Page 1

Cream Dispenser

Silver King Model SK-1

Manufactured exclusively for

McDonald’s®

By

Silver King

1600 Xenium Lane North

Minneapolis, MN 55441

customerservicemd@princecastle.com

TABLE OF CONTENTS

Product Identification…………………………………………….……...……………….Page 1

Table of Contents…..………………...……………………..…….…………………..…Page 1

Warranty Statement…………………..……………………………..………………..…Page 2

Electrical Specifications.…..….…………………..……………………………...…..…Page 3

Safety Information…...……………………….………………..….…………………..…Page 3

General…………………..……………………………………...………………………..Page 3

Important……..……….…………...………..…………………………..……………..…Page 3

Unpacking and Setup..…………………………………..……….…………………..…Page 4

Installation……………...………………………….……………………………………..Page 5

Initial Cleaning and Sanitizing…………………………..……….…………………..…Page 6

Initial Start-Up……..…………………...…..…………………………………………….Page 6

Operation— General…...………………....……..…………………………………..….Page 7

Operation — Dispensing Cream…..….….…..………………………………….…..…Page 7

Operational Flowchart……………………...……..……………………………………..Page 8

Manager Mode Flowchart………………………………..…………………...…..……..Page 9

Cleaning and Refilling the Dispenser…………..……..…..……...………………...….Page 10

Troubleshooting Guide….……………….………..……..…………...………...…....….Page 11

Parts and Exploded View……………….….………….…………………………..….…Page 13

Wiring Diagram……………………………..….……..…...……………..…..….…….…Page 14

© 2015 McDonald’s Corporation Printed in 10/2015 Printed in

All Rights Reserved EM Model 366-155 The United States of America

Page 2

Warranty Statement

Silver King warrants to the original purchaser of Silver King refrigerated equipment that the equipment shall be free from

defects in material and workmanship under normal use and service as outlined in the Technical Manual. This limited

warranty shall apply for a period of two (2) years from the date of original purchase. The Compressor will carry an

additional three (3) year warranty. All warranties are subject to specific limitations outlined below.

This limited warranty does not apply to repair or replacement required as a result of carelessness, neglect and/or abuse,

including improper installation, incorrect voltage supply, tampering with or altering components and/or equipment or failure

to perform proper maintenance. Equipment damaged in transit, by fire, flood or an act of God is not covered. This limited

warranty does not include freight, handling, installation, labor (following the two (2) year labor warranty period) or other

incidental or consequential costs including product and/or economic loss. This limited warranty is in lieu of all other

warranties, express or implied, including those of merchantability, and is non-transferable.

Specific provisions of this limited warranty are as follows:

Two (2) Year Parts Warranty

Silver King warrants to the original purchaser of new Silver King equipment that such equipment and all parts

thereof will be free of defects in material and workmanship, under normal use and service, for a period of two (2)

years from the date of original purchase or 25 months from the date of shipment from the factory, whichever

comes first, subject to all terms and conditions herein.

This warranty is limited to repairing or replacing any parts that, at Silver King’s discretion, are deemed to be

defective within the time period covered by this warranty. The warranty does not cover freight or handling charges

incurred to replace such parts. Use of non-OEM parts may, at Silver King’s discretion, void this warranty. If

approved, warranty credit for non-OEM parts will be issued at the OEM cost.

Replacement parts sold separately are warranted for 90-days from date of purchase.

Five (5) Year Compressor Warranty

Silver King warrants to the original purchaser for a period of five (5) years from the date of original purchase or five (5) years

and one (1) month from the date of shipment from the factory, whichever comes first, that it will replace the compressor with

one of similar design and capacity, exclusive of delivery and installation charges, if it is found to Silver King’s satisfaction to

be inefficient or inoperative due to defects in material or factory workmanship. It is the owner’s responsibility to return the

serial plate of the defective compressor or at Silver King’s option the complete compressor, to the factory. Failure to do so

will void the warranty.

Two (2) Year Labor Warranty

Silver King warrants to the original purchaser for a period of two (2) years from the date of purchase or 25 months from the

date of shipment from the factory, whichever comes first, a limited service labor warranty on Silver King refrigerated

equipment subject to the following terms;

A factory issued Service Authorization Number must be obtained prior to work being performed under the labor warranty.

Call your supplier or Silver King. Claims submitted without a Service Authorization Number will be paid at Silver King’s

discretion.

