WT41u

DATA SHEET

Friday, 03 February 2017

Version 1.0

VERSION HISTORY

Version Comment

0.8 First version

0.8.1 Table reformatting, value updates etc

0.8.2 Replaced “Bluecore4” with “chipset”, added ordering codes

0.8.3 Rest of table reformatting, added antenna & connector dimension drawings

0.8.4 Added current consumption, RF characteristics

0.8.5 Added certification texts

0.8.6 Added current consumption results, edit TX power variation over VDD range.

0.8.7 Slight edits to specifications

0.8.8 OPN descriptions updated

1.0 Full production

Silicon Labs

TABLE OF CONTENTS

1 Ordering Information......................................................................................................................................6

2 Pinout and Terminal Description ...................................................................................................................7

3 Electrical Characteristics ............................................................................................................................ 11

3.1 Absolute Maximum Ratings ................................................................................................................ 11

3.2 Recommended Operating Conditions ................................................................................................. 11

3.3 Input / Output Terminal Characteristics .............................................................................................. 12

3.3.1 Input/Output Terminal Characteristics (Digital) ............................................................................ 12

3.3.2 Input/Output Terminal Characteristics (USB) .............................................................................. 13

3.4 PIO Current Sink and Source Capability ............................................................................................. 13

3.5 Transmitter Performance For BDR ..................................................................................................... 14

3.6 Receiver Performance ........................................................................................................................ 15

3.7 Current Consumption .......................................................................................................................... 15

4 Physical Dimensions .................................................................................................................................. 16

5 Soldering Recommendations ..................................................................................................................... 19

6 Layout Guidelines ....................................................................................................................................... 20

7 UART Interface ........................................................................................................................................... 21

7.1 UART Bypass ...................................................................................................................................... 23

7.2 UART Configuration While Reset is Active ......................................................................................... 23

7.3 UART Bypass Mode ............................................................................................................................ 23

8 USB Interface ............................................................................................................................................. 24

8.1 USB Data Connections ....................................................................................................................... 24

8.2 USB Pull-Up resistor ........................................................................................................................... 24

8.3 USB Power Supply .............................................................................................................................. 24

8.4 Self-Powered Mode ............................................................................................................................. 24

8.5 Bus-Powered Mode ............................................................................................................................. 25

8.6 USB Suspend Current ......................................................................................................................... 26

8.7 USB Detach and Wake-Up Signaling.................................................................................................. 26

8.8 USB Driver .......................................................................................................................................... 27

8.9 USB v2.0 Compliance and Compatibility ............................................................................................ 27

9 Serial Peripheral Interface (SPI) ................................................................................................................. 28

10 PCM Codec Interface ............................................................................................................................. 29

10.1 PCM Interface Master/Slave ........................................................................................................ 29

10.2 Long Frame Sync ......................................................................................................................... 30

10.3 Short Frame Sync ........................................................................................................................ 30

10.4 Multi-slot Operation ...................................................................................................................... 31

10.5 GCI Interface ................................................................................................................................ 31

10.6 Slots and Sample Formats ........................................................................................................... 32

Silicon Labs

10.7

Additional Features ...................................................................................................................... 33

10.8 PCM_CLK and PCM_SYNC Generation ..................................................................................... 33

10.9 PCM Configuration ....................................................................................................................... 34

11 I/O Parallel Ports ..................................................................................................................................... 37

11.1 PIO Defaults ................................................................................................................................. 37

12 Reset ....................................................................................................................................................... 38

12.1 Pin States on Reset ..................................................................................................................... 39

13 Certifications ........................................................................................................................................... 40

13.1 Bluetooth ...................................................................................................................................... 40

13.2 FCC .............................................................................................................................................. 40

13.3 ISEDC .......................................................................................................................................... 41

13.3.1 ISEDC (Français) ......................................................................................................................... 41

13.4 CE ................................................................................................................................................ 42

13.5 MIC Japan .................................................................................................................................... 43

13.6 Qualified Antenna Types for WT41u-E and WT41u-N ................................................................ 44

13.7 Moisture Sensitivity Level (MSL).................................................................................................. 44

Silicon Labs

WT41u Bluetooth® Module

DESCRIPTION

WT41u is a long range class 1, Bluetooth® 2.1 +

EDR module. WT41u is a highly integrated and

sophisticated Bluetooth® module, containing all the

necessary elements from Bluetooth® radio and a

fully implemented protocol stack. Therefore, WT41u

provides an ideal solution for developers who want

to integrate Bluetooth® wireless technology into

their design with limited knowledge of Bluetooth®

and RF technologies. WT41u is optimized for long

range applications is available with an integrated

chip antenna, an RF pin for a custom on-board

antenna or a U.FL connector for an external 2dBi

dipole antenna.

By default, WT41u module is equipped with

powerful and easy-to-use iWRAP firmware. iWRAP

enables users to access Bluetooth® functionality

with simple ASCII commands delivered to the

module over serial interface - it's just like a

Bluetooth® modem.

APPLICATIONS:

• Hand held terminals

• Industrial devices

• Point-of-Sale systems

• PCs

• Personal Digital Assistants (PDAs)

• Computer Accessories

• Access Points

• Automotive Diagnostics Units

FEATURES:

• Fully Qualified Bluetooth v2.1 + EDR end

product

• CE qualified

• Full modular certification for FCC and IC

• MIC Japan compatibility fully tested with ARIB

STD-T66

• TX power: 17 dBm

• RX sensitivity: -94 dBm

• Integrated chip antenna, RF pin or U.FL

antenna connector

• Class 1, range up to 650 meters with chip

antenna or up to 1km with an external dipole

• Industrial temperature range from -40

• RoHS Compliant

• USB interface (USB 2.0 compatible)

