Page 1

Service

Product Identification

M I L K C R S K I MM

S E L E C T P

P O D U C TR

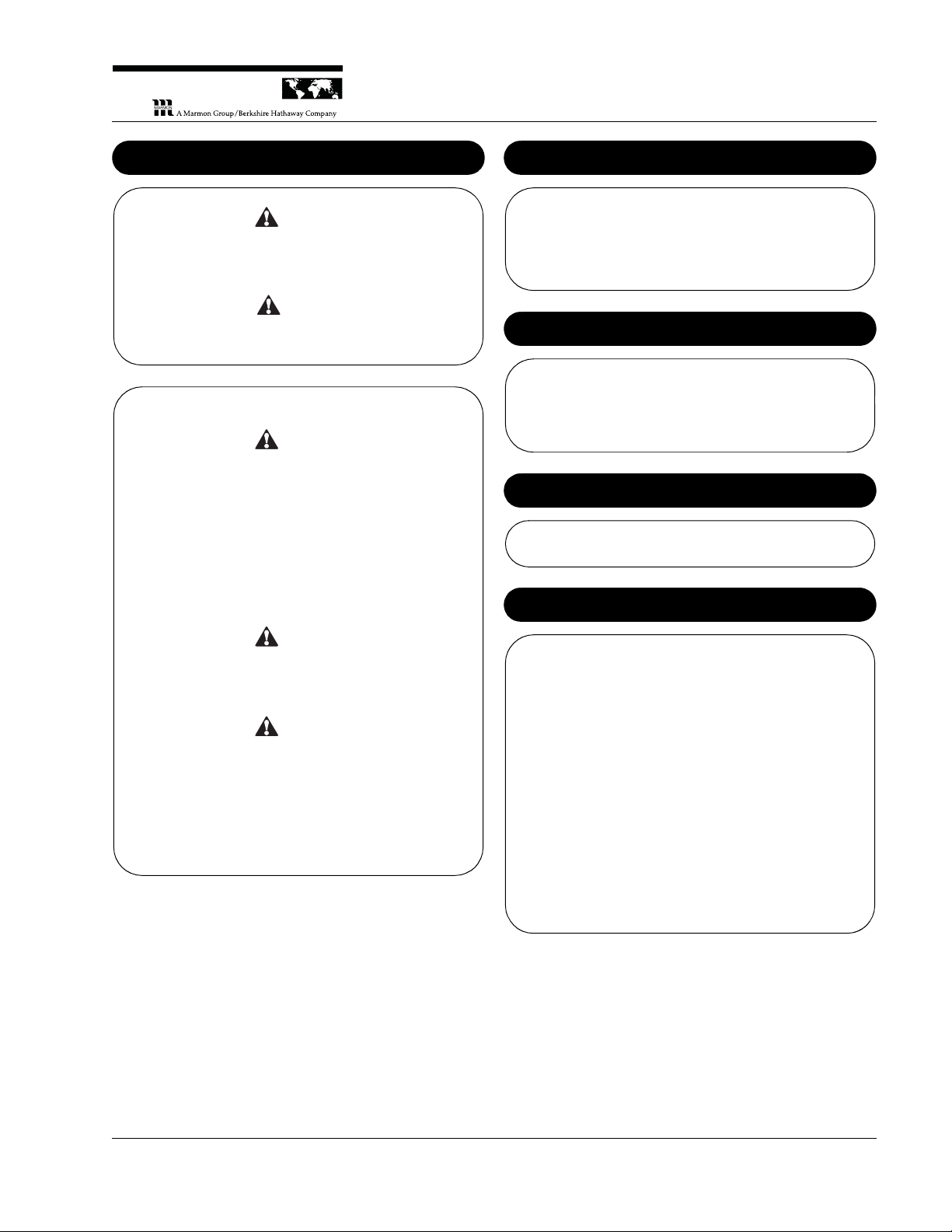

Door-Display

Connector

Cable

Display Panel

Drip Tray

Power Switch

(on side)

Product Valves

Cup Guide

USB Port

Power Cord

(under)

Home Button

Up Arrow

LCD Display

Select Button

Down Arrow

Back Button

LEDs

Size Buttons

Recipe Buttons

Product Buttons

TABLE OF CONTENTS

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Silver King Serial Number Matrix . . . . . . . . . . . . . . . . . . . . . 2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safe Service Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Display Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Resetting Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setting Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Calibrating the Unit / Adjusting Shot Size . . . . . . . . . . . . . . . 7

Shot Size Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Updating and Exporting Files . . . . . . . . . . . . . . . . . . . . . . . . . 9

Changing Set Point, Base, Low Product Thresholds,

Beeper Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Zeroing Out the Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Viewing Other Load Cell Data . . . . . . . . . . . . . . . . . . . . . . . . 12

Solenoids – Test Cycling/Viewing Status . . . . . . . . . . . . . . . . 12

Compressor – Test Cycling/Setting Up . . . . . . . . . . . . . . . . . 13

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Accessing/Servicing Components from the Front . . . . . . . . . 15

Accessing/Servicing Components from the Rear. . . . . . . . . . 18

Parts List and Exploded View . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

355 East Kehoe Blvd. • Carol Stream, IL 60188 USA

Telephone: 630-462-8800 • Toll Free: 1-800-PCASTLE

Fax: 630-462-1460 • www.princecastle.com

Manual

3-Product

Dairy Dispenser

Model SKBD3LS

808-004-EN Printed in USA 10/13 © 2013

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Page 2

3-Product Dairy Dispenser

Limited Warranty

This Silver King branded product is warranted to be free from

defects in material and/or workmanship for a period of two (2)

years from the date of original installation, not to exceed 30

months from date of shipment from our factory. Any part or

component which proves to be faulty in material and/or

workmanship (in the opinion of Prince Castle) within the warranty

period will be replaced or repaired (at the option of Prince Castle)

without cost to the customer for parts or labor, except as provided

below. The compressor will carry an additional three (3) years

parts only warranty.

This Limited Warranty is subject to the following exceptions/

conditions.

• Use of any non OEM parts voids warranty unless otherwise

approved by Prince Castle. All work must be performed by an

authorized Prince Castle Service Agent, except as provided

herein.

• All covered labor requires preauthorization from the factory

(Call 1-888-375-2938) and shall be performed during regular

work hours. Overtime premium will not be covered.

• Travel charges are to be limited to 100 miles (200 Kilometers)

round trip: 2 hours travel time per one trip repair.

• Adjustments of any kind are not covered under this Limited

Warranty.

• Damage caused by carelessness, neglect, and/or abuse (e.g.,

using incorrect voltage, dropping, tampering with or altering

electrical components, or improper cleaning) is not covered.

• Equipment damaged in shipment or by fire, flood or act of God

is not covered.

• Damage to coated surfaces is not covered by this Limited

Warranty.

• Use of refrigerants other than specified on the equipment

serial plate voids the warranty.

• Labor repair or replacement of the following parts is not

covered by this Limited Warranty:

– Main Control Board p/n 36992S; Prince Castle will provide

replacement parts to customer so customer can replace

such parts if they are defective. Replacement instructions

are included with part supplied.

– Door Gasket p/n 36956S, Product Containers and Lids (p/n

37068S, 37069S, 37070S and 811-006S), Drip Tray p/n

37281S and cup guides p/n 37436S are considered wear

items and are not included under the warranty.

PRINCE CASTLE SHALL NOT BE LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES.

