Page 1

45/90A

Gasless Turbo Mig

282562

Gasless Turbo Mig

Poste à souder Turbo MIG sans gaz

Turbo-MIG-Fülldrahtschweißgerät

Soldador sin gas Turbo Mig

Turbo mig senza gas

Gaslose MIG lasmachine

www.silverlinetools.com

Page 2

1

6

5

4

3

2

7

8

12

9

1011

15

14

13

13

14

15

16

17

2

18

19

20

21

Page 3

9 23 24

27

25

26

22

13

16

17/18

28 29 30 31

32

A B

33

343536

www.silverlinetools.com

3

Page 4

4

Page 5

45/90A

Gasless Turbo Mig

English .................. 6

Français ................ 12

Deutsch ................. 18

Español ................. 24

Italiano .................. 30

Nederlands ............ 36

www.silverlinetools.com

5

Page 6

GB

Original Instructions

Description of Symbols

The rating plate on your tool may show symbols. These represent important information

about the product or instructions on its use.

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Wear protective clothing

Wear protective shoes

Read instruction manual

Class I construction (protective earth)

Indoors use only!

Toxic fumes or gases!

Risk of fire!

Risk of electrocution!

Technical Abbreviations Key

V Volts

~, AC Alternating current

A, mA Ampere, milli-Amp

Ø Diameter

W, kW Watt, kilowatt

Specification

Input voltage: ....................................................................230V~ 50Hz

Input current: ...........................................13.5A (peak), 4.6A (average)

Efficiency: ..................................................................................... 80%

Output current range: ...............................................................45/90A

Rated duty cycle: ..........................................10% @ 90A, 60% @ 45A

No load output voltage: ...................................................................31V

Output voltage: ............................................18.5V (90A), 16.25V (45A)

Wire reel maximum weight: .......................................................0.45kg

Insulation class: ................................................................................. H

Ingress protection: ...................................................................... IP21S

Wire: ...........................................................0.8-0.9mm flux cored wire

Welding thickness range (steel): .........................................1.2-6.5mm

Internal fuse rating: ....................................................................... 16A

Plug fuse (UK only) ........................................................................ 13A

Protection class: ............................................................................

Torch cable length: ...................................................................... 2.0m

Earth cable length:.......................................................................1.5m

Power cable length: ..................................................................... 2.0m

Dimensions (H x L x W): ........................................295 x 340 x 180mm

Weight: .........................................................................................13kg

Hot surfaces - DO NOT touch!

DO NOT use in rain or damp environments!

Caution!

Danger of ultraviolet radiation!

Environmental Protection Welding equipment should not be disposed of

with household waste. Please recycle where facilities exist. Check with your

local authority or retailer for recycling advice

Conforms to relevant legislation and safety standards.

As part of our ongoing product development, specifications of Silverline products

may alter without notice.

6

Page 7

www.silverlinetools.com

Gasless Turbo Mig282562

General Safety

WARNING! When using electric power tools, basic safety precautions should always be

followed to reduce the risk of fire, electric shock and personal injury including the following

safety information. Read all these instructions before attempting to operate this product

and save these instructions for future use.

WARNING: This appliance is not intended for use by persons (including children) with

reduced, physical or mental capabilities or lack of experience or knowledge unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. Children must be supervised to ensure that they do not play

with the appliance.

CAUTION: Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be performed. Use

of the power tool for operations different from those intended could result in a hazardous

situation.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1 - Keep work area clear - Cluttered areas and benches invite injuries

2 - Consider work area environment

- Do not expose tools to rain

- Do not use tools in damp or wet locations

- Keep work area well lit

- Do not use tools in the presence of flammable liquids or gases

3 - Guard against electric shock - Avoid body contact with earthed or grounded

surfaces (e.g. pipes, radiators, ranges, refrigerators)

4 - Keep other persons away - Do not let persons, especially children, not

involved in the work touch the tool or the extension cord and keep them away

from the work area

5 - Store idle tools - When not in use, tools should be stored in a dry locked-up

place, out of reach of children

6 - Do not force the tool - It will perform the job better and safer at the rate for

which it was intended

7 - Use the right tool - Do not force small tools to do the job of a heavy duty tool

Do not use tools for purposes for which they are not intended; for example do

not use circular saws to cut tree limbs or logs

8 - Dress appropriately

- Do not wear loose clothing or jewellery, which can be caught in moving

parts

- Suitable safety footwear is recommended when working outdoors.

- Wear protective covering to contain long hair

9 - Use protective equipment

-Use safety glasses

-Use face or dust mask if working operations create dust

WARNING: Not using protective equipment or appropriate clothing can cause personal

injury or increase the severity of an injury.

10 - Connect dust extraction equipment - If the tool is provided for the

connection of dust extraction and collecting equipment, ensure these are

connected and properly used

11 - Do not abuse the power cable - Never pull the power cable to disconnect

it from the socket. Keep the power cable away from heat, oil and sharp edges.

Damaged or entangled power cables increase the risk of electric shock

12 - Secure work - Where possible use clamps or a vice to hold the work. It is

safer than using your hands

13 - Do not overreach - Keep proper footing and balance at all times

14 - Maintain tools with care

- Keeping cutting tools sharp and clean makes the tool easier to control and

less likely to bind or lock in the workpiece

- Follow instructions for lubricating and changing accessories

- Inspect tool power cables periodically and have them repaired by an

authorised service facility if damaged

- Inspect extension cables periodically and replace if damaged

- Keep handles dry, clean and free from oil and grease

WARNING: Many accidents are caused by poorly maintained power tools.

15 - Disconnect tools - Disconnect tools from the power supply when not in use,

before servicing and when changing accessories such as blades, bits and

cutters

WARNING: The use of accessories or attachments not recommended by the manufacturer

may result in a risk of injury to persons.

16 - Remove adjusting keys and wrenches - Form the habit of checking to see

that keys and adjusting wrenches are removed from the tool before switching

it on

17 - Avoid unintentional starting - Ensure switch is in “off” position when

connecting to a mains socket, inserting a battery pack, or when picking up or

carrying the tool

WARNING: Unintended starting of a tool can cause major injuries.

18 - Use outdoor extension leads - When the tool is used outdoors, use only

extension cords intended for outdoor use and so marked. Use of an extension

cable suitable for outdoor use reduces the risk of electric shock

19 - Stay alert

- Watch what you are doing, use common sense and do not operate the tool

when you are tired

- Do not use a power tool while you are under the influence of drugs, alcohol

or medication

WARNING: A moment of inattention while operating power tools may result in serious

personal injury.

20 - Check damaged parts

- Before further use of tool, it should be carefully checked to determine that it

will operate properly and perform its intended function

- Check for alignment of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation

- A guard or other part that is damaged should be properly repaired or

replaced by an authorised service centre unless otherwise indicated in this

instruction manual

- Have defective switches replaced by an authorised service centre

WARNING: Do not use the tool if the on/off switch does not switch the tool on and off. The

switch must be repaired before the tool is used.

21 - Have your tool repaired by a qualified person - This electric tool complies

with the relevant safety rules. Repairs should only be carried out by qualified

persons, otherwise this may result in considerable danger to the user

WARNING: When servicing use only identical replacement parts.

WARNING: If the power cable is damaged it must be replaced by the manufacturer or an

authorised service centre.

22 - Power tool mains plugs must match the mains socket - Never modify

the plug in any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching sockets will reduce risk of

electric shock

23 - If operating a power tool outside use a residual current device (RCD) -

Use of an RCD reduces the risk of electric shock

NOTE: The term “residual current device (RCD)” may be replaced by the term “ground fault

circuit interrupter (GFCI)” or “earth leakage circuit breaker (ELCB)”.

WARNING: Before connecting a tool to a power source (mains switch power point

receptacle, outlet, etc.) be sure that the voltage supply is the same as that specified on

the nameplate of the tool. A power source with a voltage greater than that specified for

the tool can result in serious injury to the user, and damage to the tool. If in doubt, do not

plug in the tool. Using a power source with a voltage less than the nameplate rating is

harmful to the motor.

7

Page 8

GB

Welding Safety

• Welding produces toxic fumes and can reduce oxygen levels in the work area. Always

work in a well-ventilated area. Avoid inhaling welding fumes, use a suitable respirator

where appropriate

• Some metal parts may have zinc, lead, cadmium or other coatings. Attempting to weld

through these coatings can produce highly toxic fumes. Always remove all coatings

before welding

• If you experience irritation to the lungs, throat or eyes whilst welding, STOP

IMMEDIATELY and seek fresh air

• Welding produces extremely high levels of UV light. To prevent eye damage, ALWAYS use

an approved welding face mask. Under no circumstances look directly at the arc

• The light produced when arc welding can be attractive to look at, especially to children.

