Si3210/Si3211/Si3212

S

T

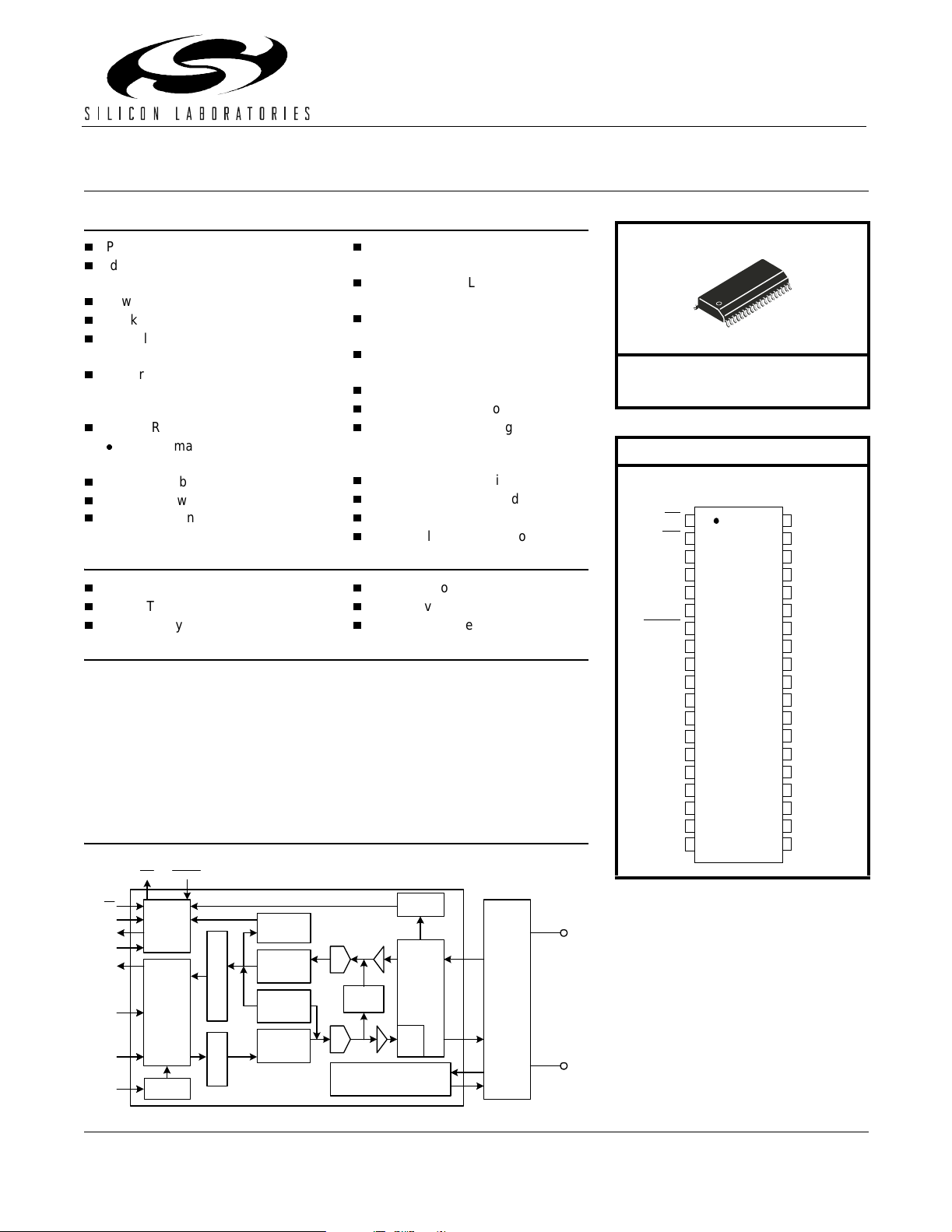

PROSLIC™ PROGRAMMABLE CMOS SLIC/CODEC

WITH RINGING/BATTERY VOLTAGE GENERATION

Features

Performs all BORSCHT Functi ons

Ideal for Short Loop Appl ications

(5 REN at 2 kft, 3 REN at 4 kft)

Low Voltage CMOS

Package: 38-Pin TSSOP

Compliant with Relevant LSSGR and

CCITT Specifications

Battery Voltage Generated Dynamically

with On-Chip DC-DC Converter

Controller (Si 3210 only)

5 REN Ringing Generator

Programmable Frequency, Amplitude,

Waveshape, and Cadence

Programmable AC I mpedance

A-Law/µ-Law, Linear PCM Companding

On-Hook Tr ansmission

Applications

Terminal Adaptors

Cable Telephony

PBX/Key Systems

Description

The ProSLIC™ is a low-voltage CMOS device that integrates SLIC, codec, and

battery generation functionality into a complete analog telephone interface. The

device is ideal for short loop applications such as terminal adaptors, cable telephony,

and wireless local loop. Th e ProSLIC is powered with a single 3.3 V or 5 V supply.

The Si3210 generates battery voltages dynamically usin g a software program mable

dc-dc converter from a 3.3 V to 35 V supply; negative high-voltage supplies are not

needed. All high voltage functions are performed locally with a few low cost discrete

components. The device is available in a 38- pin TSSOP and interfaces directly to

standard SPI and PCM bus digital interfaces.

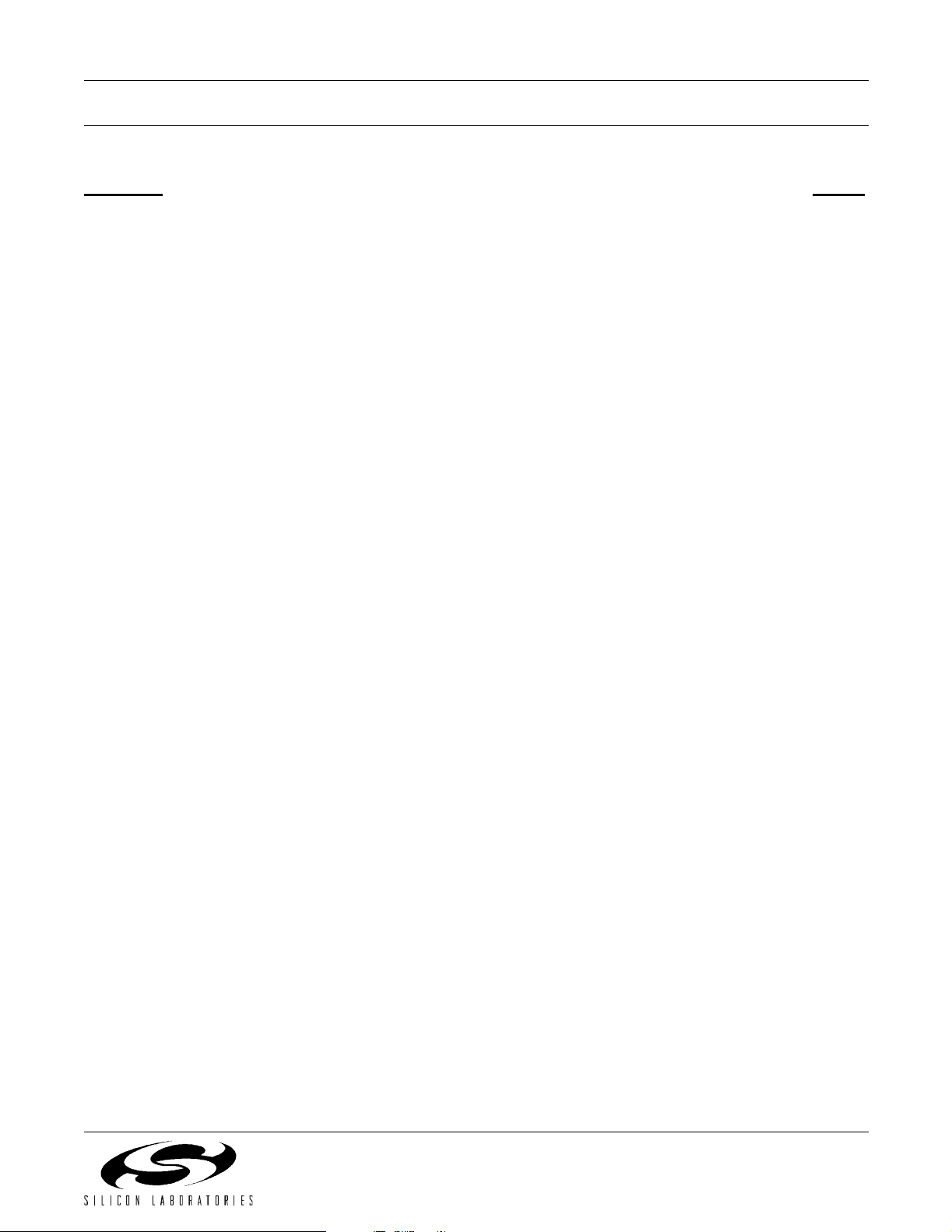

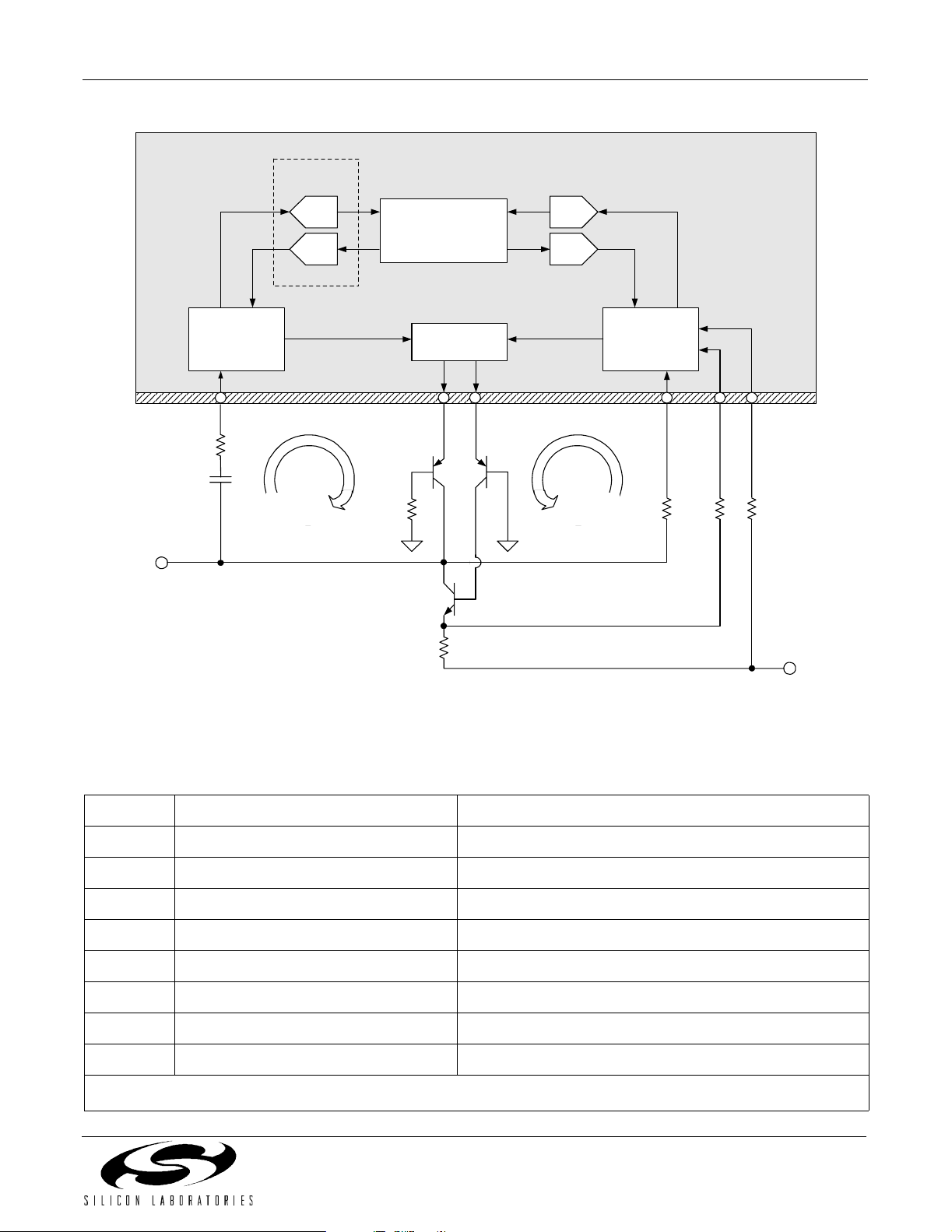

Functional Block Diagram

Programmable Constant Current

Feed (20–41 mA)

Programmable Loop Closure and

Ring Trip Thresholds with Debouncing

Loop or Ground S tart Operation and

Polarity Battery Reversal

Continuous Line V olt age and Current

Monitoring

DTMF Decoder

Dual Tone Generator

SPI and PCM Bus Digital Interf aces

with Programmable Interrupt for

Control and Data

3.3 V or 5 V Operation

Multiple Loopback Modes for Testing

Pulse Metering

FSK Caller ID Generation

Wireless Local Loop

Voice Ov er IP

Integrated Access Devices

Ordering Inform ati on

See page 118.

Pin Assignments

Si3210/11/12

CS

1

INT

DRX

DTX

IREF

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

PCLK

FSYNC

RESET

DCH/DIO1

SDCL/DIO2

VDDA1

CAPP

QGND

CAPM

STIPDC

SRINGDC

STIPE

SVBAT

SRINGE

ProSLIC

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

SCLK

SDI

SDO

SDITHRU

DCDRV/DCSW

DCFF/DOU

TEST

GNDD

VDDD

ITIPN

ITIPP

VDDA2

IRINGP

IRINGN

IGMP

GNDA

IGMN

SRINGAC

STIPAC

RESETINT

CS

SCLK

SDO

SDI

DTX

DRX

FSYNC

PCLK

Control

Interface

PCM

Interface

PLL

CompressionExpansion

Attenuation/

Attenuation/

Si3210/11/12

DTMF

Decode

Gain/

Filter

Tone

Generator

Gain/

Filter

Line

Status

A/D

Program

Hybrid

D/A

DC-DC Converter Controller

(Si3210 only)

Line

Feed

Control

Z

S

Low Cost

External

Discretes

Patents pending

TIP

RING

Preliminary Rev. 1.11 9/ 01 Copyright © 2001 by Silicon Labora tories Si3210-DS111

This in formation applies to a product under devel opment. I ts characteristics and specifications are subject to change without notice.