PRINCE CASTLE MAKES NO OTHER WARRANTY, EXPRESS

OR IMPLIED. ALL IMPLIED WARRANTIES OF

MECHANTABILITY AND/OR FITNESS FOR ANY PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED AND EXCLUDED.

Silver King Serial Number Matrix

The manufacture date (year and month) is encoded in the serial

number’s 2nd, 3rd and 4th letters. The service bench installation

date (used to determine warranty coverage) is considered to be

the end of the following month.

The refrigerant used in the unit appears as the serial number’s last

letter.

For example:

Serial Number: SAIE

53264A

Manufacture Date: April 2008

Service Bench Installation Date: May 31, 2008

Refrigerant Used: R-134a

Manufacture Date

Refrigerant Used

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012

AA AB AC AD AE AF AG AH AI AJ BA BB BC

January B AAB ABB ACB ADB AEB AFB AGB AHB AIB AJB BAB BBB BCB

February C AAC ABC ACC ADC AEC AFC AGC AHC AIC AJC BAC BBC BCC

March D AAD ABD ACD ADD AED AFD AGD AHD AID AJD BAD BBD BCD

April E AAE ABE ACE ADE AEE AFE AGE AHE AIE AJE BAE BBE BCE

May F AAF ABF ACF ADF AEF AFF AGF AHF AIF AJF BAF BBF BCF

June G AAG ABG ACG ADG AEG AFG AGG AHG AIG AJG BAG BBG BCG

July H AAH ABH ACH ADH AEH AFH AGH AHH AIH AJH BAH BBH BCH

August I AAI ABI ACI ADI AEI AFI AGI AHI AII AJI BAI BBI BCI

September J AAJ ABJ ACJ ADJ AEJ AFJ AGJ AHJ AIJ AJJ BAJ BBJ BCJ

October K AAK ABK ACK ADK AEK AFK AGK AHK AIK AJK BAK BBK BCK

November L AAL ABL ACL ADL AEL AFL AGL AHL AIL AJL BAL BBL BCL

December M AAM ABM ACM ADM AEM AFM AGM AHM AIM AJM BAM BBM BCM

ABMR

R-134a R-404a (MP-39) R401a R-22

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 2 808-004-EN

Page 3

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Safety Information

Indicates information important to the proper operation of

the unit. Failure to observe may result in damage to the

equipment and/or severe bodily injury or death.

Indicates information important to the operation of the unit.

Failure to observe may result in damage to the equipment.

WARNING

CAUTION

General Precautions

Risk of Electric Shock.

• Always unplug the power cord before servicing the unit to

avoid electric shock.

• Unit MUST be plugged into a 3-prong plug for grounding.

Cutting off the grounding spike on the power cord could

result in electric shock to the operator during operation.

• Unit must be plugged into a 15 or 20 ampere fuse- or

breaker-protected circuit. Use of a larger fuse or breaker

could result in damage to the unit and electric shock to the

operator.

Moving or Handling Hot Parts.

• Some parts may remain hot even after being unplugged.

Always use caution when servicing.

Possible Back Injury.

• Assistance in moving this piece of equipment is strongly

recommended to avoid injury.

• Always lift with your legs and not your back when lifting this

unit.

WARNING

WARNING

WARNING

General

The 3-Product Dairy Dispenser is designed to house, refrigerate

and dispense three dairy products (2% or whole milk, cream, and

skim milk). The unit has been set to maintain product within a

temperature range of 33 to 41°F.

Important

Be sure to have 3 clamps available to manually close the

tubes for any service activity that may require opening the

product valves while the tanks contain product. Office

supply binder clips work well.

Electrical Specifications

115V 60 Hz 1 Phase

Safe Service Practices

NOTE: This service manual is intended for use by persons

having electrical and mechanical training and a level of

knowledge of these subjects considered acceptable in the

service trade. Prince Castle cannot be responsible, or assume

any liability, for injury or damage arising from the use of this

manual.

To avoid personal injury and /or property damage, it is

important that Safe Service Practices be observed, including

the following limited examples:

• Do not service the unit without first reading this manual.

• Do not attempt a repair if you have any doubt as to your

ability to complete it in a safe manner.

• Do not attempt to repair or replace any component unless all

power has been disconnected.

• Prior to returning the unit to service, ensure that:

– All electrical connections are correct and secure.

– All safety grounds are correctly and securely connected.

– All components are properly re-assembled.

Model SKBD3LS

808-004-EN 3 Printed in USA 10/13 © 2013

Page 4

3-Product Dairy Dispenser

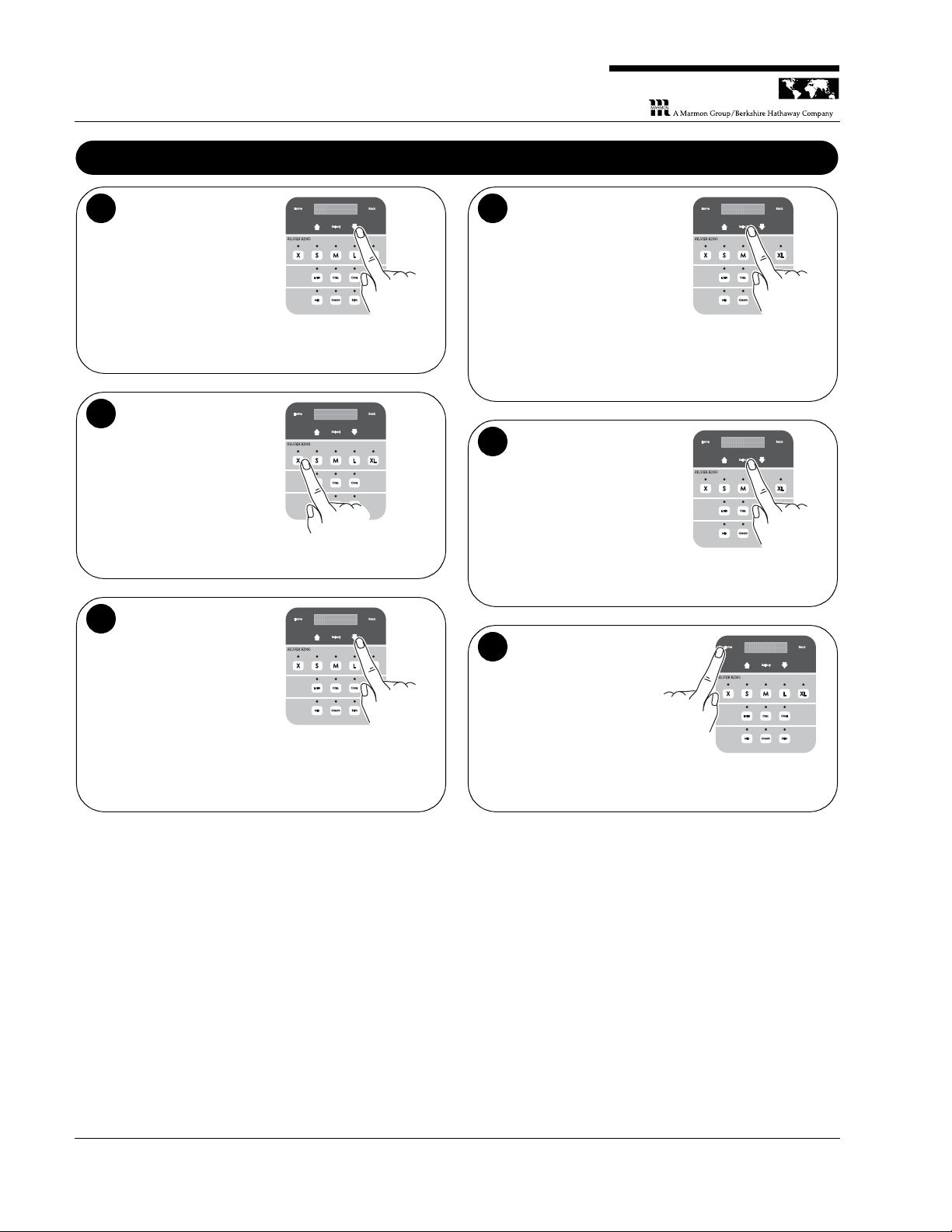

Display Menu Overview

To Panel Disable To Service Menu To Temp/Compressor

“Home”

Select Product

XXXX YYYY ZZZZ

Calibrate Disp

Select Product

Temperature XX

Manager Mode

Entr Btn Combo

Panel Disable

Press Select

To Select Product

* At Manager Mode, press “X” to enter

Manager Level.

