Page 1

Technical Manual

Replacement Parts List

Beverage

Dispenser

Specifications Subject to

Change Without Notice.

and

MODEL SKBD105P

1600 Xenium Lane North, Minneapolis, MN 55441-3787

Phone (763) 923-2441

1

Page 2

TECHNICAL MANUAL

MODEL SKBD105P CREAM DISPENSER

INSTALLATION, OPERATION AND MAINTENANCE

Thank you for purchasing Silver King food service equipment. Our goal is to provide our customers with the most reliable

equipment in the industry today. Please read this manual and the accompanying warranty information before operating your new

Silver King unit. Be sure to complete and mail the warranty card within 10 days of purchase to validate your warranty.

Upon delivery of your new Silver King unit, inspect the carton and unit for shipping damages. Report any damage immediately to

the transportation carrier and file a written freight damage claim to protect your investment. If a claim is to be filed, save all

packaging materials.

INSTALLATION

The stainless steel exterior of the cabinet has been protected by a plastic covering during manufacturing and shipping. This

covering can be readily peeled before installation. After removing this covering, wash the interior and exterior surfaces using a

warm mild soapy water solution and a sponge or cloth, rinse with clean water and wipe dry.

Location:

When locating your cream dispenser, convenience and accessibility are important considerations, but the following factors must be

observed:

• When placing the unit on a counter, the counter must be able to support a minimum of 100 pounds.

• When placed on a counter, the unit must be on the feet supplied. If the feet are removed the unit will not operate properly

and the warranty will be void.

• There must be at least two inches of clear space above, on the sides and behind the unit and open in front.

• Correct serving height is important so that those using the dispenser can operate the dispenser properly.

• The unit must be level. The feet are adjustable to aid in leveling the unit.

• Avoid placing the unit next to an oven, heating element or hot air source which would affect the performance of the unit.

Electrical Connections:

Be sure to check the data plate, located on the liner of the cabinet, for required voltage prior to connecting the unit to power. The

specifications on the data plate supersede any future discussion.

The standard dispenser is equipped with an seven (7) foot power cord that requires a 115 Volt, 60 Cycle, 1 Phase or 230 Volt, 50

Cycle, 1 Phase properly grounded electrical receptacle (please check the serial plate for voltage information). The power cord

comes with a 3 prong plug for grounding purposes. Any attempt to cut off the grounding spike or to connect to an ungrounded

adapter plug will void the warranty, terminate the manufacturer’s responsibility and could result in serious injury.

1

Page 3

Defrost:

The REFILL button must be

Operation

Initial Startup

After satisfying the installation requirements, the cream dispenser is ready to start. The unit will start when the power cord is connected

to a live electrical receptacle. This can be verified by checking the indicator panel on the front of the unit. The indicator should display

the current unit temperature. If the unit does not start when the power cord is plugged in, make sure that the switch on the back of the

unit is in the ‘on’ position. Allow the unit to run a minimum of two hours before loading it with product. It is completely normal for the

exterior of the unit to feel warm while it is running.

