Silverado BST-380 User Manual

User's Guide of BST-380 Battery System Tester

1 / 29

Congratulations on your purchase of the Silverado BST-380 Battery System Tester.Due to

the product upgrade, tiny difference between the user manual and the device will not be

further noticed. Take the device as standard. Proper use and care of this meter will

provide many years of reliable service.

BST-380 Battery System Tester

User's Guide

User's Guide of BST-380 Battery System Tester

2 / 29

CONTENT

CHAPTER 1 PRODUCT SUMMARY 4

1.1 PRODUCT PROFILE 4

1.2 PRODUCT FUNCTION 5

1.3 TECHNICAL PARAMETER: 6

1.4 WORKING ENVIORNMENT REQUIREMENT 6

CHAPTER 2 TESTER STRUCTURE 7

CHAPTER 3 OPERATION 8

3.1 PRE-TEST 8

3.1.1 CONNECT TESTER 8

3.1.2 KEY DESCRIPTION 8

3.1.3 CONNECT CURRENT CLAMP 9

3.2 TESTER STARTUP 10

3.3 BATTERY TEST 11

3.3.1 IN-VEHICLE OR OUT-OF-VEHICLE 11

3.3.2 SELECT BATTERY CHARGE STATE 12

3.3.3 SELECT BATTERY TYPE 13

3.3.4 BATTERY SYSTEM STANDARD AND RATING 14

3.3.5 BATTERY TEST RESULT 14

3.4 CRANKING TEST 17

3.5 CHARGING SYSTEM AND RECTIFIER DIODE TEST 18

3.6 CLIENT NUMBER INPUT 20

3.7 24V SYSTEM TEST 21

3.8 ADDITIONAL FUNCTION 21

3.8.1 VIEW RESULTS 22

3.8.2 PRINT RESULTS 22

3.8.3 VOLTMETER 23

3.8.4 AMMETER 23

3.8.5 THERMOMETER 23

3.8.6 THERMOMETER UNIT CHOICE 23

3.8.7 QC MODE 24

3.8.8 LICENSE PLATE NUMBER INPUT FUNCTION 23

3.8.9 SET LANGUAGE 24

3.8.10 SET DATE AND TIME FORMAT 24

3.8.11 DATE AND TIME ADJUSTMENT 25

3.8.12 SET USER INFOMARTION 26

3.8.13 SCREEN LIGHT ADJUSTMENT 26

3.8.14 SET PRINTER DEFINITION 26

User's Guide of BST-380 Battery System Tester

3 / 29

3.8.15 STANDBY POWER FUNCTION 28

CHAPTER 4 DAILY MAINTENANCE 28

4.1 ELIMINATE COMMON FAULT 28

4.1.1 SCREEN NOT LIGHT 28

4.1.2 PRINTER COMMON FAULT 28

4.1.3 CURRENT CLAMP COMMON FAULT 28

4.2 REPLACE INTERNAL BATTERY 28

CHAPTER 5 WARRANTY CLAUSE 29

User's Guide of BST-380 Battery System Tester

4 / 29

Chapter 1 : Product Summary

1.1 Product Profile

BST-380 Battery System Tester adopts currently the world's most advanced

conductance testing technology to easily, quickly and accurately measure the

actual cold cranking amps capability of the vehicle starting battery, healthy

state of the battery itself, and common fault of the vehicle starting system and

charging system, which can help maintenance personnel to find the problem

quickly and accurately, thus to achieve quick vehicle repair.

1. Test all automotive cranking lead acid battery, including ordinary lead acid

battery, AGM flat plate battery, AGM spiral battery, and Gel battery, EFB

battery etc.

2. Directly detect bad cell battery.

3. Polarity reverse connection protection, reverse connection will not damage

the tester or affect the vehicle and battery.

4. Directly test the battery with loss of electricity, no need to full charge before

testing.

5. Testing standards include currently the world's majority of battery

standards, CCA, BCI, CA, MCA, JIS, DIN, IEC, EN, SAE, GB.

