Page 1

INSTRUCTION: Z-Wave 700 Integration Guide

QFN32

5mm x 5mm

LGA64

9mm x 9mm

Chip

EFR32ZG14

Module

ZGM130S

INTEGRATION GUIDE FOR SILICON LABS ZENGECKO Z-WAVE® DEVICES

The purpose of this document is to provide an implementation guide for integrating Z-Wave 700 devices into product designs.

It is intended for product design engineers who aim for a fast integration of Z-Wave 700 devices.

1 OVERVIEW

The Z-Wave 700 device portfolio is shown in Table 1.1. The EFR32ZG14 SoC exposes the Z-Wave serial API via UART and is dedicated

to gateway applications. The ZGM130S SiP module combines a general-purpose SoC, crystal, supply decoupling components, and

RF matching components into a single small-footprint module requiring only two decoupling capacitors. The ZGM130S is mainly

targeted at end device applications and, with its built-in ARM M4 core and ultra-low power consumption, it is perfect for making

single chip sensors and other end devices that require advanced processing and low power consumption. Alternatively, the

ZGM130S SiP module can be used in gateway applications as well.

Please refer to [1] for an overview of supported Z-Wave regions and frequency bands supported by the Z-Wave protocol.

Table 1.1: Z-Wave 700 device portfolio

Type

SoC

SiP

The applicable modules are clearly stated at the beginning of each of the following sections.

INS14487-6 | 3/2021 1

Page 2

Instruction: Z-Wave Z-Wave 700 Integration Guide

2 CONTENT

1 OVERVIEW ........................................................................................................................................................................ 1

3 PROGRAMMING AND DEBUGGING INTERFACE .................................................................................................................. 3

3.1 PROGRAMMING INTERFACE OVERVIEW ......................................................................................................................................... 4

4 CALIBRATION .................................................................................................................................................................... 4

4.1 CRYSTAL ................................................................................................................................................................................. 4

5 RF VERIFICATION TOOL ...................................................................................................................................................... 4

6 COMPONENT SPECIFICATIONS ........................................................................................................................................... 5

6.1 SAW FILTER ........................................................................................................................................................................... 5

6.1.1 Recommended Components for GSM/LTE gateways .................................................................................................. 7

6.1.2 OPTIONAL Components for GSM/LTE gateways ......................................................................................................... 7

6.1.3 Z-Wave protocol support for optional SAW filter bank ............................................................................................... 7

6.2 CRYSTAL ................................................................................................................................................................................. 7

6.2.1 Recommended Components ....................................................................................................................................... 8

7 SUPPLY FILTER ................................................................................................................................................................... 8

8 MATCHING CIRCUIT ........................................................................................................................................................... 9

8.1 SUMMARY OF MATCHING + FILTERING NETWORKS .......................................................................................................................... 9

8.2 SOC TO RF LINE MATCHING ..................................................................................................................................................... 10

8.2.1 Mandatory Components for General Z-Wave ........................................................................................................... 12

8.2.2 Mandatory Components for Z-Wave Long Range ..................................................................................................... 12

8.3 ADDITIONAL FILTERING FOR Z-WAVE LONG RANGE ........................................................................................................................ 12

8.4 RF LINE TO ANTENNA MATCHING ............................................................................................................................................... 13

8.5 MEASUREMENT SETUP ............................................................................................................................................................ 14

9 PCB IMPLEMENTATION ................................................................................................................................................... 14

9.1 PLACEMENT .......................................................................................................................................................................... 14

9.2 STACK-UP ............................................................................................................................................................................. 15

9.3 POWER ROUTING ................................................................................................................................................................... 15

9.4 DECOUPLING ......................................................................................................................................................................... 15

9.4.1 For ZGM130S SiP MODULE ........................................................................................................................................ 15

9.4.2 For EFR32ZG14 SoC ................................................................................................................................................... 16

9.5 RF TRACE ............................................................................................................................................................................. 16

9.6 IC GROUNDING ..................................................................................................................................................................... 17

10 ANTENNA DESIGN........................................................................................................................................................ 17

11 ESD .............................................................................................................................................................................. 18

12 ABBREVIATIONS .......................................................................................................................................................... 19

13 REVISION HISTORY ...................................................................................................................................................... 22

14 REFERENCES ................................................................................................................................................................ 23

2 INS14487-6 | 3/2021

Page 3

Instruction: Z-Wave 700 Integration Guide

EFR32ZG14

ZGM130S

Applicable

Applicable

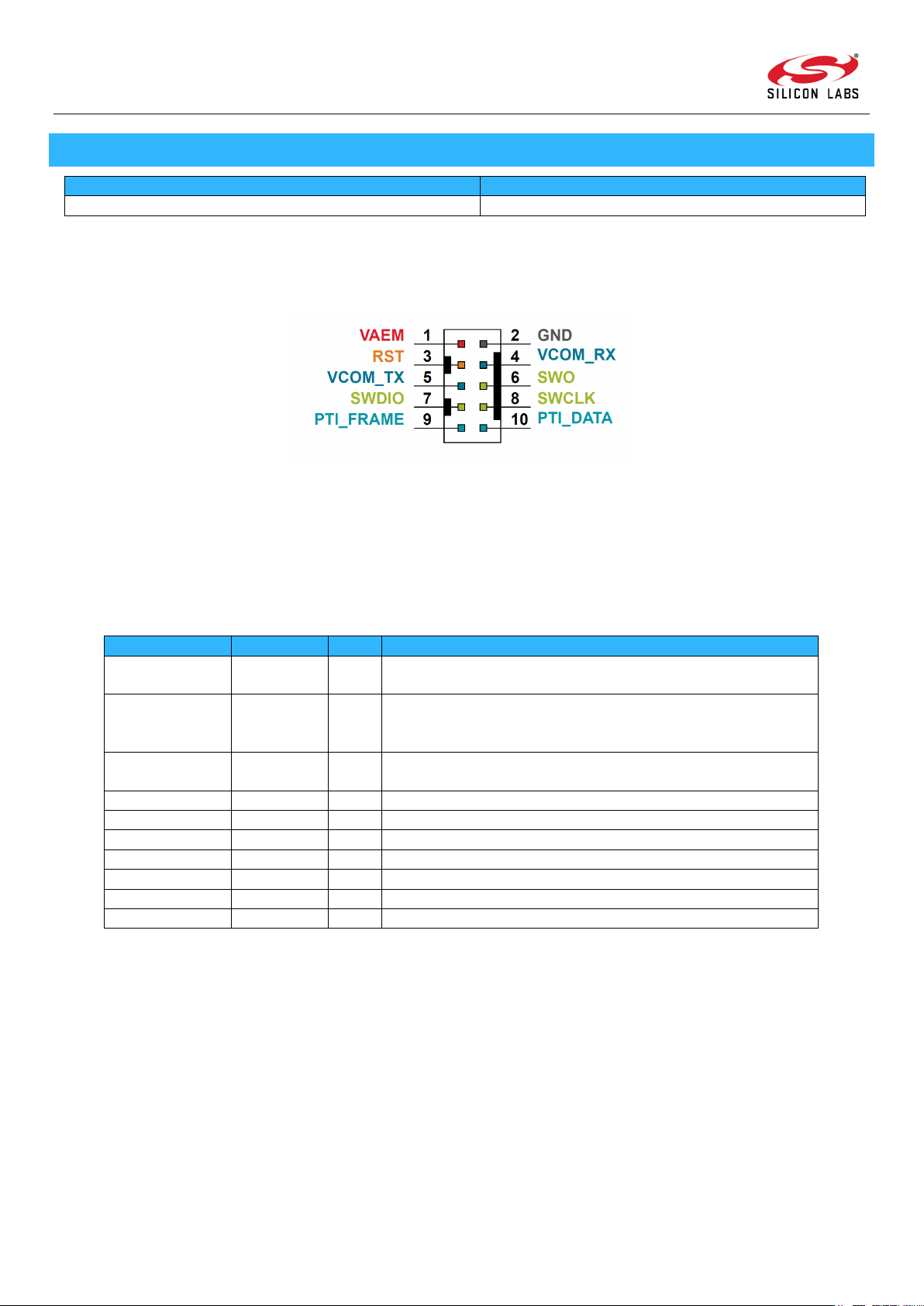

Figure 3.1: Silicon Labs Mini Simplicity Header

Pin Name

Pin Location

Type

Function

GND 2 S

Common ground between the programmer and Z-Wave 700

device

VAEM

1

S

Target voltage on the debugged application. Supplied and

"AEM" position.

