Page 1

Si5332-AM1/2/3 Automotive Grade Device

Reference Manual

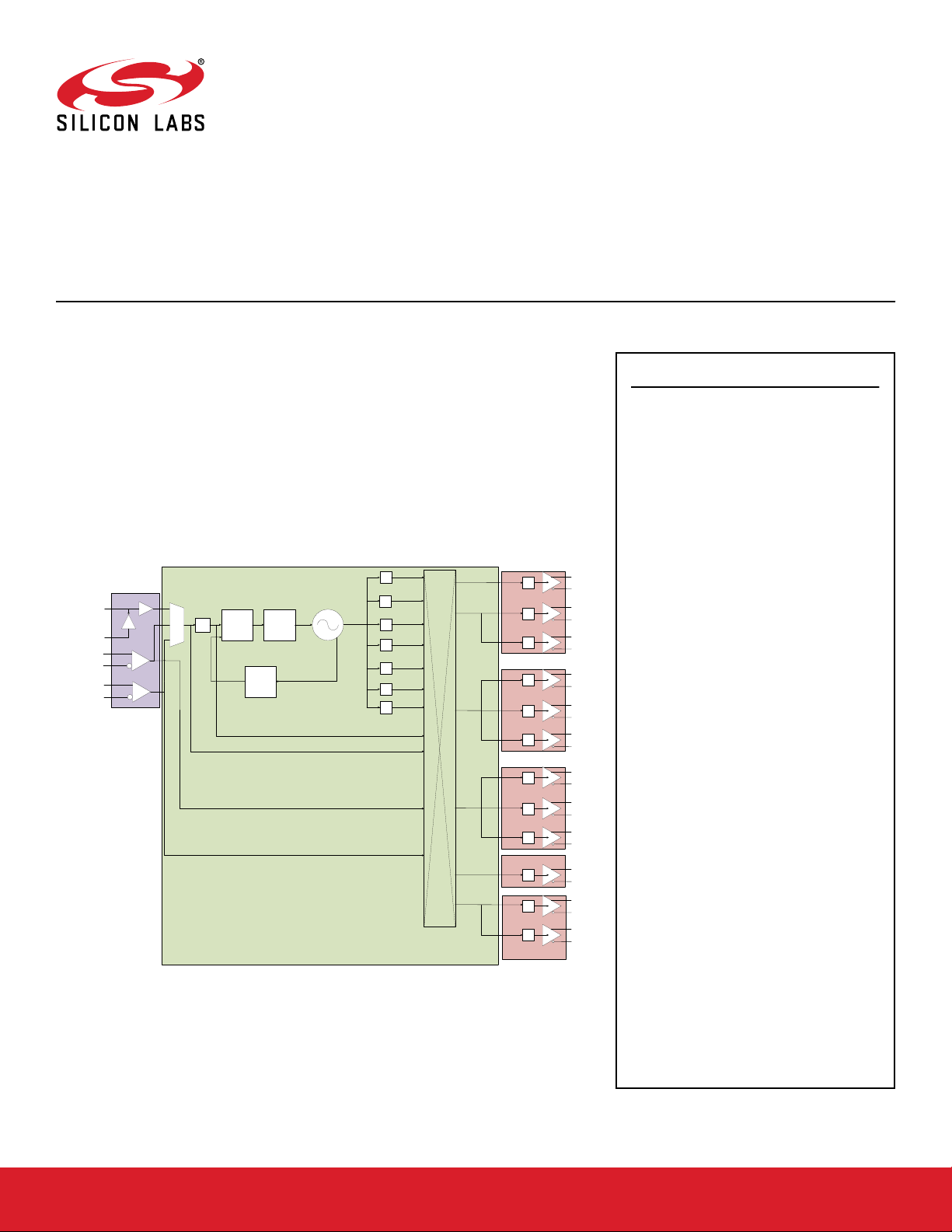

The Si5332-AM1/2/3 is a family of high-performance, low-jitter clock generators capable

of synthesizing five independent banks of user-programmable clock frequencies up to

333.33 MHz, while providing up to 12 differential or 24 single-ended output clocks. The

Si5332 supports free run operation using an external crystal as well as lock to an external clock signal. The output drivers are configurable to support common signal formats,

such as LVPECL, LVDS, HCSL, and LVCMOS. Separate output supply pins allow supply

voltages of 3.3 V, 2.5 V, 1.8 V and 1.5 V (CMOS only) to power the multi-format output

drivers. The core voltage supply (VDD) accepts 3.3 V, 2.5 V, or 1.8 V and is independent

from the output supplies (VDDOs). Using its two-stage synthesis architecture and patented high-resolution Multisynth technology, the Si5332 can generate three fully independent/non-harmonically-related bank frequencies from a single input frequency.

÷N

0

XA/CLKIN_1

CLKIN_2

nCLKIN_2

CLKIN_3

nCLKIN_3

VDDA

VDD_XTAL

10-30 MHz

XB

÷ P

1-31

PFD LF

10-50 MHz

÷M

/M

n

d

10-255

2.375-2.625 GHz

10-50 MHz

10-250 MHz

10-250 MHz

10-250 MHz

10-255

8-255

÷N

÷O

÷O

÷O

÷O

÷O

10-250 MHz

1

10-250 MHz

0

10-312.5 MHz

1

10-312.5 MHz

2

10-312.5 MHz

3

10-312.5 MHz

4

10-312.5 MHz

VDDOA

VDDOB

VDDOC

VDDOD

VDDOE

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

÷R

1-63

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

OUT9

OUT10

OUT11

RELATED DOCUMENTS

• Any-Frequency 6/8/12-output

programmable clock generators

• Offered in three different package sizes,

supporting different combinations of output

clocks and user configurable hardware

input pins

•

32-pin QFN, up to 6 outputs

• 40-pin QFN, up to 8 outputs

• 48-pin QFN, up to 12 outputs

• Multisynth technology enables any

frequency synthesis on any output up to

250 MHz using N dividers.

• Output frequencies up to 333.33 MHz

using O dividers.

• Highly configurable output path featuring a

cross point mux

• Up to three independent fractional

synthesis output paths

• Up to five independent integer dividers

• Down and center spread spectrum

• Input frequency range:

• External crystal: 16 MHz to 50 MHz

• Differential clock: 10 MHz to 250 MHz

• LVCMOS clock: 10 MHz to 170 MHz

• Output frequency range:

• Differential: 5 MHz to 333.33 MHz

• LVCMOS: 5 MHz to 170 MHz

• User-configurable clock output signal

format per output: LVDS, LVPECL, HCSL,

LVCMOS

• Easy device configuration using our

ClockBuilder Pro™ (CBPro™) software

tool available for download from our web

site

• Temperature range: –40 to +105 °C

• Pb-free, RoHS-6 compliant

• For more information, refer to the Si5332

Automotive Grade Data Sheet

silabs.com | Building a more connected world. Preliminary Rev. 0.2

This information applies to a product under development. Its characteristics and specifications are subject to change without notice.

Page 2

Table of Contents

1. Overview .................................

3

2. Power Supply Sequencing ..........................4

3. Input Clocks................................5

3.1 Input Clock Terminations ..........................5

3.1.1 External Crystal ............................5

3.1.2 External Input Clock on XA Input ......................5

3.1.3 External Input Clock on CLKIN_x/CLKIN_x# ..................6

3.2 Calculating Crystal Loading Capacitance .....................8

4. GPIO .................................10

5. Output Clock Terminations .........................11

5.1 DC-Coupled Output Clock Terminations .....................12

5.2 AC-Coupled Output Clock Terminations .....................16

6. Programming the Volatile Memory (Registers) ..................17

6.1 Programming the PLL ...........................18

6.2 Programming the Clock Path .........................21

6.3 Programming the Output Clock Frequency ....................23

6.4 Programming the Output Clock Format ......................25

6.5 Programming for Frequency Select Operations ...................27

6.6 Programming Spread Spectrum ........................28

7. Si5332 Pinout and Package Variant ......................30

8. Recommended Schematic and Layout Practices .................32

9. Register Map Overview ..........................33

9.1 Si5332 Common Registers ..........................34

9.2 Si5332 32-QFN Specific Registers .......................44

9.3 Si5332 40-QFN Specific Registers .......................49

9.4 Si5332 48-QFN Specific Registers .......................55

10. Revision History............................. 64

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 2

Page 3

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Overview

1. Overview

In addition to clock generation, the input clocks can bypass the synthesis stage, enabling the Si5332 to be used as a high-performance

clock buffer or a combination of a buffer and a generator. The Multisynth dividers have two sets of divide ratio registers, an A set and a

B set. The active in-use divide ratio can be switched between the A set or B set via external input pin or register control. This feature

allows for dynamic frequency shifting at ppb accuracy for applications such as frequency margining. Similar A set and B set divider

ratios are available for the integer dividers, but the ratios must be integer related. CBPro supports the configuration and use of A and B

divider sets. Spread spectrum is available for any clock output sourced from the Multisynth dividers and is available for use in EMI-

sensitive applications, such as PCI Express. The 2-wire I2C bus can be used to control and configure the Si5332. Alternatively, some

device features can be controlled by an external pin via CBPro configuration of one of more General Purpose I/O (GPIO) pins. Exam-

ples of GPIO pin assigned control are clock input selection, frequency A/B select, spread spectrum enable, output enable, or I2C address select.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 3

Page 4

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Power Supply Sequencing

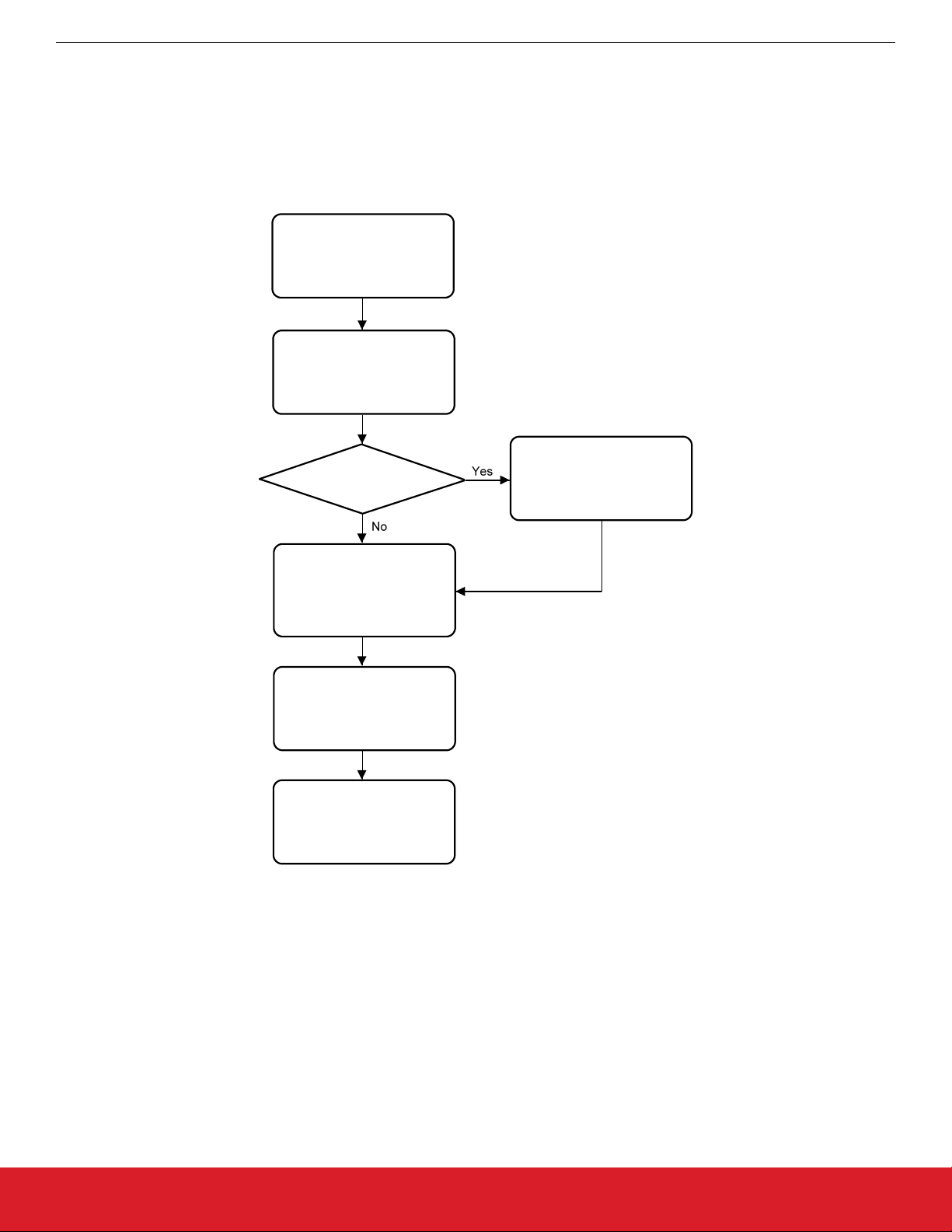

2. Power Supply Sequencing

The Si5332 VDD_core voltages are VDD_DIG, VDD_XTAL, and VDDA. These 3 VDD_core pins must all use the same voltage. Power

supply sequencing between VDD_core and any VDDOx pin is allowed in any order. However, if desiring to minimize the “bring-up” time,

it is recommended that VDD_core is powered up first; this ensures that the NVM download is completed first and the I2C master can

communicate with the Si5332 slave. The figure below shows the Si5332 device power-up sequencing and expected device behavior.

Note that a blank (unconfigured) part will stop and wait to be configured with outputs disabled.

Power supplies for

VDDA, VDD_DIG, and

VDD_XTAL stable

Time (system time delay)

for NVM download

Program Si5332 volatile

Is this a blank part?

memory with a frequency

plan

Time (system time delay)

for Oscillator startup/

Time (system time delay)

for input clock availability

Time (system time delay)

for PLL clock

Outputs available and

stable

Figure 2.1. Power Supply Sequencing for Si5332

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 4

Page 5

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Input Clocks

3. Input Clocks

The Si5332 has three input clock nodes: the XA/XB pair, the CLKIN_2/CLKIN_2# pair, and the CLKIN_3/CLKIN_3# pair.

XA/XB supports a crystal input or an external clock input whereas the CLKIN_x/CLKIN_x# pairs support ONLY external clock inputs.

The GPIO pins can be set to select the active input clock for the PLL (or the user can set the active input via register writes).

