Silicon Storage Technology Inc SST49LF020-33-4C-WH, SST49LF020-33-4C-NH Datasheet

FEATURES:

2 Megabit LPC Flash

SST49LF020

SST49LF0202 Mb LPC Flash

Advance Information

• Standard LPC Interface

– Conforms to Intel LPC Interface Specification 1.0

• Organized as 256K x8

• Flexible Erase Capability

– Uniform 4 KByte sectors

– Uniform 16 KByte overlay blocks

– 16 KBytes Top boot block protection

– Chip-Erase for PP Mode

• Single 3.0-3.6V Read and Write Operations

• Superior Reliability

– Endurance: 100,000 Cycles (typical)

– Greater than 100 years Data Retention

• Low Power Consumption

– Active Read Current: 10 mA (typical)

– Standby Current: 10 µA (typical)

• Fast Sector-Erase/Byte-Program Operation

– Sector-Erase Time: 18 ms (typical)

– Block-Erase Time: 18 ms (typical)

– Chip-Erase Time: 70 ms (typical)

– Byte-Program Time: 14 µs (typical)

– Chip Rewrite Time: 4 seconds (typical)

– Single-pulse Program or Erase

– Internal timing generation

• Two Operational Modes

– Low Pin Count (LPC) Interface mo de f or

in-system operation

– Parallel Programming (PP) Mode f or f ast productio n

programming

• LPC Interface Mode

– 5-signal communication interface supporting

byte Read and Write

– 33 MHz clock frequency operation

– WP# and TBL# pins provide hardware write protect

for entire chip and/or t op boot b lo ck

– Standard SDP Command Set

– Data# Polling and Toggle Bit for

End-of-Write detection

– 5 GPI pins for system design flexibility

• Parallel Programming (PP) Mode

– 11 pin multiplexed address and

8 pin data I/O interface

– Supports fast In-System or PROM programming

for manufacturing

• CMOS I/O Compatibility

• Packages Available

– 32-lead PLCC

– 32- l ead TSOP (8mm x 14mm)

PRODUCT DESCRIPTION

The SST49LF020 flash memory device is designed to

interface with the LPC bus for PC and Int er ne t Appl ican ce

applications. It provides protection for the storage and

update of code and data in addition to adding system

design flexibility through five General Purpose Inputs (GPI).

The SST49LF020 is in compliance with Intel Low Pin

Count (LPC) Interface Specification 1.0. Two interface

modes are suppor te d: LPC Mode for In-Syste m programming and Parallel Programming (PP) Mode for fast factory

programming.

The SST49LF020 flash memory device is manufactured

with SST’s proprietary, high performance SuperFlash

Technology. The split-gate cell design and thick oxide

tunneling injector a ttain bette r reliabil ity and man uf actur ability compared with alternate approaches. The

SST49LF0 20 device signific antly improves per formance

and reliability, while lowering power consumption. The

SST49LF020 device writes (Program or Erase) with a

single 3.0-3.6V power supply. It uses less energy during

Erase and Program than alternative flash memory technologies. The tota l en er gy consu med is a func ti on o f the

applied vol tage , curr en t and time of ap plica tio n. Sinc e for

any give voltage range, the SuperFlash technology uses

less current to prog ram and ha s a shorter erase time , the

total energy consumed during any Erase or Program

operation is less than alternative flash memory technologies. The SST49LF020 product provides a maximum

Byte-Program time of 20µsec. The entire memory can be

erased and programmed byte-by-byte typically in 4 seconds, when using status detection features such as Toggle Bit or Data# Polling to indicate the completion of

Program oper at io n. Th e Sup erF lash te chno logy provides

fixed Erase and Program time, independent of the number of Erase/Program cycles that ha ve perf ormed. Therefore the system software or hardware does not have to

be calibrated or correlated to the cumulative number of

Erase/Program cycles as is necessary with alternative

flash memory technologies, whose Erase and Program

time increase with accum ul at ed Er ase/ Prog r a m cycl es .

To protect against inadvertent write, the SST49LF020

device has on-chip hardware and software data (SDP)

protection schemes . I t is o ffered with a typical endurance

of 100,000 cycles. Data retention is rated at greater than

100 years.

©2001 Silicon Storage Technology, Inc.

S71175-02-000 5/01 526

1

MPF is a trademark of Silicon Storage Technology, Inc. Intel is a registered trademark of Intel Corporation.

The SST logo and SuperFlash are registered trademarks of Silicon Storage Technology, Inc.

These specifications are subject to change without notice.

2 Megabit LPC Flash

SST49LF020

Advance Information

To meet high density, surface mount requirements, the

SST49LF020 device is offered in 32-lead TSOP and 32lead PLCC packages. See Figures 1 and 2 for pinouts and

Table 2 for pin descriptions.

Mode Selection and Description

The SST49LF020 flash memory device operates in two

distinct inter face modes: the LPC mode and the Parallel

Programming (PP) mode. The Mode pin is used to set the

interface mode selection. If the Mode pin is set to logic

High, the device is in PP mode; while if the Mode pin is set

Low, the device is in the LPC mode. The Mo de selection

pin must be configured prior to device operation.

In LPC mode, the device is configured to its host using

standard LPC interface protocol. Communication

between Host and the SST49LF020 occurs via the 4-bit

I/O communication signals, LAD [3:0] and LFRAME#.

In PP mode, the device is programmed via an 11-bit

address and an 8-bit data I/O parallel signals. The address

inputs are multiplexed in row and column sele ct ed by control signal R/C# pin. The row addresses are mapped to the

higher inter nal addresse s, and the colum n addresses a re

mapped to the lower internal addresses. See Device Memory Map for address assignments.

LPC MODE

Device Operation

The LPC mode uses a 5-s ignal co mmun icatio n interf ace , a

4-bit address/data bus, LAD[3:0], and a control line,

LFRAME#, to control operations of the SST49LF020.

Cycle type operations such as Memory Read and Memory

Write are defi ned in Intel Low Pi n Count Inte rface Specification, Revision 1.0. JEDEC Standard SDP (Software

Data Protection) Program and Erase commands

sequences are i ncorpo rated into the sta ndard LPC me mory cycles. See Figure 8 through Figure 13 timing diagrams

for command sequences.

LPC operations are tran smitted via the 4-bi t Add ress/ Data

bus (LAD[3:0]), and follow a par tic ular sequ ence, depen ding on whether they are Read or Write operations. The

standard LPC memory cycle is defined in Table 13.

Both LPC Read and Write operations start in a similar way

as shown in Figures 6 and 7 timing diagrams. The host

(which is the term used here to describe the device driving

the memory) asserts LFRAME# for one or more clocks

and drives a start value on the LAD[3:0] bus.

At the beginnin g of an operation, the host may hold the

LFRAME# activ e f or sev era l cloc k cycles , and e ven change

the Star t value. The LAD[3:0] bus is latched every risin g

edge of the clock. On the cycle in whic h LFRAME# goes

inactive, the last latched value is taken as the Start value.

CE# must be asserted on e cycle b efore the star t cy cle to

select the SST49LF020 for Read and Write operations.

Once the SST49LF020 identifies the operation as valid (a

start value of all zeros), it next expects a nibble that indicates

whether this is a memory read or program cycle. Once this

is received, the device is now ready for the Address and

Data cycles. For Program operati on the Data cycle will follow the Address cycle, and for Read operation TAR and

SYNC cycles occur between the Address and Data cycles.

At the end of ev ery operation, the control of the bus m ust be

returned to the host by a 2 clock TAR cycle.

Device Memory Hardware Write Protection

The Top Boot Lock (TBL#) and Write Protect (WP#) pins

are provided for hardware write protection of device

memory in the SST49LF020. The TBL# pin is used to

write protect four boot sectors (16 KBytes) at the highest

memory address range. WP# pin write protects the

remaining sectors in the flash memory.

An active low signal at the TBL# pin prevents Program and

Erase operations of the top boot sectors. When TBL# pin is

held high, the write protection of the top boot sectors is disabled. The WP# pin serves the same function for the

remaining sectors of the device memory. The TBL# and

WP# pins write protection functions operate independently

of one another.

Both TBL# and WP# pins must be set to their required

protection states prior to starting a Program or Erase

operation. A logic level change occurring at the TBL# or

WP# pin during a Program or Erase operation could

cause unpredictab le resul ts.

Reset

A VIL on INIT# or RST# pins initiates a device rese t. INI T#

and RST# pins have same function internally. It is required

to drive INIT# or RST# pins low dur ing a system reset to

ensure proper CPU initialization.

