BT111: Bluetooth® Smart Ready HCI Module

DATA SHEET

Monday, 28 January 2013

Version 1.2

Copyright © 2000-2013 Bluegiga Technologies

All rights reserved.

Bluegiga Technologies assumes no responsibility for any errors which may appear in this manual.

Furthermore, Bluegiga Technologies reserves the right to alter the hardware, software, and/or specifications

detailed here at any time without notice and does not make any commitment to update the information

contained here. Bluegiga’s products are not authorized for use as critical components in life support devices

or systems.

The WRAP is a registered trademark of Bluegiga Technologies

The Bluetooth trademark is owned by the Bluetooth SIG Inc., USA and is licensed to Bluegiga Technologies.

All other trademarks listed herein are owned by their respective owners.

Bluegiga Technologies Oy

VERSION HISTORY

Version Comment

1.0 First public release

1.1 Minor changes

1.2 FCC and CE update

Bluegiga Technologies Oy

TABLE OF CONTENTS

1 BT111 Product numbering ........................................................................................................................... 7

2 Block Diagram .............................................................................................................................................. 8

3 Pinout and Terminal Descriptions ................................................................................................................ 9

4 External Dimensions and Land Pattern ...................................................................................................... 11

5 Layout Guide Lines ..................................................................................................................................... 12

5.1 BT111-A Layout Guide ....................................................................................................................... 12

6 Electrical Characteristics ............................................................................................................................ 14

6.1 Absolute Maximum Ratings ............................................................................................................... 14

6.2 Input/Output Terminal Characteristics ................................................................................................ 14

6.2.1 USB Linear Regulator ................................................................................................................... 14

6.2.2 High-voltage Linear Regulator ...................................................................................................... 15

6.2.3 Digital ............................................................................................................................................ 15

6.3 Current Consumption ......................................................................................................................... 16

7 RF Characteristics ...................................................................................................................................... 19

7.1 Transmitter Characteristics ................................................................................................................ 19

7.2 Receiver Characteristics .................................................................................................................... 20

7.3 Radiated Spurious Emissions ............................................................................................................ 21

7.4 Antenna Characteristics ..................................................................................................................... 21

8 Clock Generation ........................................................................................................................................ 22

9 Bluetooth Stack Microcontroller .................................................................................................................. 23

10 Programmable I/O Ports ......................................................................................................................... 23

11 Wi-Fi Coexistence Interface .................................................................................................................... 23

12 Memory Management ............................................................................................................................. 24

12.1 Memory Management Unit ................................................................................................................. 24

12.2 System RAM ...................................................................................................................................... 24

12.3 Internal ROM Memory (5Mb) ............................................................................................................. 24

12.4 Internal EEPROM ............................................................................................................................... 24

13 Serial Interfaces ...................................................................................................................................... 25

13.1 USB Interface ..................................................................................................................................... 25

13.2 Programming and Debug Interface .................................................................................................... 25

14 Audio Interfaces ...................................................................................................................................... 26

14.1 PCM Interface .................................................................................................................................... 26

14.1.1 PCM Interface Master/Slave ......................................................................................................... 26

14.1.2 Long Frame Sync .......................................................................................................................... 27

14.1.3 Short Frame Sync ......................................................................................................................... 27

14.2 Multi-slot Operation ............................................................................................................................ 28

14.2.1 GCI Interface ................................................................................................................................. 28

Bluegiga Technologies Oy

Slots and Sample Formats ............................................................................................................ 29

14.2.2

14.2.3 Additional Features ....................................................................................................................... 30

14.2.4 PCM Timing Information ............................................................................................................... 31

14.2.5 PCM_CLK and PCM_SYNC Generation ...................................................................................... 34

14.2.6 PCM Configuration ........................................................................................................................ 35

14.3 Digital Audio Interface (I2S) ................................................................................................................ 35

15 Power Control and Regulation ................................................................................................................ 40

15.1 Voltage Regulator Enable .................................................................................................................. 40

15.2 USB Linear Regulator ........................................................................................................................ 40

15.3 High Voltage Linear Regulator ........................................................................................................... 40

15.4 Low Voltage Linear Regulators .......................................................................................................... 41

15.5 Powering Sequence ........................................................................................................................... 41

15.6 Reset .................................................................................................................................................. 41

16 Example Schematic ................................................................................................................................ 42

17 Software .................................................................................................................................................. 43

17.1 On-chip Software ................................................................................................................................ 44

17.1.1 Bluetooth HCI Stack ...................................................................................................................... 44

17.1.2 Latest Feature of the HCI Stack .................................................................................................... 44

18 Soldering Recommendations .................................................................................................................. 45

19 Certifications ........................................................................................................................................... 46

19.1 Bluetooth ............................................................................................................................................ 46

19.2 FCC/IC (USA/Canada) ....................................................................................................................... 46

19.2.1 FCC et IC ...................................................................................................................................... 47

19.3 CE (Europe) ....................................................................................................................................... 48

19.4 KCC (South-Korea) ............................................................................................................................ 49

19.5 Japan .................................................................................................................................................. 49

20 Moisture Sensitivity Level (MSL) classification ....................................................................................... 50

21 Packaging and Reel Information ............................................................................................................. 51

22 Contact Information................................................................................................................................. 52

Bluegiga Technologies Oy

BT111: Bluetooth Smart Ready HCI Module

DESCRIPTION

BT111 is a low cost and ultra-

small Bluetooth Smart Ready HCI module that

is designed for applications where

both Bluetooth classic and Bluetooth low

energy connectivity is needed. BT111

integrates a Bluetooth 4.0 dual mode radio,

HCI software stack, USB interface and an

antenna. BT111 is compatible with Windows

and Linux operating systems and Microsoft

and BlueZ Bluetooth stacks and offers OEMs

fast and risk free way to

integrate Bluetooth 4.0 connectivity into their

applications.

APPLICATIONS

Health and fitness gateways

Point of sale

M2M connectivity

Automotive aftermarket

Personal navigation devices

Consumer electronics

Industrial and home automation

gateways

KEY FEATURES

Bluetooth v.4.0, dual mode compliant

Support Bluetooth classic

Supports Bluetooth low

energy master mode

Radio capabilities

Transmit power: +8dBm

Receiver sensitivity: -89dBm

Line-of-sight range: 100+ meters

Integrated antenna

Interfaces

HCI over USB host interface

802.11 co-existence interface

Software programmable GPIO

PCM or I2S audio interfaces

Supply voltage: 1.7V to 3.6V or 3.1V to

3.6V

Temperature range: -30C to +85C

Ultra compact size: 13.05mm x 9.30mm

Bluetooth, CE, FCC, IC and South-Korea

qualified

PHYSICAL OUTLOOK

Bluegiga Technologies Oy

1 BT111 Product numbering

BT111-A-HCI

Antenna:

A = Internal

Firmware revision

Available products and product codes

Product code Description

BT111-A-HCI BT111 Bluetooth 4.0 HCI module with integrated antenna

Bluegiga Technologies Oy

Page 7 of 52

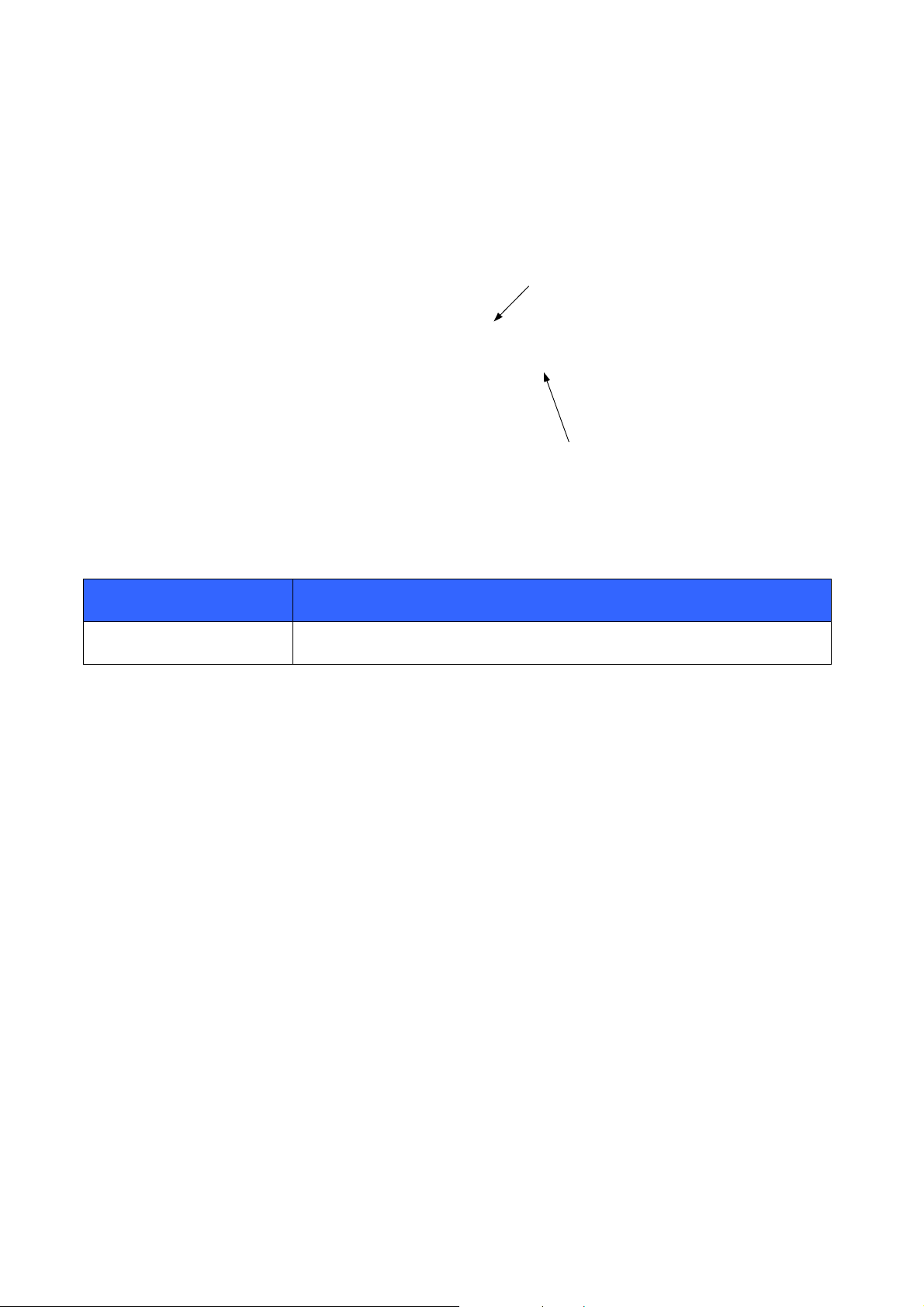

2 Block Diagram

26MHz XTAL

Antenna

BPF

RF

5V0 3V3 1V8

RAM

ROM

MMU

MCU

LDO 3V3

CSR8510

3 x LDO

LDO 1V8

1V3

I/O

PIO3

PIO4

PIO0

PIO1

PIO2

PIO5

32k EEPROM

SPI / PCM

USB

Figure 1: Block diagram of BT111

CSR8510

BT111 is based on CSR8510 dual mode chip. The chip includes all the functions required for a complete

Bluetooth radio with on chip LDO regulators. The chip provides SPI, PCM and USB interfaces. Up to 4 general

purpose I/Os are available for general usage, such as Wi-Fi coexistence or general indicators.

