Blue Gecko BGM111 Bluetooth® Smart

Module Data Sheet

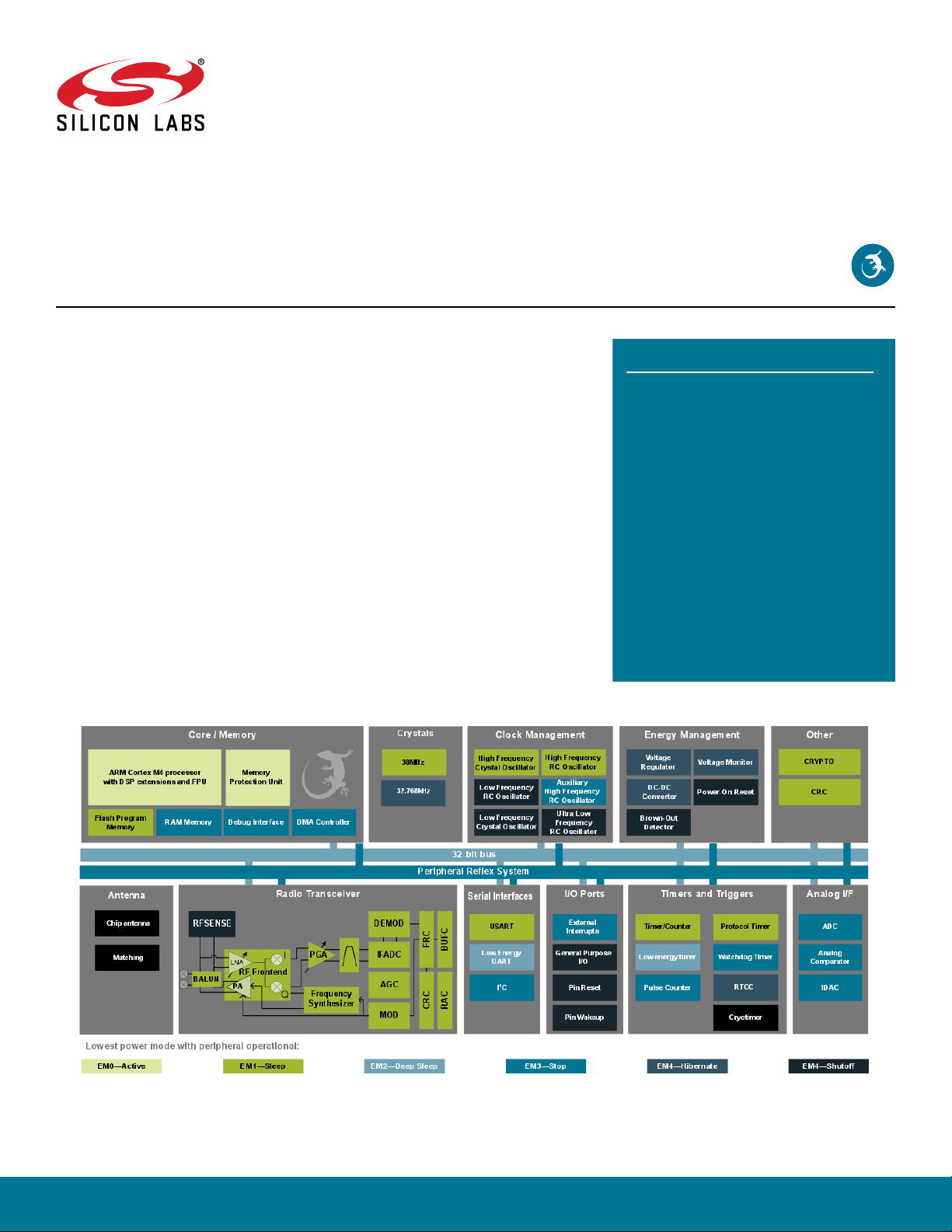

The BGM111 is a Bluetooth® Smart module targeted for Bluetooth Smart applications

where good RF performance, low power consumption and easy application development

are key requirements. At +8 dBm TX power BGM111 has best-in-class RF performance

and can provide long range, robust Bluetooth Smart connectivity.

The BGM111 integrates all of the necessary elements required for a Bluetooth Smart

application: Bluetooth radio, software stack and GATT based profiles and it can also

host end user applications, which means no external microcontroller is required in size,

price or power constrained devices. The BGM111 Bluetooth Smart module also has

highly flexible hardware interfaces to connect to different peripherals or sensors.

Although the BGM111 Bluetooth Smart Module is targeted at applications requiring high

RF performance, it still has ultra-low power consumption and can be operated using a

standard 3V coin cell battery.

BGM111 can be used in a wide variety of applications:

• Health and Fitness

• Point-of-Sales

• Consumer Electronics

• Automotive Aftermarket

• Industrial and Home Automation

• Others

KEY FEATURES

• Bluetooth 4.1 Compliant (Bluetooth Smart)

• Software upgradable to Bluetooth 4.2

• TX power: up to +8 dBm

• RX sensitivity: down to -92 dBm

• Range: up to 200 meters

•

CPU core: 32-bit ARM® Cortex-M4

• Flash memory: 256 kB

• RAM: 32 kB

• Autonomous Hardware Crypto Accelerator

and True Random Number Generator

• Integrated DC-DC Converter

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96

1. Feature List

The highlighted features are listed below.