RST 3 O

Driven low by the programmer to place the Z-Wave 700 device in

a reset state

VCOM_TX

5

I

Receive UART serial data from Z-Wave 700 device

VCOM_RX

4

O

Transmit UART serial data to Z-Wave 700 device

SWO

6

I

Serial Wire Output

SWDIO

7

I/O

Serial Wire Data

SWCLK

8

O

Serial Wire Clock

PTI_FRAME

9

I

Packet Trace Frame Signal

PTI_DATA

10

I

Packet Trace Data Signal

3 PROGRAMMING AND DEBUGGING INTERFACE

A programming interface is mandatory if In-System Programming of a Z-Wave 700 device is required, i.e., programming while

soldered onto the product PCB. To design in a footprint for the Mini Simplicity header, Silicon Labs recommends using a small 10pin 1.27 mm SMD header for both programming and debugging of chips from the Silicon Labs Gecko family.

If a connector is used, the Samtec FTSH-105-01-F-DH surface mounted or Harwin M50-3500542 through-hole male connector is

recommended and can be directly used with the

programmer’s perspective is shown in Table 3.1. Refer to [2] and [6] for programming instructions and more about the Mini

Simplicity Header.

BRD8010A STK/WSTK Debug Adapter. The functionality of the pins from the

Table 3.1: Z-Wave 700 Mini Simplicity Header Pin Functionality

monitored by the AEM when power selection switch is in the

INS14487-6 | 3/2021 3

Page 4

Instruction: Z-Wave Z-Wave 700 Integration Guide

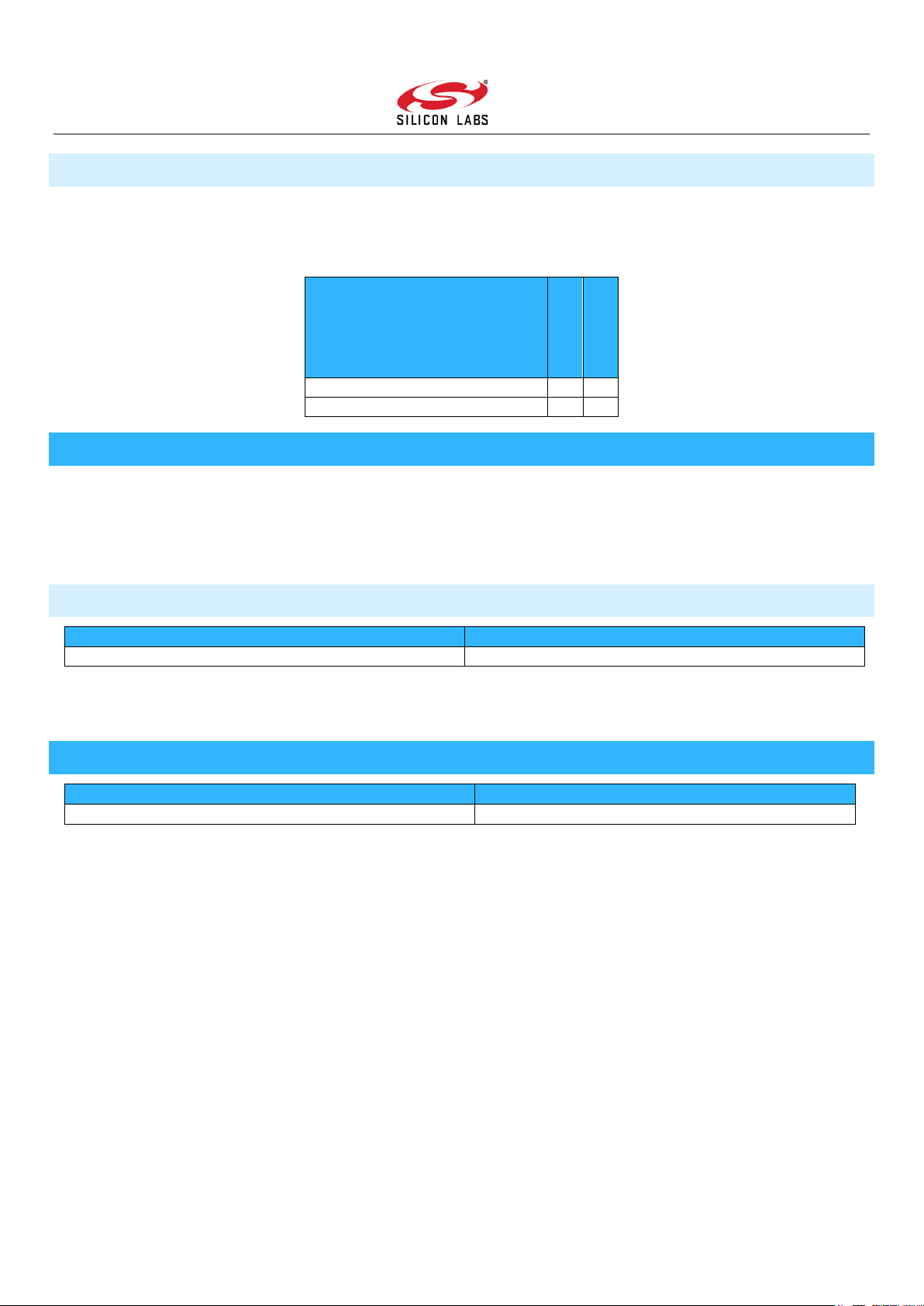

SWD programming

X

X

Boot Loader UART programming

X

X

EFR32ZG14

ZGM130S

Applicable

N/A

EFR32ZG14

ZGM130S

Applicable

Applicable

3.1 PROGRAMMING INTERFACE OVERVIEW

The table below shows which interfaces can be used to program the flash memory of the various Z-Wave 700 products:

Table 3.2: Available Programming Interfaces

ZGM130S

4 CALIBRATION

It is mandatory to calibrate the crystal in EFR32ZG14 Z-Wave 700 devices during product development to make sure that the mean

value of the crystal frequency is correct. Refer to [5] for calibration instructions. Furthermore, for best possible performance, it is

recommended that calibration be performed during production to minimize the spread in crystal frequency. All ZGM130S Z-Wave

700 devices are calibrated during production and therefore do not need any further crystal calibration.

EFR32ZG14

4.1 CRYSTAL

It is mandatory to calibrate the crystal frequency for the EFR32ZG14 devices to ensure minimum error of the radio carrier

frequency.

5 RF VERIFICATION TOOL

The RailTest tool can be used to verify the RF performance of a device without the overhead of the Z-Wave protocol. The RailTest

tool supports both ZGM130S and EFR32ZG14 devices. The same RF PHY present in the Z-Wave protocol is used. The tool is suitable

when investigating RF performance and performing RF regulatory tests. To use the tool, it is required that the chip is

programmable and the UART0 interface is connected to a terminal over RS-232 or through the WSTK. For a comprehensive user’s

manual for the RailTest tool, refer to [3] and [4].

