Page 1

Si5345, Si5344, Si5342 Rev. D Family

Reference Manual

Any-frequency, Any-output Jitter-Attenuators/Clock Multipliers

Si5345, Si5344, Si5342 Family Reference Manual

This Family Reference Manual is intended to provide system, PCB design, signal

integrity, and software engineers the necessary technical information to successfully use

the Si5345/44/42 devices in end applications. The official device specifications can be

found in the Si5345/44/42 data sheets.

RELATED DOCUMENTS

• Si5345/44/42 Rev D Data Sheet: https://

www.silabs.com/documents/public/datasheets/Si5345-44-42-D-DataSheet.pdf

• Si5345/44/42 Rev D Device Errata: https://

www.silabs.com/documents/public/errata/

Si5345-44-42-RevD-Errata.pdf

•

Si5345 Rev D -EVB User Guide: https://

www.silabs.com/documents/public/userguides/Si5345-D-EVB.pdf

• Si5344 Rev D -EVB User Guide: https://

www.silabs.com/documents/public/userguides/Si5344-D-EVB.pdf

• Si5342 Rev D -EVB User Guide: https://

www.silabs.com/documents/public/userguides/Si5342-D-EVB.pdf

• Si534x/8x Jitter Attenuators

Recommended Crystals, TCXO and

OCXOs Reference Manual: https://

www.silabs.com/documents/public/

reference-manuals/si534x-8xrecommended-crystals-rm.pdf

silabs.com | Building a more connected world. Rev. 1.3

Page 2

Table of Contents

1. Overview .................................

5

2. Work Flow Expectations with ClockBuilder Pro™ and the Register Map .........6

2.1 Family Product Comparison .........................7

2.2 Available Software Tools and Support ......................8

3. DSPLL and MultiSynth ............................9

3.1 Dividers ................................10

3.2 DSPLL Loop Bandwidth ...........................10

3.2.1 Fastlock Feature ............................11

3.2.2 Holdover Exit Bandwidth .........................11

4. Modes of Operation ............................12

4.1 Reset and Initialization ...........................13

4.2 Dynamic PLL Changes ...........................14

4.3 NVM Programming ............................15

4.4 Free Run Mode ..............................16

4.5 Acquisition Mode .............................16

4.6 Locked Mode ..............................16

4.7 Holdover Mode ..............................17

5. Clock Inputs............................... 19

5.1 Inputs (IN0, IN1, IN2, IN3) ..........................19

5.1.1 Manual Input Switching..........................19

5.1.2 Automatic Input Selection .........................20

5.2 Types of Inputs ..............................21

5.2.1 Unused Inputs.............................22

5.2.2 Hitless Input Switching with Phase Buildout ...................22

5.2.3 Ramped Input Switching .........................22

5.2.4 Hitless Switching, LOL (loss of lock) and Fastlock .................23

5.2.5 Glitchless Input Switching .........................23

5.2.6 External Clock Switching .........................23

5.2.7 Synchronizing to Gapped Input Clocks ....................23

5.2.8 Rise Time Considerations .........................24

5.3 Fault Monitoring .............................25

5.3.1 Input Loss of Signal (LOS) Fault Detection ...................26

5.3.2 Out of Frequency (OOF) Fault Detection ....................27

5.3.3 Loss of Lock (LOL) Fault Monitoring .....................29

5.4 Interrupt (INTR) Monitoring ..........................31

6. Output Clocks ..............................32

6.1 Output Crosspoint Switch ..........................33

6.2 Performance Guidelines for Outputs .......................34

silabs.com | Building a more connected world. Rev. 1.3 | 2

Page 3

6.3 Output Signal Format ............................35

6.3.1 Differential Output Terminations.......................36

6.3.2 Differential Output Swing Modes ......................37

6.3.3 Programmable Common Mode Voltage for Differential Outputs ............38

6.3.4

6.3.5 LVCMOS Output Impedance and Drive Strength Selection..............39

6.3.6 LVCMOS Output Signal Swing .......................39

6.3.7 LVCMOS Output Polarity .........................40

6.3.8 Output Driver Settings for LVPECL, LVDS, HCSL, and CML .............41

6.4 Output Enable/Disable ...........................42

6.4.1 Output Driver State When Disabled .....................42

6.4.2 Synchronous Output Disable Feature .....................43

6.5 Output Buffer Supply Voltage Selection......................43

LVCMOS Output Terminations .......................38

7. Zero Delay Mode .............................44

8. Digitally-Controlled Oscillator (DCO) Mode ...................46

8.1 DCO with Frequency Increment/Decrement Pins/Bits .................47

8.2 DCO with Direct Register Writes ........................49

9. Serial interface .............................. 50

9.1 I2C Interface ...............................51

9.2 SPI Interface...............................53

10. Field Programming............................ 58

11. XA/XB External References ........................59

11.1 Performance of External References ......................59

11.2 Recommended Crystals and External Oscillators ..................60

11.3 Register Settings to Control External XTAL Reference ................60

11.3.1 XAXB_EXTCLK_EN Reference Clock Selection Register ..............61

11.3.2 PXAXB Pre-scale Divide Ratio for Reference Clock Register ............61

12. Crystal and Device Circuit Layout Recommendations ..............62

12.1 64-Pin QFN Si5345 Layout Recommendations...................62

12.1.1 Si5345 Applications without a Crystal ....................62

12.1.2 Si5345 Crystal Guidelines ........................63

12.1.3 Output Clocks ............................69

12.2 44-Pin QFN Si5344/42 Layout Recommendations .................71

12.2.1 Si5342/44 Applications without a Crystal ...................72

12.2.2 Si5342/44 Crystal Guidelines .......................73

13. Power Management ...........................78

13.1 Power Management Features ........................78

13.2 Power Supply Recommendations .......................78

13.3 Power Supply Sequencing .........................79

13.4 Grounding Vias .............................79

silabs.com | Building a more connected world. Rev. 1.3 | 3

Page 4

14. Si5345 Register Map ...........................80

14.1 Base vs. Factory Preprogrammed Devices ....................80

14.1.1 “Base” Devices (a.k.a. “Blank” Devices)....................80

14.1.2 “Factory Preprogrammed” (Custom OPN) Devices ................80

14.2 Register Map Pages and Default Settings Values ..................81

15.

Si5345 Register Definitions ........................82

15.1 Page 0 Registers Si5345 ..........................82

15.2 Page 1 Registers Si5345 ..........................97

15.3 Page 2 Registers Si5345 .........................101

15.4 Page 3 Registers Si5345 .........................108

15.5 Page 4 Registers Si5345 .........................110

15.6 Page 5 Registers Si5345 .........................111

15.7 Page 9 Registers Si5345 .........................120

15.8 Page A Registers Si5345 .........................122

15.9 Page B Registers Si5345 .........................123

16. Si5344 Register Definitions ........................125

16.1 Page 0 Registers Si5344 .........................125

16.2 Page 1 Registers Si5344 .........................140

16.3 Page 2 Registers Si5344 .........................144

16.4 Page 3 Registers Si5344 .........................151

16.5 Page 4 Registers Si5344 .........................153

16.6 Page 5 Registers Si5344 .........................154

16.7 Page 9 Registers Si5344 .........................163

16.8 Page A Registers Si5344 .........................165

16.9 Page B Registers Si5344 .........................166

17. Si5342 Register Definitions ........................168

17.1 Page 0 Registers Si5342 .........................168

17.2 Page 1 Registers Si5342 .........................183

17.3 Page 2 Registers Si5342 .........................187

17.4 Page 3 Registers Si5342 .........................193

17.5 Page 4 Registers Si5342 .........................195

17.6 Page 5 Registers Si5342 .........................196

17.7 Page 9 Registers Si5342 .........................205

17.8 Page A Registers Si5342 .........................206

17.9 Page B Registers Si5342 .........................207

18. Setting the Differential Output Driver to Non-Standard Amplitudes ..........209

19. Revision History.............................211

silabs.com | Building a more connected world. Rev. 1.3 | 4

Page 5

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Overview

1. Overview

The Si5345/44/42 jitter attenuating clock multipliers combine 4th generation DSPLL and MultiSynth™ technologies to enable any-frequency clock generation for applications that require the highest level of jitter performance. These devices are programmable via a serial interface with in-circuit programmable non-volatile memory (NVM) ensuring power up with a known frequency configuration. Freerun, synchronous, and holdover modes of operation are supported offering both automatic and manual input clock switching. The loop

filter is fully integrated on-chip eliminating the risk of potential noise coupling associated with discrete solutions. Further, the jitter attenuation bandwidth is digitally programmable providing jitter performance optimization at the application level.

These devices are capable of generating any combination of output frequency from any input frequency within the specified input and

output range.

silabs.com | Building a more connected world. Rev. 1.3 | 5

Page 6

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Work Flow Expectations with ClockBuilder Pro™ and the Register Map

2. Work Flow Expectations with ClockBuilder Pro™ and the Register Map

This reference manual is to be used to describe all the functions and features of the parts in the product family with register map details

on how to implement them. It is important to understand that the intent is for customers to use the ClockBuilder Pro software to provide

the initial configuration for the device. Although the register map is documented, all the details of the algorithms to implement a valid

frequency plan are fairly complex and are beyond the scope of this document. Real-time changes to the frequency plan and other operating settings are supported by the devices. However, describing all the possible changes is not a primary purpose of this document.

Refer to Applications Notes and Knowledge Base article links within the ClockBuilder Pro GUI for information on how to implement the

most common, real-time frequency plan changes.

The primary purpose of the software is that it saves having to understand all the complexities of the device. The software abstracts the

details from the user to allow focus on the high level input and output configuration, making it intuitive to understand and configure for

the end application. The software walks the user through each step, with explanations about each configuration step in the process to

explain the different options available. The software will restrict the user from entering an invalid combination of selections. The final

configuration settings can be saved, written to an EVB and a custom part number can be created for customers who prefer to order a

factory preprogrammed device. The final register maps can be exported to text files, and comparisons can be done by viewing the settings in the register map described in this document.

silabs.com | Building a more connected world. Rev. 1.3 | 6

Page 7

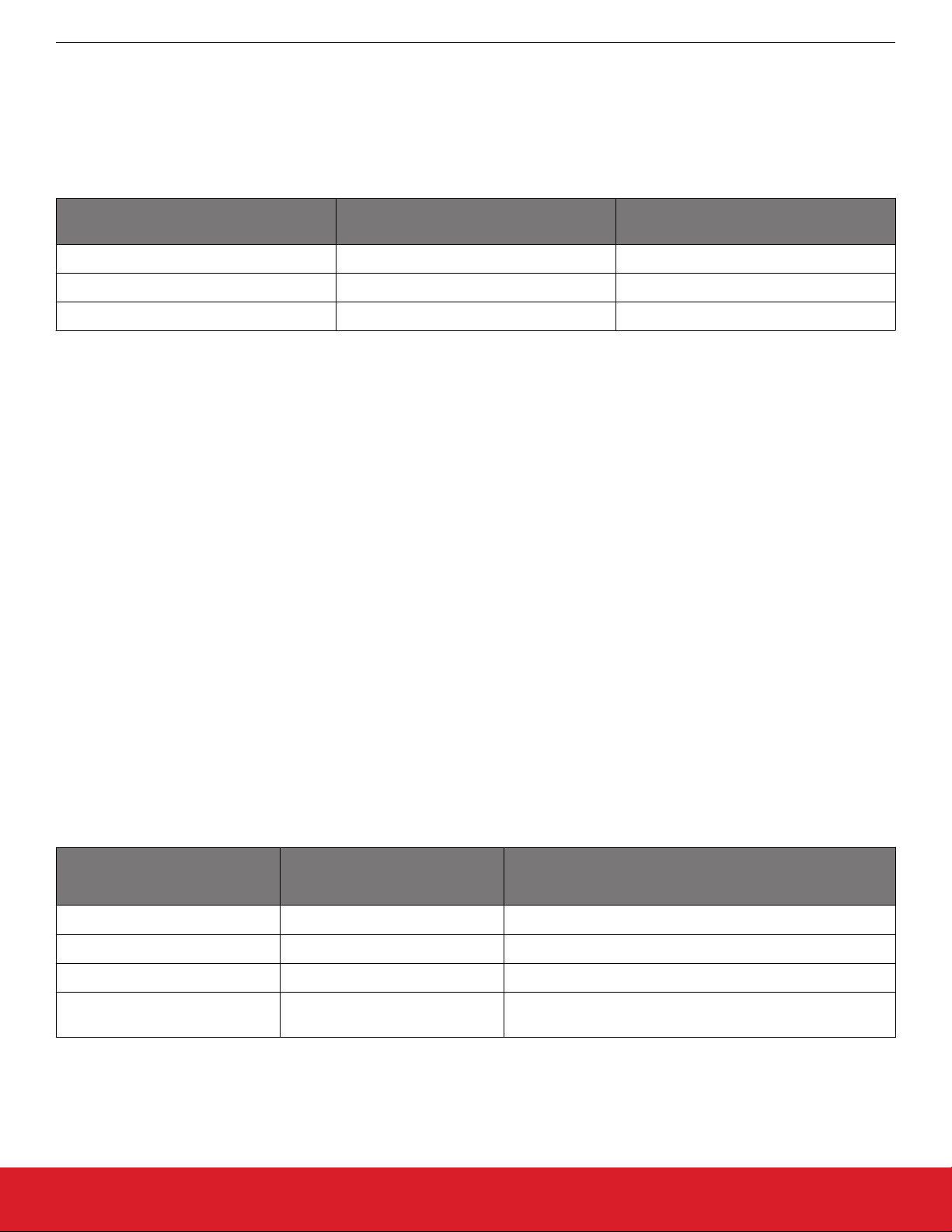

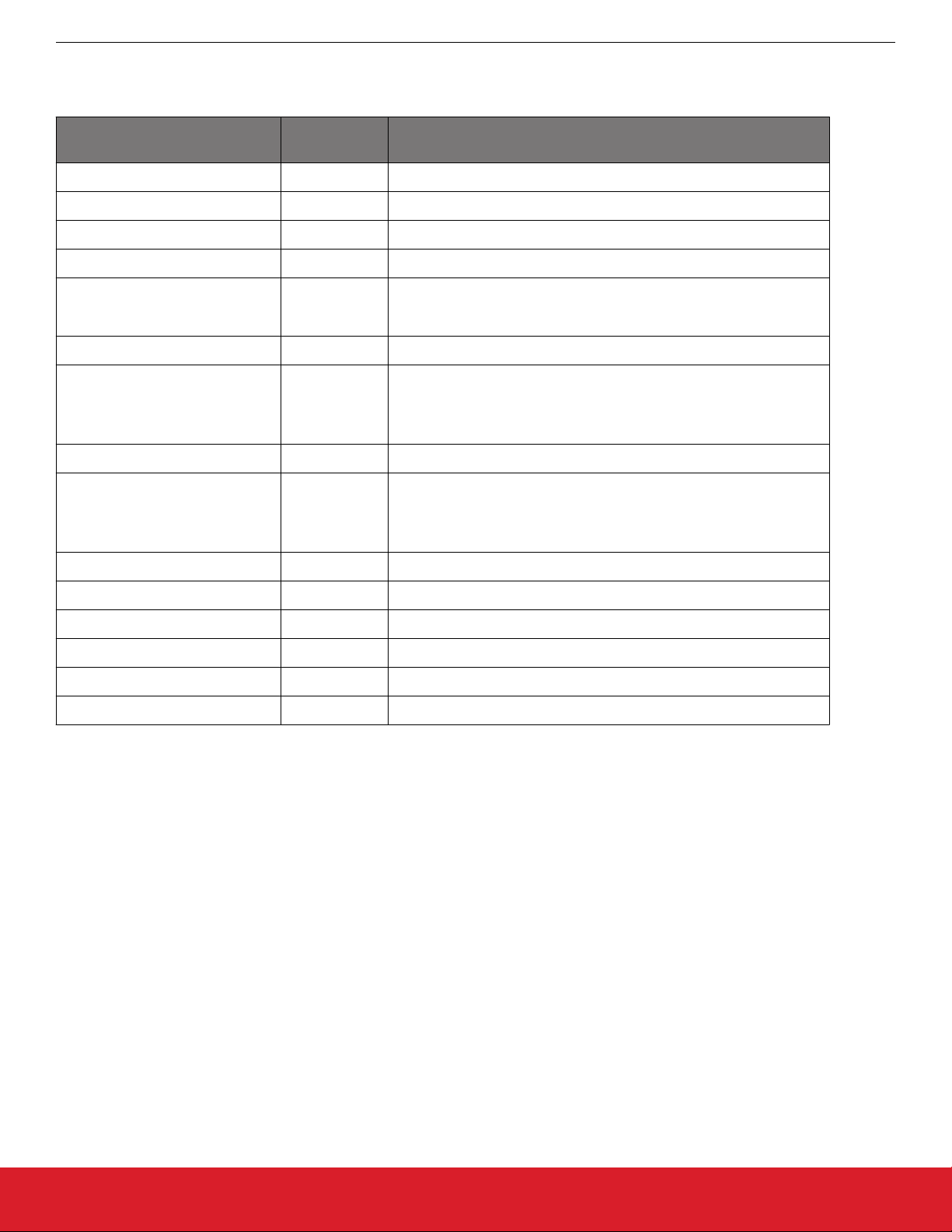

2.1 Family Product Comparison

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Work Flow Expectations with ClockBuilder Pro™ and the Register Map