Bluetooth Features

Blue Gecko BGM111 Bluetooth® Smart Module Data Sheet

Feature List

Harware Interfaces

• Bluetooth 4.1 Compliant

• Software Upgradable to Bluetooth 4.2

• Central and Peripheral Roles

• Up to 6 x BLE Connections in Central Role

Radio Features

• Integrated Antenna

• TX Power (+8 dBm)

• RX Sensitivity (-92 dBm)

• Up to 200 meters LoS range

Software Features

• Integrated Bluetooth Smart Stack

• Any GATT based Bluetooth Smart Profile

• 100 kbps throughput over BLE

•

BGAPI™ serial protocol over UART for modem (NCP) usage

•

BGLIB™ host library which implements BGAPI serial protocol

•

BGScript™ script and C programming for standalone usage

•

Profile Toolkit™ for creating GATT based services

• UART host interface

• 2 x SPI, UART and 2 x I2C peripheral interfaces

• Up to 25 x GPIO with interrupts

• 4 x 12-bit ADC and 1 x 12-bit IDAC

• Internal temperature sensor

• Internal battery voltage measurement option

• Clock generator

• Real-time counter

MCU Features

•

ARM® Cortex-M4F

• 40 MHz

• 32 kB RAM

• 256 kB Flash

• Advanced cryptography support

Electrical Characteristics

• Supply voltage: 1.8 V to 3.8 V with DC-DC bypass mode

• Supply voltage: 2.4 V to 3.8 V when using DC-DC

• 8.7 mA TX current at 0 dBM

• 8.8 mA RX current

• 63 μA/MHz @ Energy Mode 0

• 1.4 μA EM2 deep sleep current

Environmental/Regulatory

• Temperature range: -40C to +85C

• Bluetooth, CE, FCC and IC, Japan and South-Korea qualified

Dimensions

• W x L x H: 12.9 mm x 15.0 mm x 2.2 mm

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 1

Blue Gecko BGM111 Bluetooth® Smart Module Data Sheet

Ordering Information

2. Ordering Information

BGM111A256V1 (orderable part number) is the product code for a pre-production (non-certified) version of the Module based on rev A2

SoC. This (V1) product code is updated to production version (V2) when the logos of the official CE and FCC certifications are marked

into the Module’s metallic RF shield and the SoC used inside the Module is in mass production. The product code of the production

version with the certification markings is BGM111A256V2R (1000 pcs cut reel) and BGM111A256V2 (100 pcs cut reel).

Note: The only visual difference between pre-production (V1) and production module (V2) versions will be the certification codes printed on the RF shield. Silicon Labs reserves the right to deliver BGM111A256V2R or BGM111A256V2 (production version) for customers ordering BGM111A256V1R or BGM111A256V1.

Part Number Description Features

BGM111A256V1 BGM111 Bluetooth Smart Mod-

ule with internal chip antenna

Cut reel Core: ARM Cortex M4

BGM111A256V1R BGM111 Bluetooth Smart Mod-

ule with internal chip antenna

Full reel Core: ARM Cortex M4

SLWSTK6101A Blue Gecko Bluetooth Smart

Module Wireless Development

Kit (WSTK)

Radio: Bluetooth Smart 4.1, +8 dBm TX

Memory: 32 kB RAM/256 kB flash

Antenna: chip

Packaging: 100 pcs cut reel

Status: pre-production samples

Production PN: BGM111A256V2

Radio: Bluetooth Smart 4.1, +8 dBm TX

Memory: 32 kB RAM/256 kB flash

Antenna: chip

Packaging: 1000 pcs tape and reel

Status: pre-production samples

Production PN: BGM111A256V2R

BGM111 Radio Board

WSTK Main Board

Expansion Board (buttons, leds, accelerometer, joystick)

Accessories

BGM111A256V2 BGM111 Bluetooth Smart Mod-

ule with internal chip antenna

Cut reel

BGM111A256V2R BGM111 Bluetooth Smart Mod-

ule with internal chip antenna

Full reel

SLWSTK6101B Blue Gecko Bluetooth Smart

Module Wireless Development

Kit (WSTK)

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 2

See BGM111A256V1

See BGM111A256V1R

BGM111 Radio Board and BGM113 Radio Board

WSTK Main Board

Expansion Board (buttons, leds, accelerometer, joystick)

Accessories

Blue Gecko BGM111 Bluetooth

®

Smart Module Data Sheet

Interfaces

3. Interfaces

This section describes the features and functionalities of the interfaces and peripherals.