The labor warranty includes standard straight time labor charges in accordance with Silver King’s Labor Warranty Guidelines

and reasonable travel time, as determined by Silver King.

The warranty does not cover original installation, startup, normal adjustments or maintenance. Normal adjustments and

maintenance include, but are not limited to; temperature control adjustments, temperature indicator calibrations, coil and fi lter

cleaning, condensate drain cleaning.

A second service call for a related failure is not covered.

Use of refrigerants other than specified on the equipment serial plate voids the warranty.

All claims must include; model and serial number of equipment, date of purchase, date of failure, and a copy of the service

invoice detailing the defect and service performed. No claim will be processed without this information. All claims must be

filed within 60 days from date of service.

SK-1 Cream Dispenser 2 Printed in USA 10/15

366-155

Page 3

Safety Information

General Precautions

WARNING

Risk of Electric Shock.

Always unplug the power cord before servicing the unit or

removing the back panel or front apron to avoid electric

shock.

Unit MUST be plugged into a 3-prong plug for grounding.

Cutting off the grounding spike on the power cord could result in electric shock to the operator during operation.

Unit must be plugged into a 15 or 20 ampere fuse- or breaker

-protected circuit. Use of a larger fuse or breaker could result

in damage to the unit and electric shock to the operator.

Moving or Handling Hot Parts.

Some parts may remain hot even after being unplugged.

Always use caution when servicing.

Possible Back Injury.

Assistance in moving this piece of equipment is strongly

recommended to avoid injury.

Always lift with your legs and not your back when lifting this

unit.

Electrical Specification

115V 60 Hz 1 Phase

Important

Prince Castle reserves the right to change specifications

and product design without notice. Such revisions do not

entitle the buyer to corresponding changes, improvements,

additions or replacements for previously purchased

equipment.

General

The SK-1 Cream Dispenser is designed to hold and

dispense bulk coffee cream. It will dispense three portion sizes

– 1 cream packet, 2 cream packets or 3 cream packets.