• UART with bypass mode

• 6 x GPIO

• 1 x 8-bit AIO

• Integrated iWRAP

o

C

+85

firmware

TM

Bluetooth stack or HCI

o

C to

Silicon Labs

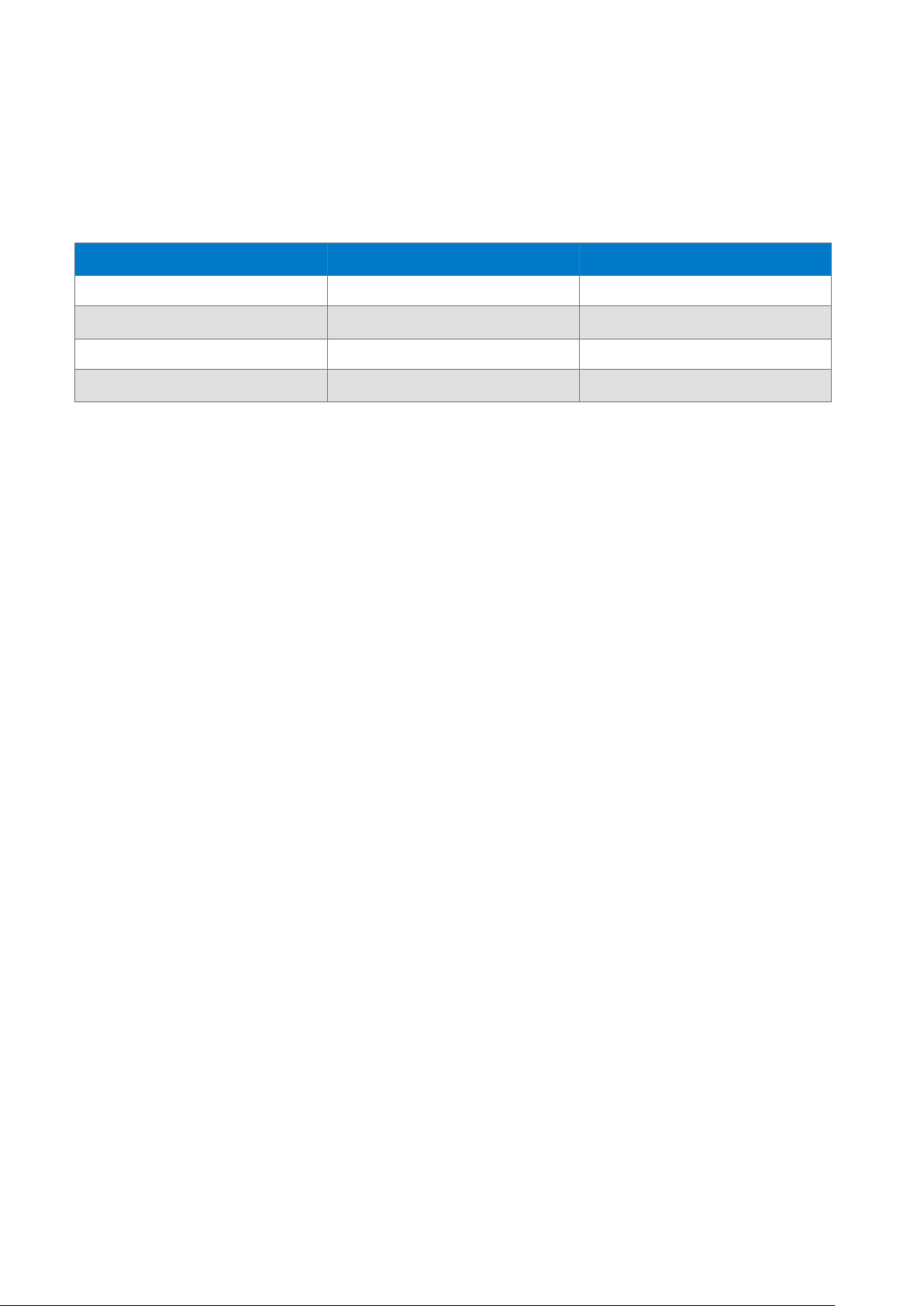

1 Ordering Information

Firmware U.FL Connector Internal chip antenna

iWRAP 5.6 firmware WT41u-E-AI56 WT41u-A-AI56

iWRAP 5.5 firmware WT41u-E-AI55 WT41u-A-AI55

iWRAP 5.0.2 firmware WT41u-E-AI5 WT41u-A-AI5

HCI firmware, BT2.1 + EDR WT41u-E-HCI21 WT41u-A-HCI21

Table 1: Ordering information

Silicon Labs

Page 6 of 44

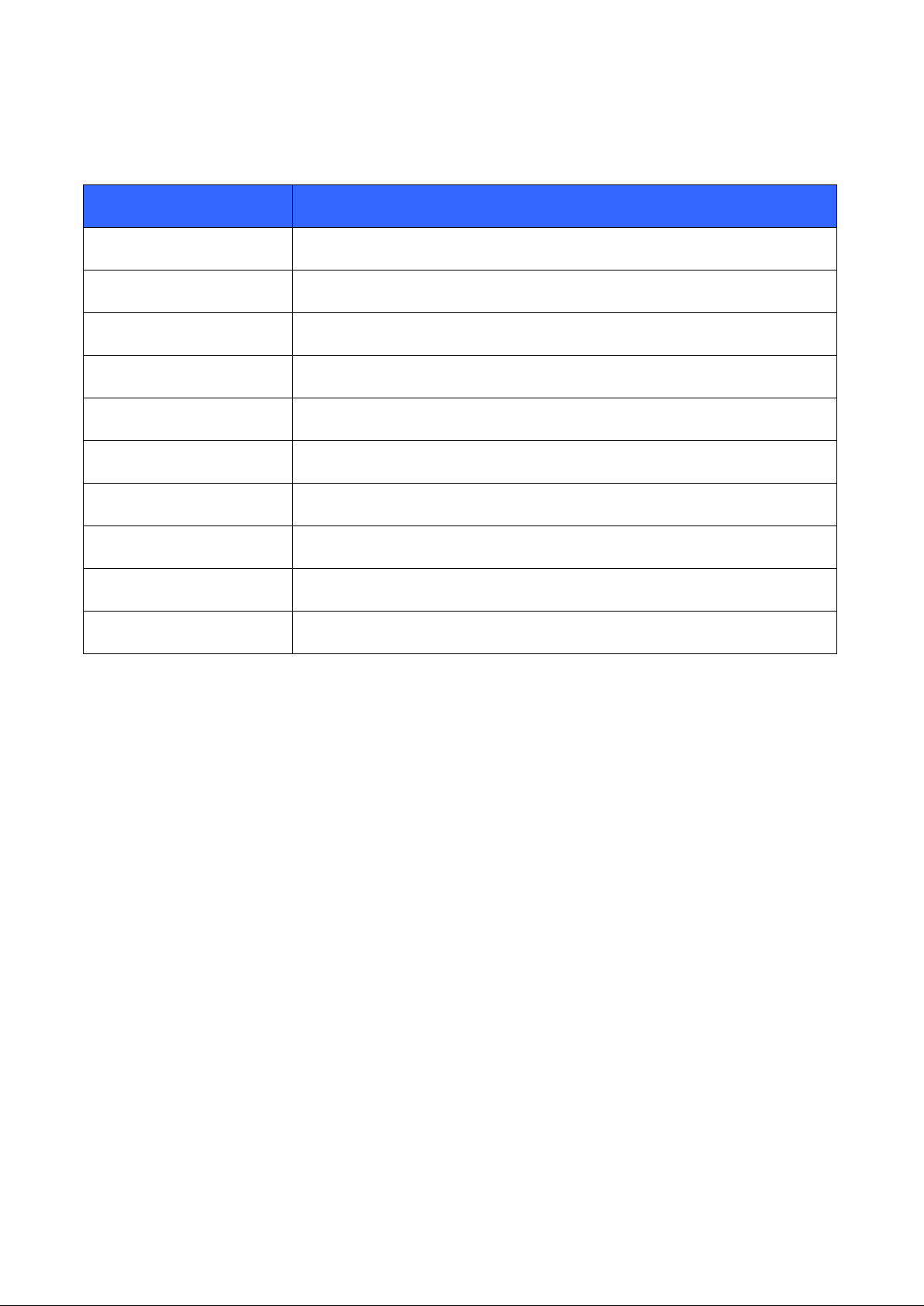

Pins 1 and 52 (GND)

are not connected

and have been

removed

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

262728

29

51

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

59

5857565554

53

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

RFGND

RF

GND

GND

GND

GND

GND

GND

VDD_PA

PIO2

PIO3

UART_RTS

UART_RX

GND

USB+

USBUART_CTS

PCM_IN

PCM_CLK

PCM_SYNC

GND

GND

GND

GND

GND

GND

PCM_OUT

PIO4

GND

VDD

RESET

PIO6

PIO7

GND

SPI_CSB

SPI_CLK

SPI_MISO

SPI_MOSI

PIO5

UART_TX

AIO

50

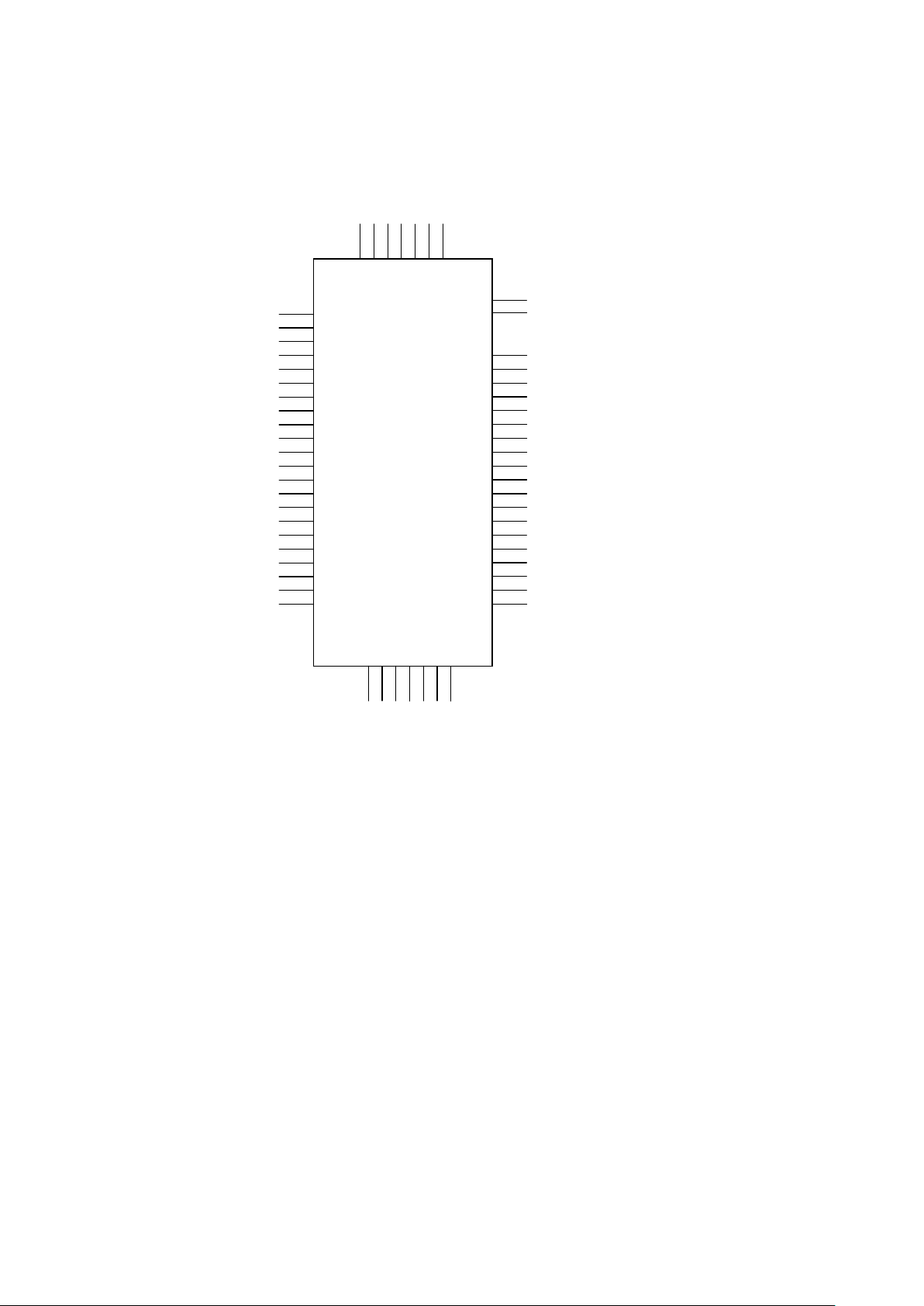

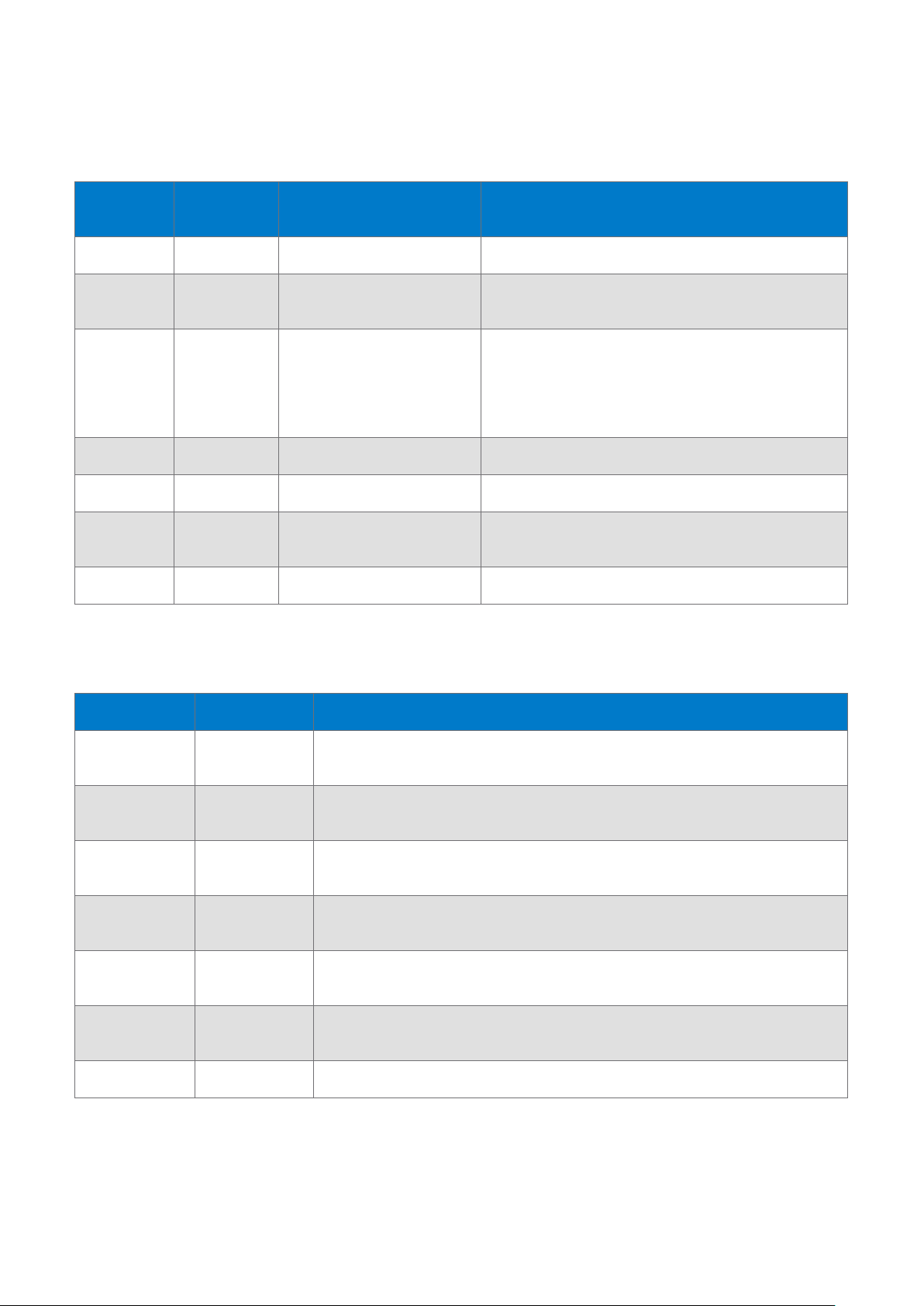

2 Pinout and Terminal Description

Figure 1: WT41u pin out

Silicon Labs

Page 7 of 44

Pad name Pad

Pad type Description

number

NC 1, 52 Not connected Pins 1 and 52 are not present on the footprint

RESET 33 Digital input Active low reset with weak internal pull-up. Ke ep

low for >5ms to reset module

GND 2-10, 16, 23,

24, 26-28,

30, 31, 36,

Ground Ground pads should all be connected to a ground

plane with minimum trace length, especially on the

antenna end of the module

44-49, 53-

59

RF 51 Not connected No internal connection

RFGND 50 Ground Connect to ground plane

VDD_PA 11 Supply voltage Supply voltage for the RF power amplifier and low

noise amplifier

VDD 32 Supply voltage Supply voltage for the Bluetooth chipset

Table 2: Supply and RF Terminal Descriptions

PIO signal Pad number Description

PIO[2] 12 Bi-directional digital in/out with programmable strength and pull-up/pull-

down

PIO[3] 13 Bi-directional digital in/out with programmable strength and pull-up/pull-

