Page 1

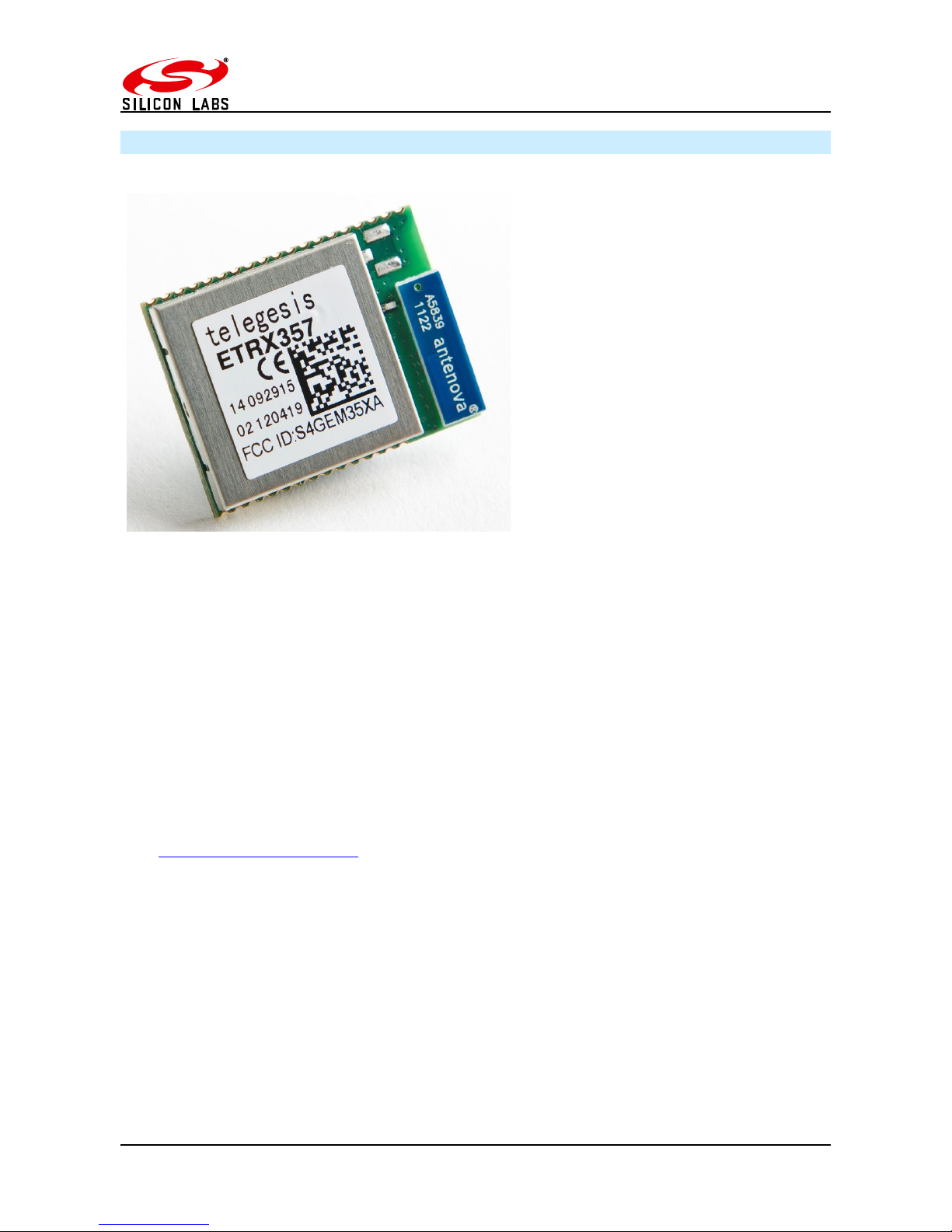

Telegesis™

TG-ETRX357DVK-PM-012-112

ETRX357DVK Development Kit

Product Manual 1.12

©2016 Silicon Labs ETRX357DVK Product Manual (Rev 1.12)

ETRX357DVK – TELEGESIS DEVELOPMENT KIT FOR ZIGBEE®

TECHNOLOGY

PRODUCT MANUAL

Telegesi s™ is a tr ad em ar k o f Sil i con Laborator i es Inc.

Page 2

ETRX357 Development Kit

©2016 Silicon Labs - 2 - ETRX357DVK Product Manual (Rev 1.12)

1 ETRX357DVK – Development Kit Functional Summary

Devkit Features

ZigBee Networking “Out-of-the-Box”

Low cost evaluation platform for ZigBee wireless mesh

networking

Designed to set up a ZigBee mesh network in only a few

minutes without the need for any embedded software

The freely downloadable Telegesis Terminal Software

application offers an easy to use interface to the modules on

the development boards.

Also works with 3rd party terminal software like

HyperTerminal.

Broad selection of modules allows range testing of any

possible module/antenna combination.

Seamlessly Integrates into the Silicon Labs InSight Toolchain

Development boards can be used as hardware platform for

trials

Battery option allows easy prototyping of end devices

USB Drivers available for Windows from

www.silabs.com/telegesissoftware

Module Features

Based on the Silicon Labs EM357 single chip ZigBee/

IEEE802.15.4 solutions

2.4GHz ISM Band

Industry’s first ARM® Cortex-M3 based family of ZigBee

modules

192kB flash and 12kB of RAM

24 general-purpose I/O lines including analogue inputs (all

GPIOs of the EM357 are accessible)

Lowest Deep Sleep Current of sub 1µA and multiple sleep

modes

The Telegesis ETRX357-DVK

development kit is an ideal starting point

for development and evaluation of the

ETRX357 series low power 2.4GHz

ZigBee modules.

The ETRX357 modules are based on the

third generation Silicon Labs EM357

chipset offering the industry’s highest

wireless networking performance and

application code space at the lowest

power consumption.

The modules’ unique AT-style command

line interface allows designers to quickly

integrate ZigBee technology without

complex software engineering. For

custom application development the

ETRX357 development kits integrate with

ease into Silicon Labs’ InSight

development environment.

Development Kit Contents

3 x USB Development Boards

3 x USB Cable

2 x ETRX357 on Carrier-Board

2 x ETRX357HR on Carrier-Board

2 x ETRX357-LRS on Carrier-Board

2 x ETRX357HR-LRS on Carrier-Board

1 x ETRX3USB stick

2 x ½-wave Antenna

2 x ¼-wave Stubby Antenna

Development Board Features

Power can be supplied via USB, Power

Jack or on board battery holder (2xAAA)

Access to the Silicon Labs InSight Port

Light and Temperature sensor

4 x Buttons, 2 x LEDs, 1 x Buzzer

Reset and Bootload Button

USB to Serial converter

Breakout of all GPIO pins

Example AT-Style Commands

AT+BCAST Sends a Broadcast

AT+UCAST:<address> Sends a Unicast

AT+EN Establish PAN network

AT+JN Join PAN

Page 3

ETRX357 Development Kit

©2016 Silicon Labs - 3 - ETRX357DVK Product Manual (Rev 1.12)

Table of Contents

1 ETRX357DVK – DEVELOPMENT KIT FUNCTIONAL SUMMARY .................................... 2

2 ABSOLUTE MAXIMUM RATINGS OF THE DEVBOARD .................................................. 4

3 OPERATING CONDITIONS OF THE DEVBOARD ............................................................. 4

4 ELECTRICAL SPECIFICATIONS ....................................................................................... 4

4.1 Power supplies ................................................................................................................. 4

4.2 ZigBee modules ............................................................................................................... 4

5 INTEROPERABILITY ......................................................................................................... 5

6 OVERVIEW ......................................................................................................................... 5

6.1 The Development Board .................................................................................................. 6

6.2 The carrier board.............................................................................................................. 6

6.3 What’s in the ETRX357DVK box? .................................................................................... 7

7 SETTING UP THE HARDWARE ......................................................................................... 8

8 ETRX357 PINOUT .............................................................................................................. 8

9 THE DEVELOPMENT BOARD ......................................................................................... 10

9.1 Development Board Interface Description ...................................................................... 10

9.2 Development Board Sensors ......................................................................................... 12

10 THE CARRIER BOARD .................................................................................................... 13

11 DRIVER INSTALLATION AND OPERATION ................................ ................................... 13

11.1 Windows 9x/XP/2k Driver Installation ............................................................................. 13

12 APPLICATION SOFTWARE ............................................................................................. 17

12.1 Software Set-up ............................................................................................................. 18

12.2 Features of the Telegesis Terminal Application for ETRX357 ........................................ 18

The buttons .................................................................................................................... 18

The device window ......................................................................................................... 18

The menu bar ................................................................................................................. 19

12.3 A Quick Start .................................................................................................................. 20

Select the correct set of buttons ..................................................................................... 20

Network Setup ............................................................................................................... 20

Mesh networking ............................................................................................................ 21

Node types ..................................................................................................................... 21

12.4 Configuring Buttons for your Setup ................................................................................ 22

12.5 Using LEDs and ADCs on the ETRX357 ........................................................................ 23

12.6 Temperature display ...................................................................................................... 24

13 FIRMWARE UPGRADES ................................................................................................. 25

13.1 Firmware Upgrades via Serial Port ................................................................................. 25

13.2 Over the Air Firmware Upgrades .................................................................................... 27

ETRX2 and ETRX357 features ...................................................................................... 27

Passthrough with an ETRX357 ...................................................................................... 27

Recovering on the default channel ................................................................................. 28

14 HARDWARE ENHANCEMENT KIT .................................................................................. 29

15 DEVBOARD SCHEMATIC ................................................................................................ 30

16 CARRIER BOARD SCHEMATIC ...................................................................................... 32

17 ETRX357 ORDERING INFORMATION ............................................................................. 33

Page 4

ETRX357 Development Kit

©2016 Silicon Labs - 4 - ETRX357DVK Product Manual (Rev 1.12)

2 Absolute Maximum Ratings of the Devboard

Parameter

Min.