Antenna

Antenna is a ceramic monopole chip antenna. See the antenna characteristics in chapter 7.

Band Pass Filter

The band pass filter filters the out of band emissions from the transmitter to meet the specific regulations for

type approvals of various countries.

32k EEPROM

The embedded 32k EEPROM can be used to store customizable parameters, such as maximum TX power,

PCM configuration, USB product ID, USB vendor ID and USB product description.

26MHz Crystal

The embedded 26MHz crystal is used for generating the internal digital clocks.

Bluegiga Technologies Oy

Page 8 of 52

y

g

g

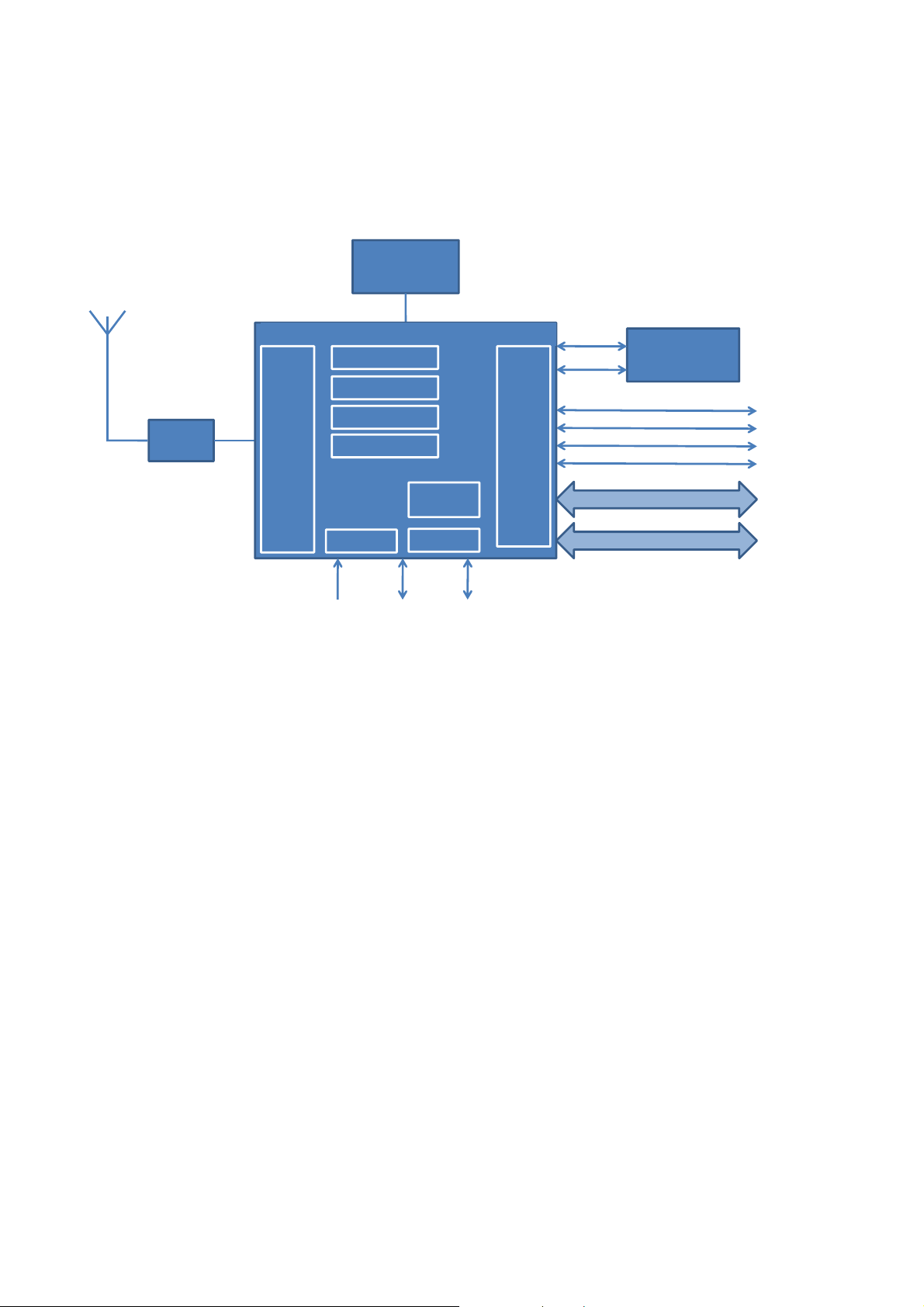

3 Pinout and Terminal Descriptions

1

GND

2

USBUSB+

3

PCM_SYNC/SPI_CS/PIO23

4

PIO5

5

PIO2

6

PCM_CLK/SPI_CLK/PIO24

7

PCM_IN/SPI_MOSI/PIO21

8

GND

9

VREG_IN_HV

10

GND

VREG_EN_RST#

VDD_PADS

VREG_OUT_HV

VREG_IN_USB

21

20

19

18

17

16VDD_HOST

PCM_OUT/SPI_MISO/PIO22

SPI_PCM_SEL

PIO01

GND

15

PIO0

121314

11

Figure 2: BT111

Power Supply Pin No. Pad Type Description

Take high to enable internal regulators. Also

acts as active low reset. Maximum voltage is

VDD_PADS

Note: USB regulator is always enabled and

not controlled b

this pin

Input to internal high-voltage regulator to

1.8V regulator, 3.3V output from USB

re

ulator.

Output from internal high-voltage to 1.8V

regulator. Input to second stage internal

ulators.

re

Input to USB regulator. Connect to external

USB bus supply, e.g. USB_VBUS

VREG_EN_RST# 20

VREG_IN_HV 10

VREG_OUT_HV 18

VREG_IN_USB 17

Input with strong

internal pull-down

Analogue regulator

input / output

Analogue regulator

output

Analogue regulator

input

VDD_HOST 16 VDD USB system positive supply

VDD_PADS 19 VDD Positive supply for digital I/O pads

Table 1: Supply Terminal Descriptions

Bluegiga Technologies Oy

Page 9 of 52

g

PIO Port Pin No. Pad Type Supply Domain Description

PIO0 11

PIO1 13

PIO2 6

Bidirectional, tristate,

with weak internal pulldown

PIO5 5

PCM Interface Pin No. Pad Type

PCM_OUT/

SPI_MISO/

PIO22

PCM_IN/

SPI_MOSI/

PIO21

PCM_SYNC/

SPI_CS#/

PIO23

PCM_CLK/

SPI_CLK/

PIO24

12

Output, tristate, with

weak internal pulldown

Input, tristate, with

8

weak internal pulldown

4

Bidirectional, tristate,

with weak internal

7

pulldown

VDD_PADS Programmable input/output line

Table 2: I/O Terminal Descriptions

Supply

Domain

VDD_PADS

Description

PCM syncronous data output

SPI data output

Programmable input/output line

PCM syncronous data input

SPI data input

Programmable input/output line

PCM syncronous dara sync

SPI chip select, active low

Programmable input/output line

PCM syncronous data clock

SPI clock

rammable input/output line

Pro

SPI_PCM#_SEL 14

Input with weak

internal pull-down

High switches SPI/PCM lines to SPI, low

switches SPI/PCM lines to PCM/PIO use

Table 3: PCM Interface

USB Interface Pin No. Pad Type

USB+ 3

USB- 2 USB data minus

Supply

Domain

VDD_HOSTBidirectional

Description

USB data plus with selectable internal 1.5k

pull-up resistor

Table 4: USB Interface

Ω

Bluegiga Technologies Oy

Page 10 of 52

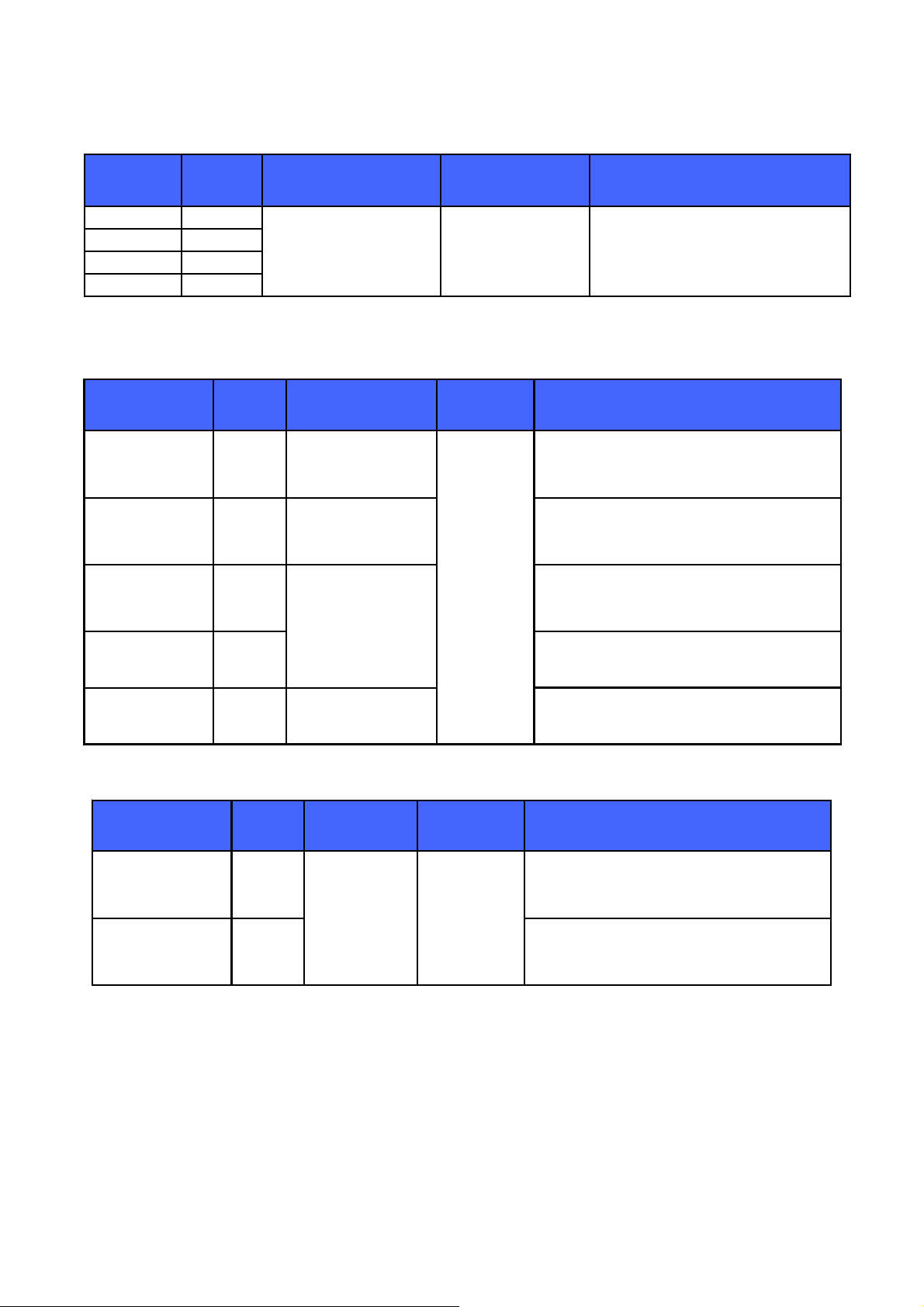

4 External Dimensions and Land Pattern

Figure 3: Footprint (top view)