Always prevent other people from viewing the arc welding light with unprotected eyes

• If there is a possibility of other people approaching the work area, erect suitable

screening to protect them from the light / glare

• Always replace the welder face mask glass as soon as it shows any signs of wear

or damage

• To prevent skin damage, ALWAYS wear a suitable fire-proof long sleeved jacket, heat

proof gloves, and cap. Keep covered up

• Always remove any flammable materials (e.g. cigarette lighter, matches) from your

clothing before welding

• Always keep a fire extinguisher nearby when welding

• Sparks generated while welding can ignite flammable materials easily in the welding

area, so it is important to remove flammable materials before commencing welding

• Only weld when the work area and all workpieces are dry

• Do not weld sealed containers (e.g. fuel tanks, air tanks, oil drums). The heat generated

from welding can cause sealed containers to burst without warning

• Be aware of transferred heat. Metal parts can conduct heat away from the work area

and cause ignition of flammable materials

• Be aware that welded parts will remain hot for some time after joining. Allow to cool

completely before handling, or leaving unattended

• Never weld where flammable gases, liquids or dust are present

• Ensure that there is always a responsible person nearby to alert you to any fire, or to

call help in an emergency

• Use of welding machines will create powerful magnetic fields. This may disturb the

operation of sensitive electronic equipment. Pacemaker wearers should consult a doctor

before using a welding machine

• Do not overload power supply. Check that your mains wiring is capable of delivering the

required current safely (see specification)

Wire feed

• Caution: The tip of welding wire can be very sharp, and is fed with adequate force to

puncture skin

• Keep the welding machine switched off until you are ready to begin welding. Never

point the torch towards people or animals

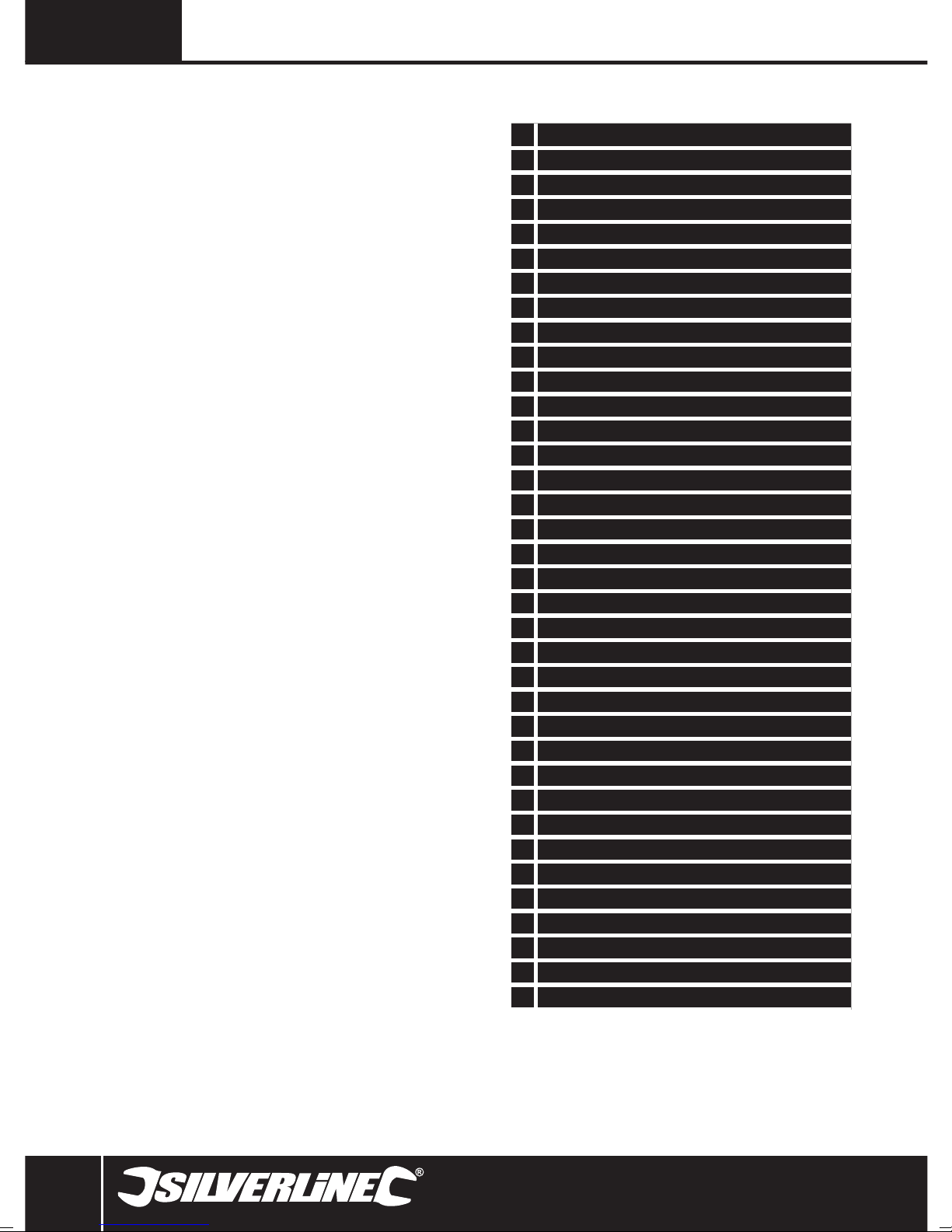

Product Familiarisation

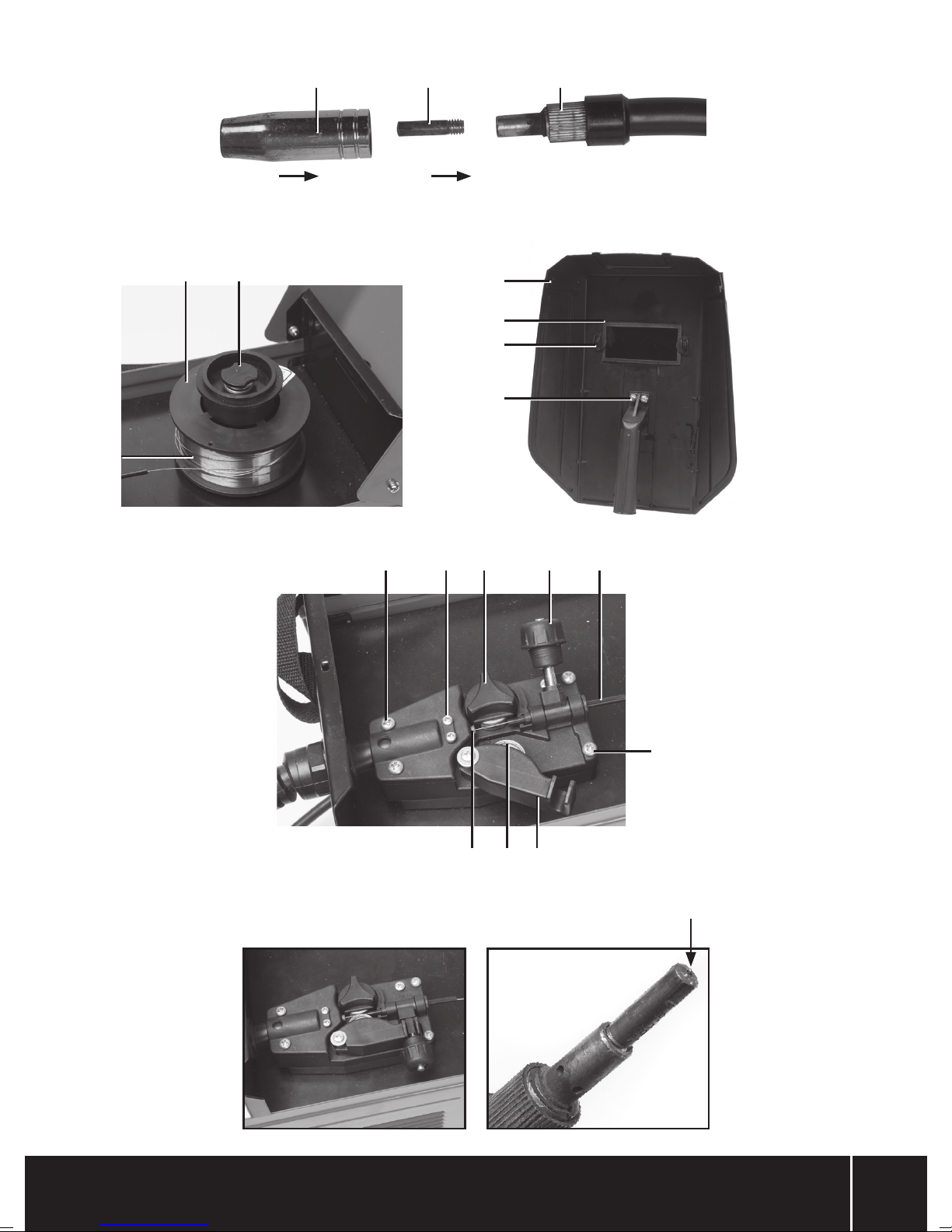

1 Case Lid Release

2 On/Off Switch

3 90/45A Switch

4 Wire Feed Speed Dial

5 Over-Heat Indicator

6 Carrying Strap

7 Torch Handle

8 Trigger

9 Shroud

10 Mains Cable

11 Earth Clamp

12 Welding Mask (assembled)

13 Filter Frame

14 Welding Glass

15 Safety Glass

16 Frame Clips (x 2)

17 Handle Nuts (x 3)

18 Handle Bolts (x 3)

19 Frame Screws (x 2)

20 Handle

21 Welding Mask

22 Mask Clips

23 Tip

24 Wire Feed Output

25 Wire Reel

26 Reel Spindle Mechanism

27 Wire

28 Feed Mechanism Cover Screws

29 Main Liner Screws

30 Feed Roller

31 Tension Knob

32 Reel Wire Liner

33 Reel Wire Liner Screw

34 Tension Latch

35 Tension Roller

36 Liner

8

Accessories (not shown):

• Chipping Hammer

• Wire Brush

Page 9

www.silverlinetools.com

Gasless Turbo Mig282562

Intended Use

Welder for light to medium-duty MIG (Metal Inert Gas) welding applications, for use with

various types of steel, using suitable flux-cored welding wires. It does not require a gas

connection as the flux-cored wire provides the shielding gas in use. This product is not

designed for commercial, trade or industrial applications.

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its features and

functions

• Ensure that all parts of the tool are present and in good condition. If any parts are

missing or damaged, have such parts replaced before attempting to use this tool

Before Use

WARNING: Always unplug the welding machine from the mains supply and allow to

cool fully before attempting to fit or replace any part.

Note: This tool is earthed and must only be connected to mains with an earth connection.

Do not attempt to use it without an earth connection.