6. Support multi-languages, customer can select different language package,

which includes: Chinese Simple, Chinese Traditional, English, Japanese,

Russian, Spanish, French, Italian, German, etc. Other languages can also

be customized according to user's need.

7. With common additional functions, such as voltmeter, ammeter,

thermometer, even as standby power for ECU.

8. Store 100 groups of test data for check and print.

User's Guide of BST-380 Battery System Tester

5 / 29

1.2 Product Function

Main functions of BST-380 Battery System Tester include: battery test,

cranking test, charging test and other additional functions.

Battery test is mainly targeted to analyze the battery healthy status to

calculate the actual cold cranking capability of the battery and the aging extent,

which provide reliable analysis evidence for the test and maintenance of the

battery.It notifies the user to replace battery in advance when the battery is

getting aged.

Cranking test is mainly to test and analyze the starting motor. Through

testing the actual required cranking current and cranking voltage of the starting

motor, it can find out whether the starting motor works fine.There are several

reasons why the starting motor is abnormal: lubricating system fault causing

the starting loaded torque increasing or rotor friction of the starting motor

causing the increasing friction of the starting motor itself.

Charging test is to check and analyze the charging system, including

generator, rectifier, rectifier diode, etc., thus to find out whether the output

voltage of the generator is normal, the rectifier diode works fine and the

charging current is normal.Suppose one of the above mentioned parts is not in

normal situation, it will lead to over charge or incomplete charge of the battery,

thus the battery will be quickly damaged and also greatly shorten the using life

of other loaded electrical appliance.

Additional functions include:

View test result, print test result, voltmeter, ammeter, thermometer and

temperature compensation, thermometer unit choice, QC mode, client code

setting, set language, set date and time format, date and time adjustment, set

user info, screen light adjustment, set printer definition, standby power

function.

