Silicon Storage Technology Inc SST27SF512-90-3C-WH, SST27SF512-90-3C-WG, SST27SF512-90-3C-PH, SST27SF512-90-3C-PG, SST27SF512-90-3C-NH Datasheet

...

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

SST27SF256 / 512 / 010 / 0205.0V-Read 256Kb / 512Kb / 1Mb / 2Mb (x8) MTP flash memories

FEATURES:

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit (x8)

Many-Time Programmable Flash

Data Sheet

• Organized as 32K x8 / 64K x8 / 128K x8 / 256K x8

• 4.5-5.5V Read Operation

• Superior Reliability

– Endurance: At least 1000 Cycles

– Greater than 100 years Data Retention

• Low Power Consumption

– Ac ti ve Current: 20 mA (typical)

– Standby Current: 10 µA (typical)

• Fast Read Access Time

– 70 ns

– 90 ns

PRODUCT DESCRIPTION

The SST27SF256/5 12/010/020 are a 32K x8 / 64K x8 /

128K x8 / 256K x8 CMOS, Many-Time Programmable

(MTP) low cost flas h, m an ufactured wi th SS T’s proprietary,

high performance SuperFlash technology. The split-gate

cell design and th ick oxide tunnelin g injector attain better

reliability and manufacturability compared with alternate

approaches. These MTP devices can be electrically erased

and programmed at least 1000 times using an external programmer with a 12 volt power supply. They have to be

erased prior to programming. These devices conform to

JEDEC standar d pino uts f or b yte -wide mem ories .

Featuring high performance Byte-Program, the

SST27SF256/512/010/020 provide a Byte-Program time of

20 µs. Designed, manufactured, and tested for a wide

spectrum of applications, these devices are offered with an

endurance of at least 1000 cycles. Data retention is rated at

greater th an 100 y ear s.

The SST27SF256 /512/010/ 020 are sui ted for applica tions

that require infrequent writes and low power nonvolatile

storage. These devices will improve flexibility, efficiency,

and performance while matching the low cost in nonvolatile

applications that currently use UV-EPROMs, OTPs, and

mask ROMs.