7.3mm (+/- 0.1mm)

1.9mm (+/- 10%)

13.05mm (+/- 0.1mm)

2.1mm (+/- 10%)

9.3mm (+/- 0.1mm)

Figure 4: External dimensions

Bluegiga Technologies Oy

Page 11 of 52

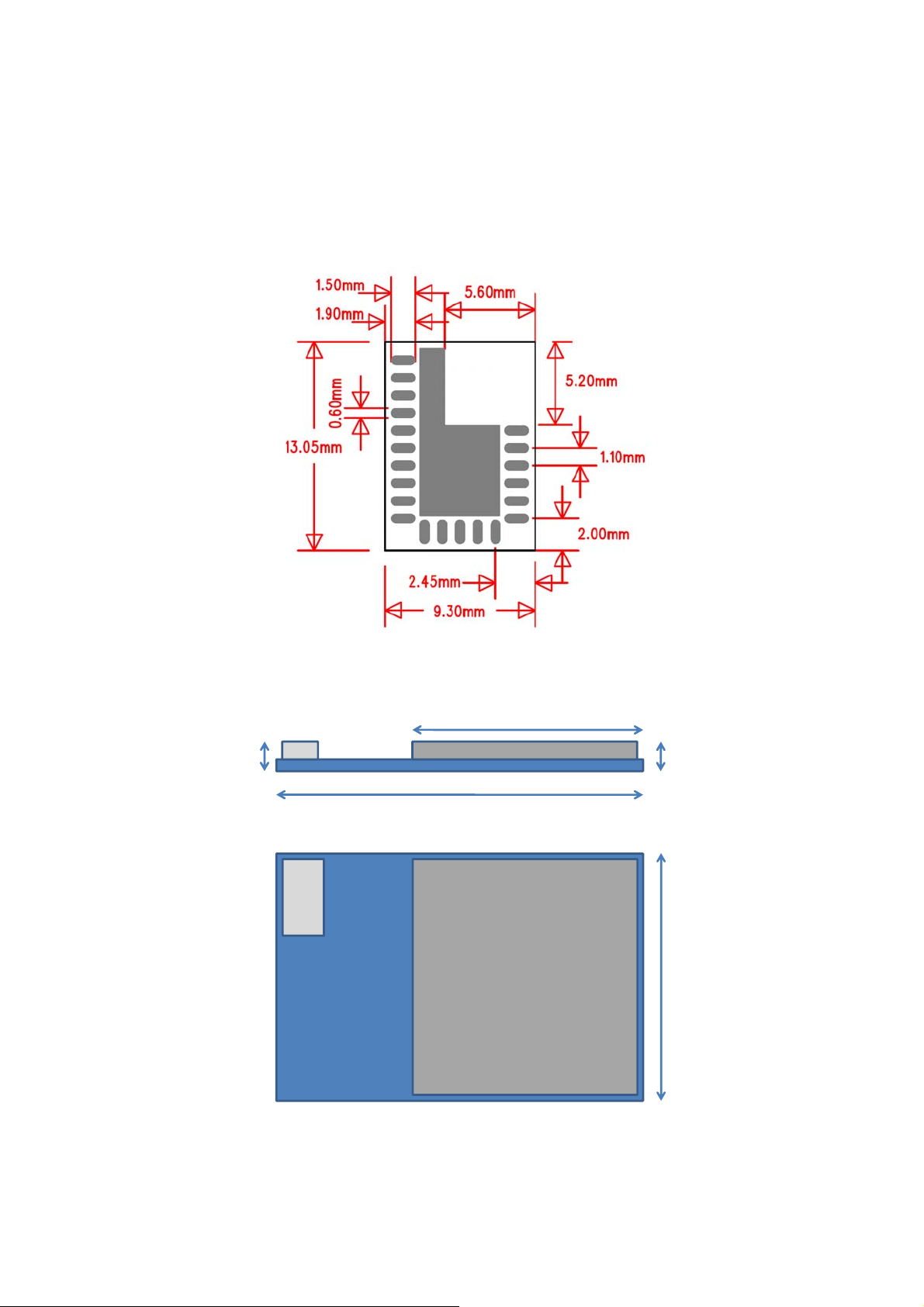

5 Layout Guide Lines

Use good layout practices to avoid excessive noise coupling to supply voltage traces or sensitive analog

signal traces. If using overlapping ground planes use stitching vias separated by max 3 mm to avoid emission

from the edges of the PCB. Connect all the GND pins directly to a solid GND plane and make sure that there

is a low impedance path for the return current following the signal and supply traces all the way from start to

the end.

A good practice is to dedicate one of the inner layers to a solid GND plane and one of the inner layers to

supply voltage planes and traces and route all the signals on top and bottom layers of the PCB. This

arrangement will make sure that any return current follows the forward current as close as possible and any

loops are minimized.

Signals

GND

Power

Signals

Figure 5: Typical 4-layer PCB construction

Overlapping GND layers without

GND stitching vias

Figure 6: Use of stitching vias to avoid emissions from the edges of the PCB

Overlapping GND layers with

GND stitching vias shielding the

RF energy

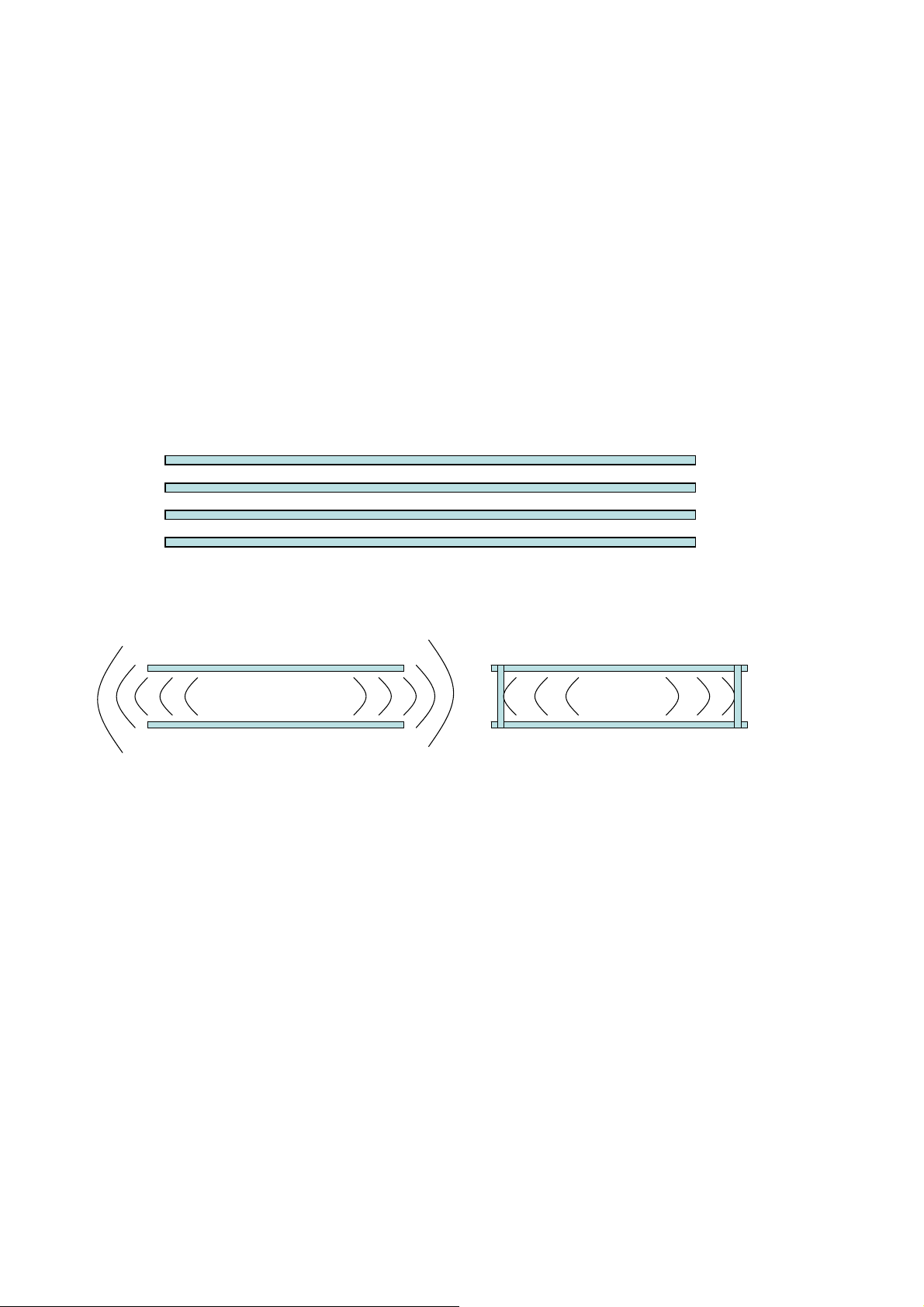

5.1 BT111-A Layout Guide

For optimal performance of the antenna place the module at the corner of the PCB of the mother board as

shown in the figure 7. Optionally the module can be placed on the long edge of the mother board. In this case

the metal clearance area must be extended minimum 10mm from the edge of the module, as shown in figure

7. The layout of the mother board has an impact on the antenna characteristic and radiation pattern, see the

antenna characteristics chapter. Do not place any metal (traces, components, battery etc.) within the

clearance area of the antenna. Connect all the GND pins directly to a solid GND plane. Place the GND vias as

close to the GND pins as possible. Use good layout practices to avoid any excessive noise coupling to signal

lines or supply voltage lines. Avoid placing plastic or any other dielectric material closer than 5 mm from the

antenna. Any dielectric closer than 5 mm from the antenna will detune the antenna to lower frequencies.