User's Guide of BST-380 Battery System Tester

6 / 29

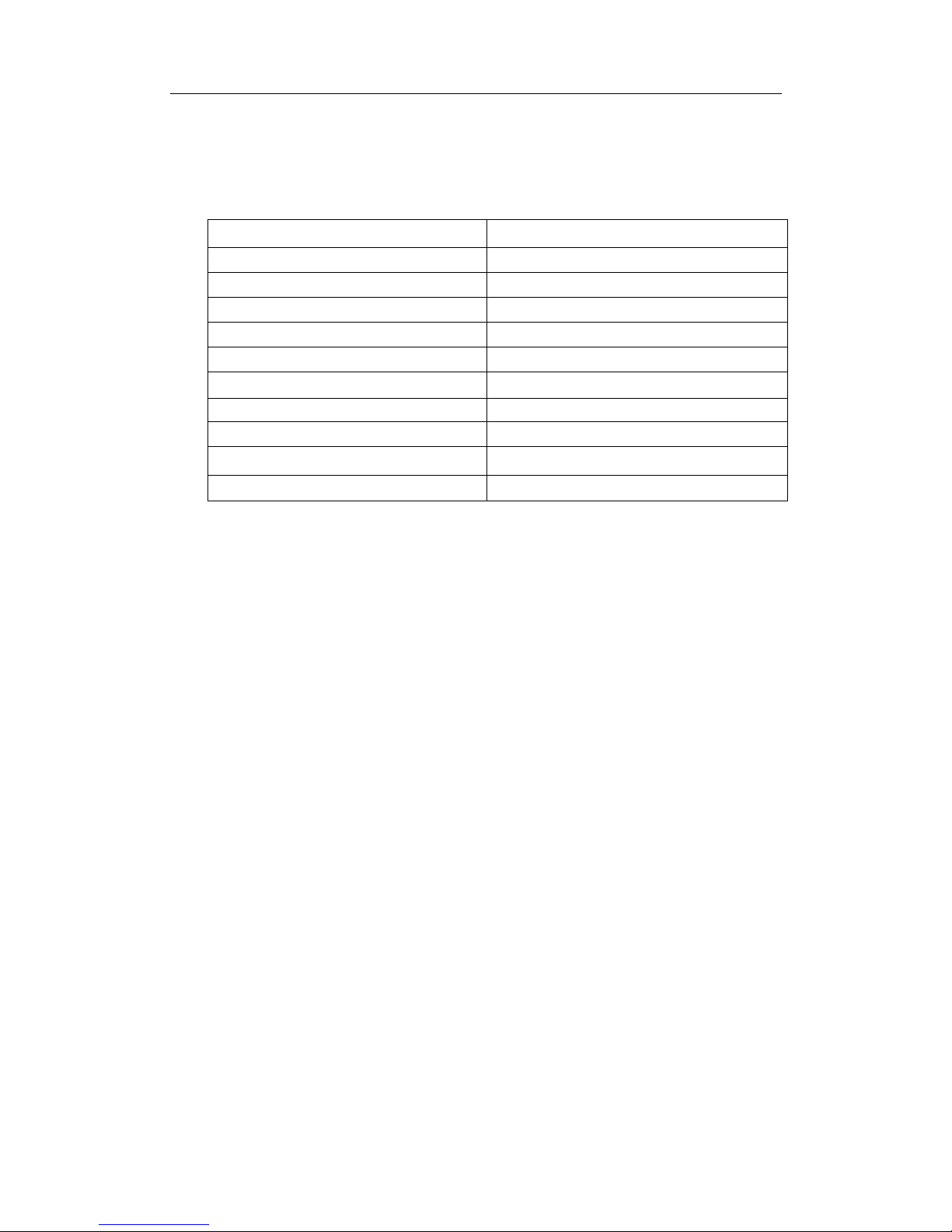

1.3 Technical Parameter

1) Cold Cranking Amps Measure Range:

Measure Standard

Measure Range

CCA

100-2000

BCI

100-2000

CA

100-2000

MCA

100-2000

JIS

26A17--245H52

DIN

100-1400

IEC

100-1400

EN

100-1400

SAE

100-2000

GB

100-1400

2) Voltage Measure Range:1.0-30VDC.

3) Current Measure Range:0-900A DC/AC.

4) Temperature Measure Range:-18°C - +70°C.

1.4 Working Enviornment Requirement

Working Environment Temp.: -20°C-60°C

It is applicable for automotive manufacturers, automotive maintenance and

repair workshops, automotive battery factories, automotive battery distributors,

and educational organizations, etc.

User's Guide of BST-380 Battery System Tester

7 / 29

Chapter 2: Tester Structure

BST-380 mainly consists of battery tester main unit, testing cables and

current clamp.

BST-380 Battery System Tester main unit cover is made of ABS

acid-resistant plastic.

Removable testing cables

Removable current clamp meter

User's Guide of BST-380 Battery System Tester

8 / 29

Chapter 3: Operation Procedure

3.1 Pre-Test

3.1.1 Connect Tester

● Before test, clean battery poles with metal wire brush and alkaline cleaner

to avoid the tolerance caused by oil and dust to the test result.

● For Group 31 or side-installed battery, connect and fix the terminal wiring

connector. Otherwise, inaccurate test result will be caused due to wrong

installation or dirty or bad wiring connectors.

● While testing, ensure none of the in-vehicle electrical appliance is on,

doors are closed and the ignition key is in OFF status.

● Connect the red test clamp with battery anode and the black test clamp

with cathode.

Shake the clamps back and forth to make sure they are well connected.