Max.

Units

Condition

Supply Voltage VDD

-0.3 9 V

Voltage on any I/O pin

-0.3

3.3

V

Storage Temperature range

-50

85

°C

Without batteries inserted

Table 1: Absolute Maximum Ratings

The absolute maximum ratings given above should under no circumstances be violated. Stress

exceeding one or more of the limiting values may cause permanent damage to the device.

Caution! ESD sensitive devices. Precautions should be used when handling the device

in order to prevent permanent damage.

3 Operating Conditions of the Devboard

Typical values at 5V 25°C.

Parameter

Min.

Typ.

Max.

Units

Condition

Supply Voltage, VDD

4 5 6 V

Supply Current

150

mA

TX with LRS-Module

Operating ambient temperature range

-20

25

40

°C

Range may be more

limited when batteries

are inserted. Consult

datasheets applicable

to your batteries

Table 2. Operating Conditions

The voltage regulators used are protected against overtemperature and overcurrent.

4 Electrical Specifications

4.1 Power supplies

Only use a mains adaptor that has been certified as a low power source according to IEC60950-1.

The power from the USB connection should be restricted in line with the requirements of IEC 60950-

1. PCs approved to IEC 60950-1 will meet this requirement.

Only good quality (vented) alkaline batteries should be used. Ensure they are inserted with the

correct polarity. Note that they may restrict the working temperature range of the equipment.

4.2 ZigBee modules

See ETRX357 and ETRX357-LRS Product Manuals

Page 5

ETRX357 Development Kit

©2016 Silicon Labs - 5 - ETRX357DVK Product Manual (Rev 1.12)

5 Interoperability

Unless otherwise specified the Development kits ships with Telegesis R3xx firmware based on

EmberZNet4.x. Please note that the R3xx Telegesis AT-Command line interpreter is based on

ZigBee PRO, but most of the functionality is implemented as a private application profile.

Interoperability with wireless mesh networking solutions from other manufacturers is only possible

when knowing the application profile specification of this device and using the provided transparent

commands. If this is a concern please contact us for advice. Telegesis also offer separate firmware

specifically developed for Home Automation and Smart Energy applications.

6 Overview

The ETRX357DVK development kit has been designed to allow quick evaluation and prototyping

using the ETRX357 ZigBee modules.

This document is intended to describe the hardware and accompanying software of the development

kits. To learn more about the usage of the ETRX357 module please refer to the following documents:

TG-ETRX357-PM-010-xxx: ETRX357 Product manual

TG-ETRX357-LRS-PM-015-xxx: ETRX357-LRS (long range) Product manual

TG-ETRX357USB-PM-014-xxx: ETRX3 USB stick Product manual

TG-ETRXn-R3xx-Commands: AT Style command dictionary for firmware R3xx

All our documents can be found at www.silabs.com/telegesisdocuments.

The ETRX357 module is available in four variants:

ETRX357 – with on-board ceramic antenna and 8dBm output power

ETRX357HR – with Hirose coaxial connector and 8dBm output power

ETRX357-LRS – with on-board ceramic antenna, LNA and 19dBm output power

ETRX357HR-LRS – with Hirose coaxial connector, LNA and 19dBm output power

Page 6

ETRX357 Development Kit

©2016 Silicon Labs - 6 - ETRX357DVK Product Manual (Rev 1.12)

