Silicon Valley Computer SHUGART 706, SHUGART 712 Reference Manual

...•..

~

..:,.,..'

...

~

~

REFERENCE

MANUAL

SHUGART

706/712

HARD

DISK

Silicon

Valley

Computer

.'.

( 40 8) 28 8- 88 37

.I

-

~

-

~

-

"

-

~

-

.~

-

~

-

,~

-

~

:

.~

-

-,

i

••

'.

:

~

..

..

.

•

••

·

~

•

•

..

j

..

~.

-

..

I!I

..

-.

.

.

'.

•

'f8

,

t

TABLE OF CONTENTS

Page

TABLE

OF

CO~S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ill

UST

OF

AGURES

vi

UST

OF

TABLES

vii

ABBREVlA

llONS/MNEMONlCS

viii

NOTICE

TO

USERS

viii

PRODUCTION

DESCRIPTION

SECTION

I

~ODUCT10N

1:1

1.1

Purpose..........................................................

I-I

1.2 General

Description

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1·1

1.3

Specifications

Summmy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-2

1.3.1

Perfonnanc~

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-2

1.3.2

Functional

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-2

1.3.3

Physical

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-2

1.3.4

Reliabtlrty

Specifications

. . . . . . . . .

..

1-3

1.4

Functional

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1·3

1.4.1

General

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1·3

1.4.2

Read/Write

and

Control Electronics 1-4

1.4.3

Drive

Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-4

1.4.4

Positioning

Mechanism.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-4

1.4.5

R~d/Write'Heads

and

Disk(s)

'

'.

. . . .

..

1-4

1.4.6

A1r

Altration

System.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-4

1.4.7

Spindle Lock and

Brake.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-6

1.4.8

R~d/Write

Head

Shipping

Zone.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-6

1.5 Functional Operations . . . . . . . . . . . . . . . . . . . . . . . .

..

1-6

1.5.1

Power

Sequendng

1-6

1.5.2

Drive

Selection

1-6

1.5.3

Track

Accessing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-7

1.5.4

Read

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-8

1.5.5

Write

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-8

1.5.6 Head

Selection

1·8

SECTION

n

ElECI'R.lCAL

OOERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-1

2.1 Introduction

2-1

2.2

Control

Input

Unes

2-2

2.2.1

Drive

Select

1-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-4

2.2.2

Direction

In

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-4

2.2.3

Step.......................................................

2-4

2.2.4

Head

Select

~

and

2'

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-5

2.2.5

Write

Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-6

2.2.6

Reduced Write Current and Precompensation

2-6

2.3

Control

O\Jtput

Unes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-6

2.3.1

Tr&ek

00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-6

2.3.2

Index......................................................

2-6

2.3.3

Ready......................................................

2-6

Ul

TABLE OF CONTENTS (CONT.)

2.3.4

Wrtte Fault .

2.3.5

Seek

Complete

· · · · · · · · · · · · · ·

..

· . · · · . · · · · · · .

2.4

Data Transfer

Unes

·

..

· . · · · · . ·

..

· · · . ·

..

· ·

2.4.1

~

Write

Data .

2.4.2

~

Read

Data .

2.5

Select Status · · · · · · · · . · · · ·

2.6

GeneralTiming

ReqUirements

.................•.....••••..•............

2.7

Power Interface · · . · . · · · · · . ·

2.8

Frame Grounding · · · · · · · · · · · · · . · . ·

SECTION III PHYSICALINTERFACE .

3.1

Introduction .

3.2

Jl!Pl

Connection · · . · · ·

..

· · · · · . · ·

3.3

J5/P5

Connection · · . · · . ·

..

· ·

3.4

J6/P6

Connection · ·

..

· · · · · ·

..

· · · · · · · · · ·

SECTION

IV

PHYSICAL

SPECIACAll0NS

.

4.1

Mechanical

Dimensions

· ' · . · · · · ·

4.2

Mounting .

SECTION

V

MEDlA DEFECTS

AND

ERRORS .

5.1

Error Mapping

and

Qualification .

5.1.1

Cause.s

of

Errors

.

5.1.2

Error Definition

.................................•.............

5.1.3 Media

Defed

Definition .

5.1.4

Error Map .

5.1.5 User

Error

Mapping .

5.2

Error Acceptance

Criteria .

5.3

System Generated

Errors .

SECTION VI RECORDING FORMAT .

6.1 Track Fonnat .

6.2

Gap

Length Calculations

I• • "

•••••••••••••••••••••

~

••••••••••••

~

•••••

"

••••

6.2.1 Gap 1 .

~

.

6.2.2

Gap 2 .

6.2.3 Gap 3

£

•••••••••

~

•••••••••••••••••••••••••••

6.2.4 Gap 4 .

. 6.3 Write

?recompensation

.

SECTION VII CUSTOMERINST

AllABLE

OPTIONS .

7.1

FuU-Height Faceplate

Kit .

7.2

Low-Power

Slow

Start

Jumper

.

)

2-7

2-7

2-7

2-8

2-8

2-8

2-8

2-9

2·9

3-1

3-1

3-1

3-2

3-2

4-1

4-1

4-2

5-1

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-2

6-1

6-1

6-1

6-1

6-2

6-2

6-2

6-2

7-1

7-1

7-2

OPERATIONS

DESCRIPTIONS

SECTION VIII

niEORY

OFOPERA

nONS

8-1

8.1

Introduction

.•••••.•...•........•.•.•••••••••.•.....•.••...........

8-1

8.2

High

Priority

Critical Tasks (Foreground)

8-2

8.2.1

Foreground

Loop

Control

8-2

8.2.2

Spindle MotorForeground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-2

8.2.3

Motor

Fault Foreground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-2

8.2.4 Step

Input

Buffering Function . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-2

8.2.5 Stepper

Damping Time

Out

Routine . . . . . . . .

..

. . . . . . . . . . . . . . . . . . . .

..

8-2

8.2.6

Seek

Function

Foreground.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-3 )

8.2.7

Foreground End

and

Interrupt Return . . . . . . . . . . . . . . . . . . . .

..

8-4

8.3

Lesser

Priority

Critical Tasks (Background) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-4

8.3.1

System Startup Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-5

8.3.2

Spindle Motor

InltializZltion

.....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-5

tv

TABLE OF CONTENTS (CONT.)

8.3.3

Microprocessor

Control

Fault indicator Function · . . . . . . . . . . . . . . ...8-7

8.3.4 .Seek

Function

lnitiallzZltion

· . · · · . ·

~

. . . . . . . . . ...8-7

8.3.5

Inttialize

Code End · . . . . . . . . . . . . . . . . . ...8-7

8.3.6 Spindle

Motor

Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-7

8.3.7

Motor

Status Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-7

8.3.8 Warm-up

Settling

Extension

Countdown · . . . . . . . . . . . . . . . . . .

..

8-7

8.3.9 System

Background

Loop

Control

8-8

8.3.10

Loss

of Index Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

~8

8.3.11

CyUnder

Address

Rezero Monitor

8-8

8.3.12 Seek

Ramping

Calculate

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-8

8.3.13

Drive

Actuator

Self-exerdse

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-8

8.3.14 Actuator Lube Unstick Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-8

8.3.15 Automatic Actuator Reset to Track

Zero

(Recal Function) 8-8

8.3.16

Write Current Control Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-9

8.3.17

Drive

Select

LED

Monitor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-9

8.3.18

Background Code End '. . . . . . . . . . . . . . . . . . . . .

..

8-9

8.4

System

Initialization

Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-9

SEcnONIX PACKAGING INSTRUcnONS

9-1

9.1

Uncrating.........................................................

9-1

9.2

Recommended

Receiving

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-1

9.2.1

Packaging and

Identification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-1

9.2.2 Mechanicallnspeetion

9-1

9.2.3 FunctionalTesting

,.

. . . . . . . . . . . . . . . . . .

..

94

9.3

Packing

for

Reshipping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

9-4

,

SEcnON

X DRIVE INTERCONNECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-1

SERVICING INFORMATION

SEcnONXI

SPAREPARTS

11-1

11.1

Routine

Order Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1

11.2 Emergency Order

Entry

' '

,.11-1

SEcnON VII

MAINl"'ENANCE

12-1

12.1 Introduction

12-1

12.2 Maintenance Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-1

12.3 Diagnostic Techniques

12-1

12.4 Test Point Locations

12-1

12.5

Troubleshooting

12-1

12.6 Checks and Adjustments

12-2

12.7 Removal and Replacement Procedures

12-4

12.7.1 RemovalofControl PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-4

12.7.2 ReplacementofControl PCB

12-4

12.8 Alignment Procedures

12-5

12.9 Preventive Maintenance

12-5

SEcnON

XIII

ILLUSTRATED

PARTS

CATAlOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-1

13.1

De-scription.......................................................

13-1

13.2

Indented Level

13-1

13.3

Quantityper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

13.4 Recommended Spare Parts Stocking Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

t

SEcnON

XN

SCHEMATIC DIAGRAMS

14-1

APPENDICES

APPENDIX

A ORDERING INFORMATION

A·l

v

Figure

Title

LIST OF FIGURES

Page

)

I-I

Shugart 706/712 Rigid Disk Storage Drive 0

••0••••

0••0

•••••••••••••••

0............

I-a

1-2

Read/Write

Head

Positioning Mechanism 0

•••

0 • • • • • • • • • • • • • •

••

1-5

1-3

AIr Filtration System · 0 • 0

•••••••••••

0

••••

0 • 0

•••••

0 0

••••••

0

•••

0 • • • • • • • • • • • • • •

••

1-5

1-4 Spindle Lock

0

•••••••••••••

0 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

••

1-6

1-5

Shipping

Zone

0 • •

••••

0 • • • • • • • • • • • • • • • • •

••

1-

7

2-1 J51nterface

andJlPower

Connections.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-1

2-2 J61nterface

Connection

0 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

••

2-2

2-3 Control Input Driver/Receiver Combination 2-3

2-4

Jumper

Locations

....