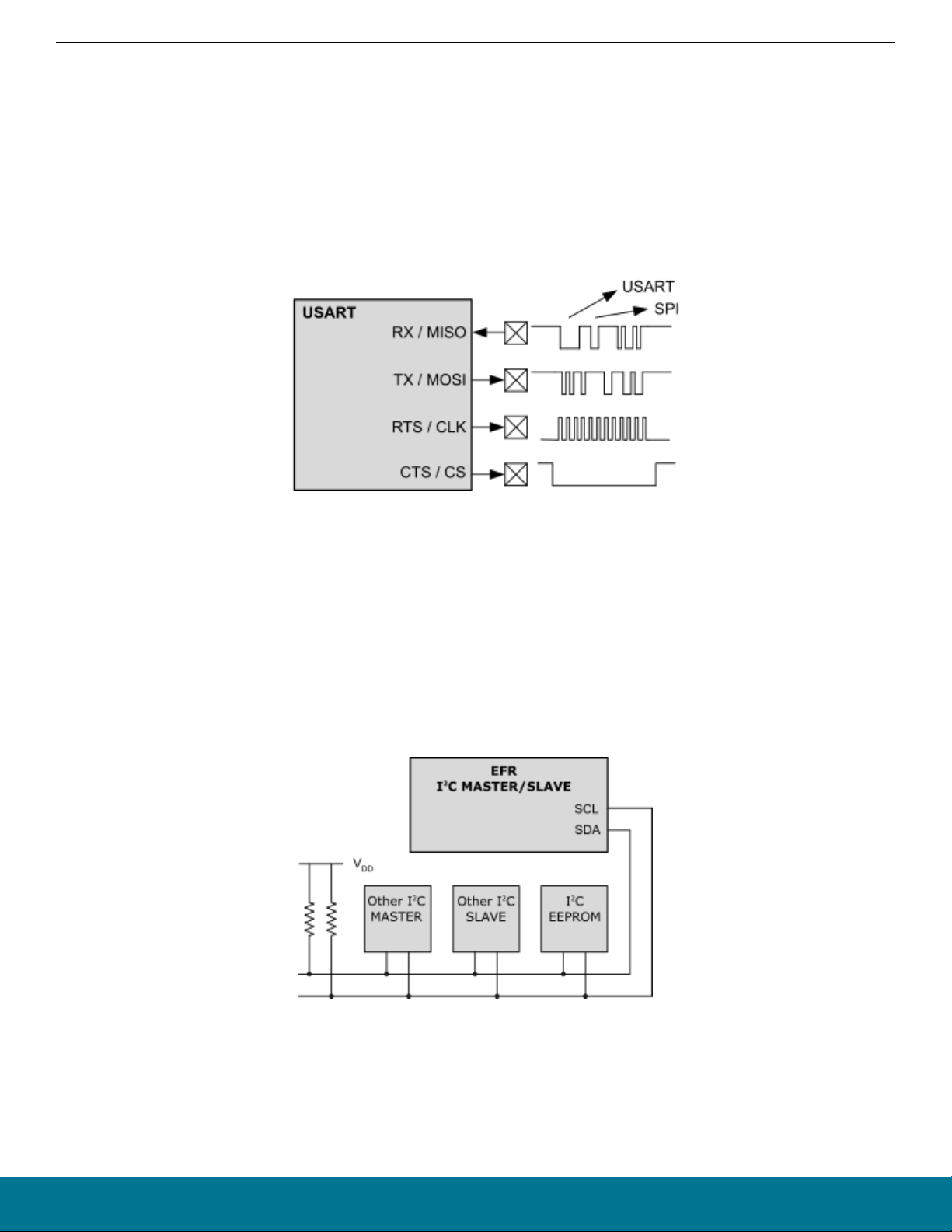

3.1 USART

The Universal Synchronous/Asynchronous Receiver/Transmitter is a flexible serial I/O module. It supports full duplex asynchronous

UART communication with hardware flow control as well as SPI.

If UART is used as BGAPI serial protocol host interface it is strongly recommended to use RTS and CTS signals for reliable data transmission.

Figure 3.1. USART

3.2 Low Energy Universal Asynchronous Receiver/Transmitter (LEUART)

The unique LEUART™ provides two-way UART communication on a strict power budget. Only a 32.768 kHz clock is needed to allow

UART communication up to 9600 baud. The LEUART includes all necessary hardware to make asynchronous serial communication

possible with a minimum of software intervention and energy consumption.

3.3 I2C

The I2C module provides an interface between the MCU and a serial I2C bus. It is capable of acting as both a master and a slave.

Standard-mode, fast-mode and fast-mode plus speeds are supported, allowing transmission rates from 10 kbit/s up to 1 Mbit/s.

Figure 3.2. I2C

3.4 Timer/Counter (TIMER)

TIMER peripherals count events, generate PWM outputs. The core of each TIMER is a 16-bit counter.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 3

®

Blue Gecko BGM111 Bluetooth

Smart Module Data Sheet

Interfaces

3.5 Real Time Counter

The Real Time Counter is a 32-bit counter providing timekeeping in all energy modes and it is capable of providing system wake-up at

user defined instances. The RTCC includes 128 bytes of general purpose data retention, allowing easy and convenient data storage in

all energy modes.

3.6 Low Energy Timer (LETIMER)

The unique LETIMER™ is a 16-bit timer that is available in energy mode EM2 DeepSleep in addition to EM1 Sleep and EM0 Active.

This allows it to be used for timing and output generation when most of the device is powered down, allowing simple tasks to be performed while the power consumption of the system is kept at an absolute minimum. The LETIMER can be used to output a variety of

waveforms with minimal software intervention.

3.7 Ultra Low Power Wake-Up Timer (CRYOTIMER)

The CRYOTIMER is a 32-bit counter that is capable of running in all energy modes. It can be clocked by either the 32.768 kHz crystal

oscillator (LFXO), the 32.768 kHz RC oscillator (LFRCO) or the 1 kHz RC oscillator (ULFRCO). It can provide periodic Wakeup events

and PRS signals which can be used to wake up peripherals from any energy mode. The CRYOTIMER provides a wide range of interrupt periods, facilitating flexible ultra-low energy operation.

3.8 Pulse Counter (PCNT)

The Pulse Counter (PCNT) peripheral can be used for counting pulses on a single input or to decode quadrature encoded inputs.

3.9 General Purpose Input/Output (GPIO)

BGM111 has 25 General Purpose Input/Output pins. Each GPIO pin can be individually configured as either an output or input. More

advanced configurations including open-drain, open-source, and glitch-filtering can be configured for each individual GPIO pin. The

GPIO pins can be overridden by peripheral connections, like SPI communication. Each peripheral connection can be routed to several

GPIO pins on the device. The GPIO subsystem supports asynchronous external pin interrupts.