down

PIO[4] 29 Bi-directional digital in/out with programmable strength and pull-up/pull-

down

PIO[5] 41 Bi-directional digital in/out with programmable strength and pull-up/pull-

down

PIO[6] 34 Bi-directional digital in/out with programmable strength and pull-up/pull-

down

PIO[7] 35 Bi-directional digital in/out with programmable strength and pull-up/pull-

down

AIO[1] 43 Bi-directional analog in/out

Table 3: GPIO Terminal Descriptions

Silicon Labs

Page 8 of 44

Output, weak internal

Output, weak internal

UART request to send,

UART data input, active

UART clear to send,

PCM signal Pad number Pad type Description

PCM_OUT 25 Output, weak internal pull-down Synchronous data output

PCM_IN 20 Input, weak internal pull-down Synchronous data input

PCM_SYNC 22 Bi-directional, weak internal pull-down Synchronous data sync

PCM_CLK 21 Bi-directional, weak internal pull-down Synchronous data clock

Table 4: PCM Terminal Descriptions

UART signal Pad number Pad type Description

UART_TX 42

pull-up

UART data output, active

high

UART_RTS# 14

pull-up

active low

UART_RX 15 Input, weak internal pull-

down

high

UART_CTS# 19 Input, weak internal pull-

down

active low

Table 5: UART Terminal Descriptions

USB signal Pad number Pad type Description

USB+ 17 Bidirectional USB data line with internal 1.5kohm pull-up

USB- 18 Bidirectional USB data line

Table 6: USB Terminal Descriptions

Silicon Labs

Page 9 of 44

SPI signal Pad

Pad type Description

number

SPI_MOSI 40 Input, weak internal pull-down SPI data input

SPI_CS# 37 Input, weak internal pull-up Chip select, active low

SPI_CLK 38 Input, weak internal pull-down SPI clock

SPI_MISO 39 Output, weak internal pull-down SPI data output

Table 7: Terminal Descriptions

Silicon Labs

Page 10 of 44

3 Electrical Characteristics

3.1 Absolute Maximum Ratings

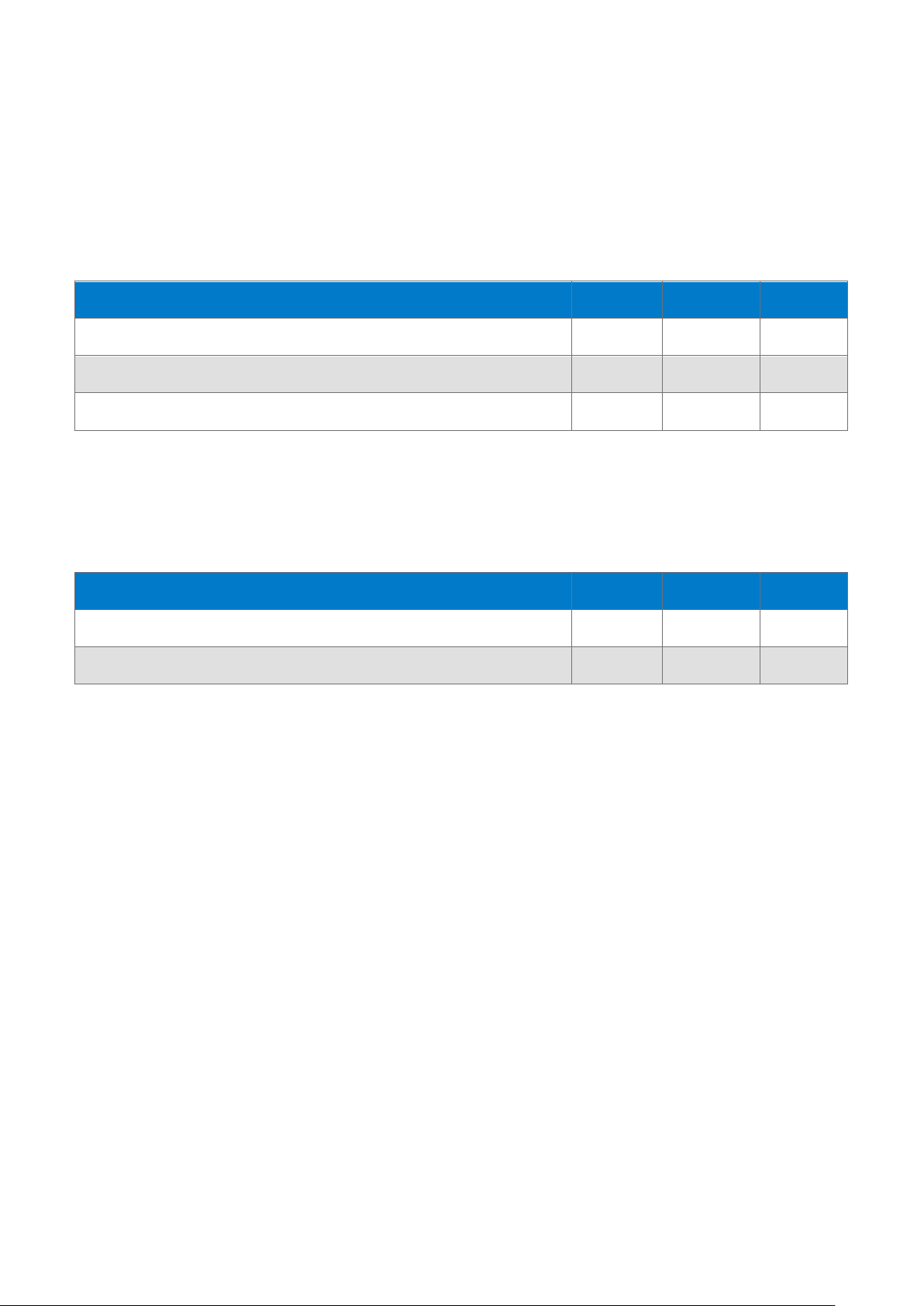

Specification Min Max Unit

Storage temperature -40 85 °C

VDD_PA, VDD -0.4 3.7 V

Other terminal voltages VSS-0.4 VDD+0.4 V

Table 8: Absolute Maximum Ratings

3.2 Recommended Operating Conditions

Specification Min Max Unit

Operating temperature -40 85 °C

VDD_PA, VDD 3.0 3.6 V

Table 9: Recommended Operating Conditions

Silicon Labs

Page 11 of 44

3.3 Input / Output Terminal Characteristics

3.3.1 Input/Output Terminal Characteristics (Digital)

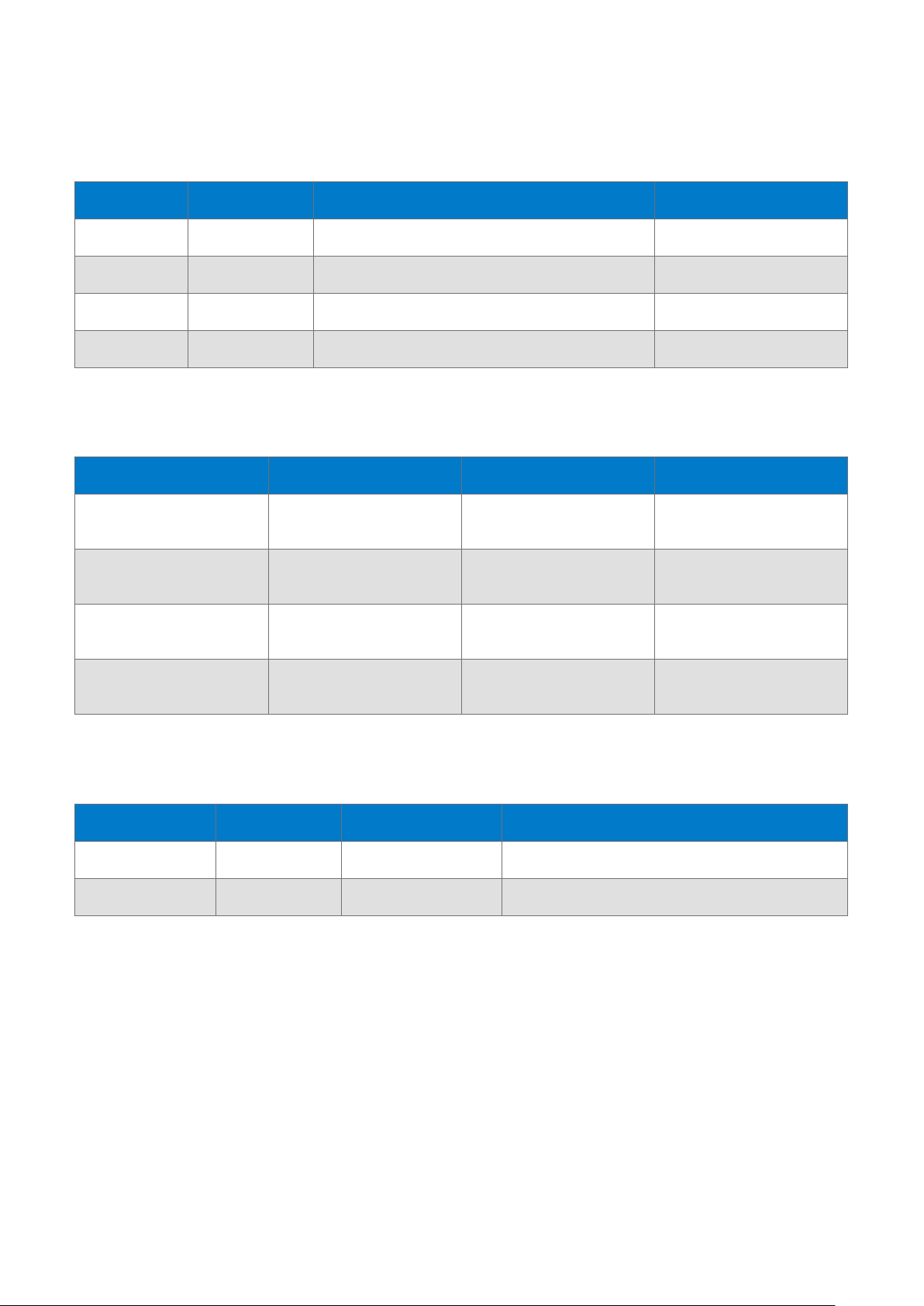

Digital Terminals Min Typ Max Unit