Indicates information important to the proper operation of the

unit. Failure to observe may result in damage to the equipment

and/or severe bodily injury or death

WARNING

CAUTION

Indicates information important to the operation of the unit. Failure

to observe may result in damage to the equipment

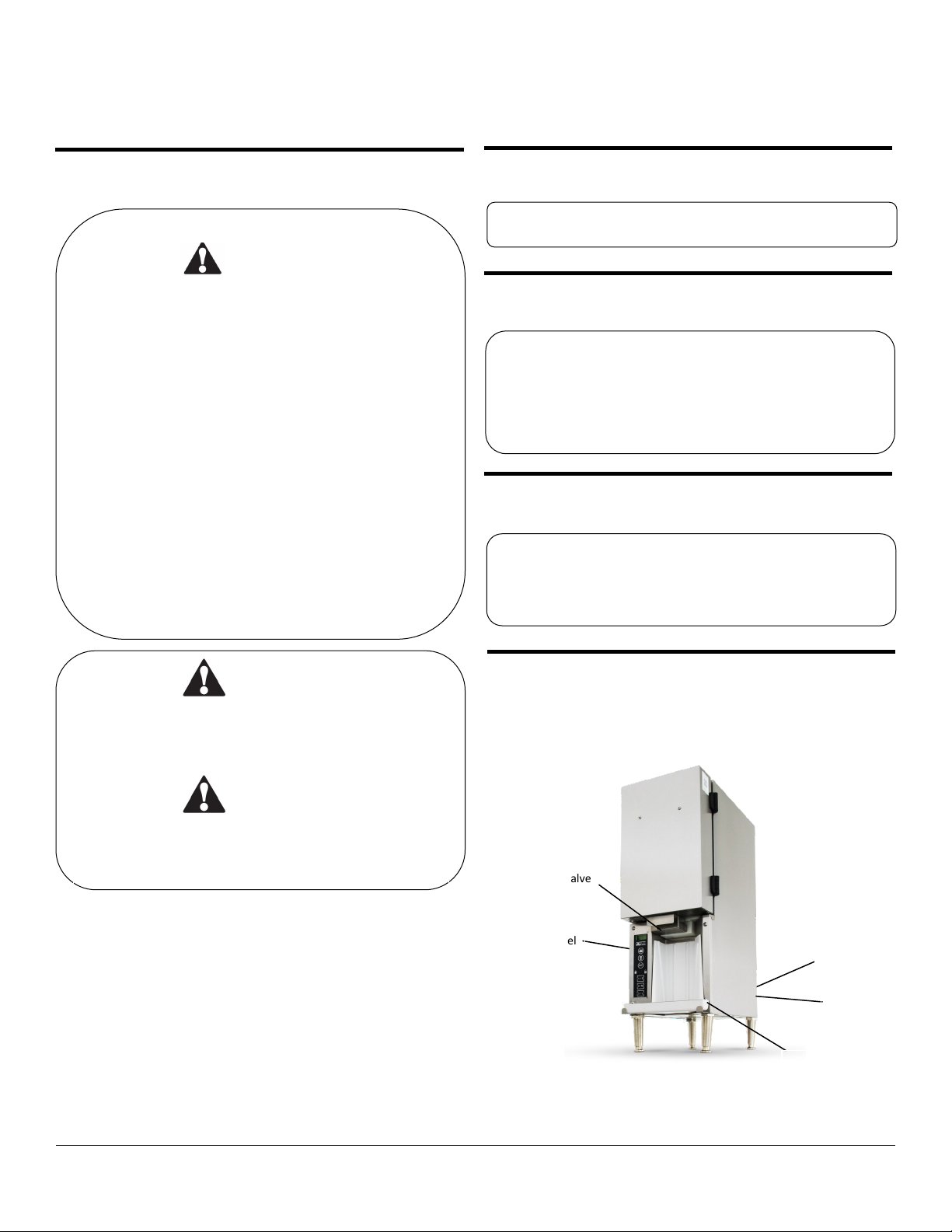

Product Identification

Product Valve

Control Panel

Power Switch

(on back side)

Power Cord

(on back side)

Drip Tray

SK-1 Cream Dispenser 3 Printed in USA 10/15

366-155

Page 4

Unpacking and Setup

1

2

3

Inspect for shipping damage. Examine the s hippi ng

container immediately upon receipt. Any damage to the

container or equipment due to shipping should be reported to the transportation company immediately.

Claims should be filed within 24 hours. Shipping damage is not the responsibility of Prince Castle nor

its Silver King division.

Unpack the unit. Take care wi th box cut ters or other sharp instruments not to nick the equipment when

opening the shipping container.

Carefully remove the unit from the shipping box. Be

sure to follow any orientation or caution labels on the

box.

Plan the unit’s location. When lo cati ng t hi s un it,

convenience and accessibility are important considerations, but the following factors must be observed:

Proximity to a 3-prong 110 VAC receptacle for

grounding (see Step 4).

When placing the unit on a counter, the counter

must be able to support a minimum of 100 lbs. (45

kg).

When placed on a counter, the unit must be on the

legs supplied. If the legs are removed, the unit will

not operate properly and the warranty will be void.

There must be at least 4" (10.2 cm) of space

above, on the sides and behind the unit and open

in front.

Correct serving height is important so that it can

be operated properly.

The unit must be level. The legs are adjustable to

aid in leveling the unit.

Avoid placing the unit next to an oven, heating

element or hot air source which would affect the

performance of the unit.

4

The power cord comes with a 3-prong plug for

grounding purposes. Any attempt to cut off this

grounding spike or to connect to an ungrounded

adapter plug could result in serious injury, will

void the warranty and terminates the

manufacturer’s responsibility.

Meet electrical requirements. Prior t o conn ecting

the unit to power, be sure to check the data plate located on the end panel of the cabinet for required voltage.

The specifications on the data plate supersede any

information contained in this manual.

The standard unit is equipped with a seven (7) foot

power cord that requires a 115 Volt, 60 Cycle, 1

Phase, properly grounded electrical receptacle,

protected with a 15 or 20 ampere fuse or breaker.

WARNING

SK-1 Cream Dispenser 4 Printed in USA 10/15

366-155

Page 5

Installation

WARNING

To avoid injury, it is recommended that the

unit be moved by two people

Locate the Unit. Move the u nit to its mount ing

1

location.

Install the four legs underneath the unit. The dis-

2

penser is shipped without legs attached. To install

them, carefully tilt the unit and thread the legs into the

four corner holes on the bottom of the dispenser.

Level the Unit. In or der for the uni t to fu nct ion

3

properly, level the unit front to back and side to side.

Adjust the legs to level the unit.

