Silicon Storage Technology Inc SST45VF512-10-4C-SA, SST45VF020-10-4C-SA, SST45VF010-10-4C-SA Datasheet

512 Kbit / 1 Mbit / 2 Mbit Serial Flash

SST45VF512 / SST45VF010 / SST45VF020

FEATURES:

• Single 2.7-3.6V Read and Write Operations

• Serial Interface Architecture

– SPI Compatible: Mode 0 and Mode 3

• Byte Serial Read with Single Command

• Superior Reliability

– Endurance: 100,000 Cycles (typical)

– Greater than 100 years Data Retention

• Low Power Consumption:

– Active Current: 20 mA (typical)

– Standby Current: 10 µA (typical)

• Sector or Chip-Erase Capability

– Uniform 4 KByte sectors

• Fast Erase and Byte-Program:

– Chip-Erase Time: 70 ms (typical)

– Sector-Erase Time: 18 ms (typical)

– Byte-Program Time: 14 µs (typical)

Advance Information

• Automatic Write Timing

– Internal VPP Generation

• End-of-Write Detection

– Software Status

• 10 MHz Max Clock Frequency

• Hardware Reset Pin (RESET#)

– Resets the device to Standby Mode

• CMOS I/O Compatibility

• Hardware Data Protection

– Protects and unprotects the device

from Write operation

• Packages Available

– 8-Pin SOIC (4.9mm x 6mm)

1

2

3

4

5

6

7

PRODUCT DESCRIPTION

The SST45VF512, SST45VF010 and SST45VF020 are

manufactured with SST’s proprietary, high performance

CMOS SuperFlash technology. The Serial Flash is

organized as 16 sectors of 4096 Bytes for SST45VF512,

32 sectors of 4096 Bytes for the SST45VF010 and

64 sectors of 4096 Bytes for the SST45VF020. The

memory is accessed for Read or Erase/Program by the

SPI bus compatible serial protocol. The bus signals are:

serial data input (SI), serial data output (SO), serial clock

(SCK), write protect (WP#), chip enable (CE#), and

hardware reset (RESET#).

The SST45VFxxx devices are offered in 8-pin SOIC

package. See Figure 1 for the pinout.

Device Operation

The SST45VFxxx uses bus cycles of 8 bits each for

commands, data, and addresses to execute operations.

The operation instructions are listed in Table 2.

All instructions are synchronized off a high to low transition of CE#. The first low to high transition on SCK will

initiate the instruction sequence. Inputs will be accepted

on the rising edge of SCK starting with the most significant bit. Any low to high transition on CE# before the input

instruction completes will terminate any instruction in

progress and return the device to the standby mode.

Read

The Read operation outputs the data in order from the

initial accessed address. While SCK is input, the address

will be incremented automatically until end (top) of the

address space, then the internal address pointer automatically increments to beginning (bottom) of the address space (00000H), and data out stream will continue.

The read data stream is continuous through all addresses until terminated by a low to high transition on

CE#.

Sector/Chip-Erase Operation

The Sector-Erase operation clears all bits in the selected

sector to “FF”. The Chip-Erase instruction clears all bits

in the device to “FF”.

Byte-Program Operation

The Byte-Program operation programs the bits in the

selected byte to the desired data. The selected byte must

be in the erased state (“FF”) when initiating a Program

operation. The data is input from bit 7 to bit 0 in order.

Software Status Operation

The Status operation determines if an Erase or Program

operation is in progress. If bit 0 is at a “0” an Erase or

Program operation is in progress, the device is busy. If bit

0 is at a “1” the device is ready for any valid operation. The

status read is continuous with ongoing clock cycles until

terminated by a low to high transition on CE#.

8

9

10

11

12

13

14

15

16

© 2000 Silicon Storage Technology, Inc. The SST logo and SuperFlash are registered trademarks of Silicon Storage Technology, Inc. These specifications are subject to change without notice.