The antenna is optimized for mother board thickness of 1.0 mm. If the mother board is thicker than this, the

resonant frequency will be tuned downwards. If the mother board thickness is thinner than 1.0 mm, the

Bluegiga Technologies Oy

Page 12 of 52

resonant frequency will be tuned upwards. S11 is a measure of how big portion of the transmitted power is

reflected back from the antenna. An adequate performance can be expected if S11 is less than – 7 dB. If

using PCB thickness more than 1.6 mm, or if there is dielectric material around the antenna which is likely to

detune the resonant frequency, the antenna can be tuned in the mother board layout by removing FR4 below

the antenna.

Min. 10mm

BT111

Mother board

Figure 7: Recommended layouts for BT111-A

Mother board

Metal clearance area

BT111

Figure 8: Impedance matching of the antenna of BT111 with two different mother board PCB thickness

Bluegiga Technologies Oy

Page 13 of 52

6 Electrical Characteristics

6.1 Absolute Maximum Ratings

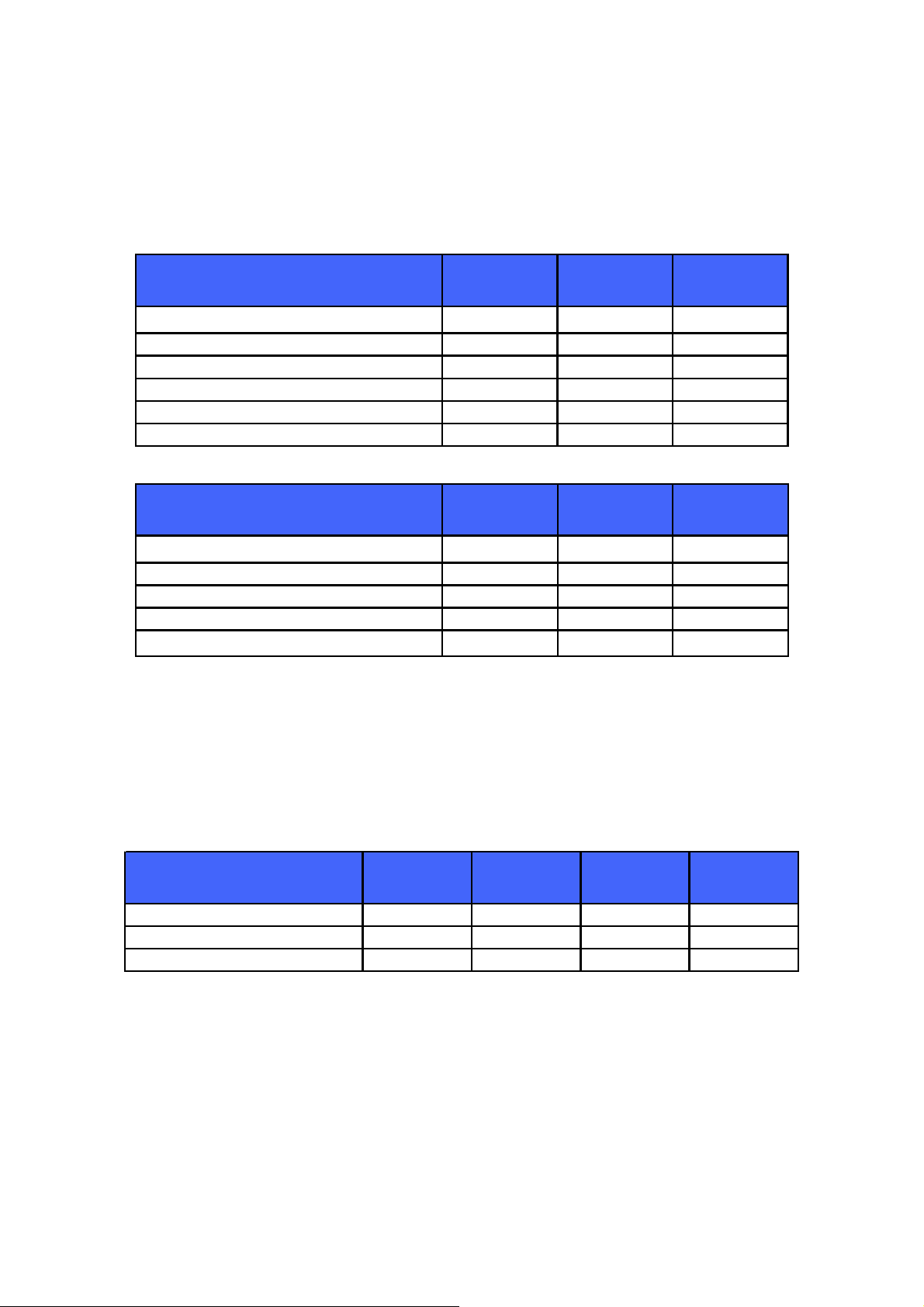

Rating Min Max Unit

Storage temperature -40

VREG_IN_USB -0.2 5.85

VREG_IN_HV -0.2 4.9

VDD_HOST -0.2 3.7

VDD_PADS -0.2 3.7

Other terminal voltages VSS - 0.4V

Table 5: Absolute maximum ratings

Rating Min Max Unit

Operating temperature -30

VREG_IN_USB 4.25

VREG_IN_HV 2.3

VDD_HOST 3.1

VDD_PADS

*) NOTE: The internal EEPROM is powered from VDD_PADS. To write the EEPROM,

minimum supply voltage is 2.7V and maximum is 3.3V. For reading the EEPROM the

minimum supply voltage is 1.7V and the maximum is 3.6V.

(*

Table 6: Recommended operating conditions

1.7

(*

+85

⁰

VDD + 0.4 V V

+85

⁰

5.75 V

4.8 V

3.6 V

(*

3.6

C

V

V

V

V

C

V

6.2 Input/Output Terminal Characteristics

6.2.1 USB Linear Regulator

Rating Min Typ Max Unit

Input voltage 4.25 5.0

Output voltage 3.2 3.3

Output current - -

Table 7: USB linear regulator

Bluegiga Technologies Oy

5.75 V

3.4 V

150 mA

Page 14 of 52

6.2.2 High-voltage Linear Regulator

)

)

Normal Operation Min Typ Max Unit

Input voltage 2.3 3.3

Output voltage 1.75 1.85

Temperature coefficient -200 Output noise (frequency range 100Hz to

100kHz

Settling time (settling ti within 10% of final

value

Output current - -

Quiescent current (excluding load, I

Low-power Mode

Quiescent current (excluding load, I

<100µA)

Table 8: High-voltage Linear Regulator

load

load

<1mA)

--

--

30 40

14 18

4.8 V

1.95 V

200 ppm/⁰C

0.4 mV rms

5µs

100 mA

60 µA

23 µA

6.2.3 Digital

Normal Operation Min Typ Max Unit

Input Voltage

input logic level low

V

IL

VIH input logic level high

Output Voltage

VOL output logic level low, IOL = 4.0mA

VOH output logic level high, IOL = 4.0mA

Input and Tristate Currents

Strong pull-up -150 -40 -10

Striong pull-down 10 40

Weak pull-up -5 -1.0

Weak pull-down 0.33 1.0

C

input capacitance

I

Table 9: Digital I/O characteristics

-0.4 -

0.7 x VDD -

--

0.75 x VDD -

1.0 -

0.4 V

VDD + 0.4 V

0.4 V

-V

150

-0.33

5.0

5.0 pF

µ

A

µ

A

µ

A

µ

A

Bluegiga Technologies Oy

Page 15 of 52

6.3 Current Consumption

Normal Operation

Idle 5

USB Suspend 200

Inguiry 73 51

File Transfer 73 58

LE Connected (Master) 74 (*

LE Scan (Master) 48 (*

*) LE AVG current consumption depends on the chosen TX interval and scanning window

Table 10: Current consumption of BT111 with 8 dBm TX power

Peak

(8 dBm)