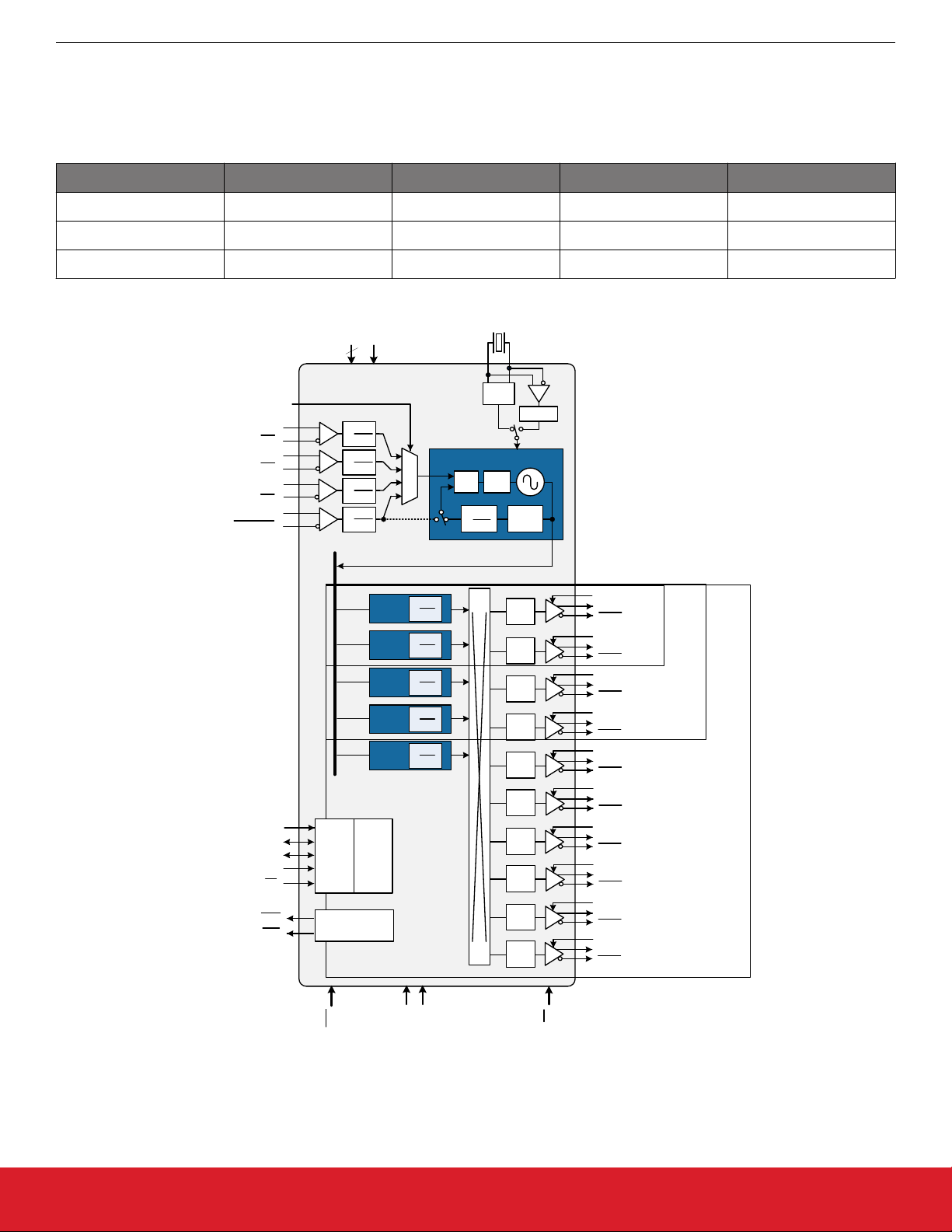

Table 2.1 Product Selection Guide on page

7 lists a comparison of the different family members.

Table 2.1. Product Selection Guide

Part Number Number of Inputs Number of MultiSynths Number of Outputs Package Type

Si5342 4 2 2 44-QFN

Si5344 4 4 4 44-QFN

Si5345 4 5 10 64-QFN

IN_SEL[1:0]

IN0

IN0

IN1

IN1

IN2

IN2

IN3/FB_IN

IN3/FB_IN

Si5345/44/42

VDDA

VDD

3

P

0n

÷

P

0d

P

1n

÷

P

1d

P

2n

÷

P

2d

P

3n

÷

Optional

P

3d

External

Feedback

25MHz,48-54MHz XTAL

or REFCLK

OSC

DSPLL

LPFPD

M

n

÷

M

d

XBXA

PXAXB

÷

÷

5

I2C_SEL

SDA/SDIO

A1/SDO

SCLK

A0/CS

INTR

LOL

SPI/

2

I

C

Status

Monitors

RST

NVM

Multi

Synth

Multi

Synth

Multi

Synth

Multi

Synth

Multi

Synth

÷

÷

÷

÷

÷

FINC

N

N

N

N

N

N

N

N

N

N

0n

0d

1n

1d

2n

2d

3n

3d

4n

4d

FDEC

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

Si5342

VDDO0

0

1

2

3

4

5

6

7

8

9

OUT0

OUT0

VDDO1

OUT1

OUT1

VDDO2

OUT2

OUT2

VDDO3

OUT3

OUT3

VDDO4

OUT4

OUT4

VDDO5

OUT5

OUT5

VDDO6

OUT6

OUT6

VDDO7

OUT7

OUT7

VDDO8

OUT8

OUT8

VDDO9

OUT9

OUT9

OE

Si5344

Si5345

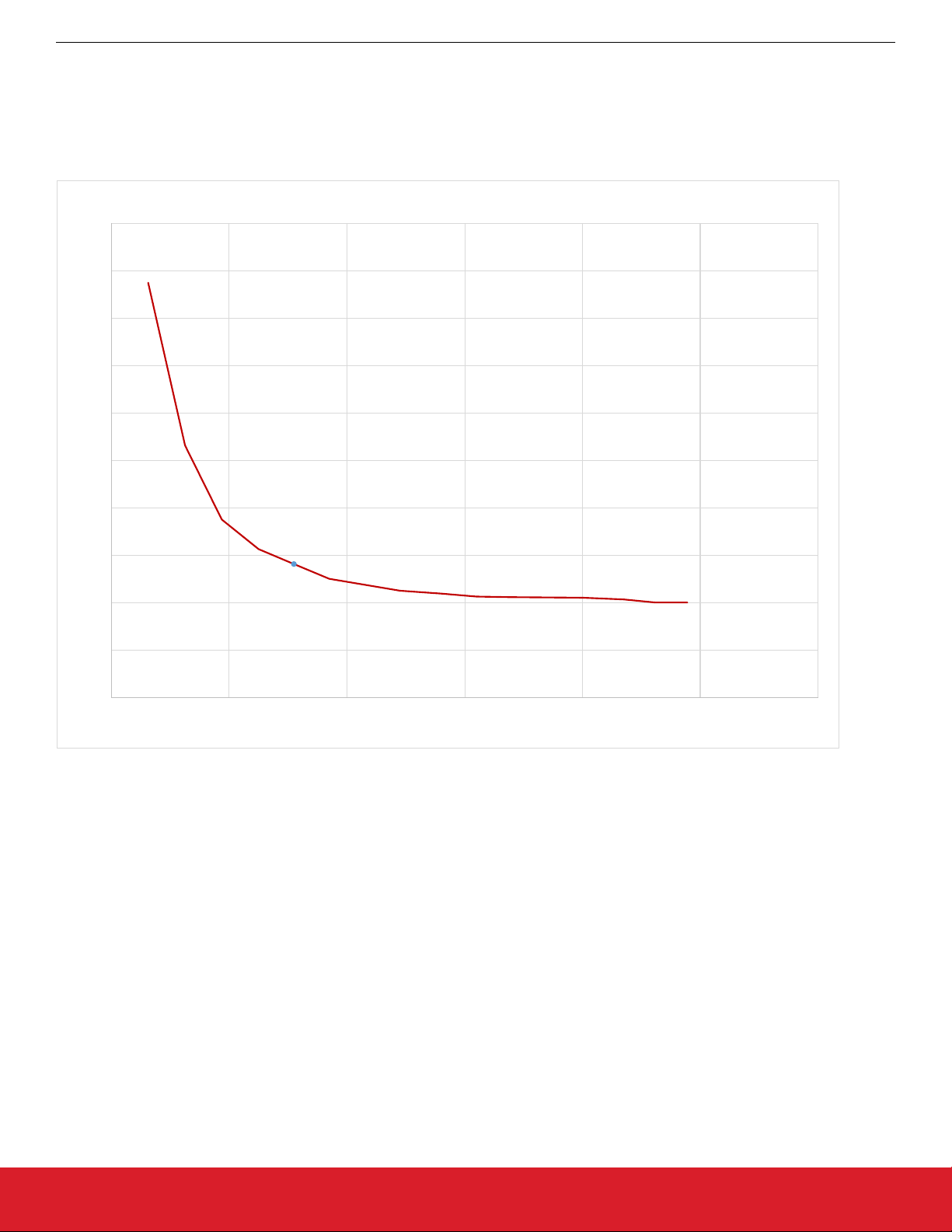

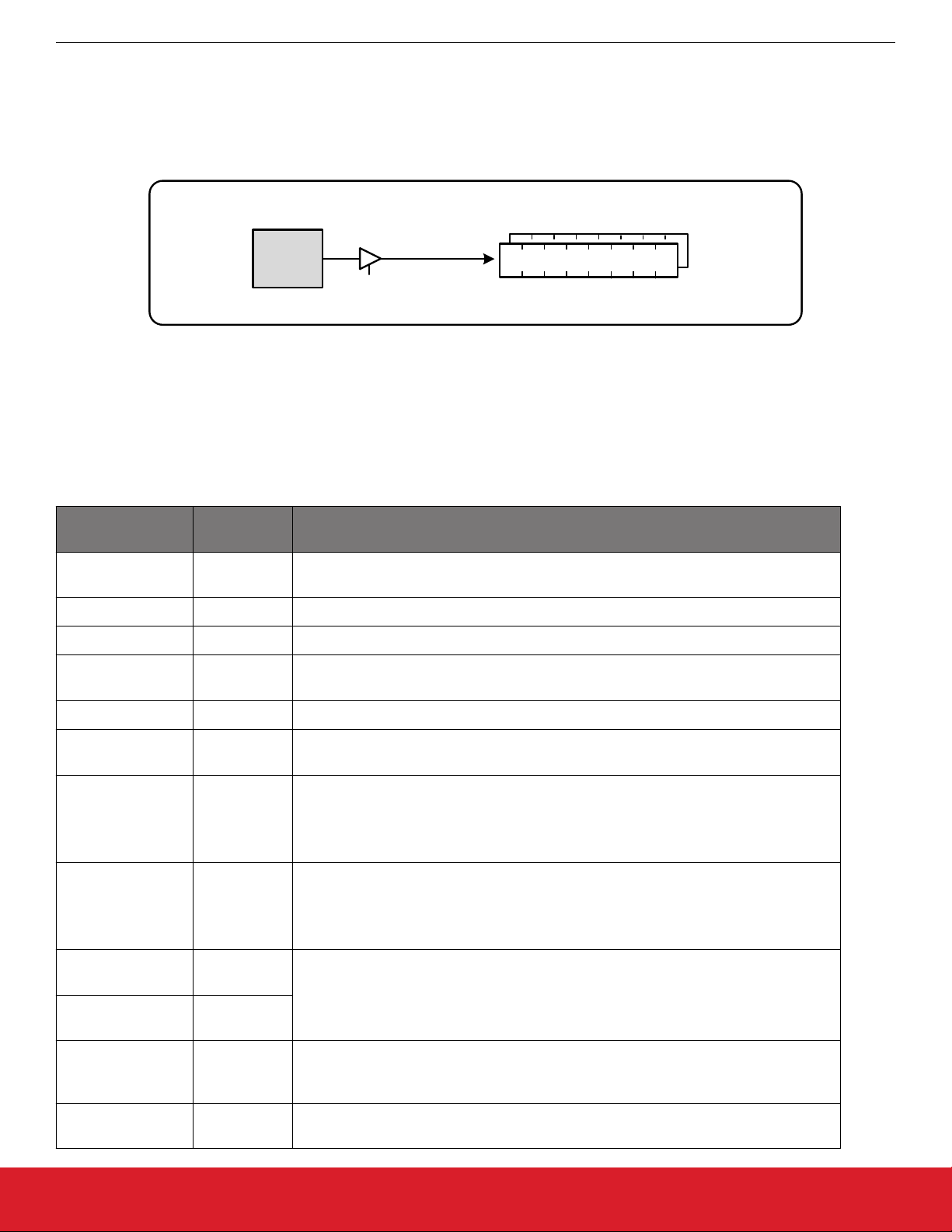

Figure 2.1. Block Diagram Si5345/44/42

silabs.com | Building a more connected world. Rev. 1.3 | 7

Page 8

2.2 Available Software Tools and Support

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Work Flow Expectations with ClockBuilder Pro™ and the Register Map

ClockBuilder Pro is a

software tool that is used for the Si5345/44/42 family and other product families, capable of configuring the timing

chip in an intuitive, easy-to-use, step-by-step process. The software abstracts the details from the user to allow focus on the high level

input and output configuration, making it intuitive to understand and configure for the end application. The software walks the user

through each step, with explanations about each configuration step in the process to explain the different options available. The software will restrict the user from entering an invalid combination of selections. The final configuration settings can be saved, written to a

device or written to the EVB and a custom part number can be created. This is all done with one software tool. ClockBuilder Pro integrates all the data sheets, application notes and information that might be helpful in one environment. It is intended that customers will

use the software tool for the proper configuration of the device. Register map descriptions given in the document should not be the only

source of information for programming the device. The complexity of the algorithms is embedded in the software tool.