As the RF PHY can be updated for new software releases, it is important to compile a RailTest version based on the same software

release that will be used in the final product.

4 INS14487-6 | 3/2021

Page 5

Instruction: Z-Wave 700 Integration Guide

6 COMPONENT SPECIFICATIONS

6.1 SAW FILTER

EFR32ZG14 ZGM130S

Applicable Applicable

It is recommended that a SAW filter is used in Z-Wave 700 gateway designs also containing GSM or LTE transceivers operating in

the sub-GHz band. A SAW filter attenuates unwanted radio emissions and improves the receiver blocking performance. Three

regions are defined to cover the global Z-Wave frequency range. The SAW filter specifications described in Table 6.1, Table 6.2,

and Table 6.3 are recommended for new designs. An overview of supported Z-Wave regions and frequencies can be found in [1].

Please find a guideline on when to use a SAW filter in [15].

INS14487-6 | 3/2021 5

Page 6

Instruction: Z-Wave Z-Wave 700 Integration Guide

Frequency Range

Unit

Minimum

Typical

Maximum

Operating temperature

-

◦

C

-30 - +85

Insertion loss

865.0 to 870.1MHz

dB - -

3.5

Amplitude ripple

865.0 to 870.1MHz

dB - -

2.0

Relative attenuation

0.1 to 800.0MHz

dB

40 - -

805 to 830MHz

dB

35 - -

835 to 855MHz

dB - - - 860 to 862MHz

dB - -

-

890 to 1000MHz

dB

40 - -

1005 to 2000MHz

dB

30 - -

2005 to 3000MHz

dB

30 - -

3005 to 4000MHz

dB

30 - -

4005 to 6000MHz

dB - -

-

In / out impedance

-

Ω

-

50

-

Frequency Range

Unit

Minimum

Typical

Maximum

Operating temperature

-

◦

C

-30 - +85

Insertion loss

908.2 to 916.3MHz

dB - -

2.5

Amplitude ripple

908.2 to 916.3MHz

dB - -

1.5

Relative attenuation

720 to 800MHz

dB

45 - -

805 to 840MHz

dB - - - 845 to 870MHz

dB

40 - -

870 to 895MHz

dB - - - 940 to 1000MHz

dB 9 - - 1005 to 2000MHz

dB 9 - - 2005 to 3000MHz

dB

17 - -

3005 to 4000MHz

dB - - - 4005 to 6000MHz

dB - -

-

In / out impedance

-

Ω

-

50

-

Frequency Range

Unit

Minimum

Typical

Maximum

Operating temperature

-

◦

C

-30 - +85

Insertion loss

919.5 to 926.5MHz

dB - -

3.2

Amplitude ripple

919.5 to 926.5MHz

dB - -

1.0

Relative attenuation

40 to 870MHz

dB

40 - -

875 to 885MHz

dB

35 - -

890 to 905MHz

dB

20 - -

945 to 955MHz

dB

20 - -

960 to 1000MHz

dB

20 - -

1005 to 1500MHz

dB

40 - -

1505 to 3000MHz

dB

20 - -

3005 to 4000MHz

dB - - - 4005 to 6000MHz

dB - -

-

In / out impedance

-

Ω

-

50

-

Table 6.1: Region E

Table 6.2: Region U

6 INS14487-6 | 3/2021

Table 6.3: Region H

Page 7

Instruction: Z-Wave 700 Integration Guide

Region

Distributor

Component Number

Note

E

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF4000-868-07-SX

Preferred

U

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF4000-914-06-SX

Preferred

H

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF1256-923-02

Preferred

Region

Distributor

Component Number

Note

E

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF4000-869-14-SX

Improved LTE rejection

Region

State of PB14

State of PB15

E

High

Low U Low

High

H

Low

Low

EFR32ZG14

ZGM130S

Applicable

NA

6.1.1 RECOMMENDED COMPONENTS FOR GSM/LTE GATEWAYS

Table 6.4: SAW filters

6.1.2 OPTIONAL COMPONENTS FOR GSM/LTE GATEWAYS

Table 6.5: LTE improved SAW filters

6.1.3 Z-WAVE PROTOCOL SUPPORT FOR OPTIONAL SAW FILTER BANK

The Z-Wave Protocol offers support for usage of a SAW filter bank. Please refer to the BRD4200A and BRD4201A reference designs

for an example of such a SAW filter bank implementation.

Two GPIO pins on the Z-Wave 700 devices, GPIO PB14 and GPIO PB15 are assigned to control the selection of which SAW filter to

use in the SAW filter bank :

Table 6.6: SAW Filter Control Pins

6.2 CRYSTAL

The crystal is part of the oscillator that generates the reference frequency for the digital system clock and RF carrier. It is a critical

component of a Z-Wave 700 device. Further, it is mandatory to calibrate the crystal for EFR32ZG14-based designs. Refer to section

4 for more information.

The EFR32ZG14 has internal crystal capacitors and does not need any external circuitry apart from the crystal itself.

INS14487-6 | 3/2021 7

Page 8

Instruction: Z-Wave Z-Wave 700 Integration Guide

Parameter

Symbol

Min

Typ

Max

Unit

Crystal frequency

fHFXO

—

39 — MHz

Supported crystal equivalent series resistance

(ESR)

ESRHFXO_39M

— — 60

Ω

Supported range of crystal load capacitance 1

CHFXO_CL

6 — 12

pF

Initial frequency tolerance for the crystal

FTHFXO

-10 10

ppm

Temperature tolerance for the crystal

FTempHFXO

-40°C - 85°C

-12 12

ppm

Aging

FAge

-3 3

ppm/5yr

Combined tolerance for the crystal

FTtotalHFXO

-25 — 25

ppm/5yr

Manufacturer

Component Number

EOL issued

TXC

8Y39072002

C3

10U

R1

0R

GND

VBAT

C1

100N

C2

100N

VBAT_IN

EFR32ZG14

ZGM130S

Applicable

Applicable

The ZGM130S has an integrated crystal and is calibrated at the time of production.

For more information about the crystal oscillator, crystals and the EFR32ZG14 device, please refer to [7].