AVG Unit

mA

µ

A

mA

mA

mA

mA

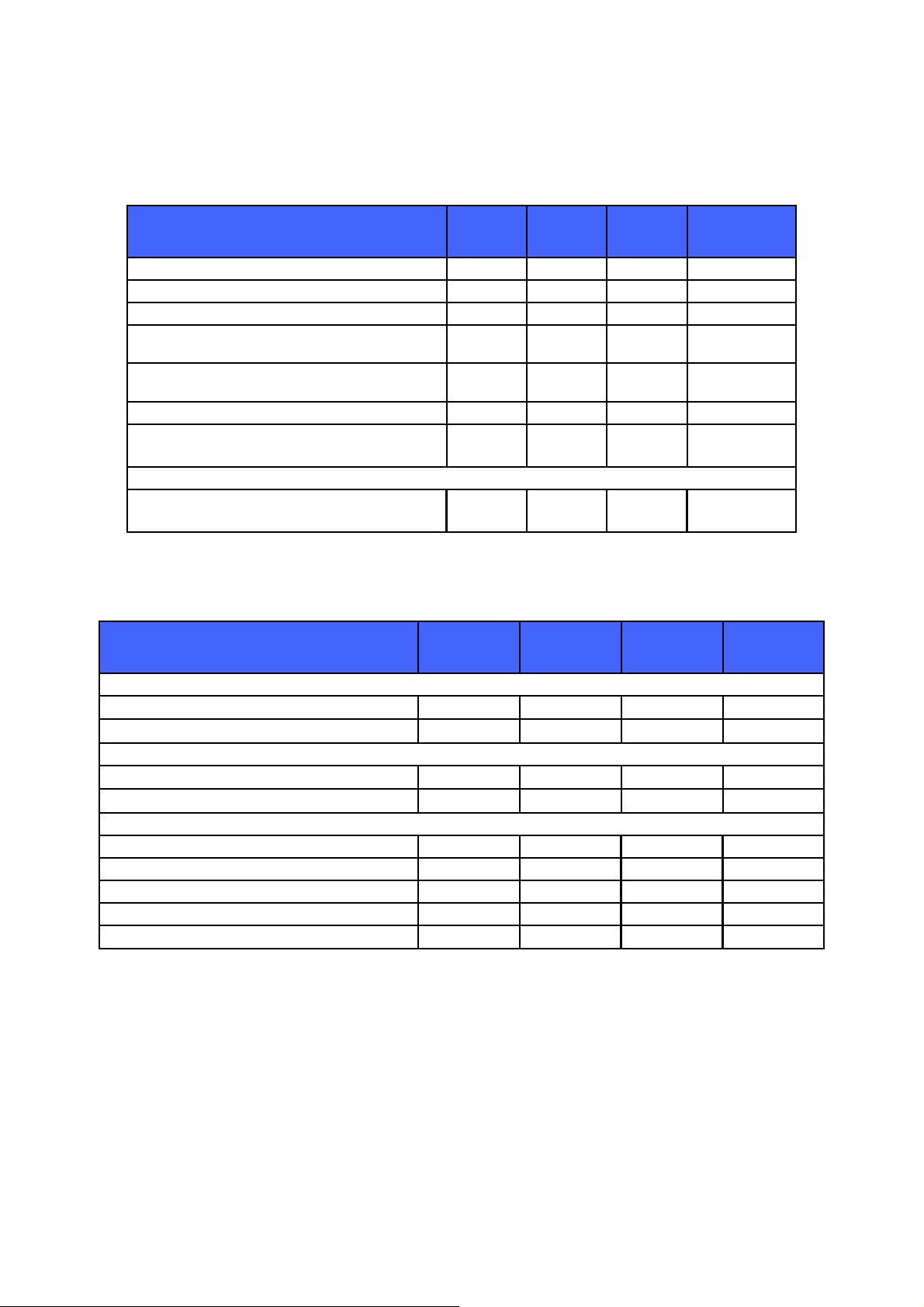

TX Peak = 73 mA

Peak = 14 mA

6.5 ms

Figure 9: Current consumption profile while creating a SPP connection

Peak = 48 mA

BGND Current = 6.4 mA

Window = 50 ms

Figure 10: LE scanning with 50 ms window

Bluegiga Technologies Oy

Page 16 of 52

Peak = 74 mA

AVG = 7.7 m A

(with 70 ms interval)

500 µs

Figure 11: LE connected with 70 ms interval

Figure 12: BDR Peak current vs TX power

Bluegiga Technologies Oy

Page 17 of 52

Figure 13: LE peak current vs. TX power

Bluegiga Technologies Oy

Page 18 of 52

7 RF Characteristics

7.1 Transmitter Characteristics

RFCharacetristics,VDD=3.3V@room

Min Typ Max

temperatureunlessotherwisespecified

maximum RF Transmit Power

RF power variation over temperature range

RF power variation over supply voltage range

RF power variation over BT band (*

RF power control range

-21 8 - dBm

20dB band width for modulated carrier

F = F

± 2MHz

0

± 3MHz

ACP (1

F = F

F = F

0

> 3MHz

0

Drift rate

ΔF

1avg

ΔF1

max

ΔF

/ ΔF

2avg

*) Channel 0 @2402Mhz has generally 1.0 dB lower TX power than all the other channels. All the channels

between 2403 MHz and 2480 MHz are within 0.5 dB.

1avg

810 20 dBm

1.5 - dB

0.2 - dB

2-dB

10 +/-25 kHz

165 140<175 kHz

168 140<175 kHz

0.9 >=0.8

Bluetooth

Specification

1000 kHz

-20

-40

-40

Unit

Table 11: Transmitter Characteristics, BDR

Bluegiga Technologies Oy

Page 19 of 52

Figure 14: Power control steps of BT111

7.2 Receiver Characteristics

RFcharacteristis,VDD=3.3V,

Packettype Min Typ Max

roomtemperature

DH1 -89 -70 dBm

DH3 -89 dBm

Sensitivity for 0.1% BER

Sensitivity variation over BT

band (*

Sensitivity variation over

temperature range

*) Channel 0 @2402Mhz is generally 1.5dB less sensitive than all the other channels. All the channels

between 2403 MHz and 2480 MHz are within 0.5 dB.

Table 12: BDR and EDR receiver sensitivity

DH5 -89 dBm

2-DH5 -92 dBm

3-DH5 -85 dBm

All 2 dB

All TBD dB

Bluetooth

Spefication

Unit

Bluegiga Technologies Oy

Page 20 of 52

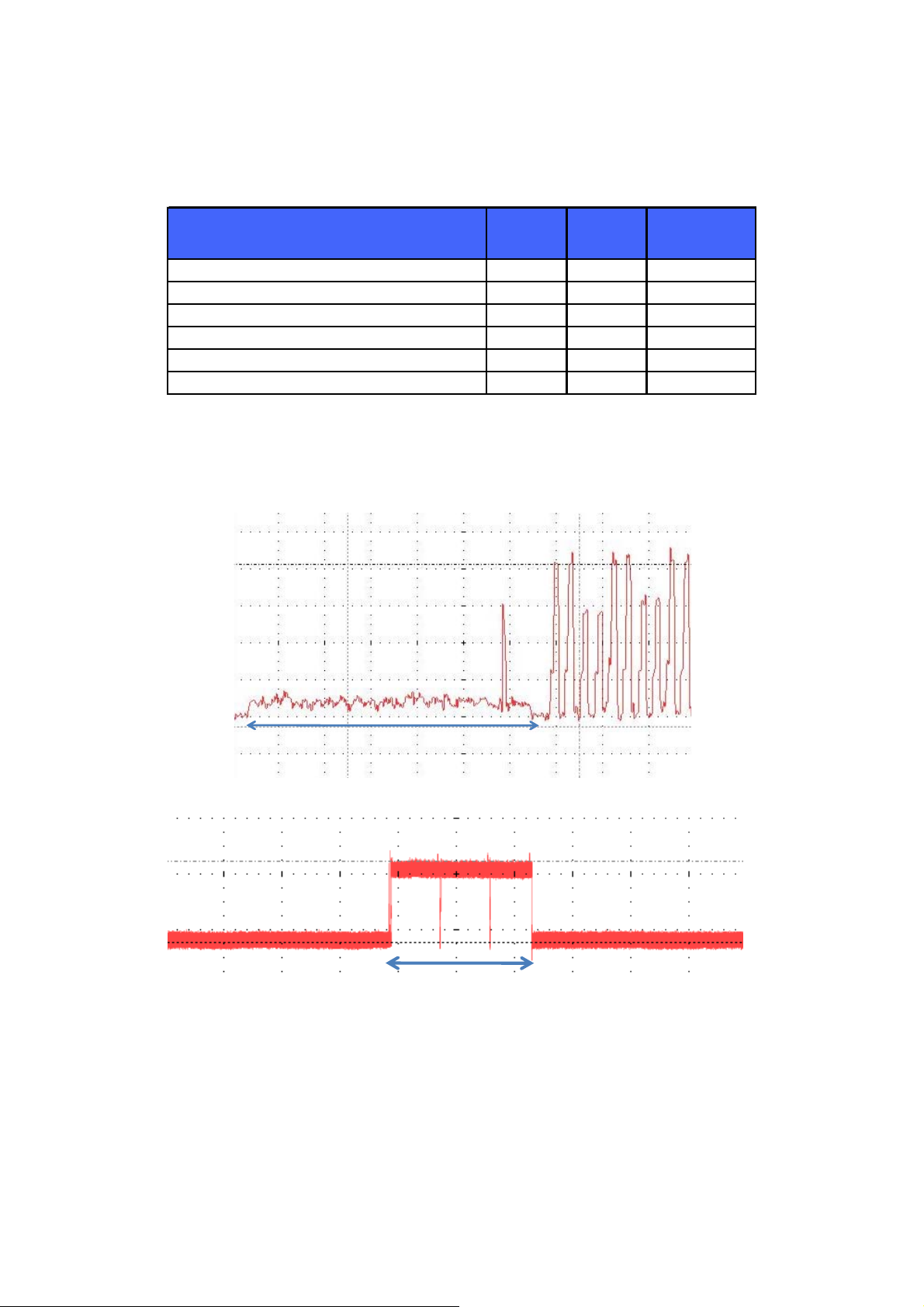

7.3 Radiated Spurious Emissions

Standard Band/Frequency

2nd harmonic 51 / 58 54 / 74 dBuV/m

3rd harmonic < 50 54 / 74 dBuV/m

Band edge

2390MHz

FCC part 15

transmitter

spurious

emissions

ETSI EN 300 328

transmitter

spurious

emissions

ETSI EN 300 328

receiver spurious

Band edge

2483.5MHz

Band edge

2400MHz

(conducted)

Band edge

2483.5MHz

(conducted)

Band edge

2400MHz

2nd harmonic -36 -30

3rd harmonic <-40 -30

(2400 - 2479) MHz <-70

(1600 - 1653) MHz <-70 -47 dBm

Min

(AVG/

PEAK)

Table 13: Radiated Spurious Emissions

Typ

(AVG/

PEAK)

-42 -30

Max

(AVG/

PEAK)

LimitbytheStandard

(AVG/PEAK)

Unit

54 / 74 dBuV/m

54 / 74 dBuV/m

-20 dBc

-20 dBc

dBm

dBm

dBm

-47 dBm

7.4 Antenna Characteristics

The antenna is a standard monopole chip antenna. The radiation pattern is strongly dependent on the layout

of the mother board. Usually the gain is highest to the directions where there is most GND and weakest to the

opposite direction. Typically the total radiated efficiency is around 25% - 35%. The maximum gain is 0.5 dBi.

Bluegiga Technologies Oy

Page 21 of 52

8 Clock Generation

BT111 is using an internal 26 MHz crystal oscillator. All internal digital clocks are generated using a phase

locked loop, which is locked to the 26 MHz crystal oscillator. 26 MHz clock is calibrated in production and the

calibrated settings are stored to the internal EEPROM of BT111. The 32.768 kHz sleep clock is generated

internally to the module. BT111 does not need any external clock sources.

Bluegiga Technologies Oy

Page 22 of 52

9 Bluetooth St ack Microcontroller

BT111 uses a 16-bit RISC MCU for low power consumption and efficient use of memory.

The MCU, interrupt controller and event timer run the Bluetooth software stack and control the Bluetooth radio

and host interfaces.

10 Programmable I/O Ports

See the Device Terminal Functions section for the list of supplies to the PIOs.

PIO lines are configured through software to have either weak or strong pull-ups or pull-downs. All PIO lines

are configured as inputs with weak pull-downs at reset and have additional individual bus keeper

configuration. The default configuration for all the IO pins is input with weak pull-up.

