Silicon Laboratories Z-WAVE 700 Integration Manual

INSTRUCTION: Z-Wave 700 Integration Guide

INS14487-3 | 2/2019 1

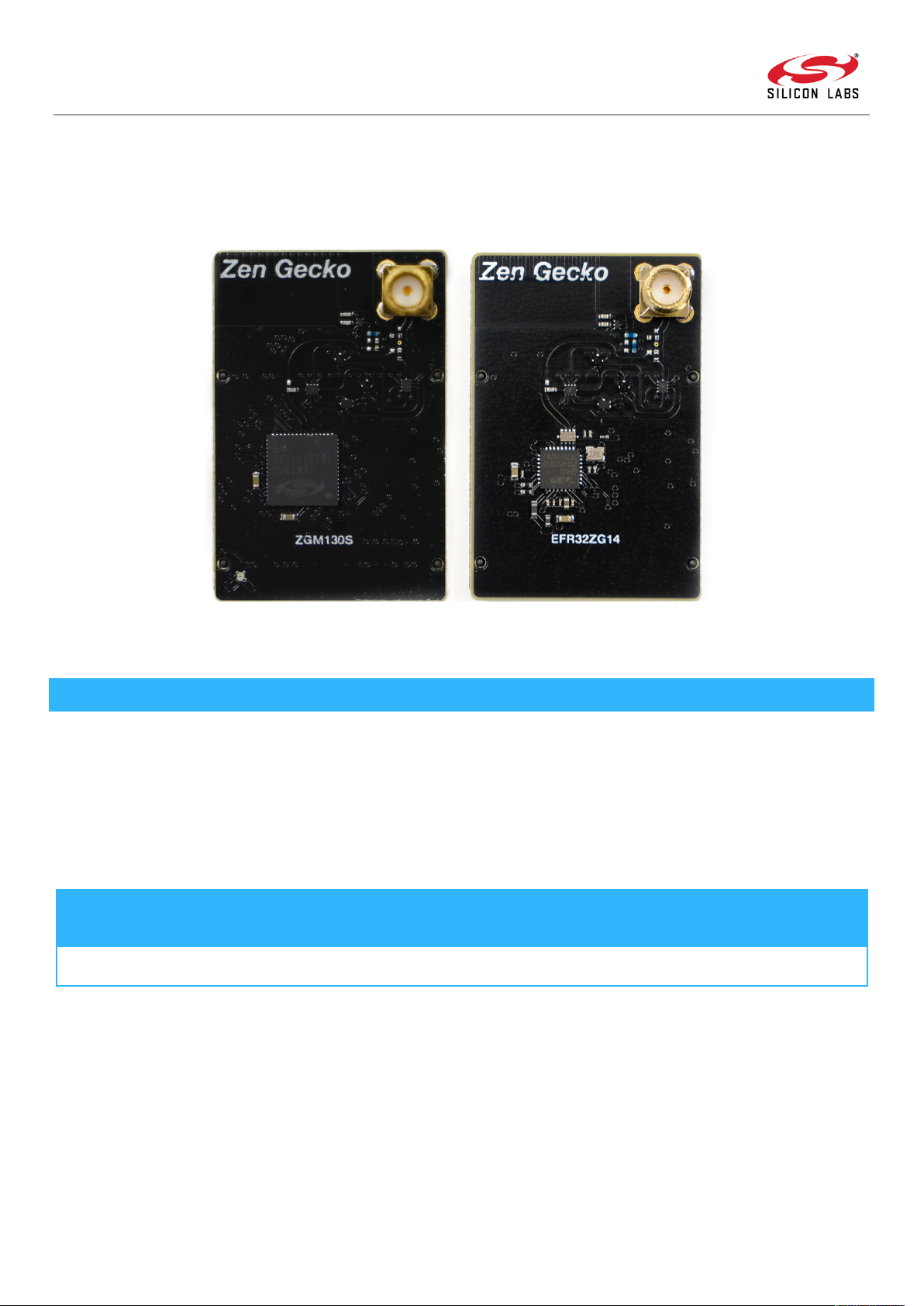

INTEGRATION GUIDE FOR SILICON LABS ZENGECKO Z-WAVE® DEVICES

Type

QFN32

SoC

5mm x 5mm

LGA64

SiP

9mm x 9mm

Chip

EFR32ZG14

Module

ZGM130S

The purpose of this document is to provide an implementation guide for integrating Z-Wave 700 devices into product designs.