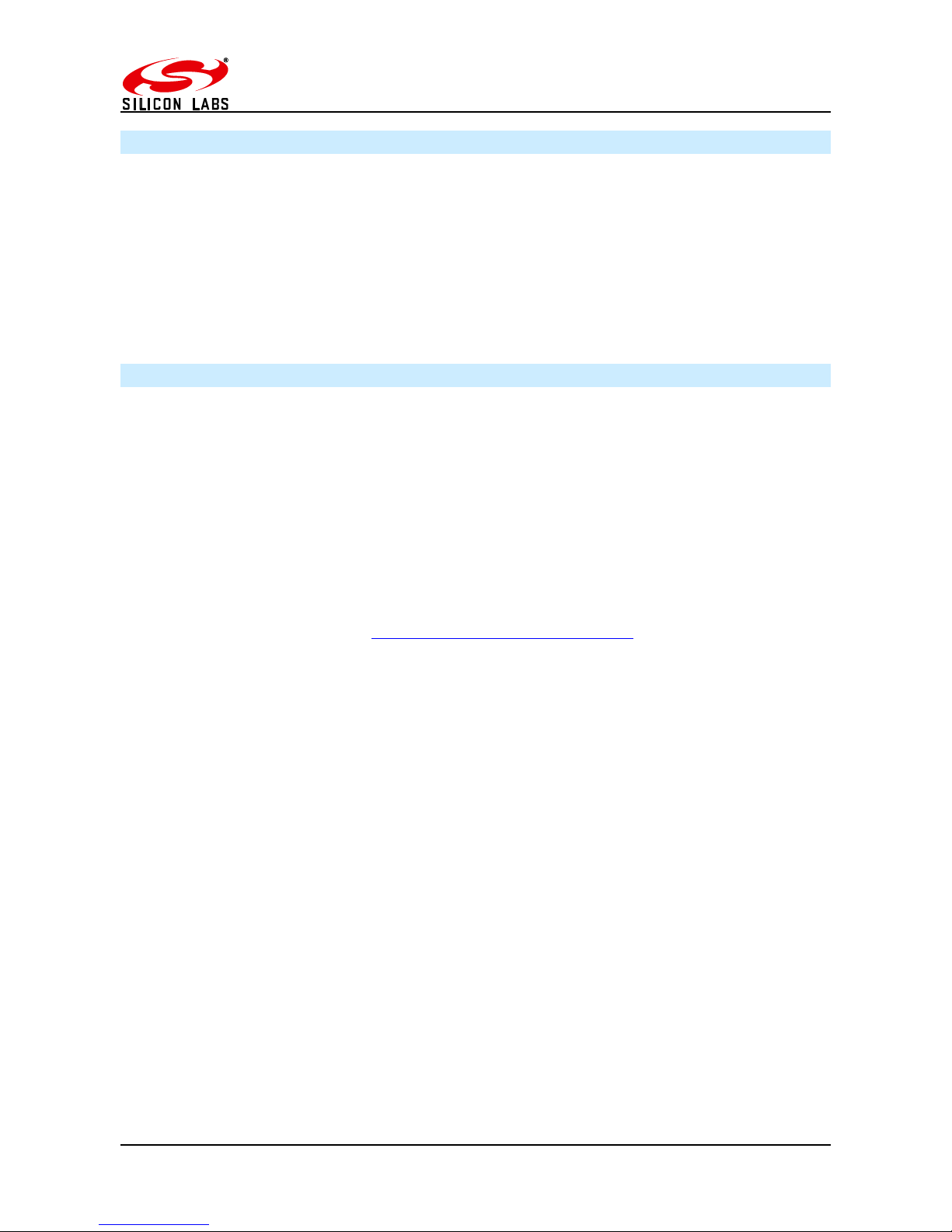

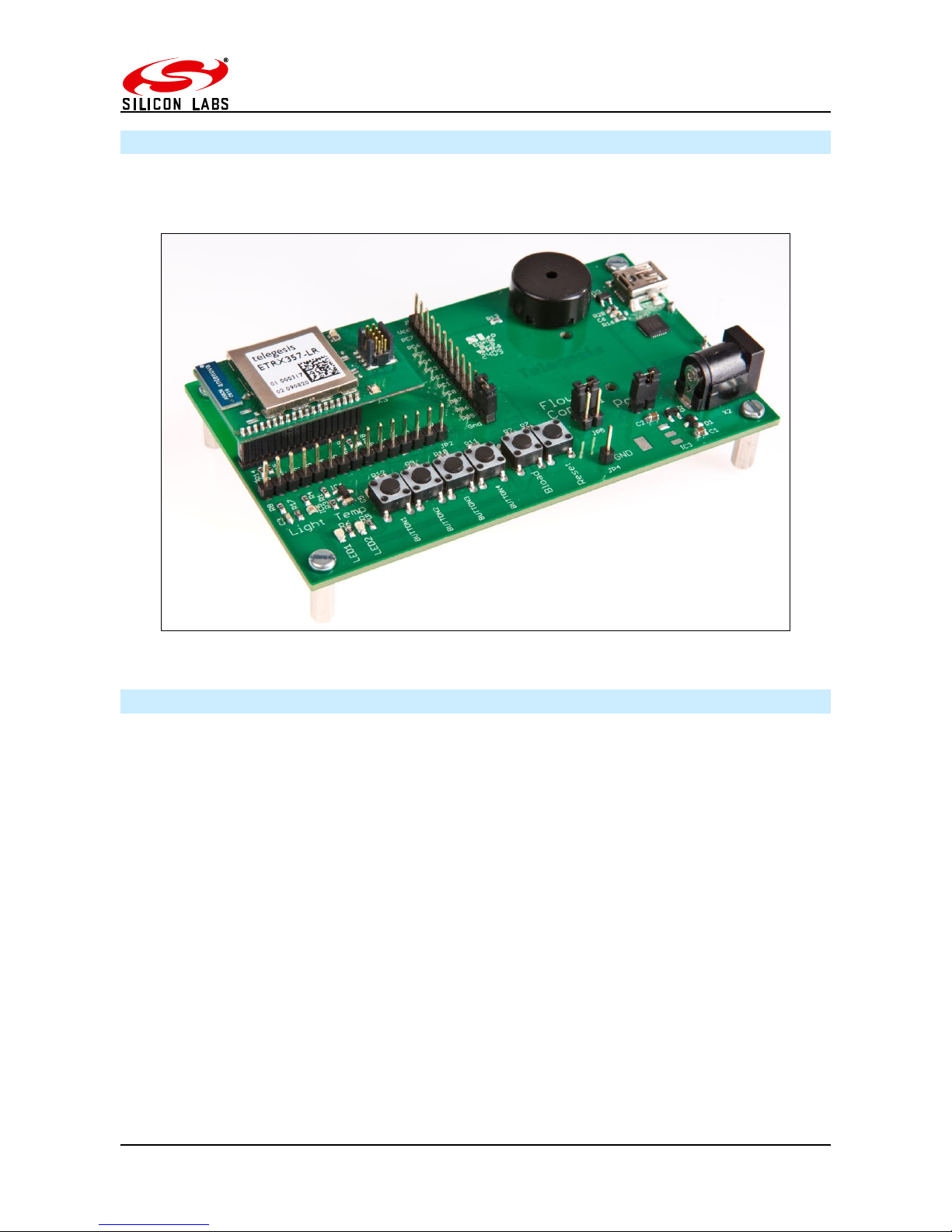

6.1 The Development Board

Figure 1. The development board

The development board which is part of the development kit hosts a USB to serial bridge as well as

voltage regulation circuitry. Furthermore it hosts a reset switch, a bootloader switch, 4 buttons, 2

LEDs and a beeper, all of are connected to the I/Os of the module as described later in this document.

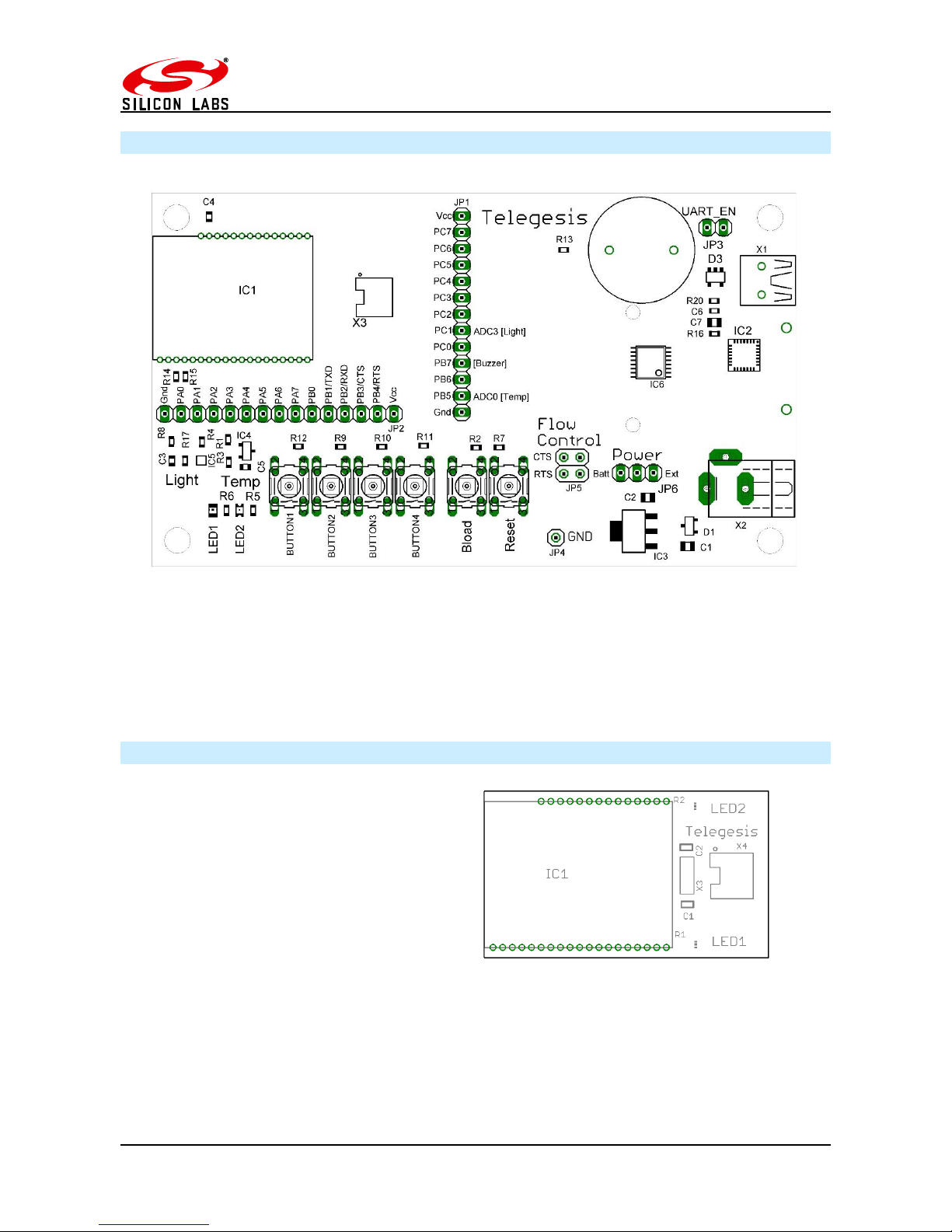

6.2 The carrier board

The carrier board has an ETRX357 module

plus two LEDs, and a connector to attach to a

Silicon Labs InSight Adaptor for reflashing the

firmware. It plugs on to the development board.

Figure 2. The carrier board

Page 7

ETRX357 Development Kit

©2016 Silicon Labs - 7 - ETRX357DVK Product Manual (Rev 1.12)

6.3 What’s in the ETRX357DVK box?

- 3 x ETRX357DV Development Boards

- 3 x USB cables

- 2 x ETRX357 on carrier boards

- 2 x ETRX357HR on carrier boards

- 2 x ETRX357-LRS on carrier boards

- 2 x ETRX357HR-LRS on carrier boards

- 1 x ETRX3USB USB stick

- 2 x ½-wave antennae

- 2 x ¼-wave antennae

These packages contain everything you need to immediately set up an ETRX357 development

platform using the enclosed modules. The ETRX357DVK currently includes an ETRX3USB stick

built around an ETRX357 module; earlier kits included the ETRX2USB stick, but the USB drivers

and the command set are the same.

Page 8

ETRX357 Development Kit

©2016 Silicon Labs - 8 - ETRX357DVK Product Manual (Rev 1.12)

7 Setting up the Hardware

In the development kits are all four versions of the module. They can be powered from either a USB

hub, the mains (via a suitable power supply) or batteries.

Figure 3. ETRX357-LR Module on Carrierboard plugged on to Devboard

8 ETRX357 pinout

The functions of each of the ETRX357 pins depend on the firmware. When using the Telegesis AT

command-based firmware the S-register settings control the configuration of the I/Os. Some of them

have a main function and an alternate function, as determined by the value of register S15. Holding

pad PA5 low when powering up or resetting the module will cause it to enter the bootloader mode;

this operation lies outside the normal firmware so it is independent of the value of S15. As the

functions are firmware-dependent and may change between versions, Table 3 should be read in

conjunction with the latest R3xx AT Command Manual.

Notes on Table 3 headings

Name is the designation of both the ETRX357 pad and the EM357 chip pin.