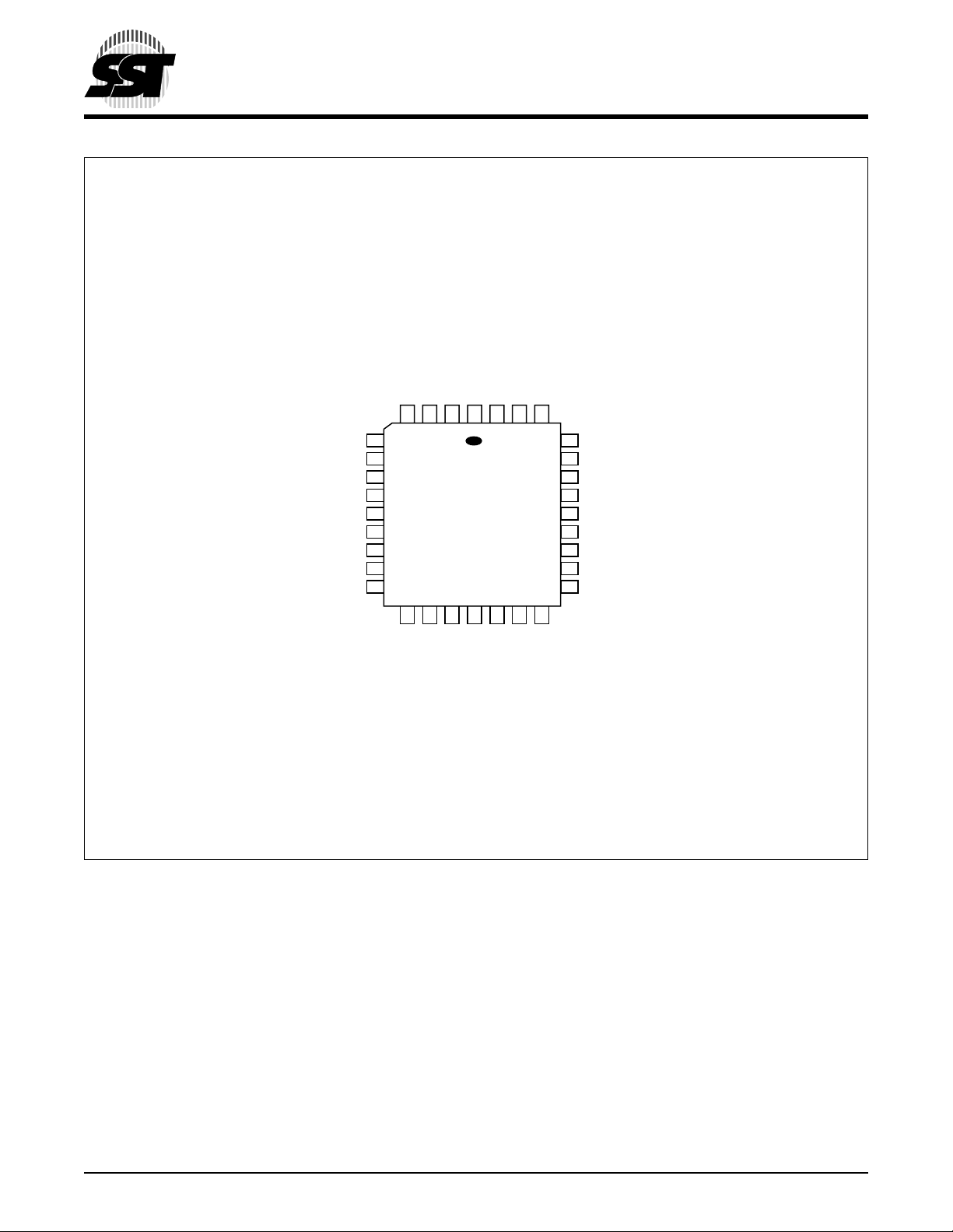

To meet surface mount and conventional through hole

requirements, the S ST27SF256/512 are o ffered in 32-pin

PLCC, 32-pin TSOP, and 28-pin PDIP packages. The

SST27SF010/ 020 are offered in 32-pin PDIP, 32-pin PLC C

and 32-pin TSOP packages. See Figures 1, 2, and 3 for

pinouts.

• Fast Byte-Program Operation

– Byte-Program Time: 20 µs (typical)

– Chip Program Time:

0.7 seconds (typical) for SST27SF256

1.4 seconds (typical) for SST27SF512

2.8 seconds (typical) for SST27SF010

5.6 seconds (typical) for SST27SF020

• Electrical Erase Using Programmer

– Does not require UV source

– Chip-Erase Time: 100 ms (typical)

• TTL I/O Compatibility

• JEDEC Standard Byte-wide EP ROM Pinouts

• Packages Available

– 32-pin PLCC

– 32-pin TSOP (8mm x 14mm)

– 28-pin PDIP for SST27SF256/512

– 32-pin PDIP for SST27SF010/020

Device Operation

The SST27SF256 /512/010/020 are a low cost flash sol ution that can be used to replace existing UV -EPR OM, O TP,

and mask ROM sockets. These devices are functionally

(read and program) an d p in com patible with industry standard EPROM products. In addition to EPROM functionality,

these devices also support electrical erase operation via an

external programmer. They do not require a UV source to

erase, and therefore the packages do not have a window.

Read

The Read operation of the SST27SF256/512/010/020 is

controlled by CE# and OE#. Both CE# and OE# have to be

low for the system to obtain data from the output s. Once

the address is s table, the addres s access time is equal t o

the delay from CE# to output (T

output after a del ay of T

OE

). Data is available at the

CE

from the falling edge of OE#,

assuming that CE# pin ha s been low and the addresses

have been stable for at least T

- TOE. When the CE# pin

CE

is high, the chip is deselected and a typical standby current

of 10 µA is consumed. OE# is the output co ntrol and is

used to gate data from the output pins. T he data bus is in

high impedance state when either CE# or OE# is high.

Byte-Prog ram Op er a ti o n

The SST27SF256/ 512/0 10/020 are programmed by usin g

an external programmer. The programming mode for

SST27SF256/010/020 is activated by asserting 12V (±5%)

©2001 Silicon Storage Technology, Inc.

S71152-02-000 5/01 502

1

The SST logo and SuperFlash are registered trademarks of Silicon Storage Technology, Inc.

MTP is a trademark of Silicon Storage Technology, Inc.

These specifications are subject to change without notice.

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

Data Sheet

on VPP pin, VDD = 5V (±5%), VIL on CE# pin, and VIH on

OE# pin. The programming mode for SST27SF512 is activated by assertin g 12V (±5%) o n OE#/V

(±5%), and V

on CE# pin. These devices are pro-

IL

pin, VDD = 5V

PP

grammed byte-by-byte with the desired data at the desired

address using a single pulse (CE# pin low for

SST27SF256/512 and PGM# pin low for SST27SF010/

020) of 20 µs. Usin g the M TP pr ogrammi ng al go rithm, the

Byte-Programming process continues byte-by-byte until

the entire chip has been programmed.

Chip-Erase Operation

The only way to change a data from a “0” to “1” is b y elec tri-

cal erase that changes every bit in the device to “1”. Unlike

traditional EPROMs, which use UV light to do the ChipErase, the SST27SF256/512/010/020 uses an electrical

Chip-Erase operation. This saves a significant amount of

time (about 30 minutes for each Erase operation). The

entire chip can be erased in a single pulse of 100 ms (CE#

pin low for SST27SF256/512 and PGM# pin for

SST27SF010/020). In order to activate the Erase mode for

SST27SF256/010/020, the 12V (±5%) is applied to V

and A9 pins, VDD = 5V (±5%), VIL on CE# pin, and VIH on

OE# pin. In ord er to acti vat e Eras e mode f or SST27S F512,

the 12V (±5%) is app lied to OE#/ V

5V (±5%), and V

on CE# pin. All ot her a ddr e ss a nd dat a

IL

and A9 pins, VDD =

PP

pins are “don’t care”. The falling edge of CE# (PGM# for

SST27SF010/020) will start the Chip-Erase operation.

Once the chip has be en eras ed, a ll bytes mus t be verifie d

for FFH. Refer to Figures 13, 14, and 15 for the flowcharts.