0••0

•••

•

••••••••••

0

•••••

0••0 0

••••••••••

0 • • • • • • • • • • • • •

••

2-3

2-5 Normal

Step

Mode

..

0 0 0

••••••••••••••••••••••••

0 0 • • • • • • • • • • • • • • • • • • • • • • • • •

••

2-4

2-6

Buffered

Step

Mode . 0

••••••••••••

0

•••••••

0 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

••

2-5

2-

7

Head

Selection Timing

o.

0

••••

0 • 0 0••0••0 • 0

••••••••

0 0

•••

0

•••••••

0

•••••••

0 • • • •

••

2-5

2-8

IndexTiming. 0

•••

0

•••••••

0

•••••••••

0

•••0••••

0

••••••••

0 • • • • • • • • • • • • • • • • • • •

••

2-6

2-9 Data Transfer Line Driver/Receiver Combination

...

0 • 0

••••

0

••••

0

•••••

0 0 • • • • • • • • • •

••

2-

7

2-10

MFM

Read/Write

Data Timing

....

0 0 0••0 0

••••••

0••0

••••••••

0

•••

0

••••

0 • • • • • • • •

••

2-8

2-11 General Control Timing Requirement

0

••••••••••••

0

•••0•••••••

0 • • • • • • • • • • • • • • • •

••

2-9

3-1

Interface

Connector

Locations 0 • 0

••0•••••

0 • 0

••••••••••••••

0 • 0••0 • • • • • • • • • • •

••

3-1

3-2

Jl

Connector

0

•••••••••••

0 • • • • • • • • • • • • • • • • • • • • • • • • • •

••

3-1

3-3

J5

Connector

Dimensions

0.0

••••••••••••••••••

0

••••••••••••

" 3-2

3-4

J6

Connector

Dimensions 0

•••

0

••••••

0

••••••••

0 0

•••••••••••••••••

'.

• • • • • • • • • • •

••

3-2

4-1 Mounting Dimensions

~

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-1

6-1

Track Format 6·1

7

-1

Full-Height Faceplate

Kit.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7·1

7-2

Low

Power

Option (Early Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-2

7-3

Jumper

Installation

and

Fabrication.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-2

8-1 Logic Diagram 0

••'.• • • • • • • • • • • •

••

8-1

8-2

Foreground Routines

Sequencing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-3

8-3

Background Routines

sequencing

0 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

••

8-6

9-1 Single Unit Packaging Configuration . '

~

..

0

•••••••

0

••••••••••

0 • • • • • • • • • • •

••

9-2

9-2 Ten Units Packaging Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

9-3

10-1 Multiple Drive Configuration 10-1

12-1 Locations Diagram 12-3

12-2

Removal/Replacement

of Control

PCB

12·4

13-1 Shugart

706/712

Assembly

13·2

13-2 Front Panel

and

Rail Assembly o

••••••••••••••••••••••••••••••••••••••••

13-3

14-1 Control

PCB

Schematic(2Sheets) 14-3

vii

2-1

Head

Select

(1

=

False. 0

=

True) · · · · · · · · . · . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-5

2-2

DC

Requirements · · ·

..

· · · . · . · · · · . · · · . · · - · · · . . . . . . . . . . . . . . . . .

..

2-9

6-1

Write Precompensation · · · · · · · . · · . · . · · . · · · · . . . . . . . . . . . . . . . . .

..

6-2

8-1

I/O

Port Configuration

..

· · . · · · · · · · · · · · · · · · · . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-4

8-2

LED

Fault

Codes. · · · · ·

..

· · · · · · · · · · · · · . . . . . . . . . . . . . . . .

..

8-

7

9-1 Print Parameters · · . · · . · · · · . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

9-4

9-2 Test Program

-.............................................................

9-4

12-1

PCB

Versus Drive Failures - 12-1

12-2 Inspection of the Drive

12-2

12-3 Signals Inspection 12-2

13-1 Shugart

706/712

Spare Parts Stocking Guide

13-4

A-I

Shugart

706/712

PSI

..

· ,

A·I

-

-

.

•

-

..

I

•

,

"

-

-,

I

-

....

-

t

•

-

.

•

-

.

-

•

-

-

~

-

"

-

-

a

-

-

..

-

-

-

•

-

-

-

~

-

•

-

-

••

-

•

..

-

.

•

-

..

-

••

-

-

...

-

...

-

-

-

;'.

-

-

~

.•

-

-

.:.

-

-

.~

-

.~

-

.~

-

-

~~

-

-

,~

-

-

I~

,

-

~

-

-

~

-

-

.~

Table

Tltl.

LIST

OF

TABLES

Page

ABBREVIATIONS/MNEMONICS

BKPC

Background Port C

MFM

Modified

FM

bpi

Bits per Inch

MLC

Machine

Language

Code

eRe

Cyclic

Redundancy

Check

PCB

Printed Circuit Bo.ard

0

Prompt Character

pp

Print Parameters

fel

Flux

Change

per

Inch

PWM

Pulse Width Modulation

10

Identification

RCFLG Recalibrate

Rag

I/O

Input/Output

R/W

Read/Write

IP

Inspect

Phase

SEL Select

LED

Light Emitting Diode

tpl

Tracks per Inch

LSI

Large

~ale

Integration

TRK

Track

NOTICE TO USERS

This manual, P/N39402-0,

supersedes,

replaces,

and

incorporates

the

OEM

manual.P/N

39252-1,

published

April.

1983.

and

further includes the Publication

Change

Notice No. 1

dated

August

18.

1983.

and

Publication

Change Notice

No.2

dated

February

20,

1984.

All

technical

changes

have

been

indicated with a

change

barinthe

text margin or a star symbol

in

the illustration. While every effort has

been

madetoensure

that the information pro-

vided herein

is

correct, please notify usinthe

eventofan

error or inconsistency. Direct

any

commentsonthe form

at the back of this

manual

to:

Shugart

Corporation

Technical Publications. MS

3-14

475

Oakmead

Parkway

Sunnyvale,

CA

94086

(U.S.A.)

Phone

(408)

737-7900

Shugart makes no representationsorwarranties with respect to

the

contents

hereof

and

specifically disclaims any

implied warranties of merchantability

or

fitness for

any

purpose.

Further, Shugart reserves

the

righttorevise this publication

and

to make

changes

from time to timeinthe contents

hereof without obligation

to

notify

any

person

of such revisions or changes.

The information contained herein

has

been

copyrighted by the Shugart Corporation.Noportionofthis document

can

be

duplicatedinany

form,orsold, without the express written

consentofShugart

Corporation.

Failure to com-

ply could entail legal action to

remedy

such violation.

viII

-

'"

- 3

}

:

.~

=

I~

:

·3

:

I~

::

;~

-~

3

..

~

.-

:3

:3

..

3

~

j

..

..

~

.,

:!

--

.~

~:

.'.

.:

.~~

: J

- -

-

~,

--:,

-

,~

,

t

SECTION I

INTRODUCTION

1.1 PURPOSE

This publication is

designedasa

reference

source

for

OEM

engineers.

system

Integrators. service

and

maintenance

technicians.

and

knowledgeable

end

users.Itis

assumed

that

the

reading

audience

is sufficiently

versedinthe state-

of-the-art

with

respecttorigid disk

drives

.

1.2

GENERAL

DESCRIPTION

The

Shugart

706/712

Disk Drives

are

random

access 5.25 inch (130

mm)

Winchester

storage

devices with

one

(706)ortwo (712)

non-removable

disksasstorage

media.

Ellch disk surface

employs

one

movable

head

to service I

320

data

tracks.

These

drive

are

available in half-height

or

fun

height configurations.

Low cost

and

high reliability

are

acheived

through

the

useofa

unique

rotary

band

actuator

design, a self-contained

microcomputer.

and

custom

LSI

circuitry.

The

706/712

interface is either

ST506orST412

compatible, allowing

easy

integration into existing systems. Some

of

the

key featuresofthis series

are

as

follows:

a.

Microprocessor-based

electronics.

b.

Three

custom

LSI devices

for

reliability.

c. BuUt-in diagnostics.

I d.

Jumper

selected

exercise routines.

e.

Dedicated

landing

zone.

f.

Single

track

seek

time is less

than

latency.

g.

Read/write

pre-amponhead

arm.

h.

3370

head

flexure design.

l. Brushless

dc

spindle motor.

j.

Winchester

design reliability In a half-heightorfun-height

package.

k.

Improved

shock

and

vibration characteristics.

1-1

...

-.