Index can be used to reference the individual pin in various S-registers (see the R3xx AT Command

Manual)

Pad is the module’s pad numbering

Default direction indicates whether the pad is normally an input or output

Main function and Alternate function indicate the purpose and connection of the pad

Default alt fn setting indicates whether the default firmware setting chooses the main or alternate

function

Page 9

ETRX357 Development Kit

©2016 Silicon Labs - 9 - ETRX357DVK Product Manual (Rev 1.12)

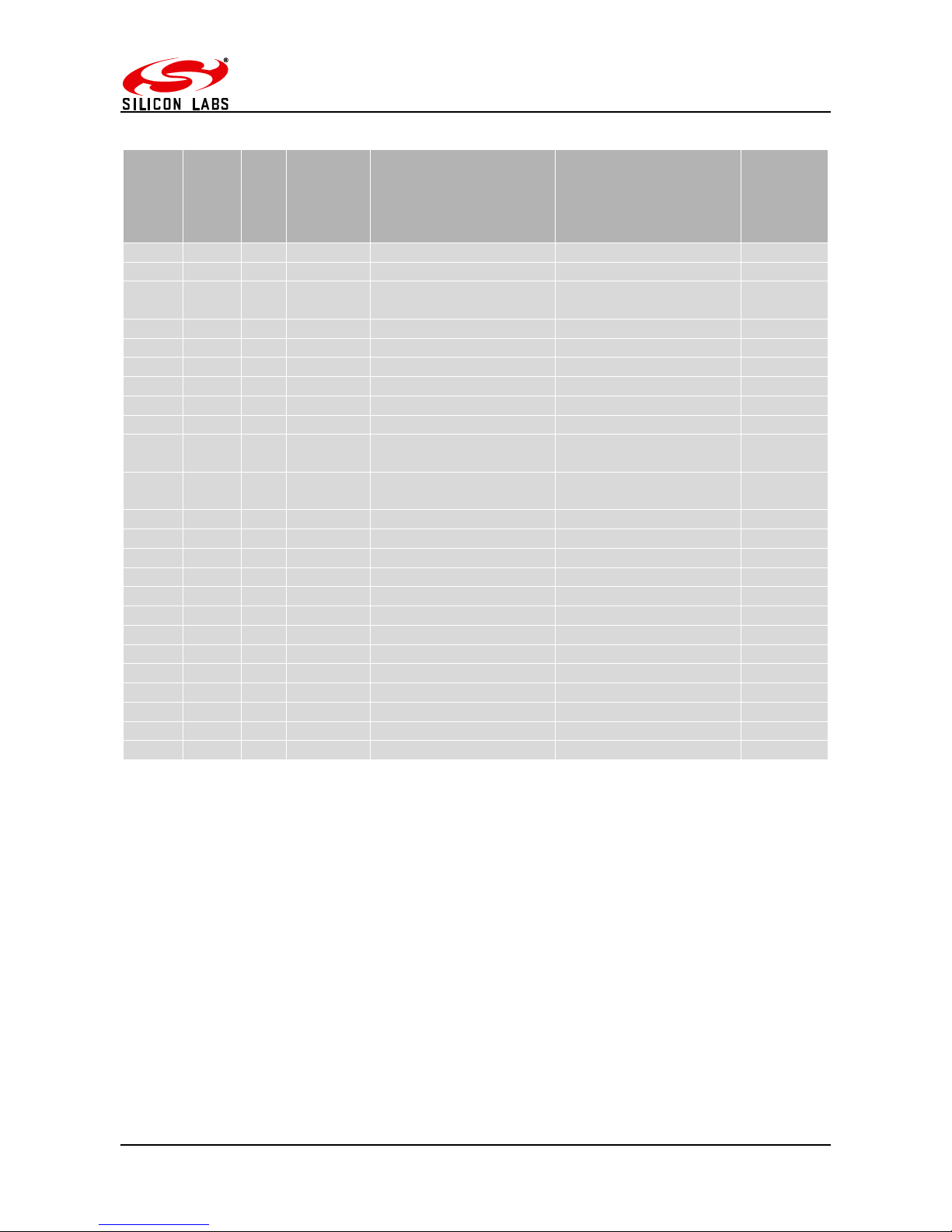

Name

Index

Pad

Default

direction

S17=

0142CC

Main function

Alternate function

Default

alt fn

setting

S15=

00000600

PC7

17 4 In

PC6

16 3 In

PC5

15 2 In

Enable TX_active on

ETRX357 {4}

PC4

14

24

In

PC3

13

23

In

PC2

12

22

In

PC1

11

26

In ADC3 (light sensor) {2}

PC0

10

27

Out

LED

PB7

F

28

In ADC2, PWM {2}

PB6

E

29

Out

LED, Button 4, IRQ3

{1}

ADC1 {2}

PB5

D

30

In

ADC0 (temp sensor)

{2} PB4

C 8 In

PB3

B 6 In

PB2

A

18

In RXD

Enabled

PB1

9

17

Out TXD

Enabled

PB0

8

25

In

Button 3, IRQ2 {1}

PA7

7 5 Out

LED

PA6

6

16

Out

LED

PA5

5

15

In

(Bootload)

PA4

4

14

In

PA3

3

12

Out

Sensor supply {3}

PA2

2

11

Out

Sensor supply {3}

PA1

1

10

In

Button 2, IRQ1 {1}

PA0

0 9 In

Button 1, IRQ0 {1}

Table 3. Module pads and functions

Notes

{1} The IRQS are always enabled; it is not necessary to activate the alternate function. PB0 is not

available for use on an ETRX357-LRS module as it is used internally to control the RF front-end

module

{2} The ADCs are normally disabled; it is necessary to activate the alternate function

{3} In a development kit, the sensor supply outputs PA2 and PA3 must be high for the sensors to

function

{4} On the ETRX357 TX_active is an output which indicates that the RF circuit is transmitting. On

the ETRX357-LRS TX_active is always selected, and is not available as an ordinary I/O because it

is connected internally to RF components.

Page 10

ETRX357 Development Kit

©2016 Silicon Labs - 10 - ETRX357DVK Product Manual (Rev 1.12)

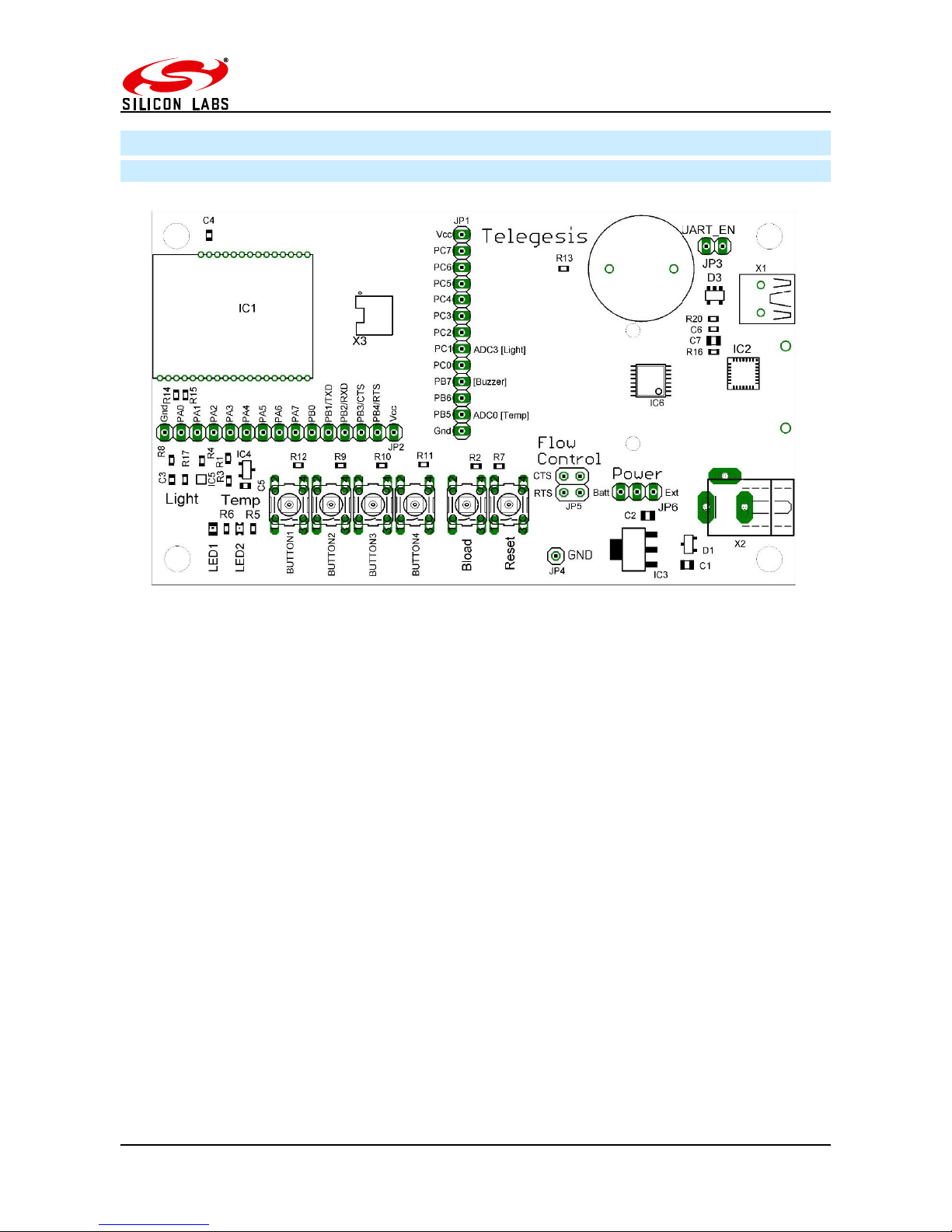

9 The Development Board

9.1 Development Board Interface Description

Figure 4. The development board

Figure 4 shows the location of the connectors described below.

