Silverline Turbo Mig 100 Gasless User Manual

Thank you for choosing this product.

This product is guaranteed to be free of defects in materials and workmanship for a period of

3 years from the purchase date.

If you experience a problem, return the product direct to us, with the original receipt at :

Silverline Tools Limited.

PO Box 2988,

Yeovil.

BA21 1WU.

We do not refund carriage. This guarantee is for Great Britain only and does not affect your

statutory rights. As you would expect fair wear and tear are not covered.

Users Manual

Turbo Mig 100 Gasless

Product Code 282562

© October 2006

282562_Instructions.indd 1 27/3/07 14:39:18

Introduction

Carefully read and understand this manual and any label attached to

the tool before use. Keep these instructions with the product for

future reference. Ensure all persons who use and service this

product are acquainted with this manual.

Electrical Safety Information

• The wires in this product are coloured:

Blue Neutral (N)

Brown Live (L)

Green & Yellow Earth (E)

• As the colours may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows.

• The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black, the

wire which is coloured brown must be connected to the terminal

which is marked L or coloured red.

• This appliance must be protected by a suitable fuse.

• To prevent fire or shock hazard, do not expose this product to

rain/water or moisture. There are no user serviceable parts inside

except those referred to in this manual. Always refer servicing to

qualified service personnel. Never remove any part of the casing

unless qualified to do so; this unit contains dangerous voltages.

• Use of a residual current device (RCD) will reduce the risk of

electric shock.

NEVER CONNECT THE BROWN OR BLUE WIRE TO THE EARTH

PIN OF THE 13 AMP PLUG. IF IN DOUBT CONSULT A QUALIFIED

ELECTRICIAN

General Safety Instructions

Even when used as prescribed it is not possible to eliminate all

residual risk factors. Use with caution.

Keep guards in position

• Always keep guards in position, in good working order, correctly

adjusted and aligned. Never attempt to use a power tool

without any guard supplied with it.

Remove adjusting keys

• Always check to see that keys and adjusting wrenches are removed

from power tool before turning on.

Clean work area

• Accidents occur where benches and work areas are cluttered or

dirty, floors must be kept clear, avoid working where the floor is

slippery.

Dangerous environment

• Do not use power tools in damp or wet conditions, or expose them

to rain. Provide adequate surrounding work space and keep are

well lit. Do not use power tools where there is a risk of explosion or

fire from combustible material, flammable liquids, flammable gases

or dust of an explosive nature. When using power tools avoid

contact with any earthed items such as pipes, radiators, cookers,

refrigerators, metal baths and taps.

Children & pets

• Children and pets should always be kept at a safe distance from

your work. Make your workshop child-proof. Lock tool away where

children can’t get access to them. Remove batteries from cordless

tools.

Use the correct power tool

• Don’t force, or attempt to use a power tool for a purpose it was not

designed for. Do not use a small tool to do the job of a heavy duty

tool.

Wear correct clothing and footwear.

• Don’t wear loose clothing, neckties or jewellery or other items which

may get caught in moving parts. Wear non-slip footwear, cover or

tie back long hair. Use safety footwear if necessary.

• Wear safety goggles at all times, every day glasses are not

sufficient for eye protection, as lenses are not impact resistant and

could shatter. Use an approved face or dust mask when operation

creates dust. Ensure dust extraction equipment is functioning and

correctly used. Hearing protection should be used if the sound

intensity level for the operator could exceed 85dB(A). Use a hard

hat where there is a risk of falling objects or striking your head on

low level obstructions.

Protect yourself from vibration.

• Hand held power tools may produce vibration. Vibration can cause

disease. Gloves to keep the operator warm and dry and therefore

maintain good blood circulation in the fingers may help. This tool

has not been designed for extended or industrial operation.

Secure work

• Always secure work. Where practical use a clamp or vice, it will

allow you to use both hands to operate your power tool.

Keep your balance

• Don’t over reach, keep proper footing at all times to ensure

correct balance.