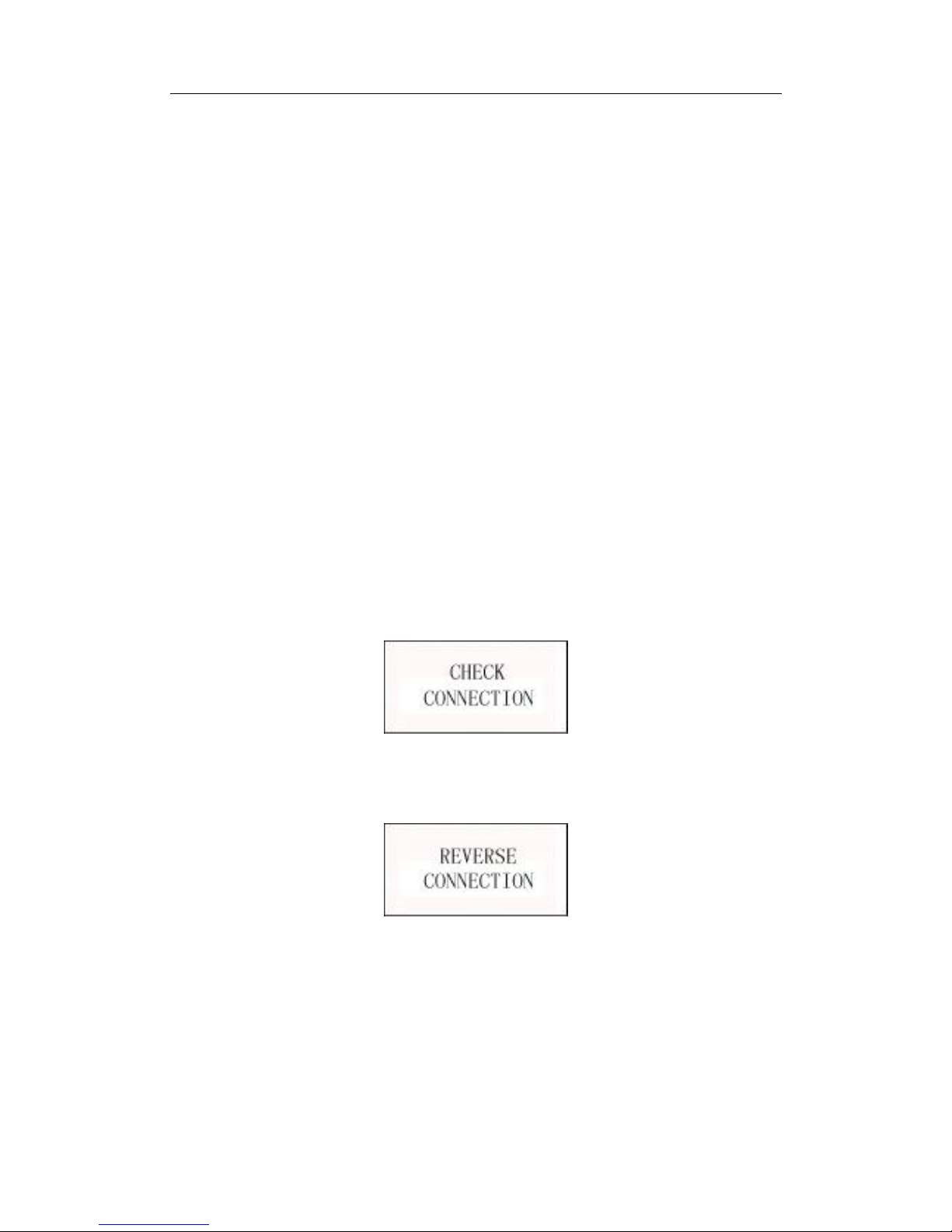

Tester requires the two clamps are well connected with the battery poles,

otherwise, the test cannot go on. When enter the battery test program, screen

prompts "Check Connection" (See below picture).Do clean the poles and

re-connect in the right way.

Tester has reverse connection protection function. When clamps are

reversely connected, tester will prompt "Reverse Connection" (See below

picture), but it damages neither the tester nor the automotive load.

NOTE: For parallel connected batteries, break off the cathode connection first,

then do single test to each battery.Suppose cathode connection is not cut off,

there will be error in test result.

User's Guide of BST-380 Battery System Tester

9 / 29

3.1.2 Key Description

● Up and Down keys

Select upwards or downwards via white UP and DOWN keys.

● Return key

Return to previous menu via blue RETURN key.

● OK key

Confirm the selection via green OK key

● MENU key

Enter additional function program via MENU key.

● Power key

Turn on/off the tester.(Refer to 3.2 Tester Startup)

Loading...

Loading...