silabs.com | Building a more connected world. Rev. 1.3 | 8

Page 9

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

DSPLL and MultiSynth

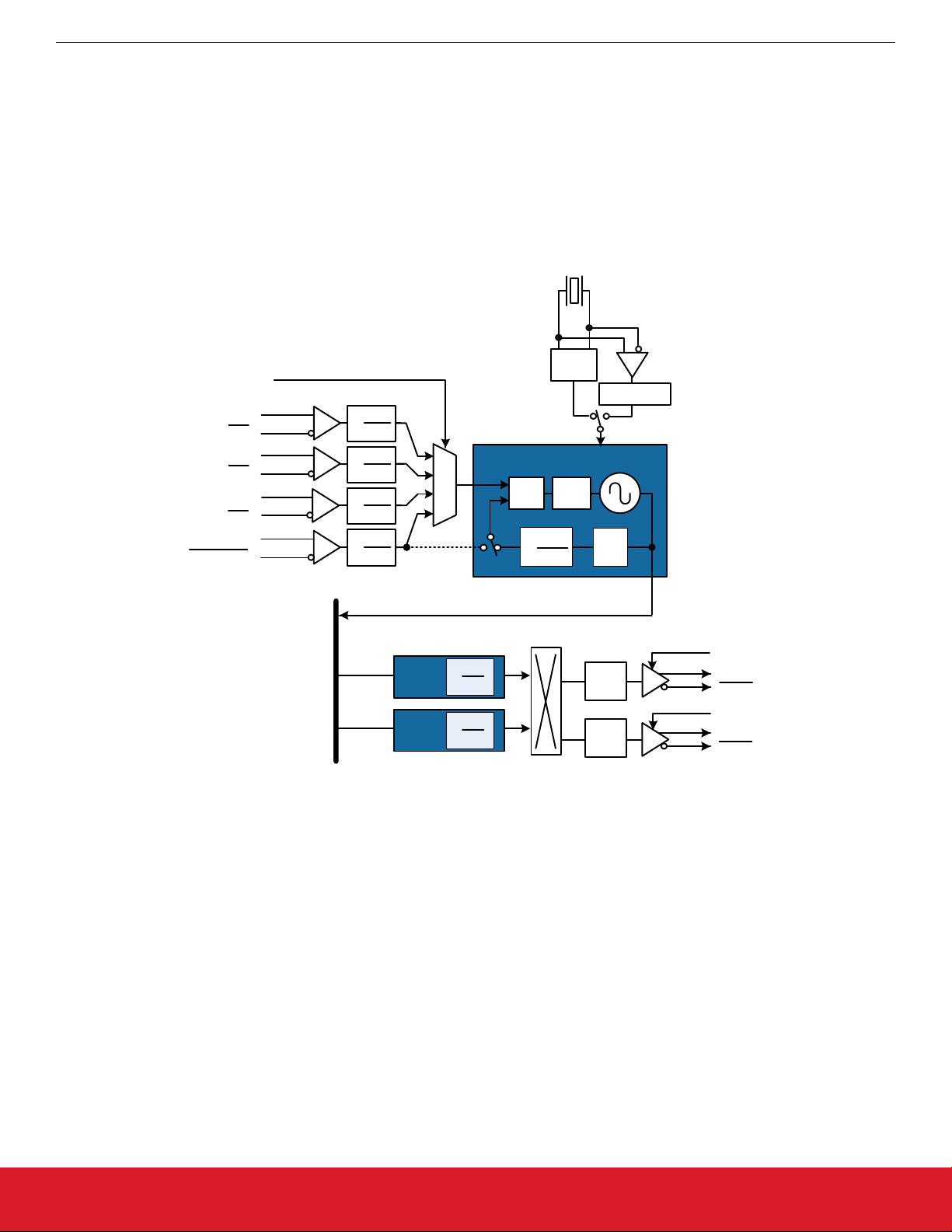

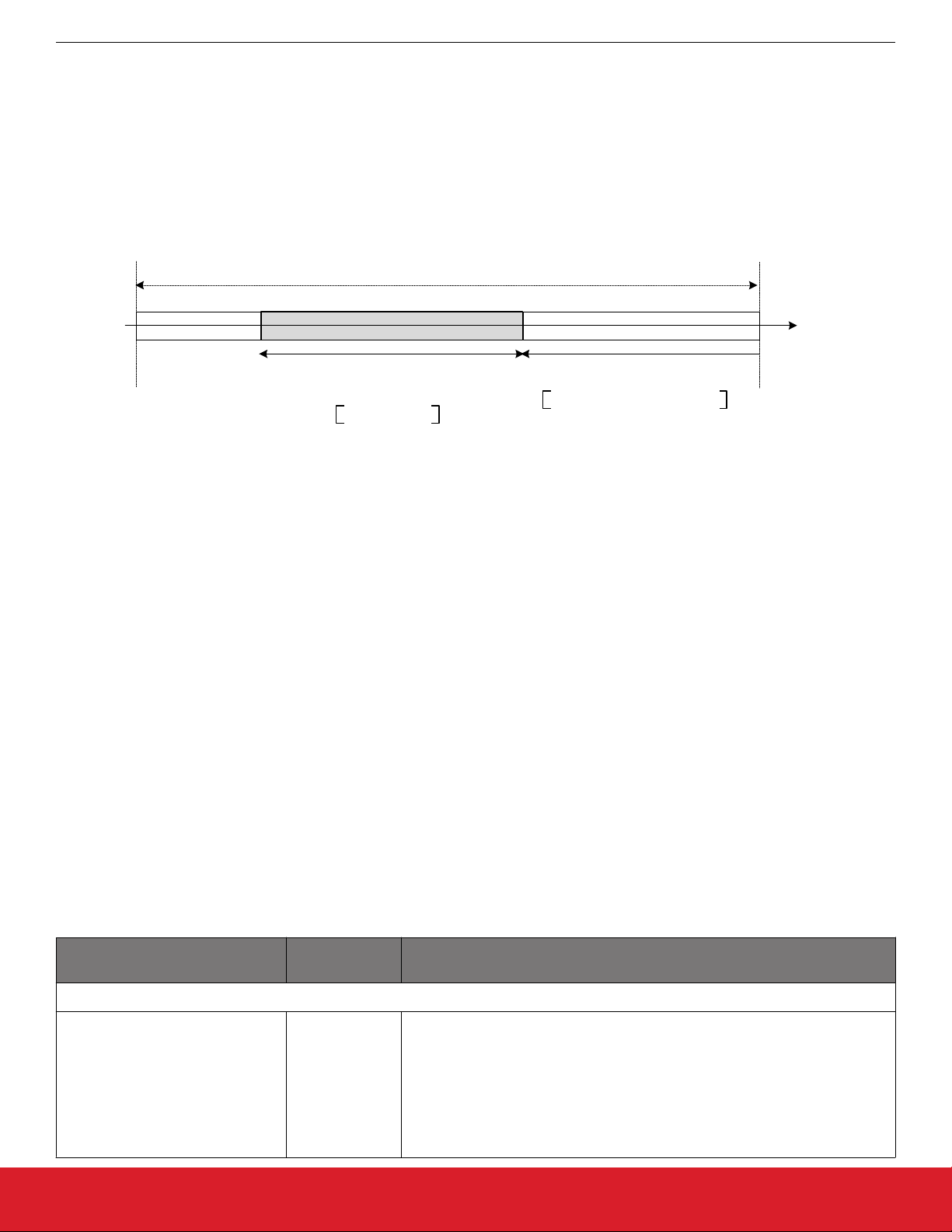

3. DSPLL and MultiSynth

The DSPLL is responsible for input frequency translation, jitter attenuation and wander filtering. Fractional input dividers (Pxn/Pxd) allow the DSPLL to perform hitless switching between input clocks (INx) that are fractionally related. Input switching is controlled manually or automatically using an internal state machine. The oscillator circuit (OSC) provides a frequency reference which determines output

frequency stability and accuracy while the device is in free-run or holdover mode. Note that a XTAL (or suitable XO reference on

XA/XB) is always required and is the jitter reference for the device. The high-performance MultiSynth dividers (Nxn/Nxd) generate integer or fractionally related output frequencies for the output stage. A crosspoint switch connects any of the MultiSynth generated frequencies to any of the outputs. A single MultiSynth output can connect to two or more output drivers. Additional integer division (R)

determines the final output frequency as shown in Figure 3.1 Si5342 DSPLL and Multisynth System Flow Diagram on page 9.

25MHz, 48-54MHz XTAL

or REFCLK

XBXA

IN_SEL[1:0]

IN0

IN0

IN1

IN1

IN2

IN2

IN3/FB_IN

IN3/FB_IN

OSC

PXAXB

÷

P

0n

÷

P

0d

P

1n

÷

P

1d

P

2n

÷

P

2d

P

3n

÷

P

3d

Optional

External

Feedback

Multi

Synth

Multi

Synth

Figure 3.1. Si5342 DSPLL and Multisynth System Flow Diagram

N

÷

N

÷

DSPLL

0n

N

0d

1n

N

1d

LPFPD

M

n

÷

M

÷ 5

d

÷R

0

÷R

1

VDDO0

OUT0

OUT0

VDDO1

OUT1

OUT1

The frequency configuration of the DSPLL is programmable through the SPI or I2C serial

interface and can also be stored in non-volatile memory or RAM. The combination of fractional input dividers (Pn/Pd), fractional frequency multiplication (Mn/Md), fractional output

MultiSynth division (Nn/Nd), and integer output division (Rn) allows the generation of virtually any output frequency on any of the outputs. All divider values for a specific frequency plan are easily determined using the ClockBuilder Pro software.

silabs.com | Building a more connected world. Rev. 1.3 | 9

Page 10

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

DSPLL and MultiSynth

3.1 Dividers

There are five divider classes within the Si5345/4/2. See Figure 1 for a block diagram that shows all of these dividers.

1. P-dividers: Wide range input dividers P3, P2, P1, P0

• MultiSynth divider: 48 bit numerator, 32 bit denominator, min value is 1

Practical range limited by phase detector and VCO range

•

• Each divider has an update bit that must be written to cause a newly written divider value to take effect.

2. Narrow range input divider: Pxaxb

• Only divides by 1, 2, 4, 8

3. Feedback M divider

• MultiSynth divider

• Integer or fractional divide values

• 56 bit numerator, 32-bit denominator

• Practical range limited by phase detector and VCO range

• Each divider has an update bit that must be written to cause a newly written divider value to take effect.

4. Output N divider

• MultiSynth divider

• Integer or fractional divide values

• 44 bit numerator, 32 bit denominator

• Each divider has an update bit that must be written to cause a newly written divider value to take effect.

5. Output R divider

• Only even integer divide values

• Min value is 2

•

Maximum value is 225 – 2

3.2 DSPLL Loop Bandwidth

The DSPLL loop bandwidth determines the amount of input clock jitter attenuation and wander filtering. Register configurable DSPLL

loop bandwidth settings in the range of 0.1 Hz to 4 kHz are available for selection. Since the loop bandwidth is controlled digitally, the

DSPLL will always remain stable with less than 0.1 dB of peaking regardless of the loop bandwidth selection. The DSPLL loop bandwidth is set in registers 0x0508-0x050D and are determined using ClockBuilder Pro.

The higher the PLL bandwidth is set relative to the phase detector frequency (F

), the more chance that F

pfd

will cause a spur in the

pfd

Phase Noise plot of the output clock and increase the output jitter. To guarantee the best phase noise/jitter it is recommended that the

normal PLL bandwidth be kept less than F

/160 although ratios of F

pfd

/100 will typically work fine.

pfd

Table 3.1. PLL Bandwidth Registers

Register Name Hex Address [Bit Field] Function

BWx_PLL 0x0508[7:0]-0x050D[7:0] Determines the loop BW for the DSPLL. This is set by CBPro. See CBPro for a

correlation of bandwidths and values.

silabs.com | Building a more connected world. Rev. 1.3 | 10

Page 11

3.2.1 Fastlock Feature

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

DSPLL and MultiSynth

Selecting a

low DSPLL loop bandwidth (e.g. 0.1 Hz) will generally lengthen the lock acquisition time. The Fastlock feature allows setting

a temporary Fastlock Loop Bandwidth that is used during the lock acquisition process to reduce lock time. Higher Fastlock loop bandwidth settings will enable the DSPLLs to lock faster. Fastlock Bandwidth settings in the range from 100 Hz up to 4 kHz are available for

selection. Once lock acquisition has completed, the DSPLL’s loop bandwidth will automatically revert to the DSPLL Loop Bandwidth

setting. The Fastlock feature can be enabled or disabled independently by register control. If enabled, when LOL is asserted Fastlock

will be automatically enabled. When LOL is no longer asserted, Fastlock will be automatically disabled.

Note: This update bit will latch new values for Loop, Fastlock, and Holdover bandwidths simultaneously.

Table 3.2. Fastlock Registers

Register Name Hex Address [Bit Field] Function

FASTLOCK_AUTO_EN 0x052B[0] Auto Fastlock Enable/Disable

FASTLOCK_MAN 0x052B[1] 0 for normal operation,

1 to force fast lock

FASTLOCK_BW_PLL 0x050E[7:0]-0x0513[7:0] Fastlock BW selection.

The loss of lock (LOL) feature is a fault monitoring mechanism. Details of the LOL feature can be found in 5.3.3 Loss

of Lock (LOL)

Fault Monitoring.

3.2.2 Holdover Exit Bandwidth

In addition to the operating loop and fastlock bandwidths, there is also a user-selectable bandwidth when exiting holdover and locking

or relocking to an input clock, available when ramping is disabled (HOLD_RAMP_BYP = 1). CBPro sets this value equal to the loop

bandwidth by default.

Note: The BW_UPDATE bit will latch new values for Loop, Fastlock, and Holodver bandwidths simultaneously.

Table 3.3. DSPLL Holdover Exit Bandwidth Registers

Register Name Hex Address Function

HOLDEXIT_BW 0x059D–0x05A2 Determines the Holdover Exit BW for the DSPLL. Parameters are generated by

ClockBuilder Pro. See CBPro for the generated values and corresponding

bandwidths.