"----'

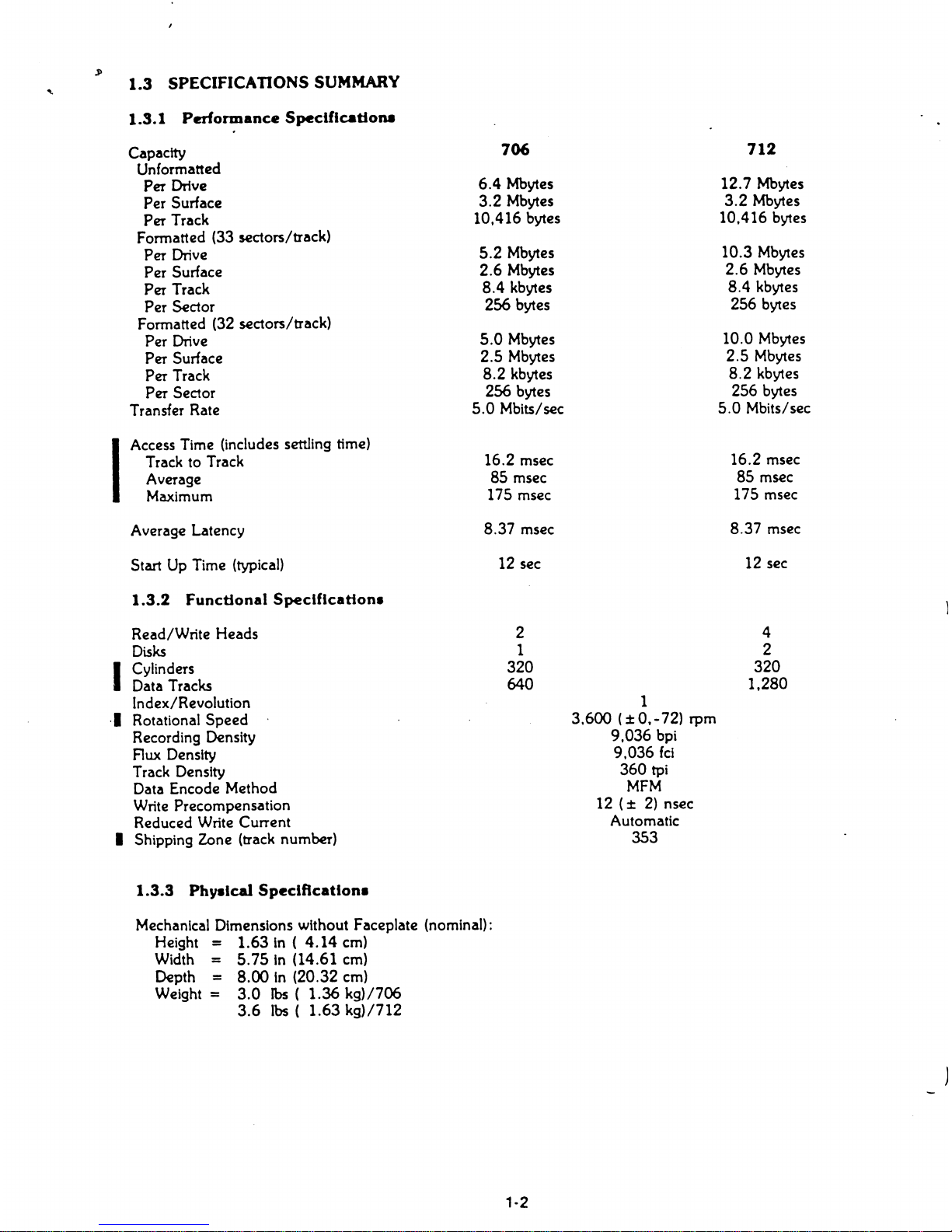

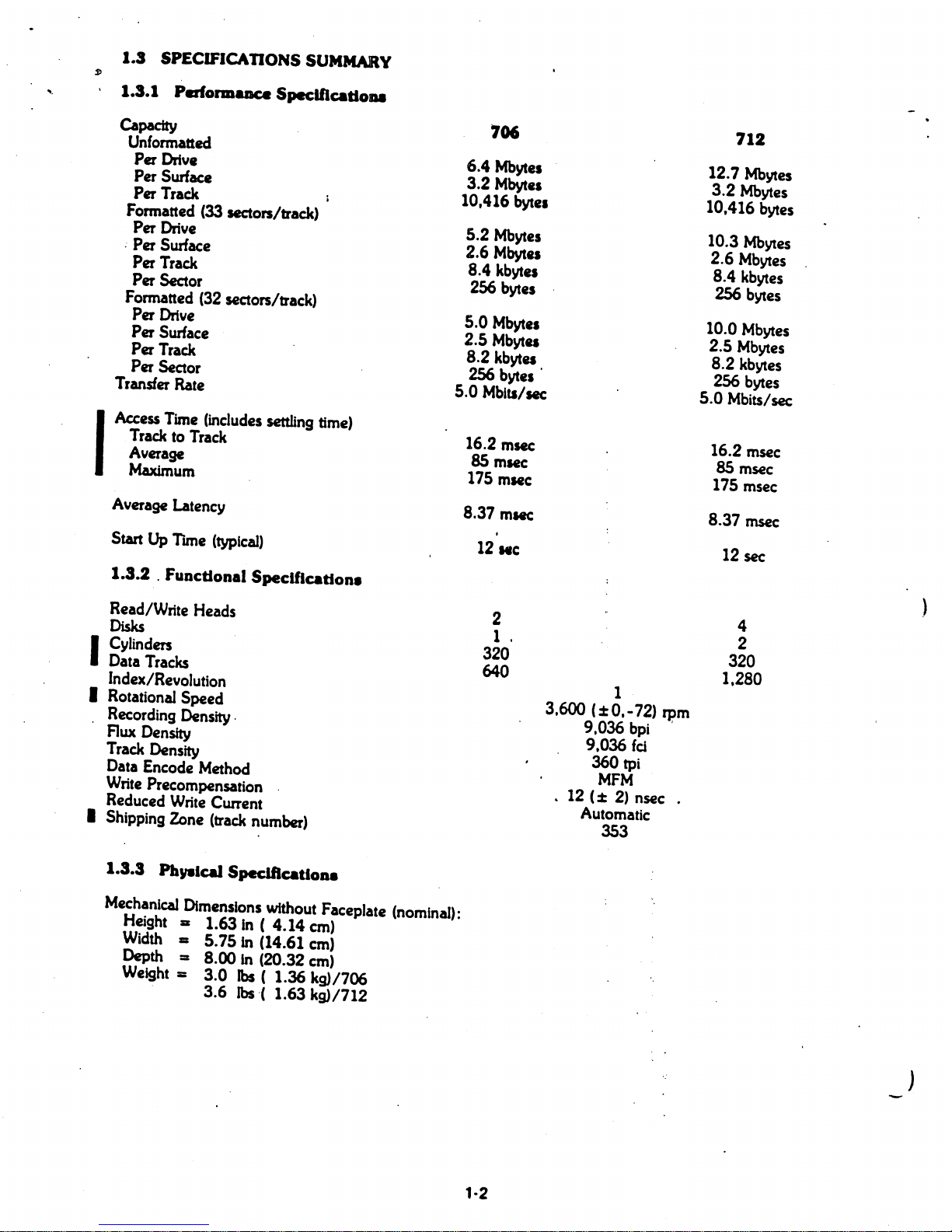

1.3 SPECIFICATIONS SUMMARY

1.3.1

Performance

Speclflcatlona

Capacity

Unformatted

Per Drive

Per

Surface

Per Track

Formatted

(33 sectors/track)

Per Drive

Per

Surface

Per Track

Per

Sector

Formatted

(32

sectors/track)

Per Drive

Per Surface

Per

Track

Per

Sector

Transfer Rate

I

Access Time (includes settling time)

Track to Track

Average

Maximum

Average Latency

Start

Up

Time (typical)

1.3.2

Functional

Specification.

706

712

6.4

Mbytes

12.7 Mbytes

3.2 Mbytes

3.2 Mbytes

10,416 bytes

10,416 bytes

5.2 Mbytes

10.3 Mbytes

2.6

Mbytes

2.6 Mbytes

8.4

kbytes

8.4 kbytes

256 bytes

256 bytes

5.0

Mbytes

10.0 Mbytes

2.5 Mbytes

2.5

Mbytes

8.2

kbytes

8.2

kbytes

256 bytes

256 bytes

5.0 Mbits/sec

5.0 Mbits/sec

16.2 msec

16.2 msec

85

msec

85

msec

175 msec

175 msec

8.37 msec

8.37 msec

12 sec

12 sec

Read/Write

Heads

Disks

I

Cylinders

Data Tracks

Index/Revolution

-I

Rotational

Speed

Recording Density

Aux

Density

Track Density

Data Encode Method

Write

Precompensation

Reduced Write

Current

I Shipping Zone (track number)

1.3.3

Phy.lcal

Speclftcatlon.

Mechanical Dimensions without Faceplate (nominal):

Height

= 1.63

in

(

4.14

cm)

Width

=

5.75

In (14.61 cm)

Depth

=

8.00In(20.32

cm)

Weight

=

3.0

Ibs

{

1.36

kg)/706

3.6

Ibs(1.63

kg)/712

2

1

320

640

1-2

1

3.600

(±0,-72)

rpm

9.036 bpi

9.036

fci

360

tpi

MFM

12

(±

2) nsec

Automatic

353

4

2

320

1,280

1.3

SPEClFlCAnONS

SUMMARY

1.3.1

Paformaace

SpecUicadoD8

Capacity

Unformatted

Per

Drive

Per

Surface

Per Track

Formatted (33 sedon/track)

Per

Drive

: Per Surface

Per Track

Per Sector

Formatted (32

seeton/track)

Per

Drive

Per

Surface

Per

Track

Per

Sector

Transfer

Rate

I

Access

Time

(includes

settling

time)

Track

to

Track

Average

Maximum

Average Latency

Start

Up

Tune (typical)

706

712

6.4

Mbytes

12.7

Mbytes

3.2

Mbyte.

3.2

Mbytes

10,416

byte_

10,416 bytes

5.2

Mbytes

10.3

Mbytes

2.6

Mbytu

2.6

Mbytes

8.4

kbytes

8.4

kbytes

256

bytes

256 bytes

5.0

Mbyte.

10.0

Mbytes

2.5

Mbyta

2.5

Mbytes

8.2 kbyta

8.2

kbytes

256 bytes ·

256 bytes

5.0 Mbltl/sec

5.0

Mbits/sec

16.2

msec

16.2

msec

85maec

85

msec

175

mMe

175

msec

8.37

maec

8.37

msec

12

He

12

sec

1.3.2 .

Functional

Specification.

Read/Write Heads

Disks

I

Cylinders

Data

Tracks

Index/Revolution

I

Rotational

Speed

Recording

Density

.

Aux

Density

Track

Density

Data Encode

Method

Write

Precompensation

Reduced

Write

Current

I

Shipping Zone

(track

number)

1.3.3

Pbplcal

SpeclftcatloDa

Mechanical

Dimensions without Faceplate (nominal):

Height

• 1.63

in (

4.14

cm)

Width

=

5.75

In

(14.61

em)

Depth

=

8.00

In (20.32

em)

Weight

=

3.0

Ibs

(

1.36

kg)/706

3.6

Ibs·(

1.63 kg)/712

2

1 .