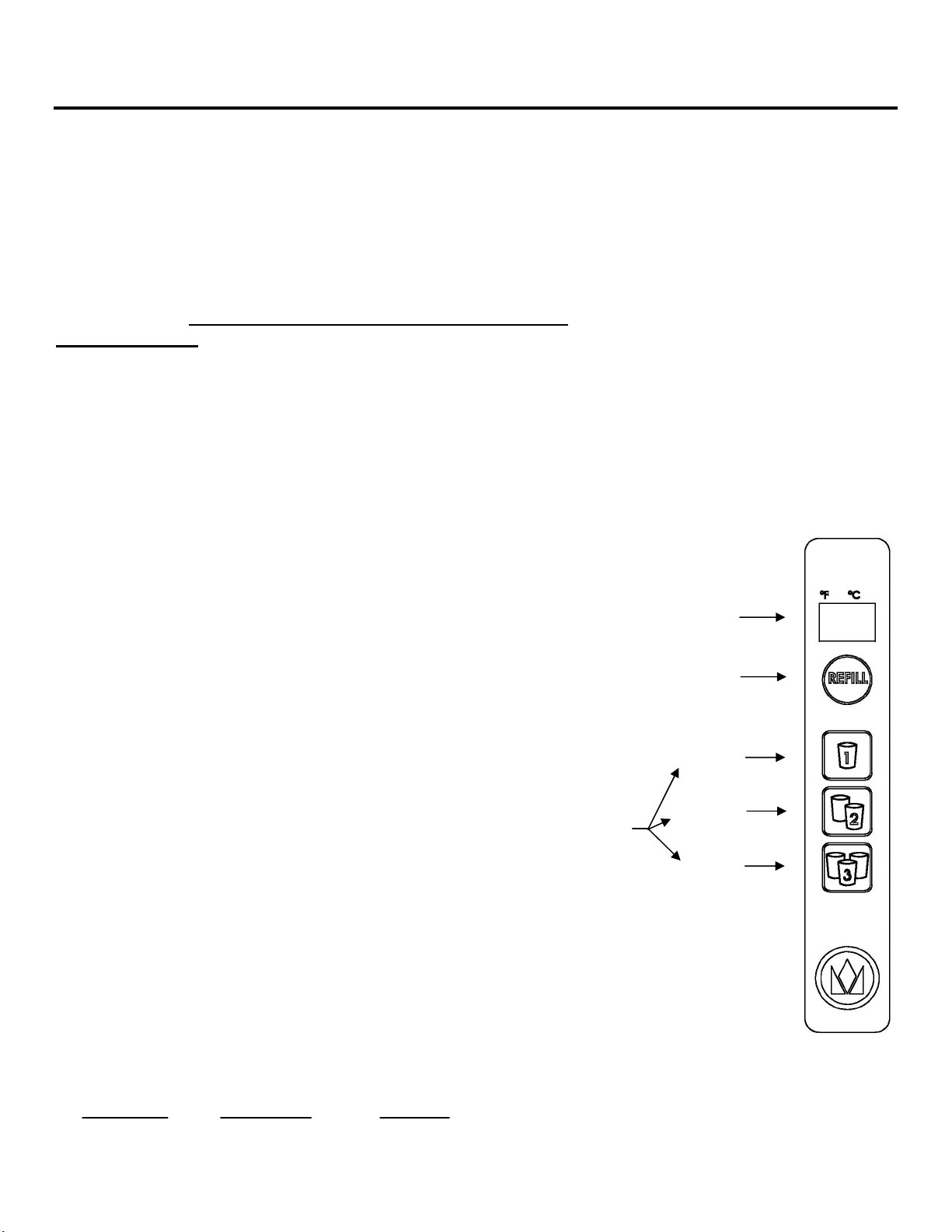

Indicator Panel

The Indicator Panel contains a digital LED display that reads the product temperature

during normal operation. The three lower buttons on the Indicator Panel are for selecting

portion sizes (small or large). The upper button is used to reset the computer whenever

the cream is refilled. This button must be pressed each time the

cream is refilled. Press and hold the REFILL button for 3

seconds until the indicator flashes 00.

Preparation for Use

Once the unit has achieved proper operating temperature, observe the procedures noted in

the label on the door liner for loading cream into the cream dispenser. When removing an

empty bag of cream, be sure to push the Valve Slide in fully before pulling the Dispensing

Tube out of the valve. It may be easier to remove or install the Dispensing Tube in the

valve by removing the Valve Insert first then removing or installing the Cream Container.

The end of the tube may need to be cleaned daily with a clean cloth to prevent buildup

which could affect the dispensing of product. After loading the creamer, press and hold

the REFILL button for 3 seconds until the indicator flashes 00.

The Silver King cream dispenser is a manual defrost unit.

The unit should be defrosted whenever the walls accumulate

a frost bank that is 1/2 inch thick. To defrost the unit, either

turn the Temperature Control knob to the ‘off’ position or

disconnect the power cord from the electrical receptacle,

and open the door. After the frost has melted or come loose

from the cabinet walls, wipe out the cabinet interior. Do not

attempt to scrape or chisel off the frost as you could do

irreparable damage to the unit.

MAINTENANCE

Preventative maintenance is minimal although these few

steps are very important to continued operation and

maximizing the life of the appliance.