514-1 10/00 S71178

1

512 Kbit / 1 Mbit / 2 Mbit Serial Flash

SST45VF512 / SST45VF010 / SST45VF020

Advance Information

Reset

Reset will terminate any operation, e.g., Read, Erase

and Program, in progress. It is activated by a high to low

transition on the RESET# pin. The device will remain in

reset condition as long as RESET# is low. Minimum reset

time is 10µs. See Figure 14 for reset timing diagram.

RESET# is internally pulled-up and could remain unconnected during normal operation. After reset, the device is

in standby mode, a high to low transition on CE# is

required to start the next operation.

An internal power-on reset circuit protects against accidental data writes. Applying a logic level low to RESET#

during the power-on process then changing to a logic

level high when V

level will provide additional protection against accidental

writes during power on.

Read SST ID/Read Device ID

The Read SST ID and Read Device ID operations read

the JEDEC assigned manufacturer identification and the

manufacturer assigned device identification codes.

These codes may be used to determine the actual device

resident in the system.

has reached the correct voltage

DD

TABLE 1: PRODUCT IDENTIFICATION

Byte Data

Manufacturer’s ID 0000 H BF H

Device ID

SST45VF512 0001 H 41 H

SST45VF010 0001 H 45 H

SST45VF020 0001 H 43 H

514 PGM T1.4

Write Protect

The WP# pin provides inadvertent write protection. The

WP# pin must be held high for any Erase or Program

operation. The WP# pin is “don’t care” for all other

operations. In typical use, the WP# pin is connected to

VSS with a standard pull-down resistor. WP# is then

driven high whenever an Erase or Program operation is

required. If the WP# pin is tied to VDD with a pull-up

resistor, then all operations may occur and the write

protection feature is disabled. The WP# pin has an

internal pull-up and could remain unconnected when not

used.