3.1 Input Clock Terminations

Supported input clock sources for the Si5332 are:

1. External crystal attached to the Si5332 XA/XB inputs.

2. External single-ended clock attached to XA (XA/CLKIN1 pin).

3. Externally supplied clock attached to available CLKIN_x/CLKINx# inputs.

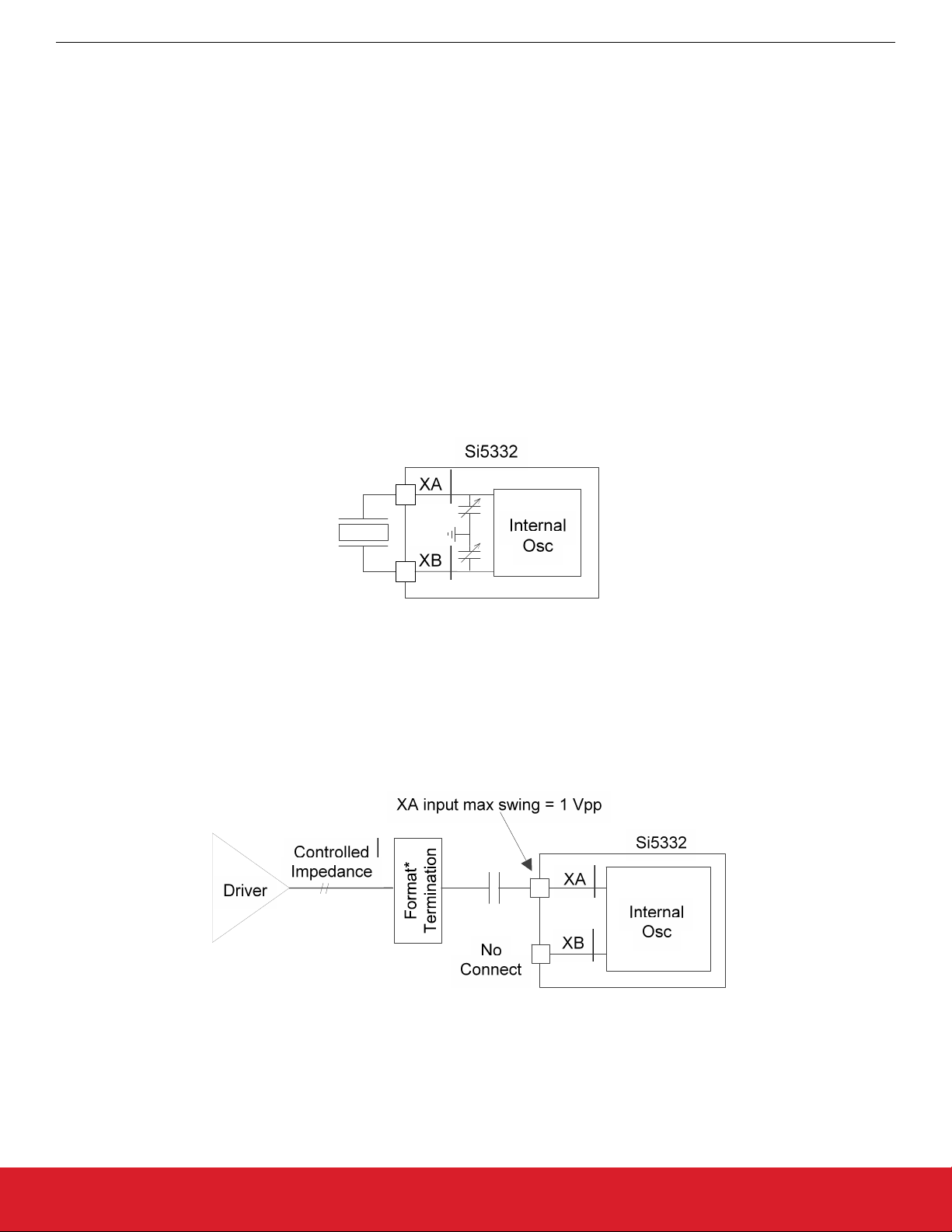

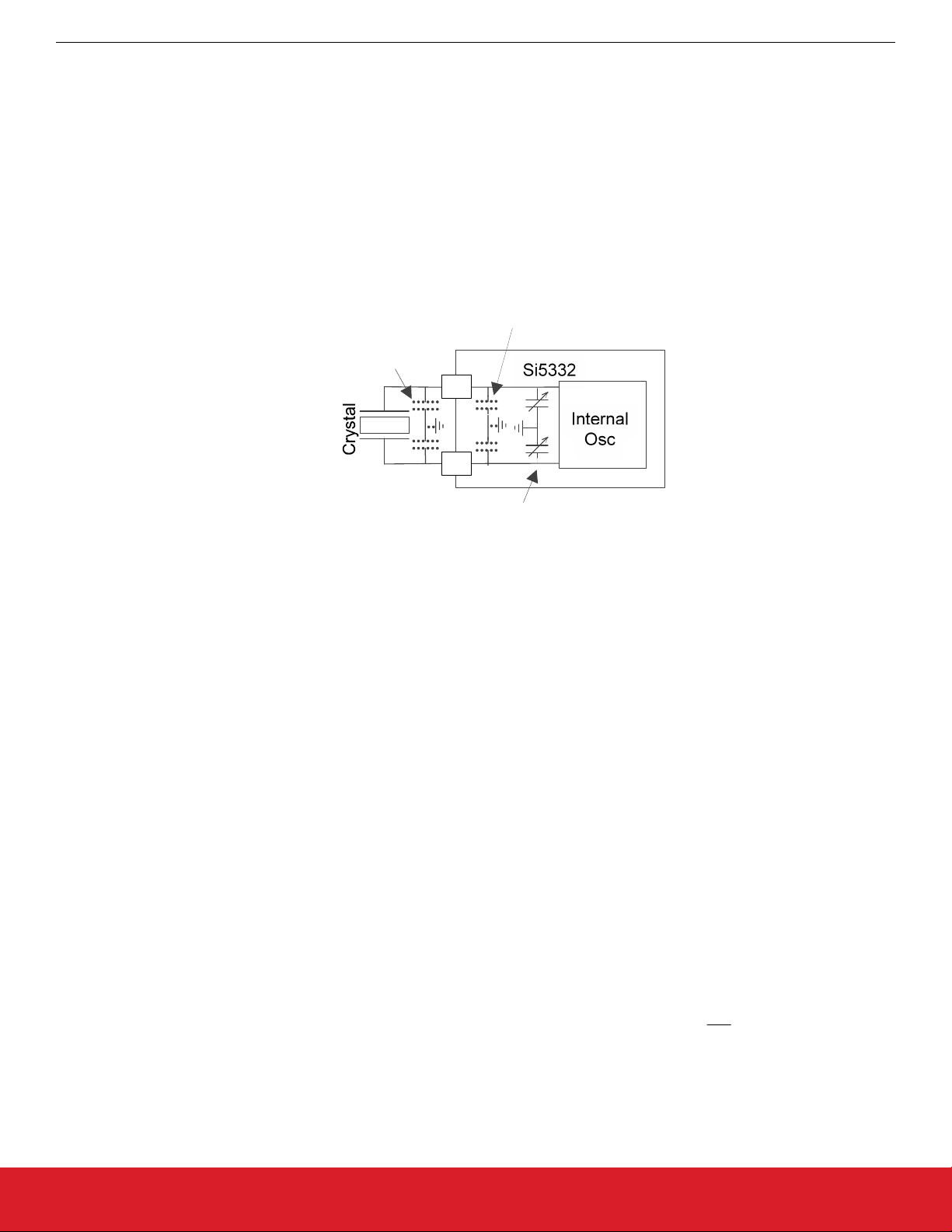

3.1.1 External Crystal

An external crystal can be connected to the Si5332’s XA/XB inputs as shown below. See Table 5.4 in the Si5332 Data Sheet for crystal

specifications when selecting a crystal. Note that the external crystal specifications in Si5332 Data Sheet must be met. A list of recommended AEC-Q200 qualified crystals for the Si5332 can be found in the Silicon Labs document “Recommended Crystal Reference

Manual for Si5332, Si5357, and Si5225x Automotive Grade Clock Generators.”

Figure 3.1. External Crystal Connection

3.1.2 External Input Clock on XA Input

The XA input (XA/CLKIN1 pin) can accept an externally supplied, AC-coupled clock with maximum voltage swing of 1 Vpp. See figure

below for connection details. The XB pin must be left open with nothing connected. If using this input clock mode, it is suggested to zero

out the internal crystal loading capacitance (CL) for best performance.”

0.1 µF

Figure 3.2. External Input Clock on XA Input

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 5

Page 6

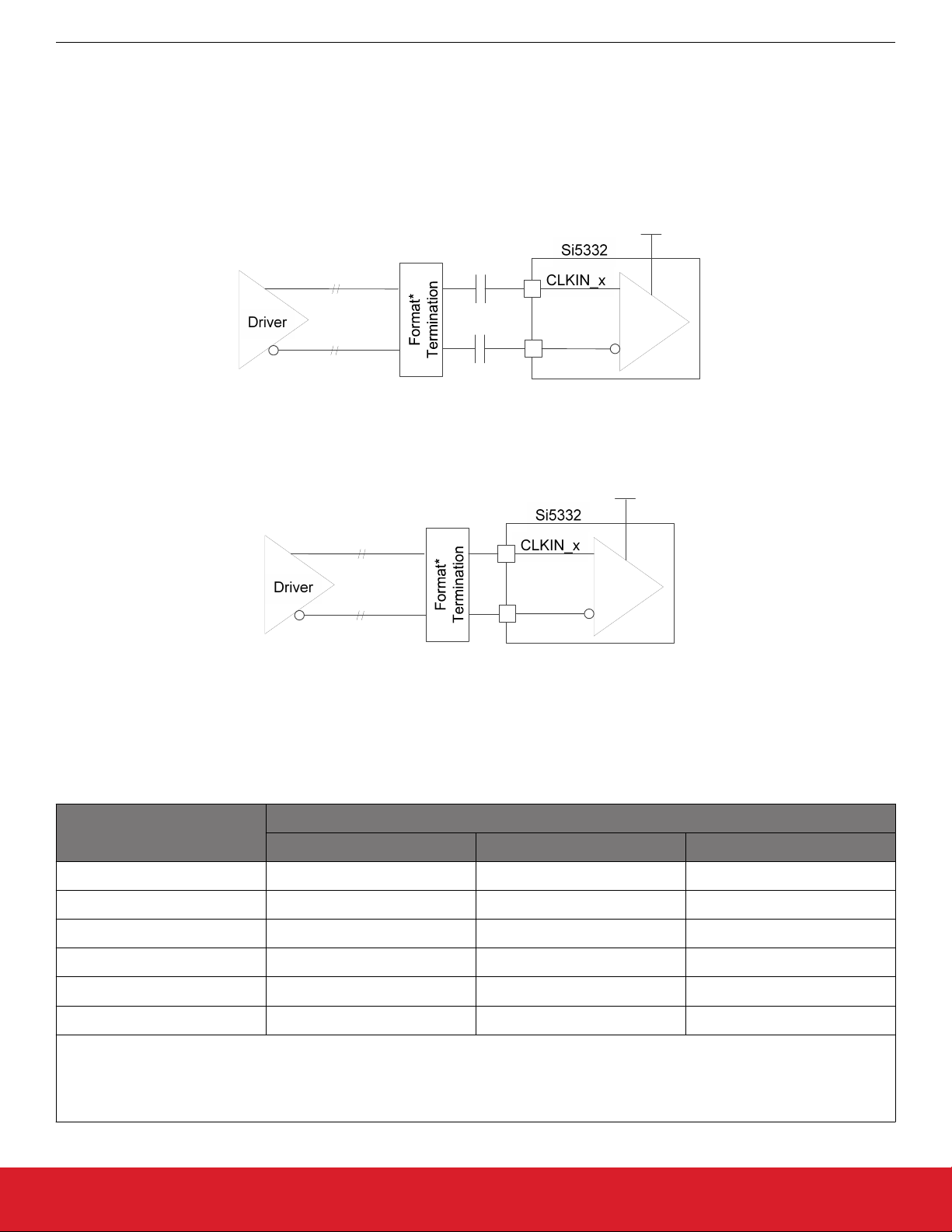

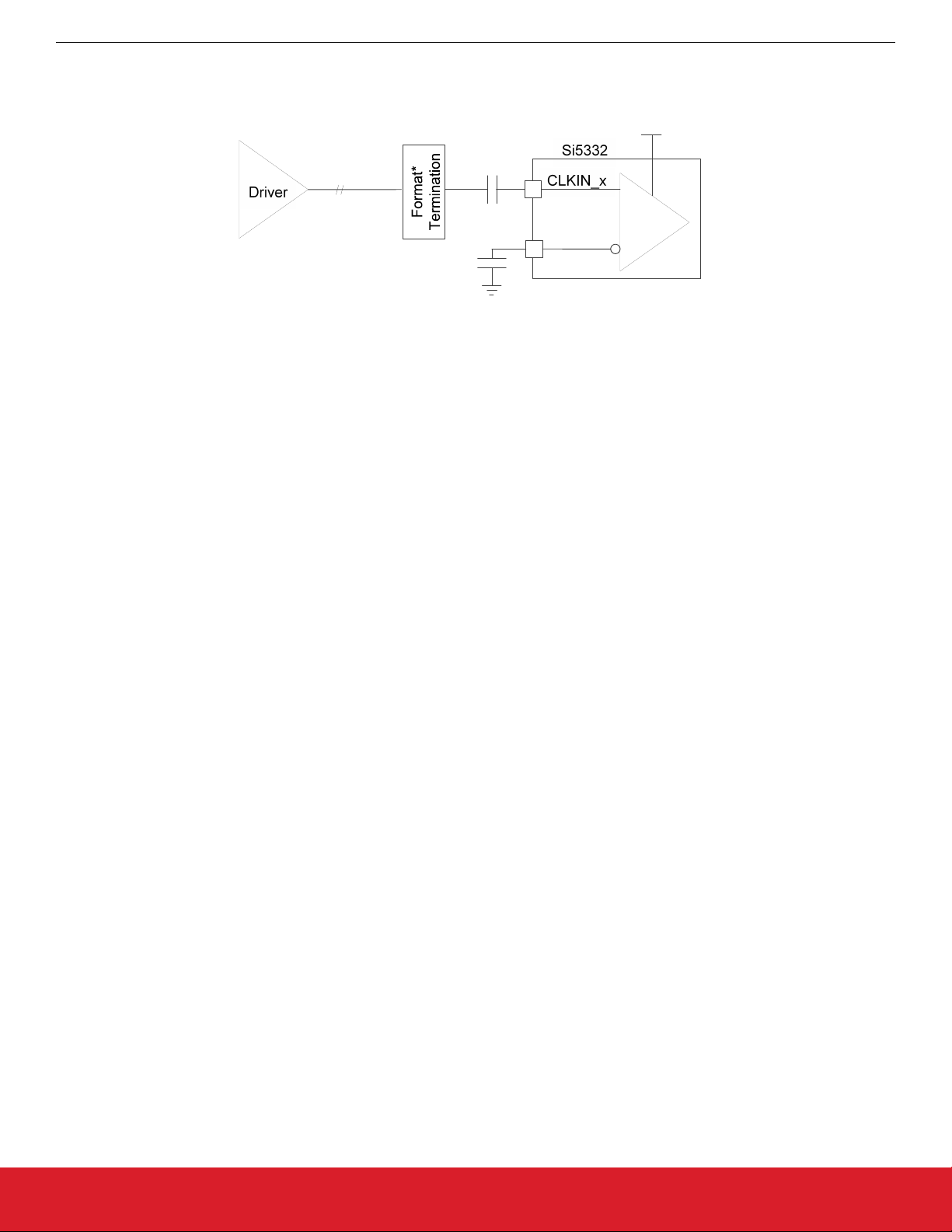

3.1.3 External Input Clock on CLKIN_x/CLKIN_x#

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Input Clocks

When supplying

the AC and DC coupled differential input clock connection to the Si5332 clock inputs. (There are some restrictions to observe when

using DC coupled input clocks as described further below.) The input clock Format Termination shown in below figures is dependent on

the driver’s termination requirements. The Si5332 clock inputs are high impedance inputs and the clock driven into the Si5332 must

meet the Si5332 Data Sheet's specified electrical requirements. When using differential input clocks, the respective Si5332 input must

be configured as a differential input using CBPro.

differential input clocks into the CLKIN_x/CLKIN_x# inputs, AC or DC coupling can be used. The figures below show

VDD Core

0.1 µF

Controlled

Impedance

CLKIN_x#

0.1 µF

Figure 3.3. AC-Coupled Differential Input Clock (LVDS, LVPECL, HCSL, CML, etc.)

VDD Core

Controlled

Impedance

Figure 3.4. DC-Coupled Differential Input Clock

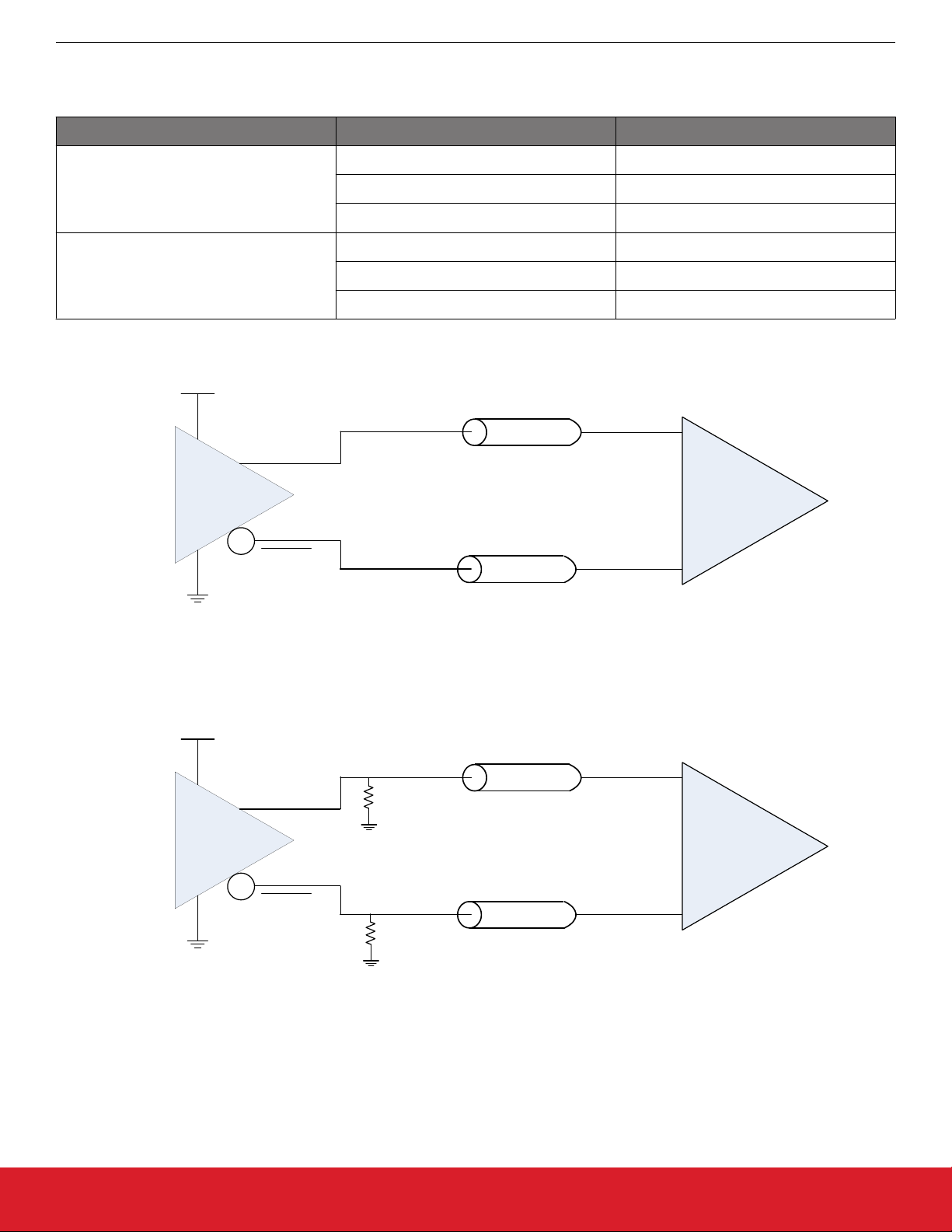

To determine if a specific DC-coupled differential input clock arrangement is supported, refer to the table below.

