Silicon Labs Si72xx-WD User Manual

UG288: Si72xx-WD-Kit User's Guide

The Si72xx-WD-Kit allows for the evaluation of the Si72xx Hall Sensors through eight

demos on

in the kit on small, postage-stamp-sized (PS) boards with an evaluation demo for each.

This user guide describes a quick-start procedure to start the evaluation easily as well

as a full description of each demo and a list of compatible PS boards.

The Si72xx-WD Rev 2 Kit includes the following:

• (1) Si72XX-EXP Rev2 Board

• (1) Si7201-B01V-EB Switch PS Board

• (1) Si7202-B01V-EB Latch PS Board

• (1) Si7210-B00V-EB I2C PS Board

• (1) Si7211-B00V-EB Analog PS Board

• (1) Si7212-B00V-EB PWM PS Board

• (1) Si7213-B00V-EB SENT PS Board

• (1) 6-pin, 8-inch ribbon cable

• (2) Loose magnets for PS demos

• (1) CR2032 Coin Cell battery

• (1) Micro USB cable

the EFM32 Happy Gecko STK. Each of the six base part types are included

KEY POINTS

• 8 demos

• Wheel demo showing wheel angular

position

•

Wheel demo showing revolution counting

• Si7210 postage-stamp-sized board demos

including magnetic field data on two

scales and temperature

• Switch, analog, PWM, and SENT postagestamp-sized board demos including

tamper indication with an Si7210

silabs.com | Building a more connected world. Rev. 0.2

UG288: Si72xx-WD-Kit User's Guide

Demos

1. Demos

1.1 Demo 1—Wheel Angular Position (Si72xx-EXP)

Section 9 of "AN1018: Using the Si72xx Hall-Effect Magnetic Position Sensors" covers how the hall sensor can be used for a positional

measurement by moving the magnetic field. Furthermore, it explains how an MCU can perform an angular position measurement by

arranging two hall sensors to sense magnetic field variations from two magnets arranged about the shaft underneath.