During a Read opera tion, driving IN IT# or RST# pins low

deselects the device and places the output drivers,

LAD[3:0], in a high-impedance state. The reset signal must

be held low for a minimal duration of time T

latency will occur if a reset procedure is performed during a

Program or Erase operation. See Table 12, Reset Timing

Param eters , for more information. A device rese t during an

active Program or Erase will abort the operation and mem-

RSTP .

A reset

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

2

2 Megabit LPC Flash

SST49LF020

Advance Information

ory contents may become invalid due to data being altered

had been disr u pte d fr om an i nc om pl ete E rase or Pr o gram

operation.

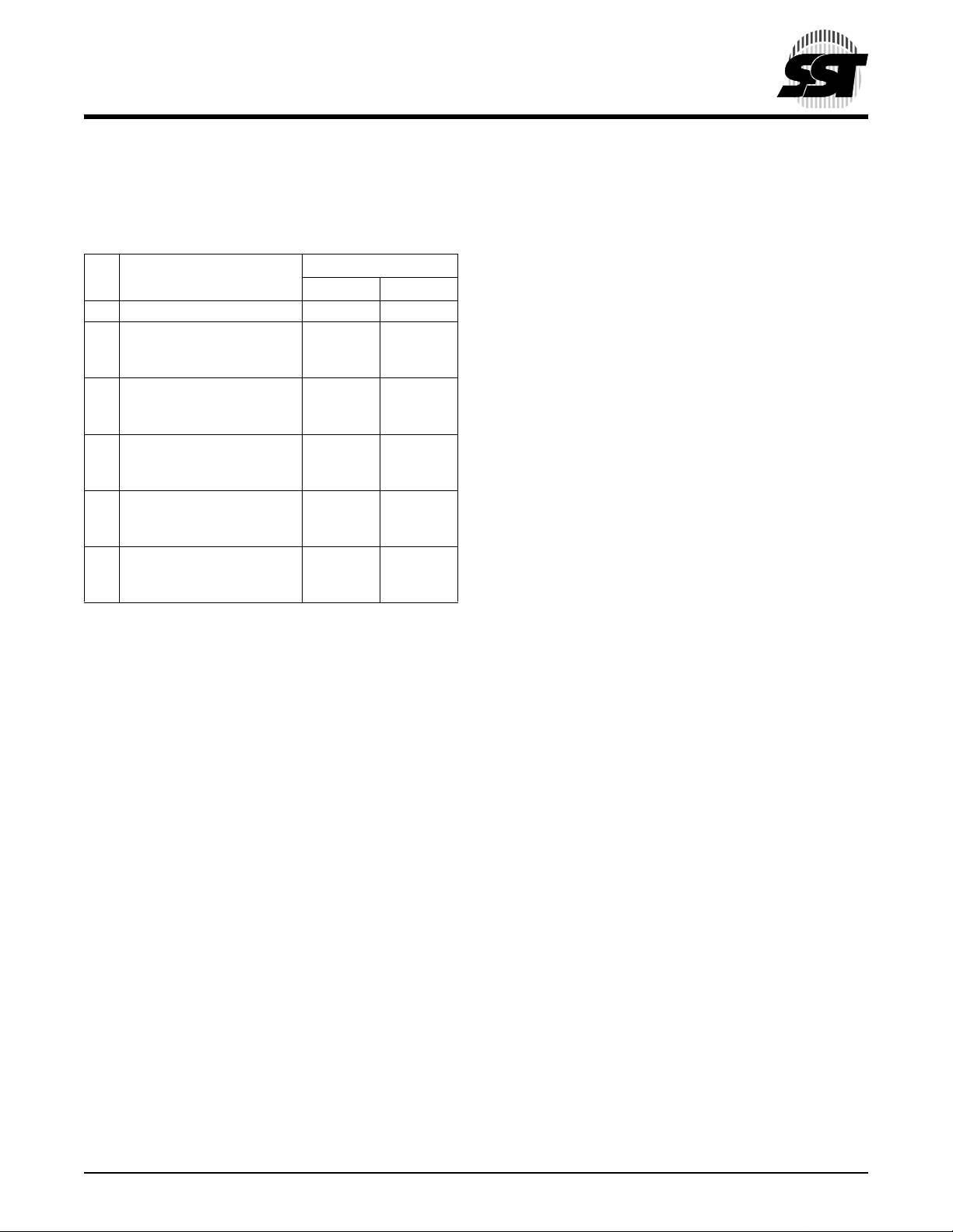

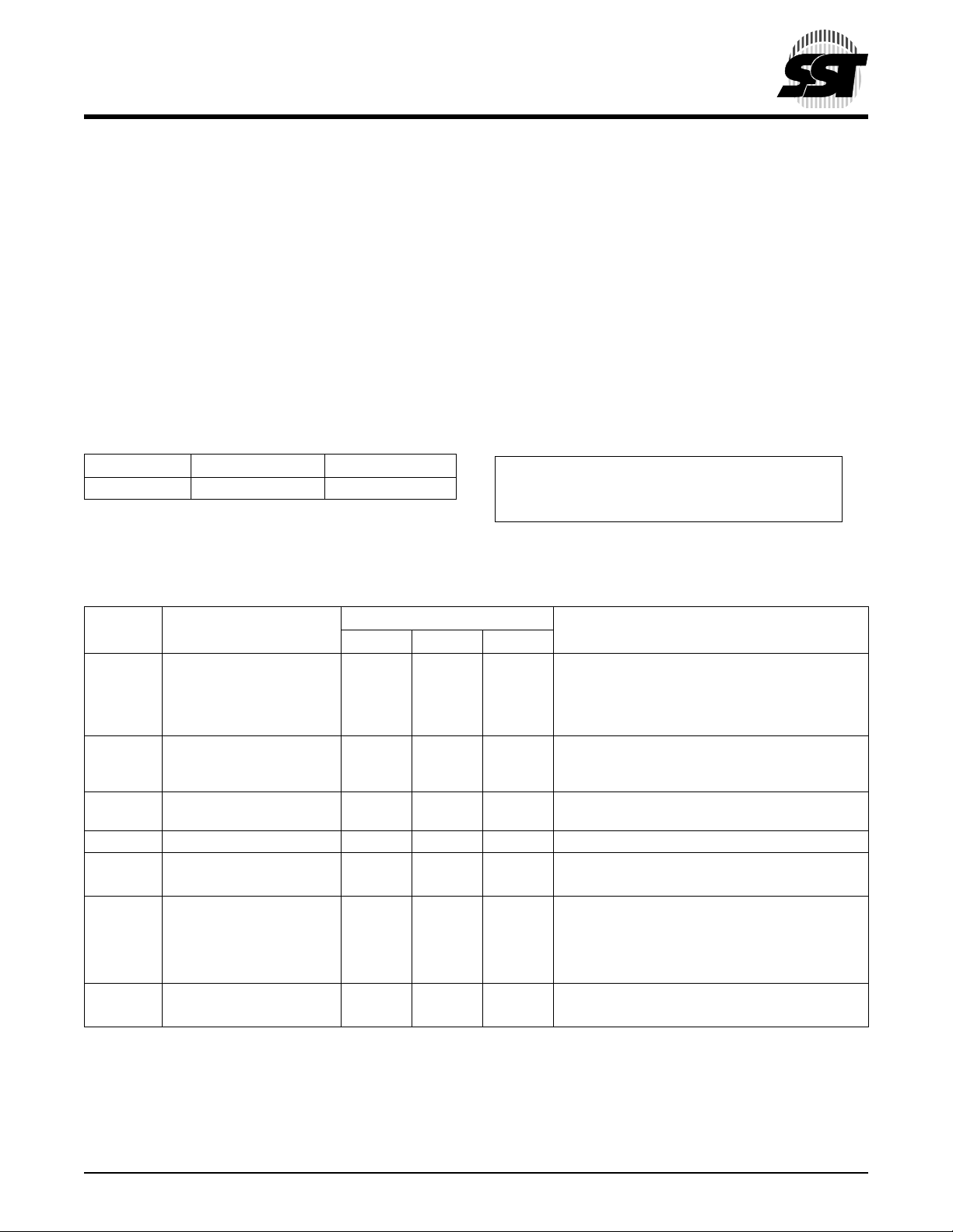

ENERAL PURPOSE INPUTS REGISTER

G

Pin#

Bit Function

7:5 Reserved - -

4 GPI[4]

Reads status of

general purpose input pin

3 GPI[3]

Reads status of

general purpose input pin

2 GPI[2]

Reads status of

general purpose input pin

1 GPI[1]

Reads status of

general purpose input pin

0 GPI[0]

Reads status of

general purpose input pin

32-PLCC 32-TSOP

30 7

15

3

416

517

618

LFRAME#

The LFRAME# signifies the start of a frame or the termination of a broken frame. Asserting LFRAME# for one or

more clock cycle and driving a valid START value on

LAD[3:0] will initiate device operation. The device enters

standby mode when LF RAME# a nd C E# are h igh an d no

internal operations is in progress.