PP

Product Identification Mode

The Product Id entification mode ide ntifies the devices as

the SST27SF256, SST27SF512, SST27SF010 and

SST27SF020 and manufacturer a s SST. This mode may

be accessed by the hardware method. To activate this

mode for SST27SF256/010/02 0, the programming equipment must force V

at V

(5V±10%) or VSS. To activate this mode for

DD

SST27SF512, th e programm ing e quipm ent must force V

(12V±5%) on address A9 with OE#/VPP pin at VIL. Two

identifier bytes may then be sequenced from the device

outputs by toggling address line A

3, 4, and 5 for hardware operation.

TABLE 1: P

Manufacturer’s ID 0000H BFH

Device ID

SST27SF256 0001H A3H

SST27SF512 0001H A4H

SST27SF010 0001H A5H

SST27SF020 0001H A6H

(12V±5%) on address A9 with VPP pin

H

. For details, see T ab les

0

RODUCT IDENTIFICATION

Address Data

T1.1 502

H

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

2

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

Data Sheet

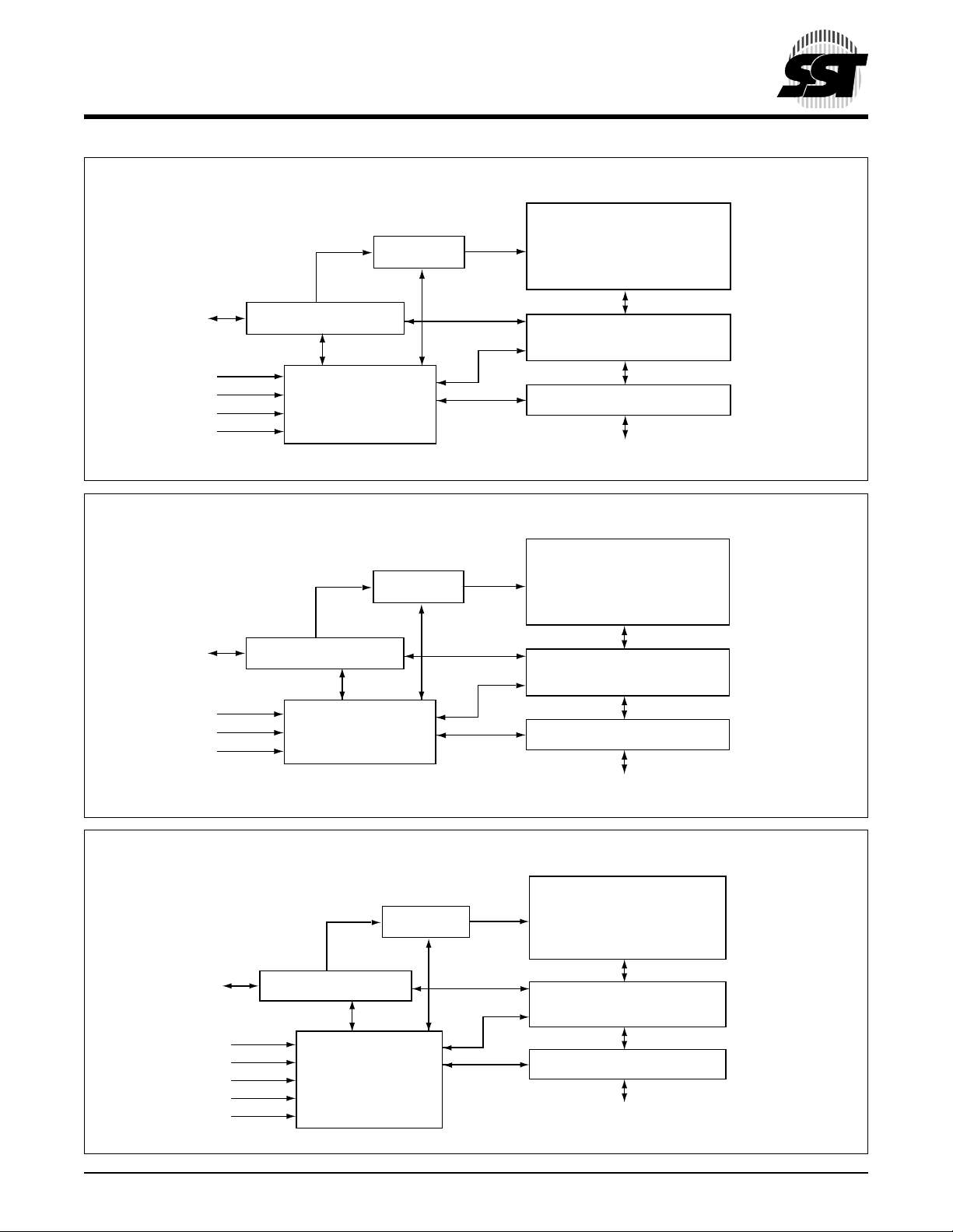

