Page 1

Operation

Product Identification

Power Switch

Refrigerated Space

Temperature Indicator Panel

Fan Guard

Limited Warranty

• Use of any non OEM parts voids warranty unless otherwise

• All covered labor requires preauthorization from the factory

(Call 1-888-375-2938) and shall be performed during regular

work hours. Overtime premium will not be covered.

• Travel charges are to be limited to 100 miles (200 Kilometers)

round trip: 2 hours travel time per one trip repair.

• Adjustments of any kind are not covered under this Limited

Warranty.

• Damage caused by carelessness, neglect, and/or abuse (e.g.,

using incorrect voltage, dropping, tampering with or altering

electrical components, or improper cleaning) is not covered.

• Equipment damaged in shipment or by fire, flood or act of God

is not covered.

• Damage to coated surfaces is not covered by this Limited

Warranty.

• Use of refrigerants other than specified on the equipment

serial plate voids the warranty.

Manual

This Silver King product is warranted to be free from defects in

material and/or workmanship for a period of two (2) years from

the date of original installation, not to exceed 30 months from

date of shipment from our factory. Any part or component which

proves to be faulty in material and/or workmanship (in the opinion

of Silver King) within the warranty period will be replaced or

repaired (at the option of Silver King) without cost to the customer

for parts or labor, except as provided below. The compressor will

carry an additional three (3) years parts only warranty.

This Limited Warranty is subject to the following exceptions/

conditions.

approved by Silver King. All work must be performed by an

authorized Silver King Service Agent, except as provided

herein.

SILVER KING SHALL NOT BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES.

SILVER KING MAKES NO OTHER WARRANTY, EXPRESS

OR IMPLIED. ALL IMPLIED WARRANTIES OF

MECHANTABILITY AND/OR FITNESS FOR ANY

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED AND

EXCLUDED.

TABLE OF CONTENTS

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking and Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Management Programming – Adjusting Set Point . . . . . . . . . 8

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parts List and Exploded View . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1600 Xenium Lane N, Plymouth , MN 55441 USA

Telephone: 763-923-2441 • Toll Free: 1-800-328-3329

Fax: 763-553-1209 • www.silverking.com

Chilled Rail

Model SKMCD-RR-5

1

FORM 36526 RevB

Printed in USA 5/2 © 2018

Page 2

Chilled Rail

Safety Information

Indicates information important to the proper operation of the unit. Failure to observe may result in damage to the equipment and/or severe bodily injury or death.

Indicates information important to the operation of the unit.

Failure to observe may result in damage to the equipment.

WARNING

CAUTION

General Precautions

Risk of Electric Shock.

• Always unplug the power cord before servicing the unit to

avoid electric shock.

• Unit MUST be plugged into a 3-prong plug for grounding.

Cutting off the grounding spike on t

he power cord could

result in electric shock to the operator during operation.

• Unit must be plugged into a 15 or 20 ampere fuse- or

breaker-protected circuit. Use of a larger fuse or breaker

could result in damage to the unit and electric shock to the

operator.

Moving or Handling Hot Parts.

• Some parts may remain hot even after being unplugged.

Always use caution when servicing.

Possible Back Injury.

• Assistance in moving this piece of equipment is strongly

recommended to avoid injury.

• Always lift with your legs and not your back when lifting this

unit.

WARNING

WARNING

WARNING

General

The SKMCD-RR-5 Chilled Rail is a condiment pan refrigerator

designed to mount to a McDonald’s high density preparation

table and hold five large (or ten small) food service pans and

serving spoons. The unit has been set to maintain product within

a temperature range of 33 to 41°F (1 to 5°C).

Important

Electrical Specifications

115V, 60 Hz, 1 Phase

Model SKMCD-RR-5

Silver King reserves the right to change specifications

and product design without notice. Such revisions do

not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously

purchased equipment.

FORM 36526 RevB

2

Printed in USA 5/2 © 2018

Page 3

Chilled Rail

Unpacking and Setup

Unpack and inspect. Upon delivery of your new Silver

King unit, uncrate at once to inspect for possible freight

damage following the instructions printed on the

exterior of the container.