Abort Mechanism

If LFRAME# is driven low for one or more clock cycles during a LPC cycle, the cycle will be terminated and the device

will wait for the ABORT command. The host must drive the

LAD[3:0] with ‘1111b’ (ABORT command) to return the

device to the ready mode. If abor t o ccurs du ring the internal write cycle, the data may be incorrectly programmed or

erased. It is required to wait for the Write operation to complete prior to initiation of the abort com mand. It is recommended to check the write status with Data# Polling (DQ

or Toggle Bit (DQ

fixed write time to expire.

) pins. One other option is to wait for the

6

)

7

Registers

There is one register available on the SST49LF020. T he

General Purpose Inputs Register. This register appears

at its respective address location in the 4 GByte system

memory map.

General Purpose Inputs Register

The GPI_REG (General Purpose Inputs Register)

passes the state of GPI[4:0] pins at power-up on the

SST49LF020. It is recommended that the GPI[4:0] pins

be in the desired state before LFRAME# is brought low

for the beg inning of the ne xt b us cycle, and remain i n that

state until the end of the cycle. There is no default value

since this is a pass-through register. The GPI register

appears at FFBC0100H in the 4 GByte s system memory

map. See General Purpose Inputs Register table for the

GPI_REG bits and f uncti o n.

CE#

The CE# pin, enables and disables the SST49LF020, controlling read and wr ite acc ess of the d evice. To enable the

SST49LF020, the CE# pin must be driven low one cycle

prior to LFRAME# being driven low. F or write (erase or program) cy cles, th e CE# pin must rema in low during the i nternal programming. W hen CE# is high, the SST49LF0 20 is

placed in low-power standby-mode.

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

3

PARALLEL PROGRAMMING MODE

2 Megabit LPC Flash

SST49LF020

Advance Information

Device Operation

Commands are used to initiate the memory operation functions of the device. The da ta por tion of th e software co mmand sequence is latched on the rising edge of WE#.

During the sof tware comman d sequenc e the row addr ess

is latched on the falling edge of R/C# and the column

address is latched on the rising edge of R/C#.

Read

The Read operation of the SST49LF020 device is controlled by OE#. OE# is the output control and is used to

gate data from the output pins. Refer to the Read cycle

timing diagram, Fi gure 15, f or further details .

Reset

Driving the RST# low will initiate a hardware reset of the

SST49LF020.

Byte-Program Operation

The SST49LF020 device is programmed on a byte-by-byte

basis. The Byte-Program operation is initiated by executing

a four-byte-command load sequence f or Software Data Protection with address (BA) and data in the last byte

sequence. During the Byte-Program operation, the row

address (A

the column address (A

of R/C#. The data bus is latched on the rising edge of WE#.

The Program operation, once initiated, will be completed,

within 20 µs. See Figures 7 and 19 for Program operation

timing diagram and Figure 31 for its flowchar t. During the

Program operation, the only valid reads are Data# Polling

and Toggle Bit. During the internal Program operation, the

host is free to perform additional tasks. Any commands written during the internal Program operation will be ignored.

) is latched on the falling edge of R/C# and

10-A0

) is latched on the rising edge

21-A11

Sector-Erase Operation

The Sector-Erase operation allows the system to erase

the device on a sector-by-sector basis. The sector architecture is based on uniform sector size of 4 KByte. The

Sector-Erase operation is initiated b y executing a six-bytecommand load sequence for Software Data Protection

with Sector-Erase command (30H) and sector address

(SA) in the last bus cycle. The internal Erase operation

begins after the sixth WE# pulse. The E nd-of-Erase can

be determined using either Data# Polling or Toggle Bit

methods. See Figure 20 for Sector-Erase timing waveforms. Any commands written during the Sector-Erase

operation will be ignored.

Block-Erase Ope ration

The Block-Erase Operation allo ws the system to erase the

device in 16 KByte unifor m block size. The Block-Erase

operation is initiated by executing a six-byte-command

load sequence for Software Data Protection with BlockErase command (50H) and block address. The internal

Block-Erase operation begins after the sixth WE# pulse.

The End-of-Erase can be determined using either Data#

Polling or Toggle Bit methods. See Figure 21 for BlockErase timing waveforms. Any commands written during

the Block-Erase operatio n will be ignored.

Chip-Erase

The SST49LF020 device p rovide s a C hip- Era se operation

only in PP Mode, which allows the user to erase the entire

memory array to the “1” state. This is useful when the entire

device must be quickly erased.

The Chip-Erase operation is initiated by executing a sixbyte Software Data Protection command sequence with

Chip-Erase command (10H) with address 5555H in the last

byte sequence. The inter nal Erase operation beg ins with

the rising edge of the sixth WE#. During the internal Erase

operation, the only valid read is T oggle Bit or Data# Polling.

See Table 4 for the command sequence, Figure 22 for

Chip-Erase timing diagram, and Figure 34 for the flowchart.

Any commands written during the Chip-Erase operation

will be ignored.

Write Operation Status Detection

The SST49LF020 device provides two software means

to detect the completion of a Write (Program or Erase)

cycle, in order to optimize the system write cycle time.

The software detection includes two status bits: Data#

Polling (DQ

detection mode is enabled after the rising edge of WE#

which initiates the in ternal Prog r am o r Er ase op er at ion .

The actual completion of the nonvolatile write is asynchronous with the system; therefore, either a Data# Polling or Toggle Bit read may be simultaneous with the

completion of the Write cycle. If this occurs, the system

may possibly g et an er rone ous re sult, i. e . , valid data may

appear to conflict w it h ei th er D Q

vent spurious rejection, if an erroneous result occurs, the

software routine should include a loop to read the

accessed location an additional two (2) times. If both

reads are valid, then the device has completed the Write

cycle, otherwise the reje ctio n is valid.

) and Toggle Bit (DQ6). The End-of-Write

7

or DQ6. In order to p re-

7

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

4

2 Megabit LPC Flash

SST49LF020

Advance Information

Data# Polling (DQ7)

When the SST49LF02 0 device is in the interna l Program

operation, any attemp t to read DQ

will produce the com-

7

plement of the tru e data. Once the Program operation is

completed, DQ

will produce true data. T he device is then

7

ready for the next operation. Dur ing inter nal Erase ope ration, any attempt to read DQ

internal Erase operation is compl eted, DQ

will produce a ‘0’. Once the

7

will produce a

7

‘1’. The Data# Polling is valid after the rising edge of fourth

WE# pulse for Program o peration. For Sector-, Block- or

Chip-Erase, the Data# Polling is valid after the r ising edge

of sixth WE# pulse. See Figures 9 and 17 for Data# Polling

timing diagram and Figure 33 for a flowchart.

Toggle Bit (DQ6)

During the inter nal Program or Erase ope ration, any consecutive attempts to read DQ

will produce alternating “0”

6

and “1”, i.e., to ggli ng be tween “0” and “1”. When the inter-

nal Program or Erase operatio n is comp leted , the toggl ing

will stop. The device is then ready for the next operation.

The Toggle Bit is valid after the risi ng edge of four th WE#

pulse for Program operation. For Sector- , Block- or ChipErase, th e Toggle Bit is valid after the rising edge of sixth

WE# pulse. See Figures 10 and 18 for Toggle Bit timing

diagram and Figure 32 for a flowchart.

Data Protection

The SST49LF020 device provides both hardware and software features to protect nonvolatile d ata from inadverten t

writes.

Hardware Data Protection

Noise/Glitch Protection: A WE# pulse of less than 5 ns will

not initiate a Write cycl e.

six byte load sequence. The SST49LF020 device is

shipped with the Software Data Protection permanently

enabled. See Ta ble 4 for the specific software command

codes. During SDP command sequence, invalid commands will abort the device to read mode, within T

RC

.

Electrical Specifications

The AC and DC specifications for the LPC interface signals

(LAD[3:0], LCLCK. LFRAME# and RST#) as defined in

Section 4.2.2 of the “PCI Local Bus specification, Rev. 2.1”.

Refer to Table 5 for the DC voltage and current specifications. Refer to Tables 11, 12, 14, and 15 for the AC timing

specifications for Clock, Read, Program, Erase and Reset

operations.