Table 3.1. Si5332 Input Clock Coupling Restrictions (AC or DC)

Format

3.3 V 2.5 V 1.8 V

LVDS 3.3 V/2.5 V AC or DC AC only AC only

LVDS 1.8 V AC or DC AC only AC only

LVPECL 3.3 V/2.5 V AC or DC AC only AC only

HCSL AC or DC AC or DC AC only

CML AC only AC only AC only

LVCMOS AC only AC only AC only

CLKIN_x#

VDD_Core

Note:

1.

For DC-coupled, input clock peak voltage must not exceed VDD_Core and minimum voltage must not be below GND.

For AC-coupled, peak swing must not exceed VDD_Core.

2.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 6

Page 7

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Input Clocks

The figure below shows how to connect single-ended input clocks, such as LVCMOS. The single-ended clock must be connected to the

positive CLKIN input as shown below.

VDD Core

Controlled

Impedance

0.1 µF

CLKIN_x#

0.1 µF

Figure 3.5. AC-Coupled Single-Ended Input Clock (LVCMOS)

For AC-coupled single-ended input clocks (such as LVCMOS) the Vswing of the clock must be limited to the maximum VDD_Core voltage. (VDD_Core is defined as the following group of VDD supply pins: VDD_DIG, VDDA, and VDD_XTAL.) The Input clock format termination is dependent on the driver format used and is usually specified by the driving device and/or industry standard clock format

specification.

For example, in the case of using a LVCMOS input clock, the driving device may recommend a series termination resistor. When using

LVCMOS input clocks the Si5332 input must be configured in LVCMOS mode in CBPro. The single-ended CLKIN input of Si5332 is a

high impedance input.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 7

Page 8

3.2 Calculating Crystal Loading Capacitance

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Input Clocks

Crystals will

resonate at their specified frequency (i.e., be “on-frequency”) if the capacitive loading across the crystal’s terminals is the

same as specified by the crystal manufacturer’s loading capacitance (CL) specification. The total loading capacitance presented to the

crystal must factor in all capacitance sources such as parasitic “stray” capacitance as well as added loading capacitance. Stray capacitance comes from sources like PCB traces, capacitive coupling to nearby components, as well as any stray capacitance within the device itself. For “on-frequency” oscillator operation, all capacitance sources must be factored into determining the correct additional capacitance to be presented to the crystal to match its required CL.

The Si5332 contains variable internal loading capacitors (CL

) to provide the necessary added crystal matching capacitance such

VAR

that external matching capacitors are not needed. The figure below shows the Si5332’s internal variable capacitance and the two main

sources of stray loading capacitance, PCB stray (CLS

) and Si5332 device stray capacitance on XA/XB input pins (CLS

EXT

INT

).

Internal Stray

Capacitance CLS

INT

External Stray

Capacitance

CLS

EXT

XA

XB

Internal Variable

Capacitance

CL

AR

V

Figure 3.6. Sources of Crystal Loading Capacitance

Using the Si5332’s internal variable loading capacitors (CL

external stray (CLS

) and internal device capacitance (CLS

EXT

), the crystal’s required CL can be matched by adding capacitance to the

VAR

) to match the crystal’s requirements. A value for CL

INT

must be se-

VAR

lected such that:

quired Crystal CL = CL

e

R

VAR

+ CL S

+ CL S

INT

EXT

Or rearranged:

= C

ry

C L

AR

V

stal CL − CL S

Note: the required Crystal CL must be greater than or equal to the total stray capacitance quantity (CLS

can’t be used as CL

is always >= 0.

VAR

− CL S

T

IN

EXT

+ CLS

INT

Equation 1

) or the crystal

EXT

For the following example, a Crystal CL value of 10 pf will be used. The internal stray capacitance (CLS

) of the Si5332 is 2.4 pf.

INT

External PCB stray capacitance (CLSEXT) is usually in the order of 2-3 pf given a reasonably compact layout. The Si5332 EVB external stray capacitance is ~ 2.75 pf. Given these example values, the required CL

can be calculated as shown below, using Equation

VAR

1.

C L

= 10 pF − 2.4 pF − 2.75 p

R

A

V

As shown in the figure above, the internal variable loading capacitor (CL

connected to the XA pin (CLXA) and one to the XB pin (CLXB) of the Si5332. The CL

F = 4.85 pF

implemented by using

) is

VAR

VAR

Using Equation 1

two capacitors in

series: one

value is therefore determined by the values of

CLXA and CLXB .

For capacitors in series, if we keep CLXA = CLXB, we can simply double the value of CL

to arrive at the correct CLXA and CL

VAR

XB

value. (This is a technique commonly used for calculating crystal loading capacitors when external loading capacitors are used.) Now,

CLXA and CLXB values are simply:

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 8

Page 9

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Input Clocks

C LXA = C L

Substituting Equation 1 for CL

C LXA = C LXB = 2 ×

Equation 3 can now be used to determine the CLXA and CLXB

of CLXA and CLXB values the Si5332 can support is 0 to 38.395 pF. CLXA and CLXB values less than 0 cannot be implemented and any

values greater than 38.395 pF cannot be implemented using internal capacitors alone. Remember, CLXA and CLXB are not derived simply from the crystal’s CL because internal and external stray capacitance must be factored into the calculations.

Once the required CLXA and CLXB have been determined using Equation 3, use the following set of formulas to calculate the required

register values to implement the desired CLXA and CLXB.

If (CL

• Register xosc_cint_ena = 0

Register xosc_ctrim_xin = Round to nearest integer (CLXA / 0.485)

•

• Register xosc_ctrim_xout = Round to nearest integer (CLXB / 0.485)

If (30.555 pF < CL

• • Register xosc_cint_ena = 1

•

Register xosc_ctrim_xin = Round to nearest integer ((CLXA - 7.84) / 0.485)

• Register xosc_ctrim_xout = Round to nearest integer (CLXB - 7.84) / 0.485)

To summarize, use Equation 3 to calculate CLXA/CLXB, then use the above set of formulas to calculate register values to implement

CLXA/CLXB in the Si5332. Note that external loading capacitors can be used to supplement the internal loading capacitors if necessary.

< 30.555 pF, then:

XA/XB

< 38.395 pF, then:

XA/XB

=

2 × C L

X

VAR

B

(

into Equation 2 will solve for CLXA/CLXB in single equation form:

= 2 × 4.85 pF = 9.7 pF

)

R

VA

Crystal CL − C L

(

values needed to set internal CLXA and CLXB register values. The range

− C L

t

in

ext

Equation 2

)

Equation 3

Note: Your unique PCB assembly’s stray capacitance value plays a role in determining correct internal capacitor settings and, conse-

quently, the crystal’s frequency of oscillation. Small differences in actual board stray capacitance value from the value you use in the

above equations will result in the crystal oscillating slightly off-frequency. Significant capacitance differences can result in significant

frequency error.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 9

Page 10

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

GPIO

4. GPIO

Si5332 features universal General Purpose Input/Output (GPIO) hardware pins whose functions must be programmed in NVM to assume a pre-defined function in ClockBuilder Pro during custom configuration file development.

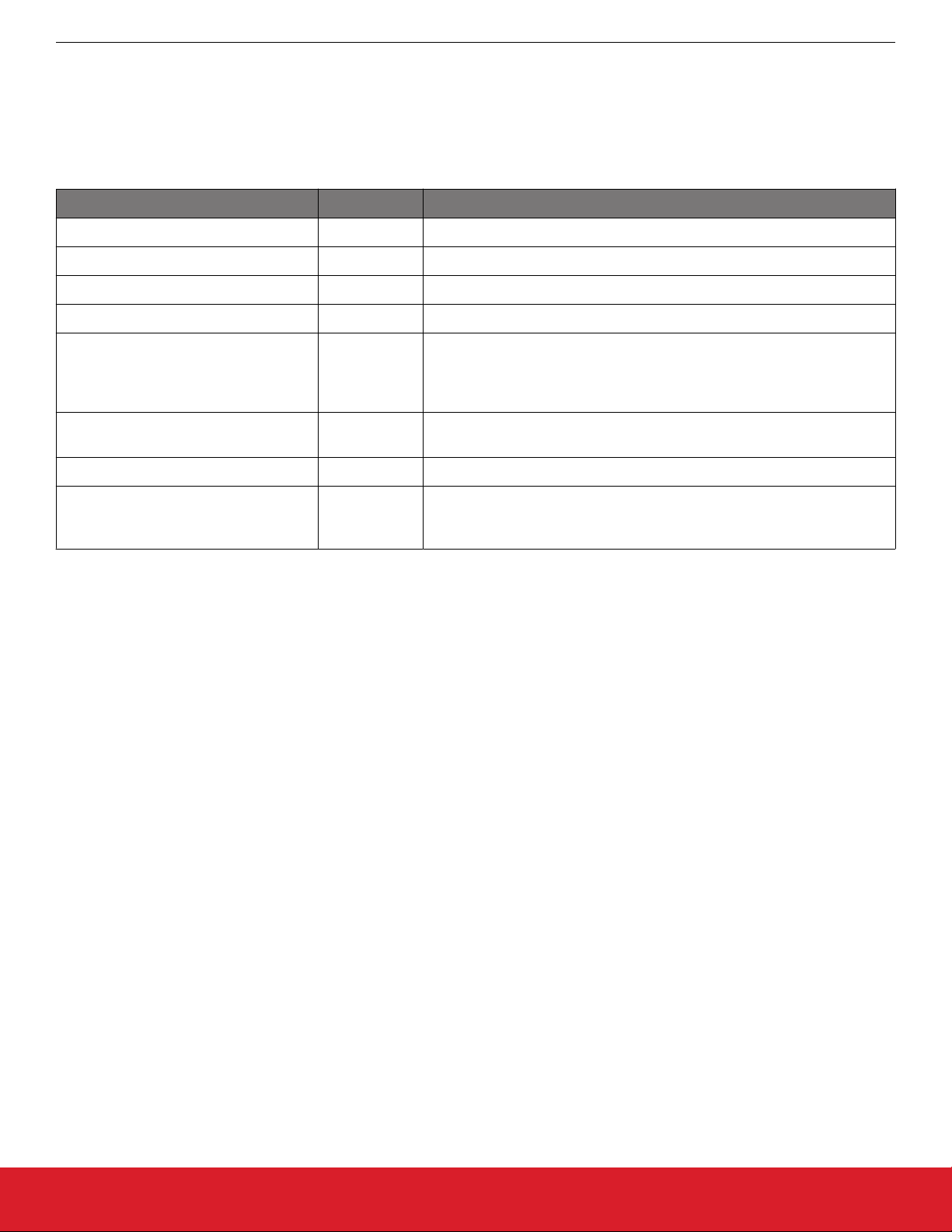

Table 4.1. Available GPIO Pin Functions

Function Name In/Out Description

OEn (up to 7) In Output enable(s) for selected output(s).

SSENn (up to 2) In Spread spectrum enable for outputs derived from N0 / N1 divider.

FSn (up to 7) In Frequency select(s) for Dividers N0, N1, O0-O4.

CLKIN_SEL [1:0] In Input clock select pins (requires use of 2 GPIOs).

Use to add 1 to I2C device base address but is logically Or’ed with I2C ad-

I2C_ADDR0 In

dress bit 0. If device I2C base address is even, assertion will add 1 to base

address. If device I2C base address is odd, assertion or de-assertion will

not change base address.

LOS Out

RESET In

FOOF Out Fast Out Of Frequency (FOOF) signal indicates PLL is not tracking input

Note: Creation of,

(OPN) generated through CBPro and then either factory programmed, or field programmed using the CBPro Field Programming Dongle. GPIO pin functionality can be evaluated/tested on a Si5332 EVB by downloading a valid CBPro configuration into the EVB, and

asserting the GPIO pins on the EVB. New GPIO configurations, or changes to existing GPIO configurations, are not available through

Si5332 I2C register programming. Blank Si5332 devices have no GPIO configuration loaded and require burning a configuration into

device NVM with the Field Programming Dongle to configure any GPIO functionality.

CBPro will allow user configuration of the available GPIOs according to the functionality restrictions of the function selected. Some functions can share a pin, some can not. For example, a single pin can control OE of one or more outputs. Some functions require two pins,

such as CLKIN_SEL0 and CLKIN_SEL1. Some functions are mutually exclusive, for instance FS_x functions can’t share a pin with OE.

For all Si5332 devices, CBPro uses a default I2C base address of 6Ah unless the base address is changed by the user.

or changes to, device GPIO pin functionality is only available when using customized Si5332 orderable part numbers

Loss of Input Clock Signal (Input clock or xtal), active low

put. Requires external pull-up resistor to VDD_CORE.

Device reset, active high input.

reference. FOOF is an active-low open-drain output. Requires external

pull-up resistor to VDD_CORE.

open drain out-

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 10

Page 11

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Output Clock Terminations

5. Output Clock Terminations

The Si5332 supports output formats of LVCMOS, LVDS, LVPECL, and HCSL with some additional format specific features. Each output driver is individually programmable to any of the supported formats by use of the following registers.