11 Wi-Fi Coexistence Interface

Dedicated hardware is provided to implement a variety of Wi-Fi coexistence schemes. There is support for:

Channel skipping AFH

Priority signaling

Channel signaling

Host passing of channel instructions

The BT111 supports the Wi-Fi coexistence schemes:

Unity-3

Unity-3e

Unity+

Contact support (support@bluegiga.com

) for more information

Bluegiga Technologies Oy

Page 23 of 52

12 Memory Management

12.1 Memory Management Unit

The MMU provides a number of dynamically allocated ring buffers that hold the data that is in transit between

the host and the air. The dynamic allocation of memory ensures efficient use of the available RAM and is

performed by a hardware MMU to minimize the overheads on the processor during data/voice transfers.

12.2 System RAM

56KB of integrated RAM supports the RISC MCU and is shared between the ring buffers for holding

voice/data for each active connection and the general-purpose memory required by the Bluetooth stack.

12.3 Internal ROM Memory (5Mb)

5Mb of internal ROM memory is available on BT111. This memory is provided for system firmware, storing

BT111 settings and program code.

12.4 Internal EEPROM

32Kb internal EEPROM is available on BT111 to store device specific configuration information (PS Keys)

such as Bluetooth address, USB descriptors, PCM configuration and maximum TX power. The internal

EEPROM is powered from VDD_PADS. The minimum supply voltage writing the EEPROM is 2.7V and the

minimum supply voltage for reading the EEPROM is 1.7V.

Bluegiga Technologies Oy

Page 24 of 52

13 Serial Interfaces

13.1 USB Interface

BT111 has a full-speed (12Mbps) USB interface for communicating with other compatible digital devices. The

USB interface on BT111 acts as a USB peripheral, responding to requests from a master host controller.

BT111 supports the Universal Serial Bus Specification, Revision v2.0 (USB v2.0 Specification) and USB

Battery Charging Specification, available from http://www.usb.org. For more information on how to integrate

the USB interface on BT111 see the WTxx / BTxxx USB Design Guide.

As well as describing USB basics and architecture, the application note describes:

Power distribution for high and low bus-powered configurations

Power distribution for self-powered configuration, which includes USB VBUS monitoring

USB enumeration

Electrical design guidelines for the power supply and data lines, as well as PCB tracks and the effects

of ferrite beads

USB suspend modes and Bluetooth low-power modes:

Global suspend

Selective suspend, includes remote wake

Wake on Bluetooth, includes permitted devices and set-up prior to selective suspend

Suspend mode current draw

PIO status in suspend mode

Resume, detach and wake PIOs

Battery charging from USB, which describes dead battery provision, charge currents, charging in

suspend

Modes and USB VBUS voltage consideration

USB termination when interface is not in use

Internal modules, certification and non-specification compliant operation

See chapter 17 for the default USB vendor and product ID settings.

13.2 Programming and Debug Interface

This SPI programming and debug interface can configure the PS Keys stored in the internal EEPROM and

can also debug BT111. Bluegiga provides the development and production tools to communicate over this

interface from a PC.

BT111 uses a 16-bit data and 16-bit address programming and debug interface. Transactions occur when the

internal processor is running or is stopped. Data is written or read one word at a time, or the auto-increment

feature is available for the block access.

Configuring the parameters of the BT111 and running test scripts is also possible via the USB interface with

certain limitations; please see Section 14 for more information.

Bluegiga Technologies Oy

Page 25 of 52

14 Audio Interfaces

BT111 has digital audio interface that is configurable as either a PCM or I2S port.

14.1 PCM Interface

The audio PCM interface on the BT111 supports:

Continuous transmission and reception of PCM encoded audio data over Bluetooth.

Processor overhead reduction through hardware support for continual transmission and reception of

PCM data.

A bidirectional digital audio interface that routes directly into the baseband layer of the firmware. It

does not pass through the HCI protocol layer.

Hardware on BT111 for sending data to and from a SCO connection.

Up to 3 SCO connections on the PCM interface at any one time.

PCM interface master, generating PCM_SYNC and PCM_CLK.

PCM interface slave, accepting externally generated PCM_SYNC and PCM_CLK.

Various clock formats including:

o Long Frame Sync

o Short Frame Sync

o GCI timing environments

13-bit or 16-bit linear, 8-bit μ-law or A-law companded sample formats.

Receives and transmits on any selection of 3 of the first 4 slots following PCM_SYNC.

The PCM configuration options are enabled by setting PSKEY_PCM_CONFIG32.

14.1.1 PCM Interface Master/Slave

When configured as the master of the PCM interface, BT111 generates PCM_CLK and PCM_SYNC.

PCM_OUT

PCM_IN

PCM_CLK

PCM_SYNC

Figure 15: BT111 as PCM master

128/256/512/1536/2400kHz

8/48kHz

Bluegiga Technologies Oy

Page 26 of 52

PCM_OUT

PCM_IN

PCM_CLK

Up to 2400kHz

PCM_SYNC

Figure 16: BT111 as PCM slave

8/48kHz

14.1.2 Long Frame Sync

Long Frame Sync is the name given to a clocking format that controls the transfer of PCM data words or

samples. In Long Frame Sync, the rising edge of PCM_SYNC indicates the start of the PCM word. When

BT111 is configured as PCM master, generating PCM_SYNC and PCM_CLK, then PCM_SYNC is 8 bits long.

When BT111 is configured as PCM Slave, PCM_SYNC is from 1 cycle PCM_CLK to half the PCM_SYNC

rate.

Figure 17: Long Frame Sync (Shown with 8-bit Companded Sample)

BT111 samples PCM_IN on the falling edge of PCM_CLK and transmits PCM_OUT on the rising edge.

PCM_OUT is configurable as high impedance on the falling edge of PCM_CLK in the LSB position or on the

rising edge.

14.1.3 Short Frame Sync

In Short Frame Sync, the falling edge of PCM_SYNC indicates the start of the PCM word. PCM_SYNC is

always 1 clock cycle long.

Bluegiga Technologies Oy

Page 27 of 52

Figure 18: Short Frame Sync (shown with 16-bit sample)

As with Long Frame Sync, BT111 samples PCM_IN on the falling edge of PCM_CLK and transmits

PCM_OUT on the rising edge. PCM_OUT is configurable as high impedance on the falling edge of PCM_CLK

in the LSB position or on the rising edge.

14.2 Multi-slot Operation

More than 1 SCO connection over the PCM interface is supported using multiple slots. Up to 3 SCO

connections are carried over any of the first 4 slots.

Figure 19: Multi-slot Operation with 2 Slots and 8-bit Companded Samples

14.2.1 GCI Interface

BT111 is compatible with the GCI, a standard synchronous 2B+D ISDN timing interface. The 2 64kbps B

channels are accessed when this mode is configured.

Bluegiga Technologies Oy

Page 28 of 52

Figure 20: GCI Interface

The start of frame is indicated by the rising edge of PCM_SYNC and runs at 8kHz.

14.2.2 Slots and Sample Formats

BT111 receives and transmits on any selection of the first 4 slots following each sync pulse. Slot durations

are either 8 or 16 clock cycles:

8 clock cycles for 8-bit sample formats.

16 clock cycles for 8-bit, 13-bit or 16-bit sample formats.

BT111 supports:

13-bit linear, 16-bit linear and 8-bit μ-law or A-law sample formats.

A sample rate of 8ksps.

Little or big endian bit order.

For 16-bit slots, the 3 or 8 unused bits in each slot are filled with sign extension, padded with zeros or

a programmable 3-bit audio attenuation compatible with some codecs.

Bluegiga Technologies Oy

Page 29 of 52

Figure 21: 16-bit Slot Length and Sample Formats

14.2.3 Additional Features

BT111 has a mute facility that forces PCM_OUT to be 0. In master mode, BT111is compatible with some

codecs which control power down by forcing PCM_SYNC to 0 while keeping PCM_CLK running.

Bluegiga Technologies Oy

Page 30 of 52

14.2.4 PCM Timing Information

Symbol Min Typ Max Unit

f

mclk

Parameter

PCM_CLK

Frequency

4MHz DDS generation.

Ffrequency selection is

programmable.

48MHz DDS generation.

Frequency selection is

128

--

256

512

kHz

2.9 - -

programmable.

--8-kHz

(a)

f

mclkh

(a)

f

mclk l

PCM_SYNC frequency for SCO connection

PCM_CLK high 4MHz DDS generation 980 - - ns

PCM_CLK low 4MHz DDS generation 730 - - ns

- PCM_CLK jitter 48MHz DDS generation - - 21 ns pk-pk

Table 14: PCM Master Timing

(a) Assumes normal system clock operation. Figures vary during low-power modes, when system speeds

are reduced.

Symbol Min Typ Max Unit

t

dmclksynch

Parameter

Delay time from

PCM_CLK high to

PCM sync high

4MHz DDS generation.

--20

48MHz DDS generation - - 40.83

t

t

t

t

t

t

dmclkpout

dmclksyncl

dmclklpoutz

dmclkhpoutz

supinclkl

hpinclkl

Delay time from PCM_CLK high to PCM_OUT

Delay time from

PCM_CLK low to

PCM sync low (long

frame sync only)

4MHz DDS generation - - 20

48MHz DDS generation - - 40.83

Delay time from PCM_CLK low to PCM_OUT

high impedance

Delay time from PCM_CLK high to PCM_OUT

high impedance

Set-up time for PCM_IN valid to PCM_CLK low

Hold time for PCM_CLK low to PCM_IN invalid

Table 15: PCM Master Mode Timing Parameters

--20

ns

--20

--20

20 - -

0- -

Bluegiga Technologies Oy

Page 31 of 52

Figure 22: PCM Master Timing Long Frame Sync

Figure 23: PCM Master Timing Short Frame Sync

Bluegiga Technologies Oy

Page 32 of 52

(

)

(

)

Symbol Parameter Min Typ Max Unit

f

sclk

f

sclk

f

sclkl

f

sclkh

PCM clock frequency

Slave mode: Input

PCM clock frequency

GCI mode

PCM_CLK low time

PCM_CLK high time

64 - 2048 kHz

128 - 4096 kHz

200 - - ns

200 - - ns

Table 16: PCM Slave Timing

Symbol Parameter Min Typ Max Unit

f

hsclksynch

f

susclksynch

f

dpout

f

dsclkhpout

Hold time from PCM_CLK low to PCM_SYNC high

Set-up time for PCM_SYNC high to PCM_CLK low

Delay time from PCM_SYNC or PCM_CLK, whichever

is later, to valid PCM_OUT data (long frame sync only)

Delay time from PCM_SYNC or PCM_CLK, whichever

is later, to valid PCM_OUT data

2--

20 - -

--15

--15

Delay time from PCM_SYNC or PCM_CLK low,

f

dpoutz

whichever is later, to PCM_OUT data line high

--20

impedance

f

supinsclkl

f

hpinsclkl

Set-up time for PCM_IN valid to PCM_CLK low

Hold time from PCM_CLK low to PCM_IN valid

20 - -

2--

Table 17: PCM Slave Mode Timing Parameters

ns

Figure 24: PCM Slave Timing Long Frame Sync

Bluegiga Technologies Oy

Page 33 of 52

Figure 25: PCM Slave Timing Short Frame Sync

14.2.5 PCM_CLK and PCM_SYNC Generation

BT111 has 2 methods of generating PCM_CLK and PCM_SYNC in master mode:

Generating these signals by DDS from BT111 internal 4MHz clock. Using this mode limits PCM_CLK

to 128, 256 or 512kHz and PCM_SYNC to 8kHz.