Input Voltage Levels

VIL input logic level low 2.7 V ≤ VDD ≤ 3.0 V -0.4 - 0.8 V

1.7 V ≤ VDD ≤ 1.9 V -0.4 - 0.4 V

VIH input logic level high 0.7 VDD - VDD + 0.4 V

Output Voltage Levels

VOL output logic level low

(IO = 4.0 mA) 2.7V ≤ VDD ≤ 3.0 V

VOL output logic level low

(IO = 4.0 mA) 1.7V ≤ VDD ≤ 1.9

VOL output logic level high

(IO = 4.0 mA) 2.7V ≤ VDD ≤ 3.0

VOL output logic level high

(IO = 4.0 mA) 1.7V ≤ VDD ≤ 1.9

Input and Tristate Current with

Strong pull-up -100 -40 -10 µA

- - 0.2 V

- - 0.4 V

VDD - 0.2 - V

VDD - 0.4 - V

Strong pull-down 10 40 100 µA

Weak pull-up -5.0 -1.0 -0.2 µA

Weak pull-down 0.2 1.0 5.0 µA

I/O pad leakage current -1 0 1 µA

CI input capacitance 1.0 - 5.0 pF

Silicon Labs

Page 12 of 44

3.3.2 Input/Output Terminal Characteristics (USB)

USB Terminals Min Typ Max Unit

VDD_USB for correct USB operation 3.1 3.6 V

Input Threshold

VIL input logic level log - - 0.3VDD_USB V

VIH input logic level high 0.7VDD_USB - - V

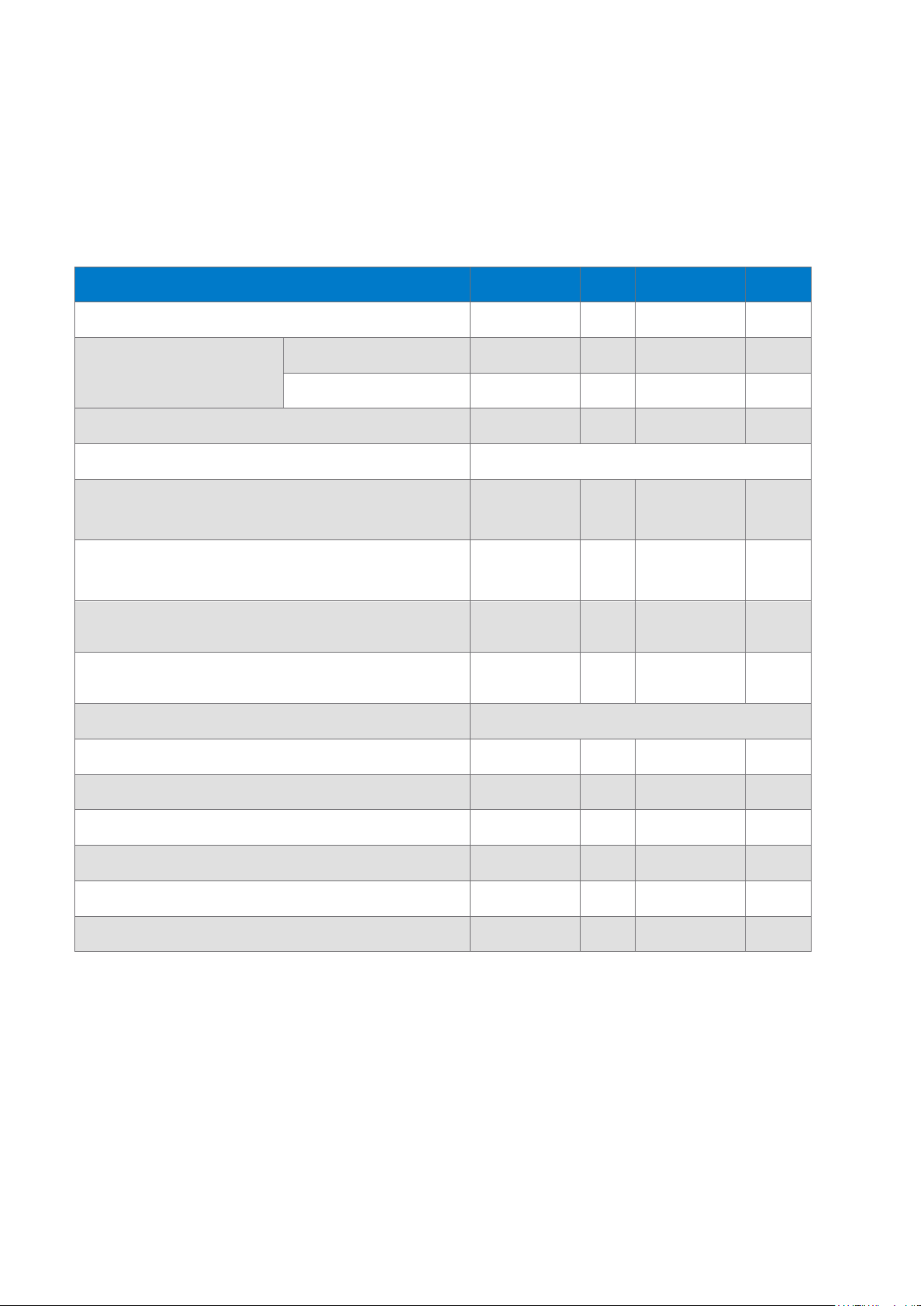

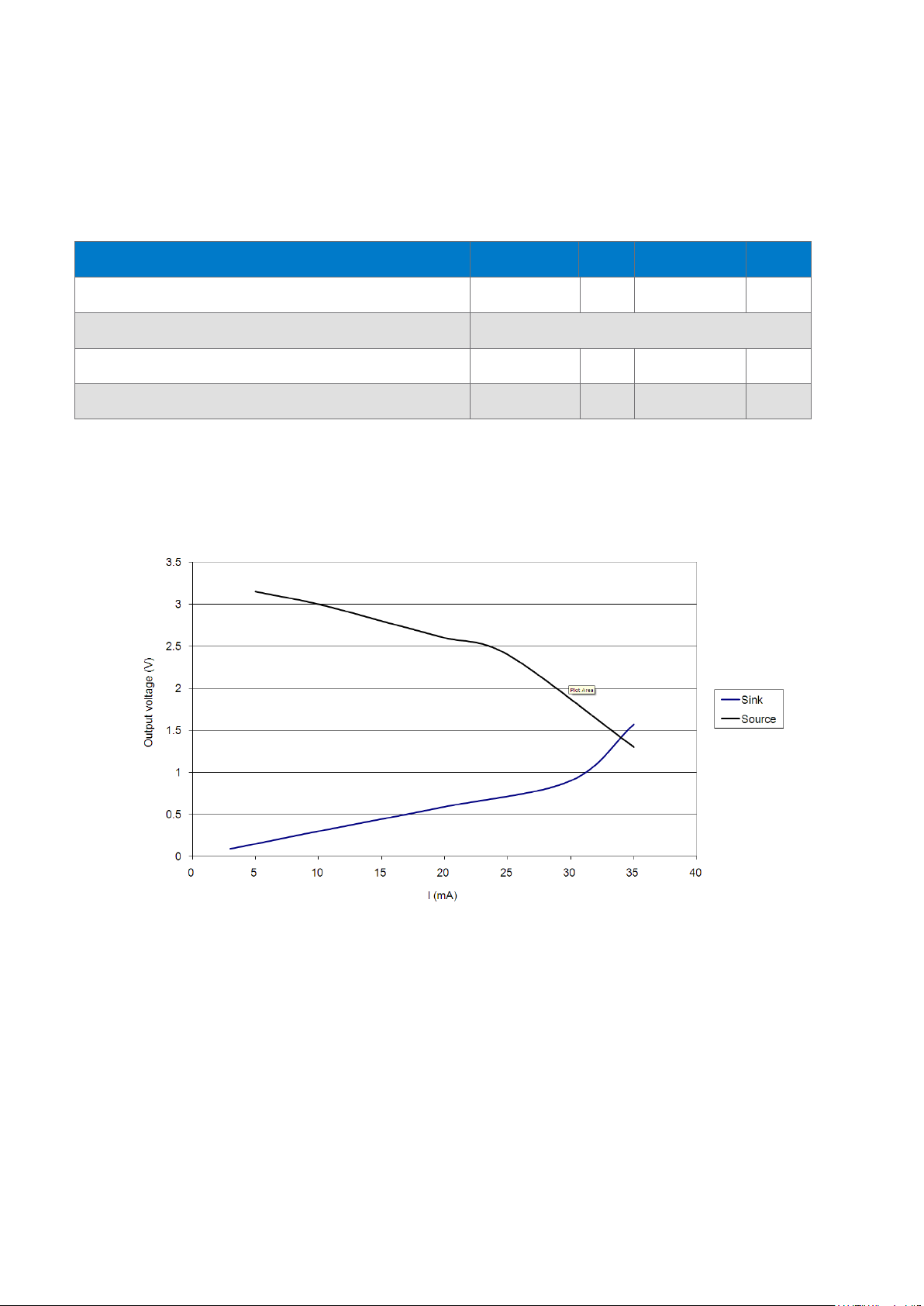

3.4 PIO Current Sink and Source Capability

Figure 2: WT41u PIO Current Drive Capability

Silicon Labs

Page 13 of 44

3.5 Transmitter Performance For BDR

RF characteristic Min Typ Max Blue to oth specification Unit

Max transmit power 16 17 18 <20 dBm

Transmit power variation over temperature

range

Transmit power variation over supply voltage

range

Transmit power variation over frequency

range

Transmit power control range -13 17 dBm

20dB bandwidth for modulated carrier 998 <1000 kHz

Avg drift -11 6 ±40 kHz

ΔF1avg 165 140 to 175 kHz

-2 2 dB

-0.5 0.5 dB

-0.5 0.5 dB

Silicon Labs

Page 14 of 44

3.6 Receiver Performance

Antenna gain not taken into account

Characteristic, VDD=3.3V, room temperature Packet type Typ Bluetooth

Sensitivity for 0.1% BER

Sensitivity variation over temperature range +/-2 dB

3.7 Current Consumption

Unit

specification

DH1 -94.1 -70 dBm

DH5 -90.5 dBm

2-DH1 -96.5 dBm

2-DH5 -94.5 dBm

3-DH1 -89.5 dBm

3-DH5 -86 dBm

Table 10: Receiver sensitivity

Operating mode Peak Average Unit

Stand-by, page mode 0 2000 1 2 mA

TX 3-DH5 108 85 mA

TX 2-DH5 108 85 mA

TX DH5 184 136 mA

RX 50 44 mA

Deep sleep, page mode 0 2000 1 0.36 mA

Inquiry 113 58 mA

Table 11: Current consumption

Silicon Labs

Page 15 of 44

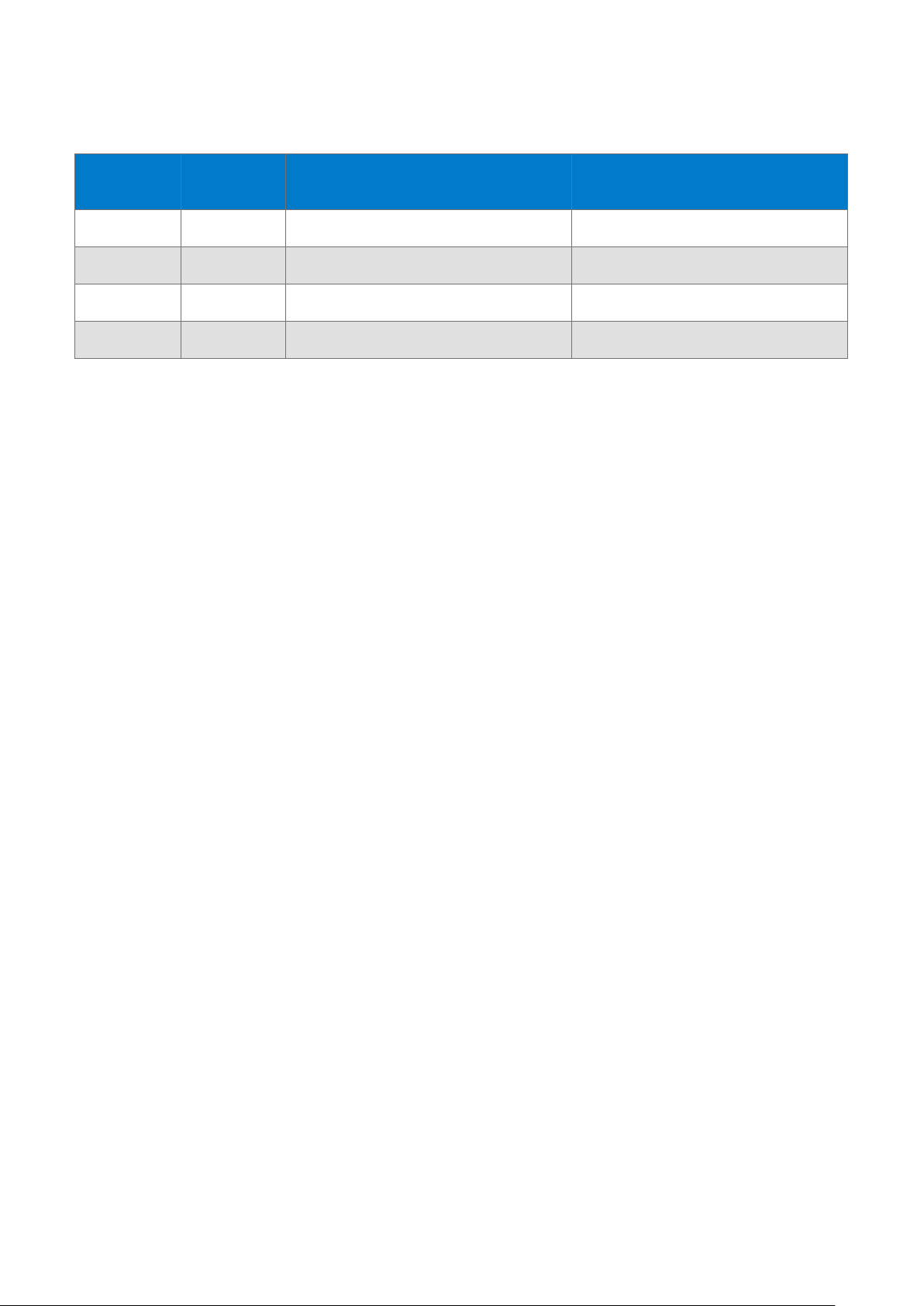

4 Physical Dimensions

Figure 3: Physical dimensions (top view)