silabs.com | Building a more connected world. Rev. 1.3 | 11

Page 12

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

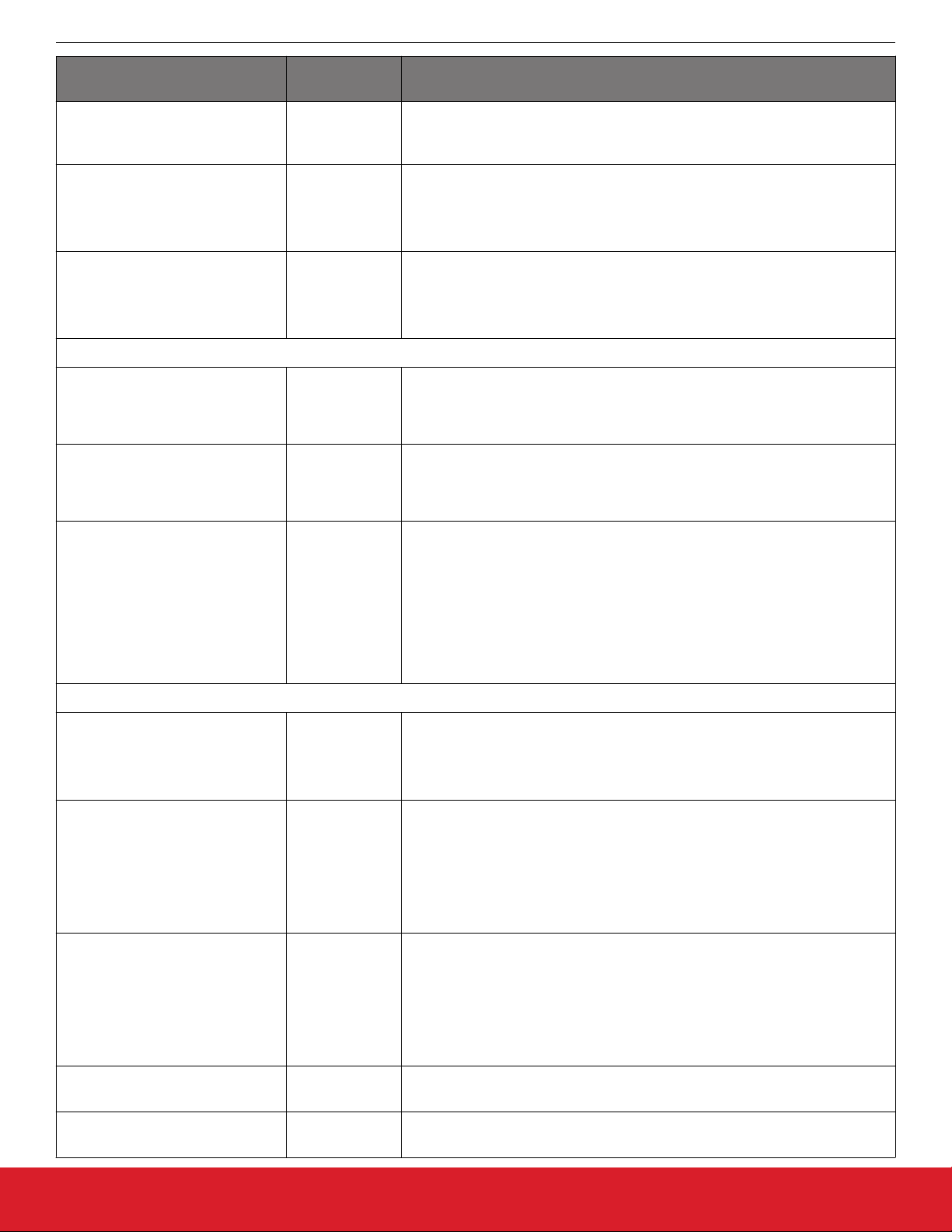

4. Modes of Operation

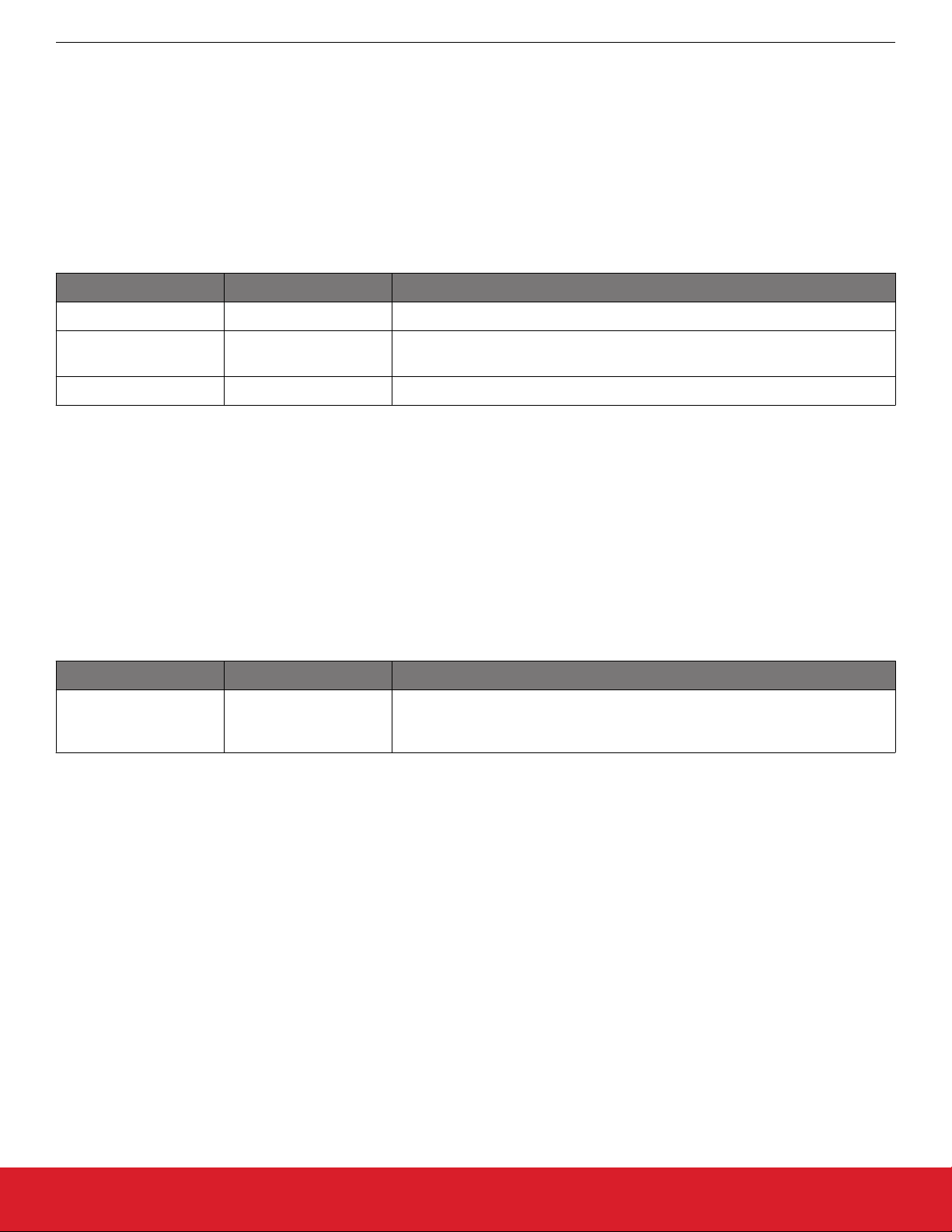

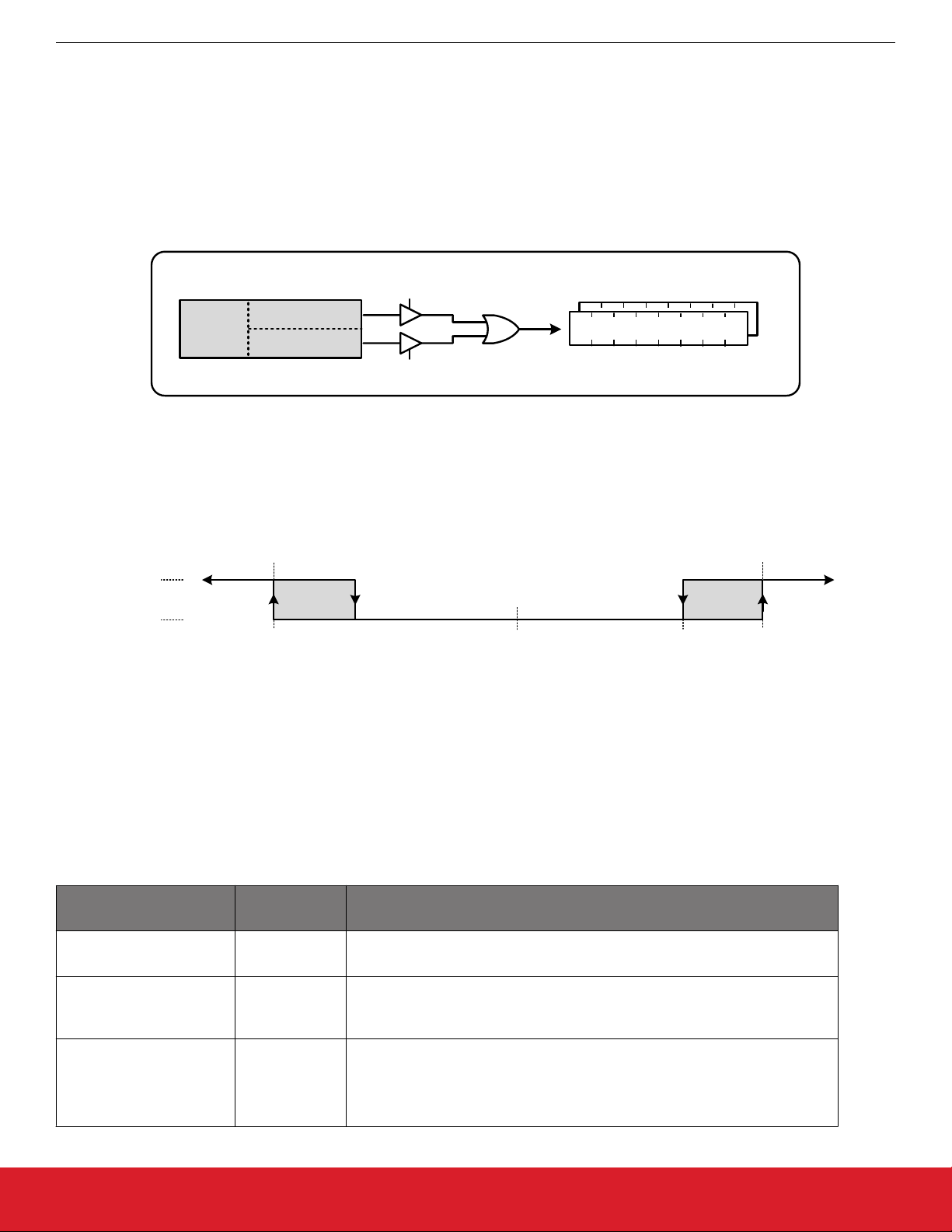

After initialization the DSPLL will operate in one of the following modes: Free-run, lock-acquisition, locked, or holdover. See Figure

4.1 Modes of Operation on page 12 below for the state diagram showing the modes of operation. The following sections describe

each of these modes in greater detail.

Power-Up

Reset and

Initialization

No

Is holdover

history valid?

No valid

input clocks

selected

An input is qualified

and available

selection

Holdover

Mode

Yes

Selected input

clock fails

Figure 4.1. Modes of Operation

for

Free-run

Valid input clock

Lock Acquisition

(Fast Lock)

Locked

Mode

selected

Phase lock on

selected input

clock is achieved

silabs.com | Building a more connected world. Rev. 1.3 | 12

Page 13

4.1 Reset and Initialization

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

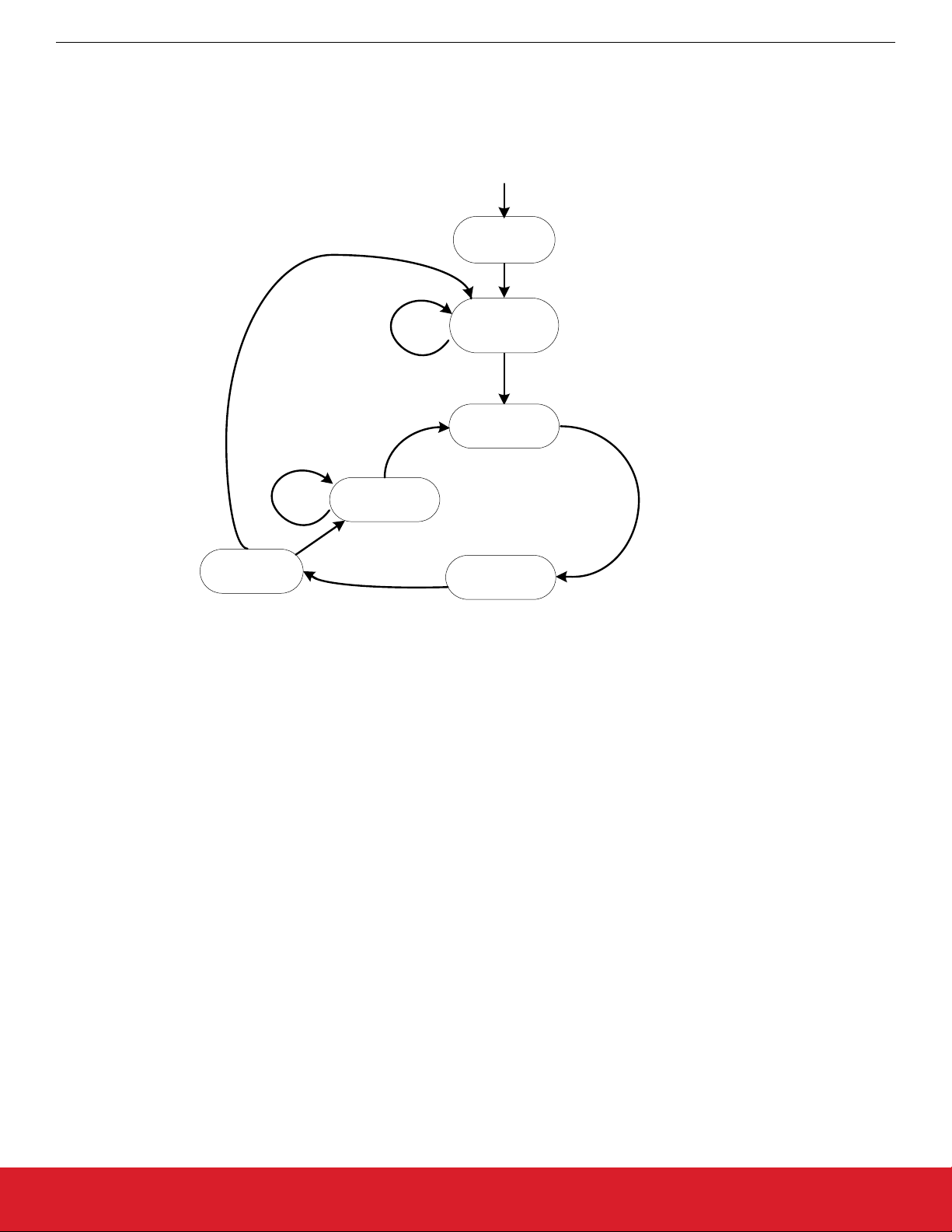

Once power

is applied, the device begins an initialization period where it downloads default register values and configuration data from

NVM and performs other initialization tasks. Communicating with the device through the serial interface is possible once this initialization period is complete. No clocks will be generated until initialization is complete.

There are two types of resets available. A hard reset is functionally similar to a device power-up. All registers are restored to the values

stored in NVM, and all circuits, including the serial interface, are restored to their initial state. A hard reset is initiated using the RST pin

or by asserting the hard reset bit. A soft reset bypasses the NVM download. It is simply used to initiate register configuration changes.

Table 4.1 Reset Registers on page 13 lists the reset and control registers.

NVM

2x

OTP

RAM

Figure 4.2. Si5345/44/42 Memory Configuration

Table 4.1. Reset Registers

Register Name Hex Ad-

Function

dress [Bit

Field]

HARD_RST 0x001E[1] Performs the same function as power cycling the device. All registers will be re-

stored to their default values.

SOFT_RST 0x001C[0] Performs a soft reset. Initiates register configuration changes.

Power-Up

NVM download

Initialization

Serial interface

ready

Hard Reset

bit asserted

Soft Reset

bit asserted

RST

pin asserted

Figure 4.3. Initialization from Hard Reset and Soft Reset

The Si5345/44/42 is fully configurable using the serial interface (I2C or

SPI). At power up the device downloads its default register values from internal non-volatile memory (NVM). Application specific default configurations can be written into NVM allowing the device to

generate specific clock frequencies at power-up. Writing default values to NVM is in-circuit programmable with normal operating power

supply voltages applied to its VDD (1.8V) and VDDA (3.3 V) pins.

silabs.com | Building a more connected world. Rev. 1.3 | 13

Page 14

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

4.2 Dynamic PLL Changes

possible for a PLL to become unresponsive (i.e., lose lock indefinitely) when it is dynamically reprogrammed or changed via the

It is

serial port. Reprogramming/changing the N divider does not affect the PLL. Any change that causes the VCO frequency to change by

more than 250 ppm since Power-up, NVM download, or SOFT_RST requires the following special sequence of writes. Changes to the

following registers require the this special sequence of writes:

• PXAXB

• MXAXB_NUM

• MXAXB_DEN

• M_NUM

• M_DEN

1. First, write in the preamble

Write 0x0B24 = 0xC0

Write 0x0B25 = 0x00

Write 0x0540 = 0x01 (NOTE: for all new designs it is recommend that this register be written as part of the preamble. In some rare

cases, omitting this write may result in a one-time LOL occurrence. However, if this issue has not occurred with your current frequency plan it is not likely to occur)

2. Wait 300 ms.

3. Then perform the desired register modifications

4. Write SOFT_RST 0x001C[0] = 1

5. Write the post-amble

Write 0x0540 = 0x00 (NOTE: for all new designs it is recommend that this register be written as part of the post-amble. In some

rare cases, omitting this write may result in a one-time LOL occurrence. However, if this issue has not occurred with your current

frequency plan it is not likely to occur)

Write 0x0B24 = 0xC3

Write 0x0B25 = 0x02

Note: This programming sequence applies only to Rev D and later and has changed for revision D and later from what it was in the

earlier revisions. The preamble and postamble values for updating certain registers during device operation are different for earlier revisions. Either the new or old values below may be written to revision D or later devices without issue. No system software changes are

necessary for legacy systems. When writing old values, note that reading back these registers will not give the written old values, but

will reflect the new values. Silicon Labs recommends using the new values for all revision D (described above) and later designs, since

the write and read values will match. Please contact Silicon Labs if you need information about an earlier revision. Please always ensure to use the correct sequence for the correct revision of the device. Also check for the latest information online. This information is

updated from time to time. The latest information is always posted online.

silabs.com | Building a more connected world. Rev. 1.3 | 14

Page 15

4.3 NVM Programming

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

Devices have

two categories of non-volatile memory: user NVM and factory (Silabs) NVM. Each type is segmented into NVM banks.

There are three user NVM banks, one of which is used for factory programming (whether a base part or an Orderable Part Number).

User NVM can be therefore be burned in the field up to two times. Factory NVM cannot be modified, and contains fixed configuration

information for the device.

The ACTIVE_NVM_BANK device setting can be used to determine which user NVM bank is currently being used and therefore how

many banks, if any, are available to burn. The following table describes possible values:

Active NVM BANK Value (Decimal) Number of User Banks Burned Number of User Banks

Available to Burn

3 (factory state) 1 2

15 2 1

63 3 0

Note: While polling DEVICE_READY during the procedure below, the following conditions must be met in order to ensure that the correct values are written into the NVM:

• VDD and VDDA power must both be stable throughout the process.

No additional registers may be written or read during DEVICE_READY polling. This includes the PAGE register at address 0x01.

•

DEVICE_READY is available on every register page, so no page change is needed to read it.

• Only the DEVICE_READY register (0xFE) should be read during this time.

The procedure for writing registers into NVM is as follows:

1. Write all registers as needed. Verify device operation before writing registers to NVM.

2. You may write to the user scratch space (Registers 0x026B to 0x0272 DESIGN_ID0-DESIGN_ID7) to identify the contents of the

NVM bank.

3. Write 0xC7 to NVM_WRITE register.

4. Poll DEVICE_READY until DEVICE_READY=0x0F.

5. Set NVM_READ_BANK 0x00E4[0]=1. This will load the NVM contents into non-volatile memory.

6. Poll DEVICE_READY until DEVICE_READY=0x0F.

7. Read ACTIVE_NVM_BANK and verify that the value is the next highest value in the table above. For example, from the factory it

will be a 3. After NVM_WRITE, the value will be 15.

Alternatively, steps 5 and 6 can be replaced with a Hard Reset, either by RSTb pin, HARD_RST register bit, or power cycling the device

to generate a POR. All of these actions will load the new NVM contents back into the device registers.

The ClockBuilder Pro Field Programmer kit is a USB attached device to program supported devices either in-system (wired to your

PCB) or in-socket (by purchasing the appropriate field programmer socket). ClockBuilder Pro software is then used to burn a device

configuration (project file). Learn more at https://www.silabs.com/products/development-tools/timing/cbprogrammer.

Table 4.2. NVM Programming Registers

Register Name Hex Address

Function

[Bit Field]

ACTIVE_NVM_BANK 0x00E2[7:0] Identifies the active NVM bank.

NVM_WRITE 0x00E3[7:0] Initiates an NVM write when written with value 0xC7.

NVM_READ_BANK 0x00E4[0] Download register values with content stored in NVM.

DEVICE_READY 0x00FE[7:0] Indicates that the device is ready to accept commands when

value = 0x0F.