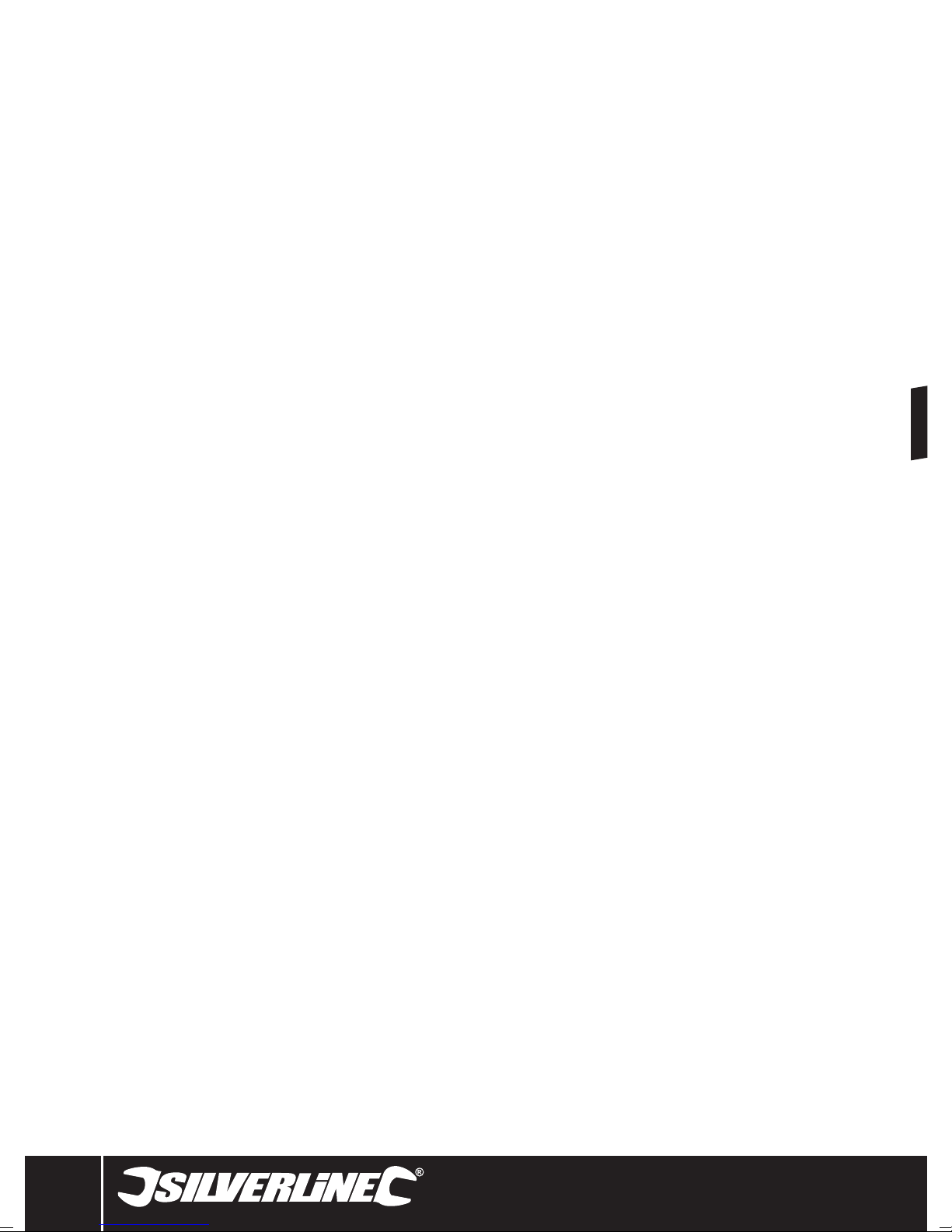

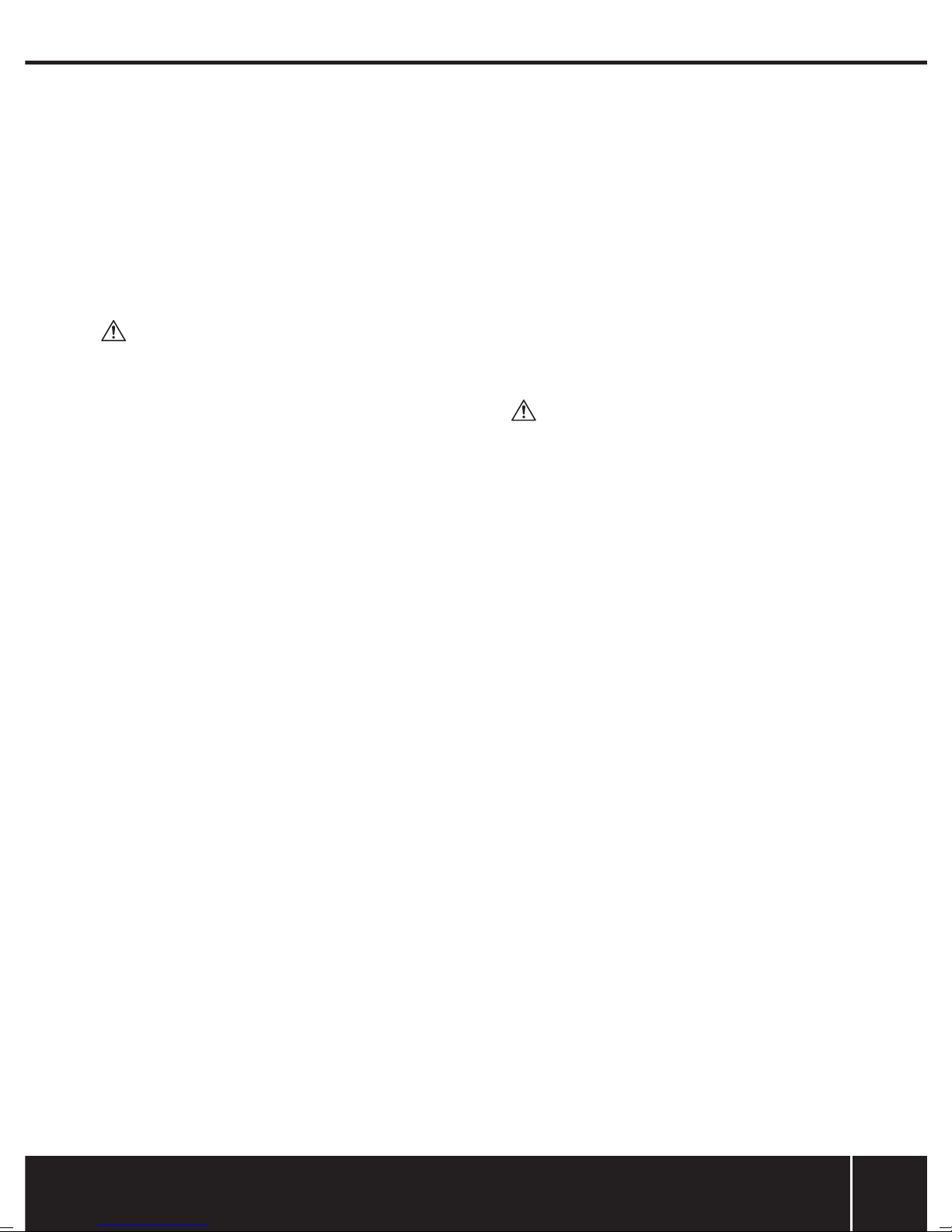

Assembling the mask

Assemble the mask as shown.

1. Use the Mask Clips (22) to assemble the flat-packed Welding Mask (21) into its normal

shape

2. Fit the Handle (20) using the Handle Nuts and Bolts (17 & 18). The Handle must be

inside the Welding Mask body to protect the operator’s hand from splatter

3. Ensure the Safety Glass (15) protects the Welding Glass (14) from weld splatter. If the

Welding Glass is fitted as the external layer it may get damaged by splatter and allow

dangerous ultra-violet light to reach the operator’s eyes

4. Fit the glass assembly into the Welding Mask using the Frame Screws (19) and Frame

Clips (16)

Installing wire

This welder requires 0.8-0.9mm flux cored wire

1. Turn the Case Lid Release (1) and lift the lid of the case

2. Turn the plastic top of the Reel Spindle Mechanism (26) anti-clockwise and remove it

carefully with the spring and top section

3. Place the supplied Wire Reel (25) over the reel holder spindle (shown already fitted),

positioning so that the Wire (27) will feed off the Wire Reel on the nearest side as

indicated by the arrow

4. Refit the top section, spring and plastic top of the Reel Spindle Mechanism. Ensure the

spring provides sufficient tension so the reel does not unravel on its own

5. Release the Tension Knob (31) so that the Tension Latch (34) can be swung clear as

shown

6. Carefully release the end of the wire from the spool and take care not to let the wire

unravel. Ensure that the wire tip is straight and is cut off cleanly

7. Slowly feed the Wire into the end of the Reel Wire Liner (32) across the Feed Roller

(30) and into the Liner (36) and push a little way into the Liner carefully

8. Swing the Tension Latch back into position, ensuring that the Wire is centred in the

grooves of the Feed Roller and Tension Roller (35)

9. Reposition the Tension Latch as shown in image A. Tension can be adjusted by rotating

the Tension Knob

10. Close the lid and secure with the Case Lid Release

11. Pull off the Shroud (9) from the torch and unscrew the Tip (23) and remove

12. Connect the welder to the mains power supply, switch on, and hold the torch

13. Move the torch away from the machine, so that the torch cable is straight

14. Ensure that the torch is not touching anything, and squeeze the Trigger (8). The wire

feed mechanism should drive the Wire through to the torch, image B

15. If the Wire is not driven through, disconnect from the mains power supply, open the

lid, and tighten the Tension Knob (31). The drive rollers should be just tight enough to

drive the Wire through to the torch, but not so tight as to prevent the drive roller from

slipping if the Wire becomes blocked

16. When the Wire is propelled out of the end of the torch, switch off and disconnect from

the mains power supply

17. Refit the Tip and the Shroud, and trim the Wire so that approximately 5mm projects

from the tip

Removing wire reel and end of wire

1. Open the lid of the welder using the Case Lid Release (1)

2. Use a pair of pliers to draw the last of the old Wire Reel out through the Tip (15) of the

torch. If the old Wire Reel (25) is not empty, cut the Wire at the spool and release the

Tension Knob (31) and move the Tension Latch (34) away from the Feed Roller (30)

3. Then proceed as per instructions for ‘Installing wire’ above

Important

• Always wear appropriate personal protective equipment for the job that you are about

to do. Use of this machine requires a welding mask, gloves, heat-resistant clothing

and, if appropriate, a respirator

• Always ensure that you have an appropriate fire extinguisher near to the work area

• Always inspect your machine for damage or wear. Pay particular attention to leads and

cables. If any damage is found, DO NOT USE

• Check that all casings or covers are properly closed and secured

• Position the welder in such a way that it will not move or tip in use. Ensure that there

is at least 500mm of clear space around the welder to allow proper ventilation

Operation

WARNING: Always unplug the welding machine from the mains supply and allow to

cool fully before attempting to fit or replace any part.