Programming Connector: The 10-way programming connector X3 is used to program the

ETRX357 module from a Silicon Labs InSight Adaptor. It is duplicated on the carrier board, and will

not normally be fitted in the Development Board.

USB Port: The USB serial port allows connectivity to a PC. This provides access to the command

line interface and the bootloader for firmware upgrades, and supplies DC power to the board.

I/O connection: JP1 and JP2 can be used to connect the I/O pins as shown in Table 4.

Reference Ground: JP4 is connected to the devboard’s ground plane. It can be used as a reference

point when making measurements on the devboard.

Page 11

ETRX357 Development Kit

©2016 Silicon Labs - 11 - ETRX357DVK Product Manual (Rev 1.12)

I/O breakout:

JP1 and JP2 give access to the I/O on the ETRX357 module. The individual pins are labelled on the

circuit board, and the pin numbering (PA0, PB1 etc) matches that of the EM357 chip inside the

module.

Pin

Devboard functionality

PA0

Button1

PA1

Button2

PA2

Temp sensor supply

PA3

Light sensor supply

PA5

Bootloader button

PB0

Button3

PB1

TXD

PB2

RXD

PB3

CTS

PB4

RTS

PB5

ADC0 (Temp sensor reading)

PB6

Button4

PB6

LED1

PB7

Buzzer

PC0

LED2

PC1

ADC3 (Light sensor reading)

Table 4. I/O Connectivity on development board

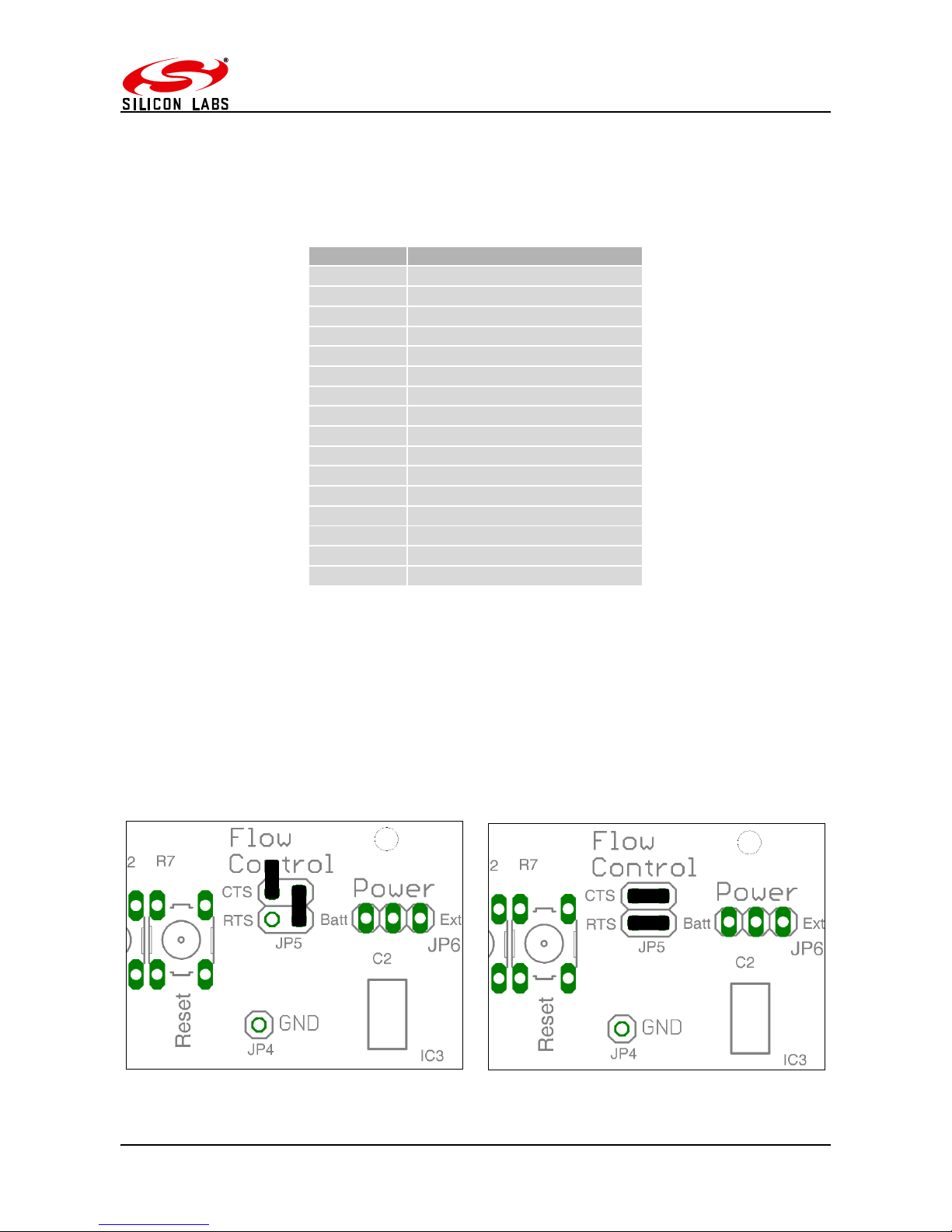

Flow Control Selection: JP5 is used to connect the RTS and CTS lines used for the flow control to

the host. By default flow control is disabled and the corresponding lines of the module are used as

standard I/Os (see the AT command dictionary on how to enable flow control), so the default setting

of JP5 does not connect those lines to the host as shown in Figure 5. When flow control is enabled

JP5 must be set as shown in Figure 6. Please make sure the jumpers are only set to this

configuration when flow control is enabled as otherwise I/Os driving against each other (via a

protective resistor) will increase the current consumption.

Figure 5. No Flow Control (default)

Figure 6. Flow control enabled

Page 12

ETRX357 Development Kit

©2016 Silicon Labs - 12 - ETRX357DVK Product Manual (Rev 1.12)

Power supply jumpers: links must be inserted at JP3 and JP6 according to the DC supply feed.

JP3 can be left connected at all time, but it disconnects the serial interface lines and prevents power

drain through them when the serial (USB) interface is not used. This will minimise the current drain

from a battery and produce a more accurate reading of the current consumption.

It permissible to attach a USB connection while the board is powered from a battery or external

supply.

There are three options:

USB power

External power through the X2

socket

Battery power

Insert JP3. Connect the centre

pin of JP6 to ‘Ext’.

Optionally, omit JP3. Connect

the centre pin of JP6 to ‘Ext’.

Optionally, omit JP3. Connect

the centre pin of JP6 to ‘Batt’.

Figure 7. Power feed options

Instead of a shorting link, a current meter can be inserted at JP6 to monitor the power consumption.

9.2 Development Board Sensors

The board’s temperature sensor IC4 is a National Semiconductor LM61 which has an offset of

600mV and a sensitivity of 10mV/deg. Hence for example 0°C give 600mV and 20° gives 800mV.

The ETRX357’s ADCs have a sensitivity of 0.1mV/LSB, so 100 LSB’s 1 degree.

The light sensor IC5 is an Avago APDS 9005; it indicates ambient light level but is not suitable for

accurate measurements.

Page 13

ETRX357 Development Kit

©2016 Silicon Labs - 13 - ETRX357DVK Product Manual (Rev 1.12)

10 The Carrier Board

Figure 8. The carrier board

The ETRX357 carrier board has two LEDs.

Pin

Carrier board functionality

PA6

LED1

PA7

LED2

Table 5. Carrier board LEDs

Programming Connector: The 10-way programming connector X4 is used to program the

ETRX357 module from a Silicon Labs InSight Adaptor.

Watch crystal: an optional 32kHz crystal and its associated capacitors can be fitted at X3, C1 and

C2. In this case, R14 and R15 should be removed from the main development board. The use of

this crystal is dependent on the user’s firmware and the latest Silicon Labs documentation should be

consulted for details of the circuit design.