320

640

1·2

1

3,600

(:0,-72)

rpm

9,036 bpi

t

9,036

fd

360

tpi

MFM

, 12

(±

2)

nsec

Automatic

353

4

2

320

1.280

)

,

1·3

DC Voltage Requirements: .

± 12 Vdc ± 5% .75 A typical (3.9 A max starting

for

10

sec)

(2.7 A max starting with low power

option)

±

·5

Vdc ± 5% 1.6 A typical (2.4 A

max)

I .

Relative

Humidity:

Operating -

8%

to 80%

Non-operating - 1%

to

959.»

Maximum

Wet

Bulb:

Operating - 78°F (25.6°C) non-eondenslng

Non~operatlng

- Non-eondenslng

I

. ,

20,000

Power-on

Houn

typical

usage

None

Required

12

minutes

(PCB

only)

5

yean

d. Provide a contaminant-free environment.

c. Read

and

write data.

b.

Position the heads over the

seleded

track.

1.4.1 General

Oper.dOD

The 706/712 fixed disk drives consist of read/writ., heada, read/write and

con;ol

electronics,

track

positioning

mechanisms, media,

and

air filtration systems. TheM components perform

the

foUowing functions:

a.

Interpret

and

generate control signals.

1.4

FUNCTIONAL CHARACTERISTICS

Mean

Time

Between Failure:

Preventive Maintenance:

Mean

Time

to Repair:

Component

ute:

Heat

Dissipation

=86 BTU/hr typical (18.4

watts)

1.3.4

Reliability Speclflcatlona

Elevation:

.

Operating -

0 to 10,000ft(0

to 3048

m)

Non-operating - -1.000

to

30,000ft(-305 to 9144 m)

Acoustic

Noise:

Less

than 50

dbA

at 3.3 It (1.0

m)

Shock:

Operating - 10 G

max

(11

msec

half

sine

wave)

Non-operating - 40 G

max

(11

msec

half

sine

wave)

Vibration:

Operating:

5 - 17

Hz

= 0.036 In

17

- 150

Hz

= 0.55 G

200 - 500

Hz

::

0.25 G

Non-operating:

5 - 22

Hz

= 0.50 G

44-

500

Hz

=2.00 G

Environmental Umtts:

Host

Ambient

Temperature:

Operating - 41° to 113°F (5° to

45°C)

Non-operating - _40° to 140°F (_40° to

60°C)

Temperature

Gradient:·

.

Operating - 10°F

(5.~OC)

per

1/2

hour

Non-operating -

212°F (100°C)

per

hour non-condenllng

~

.~

,...-

..

.j

..

~

....

'.9

..

.oj

...

Ij

~

..

.~!t

-

-

~,

-

-

.,

-

-

~!

-

-

•

-

-

.o~

-

-

••

-

-

.:~

.

•

.:~

•

!I

·

Oil

-

~CI

·

:~II

-

d'

·

°

\1

·

.,

·

u·

·

,.

·

\~

-

·

Do·

·

·

.,

·

:.L·

·

--

·

~l

-

-

-

I

.,

·

.

.:

4

"

•~:i

"

-

..

'~

..

.

,-

--

.~

1.-4.2

Read/Write

anel

Control

Electroalea

The standard

~iaoproceS50r

and electronics are packaged

o~

one printed circuit

board

containing the

foUowing

circuits:

a.

Index Generator Circuit

b.

Head Position Actuation Drivers

c.

Read/Write

Amplifiers

d.

Drive

(READY)

up to Speed Circuit

e.

Drive

Select Circuit

f.

Write

Fault Detection Circuit

g.

Read/Write Head Select Circuit

h.

Ramped (Buffered ) Stepper Circuit

I.

Track 00 Indicator

j.

Brushless Spindle Motor Control Circuits

1.4.3

Drive

Mechanlam

I

The

brushlessdcdrive

motor rotates the spindle

at

.3.600

(:t

0, -

72)

revolutions per minute.

1.4.4

Poaltlonlng

Mechanl

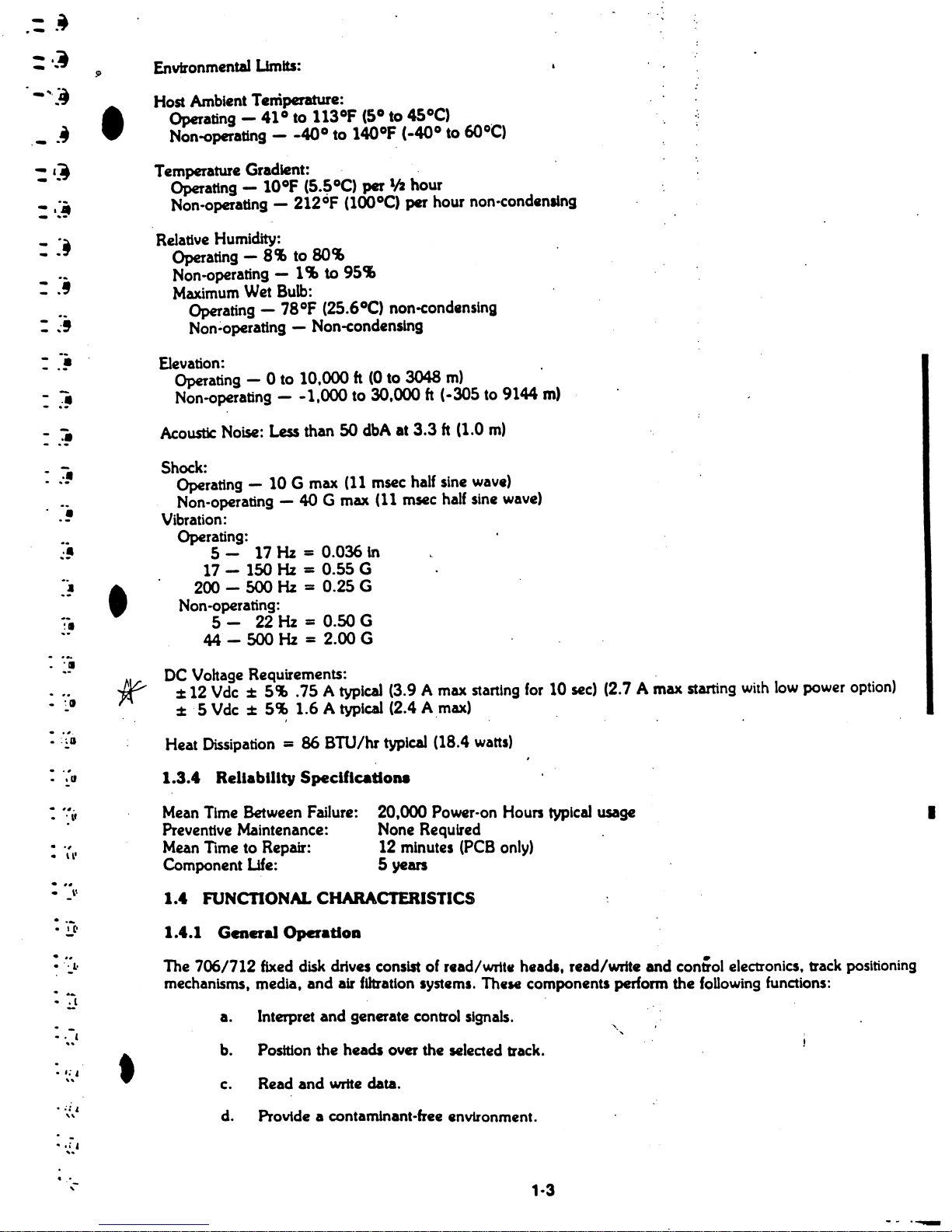

••

The

read/write heads are mounted on an arm

whichispositioned

by

I

Fasflex™

IV

rotary actuator. A stepper

motor

is

usedtoprecisely position the rotary actuator utilizing a unique

metal

band/capstan concept. Figure

1-2

u-

lustrates

thiS

positioning

mechanism. .

1.4.5

Read/Write

Head.

and

DI.k(l)

The

recording

media

consistsofa thin, lubricated, magnetic oxide coating on a 130

mdUmeter

diameter aluminum

substrate.

This

coating formulation, together

with

the

low

load

force/low

mass

Winchester-type

flying

heads, per-

mits

reliable

contact stan/stop operation.

I Data

on

each

disk

surface are read

by

one read/write head, eachofwhich

accesses

320

data tracks.

The

drive

is

availableintwo

basic

configurations: one

disk

with

two read/write heads (706)

or

two

disks

with four read/write

heads

(712).

The

heads should be positioned at cybnder 353 via

IOftware

priorto powerdown

in

order to

minimize

the potential

for

damage to the recorded data on portable systems.

Refer

to paragraph 1.4.8.