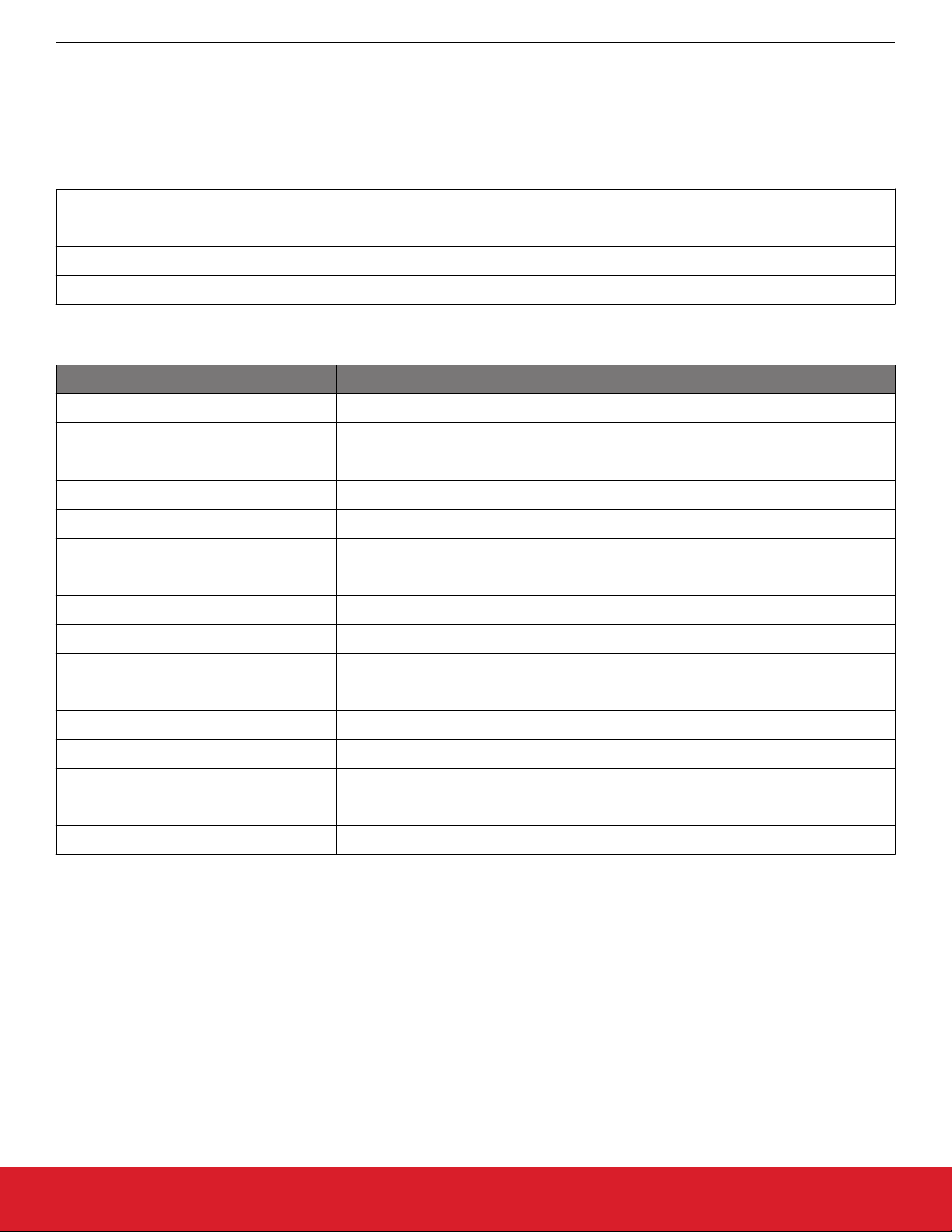

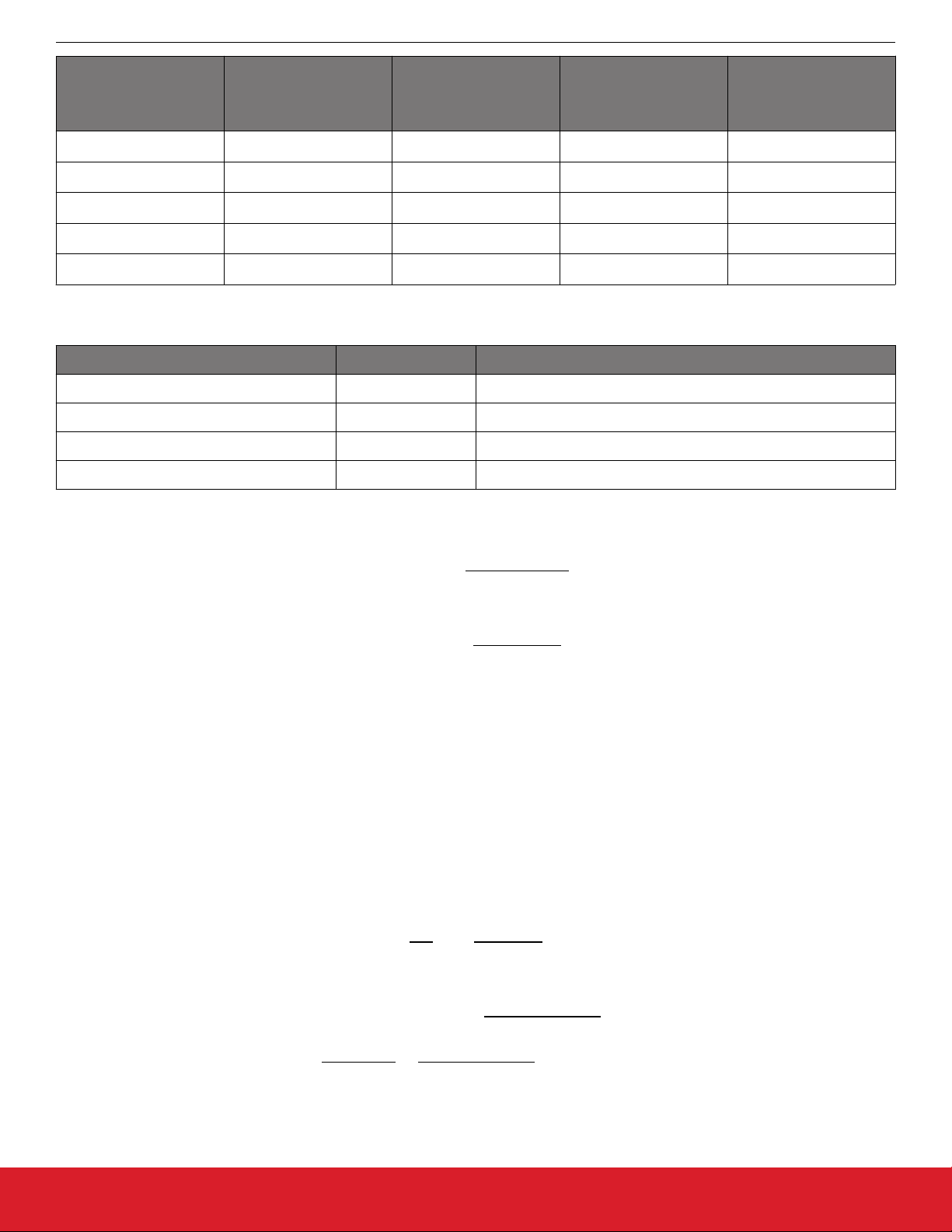

Table 5.1. Output Format Related Register Fields

outx_mode: - Sets the mode of the driver. See Table 5.2 OUTx_Mode vs Output Formats on page 11

outx_cmos_inv: - Sets the inversion state of each side of the dual output driver when in CMOS driver format.

outx_cmos_slew: - Sets the slew rate of the CMOS driver.

outx_cmos_str: - Sets the output impedance of the CMOS driver (25Ω / 50Ω).

.

Table 5.2. OUTx_Mode vs Output Formats

OUTx_MODE Driver Mode

0 off

1 CMOS on positive output only

2 CMOS on negative output only

3 dual CMOS outputs

4 2.5V/3.3V LVDS

5 1.8V LVDS

6 2.5V/3.3V LVDS fast

7 1.8V LVDS fast

8 HCSL 50 Ω (external termination)

9 HCSL 50 Ω (internal termination)

10 HCSL 42.5 Ω (external termination)

11 HCSL 42.5 Ω (internal termination)

12 LVPECL

13 Reserved

14 Reserved

15 Reserved

The recommended termination for each output format is shown in these figures: Figure 5.1

12 and Figure 5.2 LVCMOS Termination, Option 2 on page 12.

LVCMOS Termination, Option 1 on page

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 11

Page 12

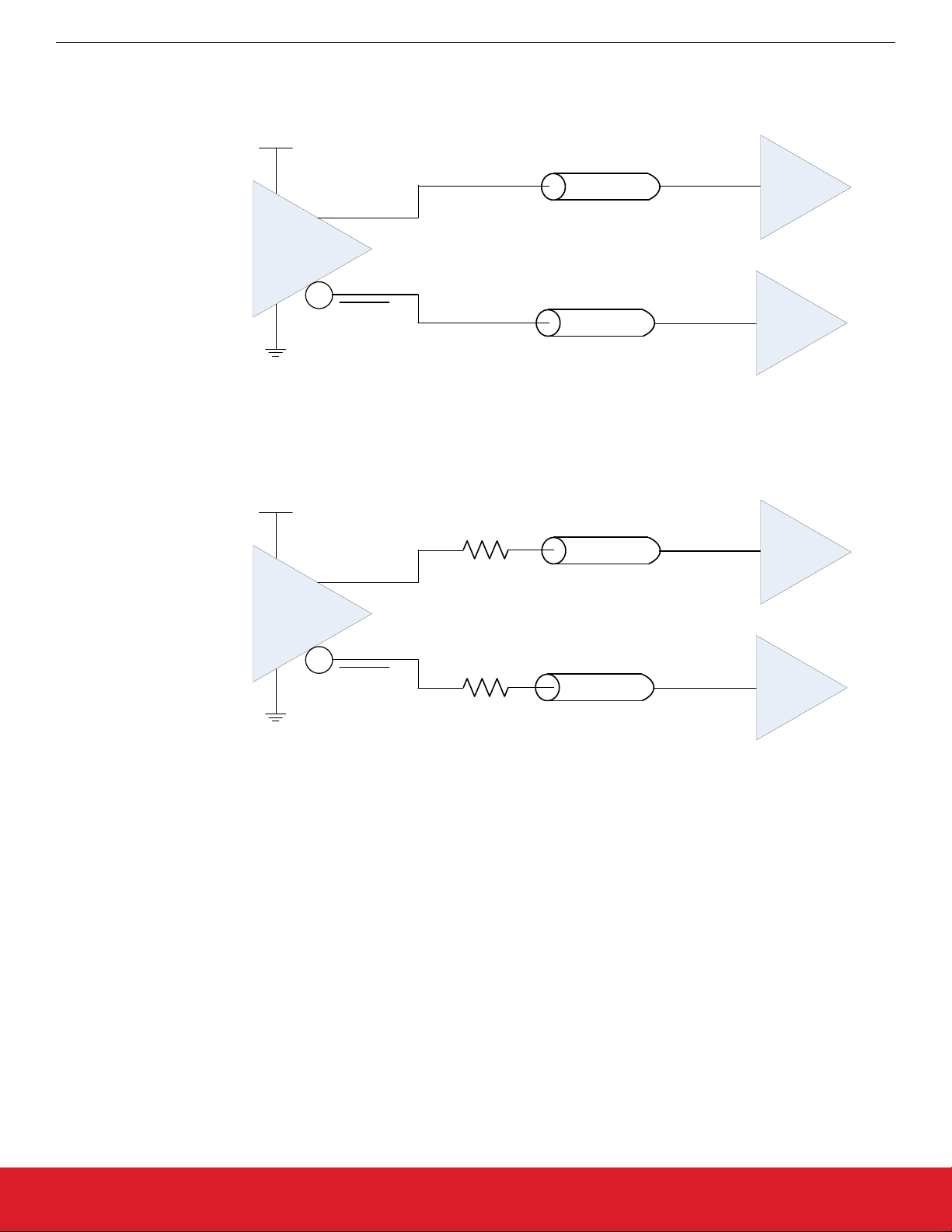

5.1 DC-Coupled Output Clock Terminations

1.43 V to 3.46 V

Set output driver

to 50 Ω mode.

Figure 5.1. LVCMOS Termination, Option 1

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Output Clock Terminations

Zo = 50 Ω

OUTx

Zo = 50 Ω

OUTx

1.43 V to 3.46 V

Set output driver

to 25 Ω mode.