Warning: Any attempt to read or write any register other than DEVICE_READY before DEVICE_READY reads as 0x0F may corrupt

NVM programming and may corrupt the register contents, as they are read from NVM. Note that this includes accesses to the

the

PAGE register.

silabs.com | Building a more connected world. Rev. 1.3 | 15

Page 16

4.4 Free Run Mode

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

The DSPLL

will automatically enter freerun mode once power is applied to the device and initialization is complete. The frequency accuracy of the generated output clocks in freerun mode is entirely dependent on the frequency accuracy of the external crystal or reference clock on the XA/XB pins. For example, if the crystal frequency is ±100 ppm, then all the output clocks will be generated at their

configured frequency ±100 ppm in freerun mode. Any drift of the crystal frequency will be tracked at the output clock frequencies. A

TCXO or OCXO is recommended for applications that need better frequency accuracy and stability while in freerun or holdover modes.

Because there is little or no jitter attenuation from the XAXB pins to the clock outputs, a low-jitter XAXB source will be needed for lowjitter clock outputs.

4.5 Acquisition Mode

The device monitors all inputs for a valid clock. If at least one valid clock is available for synchronization, the DSPLL will automatically

start the lock acquisition process. If the fast lock feature is enabled, the DSPLL will acquire lock using the Fastlock Loop Bandwidth

setting and then transition to the DSPLL Loop Bandwidth setting when lock acquisition is complete. During lock acquisition the outputs

will generate a clock that follows the VCO frequency change as it pulls-in to the input clock frequency.

4.6 Locked Mode

Once locked, the DSPLL will generate output clocks that are both frequency and phase locked to its selected input clock. At this point

any XTAL frequency drift will typically not affect the output frequency. A loss of lock pin (LOL) and status bit indicate when lock is achieved. See 5.3.3 Loss of Lock (LOL) Fault Monitoring for more details on the operation of the loss of lock circuit.

silabs.com | Building a more connected world. Rev. 1.3 | 16

Page 17

4.7 Holdover Mode

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

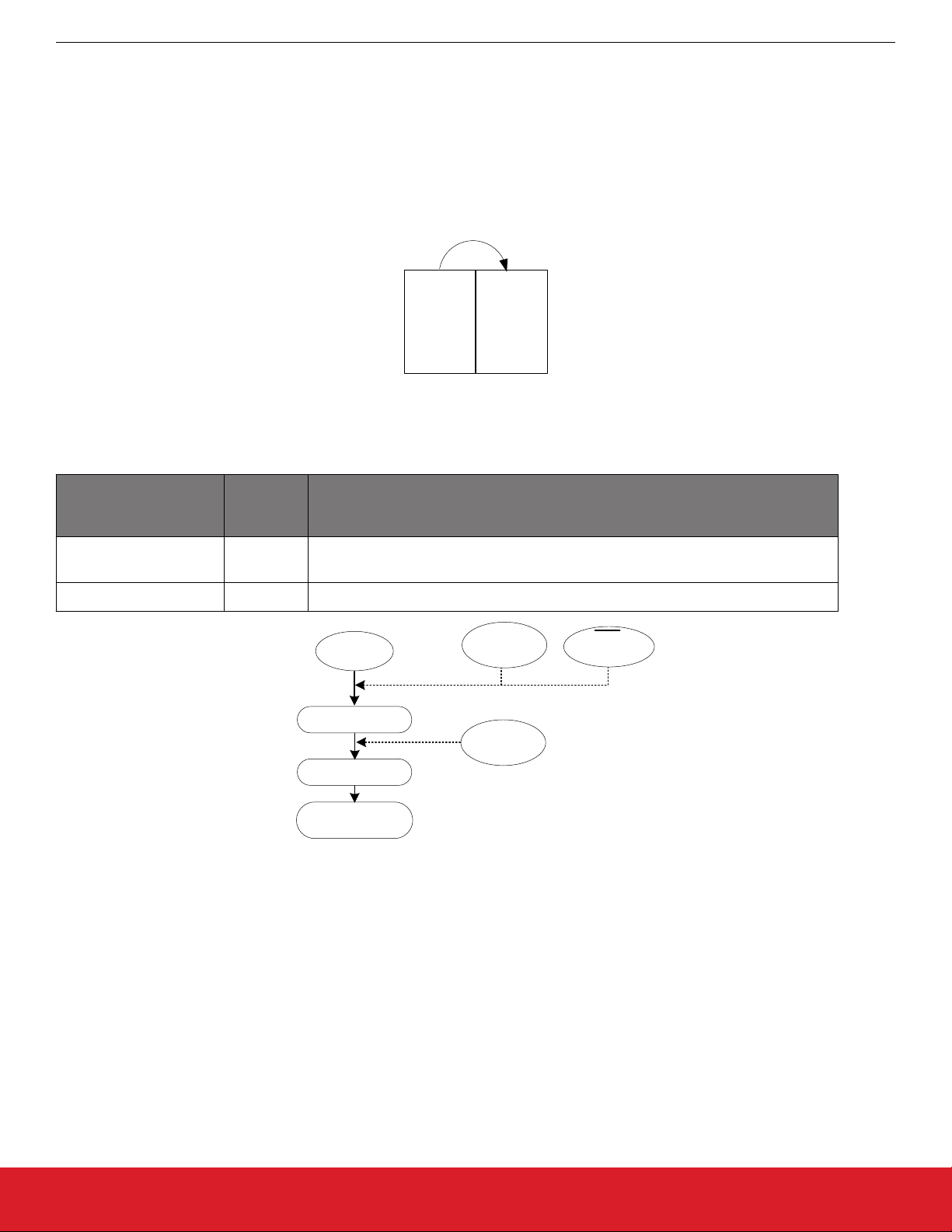

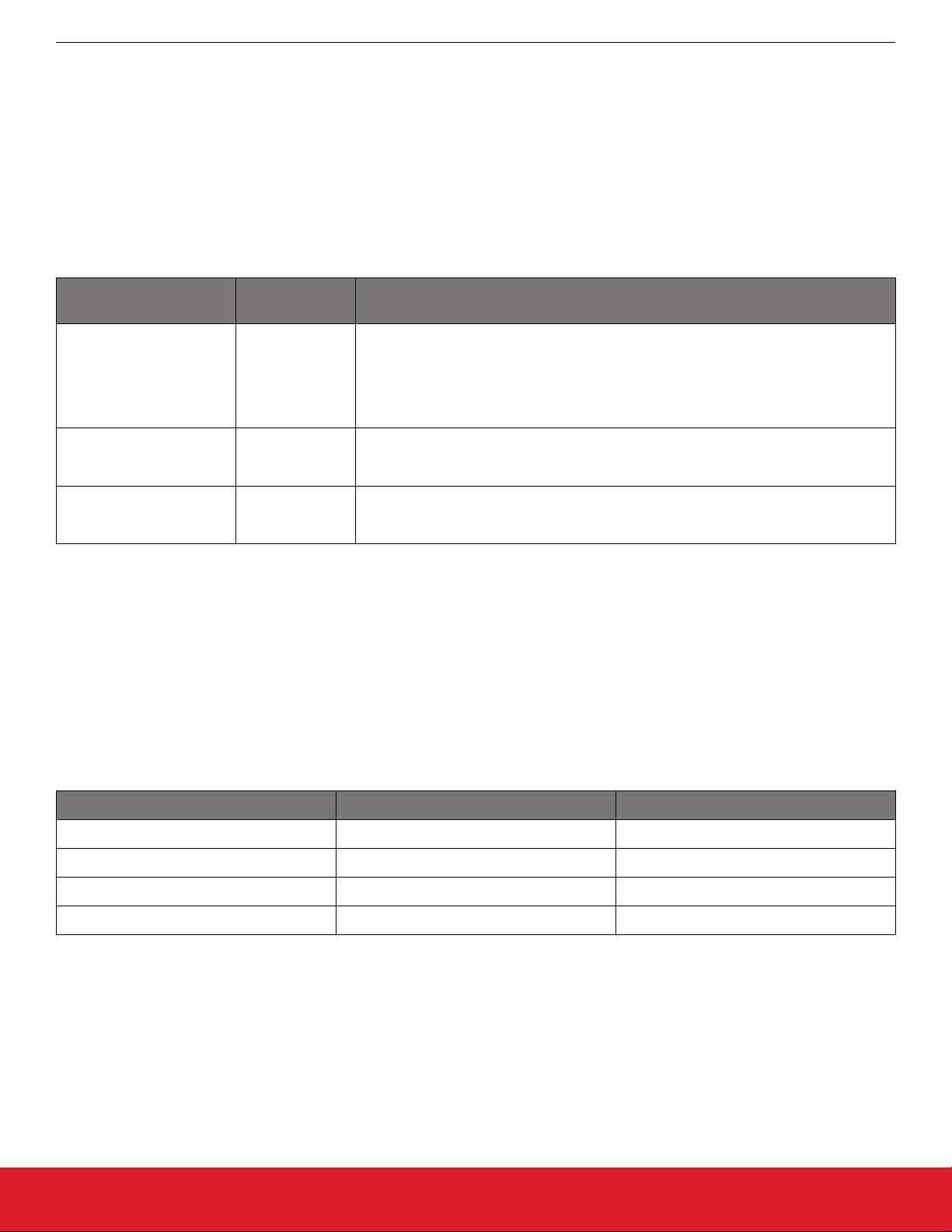

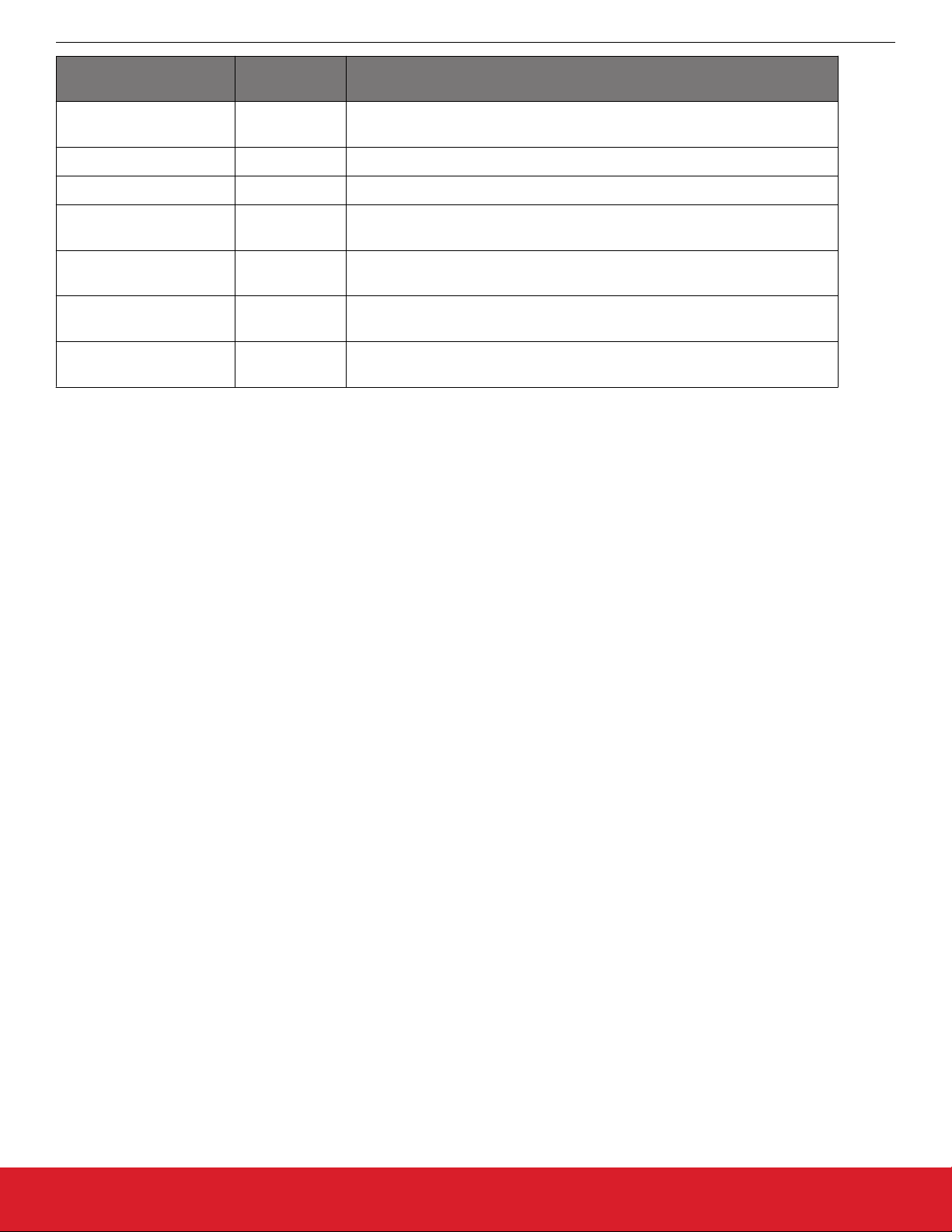

The DSPLL

if programmed for holdover mode will automatically enter Holdover mode when the selected input clock becomes invalid

and no other valid input clocks are available for selection. It uses an averaged input clock frequency as its final holdover frequency to

minimize the disturbance of the output clock phase and frequency when an input clock suddenly fails. The holdover circuit stores up to

120 seconds of historical frequency data while locked to a valid clock input. The final averaged holdover frequency value is calculated

from a programmable window within the stored historical frequency data. Both the window size and the delay are programmable as

shown in the figure below. The window size determines the amount of holdover frequency averaging. This delay value allows recent

frequency information to be ignored for Holdover in cases where the input clock source frequency changes as it is removed.

Clock Failure

and Entry into

Holdover

Historical Frequency Data Collected

time

120s

Programmable historical data window

used to

determine the final holdover value

1s,10s, 30s, 60s

Programmable delay

30ms, 60ms, 1s,10s, 30s, 60s

0s

Figure 4.4. Programmable Holdover Window

When entering Holdover, the DSPLL will pull its output clock frequency to the calculated averaged holdover frequency. While in Holdover, the

output frequency drift is entirely dependent on the external crystal or external reference clock connected to the XAXB pins. If

the clock input becomes valid, the DSPLL will automatically exit the Holdover mode and re-acquire lock to the new input clock. This

process involves pulling the output clock frequency to achieve frequency and phase lock with the input clock. This pull-in process is

Glitchless and its rate is controlled by the DSPLL bandwidth or the Fastlock bandwidth, if Fastlock is enabled. These options are register programmable.

The recommended mode of exit from holdover is a ramp in frequency. Just before the exit begins, the frequency difference between the

output frequency while in holdover and the desired, new output frequency is measured. It is quite possible (even likely) that the new

output clock frequency will not be the same as the holdover output frequency because the new input clock frequency might have

changed and the holdover history circuit may have changed the holdover output frequency. The ramp logic calculates the difference in

frequency between the holdover frequency and the new, desired output frequency. Using the user selected ramp rate, the correct ramp

time is calculated. The output ramp rate is then applied for the correct amount of time so that when the ramp ends, the output frequency

will be the desired new frequency. Using the ramp, the transition between the two frequencies is smooth and linear. The ramp rate can

be selected to be very slow (0.2 ppm/sec), very fast (40,000 ppm/sec) or any of approximately 40 values that are in between. The loop

BW values do not limit or affect the ramp rate selections and vice versa. CBPro defaults to ramped exit from holdover. Ramped exit

from holdover is also used for ramped input clock switching. See 5.2.3 Ramped Input Switching for more information.

As shown in Figure 4.1 Modes of Operation on page 12, the Holdover and Freerun modes are closely related. The device will only enter

Holdover if a valid clock has been selected long enough for the holdover history to become valid, i.e., HOLD_HIST_VALID = 1. If the

clock fails before the combined HOLD_HIST_LEN + HOLD_HIST_DELAY time has been met, HOLD_HIST_VALID = 0 and the device

will enter Freerun mode instead. Reducing the HOLD_HIST_LEN and HOLD_HIST_DELAY times will allow Holdover in less time, limited by the source clock failure and wander characteristics. Note that the Holdover history accumulation is suspended when the input

clock is removed and resumes accumulating when a valid input clock is again presented to the DSPLL.

Table 4.3. Holdover Mode Control Registers

Register Name Hex Address

Function

[Bit Field]

Holdover Status

HOLD 0x000E[5] DSPLL Holdover status indicator.

0: Normal Operation

1: In Holdover/Freerun Mode:

HOLD_HIST_VALID = 0 ? Freerun Mode

HOLD_HIST_VALID = 1 ? Holdover Mode

silabs.com | Building a more connected world. Rev. 1.3 | 17

Page 18

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Modes of Operation

Register Name Hex Address

Function

[Bit Field]

HOLD_FLG 0x0013[5] Holdover indicator sticky flag bit. Remains asserted after the indicator bit

shows a fault until cleared by the user. Writing a 0 to the flag bit will clear it if

the indicator bit is no longer asserted.