• Report any damages to the carrier responsible fo

r

transportation and promptly present a written claim

for any evidence of mishandling.

• Be sure to save all packaging materials if

a claim is

to be filed.

1

Plan the unit’s location. When locating this unit,

convenience and accessibility are important

considerations, but the following factors must be

observed:

• Proximity to a 3-prong 110 VAC receptacle fo

r

grounding (see Step 3).

• There must be at least 1" (2.5 cm) from the inlet of

the fan to the nearest surface.

• The unit must be hung from a level surface. W

hen

mounted from a level shelf surface, the unit’s

condensate troughs will drain properly into

condensate pan.

• Avoid placing the unit next to heat sources

or

ventilation drafts which would affect the

performance of the unit.

2

Meet electrical requirements. Prior to connecting the

unit to power, be sure to check the data plate located on

the end panel of the cabinet for required voltage. The

specifications on the data plate supersede any

information contained in this manual.

The standard unit is equipped with a seven (7) foot

power cord. The unit requires a 115V, 60 cycle, 1

phase, properly grounded electrical receptacle,

protected with a 15 or 20 ampere fuse or breaker.

The power cord comes with a 3-prong plug for

grounding purposes. Any attempt to cut off this

grounding spike or to connect to an ungrounded

adapter plug could result in serious injury, will

void the warranty and terminates the

manufacturer’s responsibility.

WARNING

3

This unit was specifically designed to mount to a McDonald’s

High Density Preparation Table. If after following the installation

procedure, this unit does not attach securely to the preparation

table, remove the unit from the table and contact the Kitchen

Equipment Supplier to confirm the compatibility between the

pieces of equipment.

IMPORTANT

NOTE: Unit must be placed into operating orientation for

2 hours prior to powering up.

IMPORTANT

Model SKMCD-RR-5

FORM 36526 RevB

3

Printed in USA 5/2 © 2018

Page 4

Chilled Rail

Installation

REQUIRED: Two people, Phillips head screw driver.