Setting the machine

• To achieve a good quality weld, the Wire Feed Speed Dial (4) and 90/45A Switch (3)

must be set correctly. The 10% duty setting provides 90A current and the 60% duty

setting provides 45A current

• The wire speed should be adjusted to provide a steady arc. The correct setting will

depend on distance, current, torch speed, and other factors. Experiment with wire

speeds until you find an optimum setting

Note: The welder optimises current output depending on wire speed and monitored current

levels to improve weld quality and reduce splatter.

Duty Cycle

• This machine is not designed for continuous welding. Excessive continuous

welding would cause overheating and damage to internal components

• The duty cycle defines the number of minutes, in every ten minutes, that the machine

can weld

• For a duty cycle of 10%, the machine may be used for 1 minute, and then must be

allowed 9 minutes to cool. The 60% duty cycle allows 6 minutes in every 10 minutes

• If the duty cycle is exceeded, the machine will automatically cut-out

• Using the machine at reduced current settings, and maintaining good ventilation will

maximise the duty cycle

Thermal cut-out

• When the thermal cut-out protection is operating the Over-Heat Indicator (5) will

illuminate and the welder will shut down

• Allow the machine to cool. The cut-out will automatically reset once the machine is

ready to be used

Preparing to weld

• Ensure that parts to be joined are clean and free from rust, paint, or other finishes

• All parts should be well supported, so that there is a gap of approximately 1mm where

you intend to form the welded joint

• Check that there are no flammable materials in the vicinity of the work area

• Attach the Earth Clamp (11) to a cleaned area of one of the parts, as near as practical

to where the joint will be

• Ensure that there is both a responsible person and an operable fire extinguisher at

hand

• Connect the machine to the mains power supply

Welding

WARNING: Using a welder correctly is a technical skill. A welder used incorrectly can be

highly dangerous. The information presented below is general guidance only. If you are not

entirely confident in your ability to use this tool safely DO NOT USE.

1. Move the On/Off Switch (2) to the ‘ON’ position

2. Set the Wire Feed Speed Dial (4) to the correct speed or to the mid-position if not sure

of correct setting, then adjust later if necessary

3. Hold the Torch Handle (7) in one hand and the Welding Mask (12) in the other

4. Position the torch so that the Tip (23) is approximately 10mm away from the metal, at

an angle of approximately 75˚

9

Page 10

GB

5. Hold the mask over your face and squeeze the Trigger (8)

6. An arc should strike between the metal and the tip. Hold the Trigger for 1-2 seconds

and release

7. Allow the weld to cool slightly and move the mask away from your face. If the settings

are correct, a round 'spot' weld should form

8. If the weld has not fully penetrated the metal, increase the voltage setting. If a hole

has been made in the metal, reduce the voltage setting

• Practise making welds until you are confident using the machine, and selecting

settings

• An alternative to spot welding suitable for a mig welder is a plug weld where the top

surface has holes drilled along a surface and a pool of the weld material fills each

hole. Spot welds are possible for thinner material with a mig welder but the welds are

more difficult and may not be as satisfactory

• To form a 'seam' weld, hold the Trigger for longer, and slowly move the torch forward

at the same time

• If the machine settings are correct, the arc should be steady, and produce a crackling

sound.

• If you hear a popping sound, or struggle to maintain the arc, adjust the wire speed. If

you feel the torch trying to 'push back', reduce the wire speed

• Creating neat, high quality welds is a skill that takes time to master. Practise and good

preparation should result in satisfactory welds

Accessories

• A range of accessories including personal protective equipment and welding

tools are available from your Silverline stockist. Spare parts can be obtained from

toolsparesonline.com

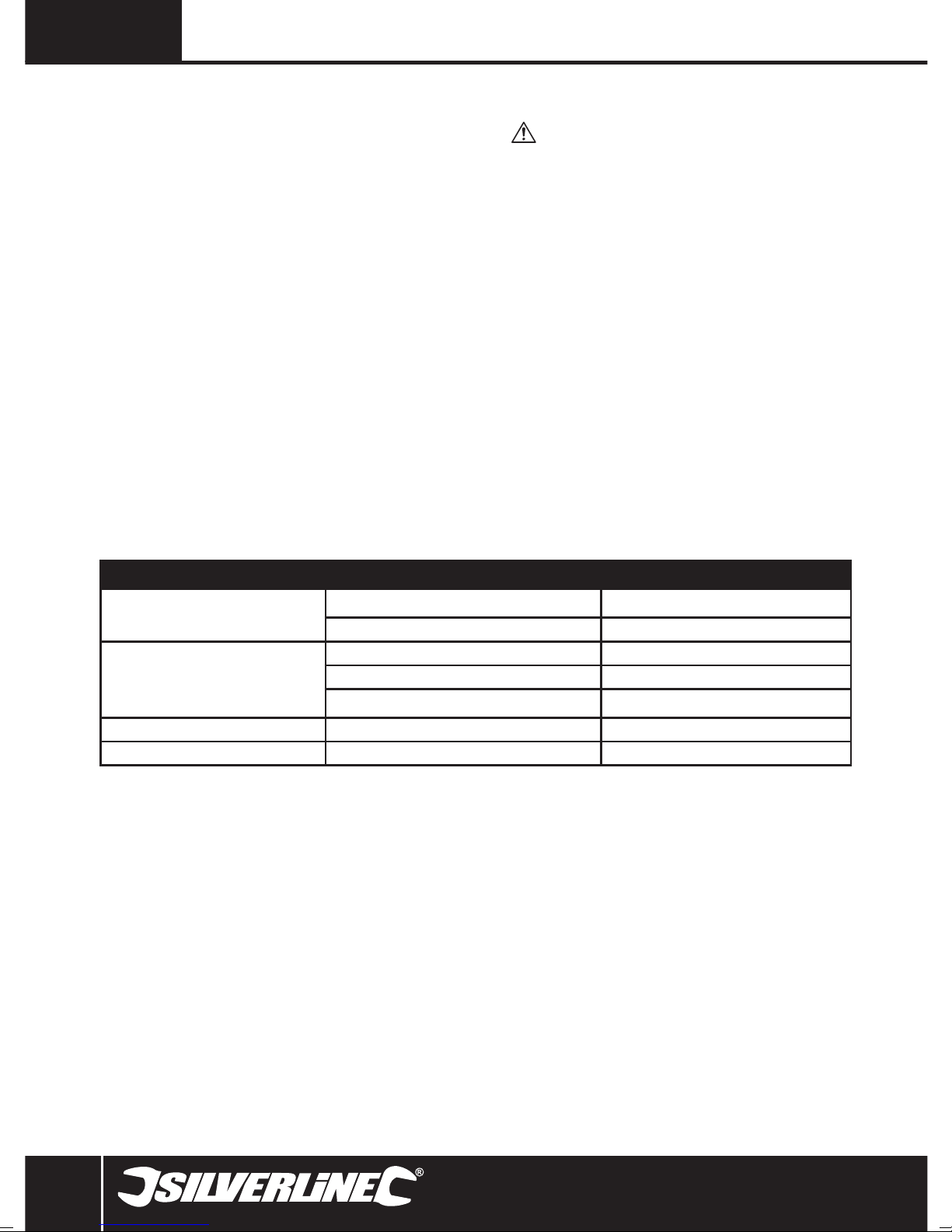

Troubleshooting

Maintenance

WARNING: Always unplug the welding machine from the mains supply and allow

to cool fully before attempting to fit or replace any part.

Replacing tips

• As the welder is used, the Tip (23) may become worn. This will make the arc difficult

to control

1. To replace the Tip, remove the Shroud (9) from the torch, and unscrew the Tip

2. Check that the new Tip is the correct size for the Wire being used

3. Thread the new Tip over the end of the Wire, and screw into the torch. Replace the

Shroud

Cleaning

Disconnect the machine from the mains supply before cleaning

• Keep your machine clean. Always clean dust or particles away and never allow

ventilation holes to become blocked

• Use a soft brush or dry cloth to clean the machine. If available, blow through the

ventilation holes with clean, dry, compressed air

Disposal

Always adhere to national regulations when disposing of electronic equipment that is no

longer functional and is not viable for repair.

• Do not dispose of power tools, or other waste electrical and electronic equipment

(WEEE), with household waste

• Contact your local waste disposal authority for information on the correct way to

dispose of electronic equipment

Problem Possible cause Solution

Feed Roller (30) does not turn No power Switch on welder

Wire Feed Speed Dial (4) set to minimum 0 setting Increase setting

Feed roller (30) turns but Wire (27) does not feed Incorrect roller pressure Adjust Tension Knob (31)

Liner (36) damaged Check and replace Liner

Wire welded to Tip (23) Release Wire from Tip

During use the welder stops working Duty cycle exceeded and Over-Heat Indicator (5) is illuminated Leave the welder for 20-30 minutes to cool down

Poor weld Incorrect current and feed settings Adjust Wire Feed Speed Dial (4) and 90/45A Switch (3)

10

Page 11

www.silverlinetools.com

Gasless Turbo Mig282562

Silverline Tools Guarantee

This Silverline product comes with a 3 year guarantee

Register this product at www.silverlinetools.com within 30 days of purchase in order to

qualify for the 3 year guarantee. Guarantee period begins according to the date of purchase

on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as detailed on your

sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the stockist where it

was purchased, with your receipt, stating details of the fault. You will receive a replacement

or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date, your name, address

and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools to establish if the

deficiencies are related to material or manufacturing of the product.

Carriage will not be refunded. Items for return must be in a suitably clean and safe state for

repair, and should be packaged carefully to prevent damage or injury during transportation.

We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized repair agents.

The repair or replacement of the product will not extend the period of guarantee

Defects recognised by us as being covered by the guarantee shall be corrected by means of

repair of the tool, free of charge (excluding carriage charges) or by replacement with a tool

in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will become the property

of Silverline Tools.

The repair or replacement of your product under guarantee provides benefits which are

additional to and do not affect your statutory rights as a consumer.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee Registration button.

You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created in PDF format for

you to print out and keep with your purchase.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline Tools that the

deficiencies were due to faulty materials or workmanship within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will replace it with a

functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating instructions eg

blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding sheets, cutting discs

and other related items.