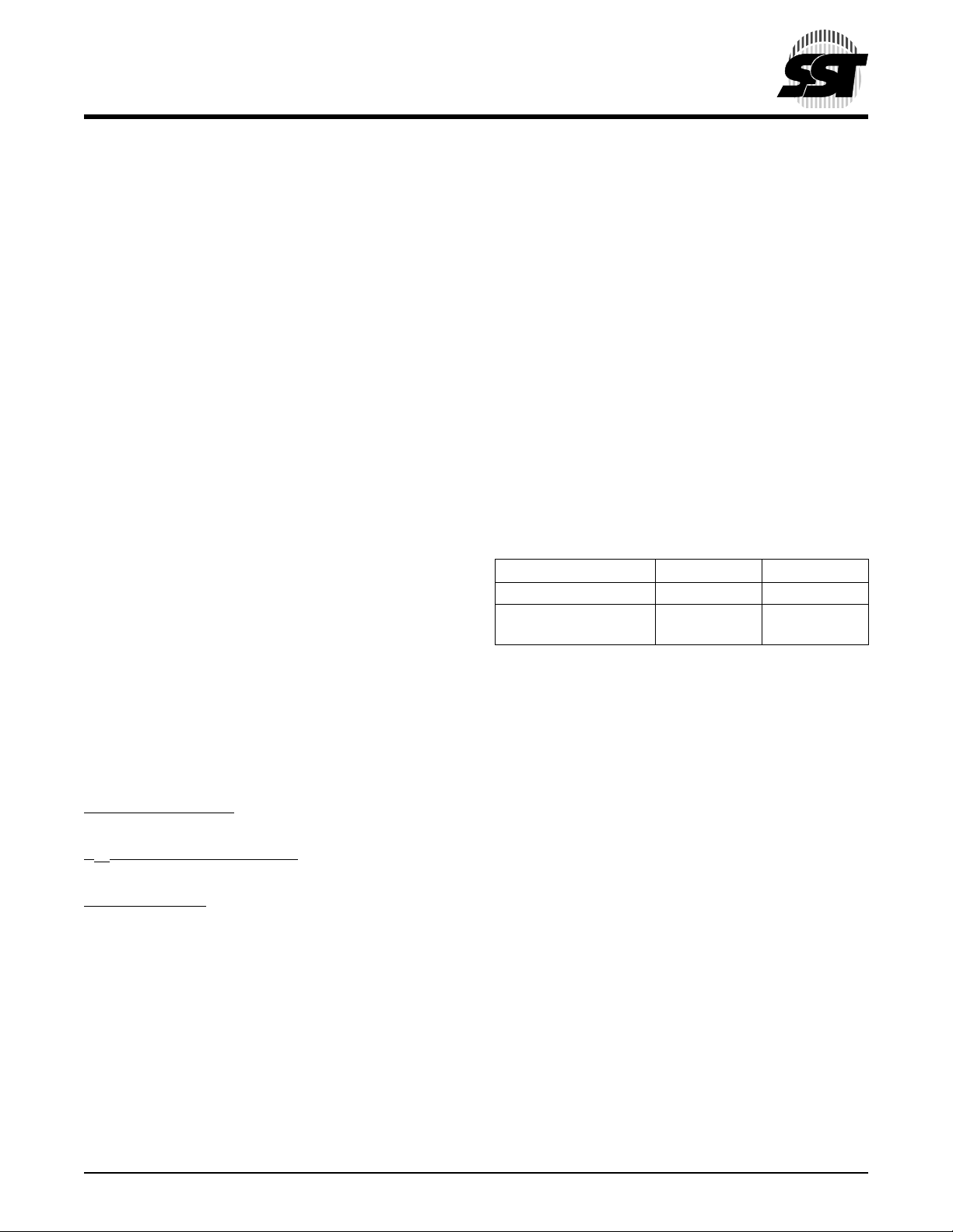

Product Identification Mode

The product identification mode identifies the device as

SST49LF020 and the manufacturer as SST .

TABLE 1: P

Manufacturer’s ID 00000H BFH

Device ID

SST49LF020

RODUCT IDENTIFICATION

Address Data

00001H 61H

T1.4 526

Design Considerations

SST recommends a high frequency 0.1 µF ceramic capacitor to be plac ed as close as possible between V

less than 1 cm away from the VDD pin of the device.

V

SS

Additionally, a low frequency 4.7 µF electroly tic capacitor

from V

to VSS should be pl aced wi thin 5 cm of th e V

DD

pin. If you use a socket for programming purposes add a n

additional 1-10 µF next to each socket.

DD

and

DD

Power Up/Down Detection: The Write operation is

V

DD

inhibited when V

Write Inhibi t Mode:

is less than 1.5V.

DD

Forcing OE# low, WE# high will inhibit

the Write operation. This prevents inadvertent writes during

power- up or po w er-do wn.

The RST# pin must remain stable at V

tion of an Erase operation. WP# must remain stable at V

for the entire duration of the Erase and Program operations

for non-boot block sectors. To write data to the top boot

block sectors, the T BL# pin must also remain stable at V

for the entire duration of the Erase and Progr am operations.

for the entire dura-

IH

Software Data Protection (SDP)

The SST49LF020 provides the JEDEC approved Software Data Protection s che me for all da ta al teration operation, i.e., Program and Erase. Any Program operation

requires the inclus ion of a series of three byte sequenc e.

The three byte-load seq uence is used to initi ate the Program operation, providing optimal protection from inadvertent Write operations, e.g., during the system power-up or

power-down. Any Erase operation requires the inclusion of

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

5

IH

IH

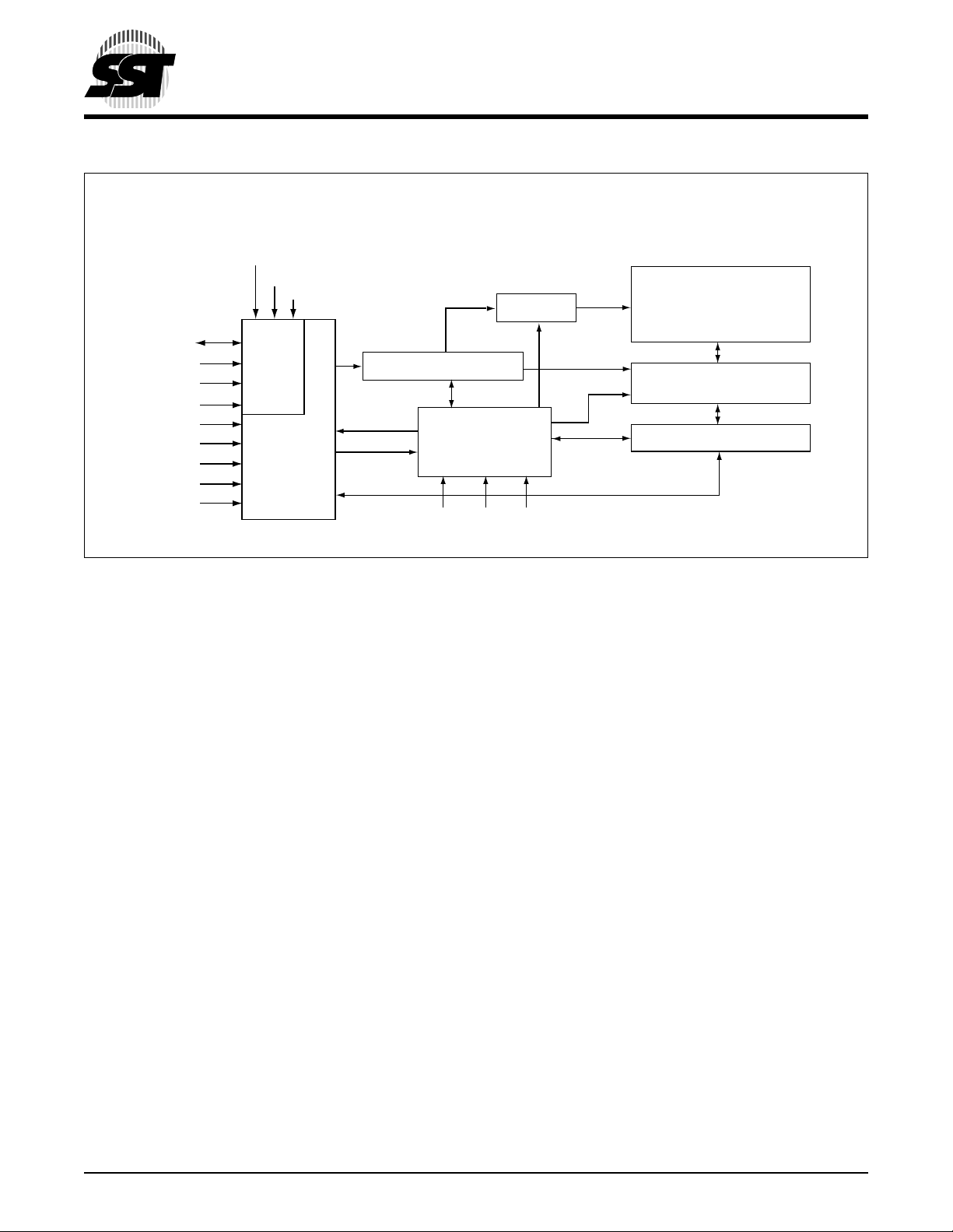

FUNCTIONAL BLOCK DIAGRAM

TBL#

WP#

INIT#

X-Decoder

2 Megabit LPC Flash

SST49LF020

Advance Information

SuperFlash

Memory

LAD[3:0]