When configured as GPIO output drive strength can be applied to pins on port by port basis and it can be either 1 mA or 10 mA.

3.10 Analog Comparator (ACMP)

The Analog Comparator is used to compare the voltage of two analog inputs, with a digital output indicating which input voltage is higher. Inputs are selected from among internal references and external pins. The tradeoff between response time and current consumption

is configurable by software. The ACMP can also be used to monitor the supply voltage from software. An interrupt can be generated

when the supply falls below or rises above a programmable threshold.

3.11 Analog to Digital Converter (ADC)

The ADC is a Successive Approximation Register (SAR) architecture, with a resolution of up to 12 bits up to 1 Msamples/sec. The output sample resolution is configurable and additional resolution is possible using integrated hardware for averaging over multiple samples. The ADC includes integrated voltage references and an integrated temperature sensor. Inputs are selectable from a wide range of

source, including pins configurable as either single-ended or differential.

3.12 Digital to Analog Current Converter (IDAC)

The Digital to Analog Current Converter can source or sink a configurable constant current. This current can be driven on an output pin

or routed to the selected ADC input pin for capacitive sensing. The current is programmable between 0.05 μA and 64 μA with several

ranges with various step sizes.

3.13 Integrated DC-DC Converter (DC-DC)

The DC-DC buck converter covers a wide range of load currents and provides high efficiency in energy modes EM0, EM1, EM2 and

EM3. The converter operates in active and bypass operating modes. Bypass mode may be entered when the input voltage is too low

for efficient operation of the DC-DC converter. In Bypass mode, the DC-DC input supply is internally connected directly to its output

through a low resistance switch. Bypass mode also supports in-rush current limiting to avoid dipping the input supply due to excessive

current transients.

Note:

• When DC/DC is enabled, supply voltage range is 2.4V to 3.8V.

• When DC/DC is disabled, supply voltage range is 1.8V to 3.8V.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 4

Blue Gecko BGM111 Bluetooth® Smart Module Data Sheet

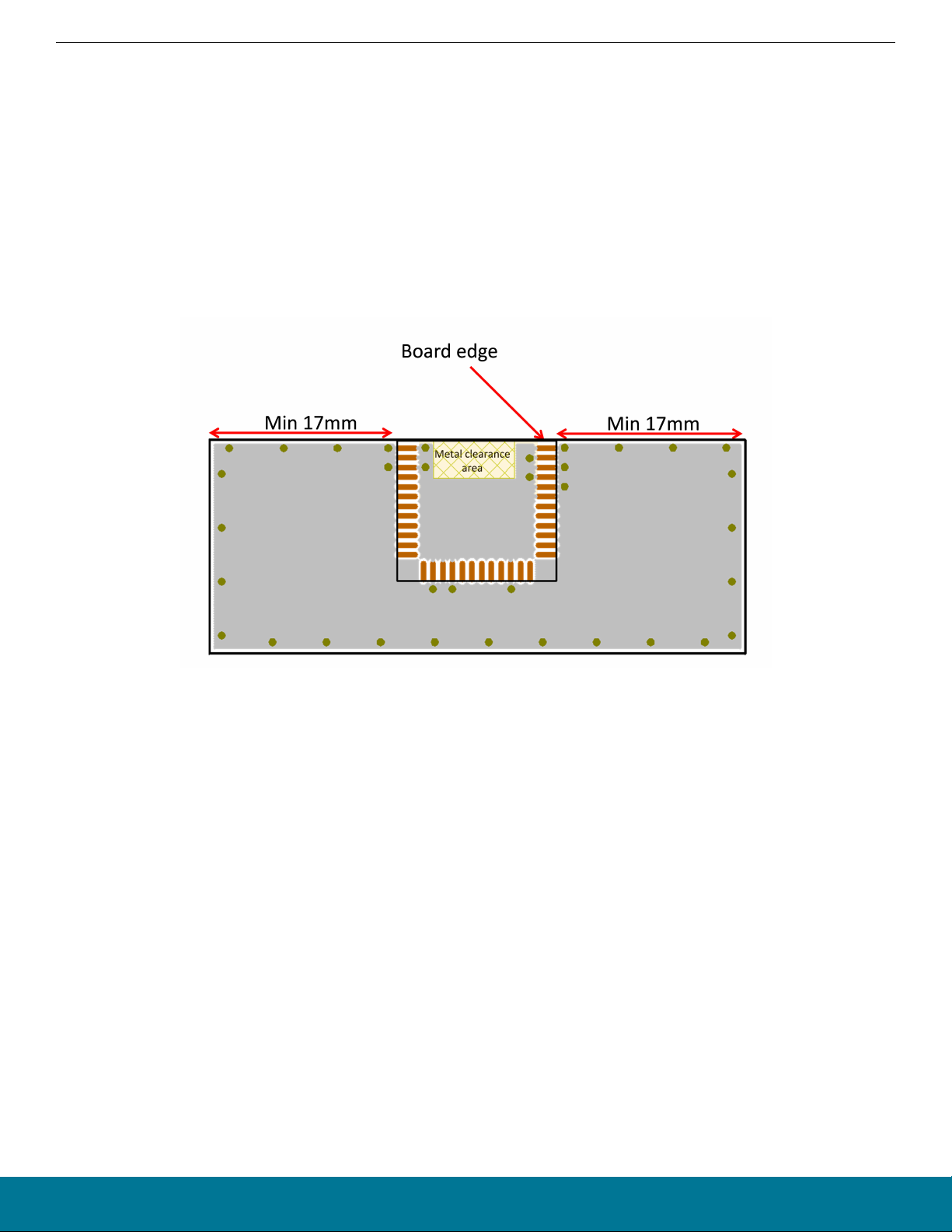

4. Antenna

This section contain design guidelines and recommendations for the BGM111 antenna.