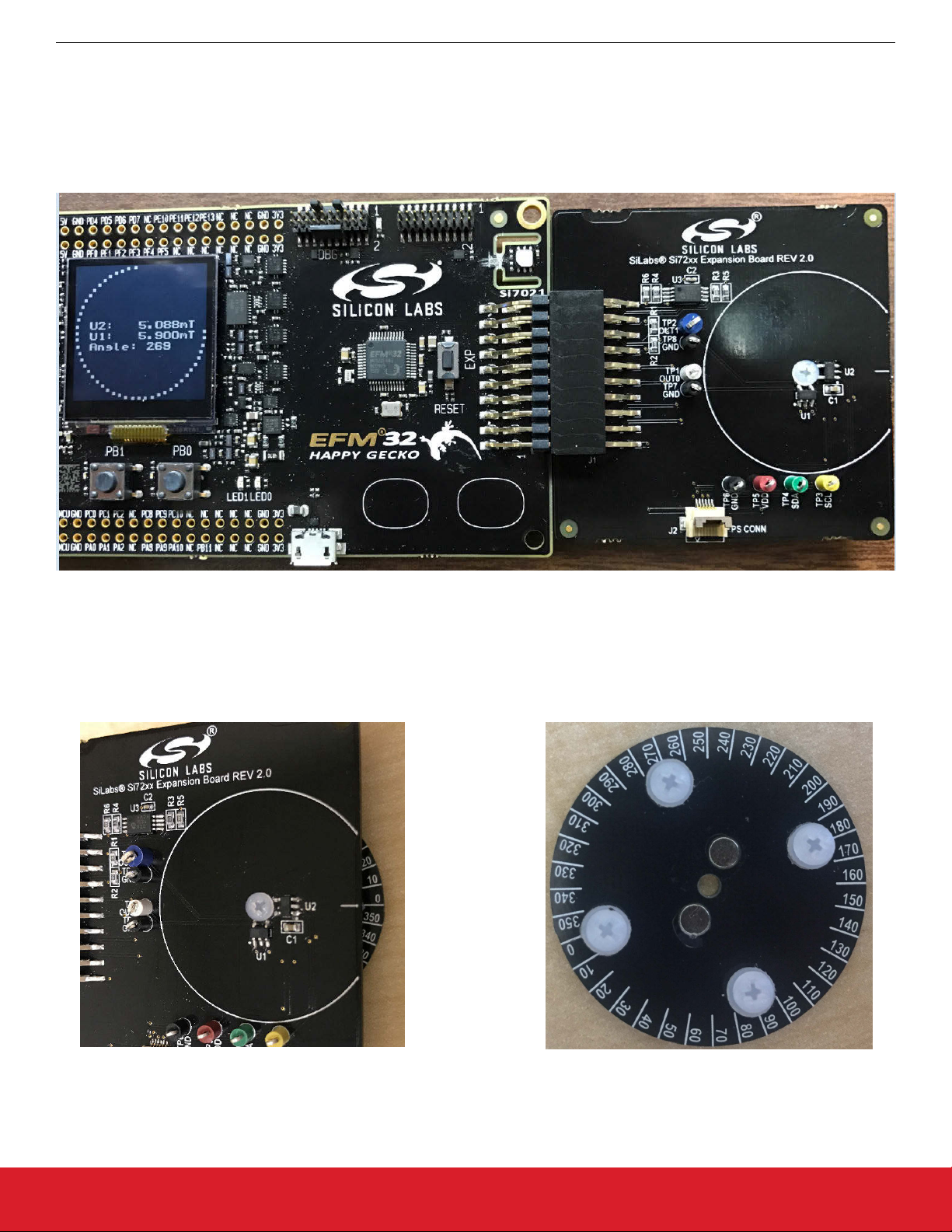

Figure 1.1. Wheel Angular Position Demo

The Wheel Angle Calculation demo determines the angular position of the wheel using two magnetic sensors mounted 90° apart on top

EXP. Underneath the sensors, a wheel board is connected by a nylon screw which houses two magnets positioned at 45° and

of the

225°. The figures below show the magnets orientated 180° apart, in opposite polarity on the wheel board and how the wheel aligns with

the EXP positioning. Using the wheel board as an angle reference, the sensors are positioned so that when U2 is at 0°, U1 is positioned

at 270°.