Generating these signals by DDS from an internal 48MHz clock, enables a greater range of

frequencies to be generated with low jitter but consumes more power. To select this second method

set bit 48M_PCM_CLK_GEN_EN in PSKEY_PCM_CONFIG32. When in this mode and with long

frame sync, the length of PCM_SYNC is either 8 or 16 cycles of PCM_CLK, determined by

LONG_LENGTH_SYNC_EN in PSKEY_PCM_CONFIG32.

Following equation describes PCM_CLK frequency when generated from the internal 48MHz clock:

Equation 1: PCM_CLK Frequency Generated Using the Internal 48MHz Clock

Set the frequency of PCM_SYNC relative to PCM_CLK using following equation:

Equation 2: PCM_SYNC Frequency Relative to PCM_CLK

CNT_RATE, CNT_LIMIT and SYNC_LIMIT are set using PSKEY_PCM_LOW_JITTER_CONFIG. As an

example, to generate PCM_CLK at 512kHz with PCM_SYNC at 8kHz, set

PSKEY_PCM_LOW_JITTER_CONFIG to 0x08080177.

Bluegiga Technologies Oy

Page 34 of 52

14.2.6 PCM Configuration

Configure the PCM by using PSKEY_PCM_CONFIG32 and PSKEY_PCM_LOW_JITTER_CONFIG, see your

PS Key file. The default for PSKEY_PCM_CONFIG32 is 0x00800000, i.e. first slot following sync is active, 13-

bit linear voice format, long frame sync and interface master generating 256kHz PCM_CLK from 4MHz

internal clock with no tri-state of PCM_OUT.

14.3 Digital Audio Interface (I2S)

The digital audio interface supports the industry standard formats for I²S, left-justified or right-justified. The

interface shares the same pins as the PCM interface, which means each audio bus is mutually exclusive in its

usage. Table 17 lists these alternative functions.

PCM Interface

PCM_OUT SD_OUT

PCM_IN SD_IN

PCM_SYNC WS

PCM_CLK SCK

2

I

S Interface

Table 18: Alternative Function of the Digital Audio Bus Interface on the PCM Interface

Configure the digital audio interface using PSKEY_DIGITAL_AUDIO_CONFIG. Table 18 describes the values

for the PS Key (PSKEY_DIGITAL_AUDIO_CONFIG) that is used to set-up the digital audio interface. For

example, to configure an I

2

S interface with 16-bit SD data set PSKEY_DIGITAL_CONFIG to 0x0406.

Bluegiga Technologies Oy

Page 35 of 52

Bit Mask Name Description

D[0] 0x0001 CONFIG_JUSTIFY_FORMAT 0 for left justified, 1 for right justified

For left justified formats: 0 is MSB of SD data

D[1] 0x0002 CONFIG_LEFT_JUSTIFY_DELAY

D[2] 0x0004 CONFIG_CHANNEL_POLARITY

D[3] 0x0008 CONFIG_AUDIO_ATTEN_EN

D[7:4] 0x00F0 CONFIG_AUDIO_ATTEN Attenuation in 6 dB steps.

D[9:8] 0x0300 CONFIG_JUSTIFY_RESOLUTION

D[10] 0x0400 CONFIG_16_BIT_CROP_EN

occurs in the first SCLK period following WS

transition. 1 is MSB of SD data occurs in the

second SCLK period.

For 0, SD data is left channel when WS is high.

For 1 SD data is right channel.

For 0, 17 bit SD data is rounded down to 16

bits. For 1, the audio attenuation defined in

CONFIG_AUDIO_ATTEN is applied over 24

bits with saturated rounding. Requires

CONFIG_16_BIT_CROP_EN to be 0.

Resolution of data on SD_IN, 00=16 bit, 01=20

bit, 10=24 bit, 11=Reserved. This is required for

right justified format and with left justified LSB

first.

For 0, 17 bit SD_IN data is rounded down to 16

bits. For 1 only the most significant 16 bits of

data are received.

Table 19: PSKEY_DIGITAL_AUDIO_CONFIG

Bluegiga Technologies Oy

Page 36 of 52

Figure 26: Digital Audio Interface Modes

The internal representation of audio samples within BT111 is 16-bit and data on SD_OUT is limited to 16-bit

per channel.

Symbol Parameter Min Typ Max Unit

- SCK Frequency

- WS Frequency

t

ch

t

cl

SCK high time

SCK low time

--6.2MHz

- - 96 kHz

80 - - ns

80 - - ns

Table 20: Digital Audio Interface Slave Timing

Bluegiga Technologies Oy

Page 37 of 52

y

Symbol Parameter Min Typ Max Unit

t

t

t

t

t

ssu

sh

opd

isu

ih

WS valid SCK high set-up

time

SCK high to WS invalid

hold time

SCK low to SD_OUT valid

time

dela

SD_IN valid to SCK high

set-up time

SCK high to SD_IN invalid

hold time

Table 21: I

2

C Slave Mode Timing

20 - - ns

2.5 - - ns

--20ns

20 - - ns

2.5 - - ns

Figure 27: Digital Audio Interface Slave Timing

Symbol Parameter Min Typ Max Unit

- SCK Frequency

- WS Frequency

--6.2MHz

- - 96 kHz

Table 22: Digital Audio Interface Master Timing

Bluegiga Technologies Oy

Page 38 of 52

y

y

Symbol Parameter Min Typ Max Unit

t

t

t

t

spd

opd

isu

ih

Table 23: I

SCK low to WS valid

dela

time

--39.27ns

SCK low to SD_OUT valid

dela

time

--18.44ns

SD_IN valid to SCK high

set-up time

18.44 - - ns

SCK high to SD_IN invalid

hold time

2

S Master Mode Timing Parameters, WS and SCK as Outputs

0--ns

Figure 28: Digital Audio Interface Master Timing

Bluegiga Technologies Oy

Page 39 of 52

15 Power Control and Regulation

VREG_EN_RST#

VBUS (4.25V – 5.75V)

Figure 29: Internal regulators and powering of BT111

LDO 3V3 LDO 1V8 LDO 1V35

LDO 1V35

LDO 1V25

VREG_IN_HV

(3.3V OUT / 2.3V – 4.8V IN)

VREG_OUT_HV

1.8V OUT / 1.7V – 1.95V IN

15.1 Voltage Regulator Enable

All the regulators are enabled, except the USB linear regulator, by taking the VREG_EN_RST# pin above 1V.

Also the BT111 firmware automatically controls the regulators.

Important Note:

VREG_EN_RST# should not be taken high before the supply on VREG_IN_HV is present.

The VREG_EN_RST# pin is connected internally to the reset function and is powered from VDD_PADS, so do

not apply voltages above VDD_PADS to the VREG_EN_RST# pin. The VREG_EN_RST# pin is pulled down

internally.

15.2 USB Linear Regulator

The integrated USB LDO linear regulator is available as a 3.30V supply rail and is intended to supply the USB

interface and the high-voltage linear regulator. The input voltage range is between 4.25V and 5.75V. The

maximum current from this regulator is 150mA.

This regulator is enabled by default. If the USB linear regulator is not required leave its input (VREG_IN_USB)

unconnected.

15.3 High Voltage Linear Regulator

The integrated high-voltage linear regulator is available to power the main 1.8V supply rail. The input voltage

range is between 2.3V and 4.8V. The maximum current from this regulator is 100mA.

Take VREG_EN_RST# high to enable this regulator.

Important Note:

VREG_EN_RST# should not be taken high before the supply on VREG_IN_HV is present.

If this regulator is not required then leave VREG_IN_HV unconnected or tied to VREG_OUT_HV.

Bluegiga Technologies Oy

Page 40 of 52

15.4 Low Voltage Linear Regulators

BT111 has three integrated low voltage linear regulators providing the internal supply voltages for RF and

digital circuits of BT111. The input voltage range is between 1.70V and 1.95V.

15.5 Powering Sequence

All the power supplies should be powered at the same time. The order of powering the supplies relative to the

I/O supply, VDD_PADS to VDD_HOST, is not important. If the I/O supply is powered before VDD_DIG, all

digital I/Os are weak pull-downs irrespective of the reset state.

15.6 Reset

The reset function is internally tied to the VREG_EN_RST# pin. BT111 is reset from several sources:

VREG_EN_RST# pin

Power-on reset

Via a software-configured watchdog timer

The VREG_EN_RST# pin is an active low reset. Assert the reset signal for a period >5ms to ensure a full

reset.

Important Note:

Bluegiga does not recommend assertions of the reset of <5ms on the VREG_EN_RST# pin, as any glitches

on this line can affect I/O integrity without triggering a reset.

A warm reset function is also available under software control. After a warm reset the RAM data remains

available.

Pin Name/Group I/O Type No Core Supply Reset Full Chip Reset

VREG_EN_RST# Digital input

SPI_CLK/PCM_CLK /

PIO[24]

SPI_CS# / PCM_SYNC /

PIO[23]

SPI_MISO / PCM_OUT /

PIO[22]

SPI_MOSI / PCM_OUT /

PIO[21]

PIO[5:0]

Digital bidirectional

tristated

Digital bidirectional

tristated

Digital output tristated

Digital input

Digital bidirectional

tristated

Table 24: Digital Pin States on Reset

Strong pull-down N/A

Weak pull-down Weak pull-down

Weak pull-up (SPI)

Weak pull-down (PCM)

Weak pull-up (SPI)

Weak pull-down (PCM /

PIO)

Weak pull-down Weak pull-down

Weak pull-down Weak pull-down

Weak pull-down Weak pull-down

Bluegiga Technologies Oy

Page 41 of 52

16 Example Schematic

Figure 30: Example schematic for BT111

Bluegiga Technologies Oy

Page 42 of 52

17 Software

BT111 is supplied with an on-chip Bluetooth v4.0 specification qualified HCI Controller stack firmware. It also

has an EEPROM chip, which allows modifications of many configuration parameters (PS-keys) of the

Bluetooth chip.

When the BT111 development kit is plugged into your PC, it will show up as a generic Bluetooth Controller,

and the Bluetooth Host stack installed on your PC will take control of it.