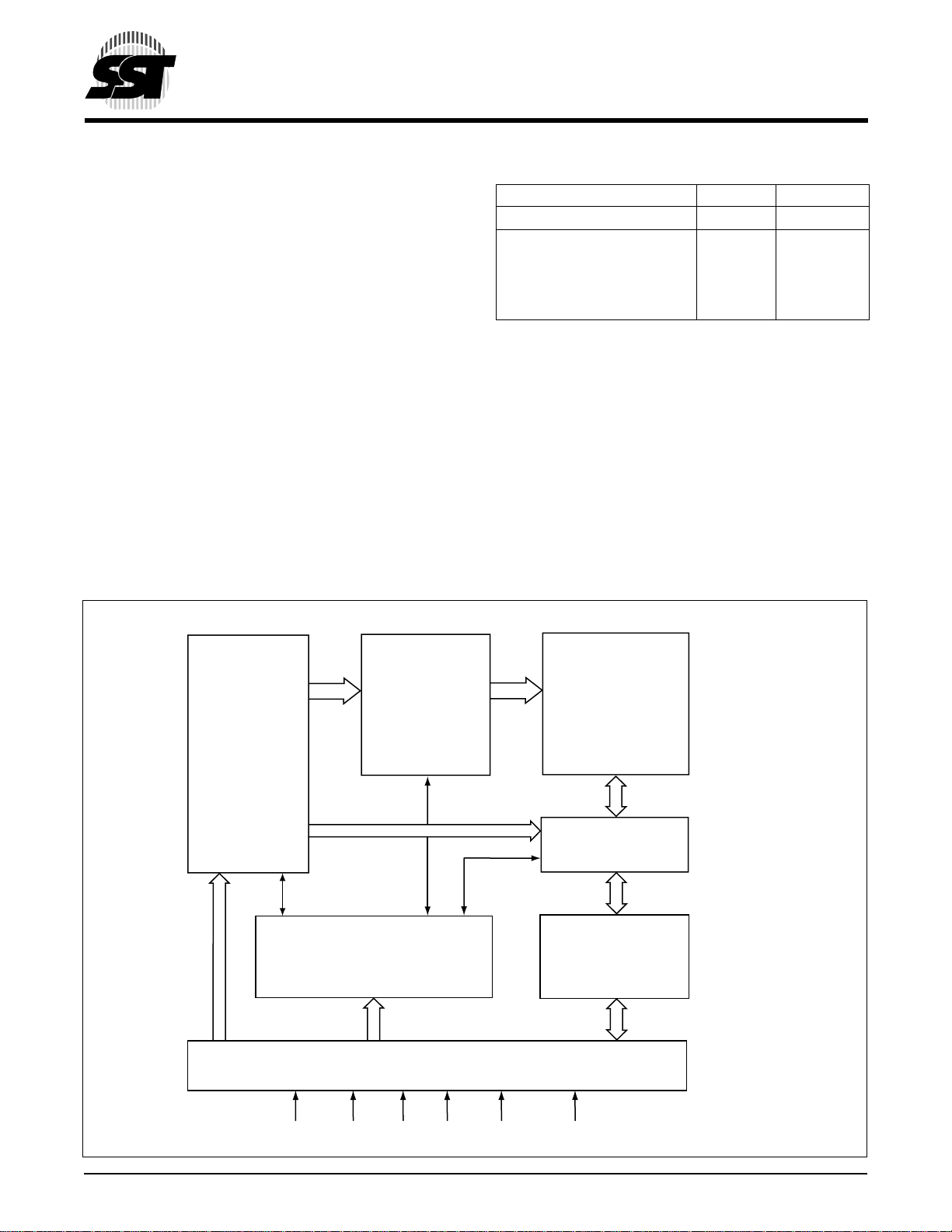

FUNCTIONAL BLOCK DIAGRAM

Address

Buffers

and

Latches

X - Decoder

Control Logic

Serial Interface

SuperFlash

Cell Array

Y - Decoder

I/O Buffers

and

Data Latches

© 2000 Silicon Storage Technology, Inc.