11 Driver Installation and Operation

The USB drivers obtainable from www.silabs.com/telegesissoftware will generate a virtual COM port

allowing easy access to the serial port of the embedded ETRX357. The ETRX357 development

board uses the same USB-to-serial device as the ETRX2USB and ETRX3USB products, so the

same USB drivers can be used. The development kit board and the USB stick use the same drivers

so you only need to install them once.

11.1 Windows 9x/XP/2k Driver Installation

Install the drivers before connecting the development kit using the provided USB cable. The driver

package should be unzipped into a local folder. When executing the file ‘TGvcpInstaller_x86.exe’ or

‘TGvcpInstaller_x64.exe’ an installer will guide you through the steps required for the driver

installation. Note that updates to the driver package may result in the various messages differing

from the screen-shots shown here.

The installer will first ask you to confirm the location for the files:

Page 14

ETRX357 Development Kit

©2016 Silicon Labs - 14 - ETRX357DVK Product Manual (Rev 1.12)

Figure 9. File location

After the files are installed you may have to restart the computer:

Figure 10. Request to restart

After you connect the devboard Windows® will prompt that new hardware has been found. If you

have not run ‘TGvcpInstaller_xx.exe’ you will have to manually point to the directory into which you

have unzipped the driver. Depending on your PC setup Windows may ask to check the internet for

updated drivers, but there is no point in doing this.

Figure 11. Found New Hardware Wizard

Page 15

ETRX357 Development Kit

©2016 Silicon Labs - 15 - ETRX357DVK Product Manual (Rev 1.12)

Figure 12. Satisfactory completion

Please note that each devboard and USB stick has a unique serial number which requires the

installation procedure to be repeated with every new unit being attached to the computer. This allows

multiple devices to be used on the same computer at any one time. If a USB stick is unplugged and

re-inserted the computer recognises it without having to repeat the installation process, and the USB

device retains its former COM port number.

In order to find out the identity/number of the virtual COM port the devboard or USB stick has been

assigned to, please open the Device Manager under the Windows Computer Management screen

(see below) and click on the Ports (COM and LPT) section where you should find the new virtual

COM port. By double clicking on the entry of the virtual COM port you can also change the number

assigned to the virtual COM port when entering the advanced setup of the device.

Page 16

ETRX357 Development Kit

©2016 Silicon Labs - 16 - ETRX357DVK Product Manual (Rev 1.12)

Figure 13. Device Manager

Once the correct COM port has been selected, the Telegesis Terminal software can be used to

control the devboard as described in chapter 11.

Figure 14. Telegesis Terminal

Page 17

ETRX357 Development Kit

©2016 Silicon Labs - 17 - ETRX357DVK Product Manual (Rev 1.12)

12 Application Software

The command line of the ETRX357 can be accessed using any terminal software program such as

HyperTerminal®. Simply set up HyperTerminal® to connect to the appropriate COM port at

19200bps, Data bits - 8, Parity - none, Stop bits - 1, Flow Control – none (ETRX357 factory default).

To speed up evaluation Telegesis provides its own Terminal Application Software program which

allows enhanced functionality especially suited to the ETRX357 modules. The AT-Style commands

can be issued by clicking on customisable ‘Command’ buttons and all of the 64-bit serial numbers

which report are listed in a separate window. This means you will not need to input any of the 64-bit

serial numbers.

For instructions on how to use the AT commands read the R3xx AT Command Manual.

Note: Telegesis Terminal does not interpret the AT commands and send instructions to the ETRX357

in a different format. It does not alter the AT commands in any way – the ETRX357 receives them

exactly as described here and in the AT Command Manual. Likewise, if you are writing your own

terminal application, it should send and receive data as formatted in our manuals.

Figure 15. Appearance of the Telegesis Terminal Application Software

Page 18

ETRX357 Development Kit

©2016 Silicon Labs - 18 - ETRX357DVK Product Manual (Rev 1.12)

12.1 Software Set-up

Telegesis Terminal R4.0 no longer needs .NET Framework Version 1.1 which was required for earlier

versions. Download Telegesis Terminal from our website at

www.silabs.com/telegesissoftware

With recent operating systems such as Windows 7, it is advisable to right-click on the Telegesis

Terminal setup program and select “Run as administrator”. This avoids problems when you try to

save customised button layout files as they are normally stored in the program folders.

After installing and starting the Telegesis Terminal Application program a single command button for

the firmware will be shown at the bottom of the window. In order to use the Telegesis Terminal

software, first open the correct button layout file for your firmware by selecting File Open Layout,

then select the correct COM port and the connection parameters (ETRX357 default 19200, 8 bits,

no parity, no flow control) and press the connect button. These settings are automatically retained

each time the software is re-started.

12.2 Features of the Telegesis Terminal Application for ETRX357

The buttons

To make life easy many of the AT commands have been pre-defined and conveniently grouped at

the bottom of the terminal window. Pressing a button (where no parameters are required) causes

the corresponding command to be issued instantly. Where a parameter is required the command is

shown in the Command bar and the required parameter can be entered manually. In order to issue

the command from the command bar simply press the <enter> or the Send button. To see the

parameters for a specific command, move and hold the mouse pointer over the chosen command

button - Figure 16.

Figure 16. Screen tips for parameters

The application software also allows you to add custom command buttons and edit existing

command buttons. New groups of commands can be created and command buttons can be moved

between groups.

The device window

Every EUI64 number reporting in is listed in a separate window which can be opened or closed by

clicking on the button labelled ‘Device List’. If a device ID is required as a parameter in the command

bar, simply double click on an entry in the device list and its EUI64 will be automatically transferred

to the current cursor position of the command bar.

Page 19

ETRX357 Development Kit

©2016 Silicon Labs - 19 - ETRX357DVK Product Manual (Rev 1.12)

To allow for easier identification, the EUI64 IDs in the device list can be named. When right clicking

on any EUI64 ID a name can be associated with the respective ID - Figure 17.

Figure 17. Device Naming

The menu bar

Figure 18. Telegesis Terminal menu bar

File To open and save button layout files

Connection To switch connection address mode between COM port and IP address

Commands To open a button layout editor

Log To save a record of the session

Tools Refresh COM Ports – update the drop-down list of ports

Transfer File – open an XMODEM dialogue window

Send Text – import a file into the large dialogue window

Show STX ETX – displays <stx> and <etx> characters when the firmware

uses them to bracket its output

Use Nonprinting Characters – characters can be entered as two

hexadecimal characters bracketed by <…>, eg <41> for A or <0D> for

carriage return

Help Shows the software version

Button layout files are normally found in the folder into which Telegesis Terminal was installed. They

are xml files so they can be edited by a text editor or by a tool such as the Microsoft XML Notepad,

as well as from within Telegesis Terminal itself. Buttons usually have a single AT command attached

to them, but v4 of Telegesis Terminal allows a button to have multiple commands, each terminated

by <cr>. When the button is pressed a 100ms delay is inserted after each command.

Connection can be made to a COM port or to an IP address and port number; the latter opens a TCP

connection.

Page 20

ETRX357 Development Kit

©2016 Silicon Labs - 20 - ETRX357DVK Product Manual (Rev 1.12)

XMODEM is generally used when bootloading a new firmware file on to a module.

12.3 A Quick Start

This section gives you a quick introduction on how to get started. Power up the node connected to

the PC and open a connection to the correct device; refresh the list of COM ports if the expected

device is not shown. Type AT followed by <enter>. If the communication to the module is working

the module will prompt OK, if not check the USB connectivity and driver status and make sure you

have connected to the correct COM port with the correct speed. Please note that even when

connected to the wrong COM port there may be a reply to AT, for example when you are

communicating with your PC’s modem or Bluetooth device. To double check you are actually

communicating with a Telegesis ZigBee device use the ATI command described below.

Select the correct set of buttons

Type ATI<enter> to verify your firmware version (eg R308C). Then select File Open Layout on

the menu bar and open the appropriate xml file – usually R3xx.xml. This attaches the correct set of

AT commands to the buttons. You can create your own button configurations for different situations

and save them as separate files. Telegesis Terminal starts up using the configuration of the previous

session.

Network Setup

Figure 19. Command Line Interactions

To establish a PAN network issue the

AT+EN command, or alternatively

press the ‘Establish PAN’ button.

The local unit will now scan all

available 16 channels and establish a

PAN with a random PAN ID, on the

quietest available one. This may take

up to 16 seconds and leads to the

node becoming the network’s

coordinator. When successful the

module will prompt ‘JPAN’ followed by

the details of the newly created PAN.

If you get an error message instead, it

is likely that the module was already

part of a PAN, so you will need to

issue the AT+DASSL command or

press the ‘Disas Local’ button to

leave the PAN before going back to

starting a new one. In order to find out

about the network status simply issue

the AT+N command or press the

‘NWK Info’ button.