Operator Level

Manager Mode

Temp Set Pt: XX

Manager Mode

Base Select

Manager Mode

Default Dispense

Press Select To

Update Display

Press Select To

Update Relay

Export Files

To USB

Set Date/Time

MM/DD/YY HR:MM

Set Low Mlk/Skm

Threshold: XXXX

Set Low Cream

Threshold: XXXX

Manager Mode

Beeper XX

Service Menu

Etr Setup Code

** At Service Menu, press “X” + “Cap.” + “XL”

to enter Service Level.

Manager Level

**

Service Menu

Load Cells

Service Menu

Factory Default

Service Menu

Solenoids

Service Menu

Temp/Compressor

To Load Cells

Service Level

Model SKBD3LS

P

RINC

E

C

A

STL

WORLDWIDE

E

LLC

*

Printed in USA 10/13 © 2013 4 808-004-EN

Page 5

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Display Menu Overview (continued)

Error Messages

NOTE: Error messages replace the Home screen: Non-fatal errors will blink 2 seconds on and 2 seconds off. Fatal errors will stay on

until the error is fixed.

Message on Display Description Message on Display Description

Check Temp Sense Temperature probe error, open or short. No USB Detected Error during updating/exporting files, no connection.

Check Skim LC Skim tank’s load cell connection open. USB Error Please Check USB Error during updating/exporting files, problems

initializing.

Check Cream LC Cream tank’s load cell connection open.

Check Milk LC Milk tank’s load cell connection open. No File Detected On USB Error during updating files, no file detected on the

flash drive.

Board Comm Error Display-to-relay communication error.

Replace Battery Replace the battery (on control board). Bad File Detected On USB Error during updating files, a bad file detected on the

flash drive.

RTC Comm Error Real Time Clock communication error.

Resetting Factory Defaults

All data and adjustments will be reset to from-the-factory status.

CAUTION

Enter the Manager Level.

On the display panel, press the Up or Down arrow until

Manager Mode is displayed. Press the “X” button in the

Size row.

Manager Mode

Entr Btn Combo

1

Enter the Service Level.

Press the Up or Down arrow until Service Menu is

displayed. Press the Setup Code, which is “X” + “Cap.”

+ “XL”.

NOTE: If the code is not entered correctly, press the

Up arrow once and then the Down arrow once and reenter the code.

Service Menu

Etr Setup Code

2

Reset to factory defaults.

Press the Down arrow to the Factory Default screen

and press Select.

Service Menu

Factory Default

3

Model SKBD3LS

808-004-EN 5 Printed in USA 10/13 © 2013

Page 6

3-Product Dairy Dispenser

Setting Time and Date

Navigate to the

Manager Level. On

the display panel,

press the Down arrow

until Manager Mode is

displayed.

1

Press the “X”

button. The

“Manager Button

Combination” is the

“X” button in the Size

row.

2

Navigate to the

screen. Press the

Down arrow until the

Set Date/Time screen

is displayed.

3

Adjust the date and

time. Press Select to

begin the adjustment,

then use display panel

buttons to make

changes:

• Use the Home

button to tab right.

• Use the Back

button to tab left.

• Use the Up and Down arrows to change the values.

4

Press Select to

accept the changes.

5

Return to normal

operation. Press the

Home button to return

to the main menu.

6

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 6 808-004-EN

Page 7

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Calibrating the Unit / Adjusting Shot Size

NOTE: Unit must be calibrated before the unit is put into

operation and as needed thereafter to ensure that the unit is

dispensing within the required specifications.

Exercise the tubes. If unit has been idle (no shots

taken for over a half hour) take one shot of size Medium

(coffee) for each product to exercise the tubes.

1

Place a cup on the external scale and press tare.

2

Dispense a shot.

Press the button of the

product to be

dispensed, place the

cup under the proper

product tube, and then

press the “M” button to

dispense product

amount for a medium

coffee.

1

2

3

Weigh the product on the external scale. If the shot

weight is within the specified range listed in the Shot

Size Targets (41 - 51 g), then you can move on to the

next product. If the shot weight is outside of the

specified range, then a simple calibration is required. To

calibrate the unit, follow Steps 5 to 9.

4

Repeat Step 2.

5

Go to the

Calibration menu.

Press the Down arrow

once.

6

Dispense a shot.

NOTE: Make sure the

cup is under the valve

at this time, because

a medium sized shot

is dispensed.

The display now reads

“Calibrate Disp Select

Product”. Press the

button of the product

you wish to calibrate

(Milk, Cream or Skim)

and then press the “M”

button.

e e l l e e c c t t P P o o d d u u c c t t r r

C C a a l l i i b b r r a a t t D i i s s p p e e

S S

1

2

7

Weigh the cup on the external scale.

8

Enter the weight.

The display now reads

“Enter Weight 46

Grams”. Press the Up

or Down arrow until

the value on the

display matches the

weight that you

measured using the

external scale and

then press Select.

4 4 6 G G r r a a m m s s

E E n n t t e e r r W W e e g g h t t i i

1

2

9

Calibrate the next

product. The display

again reads “Calibrate

Disp Select Product”.

You may now select

the next product to

calibrate or press the

Home button to return

to normal operation.