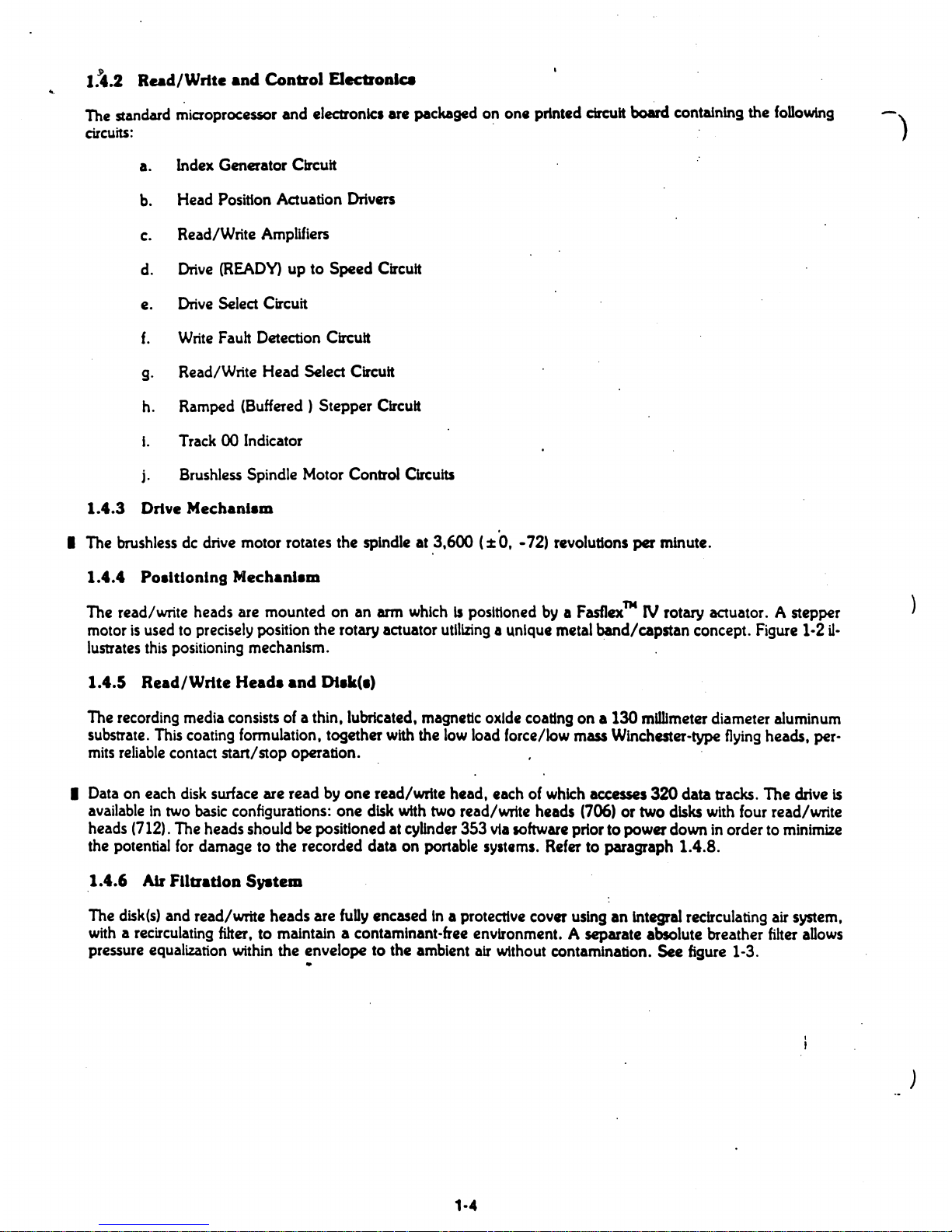

1.4.6

AIr flltratioD

Syatem

The

disk(s)

and read/write heads are

fuUy

encased In a protective cover using an integral

recirculating

air

system,

with

a recirculating

filter.

to maintain a contaminant-free environment. A separate absolute breather

filter

allows

pressure equalization within the envelopetothe ambient

air

without contamination.

See

figure 1-3.

.

'-4

)

ACTUATOR

SPINDLE

ASSEMBLY

PJW

HEAD

ASSEMBLY

BAND

STEPPER

.MOTOR

CAPSTAN

*FIGURE 1·2.

READ/WRITE

HEAD

POSITIONING

MECHANISM

.

COVER

0.3 MICRON

BAROMETRIC

FILTER

0.3 MICRON

FILTER

*FIGURE 1·3. AIR FILTRATION SYSTEM

1·5

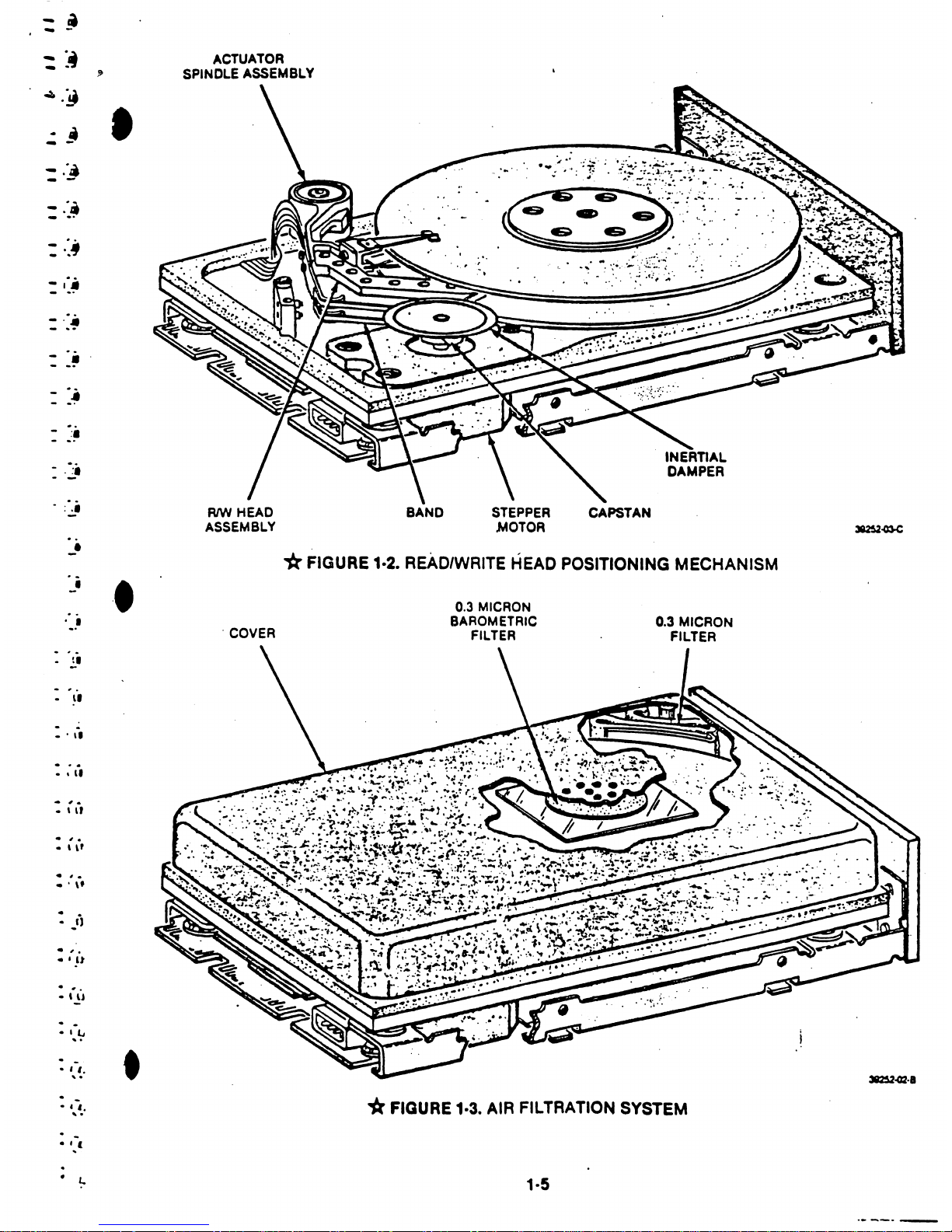

1.4.7 Spindle Lock and Brake

,

These drives

are

provided withanintegral

fall·sal.

spindle

lock

and

brake.

ThIs

lOIenold

operated.

mechanical

brake

is actuated when

de

power

is applied to the drive, allowing the spindle to rotate. When the drive is powered

off,

the

solenoid is deae:ttvated

allowing

the brake to engage

the

spindle.

This

preventsthe

possibilityofdisk

move·

ment

during

shipping or

movement

ofthe drive. During spin down, the

brake

decelerates the spinning

disks

quickly

to

reduce

the

amount

of

time

that

the heads are In unltable flight.

Se.

figure

1-4.

)