Table 6.7: Crystal specification for Z-Wave 700 devices

6.2.1 RECOMMENDED COMPONENTS

Table 6.8: Recommended crystals

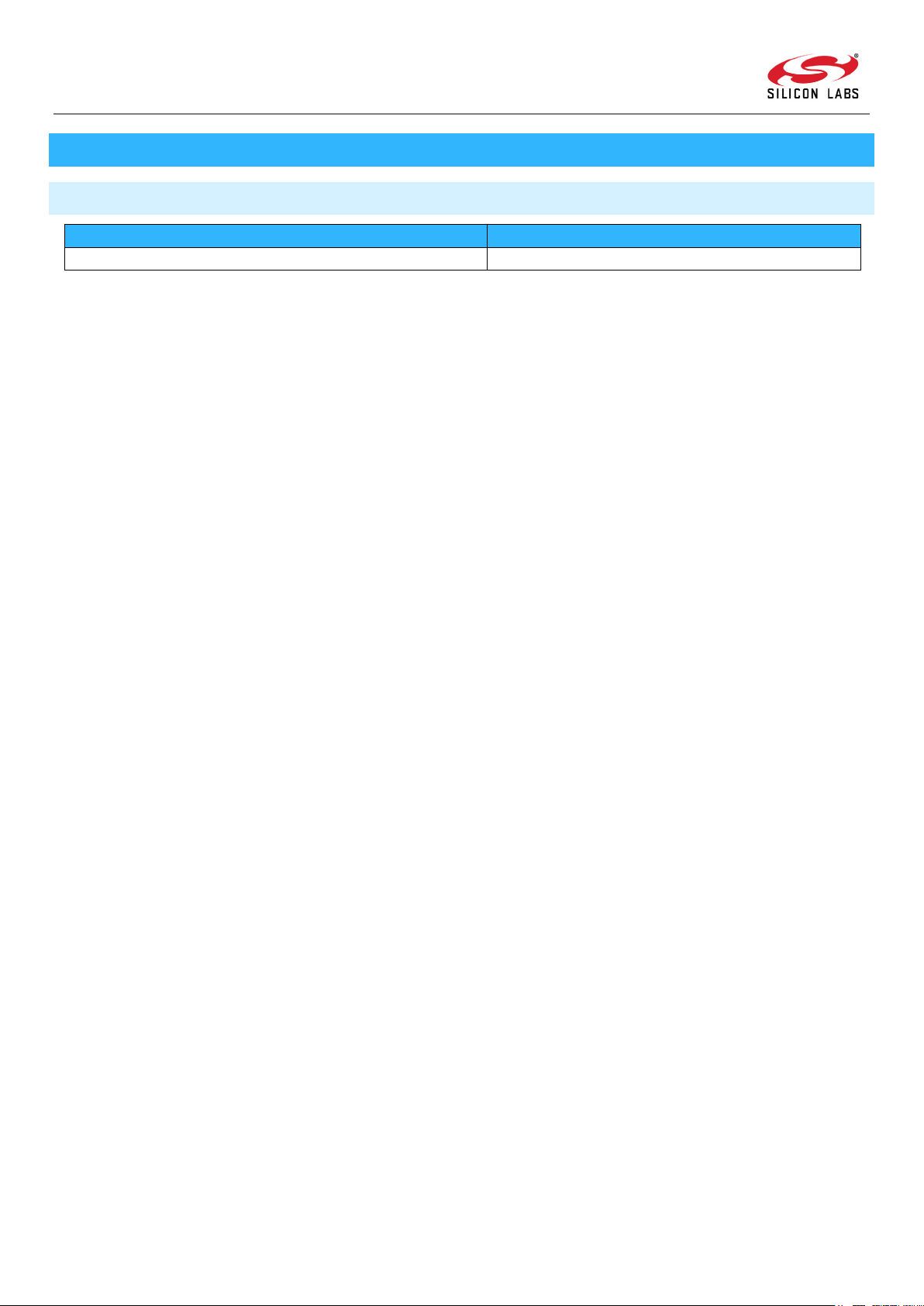

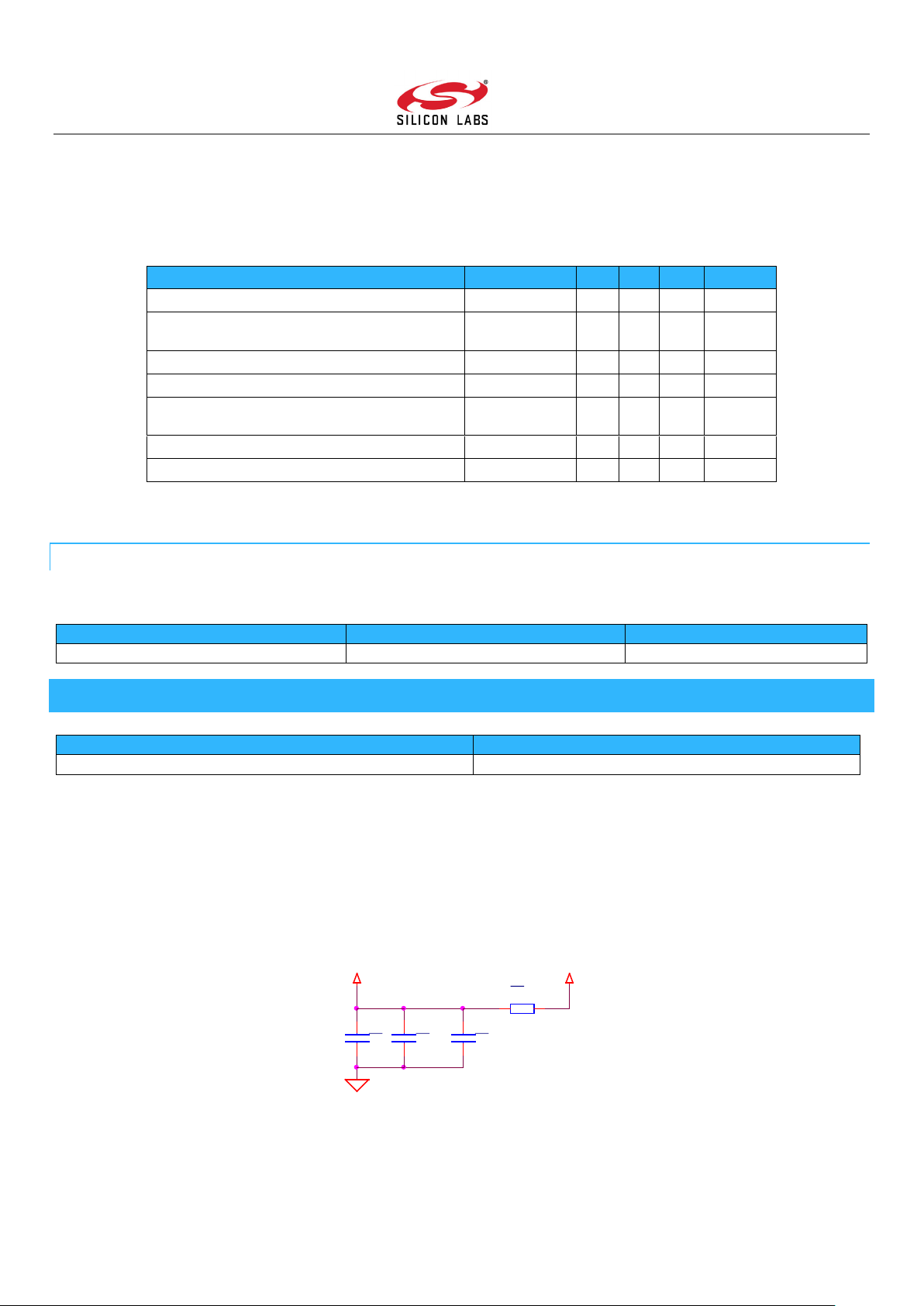

7 SUPPLY FILTER

A good power supply filter is strongly recommended as part of the schematic. A filter with a ferrite and a capacitor can be used as

seen in Figure 8.1. The ferrite suppresses high frequency noise, while the capacitors decouple the power supply by acting as a

source for fast transient currents.

For Z-Wave 700 devices, the filter shown in Figure 7.1 is strongly recommended. For normal scenarios, this will provide adequate

filtering with a low BOM cost. In case of excessive supply noise, the 0 Ω resistor can be swapped for a ferrite bead to improve

filtering.

For more about supply decoupling, please refer to section 9.4. More in-depth information about decoupling strategies and the

Figure 7.1: Recommended Supply Filter for Z-Wave 700 Devices

power supply system of the Z-Wave devices can be found in [8] and [9].