It is intended for product design engineers who aim for a fast integration of Z-Wave 700 devices.

1 OV ERVI EW

The Z-Wave 700 device portfolio is shown in Table 1.1. The EFR32ZG14 gateway SoC exposes the Z-Wave serial API via UART and

is dedicated to gateway applications. The ZGM130S SiP module combines a general-purpose SoC, crystal, supply decoupling

components, and RF matching components into a single small-footprint module requiring only two decoupling capacitors. The

ZGM130S is targeted at end device applications and, with its built-in ARM M4 core and ultra-low power consumption, it is perfect

for making single chip sensors and other end devices that require advanced processing and low power consumption.

Table 1.1: Z-Wave 700 device portfolio

The applicable modules are clearly stated at the beginning of each of the following sections.

Instruction: Z-Wave Z-Wave 700 Integration Guide

2 INS14487-3 | 2/2019

2 CON TENT

1 OVERVIEW.........................................................................................................................................................................1

3 PROGRAMMING AND DEBUGGING INTERFACE ..................................................................................................................3

3.1 PROGRAMMING INTERFACE OVERVIEW .........................................................................................................................................4

4 CALIBRATION.....................................................................................................................................................................4

4.1 CRYSTAL .................................................................................................................................................................................4

5 RF VERIFICATION TOOL......................................................................................................................................................4

6 COMPONENT SPECIFICATIONS ...........................................................................................................................................4

6.1 SAW FILTER............................................................................................................................................................................4

6.1.1 Recommended Components for GSM/LTE gateways ..................................................................................................6

6.1.2 OPTIONAL Components for GSM/LTE gateways..........................................................................................................6

6.2 CRYSTAL .................................................................................................................................................................................6

6.2.1 Recommended Components ........................................................................................................................................7

7 SUPPLY FILTER ...................................................................................................................................................................7

8 MATCHING CIRCUIT ...........................................................................................................................................................7

8.1 SOC TO RF LINE MATCHING ........................................................................................................................................................7

8.1.1 Mandatory Components..............................................................................................................................................8

8.2 RF LINE TO ANTENNA MATCHING .................................................................................................................................................8

8.3 MEASUREMENT SETUP ..............................................................................................................................................................9

9 PCB IMPLEMENTATION....................................................................................................................................................10

9.1 PLACEMENT ..........................................................................................................................................................................10

9.2 STACK-UP .............................................................................................................................................................................10

9.3 POWER ROUTING ...................................................................................................................................................................10

9.4 DECOUPLING .........................................................................................................................................................................11

9.4.1 For ZGM130S end device SiP......................................................................................................................................11

9.4.2 For EFR32ZG14 gateway SoC.....................................................................................................................................11

9.5 RF TRACE .............................................................................................................................................................................12

9.6 IC GROUNDING......................................................................................................................................................................13

10 ANTENNA DESIGN ........................................................................................................................................................13

11 ESD ..............................................................................................................................................................................13

12 ABBREVIATIONS...........................................................................................................................................................14

13 REVISION HISTORY .......................................................................................................................................................16

14 REFERENCES.................................................................................................................................................................17