Si3210/Si3211/Si3212

2 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

TABLE OF CONTENTS

Section Page

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Linefeed Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Battery Voltage Generation and Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Tone Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ringing Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pulse Metering Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

DTMF Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Audio Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Two-Wire Impedance Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Clock Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Interrupt Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Serial Peripheral Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

PCM Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Companding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Control Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Indirect Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

DTMF Decoding (Si3210 and Si3211 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Digital Programmable Gain/Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

SLIC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

FSK Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Pin Descriptions: Si3210/11/12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Package Outline: 38-Pin TSSOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Preliminary Rev. 1.11 3

Si3210/Si3211/Si3212

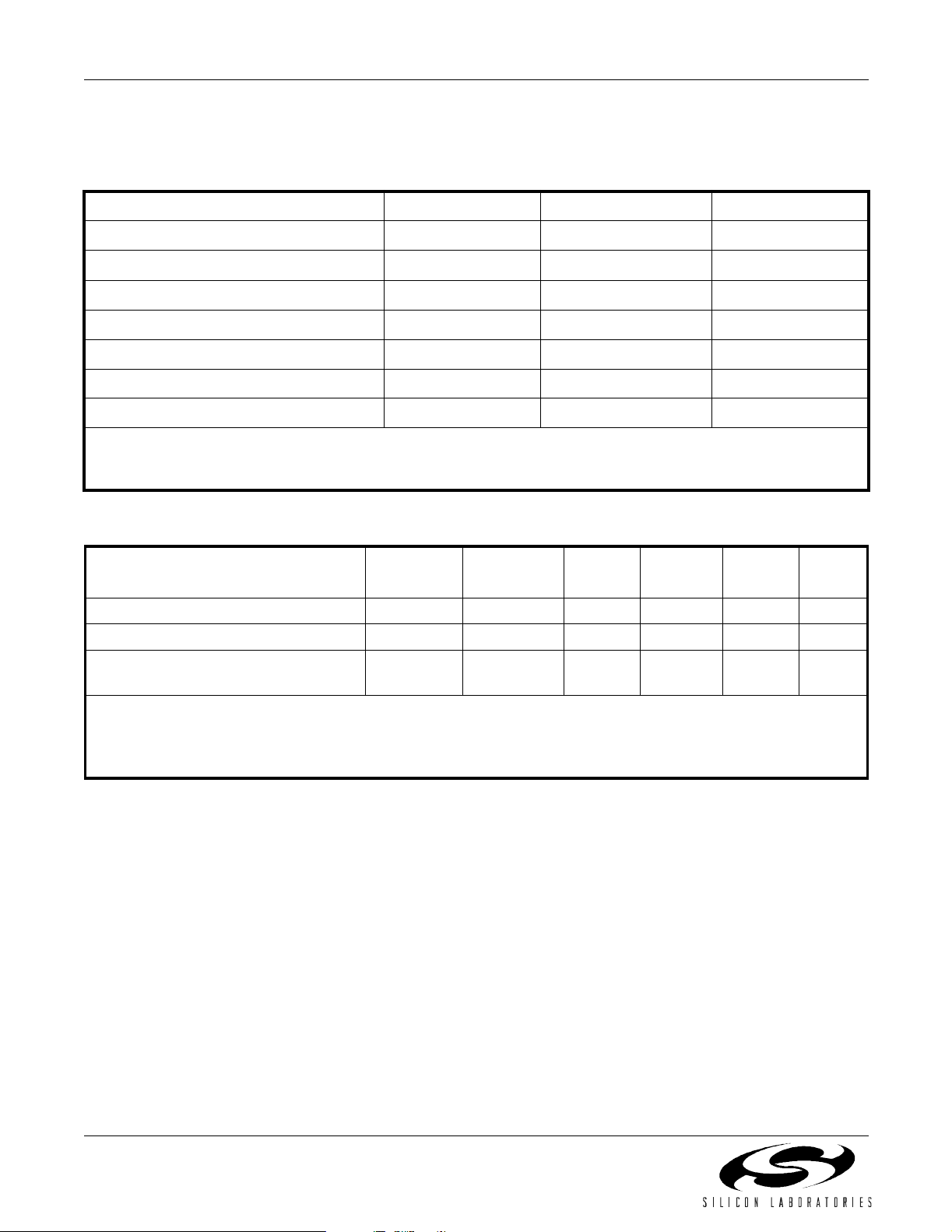

Electrical Specifications

Table 1. Absolute Maximum Ratings and Thermal Information

*

Parameter Symbol Value Unit

DC Supply Voltage

Input Current, Digital Input Pins

Digital Input Voltage

ESD, Si3210/11/12 (Human Body Model)

Operating Temp erature Rang e

Storage Temperature Range

TSSOP-38 Thermal Resistance, Typical

*Note: Permanent device damage may occur if the above Absolute Maximum Ratings are exceeded. Functional operation

should be restricted to the conditions as specified in the operati onal sections of this data sheet. Exposure to absolute

maximum rating conditions for extende d periods may affect device reliability.

V

DDD

, V

DDA1

I

V

IND

T

T

STG

θ

IN

JA

, V

DDA2

–0.5 to 6.0 V

±10 mA

–0.3 to (V

+ 0.3) V

DDD

2000 V

A

–40 to 100 °C

–40 to 150 °C

50 °C/W

Table 2. Recommended Operating Condit ions

Parameter Symbol

Ambient Temperature T

Ambient Temperature T

Si3210/11/12 Supply Voltage V

*Note: All minimum and maximum speci fications are guara nteed and apply across the recommended operatin g conditions.

T ypical values apply at nominal supply voltag es and an operating temperature of 25

Product specifications are only guaranteed when the typical application circ uit (including compo nent tolerances) is

used.

A

A

DDD,VDDA1

,V

DDA2

Test

Condition

K-grade 0 25 70

B-grade –40 25 85

Min* Typ Max* Unit

o

C

o

C

3.13 3.3/5.0 5.25 V

o

C unless other wise stated.

4 Preliminary Rev. 1.11

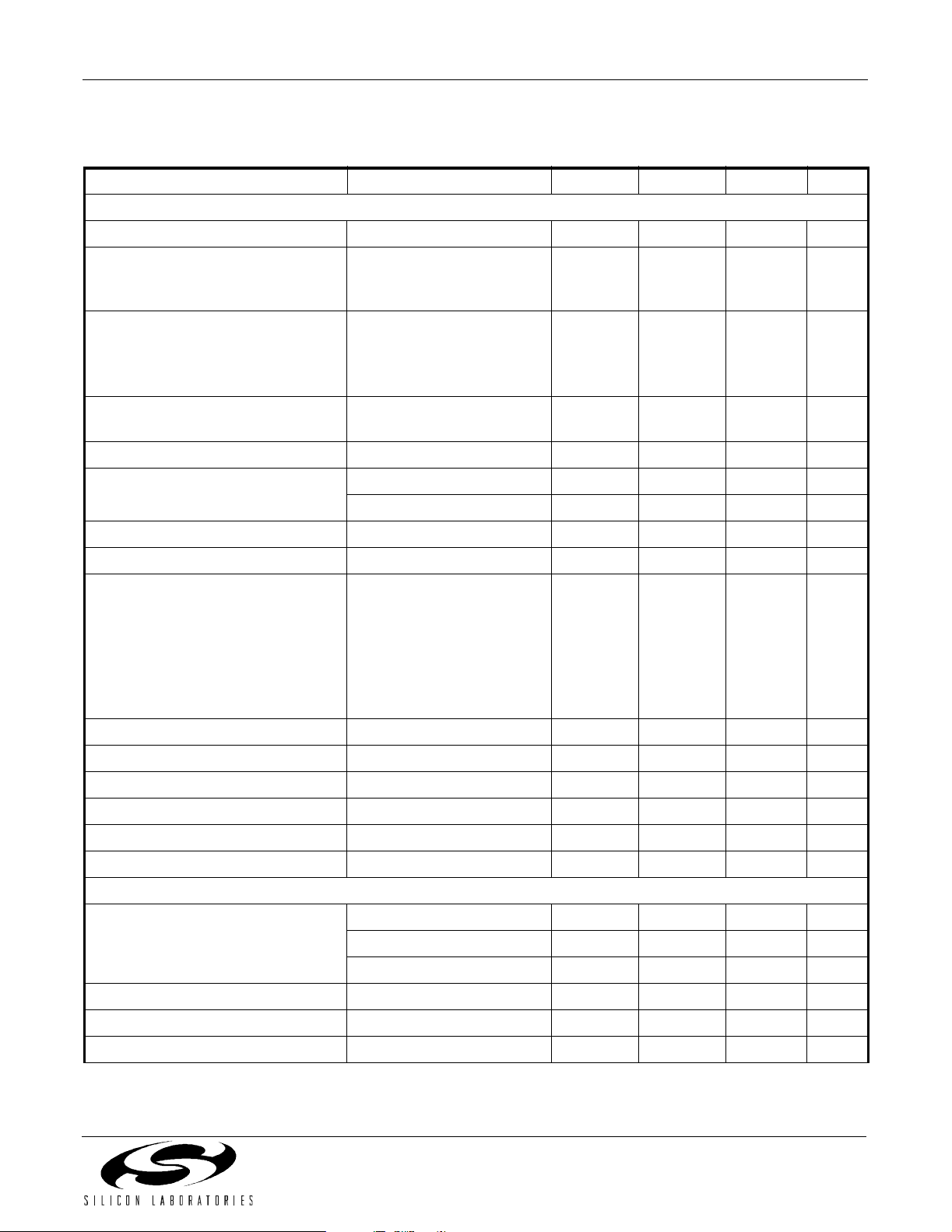

Si3210/Si3211/Si3212

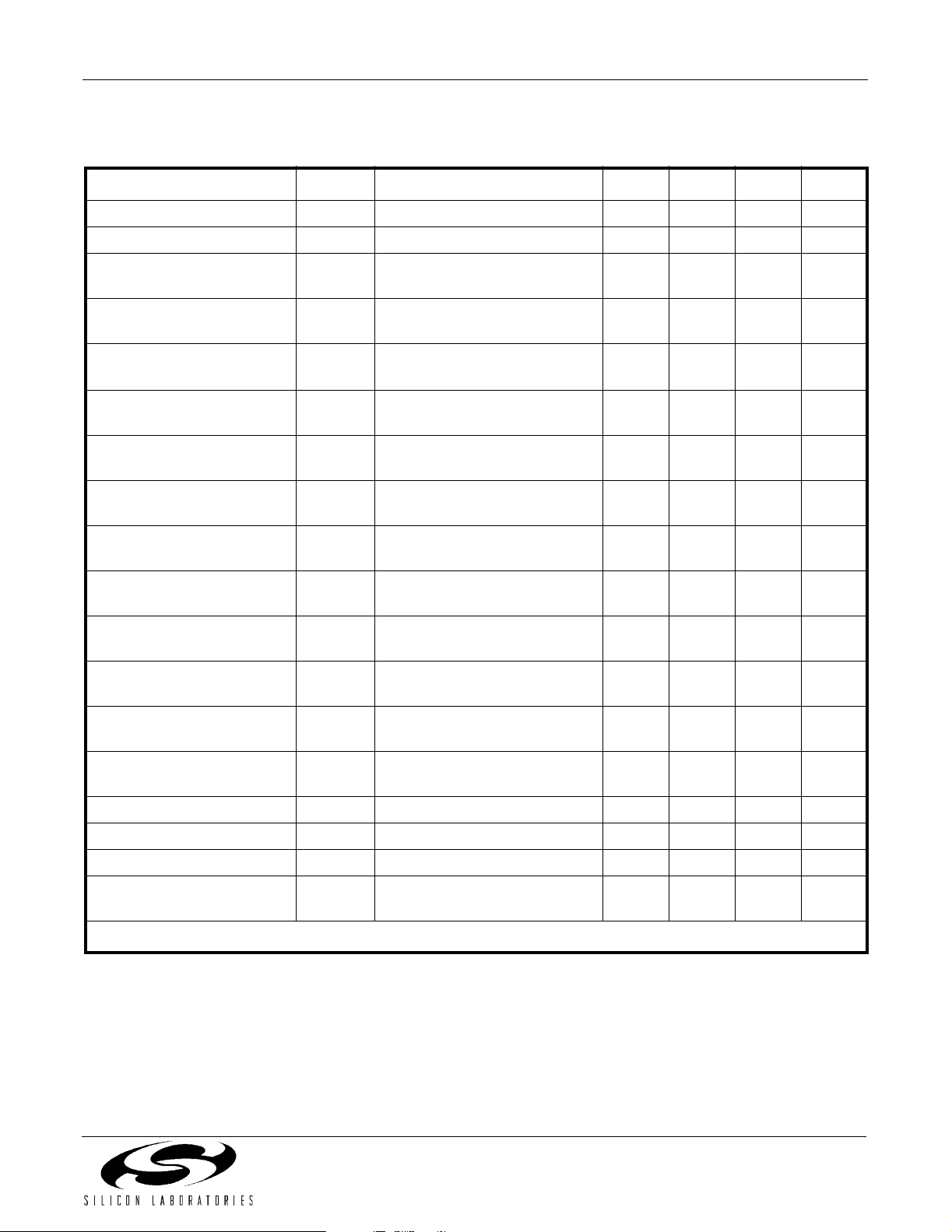

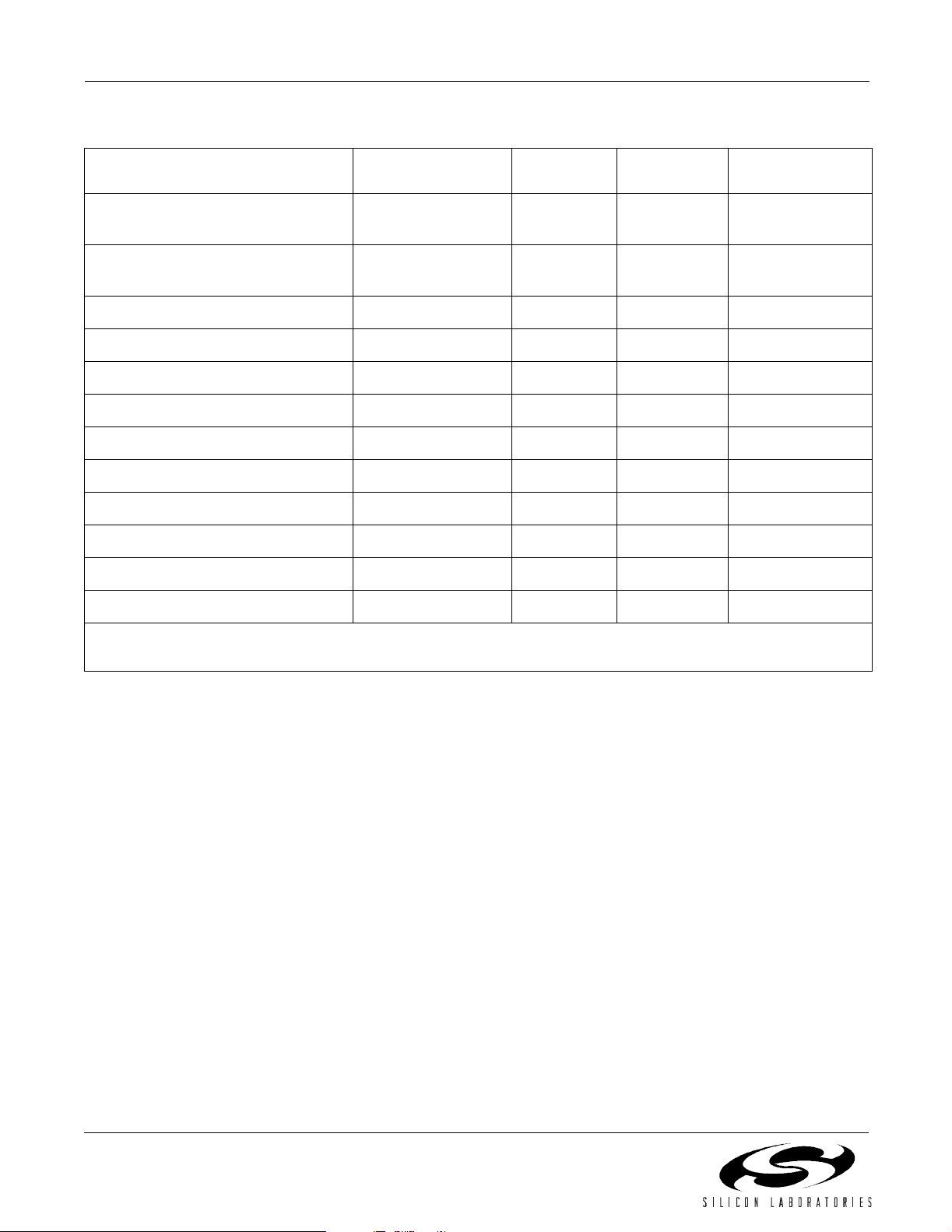

Table 3. AC Characteristics

(V

, V

DDA

Paramete r Test Condi t ion Min Typ Max Unit

= 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

DDD

TX/RX Performance

Overload Level THD = 1.5% 2.5 — — V

Single Frequency Distortion

1

2-wire – PCM or

— — –45 dB

PCM – 2-wire:

200 Hz–3.4 kHz

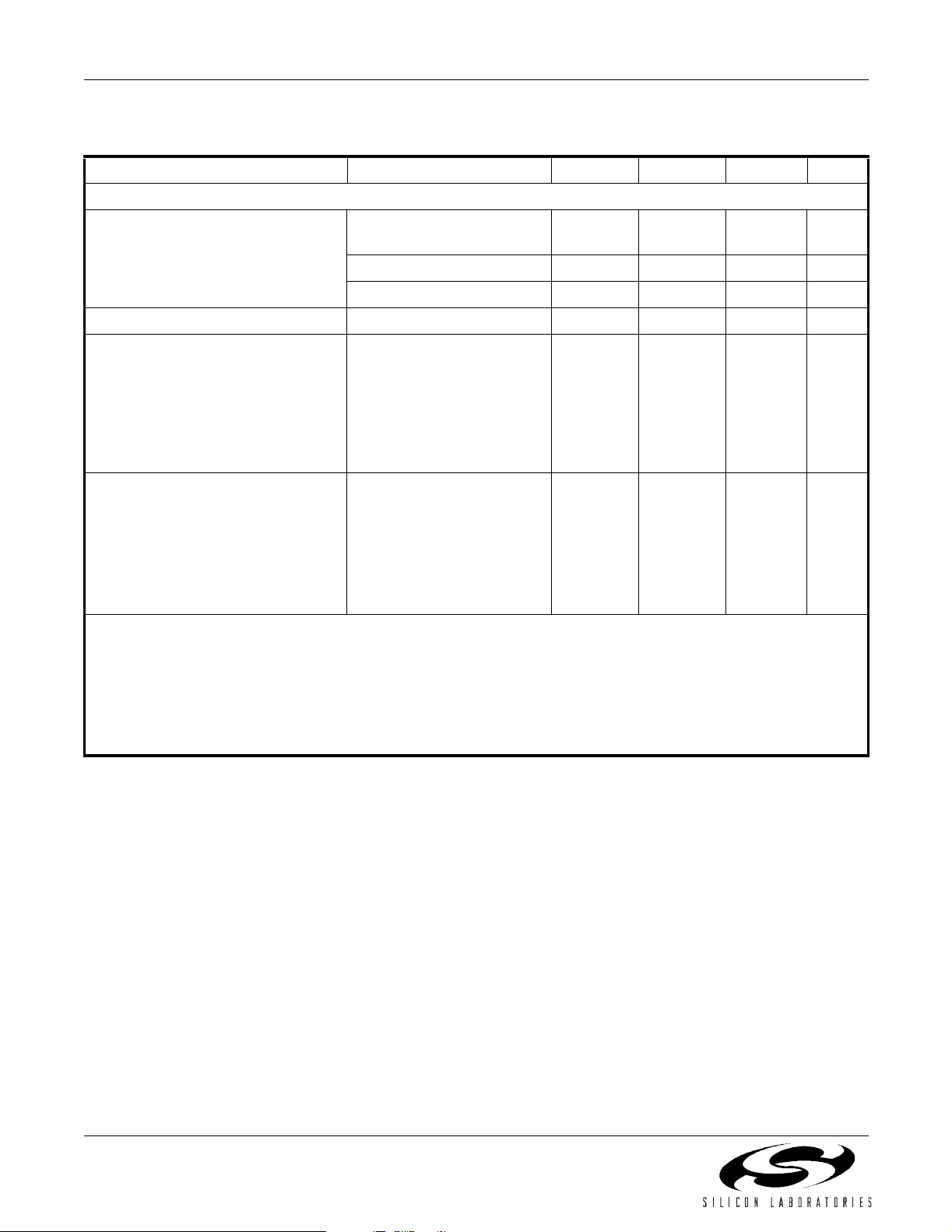

Signal-to-(Noise + Distortion) Ratio

2

200Hz to 3.4kHz

Figure 1 — —

D/A or A/D 8-bit

Active off-hook, and OHT,

any ZAC

Audio Tone Gene rator

Signal-to-Distortion Ratio

2

0 dBm0, Active off-hook,

and OHT , any Zac

45 — — dB

Intermodulation Distortion — — –41 dB

Gain Accuracy

2

2-wire to PCM, 1014 Hz –0.5 0 0.5 dB

PCM to 2-wire, 1014 Hz –0.5 0 0.5 dB

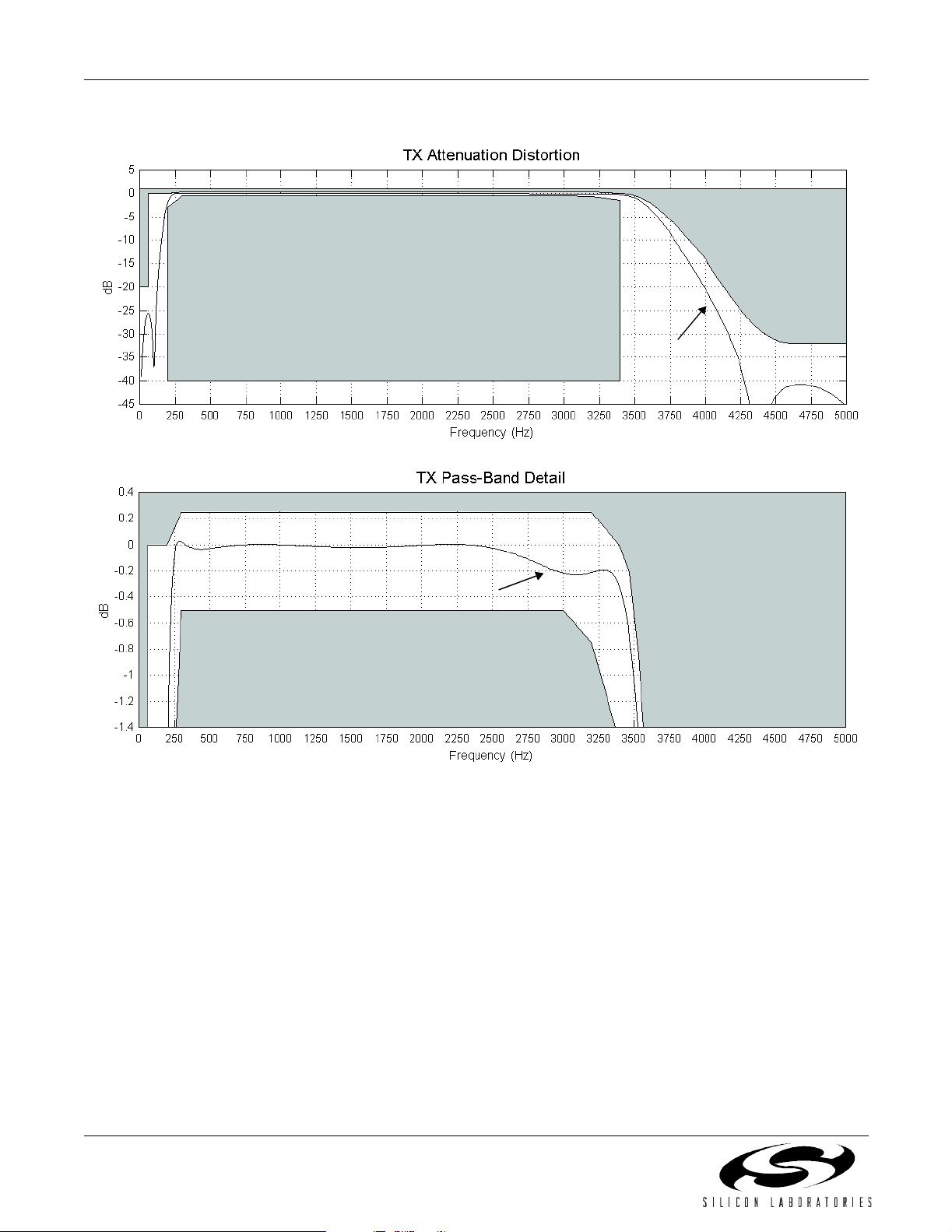

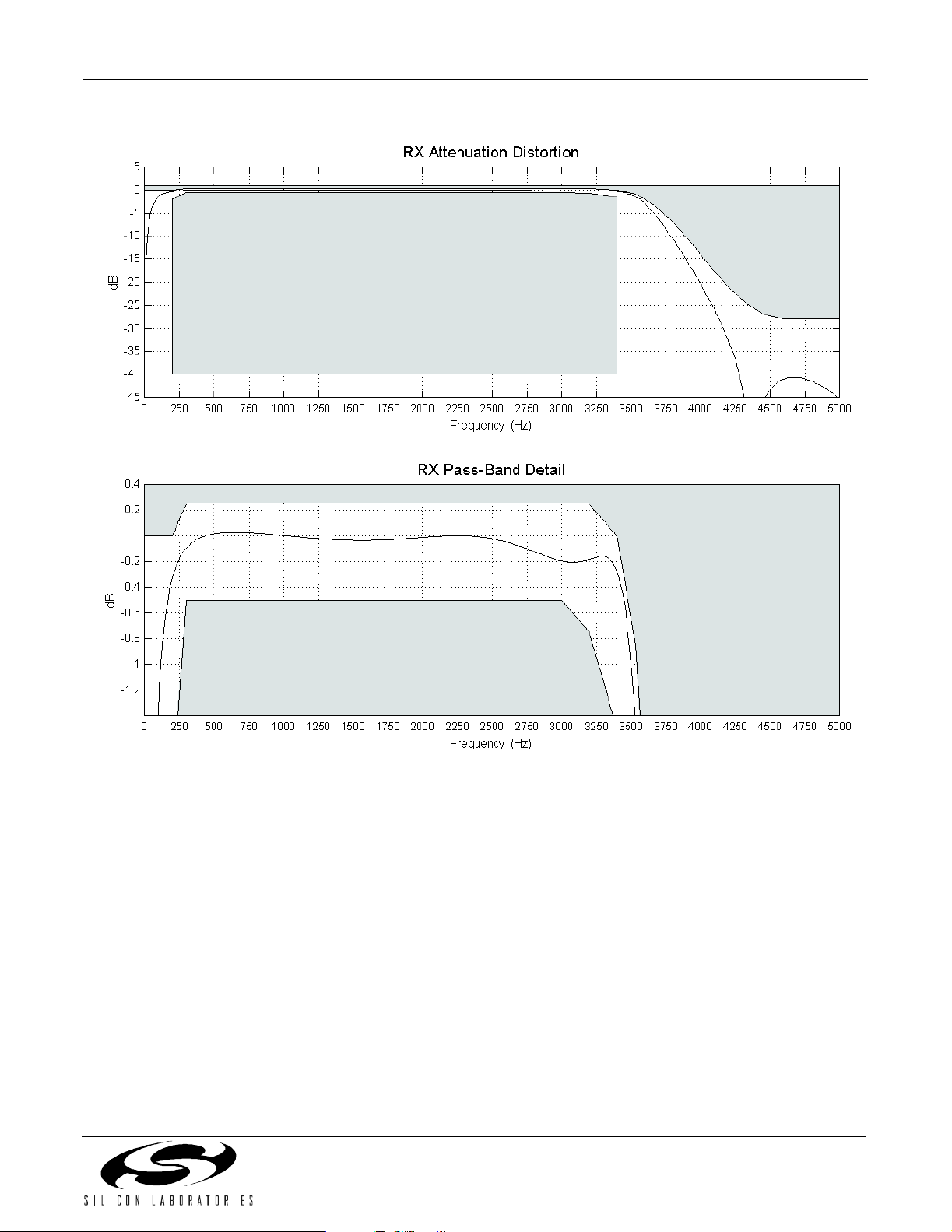

Gain Accuracy Over Frequency Figure 3,4 — —

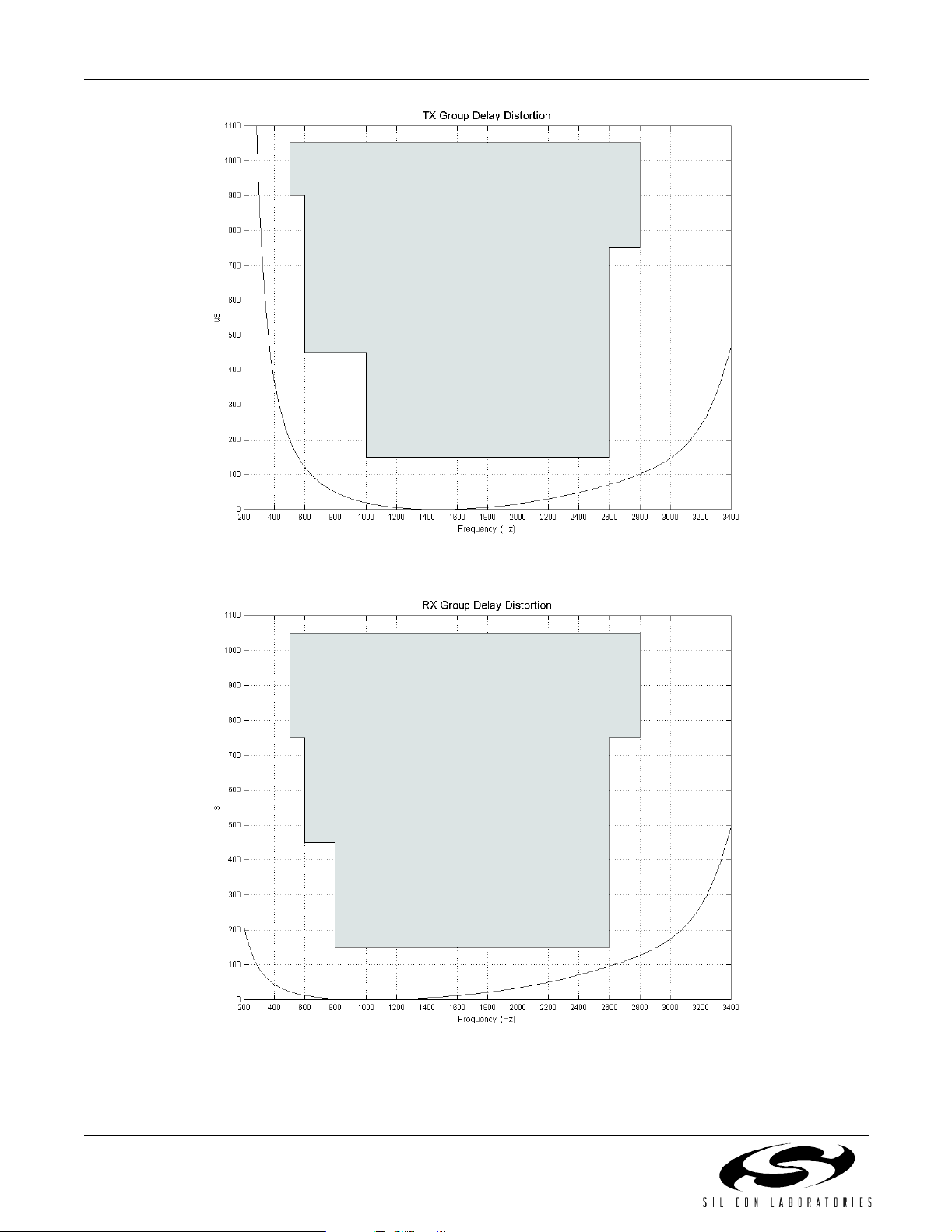

Group Delay Over Frequency Figure 5,6 — —

Gain Tracking

3

1014 Hz sine wave, refer-

ence level –10 dBm

signal level:

3 dB to –37 dB –0.25 — 0.25 dB

–37 dB to –50 dB –0.5 — 0. 5 dB

–50 dB to –60 dB –1.0 — 1. 0 dB

PK

Round-Trip Group Delay at 1000 Hz — 1100 — µs

Gain Step Accuracy –6 dB to 6 dB –0.017 — 0.017 dB

Gain Variation with Temperature All gain settings –0.25 — 0.25 dB

Gain Variation with Supply V

DDA

= V

3.3/5 V ± 5% –0.1 — 0.1 dB

DDA =

2-Wire Return Loss 2 00 Hz to 3.4 kHz 30 35 — dB

Transhybrid Balance 300 Hz to 3.4 kHz 30 — — dB

Noise Performance

Idle Channel Noise

4

C-Message Weighted — — 15 dBrnC

Psophometric Weighted — — –75 dBmP

3 kHz flat — — 18 dBrn

PSRR from VDDA RX and TX, DC to 3.4 kHz 40 — — dB

PSRR from VDDD RX and TX, DC to 3.4 kHz 40 — — dB

PSRR from VBAT RX and TX, DC to 3.4 kHz 40 — — dB

Preliminary Rev. 1.11 5

Si3210/Si3211/Si3212

Table 3. AC Characteristics (Continued)

(V

, V

DDA

Paramete r Test Condi t ion Min Typ Max Unit

= 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

DDD

Longitudinal Performance

Longitudinal to Metallic or PCM

Balance

200 Hz to 3.4 kHz, β

150, 1% mismatch

β

= 60 to 240

Q1,Q2

β

= 300 to 800

Q1,Q2

Q1,Q2

5

5

≥

56 60 — dB

43 60 — dB

53 60 — dB

Metallic to Lon g it u din al Balanc e 200 Hz t o 3.4 k H z 40 — — dB

Longitudinal Impedance 200 Hz to 3.4 kHz at TIP or

RING

Register selectable

ETBO/ETBA

00

01

10

—

—

—

33

17

17

—

—

—

Ω

Ω

Ω

Longitudinal Current per Pin Active off-hook

200 Hz to 3.4 kHz

Register selectable

ETBO/ETBA

00

01

10

Notes:

1. The input signal level should be 0 dBm0 for frequencies greater than 100 Hz. For 100 Hz and below, the level should be

–10 dBm0. The output signal magnitude at any other frequency will be smaller than the maximum value specified.

2. Analog signal measured as V

3. The quantization errors inherent in the µ/A-law companding process can generate slightly worse gain tracking performance

in the signal range of 3 dB to –37 dB for signal frequencies that are integer divisors of the 8 kHz PCM sampling rate.

4. The level of any unwanted tones within the bandwidth of 0 to 4 kHz does not exceed –55 dBm.

5. Assumes normal distribution of betas.

TIP

– V

. Assumes ideal line impedance matching.

RING

—

—

—

4

8

8

—

—

—

mA

mA

mA

6 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

Figure 1. Transmit and Receive Path SNDR

9

8

7

6

Fundamental

Output Power

(dBm0)

5

4

3

2.6

2

1

123456789

0

Fundamental Input Power (dBm0)

Acceptable

Region

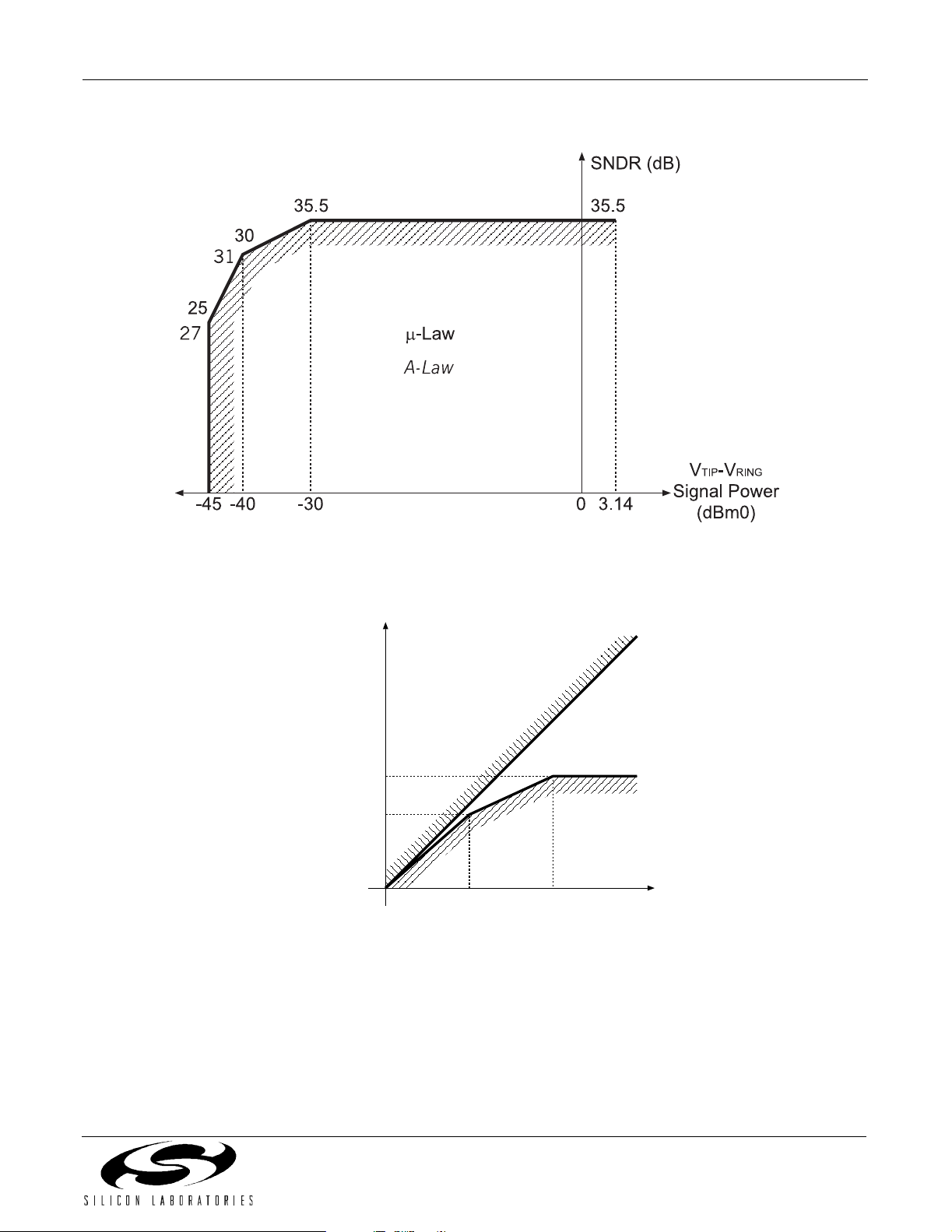

Figure 2. Overload Compression Performance

Preliminary Rev. 1.11 7

Si3210/Si3211/Si3212

Typical Response

Typical R esponse

Figure 3. Transmit Path Frequency Response

8 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

Figure 4. Receive Path Frequency Response

Preliminary Rev. 1.11 9

Si3210/Si3211/Si3212

Figure 5. Transmit Group Delay Distortion

Figure 6. Receive Group Delay Distortion

10 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

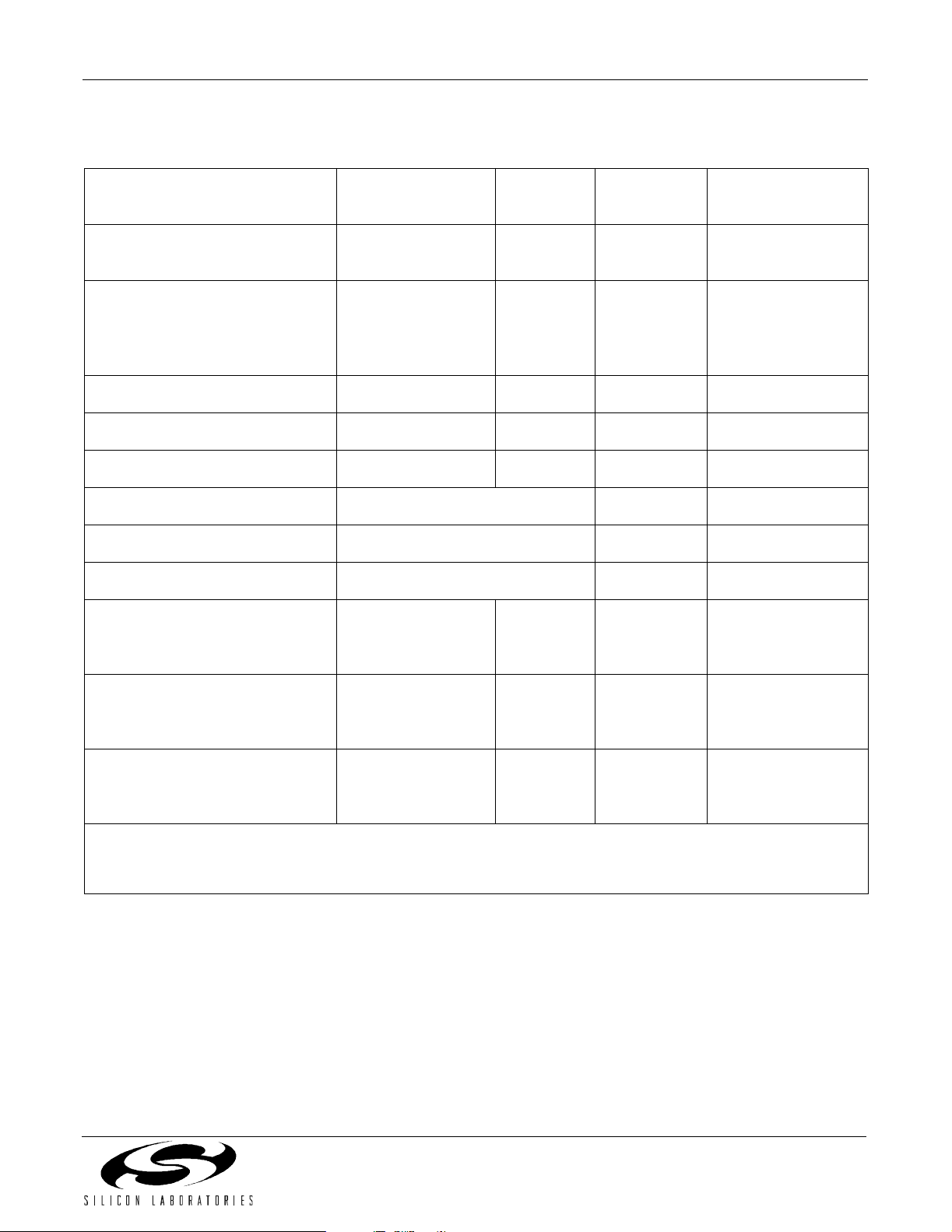

Table 4. Linefeed Characteristics

(V

, V

DDA

Parameter Symbol Test Condition Min Typ Max Unit

= 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

DDD

Loop Resistance Range R

LOOP

DC Loop Current Accuracy I

DC Open Circuit Voltage

Accuracy

DC Differential Output

R

DO

LIM

Active Mode; V

See note.* 0 — 16 0 Ω

= 29 mA, ETBA = 4 mA –10 — 10 %

= 48 V,

– V

< I

OC

RING

LIM

V

TIP

I

LOOP

Resistance

DC Open Circuit Voltage—

Ground Start

DC Output Resistance—

V

OCTO

R

ROTO

I

RING<ILIM

I

RING<ILIM

; V

V

OC

wrt ground

RING

= 48 V

; RING to ground — 160 — Ω

Ground Start

DC Output Resistance—

R

TOTO

TIP to ground 150 — — kΩ

Ground Start

Loop Closure/Ring Ground

I

= 11.43 mA –20 — 20 %

THR

Detect Threshold Accuracy

Ring Trip Threshold

R

= 11 00 Ω –20 — 20 %

THR

Accuracy

Ring Trip Response Time User Programmable Register 70

and Indir ect Register 36

Ring Amplitude V

Ring DC Offset R

TR

OS

5 REN load; sine wave;

R

LOOP

= 160 Ω, V

BAT

= –75 V

Programmable in Indirect

Register 19

–4 — 4 V

—160— Ω

–4 — 4 V

———

44 — — V

RMS

0——V

Trapezoidal Ring Crest

Crest factor = 1.3 – .05 — .05

Factor Accuracy

Sinusoidal Ring Crest

R

CF

1.35 — 1.45

Factor

Ringing Frequency Accuracy f = 20 Hz –1 — 1 %

Ringing Cadence Accuracy Accuracy of ON/OFF Times –50 — 50 msec

Calibration Time ↑CAL to ↓CAL Bit — — 600 msec

Power Alarm Threshold

At Power Threshold = 300 mW –25 — 25 %

Accuracy

*Note: DC resistance round trip; 160 Ω corresponds to 2 kft 26 gauge AWG.