Zo = 50 Ω

OUTx

Rs

Zo = 50 Ω

OUTx

Rs

Rs = Zo - Rdrv

Figure 5.2. LVCMOS Termination, Option 2

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 12

Page 13

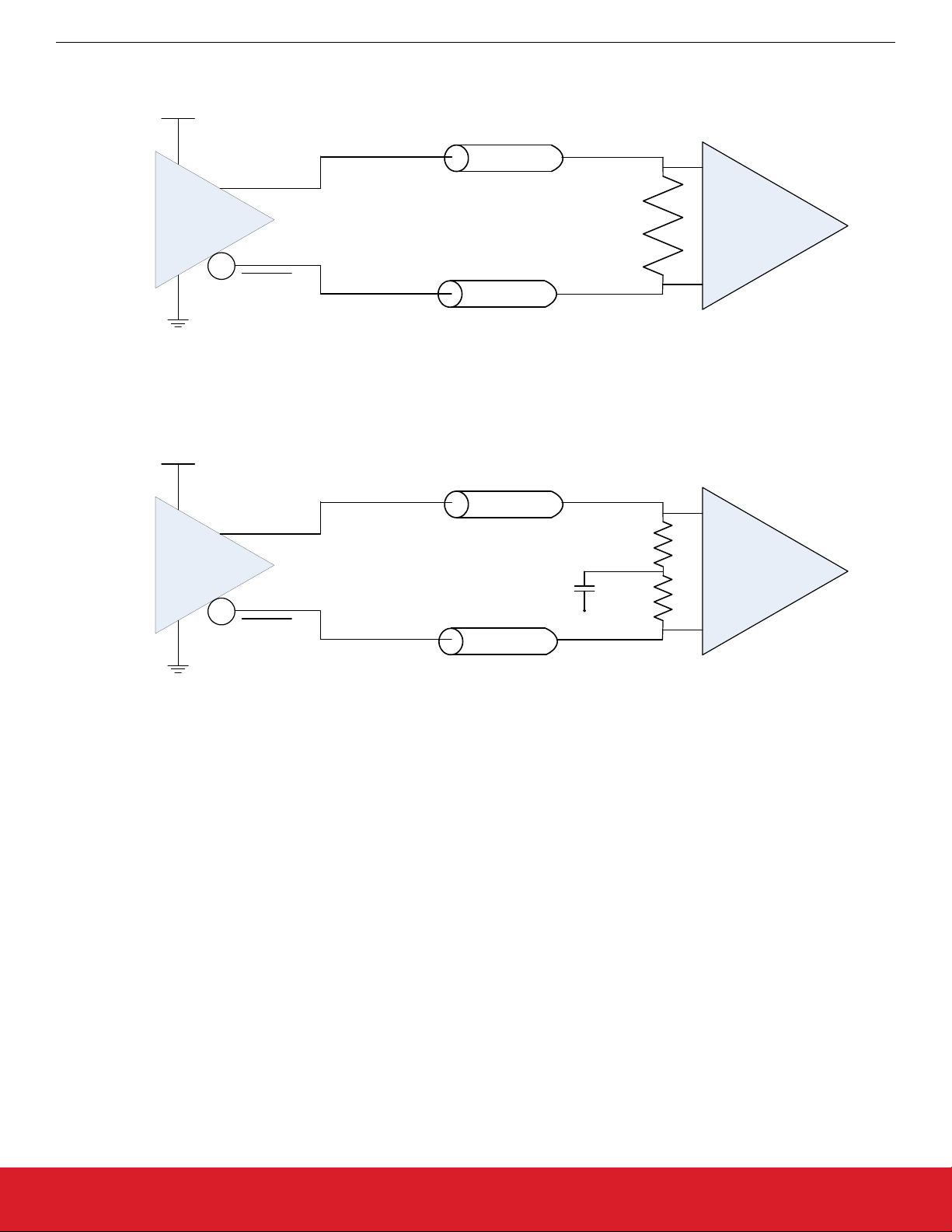

1.71 V to 3.46 V

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Output Clock Terminations

LVDS

driver

1.71 V to 3.46 V

LVDS

driver

OUTx

OUTx

OUTx

OUTx

Zo = R

Zo = R

Figure 5.3. LVDS/LVDS Fast Termination, Option 1

Zo = R

Zo = R

/2

T

/2

T

/2

T

/2

T

R

R

R

T

/2

T

/2

T

LVDS

receiver

LVDS

receiver

Figure 5.4. LVDS/LVDS Fast Termination, Option 2

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 13

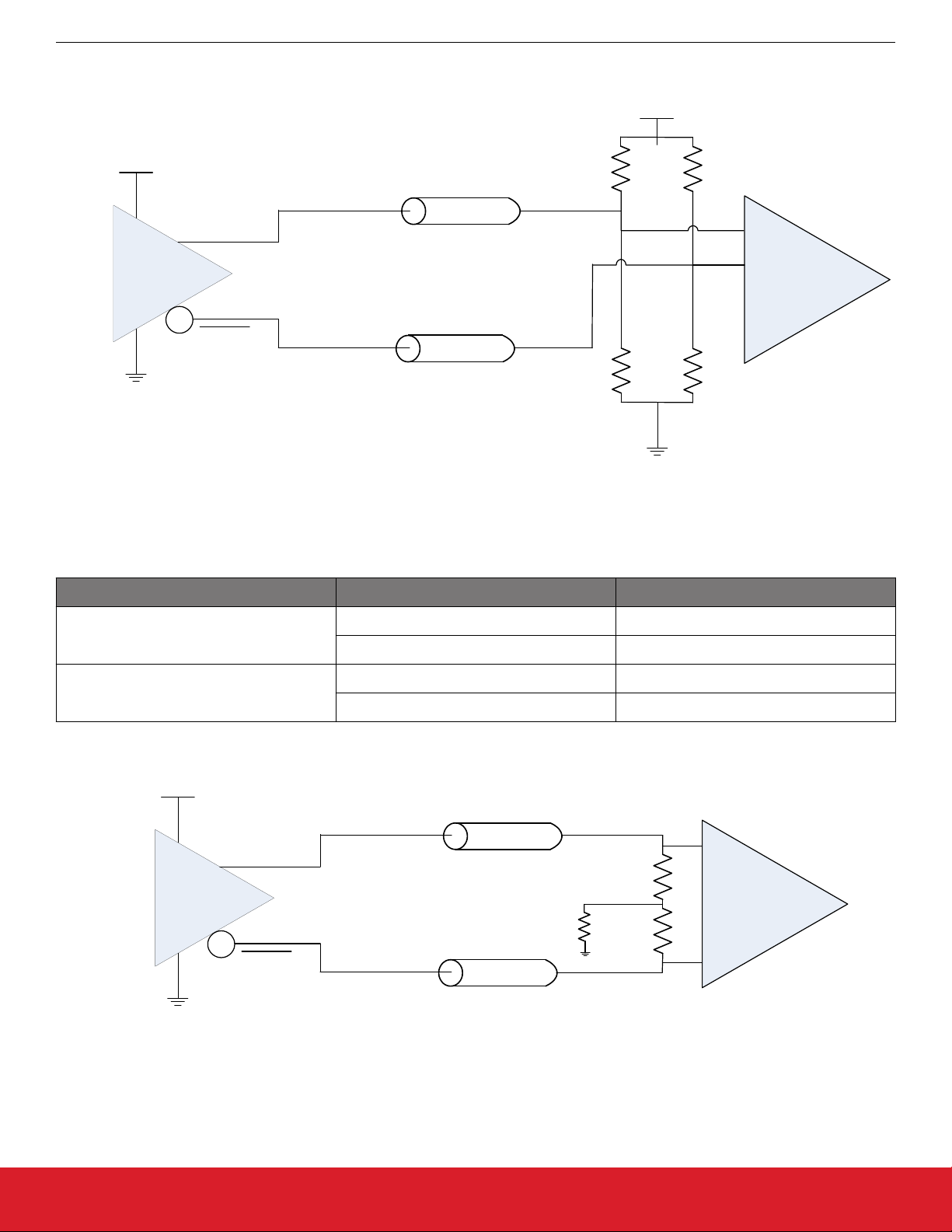

Page 14

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Output Clock Terminations

2.25 V to 3.46 V

2.25 V to 3.46 V

LVPECL

driver

VDD Standard Resistance Resistance Value

OUTx

OUTx

R1

Zo = 50 Ω

Zo = 50 Ω

R2

Figure 5.5. LVPECL Termination, Option 1

Table 5.3. LVPECL Termination, Option 1

R1

LVPECL

receiver

R2

2.5

3.3

2.25 V to 3.46 V

LVPECL

driver

OUTx

OUTx

R1 250

R2 62.5

R1 125

R2 84

Zo = 50 Ω

R3

Zo = 50 Ω

Figure 5.6. LVPECL Termination, Option 2

R1

LVPECL

receiver

R2

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 14

Page 15

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Output Clock Terminations

Table 5.4. LVPECL Termination, Option 2

VDD Standard Resistance Resistance Value

R1 50

2.5

3.3

1.71 V to 3.46 V

HCSL

driver

OUTx

OUTx

R2 50

R3 29.5

R1 50

R2 50

R3 54 or 0

Zo = 42.5 Ω

or 50 Ω

HCSL

receiver

Zo = 42.5 Ω

or 50 Ω

1.71 V to 3.46 V

HCSL

driver

OUTx

OUTx

Figure 5.7. HCSL Internal Termination Mode

Zo = 42.5 Ω

R

= Zo

T

or 50 Ω

Zo = 42.5 Ω

or 50 Ω

= Zo

R

T

Figure 5.8. HCSL External Termination Mode

HCSL

receiver

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 15

Page 16

5.2 AC-Coupled Output Clock Terminations

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Output Clock Terminations

1.71 V to 3.46 V

HCSL

driver

1.71 V to 3.46 V

HCSL

driver

Zo = 42.5 Ω

or 50 Ω

OUTx

R

= Zo

T

Zo = 42.5 Ω

or 50 Ω

OUTx

= Zo

R

T

Figure 5.9. HCSL External Termination Mode

Zo = 42.5 Ω

or 50 Ω

OUTx

Zo = 42.5 Ω

or 50 Ω

OUTx

0.1 µF

HCSL

receiver

0.1 µF

0.1 µF

HCSL

receiver

0.1 µF

Figure 5.10. HCSL Internal Termination Mode

1.71 V to 3.46 V for LVDS

Zo = 50 Ω

0.1 µF

OUTx

LVPECL

or LVDS

driver

100 Ω

LVPECL

or LVDS

receiver

Zo = 50 Ω

OUTx

Figure 5.11. LVDS Termination

The terminations shown in Figure 5.3 LVDS/LVDS Fast Termination, Option 1 on page 13 through Figure 5.6 LVPECL Termination,

Option 2 on page 14 can also be converted by adding DC-blocking capacitances right before the receiver pins. However, the recom-

mendation shown in Figure 5.11 LVDS Termination on page 16 is the simplest way to realize AC-coupling (i.e., the least number of

components) and the recommended circuit for AC-coupled termination circuits.

0.1 µF

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 16

Page 17

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

6. Programming the Volatile Memory (Registers)

The process described in this section is very complex to implement and/or calculate. A device register solution is most easily calculated

using CBPro and then exporting the resulting register file to simply download into the device. Using CBPro to craft your register set-

ting solution is the most highly recommended approach. The following descriptions of register value calculations are for reference

only.

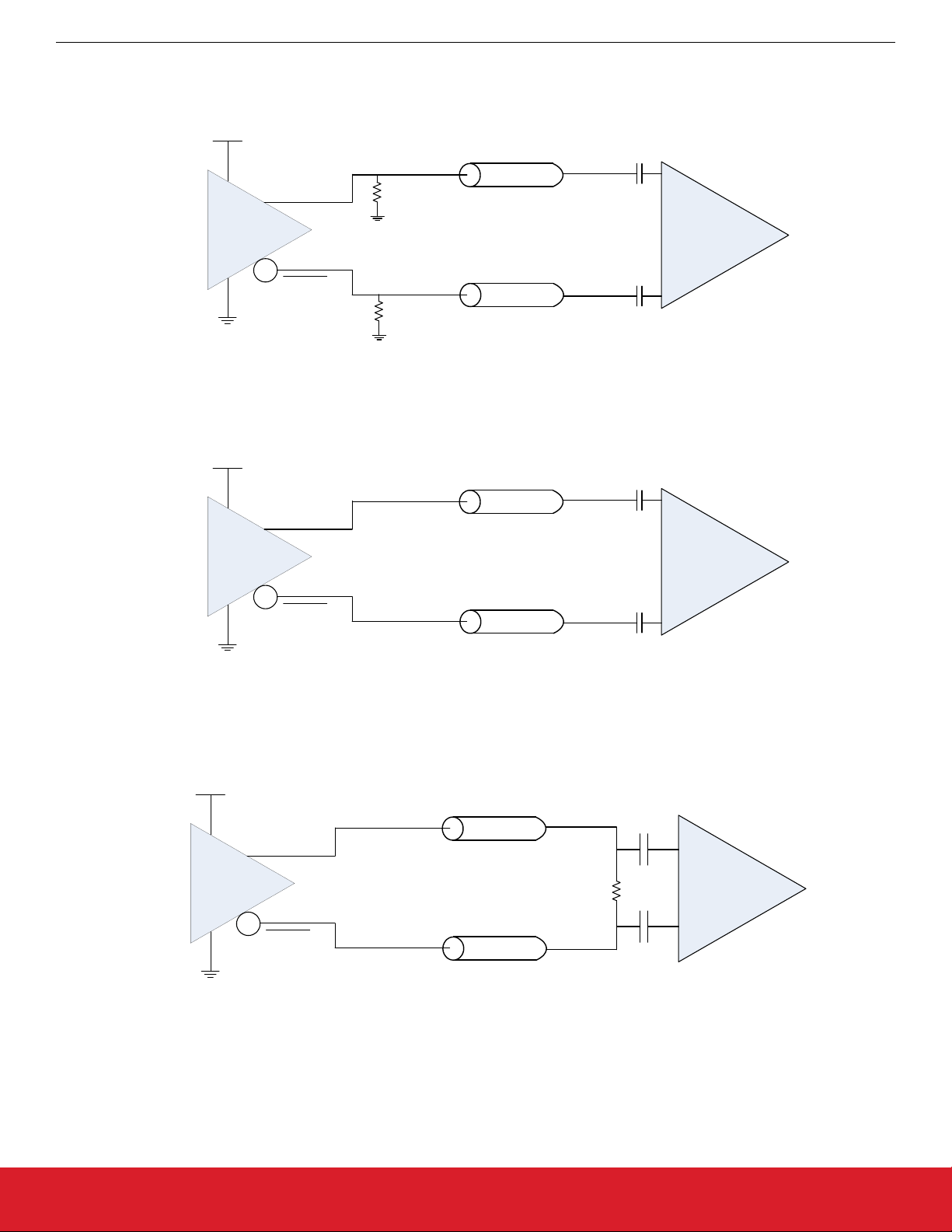

The volatile memory can be programmed to set up the various functions necessary to realize a PLL function, a clock output to clock

input relationship and can be used to monitor input clock that controls the PLL. The top-level block diagram is repeated here to refresh

the various limits and possibilities that are necessary for the calculations below.

÷N

0a

÷N

0b

÷N

1a

÷N

1b

÷O

0a

÷O

0b

÷O

1a

÷O

1b

÷O

2a

÷O

2b

VDDOA

VDDOB

÷R

÷R

÷R

÷R

÷R

OUT0

OUT1

OUT2

OUT3

OUT4

XA/CLKIN_1

XB

CLKIN_2

nCLKIN_2

CLKIN_3

nCLKIN_3

VDD_XTAL

VDDA

÷ P

PFD LF

÷M

/M

n

d

÷O

3a

÷O

3b

÷O

4a

÷O

4b

Figure 6.1. Top-Level Block Diagram

VDDOC

VDDOD

VDDOE

÷R

÷R

÷R

÷R

÷R

÷R

÷R

1-63

OUT5

OUT6

OUT7

OUT8

OUT9

OUT10

OUT11

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 17

Page 18

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

6.1 Programming the PLL

The PLL programming involves three distinct constraints:

1. The minimum

frequency that sets the input divider P and the active input clock as selected by the IN SEL pins or registers.

2. The VCO frequency that is set by feedback divider (Mn/Md) and the PFD frequency also has a limited range that is unique to

Si5332.

3. The PLL closed loop transfer function characterized by its loop band width and peaking is set by programming the loop parameters.

The table below lists the constraints for the PLL reference frequency and the VCO frequency. The PLL reference frequency

(pllRefFreq) and the VCO frequency (vcoFreq) are related by the equation below:

For a given plan, the pllRefFreq can be readily solved as it is derived from the input clock frequency. To get to this optimization, the

“active” input to the PLL must be selected from the XA/XB, CLKIN_1, CLKIN_2, in 1 p/m input clocks using either the IMUX_SEL register field or the CLKIN_SEL pins (if CKIN_SEL pins are available in the custom part that was chosen to reprogrammed). PllRefFreq is

given by the In-Freq (active clock input frequency) and P as:

and the maximum frequencies possible for the PFD (Phase Frequency Detector) at lock. This is set by the reference

v

coFreq = pllRefFreq ×

RefFreq =

Pll

InFreq

Mn

(

)

Md

P

Table 6.1. Constraints for PLL Reference Frequency and VCO Frequency

Field Name Value Description

pllMinRefFreq 10 MHz The minimum reference frequency the PLL can tolerate

pllMaxRefFreq 50 MHz The maximum reference frequency the PLL can tolerate

vcoCenterFreq 2.5 GHz The center frequency of the VCO’s tuning range

vcoMinFreq 2.375 GHz The minimum frequency of the VCO’s tuning range

vcoMaxFreq 2.675 GHz The maximum frequency of the VCO’s tuning range

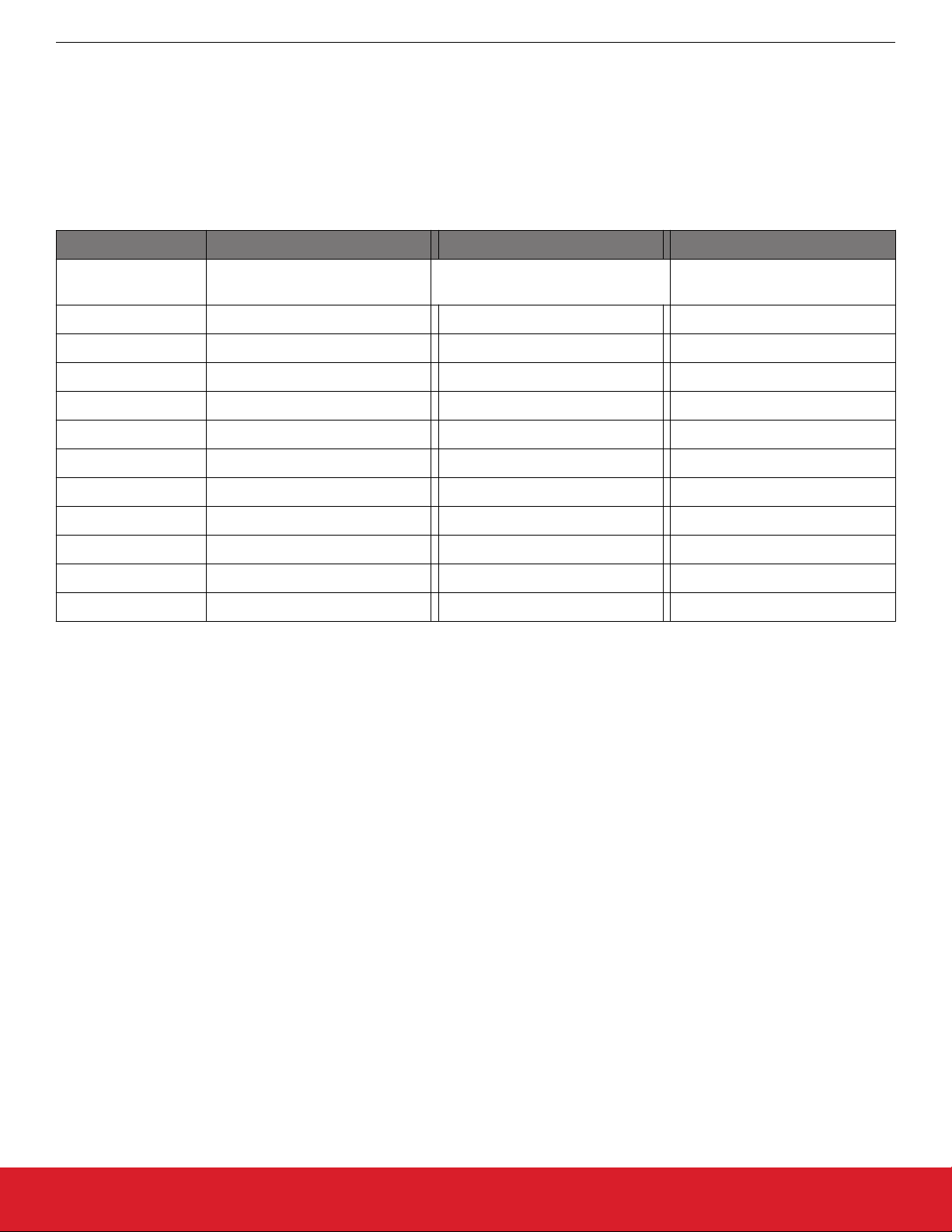

List all required output frequencies, Fxy, in groups denoted by Gx, where x = 0,1,2,3,4,5 and y = a,b,c. This grouping is done such that

frequencies related

to each other by rational fractions of integers between 1 and 63 are in that group. For example, 100 MHz/80 MHz =

5/4 is a rational fraction. Each group Gx is associated with a single output voltage supply driver inside Si5332 and is shown in Table

6.2 Output Frequency Variables Grouping and Mapping to Actual Output Pins on page 18. The table also shows the output frequency

symbol Fxy mapped to the output name in the Si5332 pin descriptions. The integer O-dividers are denoted by hsdiv. Each Oi divider

maps to a hsdivi in the solver where i is an integer between 0 and 4. Similarly, the two Multisynth N-dividers, Nj map to IDj and j = 0 or

1. The constraints for these divider values are listed in Table 6.3 Constraints for hsdiv and id on page 19.

Table 6.2. Output Frequency Variables Grouping and Mapping to Actual Output Pins

Si5332 12-Output Part

Output Pair

Si5332 8-Output Part

Output Pair

Si5332 6-Output Part

Output Pair

Output Frequency

Variable for Solver

The Output Frequency

Group

(Future Device)

OUT0 OUT0 OUT0 F

OUT1 OUT1 OUT1 F

OUT2 F

OUT3 OUT2 OUT2 F

OUT4 OUT3 F

OUT5 F

OUT6 OUT4 OUT3 F

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 18

0A

1A

1B

2A

2B

2C

3A

G

0

G

1

G

1

G

2

G

2

G

2

G

3

Page 19

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Si5332 12-Output Part

Output Pair

(Future Device)

OUT7 OUT5 F

OUT8 F

OUT9 OUT6 OUT4 F

OUT10 OUT7 OUT5 F

OUT11 F

Field Name Value Description

hsdivMinDiv 8 The minimum divide value that the HSDIV can support

hsdivMaxDiv 255 The maximum divide value that the HSDIV can support

idMinDiv 10 The minimum divide value that the ID can support

idMaxDiv 255 The maximum divide value that the ID can support

Each output frequency Foutxy is given by:

Si5332 8-Output Part

Output Pair

Si5332 6-Output Part

Output Pair

Table 6.3. Constraints for hsdiv and id

Output Frequency

Variable for Solver

3B

3C

4A

5A

5B

The Output Frequency

Group

G

3

G

3

G

4

G

5

G

5

For the integer dividers (O0 – O4):

outxy =

F

For the fractional dividers (N0, N1):

utxy =

Fo

or N

An hsdiv

PllRefFreq that satisfies the constraints in Table 6.4 Loop BW Options on page 20. The search for VcoFreq can be broken down into

the following steps:

1. From the output frequency set, form a set of “M” non-equal frequencies. Group the (N-M) equal frequencies into the same “x” in

Foutxy grouping

2. Now form MC2 groups of {M-2} output frequencies. Find the LCM of each group and find an integer “I” that can such that:

a. vcoFreq = I*LCM can meet the constraint for vcoFreq in Table 6.1 Constraints for PLL Reference Frequency and VCO Fre-

b. List the “L” groups that provide a legal vcoFreq, i.e., a vcoFreq that satisfies the condition in step a.

