Page 1

ToolStick-CapTouchSenseDC

TOOLSTICK CAPTOUCHS ENSE DAUGHTER CARD USER’S GUIDE

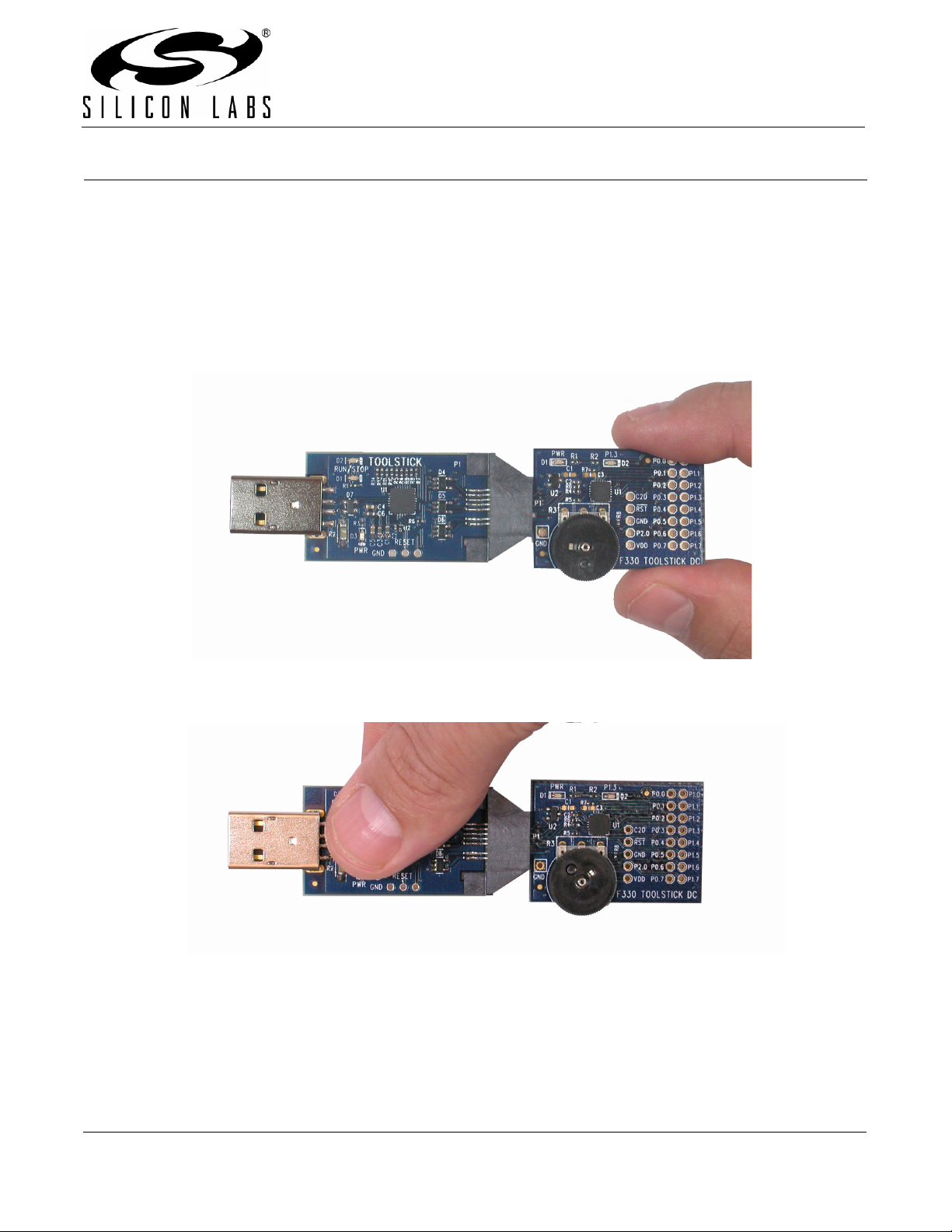

1. Handling Recommendations

To enable development, the ToolStick Base Adapter and daughter cards are distributed without any protective

plastics. To prevent damage to the devices and/or the host PC, please take into consideration the following

recommendations when using the ToolStick:

Never connect or disconnect a daughter card to or from the ToolStick Base Adapter while the Base Adapter is

connected to a PC.

Always connect and disconnect the ToolStick Base Adapter from the PC by holding the edges of the boards.