Once the network is established, remote nodes can be powered up ready to join in. If you have

serial access to remote nodes simply issue the AT+JN command or press the ‘Join any PAN’ button,

to join the newly established PAN. If you do not have serial access to the remote nodes (as is the

Page 21

ETRX357 Development Kit

©2016 Silicon Labs - 21 - ETRX357DVK Product Manual (Rev 1.12)

case of the two MCBs provided with the previous ETRX2-based DVKA) you will just need to wait for

them to join the network automatically. By default, once every minute all nodes (except coordinators)

are set up to check whether there are any neighbours on the same PAN nearby, or if they have been

orphaned. If no neighbours are found after 5 consecutive tries, the unit will leave the (deserted) PAN

and then try to join a new one once every minute.

This initial network set-up can take a few minutes, especially with no serial access to remote nodes,

but once the network is set up it will remain set even after power cycles. New nodes joining will

cause a prompt ‘NEWNODE:’ on the remote side and display the JPAN message locally as

described above.

The ETRX357 stores its network parameters in non-volatile memory, so if you reset or power-cycle

a module there is no need to re-establish or join the PAN again.

If devices do not join the desired PAN automatically, check that they are not already in a network of

their own. The command AT+PANSCAN will reveal the presence of other networks in the vicinity.

To learn more about setting up and maintaining a PAN please refer to the user guide and the AT

Command Dictionary.

Mesh networking

A typical ZigBee network is a mesh, where every device can send a message to any other device.

If the two devices are in radio range of each other the message passes directly, but if they are too

far apart the message is relayed via an intermediate device. The routing is taken care of by the

firmware and the user is generally not even aware that it is happening. You can easily discover the

basic principles of mesh networking: simply move a Development Board out of range (if you do not

have enough space simply turn the transmit power down or put it behind a metal screen) and then

add another Development Board between the local node and the remote one. You will find that the

network has healed the broken link and all three nodes are accessible again.

Node types

A ZigBee node is one of several types:

Router. If you have started a network as described so far in this manual, all the devices are

routers and can communicate directly with each other

Coordinator. This is merely the device which first established the network. It is also the trust

centre which grants permission for other devices to join, so do not disassociate it from your

network

Sleepy End Device. SEDs do not play any part in the routing so they can be put into a sleep

state while they do not need to send or receive messages. To turn a device into an SED

disassociate it from your network, set bit E of register S0A with the command

ATS0AE=1;password then let it join the network. An SED is adopted by a parent router which

buffers any messages sent to the SED until it sends a Data Request (or poll) to its parent to

indicate it is ready to receive. The power mode is defined in register S39, so refer to the AT

command manual for more details

Mobile End Device. MEDs are like SEDs but they react more quickly when they move of range

of their parent and need to find a new one. Set bits E and F of register S0A to create an MED

ZigBee End Device. ZEDs cannot be put into a sleep state to save power nor do they take part

in the routing, so they are of very limited use

Page 22

ETRX357 Development Kit

©2016 Silicon Labs - 22 - ETRX357DVK Product Manual (Rev 1.12)

12.4 Configuring Buttons for your Setup

You can open several copies of Telegesis Terminal on the same PC, so if you have two or more

development boards connected to a PC try sending messages between them using the Broadcast

or Unicast buttons. This will begin to give you an understanding on how to integrate the ETRX357

into your application. The Telegesis Terminal Application also allows you to create custom command

buttons for your individual application, just click on Commands / Add command button.

Figure 20. Button editor

In this way you can add buttons that are specific to your tests, reduce the number of buttons to a

simple layout for demonstrations, or create a sequence of operations for commissioning devices and

systems.

The first button on the pre-supplied layouts is . When you click on this, the local

device executes the AT+SN command to scan the network for other devices and for each one it adds

three new buttons:

, (in the Send Data – R3xx group)

(in the Register Access – R3xx group).

Clicking any of these controls the LEDs on the corresponding dev board, or sounds its buzzer.

For a more detailed description of the AT command interface please refer to the appropriate

command manual for your version of firmware R3xx.

Some useful I/O commands for the ETRX357 are given in the next section.

Configure

LEDS n ON

LEDS n OFF

Ident Noden

Page 23

ETRX357 Development Kit

©2016 Silicon Labs - 23 - ETRX357DVK Product Manual (Rev 1.12)

12.5 Using LEDs and ADCs on the ETRX357

The LEDs are connected to the ETRX357 in a pull-down arrangement so each output must be set

to ‘0’ to turn on its LED. Refer to Table 3 for details of the various connections; since they are

distributed across the 16 I/O pins some examples of typical functions are given here for convenience.

The four LED pins are configured as outputs by default so they can be used immediately. Before

each ADC can be used, its pin must be set to use the alternate function in register S15, but it does

not matter whether it is defined as a digital input or output. The temperature and light sensors on

the circuit board are powered from two of the ETRX357’s outputs, so these pins must be set high in

order for the sensors to function.

Turn on local LEDs

ATS18=00000000

Turn off local LEDs

ATS18=000140C0

Turn off LEDs at EUI64 000D6F0000D5ED27

ATREMS:000D6F0000D5ED27,18=000140C0

Turn off all remote LEDs in the network

ATSALL,FFFF,18=000140C0

Turn on local LEDs and supply power to

temperature and light sensors

ATS18=0000000C

Enable temperature and light ADCs

ATS15=0002E600

Read local light sensor

ATS22?

Note that these immediately change the actual values of the registers described but not their default

values.

The ADC registers can be read on a local or remote device by using the ATS or ATREMS commands,

but they can also be sent automatically to the network sink by using function 0110 or 0130; consult

the AT Command Manual for the details, and see section 12.6 here.

Page 24

ETRX357 Development Kit

©2016 Silicon Labs - 24 - ETRX357DVK Product Manual (Rev 1.12)

12.6 Temperature display

The AT command set provides two powerful features:

1. A node can be defined as a “sink”. It broadcasts its address to the rest of the network, so the

other devices can use commands and built-in functions that send data to the sink. In this way, an

application can be designed without the need to know in advance the address of the sink node, which

will be different in each installation.

2. Software timers implemented in the firmware can execute various predefined functions. Simple

applications can therefore often be implemented without the need for a host processor to send AT

commands to a device.

As an example of both of these features, the following commands demonstrate how to collect

temperature information from development kit boards:

1. Define the module on the data-gathering development board as the network sink with the

command

ATS104=1

2. Instruct one or more sensor development boards to send their ADC readings to the sink at

regular intervals by setting a Timer/Counter on the ETRX357, eg to send every second

using Timer/Counter 5 use these commands on each sensor board:

ATS33=0004

ATS34=8130

3. Activate all four ADCs on each sensor board with the command

ATS15=0002E600

4. Turn on the sensor power on each sensor board with the commands

ATS182=1

ATS183=1

5. The ADC readings will appear at the sink in the form of a “FN130” prompt, which also

contains the digital I/O values and the contents of the S46 counter register. See the AT

Command Manual for full details of the prompt and the registers used here. The units are

0.1mV; the sensor has a slope of 10mV/deg with a 600mV offset.

It is usually easiest to set the sensor device’s registers by accessing them via USB, but you can also

use the ATREMS command from the sink node.

Page 25

ETRX357 Development Kit

©2016 Silicon Labs - 25 - ETRX357DVK Product Manual (Rev 1.12)

13 Firmware upgrades

If required, the firmware of the ETRX357 modules can be upgraded serially as well as over the air.

Over-the-air upgrading is primarily a function of the Silicon Labs bootloader and it is not available

with the early bootloader versions. See section 13.2 for more details.

13.1 Firmware Upgrades via Serial Port

In order to upgrade the firmware of the ETRX357 module using the serial bootloader, issue the

“AT+BLOAD” command either by typing it in, or by pressing the respective button in the “Module

Control” group of the Telegesis Terminal Application.

Alternatively the button labelled “Bload” can be pressed on the development board whilst the reset

button is pressed and released.

After entering the bootloader, the connection parameters need to be changed to 115200bps, 8 data

bits, 1 stop bit, no parity, no flow control (providing that it is not already set to these values).

After pressing ‘Enter’, the bootloader menu will be shown in the terminal window as shown in Figure

21.

Figure 21. Bootloader Menu

Pressing ‘1’ initiates the upload of the new firmware and a number of ‘C’ characters will indicate that

the ETRX357 is ready to receive data. Within 60 seconds, select Tools / Transfer File… and browse

for the new firmware file.

Firmware files for the ETRX357 will be in the format ETRX357_R3xxC.ebl. After checking that the

protocol is set to XMODEM (128 Bytes), press the Send button and the new firmware will be

downloaded as shown in Figure 22.

Page 26

ETRX357 Development Kit

©2016 Silicon Labs - 26 - ETRX357DVK Product Manual (Rev 1.12)

Figure 22. File Transfer Window

When the transfer has been completed successfully, press Enter again in order to return to the

bootloader menu (shown in Figure 21) and option ‘2‘ to run the downloaded application software. If

the application software has a baudrate other than 115200bps, this will need to be changed to the

application baudrate as described above – 19200 baud in the case of R3xx firmware.