4.1 PCB Design Guidelines

For optimal performance of the BGM111, please follow the following guidelines:

• Place the module at the edge of the PCB as shown in the the figure below.

• Do not place any metal (traces, components, battery etc.) within the clearance area of the antenna.

• Connect all the GND pins directly to a solid GND plane.

• Place the GND vias as close to the GND pins as possible.

• Do not place plastic or any other dielectric material in touch with the antenna.

Antenna

Figure 4.1. Recommended Layout for BGM111

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 5

Blue Gecko BGM111 Bluetooth

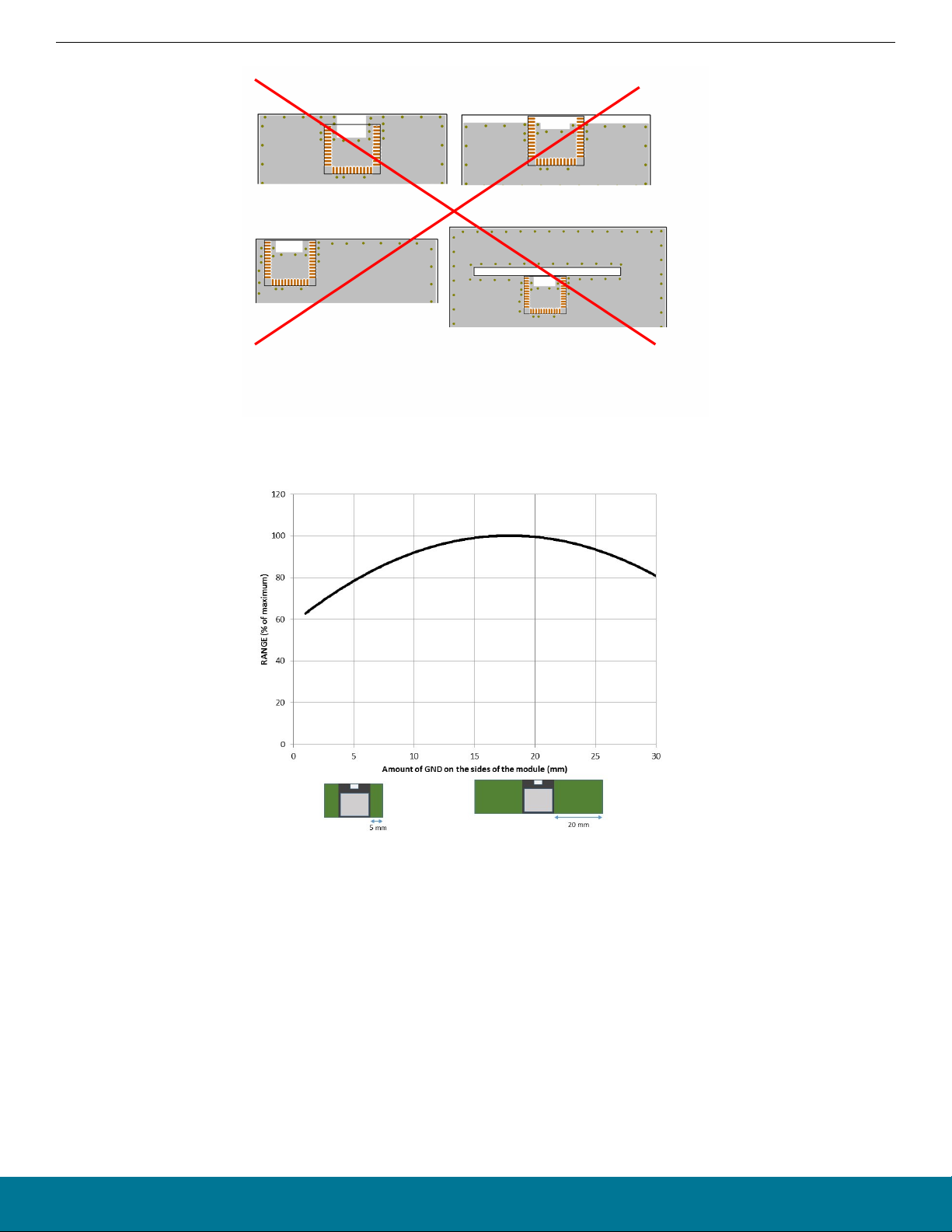

Figure 4.2. Poor Layouts for BGM111

®

Smart Module Data Sheet

Antenna

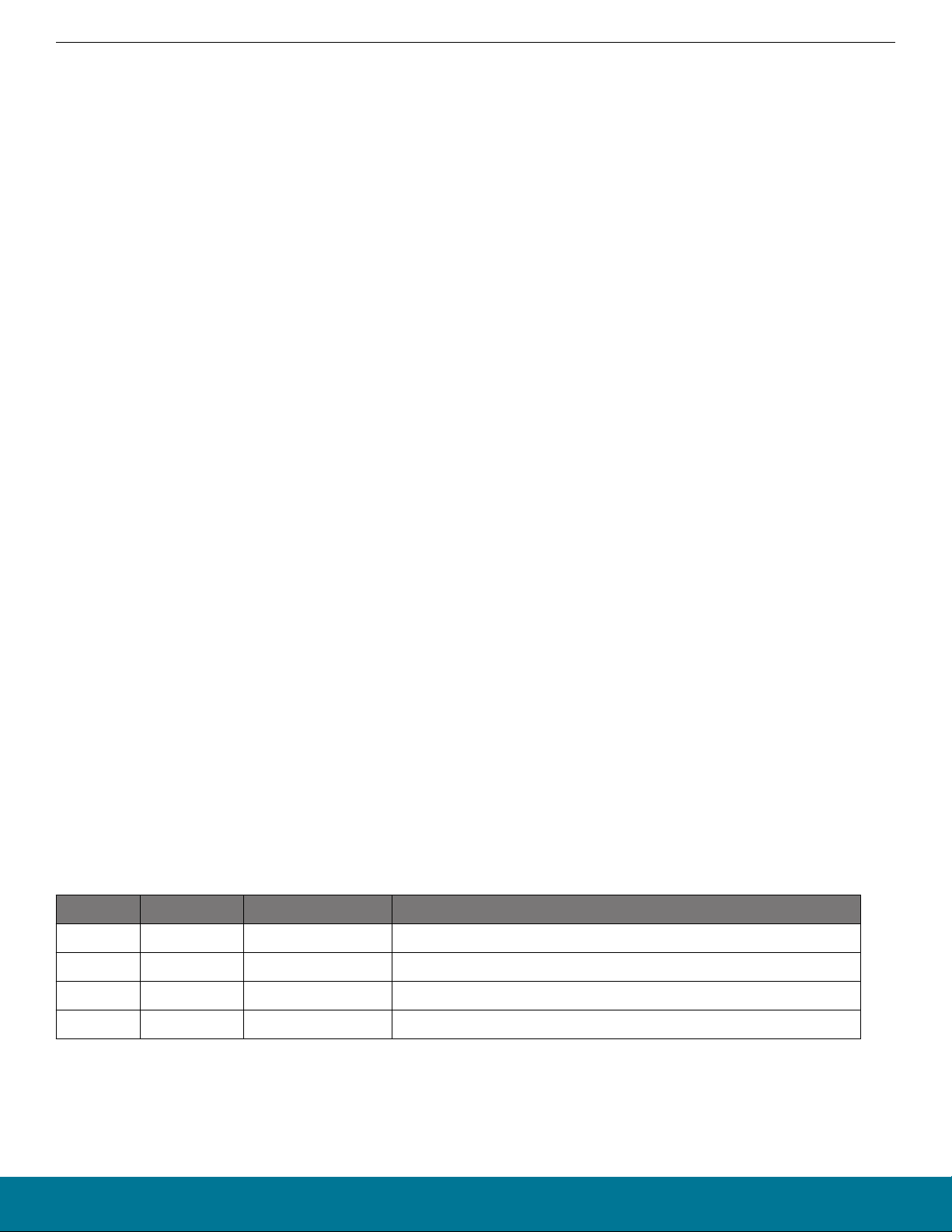

Figure 4.3. Impact of the Size of GND Plane to the BGM111 Range

4.2 Effect of Plastic and Metal Materials

Do not place plastic or any other dielectric material in touch with the antenna.

Any metallic objects in close proximity to the antenna will prevent the antenna from radiating freely. The minimum recommended distance of metallic and/or conductive objects is 10 mm in any direction from the antenna except in the directions of the application PCB

ground planes.

4.3 Locating the Module Close to Human Body

Note: Placing the module in touch or very close to the human body will have a negative impact on the efficiency of the antenna thus

reducing range.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 6

Blue Gecko BGM111 Bluetooth

®

Smart Module Data Sheet

Hardware Design Guidelines

5. Hardware Design Guidelines

The BMG111 is an easy-to-use module with regard to hardware application design but certain design guidelines must be followed to

guarantee optimal performance. These guidelines are listed in the next sub-sections.

5.1 Power Supply Requirements