Figure 1. Proper Method of Holding the ToolStick

Avoid directly touching any of the other components.

Figure 2. Improper Method of Holding the ToolStick

Manipulate mechanical devices on the daughter cards, such as potentiometers, with care to prevent the Base

Adapter or daughter card from accidentally dislodging from their sockets.

Rev. 0.2 5/08 Copyright © 2008 by Silicon Laboratories ToolStick-CapTouchSenseDC

Page 2

ToolStick-CapTouchSenseDC

2. Contents

The ToolStick-CapTouchSenseDC kit contains the following items:

ToolStick CapTouchSense Daughter Card

One A76 battery

A ToolStick daughter card requires a ToolStick Base Adapter to communicate with the PC. ToolStick Base Adapters

can be purchased at www.silabs.com/toolstick. The ToolStick-CapTouchSenseDC is also available as part of a

ToolStick Starter Kit (CapTouchSenseSK) that includes a CapTouchSenseDC, Toolstick Base Adapter, and USB

Extension Cable and may be purchased from the same link.

3. ToolStick Overview

The purpose of the ToolStick is to provide a development and demonstration platform for Silicon Laboratories

microcontrollers and to demonstrate the Silicon Laboratories software tools, including the Integrated Development

Environment (IDE).

The ToolStick development platform consists of two components: the ToolStick Base Adapter and a daughter card.

The ToolStick Base Adapter provides a USB debug interface and data communications path between a Windows

PC and a target microcontroller.

The target microcontroller and application circuitry are located on the daughter card. Some daughter cards, such

as the CapTouchSense Daughter Card, are used to demonstrate a specific feature or application and some are

used as general-purpose development platforms for the target microcontrollers.