Given that vcoFreq, calculate the fractional feedback divider as:

The Mn/Md

divider is common for output frequencies grouped in a given Gx. Given these constraints, the solver must first choose a

quency.

c. Choose the vcoFreq that has most number of performance critical clocks that do not need “spread spectrum” clocking as part

of the “M-2” output clocks.

Mn

=

Md

fraction is represented in register fields IDPA_INTG, IDPA_RES and IDPA_DEN

ID

PA_INTG = floor

vcoFreq

hsdivj × Rxy

vcoFreq

Nxj × Rxy

vcoFreq

pllRefFreq

128 × vcoFreq

(

pllRefFreq

)

IDPA_RES

IDPA_DEN

As can be seen from the above equations, the ratio IDPA_RES/ IDPA_DEN will always be less than 1.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 19

128 × vcoFreq

=

(

pllRefFreq

– IDPA_INTG

)

Page 20

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Note: All these register fields are 15 bits wide. Therefore, the fraction will need to truncate up to this precision. This section fully deter-

the VCO frequency, the P-divider and the feedback divider for this plan given the choice of using O-dividers {HSDIV} for M-2

mines

output clocks and N-dividers {ID} for two output clocks.

The next step will be to determine the closed loop response that is required from the PLL. The table below lists the different loop BW

settings possible and the register field value that will enable that loop BW setting:

Table 6.4. Loop BW Options

PLL_MODE Loop Bandwidth (kHz) PLL. Ref. Freq. Min (MHz) PLL. Ref. Freq. Max. (MHz)

0 ILLEGAL IF PLL MODE IS ENA-

BLED

1 350 10 15

2 250 10 15

3 175 10 15

4 500 15 30

5 350 15 30

6 250 15 30

7 175 15 30

8 500 30 50

9 350 30 50

10 250 30 50

11 175 30 50

This algorithm will result in a final solution for a VCO frequency, vcoFreq, that can then be used to calculate the O-divider, N-divider,

and R-divider values needed to derive each output frequency, Foutxy.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 20

Page 21

6.2 Programming the Clock Path

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Given a

valid VCO frequency for the M unique frequencies, segregate the N-M equal frequencies into outputs from each group Gx in

Table 6.2 Output Frequency Variables Grouping and Mapping to Actual Output Pins on page 18. When arranging outputs, care must be

taken to minimize crosstalk (without violating the constraints imposed from the grouping of output frequencies into the VDDO “banks”).

Whenever several high frequencies, fast rise time, large amplitude signals are all close to one another, the laws of physics dictate that

there will be some amount of crosstalk. The jitter of the Si5332 is low, and, therefore, crosstalk can become a significant portion of the

final measured output jitter. Some of the source of the crosstalk will be the Si5332 and some will be introduced by the PCB. For extra

fine tuning and optimization in addition to following the usual PCB layout guidelines, crosstalk can be minimized by modifying the arrangements of different output clocks:

1. Avoid adjacent frequency values that are close. A 155.52 MHz clock should not be next to a 156.25 MHz clock. If the jitter integration bandwidth goes up to 20 MHz, then keep adjacent frequencies at least 20 MHz apart.

2. Adjacent frequency values that are integer multiples of one another are okay and these outputs should be grouped accordingly.

3. Unused outputs can be used to separate clock outputs that might otherwise interfere with one another. If some outputs have tight

jitter requirements while others are relatively loose, rearrange the clock outputs so that the critical outputs are the least susceptible

to crosstalk. These guidelines typically only need to be followed by those applications that wish to achieve the highest possible

levels of jitter performance. Because CMOS outputs have large pk-pk swings and do not present a balanced load to the VDDO

supplies, CMOS outputs generate much more crosstalk than differential outputs. For this reason, CMOS outputs should be avoided

whenever possible. When CMOS is unavoidable, even greater care must be taken with respect to the above guidelines.

An output multiplexer (output mux) or crosspoint mux needs to be programmed such that each group Gx is set to the correct O-divider,

N-divider, or input clock (in the case of buffering). Each output, Foutxy, has this common divider or input clock reference that needs to

be set. The multiplexer setting that routes the correct divider/clock source to the correct group is shown in the following table.

Table 6.5. Output Mux (Crosspoint Mux) Settings

Register Field Description

Selects output mux clock for output clocks in group Gx:

0 = PLL reference clock before pre-scaler

omuxx_sel0

1 = PLL reference clock after pre-scaler

2 = Clock from input buffer 0

3 = Clock from input buffer 1

Selects output mux clock for output clocks in group Gx:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

omuxx_sel1

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from omux1_sel0

The final steps will be to program the hsdiv and id (N)

dividers. The equations below show the relationship between hsdiv, id divider

values with their associated output frequency. They also show the register fields that need to be programmed to set up the divider values correctly. The register field and the divider value are both denoted by:

divxa_div =

hs

vcoFreq

Foutxa × Rxa

The id (i.e. N) dividers are calculated as below:

xa =

id

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 21

vcoFreq

Foutxa × Rxa

Page 22

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

The ida fraction is represented in register fields IDPA_INTG, IDPA_RES and IDPA_DEN:

xA_INTG = floor

ID

128 × vcoFreq

(

Foutxa × Rxa

)

IDxA_RES

IDxA_DEN

128 × vcoFreq

=

(

Foutxa × Rxa

- IDxA_INTG

)

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 22

Page 23

6.3 Programming the Output Clock Frequency

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

The Rxy register

fields are programmed as shown in the table below. This last step completes the settings of all dividers that will result

in the frequency plan. When a valid divider solution space cannot be determined, that frequency plan is not realizable in the Si5332.

Table 6.6. Rxy to Register Field Mapping

Divider Value Register Field Description

Driver divider ratio.

R0A OUT0_DIV

0 = disabled

1–63 = divide value

Driver divider ratio.

R1A OUT1_DIV

0 = disabled

1–63 = divide value

Driver divider ratio.

R1B OUT2_DIV

0 = disabled

1–63 = divide value

Driver divider ratio.

R2A OUT3_DIV

0 = disabled

1–63 = divide value

R2B OUT4_DIV

R2C OUT5_DIV

R3A OUT6_DIV

R3B OUT7_DIV

R3C OUT8_DIV

Driver divider ratio.

0 = disabled

1–63 = divide value

Driver divider ratio.

0 = disabled

1–63 = divide value

Driver divider ratio.

0 = disabled

1–63 = divide value

Driver divider ratio.

0 = disabled

1–63 = divide value

Driver divider ratio.

0 = disabled

1–63 = divide value

Driver divider ratio.

R4A OUT9_DIV

0 = disabled

1–63 = divide value

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 23

Page 24

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Divider Value Register Field Description

Driver divider ratio.

R5A OUT10_DIV

R5B OUT11_DIV

0 = disabled

1–63 = divide value

Driver divider ratio.

0 = disabled

1–63 = divide value

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 24

Page 25

6.4 Programming the Output Clock Format

The following tables provide the method to fully define every driver.

Table 6.7. Driver Set Up Options

Driver Register Field Description

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Driver for output OUTx

OUTx_mode

OUTx _skew

OUTx _stop_highz

OUTx _cmos_inv

OUTx _cmos_slew

OUTx _cmos_str

Software interpreted driver configuration. See Table 6.8 Driver

Mode Options

on page 25.

Skew control. Programmed as an unsigned integer. Can add delay of 35 ps/step up to 280 ps.

Driver output state when stopped.

0 = low-z

1 = high-z

Sets the polarity of the two outputs in dual CMOS mode

0 = no inversion

1 = OUTx~ inverted

Controls CMOS slew rate from fast to slow.

00 = fastest

01 = slow

10 = slower

11 = slowest

CMOS output impedance control.

0 = 50 Ω

1 = 25 Ω

Table 6.8. Driver Mode Options

drvxy_MODE Driver Mode

0 off

1 CMOS on positive output only

2 CMOS on negative output only

3 dual CMOS outputs

4 2.5 V/3.3 V LVDS

5 1.8 V LVDS

6 2.5 V/3.3 V LVDS fast

7 1.8 V LVDS fast

8 HCSL 50 Ω (external termination)

9 HCSL 50 Ω (internal termination)

10 HCSL 42.5 Ω (external termination)

11 HCSL 42.5 Ω (internal termination)

12 LVPECL

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 25

Page 26

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

drvxy_MODE Driver Mode

13 Reserved

14 Reserved

15 Reserved

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 26

Page 27

6.5 Programming for Frequency Select Operations

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Every hsdiv and id

dividers. Any FS frequency will be:

Or

Any output associated with either idxa

divider is as shown in table below.

Register Field Description

hsdivx_div_sel

idx_cfg_sel

has a Bank A and a Bank B divider. The register field names that begin with hsdivxb or idxb denote Bank B

Table 6.9. The Control Register Bit to Switch Frequencies

Selects bank A or bank B divider HSDIV0 settings. The HSDIV0 supports dynamic integer divider

changes through this divider select control bit.

0 = bank A divider

1 = bank B divider

Output interpolative divider 0 configuration bank select. The interpolative divider supports dynamically switching between two complete configurations controlled by this bit. Reconfiguration should

be done on the unselected bank. If ID0_CFG=0, running based off bank A, then bank B may be

freely reconfigured and once ready all changes will be applied to the ID once ID0_CFG=1 thus

changing the ID from bank A to bank B. Spread spectrum enable fields ID0A_SS_ENA and

ID0B_SS_ENA are the only exception and may be enabled/disabled while bank is selected.

or hsdivxa

utx yFS =

Fo

utx yFS =

Fo

can be switched into the above FS frequency. The control that selects the Bank B

vcoFreq

idxb

vcoFreq

hsdivb

0 = bank A

1 = bank B

In a factory-programmed part, a pin (the FS pin) can be used for the same purpose as the control registers. Once a control bit is set, the

backup divider values control the output frequency and that is described by the equations below:

For O-Divider

s

divxb_div =

h

For N-Divider

xb =

id

The ida fraction is represented in register fields IDPB_INTG, IDPB_RES and IDPB_DEN

DxB

_INTG = floor

I

IDxB_RES

IDxB_DEN

As can be seen from the equations above, the backup divider values limit the possible values for the output frequency in this backup

mode. Another

quency updates is to program either divider a or b (when divider b or a is currently driving the output frequency), and then switch this

divider.

key feature is that the switch to a FS frequency is “glitchless”. Therefore, the recommended method for glitchless fre-

=

Foutxb × Rxa

128 × vcoFreq

(

Foutxb × Rxa

vcoFreq

Foutxb × Rxa

vcoFreq

128 × vcoFreq

(

Foutxb × Rxa

- IDxB_INTG

)

)

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 27

Page 28

6.6 Programming Spread Spectrum

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

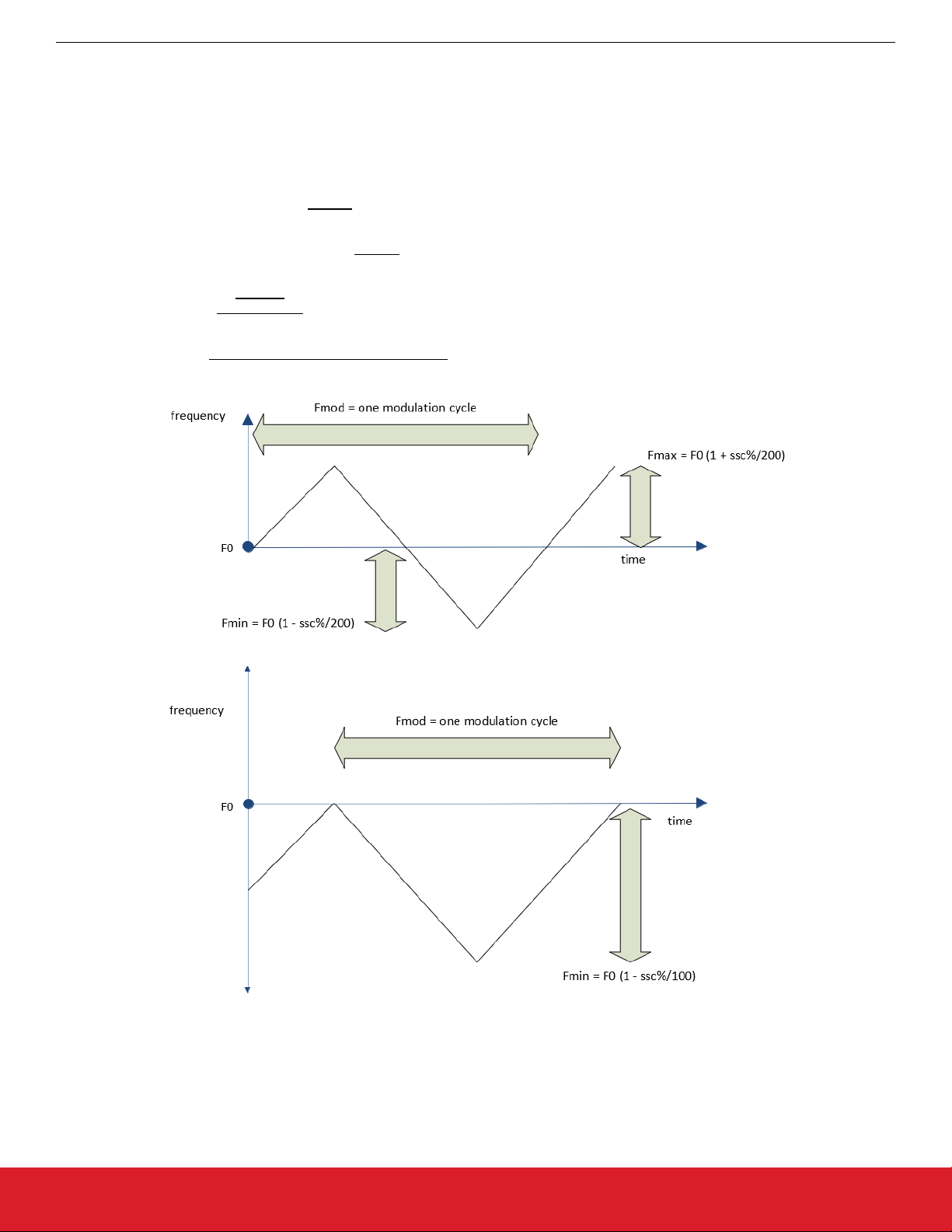

Spread spectrum

clocking (SSC) is available only on the Multisynth outputs. Each Multisynth can implement spread spectrum in either

the main divider or the backup divider (the FS option). Therefore, the user can program a maximum of four different spread spectrum

“profiles” from the same part, although only two profile are available on outputs at any given time. The amplitude of the SSC clock frequency (as illustrated in the figure below) is denoted by ssc%. The variable, Amod, in the equation below is a real number

representation of the ssc%, which is a percentage value. The modulation rate (also illustrated in the figure below) is denoted by Fmod

in the equations below.