Instruction: Z-Wave 700 Integration Guide

INS14487-3 | 2/2019 3

3 PRO GRAM MING AND DEB UGGI NG I NTERFACE

EFR32ZG14

ZGM130S

Applicable

Applicable

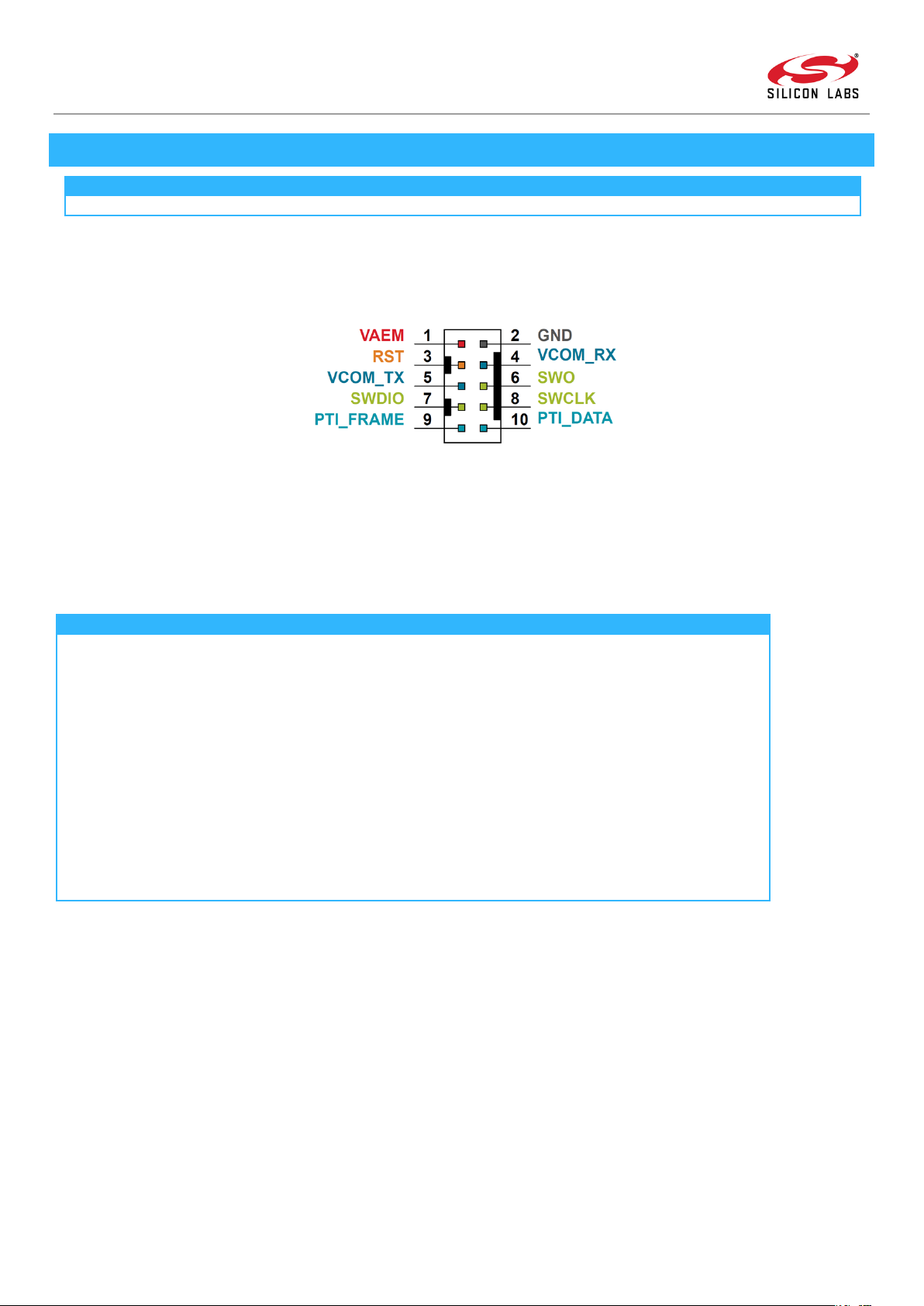

Figure 3.1: Silicon Labs Mini Simplicity Header

Pin Name

Pin Location

Type

Function

GND2S

Common ground between the programmer and Z-Wave 700

device

VAEM

1STarget voltage on the debugged application. Supplied and

monitored by the AEM when power selection switch is in the

"AEM" position.