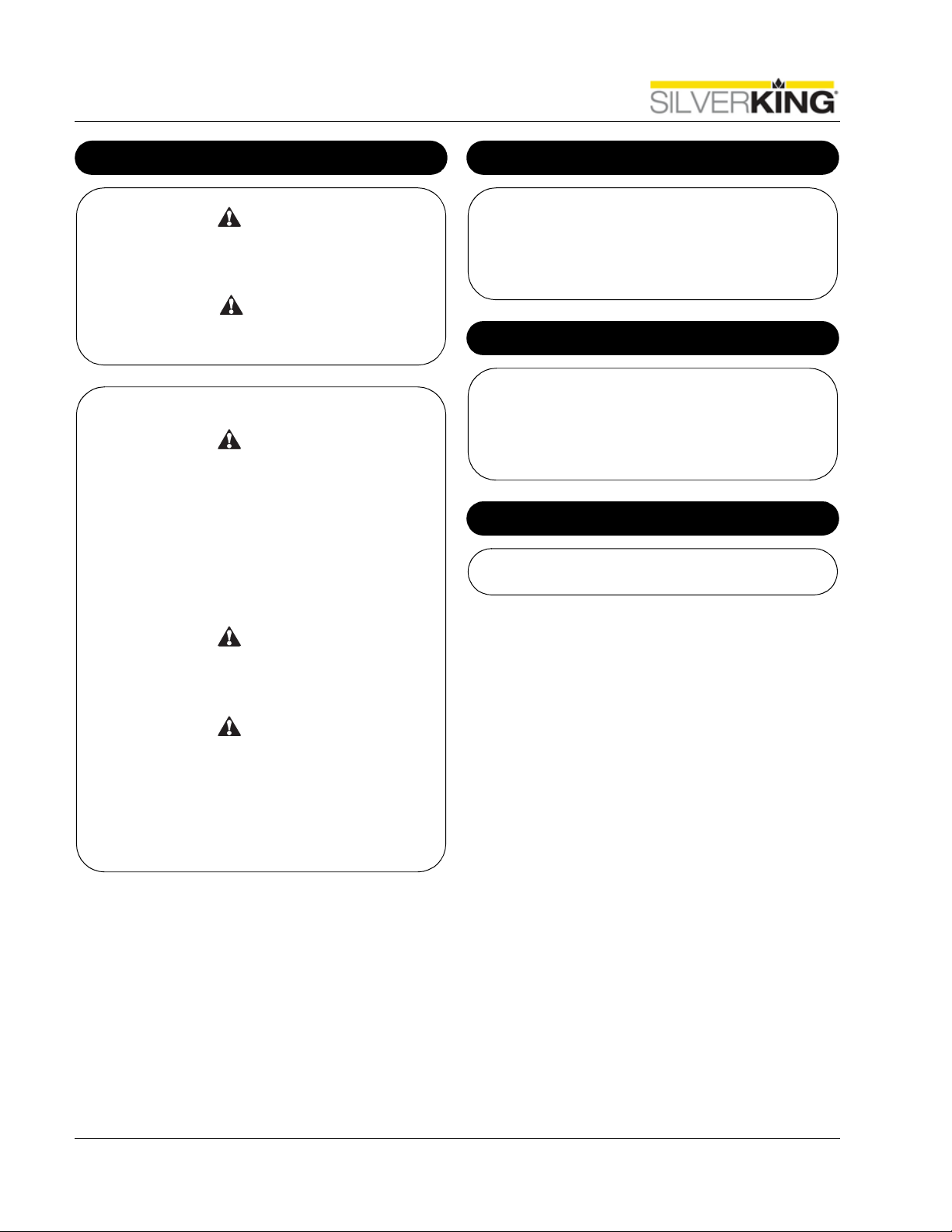

After removing the

Chilled Rail from the

box, position it

under the prep table

over-shelf. Make

sure the cord can

reach the intended

power outlet.

1

Locate the

mounting brackets

on each end of the

rail. Using the Phillips

head screw driver,

remove 1 bracket from

each end of the rail.