Accidental damage, faults caused by negligent use or care, misuse, neglect, careless

operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its authorized

repair agents.

Claims other than the right to correction of faults on the tool named in these guarantee

conditions are not covered by the guarantee.

Battery Guarantee

Silverline batteries are guaranteed for 30 days. If a defect occurs on a registered battery

during the term of the Battery Guarantee, due to material or manufacturing fault, then

Silverline will replace it free of charge. This guarantee does not apply to commercial use nor

does it extend to normal wear and tear or damage as a result of accident, abuse or misuse.

CE Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that

Identification code: 282562

Description: Gasless Turbo Mig

Conforms to the following directives and standards:

• Low Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

• RoHS Directive 2011/65/EU

• EN60974-1:2012

• EN60974-10:2007

Notified body: TÜV Rheinland

The technical documentation is kept by: Silverline Tools

Date: 09/09/15

Signed:

Mr Darrell Morris

Managing Director

Name and address of the manufacturer:

Powerbox International Limited, Company No. 06897059. Registered address:

Central House, Church Street, Yeovil, Somerset BA20 1HH, United Kingdom.

11

Page 12

FR

La plaque signalétique figurant sur votre outil peut présenter des symboles. Ces symboles

constituent des informations importantes relatives au produit ou des instructions

concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masques respiratoires

Port du casque

Traductions des instructions originales

Légende des abréviationsDescription des symboles

V Volts

~, CA Courant alternatif

A, mA Ampère, milliampère

Ø Diamètre

W, kW Watt, kilowatt

Port de gants

Port de vêtements de sécurité

Port de chaussures de sécurité

Lire le manuel d’instructions

Construction de classe I (Mise à la terre)

Pour usage à l’intérieur uniquement !

Émanation de vapeurs ou de gaz toxiques !

Risque d’incendie

Risque d’électrocution

Caractéristiques techniques

Tension : ..........................................................................230 V~ 50 Hz

Intensité absorbée :...............................13,5 A (crête), 4,6 A (moyenne)

Efficacité : .....................................................................................80 %

Intensité de soudage : ...............................................................45-90 A

Cycle d’utilisation nominal : ...............10 % sous 90 A, 60 % sous 45 A

Tension de sortie à vide : ............................................................... 31 V

Tension de sortie : .................................... 18,5 V (90 A), 16, 25 V (45 A)

Poids maximal du dévidoir de fil :............................................. .0,45 kg

Classe d’isolation : ..............................................................................H

Indice de protection : ...................................................................IP21S

Fil : .......................................................................Fil fourré 0,8-0,9 mm

Plage de soudage (acier) : ................................................ 1,2 - 6,5 mm

Calibre du fusible interne : .............................................................16 A

Fusible de la prise (Royaume-Uni uniquement) : ............................13 A

Classe de protection : .....................................................................

Longueur du câble de la torche à souder : ...................................2,0 m

Longueur du câble de mise à la masse : ......................................1,5 m

Longueur du câble d’alimentation : ..............................................2,0 m

Dimensions (H x L x l) : ........................................295 x 340 x 180 mm

Poids : .......................................................................................... 13 kg

Surface chaude. NE PAS TOUCHER !

NE PAS utiliser sous la pluie ou un dans environnement humide !

Attention !

Danger de radiations d’ultraviolets !

Protection de l’environnement

Les appareils de soudure ne doivent pas être jetés avec les ordures

ménagères. Veuillez les recycler dans les centres prévus à cet effet. Pour

de plus amples informations, veuillez contacter votre municipalité ou

point de vente.

Conforme à la règlementation et aux normes de sécurité pertinentes

Du fait de l’évolution constante de notre développement produit, les caractéristiques

des produits Silverline peuvent changer sans notification préalable.

12

Page 13

www.silverlinetools.com

Poste à souder Turbo MIG sans gaz282562

Consignes générales de

sécurité relatives aux appareils

électriques

AVERTISSEMENT ! Certaines précautions fondamentales, dont les consignes ci-dessous,

doivent impérativement être respectées lors de l’emploi d’outils électriques afin de réduire

le risque d’incendie, de choc électrique et de blessures corporelles. Veuillez lire l’intégralité

de ces consignes avant de mettre en marche ce produit et veuillez les conserver pour toute

consultation ultérieure

AVERTISSEMENT : Cet appareil n’est pas conçu pour être utilisé par des personnes (y

compris les enfants) ayant des capacités physiques ou mentales réduites, ou n’ayant pas la

connaissance ou l’expérience requise, à moins d’être sous la supervision d’une personne

responsable de leur sécurité ou d’avoir reçu les instructions nécessaires. Les enfants ne

doivent pas jouer avec cet appareil

ATTENTION : Utiliser l’appareil électrique, les accessoires et outils à monter conformément

à ces instructions, en tenant compte des conditions de travail et de la tâche à réaliser.

Toute utilisation d’un appareil électrique autre que celle pour laquelle il a été conçu peut

entraîner des situations à risque

L’expression « appareil électrique » employée dans les présentes consignes recouvre aussi

bien les appareils filaires à brancher sur le secteur que les appareils sans fil fonctionnant

sous batterie

1. Maintenir une zone de travail propre. Des zones encombrées et mal

éclairées sont sources d’accidents

2. Prendre en compte la zone de travail :

- Ne pas exposer les outils à la pluie

- Ne pas utiliser les outils dans des endroits humides

- Travailler dans une zone bien éclairée

- Ne pas utiliser d’outils électriques dans des environnements explosifs, tels

qu’à proximité de liquides, de gaz ou de poussières inflammables

3. Éviter les décharges électriques. Éviter le contact corporel avec les surfaces

mises à la terre telles que tuyaux, radiateurs, cuisinières et réfrigérateurs

4. Éloigner les personnes aux alentours. Ne laisser aucune personne dont la

présence n’est pas nécessaire, surtout les enfants, s’approcher de la zone de

travail ou venir en contact avec l’appareil

5. Ranger les appareils électriques inutilisés dans un endroit sûr, sec et hors

de portée des enfants

6. Ne pas forcer sur l’appareil électrique. Un appareil électrique adapté et

employé au rythme pour lequel il a été conçu permettra de réaliser un travail

de meilleure qualité et dans de meilleures conditions de sécurité

7. Utiliser l’appareil électrique approprié au travail à effectuer. Ne pas utiliser

de petits outils pour des tâches lourdes. N’utilisez pas l’outil pour une tâche

pour laquelle il n’a pas été prévu ; par exemple n’employez pas une scie

circulaire pour couper une branche d’arbre ou fendre des bûches

8. Porter des vêtements appropriés

- Ne pas porter de vêtements amples ou des bijoux pendants qui peuvent être

happés par les pièces en rotation

- Le port de chaussures antidérapantes est recommandé en extérieur

- Attacher ou protéger les cheveux longs

9. Porter un équipement de protection approprié

- Porter une protection oculaire

- Porter un masque à poussières lors de travaux créant de la poussière

AVERTISSEMENT : Ne pas porter d’équipements de protection ou de vêtements appropriés

peut engendrer et aggraver des blessures

10. Brancher un système d’extraction de la poussière : si l’appareil est pourvu

de dispositifs destinés au raccord d’équipements d’extraction et de

récupération de la poussière/sciure, s’assurer qu’ils soient bien fixés et utilisés

correctement

11. Ne pas maltraiter le cordon électrique. Ne jamais utiliser le cordon

électrique pour porter, tirer ou débrancher l’appareil. Protéger le cordon

électrique de la chaleur, du contact avec l’essence, des bords tranchants et

pièces rotatives. Un cordon électrique endommagé ou entortillé accroît le

risque de décharge électrique

12. Immobiliser votre travail. Si possible, utiliser des serre-joints ou un étau

pour maintenir la pièce de travail. Cela offre davantage de sécurité que de tenir

la pièce avec la main

13. Ne pas essayer d’atteindre une zone hors de portée. Se tenir toujours en

position stable permettant de conserver l’équilibre

14. Veiller à l’entretien des appareils électriques

- Veiller à ce que les outils de coupe soient tenus affûtés et propres, ce qui

favorise leur maîtrise et leur bon fonctionnement

- Suivre les instructions de lubrification et de changement des accessoires

- Vérifier régulièrement les câbles et les faire réparer/remplacer par un centre

agrée

- Vérifier également l’état des rallonges utilisées

- Tenir les poignées de l’appareil propres (sans graisse ni huile) et sèches

AVERTISSEMENT : de nombreux accidents sont dus à l’utilisation d’appareils électriques

mal entretenus

15. Débrancher l’appareil électrique. Lorsque l’appareil n’est pas utilisé,

ou avant tout opération d’entretien ou de changement d’accessoires, veiller à

débrancher l’appareil de sa source d’alimentation

AVERTISSEMENT : utiliser des accessoires non recommandés par le fabricant peut

engendrer des blessures

16. Enlever les clés et outils de réglage. Prendre l’habitude de retirer ces outils

avant de mettre l’appareil en marche

17. Éviter tout démarrage accidentel ou intempestif. S’assurer que

l’interrupteur marche-arrêt soit en position d’arrêt avant de brancher l’appareil

sur l’alimentation secteur ou d’installer la batterie, de prendre l’appareil ou de

le transporter

AVERTISSEMENT : les démarrages accidentels peuvent être dangereux

18. Usage en extérieur : lors d’une utilisation de l’appareil électrique en extérieur,

se servir d’une rallonge appropriée à une utilisation en extérieur. Cela réduit le

risque de décharge électrique

19. Rester vigilant

- Faire preuve de bon sens lors de la manipulation de l’appareil

- Ne pas utiliser un appareil électrique lorsque l’on se trouve dans un état de

fatigue, ou sous l’influence de drogues, d’alcool ou de médicaments

AVERTISSEMENT : un moment d’inattention pendant l’utilisation d’un outil électrique peut

se traduire par des blessures graves

20. Inspecter les pièces endommagées

- Avant d’utiliser un appareil, toujours vérifier qu’il soit en bon état de marche