RST3O

Driven low by the programmer to place the Z-Wave 700 device in

a reset state

VCOM_TX

5IReceive UART serial data from Z-Wave 700 device

VCOM_RX

4OTransmit UART serial data to Z-Wave 700 device

SWO

6ISerial Wire Output

SWDIO

7

I/O

Serial Wire Data

SWCLK

8OSerial Wire Clock

PTI_FRAME

9IPacket Trace Frame Signal

PTI_DATA

10IPacket Trace Data Signal

A programming interface is mandatory if In-System Programming of a Z-Wave 700 device is required, i.e., programming while

soldered onto the product PCB. To design in a footprint for the Mini Simplicity header, Silicon Labs recommends using a small 10pin 1.27 mm SMD header for both programming and debugging of chips from the Silicon Labs Gecko family.

If a connector is used, the Samtec FTSH-105-01-F-DH surface mounted or Harwin M50-3500542 through-hole male connector is

recommended and can be directly used with the BRD8010A STK/WSTK Debug Adapter. The functionality of the pins from the

programmer’s perspective is shown in Table 3.1. Refer to [1] for programming instructions.

Table 3.1: Z-Wave 700 Mini Simplicity Header Pin Functionality

Instruction: Z-Wave Z-Wave 700 Integration Guide

4 INS14487-3 | 2/2019

3.1 PRO GRAM MING INT ERFA CE O VERV IEW

EFR32ZG14

ZGM130S

SWD programming

XXBoot Loader UART programming

X

X

EFR32ZG14

ZGM130S

Applicable

N/A

EFR32ZG14

ZGM130S

Applicable

Applicable

EFR32ZG14

ZGM130S

Applicable

NA

The table below shows which interfaces can be used to program the flash memory of the various Z-Wave 700 products:

Table 3.2: Available programming interfaces

4 CAL IBRA TION

It is mandatory to calibrate the crystal in EFR32ZG14 Z-Wave 700 devices during product development to make sure that the mean

value of the crystal frequency is correct. Refer to [4] for calibration instructions. Furthermore, for best possible performance, it is

recommended that calibration be performed during production to minimize the spread in crystal frequency. All ZGM130S Z-Wave

700 devices are calibrated during production and therefore do not need any further crystal calibration.

4.1 CRY STAL

It is recommended to calibrate the crystal frequency for the gateway devices to ensure minimum error of the radio carrier

frequency.

5 RF VERI FICA TION TOO L

The RailTest tool can be used to verify the RF performance of a device without the overhead of the Z-Wave protocol. The same RF

PHY present in the Z-Wave protocol is used. The tool is suitable when investigating RF performance and performing RF regulatory

tests. To use the tool, it is required that the chip is programmable and the UART0 is connected to a terminal over RS-232 or

through the WSTK. For a comprehensive user’s manual for the RailTest tool, refer to [2] and [3].

As the RF PHY can be updated for new software releases, it is important to compile a RailTest version based on the same software

release that will be used in the final product.

6 COM PONE NT S PECI FICA TION S

6.1 SAW FIL TER

It is recommended that a SAW filter is used in Z-Wave 700 gateway designs also containing GSM or LTE transceivers operating in

the subGHz band. A SAW filter attenuates unwanted radio emissions and improves the receiver blocking performance. Three

Instruction: Z-Wave 700 Integration Guide

INS14487-3 | 2/2019 5

regions are defined to cover the global Z-Wave frequency range. The SAW filter specifications described in Table 6.1, Table 6.2,