2

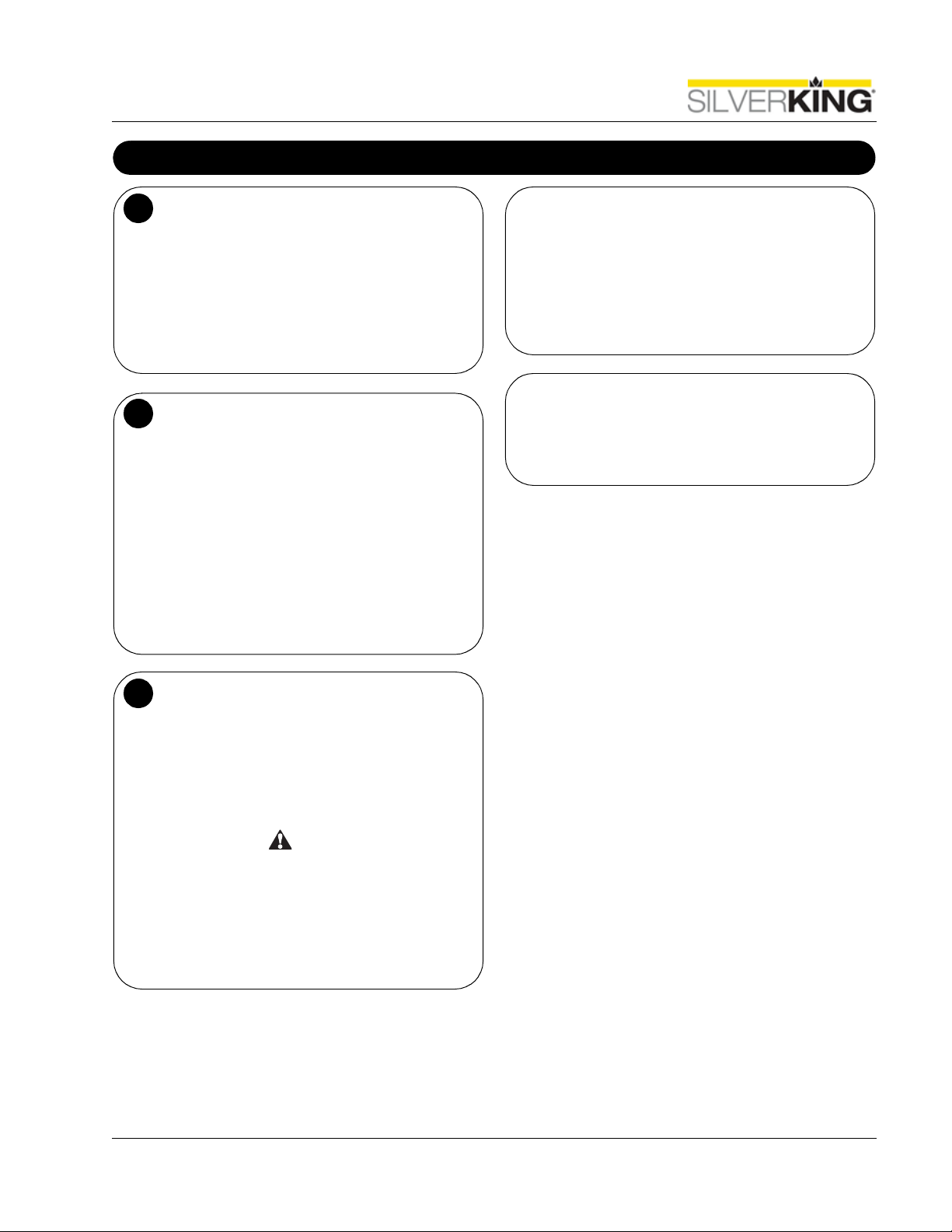

Lift the Chilled Rail

into position

underneath the

over-shelf. Tilt the rail

so that the mounting

bracket fits on the lip

of the over-shelf.

3

Hold the rail flush to

the over-shelf and

reattach the

mounting brackets

to each end.

4

Slide the rail all the

way to the end of

the over-shelf so the

Chilled Rail can be

plugged in.

5

Model SKMCD-RR-5

FORM 36526 RevB

4

Printed in USA 5/2 © 2018

Page 5

Chilled Rail

Cleaning

Tools and supplies needed:

Clean, sanitizer-

soaked towels

Bucket, soiled

towels

KAY® SolidSense™

All Purpose Super

Concentrate (APSC)

Solution

KAY® SolidSense™

Sanitizer Solution

Drain Tube Brush

(Supplied with unit)

KAY® QSR Glass &

Multi-Surface

Cleaner Solution

Turn the unit OFF. Push the

power switch to the off position.

The display will turn off. Allow the

unit to warm to room temperature

(approximately 20-30 minutes)

before starting to clean and

sanitize.

1

Remove all of the pans and

spoons from the unit. Remove

all food product from the pans.

NOTE: Wash, rinse and sanitize

the pans per manufacturer’s and/

or store’s kitchen cleaning procedures. Allow the pans

to air dry thoroughly before storing any food product.

APSC or McDonald’s recognized cleaner and Sanitizer

solution.

2

Clean the liner, trough and

exposed stainless steel

surfaces. Wipe any food or debris

from the liner and trough surfaces

into drain holes located at end of

both troughs with a clean, sanitizer-soaked towel. Using

KAY All Purpose Super Concentrate (APSC) Solution or

other McDonald’s recognized (approved) cleaner, spray

liner, trough and exposed interior and exterior stainless

surfaces (except the fan area). Wipe them with a clean,

sanitizer-soaked towel.

For stubborn soils, spray the surfaces with KAY Glass &

Multi-Surface Cleaner solution and wipe with a clean,

sanitizer-soaked towel. Spray all interior surfaces with

KAY Sanitizer solution. Allow to air dry.

APSC or McDonald’s recognized cleaner and Sanitizer

solution.

3

Clean the fan area. NOTE: Do

not directly spray the fan area.