8 INS14487-6 | 3/2021

Page 9

Instruction: Z-Wave 700 Integration Guide

General Z-Wave

Z-Wave Long Range

EFR32ZG14

ZGM130S

EFR32ZG14

ZGM130S

Matching

IPD + DC-blocking cap

DC blocking cap

Discrete match with ceramic

DC blocking cap

Matching

IPD + DC-blocking cap

DC blocking cap

Discrete match with ceramic

TX/RX path

DC blocking cap

Max. power

for US

-1 dBm

-1 dBm

14 dBm

14 dBm

Max. power

for EU

14 dBm

14 dBm

N/A

N/A

8 MATCHING CIRCUIT

The PA of the transmitter should be matched for maximum power transfer and the LNA of the receiver must be matched for

lowest noise. The matching is divided into the following operations:

1. Matching the SoC transceiver to a 50 Ω RF line on the PCB.

2. Additional filtering for Z-Wave Long Range.

3. Matching the 50 Ω RF line of the PCB to the antenna.

The first part is already done in the ZGM130S SiP and is therefore only applicable to the EFR32ZG14. The second part applies to

ZGM130S only when targeting Z-Wave Long Range. The third part must be done for all implementations unless a naturally matched

antenna like the ones on the BRD4206A or BRD4207A radio boards are used.

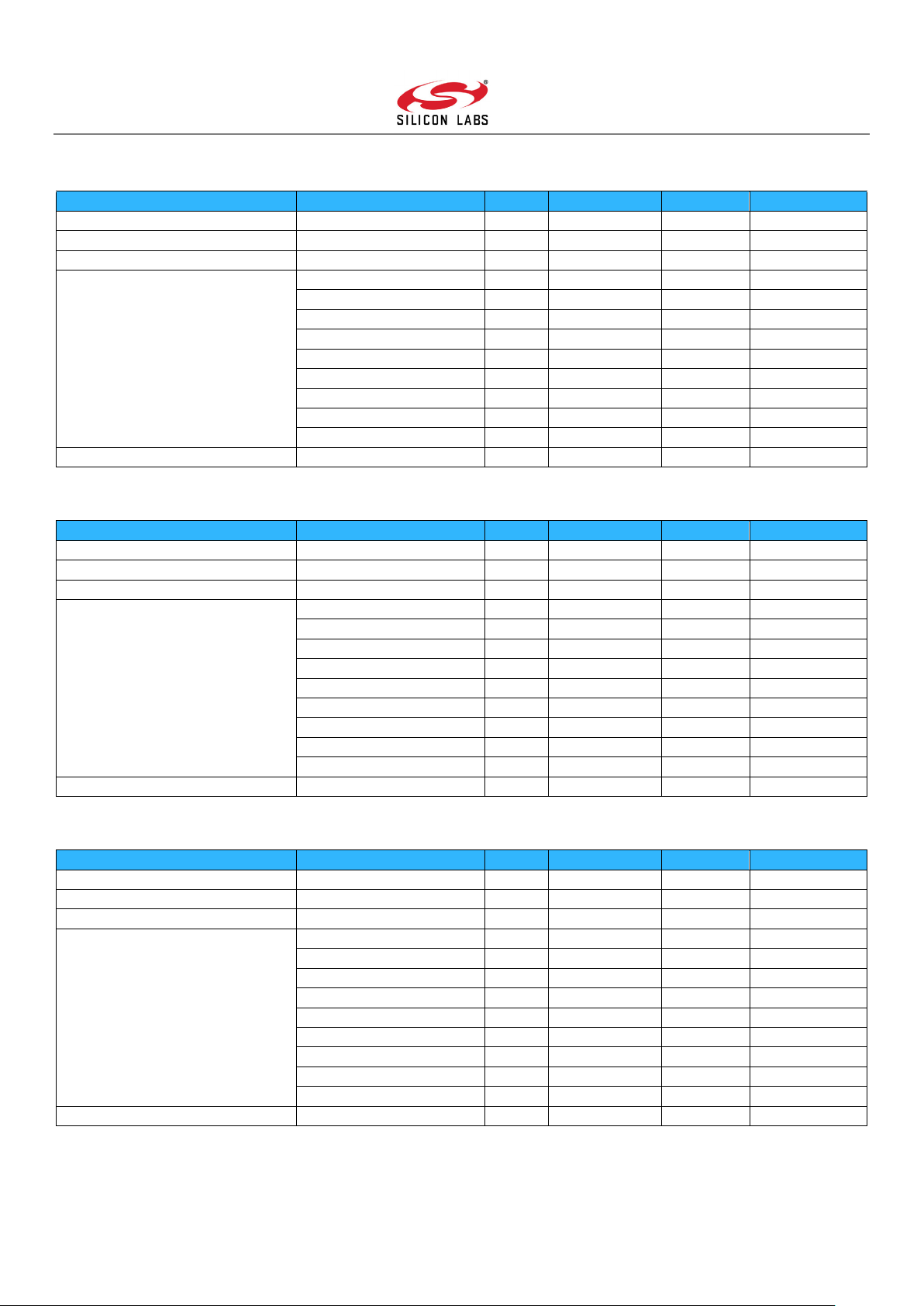

8.1 SUMMARY OF MATCHING + FILTERING NETWORKS

The recommended matching + filtering networks for General Z-Wave and Z-Wave Long Range can be found below:

Table 8.1: Z-Wave Recommended Matches

w/o SAW

w/SAW

The IPD and Discrete match with ceramic balun solutions are detailed in section 8.2.

+ SAW in TX/RX path

(BRD4201A)

(BRD4202A)

+ SAW in TX/RX

path (BRD4200A)

balun

+ 5-element Pi filter

(BRD4206A)

balun

+ 5-element Pi filter + SAW in

+ 3-element Pi filter

(BRD4207A)

+ SAW in TX/RX path

INS14487-6 | 3/2021 9

Page 10

Instruction: Z-Wave Z-Wave 700 Integration Guide

General Z-wave

Z-wave Long Range

EFR32ZG14

EFR32ZG14

Matching w/o SAW

Discrete match with ceramic balun

IPD + DC blocking cap

Full discrete match

Full discrete match

Matching w SAW

Discrete match with ceramic balun

IPD + DC-blocking cap

Max. power for US

-1 dBm

14 dBm

Max. power for EU

14 dBm

N/A

Alternatively, the following matching + filtering networks can be used for EFR32ZG14:

Table 8.2: Z-Wave Alternative Matches

+ 5-element Pi filter (Validated)

+ 5-element Pi filter (Tested)

+ 5-element Pi filter + SAW in TX/RX path (Validated)

The ‘Discrete match with ceramic balun + 5-element Pi filter’ is the same design that is present on BRD4206A. This solution is fully

characterized and validated.

The details about the ‘Full discrete match + 5-element Pi filter’ can be found in [16] section 3. This matching network has not been

validated yet but has been optimized on prototype PCBs.

The Murata LFD21868MMF5E233 IPD is recommended for General Z-Wave for EFR32ZG14 but can be used for Z-Wave Long Range

as well if an additional 3-element Pi filter is connected after the IPD for improved harmonic suppression. The proper component

values for the 3-element Pi filter can be found on Figure 8.3.

+ 3-element Pi filter (Tested)

+ 5-element Pi filter (Tested)

+ SAW in TX/RX path (Tested)

8.2 SOC TO RF LINE MATCHING

EFR32ZG14 ZGM130S

Applicable NA

The EFR32ZG14 has separate differential LNA input and PA outputs and will therefore require both balun and matching externally.

The recommended matching network for General Z-Wave with EFR32ZG14 is the Murata LFD21868MMF5E233 IPD, which matches

the EFR32ZG14 PA to the 50 Ω RF line as shown in Figure 8.1. This gives an easy and clean RF design with a very compact footprint

with only the IPD, two decoupling capacitors, and a ferrite for suppressing high frequency noise on the supply for the PA.