For Down Spread:

For Center Spread:

idxy_ss_step_num =

idxy_ss_step_res =

Amod =

A

mod = 2 ×

vcoFreq

idxy

Fmod × 4

Amod × idxy_den × idxy × 128

2 × idxy_ss_step_num

ssc %

100

ssc %

100

Figure 6.2. Center and Down Spread SSC Clocks as Frequency vs Time

The table below shows the register fields (and terms) idxy_ss_step_num and idxy_ss_step_res

. idxy_ss_step_num is the number of

frequency steps between the mean and the maximum/minimum frequencies in SSC clocking and idxy_ss_step_res is the frequency

resolution that is required in each step. The goal is to maximize the number of steps and minimize the resolution. However, the number

of steps is set by the modulation rate (typically 30–33 kHz). The step resolution can be minimized by setting the largest value possible

for idxy_den. Idxy_den is the denominator of the id divider and setting it as close as possible to 215 – 1 is desired.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 28

Page 29

idxy_ss_ena

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Programming the Volatile Memory (Registers)

Table 6.10. SSC Register Fields

Spread spectrum enable. This is the only bank configuration field which may be changed dynamically while the bank is selected as the active bank. Users may freely enable/disable spread spectrum.

0 = spread spectrum disabled

1 = spread spectrum enabled

Spread spectrum mode.

0 = disabled

idxy_ss_mode

1 = center

2 = invalid

3 = down

idxy_ss_clk_num Number of output clocks for each frequency step.

idxy_ss_step_num

idxy_ss_step_intg Divide ratio spread step size.

idxy_ss_step_res Numerator of spread step size error term.

idxy_ss_step_den Denominator of spread step size error term.

To enable SSC, idxy_ss_ena needs

Number of frequency steps in one quarter SSC modulation period, allows for frequency step every

output clock.

to be set and the right mode selected in idxy_ss_mode. The number of output clocks in each

frequency step, idxy_ss_clk_num, needs to be set to 1 and idxy_ss_step_den is the same as idxy_den and idxy_ss_step_intg is

always zero.

The following flow needs to be followed to program the registers into Si5332:

1. Write 0x01h to register 0x06h and put the Si5332 into the READY state.

2. Write all the relevant registers as calculated from the steps above.

3. Ensure that the valid input clocks are available for the Si5332 to attempt a PLL lock.

4. Write 0x02h to register 0x06h and put the Si5332 into the ACTIVE state.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 29

Page 30

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Si5332 Pinout and Package Variant

7. Si5332 Pinout and Package Variant

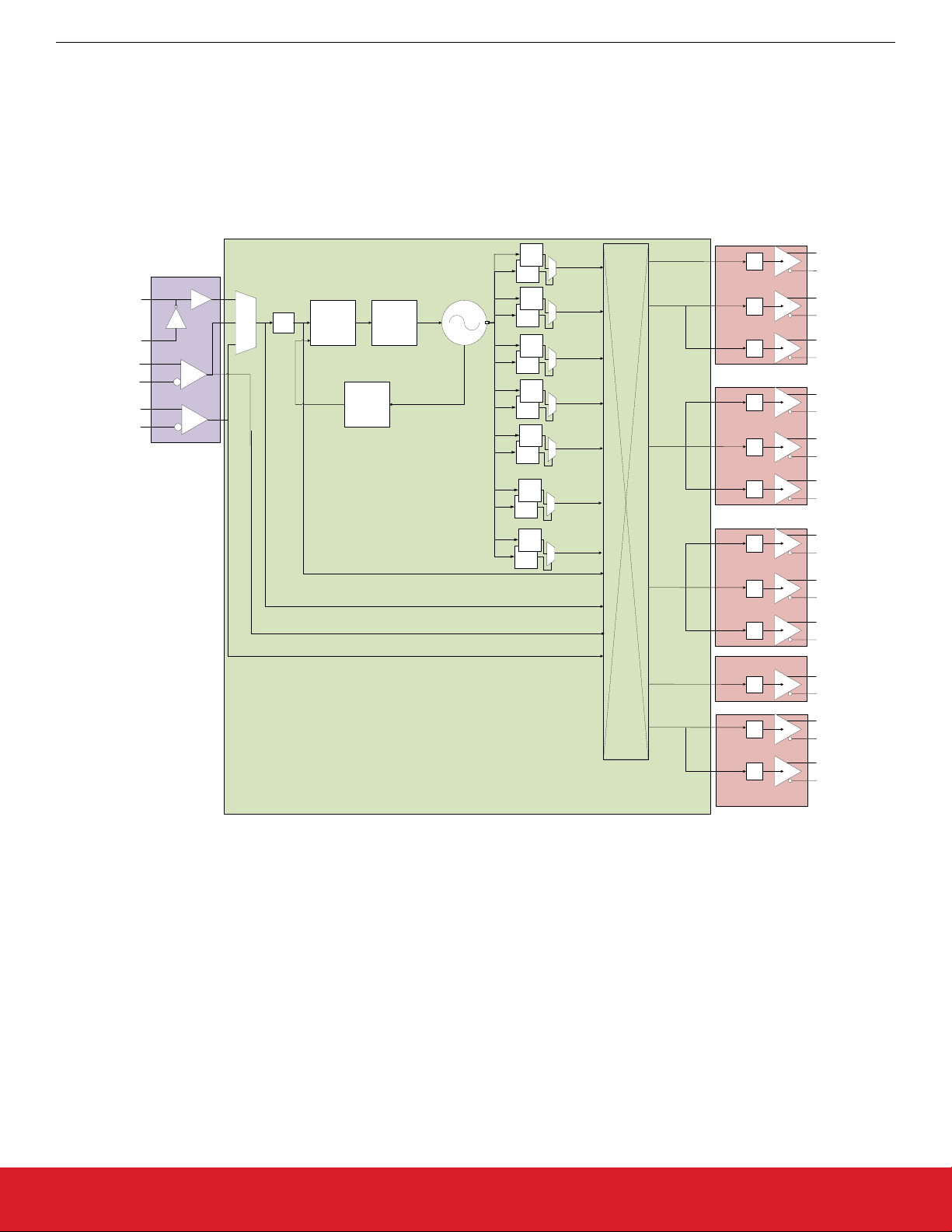

There are three versions of the Si5332 available for customers. The pinout for each is shown in the figures below.

Figure 7.1. 12-Output Si5332 7x7 mm QFN Package

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 30

Page 31

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Si5332 Pinout and Package Variant

Figure 7.2. 8-Output Si5332 6x6 mm QFN Package

Figure 7.3. 6-Output Si5332 5x5 mm QFN Package

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 31

Page 32

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Recommended Schematic and Layout Practices

8. Recommended Schematic and Layout Practices

The Si5332 schematic and layout design can be referenced from the respective EVB design for Si5332. For each package, the User’s

Guide (links below) outlines the EVB design and provides links to schematic and layout references for each package type.

• UG398: Si5332-8A-EVB User's Guide

• UG397: Si5332-6A-EVB User's Guide

• UG462: Si5332-12A-EVB User’s Guide

At the schematic/placement/layout design time, these are the following guidelines:

1. Power supply filtering:

a. The Si5332 can tolerate up to 100 mV (+/-50 mV) of noise for each supply node. The Application Note, AN1107: Si5332 Pow-

er Supply Noise Rejection, provides the performance to be expected with such a noise.

i. As can be seen, this noise can be from a switched mode power supply (which causes noise over a wide band of frequen-

cies) or can be noise due to some oscillatory behavior from an LDO regulator.

ii. The only filtering needed on each supply node is a 1 μF and a 0.1 μF placed as close as possible to that node.

iii. The Si5332 EVBs have a much larger capacitance on the regulator end, mainly to compensate for the regulator loop so

that there is no oscillatory behavior from the regulators regardless of the voltage supply value set for that regulator. The

regulator supply design on the EVB is not required for Si5332 in system designs.

2. Crystal placement:

a. The crystals should be placed as close as possible to the XA/XB pins. This placement ensures that the crystal oscillator traces

do not cause undue delays and hence, cause either an unusually long crystal start up time or get susceptible to crosstalk and

thereby increase jitter on the output clocks.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 32

Page 33

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

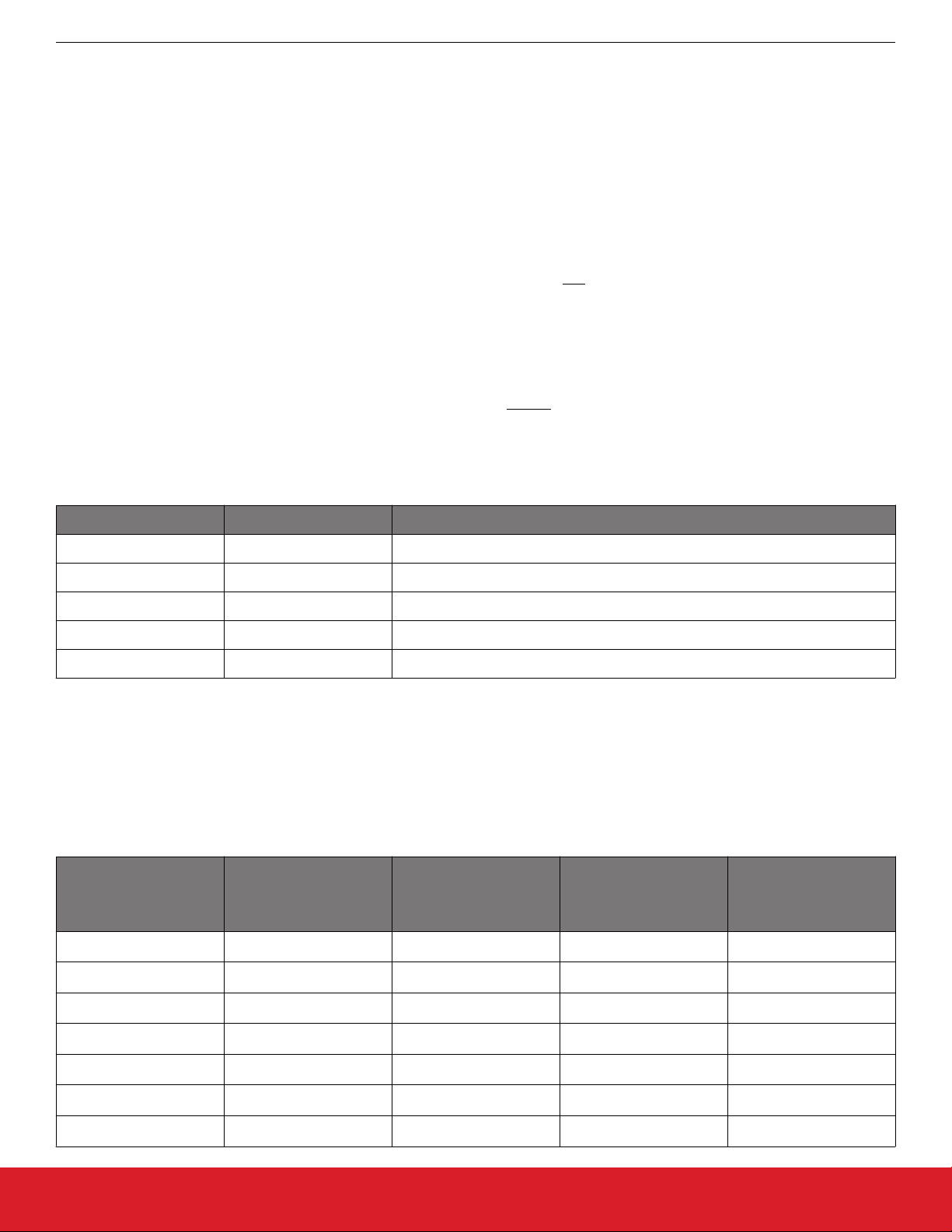

9. Register Map Overview

All common registers are listed in the table below. The registers that are specific to the 32-QFN part are listed in Si5332 32-QFN Regis-

ters. The registers that are specific to the 40-QFN part are listed in Si5332 40-QFN Registers. The registers that are specific to the 48-

QFN part are listed in Si5332 48-QFN Registers. The fields in these tables are the register field name, address, base, bit length, “R/W/

RW”, description, and device mode. Note that all registers hold values that are "big-endian" (i.e., bit 7 is the MSB in an eight-bit field).

The definitions for these fields are as follows:

1. Register Field Name: The name for the register field in this FRM as referenced in the tables below and in other sections in this

FRM.

2. Address: The 8-bit register address to be used in the I2C transactions when the register field needs to be addressed.

3. Base: Every register field address addresses an 8-bit wide location. However, the register field may not occupy that entire location.

In those cases, they may also not start at the LSB (i.e., bit #0 of that location). Base provides the bit #i from which this register field

begins in the addressed location.

4. Bit Length: Bit length indicates the “number of bits” that the register field occupies in the addressed location.

5. R/W/RW: This field indicates if the register field is Read only (R), Write only (W) or Read/Write (RW).

6. Description: Description is an explanation on the purpose and programmability offered by the register field.

7. Device Mode: Device mode is the mode of Si5332 in which the register field can be accessed. Si5332 has two modes of function

“READY” where the Si5332 is ready for programming in which time there will no outputs from Si5332 and “ACTIVE” where the

Si5332 is actively locked to an input and is providing outputs. Some register fields can be programmed in either READY or ACTIVE

mode (READY/ACTIVE) whereas others can only be programmed in READY mode (READY). Device mode provides input on

which mode applies to a register field a user intends to modify.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 33

Page 34

9.1 Si5332 Common Registers

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Table 9.1. Si5332 Register Map

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

VDD_XTAL_OK 5 7 1 R Flag that VDD_XTAL is greater than its min-

imum level, which is about 1.5 V.

VDDO_OK 5 0 6 R Each bit in the VDDO_OK register field indi-

cates a specific VDDO supply is above 1.2

V, with bit position corresponding to VDDO

supply number. Bit 0 is VDDO0 status, Bit 1

is VDDO1 status, Bit 2 is VDDO2 status,

and so on up to Bit 5 is VDDO5 status.

USYS_CTRL 6 0 8 RW User System Control. Use this write-only

register to command the device to transition

to ACTIVE or READY state. (Use

USYS_STAT to read present state.) Writing

0x01 to command device to enter READY

state, write 0x02 to enter ACTIVE state.

USYS_STAT 7 0 8 R User System Status. This read-only register

indicates the present device operational

state. Can be used with USYS_CTRL to

confirm device has entered the commanded

state (i.e., ACTIVE or READY). Reading

0x01 indicates in READY state, 0x02 indicates in ACTIVE state. If 0x89 is read this

indicates device has not detected an input

clock source and can't proceed to ACTIVE

state.

READY/ ACTIVE

READY/ ACTIVE

READY/ ACTIVE

UDRV_OE_ENA 8 0 1 RW User master output enable. Resets to 1.

READY/ ACTIVE

This bit controls simultaneously the driver

start for all drivers.

USER_SCRATCH0 9 0 8 RW

USER_SCRATCH1 A 0 8 RW

User scratch pad registers, freely R/W any

time. This is just run time scratch area, not

READY/ ACTIVE

initialized from NVM. The reset value is

USER_SCRATCH2 B 0 8 RW

USER_SCRATCH3 C 0 8 RW

0x00 for all bytes. Can be I2C read and

written any time.

DEVICE_PN_BASE D 0 8 R Device part number (For CBPro use) READY/ ACTIVE

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 34

Page 35

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

DEVICE_REV E 0 8 R Device revision (For CBPro use) READY/ ACTIVE

DEVICE_GRADE F 0 8 R Device grade information (For CBPro use)

FACTORY_OPN_ID0 10 0 4 R The Orderable part number identification,

OPN ID-0.

Example:

For Si5332AD9876

5-AM1, ID-0 = 5.

FACTORY_OPN_ID1 10 4 4 R The Orderable part number identification,

OPN ID-1.