- Vérifier que les éléments rotatifs soient bien alignés et non grippés. S’assurer

de l’absence de pièces cassées ou endommagées susceptibles de nuire au

bon fonctionnement de l'appareil

- Une protection ou partie défectueuse doit être réparée ou remplacée par un

centre agrée, sauf en cas d’indication contraire dans le manuel

- Les interrupteurs défectueux doivent être remplacés par un centre agréé

AVERTISSEMENT : ne pas utiliser un appareil électrique dont la commande ne s’effectue

plus par l’interrupteur marche-arrêt. Il est dangereux et doit être réparé

21. Ne faire réparer votre appareil électrique que par un réparateur qualifié.

Cet appareil est conforme aux normes de sécurité en vigueur. Toute réparation

doit être effectuée par une personne qualifiée afin de garantir la sécurité de

l’utilisateur

AVERTISSEMENT : utiliser uniquement des pièces de rechange identiques

AVERTISSEMENT : si le câble d’alimentation est endommagé, le faire remplacer par un

centre agréé

22. La prise d’un appareil électrique doit être adaptée à la prise du secteur.

Ne jamais modifier la prise en aucune façon. Ne jamais utiliser d’adaptateur

sur la prise électrique d’appareils mis à la terre. Des prises non modifiées,

adaptées aux boîtiers de prise de courant, réduiront le risque de décharge

électrique

23. En cas d’utilisation en extérieur, utiliser une alimentation protégée par un

disjoncteur différentiel. L’utilisation d’un disjoncteur différentiel réduit le

risque de décharge électrique

AVERTISSEMENT : Avant de brancher un appareil sur une source d’alimentation (prise

secteur, groupe électrogène, etc.) assurez-vous que la tension fournie soit la même que

celle spécifiée sur la plaque de l’appareil. Une source d’alimentation délivrant une tension

supérieure à celle indiquée sur l’appareil peut engendrer de sérieuses blessures pour

l’utilisateur et endommager l’appareil. En cas de doute, ne branchez pas l’appareil. Une

source d’alimentation délivrant une tension inférieure à celle indiquée sur l’appareil est

néfaste pour le moteur

13

Page 14

FR

Consignes de sécurité relatives

au soudage

• L’action de souder peut produire de la fumée toxique et réduire le taux d’oxygène

présent dans la zone de travail. Travaillez toujours dans un endroit bien ventilé. Évitez

d’inhaler la fumée émise durant le soudage et portez un masque respiratoire si

nécessaire

• Certaines parties métalliques peuvent être galvanisées ou revêtues de plomb, de

cadmium ou d’autres revêtements. Souder sur ces revêtements peut produire de la

fumée hautement toxique. Décapez toujours la surface avant de procéder au soudage

• Si vous ressentez une irritation aux poumons, à la gorge ou aux yeux pendant le

soudage, ARRÊTEZ-VOUS IMMÉDIATEMENT et sortez à l’air pur

• L’action de souder produit des taux extrêmement élevés d’ultraviolets. Pour éviter

d’altérer votre vue, portez TOUJOURS un masque à souder agréé. Ne regardez JAMAIS

directement l’arc

• La lumière produite lors du soudage à l’arc peut fasciner et donner envie de la regarder,

surtout aux enfants. Évitez de laisser d’autres personnes regarder la lumière pendant le

soudage à l’arc sans protection

• Si d’autres personnes risquent de s’approcher de la zone de travail, installez un écran

approprié pour les protéger des ultraviolets / de la lumière éblouissante

• Remplacez immédiatement le verre du masque de soudeur lorsqu’il présente des

signes d’usure ou des dommages

• Pour éviter les brûlures de la peau, portez TOUJOURS une veste ignifugée à manches

longues appropriée, des gants résistants à la chaleur et une casquette. Restez bien

couvert

• Retirez toujours toute source de combustion (par exemple : briquet, allumettes) de vos

vêtements avant de souder

• Gardez toujours un extincteur à proximité de la zone de soudage

• Les étincelles générées lors du soudage peuvent provoquer des incendies lorsqu’elles

entrent en contact avec des matériaux inflammables, il est important d’enlever tous

matériaux inflammables avant de commencer à souder

• Soudez uniquement lorsque toutes les pièces à souder et la zone de travail sont sèches

• Ne soudez pas de conteneurs scellés (par exemple : réservoirs à essence ou à air,

citernes à pétrole). La chaleur produite par le soudage peut faire subitement exploser

les conteneurs scellés

• Soyez conscient de la propagation de la chaleur. Les éléments métalliques peuvent

communiquer la chaleur à tout matériel se trouvant à proximité de votre zone de travail,

ce qui peut à son tour enflammer des matériaux combustibles

• Sachez que les pièces soudées resteront chaudes pendant quelques temps après leur

soudure. Laissez-les refroidir complètement avant de les manipuler ou de vous en

éloigner

• Ne soudez jamais à proximité de gaz, de liquides ou de poussières inflammables

• Assurez-vous toujours qu’une personne qualifiée se trouve à proximité afin de vous

assister en cas d’incendie ou d’appeler de l’aide en cas d’urgence

• L’utilisation de postes à souder créera des champs magnétiques puissants, susceptibles

de perturber le fonctionnement des équipements électroniques sensibles. Il est

recommandé que les personnes portant un stimulateur cardiaque consultent l’avis d’un

médecin avant d’utiliser un poste à souder

• Ne surchargez pas l’alimentation secteur. Vérifiez que votre installation électrique peut

fournir les courants requis en toute sécurité (voir les caractéristiques techniques)

Avancée du fil

• Attention : La pointe du fil à souder peut être très pointue et avance avec suffisamment

de puissance pour perforer la peau

• Tenez ce poste à souder éteint tant que vous n’êtes pas totalement prêt à commencer

le soudage. Ne dirigez jamais la torche à souder vers des personnes ou des animaux

Descriptif du produit

1 Bouton de dégagement du capot

2 Interrupteur

3 commutateur 90 A / 45 A

4 Sélecteur de vitesse du fil

5 Indicateur de surchauffe

6 Sangle de transport

7 Poignée de la torche

8 Gâchette

9 Buse

10 Câble d’alimentation

11 Pince de mise à la masse

12 Masque de soudeur (assemblé)

13 Support de filtre

14 Verre de soudage

15 Verre de sécurité

16 Agrafes du support (x 2)

17 Écrous de la poignée (x 3)

18 Boulons de la poignée (x 3)

19 Vis du support (x 2)

20 Poignée

21 Masque de soudeur

22 Agrafes du masque

23 Pointe

24 Sortie du fil

25 Dévidoir de fil

26 Mécanisme de l’arbre du dévidoir

27 Fil

28 Vis du capot du mécanisme d’avancée

29 Vis de la gaine

30 Galet d’avancée

31 Bouton tendeur

32 Gaine de fil du dévidoir

33 Vis de la gaine de fil du dévidoir

34 Verrou du tendeur

35 Galet tendeur

36 Guide-fil

Accessoires (non illustrés)

Marteau de soudeur

Brosse métallique

14

Page 15

www.silverlinetools.com

Poste à souder Turbo MIG sans gaz282562

Usage conforme

Poste à souder pour les travaux de soudage MIG (soudage de métaux sous gaz inerte)

légers et moyens à l’aide fils à souder fourrés adéquats. Cet appareil ne demande pas

l’apport d’un gaz séparé car les fils fourrés assurent eux-mêmes l’apport de gaz protecteur.

Ce produit n’est pas conçu pour un usage commercial, professionnel ou industriel

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage et

familiarisez-vous avec toutes les caractéristiques du produit

• Si des pièces sont endommagées ou manquantes, faites-les réparer ou remplacer

avant d’utiliser l’appareil

Avant l’utilisation

AVERTISSEMENT : Débranchez toujours la machine et laissez-la refroidir avant d’y

installer ou d’en remplacer tout élément

Remarque : Cet appareil est mis à la terre et ne doit être branché sur le secteur qu’à l’aide

d’une prise mise à la terre. Ne pas employer cette machine sans mise à la terre

Assemblage du masque

Assemblez le masque selon la manière représentée sur l’illustration

1. À l’aide des agrafes du masque (22), donnez sa forme normale au masque de soudeur

(21) fraîchement déballé

2. Installez la poignée (20) au moyen des écrous et boulons de la poignée (17 et 18). La

poignée doit se situer sur l’intérieur du masque de soudeur afin de protéger la main

du soudeur des éclaboussures

3. Veillez à ce que le verre de sécurité (15) protège le verre de soudage (14) des

éclaboussures. Si le verre de soudage est monté sur l’extérieur, il risque d’être

dégradé par les éclaboussures et de laisser passer les rayons ultraviolets dangereux

pour les yeux du soudeur

4. Installez l’ensemble constitué par les verres sur le masque de soudeur au moyen des

vis du support (19) des agrafes du support (16)

Installation du fil

Cet appareil demande l’utilisation de fil fourré de 0,8 à 0,9 mm

1. Tournez le bouton de dégagement du capot (1) et soulevez le capot

2. Tournez le capot de plastique du mécanisme de l’arbre du dévidoir (26) dans le sens

inverse des aiguilles d’une montre et retirez-le prudemment, avec le ressort et la

section supérieure

3. Placez le dévidoir de fil (25) fourni sur l’arbre porte-dévidoir (illustré déjà installé),

en vous assurant que le fil (27) sortira du dévidoir du côté le plus proche, comme

l’indique la flèche

4. Réinstallez la section supérieure, le ressort et le capot en plastique du mécanisme

de l’arbre du dévidoir. Veillez que le ressort assure une tension suffisante pour que le

dévidoir ne se vide pas tout seul

5. Dévissez le bouton tendeur (31) de manière que le verrou du tendeur (34) puisse être

dégagé de la manière illustrée

6. Sortez l’extrémité du fil du dévidoir, en prenant garde de ne pas laisser le fil se défaire.

Vérifiez que l’extrémité du fil est droite et avec une coupure nette et propre

7. Amenez lentement le fil dans l’extrémité de la gaine de fil du dévidoir (32), en le

faisant passer sur le galet d’avancée (30) et jusque dans le guide-fil (36) ; forcez-le

légèrement dans le guide-fil

8. Repoussez le verrou du tendeur en position, en vous assurant que le fil soit centré

dans les rainures du galet d’avancée et du galet tendeur (35)