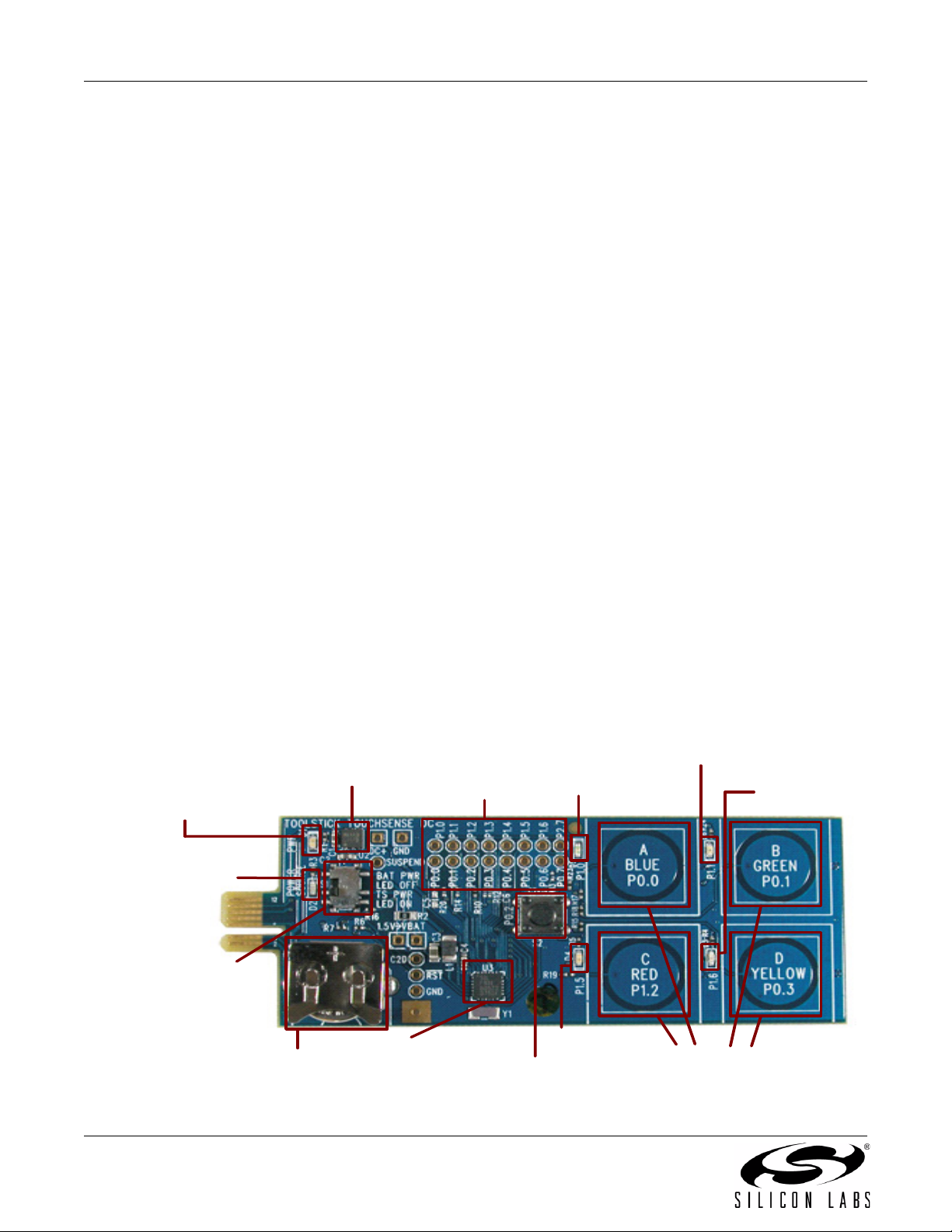

The CapTouchSense Daughter Card includes a C8051F931 MCU, four GPIO controlled LEDs, a switch connected

to a GPIO, four capacitive touch sense switches, and a small prototyping area which provides access to all of the

pins of the device. This prototyping area can be used to connect additional hardware to the microcontroller and use

the daughter card as a development platform. The CapTouchSense Daughter Card also includes an A76 1.5 V

alkaline battery which can be used to power the board when not connected to the Toolstick Base Adapter. The

C8051F931 MCU on this daughter card will continue to operate from the single “button cell” battery until the supply

voltage drops below 0.9 V.

Figure 3 shows the ToolStick CapTouchSense Daughter Card and identifies the various components.

Voltage Regulator

(3.3 V to 1.5V)

ToolStick Power Available

Red LED

Power Source Indicator

Yellow LED

Power Source

Selector

Switch (S1)

1.5V Battery

Holder

C8051F931

MCU

Full Pin Access

P0.2 Push

Button Switch (S2)

Figure 3. ToolStick CapTouchSense Daughter Card

2 Rev. 0.2

P1.0

Blue LED

P1.5

Red LED

P1.1

Green LED

P1.6

Yellow LED

Capacitive Touch

Sense Switches

Page 3

ToolStick-CapTouchSenseDC

4. Getting Started

The necessary software to download, debug and communicate with the target microcontroller must be downloaded

from www.silabs.com/toolstick. The following software is necessary to build a project, download code to, and

communicate with the target microcontroller:

Silicon Laboratories Integrated Development Environment (IDE)

Keil Demonstration Tools

ToolStick Terminal application

The Keil Demo Tools include a compiler, assembler, and linker. See Section “5.2. Keil Demonstration Toolset” for

more information about the evaluation version limitations. ToolStick Terminal communicates with the target

microcontroller's UART through the ToolStick Base Adapter. It can also read/write the two GPIO pins available on

the ToolStick Base Adapter.

Other useful software that is provided on the Silicon Labs Downloads (www.silabs.com/mcudownloads) website

includes the following:

Configuration Wizard 2

Keil µVision2 and µVision3 Drivers

All of the above software is described in more detail in Section “5. Software Overview”.

The software described above is provided in several download packages. The ToolStick Download package

includes example code, documentation including user’s guides and data sheets, and the ToolStick Terminal

application. The IDE, Keil Demonstration Tools, Configuration Wizard 2, and the Keil µVision Drivers are available

as separate downloads. After downloading and installing these packages, see the following sections for information

regarding the software and running one of the demo applications.

5. Software Overview

5.1. Silicon Laboratories IDE

The Silicon Laboratories IDE integrates a source-code editor, source-level debugger, and an in-system Flash

programmer. See Section “7. ToolStick CapTouchSense Daughter Card Example Code” for information on how to

use the IDE. The Keil Demonstration Toolset includes a compiler, linker, and assembler and easily integrates into

the IDE. The use of third-party compilers and assemblers is also supported.

5.1.1. IDE System Requirements

The Silicon Laboratories IDE requirements:

Pentium-class host PC running Microsoft Windows 2000 or Windows XP.

One available USB port.

64 MB RAM and 40 MB free HD space recommended.

5.1.2. 3rd Party Toolsets

The Silicon Laboratories IDE has native support for many 8051 compilers. The full list of natively supported tools is

as follows:

Keil

IAR

Raisonance

Tasking

Hi-Tech

SDCC

The demo applications for the CapTouchSense Daughter Card are written for the Keil and SDCC toolsets.