Coin cell batteries cannot withstand high peak currents (e.g. higher than 15 mA). If the peak current exceeds 15 mA it’s recommended

to place 47 - 100 µF capacitor in parallel with the coin cell battery to improve the battery life time. Notice that the total current consumption of your application is a combination of the radio, peripherals and MCU current consumption so you must take all of these into account. BGM111 should be powered by a unipolar supply voltage with nominal value of 3.3 V. Operating voltage range of the module is

2.4 - 3.8 V when using the built-in DC/DC converter.

External high frequency bypass capacitors are not needed because the module contains the required supply filter capacitors. However,

care should be taken to prevent strong switching noise from being superimposed on the supply line. Such noise can be generated e.g.

by on-board charge pump converters used in RS232 level shifters. If this type of switching noise is present, a power filter circuit on the

VDD input is recommended. Note that there is a total of about 4.8 µF of low ESR ceramic capacitors on the VDD line inside the module.

When using low-dropout linear regulators to generate a regulated supply for the VDD line, the stability of the regulator with the low ESR

provided by these capacitors should be checked. Many linear regulators and also some switched mode regulators are not stable when

using ceramic output capacitors. The datasheet of the regulator typically lists recommendations concerning suitable capacitors including data on ESR range and/or stability curves. A regulator which is stated “stable with ceramic capacitors” is recommended.

5.2 Power Saving Functions

EM power saving modes are automatically controlled by the firmware and it always enters the lowest possible power save mode possible depending on the radio, peripheral and software activity.