9. Repositionnez le verrou du tendeur de la manière illustrée sur l’image A. La tension est

réglable au moyen du bouton tendeur

10. Refermez le capot et fixez-le avec le bouton de dégagement du capot

11. Tirez sur la buse (9) pour la dégager de la torche et dévissez et retirez la pointe (23)

12. Branchez l’appareil sur le secteur, allumez-le et tenez la torche

13. Écartez la torche de la machine de manière à tendre son câble

14. Vérifiez que la torche ne touche rien et appuyez sur la gâchette (8). Le mécanisme

d’avancé du fil devrait amener le fil dans la torche, image B

15. Si ce n’est pas le cas, débranchez l’appareil, ouvrez le capot et resserrez le bouton

tendeur (31). Les galets d’entraînement doivent être suffisamment serrés pour pouvoir

entraîner le fil jusqu’à la torche mais pas trop serrés, ce qui entraînerait un arrêt de la

rotation des galets et un blocage du fil

16. Lorsque le fil est correctement expulsé par la torche, éteignez et débranchez la

machine

17. Remettez en place la pointe et la buse, coupez le fil pour qu’il ne dépasse que

d’environ 5 mm

Retrait du dévidoir de fil et du fil restant

1. Ouvrez le capot de la machine au moyen du bouton de dégagement du capot (1)

2. À l’aide d’une pince, retirez le restant de fil par la pointe (15) de la torche. Si l’ancien

dévidoir de fil (25) n’est pas vide, coupez le fil au niveau du dévidoir et dévissez le

bouton tendeur (31) et éloignez le verrou du tendeur (34) du galet d’avancée (30)

3. Procédez ensuite selon les instructions données ci-dessus pour l’installation du fil

Important

• Portez toujours l’équipement de protection approprié au travail envisagé. L’utilisation

de cet appareil demande l’usage d’un masque de soudeur, de gants, de vêtements

résistant à la chaleur et, éventuellement, d’un masque de protection respiratoire

• Gardez toujours un extincteur à proximité de la zone de soudage

• Inspectez toujours la machine, recherchez les signes de dommages et d’usure. Prêtez

une attention toute particulière aux fils électriques et câbles. En cas de dommage,

N’UTILISEZ PAS L’APPAREIL.

• Vérifiez que tous les boîtiers, carters et couvercles soient convenablement fermés

• Choisissez avec soin l’emplacement du poste à souder de manière qu’il reste bien

immobile et ne puisse se renverser pendant son utilisation. Assurez-vous de maintenir

un espace vide d’au moins 50 cm de chaque côté du poste pour garantir une bonne

ventilation de l’appareil

Consignes d’utilisation

AVERTISSEMENT : Débranchez toujours la machine et laissez-la refroidir avant d’y

installer ou d’en remplacer tout élément

Réglage de la machine

• Pour obtenir une soudure de bonne qualité, le sélecteur de vitesse du fil (4) et le

commutateur 90 A / 45 A (3) doivent être réglés sur la bonne position. Le réglage sur

10 % fournit une intensité de 90 A et le réglage sur 60 % fournit une intensité de 45 A.

• La vitesse d’amenée du fil doit être réglée pour assurer un arc stable. Le réglage

correct est fonction de la distance, de l’intensité électrique, de la vitesse de

déplacement de la torche et d’autres facteurs. Faites des essais avec différentes

vitesses de fil pour obtenir le réglage optimal

Remarque : Ce poste à souder optimise l’intensité en fonction de la vitesse du fil et des

niveaux d’intensité détectés afin d’améliorer la qualité de la soudure et de réduire les

projections

Cycle d’utilisation

• Cette machine n’est pas conçue pour un usage ininterrompu. Toute opération de

soudage excessivement prolongée entraîne une surchauffe et une détérioration des

composants internes

• Le cycle d’utilisation définit la durée maximale en minutes, sur une période de dix

minutes, pendant laquelle la machine peut fonctionner

• Dans le cas d’un cycle d’utilisation de 10 %, la machine peut être utilisée pendant 1

minute, avec une pause obligatoire de 9 minutes pour le refroidissement. Un cycle de

60 % permet une utilisation de 6 minutes sur une période de 10 minutes

• Si le cycle d’utilisation n’est pas respecté, la machine se déconnectera

automatiquement

• Pour profiter au mieux du cycle d’utilisation, utilisez une intensité plus basse et une

bonne ventilation de la zone de travail

Coupure thermique automatique

• Lorsque la protection thermique automatique se déclenche, l’indicateur de surchauffe

(5) s’allume et l’appareil s’éteint

• Laissez la machine refroidir. Le coupe-circuit thermique se réinitialisera

automatiquement dès que la machine pourra de nouveau être utilisée

Préparation au soudage

• Vérifiez que les pièces à souder soient propres, sans rouille ni peinture ou autre

revêtement

• Toutes les pièces doivent être sur un support approprié, en étant séparées d’un

millimètre à l’endroit prévu pour la soudure

• Vérifiez qu’il ne se trouve aucun matériau inflammable à proximité de la zone de

travail

• Fixez la pince de mise à la masse (11) sur une zone propre de l’une des pièces, aussi

proche que possible de la zone à souder mais sans possibilité de gêner le travail

• Vérifiez qu’une personne qualifiée se trouve à proximité afin de vous assister en cas

de besoin et qu’un extincteur soient disponible à proximité

• Branchez la machine à l’alimentation secteur

15

Page 16

FR

Soudage

AVERTISSEMENT : La bonne utilisation d’un poste à souder demande certaines

compétences techniques. Une mauvaise utilisation peut s’avérer extrêmement dangereuse.

Ce document ne décrit que le principe d’utilisation. Si vous n’êtes pas certain de votre

aptitude à utiliser cet outil sans prendre de risque, NE L’UTILISEZ PAS

1. Placez l’interrupteur (2) sur la position 'ON'

2. Réglez le Sélecteur de vitesse du fil (4) à la bonne vitesse ou, à défaut de savoir la

vitesse exacte requise, positionnez dans un premier temps sur la vitesse moyenne

puis ajuster ultérieurement si nécessaire

3. Tenez la torche d’une main par sa poignée (7) et le masque (12) de l’autre

4. Positionnez la torche de manière que la pointe (23) se trouve à environ 10 mm du

métal et à un angle de 75˚ environ

5. Placez le masque de protection devant votre visage et appuyez sur la gâchette (8)

6. Un arc doit se former entre le métal et la pointe. Maintenez la gâchette pendant 1 ou 2

secondes puis relâchez

7. Laissez la soudure refroidir un peu, puis enlevez le masque de votre visage. Si les

réglages sont corrects, il doit s’être formé un point de soudage rond

8. Si le métal n’a pas été suffisamment pénétré, passez au réglage de tension supérieur.

Si le métal a été perforé, passez au réglage de tension inférieur

• Entraînez-vous en faisant des points de soudage successifs, jusqu’à avoir la certitude

d’avoir choisi le bon réglage et de manipuler la machine sans difficulté

• Pour réaliser un cordon de soudage, maintenez la gâchette plus longtemps tout en

déplaçant lentement le bec le long de la ligne de soudage

• Si la machine est correctement paramétrée, l’arc doit être stable et produire un

crépitement

• Si vous entendez des sons d’éclatement ou si l’arc est difficile à maintenir, modifiez

la vitesse du fil. Si vous avez l’impression que la torche est repoussée, réduisez la

vitesse du fil

• La réalisation de soudures propres et de bonne qualité est une compétence qui

s’acquiert avec le temps et la pratique. Une bonne préparation et un bon entraînement

permettent d’obtenir de bons résultats

Accessoires

Une large gamme d’accessoires, parmi lesquels des équipements de protection et des

outils pour le soudage, est disponible chez votre revendeur Silverline. Des pièces de

rechange peuvent être obtenues sur toolsparesonline.com

Entretien

AVERTISSEMENT : Toujours débrancher l’appareil de l’alimentation secteur et le

laisser refroidir avant de réaliser tout travail d’entretien ou de nettoyage

Remplacement des pointes

• Avec le temps, la pointe (23) s’use. Il devient alors plus difficile de contrôler l’arc de

soudage

1. Pour remplacer la pointe, retirez la buse (9) de la torche et dévissez la pointe en place

2. Vérifiez que la nouvelle pointe soit de dimension appropriée pour le fil à utiliser

3. Passez la nouvelle pointe sur l’extrémité du fil et vissez-la en place dans la torche.

Remettez la buse (1) en place

Nettoyage

• Toujours débrancher l’appareil de l’alimentation secteur avant de réaliser tout travail

de nettoyage

• Gardez l’appareil propre. Éliminez toujours la poussière et les particules et ne laissez

jamais les orifices de ventilation se boucher

• Utilisez une brosse souple ou un chiffon sec pour le nettoyage. Si possible, nettoyez

les orifices de ventilation à l’air comprimé propre et sec

Recyclage

Lorsque l’appareil n’est plus en état de fonctionner et qu’il n’est pas réparable, recyclez

l’appareil conformément aux régulations nationales

• Ne jetez pas les outils électriques, batteries et autres déchets d’équipements

électriques ou électroniques (DEEE) avec les ordures ménagères

• Contactez les autorités locales compétentes en matière de gestion des déchets pour

vous informer de la procédure à suivre pour recycler les outils électriques

Si mon appareil ne marche pas

Problème Cause possible Solution

Le galet d’avancée (30) ne tourne pas L’appareil n’est pas sous tension Allumez l’appareil

Le sélecteur de vitesse du fil (4) est sur le réglage minimal 0 Passez à un réglage supérieur

Le galet d’avancée (30) tourne mais le fil (27)

n’avance pas

L’appareil cesse soudain de fonctionner Le cycle de service a été dépassé et l’indicateur de surchauffe (5)

Soudure de mauvaise qualité Mauvais réglages d’intensité et d’avancée du fil Réglez le sélecteur de vitesse du fil (4) et le commutateur

La tension est insuffisante sur le galet Réglez le bouton tendeur (31)

Le guide-fil (36) est endommagé Vérifiez et remplacez le guide-fil

Le fil s’est soudé à la pointe (23) Dégagez le fil de la pointe

s’est allumé

Laissez refroidir l’appareil 20 à 30 minutes

90 A / 45 A (3)

16

Page 17

www.silverlinetools.com

Poste à souder Turbo MIG sans gaz282562

Garantie Silverline Tools

Garantie Silverline

Ce produit Silverline bénéficie d’une garantie de

3 ans

Enregistrez ce produit sur le site silverlinetools.com dans les 30 jours

suivant l’achat afin de bénéficier de la garantie de 3 ans. La période de

garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Conditions de garantie des outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat, retournez-le au

magasin où vous l’avez acheté, avec votre facture, en expliquant en détail le problème. Le

produit sera remplacé ou vous serez remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture d’achat originale sur

laquelle doivent figurer la date d’achat, votre nom, votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de garantie seront vérifiées

par Silverline Tools pour établir si la défaillance du produit est liée à un vice de matériau

ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent être

convenablement propres et sûrs pour être réparés et devraient être emballés soigneusement

pour éviter tout dommage ou toute blessure pendant le transport. Nous pouvons refuser les

livraisons qui ne sont pas convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie seront rectifiées par

la réparation de l’outil, sans frais (hormis les frais de port) ou par son remplacement par un

outil en parfait état de fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous apporte des

avantages ; ces avantages s’ajoutent à vos droits statutaires en tant que consommateur

sans les affecter aucunement.