LCLK

LFRAME#

GPI[4:0]

R/C#

A[10:0]

DQ[7:0]

OE#

WE#

LPC

Interface

Programmer

Interface

Address Buffers & Latches

Control Logic

RST#

Y-Decoder

I/O Buffers and Data Latches

CE#MODE

526 ILL B1.1

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

6

2 Megabit LPC Flash

SST49LF020

Advance Information

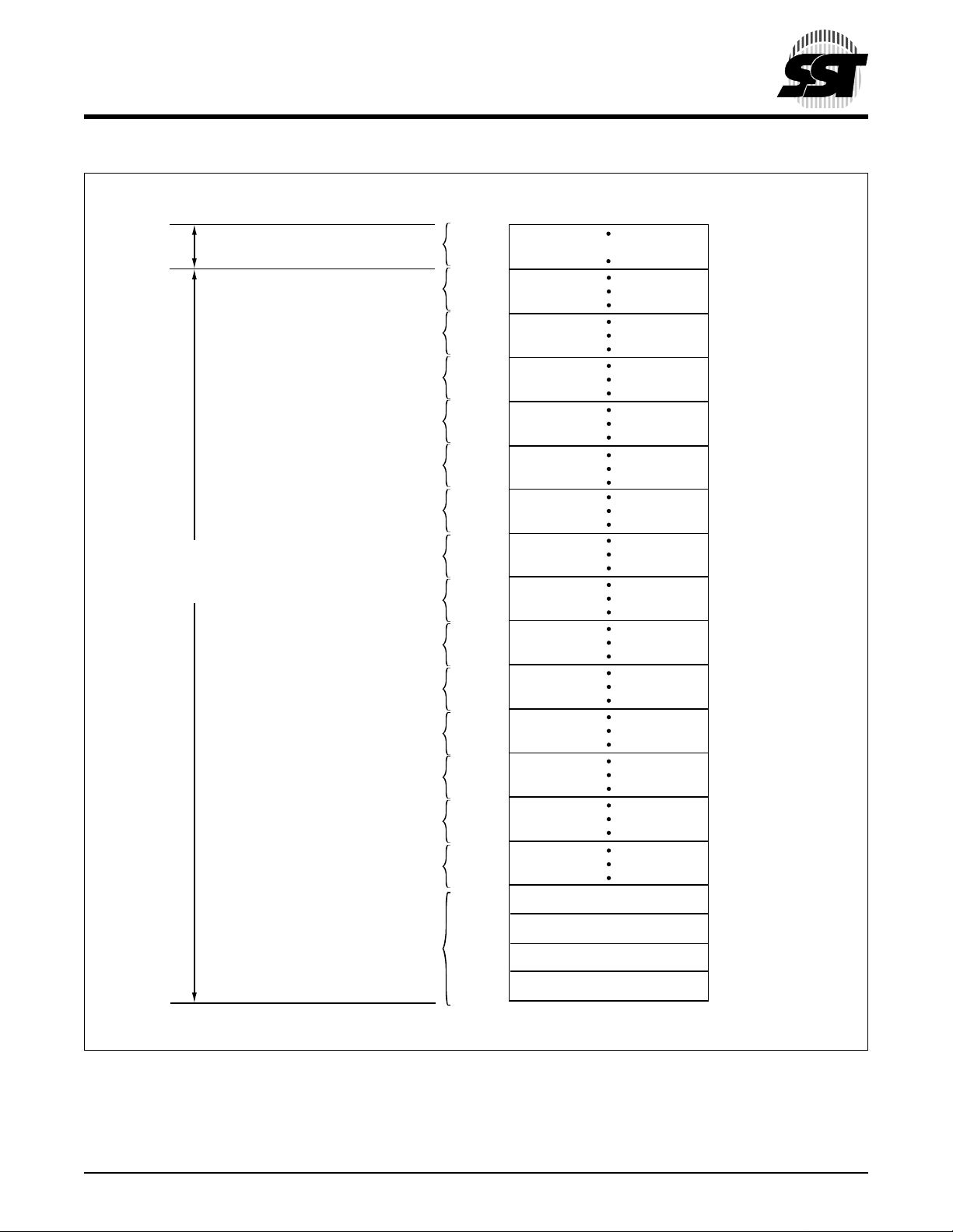

TBL#

WP# for

Block 0~14

Block 15

Block 14

Block 13

Block 12

Block 11

Block 10

Block 9

Block 8

Block 7

Block 6

Block 5

Block 4

Block 3

Block 2

Block 1

Block 0

(16 KByte)