5.3 Reset Functions

The BGM111 can be reset by three different methods: by pulling the RESET line low, by the internal watchdog timer or software command. The reset state in BGM111 does not provide any power saving functionality and thus is not recommended as a means to conserve power. BGM111 has an internal system power-up reset function. The RESET pin includes an on-chip pull-up resistor and can

therefore be left unconnected if no external reset switch or source is needed.

5.4 Debug and Firmware Updates

This section contains information on debug and firmware update methods.

5.4.1 JTAG

It is recommended to expose the JTAG debug pins in your own hardware design for firmware update and debug purposes. The following table lists the required pins for JTAG connection.

The debug pins have pull-down and pull-up enabled by default, so leaving them enabled may increase current consumption if left connected to supply or ground. If enabling the JTAG pins the module must be power cycled to enable a SWD debug session.

Table 5.1. JTAG Pads

PAD NAME PAD NUMBER JTAG SIGNAL NAME COMMENTS

PF3 24 TDI This pin is disabled after reset. Once enabled the pin has a built-in pull-up.

PF2 23 TDO This pin is disabled after reset

PF1 22 TMS Pin is enabled after reset and has a built-in pull-up

PF0 21 TCK Pin is enabled after reset and has a built-in pull-down

5.4.2 DFU

It is also possible to update the firmware over UART using DFU protocol. However the bootloader cannot be updated using DFU but

requires that the firmware is updated using JTAG.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 7

Blue Gecko BGM111 Bluetooth® Smart Module Data Sheet

Bluetooth Stack Software

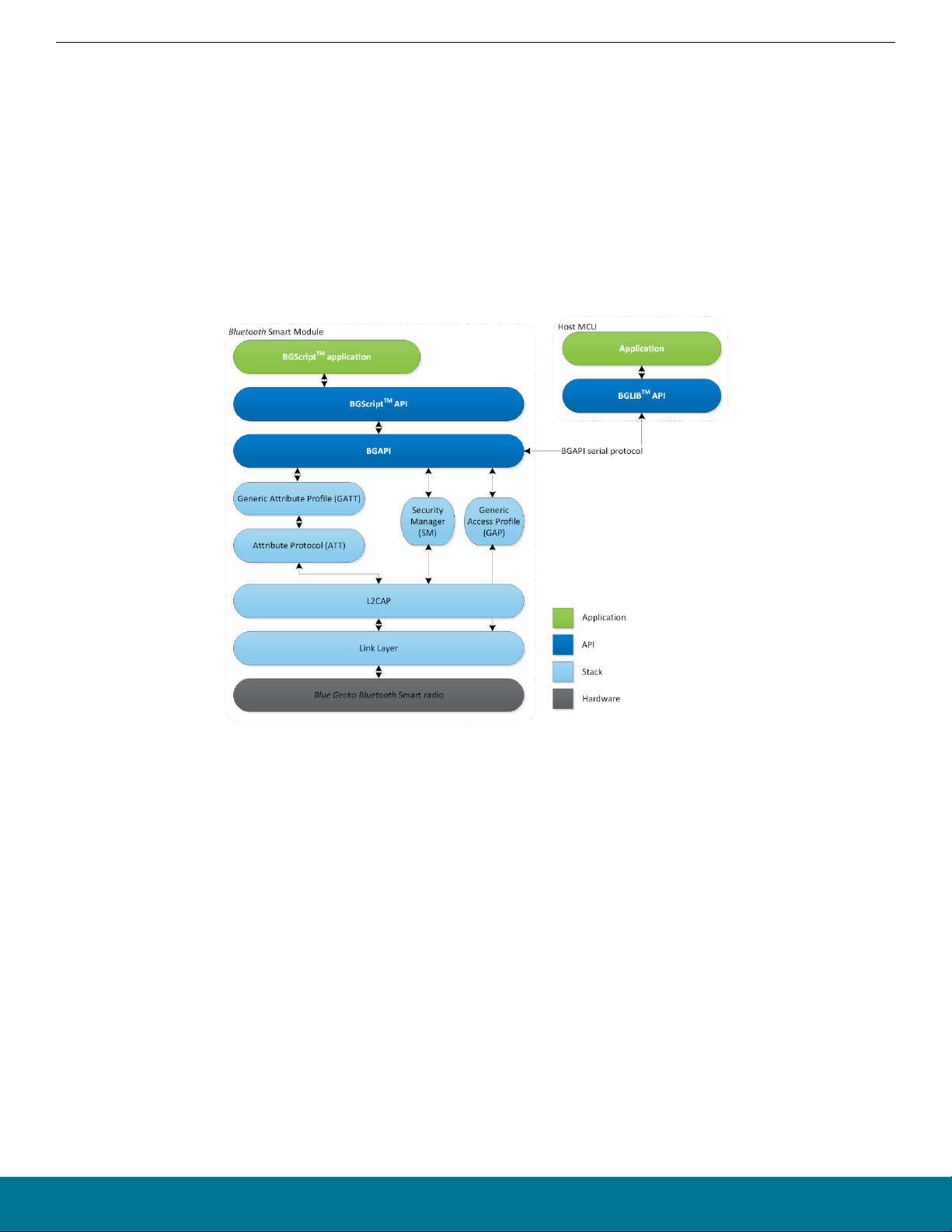

6. Bluetooth Stack Software

Silicon Labs’ Bluetooth Smart Software is a complete Bluetooth Smart software stack for the BGM111 Bluetooth Smart module. The

software implements a full Bluetooth LE compatible stack and L2CAP, RFCOMM, SMP and ATT protocols along with any GATT based

Bluetooth Smart profiles.