Rev. 0.2 3

Page 4

ToolStick-CapTouchSenseDC

5.2. Keil Demonstration Toolset

5.2.1. Keil Assembler and Linker

The Keil demonstration toolset assembler and linker place no restrictions on code size.

5.2.2. Keil Demonstration C51 C Compiler

The evaluation version of the C51 compiler is the same as the full version with the following limitations: (1)

Maximum 4 kB code generation, (2) There is no floating point library included. When initially installed, the C51

compiler is limited to a code size of 2 kB, and programs start at code address 0x0800. Refer to “AN104: Integrating

Keil Tools into the Silicon Labs IDE" for instructions to change the limitation to 4 kB and have the programs start at

code address 0x0000.

5.3. Configuration Wizard 2

The Configuration Wizard 2 is a code generation tool for all of the Silicon Laboratories devices. Code is generated

through the use of dialog boxes for each of the device's peripherals.

Figure 4. Configuration Wizard 2 Utility

The Configuration Wizard 2 utility helps accelerate development by automatically generating initialization source

code to configure and enable the on-chip resources needed by most design projects. In just a few steps, the wizard

creates complete startup code for a specific Silicon Laboratories MCU. The program is configurable to provide the

output in C or assembly.

For more information, please refer to the Configuration Wizard 2 documentation. The documentation and software

are available from the Downloads webpage (www.silabs.com/mcudownloads).

4 Rev. 0.2

Page 5

ToolStick-CapTouchSenseDC

5.4. Keil µVision2 and µVision3 Silicon Laboratories Drivers

As an alternative to the Silicon Laboratories IDE, the uVision debug driver allows the Keil µVision2 and µVision3

IDEs to communicate with Silicon Laboratories on-chip debug logic. In-system Flash memory programming

integrated into the driver allows for rapidly updating target code. The µVision2 and µVision3 IDEs can be used to

start and stop program execution, set breakpoints, check variables, inspect and modify memory contents, and

single-step through programs running on the actual target hardware.

For more information, please refer to the µVision driver documentation. The documentation and software are

available from the Downloads webpage (www.silabs.com/mcudownloads).

5.5. ToolStick Terminal

The ToolStick Terminal program provides the standard terminal interface to the target microcontroller's UART.

However, instead of requiring the usual RS-232 and COM port connection, ToolStick Terminal uses the USB

interface of the ToolStick Base Adapter to provide the same functionality.

In addition to the standard terminal functions (send file, receive file, change baud rate), two GPIO pins on the target

microcontroller can be controlled using the Terminal for either RTS/CTS handshaking or software-configurable

purposes (see the demo software for an example).

The software is available on the ToolStick webpage (www.silabs.com/toolstick).

Rev. 0.2 5

Page 6

ToolStick-CapTouchSenseDC

6. ToolStick CapTouchSense Daughter Card Memory Game Demo

The ToolStick CapTouchSense Daughter Card is pre-loaded with a memory game firmware that can be played

without connecting to the ToolStick Base Adapter. When disconnected from the ToolStick Base Adapter, the

daughter card may be powered from the included A76 alkaline battery. When connected to a ToolStick Base

Adapter, the daughter card can be powered from the USB port.

6.1. Hardware Setup

To use the CapTouchSense Daughter Card in standalone mode (battery powered) perform the following steps:

1. Insert the A76 alkaline “button cell” battery into the battery holder (BAT1) ensuring that the “+” terminal is on the

top side as marked on the battery holder.

2. Set the Power Select Switch (S1) to select Battery Power (BAT PWR). The yellow power source indicator LED

should be OFF.

To use the CapTouchSense Daughter Card with a ToolStick Base Adapter (USB powered) perform the following

steps:

1. Connect the ToolStick Base Adapter to the ToolStick CapTouchSense Daughter Card taking note of the

recommendations in Section 1.

2. If available, connect the USB extension cable to the ToolStick Base Adapter.

3. Set the Power Select Switch (S1) to select ToolStick Power (TS PWR). The yellow power source indicator LED

should be ON.

4. Connect the ToolStick to a USB port on a PC.

See Figure 5 for an example hardware setup using the C8051F330 ToolStick Daughter Card.