3FFFFH

3C000H

3BFFFH

38000H

37FFFH

34000H

33FFFH

30000H

2FFFFH

2C000H

2BFFFH

28000H

27FFFH

24000H

23FFFH

20000H

1FFFFH

1C000H

1BFFFH

18000H

17FFFH

14000H

13FFFH

10000H

0FFFFH

0C000H

0BFFFH

08000H

07FFFH

04000H

03FFFH

300000

02FFFH

02000H

01FFFH

01000H

00FFFH

00000H

Boot Block

4 KByte Sector 3

4 KByte Sector 2

4 KByte Sector 1

4 KByte Sector 0

526 ILL F52.3

DEVICE MEMORY MAP FOR SST49LF02 0

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

7

2 Megabit LPC Flash

SST49LF020

Advance Information

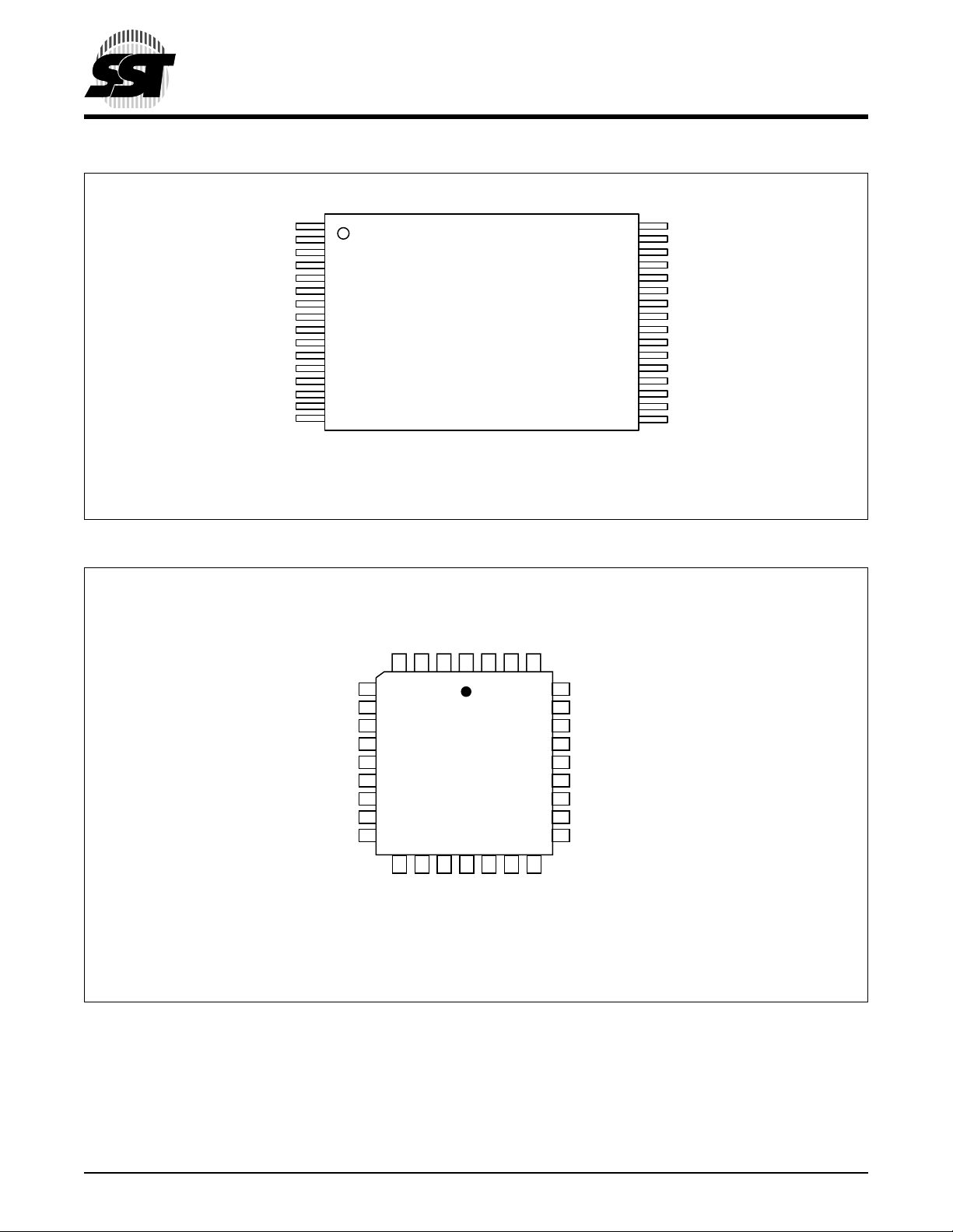

NC

NC

NC

NC (CE#)

MODE (MODE)

A10 (GPI4)

R/C# (LCLK)

V

DD (VDD

NC

RST# (RST#)

A9 (GPI3)

A8 (GPI2)

A7 (GPI1)

A6 (GPI0)

A5 (WP#)

A4 (TBL#)

1

2

3

4

5

6

7

)

8

9

10

11

12

13

14

15

16

Standard Pinout

T op Vie w

Die Up

( ) Designates LPC Mode

FIGURE 1: PIN ASSIGNMENTS FOR 32-LE A D TSOP (8MM X 14MM)

)

DD

(V

DD

R/C# (LCLK)

A8 (GPI2)

A9 (GPI3)

RST# (RST#)NCV

A10 (GPI4)

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE# (INIT#)

WE# (LFRAME#)

VDD (VDD)

DQ7 (RES)

DQ6 (RES)

DQ5 (RES)

DQ4 (RES)

DQ3 (LAD3)

V

SS (VSS

DQ2 (LAD2)

DQ1 (LAD1)

DQ0 (LAD0)

A0 (RES)

A1 (RES)

A2 (RES)

A3 (RES)

526 ILL F01.2

)

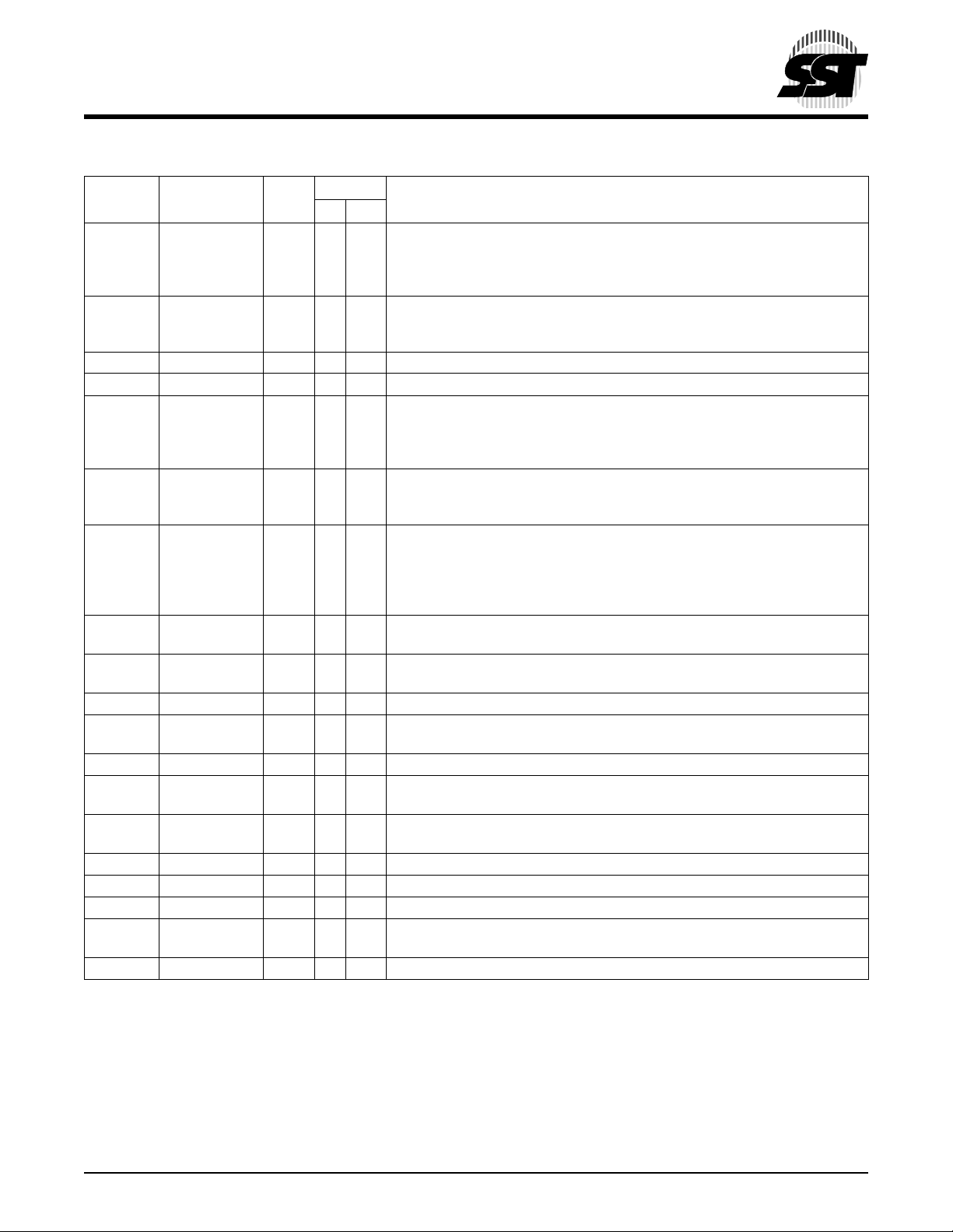

FIGURE 2: P

4 3 2 1 32 31 30

A7(GPI1)

A6 (GPI0)

A5 (WP#)

A4 (TBL#)

A3 (RES)

A2 (RES)

A1 (RES)

A0 (RES)

DQ0 (LAD0)

5

6

7

8

32-lead PLCC

9

10

T op Vie w

11

12

13

14 15 16 17 18 19 20

DQ1 (LAD1)

DQ2 (LAD2)

( ) Designates LPC Mode

IN ASSIGNMENTS FOR 32-LEAD PLCC

)

SS

(V

SS

V

DQ3 (LAD3)

DQ4 (RES)

DQ5 (RES)

29

MODE (MODE)

28

NC (CE#)

27

NC

26

NC

25

VDD (VDD)

24

OE# (INIT#)

23

WE# (LFRAME#)

NC

22

DQ7 (RES)

21

DQ6 (RES)