HOLD_INTR_MSK 0x0019[5] Masks Holdover/Freerun from generating INTR interrupt.

0: Allow Holdover/Freerun interrupt (default)

1: Mask (ignore) Holdover/Freerun for interrupt

HOLD_HIST_VALID 0x053F[1] Holdover historical frequency data valid.

0: Incomplete Holdover history, Freerun mode available

1: Valid Holdover history, Holdover mode available

Holdover Control and Settings

HOLD_HIST_LEN 0x052E[4:0] Window Length time for historical average frequency used in Holdover mode.

Window Length in seconds (s):

Window Length = ((2

LEN

) – 1) x 268 ns

HOLD_HIST_DELAY 0x052F[4:0] Delay Time to ignore data for historical average frequency in Holdover mode.

Delay Time in seconds (s):

Delay Time (s) = (2

DELAY

) x 268 ns

FORCE_HOLD 0x0535[0] Force the device into Holdover mode. Used to hold the device output clocks

while retraining an upstream input clock.

0: Normal Operation

1: Force Holdover/Freerun Mode:

HOLD_HIST_VALID = 0 ? Freerun Mode

HOLD_HIST_VALID = 1 ? Holdover Mode

Holdover Exit Control

HOLD_RAMP_BYP 0x052C[3] Holdover Exit Ramp Bypass

0: Use Ramp when exiting from Holdover (default)

1: Use Holdover/Fastlock/Loop bandwidth when exiting from Holdover

HOLDEXIT_BW_SEL0 0x059B[6] Select the exit bandwidth from Holdover when ramped exit is not selected

(HOLD_RAMP_BYP = 1).

00: Use Fastlock bandwidth on Holdover exit

01: Use Holdover Exit bandwidth on Holdover exit (default)

10, 11: Use Normal Loop bandwidth on Holdover exit

HOLDEXIT_BW_SEL1 0x052C[4] Select the exit bandwidth from Holdover when ramped exit is not selected

(HOLD_RAMP_BYP = 1).

00: Use Fastlock bandwidth on Holdover exit

01: Use Holdover Exit bandwidth on Holdover exit (default)

10, 11: Use Normal Loop bandwidth on Holdover exit

RAMP_STEP_INTERVAL 0x052C[7:5] Time Interval of the frequency ramp steps when ramping between inputs or

exiting holdover.

RAMP_STEP_SIZE 0x05A6[2:0] Size of the frequency ramp steps when ramping between inputs or exiting

holdover.

silabs.com | Building a more connected world. Rev. 1.3 | 18

Page 19

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

5. Clock Inputs

The Si5342/44/45 support 4 inputs that can be used to synchronize to the internal DSPLL.

5.1 Inputs (IN0, IN1, IN2, IN3)

The inputs accept both standard format inputs and low-duty-cycle pulsed CMOS clocks. Input selection from CLK_SWITCH_MODE can

be manual (pin or register controlled) or automatic with user definable priorities. Register 0x052A is used to select pin or register control, and to configure the input as shown below in Table 5.1 Input Selection Configuration on page 19.

Table 5.1. Input Selection Configuration

Register Name Hex Address

[Bit Field]

CLK_SWITCH_MODE 0x0536[1:0] Selects manual or automatic switching modes. Automatic mode can be revertive or

non-revertive. Selections are the following:

00 Manual,01 Automatic non-revertive

02 Automatic revertive, 03 Reserved

IN_SEL_REGCTRL 0x052A [0] 0 for pin controlled clock selection

1 for register controlled clock selection

IN_SEL 0x052A [2:1] 0 for IN0, 1 for IN1,

2 for IN2, 3 for IN3 (or FB_IN)

5.1.1 Manual Input Switching

In manual mode, CLK_SWITCH_MODE=0x00.

Input switching

0 of register 0x052A determines if the input selection is pin selectable or register selectable. The default is pin selectable. The following

table describes the input selection on the pins. Note that when Zero Delay Mode is enabled, the FB_IN pins will become the feedback

input and IN3 therefore is not available as a clock input. Also, in Zero Delay Mode, ZDM_EN must be set and register based input clock

selection must be done with ZDM_IN_SEL. If there is no clock signal on the selected input, the device will automatically enter free-run

or holdover mode.

can be done manually using the IN_SEL[1:0] device pins from the package or through register 0x052A IN_SEL[2:1]. Bit

Function

Table 5.2. Manual Input Selection using IN_SEL[1:0] Pins

IN_SEL[1:0] DEVICE PINS Zero Delay Mode Disabled Zero Delay Mode Enabled

00 IN0 IN0

01 IN1 IN1

10 IN2 IN2

11 IN3 Reserved

silabs.com | Building a more connected world. Rev. 1.3 | 19

Page 20

5.1.2 Automatic Input Selection

In automatic mode CLK_SWITCH_MODE = 0x01 (non-revertive) or 0x02 (revertive)

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

An automatic

input selection is available in addition to the above mentioned manual switching option described in 5.1.1 Manual Input

Switching. In automatic mode, the selection criteria is based on input clock qualification, input priority and the revertive option. The

IN_SEL[1:0] pins or IN_SEL[2:1] register bits are not used in automatic input selection. Also, only input clocks that are valid (i.e., with

no active alarms) can be selected by the automatic clock selection. If there are no valid input clocks available the DSPLL will enter the

holdover mode. With revertive switching enabled, the highest priority input with a valid input clock is always selected. If an input with a

higher priority becomes valid then an automatic switchover to that input will be initiated. With non-revertive switching, the active input

will always remain selected while it is valid. If it becomes invalid an automatic switchover to a valid input with the highest priority will be

initiated.

Table 5.3. Registers for Automatic Input Selection

Register Name

CLK_SWITCH_MOD

E

Hex Address [Bit

Field]

0x0536[1:0]

Function

Selects manual or automatic switching modes. Automatic mode can be revertive or nonrevertive. Selections are the following: 00 Manual,01 Automatic non-revertive 02 Automatic revertive, 03 Reserved

0: disable zero delay mode

ZDM_EN 0x0487[0]

1: enable zero delay mode

ZDM_IN_SEL 0x0487[2:1]

Selects the input when in manual register controlled mode when zero delay mode is enabled. Selections are IN0, IN1, IN2. A register value of 3 is not allowed.

0: automatic switching disabled for zero-delay mode

ZDM_AUTOSW_EN 0x0487[4]

1: automatic input switching enabled and input clock selection governed by automatic input switching engine

IN0_PRIORITY 0x0538[2:0]

IN1_PRIORITY 0x0538[6:4]

IN2_PRIORITY 0x0539[2:0]

IN0, IN1, IN2, IN3 priority select for the automatic selection state machine. Priority selections are 1,2,3,4, or zero for no priority.

IN3_PRIORITY 0x0539[6:4]

Determines the LOS status for IN3,2,1,0 and is used in determining a valid clock for au-

IN_LOS_MSK 0x0537[3:0]

tomatic input selection

0 to use LOS in clock selection logic, 1 to mask LOS from the clock selection logic

Determines the OOF status for IN3,2,1,0 and is used in determining a valid clock for the

automatic input selection

IN_OOF_MSK 0x0537[7:4]

0 to use OOF in the clock selection logic, 1 to mask the OOF from the clock selection

logic

When in zero delay mode (ZDM_EN (0x0487[0]) the phase difference between the output, which is connected to the selected input, will

be nulled to zero. However the IO delay variation will substantially increase in ZDM mode if the Fpfd is below 128 kHz. When in zero

delay mode, the DSPLL must have the phase buildout turned off for input switching or else the IO delay can change on each input

switch. Manual control of the input clock selection is by either pin or register and also depends upon the device being in zero delay

mode or not. See Table 5.4 Register 0x0949 Clock Input Control and Configuration on page 22.

silabs.com | Building a more connected world. Rev. 1.3 | 20

Page 21

5.2 Types of Inputs

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

Each of

the four different inputs IN0–IN3 can be configured as standard LVDS, LVPECL, HCL, CML, and single-ended LVCMOS formats, or as a low duty cycle pulsed CMOS format. The standard format inputs have a nominal 50% duty cycle, must be ac-coupled and

use the “Standard” Input Buffer selection as these pins are internally dc-biased to approximately 0.83 V. The pulsed CMOS input format

allows pulse-based inputs, such as frame-sync and other synchronization signals, having a duty cycle much less than 50%. These

pulsed CMOS signals are dc-coupled and use the “Pulsed CMOS” Input Buffer selection. In all cases, the inputs should be terminated

near the device input pins as shown in Figure 5.1 Input Termination for Standard and Pulsed CMOS Inputs on page 21. The resistor

divider values given below will work with up to 1 MHz pulsed inputs.

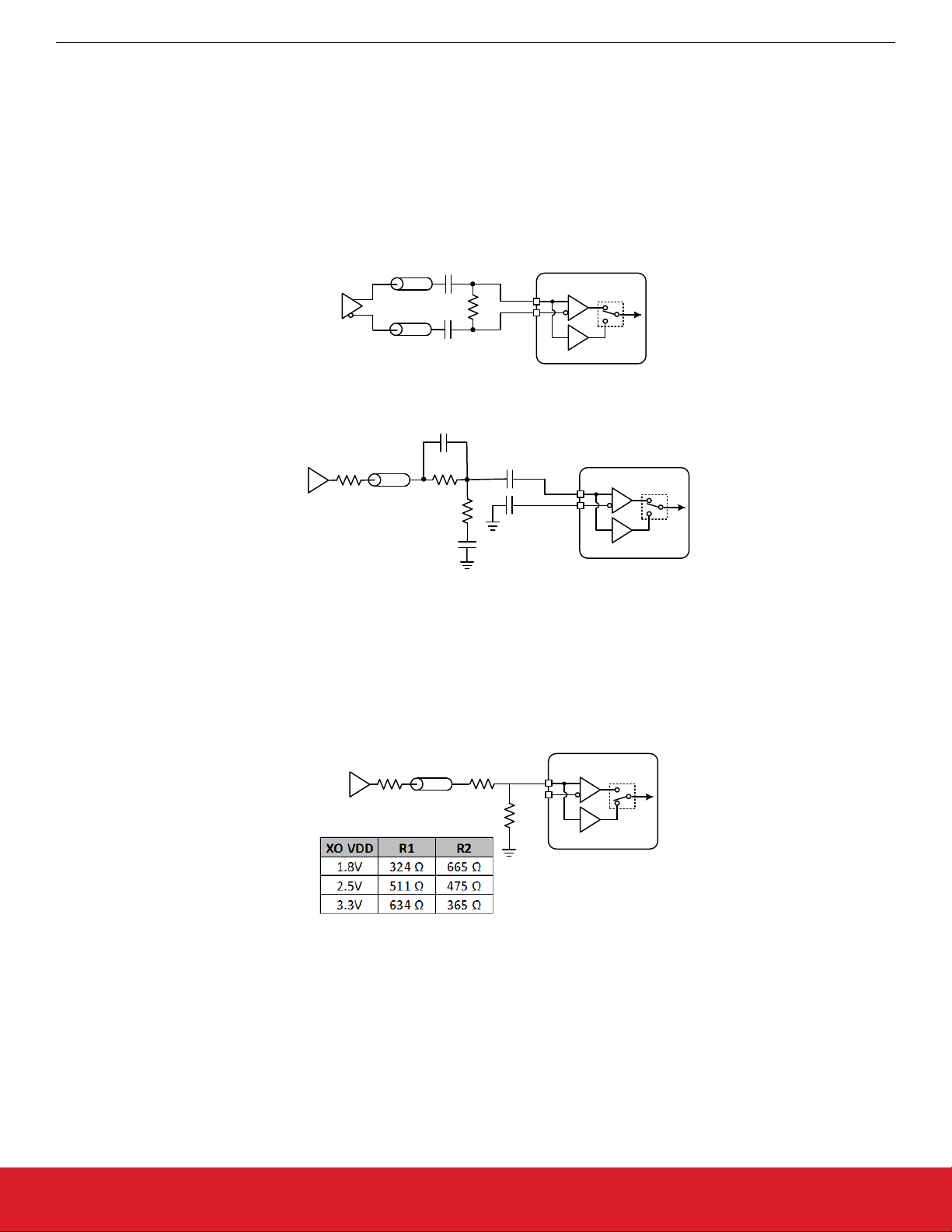

Standard AC-Coupled Differential (IN0-IN3)

0.1uF *

50

100

L

VDS, LVPECL, CML

* These caps should have < ~5 ohms capacitive reactance at the

50

0.1uF *

c

lock inpu

INxb

t frequency.

INx

Standard

Pulsed CMOS

Standard AC-Coupled Single-Ended (IN0-IN3)

RS

3.3/2.5/1.8V LVCMOS

RS matches the CMOS driver to a 50 ohm

transmission line (if used)

50

R1

0.1uF *

C1

R

2

0.1uF

0.1uF

INx

INxb

Standard

Pulsed CMOS

Only when 3.3V LVCMOS driver is present, use R2 = 845 ohm and R1 = 267

ohm if needed to keep the signal at INx < 3.6 Vpp_se. Including C1 = 6 pf

may improve the output jitter due to faster input slew rate at INx. If

attenuation is not needed for Inx<3.6Vppse, make R1 = 0 ohm and omit C1,

R2 and the capacitor below R2. C1, R1, and R2 should be physically placed

as close as practicle to the device input pins. *This cap should have less than

~20 ohms of capacitive reactance at the clock input frequency

DC-Coupled Pulsed CMOS only for Frequencies

< 1MHz (IN0-IN3)

RS matches the CMOS driver to a 50 ohm

3.3V, 2.5V, 1.8V

line (if used)

transmission

RS

LVCMOS

R1

50

R

2

Note: See Datasheet for input clock specifications

INx

INxb

Standard

Pulsed CMOS

Figure 5.1. Input Termination for Standard and Pulsed CMOS Inputs

Note: Floating clock inputs are noise sensitive. Add a cap to non-CMOS unused clock inputs.

Input clock buffers are enabled by setting the IN_EN 0x0949[3:0] bits appropriately for IN3 through IN0. Unused clock inputs may be

powered down and left unconnected at the system level. For standard mode inputs, both input pins must be properly connected as

shown in Figure 5.1 Input Termination for Standard and Pulsed CMOS Inputs on page 21 above, including the “Standard AC Coupled

Single Ended” case. In Pulsed CMOS mode, it is not necessary to connect the inverting INx input pin. To place the input buffer into

Pulsed CMOS mode, the corresponding bit must be set in IN_PULSED_CMOS_EN 0x0949[7:4] for IN3 through IN0.

silabs.com | Building a more connected world. Rev. 1.3 | 21

Page 22

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Table 5.4. Register 0x0949 Clock Input Control and Configuration

Clock Inputs

Register Name Hex Address

Function

[Bit Field]

IN_EN 0x0949[3:0] Enables for the four inputs clocks, IN0 through IN3.

1 to enable.

IN_PULSED_CMOS_EN 0x0949[7:4] Selects CMOS or differential receiver for IN3, IN2, IN1, IN0. Defaults to dif-

ferential input.

Differential = 0, CMOS = 1

5.2.1 Unused Inputs

Unused inputs

can be disabled and left unconnected when not in use. Register 0x0949[3:0] defaults the input clocks to being enabled.

Clearing the unused input bits will disable them.

5.2.2 Hitless Input Switching with Phase Buildout

Phase buildout, also referred to as hitless switching, prevents a phase change from propagating to the output when switching between

two clock inputs with the exact same frequency and a fixed phase relationship (i.e., they are phase/frequency locked, but with a nonzero phase difference). When phase buildout is enabled, the DSPLL absorbs the phase difference between the two input clocks during

a clock switch. When phase buildout is disabled, the phase difference between the two inputs is propagated to the output at a rate

determined by the DSPLL loop bandwidth. It supports a minimum input frequency of 8 kHz, but if a fractional P input divider is used, the

input frequency must be 300 MHz or higher in order to ensure proper operation. Note that hitless switching is not available in zero delay

mode.

Table 5.5. Hitless Switching Enable Bit

Register Name Hex Ad-

Function

dress [Bit

Field]

HSW_EN 0x0536[2] Hitless switching is enabled = 1, or disabled = 0.

5.2.3 Ramped Input Switching

If switching

between input clocks that are not exactly the same frequency (i.e. are plesiochronous), ramped switching should be enabled to ensure a smooth transition between the two inputs. In this situation, it is also advisable to enable phase buildout to minimize the

input-to-output clock skew after the clock switch ramp has completed.

When ramped clock switching is enabled, the Si5345/44/42 will very briefly go into holdover and then immediately exit from holdover.

This means that ramped switching will behave the same as an exit from holdover. This is particularly important when switching between

two input clocks that are not the same frequency because the transition between the two frequencies will be smooth and linear. Ramped switching should be turned off when switching between input clocks that are always frequency-locked (i.e., are the same exact

frequency). Because ramped switching avoids frequency transients and overshoot when switching between clocks that are not the

same frequency, CBPro defaults to ramped clock switching. The same ramp rate settings are used for both exit from holdover and clock

switching. For more information on ramped exit from holdover including the ramp rate, see 4.7 Holdover Mode.