FUNCTIONAL BLOCK DIAGRAM OF THE SST27SF256

X-Decoder

A14 - A

0

Address Buffer

CE#

OE#

V

PP

A

9

Control Logic

FUNCTIONAL BLOCK DIAGRAM OF THE SST27SF512

X-Decoder

A15 - A

0

Address Buffer

SuperFlash

Memory

Y-Decoder

I/O Buffers

DQ7 - DQ

SuperFlash

Memory

Y-Decoder

0

502 ILL B1.1

CE#

OE#/V

PP

A

9

Control Logic

FUNCTIONAL BLOCK DIAGRAM OF THE SST27SF010/020

X-Decoder

A

- A

MS

0

CE#

OE#

A

9

V

PP

PGM#

AMS = A17 for SST27SF020, A16 for SST27SF010

Address Buffer

Control Logic

I/O Buffers

DQ7 - DQ

SuperFlash

Memory

Y-Decoder

I/O Buffers

DQ7 - DQ

0

502 ILL B2.1

0

502 ILL B3.2

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

3

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

A12

A15

A16

VPPVDDPGM#

A12

A15

A16

VPPVDDPGM#

A7

A12

A15NCVDDA14

A7

A12

VPPNC

SST27SF256SST27SF512 SST27SF512SST27SF010 SST27SF010SST27SF020 SST27SF020SST27SF256

A6

A5

A4

A3

A2

A1

A0

NC

DQ0

A6

A5

A4

A3

A2

A1

A0

NC

DQ0

4 3 2 1 32 31 30