526 ILL F02.2

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

8

2 Megabit LPC Flash

SST49LF020

Advance Information

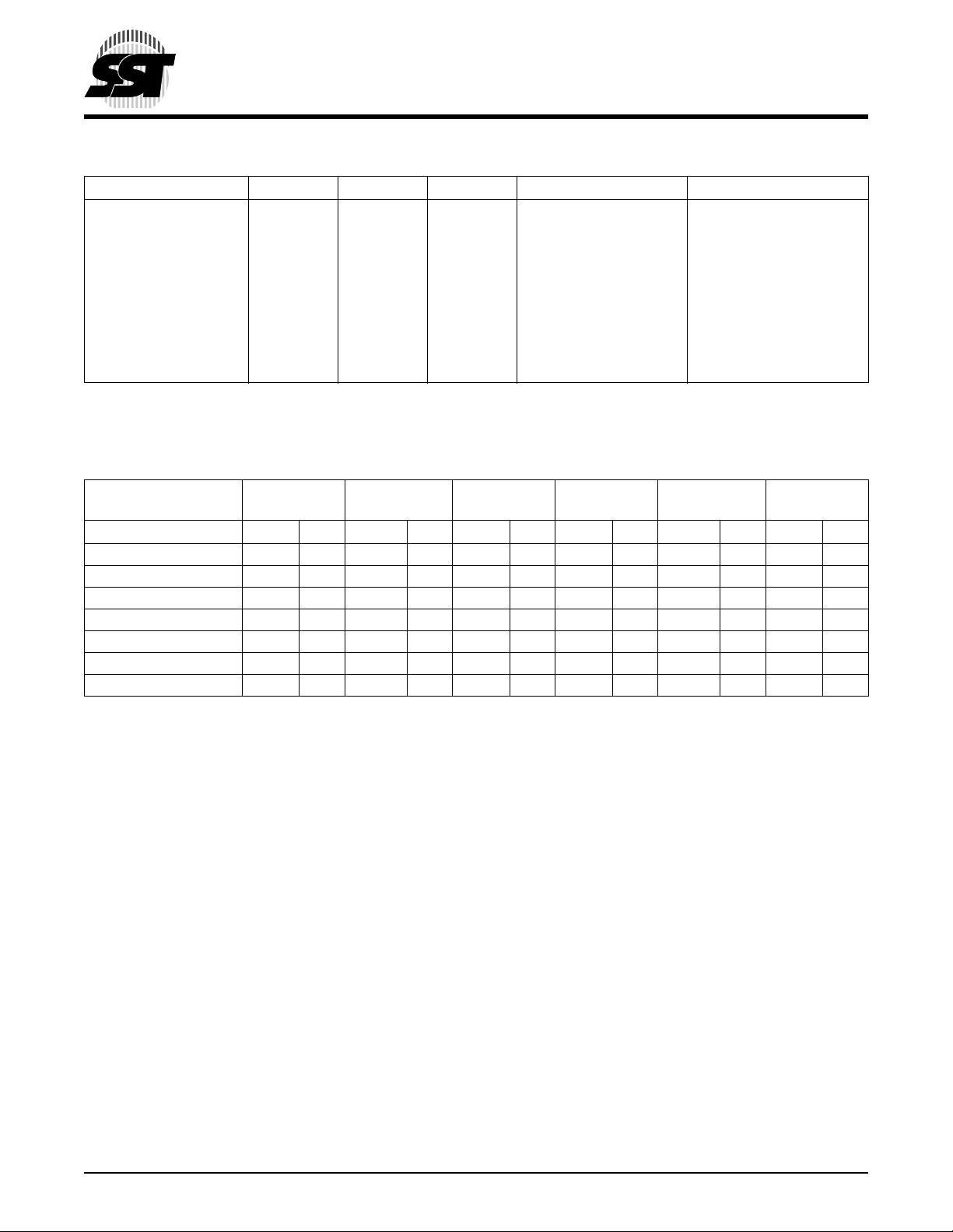

TABLE 2: PIN DESCRIPTION

Interface

Symbol Pin Name Type

A

10-A0

-DQ0Data I/O X To output data during Read cycles and receive input data during Write cycles.

DQ

7

Address I X Inputs for low-order addresses during Read and Write operations. Addresses

OE# Output Enable I X To gate the data output buffers.

WE# Write Enable I X To control the Write operations.

MODE Interface

Mode Select

INIT# Initialize I X This is the second reset pin for in-system use. This pin is internally combined

GPI[4:0] General

Purpose Inputs

TBL# T op Block Lock I X When low, prevents programming boot block sectors at top of memory. When

LAD[3:0] Address and

Data

LCLK Clock I X T o provide a clock input to the control unit

LFRAME# Frame I X To indicate start of a data tr an sf er opera tion; also used t o a bort an LPC cy cle

RST# Reset I X X To reset the operation of the device

WP# Write Protect I X When low, pre v ents programming to all but the highest addressable top boot

R/C# Row/Column

Select

RES Reserved X These pins must be left unconnected.

V

DD

Power Supply I X X To provide power supply (3.0-3.6V)

Vss Ground I X X Circuit ground (OV reference)

CE# Chip Enable I X This signal must b e a s se rted to se lect the device. Wh en C E# is low, the d evice

NC No Connection I X X Unconnected pins.

1. I=Input, O=Output

1

FunctionsPP LPC

are internally latched during a Write cycle. For the programming interface, these

addresses are latched by R/C# and share the same pins as the high-order

address inputs.

Data is internally latched during a Write cycle. The outputs are in tri-state when

OE# is high.

I X X This pin determines which interf a ce is opera tiona l. When hel d high, prog ram mer

mode is enabled and w hen held low, LPC mode is enabled. This pin mus t be

setup at power-up or befo re return from reset and not change during de vice operation. This pin is internally pulled do wn with a resistor b etwe en 20-100KΩ.

with the RST# pin; If this pin or RST# pin is driven low, identical operation is

exhibited.

I X These individual inputs can be used for additional board flexibility. The state of

these pins can be read through LPC registers. These inputs should be at their

desired state before the start of the PCI clock cycle during which the read is

attempted, and should remain in place until the end of the Read cycle. Unused

GPI pins must not be floated.

TBL# is high it disables hardware write protection for the top block sectors.

I/O X To provide LPC control signals, as well as addresses and Command

Inputs/Outputs data.

in progress.

blocks. When WP# is high it disables hardware write protection for these b locks.

I X Select for the Programming interface, this pin determines whether the address

pins are pointing to the row addresses, or to the column addresses.

is enabled. When CE# is high, the device is placed in low power standby mode.

T2.3 526

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

9

2 Megabit LPC Flash

SST49LF020

Advance Information

TABLE 3: OPERATION MODES SELECTION (PP MODE)

Mode RST# OE# WE# DQ Address

Read

Program V

Erase V

Reset V

Write Inhibit

V

IH

IH

IH

IL

V

IH

X

Product Identification V

1. X can be VIL or VIH, but no other value.

2. Device ID = 61H

IH

TABLE 4: SOFTWARE COMMAND SEQUENCE

1

1st

Command Sequence

Byte-Program 5555H AAH 2AAAH 55H 5555H A0H BA

Sector-Erase 5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H SAx

Block-Erase 5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H BAx

Chip-Erase

Software ID Entry

Software ID Exit

Software ID Exit

1. LPC Mode use consecutive Write cycles to complete a command sequence;

2. Address format A14-A0 (Hex), Addresses A15-A21 can be VIL or VIH, but no other value, for the Command sequence in PP Mode.

3. BA = Program Byte address

4. SAx for Sector-Erase Address

5. BAx for Block-Erase Address

6. Chip-Erase is supported in PP Mode only

7. With A17-A1=0;SST Manufacturer’s ID=BFH, is read with A0=0.

8. Both Software ID Exit operations are equivalent

6

7

8

8

PP Mode use consecutive bus cycles to complete a command sequence.

SST49LF020 Device ID = 61H, is read with A

Write Cycle

2

Addr

Data Addr2Data Addr2Data Addr2Data Addr2Data Addr2Data

5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H 5555H 10H

5555H AAH 2AAAH 55H 5555H 90H

XXH F0H

5555H AAH 2AAAH 55H 5555H F0H

V

IL

V

IH

V

IH

V

IL

V

IL

V

IL

D

D

X

OUT

IN

1

A

IN

A

IN

Sector or Block address,

XXH for Chip-Erase

XXHigh Z X

V

IL

V

IH

V

IL

1

2nd

Write Cycle

V

IL

X

V

IL

3rd

Write Cycle

=1.

0

High Z/D

High Z/D

OUT

OUT

Manufacturer’s ID (BFH)

Device ID

1

2

1

4th

Write Cycle

3

Data

X

X

A18-A1=VIL, A0=V

A18-A1=VIL, A0=V

1

5th

Write Cycle

Write Cycle

IL

IH

6th

4

5

T3.2 526

1

30H

50H

T4.5 526

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

10

2 Megabit LPC Flash

SST49LF020

Advance Information

Absolute Maximum Stress Ratings (Applied conditions greater than those listed under “Absolute Maximum

Stress Ratings” may cause pe r manent dama ge to the device. This is a stres s rating only and funct ional operatio n

of the device at these conditions or conditions greater tha n those defined in the ope rational sections of this data

sheet is not implied. Exposure to absolute maximum stress rating conditions may affect device reliability.)