STEPPER

MOTOR

BRUSHLESS

DC

SPINDLE

MOTOR

FIGURE 1-4. SPINDLE LOCK

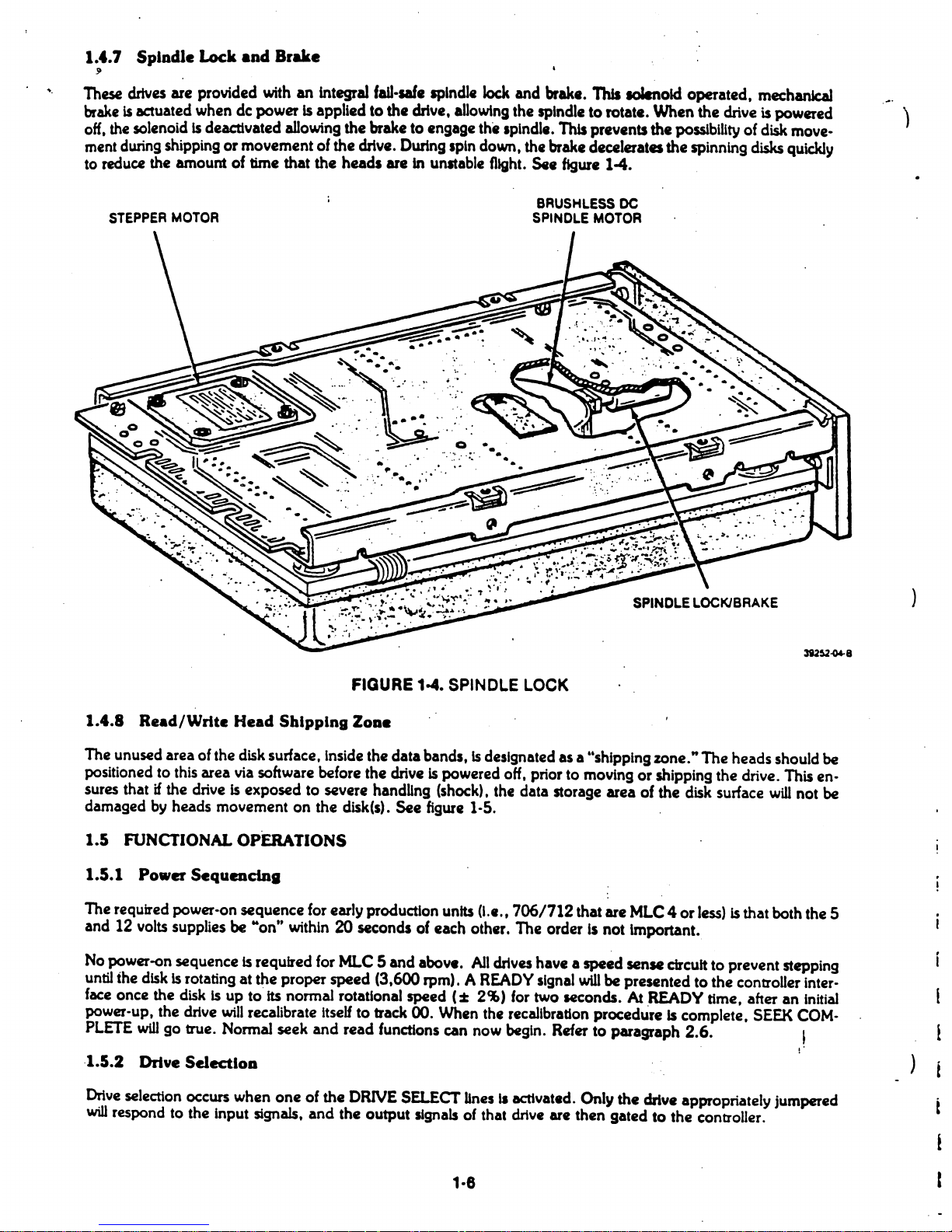

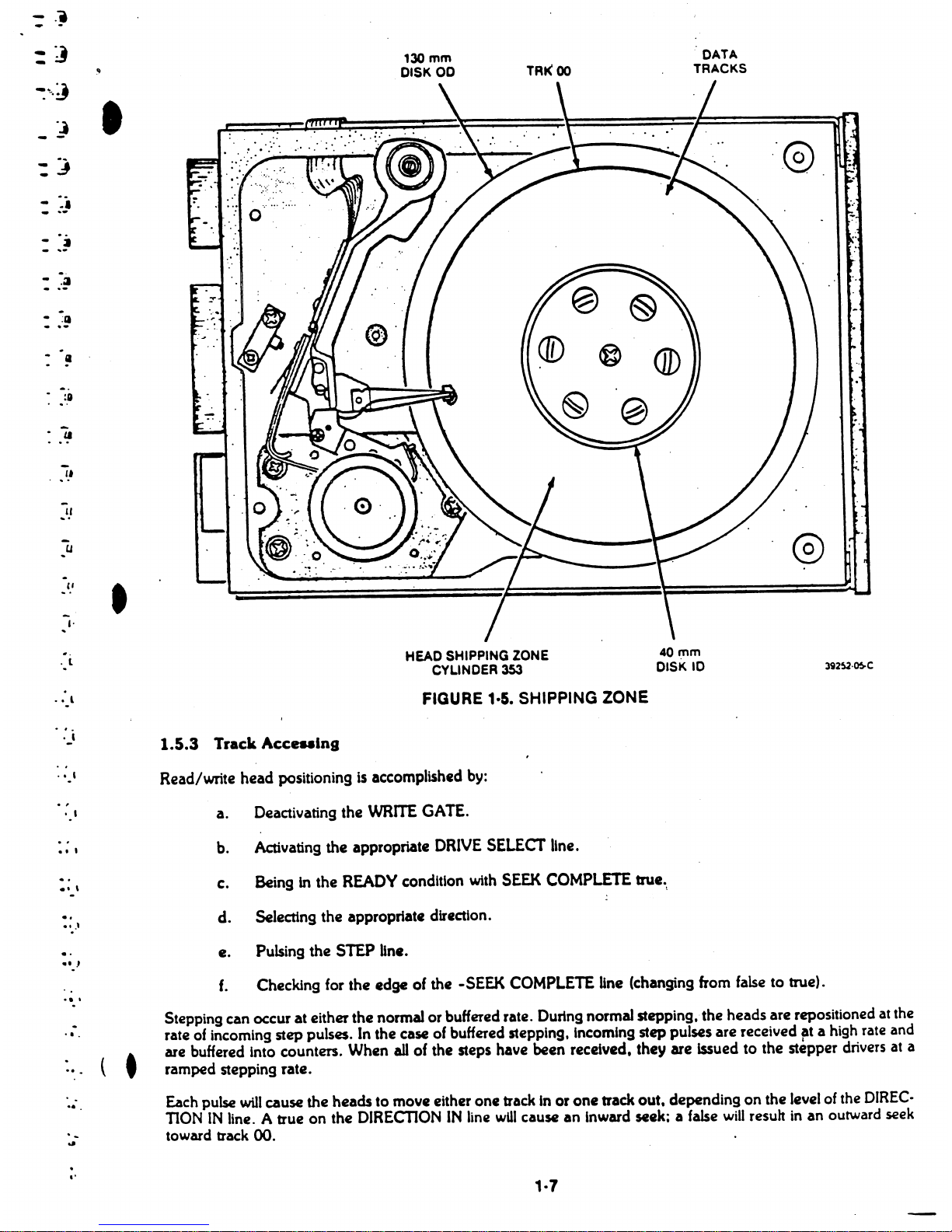

1.4.8

Read/Write

Head

Shipping

Zoae

The

unused

area

ofthe disk surface. Inside

the

data

bands, is designatedasa "shipping

zone."

The

heads

should be

positionedtothis

area

via software before

the

drive15powered off. priortomovingorshipping

the

drive. This en-

sures that if the

drive

is

exposedtosevere handling

(shock).

the

data

storage

area

of

the disk surface

will

not

be

damagedbyheads

movementonthe

disk(s).

See

figure }-5.

1.5

FUNCTIONAL OpERATIONS

1.5.1 Power SequencIDl

The required power-on

sequence

for early production

units

(1.8., 706/712 that are

MLC

4orless)

is that both

the

5

and12volts supplies

be

M

on

" within20secondsofeach

other.

The

orderisnot

important.

No power-on

sequence

is required for

MLC

5 and above.

All

drtves have a

speed

sense ctrcult

to

prevent stepping

until

the

disk

is rotating

at

the

proper

speed

(3,600 rpm). A READY signal

will

be

presentedtothe

controller inter- l

face

once

the

disk is

up

to' Its normal rotational

speed

(:t

2%)

for two seconds.

At

.READV

time, afteraninitial

power-up, the drive will recalibrate Itselftotrack

00.

When the recallbration

procedure

Is complete. SEEK COM-

PLETE

will

go

true. Normal

seek

and

read

functions

can

now

begin. Refertoparagraph

2.6.

! i

·1.5.2 Drive SelectlOD )

Drive selection occurs when

one

of

the

DRIVE SELECT Ilnes

II

activated. Only

the

drive appropriately jumpered

will respond to

the

input signals.

and

the

output

signals of that drive

are

then

gatedtothe

controller.

1·8

.,

.'@

-

DATA

TRACKS

40mm

DISK

10

TRt<

00

130

mm

DISK

00

HEAD SHIPPING ZONE

CYLINDER

353

..

· l

.

"

u

"

I,

• lJ

-

.:1

:

..

~

-

...

-

..

....

:~

.•

l

FIGURE 1·5. SHIPPING ZONE

._'

..

,

t I

..

,

.'

,

..

• t•

.'

..

,

1.5.3

Track Acceaalng

Read/write head positioningisaccomplished

by:

a. Deactivating the

WRITE

GATE.

b.

Activating

the

appropriate

DRIVE

SELECT

line

.

c. Being

in the

READY

condition

with

SEEK

COMPlETE

true.\

d. Selecttng the appropriate direction.

e. Pulsing the STEP

Un

•.

f.

Checking

for

the edge of the -SEEK

COMPLETE

line

(changing

from

false

to true).

.

·

..

...

...

( t

Stepping

can

occurateither the

normalorbuffered rate. DUring normal stepping,-the heads

are

repositioned at the

rate of incoming step pulses. In the

case

of

buffered stepping,

Incoming

step pulses

are

received at a high rate and

are

buffered

Into

counters.

When

all

of

the

steps

have

been received, they

are

Issuedtothe

stepper drivers at a

ramped stepping rate.

Each

pulse

will

cause

the headstomove either one track In or one track out,

depending

on the

levelofthe

DIREC-

TION

IN

line. A trueonthe

DIRECTIONINline

wUI

cause an

Inward

seek: a

false

will

result

in

an outward seek

toward track00.

.

t'

'·7

1.~4

Reacl

OperaUoUl

Reading

data

&om

the

d1sk

Is

accompUshecl

by:

a. Deactivating"the

WRITE

GATE

line.

r

b.

Activating the appropriate

D~

SELECT

line.

c. Assuring that

the

drive

ts

READY.

d. Selecting the appropriate head.

1.5.5 Write Operation

Writing data onto the

disk

is accomplished by:

a. Activating the appropriate

DRIVE

SELECT

Une.

b. Assuring that

the

drive is

READY.

c.

Clearing

any

write

fault

conditions (if that exist).byreselceting the drive.

d.

Selecting the

proper

head.

e.

Activating

the

WRITE

GATE

and plactng dataonthe

WRITE

DATA

Un

••

1.5.6

Head

Selection

Any

of

the

twotofour

possible

heads can

be

selededbyplacing

the

binary

address of that head on the

two

HEAD

SELECT

Unes.