Figure 5. Hardware Setup Example

6 Rev. 0.2

Page 7

ToolStick-CapTouchSenseDC

6.2. Playing the Memory Game

This section describes how to play the memory game using the capacitive touch sense switches on the

CapTouchSenseDC. The objective of the game is to remember a sequence of lights and press the corresponding

switches. As the player correctly presses the sequence of switches and advances to the next level, the number of

switch presses in a sequence increases. The player wins when the correct sequence at the last level is entered.

1. Press the S2 switch on the daughter card to enter the game. After pressing the S2 switch, all four LEDs will light

up.

2. Press one of the capacitive touch sense switches to select the difficulty level and start the game. Switches A, B,

C, and D select 4, 8, 16, and 32 levels, respectively.

3. The game begins at level 1. One LED will blink. Press the corresponding switch to advance to the next level.

4. In the second level, there will be a sequence of two blinks. Press the corresponding switches in the same

sequence as the LED blinks to advance to the next level.

5. Continue the game until you complete all levels to win the game. A game win is indicated by the blue and green

LEDs blinking alternately. If you press a switch in the wrong sequence, an error will be indicated by the red LED

blinking four times. The game will then restart at the same level and you will have two such retries. The third

error will end the game. This will be indicated by the red and yellow LED blinking alternately.

6. The game can be restarted by pressing the S2 switch.

6.3. Evaluating the Capacitive Touch Sense Switch Sensitivity

Holding the S2 switch for longer than 5 seconds places the device in a switch sensitivity test mode where the

corresponding LED lights up each time a switch press is detected. If connected to the ToolStick Terminal, the raw

codes corresponding to the relaxation oscillator period are displayed on the screen. When the switch capacitance

increases (i.e., the switch is touched), the raw code from the switch should increase. By knowing the approximate

value of "switch pressed" and "switch idle", the appropriate finger-detect threshold can be determined.

When ToolStick Terminal is connected, ensure that the GPIO0 and GPIO1 pins are configured as inputs so that

they do not interfere with the MCU. While running this software, the GPIO pins should only be driven by the MCU.

See the board schematic in "12. ToolStick CapTouchSense Daughter Card Schematic‚" on page 13 to see the

connection between the GPIO pins and the MCU.

Rev. 0.2 7

Page 8

ToolStick-CapTouchSenseDC

7. ToolStick CapTouchSense Daughter Card Example Code

The ToolStick kit includes two code examples. One of them is titled CapTouchSenseDC_SwitchSensitivity. This

example can be used by a new user to learn the features and capabilities of the IDE and the microcontroller’s onchip debug capabilities. A ToolStick Base Adapter is required to be able to download code to the daughter card and

perform debugging.

7.1. Hardware Setup

Connect the ToolStick hardware to the PC using the steps below while taking note of the recommendations in

Section 1:

1. Connect the ToolStick Base Adapter to the ToolStick CapTouchSense Daughter Card.

2. If available, connect the USB extension cable to the ToolStick Base Adapter.

3. Set the Power Select Switch (S1) to select ToolStick Power (TS PWR).

4. Connect the ToolStick to a USB port on a PC.

See Figure 5 for an example hardware setup using the C8051F330 ToolStick Daughter Card.

7.2. Connecting to the Device and Downloading Firmware

This section describes how to open the IDE, open and build a project, connect to a device and download the

firmware.

1. Open the Silicon Laboratories IDE from the Start → Programs → Silicon Laboratories menu.

2. In the IDE, go to Project → Open Project.

3. Browse to the default installation location C:\SiLabs\MCU\ToolStick\CapTouchSenseDC\Firmware\.

4. Select CapTouchSenseDC_SwitchSensitivity.wsp and click OK.

5. In the IDE, select Project → Rebuild Project.

6. Go to Options → Connection Options.

7. Select “USB Debug Adapter” for the Serial Adapter and “C2” for the Debug Interface, and then click “OK”. If

you have other Silicon Labs debug adapters connected to the PC, ensure that the correct ToolStick is selected

in the drop-down box.

8. Go to Debug → Connect.

9. Erase code space using the Tools → Erase Code Space command to remove configuration constants stored

by the memory game in non-volatile Flash. It is not required when re-downloading the same software project.

10.Download the code using the download button on the menu bar or use alt-D.