Table 5.6. Ramped Input Switching Control Registers

Setting Name Hex Address [Bit Field] Function

RAMP_SWITCH_EN 0x05A6[3] Enable frequency ramping on an input switch.

HSW_MODE 0x053A[1:0] Input switching mode select.

silabs.com | Building a more connected world. Rev. 1.3 | 22

Page 23

5.2.4 Hitless Switching, LOL (loss of lock) and Fastlock

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

When doing

a clock switch between clock inputs that are frequency locked, LOL might momentarily be asserted. If so programmed, the

assertion of LOL with invoke Fastlock. Because Fastlock temporarily increases the loop BW by asynchronously inserting new filter parameters into the DSPLL’s closed loop, there may be transients at the clock outputs when Fastlock is either entered or exited. For this

reason, it is suggested that automatic entry into Fastlock be disabled by writing a zero to FASTLOCK_AUTO_EN at 0x52B[0] whenever

a clock switch might occur. For more details on hitless switching please refer to AN1057: Hitless Switching using Si534x/8x Devices.

5.2.5 Glitchless Input Switching

The DSPLL has the ability to switch between two input clock frequencies that are up to ±500 ppm apart. The DSPLL will pull-in to the

new frequency at a rate determined by the DSPLL loop bandwidth. The DSPLL loop bandwidth is set using registers 0x0508–0x050D.

Note that if “Fastlock” is enabled then the DSPLL will pull-in to the new frequency using the Fastlock Loop Bandwidth. Depending on

the LOL configuration settings, the loss of lock (LOL) indicator may assert while the DSPLL is pulling-in to the new clock frequency.

There will never be output runt pulses generated at the output during the transition.

5.2.6 External Clock Switching

External clock switches should be avoided because the Si5342/4/5 has no way of knowing when a clock switch will or has occurred.

Because of this, neither the phase buildout engine or the ramp logic can be used. If expansion beyond the four clock inputs is an important issue, please see AN1111: Si534x/8x Input Clock Expander which describes how an external FPGA can be used for this purpose.

5.2.7 Synchronizing to Gapped Input Clocks

The DSPLL supports locking to an input clock that has missing clock periods. This is also referred to as a gapped clock. The purpose of

gapped clocking is to modulate the frequency of a periodic clock by selectively removing some of its cycles. Gapping a clock severely

increases its jitter so a phase-locked loop with high jitter tolerance and low loop bandwidth is required to produce a low-jitter, truly periodic clock. The resulting output will be a periodic non-gapped clock with an average frequency of the input with its missing cycles. For

example, an input clock of 100 MHz with one cycle removed every 10 cycles will result in a 90 MHz periodic non-gapped output clock. A

valid gapped clock input must have a minimum frequency of 10 MHz with a maximum of 2 missing cycles out of every 8.

When properly configured, locking to a gapped clock will not trigger the LOS, OOF, and LOL fault monitors. Clock switching between

gapped clocks may violate the hitless switching specification for a maximum phase transient, when the switch occurs during a gap in

either input clocks. Figure 5.2 Generating an Averaged Non Gapped Output Frequency from a Gapped Input on page 23 shows a

100 MHz clock with one cycle removed every 10 cycles, which results in a 90 MHz periodic non-gapped output clock.

Gapped Input Clock Periodic Output Clock

100 MHz clock

1 missing period

100 ns 100 ns

every

10

90 MHz non-gapped clock

DSPLL

1 2 3 4 5 6 7 8 9 10

10 ns

Period Removed

Figure 5.2. Generating an Averaged Non Gapped Output Frequency from a Gapped Input

1 2 3 4 5 6 7 8 9

11.11111... ns

silabs.com | Building a more connected world. Rev. 1.3 | 23

Page 24

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

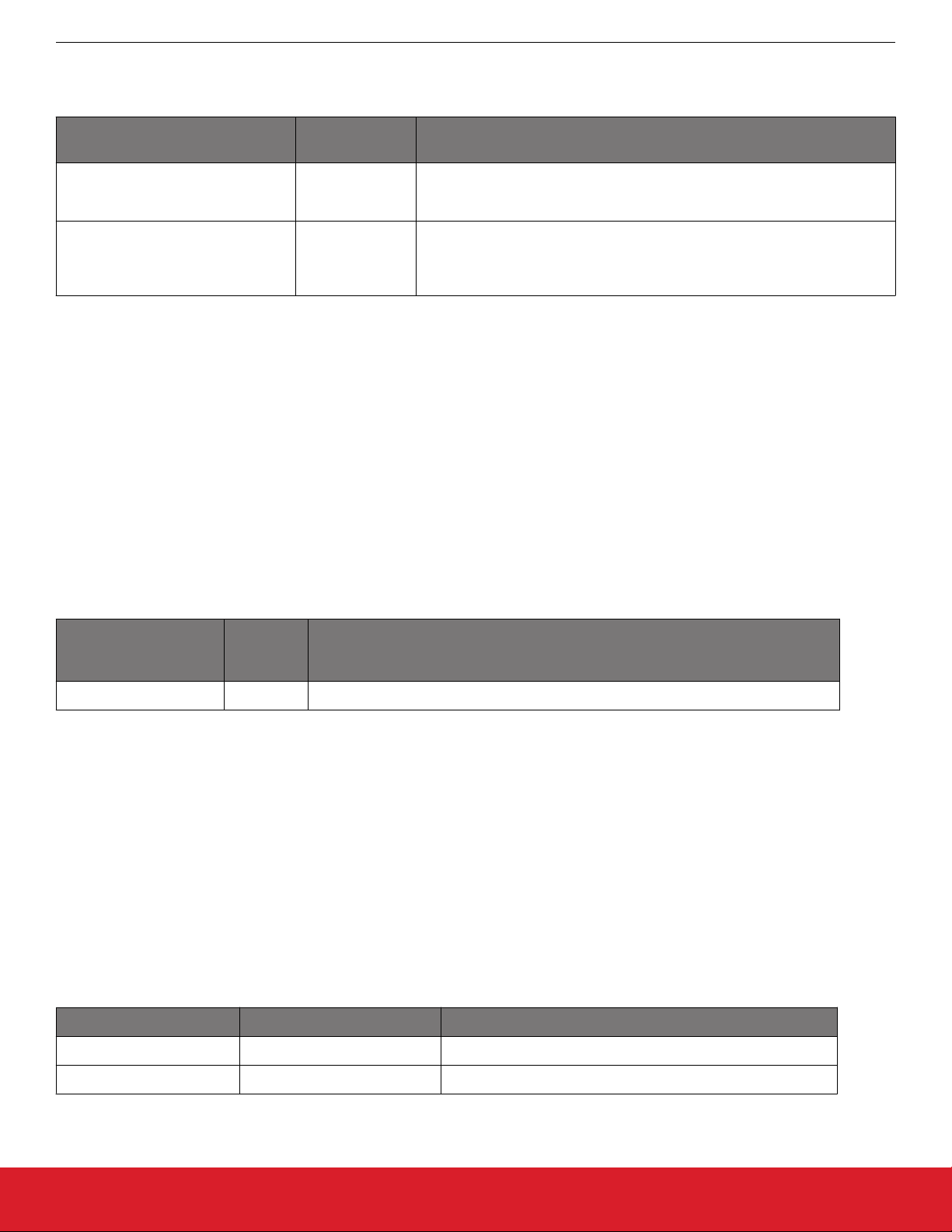

5.2.8 Rise Time Considerations

well known that slow rise time signals with low slew rates are a cause of increased jitter. In spite of the fact that the low loop BW of

It is

the Si5342/44/45 will attenuate a good portion of the jitter that is associated with a slow rise time clock input, if the slew rate is low

enough, the output jitter will increase. The following figure shows the effect of a low slew rate on RMS jitter for a differential clock input.

The figure shows the relative increase in the amount of RMS jitter due to slow rise time and is not intended to show absolute jitter

values.

IN_X Slew Rate in Differential Mode

5

4.5

4

3.5

3

2.5

Relateive Jitter

2

1.5

J

TYP

1

0.5

0

0 100 200 300 400 500 600

Input Slew (V/us)

Figure 5.3. Effect of Low Slew Rate on RMS Jitter

silabs.com | Building a more connected world. Rev. 1.3 | 24

Page 25

5.3 Fault Monitoring

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

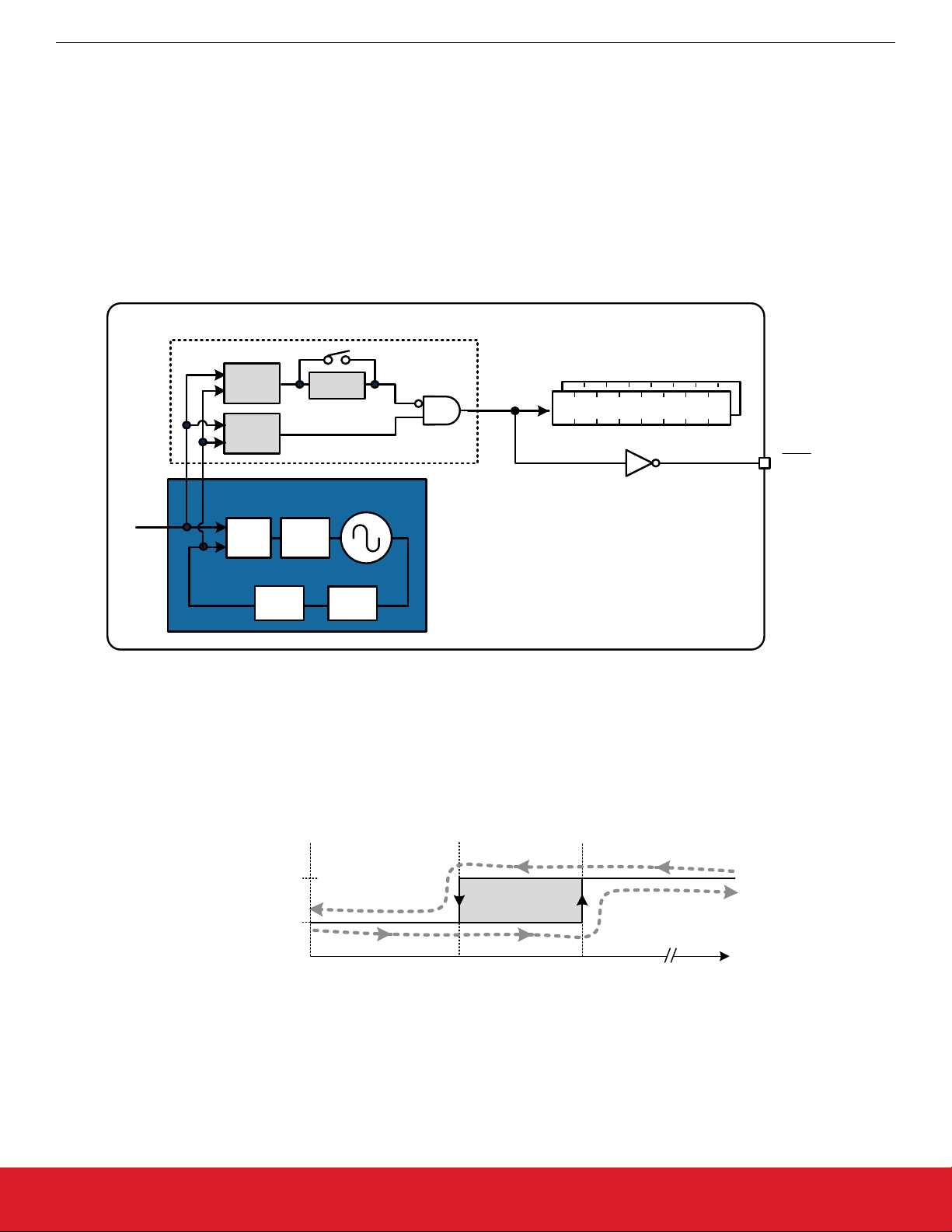

The four

at the XA/XB pins is also monitored for LOS since it provides a critical reference clock for the DSPLL. There is also a Loss of Lock

(LOL) indicator asserted when the DSPLL loses synchronization within the feedback loop. Figure 5.4 Si5342/44/45 Fault Monitors on

page 25 shows the fault monitors for each input path going into the DSPLL, which includes the crystal input as well as IN0-3.

clocks (IN0, IN1, IN2, IN3/FB_IN) are monitored for loss of signal (LOS) and out-of-frequency (OOF). Note that the reference

XB

XA

Si5345/44/42

OSC

IN0

IN0

IN1

IN1

IN2

IN2

IN3/FB_IN

IN3/FB_IN

÷P

÷P

÷P

÷P

LOS

0

LOS

1

LOS

2

LOS

3

OOF

OOF

OOF

OOF

Precision

Fast

Precision

Fast

Precision

Fast

Precision

Fast

LOL

÷M

LOS

DSPLL

LPFPD

÷5

Figure 5.4. Si5342/44/45 Fault Monitors

silabs.com | Building a more connected world. Rev. 1.3 | 25

Page 26

5.3.1 Input Loss of Signal (LOS) Fault Detection

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

The loss

of signal monitor measures the period of each input clock cycle to detect phase irregularities or missing clock edges. Each of

the input LOS circuits has its own programmable sensitivity which allows ignoring missing edges or intermittent errors. Loss of signal

sensitivity is configurable using the ClockBuilder Pro utility. The LOS status for each of the monitors is accessible by reading a status

register. The live LOS register always displays the current LOS state and a sticky register when set, always stays asserted until cleared

by the user.

Monitor

LOS

en

Live

LOS

LOS

Sticky

Figure 5.5. LOS Status Indicators

A LOS monitor is also available to ensure that the external crystal or reference clock is valid. By default the output clocks are disabled

when LOSXAXB is detected. This feature can be disabled such that the device will continue to produce output clocks even when LOSXAXB is detected. Single-ended inputs must be connected to the XA input pin with the XB pin terminated properly for LOSXAXB to

function correctly. The table below lists the loss of signal status indicators and fault monitoring control registers.

Table 5.7. Loss of Signal Status Monitoring and Control Registers

Register Name Hex Address

Function

[Bit Field]

LOS 0x000D[3:0] LOS status monitor for IN3 (bit3), IN2 (bit2), IN1(bit1), IN0 (bit0) indicates if a valid

clock is detected. A set bit indicates the input is LOS.

SYSINCAL 0x000C[0] Asserted when in calibration

LOSXAXB 0x000C[1] LOS status monitor for the STAL or REFCLK at the XA/XB pins

LOS_FLG 0x0012[3:0] LOS status monitor sticky bits for IN3, IN2, IN1, IN0. Sticky bits will remain asserted

when a LOS event occurs until manually cleared. Writing zero to the bit will clear it.

SYSINCAL_FLG 0x0011[0] SYSINCAL sticky bit. Sticky bits will remain asserted until written with a zero to clear.

LOSXAXB_FLG 0x0011[1] LOS status monitor sticky bits for XAXB. Sticky bits will remain asserted when a LOS

event occurs until cleared. Writing zero to the bit will clear it.

LOS_EN 0x002C[3:0] LOS monitor enable for IN3, IN2, IN1, IN0. Allows disabling the monitor if unused.

0: Disable LOS Detection

1: Enable LOS Detection (default)

LOSXAXB_DIS 0x002C[4] Enable LOS detection on the XAXB inputs.

0: Enable LOS Detection (default)

1: Disable LOS Detection

LOS_TRIG_THR 0x002E[7:0]-0

x0035[7:0]

Sets the LOS trigger threshold and clear sensitivity for IN3, IN2, IN1, IN0. These 16- bit

values are determined by ClockBuilder Pro

LOS_CLR_THR 0x0036[7:0]-0

x003D[7:0]

LOS_VAL_TIME 0x002D[7:0] LOS clear validation time for IN3, IN2, IN1, IN0. This sets the time that an input must

have a valid clock before the LOS condition is cleared. Settings of 2ms, 100ms,

200ms, and 1 s are available.

LOS_INTR_MSK 0x0018[3:0] This is the LOS interrupt mask, which can be cleared to trigger an interrupt on the

INTR pin if an LOS occurs for IN0-3.

silabs.com | Building a more connected world. Rev. 1.3 | 26

Page 27

5.3.2 Out of Frequency (OOF) Fault Detection

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

Each input

clock is monitored for frequency accuracy with respect to an OOF reference which it considers as its 0 ppm reference. This

OOF reference can be selected as either:

XA/XB pins

Any input clock (IN0, IN1, IN2, IN3)

The final OOF status is determined by the combination of both a precise OOF monitor and a fast OOF monitor as shown in Figure 9. An

option to disable either monitor is also available. The live OOF register always displays the current OOF state and its sticky register bit

stays asserted until cleared.