e e l l e e c c t t P P o o d d u u c c t t r r

C C a a l l i i b b r r a a t t D i i s s p p e e

S S

or

10

Model SKBD3LS

808-004-EN 7 Printed in USA 10/13 © 2013

Page 8

3-Product Dairy Dispenser

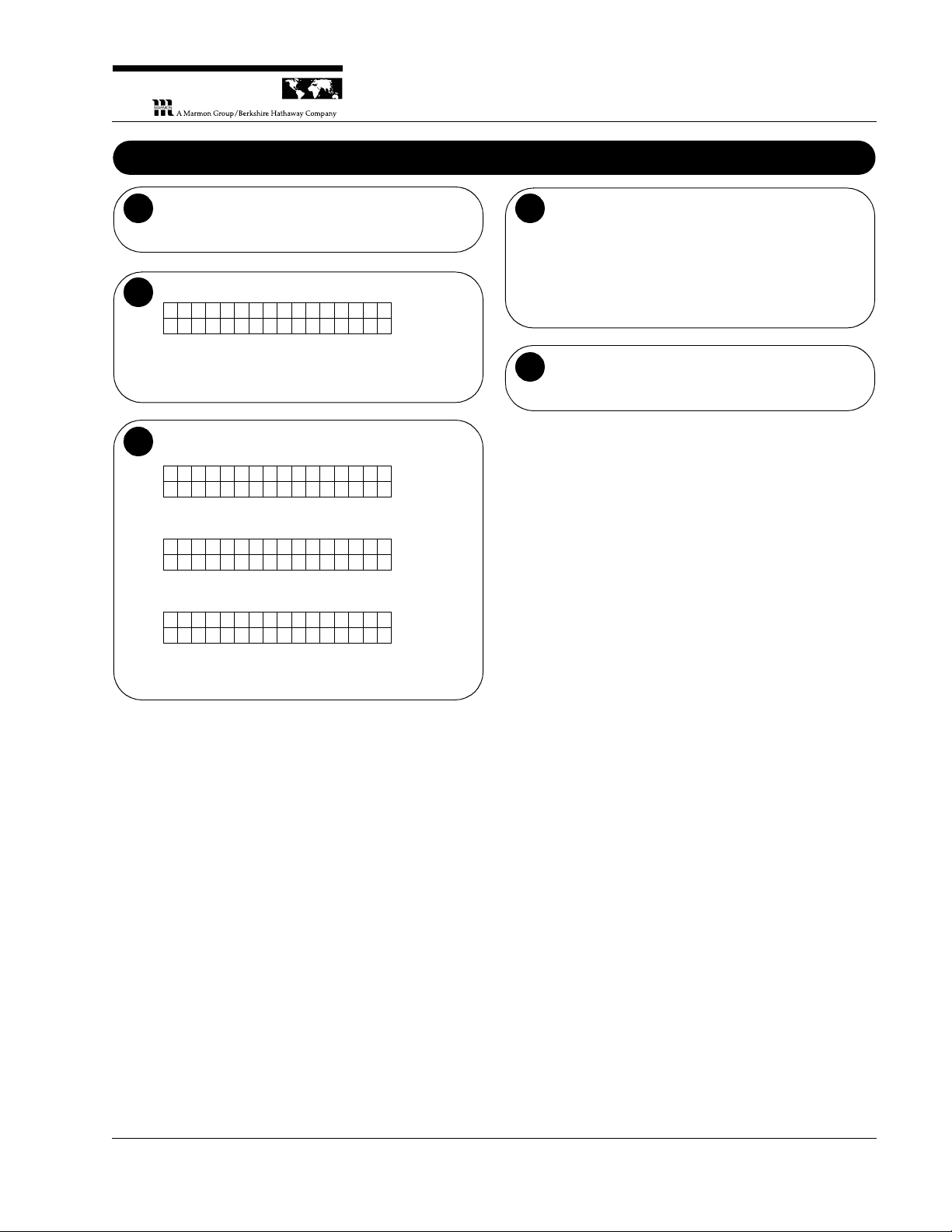

Shot Size Targets

With machine set to COFFEE

Base

ALL SHOTS ARE LISTED AND MEASURED IN GRAMS

MIN TARGET MAX

COFFEE XS

13 15 17

SM

27 31 34

MED

41 46 51

LG

54 61 67

XLG

68 76 84

LATTE SM

164 183 202

MED

247 275 303

LG

329 367 404

CAPPUCCINO SM

109 122 135

MED

164 183 202

LG

219 244 269

COOLATTA XS

54 61 67

SM

109 122 135

MED

163 183 202

LG

217 243 269

With machine set to NEUTRAL

Base

ALL SHOTS ARE LISTED AND MEASURED IN GRAMS

MIN TARGET MAX

COFFEE XS

13 15 17

SM

27 31 34

MED

41 46 51

LG

54 61 67

XLG

68 76 84

LATTE SM

164 183 202

MED

247 275 303

LG

329 367 404

CAPPUCCINO SM

109 122 135

MED

164 183 202

LG

219 244 269

COOLATTA XS

41 46 50

SM

82 91 100

MED

123 137 150

LG

164 182 200

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 8 808-004-EN

Page 9

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Updating and Exporting Files

Remove the plug covering the USB port and attach

a Flash drive.

1

Enter the Manager Level.

On the display panel, press the Up or Down arrow until

Manager Mode is displayed. Press the “X” button in the

Size row.

Manager Mode

Entr Btn Combo

2

Navigate to the screen. Press the Up or Down arrow

until the appropriate screen appears. Choose:

• Press Select To Update Display to download an

updated display file from a Flash drive.

• Press Select To Update Relay to download an

updated relay file from a Flash drive.

• Export Files To USB to upload files from the unit to

a Flash drive.

Press Select To

Update Display

Press Select To

Update Relay

Export Files

To USB

3

Press Select to initiate the download/upload. A

status message will appear in the display. (If an error

code appears, see Error Messages on page 5.)

• When a download is complete, the screen will

automatically return to the main menu.

• When an upload is complete, the screen will

automatically return to the main menu.

4

Remove the Flash drive and insert the USB port

plug.

5

Model SKBD3LS

808-004-EN 9 Printed in USA 10/13 © 2013

Page 10

3-Product Dairy Dispenser

Changing Set Point, Base, Low Product Thresholds, Beeper Status

Enter the Manager Level.

On the display panel, press the Up or Down arrow until

Manager Mode is displayed. Press the “X” button in the

Size row.

Manager Mode

Entr Btn Combo

1

Navigate to the screen and change settings. Press

the Up or Down arrow until the appropriate screen

appears. Choose:

A. Manager Mode Temp Set Pt: XX to change the

unit’s set point.

1. Press Select to initiate the change.

2. Press the Up or Down arrow to choose the

desired temperature (between 35 and 40°F).

3. Press Select again to accept the change.

B. Manager Mode Base Select to change to “coffee”

or “neutral” Coolatta base.

1. Press Select to initiate the change.

2. Press the Up or Down arrow to choose the

correct term.

3. Press Select again to accept the change.

C. Set Low Mlk/Skm Threshold or Set Low Cream

Threshold to change the amount at which the unit

goes into lockout (will not dispense).

1. Press Select to initiate the change.

2. Press the Up or Down arrow to change the

amount in increments of 50 g. Default Milk and

Skim levels are 600 g and the default Cream

level is 850 g.

3. Press Select again to accept the change.

D Manager Mode Beeper On (or Off) to enable/

disable the audible alarm.

1. Press Select to initiate the change.

2. Press the Up or Down arrow to toggle between

On and Off.

3. Press Select again to accept the change.

Manager Mode

Temp Set Pt: XX

Manager Mode

Base Select

Set Low Mlk/Skm

Threshold: XXXX

Manager Mode

Beeper XX

2

Press the Home button to return to the main menu

or choose another setting to change.

3

Model SKBD3LS

Printed in USA 10/13 © 2013 10 808-004-EN

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Page 11

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Zeroing Out the Load Cells

When replacing a control board (p/n 36992S) or load cell (p/n

37168S) it will be necessary to zero out the load cells. Please

carefully follow each step of the load cell calibration instructions

listed below.

IMPORTANT

Power up the unit. Connect the power cord to a

115 VAC outlet. Turn the unit on and wait while the

controller initiates.

1

Remove all product tanks from the unit. Make sure

nothing is on any of the load cells.

2

Press Home on the display panel.

3

Enter the Manager Menu.

Press the Up or Down arrow until Manager Mode is

displayed. Press the “X” button in the Size row.

Manager Mode

Entr Btn Combo

4

Enter the Service Menu.