CE#

SCK SI SO WP# RESET#

2

514ILL B1.0

S71178

514-1 10/00

512 Kbit / 1 Mbit / 2 Mbit Serial Flash

SST45VF512 / SST45VF010 / SST45VF020

Advance Information

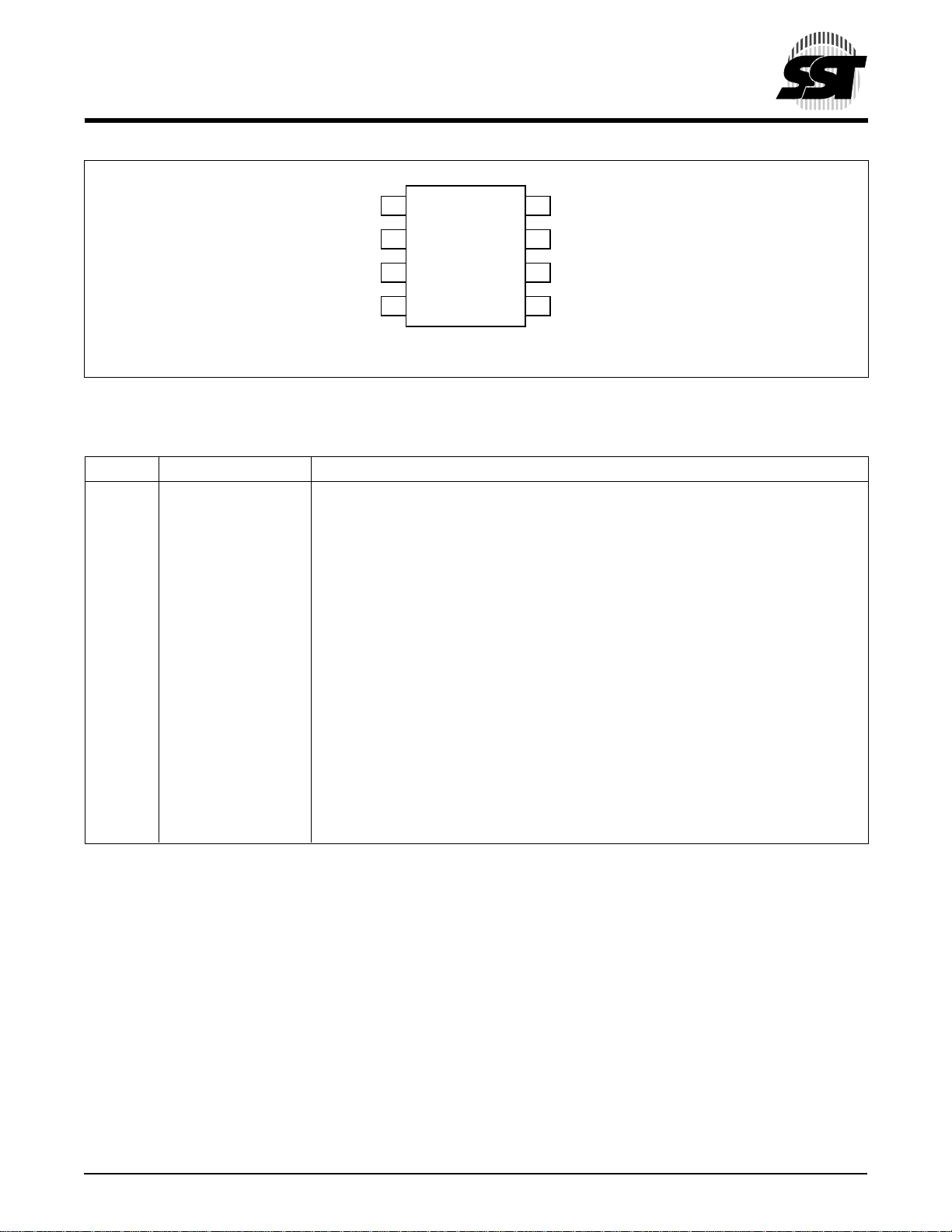

WP#

V

DD

CE#

SCK

FIGURE 1: PIN ASSIGNMENTS FOR 8-PIN SOIC

TABLE 2: PIN DESCRIPTION

Symbol Pin Name Functions

SCK Serial Clock To provide the timing of the serial interface. Commands, addresses, or

input data are latched on the rising edge of the clock input, while output

data is shifted out on the falling edge of the clock input.

SI Serial Data Input To transfer commands, addresses, or data serially into the device. Inputs

are latched on the rising edge of the serial clock.

SO Serial Data Output To transfer data serially out of the device. Data is shifted out on the

falling edge of the serial clock.

CE# Chip Enable The device is enabled by a high to low transition on CE#.

WP# Write Protect To protect the device from unintentional Write (Erase or Program)

operations. When WP# is low, all Erase and Program commands are

ignored. When WP# is high, the device may be erased or programmed.

This pin has an internal pull-up and could remain unconnected when not used.

RESET# Reset A high to low transition on RESET# will terminate any operation in progress

and reset the internal logic to the standby mode. The device will remain in the

reset condition as long as the RESET# is low. Operations may only occur

when RESET# is high. This pin has an internal pull-up and could remain

unconnected when not used.

V

DD

V

SS

Power Supply To provide power supply (2.7-3.6V).

Ground

1

2

Standard Pinout

T op Vie w

3

Die Up

4

8

7

6

5

514 ILL F01.0

RESET#

V

SS

SO

SI

514 PGM T2.2

1

2

3

4

5

6

7

8

9

10

11

12

© 2000 Silicon Storage Technology, Inc.