Temperature Under Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

D. C. Voltage on Any Pin to Ground Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to

Transient Voltage (<20 ns) on Any Pin to Ground Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . -1.0V to

Package Power Dissipation Capability (Ta=25°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0W

Surface Mount Lead Soldering Temperature (3 Seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240°C

1

Output Short Circ uit Curr ent

1. Outputs shorted for no more than one second. No more than one output shorted at a time.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 mA

V

DD

V

DD

+ 0.5V

+ 1.0V

OPERATING RANGE

Range Ambient Temp V

Commercial 0°C to +85°C 3.0-3.6V

DD

AC CONDITIONS OF TEST

Input Rise/Fall Time . . . . . . . . . . . . . . . 3 ns

Output Load . . . . . . . . . . . . . . . . . . . . . C

See Figures 25 and 26

1. LPC interface signals use PCI load condition.

TABLE 5: DC OPERATING CHARACTERISTICS (ALL INTERFACES)

Limits

Symbol Parameter

I

DD

I

SB

1

I

RY

I

I

I

LI

I

LO

V

IHI

V

ILI

V

IL

V

IH

V

OL

V

OH

1. The device is in Ready Mode when no activity is on the LPC bus.

Power Supply Current Address input=VIL/VIH, at f=1/TRC Min,

Read 12 mA OE#=VIH, WE#=V

Write 24 mA OE#=VIH, WE#=VIL, VDD=VDD Max (PP Mode)

Standby VDD Current

100 µA LFRAME#=VIH, f=33 MHz, CE#=V

(LPC Interface)

Ready Mode VDD Current

10 mA LFRAME#=VIL, f=33 MHz, VDD=VDD Max

(LPC Interface)

Input Current for IC Pin 200 µA VIN=GND to VDD, VDD=VDD Max

Input Leakage Current 1 µA VIN=GND to VDD, VDD=VDD Max

Output Leakage Current 1 µA V

INIT# Input High Voltage 1.0 VDD+0.5 V VDD=VDD Max

INIT# Input Low Voltage -0.5 0.4 V VDD=VDD Max

Input Low Voltage -0.5 0.3 V

Input High Voltage 0.5 V

DDVDD

Output Low Voltage 0.1 V

Output High Voltage 0.9 V

DD

DD

+0.5 V VDD=VDD Max

DD

VVDD=VDD Min

VIOL=1500 µA, VDD=VDD Min

VIOH=-500 µA, VDD=VDD Min

1

Test Condit ionsMin Max Units

V

DD=VDD

Max (PP Mode)

IH

VDD=VDD Max,

All other inputs ≥ 0.9 V

All other inputs ≥ 0.9 V

=GND to VDD, VDD=VDD Max

OUT

or ≤ 0.1 V

DD

or ≤ 0.1 V

DD

= 30 pF

L

IH

DD

DD

T5.5 526

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

11

2 Megabit LPC Flash

SST49LF020

Advance Information

TABLE 6: RECOMMENDED SYSTEM POWER-UP TIMINGS

Symbol Parameter Minimum Units

T

PU-READ

T

PU-WRITE

1

1

1. This parameter is measured only for initial qualification and after a design or process change that could affect this parameter

Power-up to Read Operation 100 µs

Power-up to Write Operation 100 µs

T6.1 526

TABLE 7: PIN CAPACITANCE (V

=3.3V, Ta=25 °C, f=1 Mhz, other pins open)

DD

Parameter Description Test Condition Maximum

1

C

I/O

1

C

IN

2

L

PIN

1. This parameter is measured only for initial qualification and after a design or process change that could affect this parameter.

2. Refer to PCI Spec.

I/O Pin Capacitance V

=0V 12 pF

I/O

Input Capacitance VIN=0V 6 pF

Pin Inductance 20 nH

TABLE 8: RELIABILITY CHARACTERISTICS

Minimum

Symbol Parameter

1

N

END

1

T

DR

1

I

LTH

1. This parameter is measured only for initial qualification and after a design or process change that could affect this parameter.

Endurance 10,00 0 Cycles JEDEC Standard A117

Data Retention 100 Years JEDEC Standard A103

Latch Up 100 + I

Specification Units Test Method

DD

mA JEDEC Standard 78

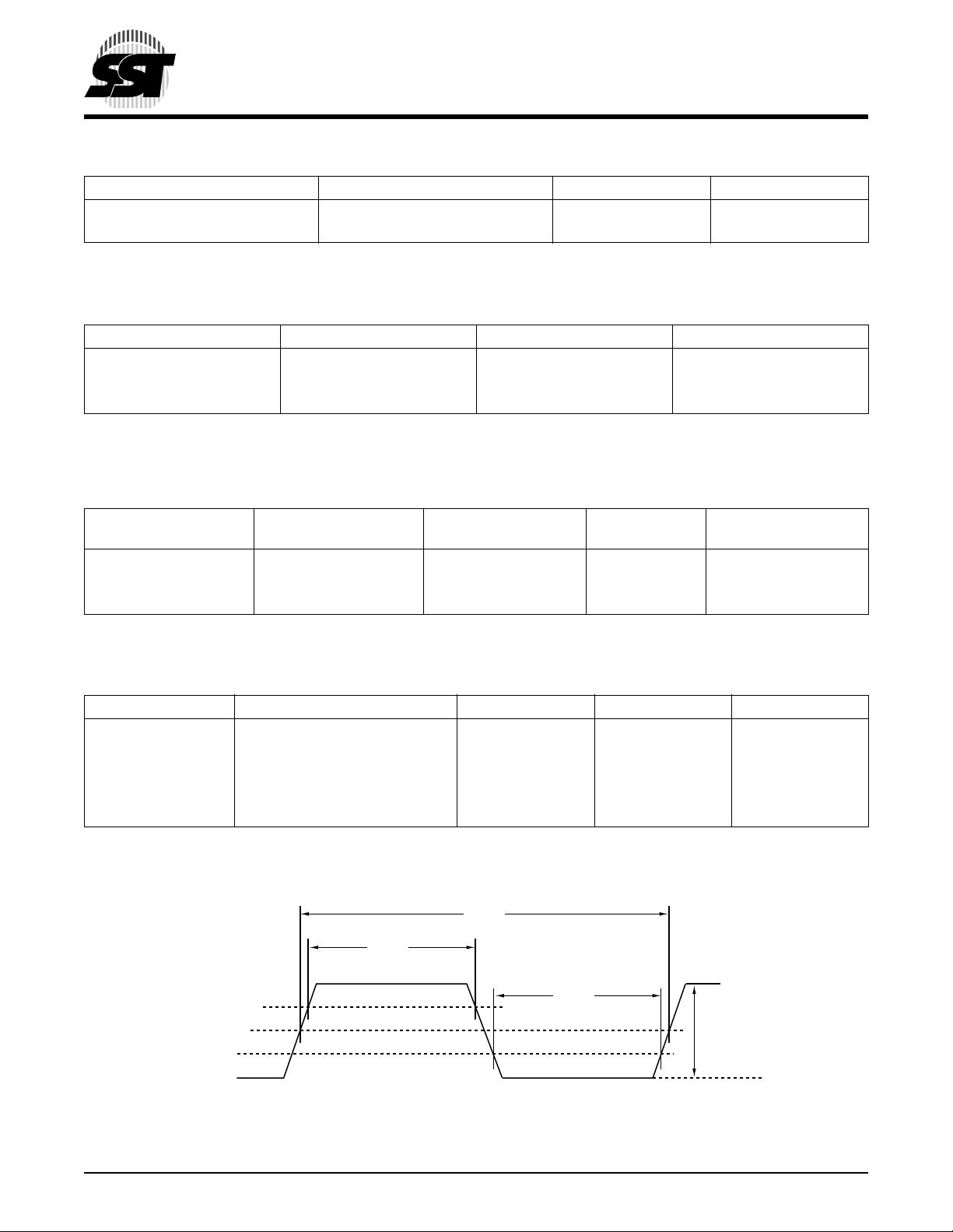

TABLE 9: CLOCK TIMING PARAMETERS (LPC MODE)

Symbol Parameter Min Max Units

T

CYC

T

HIGH

T

LOW

- LCLK Slew Rate (peak-to-peak) 1 4 V/ns

- RST# or INIT# Slew Rate 50 mV/ns

LCLK Cycle Time 30 ns

LCLK High T i me 11 ns

LCLK Low Time 11 ns

T7.0 526

T8.1 526

T9.0 526

T

cyc

T

high

0.6 V

0.4 V

0.3 V

0.5 V

DD

DD

DD

DD

T

low

0.2 V

DD

0.4 V

DD

(minimum)

526 ILL F27.0

p-to-p

FIGURE 3: LCLK WAVEFORM

©2001 Silicon Storage Technology, Inc. S71175-02-000 5/01 526

12

Loading...

Loading...