Press the Up or Down arrow until Service Menu is

displayed. Press the Setup Code, which is “X” + “Cap.”

+ “XL”.

NOTE: If the code is not entered correctly, press the

Up arrow once and then the Down arrow once and reenter the code.

Service Menue

Etr Setup Code

5

Press Select 3 times. A “Calibration Done” message

will appear on the display.

6

Press the Home button to return to the main menu.

7

Load the tanks and product back into the machine.

8

Follow the instructions under Calibrating the Unit /

Adjusting Shot Size.

9

Model SKBD3LS

808-004-EN 11 Printed in USA 10/13 © 2013

Page 12

3-Product Dairy Dispenser

Viewing Other Load Cell Data

Enter the Manager Menu.

Press the Up or Down arrow until Manager Mode is

displayed. Press the “X” button in the Size row.

Manager Mode

Entr Btn Combo

1

Enter the Service Menu.

Press the Up or Down arrow until Service Menu is

displayed. Press the Setup Code, which is “X” + “Cap.”

+ “XL”.

NOTE: If the code is not entered correctly, press the

Up arrow once and then the Down arrow once and reenter the code.

Service Menu

Etr Setup Code

Service Menu

Load Cells

2

Press Select.

3

Navigate to the screen and view data. Press the Up

or Down arrow until the appropriate screen appears.

Choose:

A. Load Cell Counts to view the activation count.

B. Calibration Zero to view Load Cell 1 zero, Load

Cell 2 zero and Load Cell 3 zero.

C. Calibration Span to view Load Cell 1 span, Load

Cell 2 span and Load Cell 3 span.

4

Press the Home button to return to the main menu.

5

Solenoids – Test Cycling/Viewing Status

Enter the Manager Menu.

Press the Up or Down arrow until Manager Mode is

displayed. Press the “X” button in the Size row.

Manager Mode

Entr Btn Combo

1

Enter the Service Menu.

Press the Up or Down arrow until Service Menu is

displayed. Press the Setup Code, which is “X” + “Cap.”

+ “XL”.

NOTE: If the code is not entered correctly, press the

Up arrow once and then the Down arrow once and reenter the code.

Service Menu

Etr Setup Code

Service Menu

Load Cells

2

Navigate to the Service Menu Solenoids screen.

Press the Up or Down arrow until the screen appears.

Service Menu

Solenoids

3

Press Select.

4

Navigate to the desired screen (Milk Solenoid,

Cream Solenoid, Skim Solenoid).

Press the Down arrow until the appropriate screen

appears.

Milk Solenoid

S=ON L=OFF

5

Cycle the solenoid.

A. Use the “S” button on the display to turn on the

solenoid.

B. Use the “L” button on the display to turn off the

solenoid.

C. Use the Down arrow to move on to the next screen.

NOTE: After the Skim Solenoid screen are lifetime

cycle counts for the three solenoids.

Milk Sol. Cyl.

XXXX

6

Press the Home button to return to the main menu.

7

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 12 808-004-EN

Page 13

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Compressor – Test Cycling/Setting Up

Enter the Manager Menu.

Press the Up or Down arrow until Manager Mode is

displayed. Press the “X” button in the Size row.

Manager Mode

Entr Btn Combo

1

Enter the Service Menu.

Press the Up or Down arrow until Service Menu is

displayed. Press the Setup Code, which is “X” + “Cap.”

+ “XL”.

NOTE: If the code is not entered correctly, press the

Up arrow once and then the Down arrow once and reenter the code.

Service Menu

Etr Setup Code

Service Menu

Load Cells

2

Navigate to the Service Menu Temp/Compressor

screen. Press the Up or Down arrow until the screen

appears.

Service Menu

Temp/Compressor

3

Press Select.

4

Navigate to the screen and change settings. Press

the Up or Down arrow until the appropriate screen

appears. Choose:

A. Temp/Compressor/Short Cycle Timer to change

the compressor’s timer.

1. Press Select to initiate the change.

2. Press the Up or Down arrow to choose the

desired time in minutes.

3. Press Select again to accept the change.

B. Temp/Compressor/Temp Offset to change the

temperature offset between probe and display.

1. Press Select to initiate the change.

2. Press the Up or Down arrow to choose the offset.

3. Press Select again to accept the change.

C. Temp/Compressor/Temp Diff to change the

compressors’ temperature differential between set

point and cutout.

1. Press Select to initiate the change.

2. Press the Up or Down arrow to change the

differential.

3. Press Select again to accept the change.

D. Compressor S = ON L = OFF to force the

compressor ON/OFF.

1. Press Select to initiate the change.

2. Press the “S” on the display to turn the

compressor on or press the “L” on the display to

turn the compressor off.

3. Press Select again to accept the change.

Temp/Compressor

Scycle Timer: XX

Temp/Compressor

Temp Offset XX

Temp/Compressor

Temp Diff: XX

Compressor

S=ON L=OFF

5

Press the Home button to return to the main menu

or choose another setting to change.

6

Model SKBD3LS

808-004-EN 13 Printed in USA 10/13 © 2013

Page 14

3-Product Dairy Dispenser

Troubleshooting Guide

Model SKBD3LS

PROBLEM PROBABLE CAUSE SOLUTION

Not dispensing accurately Containers not in correct position Check container position (L,C,R).

Wrong tubes being used Use Silver King tubes only (Part No. 37222).

Unit out of calibration Run daily calibration (See Calibrating the Unit).

Valve hanging up Replace valve.

Not dispensing Container empty Fill container.

Bad relay Replace relay.

Bad solenoid Replace solenoid.

Poor connect to solenoid Check connection.

Broken valve Replace valve.

Buttons not responding Replace door.

“CHECK (Product name) LC” is

displayed

“EMPT” is displayed when

container is full

Display is blank Unit not receiving power Check that service cord is firmly connected to the wall socket and

Unit will not stop dispensing Bad relay Replace relay.

Ice buildup Door not sealing Check that door is properly closed. Close the tank covers, the top

Bad connection Replace load cell.

Bad terminal board Replace terminal board.

Unit needs to be zeroed See Zeroing Out the Load Cells.

Bad load cell Replace load cell.

the unit, and the power switch is in the “ON” position.

Door cable Check door cable to make sure it is secure. If secure, replace

cable.

Bad power supply Replace power supply.

Bad display Replace door.

Bad valve Replace valve.

Bad solenoid Replace solenoid.

access door, and then the front door of the unit. NOTE: Closing

front door before top access can create a gap which may lead to

increased ice buildup and/or warm dairy product.

Bad gasket Replace gasket.

Bad temperature probe Replace probe.