Preliminary Rev. 1.11 11

Si3210/Si3211/Si3212

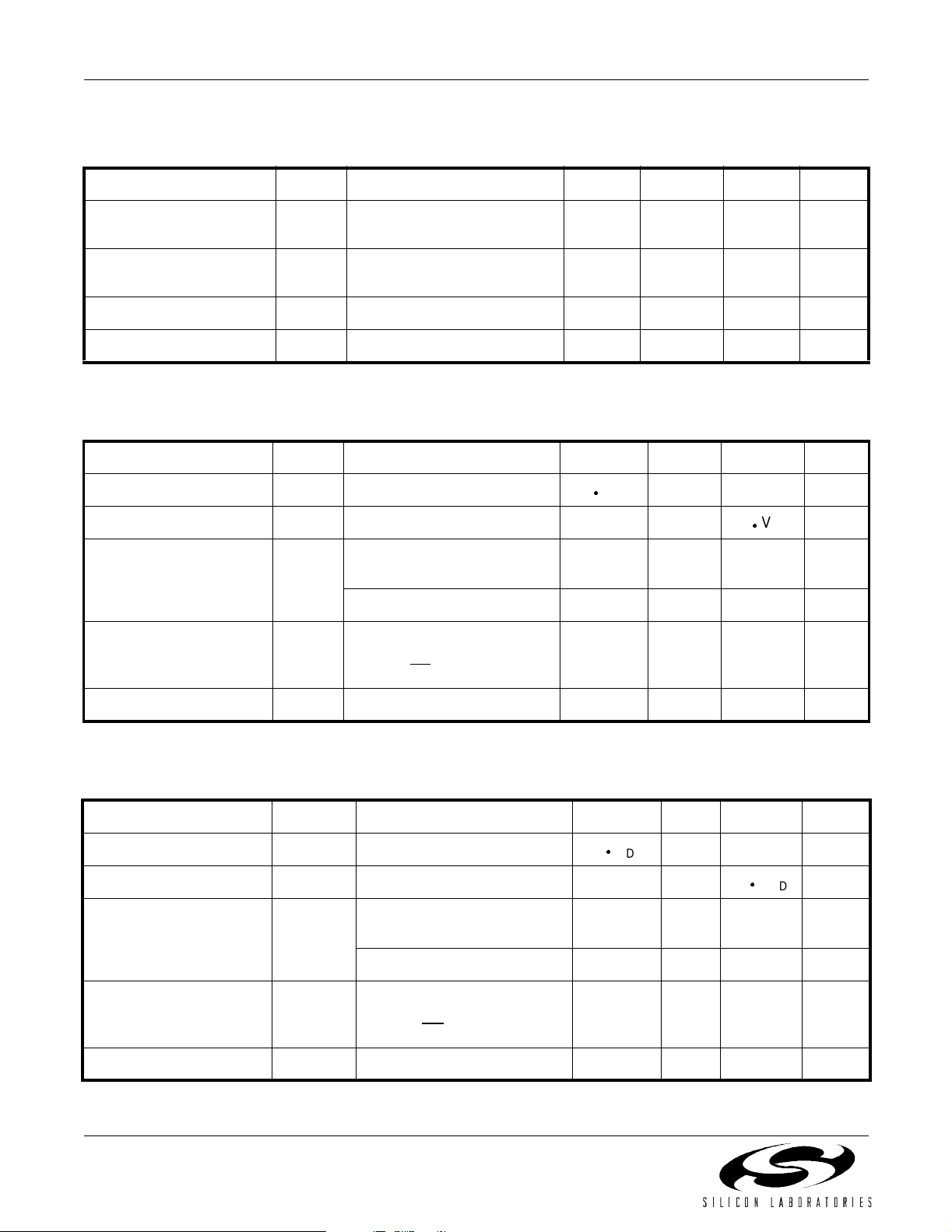

Table 5. Monitor AD C Character i sti cs

(V

, V

DDA

Parameter Symbol Test Condition Min Typ Max Unit

= 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

DDD

Differential Nonlinearity

DNLE –1/2 — 1/2 LSB

(6-bit resolution)

Integral Nonlinearity

INLE –1 — 1 LSB

(6-bit resolution)

Gain Error (voltage) — — 10 %

Gain Error (current) — — 20 %

Table 6. Si321x DC Characteristics, V

(V

DDA,VDDD

= 4.75 V to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

DDA

= V

DDD

= 5.0 V

Parameter S ymb ol Test Condition Min Typ Max Unit

High Level Input Voltage V

Low Level Input Volt age V

High Level Output Voltage V

Low Level Output Voltage V

IH

IL

DIO1,DIO2,SDITHRU:IO = –4 mA

OH

OL

SDO, DTX:I

DOUT: IO = –40 mA

DIO1,DIO2,DOUT,SDITHRU:

I

= 4 mA

O

SDO,INT

,DTX:IO = 8 mA

= –8 mA

O

0.7 V

DDD

— — 0.3 V

V

– 0.6 — — V

DDD

V

– 0.8 — — V

DDD

——0.4V

——V

DDD

V

Input Leakage Current I

L

Table 7. Si321x DC Characteristics, V

(V

DDA,VDDD

= 3.13 V to 3.47 V , TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

DDA

= V

DDD

= 3.3 V

–10 — 10 µA

Parameter Symbol Test Condition Min Typ Max Unit

High Level Input Voltage V

Low Level Input Voltage V

High Level Output Voltage V

Low Level Output Voltage V

Input Leakage Current I

IH

IL

OH

OL

L

DIO1,DIO2,SDITHRU:IO = –2 mA

SDO, DTX:I

DOUT: IO = –40 mA

DIO1,DIO2,DOUT,SDITHRU:

SDO,INT

= –4 mA

O

I

= 2 mA

O

,DTX:IO = 4 mA

0.7 V

DDD

— — 0.3 V

V

– 0.6 — — V

DDD

V

– 0.8 — — V

DDD

——0.4V

–10 — 10 µA

—— V

DDD

V

12 Preliminary Rev. 1.11

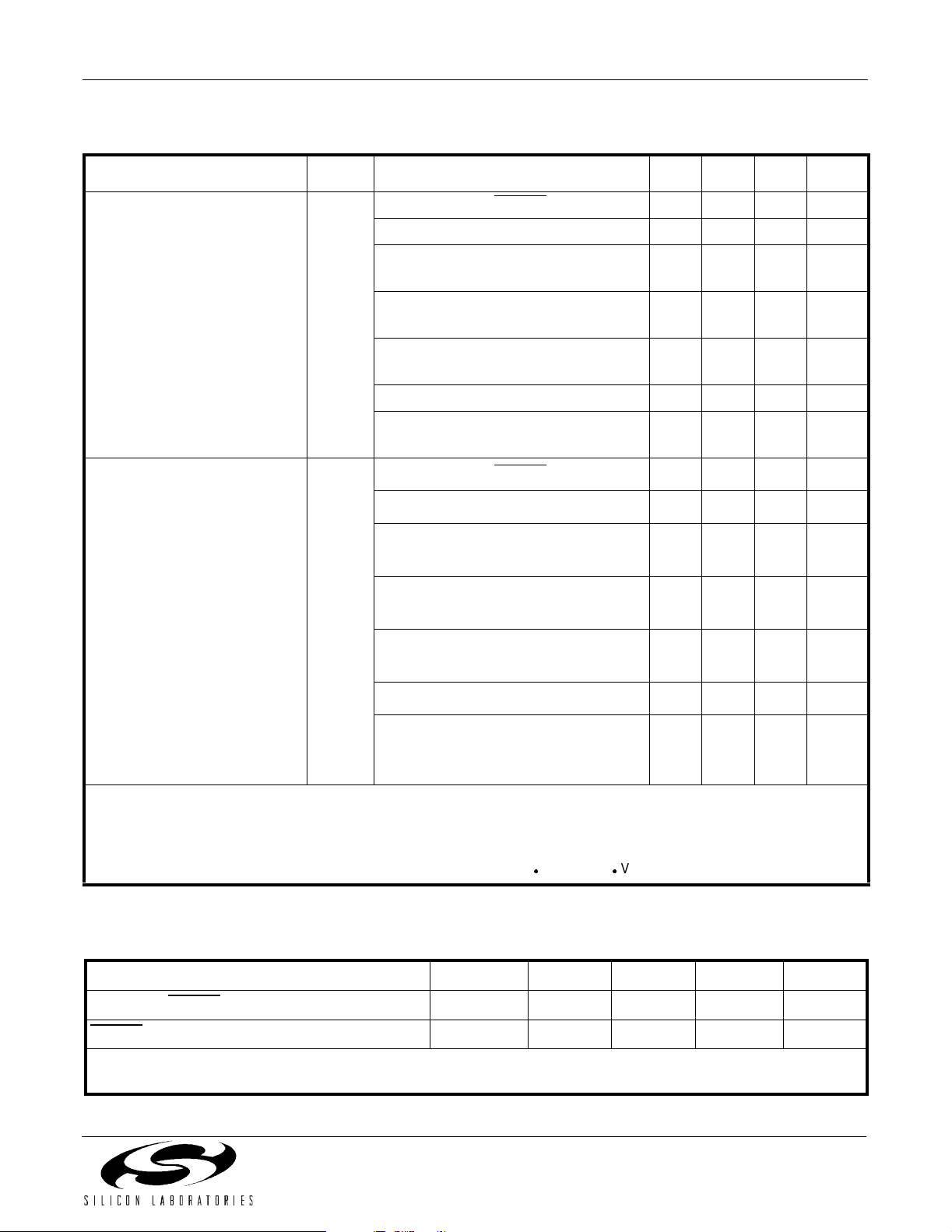

Table 8. Power Supply Characteristics

(V

DDA,VDDD

= 3.13 V to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade)

Si3210/Si3211/Si3212

Parameter

Power Supply Current,

Analog and Digital

Power Supply Current, V

BAT

Symbol Test Condi t io n

+ I

I

A

D

Sleep (RESET = 0) 0.1 0.25 0.42 mA

Open 33 42.8 49 m A

Active on-hook

ETBO = 4 mA

Active OHT

ETBO = 4 mA 57 72 83 mA

Active off-hook

ETBA = 4 mA, I

Ground-start 36 47 55 mA

Ringing

Sinewave, REN = 1, V

3

I

BAT

Sleep (RESET = 0) — 0 — m A

Open (DCOF = 1) — 0 — mA

Active on-hook

= 48 V, ETBO = 4 mA — 3 —

V

OC

Active OHT

ETBO = 4 mA — 11 —

1

Typ

Typ

46 57 68 mA

= 20 mA 73 88 9 9

LIM

= 56 V 45 55 65

PK

2

Max Unit

mA

mA

mA

mA

Active off-hook

ETBA = 4 mA, I

= 20 mA — 30 —

LIM

mA

Ground-start — 2 — m A

Ringing

V

PK_RING

= 56 VPK,

—5.5—

mA

sinewave ringing, REN = 1

Notes:

1. V

2. V

3. I

, V

, V

DDA

DDA

= 3.3 V.

= 5.25 V.

(the large negative supply). For a switched-mode power supply regulator efficiency of 71%,

BAT

DDD

DDD

= current from V

BAT

the user can calculate the regulator current consumption as I

BAT

V

BAT

/(0.71 VDC).

Table 9. Switching Characteristics—General Inputs

V

= V

DDA

Parameter Symbol Min Typ Max Unit

Rise Time, RESET

RESET

Note: All timing (except Rise and Fall time) is referenced to the 50% level of the waveform. In put t est levels are VIH = VD –

= 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade, CL = 20 pF)

DDA

Pulse W i dt h t

0.4 V, V

= 0.4 V. Rise and Fall times are refer enced to the 20% and 80% levels of the waveform.

IL

t

r

rl

— — 20 ns

100 — — ns

Preliminary Rev. 1.11 13

Si3210/Si3211/Si3212

Table 10. Switching Characteristics—SPI

V

DDA

= V

= 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade, CL = 20 pF

DDA

Parameter

Symbol

Cycle Time SCLK t

Rise Time, SCLK t

Fall Time, SCL K t

Delay Time, SCL K Fall to SDO Active t

Delay Time, SCL K Fall to SDO

Transition

Delay Time, CS

Setup Time, CS

Hold Time, CS

Rise to SDO Tri-state t

to SCLK Fall t

to SCLK Rise t

Setu p Time, SD I to SCL K Rise t

Hold Time, SDI to SCLK Rise t

Delay Time between Chip Selects t

SDI to SDITHRU Propagation Delay t

d1

t

d2

d3

su1

h1

su2

h2

cs

cs

Test

Conditions

c

r

f

Min Typ Max Unit

0.062 — — µsec

— — 25 ns

— — 25 ns

— — 20 ns

— — 20 ns

— — 20 ns

25 — — ns

20 — — ns

25 — — ns

20 — — ns

220 — — ns

—4—ns

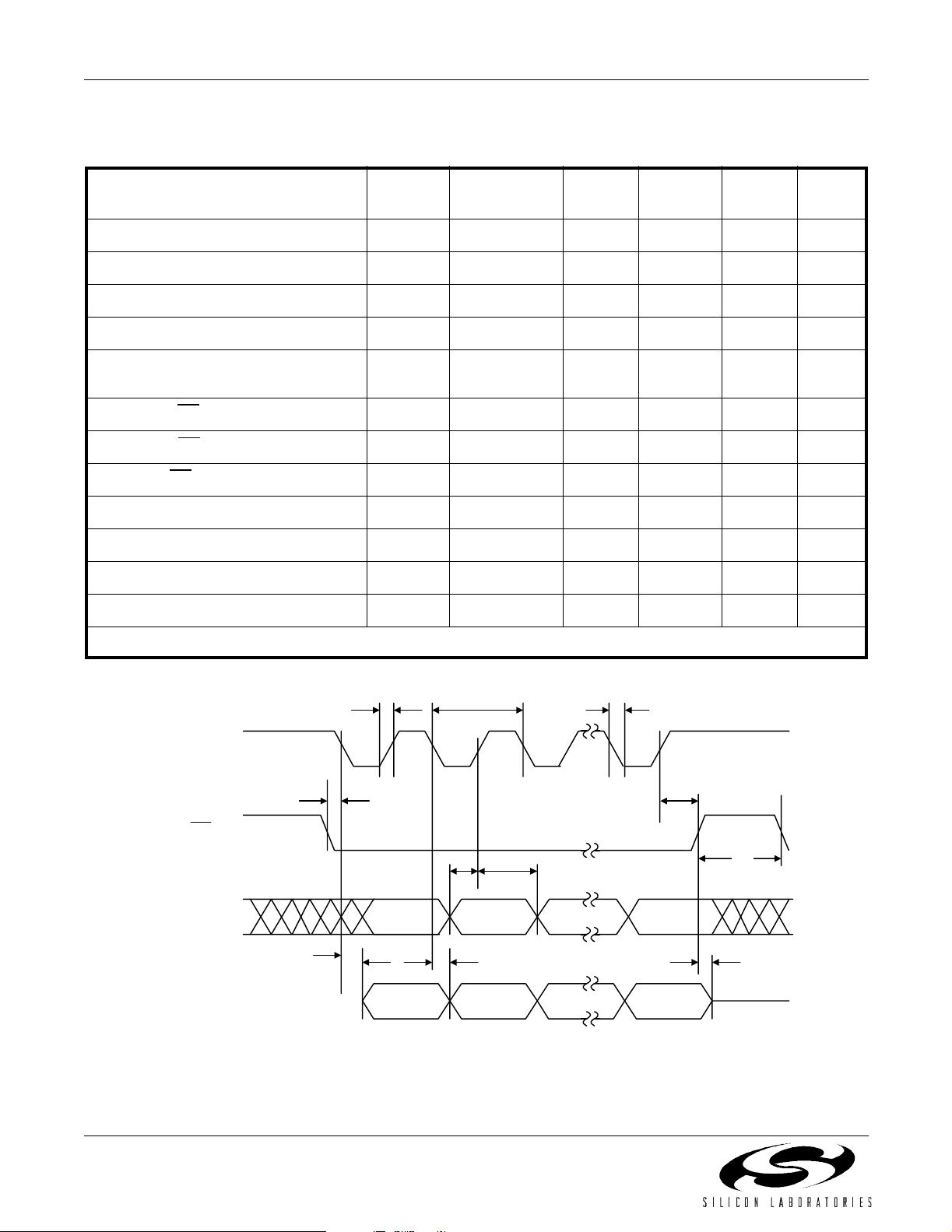

Note: All timing is referenced to the 50% level of the waveform. Input test levels are V