Spray a clean, sanitizer-soaked

towel with APSC solution. Make

sure the towel is damp, and then

wipe the fan area.

APSC or McDonald’s recognized cleaner and Sanitizer

solution.

4

Model SKMCD-RR-5

FORM 36526 RevB

5

Printed in USA 5/2 © 2018

Page 6

Chilled Rail

Cleaning (continued)

Clean the drain tubes. Spray the

inside of the drain holes with KAY

SolidSense Sanitizer Solution. Run

the drain tube brush repeatedly

toward the drain holes located at the

end of each trough, inserting it in and

out of drain holes. Brush inside the

drain holes and scrub to remove

debris. Wipe the drain surfaces with

clean, sanitizer-soaked towel. Spray

the trough with KAY SolidSense

Sanitizer solution. Allow to air dry.

Wash, rinse and sanitize the brush at

the 3-compartment sink. NOTE: Do

not scrub other areas of the unit with the brush.

APSC and Sanitizer solution.

5

Remove the condensate tray from

the condensate compartment.

Open the access door to the

condensate compartment and lightly

grab the tab end on the condensate

tray inside. Remove and empty the

condensate tray.

6

Clean the condensate tray.

Wash, rinse and sanitize the

condensate tray at the

3-compartment sink. Allow th

e

condensate tray to air dry.

APSC and Sanitizer solution.

7

Replace the condensate tray into

the condensate compartment.

Close the access door.

8

Replace the pans. With the

cleaning procedure complete,

return the pans and spoons to the

unit.

9

Turn on the power switch. The

LED display will light and the fan

will turn on. Note: Allow unit to run

for 30 minutes before returning

food product.

10

Deposit soiled towels. Place all soiled/dirty towels

used for unit cleaning inside soiled towels bucket.