Sticky

OOF

Monitor

Precision

en

LOS

OOF

Fast

en

Figure 5.6. OOF Status Indicator

The Precision OOF monitor circuit measures the frequency of all input clocks to within up to ±0.0625 ppm accuracy with respect to the

selected OOF frequency reference. A valid input clock frequency is one that remains within the register-programmable OOF frequency

range of from ±0.0625 ppm to ±512 ppm in steps of 1/16 ppm. A configurable amount of hysteresis is also available to prevent the OOF

status from toggling at the failure boundary. An example is shown in the figure below. In this case, the OOF monitor is configured with a

valid frequency range of ±6 ppm and with 2 ppm of hysteresis. An option to use one of the input pins (IN0–IN3) as the 0 ppm OOF

reference instead of the XAXB pins is available. These options are all register configurable.

Live

OOF Declared

f

IN

Hysteresis Hysteresis

OOF Cleared

-6 ppm

(Set)

-4 ppm

(Clear)

0 ppm

OOF

+4 ppm

(Clear)

+6 ppm

(Set)

Reference

Figure 5.7. Example of Precise OOF Monitor Assertion and De-assertion Triggers

Table 5.8 Out-of-Frequency Status Monitoring and Control Registers on page 27 lists

the OOF monitoring and control registers. Because the precision OOF monitor needs to provide 1/16 ppm of frequency measurement accuracy, it must measure the monitored input

clock frequencies over a relatively long period of time. This may be too slow to detect an input clock that is quickly ramping in frequency. An additional level of OOF monitoring called the Fast OOF monitor runs in parallel with the precision OOF monitors to quickly detect

a ramping input frequency. The Fast OOF responds more quickly and has larger thresholds.

Table 5.8. Out-of-Frequency Status Monitoring and Control Registers

Register Name Hex Address

Function

[Bit Field]

OOF 0x000D[7:4] OOF status monitor for IN3, IN2, IN1, IN0. Indicates if a valid clock is detec-

ted or if a OOF condition is detected.

OOF_FLG 0x0012[7:4] OOF status monitor sticky bits for IN3, IN2, IN1, IN0. Stick bits will remain as-

serted when an OOF event occurs until cleared. Writing zero to the bit will

clear it.

OOF_INTR_MSK 0x0018[7:4] Masks OOF from generating INTR interrupt for IN3 – IN0.

0: Allow OOF interrupt (default)

1: Mask (ignore) OOF for interrupt

silabs.com | Building a more connected world. Rev. 1.3 | 27

Page 28

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

Register Name Hex Address

Function

[Bit Field]

OOF_REF_SEL 0x0040[2:0] This selects the clock that the OOF monitors use as the 0 ppm reference. Se-

lections are XA/XB, IN0, IN1, IN2, IN3. Default is XAXB.

OOF_EN 0x003F[3:0] This allows to enable/disable the precision OOF monitor for IN3, IN2, IN1, IN0

FAST_OOF_EN 0x003F[7:4] This allows to enable/disable the fast OOF monitor for IN3, IN2, IN1, IN0

OOF_SET_THR 0x0046[7:0]-0x0

OOF Set threshold. Range is up to ±500 ppm in steps of 1/16 ppm

049[7:0]

OOF_CLR_THR 0x004A[7:0]-0x0

OOF Clear threshold. Range is up to ±500 ppm in steps of 1/16 ppm

04D[7:0]

FAST_OOF_SET_THR 0x0051[7:0]-0x0

Determines the fast OOF alarm set threshold for IN3, IN2, IN1, IN0.

054[7:0]

FAST_OOF_CLR_THR 0x0055[7:0]-0x0

Determines the fast OOF alarm clear threshold for IN3, IN2, IN1, IN0.

058[7:0]

silabs.com | Building a more connected world. Rev. 1.3 | 28

Page 29

5.3.3 Loss of Lock (LOL) Fault Monitoring

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

The Loss

is also a dedicated loss of lock pin that reflects the loss of lock condition. The LOL monitor functions by measuring the frequency difference between the input and feedback clocks at the phase detector. There are four parameters that control the LOL monitor. First, there

is an assert threshold which sets the LOL assertion threshold. The user sets this threshold in ppm in CBPro. Then, there is a fast

assert threshold. CBPro sets this to ~100 times the assert threshold. Then there is a de-assert threshold to clear the LOL, which is

set in ppm in CBPro. Then, there is a clear delay, which CBPro sets based upon the project plan.

Note: A very large ppm error in a short time will assert LOL.

A block diagram of the LOL monitor is shown in Figure 5.8 LOL Status Indicators on page 29. The live LOL register always displays

the current LOL state and a sticky register always stays asserted until cleared. The LOL pin reflects the current state of the LOL monitor.

of Lock (LOL) monitor asserts a LOL register bit when the DSPLL has lost synchronization with its selected input clock. There

LOL Monitor

LOL

Clear

Timer

LOS

LOL

Sticky

LOL

Set

Live

LOL

DSPLL

f

IN

LPFPD

Feedback

Clock

÷M

÷5

Si5345/44/42

Figure 5.8. LOL Status Indicators

The LOL frequency monitors have an adjustable sensitivity which is register configurable from 0.1 ppm to 10000 ppm. CBPro provides

a wide range of set and clear thresholds for the LOL function. Having two separate frequency monitors allows for hysteresis to help

prevent chattering of LOL status. An example configuration of the LOL set and clear thresholds is shown in Figure 5.9 LOL Set and

Clear Thresholds on page 29.

LOL

LOCKED

Clear LOL

Threshold

Hysteresis

0

0.1 1

Phase Detector Frequency Difference (ppm)

Set LOL

Threshold

Lock Acquisition

Lost Lock

10,000

Figure 5.9. LOL Set and Clear Thresholds

silabs.com | Building a more connected world. Rev. 1.3 | 29

Page 30

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Table 5.9. Loss of Lock Status Monitor and Control Registers

Clock Inputs

Register Name Hex Address

Function

[Bit Field]

LOL 0x000E[1] Status bit that indicates if the DSPLL is locked to an input clock

LOL_FLG 0x0013[1] Sticky bits for LOL register. Writing 0 to a sticky bit will clear it.

LOL_SET_THR 0x009E[7:4] Configures the loss of lock set threshold in ppm.

LOL_CLR_THR 0x00A0[7:4] Configures the loss of lock clear threshold in ppm.

LOL_TIMER_EN 0x00A2[1] Allows bypassing the LOL clear delay timer.

0-bypassed, 1-enabled. Set by CBPro.

LOL_NOSIG_TIME 0x02B7[3:2] Sets 417 μs as time without an input to assert LOL. Set by CBPro.

LOL_CLR_DELAY_DIV256 [ 0x00AC[4:0]

0x00AB[7:0]

This 29 bit timer sets the delay value for the LOL clear delay timer.

Set by CBPro.

0x00AA[7:0]

0x00A9[7:0] ]

FASTLOCK_EXTEND_EN 0x00E5[5] Enables FASTLOCK_EXTEND.

FASTLOCK_EXTEND [ 0x00ED[4:0]

0x00EC[7:0]

Set by CBPro to minimize phase transients when switching the PLL

bandwidth.

0x00EB[7:0]

0x00EA[7:0] ]

FASTLOCK_EXTEND_SCL 0x0294[7:4] Set by CBPro.

LOL_SLW_VALWIN_SELX 0x0296[1] Set by CBPro.

FASTLOCK_DLY_ONSW_EN 0x0297[1] Set by CBPro.

FASTLOCK_DLY_ONSW 0x02A9[19:0] Set by CBPro.

FASTLOCK_DLY_ONLOL_EN 0x0299[1] Set by CBPro.

FASTLOCK_DLY_ONLOL 0x029D[19:0] Set by CBPro.

The settings in Table 5.9

Loss of Lock Status Monitor and Control Registers on page 30 are handled by ClockBuilder Pro. Manual set-

tings should be avoided.

silabs.com | Building a more connected world. Rev. 1.3 | 30

Page 31

5.4 Interrupt (INTR) Monitoring

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Clock Inputs

There is

an interrupt pin available on the device which is used to indicate a change in state of one or several of the status indicators.

Any of the status indicators are maskable to prevent assertion of the interrupt pin. The state of the INTR pin is reset by clearing the

status register that caused the interrupt. If an interrupt occurs the various status registers from the unmasked flags must be checked

and then cleared.

Register Bit Locations

mask

0x0012[0]

0x0012[4]

0x0012[1]

0x0012[5]

0x0012[2]

0x0012[6]

0x0012[3]

0x0012[7]

0x0013[1]

0x0013[5]

0x0011[1]

IN0_LOS_FLG

IN0_OOF_FLG

IN1_LOS_FLG

IN1_OOF_FLG

IN2_LOS_FLG

IN2_OOF_FLG

IN3_LOS_FLG

IN3_OOF_FLG

LOL_FLG

HOLD_FLG

XAXB_LOS_FLG

mask

mask

mask

mask

mask

mask

mask

mask

mask

mask

IN0

IN1

IN2

INTR

IN3

Figure 5.10. Interrupt Pin Source Masking Options

The _FLG bits are “sticky” versions of the alarm bits and will stay high until cleared. An _FLG bit can be cleared by writing a zero to the

_FLG bit. When an _FLG bit is high and its corresponding alarm bit is low, the _FLG bit can be cleared.

During run time, the source of an interrupt can be determined by reading the _FLG register values and logically ANDing them with the

corresponding _MSK register bits (after inverting the _MSK bit values). If the result is a logic one, then the _FLG bit will cause an interrupt.

For example, if LOS_FLG[0] is high and LOS_INTR_MSK[0] is low, then the INTR pin will be active (low) and cause an interrupt. If

LOS[0] is zero and LOS_MSK[0] is one, writing a zero to LOS_MSK[0] will clear the interrupt (assuming that there are no other interrupt

sources). If LOS[0] is high, then LOS_FLG[0] and the interrupt cannot be cleared.

silabs.com | Building a more connected world. Rev. 1.3 | 31

Page 32

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Output Clocks

6. Output Clocks

Each driver has a configurable voltage swing and common mode voltage covering a wide variety of differential signal formats including

LVPECL, LVDS, HCSL, and CML. In addition to supporting differential signals, any of the outputs can be configured as single-ended

LVCMOS (3.3, 2.5, or 1.8 V) providing up to 20 single-ended outputs or any combination of differential and single-ended outputs.

silabs.com | Building a more connected world. Rev. 1.3 | 32

Page 33

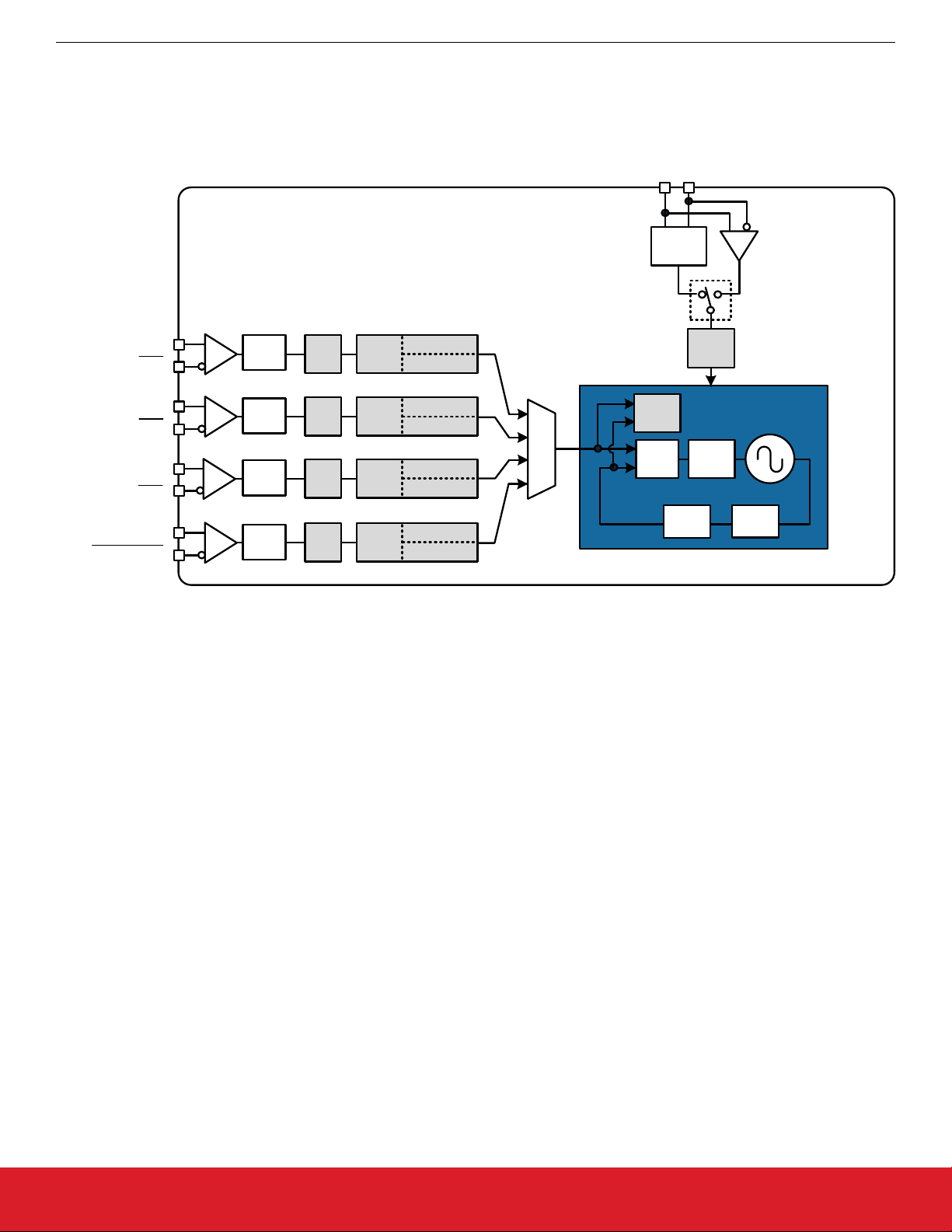

6.1 Output Crosspoint Switch

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Output Clocks

A crosspoint

switch allows any of the output drivers to connect with any of the MultiSynths as shown in Figure 6.1 MultiSynth to Output

Driver Crosspoint on page 33. The crosspoint configuration is programmable and can be stored in NVM so that the desired output

configuration is ready at power up. Any MultiSynth output can connect to multiple output drivers.

Multi

Synth

Multi

Synth

Multi

Synth

Multi

Synth

Multi

Synth

N

0n

÷

÷

÷

÷

÷

t

N

N

N

N

N

N

N

N

N

0

0d

1n

t

1

1d

2n

t

2

2d

3n

t

3

3d

4n

t

4

4d

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

0

1

2

3

4

5

6

7

8

9

VDDO0

OUT0

OUT0

VDDO1

OUT1

OUT1

VDDO2

OUT2

OUT2

VDDO3

OUT3

OUT3

VDDO4

OUT4

OUT4

VDDO5

OUT5

OUT5

VDDO6

OUT6

OUT6

VDDO7

OUT7

OUT7

VDDO8

OUT8

OUT8

VDDO9

OUT9

OUT9

Figure 6.1. MultiSynth to Output Driver Crosspoint

Table 6.1 Output Driver Crosspoint Configuration Registers on page 33 is used to set up the routing from the MultiSynth frequency

selection to the output.

Table 6.1. Output Driver Crosspoint Configuration Registers

Register Name Hex Address [Bit Field] Function

Si5345 Si5344 Si5342

OUT0_MUX_SEL 0x010B[2:0] 0x0115[2:0] 0x0115[2:0] Connects the output drivers to one of the N dividers.

OUT1_MUX_SEL 0x0110[2:0] 0x011A[2:0] 0x011A[2:0]

Selections are N0, N1, N2, N3, N4 for each output divider.

OUT2_MUX_SEL 0x0115[2:0] 0x0129[2:0] —

OUT3_MUX_SEL 0x011A[2:0] 0x012E[2:0] —

OUT4_MUX_SEL 0x011F[2:0] — —

OUT5_MUX_SEL 0x0124[2:0] — —

OUT6_MUX_SEL 0x0129[2:0] — —

OUT7_MUX_SEL 0x012E[2:0] — —

OUT8_MUX_SEL 0x0133[2:0] — —

OUT9_MUX_SEL 0x013D[2:0] — —

silabs.com | Building a more connected world. Rev. 1.3 | 33

Page 34

6.2 Performance Guidelines for Outputs

Si5345, Si5344, Si5342 Rev. D Family Reference Manual

Output Clocks

Whenever a

number of high frequency, fast rise time, large amplitude signals are all close to one another, there will be some amount of

crosstalk. The jitter of the Si5342/44/45 is so low that crosstalk can become a significant portion of the final measured output jitter.