5

6

7

8

32-pin PLCC

9

10

11

12

13

T op Vie w

14 15 16 17 18 19 20

VDDA14

A17

NC

A13

A13

29

28

27

26

25

24

23

22

21

A8

A9

A11

NC

OE#

A10

CE#

DQ7

DQ6

A8

A9

A11

NC

OE#/V

A10

CE#

DQ7

DQ6

PP

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

Data Sheet

DQ1

SST27SF256SST27SF512 SST27SF512SST27SF010 SST27SF010SST27SF020 SST27SF020SST27SF256

DQ1

DQ1

DQ1

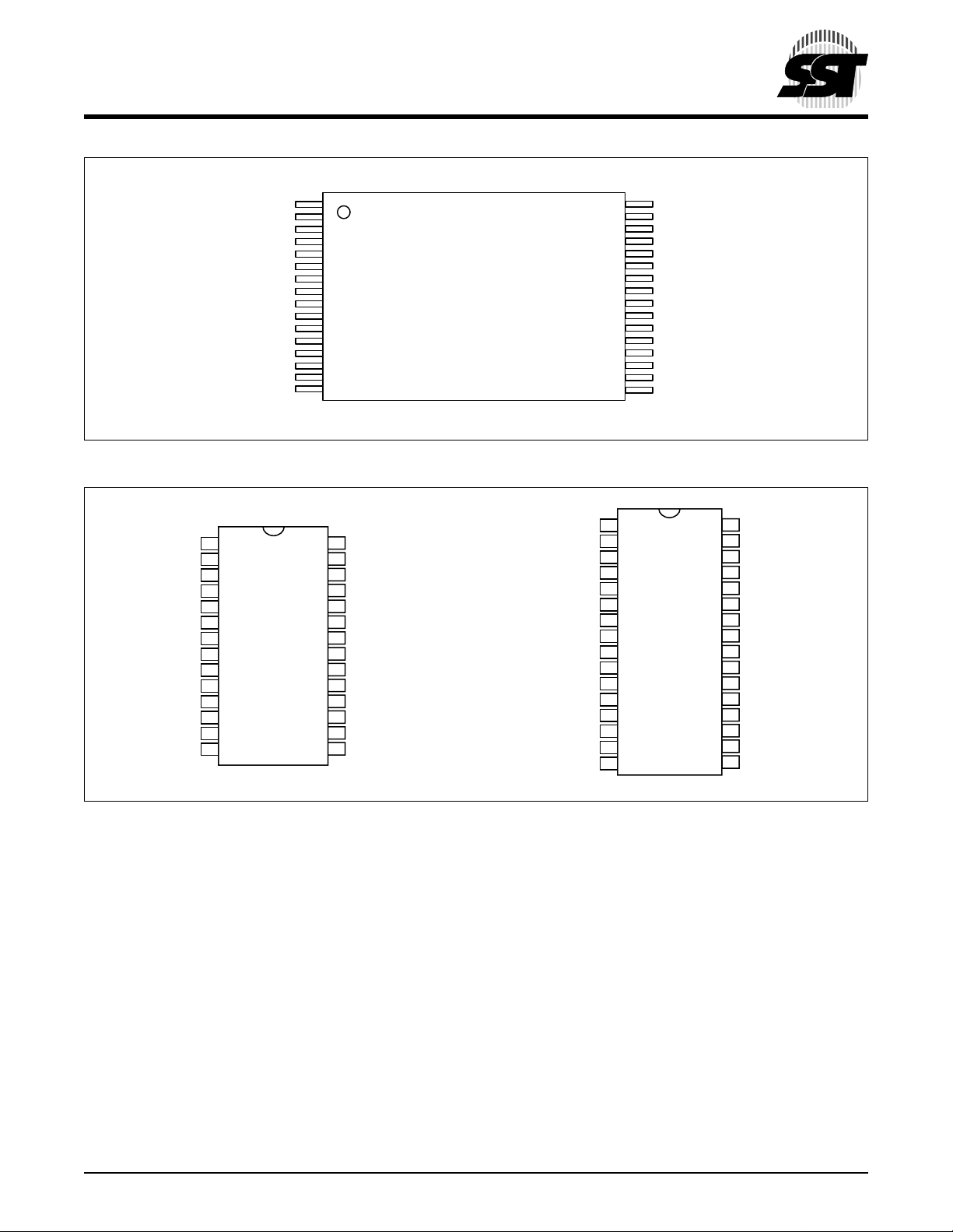

FIGURE 1: PIN ASSIGNMENTS FOR 32 -PIN PLCC

DQ2

DQ2

DQ2

DQ2

V

V

V

V

SS

SS

SS

SS

NC

NC

DQ3

DQ3

DQ3

DQ3

DQ4

DQ4

DQ4

DQ4

DQ5

DQ5

DQ5

DQ5

DQ6

DQ6

502 ILL F02c.2

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

4

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

Data Sheet

SST27SF256SST27SF512 SST27SF512SST27SF010 SST27SF010SST27SF020 SST27SF020SST27SF256

A11

A9

A8

A13

A14

A17

PGM#

V

DD

V

PP

A16

A15

A12

A7

A6

A5

A4

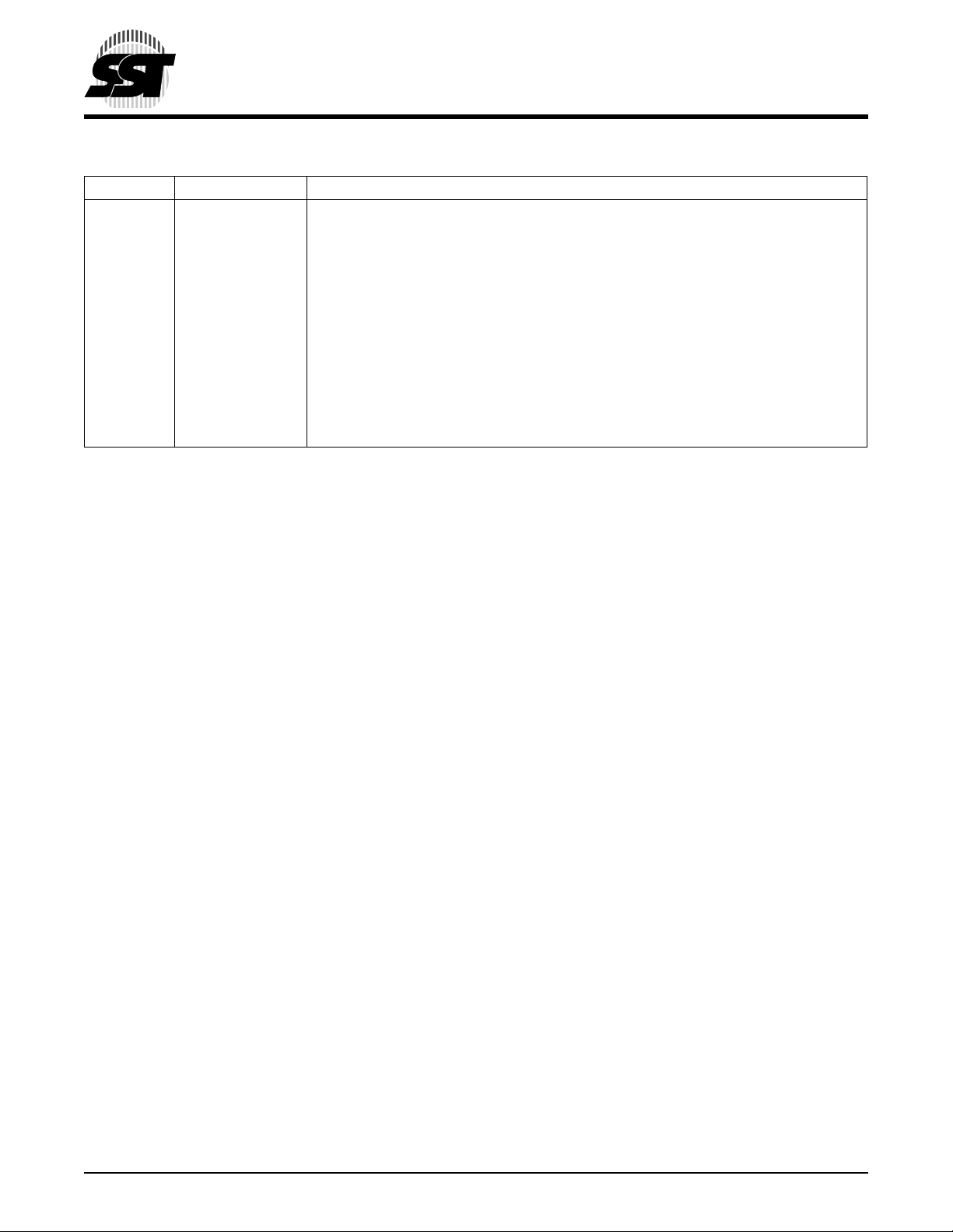

FIGURE 2: PIN ASSIGNMENTS FOR 32 -PIN TSOP (8MM X 14MM)