t

t

r

thru

t

c

SCLK

t

su1

CS

t

t

su2

h2

SDI

t

d1

t

d2

SDO

Figure 7. SPI Timing Diagram

IH

= V

–0.4 V, VIL = 0.4 V

DDD

t

r

t

h1

t

cs

t

d3

14 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

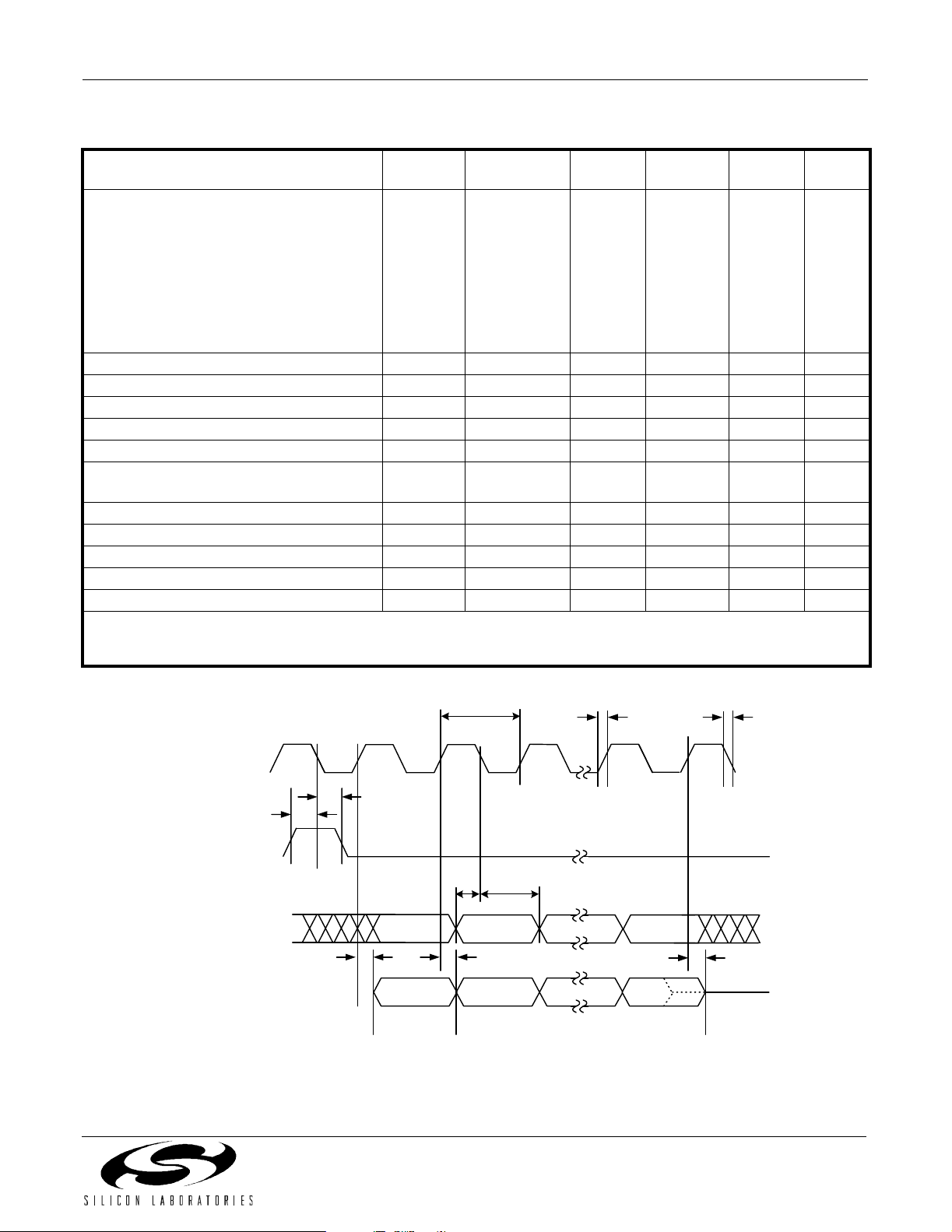

Table 11. Switchi n g C h ar acteristic s—PCM H igh way Seri al I n ter face

VD = 3.13 to 5.25 V, TA = 0 to 70°C for K-Grade, –40 to 85°C for B-Grade, CL = 20 pF

Parameter

Symbol

PCLK Frequency 1/t

PCLK Duty Cycle Tolerance t

PCLK Period Jitter Tolerance t

jitter

Rise Time, PCLK t

Fall Time, PCL K t

Delay Time, PCLK Rise to DTX Active t

Delay Time, PCLK Rise to DTX

t

c

dty

r

f

d1

d2

Test

Conditions

Transition

Delay Time, PCLK Rise to DTX Tri-state

Setup Time, FSYNC to PCLK Fall t

Hold Time, FSYNC to PCLK Fall t

Setup Time, DRX to PCLK Fall t

Hold Time, DRX to PCLK Fall t

Notes:

1. All timing is ref erenced to the 50% level of the waveform. Input test levels are V

2. Spec applies to PCLK fall to DTX tri-state when th at mode is selected (TRI = 0).

2

t

d3

su1

h1

su2

h2

Min

—

—

—

—

—

—

—

—

1

Typ

0.256

0.512

0.768

1.024

1.536

2.048

4.096

8.192

1

Max

—

—

—

—

—

—

—

—

1

Units

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

40 50 60 %

–120 — 120 ns

— — 25 ns

— — 25 ns

— — 20 ns

— — 20 ns

— — 20 ns

25 — — ns

20 — — ns

25 — — ns

20 — — ns

IH – VI/O –

0.4V, VIL = 0.4V

PCLK

FSYNC

DRX

DTX

t

r

t

su1

t

c

t

h1

t

su2th2

t

d1

t

d2

Figure 8. PCM Highway Interface Timing Diagram

t

f

t

d3

Preliminary Rev. 1.11 15

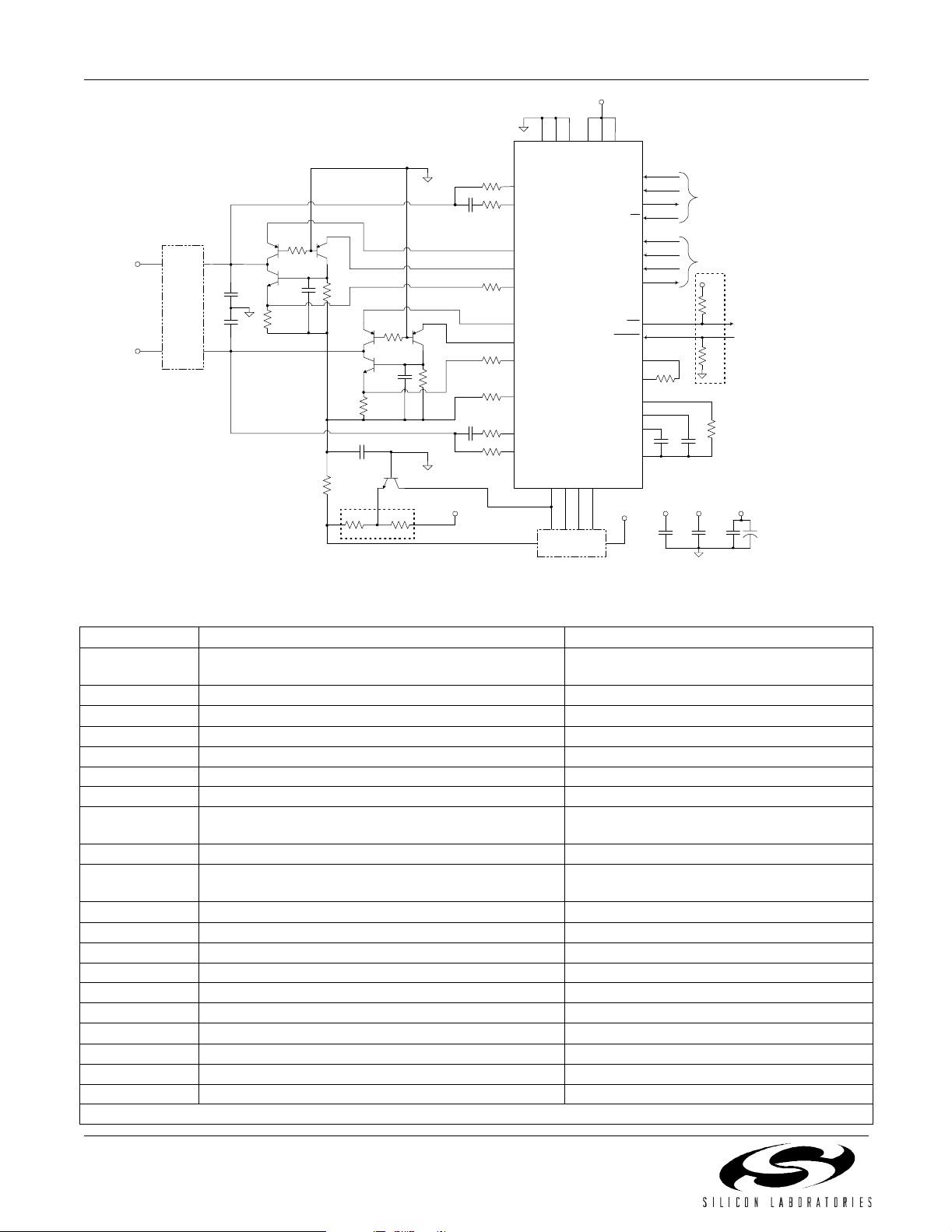

Si3210/Si3211/Si3212

0

F

220nF

Q4

5401

R10

10

C8

R13

5.1k

Q2

5401

R11

10

Q5

5551

C7

220nF

R7

80.6

C26

0.1uF

R21

15

Q9

2N2222

1

1

R28

R29

Note 1

Q1

5401

TIP

Protection

Circuit

22nF

22nF

Q6

5551

C5

C6

RING

Notes:

1. Values and configurations for these

components can be derived from Table 19

or from App Note 45.

2. Only one component per system needed.

3. All circuit grounds should have a singlepoint connection to the ground plane.

R6

80.6

GND

5401

GND

VCC

GND

3123102730

32

TEST

R1

200k

15

20

R8

C3

470

220nF

28

29

17

R2

200k

220nF

26

25

R4

200k

19

R5

200k

18

C4

R9

470

21

16

R3

200k

Q3

R12

5.1k

VCC

GNDD

STIPDC

STIPAC

ITIPP

ITIPN

STIPE

IRINGP

IRINGN

SRINGE

SVBAT

SRINGAC

SRINGDC

SDCL

SDCH

9

8

SDCL

SDCH

DC-DC Converter

VBAT VDC

Circuit

GNDA

Si3210/Si3210M

DCDRV

34

DCDRV

VDDD

VDDA2

VDDA1

DCFF

33

DCFF

SCLK

SDI

SDO

FSYNC

PCLK

DRX

DTX

INT

RESET

IGMP

IGMN

IREF

CAPP

CAPM

QGND

VDC

38

37

36

1

CS

6

3

4

5

2

7

24

22

11

12

14

13

VDDA1

C15

0.1uF

R15

243

C2

10uFC110uF

C16

0.1uF

SPI Bus

PCM Bus

VCC

2

R32

10k

Note 2

2

R26

40.2k

R14

40.2k

VDDA2 VDDD

C17

0.1uF

C3

10u

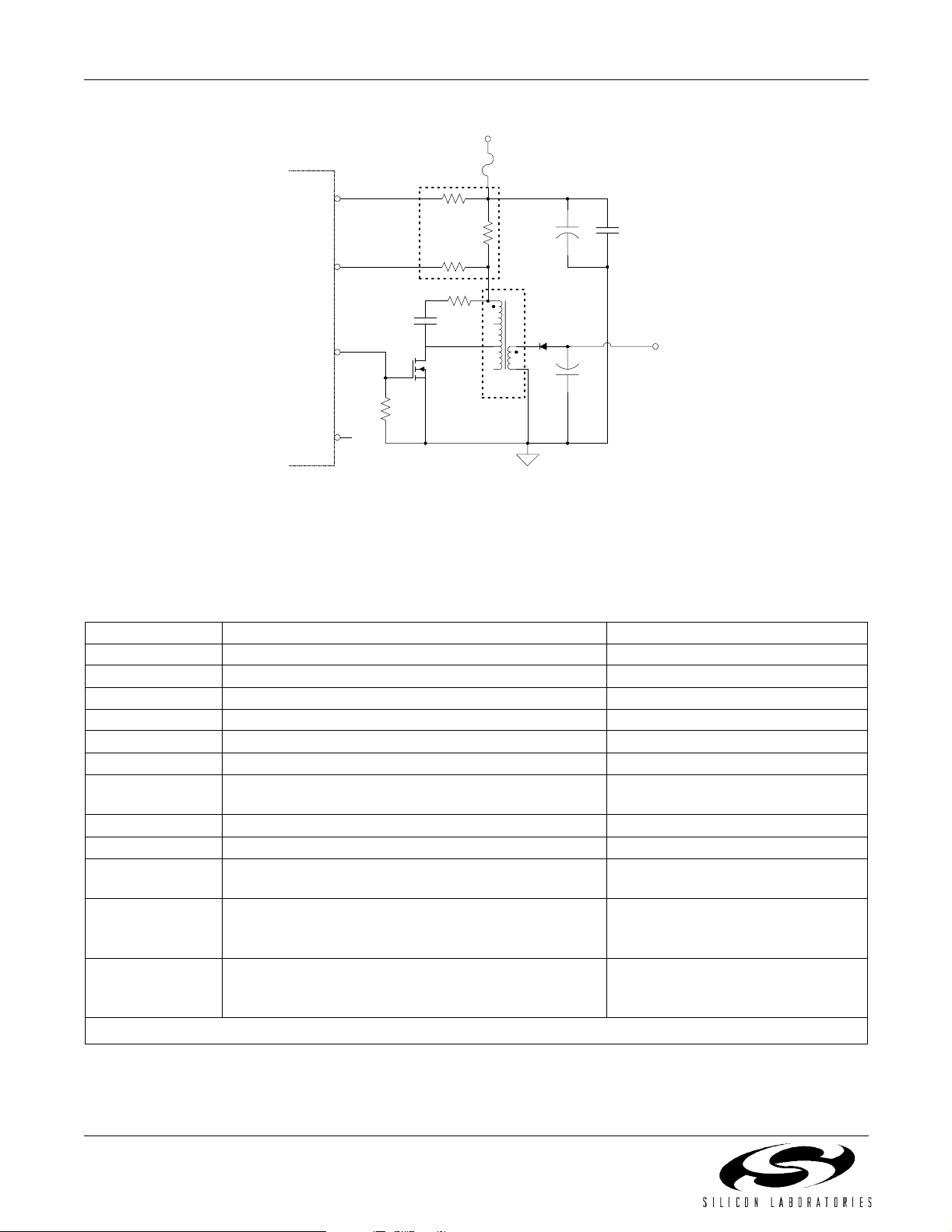

Figure 9. Si3210/Si3210M Typical Application Circuit Using Integrated DC-DC Converter