11

Model SKMCD-RR-5

FORM 36526 RevB

6

Printed in USA 5/2 © 2018

Page 7

Chilled Rail

Operation

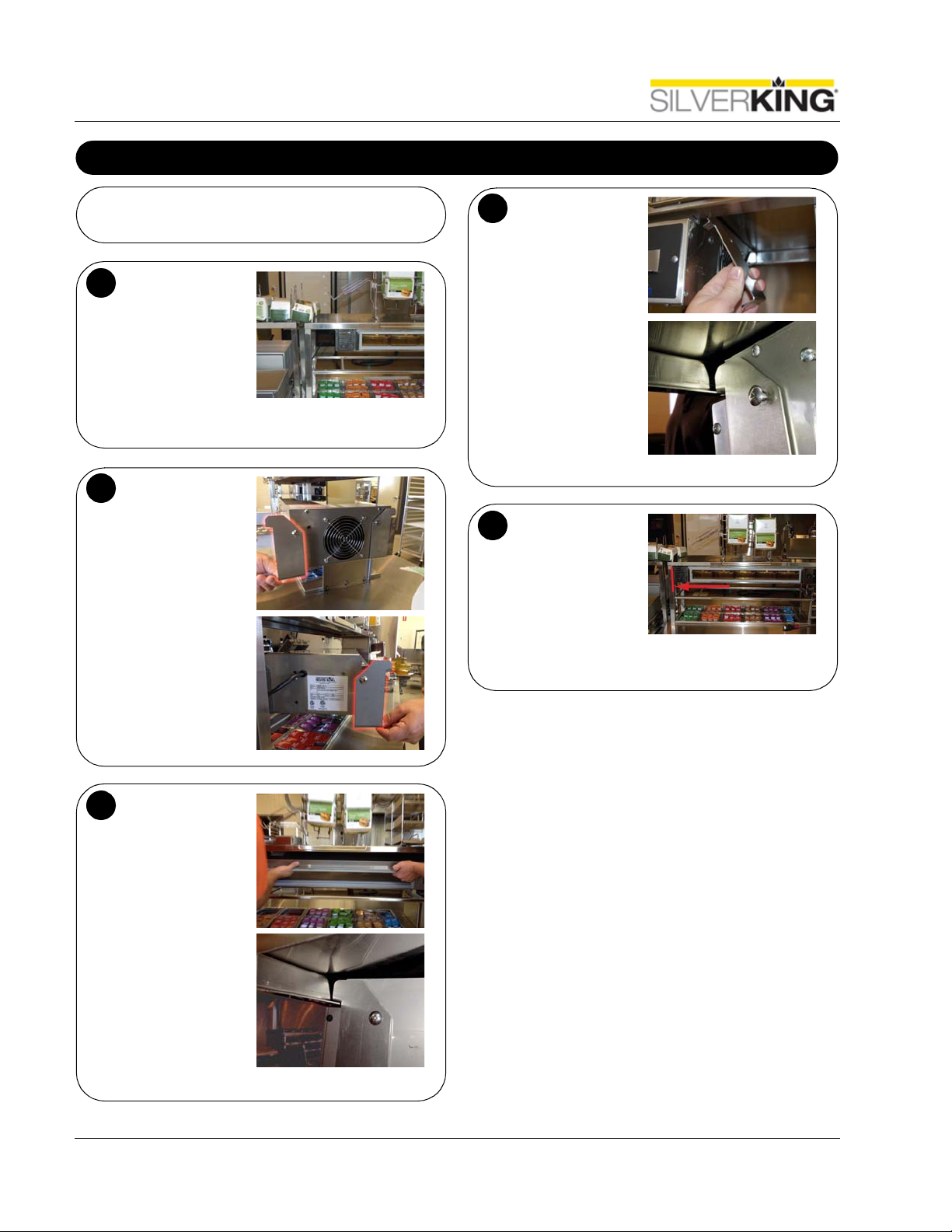

Turn on the power

switch located left

of the temperature

indicator panel. The

indicator should

display the current unit

temperature and the

fan should turn on.

Power Switch

Temperature indicator Panel

1

Allow the unit to run for 20 minutes before loading with product.

2

Insert the trays and

spoons. Insert the

plastic food trays and

serving spoons (not

supplied with unit) into

the refrigerated space.

Spoons should rest in the recessed corners of the trays,

otherwise trays will not slide through the area, resulting

in warm product temperatures.

CAUTION

3

Model SKMCD-RR-5

FORM 36526 RevB

7

Printed in USA 5/2 © 2018

Page 8

Chilled Rail

Management Programming – Adjusting Set Point

To adjust the temperature setting:

• Unlock the programming lockout function.

• Change the set point.

• Relock the programming lockout function

IMPORTANT

TO UNLOCK PROGRAMMING LOCKOUT FUNCTION:

1. Press the SET button on the temperature indicator panel until “PS” flashes on the display.

2. Press the SET button and use the up arrow to display “22”.

3. Press the SET button once more and use the down arrow until “H2” is displayed.

4. Press the SET button and use the up arrow to displ

ay

“1”.

5.

Press the SET button once more.

TO CHANGE THE SET POINT:

1. Press the SET button and

the HOLD button

simultaneously until the

set p

oint displays.

2. Press the SET button until the set point flashes.

3. Adjust the set point using the up and down arrows.

TO RELOCK PROGRAMMING LOCKOUT FUNCTION:

1. Press the SET button on

the temperature indicator

panel until “PS” flashes on

the display.

2. Press the SET button and

use the up arrow to

display “22”.

3. Press the SET button once

more and use the down

arrow until “H2” is

displayed.

4. Press the SET button and use the up arrow to displ

ay

“0”.

5. Press the SET button once more.

Model SKMCD-RR-5

FORM 36526 RevB

8

Printed in USA 5/2 © 2018

Page 9

Chilled Rail

Troubleshooting Guide

WARNING

Model SKMCD-RR-5

RISK OF ELECTRIC SHOCK! Always unplug the power cord before servicing the unit to avoid electric shock.

PROBLEM PROBABLE CAUSE SOLUTION

Compressor will not run No voltage at wall receptacle Check circuit breaker or fuse.

Service cord pulled out of wall receptacle Replace.

Low voltage causing compressor to cycle on

overload

Power switch is in “Off” position Turn switch on.