Figure 4: Dimensions for the RF pin used as antenna connection on WT41u-N (top view)

Silicon Labs

Page 16 of 44

Figure 5: Dimensions of WT41u-E

Figure 6: Dimensions of WT41u-A

Silicon Labs

Page 17 of 44

Figure 7: Recommended land pattern

Silicon Labs

Page 18 of 44

5 Soldering Recommendations

This section describes the soldering recommendations regarding WT41u Module.

WT41u is compatible with industrial standard reflow profile for Pb-free solders. The reflow profile used is

dependent on the thermal mass of the entire populated PCB, heat transfer efficiency of the oven, and

particular type of solder paste used.

• Refer to technical documentations of particular solder paste for profile configurations.

• Avoid using more than two reflow cycles.

• Aperture size of the stencil should be 1:1 with the pad size.

• A no-clean, type-3 solder paste is recommended.

• For further recommendation, please refer to the JEDEC/IPC J-STD-020, IPC-SM-782 and IPC 7351

guidelines.

Silicon Labs

Page 19 of 44

Signals

GND

Power

Signals

Overlapping GND layers without

GND stitching vias

Overlapping GND layers with

GND stitching vias shielding the

RF energy

6 Layout Guidelin es

Use good layout practices to avoid excessive noise coupling to supply voltage traces or sensitive analog

signal traces, such as analog audio signa ls. If using overlapp ing ground planes use stitching vias se parated

by max 3 mm to avoid emission f rom the edges of the PC B. Connect all the G ND pins direc tly to a solid GND

plane and make s ure that ther e is a lo w impedanc e path for the r eturn cur rent f ollowing the s ignal an d supp ly

traces all the way from start to the end.

A good practice is to dedicate one of the inner layers to a solid GND plane and one of the inner layers t o

supply voltage planes and traces and route all the signals on top and bottom layers of the PCB. This

arrangement will m ake sure that an y return current fo llows the forward c urrent as close as possible and any

loops are minimized.

Figure 8: Typical 4-layer PCB construction

Figure 9: Use of stitching vias to avoid emissions from the edges of the PCB

Page 20 of 44

Silicon Labs

7 UART Interface

This is a standard UART interface for communicating with other serial devices.WT41u UART interface

provides a simple mechanism for communicating with other serial devices using the RS232 protocol.

Four signals are used to implement the UART function. When WT41u is connected to another digital device,

UART_RX and UART_TX transfer data between the two devices. The remaining two signals, UART_CTS and

UART_RTS, can be used to implement RS232 hardware flow control where both are active low indicators. All

UART connections are implemented using CMOS technology and have signalling levels of 0V and VDD.

UART configuration parameters, such as data rate and packet format, are set using WT41u software.

Note:

In order to commun icate with the U ART at its maximum da ta rate using a standa rd PC, an acc elerated seri al

port adapter card is required for the PC.

Parameter Possible values

Data rate Minimum 1200bps (2% error)

9600bps (1% error)

Maximum 3Mbps (1% error)

Flow control RTS/CTS or None

Parity None, Odd or Even

Number of stop bits 1 or 2

Bits per channel 8

Table 12: Possible UART Settings

The UART interface is capabl e of r esetti ng WT41u upon recept ion of a bre ak signal. A break is ide ntified b y a

continuous logic low (0 V) on the UART _RX terminal, as shown in Figure 10. If tBRK is longer than the value,

defined by PSKEY_HOST_IO_UART_RESET_TIMEOUT, (0x1a4), a reset will occur. This feature allows a

host to initialise the system to a known state. Also, WT41u can emit a break character that may be used to

wake the host.

Figure 10: Break Signal

Table 17 shows a list of commonly used data rates and their associated values for

PSKEY_UART _BAUD_RATE (0x2 04). There is no requirem ent to use these standard values. An y data rate

within the supported range can be set in the PS Key according to the formula in Equation 1.

Silicon Labs

Page 21 of 44

Equation 1: Data Rate

Data rate [bits/s] Persistent store value

Error [bits/s] Error [%]

(Hex)

1200 0x0005 5 1.73

2400 0x000A 10 1.73

4800 0x0014 20 1.73

9600 0x0027 39 -0.82

19200 0x004F 79 0.45

38400 0x009D 157 -0.18

57600 0x00EC 236 0.03

76800 0x013B 315 0.14

115200 0x01D8 472 0.03

230400 0x03B0 944 0.03

460800 0x075F 1887 -0.02

921600 0x0EBF 3775 0

1382400 0x161E 5662 -0.01

1843200 0x1D7E 7550 0

2764800 0x2C3D 11325 0

Table 13: Standard Data Rates

Silicon Labs

Page 22 of 44

7.1 UART Bypass

Figure 11: UART Bypass Architecture

7.2 UART Configuration While Reset is Active

The UART interface for WT41u while the chip is being held in reset is tr istate. T his will allow the user to dais y

chain devices onto the ph ysical UART bus. The constr aint on this method is that any devices c onnected to

this bus must tristate when WT41u reset is de-asserted and the firmware begins to run.

7.3 UART Bypass Mo de

Alternatively, for de vices that do not tristate the UART bus, the UART bypass mode on the chipset can be

used. The default state of the c hipset after reset is de-ass erted; this is for the hos t UART bus to be connec ted

to the chipset U ART, thereby allowing communication to the chipset via the UART. All UART bypass mode

connections are implemented using CMOS technology and have signalling levels of 0V and VDD.

In order to apply the UART bypass mode, a BCCMD command will be issued to the chipset. Upon this issue, it

will switch the bypass to P IO[7:4] as Figure 11 indica tes. Once the bypass mode has been invoked, WT41u

will enter the Deep Sleep state indefinitely.

In order to re-estab lish communication with WT41u, the chip m ust be reset so that the def ault configuration

takes effect.

It is important for the host to ensure a clean Bluetooth disconnection of a ny active links before the b ypass

mode is invoked. Therefore, it is not possible to have active Bluetooth links while operating the bypass mode.

The current consum ption for a device in UART bypass mode is equal to t he values quoted for a device in

standby mode.

Silicon Labs

Page 23 of 44

8 USB Interface

This is a full speed (12Mbit s/s ) USB interf ace f or comm unicating with other com patible dig ital de vices. WT41u

acts as a USB peripheral, responding to requests from a master host controller such as a PC.

The USB interface is capa ble of driving a USB cable directl y. No external USB transceiver is r equired. The

device operates as a U SB peripheral, responding to requests from a master host controller such as a PC.

Both the OHCI and the UHCI standards are supported. The set of USB endpoints implemented can behave as

specified in the USB sec tion of the Blue tooth v2.1 + EDR specificat ion or alternat ively can appe ar as a set of

endpoints appropriate to USB audio devices such as speak er s .

As USB is a master/slave oriented system (in common with other USB peripherals), WT41u only supports

USB Slave operation.

8.1 USB Data Connections

The USB data lines em erge as pins USB_DP and USB_DN. These term inals are connected to the internal

USB I/O buffers of the the c hipset, therefore, have a low output impedance. To matc h the connection to the

characteristic impedance of the U SB c ab le, res ist ors m us t be p laced in series with US B_D P/U SB _DN and the

cable.

8.2 USB Pull-Up resistor

WT41u features an internal USB pull-up resistor. This pulls the USB_DP pin weakly high when WT41u is

ready to enumerate. It signals to the PC that it is a full speed (12Mbits/s) USB device.

The USB internal pu ll-up is implem ented as a current source, and is compliant with section 7.1.5 of the USB

specification v1.2. T he internal pull-up pulls USB_D P high to at least 2.8V when loaded with a 15kΩ 5% pulldown resistor (in the hub/h ost) when VDD_PADS = 3.1V. T his presents a Thevenin resista nce to the host of

at least 900Ω. Alternati vely, an external 1.5kΩ pull-up resistor can be placed be tween a PIO line and D+ on

the USB cable. T he firmware must be alerted to whic h mode is used by s etting PSKEY_US B_PIO_PULLUP

appropriately. The default setting uses the internal pull-up resistor.

8.3 USB Power Supply

The USB specificatio n dictates that the minimum output h igh voltage for USB data lines is 2.8 V. To safely

meet the USB specification , the voltage on the VDD supply terminal must be an absolute minimum of 3.1V.

Silicon Labs recommends 3.3V for optimal USB signal quality.

8.4 Self-Powered Mode

In self-powered mode, the circuit is powered from its own power supply and not from the VBUS (5V) line of the

USB cable. It draws only a small leakage current (below 0.5mA) from VBUS on the USB cable. This is the

easier mode for wh ich to design, as the des ign is not limited by the power that can be dra wn from the USB

hub or root port. However, it requires that VBUS be connected to WT41u via a resistor network (R

), so WT41u can detect when VBUS is powered u p. T he chipset will not pull USB_DP high when VBUS is

R

vb2

off.

vb1

and

Self-powered USB designs (powered f rom a batter y or PSU) must ens ure that a PIO line is a llocated f or USB

pullup purposes. A 1. 5kΩ 5% pull-up resis tor between USB_D P and the selecte d PIO line sho uld be fitted t o

the design. Failure to fit this resistor may result in the design failing to be USB compliant in self-powered

mode. The internal pull-up in the chipset is only suitable for bus-powered USB devices, e.g., dongles.

Silicon Labs

Page 24 of 44

Figure 12: USB Connections for Self-Powered Mode

The terminal mark ed USB_ON can be any free PIO pin. The PIO pi n selected must be registered b y setting

PSKEY_USB_PIO_VBUS to the corresponding pin number.

Identifier Value Function

Rs 27Ω nominal Impedance matching to USB cable

R

22kΩ 5% VBUS ON sense divider

vb1

R

47kΩ 5% VBUS ON sense divider

vb2

Figure 13: USB Interface Component Values

8.5 Bus-Powered Mode

In bus-powered m ode, the application circuit dra ws its current from the 5V VBU S supply on the USB cabl e.

WT41u negot iates with the PC during the US B enumeration stage about ho w much current it is allowed to

consume. O n power-up the device must not draw more than 100 m A but af ter being conf igured it c an dra w up

to 500 mA.