To access BT111’s configuration parameters, which are stored on its EEPROM chip, you need the included

SPI connector and PSTool software from the CSR BlueSuite tool collection. BlueSuite is available on the

Bluegiga Techforum at http://techforum.bluegiga.com

PSTool contains a full list of the parameters that are possible to modify, along with their descriptions. Some

common parameter keys are:

- (0x0108) PSKEY_DEVICE_NAME – Bluetooth name of the device

- (0x02be) PSKEY_USB_VENDOR_ID – USB Vendor ID, if you have your own VID and wish to use it

(Default is 0a12 which is CSR’s VID)

- (0x02bf) PSKEY_USB_PRODUCT_ID – USB Product ID (Default is 0)

.

Please see the quick start guide for more information and examples.

Bluegiga Technologies Oy

Page 43 of 52

17.1 On-chip Software

17.1.1 Bluetooth HCI Stack

Figure 26 shows an example implementation. An internal processor runs the Bluetooth stack up to the HCI.

The host processor must provide all the upper layers of Bluetooth protocol including the application.

PCM

Host Trasport Device Drivers

Generic Comm and and Event Handling

Blu etoot h HC I Handling ULP HIF Handlin g

LM ULP LL Control Handling

LC: Bluetooth per Pac ket Code LC: ULP per packet Code

LC: Bluetooth per Pac ket Code LC: ULP per Packet Code

USB

Generic HCI Handling

LC Core Scheduler

2.4GHz Radio Hardware

Figure 31: Example FW Architecture

17.1.2 Latest Feature of the HCI Stack

BT111 is based on Bluetooth v4.0 qualified chip CSR8510 by CSR. This introduces the following features:

Generic Alternate MAC/PHY (AMP)

Generic Test Methodology for AMP

802.11 Protocol Adaptation Layer

Enhanced Power Control

Enhanced USB and SDIO HCI Transports

HCI read Encryption Key Size command

Unicast Connectionless Data

For Bluetooth v3.0 + HS operation a separate 802.11 IC is used in conjunction with BT111

Bluegiga Technologies Oy

Page 44 of 52

18 Soldering Recommendations

BT111 is compatible with a industrial standard reflow profile for Pb-free solders. The reflow profile used is

dependent on the thermal mass of the entire populated PCB, heat transfer efficiency of the oven and

particular type of solder paste used. Consult the datasheet of particular solder paste for profile configurations.

Bluegiga Technologies will give following recommendations for soldering the module to ensure the reliable

solder joint and operation of the module after soldering. Since the profile used is process and layout

dependent, the optimal profile should be studied case by case. Thus the following recommendation should be

taken into account as a starting point.

Refer to technical documentations of particular solder paste for profile configurations

Avoid using more than one flow.

Reliability of the solder joint and self-alignment of the component are dependent on the solder

volume. Minimum of 150m stencil thickness is recommended.

Aperture size of the stencil should be 1:1 with the pad size.

A low residue, “no clean” solder paste should be used due to low mounted height of the

component.

Bluegiga Technologies Oy

Page 45 of 52

19 Certifications

19.1 Bluetooth

BT111 is based on Bluetooth v4.0 qualified chip CSR8510 by CSR. BT111 can be used as a controller

subsystem with the Bluetooth QD ID B017701. To make a complete Bluetooth end product, Controller

Subsystem is used together with a qualified Host Subsystem.

19.2 FCC/IC (USA/Canada)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

Any changes or modifications not expressly approved by Bluegiga Technologies could void the

user’s authority to operate the equipment.

FCC RF Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. End

users must follow the specific operating instructions for satisfying RF exposure compliance. This transmitter

meets both portable and mobile limits as demonstrated in the RF Exposure Analysis and should not be used

closer than 5 mm from a human body in portable configuration. This transmitter must not be co-located or

operating in conjunction with any other antenna or transmitter except in accordance with FCC multi-transmitter

product procedures.

IC Statements:

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

OEM Responsibilities to comply with FCC and Industry Canada Regulations

The BT111 module has been certified for integration into products only by OEM integrators under the following

condition:

The antenna(s) must be installed such that a minimum separation distance of 5 mm is maintained

between the radiator (antenna) and all persons at all times.

The transmitter module must not be co-located or operating in conjunction with any other antenna or

transmitter except in accordance with FCC multi-transmitter product procedures.

As long as the two condition above is met, further transmitter testing will not be required. However, the OEM

integrator is still responsible for testing their end-product for any additional compliance requirements required

with this module installed (for example, digital device emissions, PC peripheral requirements, etc.).

Bluegiga Technologies Oy

Page 46 of 52

IMPORTANT NOTE: In the event that these conditions can not be met (for certain configurations or co-

location with another transmitter), then the FCC and Industry Canada authorizations are no longer considered

valid and the FCC ID and IC Certification Number can not be used on the final product. In these

circumstances, the OEM integrator will be responsible for re-evaluating the end product (including the

transmitter) and obtaining a separate FCC and Industry Canada authorization.

End Product Labeling

The BT111 module is labeled with its own FCC ID and IC Certification Number. If the FCC ID and IC

Certification Number are not visible when the module is installed inside another device, then the outside of the

device into which the module is installed must also display a label referring to the enclosed module. In that

case, the final end product must be labeled in a visible area with the following:

“Contains Transmitter Module FCC ID: QOQBT111”

“Contains Transmitter Module IC: 5123A-BGTBT111”

or

“Contains FCC ID: QOQBT112”

“Contains IC: 5123A-BGTBT111”

The OEM of the BT111 module must only use the approved antenna(s) listed in table 8, which have been

certified with this module.

The OEM integrator has to be aware not to provide information to the end user regarding how to install or

remove this RF module or change RF related parameters in the user manual of the end product.

19.2.1 FCC et IC

Déclaration d’IC :

Ce dispositif est conforme aux normes RSS exemptes de licence d’Industrie Canada. Son fonctionnement est

assujetti aux deux conditions suivantes : (1) ce dispositif ne doit pas provoquer de perturbation et (2) ce

dispositif doit accepter toute perturbation, y compris les perturbations qui peuvent entraîner un fonctionnement

non désiré du dispositif.

Responsabilités des OEM quant à la conformité avec les réglementations de FCC et d’Industrie

Canada

Les modules BT111 ont été certifiés pour entrer dans la fabrication de produits exclusivement réalisés par des

intégrateurs dans les conditions suivantes :

L’antenne (ou les antennes) doit être installée de façon à maintenir à tout instant une distance

minimum de 5 mm entre la source de radiation (l’antenne) et toute personne physique.

Bluegiga Technologies Oy

Page 47 of 52

Le module transmetteur ne doit pas être installé ou utilisé en concomitance avec une autre antenne

ou un autre transmetteur.

Tant que ces deux conditions sont réunies, il n’est pas nécessaire de procéder à des tests supplémentaires

sur le transmetteur. Cependant, l’intégrateur est responsable des tests effectués sur le produit final afin de se

mettre en conformité avec d’éventuelles exigences complémentaires lorsque le module est installé (exemple :

émissions provenant d’appareils numériques, exigences vis-à-vis de périphériques informatiques, etc.)

REMARQUE IMPORTANTE : En cas d’inobservance de ces conditions (en ce qui concerne certaines

configurations ou l’emplacement du dispositif à proximité d’un autre émetteur), les autorisations de FCC et

d’Industrie Canada ne seront plus considérées valables et l’identification de FCC et le numéro de certification

d’IC ne pourront pas être utilisés sur le produit final. Dans ces cas, l’intégrateur OEM sera chargé d’évaluer à

nouveau le produit final (y compris l’émetteur) et d’obtenir une autorisation indépendante de FCC et

d’Industrie Canada.

Étiquetage du produit final

Le module BT111 est étiqueté avec sa propre identification FCC et son propre numéro de certification IC. Si

l’identification FCC et le numéro de certification IC ne sont pas visibles lorsque le module est installé à

l’intérieur d’un autre dispositif, la partie externe du dispositif dans lequel le module est installé devra

également présenter une étiquette faisant référence au module inclus. Dans ce cas, le produit final devra être

étiqueté sur une zone visible avec les informations suivantes :

« Contient module émetteur identification FCC : QOQBT111 »

« Contient module émetteur IC : 5123A-BGTBT111 »

ou

« Contient identification FCC : QOQBT111 »

« Contient IC : 5123A-BGTBT111 »

L’OEM du module BT111 ne doit utiliser que la ou les antennes approuvées énumérées dans le tableau 8, qui

ont été certifiées avec ce module.

Dans le guide d’utilisation du produit final, l’intégrateur OEM doit s’abstenir de fournir des informations à

l’utilisateur final portant sur les procédures à suivre pour installer ou retirer ce module RF ou pour changer les

paramètres RF.

19.3 CE (Europe)

BLE112 is in conformity with the essential requirements and other relevant requirements of the R&TTE

Directive (1999/5/EC). The product is conformity with the following standards and/or normative documents.

EMC (immunity only) EN 301 489-17 V2.1.1

Radiated emissions EN 300 328 V1.7.1

Safety EN60950-1:2006+A11:2009+A1:2010+A12:2011

Bluegiga Technologies Oy

Page 48 of 52

19.4 KCC (South-Korea)

TBA

19.5 Japan

TBA

Bluegiga Technologies Oy

Page 49 of 52

20 Moisture Sensitivity Level (MSL) classification

Moisture sensitivity level (MSL) of this product is 3. Please follow the handling guidelines of the standard

IPC/JEDEC J-STD-020 and J-STD-033.

Bluegiga Technologies Oy

Page 50 of 52

21 Packaging and Reel Information

TBA

Bluegiga Technologies Oy

Page 51 of 52

22 Contact Information

Sales: sales@bluegiga.com

Technical support: support@bluegiga.com

http://techforum.bluegiga.com

Orders: orders@bluegiga.com

WWW: www.bluegiga.com

www.bluegiga.hk

Head Office / Finland:

Phone: +358-9-4355 060

Fax: +358-9-4355 0660

Sinikalliontie 5A

02630 ESPOO

FINLAND

Postal address / Finland:

P.O. BOX 120

02631 ESPOO

Sales Office / USA:

Sales Office / Hong-Kong:

FINLAND

Phone: +1 770 291 2181

Fax:

+1 770 291 2183

Bluegiga Technologies, Inc.

3235 Satellite Boulevard, Building 400, Suite 300

Duluth, GA, 30096, USA

Phone: +852 3182 7321

Fax:

+852 3972 5777

Bluegiga Technologies, Inc.

19/F Silver Fortune Plaza, 1 Wellington Street,

Central Hong Kong

Bluegiga Technologies Oy

Page 52 of 52

Loading...

Loading...