Shake link

1

15.

Reservior

1

74.

Spring

2

16.

O-ring d10×2.65

1

75.

Retainer 10

2

17.

Filler screw

1

76.

Pin axle

2

18.

Washer for reservior

1

77.

Link 2 19.

Steel ball 5

1

78.

Wheel

2

20.

Spring base

1

79.

Nut M10

16

21.

Regulating pressure spring

1

80.

Spring washer 10

16

22.

Regulating pressure screw

1

81.

Washer 10

36

23.

O-ring d7.1×1.8

1

82.

Hex soch screw M10×25

16

24.

End cover

1

83.

Wheel

2

25.

O-ring d15×2.65

2

84.

axle 1 26.

Regulating speed spring

1

85.

Retainer 20

7

27.

Regulating slide-valve

1

86.

Chassis

1

28.

Regulating speed spring casing

1

87.

Table

1

29.

Regulating speed slide-casing

1

88.

Roller for table

2

30.

Steel ball 7

1

89.

Bushing

2

31.

O-ring d6.9×1.8

1

90.

Split pin 3.2×26

1

32.

Conical valve

1

91.

Nut M16

1

33.

Spring

1

92.

Washing

1

34.

Check valve casing

1

93.

Bushing

4

35.

O-ring d10×1.8

1

94.

Spring pin 8×30

2

36.

Check valve screw

1

95.

Screw bolt M10×40

2

37.

Seal cover d18×D25×4.5

1

96.

Safety rod

2

38.

O-ring d18×2.65

1

97.

Nut M10

2

39.

Pump plunger

1

98.

External scissors lever

1

40.

Y-ring 1 99.

Bushing

2

41.

Pump body for plunger

1

100.

Roller for chassis

2

Page 14

14

42.

O-ring D28×3.1

1

101.

Internal scissors lever

1

43.

Pump body

1

102.

Pin axle for chassis

1

44.

O-ring d10.6×2.65

1

103.

Spring washer 8

1

45.

Spring

1

104.

Hex screw M8×16

1

46.

Reflux rod

1

105.

Pin axle for scissons

1

47.

O-ring d4×1.8

1

106.

Pin axle for table

1

48.

Guide casing

1

107.

Bushing

2

49.

Protect casing

1

108.

Bolt M8×12

1

50.

Lever

1

109.

Oil cup

2

51.

Lever bushing

1

110

Bolt M6×8

1

52.

Washer 6

2

111

Screw M6×30

1

53.

Spring washer 6

2

112

Cover-type nut M6

1

A

Pump ass’y

1~49

B

Swivel wheel ass’y

78 C Front wheel ass’y

83 D Sealkit ass’y

1,3,4,7,8,9,16,23,25,31,35,37,38,40,42,44,47

E

Handle ass’y

52,53,55,60,61,62,66,67,111,112

Page 15

15

Page 16

16

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1.

Seal cover d35×D43.5×5

1

56.

Put pressure assembly line

1

2.

Cylinder cover

1

59.

Washer 8

2

3.

O-ring d75×3.55

1

61.

Spring pin

1

4.

O-ring d35.5×3.55

1

62.

Control link

1

5.

Piston Rod

1

63.

Handle

1

6.

Spacing casing

1

64.

Spacing casing

2

7.

Guideing δ2×15

1

65.

Spring washer 12

2

8.

O-ring D20×2.4

1

66.

Hex screw M12×30

2

9.

Seal ring d39×D45×4.5

1

67.

Split pin 2×15

1

10.

Retainer for piston rod

1

68.

Pin 1 11.

Spacing retainer 18

1

72.

Pedal bent pipe

1

12.

Piston

1

73.

Hex screw M8×20

2

13.

Cylinder

1

74.

Shake link

1

14.

Washer for cylinder

1

75.

Spring

2

15.

Reservior

1

76.

Pin axle

2

16.

O-ring d10×2.65

1

77.

Retainer 10

2

17.

Filler screw

1

78.

Link 2 18.

O-ring d75×2.65

1

79.

Table

1

19.

Washer for reservior

1

80.

Retainer 20

7

20.

Steel ball 5

1

81.

Roller for table

2

21.

Spring base

1

82.

Bushing

2

22.

Regulating pressure spring

1

83.

Split pin 3.2×26

2

23.

Regulating pressure screw

1

84.

Nut M16

2

24.

O-ring d7.1×1.8

1

85.

Washing

2

25.

End cover

1

86.

Bushing

2

26.

O-ring d15×2.65

2

87.

Pin axle for scissors

2

27.

Regulating speed spring

1

88.

Spring washer 8

2

28.

Regulating slide-valve

1

89.