A11

A13

A14

NC

PGM#

V

DD

V

PP

A16

A15

A12

V

A11

A13

A14

NC

NC

DD

NC

NC

A15

A12

A9

A8

A7

A6

A5

A4

A11

A9

A8

A7

A6

A5

A4

V

V

A13

A14

A12

NC

NC

DD

PP

NC

NC

A9

A8

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Standard Pinout

T op Vie w

Die Up

OE#

32

A10

31

CE#

30

DQ7

29

DQ6

28

DQ5

27

DQ4

26

DQ3

25

V

24

DQ2

23

DQ1

22

DQ0

21

A0

20

A1

19

A2

18

A3

17

502 ILL F01.1

OE#/V

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

V

DQ2

DQ1

DQ0

A0

A1

A2

A3

SS

SS

OE#

PP

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A3

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A3

A7

A6

A5

A4

A3

A2

A1

A0

SS

V

PP

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

A15

A12

DQ0

DQ1

DQ2

V

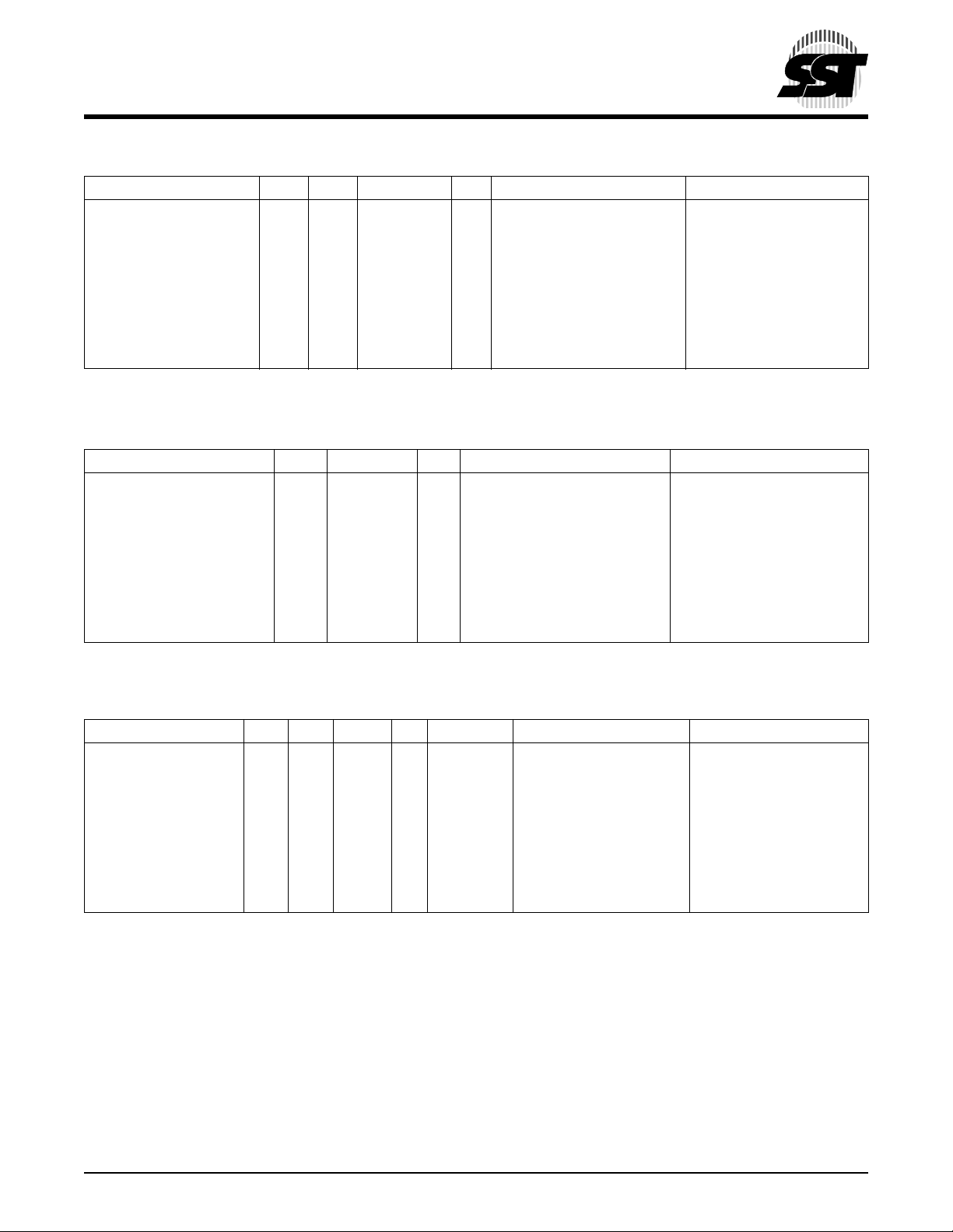

FIGURE 3: P

SST27SF512SST27SF256SST27SF512 SST27SF256

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28-pin

PDIP

T op Vie w

28

27

26

25

24

23

22

21

20

19

18

17

16

15

V

DD

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

502 ILL F02a.1

V

DD

A14

A13

A8

A9

A11

OE#/V

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

PP

IN ASSIGNMEN TS FOR 28-PIN AND 32-PIN PDIP

SST27SF010 SST27SF010SST27SF020 SST27SF020

V

PP

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

V

PP

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32-pin

PDIP

T op Vie w

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

502 ILL F02b.1

V

DD

PGM#

NC

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

V

DD

PGM#

A17

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

5

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

TABLE 2: PIN DESCR IPTION

Symbol Pin Name Functions

1

-A

A

MS

DQ7-DQ

CE# Chip Enable To activate the device when CE# is low

OE# Output Enable For SST27SF256/010/020, to gate the data output buffers during Read operation

OE#/V

PP

V

PP

V

DD

V

SS

NC No Connection Unconnected pins.

1. AMS = Most significant address

A

MS

Address Inputs To provide memory addresses

0

Data Input/output To output data during Read cycles and receive input data during Program cycles

0

The outputs are in tri-state when OE# or CE# is high.