Maintain your power tool

• Keep your power tool in good working order, keep tools sharp and

clean for best and safest performance. Ensure ventilation holes are

kept clean and unrestricted at all times.

Always disconnect.

• Before changing tools, always ensure they are disconnected from

the power source.

Accessories

• The use of any attachment or accessory other than those

mentioned in this manual could result in damage or injury. The use

of improper accessories could be dangerous.

Never stand on your power tool

• Standing on your power tool or its stand could cause serious injury

if the tool is tipped or if the cutting tool is accidentally contacted. Do

not store materials above or near the tool so that it is necessary to

stand on the tool or its stand to reach them.

Switch off before connecting.

• Ensure the power tool is switched off before connecting to the

power source. If the power tool stops unexpectedly turn the power

switch to off.

Do not abuse the power cord.

• Be sure your cable/extension cable is properly wired and in good

condition. Always replace a damaged cable/extension cable or have

it repaired by a qualified person before using it. Never yank or pull

the cable to disconnect it from the power socket. Never carry your

power tool by it’s cable. Keep the cable away from damp, heat, oil,

solvents, and sharp edges.

Check for damaged or missing parts.

• Before each use check if any part of the power tool is damaged or

missing, check carefully that it will operate properly and perform its

intended function. Check alignment of moving parts for binding. Any

guard or other part that is damaged should be correctly repaired or

replaced. Do not use if the power switch does not turn the power on

and off. Check any other condition that may affect the safety of the

power tool. DO NOT USE IF DEFECTIVE.

Direction of feed

• Feed work into a blade or cutter against the direction of rotation of

the blade or cutter only.

Don’t leave the tool running unattended

• Always wait until your power tool has come to a complete stop

before leaving it and then disconnect from power source.

Double Insulated

FUSE

BROWN

(Live)

BLUE

(Neutral)

E

L

N

FUSE

GREEN/YELLOW

OR GREEN

FUSE

BROWN

(Live)

BLUE

(Neutral)

E

L

N

FUSE

Earthed

Additional safety instructions

BEFORE OPERATING THE WELDER YOU MUST OBSERVE THE

SAFETY NOTICES GIVEN BELOW

• Electrical repairs must be carried out by a qualified approved

engineer and only with the welder disconnected from the power

source.

• Operating the welder with the covers removed is prohibited.

• Ensure that the unit is correctly set up.

• MIG welders are easy and safe to operate under normal conditions.

DO NOT OPERATE THE WELDER IN THE RAIN OR IN DAMP

CONDITIONS.

• Do not attempt to lift the welder with the gas bottle mounted on the

rear platform always remove the gas bottle before lifting the welder.

• The unit can be used on an inclined flat surface of up to 15 degrees

however if wheels are fitted to the welder ensure that you check

them.

ADDITIONAL PRECAUTIONS

• All flammable materials must be removed from the welding area.

• DO NOT strike an Arc on or near the gas bottle.

• DO NOT attempt to weld fuel or gas containers.

• Toxic gases are given off during the MIG welding process, always

ensure that you weld in a well ventilated area.

• Always use a face shield or welding helmet fitted with the correct

glass filter. Never use damaged safety equipment.

• Wear welding gloves at all times when welding. They will protect

hands from ultra violet radiation and the heat of the Arc. We also

recommend wearing overalls.

• When welding at higher settings a leather apron should be worn to

protect the operator from spatter.

• When welding in the overhead position suitable headwear should

be worn to protect the head and neck.

• It is recommended that industrial footwear including steel toe caps

are worn when welding.

IMPORTANT

• These units must never be exposed to rain or snow.

• Do not use in a wet or damp environment.

• Do not attempt to thaw pipes.

The units should be connected to the mains supply via a circuit

breaker.