For WT41u, the USB power descriptor should be altered to reflect the amount of power required. This is

accomplished by setti ng PSKEY_USB_MAX_POWER (0x2c6) . This is higher than for a Class 2 applicat ion

due to the extra current drawn by the Transmit RF PA. By default for WT41u the setting is 300 mA.

When selecting a re gulator, be awar e that VBUS m ay go as low as 4.4V. The inrus h current (when charging

reservoir and suppl y decoupling capacitors) is limited by the USB s pecification. See the USB Specification.

Some applications m ay require sof t start c ircuitry to li mit inrush cur rent if m ore than 10uF is present between

VBUS and GND. The 5V V BUS lin e emerging from a PC is of ten e lec tric al ly noisy. As well as regulation dow n

to 3.3V and 1.8V, applications should include careful filtering of the 5V line to attenuate noise that is above the

voltage regulator bandw idth. Excessive nois e on WT41u supply pins will result i n reduced receiver sensitivity

and a distorted RF transmit signal.

Silicon Labs

Page 25 of 44

Figure 14: USB Connections for Bus-Po wered Mode

8.6 USB Suspend Current

All USB devices must permit the USB controller to place them in a USB suspend mode. While in USB

Suspend, bus-powered dev ices m ust not dra w more th an 2.5m A from USB VBU S (se lf-powered devices m ay

draw more than 2.5mA fr om their own su pply). This c urrent draw r equirement pr events operat ion of the r adio

by bus-powered devices during USB Suspend.

When computing suspend current, the current from VBUS through the bus pull-up and pull-down resistors

must be included. The pu ll-up resistor at t he device is 1.5 k Ω. (nominal). The pul l-down resistor at th e hub is

14.25kΩ. to 24.80kΩ. The pull-up voltage is nominall y 3.3V, which means that holding o ne of the signal lines

high takes approximately 200uA, leaving only 2.3mA available from a 2.5mA budget. Ensure that external

LEDs and/or amplifiers can be turned off by the chipset. The entire circuit m ust be able to enter the s uspend

mode.

8.7 USB Detach and Wake-Up Signaling

WT41u can provide out-of-band signa ling to a host controller b y using the control lines cal led USB_DETACH

and USB_WAKE_UP. These are outside the USB specification (no w ires exis t f or t hem inside the USB cable) ,

but can be useful when embedding WT41u into a circuit where no extern al USB is visible t o the user. Both

control lines are shared with PIO pins and can be assigned to any PIO pin by setting

PSKEY_USB_PIO_DETACH and PSKEY_USB_PIO_WAKEUP to the selected PIO number.

USB_DETACH is an i nput which, when assert ed high, causes WT41u to put USB_DN an d USB_DP in high

impedance state and turns off the pull-up resistor on DP. This detaches the device from the bus and is

logically equivalent t o unplugging the dev ice. When USB_DET ACH is taken low, WT41u will connect back to

USB and await enumeration by the USB host.

USB_WAKE_UP is an active high out put (used only when U SB_DETACH is ac tive) to wak e up the host a nd

allow USB comm unication to recom mence. It repl aces the functi on of the soft ware USB W AKE_UP mes sage

(which runs over the USB cable) an d cannot be sent while the chipset is effectively disconnected from the

bus.

Silicon Labs

Page 26 of 44

Figure 15: USB_Detach and USB_Wake_Up Signals

8.8 USB Driver

A USB Bluetooth device dr iver is required to provide a software interface betwe en the chipset and Bluetoo th

software running on the host computer. Please, contact Silicon Labs support at http://www.silabs.com

suitable drivers.

for

8.9 USB v2.0 Compliance and Compatibility

Although WT41u meets the USB specification, Silicon Labs cannot guarantee that an application circuit

designed around the m odule is USB com pliant. The choic e of applicat ion circuit, component c hoice and PC B

layout all affect USB sig nal quality and e lectrical char acteristics. T he inform ation in this document is intended

as a guide and should be read in assoc iation with the USB spec ification, with part icular attention being gi ven

to Chapter 7. Independent USB qual ification must be sought bef ore an applicatio n is deemed USB complian t

and can bear the US B logo. Such qua lification can be obtained f rom a USB plugf est or from an in dependent

USB test house.

Terminals USB_DP and USB_DN adhere to the USB Specification v2.0 (Chapter 7) electrical requirements.

The chipset is compatible with U SB v2.0 host contr ollers; under thes e circumstances the t wo ends agree the

mutually acceptable rate of 12Mbits/s according to the USB v2.0 specification.

Silicon Labs

Page 27 of 44

9 Serial Peripheral Interface (SPI)

The SPI port can be us ed for system debugg ing. It can also be used for programm ing the Flash m emory and

setting the PSKEY configurations. WT41u uses 16-bit d ata a nd 1 6-bit address serial per ip hera l in terface, where

transactions may occur wh en the interna l processor is running or is s topped. SPI interface is c onnected usin g

the MOSI, MISO, CS B and CLK pins. Please, contact the Silicon Labs support at http://www.silabs.com

detailed information about the instruction cycle.

for

Silicon Labs

Page 28 of 44

10 PCM Codec Interface

PCM is a standard method used to digitize audio (particularly voice) for transmission over digital

communication chann els. T hrough its PCM int erfac e, WT41u has hardware sup port f or c ontinual trans m ission

and reception of PCM data, thus reducing processor overhead for wireless headset applications. WT41u

offers a bidirection al digi tal aud io int er f ac e that r out es directly into the baseband la yer of the on-chip firmware.

It does not pass through the HCI protocol layer.

Hardware on WT41u allows the data to be sent to and received f rom a SCO connection. Up to t hree SCO

connections can be supported by the PCM interface at any one time.

WT41u can operate as the PCM interface master generating a n output clock of 128, 256 or 512kHz. When

configured as PCM interface slave, it can operate with an input clock up to 20 48kHz. WT41u is compatible

with a variety of clock formats, including Long Frame Sync, Short Frame Sync and GCI timing environments.

It supports 13-bit or 16-bit linear, 8-bit µ-law or A-law companded sam ple formats at 8ksamples/s and can

receive and transmit on any selection of three of the first four slots following PCM_SYNC. The PCM

configuration options are enab led b y setting PS K EY_ PCM_CONFIG32.

WT41u interfaces directly to PCM audio devices.

NOTE: Analog audio lines are very sensitive to RF disturbance. Use g ood layout practices to ensure noise

less audio. Make sure that the r eturn path for the audio signals fo llow s t he forw ar d c ur rent all th e way as clos e

as possible and use fully differential signals when possible. Do not compromise audio routing.

10.1 PCM Interface Master/Slave

When configured as the master of the PCM interface, WT41u generates PCM_CLK and PCM_SYNC.

Figure 16: PCM Interface Master

When configured as the Slave of the PCM interface, WT41u accepts PCM_CLK rates up to 2048kHz.

Silicon Labs

Page 29 of 44

10.2 Long Frame Sync

Figure 17: PCM Interface Slave

Long Frame Sync is the name given to a clocking format that controls the transfer of PCM data words or

samples. In Long Frame Sync, the rising edge of PCM_SYNC indicates the start of the PCM word. When

WT41u is configured as PCM master, generating PCM_SYNC and PCM_CLK, then PCM_SYNC is 8-bits

long. W hen WT41u is conf igured as PCM Slave, PCM_S YNC may be from two consec utive falling edges of

PCM_CLK to half the PCM_SYNC rate, i.e., 62.5s long.

Figure 18: Long Frame Sync (Shown with 8-bit Companded Sample)

WT41u samples PCM_IN on the falling edge of PCM_CLK and transmits PCM_OUT on the rising edge.

PCM_OUT may be configur ed to be high impedance on the fallin g edge of PCM_CLK in the LSB posit ion or

on the rising edge.

10.3 Short Frame Sync

In Short Frame Sync, the falling edge of PCM_SYNC indicates the start of the PCM word. PCM_SYNC is

always one clock cycle long.

Silicon Labs

Page 30 of 44

Figure 19: Short Frame Sync (Shown with 16-bit Sample)

As with Long Frame Sync, WT41u samples PCM_IN on the falling edge of PCM_CLK and transmits

PCM_OUT on the ris ing edge. PCM_OUT may be conf igured to be high impedance on the falling edge of

PCM_CLK in the LSB position or on the rising edge.

10.4 Multi-slot Operation

More than one SCO c onnection over the PCM interf ace is supported using multi ple slots. Up to three SCO

connections can be carried over any of the first four slots.

Figure 20: Multi-slot Operation with Two Slots and 8-bit Companded Samples

10.5 GCI Interface

WT41u is com patible with the GCI, a standar d sync hronous 2B +D ISDN tim ing i nterface. T he two 64k bits/s B

channels can be accessed when this mode is configured.

Silicon Labs

Page 31 of 44

Figure 21: GCI Interface

The start of fram e is indicated by the rising edge of PCM_SYNC and runs at 8k Hz. With WT41u in Slave

mode, the frequency of PCM_CLK can be up to 4.096MHz.

10.6 Slots and Sample Formats

WT41u can receive and transmit on any selection of the first four slots following each sync pulse. Slot

durations can be either 8 or 16 c lock cycles. Durations of 8 clock cycles may only be used with 8-bit s ample

formats. Durations of 16 clocks may be used with 8-bit, 13-bit or 16-bit sample formats.

WT41u supports 13-bit linear, 16-bit linear and 8-bit -law or A-law sample formats. The sample rate is

8ksamples/s. The bit order may be little or big endian. W hen 16-bit slots are used, the 3 or 8 unused bits in

each slot may be filled with sign extension, padded with zeros or a programmable 3-bit audio attenuation

compatible with some Motorola codecs.

Silicon Labs

Page 32 of 44

Figure 22: 16-bit Slot Length and Sample Formats

10.7 Additional Features

WT41u has a mute f acility that f orces PCM_OUT to be 0. In m as ter mode, PCM_S YNC m a y also be forced to

0 while keeping PCM_CLK running which some codecs use to control power down.

10.8 PCM_CLK and PCM_SYNC Generation

WT41u has two m ethods of generating PCM_CL K and PCM_SYNC in mas ter mode. The first is generating

these signals by DD S from the chipset interna l 4MHz clock. Using this mode limits PCM_CLK to 128, 25 6 or

512kHz and PCM_SYNC to 8kHz. The second is generating PCM_C LK and PCM_SYNC by DDS from an

internal 48MHz clock (which allows a greater range of frequencies to be generated with low jitter but

consumes more power). This second method is selected by setting bit 48M_PCM_CLK_GEN_EN in

PSKEY_PCM_CONFIG3 2. When in this mode and with long fram e sync, the length of PCM_S YNC can be

either 8 or 16 cycles of PCM_CLK, determined by LONG_LENGTH_SYNC_EN in PSKEY_PCM_CONFIG32.

The Equation 2 describes PCM_CLK frequency when being generated using the internal 48MHz clock:

Silicon Labs

Page 33 of 44

Equation 2: PCM_CLK Frequency When Being Generated Using the Internal 48MHz Clock

The frequency of PCM_SYNC relative to PCM_CLK can be set using Equation 3:

Equation 3: PCM_SYNC Frequency Relative to PCM_CLK

CNT_RATE, CNT_LIMIT and SYNC_LIMIT are set using PSKEY_PCM_LOW_JITTER_CONFIG. As an

example, to generate PCM_CLK at 512kHz with PCM_SYNC at 8kHz, set

PSKEY_PCM_LOW_JITTER_CONFIG to 0x08080177.