Table 12. Si3210/Si3210M External Component Values

Compon ent Value Suppl ier/Part Number

C1,C2 10 µF, 6 V Ceramic/Tantalum or 16 V Low Leakage Elec-

trolytic, ±20%

C3,C4 220 nF, 100 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C5,C6 22 nF, 100 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C7,C8 220 nF , 50 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C15,C16,C17 0.1 µF, 6 V, Y5V, ±20% Murata, Johanson, Novacap, Venkel

C26 0.1 µF, 100 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C30 10 µF, 16 V , Electrolytic, ±20% Panasonic

Q1,Q2,Q3,Q4 100 V, PNP, BJT Central Semi CMPT5 401; ON Semi

Q5,Q6 100 V, NPN, BJT Cent ral Semi CZT5551, ON Semi 2N5551

Q9 NPN General Purpose BJT ON Semi MMBT2222ALT1, MPS2222A; Cent ral

R1,R2,R3,R4,R5 200 kΩ, 1/10 W , ±1%

R6,R7 80.6 Ω, 1/4 W, ±1%

R8,R9 470 Ω, 1/10 W, ±1%

R10,R11 10 Ω, 1/10 W, ±5%

R12,R13 5.1 kΩ, 1/10 W, ±5%

R14,R26* 40.2 kΩ, 1/10 W, ±1%

R15 243 Ω, 1/ 1 0 W, ±1%

R21 15 Ω, 1/4 W, ±1%

R28,R29 1/10 W, ±1% (See AN45 or Table 17 for value selection)

R32* 10 kΩ, 1/10 W, ±5%

*Note: Only one component per system needed.

Murata, Panasonic, Nichicon URL16100MD,

Panasonic Z Series

MMBT5401LT1, 2N5401; Zetex FMMT5401

Semi CMPT2222A; Zetex FMMT2222

16 Preliminary Rev. 1.11

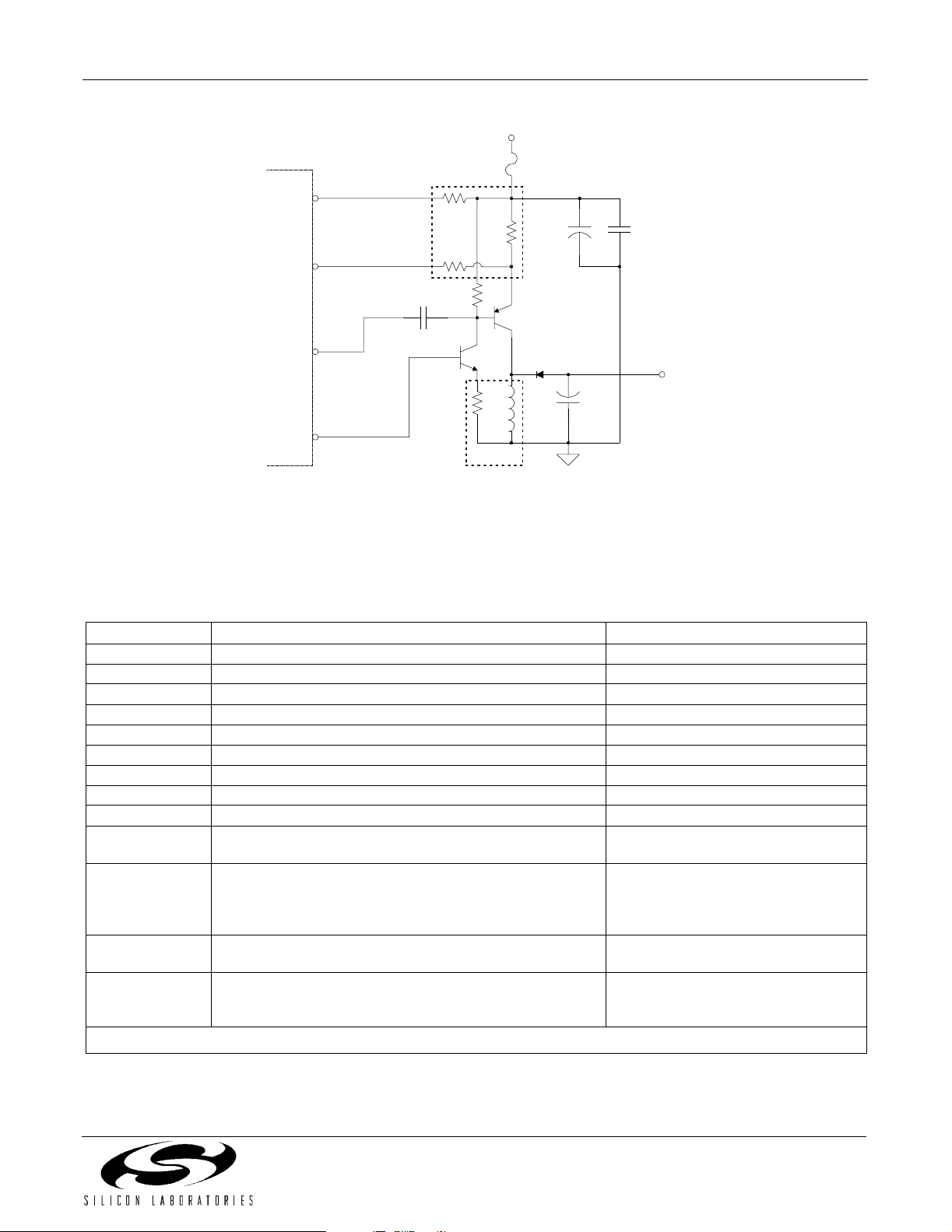

Si3210/Si3211/Si3212

T

VDC

F1

SDCH

SDCL

Si3210

DCFF

DCDRV

Notes:

1. Values and configurations for these components can be derived

from Table 21 or from App Note 45.

2. Voltage rating for C14 and C25 must be greater than VDC.

C10

22nF

1

R19

Note 1

1

R20

R16

200

R18

Q8

2N2222

R17

Note 1

L1

1

Q8

FZT953

D1

ES1D

C25

10uF

2

GND

10uF

2

C14

0.1uF

VBA

C9

Figure 10. Si3210 BJT/Induc tor DC-DC Converter Circuit

T a ble 13. Si3210 BJT/Inductor DC-DC Converter Component Values

Component (s) Value Supplier

C9 10 µF, 100 V, Electrolytic, ±20% Panasonic

C10 22 nF, 50 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C14* 0.1 µF, X7R, ±20% Murata, Johanson, Novacap, V enkel

C25* 10µF, Electrolytic, ±20% Panasonic

R16 200 Ω, 1/10 W, ±5%

R17 1/10 W, ±5% (See AN45 or Table 19 for value selecti on)

R18 1/4 W, ±5% (See AN45 or Table 19 for value selection)

R19,R20 1/10 W, ±1% (See AN45 or Table 19 for value selection)

F1 Fuse Belfuse SSQ Series

D1 Ultra Fast Recovery 200V, 1A Rectifier General Semi ES1D; Central Semi

CMR1U-02

L1 1A, Shielded Inductor (See AN45

Table 19 for value selecti on)

Q7 120 V, High Current Switching PNP Zetex FZT95 3, FZT955, ZTX953,

Q8 60 V, General Purpose Swit ching NPN ON Semi MMBT2222ALT1, MPS2222A;

*Note: Voltage rating of thi s device must be greater than V

DC

or

.

API Delevan SPD127 series, Sumida

CDRH127 series, Datatro nics DR340-1

series, Coilcraft DS5022, TDK

SLF12565

ZTX955

Central Semi CMPT2222A; Zetex

FMMT2222

Preliminary Rev. 1.11 17

Si3210/Si3211/Si3212

T

VDC

F1

SDCH

SDCL

C27

Si3210M

DCFF

DCDRV

Notes:

1. Values and configurations for these components can be derived

2. Voltage rating for C14 and C25 must be greater than VDC.

470pF

R17

200k

NC

from Table 20 or from App Note 45.

R19

Note 1

R20

M1

IRLL014N

R22

1

2

1

R18

1

22

Note 1

C25

10uF

1

2

D1

ES1D

3

6

4

10

1

T1

GND

C9

10uF

C14

0.1uF

2

VBA

Figure 11. Si3210M MOSFET/Transformer DC-DC Converter Circuit

Table 14. Si3210M MOSFET/Transformer DC-DC Converter Component Values

Component (s) Value Supplier

C9 10 µF, 100 V, El ec trolyt ic , ±20% Panas onic

C14* 0.1

C25* 10

C27 470 pF, 100 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

R17 200 k

R18 1/4 W, ±5% (See AN45 or Table 18 for value selection)

R19,R20 1/10 W , ± 1% (See AN45 or Table 18

R22 22

F1 Fuse Belfuse SSQ Series

D1 Ultra Fast Recovery 200 V, 1A Rectifier General Semi ES1D; Central Sem i

T1 Power Transformer Coiltronic CTX01-15275;

M1 100 V, Logic Level Input MOSFET Intl Rect. IRLL014N; Intersil

*Note: V oltage rating of this device must be greater t han VDC.

µF, X7R, ±20% Murata, Johanson, Novacap, Venkel

µF, Electrolytic, ±20% Panasonic

Ω, 1/10 W, ± 5%

for value selection)

Ω, 1/10 W, ±5%

CMR1U-02

Datatronics SM76315;

Midcom 31353R-02

HUF76609D3S; ST Micro

STD5NE10L, STN2NE10L

18 Preliminary Rev. 1.11

Q1

5401

TIP

Protection

Circuit

22nF

22nF

C5

C6

5551

Q6

R6

80.6

RING

Notes:

1. Only one component per system needed.

2. All circuit grounds should hav e a singl e-point

connection to the ground plane.

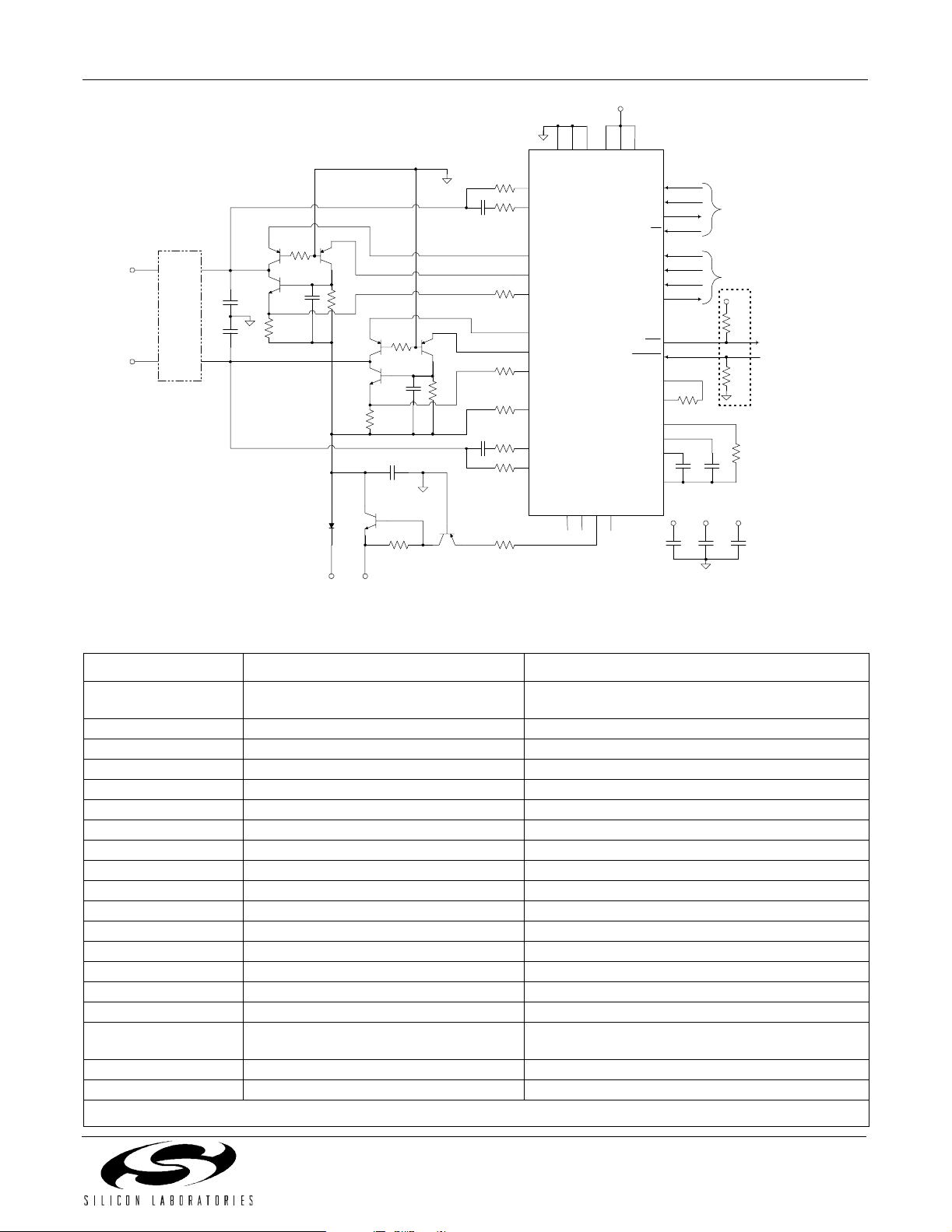

Figure 12. Si3211/12 Typical Application Circuit Using Extended Battery

C8

220nF

Si3210/Si3211/Si3212

VCC

3123102730

32

R1

C3

220nF

220nF

200k

R8

470

R2

200k

R4

200k

R5

200k

C4

R9

470

R3

200k

R18

1.8k

GND

Q4

5401

R10

10

R13

5.1k

C7

C9

R16

200k

Q3

5401

R11

10

R12

5.1k

GND

Q7

5401

VBATL

4003

Q2

5401

Q5

5551

220nF

R7

80.6

0.1uF

Q8

5551

D1

VBATH

15

STIPDC

20

STIPAC

28

ITIPP

29

ITIPN

17

STIPE

26

IRINGP

25

IRINGN

19

SRINGE

18

SVBAT

21

SRINGAC

16

SRINGDC

TEST

GNDA

GNDD

Si3211/Si3212

DIO2

DIO1

DCSW

9

8

34

NC NC NC

VDDD

VDDA2

VDDA1

DOUT

33

SCLK

SDI

SDO

FSYNC

PCLK

DRX

DTX

INT

RESET

IGMP

IGMN

IREF

CAPP

CAPM

QGND

CS

C15

0.1uF

38

37

36

1

6

3

4

5

2

7

24

R15

243

22

11

12

C2

14

13

C1

10uF

10uF

VDDA1 VDDA2 VDDD

C17

C16

0.1uF

0.1uF

SPI Bus

PCM Bus

VCC

1

R32

10k

Note 1

1

R26

40.2k

R14

40.2k

Table 15. Si3211/12 External Component Values

Component Value Supplier/Part Number

C1,C2 10 µF, 6 V Ceramic/Tantalum or 16 V Low

Leakage Electrolytic, ±20%

C3,C4 220 nF, 100 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C5,C6 22 nF , 100 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C7,C8 220 nF, 50 V, X7R, ±20% Murata, Johanson, Novacap, Venkel

C9 0.1 µF, 100 V, Electrolytic, ±20% Panasonic

C15,C16,C17 0.1 µF, 6 V, Y5V, ±20% Murata, Johanson, Novacap, Venkel

R1,R2,R3,R4,R5,R16 200 kΩ, 1/1 0 W, ±1%

R6,R7 80.6 Ω, 1/4 W, ±1%

R8,R9 470 Ω, 1/10 W, ±1%

R10,R11 10 Ω, 1/10 W, ±5%

R12,R13 5.1 kΩ, 1/10 W, ±5%

R14,R26* 40.2 kΩ, 1/10 W, ±1%

R15 243 Ω, 1/10 W, ±1%

R18 1.8 kΩ, 1/10 W, ±5%

R32* 10 kΩ, 1/10 W, ±5%

D1 200V 1A Rectifier ON Semi MRA4003, 1N4003

Q1,Q2,Q3,Q4,Q7 100 V, PNP, BJT Central Semi CMPT5401; ON Semi MMBT5401LT1,

Q5,Q6 100 V, NPN, BJT Central Semi CZT5551, ON Semi 2N5551

Q8 100 V, NPN, BJT Centr al Semi CMPT5551, ON Semi 2N5551

*Note: Only one component per system needed.