Page 27

ETRX357 Development Kit

©2016 Silicon Labs - 27 - ETRX357DVK Product Manual (Rev 1.12)

13.2 Over the Air Firmware Upgrades

ETRX2 and ETRX357 features

With the ETRX2, upgrading over the air is possible by cloning a local node’s firmware to a remote

node, so if new firmware has to be introduced to the network it can be downloaded serially to a

master node, which then can clone itself to one node after the other in turn given the target node is

only a single hop away. Cloning between some firmware releases may not always be possible, so

check the Firmware Revision History for relevant comments.

The ETRX357 uses passthrough OTA bootloading, so the new file is stored in the host processor

and loaded on to the target device by transmitting it through the local device. The local device is

therefore not required to have the same firmware as the updated target.

The ETRX2 and ETRX357 have different bootloaders and firmware files as well as different modes

of transferring the new file. Consequently you cannot upgrade an ETRX357 via an ETRX2 or viceversa.

Passthrough with an ETRX357

You should first verify that the module’s bootloaders are sufficiently recent, as this feature was not

included in the earliest versions. Start the bootloader with the AT+BLOAD command, enter a <cr>

and check the response, then exit the bootloader without altering the firmware by selecting option 2

(‘run’). The bootloader needs to be version v42 or higher for passthrough to be possible, or else v01

which is a Telegesis variant of the Silicon Labs bootloader. A new bootloader can only be installed

by reflashing the module’s memory with a Silicon Labs Insight Adaptor.

The passthrough process is similar to bootloading a file on to the local device, except that there is

no need to change the baud rate. Use the command

AT+PASSTHROUGH:<EUI64 of the target device>:<Target device’s password>

The device will respond with a prompt and a sequence of ‘C’ characters. Select Tools / Transfer

File… from the drop-down menu of Telegesis Terminal and browse for the new firmware file.

Firmware files for the ETRX357 will be in the format ETRX357_R3xxC.ebl. After checking that the

protocol is set to XMODEM (128 Bytes), press the Send button and the new firmware will be

downloaded as shown in Figure 22.

Passthrough bootloading on to an End Device or across multiple hops is not possible.

Page 28

ETRX357 Development Kit

©2016 Silicon Labs - 28 - ETRX357DVK Product Manual (Rev 1.12)

Figure 23. Passthrough bootloading

Recovering on the default channel

If the target device is reset or power cycled whilst in the bootloader, the unit will listen for new

firmware files on channel 13. It is therefore required to set up a node on channel 13 and repeat the

recovery action described in the previous section.

To set up a node on channel 13 use the following commands:

AT+DASSL – leave the current network (will show an error if not currently part of a network)

ATS00=0004 – Only allow channel 13

AT+EN – establish new network on channel 13

This will cause the local node to become a coordinator on channel 13.

AT+RECOVER

The local node will search for a remote node in bootload mode and clone the local firmware to that

remote node.

Page 29

ETRX357 Development Kit

©2016 Silicon Labs - 29 - ETRX357DVK Product Manual (Rev 1.12)

14 Hardware enhancement kit

For users who are developing their own firmware on the Silicon Labs EM3587 chip, Telegesis offer

an enhancement pack for the ETRX357 Development Kit or the Silicon Labs EM35x Development

Kit that contains EM3587-based modules on carrier boards. This will enable you to download your

application to the modules and verify its operation on our development kit boards. In this way you

can demonstrate that your firmware is portable on to the ETRX3587, that it functions correctly with

the power amplifier of the ETRX3587-LRS, and that it is over-the-air compatible with the ETRX357.

Each enhancement pack contains two examples of the following, each on a carrier board:

Model

Antenna

Max RF power

ETRX3587

Antenova Rufa

8dBm

ETRX3587HR

Hirose U.FL connector for external antenna

8dBm

ETRX3587-LRS

Antenova Rufa

20dBm

ETRX3587HR-LRS

Hirose U.FL connector for external antenna

20dBm

Table 6. ETRX3587 Enhancement Pack contents

The devices in the enhancement pack will be supplied with the Silicon Labs nodetest firmware.

Connect to the COM port of the board at 115200 baud and type help, which returns a list of the

available commands. There is some information about the commands in the SiLabs application note

AN710 Bringing Up Custom Devices For The Ember® Em35x Soc Platform at

www.silabs.com/support/pages/document-library.aspx?p=Wireless&f=ZigBee&pn=EM357

but the command set is otherwise undocumented.

Page 30

ETRX357 Development Kit

©2016 Silicon Labs - 30 - ETRX357DVK Product Manual (Rev 1.12)

15 Devboard Schematic

Page 31

ETRX357 Development Kit

©2016 Silicon Labs - 31 - ETRX357DVK Product Manual (Rev 1.12)

Page 32

ETRX357 Development Kit

©2016 Silicon Labs - 32 - ETRX357DVK Product Manual (Rev 1.12)

16 Carrier Board Schematic

Page 33

ETRX357 Development Kit

©2016 Silicon Labs - 33 - ETRX357DVK Product Manual (Rev 1.12)

17 ETRX357 Ordering Information

Ordering/Product Code

Description

ETRX357

Telegesis Wireless Mesh Networking Module with Silicon Labs

ZigBee® Technology:

Telegesis AT Style Command Interpreter based on

Silicon Labs’ EmberZNet stack

Integrated 2.4GHz Antenna

ETRX357HR

Telegesis Wireless Mesh Networking Module with Silicon Labs

ZigBee® Technology:

Telegesis AT Style Command Interpreter based on

Silicon Labs’ EmberZNet stack

Hirose U.FL Antenna Connector

ETRX357DVK

Telegesis Development Kit with:

3 x ETRX357DV Development Boards

2 x ETRX357 Modules on Carrier Boards

2 x ETRX357HR Modules on Carrier Boards

2 x ETRX357-LRS Modules on Carrier Boards

2 x ETRX357HR-LRS Modules on Carrier Boards

1 x ETRX3USB stick

2 x ½-wave antennae

2 x ¼-wave antennae

3 x USB Cables

ETRX3587 Enhancement Pack

2 x ETRX3587 Modules on Carrier Boards

2 x ETRX3587HR Modules on Carrier Boards

2 x ETRX3587-LRS Modules on Carrier Boards

2 x ETRX3587HR-LRS Modules on Carrier Boards

Notes:

Customers’ PO’s must state the Ordering/Product Code.

There is no “blank” version of the ETRX357 Module available. All Modules carry the

Telegesis AT style Command Layer based on the EmberZNet Stack. (Where customers

wish to add their own firmware they can re-program the flash memory of the embedded

EM357).

Please contact Telegesis if you require additional AT style commands or specific integration

assistance.

Page 34

Smart.

Connected.

Energy-Friendly

Products

www.silabs.com/products

Disclaimer

Silicon Laboratories intends to provide customers with the latest, accurate, and in-depth documentation of all peripherals and modules available for system and software implementers using

or intending to use the Silicon Laboratories products. Characterization data, available modules and peripherals, memory sizes and memory addresses refer to each specific device, and

"Typical" parameters provided can and do vary in different applications. Application examples described herein are for illustrative purposes only. Silicon Laboratories reserves the right to

make changes without further notice and limitation to product information, specifications, and descriptions herein, and does not give warranties as to the accuracy or completeness of the

included information. Silicon Laboratories shall have no liability for the consequences of use of the information supplied herein. This document does not imply or express copyright licenses

granted hereunder to design or fabricate any integrated circuits. The products are not designed or authorized to be used within any Life Support System without the specific written consent

of Silicon Laboratories. A "Life Support System" is any product or system intended to support or sustain life and/or health, which, if it fails, can be reasonably expected to result in significant

personal injury or death. Silicon Laboratories products are not designed or authorized for military applications. Silicon Laboratories products shall under no circumstances be used in

weapons of mass destruction including (but not limited to) nuclear, biological or chemical weapons, or missiles capable of delivering such weapons.

Trademark Information

Silicon Laboratories Inc.® , Silicon Laboratories®, Silicon Labs®, SiLabs® and the Silicon Labs logo®, Bluegiga®, Bluegiga Logo®, Clockbuilder®, CMEMS®, DSPLL®, EFM®, EFM32®,

EFR, Ember®, Energy Micro, Energy Micro logo and combinations thereof, "the world’s most energy friendly microcontrollers", Ember®, EZLink®, EZRadio®, EZRadioPRO®, Gecko®,

ISOmodem®, Precision32®, ProSLIC®, Simplicity Studio®, SiPHY®, Telegesis, the Telegesis Logo®, USBXpress® and others are trademarks or registered trademarks of Silicon Laboratories Inc. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or registered trademarks of ARM Holdings. Keil is a registered trademark of ARM Limited. All other products or brand

names mentioned herein are trademarks of their respective holders.

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

USA

Quality

www.silabs.com/quality

Support and Community

community.silabs.com

http://www.silabs.com

Loading...

Loading...