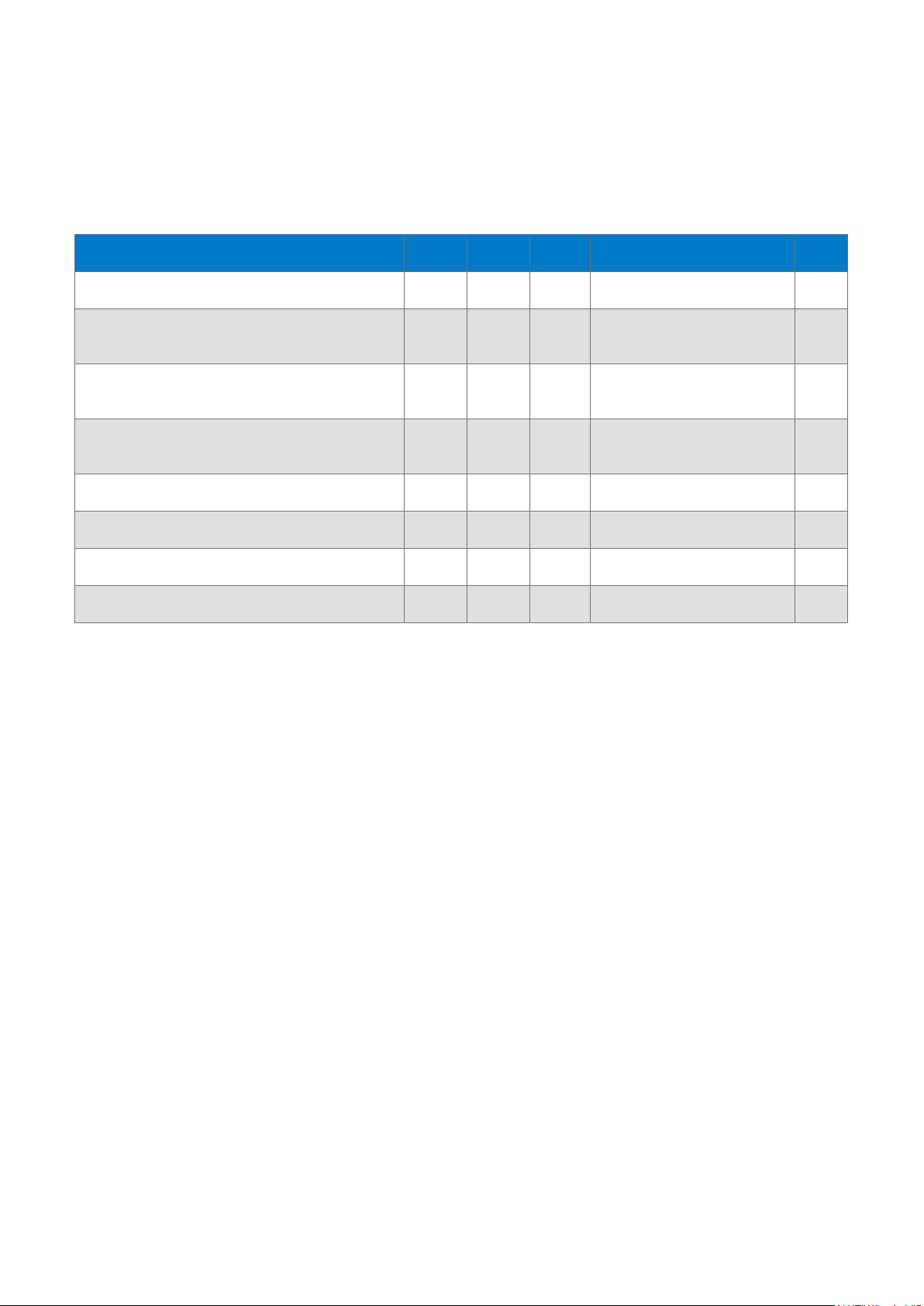

10.9 PCM Configuration

The PCM configuration is set using two PS Keys, PSKEY_PCM_CONFIG32 detailed in Table 18 and

PSKEY_PCM_LOW _JITT ER_CONFIG in Tabl e 19. Th e default f or P SKEY_PC M_CO NFIG 32 is 0x 008000 00,

i.e., first slot following sync is active, 13-bit linear voice format, long frame sync and interface master

generating 256kHz PCM_CLK from 4MHz internal clock with no tri-state of PCM_OUT.

Silicon Labs

Page 34 of 44

Name Bit

Description

position

- 0 Set to 0

SLAVE MODE EN 1 0 selects Master mode with internal generation of PCM_CLK and

PCM_SYNC. 1 selects Slave mode requiring externally generated

PCM_CLK and PCM_SYNC. This should be set to 1 if

48M_PCM_CLK_GEN_EN (bit 11) is set.

SHORT SYNC EN 2 0 selects long frame sync (rising edge indicates start of frame),

- 3 Set to 0

SIGN EXTENDED

EN

4 0 selects long frame sync (rising edge indicates start of frame), 1 selects

short frame sync (falling edge indicates start of frame).

LSB FIRST EN 5 0 transmits and receives voice samples MSB first, 1 uses LSB

TX TRISTATE EN 6 0 transmits and receives voice samples MSB first, 1 uses LSB

TX TRISTATE

RISING EDGE EN

7 0 tristates PCM_OUT immediately after the falling edge of PCM_CLK in the

last bit of an active slot, assuming the next slot is also not active. 1 tristates

PCM_OUT after the rising edge of PCM_CLK.

SYNC SUPPRESS

EN

8 0 enables PCM_SYNC output when master, 1 suppresses PCM_SYNC

whilst keeping PCM_CLK running. Some CODECS utilize this to enter a

low power state

GCI MODE EN 9 1 enables GCI mode.

MUTE EN 10 1 forces PCM_OUT to 0.

48M PCM CLK GEN

EN

11 0 sets PCM_CLK and PCM_SYNC generation via DDS from internal 4

MHz clock. 1 sets PCM_CLK and PCM_SYNC generation via DDS from

internal 48 MHz clock.

LONG LENGTH

SYNC EN

12 0 sets PCM_SYNC length to 8 PCM_CLK cycles and 1 sets length to 16

PCM_CLK cycles. Only applies for long frame sync and with

48M_PCM_CLK_GEN_EN set to 1.

- [20:16] Set to 0b00000.

MASTER CLK RATE [22:21] Selects 128 (0b01), 256 (0b00), 512 (0b10) kHz PCM_CLK frequency

when master and 48M_PCM_CLK_GEN_EN (bit 11) is low.

ACTIVE SLOT [26:23] Default is 0001. Ignored by firmaware

SAMPLE FORMAT [28:27] Selects between 13 (0b00), 16 (0b01), 8 (0b10) bit sample with 16 cycle

slot duration 8 (0b11) bit sample 8 cycle slot duration.

Table 14: PSKEY_PCM_CONFIG32 description

Silicon Labs

Page 35 of 44

Name Bit position Description

CNT LIMIT [12:0] Sets PCM_CLK counter limit

CNT RATE [23:16] Sets PCM_CLK count rate

SYNC LIMIT [31:24] Sets PCM_SYNC division relative to PCM_CLK

Table 15: PSKEY_PCM_LOW_JITTER_CONFIG Description

Silicon Labs

Page 36 of 44

11 I/O Parallel Ports

Six lines of programmable bidirectional input/outputs (I/O) are provided. All the PIO lines are power from VDD.

PIO lines can be c onfigured through software to have either weak or strong pull-ups or pull-downs. All PI O

lines are configured as inputs with weak pull-downs at reset. Any of the PIO lines can be configured as

interrupt request lines or as wake-up lines from sleep modes.

WT41u has a general purpose analogue interface pin AIO[1]. This is used to access internal circuitry and

control signals. It may be configured to provide additional functionality.

Auxiliary functions available via AIO[1] includ e an 8-bit ADC and an 8-bit DAC. Typically the A DC is used for

battery voltage measurement. Signals selectable at this pin include the band gap reference voltage and a

variety of clock signals: 48, 24, 16, 8MHz and the XTAL cl ock frequency. When used with analogue sign als,

the voltage range is constrained by the analogue supply voltage internally to the module (1.8V). When

configured to drive out digital level signals (e.g., clocks), the output voltage lev el is determined by VDD.

11.1 PIO Defaults

Silicon Labs can not guarantee that these term inal functions remain the sam e. Refer to the software releas e

note for the implementation of these PIO lines, as they are firmware build-specific.

Silicon Labs

Page 37 of 44

12 Reset

WT41u may be reset from several sources: RESET pin, power on reset, a UART break character or via

software configured watc hdog timer. The RESET pin is an active lo w reset and is internally filtered using the

internal low frequenc y clock oscillator. A reset will be per formed between 1.5 and 4.0ms following RES ETB

being active. It is recommended that RESET be applied for a period greater than 5ms.

The power on reset occurs when the VDD_CORE supply internally to the m odule f alls below typically 1.5V

and is released when VDD _CORE rises above t ypically 1.6V. At res et the digital I/O pins ar e set to inputs for

bidirectional pins and outputs are tri-state.

The reset should be held active at power up until all the supply voltages have stabilized to ensure correct

operation of the internal f lash m emory. Foll owing f igure sho ws an example of a s imple pow er up reset circuit.

Time constant of the RC circuitry is set so that the supply voltage is safely stabilized before the reset

deactivates.

Figure 23: Example of a simple power on reset circuit.

Silicon Labs

Page 38 of 44

12.1 Pin States on Reset

Pad name State

PIO[7:2] Input, weak pull-down

PCM_OUT 3-state, weak pull-down

PCM_IN Input, weak pull-down

PCM_SYNC Input, weak pull-down

PCM_CLK Input, weak pull-down

UART_TX 3-state, weak pull-up

UART_RX Input, weak pull-down

UART_RTS 3-state, weak pull-up

UART_CTS Input, weak pull-down

USB+ Input, weak pull-down

USB- Input, weak pull-down

SPI_CSB Input, weak pull-down

SPI_CLK Input, weak pull-down

SPI_MOSI Input, weak pull-down

SPI_MISO 3-state, weak pull-down

AIO[1] Output, driving low

Table 16: Pin States on Reset

Silicon Labs

Page 39 of 44

13 Certifications

13.1 Bluetooth

The WT41u is Bluetooth qualified and the declaration ID is B015141 (QDID 22298)

13.2 FCC

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesirable operation.

Any changes or modifications not expressly approved by Silicon Labs could void the user’s authority to

operate the equipment.

FCC RF Radiation Exposure Statement:

This equipment com plies with FCC radiation exposure lim its set forth for an uncontrolled e nvironment. End

users must follow th e specific operating ins tructions for satisfying RF exposure compliance. T his transmitter

meets both portable and mobi le l im its as demonstrated in the RF Exposure Ana l ysis . This tr ansm itter m us t not

be co-located or operating in c onj unct ion w ith any other antenna or transm itter ex cept in acc ordance with FCC

multi-transmitter product pr ocedures . As long as the c ondition above is met, f urther trans mitter tes ting wil l not

be required. Howev er, the OEM integrator is s till responsible for testi ng their end-product for any additional

compliance requirements required with this module installed (for example, digital device emissions, PC

peripheral requirements, etc.).

OEM Responsibilities to comply with FCC Regulations

The WT41u Module has been certified for integration into products only by OEM integrators under the

following condition:

• The antenna(s) must be installed such that a minimum separation distance of 42 mm is

maintained between the radiator (antenna) and all persons at all times.

• The transmitter module must not be co-located or operating in conjunction with any other

antenna or transmitter except in accordance with FCC multi-transmitter product procedures.