Output En able/VPPFor SST27SF512, to ga te the data ou tput b uff ers during Rea d opera tion and high v oltage

pin during Chip-Erase and programming operation

Power Supply for

Program or Erase

For SST27SF256/010/020, high voltage pin during Chip-Erase and programming opera-

tion 12V (±5%)

Power Supply To provide 5.0V supply (±10%)

Ground

= A14 for SST27SF256, A15 for SST27SF512, A16 for SST27SF010, and A17 for SST27SF020

Data Sheet

T2.3 502

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

6

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

Data Sheet

TABLE 3: OPERATION MODES SELECTION FOR SST27SF256

Mode CE# OE# V

Read V

Output Disable V

Byte-Program V

Standby V

Chip-Erase V

Program/Erase Inhibit V

Product Identification V

Note: X = VIL or V

V

PPH

IH

= 12V±5%, VH = 12V±5%

IL

IL

IL

IH

IL

IH

IL

VILVDD or V

V

IHVDD

V

IHVPPH

XVDD or V

V

IHVPPH

XV

V

IL

PP

or V

PPH

VDD or V

TABLE 4: OPERATION MODES SELECTION FOR SST27SF512

Mode CE# OE#/V

Read V

Output Disable V

Program V

Standby V

Chip-Erase V

Program/Erase Inhibit V

Product Identification V

Note: X = V

or V

IL

V

PPH

IH

= 12V±5%, VH = 12V±5%

IL

IL

IL

IH

IL

IH

IL

PP

V

IL

V

IH

V

PPH

X X High Z X

V

PPH

V

PPH

V

IL

A9DQ Address

AIND

SS

SS

SS

OUT

XHigh Z X

AIND

IN

XHigh Z X

VHHigh Z X

XHigh Z X

VHManufacturer’s ID (BFH)

SS

Device ID (A3H)

A9DQ Address

AIND

OUT

X High Z X

AIND

IN

VHHigh Z X

X High Z X

VHManufacturer’s ID (BFH)

Device ID (A4H)

A

IN

A

IN

A14 - A1 = VIL, A0 = V

A14 - A1 = VIL, A0 = V

A

IN

A

IN

A15 - A1 = VIL, A0 = V

A15 - A1 = VIL, A0 = V

IL

IH

T3.1 502

IL

IH

T4.1 502

TABLE 5: OPERATION MODES SELECTION FOR SST27SF010/020

Mode CE# OE# PGM# A9V

Read V

Output Disable V

Program V

Standby V

Chip-Erase V

Program/Erase Inhibit V

Product Identification V

1. Device ID = A5H for SST27SF010 and A6H for SST27SF020

2. AMS = Most significant address

= A16 for SST27SF010 and A17 for SST27SF020

A

MS

Note: X = V

or V

IL

V

PPH

IH

= 12V±5%, VH = 12V±5%

V

IL

V

IL

V

IL

XXXVDD or V

IH

V

IL

XXXV

IH

V

IL

XAINVDD or V

IL

XXVDD or V

IH

V

IH

IH

IL

IL

V

IL

XVHVDD or V

AINV

VHV

PP

SSDOUT

SS

PPH

SS

PPH

PPH

SS

DQ Address

A

IN

High Z A

D

IN

IN

A

IN

High Z X

High Z X

High Z X

Manufacturer’s ID (BFH)

Device ID

1

2

A

- A1 = VIL, A0 = V

MS

2

A

- A1 = VIL, A0 = V

MS

IL

IH

T5.1 502

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

7

256 Kbit / 512 Kbit / 1 Mbit / 2 Mbit Multi-Purpose Flash

SST27SF256 / SST27SF512 / SST27SF010 / SST27SF020

Data Sheet

Absolute Maximum Stress Ratings (Applied conditions greater than those listed under “Absolute Maximum

Stress Ratings” may cause pe r manent dama ge to the device. This is a stres s rating only and funct ional operatio n

of the device at these conditions or conditions greater tha n those defined in the ope rational sections of this data

sheet is not implied. Exposure to absolute maximum stress rating conditions may affect device reliability.)

Temperature Under Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

D. C. Voltage on Any Pin to Ground Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.5V to V

Transient Voltage (<20 ns) on Any Pin to Ground Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-1.0V to V

Voltage on A

and VPP Pin to Ground Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to 14.0V

9

Package Power Dissipation Capability (Ta = 25°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0W

Through Hold Lead Soldering Temperature (10 Seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300°C

Surface Mount Lead Soldering Temperature (3 Seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240°C

1

Output Short Circ uit Curr ent

1. Outputs shorted for no more than one second. No more than one output shorted at a time.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mA