Once these steps are completed, the firmware is built into an object file (step 5) and downloaded to the device

(step 9). The device is now ready to begin executing code. If all of these steps were followed successfully, the “Go”

option is enabled in the Debug menu. A green circle icon in the IDE toolbar also indicates that the device is ready

to run. If one of the steps leads to an error, make sure that the ToolStick is properly inserted in a USB port and start

again with step 6.

8 Rev. 0.2

Page 9

ToolStick-CapTouchSenseDC

7.3. Running and Stopping Code Execution

Once the IDE is connected to the device and the firmware is loaded, the IDE can start and stop the code execution.

The following steps can be performed using the buttons on the toolbar or using the options in the Debug menu.

1. To start code execution, click the green “Go” button on the toolbar or use the Debug → Go menu option. The

debug commands in the IDE (single-step, multiple-step, set breakpoint, and others) are disabled when the

device is running.

corresponding LED. The less sensitive switches will require a firmer touch to turn on the LED, and the more

sensitive switches will require only a light touch. The first time the firmware runs, it will enter the configuration

mode described in Section

2. To stop code execution, click the red “Stop” button on the toolbar or use the Debug → Stop menu option. The

device will halt code execution and all of the registers and pins on the device will hold their state.

All debug windows and watch windows are refreshed when the device is stopped. If any of the values in these

windows have changed since the last time the device was halted, the new value is shown in red text instead of

black text.

While the firmware is running,

7.4.

pressing any switch on the daughter card will turn on the

7.4. Configuring the Capacitive Touch Sense Switches

The CapTouchSenseDC_SwitchSensitivity example includes code that allows the configuration of the capacitive

touch sense switches. This code is executed the first time firmware is run or when the code constants are removed

from Flash memory (e.g., using the Erase Code Space command).

1. Start code execution by clicking the green “Go” button on the toolbar or using the Debug → Go menu option.

The blue LED will light up to indicate that no calibration values are present. If the blue LED is not on, press the

mechanical switch (S2) to start configuration.

2. Put your finger on touch sensitive switch A and press and release the mechanical switch.

3. Repeat Step 2 for the remaining three switches. The LED will turn on to indicate which switch to put your finger

on.

4. Touching each switch should now light up the corresponding LED.

7.5. Restoring the Memory Game Demo

The CapTouchSenseDC_Memory_Game can be restored in the CapTouchSense daughter card using the

following steps.

1. Close the current project or open a new instance of the Silicon Laboratories IDE.

2. Connect to the target.

3. Click the download button on the menu bar or use alt-D.

4. Click Erase All Code Space. Click OK to erase all code and the configuration values stored in the scratchpad

memory.

5. Browse for the HEX file named CAPTOUCHSENSEDC_MEMORY_GAME.hex.

6. Click Download.

7. Disconnect from the target to start executing code. The red and yellow will light up to indicate that no calibration

values are present.

8. Press the S2 switch to begin configuration. Be careful not to touch the capacitive touch sense switches while

Rev. 0.2 9

Page 10

ToolStick-CapTouchSenseDC

pressing the S2 switch. The blue and green LEDs will blink a few times and switch off. This indicates

configuration is complete.

9. Press each of the capacitive touch sense switches to test the configuration, and finally press the S2 switch to

return to the game. All four LEDs will light up to indicate that the calibration is complete and the game is ready

to be played.

8. Additional Demo Examples

In addition to the CapTouchSenseDC_SwitchSensitivity example firmware, the ToolStick download package also

includes another example project named CapTouchSenseDC_Memory_Game. The instructions for running this

example can be found at the top of the source file.

The project and source files for these examples can be found by default in the

C:\SiLabs\MCU\ToolStick\CapTouchSenseDC\Firmware\ folder.

10 Rev. 0.2

Page 11

ToolStick-CapTouchSenseDC

9. Using the CapTouchSense Daughter Card as a Development Platform

The prototyping area on the ToolStick CapTouchSense Daughter Card makes it easy to interface to external

hardware. All of the digital I/O pins of the C8051F931 MCU are available so it is possible to create a complete

system.

9.1. C8051F931 Pin Connections

It is important to note that if external hardware is being added, some of the existing components on the board can

interfere with the signaling. The following is a list of port pins on the C8051F931 that are connected to other

components:

P0.2—This pin is connected to the P0.2 switch. The switch and R10 can be safely removed from the daughter

card if they are not needed.

P0.0, P0.1, P0.3, P1.2—These pins are connected to capacitive touch sense switches. The 0 Ω resistors R15,

R17, R18, and R19 be safely removed from the daughter card if the capacitive touch sense switches are not

needed.