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement et

saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline Tools, que les

défaillances du produit ont été provoquées par un vice de matériau ou de fabrication au

cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la remplacera par

une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions d’utilisation, par

exemple les lames, les charbons, les courroies, les ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les feuilles

abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou un entretien

négligent, une mauvaise utilisation, un manque d’entretien ou une utilisation ou une

manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants véritables de

Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que Silverline Tools ou ses

agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances de l’outil indiquées

dans ces conditions de garantie ne sont pas couvertes par cette garantie.

Garantie batterie

Les batteries de Silverline sont garanties pour 30 jours. En cas de défaut sur une batterie

enregistrée lors de la période de garantie batterie, Silverline la remplacera gratuitement.

Cette garantie ne s’applique pas à l’utilisation commerciale et ne s’étend pas non plus à

l’usure normale ou aux dommages causés par des accidents, des mauvais traitements ou

une utilisation impropre.

Déclaration de conformité CE

Le soussigné : M. Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 282562

Description: Poste à souder Turbo MIG sans gaz

Est conforme aux directives suivantes :

• Directive sur les basses tensions 2006/95/CE

• Directive sur la compatibilité électromagnétique 2004/108/CE

• Directive RoHS 2011/65/UE

• EN60974-1:2012

• EN60974-10:2007

Organisme notifié : TÜV Rheinland

La documentation technique est conservée par : Silverline Tools

Date : 09/09/15

Signature :

M. Darrell Morris

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox International Limited, numéro d’entreprise 06897059. Adresse légale : Central

House, Church Street, Yeovil, Somerset BA20 1HH, Royaume-Uni.

17

Page 18

DE

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole abgebildet. Sie

vermitteln wichtige Informationen über das Produkt oder dienen als Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Übersetzung der Originalbetriebsanleitung

AbkürzungsverzeichnisBeschreibung der Symbole

V Volt

~, AC Wechselspannung

A, mA Ampere, Milli-Ampere

Ø Durchmesser

W, kW Watt, Kilowatt

Schutzhandschuhe tragen

Schutzkleidung tragen

Sicherheitsschuhe tragen

Bedienungsanleitung sorgfältig lesen

Schutzklasse I (Schutzleiter)

Nur für den Innengebrauch!

Giftige Dämpfe oder Gase!

Brandgefahr!

Stromschlaggefahr!

Gefahr durch heiße Oberflächen – NICHT berühren!

Nicht im Regen oder in feuchter Umgebung verwenden!

Technische Daten

Eingangsspannung ......................................................... 230 V~, 50 Hz

Eingangsleistung .................................................. 13,5 A (Höchstwert), 4,6

A (Durchschnittswert)

Effizienz .........................................................................................80%

Regelbereich ........................................................................... 45–90 A

Betriebsdauer ....................................................... 10 % - 90 A, 60 % - 45 A

Leerlaufspannung.......................................................................... 31 V

Ausgangsspannung .............................................. 18,5 V (90 A), 16,25 V

(45 A)

Drahtspulengewicht ................................................................. 0,45 kg

Isolationsklasse .................................................................................. H

Schutzart ...................................................................................... IP 21

Schweißdraht ....................................................... Fülldraht, Ø 0,8 – 0,9 mm

Max. Blechstärke .............................................................1,2 – 6,5 mm

Sicherung ...................................................................................... 16 A

Schutzklasse ..................................................................................

Brennerkabellänge ......................................................................... 2 m

Massekabellänge ........................................................................ 1,5 m

Netzkabellänge ............................................................................... 2 m

Abmessungen (L x H x B) ..................................... 340 x 295 x 180 mm

Gewicht: ...................................................................................... 13 kg

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte können sich die

technischen Daten von Silverline-Produkten ohne vorherige Ankündigung ändern.

Achtung, Gefahr!

Gefahr durch UV-Strahlung!

Umweltschutz

Schweißausrüstung darf nicht über den Hausmüll entsorgt werden. Bitte

über entsprechende Einrichtungen entsorgen. Lassen Sie sich bezüglich

der sachgemäßen Entsorgung von der zuständigen Behörde oder dem

Händler beraten.

Erfüllt die einschlägigen Rechtsvorschriften und Sicherheitsnormen

18

Page 19

www.silverlinetools.com

Turbo-MIG-Fülldrahtschweißgerät282562

Allgemeine Sicherheitshinweise

WARNUNG! Bei der Benutzung von Elektrowerkzeugen müssen stets grundliegende

Sicherheitsmaßnahmen einschließlich der folgenden Anweisungen getroffen werden,

um das Risiko von Bränden, Elektroschocks und Personenschäden zu vermindern.

Lesen Sie alle Anweisungen aufmerksam durch und bewahren Sie diese für zukünftiges

Nachschlagen mit dem Gerät auf.

WARNUNG! Dieses Gerät darf nicht von Personen (wie z.B. Kindern) mit eingeschränkten

körperlichen oder geistigen Fähigkeiten oder von Personen ohne Erfahrung im Umgang

mit einem solchen Gerät betrieben werden, außer wenn sie von einer für ihre persönliche

Sicherheit verantwortlichen Person in der Benutzung unterwiesen worden sind und dabei

beaufsichtigt werden. Kinder müssen beaufsichtigt werden, um sicherzustellen, dass sie

das Gerät nicht als Spielzeug verwenden.

ACHTUNG! Verwenden Sie Elektrowerkzeuge stets in Übereinstimmung mit diesen

Anweisungen und beachten Sie dabei die Arbeitsplatzbedingungen und die auszuführenden

Tätigkeiten. Eine Benutzung von Elektrowerkzeugen für Tätigkeiten, für die sie nicht

konzipiert wurden, kann zu gefährlichen Situationen führen.

Der Begriff „Elektrowerkzeug” in den folgenden Warnhinweisen bezieht sich sowohl auf

netzgebundene Geräte sowie Akkugeräte (schnurlose Geräte).

1 – Halten Sie den Arbeitsbereich sauber und aufgeräumt. – Unordnung auf

Werkbänken und Böden begünstigt Verletzungen.

2 – Beachten Sie die Arbeitsplatzbedingungen.

- Verwenden Sie Werkzeuge niemals im Regen.

- Verwenden Sie Werkzeuge niemals in feuchten oder nassen Bereichen.

- Sorgen Sie für angemessene Beleuchtung von Arbeitsbereichen.

- Verwenden Sie Werkzeuge niemals in der Nähe von brennbaren

Flüssigkeiten.

– Schützen Sie sich vor elektrischen Schlägen. – Vermeiden Sie Kontakt

mit geerdeten Objekten und Oberflächen wie z.B. Rohrleitungen, Heizkörpern,

Haushaltsgeräten usw.

4 – Halten Sie andere Personen vom Arbeitsplatz fern. – Achten Sie darauf,

dass Personen, die nicht direkt am Arbeitsvorgang beteiligt sind,

insbesondere Kinder, von Werkzeugen und Werkstücken fernbleiben,

Werkzeuge und deren Anschlussleitungen nicht berühren und sich nicht im

Arbeitsbereich aufhalten.

5 – Entfernen Sie nicht benötigte Werkzeuge aus dem Arbeitsbereich. –

Nicht verwendete Werkzeuge sollten an einem sicheren, trockenen Ort

außerhalb der Reichweite von Kindern gelagert und eingeschlossen werden.

6 – Wenden Sie bei der Benutzung von Werkzeugen keine Gewalt an.

– Werkzeuge erzeugen die besten und effektivsten Ergebnisse, wenn sie

mit der Geschwindigkeit und dem Vorschub verwendet werden, für welche

sie konzipiert wurden.

7 – Verwenden Sie für die auszuführende Aufgabe geeignete Werkzeuge.

– Kleine, leichte Werkzeuge verfügen nicht über die gleiche Leistung wie

schwere Profi-Werkzeuge.

Verwenden Sie Werkzeuge niemals zweckentfremdet; z.B. dürfen Kreissägen

nicht zum Sägen von Baumstämmen oder Ästen verwendet werden.

8 – Tragen Sie geeignete Arbeitskleidung.

- Tragen Sie weder lose Kleidung noch Schmuck, da sich diese in den

beweglichen Komponenten von Maschinen verfangen könnten.

- Tragen Sie stets geeignete Sicherheitsschuhe.

- Decken Sie lange Haare ab.

9 – Verwenden Sie geeignete persönliche Schutzausrüstung.

- Tragen Sie stets eine geeignete Schutzbrille.

- Tragen Sie bei staubigen Arbeiten stets eine Atemschutzmaske.

WARNUNG! Falls keine persönliche Schutzausrüstung getragen wird, können

schwerwiegende Verletzungen und Erkrankungen auftreten.

10 – Verwenden Sie Staubabsaugausrüstung. – Verwenden Sie Geräte mit

Staubabsauganschluss stets mit einer geeigneten Absaugvorrichtung.

11 – Verwenden Sie die Anschlussleitung nicht missbräuchlich. – Ziehen

Sie niemals am Kabel, um dieses aus der Steckdose zu entfernen. Halten