1·8

)

\

~

t

- J

• .J

·

• .J

•

.1

: -'

:

:~

,

SECTION

II

ELECTRICAL

INTERFACE

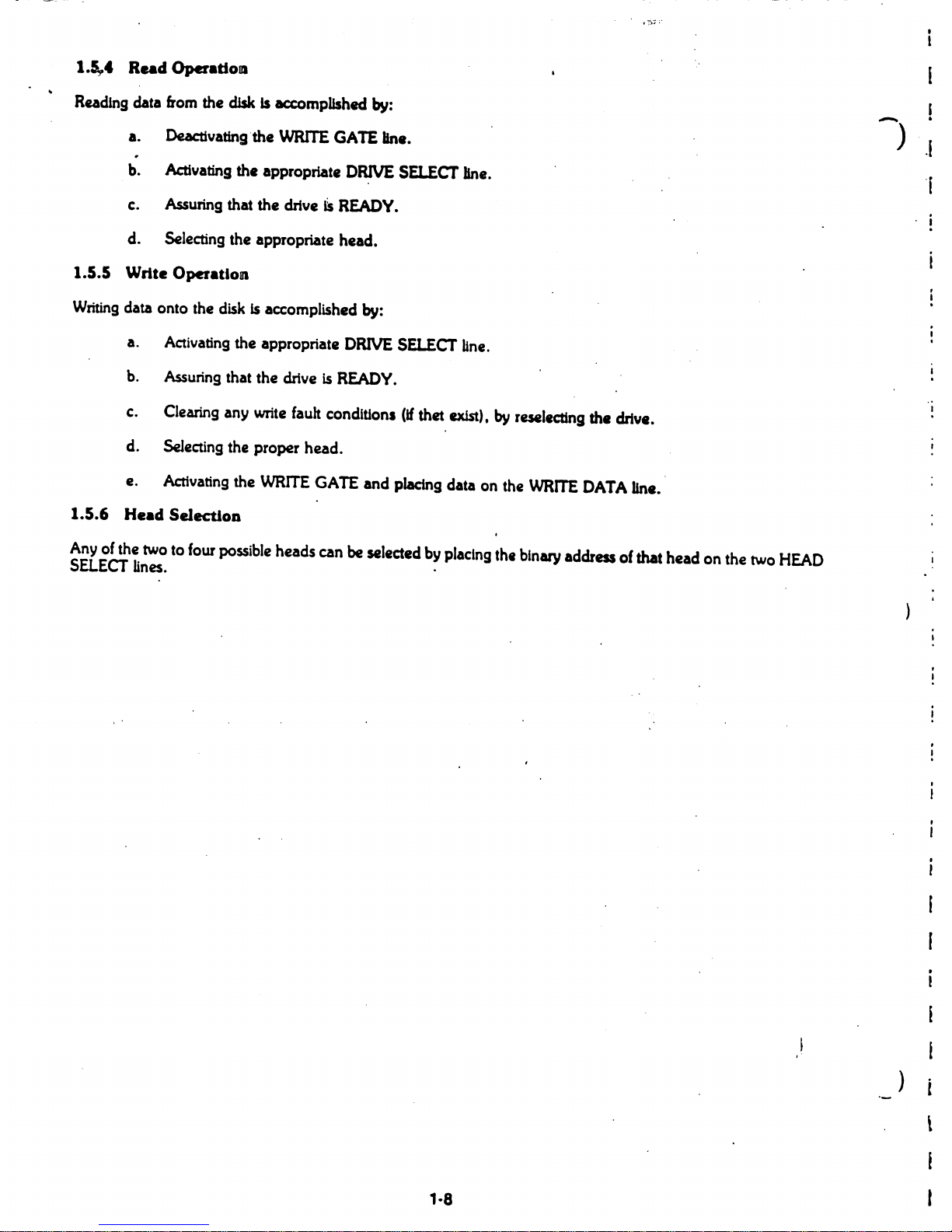

2.1

INTRODUCTION

The interface for a

706/712

has

drive

control signal pin ualgnmentl

per

Industry standards. See figure 2·1

for

the

pin assignments.

HOST

7OeI712

• l.

.1

..

1

(.

.1

'.

-

tC

-

•

,r

-

.r

• I

· .

·

."

· .

·

'-'

·

,.

.

-'

.,.

·.

•

',a

· "

• •

-

..

-

• •

• •

,

~~

RESERVED

-

2

-

3

RESERVED

-

•

5

-WRITE

GATE

-

•

7

-SEEK

COMPLETl

~

•

t

-TRACK

00

10

"

-WR'TE

FAULT

I'

13

-HEAD

SELECT

2'

-

t.

-

15

RESERVED

11.

-

17

FLAT

-HEAD

SELECT

2' •

AlIBON

-

'1

20 FT. MAX.

11

ce"mm)

-INDEx

-

a

~

~

-~EADY

22

23

-STEP

-

N

25

-DAIVE

SELECT

t

-

a

zr

-DRIVE

SILECT 2

•

-

21

-DAIVE

IllECT

3

-

-

3D

31

- DRIVI SILECT •

-

-

3Z

33

-DIRECTION IN

.

-

,.

--..

•~v

DC

..,,1P1

A

•~RETURN

-

•

3

-

•

'2YDC

-

-

..£:

X

•12RETURN

-

1

2

-

~

DCGNO

rh--=-

rJ

GND

TWISTED

PAIR

IfRAUEGND

*FIGURE 2·1. J5 INTERFACE

AND

J1

POWER

CONNECTIONS

2·1

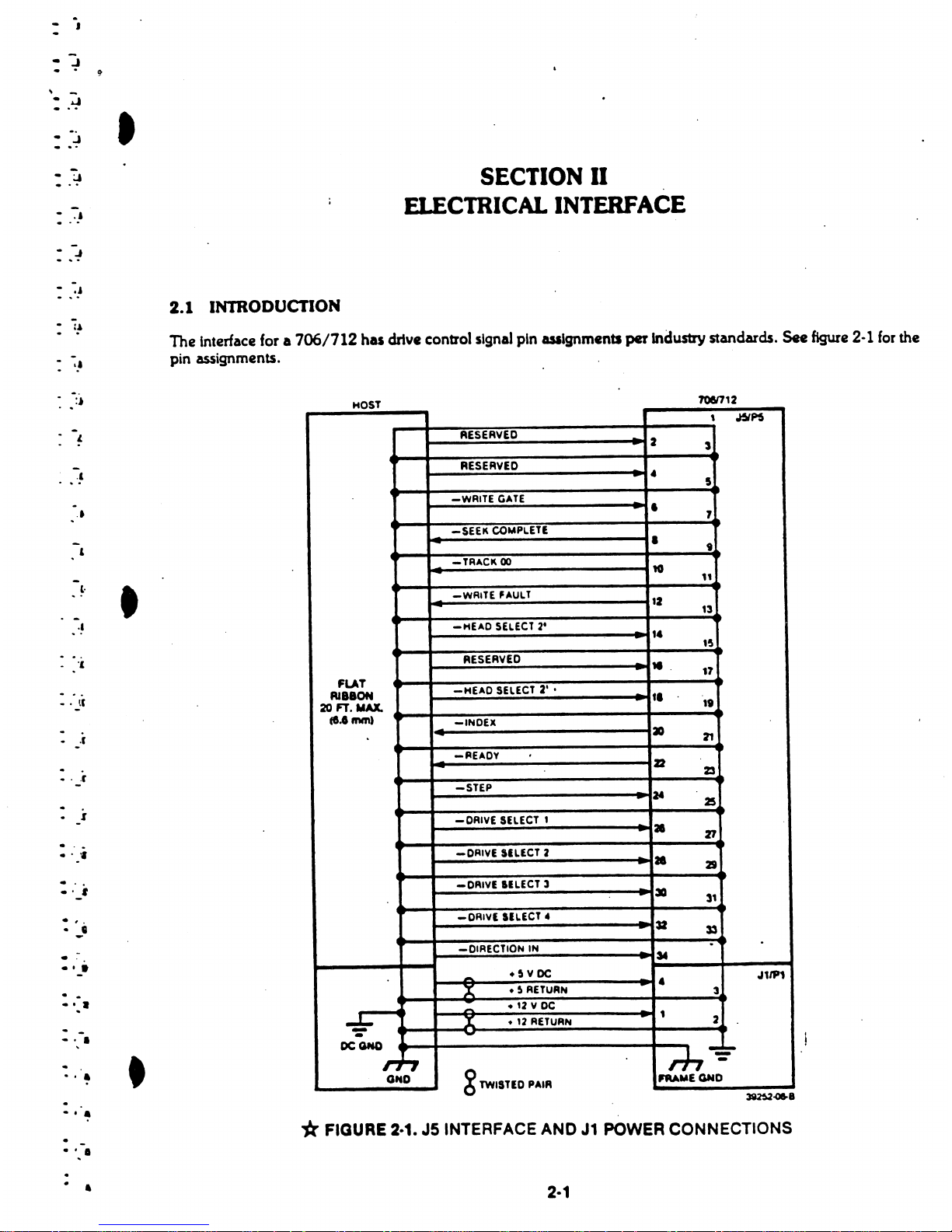

The

sJgna11nterface

consists of three categories:

a. Control Input

Una

b.

Control Output

Una

c.

Data

Transfer

Una

AD

control

lines

are digitalin nature

and

either provide

signalstothe drive (input) or provide signals to the host (out-

I

put) viathe interface connector

JS/P5.

The data transfer slgnall

are

differentialln nature. They provide data either

toorfrom

the drive.

via

J6/P6. See

figure

2-2

for

the

J6/P6

pin

assignments.

HOST

706n12

-

DRIVE

SELECTED

1

-

GND

2

SPARE

3

GND

~

SPARE

5

GNO

8

J6/Pe

RESERVED

7

GND

8

SPARE

,

FLAT

CABLE

GND

10

20FTMAX

GND

'1

(8.6

mm)

GND 12

+ MFM WRITE DATA

13

-MFM

WRITE DATA

-

GND

-

,

..

15

GND

16

-

+ MFM

READ

DATA

17

-

-MFM

READ

DATA

-

18

-

GNO

19

GND

20

--:

-

..