10 INS14487-6 | 3/2021

Page 11

Instruction: Z-Wave 700 Integration Guide

Sub-GHz

matching

network

C106

220N

U2

LFD21868MMF5E233

TXP

9

R XP

7

R XN

6

TXN

8

GND2

3

GND1

1

ANT

2

GND3

4

GND4

5

VDD

10

VDCDC

RF I/O

SUBGRF _OP

9

SUBGRF _ON

10

SUBGRF_IP

11

SUBGRF_IN

12

GND

L103

BLM03AX241SN1D

GND

50R_RF _OUT

C107

56P

Figure 8.1: Recommended RF Matching Component for the EFR32ZG14 SoC for General Z-Wave:

Murata LFD21868MMF5E233 IPD

The Murata part LFD21868MMF5E233 used for EFR32ZG14 circuits covers all supported Z-Wave regions and frequencies. The

IPD contains a matching network, a balun, and harmonic filtering as well, which provides sufficient harmonic suppression for

General Z-Wave applications.

For more in-depth knowledge about the IPD component and IPD’s in general, please refer to [13] and [14].

It is mandatory to connect the VDD pin of the IPD (U2) as shown in Figure 8.1. Connecting the VDD pin of the IPD to e.g. 3.3V is

not supported.

Z-Wave Long Range requires stronger harmonic suppression in the RF front-end, which the LFD21868MMF5E233 itself cannot

provide. For Z-Wave Long Range the recommended matching network is a discrete match combined with a ceramic balun and a

5-element low-pass filter:

Figure 8.2: Recommended Matching Network for the EFR32ZG14 SoC for Z-Wave Long Range

INS14487-6 | 3/2021 11

Page 12

Instruction: Z-Wave Z-Wave 700 Integration Guide

Manufacturer

Component Number

EOL issued

Murata

LFD21868MMF5E233

Manufacturer

Component Number

EOL issued

Johanson Technology

0900BL15C050

EFR32ZG14

ZGM130S

NA

Applicable

The matching network shown on Figure 8.2 used for EFR32ZG14 circuits is mainly recommended for Z-Wave Long Range but can

be used for General Z-Wave applications and other Z-Wave regions as well. The circuit contains a match to 50 Ω, a differential to

a single-ended balun, and a 5-element harmonic filtering network.

It is mandatory to connect the VDD pin of the balun (BAL1) as shown in Figure 8.2. Connecting the VDD pin of the balun (and the

EFR32ZG14 PA) to, e.g. 3.3V, is not supported.

For more in-depth knowledge about matching circuits, please refer to [10].

8.2.1 MANDATORY COMPONENTS FOR GENERAL Z-WAVE

Table 8.3: IPD

8.2.2 MANDATORY COMPONENTS FOR Z-WAVE LONG RANGE

Table 8.4: Balun

8.3 ADDITIONAL FILTERING FOR Z-WAVE LONG RANGE

ZGM130S has the matching and filtering network built-in, which provides acceptable harmonic performance for all Z-Wave regions

when targeting General Z-Wave. However, Z-Wave Long Range allows higher transmit power, therefore, additional harmonic

filtering is necessary. The following 3-element Pi filter should be connected to ZGM130S RF_ANT pin besides the DC blocking

capacitor (C11) when targeting Z-Wave Long Range.

Figure 8.3: Recommended Three-Element Pi Filter

12 INS14487-6 | 3/2021

Page 13

Instruction: Z-Wave 700 Integration Guide

RF_line

ANTENNA

1

R2

0R

GND

R1

0R

NM

R3

0R

NM

GND

8.4 RF LINE TO ANTENNA MATCHING

EFR32ZG14 ZGM130S

Applicable Applicable

Finding appropriate values for the components should be considered an iterative task. It is recommended to add a pi network for

matching as shown in Figure 8.4. The following matching strategy is proposed:

1. Calibrate your Vector Network Analyzer (VNA) for a frequency range larger than the intended bandwidth of the antenna.

2. Connect an RF coaxial cable to the RF line (for instance by soldering a pigtail to the line). Connect the RF coaxial cable to

a VNA to measure the reflection coefficient, S11, looking into the antenna through the matching network.

a. Be sure to have a good connection to the ground plane to get the best electrical performance and the highest

mechanical robustness during the measurement.

b. Make sure to route the pigtail towards the center of the PCB and then perpendicularly away from the PCB at the

center point. This will limit the effect of the cable on the measured data as much as possible.

3. Start out with no components on the antenna network shown in Figure 8.4:

a. The shunt components are not mounted.

b. The series component is not mounted.

4. Use line extension on the VNA to move the reference point to the footprint of R1 and R2.

a. This is achieved when the locus of the S-parameters in the Smith chart on the VNA have assembled in a point at

the right edge of the Smith chart.

5. Mount a 0 Ω resistor at R2 in Figure 8.4

6. Measure reflection coefficient for the frequency of interest (the frequency half way between the lowest frequency and

the highest frequency of the region of interest).

7. Use an online matching tool to calculate series and shunt component values to achieve 50 Ω match on the coaxial line.

a. This will give a good starting point and should result in a reasonably good match at first attempt.

8. Iteratively change component values until match is acceptable.

a. The standard matching criterion is either -6 dB or -10 dB reflection across all frequencies of interest.

b. When this goal is achieved, it is recommended to use the same values on a small sample of boards to make sure

that the matching is acceptable across production tolerances.

Figure 8.4: Recommended Antenna Matching Pi Network

A description of various antenna topologies can be found in [11]. Please also refer to the reference designs BRD4206A, BRD4207A,

and UZB7 for various methods of antenna implementations.

INS14487-6 | 3/2021 13

Page 14

Instruction: Z-Wave Z-Wave 700 Integration Guide

DUT Spectrum Analyzer

10

dB Attenuator

DUT

Z-Wave Frame

Generator

Attenuator

Variable Attenuator

1dB Steps

EFR32ZG14

ZGM130S

Applicable

Applicable except section 9.6

8.5 MEASUREMENT SETUP

The output power should be measured with a spectrum analyzer as shown in Figure 8.5 and sensitivity as shown in Figure 8.6. In

both cases, place the fixed attenuator as close as possible to the transmitter. The fixed attenuator prevents RF reflections in the

measurement setup.

Figure 8.5: Measuring Transmitter Output Power

When measuring the sensitivity, first measure and record the output power of the Z-Wave frame generator using the spectrum

analyzer. A Z-Wave 700 module programmed with the RailTest tool can be used as the Z-Wave frame generator. Then a fixed

attenuator can be used along with a variable attenuator to adjust the input power of the DUT. For example, by setting the output

power of the Z-Wave generator to -20dBm, a fixed 50dB attenuator and a variable 50dB attenuator can be used to measure the

sensitivity with a 1dB resolution. Place the fixed attenuator close to the Z-Wave generator and conduct the measurements in a

radio silent environment, e.g. by placing the DUT in a RF shielded box.

Figure 8.6: Measuring Receiver Sensitivity

9 PCB IMPLEMENTATION

A good PCB implementation is required to obtain the best performance from a Z-Wave 700 device. The following subsections

describe items that should be considered when designing the PCB layout.

Besides the descriptions below, please use the reference designs for the ZGM130S and the EFR32ZG14 devices as guidelines. The

reference designs for the ZGM130S are: BRD4200A, BRD4202A, and BRD4207A. The reference designs for the EFR32ZG14 are:

BRD4201A, BRD4206A, and UZB-7.

Further layout guidelines can be found in [12].

9.1 PLACEMENT

In general, it is mandatory that all decoupling and matching components are placed as close as possible to the Z-Wave 700 device,

and on the same layer to reduce trace parasitics. For gateway devices with GSM or LTE transceivers, it is also strongly

recommended to place the SAW filter as close as possible to the RF pin of the Z-Wave 700 device.