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 14 808-004-EN

Page 15

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

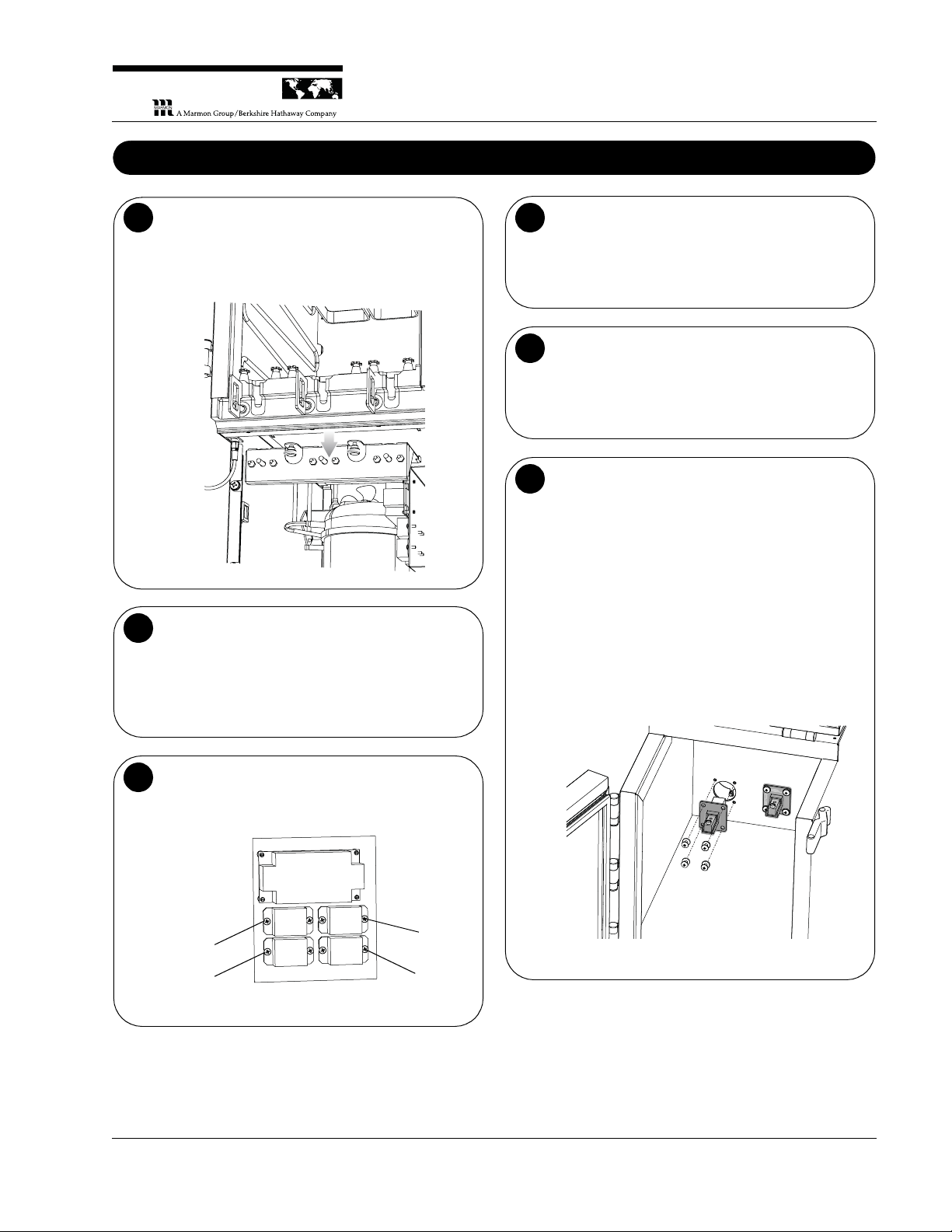

Accessing/Servicing Components from the Front

Door-Display Connector Cable • Door Assembly, Door Gasket • Temperature Probe

• Valve Plunger Assemblies • Solenoids, Solenoid Rack Assembly • Control Board

• Relays • Terminal Board • Power Supply • Load Cell Assemblies

Risk of Electric Shock.

Always unplug the power cord before servicing the unit to

avoid electric shock.

WARNING

Silver King tubes (Part No. 37222) must be on order for this unit.

Be sure to have 3 clamps available to manually close the tubes

for any service activity that may require opening the product

valves while the tanks contain product. Office supply binder clips

work well.

IMPORTANT

Turn off the power

switch and

unplug the unit.

The power switch is

on the left side of

the unit near the

front.

1

Uninstall the cup guide and the drip tray.

Cup Guide

Drip Tray

Mount

Drip Tray

Mount

2

Remove the panel. Remove the 4 screws and remove

the lower front panel.

3

Model SKBD3LS

808-004-EN 15 Printed in USA 10/13 © 2013

Page 16

3-Product Dairy Dispenser

Accessing/Servicing Components from the Front (continued)

G

H

I

J

A

B

C

D

F

E

Door-Display

Connector Cable.

Always ensure the

connections are

secure.

Replace by handtightening the

threaded connectors.

A

Door Assembly, Door Gasket.

The display is part of the door assembly.

B

Temperature Probe.

The temperature probe is behind a shield in the right

rear of the tank cavity.

C

Valve Plunger Assemblies.

If a valve is not working, take an ohm reading at the clip

disconnect.

D

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 16 808-004-EN

Page 17

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Accessing/Servicing Components from the Front (continued)

Solenoids, Solenoid Rack Assembly.

Solenoids can be replaced individually. To remove the

solenoid rack assembly, loosen the two captured

screws and pull the rack down.

E

Control Board.

The control board simply slides out from the control

assembly.

After replacing the control board, it will be necessary to

zero out the load cells for proper operation. Follow the

instructions, Zeroing Out the Load Cells.

F

Relays.

To better access the relays, loosen the 2 nuts that

attach the control assembly to the unit and remove the

whole control assembly.

Center

(Cream)

Compressor

Right

(Skim)

Left

(Milk)

G

Terminal Board.

To better access the terminal board, loosen the 2 nuts

that attach the control assembly to the unit and remove

the whole control assembly.

The terminal board is labeled for each connection.

H

Power Supply.

To better access the power supply, loosen the 2 nuts

that attach the control assembly to the unit and remove

the whole control assembly.

I

Load Cell Assemblies.

To remove a load cell:

1. Access the unit from both the front and rear.

2. At the front, disconnect the load cell connector

from the terminal board.

3. Cut the wire tie.

4. Remove the 4 screws that hold the assembly.

5. Pull the load cell through the load cell mounting

hole, making sure to guide the cable through

carefully from the rear to prevent cutting the load

cell cable insulation.

To install a load cell, reverse the removal process.

After replacing a load cell, it will be necessary to zero

out the load cells for proper operation. Follow the

instructions, Zeroing Out the Load Cells.