13

14

15

16

3

S71178

514-1 10/00

512 Kbit / 1 Mbit / 2 Mbit Serial Flash

SST45VF512 / SST45VF010 / SST45VF020

Advance Information

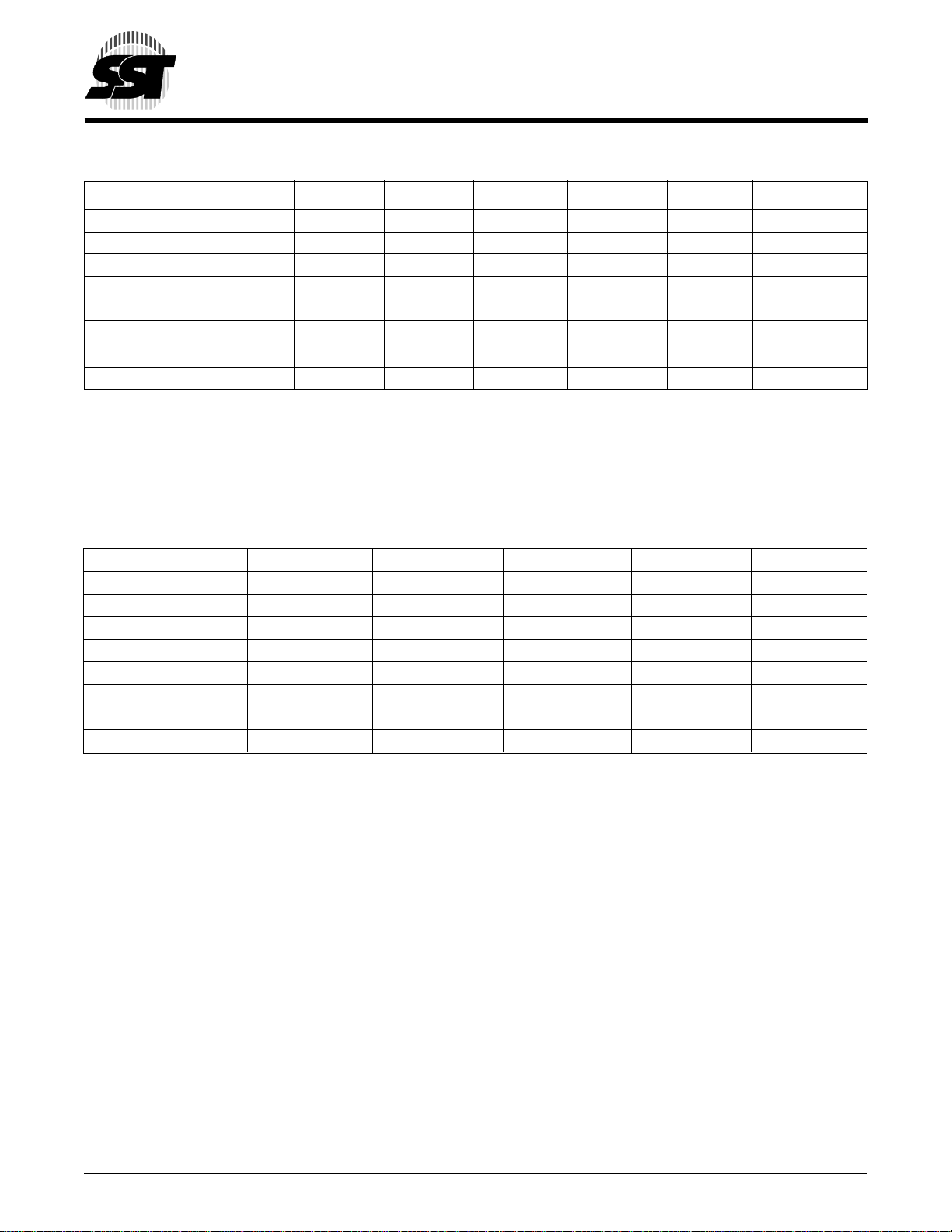

TABLE 3: DEVICE OPERATION INSTRUCTIONS

Bus Cycle 1 2 3 4 5 6 7 and after

1

Operation/Type Command Address

Read FFH A

Sector-Erase

2

20H A23-A

23-A16

16

Chip-Erase 60H X X X D0H X

Byte-Program 10H A23-A

16

Software-Status 9FH Dout

Read SST ID 90H X X A

Read Device ID

Notes:

1. A23-A16 are “Don't Care” for SST45VF512, A23-A17 are “Don't Care” for SST45VF010, A23-A18 are “Don't Care” for SST45VF020.

2. A16-A12 are used to determine sector address, A11-A8 are don't care.

3. With A15-A1 = 0, SST45VF512 Device ID = 41H, is read with A0 = 1.

With A16-A1 = 0, SST45VF010 Device ID = 45H, is read with A0 = 1.