~

)

*FIGURE 2·2.

J6

INTERFACE CONNECTION

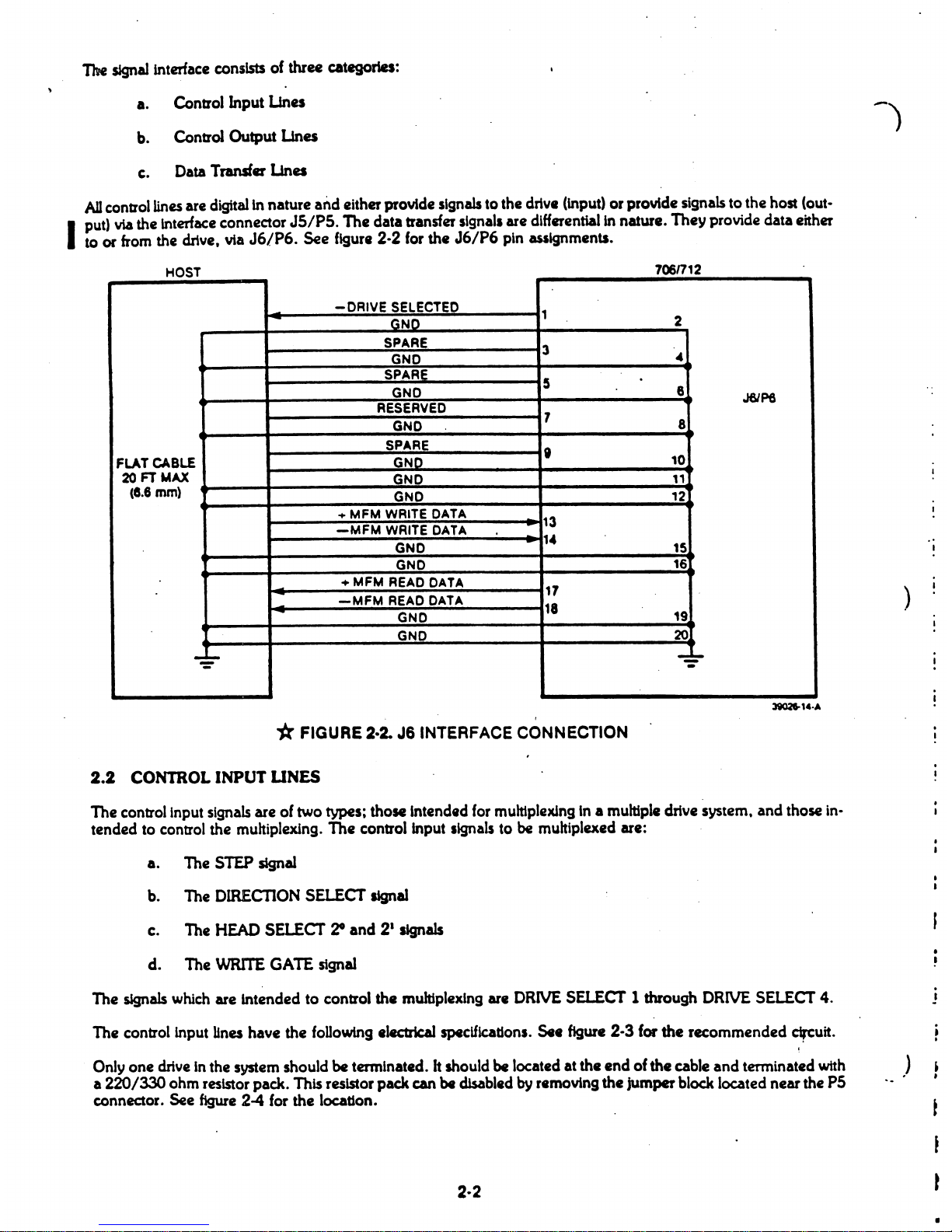

2.2

CONTROL INPUT UNES

The control1nput

signals

are

of

two

types; those Intended for multiplexing In a multiple drive system,

and

those in-

tended to control the multiplexing. The controllnput Ilgnals tobemultiplexed are:

a. The STEP signal

b.

The

DIRECTION

SELECT

signal

c.

The

HEAD

SELECT

20

and 2

1

signals

d. The

WRITE

GATE

signal

The

signals

which

are intended

to

control

the

multiplexing

are

DRIVE

SELECT

1through

DRIVE

SELECT

4.

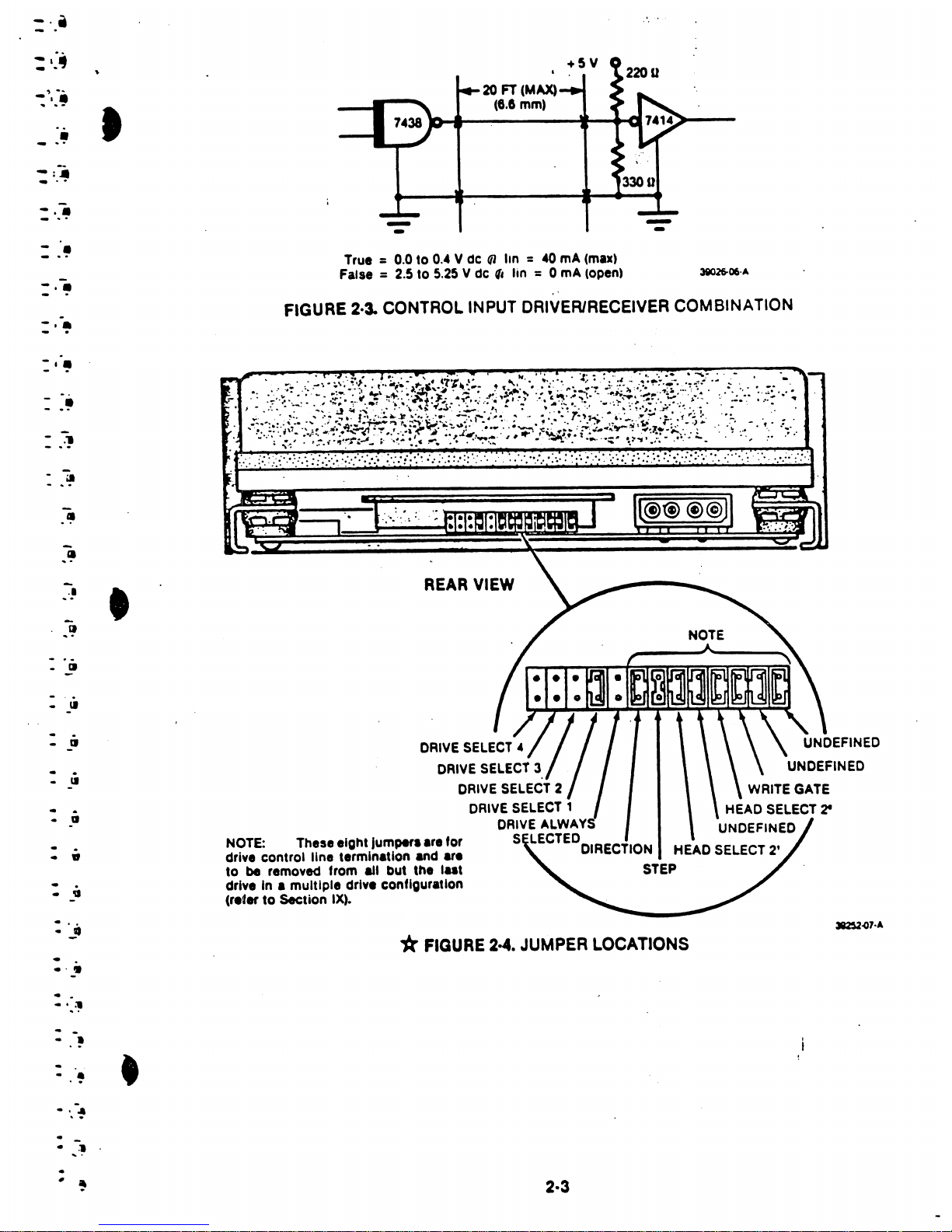

The controllnput lines have the following .lectrical specifications.

541.

figure

2-3 for the recommended

cIrCuit.

Only

one

drive

In the system should

be

terminated. h shouldbelocated at the end ofthe cable and terminated

with

a 220/330 ohm resistor pack. This resistor pack can

be

disabledbyremoving the jumperblock located near the P5

connector. See

figure

2-4 for the location.

)

t

l

t

UNDEFINED

UNDEFINED

WRITE

GATE

HEAD

SELECT

21

UNDEFINED

20

FT

(MAX)

(6.0

mm)

DRIVE

SELECT. I /

DRIVE

SELECT

3./

.j

DRIVE

SELECT

2

DRIVE

SELECT

1

DRIVE

ALWAYS

5

LECTED

DIRECTION HEAD SELECT

2'

STEP

REAR

VIEW

*

FIGURE

2·4.

JUMPER LOCATIONS

- -

- -

True =0.0 to 0

.•Vdefllin=.0mA(max)

False

=2.5

to

5.25 V

de

" lin =0

mA

(open) 3i026-06·A

FIGURE 2·3. CONTROL

INPUT

DRIVER/RECEIVER COMBINATION

NOTE: These

eight

Jumper.are

for

drive control line termination and

.r.

to

be removed from ai, but the

Int

drive in a multiple drive configuraUon

(r.fertoSection IX).

.1

•

C!I

• 'II

-

II

• •

•

II

-

..

-

tI

....

· .

-

II

· .

• a

-

i

-

~

l·~

....

")

-

...

~l

..

!

-

..

~

t

..

:

..

~

..

-

..

ill

-

-

.~

-

-

•

-

-

.

•

-

-

.

•

~

-

-

.~

-

...

-

-

..

·.

• '..=!I

· -

·.

~

-

.,

.

.,

2·3

Loading...

Loading...