Hex screw M8×16

2

29.

Regulating speed spring casing

1

90.

Spring pin 8×30

2

30.

Regulating speed slide-casing

1

91.

Screw bolt M10×40

2

31.

Steel ball 7

1

92.

Washer 10

36

32.

O-ring d6.9×1.8

1

93.

Safety rod

2

33.

Conical valve

1

94.

Spring washer 10

16

34.

Spring

1

95.

Nut M10

2

35.

Check valve casing

1

96.

External scissors lever

1

36.

O-ring d10×1.8

1

97.

Bushing

2

37.

Check valve screw

1

98.

Roller for chassis

2

38.

Seal cover d18×D25×4.5

1

99.

Bushing

2

39.

O-ring d18×2.65

1

100.

Pin axle for chassis

1

40.

Pump plunger

1

101.

Pin axle for table

1

41.

Y-ring d10×D18×6

1

102.

Bushing

2

Page 17

17

42.

Pump body for plunger

1

103.

Oil cup

1

43.

O-ring D28×3.1

1

104.

Bolt M8×12

1

44.

Pump body

1

105.

Internal scissors lever

1

45.

O-ring d10.6×2.65

1

106.

Chassis

1

46.

Spring

1

107.

axle 1 47.

Reflux rod

1

108.

Hex soch screw M10×25

16

48.

O-ring d4×1.8

1

109.

Nut M10

16

49.

Guide casing

1

110.

Wheel

2

50.

Protect casing

1

111.

Wheel

2

51.

Lever 1 112

Rod 1 52.

Lever bushing

1

113

Rod 1 53.

Washer 6

2

114

Bolt M6×8

1

54.

Spring washer 6

2

115

Screw M6×30

1

55.

Hex soch screw M6×16

1

116

Cover-type nut M6

1

A Pump ass’y

1~50,112,113

B

Swivel wheel ass’y

111 C Front wheel ass’y

110 D Sealkit ass’y

1,3,4,7,8,9,16,18,24,26,32,36,39,41,43,45,48

E

Handle ass’y

53,54,56,61,62,63,67,68,115,116

Page 18

18

Page 19

19

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1.

Seal cover d35×D43.5×5

1

56.

Put pressure assembly line

1

2.

Cylinder cover

1

59.

Washer 8

2

3.

O-ring d75×3.55

1

61.

Spring pin

1

4.

O-ring d35.5×3.55

1

62.

Control link

1

5.

Piston Rod

1

63.

Handle

1

6.

Spacing casing

1

64.

Spacing casing

2

7.

Guideing δ2×15

1

65.

Spring washer 12

2

8.

O-ring D20×2.4

1

66.

Hex screw M12×30

2

9.

Seal ring d39×D45×4.5

1

67.

Split pin 2×15

1

10.

Retainer for piston rod

1

68.

Pin

1

11.

Spacing retainer 18

1

72.

Pedal bent pipe

1

12.

Piston

1

73.

Hex screw M8×20

2

13.

Cylinder

1

74.

Shake link

1

14.

Washer for cylinder

1

75.

Spring

2

15.

Reservior

1

76.

Pin axle

2

16.

O-ring d10×2.65

1

77.

Retainer 10

2

17.

Filler screw

1

78.

Link 2 18.

O-ring d75×2.65

1

79.

Table

1

19.

Washer for reservior

1

80.

Retainer 20

7

20.

Steel ball 5

1

81.

Roller for table

2

21.

Spring base

1

82.

Bushing

2

22.

Regulating pressure spring

1

83.

Split pin 3.2×26

2

23.

Regulating pressure screw

1

84.

Nut M16

2

24.

O-ring d7.1×1.8

1

85.

Washing

2

25.

End cover

1

86.

Bushing

2

26.

O-ring d15×2.65

2

87.

Pin axle for scissors

2

27.

Regulating speed spring

1

88.

Spring washer 8

2

28.

Regulating slide-valve

1

89.

Hex screw M8×16

2

29.

Regulating speed spring casing

1

90.

Spring pin 8×30

2

30.

Regulating speed slide-casing

1

91.

Screw bolt M10×40

2

31.

Steel ball 7

1

92.

Washer 10

36

32.

O-ring d6.9×1.8

1

93.

Safety rod

2

33.

Conical valve

1

94.

Spring washer 10

16

34.

Spring

1

95.

Nut M10

2

35.

Check valve casing

1

96.

External scissors lever

1

36.

O-ring d10×1.8

1

97.

Bushing

2

37.

Check valve screw

1

98.

Roller for chassis

2

38.

Seal cover d18×D25×4.5

1

99.

Bushing

2

39.

O-ring d18×2.65

1

100.