P0.4, P0.5—These pins are connected directly to the ToolStick Base Adapter for UART communication.

P1.0, P1.1—These pins are connected directly to the ToolStick Base Adapter’s GPIO pins. By default, these

GPIO pins on the Base Adapter are high-impedance pins so they will not affect any signaling. Configuring these

pins on the Base Adapter to output pin or handshaking pins could affect signaling.

P1.3—This pin is connected to the power source detect signal.

P1.0—This pin is connected to the cathode (-) of the blue LED on the daughter card. The LED or R23 resistor

can be removed to disconnect the LED from the pin.

P1.1—This pin is connected to the cathode (-) of the green LED on the daughter card. The LED or R24 resistor

can be removed to disconnect the LED from the pin.

P1.5—This pin is connected to the cathode (-) of the red LED on the daughter card. The LED or R5 resistor can

be removed to disconnect the LED from the pin.

P1.6—This pin is connected to the cathode (-) of the yellow LED on the daughter card. The LED or R4 resistor

can be removed to disconnect the LED from the pin.

See the daughter card schematic in Section 12 for more information.

9.2. VREF Capacitor

On the C8051F931 devices, if VREF is generated using the High-Speed Internal Reference, no output capacitor is

required. If using the on-chip Precision Voltage Reference, it is highly recommended to place a capacitor on the

VREF output pin. On the ToolStick CapTouchSense Daughter Card, there are pads on the board (C5) to populate a

0603 surface mount capacitor. There are also pads on the board (R14) to facilitate shorting P0.1 to the ground

plane for use as an analog ground reference (AGND). The firmware examples for the daughter card use the HighSpeed Internal Reference as VREF and the GND pin as a ground reference, so no external capacitor on P0.0 is

necessary for proper operation. Also, P0.1 may be used for general purpose I/O.

9.3. C2 Pin Sharing

On the C8051F931, the debug pins, C2CK, and C2D, are shared with the pins /RST and P2.7 respectively. The

daughter card includes the resistors necessary to enable pin sharing which allow the /RST and P2.7 pins to be

used normally while simultaneously debugging the device. See Application Note “AN124: Pin Sharing Techniques

for the C2 Interface” at www.silabs.com for more information regarding pin sharing.

Rev. 0.2 11

Page 12

ToolStick-CapTouchSenseDC

10. Capacitive Touch Sense Switches

The capacitive touch sensitive switches on the CapTouchSenseDC are implemented as relaxation oscillators, with

the PCB trace forming the touch-sensitive capacitive element. The relaxation oscillator is constructed using the onchip analog comparator, on-chip resistors in the C8051F931 MCU. The on-chip analog multiplexer allows multiple

switches to be operated using one comparator. See Application Note “AN338: Capacitive Touch Sense Solution” at

www.silabs.com for more information related to the capacitive touch sense switches.

11. Information Locations

Example source code is installed by default in the “C:\SiLabs\MCU\ToolStick\CapTouchSenseDC\Firmware”

directory during the ToolStick installation.

Documentation for the ToolStick kit, including this User’s Guide, can be found by default in the

C:\SiLabs\MCU\ToolStick\Documentation and the C:\SiLabs\MCU\ToolStick\CapTouchSenseDC\Documentation

directories.

The installer for the ToolStick software is available at www.silabs.com/toolstick.

All application notes are available at http://www.silabs.com/products/microcontroller/applications.asp.

12 Rev. 0.2

Page 13

ToolStick-CapTouchSenseDC

12. ToolStick CapTouchSense Daughter Card Schematic

C2D

C2CK

GND

TP22

TP23

TP24

C2CKC2CK

P2.7

DEBUG CI RCUIT

C2DC2D

R6

DC+

1K

1K

R7

S4

S5

S2

A

R17 0.0

R10 1K

P0.0

P0.2

S6

B

TOU CH SENSE SW ITCH

R18 0.0

P0.1

S3

C

TOU CH SENSE SW ITCH

TOU CH SENSE SW ITCH

R19 0.0

P1.2

DC+

R41k2

R51k2

R23330

R24750

D

TOU CH SENSE SW ITCH

R15 0.0

P0.3

D4

D3

1.8V RED

1.8V YELLO W

P1.6

P1.5

D6

D5

2.9V BLUE

2.2V GREEN

P1.0

P1.1

1

OFSHEET:

1

ENGINEER:

SIZE :DATE:

SILICON LABS

SA-TS054PCB-000

R

ToGr

TOOLSTICK TOUCHSENSE DC

TITLE:

November 20, 2007 B

DRAWN BY :

PART NUMBER:

P0.0

P0.1

DC+

R20

NO POP

DC+

SUSPE ND

TP25

R3

330

VDD

DC+

C2D

2

4

6

TOP SIDEBOTTOM SIDE

VIO(IN)

TCK_C2D

VDD(3.3V)

J1

EDGE-MEC1-108-02-F-D-EM2

CARD EDGE CONNECTOR

GND

VBUS(5V)

TDI_C2CK

5

3

1

GND

C2CK

VBUS_OUT

DC+

P1.1

P0.4

8

12

14

10

GPIO1_CTS

TDO_C2CKPS

VPPCTL(OUT)

TSTERMINAL_RX

GPIO0_RTS

SUSPE ND(OU T)

TDO_C2DPS

TSTERMINAL_TX

9

7

11

13

P0.5

P1.0

P2.7

SUSPE ND

C5

1.8V YELLO W

D2

Power

select

GND

S1

1

U2

VDD

NO POP

X7R

U3

C8051F931

DC+

P1.3

R16 1K

456

123

C2

2

GND

VOUT

VIN

C1

P0.3

R12

NO POP

C6

R14

P0.4

P0.2

NO POP

19

20

21

23

24

P0.4/TX

P0.0/VREF

P0.1/AGND

P0.3/XTAL222P0.2/XTAL1

GND/DC-

VDD/DC+

1

3

X7R

C4

1.0UF

DC+

X7R

1.0UF

7

BAT1

DAP

LP3990SD-1.5

3NC4NC5EN6

X7R

1.0UF

P0.7

C7

NO POP

P1.0

P0.6

P0.5

17

18

P0.5/RX

P0.7/IREF0

P0.6/CNVSTR

1

POS

Button Cell

VBUS_OUT

NO POP

R13

NO POP

C2CK

C2D

P1.6

P1.5

P1.4

P1.3

P1.2

P1.1

2

NEG

32.768KHZ

Y1

7

8

10

6

P1.611P1.512P1.413P1.314P1.215P1.116P1.0

XTAL49XTAL3

P2.7/C2D

RST/C2CK

DAP

GND

DCEN5VBAT

2

4

25

L1

680nH

X7R

C3

4.7UF

R2 0.0

I measure

TP4 TP5

GND

3

POS

POS2NEG

BAT2

1

1.5V 11.6mm

NEG_BATTERY_CONTACT

R1

4k7

GND

1.8V RED

D1

Power

Sourc e

(GPIO0_RTS/Blue LED)

(GPIO1_CTS/Green LED)

(TouchSenseC/GPIO)

(Power Source)

(GPIO)

(Orange LED)

(C2D/GPIO)

P1/P2P0

P1.0

P1.1

TP14

TP15

TP16

(TouchSenseA/GPIO)

(TouchSenseB/GPIO)

P0.0

P0.1

TP6

TP7

TP8

(Red LED)

P1.2

P1.3

P1.4

P1.5

P1.6

P2.7

TP17

TP18

TP19

TP20

TP21

(XTAL1/Switch/GPIO)

(XTAL2/TouchSenseD/GPIO)

(TX)

(RX)

(CNVSTR/GPIO)

P0.2

P0.3

TP9

TP10

DC+

FI2

FI1

(IREF0/GPIO)

P0.4

P0.5

P0.6

P0.7

TP11

TP12

TP13

TP3

TP1

TP26

FIDUCIAL

FIDUCIAL

Rev. 0.2 13

Page 14

ToolStick-CapTouchSenseDC

CONTACT INFORMATION

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

Email: MCUinfo@silabs.com

Internet:

www.silabs.com

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change without notice.

Silicon Laboratories assumes no responsibility for errors and omissions, and disclaims responsibility for any consequences resulting from

the use of information included herein. Additionally, Silicon Laboratories assumes no responsibility for the functioning of undescribed features

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Silicon Laboratories assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life, or for any other application in which the failure of the Silicon Laboratories product could create a situation where personal injury or death may occur. Should Buyer purchase or use Silicon Laboratories products for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

Silicon Laboratories and Silicon Labs are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

14 Rev. 0.2

Loading...

Loading...