With A17-A1 = 0, SST45VF020 Device ID = 43H, is read with A0 = 1.

3

90H X X A0=1 Device ID

Address Address Data Dummy Data

A15-A

A15-A

A15-A

8

8

8

A7-A

0

X X Dout

X D0H X

A7-A

0

=0 BFH

0

Din X

514 PGM T3.3

TABLE 4: DEVICE OPERATION TABLE

Operation SI SO CE#

1

WP# RESET#

Read X Dout Low X High

Sector-Erase X X Low High High

Chip-Erase X X Low High High

Byte-Program Din X Low High High

Software-Status X Dout Low X High

2

Reset

X XXXLow

Read SST ID X Dout Low X High

Read Device ID X Dout Low X High

Notes:

1. A high to low transition on CE# will be required to start any device operation except for Reset.

2. The RESET# low will return the device to standby and terminate any Erase or Program operation in progress.

514 PGM T4.1

© 2000 Silicon Storage Technology, Inc.

4

S71178

514-1 10/00

512 Kbit / 1 Mbit / 2 Mbit Serial Flash

SST45VF512 / SST45VF010 / SST45VF020

Advance Information

Absolute Maximum Stress Ratings (Applied conditions greater than those listed under “Absolute maximum Stress

Ratings” may cause permanent damage to the device. This is a stress rating only and functional operation of the device

at these conditions or conditions greater than those defined in the operational sections of this data sheet is not implied.

Exposure to absolute maximum stress rating conditions may affect device reliability.)

1

Temperature Under Bias ................................................................................................................. -55°C to +125°C

Storage Temperature ...................................................................................................................... -65°C to +150°C

D. C. Voltage on Any Pin to Ground Potential ............................................................................ -0.5V to V

Transient Voltage (<20 ns) on Any Pin to Ground Potential........................................................ -1.0V to V

DD

+ 1.0V

DD

+ 0.5V

Package Power Dissipation Capability (Ta = 25°C) ........................................................................................... 1.0W

Surface Mount Lead Soldering Temperature (3 Seconds)............................................................................... 240°C

Output Short Circuit Current

OPERATING RANGE

Range Ambient Temp V

Commercial 0 °C to +70 °C 2.7-3.6V

1

................................................................................................................................................................... 50 mA

AC CONDITIONS OF TEST

DD

Input Rise/Fall Time......... 5 ns

Output Load.....................CL = 30 pF

See Figures 2 and 3

TABLE 5: DC OPERATING CHARACTERISTICS VDD = 2.7-3.6V

Limits

Symbol Parameter Min Max Units Test Conditions

Power Supply Current f = 10 MHz

I

DD

I

SB

I

I

LO

I

V

V

V

IHC

V

V

Note: 1. Outputs shorted for no more than one second. No more than one output shorted at a time.

Read 20 mA CE# = VIL, V

Program and Erase 30 mA CE# = VIL, V

Standby Current 15 µA CE# = V

Input Leakage Current 1 µA VIN =GND to VDD, V

LI

Output Leakage Current 1 µA V

Input Low Current

IL

Input Low Voltage 0.8 V V

IL

Input High Voltage 0.7 V

IH

(2)

360 µA WP#, RESET# = GND

DD

VV

Input High Voltage (CMOS) VDD-0.3 V V

Output Low Voltage 0.2 V IOL = 100 µA, V

OL

Output High Voltage VDD-0.2 V IOH = -100 µA, V

OH

2. This parameter only applies to WP# and RESET# pins.

OUT

= VDD Min.

DD

= VDD Max.

DD

= VDD Max.

DD

= VDD Max.

DD

= VDD Max.

DD

, V

IHC

= VDD Max.

DD

DD

=GND to VDD, V

= VDD Min.

DD

= VDD Min.

DD

= VDD Max.

= VDD Max.

DD

514 PGM T5.2

2

3

4

5

6

7

8

9

10

11

12

13

14

© 2000 Silicon Storage Technology, Inc.

15

16

5

S71178

514-1 10/00

Loading...

Loading...