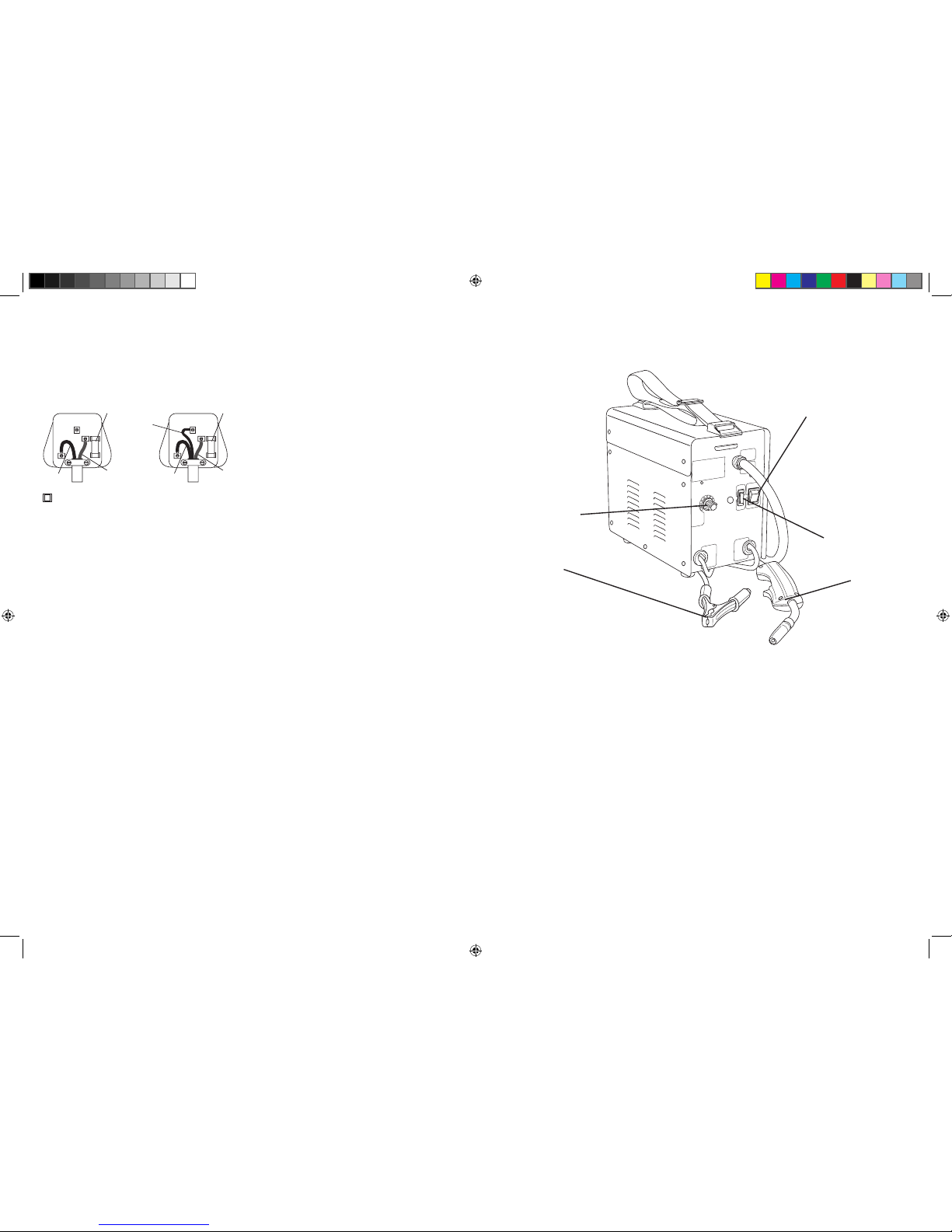

Product Familiarisation

Turbo Mig 100 Gasless

1. On/off switch

2. Output settings

3. Amp selector

4. Earth clamp

5. Torch

SPECIFICATION

Voltage:

230V

No-load voltage: 26-30V

Current arrange: 50-90A

Rated duty cycle:

10%

Adjustment positions: 4

Input capacity:

2.4kW

Class of insulation: H

Applied welding wire: 0.9mm flux wire

Fuse:

10A

4

3

5

2

1

282562_Instructions.indd 2 27/3/07 14:39:25

Loading...

Loading...