J

Model SKBD3LS

808-004-EN 17 Printed in USA 10/13 © 2013

Page 18

3-Product Dairy Dispenser

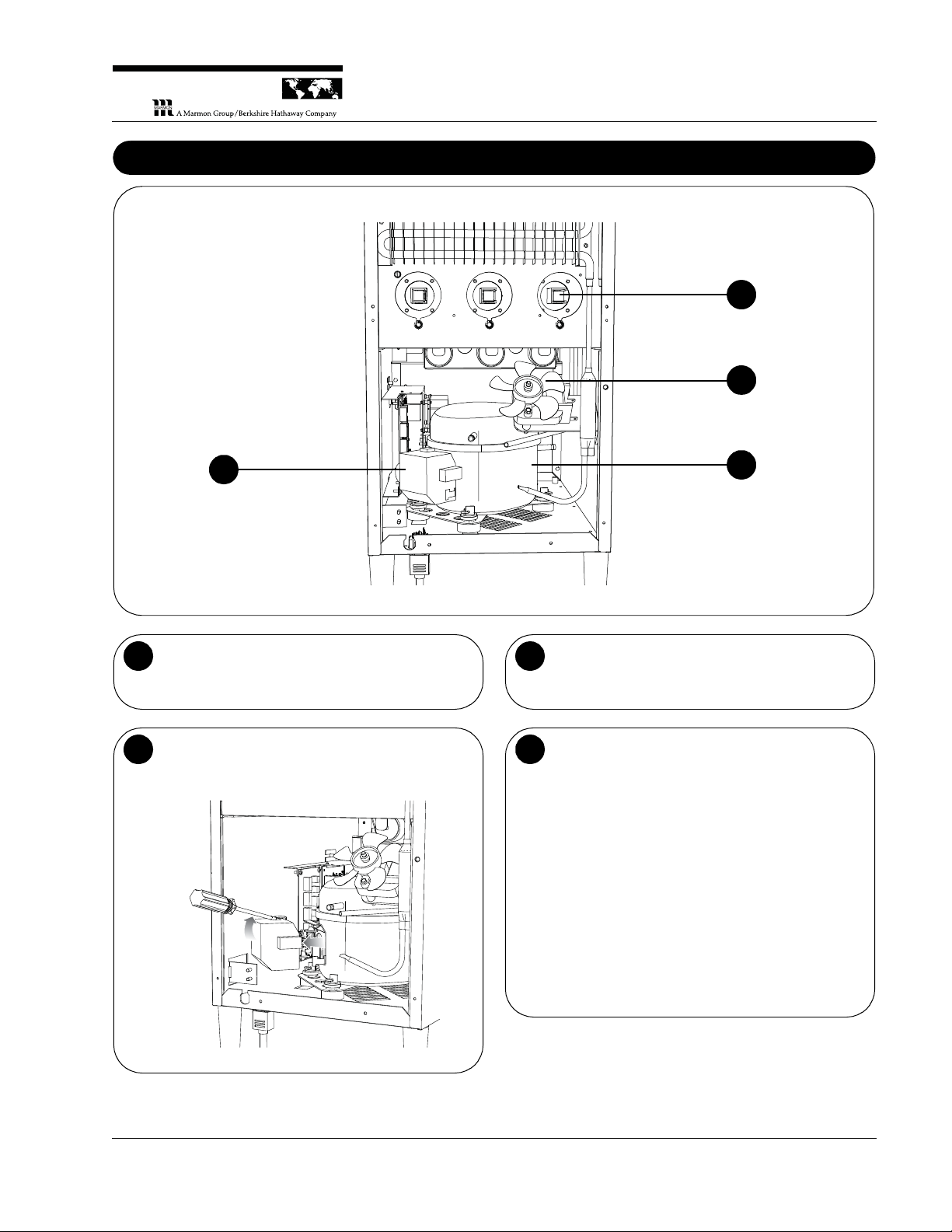

Accessing/Servicing Components from the Rear

Fan Assembly • Compressor Start Components • Compressor • Load Cell Assemblies

Risk of Electric Shock.

Always unplug the power cord before servicing the unit to

avoid electric shock.

WARNING

Silver King tubes (Part No. 37222/DCP SKU 711490) must be

used for this unit. Be sure to have 3 clamps available to manually

close the tubes for any service activity that may require opening

the product valves while the tanks contain product. Office supply

binder clips work well.

IMPORTANT

Turn off the power

switch and

unplug the unit.

The power switch is

on the left side of

the unit near the

front.

1

Remove the panel(s). Remove the 8 screws and

remove the main rear panel. To access the load cell

assemblies, remove the 4 screws and remove the load

cell access panel.

2

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 18 808-004-EN

Page 19

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Accessing/Servicing Components from the Rear (continued)

D

A

B

C

Fan Assembly.

Without accessing, a non-working fan is evident when

no air is flowing out of the top rear of the unit.

A

Compressor Start Components.

To access the overload and start relay, pop off the gray

cover.

B

Compressor.

The compressor is a closed system. To service the

compressor, a service valve must be provided.

C

Load Cell Assemblies.

To remove a load cell:

1. Access the unit from both the front and rear.

2. At the front, disconnect the load cell connector

from the terminal board.

3. Cut the wire tie.

4. Remove the 4 screws that hold the assembly.

5. Pull the load cell through the load cell mounting

hole, making sure to guide the cable through

carefully from the rear to prevent cutting the load

cell cable insulation.

To install a load cell, reverse the removal process..

After replacing a load cell, it will be necessary to zero

out the load cells for proper operation. Follow the

instructions, Zeroing Out the Load Cells.

D

Model SKBD3LS

808-004-EN 19 Printed in USA 10/13 © 2013

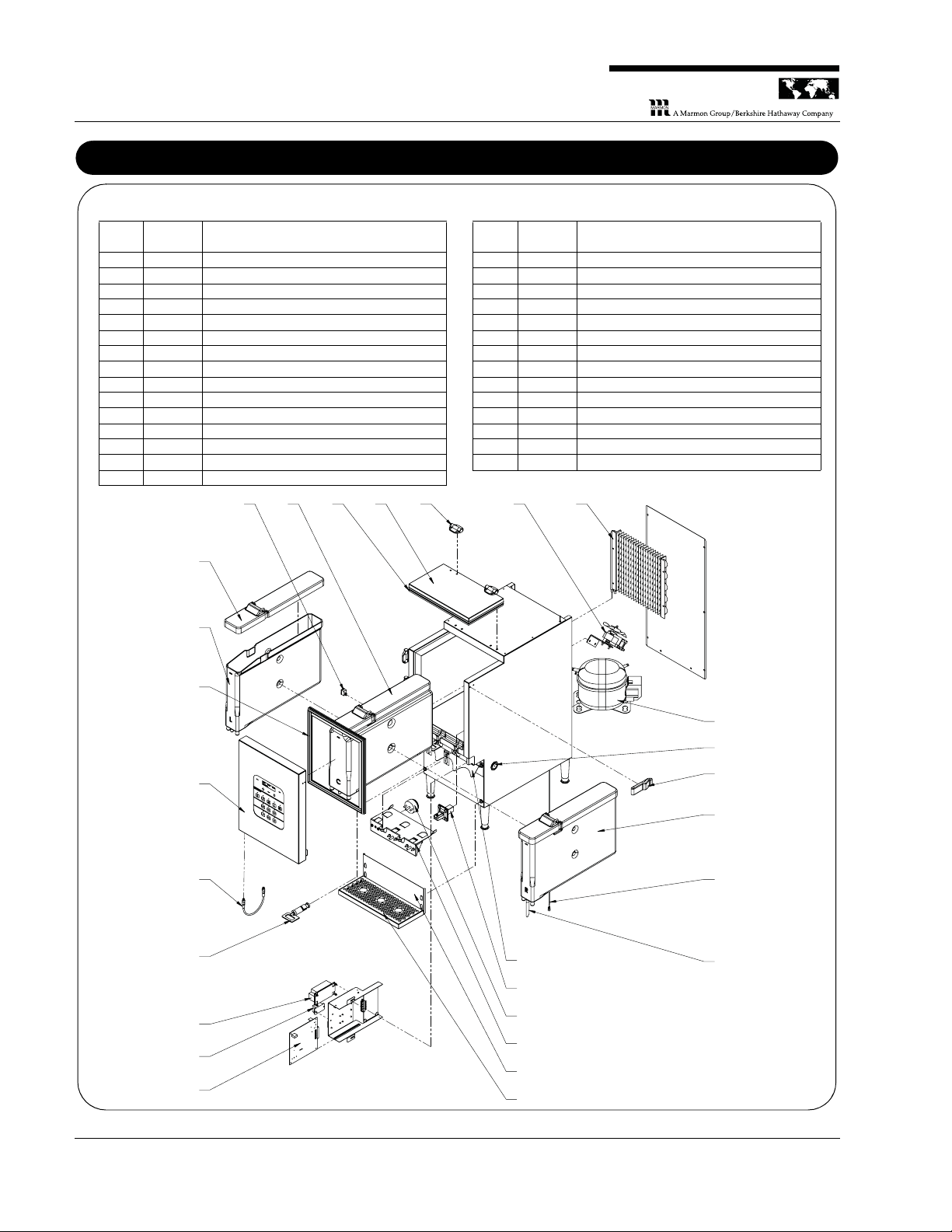

Page 20

3-Product Dairy Dispenser

Parts List and Exploded View

NOTE: To order Parts/Service, Contact Silver King Refrigeration at 800-328-3329 for technical assistance.