Figure 1.2. SI72xx-EXP Wheel Alignment

silabs.com | Building a more connected world. Rev. 0.2 | 2

Figure 1.3. Wheel Magnet Orientation

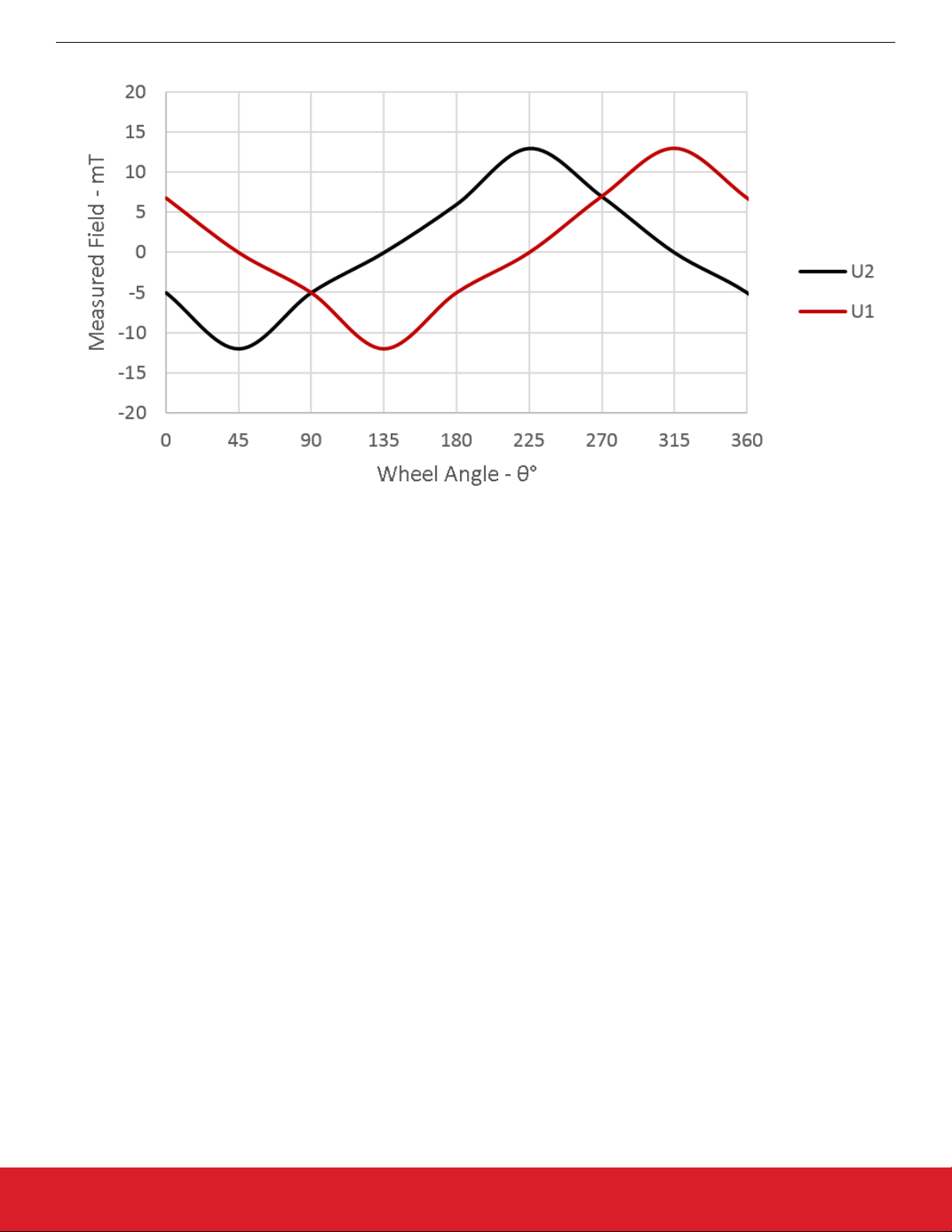

As the angular position varies, the measured magnetic field from each sensor varies as shown below.

UG288: Si72xx-WD-Kit User's Guide

Demos

Figure 1.4. Magnetic Field Strength vs. Angle Position

To calculate the angular position, interpolation is applied using the ratio of magnetic field strengths from each sensor against a lookup

table. Without calibration, the angle accuracy is within ±5° due to variations in the magnets, mechanical alignment and variations in the

sensors. The lookup table consists of 36 reference points for each sensor 10° apart. To activate the calibration procedure, follow these

steps:

1. Press and hold-down push-button PB1 on the MCU STK.

2. While holding-down PB1, press push-button PB0 on the MCU STK.

Carefully and accurately position the wheel at each angular position to calibrate the lookup table properly. The calibration requires 36

points of calibration that are 10° apart, from 0° to 350°. With calibration, accuracy is better than ±1°. Due to higher voltage required for

flash programming, only perform the calibration with a fresh battery or when USB powered.