Inoperative control Call for service (888-375-2938).

Compressor stuck Call for service (888-375-2938).

Compressor windings open Call for service (888-375-2938).

Compressor overload stuck open Call for service (888-375-2938).

Relay lead loose Call for service (888-375-2938).

Relay loose or inoperative Call for service (888-375-2938).

Power cord disconnected from unit Call for service (888-375-2938).

Faulty cabinet wiring Call for service (888-375-2938).

Compressor runs but no refrigeration System out of refrigerant Call for service (888-375-2938).

Compressor not pumping Call for service (888-375-2938).

Restricted filter drier Call for service (888-375-2938).

Restricted capillary tube Call for service (888-375-2938).

Moisture in system Call for service (888-375-2938).

Compressor short cycles Erratic control thermostat Call for service (888-375-2938).

Faulty relay Call for service (888-375-2938).

Low voltage Contact power company and confirm that

Compressor draws excessive wattage Call for service (888-375-2938).

Compressor runs too much or

constantly

Noisy Tubing vibrates Call for service (888-375-2938).

Temperature set too low Call for service (888-375-2938).

Erratic control Call for service (888-375-2938).

Abnormally high room temperature Reduce room temperature.

Pans not in place Insert pans.

System undercharged due to leaks Call for service (888-375-2938).

System undercharged from factory Call for service (888-375-2938).

System overcharged Call for service (888-375-2938).

System not clean Call for service (888-375-2938).

Restricted filter drier Call for service (888-375-2938).

Restricted capillary tube Call for service (888-375-2938).

Internal compressor noise Call for service (888-375-2938).

Compressor vibrating on cabinet frame Call for service (888-375-2938).

Contact power company and confirm that

voltage fluctuation does not exceed 10% plus

or minus from the nominal rating.

voltage fluctuation does not exceed 10% plus

or minus from the nominal rating.

FORM 36526 RevB

9

Printed in USA 5/2 © 2018

Page 10

Chilled Rail

Parts List and Exploded View

11

4

1

8

6

10

7

2

5

9

NOTE: To order Parts/Service, Contact Silver King Refrigeration at 800-328-3329 for technical assistance.

Item NoPart

No Description

1

Power Switch

2

Electronic Control

3

4

Fan Guard

5

6

Condenser Coil

7

Heater

8

Hanging Bracket, LH

9

Hanging Bracket, RH

10

Drier

11

12

Condensate Pan

13

Label ID Cover

Item NoPart

No Description

13

3

12

Model SKMCD-RR-5

078-233

37868

37736 Condens

35253

10343-103

36523

38021

Compressor w/ Electricals and Drier 115V/60HZ

er Fan Motor 115V

36047

36046

22677

32199

36369

38172

Power Cord 115V

FORM 36526 RevB

10

Printed in USA 5/2 © 2018

Page 11

Chilled Rail

Wiring Diagram

OVERLOAD

COMPRESSOR

RELAY (115 VAC)

PTC (220 VAC)

GREEN

COMPRESSOR

JUNCTION

POWER SWITCH

INTERNAL

CONNECTION

INTERNAL

CONNECTION

123 456

RED 3

WHT 4

COMPRESSOR

LINE

NEUTRAL

NTC PROBE

COMMON

NTC PROBE

TEMPERATURE CONTROL

BLK 1

FAN

BLK 2

BLKBLK

WHTWHT

PAN HEATER

WHT 5

WHT5

4

1

5

2

WHT4

RED3

BLK 2

NTC TEMP. PROBE

BLACK (115 VAC)

BROWN (220 VAC)

WHITE (115 VAC)

BLUE (220 VAC)

SEE SERIAL PLATE FOR CORRECT VOLTAGE

115 VAC, 60HZ, 1 PHASE

OR

220 VAC, 50/60 HZ, 1 PHASE

POWER CORD TO BE WIRED TO TERMINALS

5 AND 2 ON SWITCH FOR LIGHT TO WORK

Model SKMCD-RR-5

FORM 36526 RevB

11

Printed in USA 5/2 © 2018

Loading...

Loading...