Pin axle for chassis

1

40.

Pump plunger

1

101.

Pin axle for table

1

Page 20

20

41.

Y-ring d10×D18×6

1

102.

Bushing

2

42.

Pump body for plunger

1

103.

Oil cup

1

43.

O-ring D28×3.1

1

104.

Bolt M8×12

1

44.

Pump body

1

105.

Internal scissors lever

1

45.

O-ring d10.6×2.65

1

106.

Chassis

1

46.

Spring

1

107.

axle 1 47.

Reflux rod

1

108.

Hex soch screw M10×25

16

48.

O-ring d4×1.8

1

109.

Nut M10

16

49.

Guide casing

1

110.

Wheel

2

50.

Protect casing

1

111.

Wheel

2

51.

Lever 1 112

Rod 1 52.

Lever bushing

1

113

Rod

1

53.

Washer 6

2

114

Bolt M6×8

1

54.

Spring washer 6

2

115

Screw M6×30

1

55.

Hex soch screw M6×16

1

116

Cover-type nut M6

1

A Pump ass’y

1~50,112,113

B

Swivel wheel ass’y

111 C Front wheel ass’y

110 D Sealkit ass’y

1,3,4,7,8,9,16,18,24,26,32,36,39,41,43,45,48

E

Handle ass’y

53,54,56,61,62,63,67,68,115,116

Page 21

21

Page 22

22

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1.

Seal cover d30×D42×7

1

55.

Put pressure assembly line

1

2.

Cylinder cover

1

58.

Washer 8

2

3.

O-ring d63×2.65

2

60.

Spring pin

1

4.

O-ring d30×3.55

1

61.

Control link

1

5.

Piston Rod

1

62.

Handle

1

6.

Spacing casing

1

63.

Spacing casing

2

7.

Guideing δ1.5×15

1

64.

Spring washer 12

2

8.

O-ring D20×2.4

1

65.

Hex screw M12×30

2

9.

Seal ring d34×D40×4.5

1

66.

Split pin 2×15

1

10.

Retainer for piston rod

1

67.

Pin 1 11.

Spacing retainer 18

1

71.

Pedal bent pipe

1

12.

Piston

1

72.

Hex soch screw M8×20

2

13.

Cylinder

1

73.

Shake link

1

14.

Washer for cylinder

1

74.

Spring

2

15.

Reservior

1

75.

Retainer 10

2

16.

O-ring d10×2.65

1

76.

Pin axle

2

17.

Filler screw

1

77.

Link 2 18.

Washer for reservior

1

78.

Wheel

2

19.

Steel ball 5

1

79.

Nut M10

16

20.

Spring base

1

80.

Spring washer 10

16

21.

Regulating pressure spring

1

81.

Washer 10

36

22.

Regulating pressure screw

1

82.

Hex soch screw M10×25

16

23.

O-ring d7.1×1.8

1

83.

Wheel

2

24.

End cover

1

84.

axle 1 25.

O-ring d15×2.65

2

85.

Retainer 20

7

26.

Regulating speed spring

1

86.

Chassis

1

27.

Regulating slide-valve

1

87.

Hex screw M8×16

5

28.

Regulating speed spring casing

1

88.

Pin axle for chassis

1

29.

Regulating speed slide-casing

1

89.

Bushing

10

30.

Steel ball 7

1

90.

Washing

5

31.

O-ring d6.9×1.8

1

91.

Slotting nut M16×1.5

5

32.

Conical valve

1

92.

Split pin 3.2×26

5

33.

Spring

1

93.

Pin axle

3

34.

Check valve casing

1

94.

Pin axle for table

1

35.

O-ring d10×1.8

1

95.

Hex socket set screw M8×12

1

36.

Check valve screw

1

96.

Bushing

2

37.

Seal cover d18×D25×4.5

1

97.

Oil cup

4

38.

O-ring d18×2.65

1

98.

External scissors lever for table

1

39.

Pump plunger

1

99.

Internal scissors lever for table

1

40.

Y-ring

1

100.

Bushing

2

41.

Pump body for plunger

1

101.

Roller for table

2

Page 23

23

42.

O-ring D28×3.1

1

102.

Table

1

43.

Pump body

1

103.

Spring pin 8×30

2

44.

O-ring d10.6×2.65

1

104.

Screw bolt M10×40

2

45.

Spring

1

105.

Safety rod

2

46.

Reflux rod

1

106.

Nut M10

2

47.

O-ring d4×1.8

1

107.

External scissors lever for

chassis

1

48.

Guide casing

1

108.

Internal scissors lever for

chassis

1

49.

Protect casing

1

109.

Bushing

2

50.

Lever

1

110.