Cabinet Surfaces:

The cabinet interior and exterior are stainless steel and

should be cleaned periodically with a solution of warm water

and a mild soap, rinsed and wiped dry with a clean soft

cloth. A stainless steel cleaner can also be used. Should a

surface become stained or discolored, do not attempt to

clean with an abrasive cleaner or scouring pad. Use a soft

cleaner and rub with the grain of the metal to avoid

scratching the surface. Do not use chlorinated cleaners.

pressed for 3 seconds each

time the cream is replaced

The three lower buttons on

the Indicator Panel are for

selecting portion size

Indicator Panel

Small

Medium

Large

2

Page 4

3

Page 5

4

Page 6

WHEN ORDERING REPLACEMENT PARTS, PLEASE PROVIDE MODEL AND SERIAL NUMBERS

5

Page 7

Cleaning and Refilling Procedures

Removing Valve Insert

Cleaning

Insert New Bag into Container

Insert a new beverage bag into the

container as shown. Lock the tube

into place at the bottom of the

container.

To remove the valve insert once the beverage

container is empty, simply press on the valve slide and

remove the valve insert by pulling it straight up.

Once removed, the valve can be cleaned with a brush

and warm soapy water or in a dishwasher. The valve

area in the dispenser should also be cleaned with a brush

and warm soapy water.

6

Page 8

Cleaning and Refilling Procedures

Install Container and Bag

Install Valve Insert

Cut Tube

Press REFILL Button

Place container inside cabinet and guide

tube through valve area. Be sure the tube

is straight and centered to avoid kinking,

which could result in reduced product flow

or leaking.

Push and hold valve slide while inserting

the valve insert from above.

Cut the tube one inch below the

valve.

Press and hold the REFILL button

for 3 seconds (display 00) to alert the

dispenser that a new beverage bag

has been installed.

7

Page 9

Troubleshooting Guide

Complaint Cause Solution

1. No voltage at wall receptacle

2. Service cord pulled out of wall

3. Low voltage causing

4. Power switch is in “Off”

Compressor

will not run

Compressor

runs but no

refrigeration

Compressor

short cycles

Compressor

runs too much

or constantly

5. Inoperative control

6. Compressor stuck

7. Compressor windings open

8. Compressor overload stuck

9. Relay lead loose

10. Relay loose or inoperative

11. Power cord disconnected from

12. Faulty cabinet wiring

1. System out of refrigerant

2. Compressor not pumping

3. Restricted filter drier

4. Restricted capillary tube

5. Moisture in system

1. Erratic control thermostat

2. Faulty relay

3. Low voltage

4. Compressor draws excessive

1. Temperature to low

2. Erratic control

3. Abnormally high room

4. Door or lid gaskets not sealing

5. System undercharged due to

6. System undercharged from

7. System overcharged

8. System not clean

9. Restricted filter drier

10. Restricted capillary tube

receptacle

compressor to cycle on

overload

position

open

dispenser

wattage

temperature

leaks

factory

1. Check circuit breaker or fuse

2. Replace

3. Contact power company and

confirm that voltage

fluctuation does not exceed

10% plus or minus from the

nominal rating

4. Turn switch on

5. Call service technician

6. Call service technician

7. Call service technician

8. Call service technician

9. Call service technician

10. Call service technician

11. Call service technician

12. Call service technician

1. Call service technician

2. Call service technician

3. Call service technician

4. Call service technician

5. Call service technician

1. Call service technician

2. Call service technician

3. Contact power company and

confirm that voltage

fluctuation does not exceed

10% plus or minus from the

nominal rating

4. Call service technician

1. Adjust temperature control

2. Call service technician

3. Reduce room temperature or

relocate dispenser

4. Adjust or call service

technician

5. Call service technician

6. Call service technician

7. Call service technician

8. Call service technician

9. Call service technician

10. Call service technician

8

Page 10

1. Tubing vibrates

Noisy

Beverage

leaking or not

flowing

2. Internal compressor noise

3. Compressor vibrating on

cabinet frame

1. Tube kinked

2. Valve stuck

Ordering Parts/Service

Contact Silver King Refrigeration at 800-328-3329 for technical assistance.

1. Call service technician

2. Call service technician

3. Call service technician

1. Remove valve and pull tube

straight through valve area

2. Clean valve and valve area or

call for service

Model__________________ Serial No.___________________ Date Installed__________________

FORM NO. 33503 REV E

9

Loading...

Loading...