Item NoPart

No Description

1 25226S Hinge w/Screws & Covers

2 25227S Latch

3 36954S Lid Gasket SKBD3LS

4 36955S Lid Assembly SKBD3LS

5 36956S Door Gasket SKBD3LS

6 36957S Door Assembly SKBD3LS

7 36992S Control Board

8 37016S Condenser Coil SKBD3LS

9 37052S Platform for Drip Tray

10 37068S Container Assembly Left

11 37069S Container Assembly Center

12 37070S Container Assembly Right

13 811-006S Lid, Container SKBD3LS

14 37133S Valve Plunger Assembly

15 37146S Power Supply

16 37147S Relay

17 37461S Solenoid Rack Assembly

18 37168S Load Cell Assembly SKBD3LS

19 37202S Fan Assembly SKBD3LS

20 37210S Connector, Door-Display SKBD3LS

21 37222 3" Tubes (Carton of 300)

22 37239S Rocker Switch SKBD3LS

23 37281S Drip Tray SKBD3LS

24 37364S Probe Temp SKBD3LS

25 37436S Upper Cup Guide

26 37485S Solenoid

27 10343-02 Compressor 115V/60HZ EMI30HER

10344-02 Electricals - Compressor

28 37358S USB Hole Plug - 1" Dia

Item NoPart

No Description

22 11 3 4 1 19 8

6

5

13

10

20

7

14

15

16

18

26

17

21

24

12

2

28

27

9

23

25

Model SKBD3LS

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 10/13 © 2013 20 808-004-EN

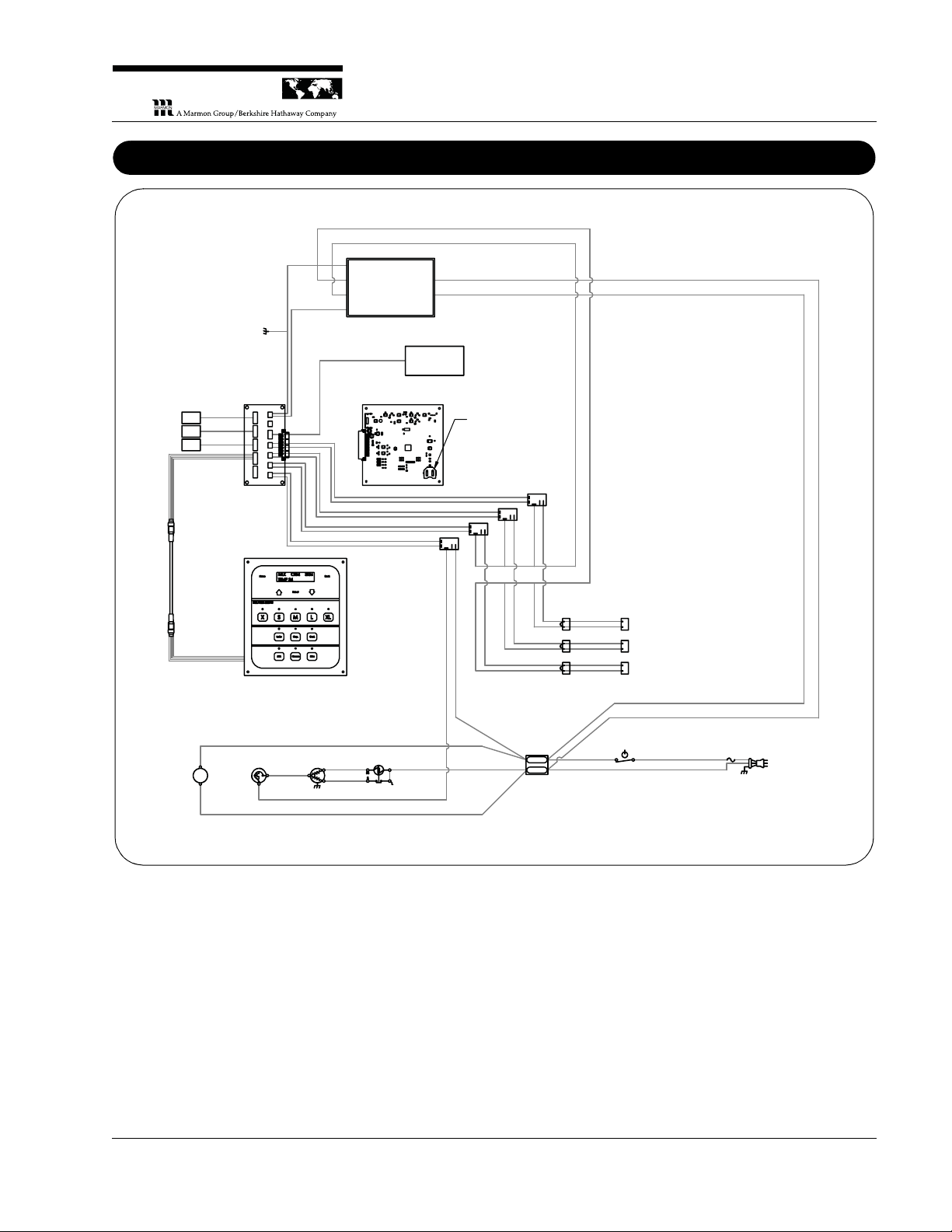

Page 21

3-Product Dairy Dispenser

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Wiring Diagram

POWER

SUPPLY

4

3

2

1

LOAD CELLS

LEFT

CENTER

TEMP

SENSOR

BATTERY

CR2032H

CONTROL

BOARD

DATA

CABLE

TO

DOOR

CONNECTOR

BOARD

DISPLAY

#1

#2

#3

COMPRESSOR

RELAY

SOLENOIDS

POWER

SWITCH

TERMINAL

BLOCK

COND

FAN

COMP

OVERLOAD

RELAY

RED

WHITE

WHITE

SOLENOID

RELAYS

POWER CORD

115V/60HZ

BLACK

WHITE

SKBD3LS

36946

REV: B

RED

#1 LEFT

#2 CENTER

#3 RIGHT

GROUND

120V AC

IN

BLACK

(-)

RED (+)

#1

#2

#3

GROUND

RED

AS VIEWED

FROM FRONT

OF MACHINE

AS VIEWED

FROM FRONT

OF MACHINE

←

24V DC

OUT

RIGHT

RED (+)

BLACK

(-)

RED

WHITE

RED

FUSE

T10AL250VP

RED

WHITE

GRAY

BLACK

BLUE

BLUE

BROWN

BLUE

BROWN

BROWN

BROWN

BLUE

WHITE

WHITE

RED

RED

RED

BLACK

BLACK

BLACK

Model SKBD3LS

808-004-EN 21 Printed in USA 10/13 © 2013

Loading...

Loading...