As long as the conditio ns above are met, fur ther transmitter testing will no t be required. However, the O EM

integrator is still resp onsible f or testing their e nd-product f or any addition al compliance r equirements required

with this module installed (for example, digital device emissions, PC peripheral requirements, etc.).

Note: In the event that this condition cannot be met (for certain configurations or co-location with another

transmitter), then the FCC authorization is no longer c onsidered va lid and the FC C ID cannot be us ed on the

final product. In thes e circu m stances , the OEM i ntegr ator will be r espo nsible f or re-evaluating the end pr oduc t

(including the transmitter) and obtaining a separate FCC authorization.

End Product Labeling

The WT41u Mod ule is labeled with its o wn FCC ID. If the FCC ID is not visible when the m odule is installed

inside another de vice, then the outside of the device into which the m odule is installed m ust also display a

label referring to the enclosed module. In that case, the final end product must be labeled in a visible area with

the following:

"Contains Transmitter Module FCC ID: QOQWT41u"

or

"Contains FCC ID: QOQWT41u"

Silicon Labs

Page 40 of 44

The OEM integrator must not provide information to t he end user regardi ng how to install or remove this RF

module or change RF related parameters in the user manual of the end product.

13.3 ISEDC

This radio transmitter (IC: 5123A-WT41U) has been approved by Industry Canada to operate with the

embedded chip antenna. Other antenna types are strictly prohibited for use with this device.

This device complies with Industry Canada’s license-exempt RSS standards. Operation is subject to the

following two conditions:

1. This device may not cause interference; and

2. This device m ust ac cept an y inter ferenc e, inc luding inter ferenc e that m a y cause und esired operat ion

of the device.

RF Exposure Statement

Exception from routine SAR evaluation limits are given in RSS-102 Issue 5. WT41u meets the given

requirements when the m inimum separation dista nce to hum an body 40 mm. RF exposure or S AR evaluatio n

is not required whe n the separ ation dista nce is 40 mm or m ore. If the separ ation distance is less tha n 40 mm

the OEM integrator is responsible for evaluating the SAR.

OEM Responsibilities to c om pl y with IC Regu lations T he WT41u Module has bee n cer tified f or integr ation int o

products only by OEM integrators under the following conditions:

• The antenna(s) must be instal led such that a minimum separation distance of 40 mm is maintained

between the radiator (antenna) and all persons at all times.

• The transmitter m odule must not be co-located or operating in c onjunction wit h any other ante nna or

transmitter.

As long as the two conditions above are met, further transm itter testing will not be required. However, the

OEM integrator is still responsible for testing their end-product for any additional compliance requirements

required with this module installed (for example, digital device emissions, PC peripheral requirements, etc.).

Note: In the event that these c onditions cannot be m et (for certain configur ations or co-locatio n with another

transmitter), then the IC authorizatio n is no longer con sidered valid and t he IC ID cannot b e used on the final

product. In these circumstances, the OEM integrator will be responsible for re-evaluating the end product

(including the transmitter) and obtaining a separate IC authorization.

End Product Labeling

The WT41u module is labeled w ith its own IC ID. If the IC ID is not vis ible when t he module is ins talled ins ide

another device, then the outside of the device into which the module is installed must also display a label

referring to the e nclosed m odule. In that case, the f inal end pr oduct m ust be labeled in a visibl e area w ith th e

following:

"Contains Transmitter Module IC: 5123A-WT41u"

or

"Contains IC: 5123A-WT41u"

The OEM integrator has to be aware not to prov ide information to the end us er regarding how to install o r

remove this RF module or change RF related parameters in the user manual of the end product.

13.3.1 ISEDC (Français)

Cet émetteur radio (IC : 5 123A-WT41u) a reçu l'approbation d'Indus trie Canada pour une exploitation av ec

l'antenne puce incorporée. Il est strictement interdit d'utiliser d'autres types d'antenne avec cet appareil.

Silicon Labs

Page 41 of 44

Le présent appareil es t conforme aux CNR d’Industri e Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes:

1. L’appareil ne doit pas produire de brouillage; et

2. L’appareil doit accept er tout brouillage r adioélectr ique subi, m ême si le brouillage est s usceptible de

provoquer un fonctionnement non désiré de l’appareil.

Déclaration relative à l'exposition aux radiofréquences (RF)

Les limites applicables à l’exemption de l’évaluation c ourante du DAS sont énoncées dans l e CNR 102, 5e

édition. Le module Bluetooth WT41u répond aux exigences données quand la distance de séparation

minimum par rapport a u c o r ps humain est de 40 mm. L'évaluat ion de l'exposi tion aux RF ou du DAS n'est pas

requise quand la distance de séparation est de 40 mm ou plus. Si la distance de séparation est inférieure à 40

mm, il incombe à l'intégrateur FEO d'évaluer le DAS.

Responsabilités du FEO ayant trait à la conformité avec les règlements IC

Le Module Bluetooth WT41u a été certifié pour une intégration dans des produits uniquement par les

intégrateurs FEO dans les conditions suivantes:

• La ou les antennes do ivent être inst allées de te lle façon qu'une distance de séparation m inimum de 40 mm

soit maintenue entre le radiateur (antenne) et toute personne à tout moment.

• Le module émetteur ne d oit pas être install é au m êm e endroit ou f onctionner conjoin tem ent avec to ute au tre

antenne ou émetteur.

Dès lors que les deux con ditions ci-dessus sont r espectées, aucun test supplémentaire de l ’émetteur n’est

obligatoire. Cependa nt, il in com be toujo urs à l'intégra t eur FEO de tes ter la conf orm ité de son pro duit f inal vis à-vis de toute exigence supplémentaire requise avec ce module installé (par exemple, émissions de

dispositifs numériques, exigences relatives aux matériels périphériques PC, etc).

Note: S'il s'avère que ces conditions ne peuvent être respectées (pour certaines configurations ou la

colocation avec un autre émetteur), alors l'autorisation IC n'est plus cons i dér ée comme valide et l'identifiant IC

ne peut plus être emplo yé sur le produ it f inal . Dans c es c irc ons tanc es, l'intégr ate ur FEO aura la r esponsabilité

de réévaluer le produit final (y compris l'émetteur) et d'obtenir une autorisation IC distincte.

Étiquetage du produit final

L'étiquette du Module WT41u porte son propre identifiant IC. Si l'identifiant IC n'est pas visible quand le

module est installé à l'intérieur d'un autre appareil, alors l'extérieur de l'appareil dans lequel le module est

installé doit aus si porter une étiquette fais ant référence au module qu' il contient. Dans ce cas, un e étiquette

comportant les informations suivantes doit être apposée sur une partie visible du produit final.

"Contient le module émetteur IC: 5123A-WT41U"

ou

"Contient IC : 5123A-WT41U"

L'intégrateur FEO doit être conscient de ne pas fournir d'inf ormations à l'utilis ateur final perm ettant d'installer

ou de retirer ce module RF ou de changer les paramètres liés aux RF dans le mode d'emploi du produit final.

13.4 CE

The Declaration of Compliance and the test documentation can be consulted in www.silabs.com.

Please note that ever y application us ing the WT 41-A or WT41-N will need to perform the radio EMC tests on

the end product according to EN 301 489-17.

RF exposure requirements must be verified in an end product assembly.

Test documentation an d software for the EN 300 328 radi ated spurious emissions testin g can be requested

from the Silicon Labs support.

Silicon Labs

Page 42 of 44

13.5 MIC Japan

The WT 41u module in cer tified for Japan. Certification num ber: 209-J00231 Sin ce September 1, 2014 it is

allowed (and highl y rec om mended) that a manuf act urer who int egr at es a rad io module in their hos t e qu ipment

can place the certif ication m ark and certificatio n number (the sam e marking/nu mber as depict ed on the label

of the radio module) on the outside of the host equipment. The certification mark and certification number

must be placed cl ose to t he text in th e Jap anese lang uage which is pro vided b elo w. This c hange in th e R adio

Law has been made in order to enable users of the com bination of host and r adio m odule to verify if t hey are

actually using a radio device which is approved for use in Japan.

当該機器には電波法に基づく、技術基準適合証明等を受けた特定無線設備を装着している。

Translation: “This equipment contains specified radio equipment that has been certified to the Technical

Regulation Conformity Certification under the Radio Law.”

Silicon Labs

Page 43 of 44

13.6 Qualified Antenna Types for WT41u-E and WT41u-N

This device has been desig ned to oper ate with a stand ard 2.14 dBi dipole antenna. Any antenna of a diff erent

type or with a gain higher than 2. 14 dBi is strictly prohib ited for use with this device. Using an ante nna of a

different type or gain more than 2.14 dBi will require additional testing for FCC, CE and IC. The required

antenna impedance is 50 Ω.

Antenna type Maximum gain

Dipole 2.14 dBi

Table 17: Qualified Antenna Types for WT41u-E/N

To reduce potential radio inter ference to other users, t he antenna type and its gain shou ld be so chosen that

the equivalent isotropically radiated power (EIRP) is not more than that permitted for successful

communication.

Any standard 2.14 dBi dipole antenna can be used without an additional application to FCC.

13.7 Moisture Sensitivity Level (MSL)

Moisture sensitivit y level (MSL) of this product is 3. For the hand ling instructions please refer to JEDEC JSTD-020 and JEDEC J-STD-033.

If baking is required, devices may be baked for 12 hours at 125°C +/-5°C for high temperature device

containers.

Silicon Labs

Page 44 of 44

Simplicity Studio

One-click access to MCU and

wireless tools, documentation,

software, source code libraries &

more. Available for Windows,

Mac and Linux!

IoT Portfolio

www.silabs.com/IoT

Disclaimer

Silicon Labs intends to provide customers with the latest, accurate, and in-depth documentation of all peripherals and modules available for system and software implementers using or

intending to use the Silicon Labs products. Characterization data, available modules and peripherals, memory sizes and memory addresses refer to each specific device, and "Typical"

parameters provided can and do vary in different applications. Application examples described herein are for illustrative purposes only. Silicon Labs reserves the right to make changes

without further notice and limitation to product information, specifications, and descriptions herein, and does not give warranties as to the accuracy or completeness of the included

information. Silicon Labs shall have no liability for the consequences of use of the information supplied herein. This document does not imply or express copyright licenses granted

hereunder to design or fabricate any integrated circuits. The products are not designed or authorized to be used within any Life Support System without the specific written consent of

Silicon Labs. A "Life Support System" is any product or system intended to support or sustain life and/or health, which, if it fails, can be reasonably expected to result in significant personal

injury or death. Silicon Labs products are not designed or authorized for military applications. Silicon Labs products shall under no circumstances be used in weapons of mass

destruction including (but not limited to) nuclear, biological or chemical weapons, or missiles capable of delivering such weapons.

Trademark Information

Silicon Laboratories Inc.® , Silicon Laboratories®, Silicon Labs®, SiLabs® and the Silicon Labs logo®, Bluegiga®, Bluegiga Logo®, Clockbuilder®, CMEMS®, DSPLL®,

EFR, Ember®, Energy Micro, Energy Micro logo and combinations thereof, "the world’s most energy friendly microcontrollers", Ember®, EZLink®, EZRadio®, EZRadioPRO®,

Gecko®, ISOmodem®, Precision32®, ProSLIC®, Simplicity Studio®, SiPHY®, Telegesis, the Telegesis Logo®, USBXpress® and others are trademarks or registered trademarks of Silicon

Labs. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or registered trademarks of ARM Holdings. Keil is a registered trademark of ARM Limited. All other products or brand

names mentioned herein are trademarks of their respective holders.

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

USA

SW/HW

www.silabs.com/simplicity

Quality

www.silabs.com/quality

Support and Community

community.silabs.com

EFM®, EFM32®,

http://www.silabs.com

Loading...

Loading...