14 INS14487-6 | 3/2021

Page 15

Instruction: Z-Wave 700 Integration Guide

Prepreg

FR4

Prepreg

Signal

L1

L

2

L3

L4

Ground plane

Power and signal

Signal

Power in Power out

Low value capacitors High value capacitors

Via

Figure 9.3: Pin Decoupling

When implementing a Z-Wave system into a product, it is strongly recommended that the Z-Wave 700 device is placed close to a

corner of the product’s PCB, away from any high frequency switching circuits used elsewhere in the product, e.g. host CPU systems,

switching DC supplies, motor-controllers etc.

9.2 STACK-UP

If designing a product with the EFR32ZG14, it is recommended to use a 4-layer stack-up PCB as shown in Figure 9.1. The thickness

of the PCB stack-up can be chosen to optimize cost. It is strongly recommended that a solid copper plane be used as the ground

plane layer L2.

Figure 9.1: 4-layer stack-up

With the ZGM130S, the complex circuitry is contained inside the SiP. Therefore, there are good possibilities for making a cheap

two-layer PCB design with ZGM130S. This does require extra care in designing the RF routing, power supply, and ground layout as

no full-layer power and ground planes can be included.

Please refer to the BRD4206A and BRD4207A designs for more information.

9.3 POWER ROUTING

Use as short VDD traces as possible. The VDD trace can be a hidden, unwanted radiator so it is important to simplify the VDD

routing as much as possible and use large, continuous GND pours with many stitching vias. To achieve the simplified VDD routing,

try to avoid star topology of VDD traces (i.e., avoid connecting all VDD traces in one common point).

Please consider using the reference designs BRD4206A and BRD4207A as the reference designs when creating the power routing.

9.4 DECOUPLING

Power should be driven through decoupling capacitors to prevent parasitic inductances as shown in Figure 9.3. At least two

grounding vias is recommended for each component as shown in Figure 9.2.

Figure 9.2: Grounded Components

9.4.1 FOR ZGM130S SIP MODULE

For the ZGM130S, most of the decoupling is built in. This includes all supply decoupling except for two 10 µF capacitors, one on

AVDD and one on VDD and VDDIO combined.

INS14487-6 | 3/2021 15

Page 16

Instruction: Z-Wave Z-Wave 700 Integration Guide

Signal L1

L2Ground plane

Prepreg

Ground pour

Impedance

controlled trace

Ground pour

GND

C103

56P

VDCDC

Ground

RF Analog Power

RFVDD

5

RFVSS

13

C102

220N

GND

GND

GND

C116

10N

VDCDC

GND

GND

VMC U

GND

GND

C115

4U7

L100

4U7

C118

2U2

VMC U

GND

DC/DC Regulator

Analog Supply

I/O Supply

Reset

Ground

Digital Supply

Digital Logic

Digital Regulator

U1C

EFR32Z G14

RESETn

8

DVDD

28

DECOU PLE

29

IOVDD

30

VSS_PAD

0

AVDD

22

VREGVDD

27

VREGSW

26

VREGVSS

25

RADI O_#RESET

C111

220N

C110

10U

C113

10N

C114

220N

GND

C117

10N

C112

10U

VMC U

Figure 9.4: Recommended External Supply Decoupling for the ZGM130S

9.4.2 FOR EFR32ZG14 SOC

For an EFR32ZG14 device, the decoupling topology shown in Figure 9.5 is strongly recommended.

Figure 9.5: Minimum Supply Decoupling Required for the EFR32ZG14 SoC

9.5 RF TRACE

For RF traces longer than λ/16 at the fundamental frequency, it is mandatory to design the trace as a transmission line with a 50Ω

characteristic impedance. A coplanar waveguide similar to Figure 9.6 is recommended for a transmission line on signal layer L1.

16 INS14487-6 | 3/2021

Figure 9.6: Coplanar Waveguide

Page 17

Instruction: Z-Wave 700 Integration Guide

Ground pour

Ground pour

Via

Impedance controlled trace

Via

Applicable

Applicable

A via fence is recommended on both sides of a coplanar waveguide, as shown Figure 9.7, to short any return currents induced on

the top layer to ground.

Figure 9.7: Via Fence

A free tool, such as Saturn PCB Design Toolkit (http://www.saturnpcb.com/pcb_toolkit.htm

dimensions of the traces conveniently.

), can be used to calculate the

9.6 IC GROUNDING

QFN chips should be provided with a ground paddle with stitched-vias to minimize parasitic inductance and to provide a good

thermal heat sink as shown in Figure 9.8.

Figure 9.8: IC Ground Paddle

Please refer to the BRD4206A layout to see a practical implementation of a QFN footprint with exposed pad.

10 ANTENNA DESIGN

EFR32ZG14 ZGM130S

Since antenna design is very product dependent, it is mandatory to perform the antenna matching as described in Section 8.4.

Each product requires an individual antenna design for best power transfer and radiation characteristics.

The BRD4206A and BRD4207A radio boards example antenna designs are shown with naturally matched antennas not requiring

any lumped components.

INS14487-6 | 3/2021 17

Page 18

Instruction: Z-Wave Z-Wave 700 Integration Guide

EFR32ZG14

ZGM130S

Applicable

Applicable

11 ESD

Since ESD can destroy the Z-Wave 700 product, great care must be taken during manufacturing and assembly of final goods to

avoid ESD.

By design, all pins of EFR32ZG14 and ZGM130S are ESD protected up to a level of 2.5 kV HBM.

The ESD level of a SAW filter is typically << 2 kV HBM.