Frequency Range

Unit

Minimum

Typical

Maximum

Operating temperature

-

◦

C

-30-+85

Insertion loss

865.0 to 870.1MHz

dB

--3.5

Amplitude ripple

865.0 to 870.1MHz

dB

--2.0

Relative attenuation

0.1 to 800.0MHz

dB

40--

805 to 830MHz

dB

35--

835 to 855MHz

dB

---

860 to 862MHz

dB

---

890 to 1000MHz

dB

40--

1005 to 2000MHz

dB

30--

2005 to 3000MHz

dB

30--

3005 to 4000MHz

dB

30--

4005 to 6000MHz

dB

---

In / out impedance

-Ω-50-

Frequency Range

Unit

Minimum

Typical

Maximum

Operating temperature

-

◦

C

-30-+85

Insertion loss

908.2 to 916.3MHz

dB

--2.5

Amplitude ripple

908.2 to 916.3MHz

dB

--1.5

Relative attenuation

720 to 800MHz

dB

45--

805 to 840MHz

dB

---

845 to 870MHz

dB

40--

870 to 895MHz

dB

---

940 to 1000MHz

dB

9--

1005 to 2000MHz

dB

9--

2005 to 3000MHz

dB

17--

3005 to 4000MHz

dB

---

4005 to 6000MHz

dB

---

In / out impedance

-Ω-50-

Frequency Range

Unit

Minimum

Typical

Maximum

Operating temperature

-

◦

C

-30-+85

Insertion loss

919.5 to 926.5MHz

dB

--3.2

Amplitude ripple

919.5 to 926.5MHz

dB

--1.0

Relative attenuation

40 to 870MHz

dB

40--

875 to 885MHz

dB

35--

890 to 905MHz

dB

20--

945 to 955MHz

dB

20--

960 to 1000MHz

dB

20--

1005 to 1500MHz

dB

40--

1505 to 3000MHz

dB

20--

3005 to 4000MHz

dB

---

4005 to 6000MHz

dB

---

In / out impedance

-Ω-50-

and Table 6.3 are recommended for new designs.

Table 6.1: Region E

Table 6.2: Region U

Table 6.3: Region H

Instruction: Z-Wave Z-Wave 700 Integration Guide

6 INS14487-3 | 2/2019

6.1 .1 REC OMME NDED COM PONE NTS FOR GSM/LTE G ATEW AYS

Region

Distributor

Component Number

Note

E

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF4000-868-07-SX

Preferred

U

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF4000-914-06-SX

Preferred

H

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF1256-923-02

Preferred

Region

Distributor

Component Number

Note

E

ACTE A/S, www.acte.dk, salessupport@acte.dk

SF4000-869-14-SX

Improved LTE rejection

EFR32ZG14

ZGM130S

Applicable

NA

Parameter

Symbol

Min

Typ

Max

Unit

Crystal frequency

fHFXO

—39—

MHz

Supported crystal equivalent series resistance (ESR)

ESRHFXO_39M

——60

Ω

Supported range of crystal load capacitance 1

CHFXO_CL

6—12

pF

Initial frequency tolerance for the crystal

FTHFXO

-10 10

ppm

Temperatur tolerance for the crystal

FTempHFXO

-40°C - 85°C

-12 12

ppm

Aging

FAge

-3 3

ppm/5yr

Combined tolerance for the crystal

FTtotalHFXO

-25—25

ppm/5yr

Table 6.4: SAW filters

6.1 .2 OPT IONA L CO MPON ENTS FOR GSM /LTE GATE WAYS

Table 6.5: LTE improved SAW filters

6.2 CRY STAL

The crystal is part of the oscillator that generates the reference frequency for the digital system clock and RF carrier. It is a critical

component of a Z-Wave 700 device. Further, it is mandatory to calibrate the crystal for gateway designs. Refer to section 4 for

more information.

The EFR32ZG14 has internal crystal capacitors and does not need any external circuitry apart from the crystal itself.

The ZGM130S has an integrated crystal and is calibrated at the time of production.

Table 6.6: Crystal specification for Z-Wave 700 devices