Connect the unit to power. Plug in the pow er c ord

5

on the back of the unit, at the left rear. Run the cord

along the rear of the shelf and plug it into the designated outlet.

The power cord comes with a 3-prong plug for grounding pur-

poses. Any aempt to cut o this grounding spike or to connect

to an ungrounded adapter plug could result in serious injury,

will void the warranty and terminates the manufacturer’s

responsibility.

After installation and assembly and before the unit goes into

service, it must be cleaned and sanitized

WARNING

IMPORTANT

Install the drip tray and drip tray cover

4

SK-1 Cream Dispenser 5 Printed in USA 10/15

366-155

Page 6

Initial Cleaning and Sanitizing Initial Start-Up

1

2

3

4

Make sure that the

switch on the back

of the unit is in the

“off position”. The

indicator panel should

be unlit

Wash the surfaces of the unit with warm, soapy

water.

Rinse the surfaces with warm water.

Turn the valve

insert. Pull and

turn valve to expose cold block.

Power Switch

1

2

3

Place the switch on

the back of the unit in

the “on” position. The

indicator panel should

display the current unit

temperature.

Allow the unit to run a minimum of two hours before loading it with product.

Note: It is completely normal for the exterior of the unit

to feel warm while it is running.

Load cream into the cream dispenser. Once the

unit has achieved proper operating temperature,

observe the procedures noted in the label on the

door liner for loading cream in the cream dispenser

Clean the valve and valve area. Use a brush and warm,

5

soapy water to clean the valve. Clean the valve area of the

dispenser with a brush and warm, soapy water. Rinse with

warm water.

Sanitize the valve and valve area. Wit h an appr oved

6

sanitizing solution, thoroughly clean the valve and valve

area. Allow to air dry.

SK-1 Cream Dispenser 6 Printed in USA 10/15

366-155

Page 7

Operation—General Operation—Dispensing Cream

1

Indicator Panel — The in di cato r panel contain s

a digital LED display that reads the product temperature during normal operation

Drink Selection Buttons– The thr ee upp er buttons on the indicator panel are for selecting types

of drinks (Hot, Iced, Special)

Lock Button— Used t o lock butto ns o n touch

panel, and prevent any unwanted dispenses.

Size Buttons– The th ree lower bu ttons on t he

indicator panel are for selecting portion sizes (One

Shot, Two Shots, Three Shots)

Indicator Panel

Hot Drink Selection

Iced Drink Selection

Special Drink Selection

Lock Button

One Shot

Two Shots

Three Shots

1

2

3

Place the drink under the dispensing tube.

Select the Type of

Drink. Press t he

proper drink selection

button to dispense the

correct amount of

cream. The Hot Drink

Selection button is

selected by default if

no button is pressed.

Select the size. Press

the proper drink size

button to dispense the

correct amount of cream.

NOTE: The end of the

tube may need to be

cleaned daily with a

clean cloth to prevent

buildup which could affect the dispensing of the

correct amount of cream.

SK-1 Cream Dispenser 7 Printed in USA 10/15

366-155

Page 8

Operational Flowchart

SK-1 Cream Dispenser 8 Printed in USA 10/15

366-155

Page 9

Manager Mode Flowchart

SK-1 Cream Dispenser 9 Printed in USA 10/15

366-155

Page 10

Cleaning the Dispenser

Tools and Supplies Required

1

2

Bucket, Clean and

Sanitized Towels

Turn the Creamer off

and remove empty

creamer bag. Pull and

turn valve to release

cream tube. Remove

the cream bag from the

compartment

Clean drip tray.

Take the drip tray

to 3 compartment

sink to wash,

rinse, and sanitize

Bucket, Soiled

Towels

Gastro norm Metal

Pan

Gloves, Neoprene McD All Purpose

Wipe down creamer once it has defrosted com-

3

pletely. Wipe down the col d bloc k and insid e of

creamer with APSC and Sanitizer Solution.

Refill Creamer. In-

4

sert a new bag of

cream into dispenser.

Pull and turn valve to

secure cream tube.

Replace the drip tray.

Super Concentrate

(APSC) solution

SK-1 Cream Dispenser 10 Printed in USA 10/15

366-155

Page 11

Troubleshooting Steps

Master Display Messages

PROBLEM PROBABLE CAUSE SOLUTION

Compressor will not run No Voltage at wall receptacle Check circuit breaker or fuse

Service cord pulled out of wall receptacle Call for service (888-375-2938).