Roller for chassis

2

51.

Lever bushing

1

111.

Pin axle

2

52.

Washer 6

2

112

Bolt M6×8

1

53.

Spring washer 6

2

113

Screw M6×30

1

54.

Hex soch screw M6×16

1

114

Cover-type nut M6

1

A Pump ass’y

1~49,113,114

B

Swivel wheel ass’y

78 C Front wheel ass’y

83 D Sealkit ass’y

1,3,3A,4,7,8,9,16,23,25,31,35,37,38,40,42,44,47

E

Handle ass’y

52,53,55,60,61,62,66,67,115,116

Page 24

24

Page 25

25

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1.

Seal cover d35×D43.5×5

1

60.

Spring pin

1

2.

Cylinder cover

1

61.

Control link

1

3.

O-ring d75×3.55

1

62.

Handle

1

3A

O-ring d75×2.65

1

63.

Spacing casing

2

4.

O-ring d35.5×3.55

1

64.

Spring washer 12

2

5.

Piston Rod

1

65.

Hex screw M12×30

2

6.

Spacing casing

1

66.

Split pin 2×15

1

7.

Guideing δ2×15

1

67.

Pin 1 8.

O-ring D20×2.4

1

71.

Pedal bent pipe

1

9.

Seal ring d39×D45×4.5

1

72.

Hex soch screw M8×20

2

10.

Retainer for piston rod

1

73.

Shake link

1

11.

Spacing retainer 18

1

74.

Spring

2

12.

Piston

1

75.

Retainer 10

2

13.

Cylinder

1

76.

Pin axle

2

14.

Washer for cylinder

1

77.

Link 2 15.

Reservior

1

78.

Wheel

2

16.

O-ring d10×2.65

1

79.

Nut M10

16

17.

Filler screw

1

80.

Spring washer 10

16

18.

Washer for reservior

1

81.

Washer 10

36

19.

Steel ball 5

1

82.

Hex soch screw M10×25

16

20.

Spring base

1

83.

Wheel

2

21.

Regulating pressure spring

1

84.

axle 1 22.

Regulating pressure screw

1

85.

Retainer 20

7

23.

O-ring d7.1×1.8

1

86.

Chassis

1

24.

End cover

1

87.

Hex screw M8×16

5

25.

O-ring d15×2.65

2

88.

Pin axle for chassis

1

26.

Regulating speed spring

1

89.

Bushing

8

27.

Regulating slide-valve

1

89A

Bushing

2

28.

Regulating speed spring casing

1

90.

Washing

3

29.

Regulating speed slide casing

1

90A.

Washing

2

30.

Steel ball 7

1

91.

Slotting nut M16×1.5

5

31.

O-ring d6.9×1.8

1

92.

Split pin 3.2×26

5

32.

Conical valve

1

93.

Pin axle

3

33.

Spring

1

94.

Pin axle for table

1

34.

Check valve casing

1

95.

Hex socket set screw M8×12

1

35.

O-ring d10×1.8

1

96.

Bushing

2

36.

Check valve screw

1

97.

Oil cup

4

37.

Seal cover d18×D25×4.5

1

98.

External scissors lever for table

1

38.

O-ring d18×2.65

1

99.

Internal scissors lever for table

1

39.

Pump plunger

1

100.

Bushing

2

40.

Y-ring d10×D18×6

1

101.

Roller for table

2

Page 26

26

41.

Pump body for plunger

1

102.

Table

1

42.

O-ring D28×3.1

1

103.

Spring pin 8×30

2

43.

Pump body

1

104.

Screw bolt M10×40

2

44.

O-ring d10.6×2.65

1

105.

Safety rod

2

45.

Spring

1

106.

Nut M10

2

46.

Reflux rod

1

107.

External scissors lever for chassis

1

47.

O-ring d4×1.8

1

108.

Internal scissors lever for chassis

1

48.

Guide casing

1

109.

Bushing

2

49.

Protect casing

1

110.

Roller for chassis

2

50.

Lever

1

111.

Pin axle

2

51.

Lever bushing

1

112.

Bolt M6×8

1

52.

Washer 6

2

113.

Rod

1

53.

Spring washer 6

2

114.

Rod

1

55.

Put pressure assembly line

1

115.

Screw M6×30

1

58.

Washer 8

2

116.

Cover-type nut M6

1

A Pump ass’y 1~49,113,114

1~49,113,114

B

Swivel wheel ass’y

78 C Front wheel ass’y

83 D Sealkit ass’y

1,3,3A,4,7,8,9,16,23,25,31,35,37,38,40,42,44,47

E

Handle ass’y

52,53,55,60,61,62,66,67,115,116

Loading...

Loading...