Example:

For Si5332AD987

65-AM1, ID-1 = 6.

FACTORY_OPN_ID2 11 4 4 R The Orderable part number identification,

OPN ID-2.

Example:

For Si5332AD98765-AM1, ID-2 = 7.

FACTORY_OPN_ID3 11 0 4 R The Orderable part number identification,

OPN ID-3.

Example:

For Si5332AD98765-AM1, ID-3 = 8.

FACTORY_OPN_ID4 12 0 4 R The Orderable part number identification,

OPN ID-4.

Example:

For Si5332AD98765-AM1, ID-4 = 9.

FACTORY_OPN_RE-

VISION

DESIGN_ID0 17 0 8 R

DESIGN_ID1 18 0 8 R

12 4 4 R The Orderable part number's product revi-

sion number.

READY/ ACTIVE

Design identification set by user in CBPro

project file

DESIGN_ID2 19 0 8 R

I2C_ADDR 21 0 7 R I2C mode device address. Reset value is

110_1010 binary.

I2C_SCL_PUP_ENA 23 0 1 RW Enable 50 kΩ pullup resistor on SCL pad. READY/ ACTIVE

I2C_SDA_PUP_ENA 23 1 1 RW Enable 50 kΩ pullup resistor on SDA pad. READY/ ACTIVE

OMUX0_SEL0 25 0 2 RW Selects output mux clock source for output

READY/ ACTIVE

clocks in group G0:OUT0 for AM1, AM2:

0 = PLL reference clock before pre-scaler

1 = PLL reference clock after pre-scaler

2 = Clock from input buffer CLKIN_2

3 = Clock from input buffer CLKIN_3

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 35

Page 36

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

OMUX0_SEL1 25 4 3 RW Selects output mux clock source for output

clocks in group G0:OUT0 for AM1, AM2:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from OMUX0_SEL0

Note that the OMUX0_SEL1 value is forced

to 7 whenever the PLL is disabled

OMUX1_SEL0 26 0 2 RW Selects output mux clock source for output

clocks in group G1: OUT1 for AM1, AM2:

0 = PLL reference clock before pre-scaler

1 = PLL reference clock after pre-scaler

READY/ ACTIVE

READY/ ACTIVE

2 = Clock from input buffer CLKIN_2

3 = Clock from input buffer CLKIN_3

OMUX1_SEL1 26 4 3 RW Selects output mux clock source for output

clocks in group G1: OUT1 for AM1, AM2:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from OMUX1_SEL0

Note that the OMUX1_SEL1 value is forced

to 7 whenever the PLL is disabled

OMUX2_SEL0 27 0 2 RW Selects output mux clock source for output

clocks in group G2: OUT2 for AM1; OUT2,

OUT3 for AM2:

0 = PLL reference clock before pre-scaler

READY/ ACTIVE

READY/ ACTIVE

1 = PLL reference clock after pre-scaler

2 = Clock from input buffer CLKIN_2

3 = Clock from input buffer CLKIN_3

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 36

Page 37

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

OMUX2_SEL1 27 4 3 RW Selects output mux clock source for output

clocks in group G2: OUT2 for AM1; OUT2,

OUT3 for AM2:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from OMUX2_SEL0

Note that the OMUX2_SEL1 value is forced

to 7 whenever the PLL is disabled

OMUX3_SEL0 28 0 2 RW Selects output mux clock source for output

clocks in group G3: OUT3 for AM1; OUT4,

OUT5 for AM2:

0 = PLL reference clock before pre-scaler

READY/ ACTIVE

READY/ ACTIVE

1 = PLL reference clock after pre-scaler

2 = Clock from input buffer CLKIN_2

3 = Clock from input buffer CLKIN_3

OMUX3_SEL1 28 4 3 RW Selects output mux clock source for output

clocks in group G3: OUT3 for AM1; OUT4,

OUT5 for AM2:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from OMUX3_SEL0

Note that the OMUX3_SEL1 value is forced

to 7 whenever the PLL is disabled

OMUX4_SEL0 29 0 2 RW Selects output mux clock source for output

clocks in group G4: OUT4 for AM1; OUT6

for AM2:

READY/ ACTIVE

READY/ ACTIVE

0 = PLL reference clock before pre-scaler

1 = PLL reference clock after pre-scaler

2 = Clock from input buffer CLKIN_2

3 = Clock from input buffer CLKIN_3

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 37

Page 38

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

OMUX4_SEL1 29 4 3 RW Selects output mux clock source for output

clocks in group G4: OUT4 for AM1; OUT6

for AM2:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from OMUX4_SEL0

Note that the OMUX4_SEL1 value is forced

to 7 whenever the PLL is disabled

OMUX5_SEL0 2A 0 2 RW Selects output mux clock source for output

clocks in group G5: OUT5 for AM1; OUT7

for AM2:

0 = PLL reference clock before pre-scaler

READY/ ACTIVE

READY/ ACTIVE

1 = PLL reference clock after pre-scaler

2 = Clock from input buffer CLKIN_2

3 = Clock from input buffer CLKIN_3

OMUX5_SEL1 2A 4 3 RW Selects output mux clock source for output

READY/ ACTIVE

clocks in group G5: OUT5 for AM1; OUT7

for AM2:

0 = HSDIV0

1 = HSDIV1

2 = HSDIV2

3 = HSDIV3

4 = HSDIV4

5 = ID0

6 = ID1

7 = Clock from OMUX5_SEL0

Note that the OMUX5_SEL1 value is forced

to 7 whenever the PLL is disabled

HSDIV0A_DIV 2B 0 8 RW O0 divider value READY if divider is

currently driving the

output else,

READY/ACTIVE

HSDIV0B_DIV 2C 0 8 RW O0 divider value for bank A

HSDIV1A_DIV 2D 0 8 RW O1 divider value for bank A

HSDIV1B_DIV 2E 0 8 RW O1 divider value for bank B

HSDIV2A_DIV 2F 0 8 RW O2 divider value for bank A

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 38

Page 39

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

HSDIV2B_DIV 30 0 8 RW O2 divider value for bank B

HSDIV3A_DIV 31 0 8 RW O3 divider value for bank A

HSDIV3B_DIV 32 0 8 RW O3 divider value for bank B

HSDIV4A_DIV 33 0 8 RW O4 divider value for bank A

HSDIV4B_DIV 34 0 8 RW O4 divider value for bank B

HSDIV3_DIV_SEL 35 3 1 RW Selects bank A (0) or bank B (1) O3 divider

settings. Same description applies as for

HSDIV0_DIV_SEL.

ID0_CFG_SEL 35 6 1 RW N0 configuration bank select. The divider

supports dynamically switching between

two complete configurations controlled by

this bit. Reconfiguration should be done on

the unselected bank. If ID0_CFG=0, running based off bank A, then bank B may be

freely reconfigured and once ready all

changes will be applied to the ID once

ID0_CFG=1 thus changing the ID from

bank A to bank B. Spread spectrum enable

fields ID0A_SS_ENA and ID0B_SS_ENA

are the only exception and may be enabled/

disabled while bank is selected.

READY/ ACTIVE

READY/ ACTIVE

0 = bank A

1 = bank B

HSDIV4_DIV_SEL 35 4 1 RW Selects bank A (0) or bank B (1) O4 divider

settings. Same description applies as for

HSDIV0_DIV_SEL.

ID1_CFG_SEL 35 7 1 RW N1 configuration bank select. Same de-

scription related to ID1 applies as in the

ID0_CFG description.

0 = bank A

1 = bank B

HSDIV2_DIV_SEL 35 2 1 RW Selects bank A (0) or bank B (1) O2 divider

settings. Same description applies as for

HSDIV0_DIV_SEL.

HSDIV0_DIV_SEL 35 0 1 RW Selects bank A or bank B divider O0 set-

tings. O0 supports dynamic integer divider

changes through this divider select control

bit.

0 = bank A divider

1 = bank B divider

HSDIV1_DIV_SEL 35 1 1 RW Selects bank A (0) or bank B (1) O1 divider

settings. Same description applies as for

HSDIV0_DIV_SEL.

READY/ ACTIVE

READY/ ACTIVE

READY/ ACTIVE

READY/ ACTIVE

READY/ ACTIVE

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 39

Page 40

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

ID0A_INTG 36 0 15 RW The terms of an a + b/c desired divider set-

ting must be processed into ID0A_INTG,

ID0A_RES, and ID0A_DEN register terms.

INTG = floor(((a*c+b)*128/c) - 512).

ID0A_RES 38 0 15 RW res = mod(b*128, c)

ID0A_DEN 3A 0 15 RW den = c

ID0A_SS_ENA 3C 0 1 RW Spread spectrum enable. This is the only

bank configuration field which may be

changed dynamically while the bank is selected as the active bank. Users may freely

enable/disable spread spectrum.

0 = spread spectrum disabled

1 = spread spectrum enabled

ID0A_SS_MODE 3C 1 2 RW Spread spectrum mode.

0 = disabled

1 = center

2 = invalid

READY if divider is

currently driving the

output, else,

READY/ACTIVE

READY if divider is

currently driving the

output, else,

READY/ACTIVE

3 = down

ID0A_SS_STEP_NUM 3D 0 12 RW Number of frequency steps in one quarter

SSC modulation period, allows for frequency step every output clock.

ID0A_SS_STEP_INTG 3F 0 12 RW Divide ratio spread step size.

ID0A_SS_STEP_RES 40 0 15 RW Numerator of spread step size error term.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 40

Page 41

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

ID0B_INTG 42 0 15 RW The terms of an a + b/c desired divider set-

ting must be processed into ID0B_INTG,

ID0B_RES, and ID0B_DEN register terms.

INTG = floor(((a*c+b)*128/c) - 512).

ID0B_RES 44 0 15 RW res = mod(b*128, c)

ID0B_DEN 46 0 15 RW den = c

ID0B_SS_ENA 48 0 1 RW Spread spectrum enable. This is the only

bank configuration field which may be

changed dynamically while the bank is selected as the active bank. Users may freely

enable/disable spread spectrum.

0 = spread spectrum disabled

1 = spread spectrum enabled

ID0B_SS_MODE 48 1 2 RW Spread spectrum mode.

0 = disabled

1 = center

2 = invalid

READY if divider is

currently driving the

output, else,

READY/ACTIVE

3 = down

ID0B_SS_STEP_NUM 49 0 12 RW Number of frequency steps in one quarter

SSC modulation period, allows for frequency step every output clock.

ID0B_SS_STEP_INTG 4B 0 12 RW Divide ratio spread step size.

ID0B_SS_STEP_RES 4C 0 15 RW Numerator of spread step size error term.

ID1A_INTG 4E 0 15 RW The terms of an a + b/c desired interpola-

tive divider setting must be processed into

ID1A_INTG, ID1A_RES, and ID1A_DEN

register terms. INTG = floor(((a*c+b)*128/c)

- 512).

ID1A_RES 50 0 15 RW res = mod(b*128, c)

ID1A_DEN 52 0 15 RW den = c

READY if divider is

currently driving the

output, else,

READY/ACTIVE

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 41

Page 42

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

ID1A_SS_ENA 54 0 1 RW Spread spectrum enable. This is the only

bank configuration field which may be

changed dynamically while the bank is selected as the active bank. Users may freely

enable/disable spread spectrum.

0 = spread spectrum disabled

1 = spread spectrum enabled

ID1A_SS_MODE 54 1 2 RW Spread spectrum mode.

0 = disabled

1 = center

2 = invalid (up)

3 = down

ID1A_SS_STEP_NUM 55 0 12 RW Number of frequency steps in one quadrate,

allows for frequency step every output

clock.

ID1A_SS_STEP_INTG 57 0 12 RW Divide ratio spread step size.

ID1A_SS_STEP_RES 58 0 15 RW Numerator of spread step size error term.

READY if divider is

currently driving the

output, else,

READY/ACTIVE

ID1B_INTG 5A 0 15 RW The terms of an a + b/c desired interpola-

tive divider setting must be processed into

ID1A_INTG, ID1A_RES, and ID1A_DEN

register terms. INTG = floor(((a*c+b)*128/c)

- 512).

ID1B_RES 5C 0 15 RW res = mod(b*128, c)

ID1B_DEN 5E 0 15 RW den = c

ID1B_SS_ENA 60 0 1 RW Spread spectrum enable. This is the only

bank configuration field which may be

changed dynamically while the bank is selected as the active bank. Users may freely

enable/disable spread spectrum.

0 = spread spectrum disabled

1 = spread spectrum enabled

ID1B_SS_MODE 60 1 2 RW Spread spectrum mode.

0 = disabled

1 = center

2 = invalid (up)

3 = down

READY if divider is

currently driving the

output, else,

READY/ACTIVE

ID1B_SS_STEP_NUM 61 0 12 RW Number of frequency steps in one quadrate,

allows for frequency step every output

clock.

ID1B_SS_STEP_INTG 63 0 12 RW Divide ratio spread step size.

ID1B_SS_STEP_RES 64 0 15 RW Numerator of spread step size error term.

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 42

Page 43

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

IDPA_INTG 67 0 15 RW The terms of an a + b/c desired divider set-

ting must be processed into IDPA_INTG,

IDPA_RES, and IDPA_DEN register terms.

INTG = floor(((a*c+b)*128/c) - 512).

IDPA_RES 69 0 15 RW res = mod(b*128, c) READY

IDPA_DEN 6B 0 15 RW den = c READY

PDIV_DIV 75 0 5 RW Chooses the PLL prescalar divide ratio. READY

USYS_START B8 0 8 RW User defined application startup behavior.

Flags for SW what to do at the startup, for

example moving to ACTIVE on its own

upon startup or waiting in READY state for

a command. Used only upon startup, Initialized from NVM.

PLL_MODE BE 2 4 RW Sets PLL BW. See Table 6.1 Constraints for

PLL Reference Frequency and VCO Frequency

on page 18.

XOSC_CINT_ENA BF 7 1 RW Enables a fixed 7.84 pf of internal loading

capacitance to values set by

XOSC_CTRIM_XA/XB registers. Refer to

Section 3.2 Calculating Crystal Loading Capacitance for information on use of this reg-

ister.

READY

READY

READY

READY

XOSC_CTRIM_XA C0 0 6 RW Load capacitance trim on XA. Refer to Sec-

tion 3.2 Calculating Crystal Loading Capacitance for information on use of this register.

XOSC_CTRIM_XB C1 0 6 RW Load capacitance trim on XB. Refer to Sec-

tion 3.2 Calculating Crystal Loading Capacitance for information on use of this register.

READY

READY

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 43

Page 44

9.2 Si5332 32-QFN Specific Registers

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Table 9.2. Si5332 32-QFN Registers

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

OUT0_MODE 7A 0 4 RW Software interpreted driver configu-

ration. See Table 6.7 Driver Set Up

Options on page

25

.

OUT0_DIV 7B 0 6 RW Driver divider ratio.

0 = disabled

1-63 = divide value

OUT0_SKEW 7C 0 3 RW Skew control. Programmed as an

unsigned integer. Can add delay of

35 ps/step up to 280 ps.

OUT0_STOP_HIGHZ 7D 0 1 RW Driver output state when stopped.

0 = low-Z

1 = high-Z

OUT0_CMOS_INV 7D 4 2 RW Sets the polarity of the two outputs

in dual CMOS mode.

0 = no inversion

1 = OUT0b inverted

OUT0_CMOS_SLEW 7E 0 2 RW Controls CMOS slew rate from fast

to slow.

READY

READY

READY

READY

READY

READY

00 = fastest

01 = slow

10 = slower

11 = slowest

OUT0_CMOS_STR 7E 2 1 RW CMOS output impedance control.

0 = 50 Ω

1 = 25 Ω

OUT1_MODE 7F 0 4 RW Software interpreted driver configu-

ration. See Table 6.7 Driver Set Up

Options on page

25

.

OUT1_DIV 80 0 6 RW Driver divider ratio.

0 = disabled

1–63 = divide value

OUT1_SKEW 81 0 3 RW Skew control. Programmed as an

unsigned integer. Can add delay of

35 ps/step up to 280 ps.

OUT1_STOP_HIGHZ 82 0 2 RW Driver output state when stopped.

0 = low-Z

READY

READY

READY

READY

READY

1 = high-Z

silabs.com | Building a more connected world. Preliminary Rev. 0.2 | 44

Page 45

Si5332-AM1/2/3 Automotive Grade Device Reference Manual

Register Map Overview

Register Field Name Address Base

Bit

Length

R/W/RW Description Device Mode

OUT1_CMOS_INV 82 4 1 RW Sets the polarity of the two outputs