silabs.com | Building a more connected world. Rev. 0.2 | 3

1.2 Demo 2—Revolution Counter Using the MCU Pulse Counter (Si72xx-EXP)

UG288: Si72xx-WD-Kit User's Guide

Demos

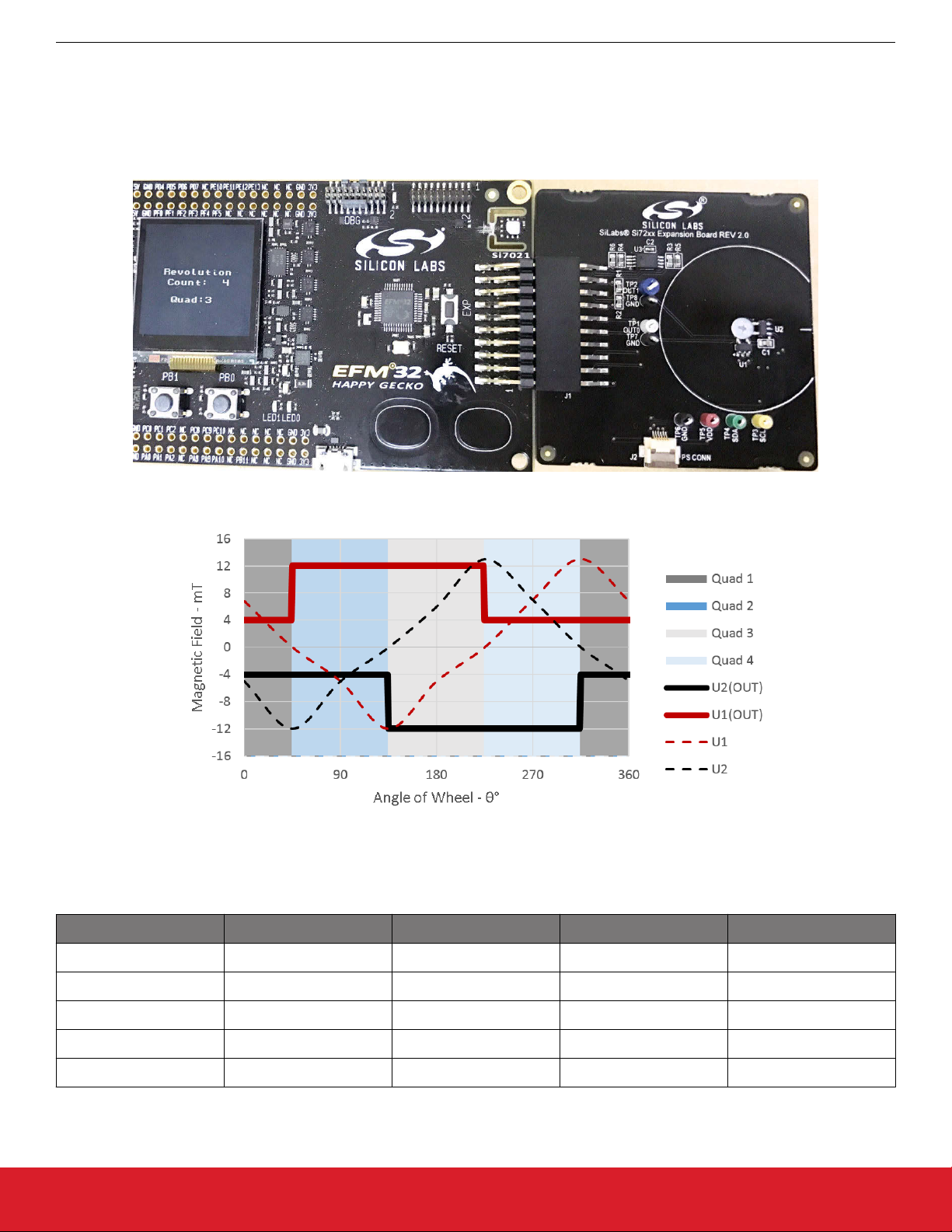

Section 10

of "AN1018: Using the Si72xx Hall-Effect Magnetic Position Sensors" explains how the same rotary shaft configuration of

the angular position demo can be used for detecting direction and quadrature positioning. Placing the Si7210 sensors on the Si72xxEXP into a latch mode, the demo counts the total number of wheel revolutions in either direction, with a maximum number of 15 revolutions. To activate the quadrature decoder, press push-button PB1 on the MCU STK. The STK screen will display the quadrature positioning and update the screen once the quadrature position has changed.

Figure 1.5. Revolution Counter Demo

Figure 1.6. Quadrant vs. Wheel Position

Table 1.1. Quadrant Assignments vs. Wheel Position

Quadrant 1 2 3 4

U2 OUT HIGH HIGH LOW LOW

U1 OUT LOW HIGH HIGH LOW

U2 Field Polarity Negative Negative Positive Positive

U1 Field Polarity Positive Negative Negative Positive

Angle Interval 315° to 45° 45° to 135° 135° to 225° 225° to 315°

silabs.com | Building a more connected world. Rev. 0.2 | 4

1.3 Demo 3—PS Magnetic Field Strength over I2C (SI7210-B00V-EB)

UG288: Si72xx-WD-Kit User's Guide

Demos

With the

Si7210-B00V-EB PS board connected by ribbon cable, the magnetic field readings from the hall sensor on the PS board are

displayed on the MCU LCD screen. A magnetic field can be applied to the hall sensor by placing one of the provided loose magnets

within near range of the sensor. As detailed in Section 2 of "AN1018: Using the Si72xx Hall-Effect Magnetic Position Sensors", the hall

sensor detects the magnetic field going into the bottom of the package. Therefore, it is best to use the magnet positioning shown in the

following figures to measure the magnetic field strength for a given distance. The sensor’s magnetic field readings are displayed on the

STK screen once every second. By default, the sensor uses a ±20 mT full-scale range for performing magnetic field conversions. This

can be converted to a ±200 mT full-scale range by pressing the push-button PB1 on the STK.

Figure 1.7. 20 mT Data Screen with Negative Field

silabs.com | Building a more connected world. Rev. 0.2 | 5

Loading...

Loading...