DD

DD

+0.5V

+1.0V

OPERATING RANGE

Range Ambient Temp V

DD

Commercial 0°C to +70°C5.0V±10%12V±5%

V

PP

AC CONDITIONS OF TEST

Input Rise/Fall Time . . . . . . . . . . . 10 ns

Output Load . . . . . . . . . . . . . . . . . C

Output Load . . . . . . . . . . . . . . . . . C

See Figures 11 and 12

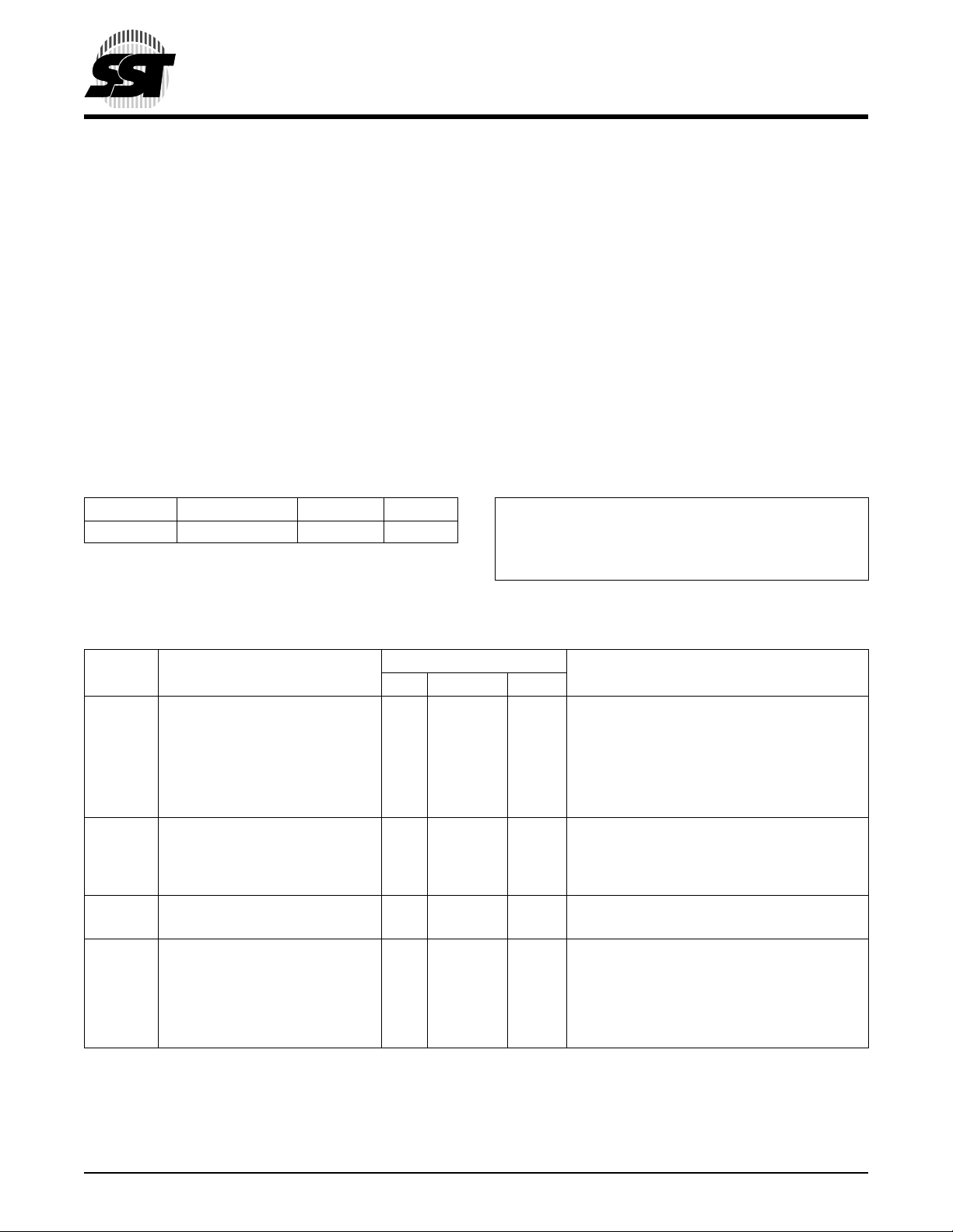

TABLE 6: READ MODE DC OPERATING CHARACTERISTICS FOR SST27SF256/512/010/020

= 5.0V±10%, VPP=VDD OR V

V

DD

Symbol Parameter

I

DD

I

PPR

I

SB1

VDD Read Current Address input=VIL/VIH at f=1/TRC Min

VPP Read Current Address input=VIL/VIH at f=1/TRC Min

Standby VDD Current

(TTL input)

I

SB2

Standby VDD Current

(CMOS input)

I

LI

I

LO

V

IL

V

IH

V

OL

V

OH

I

H

Input Leakage Current 1 µA VIN=GND to VDD, VDD=VDD Max

Output Leakage Current 10 µA V

Input Low Voltage 0.8 V VDD=VDD Min

Input High Voltage 2.0 VDD+0.5 V VDD=VDD Max

Output Low Voltage 0.2 V IOL=2.1 mA, VDD=VDD Min

Output High Voltage 2.4 V IOH=-400 µA, VDD=VDD Min

Supervoltage Current for A

9

(Ta = 0°C to +70°C (Commercial))

SS

Limits

30 mA CE#=OE#=V

100 µA CE#=OE#=VIL, all I/Os open

3mACE#=V

100 µA CE#=VDD-0.3

100 µA CE#=OE#=VIL, A9=VH Max

Test ConditionsMin Max Units

V

DD=VDD

V

DD=VDD

V

DD=VDD

OUT

Max

, all I/Os open

IL

Max, VPP=V

, VDD=VDD Max

IH

Max

=GND to VDD, VDD=VDD Max

= 100 pF for 90 ns

L

= 30 pF for 70 ns

L

DD

T6.3 502

©2001 Silicon Storage Technology, Inc. S71152-02-000 5/01 502

8

Loading...

Loading...