The Bluetooth Smart Ready Software also is supported by a complete SDK for developing Bluetooth Smart applications using either an

external host with the BGAPI™ serial protocol over UART or fully standalone applications based on a simple scripting language called

BGScript™.

Several profiles and software project examples are offered as part of the Bluetooth Smart SDK to help expedite the development of

Bluetooth Smart compatible end-user products.

The main parts of the Bluetooth Smart software stack are shown below.

Figure 6.1. Bluetooth Smart Ready Software Stack

Note: To learn more about the Bluetooth Smart software stack, the SDK, and the APIs please read QSG108: Blue Gecko Bluetooth

Smart Software Quick-Start Guide.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 8

Blue Gecko BGM111 Bluetooth® Smart Module Data Sheet

Host Interface

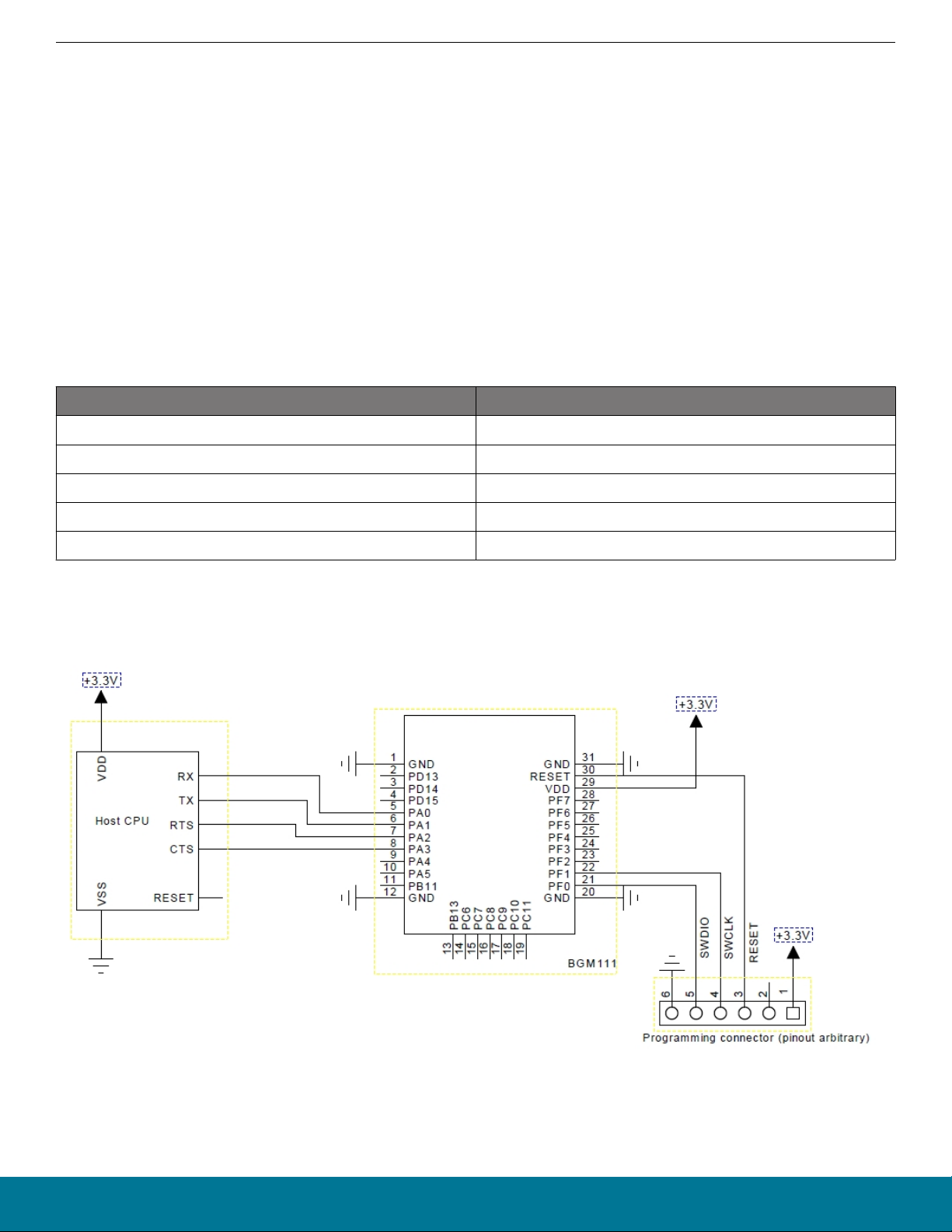

7. Host Interface

This section contains information about the host interface available on the BGM111 module.

7.1 UART

The BGM111 can be controlled over the UART interface as a peripheral to an external processor. In order for the communication to be

reliable, hardware flow control signals (RTS and CTS) must be present between the host and the module. For baud rates exceeding

115200 kbps the controlling processor should have a clock frequency accurate to within 1% in order for the UART signaling to work

reliably.

When UART is used as a host interface (network co-processor mode) two optional I/O pins can be used either to wake-up the BGM111

from EM2 sleep mode when the host has commands or data to send or alternatively to wake-up the host when the BGM111 has events

or data to the host.

Default UART settings are listed below:

Table 7.1. BGM111 UART Interface Default Settings

Parameter Default setting

UART baud rate 115200 kbs

RTS/CTS flow control Enabled

Data bits 8

Parity None

Stop bits 1

The figure below shows the recommended layout for connecting BGM111 with an external host.

Note: A programming connector as shown in the figure below must be available in the design for BGM111 firmware update.

Figure 7.1. Connecting BGM111 with an external host

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.96 | 9

Loading...

Loading...