18 INS14487-6 | 3/2021

Page 19

Instruction: Z-Wave 700 Integration Guide

Abbreviation

Description

2FSK

2-key Frequency Shift Keying

2GFSK

2-key Gaussian Frequency Shift Keying

ACM

Abstract Control Model

ACMA

Australian Communications and Media Authority

ADC

Analog-to-Digital Converter

AES

Advanced Encryption Standard

API

Application Programming Interface

APM

Auto Programming Mode

AV

Audio Video

BALUN

Balanced to Unbalanced converter

BOD

Brown-Out Detector

CBC

Cipher-Block Chaining

CDC

Communications Device Class

CE

Conformité Européenne

COM

Communication

CPU

Central Processing Unit

CRC

Cyclic Redundancy Check

D

Differential

D-

Differential Minus

D+

Differential Plus

DAC

Digital-to-Analog Converter

DC

Direct Current

DMA

Direct Memory Access

DUT

Device Under Test

ECB

Electronic CodeBook

EMS

Electronic Manufacturing Services

EOL

End Of Life

ESD

Electro Static Discharge

ESR

Equivalent Series Resistance

FCC

Federal Communications Commission

FET

Field Effect Transistor

FER

Frame Error Rate

FLiRS

Frequently Listening Routing Slave

FR4

Flame Retardant 4

FSK

Frequency Shift Keying

GFSK

Gaussian Frequency Shift Keying

GP

General Purpose

GPIO

General Purpose Input Output

HBM

Human Body Model

I

Input

I/O

Input / Output

IC

Integrated Circuit

IDC

Insulation-Displacement Connector

IF

Intermediate Frequency

IGBT

Insulated-Gate Bipolar Transistor

INT

Interrupt

IPC

Interconnecting and Packaging Circuits

IPD

Integrated Passive Device

IR

Infrared

IRAM

Indirectly Addressable Random Access Memory

12 ABBREVIATIONS

INS14487-6 | 3/2021 19

Page 20

Instruction: Z-Wave Z-Wave 700 Integration Guide

Abbreviation

Description

ISM

Industrial, Scientific, and Medical

ISP

In-System Programming

ITU

International Telecommunications Union

JEDEC

Joint Electron Device Engineering Council

LED

Light-Emitting Diode

LNA

Low-Noise Amplifier

LO

Local Oscillator

lsb

Least Significant Bit

LSB

Least Significant Byte

MCU

Microcontroller Unit

MIC

Ministry of Internal affairs and Communications, Japan

MISO

Master In, Slave Out

MOSI

Master Out, Slave In

msb

Most Significant Bit

MSB

Most Significant Byte

NA

Not Applicable

NMI

Non-Maskable Interrupt

NRZ

Non-Return-to-Zero

NVM

Non-Volatile Memory

NVR

Non-Volatile Registers

O

Output

OEM

Original Equipment Manufacturer

OFB

Output FeedBack

OTP

One-Time Programmable

PA

Power Amplifier

Pb

Lead

PCB

Printed Circuit Board

PHY

L1 Physical Layer

POR

Power-On Reset

PWM

Pulse Width Modulator

QFN

Quad-Flat No-leads

RAM

Random Access Memory

RF

Radio Frequency

RoHS

Restriction of Hazardous Substances

ROM

Read Only Memory

RS-232

Recommended Standard 232

RX

Receive

S

Supply

SAW

Surface Acoustic Wave

SCK

Serial Clock

SFR

Special Function Register

SiP

System-in-Package

SPI

Serial Peripheral Interface

SRAM

Static Random Access Memory

T0

Timer 0

T1

Timer 1

TX

Transmit

UART

Universal Asynchronous Receiver Transmitter

USB

Universal Serial Bus

VNA

Vector Network Analyzer

WUT

Wake-Up Timer

20 INS14487-6 | 3/2021

Page 21

Instruction: Z-Wave 700 Integration Guide

Abbreviation

Description

XRAM

External Random Access Memory

XTAL

Crystal

ZEROX

Zero Crossing

INS14487-6 | 3/2021 21

Page 22

Instruction: Z-Wave Z-Wave 700 Integration Guide

Date

Version

Affected

Revision

2018/11/26

1A

§All

Initial draft based on INS12213-15: "500 Series Integration Guide”

2018/12/3

1B

P. 1, 3-5, 7, 9, 14, 18

Updated based on comments from JFR and OPP

2018/12/4

1C

P. 4, 6, 14

Updated based on comments from NTJ and MHANSEN

2018/12/4

1D

§All

Table 6.6 added and all references to devices corrected to ‘Z-Wave 700’

2018/12/5

1E

P. 18

Legal disclaimer updated based on Silicon Labs disclaimer from AN961

2018/12/5

1F

Front page

Corrected title to "Z-Wave 700 Integration Guide"

2018/12/6

1G

Table 6.6

Corrected temp range (-40 °C – 85 °C) and removed size specification

2019/02/26

1H

§All

Added references, corrected language and clarified content.

2019/03/14

1I

Section 1,

6.1,6.1.3,8.1

Minor corrections and additions of references

2020/12/1

1J

All

Added support for Z-Wave Long Range

2021/03/10

1K

Section 6.1, Table

Changing ZGM130S to applicable for SAW filters, minor corrections in

Table 8.2

13 REVISION HISTORY

8.1, Table 8.2

Table 8.1 and Table 8.2, minor changes in content to reflect ZGM130S

usability as a gateway, removed Split TX / RX + RF Switch option from

22 INS14487-6 | 3/2021

Page 23

Instruction: Z-Wave 700 Integration Guide

14 REFERENCES

[1] https://www.silabs.com/products/wireless/mesh-networking/z-wave/benefits/technology/global-regions

[2] Silicon Labs, “Silicon Labs Production Programming Options”, AN136

[3] Silicon Labs, “Instruction for Bring-up/test HW development”, INS14283

[4] Silicon Labs, “AN972: EFR32 RF Evaluation Guide”, AN972

[5] Silicon Labs, “Instruction for Mandatory crystal adjustment for EFR32ZG14 based products”, INS14498

[6] Silicon Labs, “Debugging and Programming Interfaces for Custom Designs”, AN958

[7] Silicon Labs, “Oscillator Design Considerations”, AN0016.1

[8] Silicon Labs, “EFM32 and EFR32 Series 1 Power Configurations and DC-DC”, AN0948

[9] Silicon Labs, “EFM32 and EFR32 Wireless Gecko Series 1 Hardware Design Considerations”, AN0002.1

[10] Silicon Labs, “EFR32 Series 1 sub-GHz Matching Guide”, AN923.1

[11] Silicon Labs, “Antennas for Short Range Devices”, APL10045

[12] Silicon Labs, “EFR32 Series 1 Layout Design Guide”, AN928.1

[13] Silicon Labs, “Integrated Passive Devices for EFR32 Sub-GHz RF Matching”, AN1081

[14] Silicon Labs, “Murata 868 MHz IPDs for EFR32 Wireless SOCs”, AN1149

[15] Silicon Labs, “Z-Wave 700: SAW filter recommendations” :

wave/knowledge-base.entry.html/2019/01/16/z-wave_700_saw_filt-s5Ev

[16] Silicon Labs, “EFR32 Series 1 sub-GHz Discrete Matching Solutions”, AN1180

https://www.silabs.com/community/wireless/z-

INS14487-6 | 3/2021 23

Page 24

Instruction: Z-Wave Z-Wave 700 Integration Guide

DISCLAIMER

Silicon Labs intends to provide customers with the latest, accurate, and in-depth documentation of all peripherals and modules

available for system and software implementers using or intending to use the Silicon Labs products. Characterization data,

available modules and peripherals, memory sizes and memory addresses refer to each specific device, and "Typical" parameters

provided can and do vary in different applications. Application examples described herein are for illustrative purposes only. Silicon

Labs reserves the right to make changes without further notice and limitation to product information, specifications, and

descriptions herein, and does not give warranties as to the accuracy or completeness of the included information. Silicon Labs

shall have no liability for the consequences of use of the information supplied herein. This document does not imply or express

copyright licenses granted hereunder to design or fabricate any integrated circuits. The products are not designed or authorized

to be used within any Life Support System without the specific written consent of Silicon Labs. A "Life Support System" is any

product or system intended to support or sustain life and/or health, which, if it fails, can be reasonably expected to result in

significant personal injury or death. Silicon Labs products are not designed or authorized for military applications. Silicon Labs

products shall under no circumstances be used in weapons of mass destruction including (but not limited to) nuclear, biological

or chemical weapons, or missiles capable of delivering such weapons.

TRADEMARKS

Silicon Laboratories Inc.® , Silicon Laboratories®, Silicon Labs®, SiLabs® and the Silicon Labs logo®, Z-Wave®, Z-Wave Logo®,

Bluegiga®, Bluegiga Logo®, Clockbuilder®, CMEMS®, DSPLL®, EFM®, EFM32®, EFR, Ember®, Energy Micro, Energy Micro logo and

combinations thereof, "the world’s most energy friendly microcontrollers", Ember®, EZLink®, EZRadio®, EZRadioPRO®, Gecko®,

ISOmodem®, Micrium, Precision32®, ProSLIC®, Simplicity Studio®, SiPHY®, Telegesis, the Telegesis Logo®, USBXpress®, Zentri and

others are trademarks or registered trademarks of Silicon Labs. ARM, CORTEX, Cortex-M4 and THUMB are trademarks or

registered trademarks of ARM Holdings. Keil is a registered trademark of ARM Limited. All other products or brand names

mentioned herein are trademarks of their respective holders.

SALES OFFICE AND DISTRIBUTOR CONTACT INFORMATION

https://www.silabs.com/about-us/contact-sales

HEADQUARTERS

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

USA

www.silabs.com

24 INS14487-6 | 3/2021

Loading...

Loading...