Low voltage causing compressor to cycle on

overload

Power switch is in “Off” position Turn switch on

Inoperative Control Call for service (888-375-2938).

Compressor stuck Call for service (888-375-2938).

Compressor windings open Call for service (888-375-2938).

Compressor overload stuck open Call for service (888-375-2938).

Relay lead loose Call for service (888-375-2938).

Relay loose or inoperative Call for service (888-375-2938).

Power cord disconnected from dispenser Call for service (888-375-2938).

Faulty cabinet wiring Call for service (888-375-2938).

Compressor runs but no refrigeration System out of refrigerant Call for service (888-375-2938).

Compressor not pumping Call for service (888-375-2938).

Restricted filter drier Call for service (888-375-2938).

Restricted capillary tube Call for service (888-375-2938).

Moisture in system Call for service (888-375-2938).

Compressor short cycles Erratic Control Thermostat Call for service (888-375-2938).

Low Voltage Contact power company and confirm that

Compressor draws excessive wattage Call for service (888-375-2938).

Faulty relay Call for service (888-375-2938).

Compressor runs too much or constantly Temperature too low Adjust temperature control

Erratic Control Call service technician

Abnormally high room temperature Reduce room temperature or relocate dis-

Door or lid gaskets not sealing Adjust or Call for service (888-375-2938).

System undercharged due to leaks Call for service (888-375-2938).

System undercharged from factory Call for service (888-375-2938).

System overcharged Call for service (888-375-2938).

Contact power company and confirm that

voltage fluctuation does not exceed 10%

plus or minus from the nominal rating.

voltage fluctuation does not exceed 10%

plus or minus from the nominal rating.

penser

System not clean Call for service (888-375-2938).

Restricted filter drier Call for service (888-375-2938).

Restricted capillary tube Call for service (888-375-2938).

SK-1 Cream Dispenser 11 Printed in USA 10/15

366-155

Page 12

Troubleshooting Steps (Continued)

Master Display Messages

PROBLEM PROBABLE CAUSE SOLUTION

Noisy Tubing Vibrates Call for service (888-375-2938).

Internal compressor noise Call for service (888-375-2938).

Compressor vibrating on cabinet frame Call for service (888-375-2938).

Beverage leaking or not flowing Tube Kinked Remove valve and pull tube straight through

valve area.

Valve stuck Clean valve and valve area or call for

service (888-375-2938).

SK-1 Cream Dispenser 12 Printed in USA 10/15

366-155

Page 13

Parts List and Exploded View

Item Part Number Description Qty

1 366-124S ASSY DOOR SKMCD1P 1

2 31126S GSKT DOOR 1

3 25226S HINGE W/SCREWS & COVERS 2

4 25473S COMPR 115V/60HZ EM20HHR 1

5 30876S ASSY EXCHNGR HEAT 1

6 26378 SWITCH ROCKER 115V/230V 1

7 35826

8 20481P GROMMET MTG COMPR LONG 4

9 98106P CLIP HAIRPIN 4

10 22401P WASHER MOUNT COMPR 4

11 37133S ASSY VALVE PLUNGER 1

12 366-132S ASSY RACK SOLENOID 1

13 24048S

14 24050S

MODULE POWER ENTRY 115V

(W/1 FUSE)

LABEL CAUTION HAZARDOUS

MOVING

LABEL ELECTRIC SHOCK HAZ-

ARD

1

1

1

Item Part Number Description Qty

15 366-135S POWER SUPPLY ASSY 1

16 366-139S ASSY APRON 1

17 366-142S ASSY TRAY, DRIP - CREAMER 1

18 366-151S

19 366-137S ELECTRONICS ASSEMBLY 1

20 366-144S LOAD CELL ASSY 1

21 10314-89 LEG 4" NP FLG FOOT 1

22 24904S TUBE WELL GUARD 1

23 37364S PROBE TEMP SKBD3LS 1

24 33883 CORDSET 115V 1

25 37358S ERGONOMICS PLUG 1" DIA. 1

26 366-149S BAG GUARD **(NOT SHOWN)** 1

CONTAINER CREAM PLASTIC

SINGLE

1

SK-1 Cream Dispenser 13 Printed in USA 10/15

366-155

Page 14

Wiring Diagram

SK-1 Cream Dispenser 14 Printed in USA 10/15

366-155

Loading...

Loading...