Murata, Panasonic, Nichicon URL16100MD, Pana-

sonic Z Seri es

2N5401; Zetex FMMT5401

Preliminary Rev. 1.11 19

Si3210/Si3211/Si3212

RRE

80.6

QRDN

Q3

5401

R23

RRBN0

3.0k

RTE

80.6

QTN

Q6

5551

R6

QRP

Q5

5551

R12

R7

RRBN

5.1k

CRBN

100 nF

C7

R13

RTBN

5.1k

QTDN

Q4

5401

R24

RTBN0

3.0k

C8

CTBN

100 nF

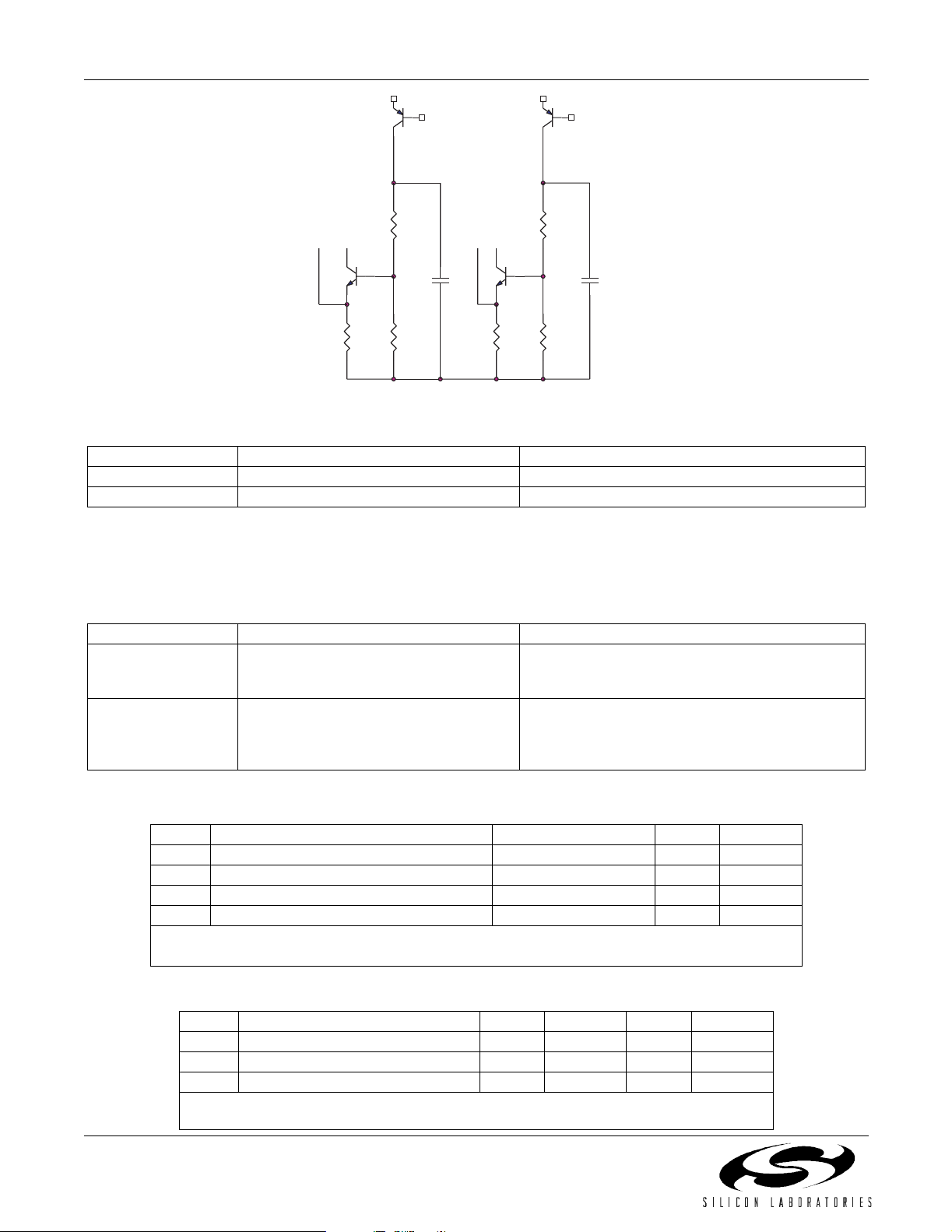

Figure 13. Si321x Optional Equivalent Q5, Q6 Bias Circuit

Table 16. Si321x Optional Bias Component Values

Component Value Supplier/Part Number

C7,C8 100 nF, 100 V, X7R, ±20% Murata, Johanson, Venkel

R23,R24 3.0 kΩ, 1/10 W, ±5%

The subcircuit above can be substituted into any of the ProSLIC solutions as an optional bias circuit for Q5, Q6. For

this optional subcircuit, C7 and C8 are different in voltage and capacitance to the standard circuit. R23 and R24 are

additional components.

Table 17. Component Value Selection for Si3210/Si3210M

Component Val ue Comments

R28 1/10 W, 1% resistor

For V

For V

= 3.3 V: 26.1 kΩ

DD

= 5.0 V: 37.4 kΩ

DD

R29 1/10 W, 1% resistor

For V

For V

For V

= 80 V: 541 kΩ

CLAMP

= 85 V: 574 kΩ

CLAMP

= 100 V: 676 kΩ

CLAMP

where V

where V

R28 = (V

BE

R29 = V

CLAMP

+ VBE)/148 µA

DD

is the nominal VBE for Q9

/148 µA

CLAMP

is the cl amping voltage for V

BAT

Tab le 18. Compo nent Value Selection Examples for Si3210M MOSFET/Transformer DC-DC Converter

VDC Ringing Load/Loop Resistance Transformer Ratio R18 R19, R20

3.3 V 3 REN/117 Ω 1 - 2 0.56 Ω 7.15 kΩ

5.0 V 5 REN/117 Ω 1 - 2 0.10 Ω 16.5 kΩ

12 V 5 REN/1 17 Ω 1 - 3 0.68 Ω 56.2 kΩ

24 V 5 REN/1 17 Ω 1 - 4 2.20 Ω 121 kΩ

Note: There ar e other system and software condit ions that influen ce component value selection, so pl ease refer to

AN45 “Design Guide for the Si3210 DC -DC Conv er ter for detailed guidance.

Table 19. Component Value Selection Examples for Si3210 BJT/Inductor DC-DC Converter

VDC Ringing Load/Loop Length L1 R17 R18 R19, R20

5 V 3 REN/11 7 Ω 33 µH100Ω 0.12Ω 16.5 kΩ

12 V 5 REN/117Ω 150 µH162Ω 0.56Ω 56.2kΩ

24 V 5 REN/117Ω 560 µH274Ω 2.2 Ω 121 kΩ

Note: There are other s ystem and software conditions that influence component value selection, so

please refer to AN45 “Design Guide for the Si3210 DC-DC Converter for detailed guidance.

20 Preliminary Rev. 1.11

Functional Description

t

Si3210/Si3211/Si3212

The ProSLIC™ is a single low-voltage CMOS device

that provides all the SLIC, codec, DTM F detection, and

signal generation functions needed for a complete

analog telephone interface. The ProSLIC performs all

battery, overvoltage, ringing, supervision, codec, hybrid,

and test (BORSCHT) function s. Unlike most monolithic

SLICs, the Si3210 does not require externally supplied

high-voltage battery supplies. Instead, it generates all

necessary battery voltages from a positive dc supply

using its own dc-dc converter controller. Two fully

programmable tone generators can produce DTMF

tones, phase continu ous FSK (caller ID) signaling, and

call progress tones. DTMF decoding and pulse metering

signal generation are also integrated.

The ProSLIC is ideal for short loop applications, such as

terminal adapters, cable telephony, PBX/key systems,

wireless local loop (WLL) , and voice over IP solutions.

The device meets all relevant LSSGR and CCITT

standards.

The linefeed provides programmable on-hook voltage,

programmable off-hook loop current, reverse battery

operation, loop or gro und start operation, and on-hook

transmission ringing voltage. Loop curr ent and voltage

are continuously monitored using an integrated A/D

converter. Balanced 5 REN ringing with or without a

programmable dc offset is integrated. The available

offset, frequency, w aveshape, and cadence options are

designed to ri ng the widest variety of terminal devices

and to reduce external controller re quirem ents.

A complete audio transmit and receive path is

integrated, including DTMF decoding, ac impedance,

and hybrid gain. These features are software

programmable, all owing for a single hardwar e design to

meet international requirements. Digital voice data

transfer occurs over a standard PCM bus. Cont rol data

is transferred using a standard SPI. The device is

available in a 38-pin TSSOP.

Linefeed Interface

The ProSLIC’s linefeed interface offers a rich set of

features and programmable flexibility to meet the

broadest applications requirements. The dc linefeed

characteristics are software program mable; key current,

voltage, and power measurements are acquired in

realtime and provided in software registers.

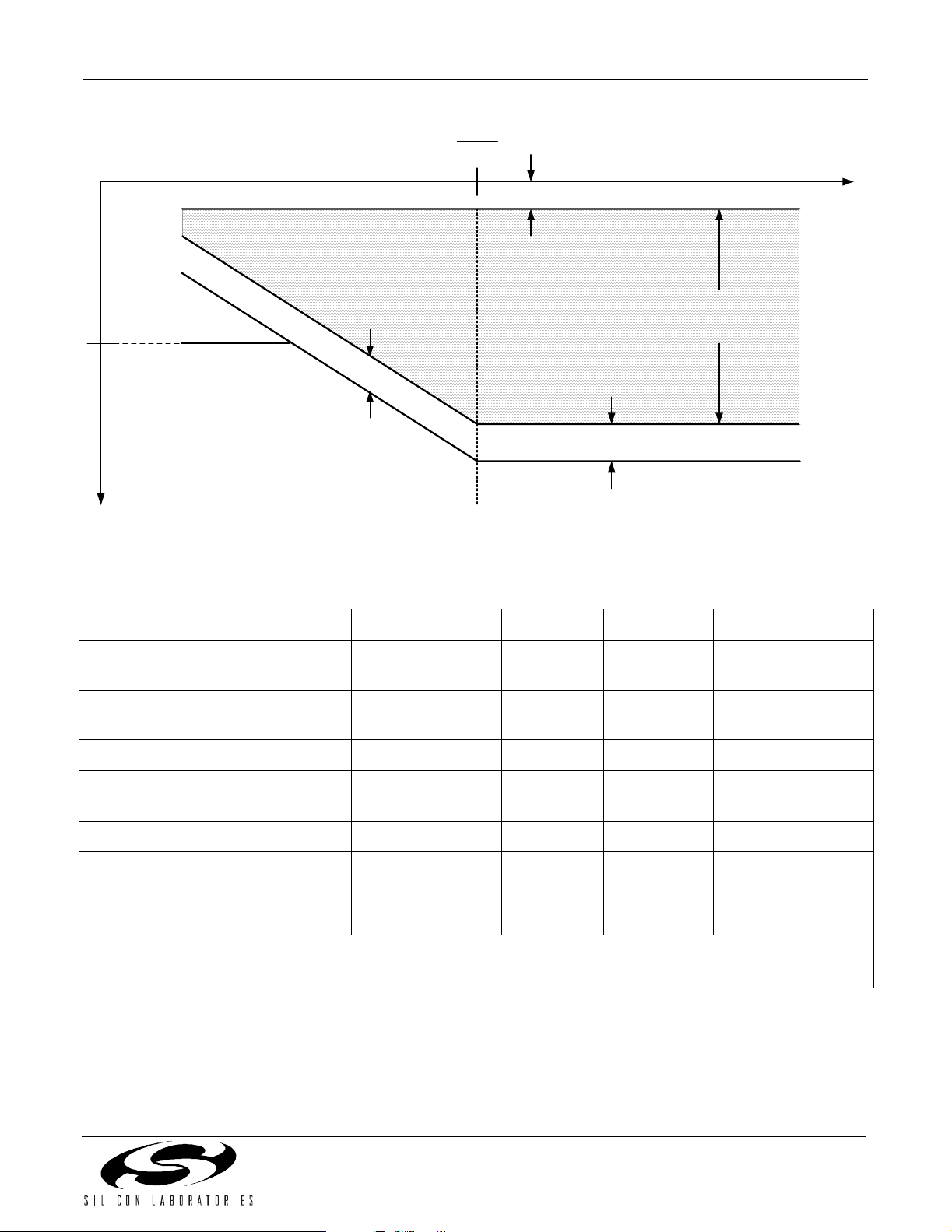

1.5 V steps. The loop current limit (I

) defines the

LIM

constant current zone and is programmable from 20 mA

to 41 mA i n 3 mA steps. The ProSLIC has an inherent

dc output resistance (R

V

(TIP-RING)

V

(V)

OC

) of 160 Ω.

O

Constant

Voltage

Zone

R

=160 Ω Constant Curren

O

I

LIM

Zone

I

LOOP

(mA )

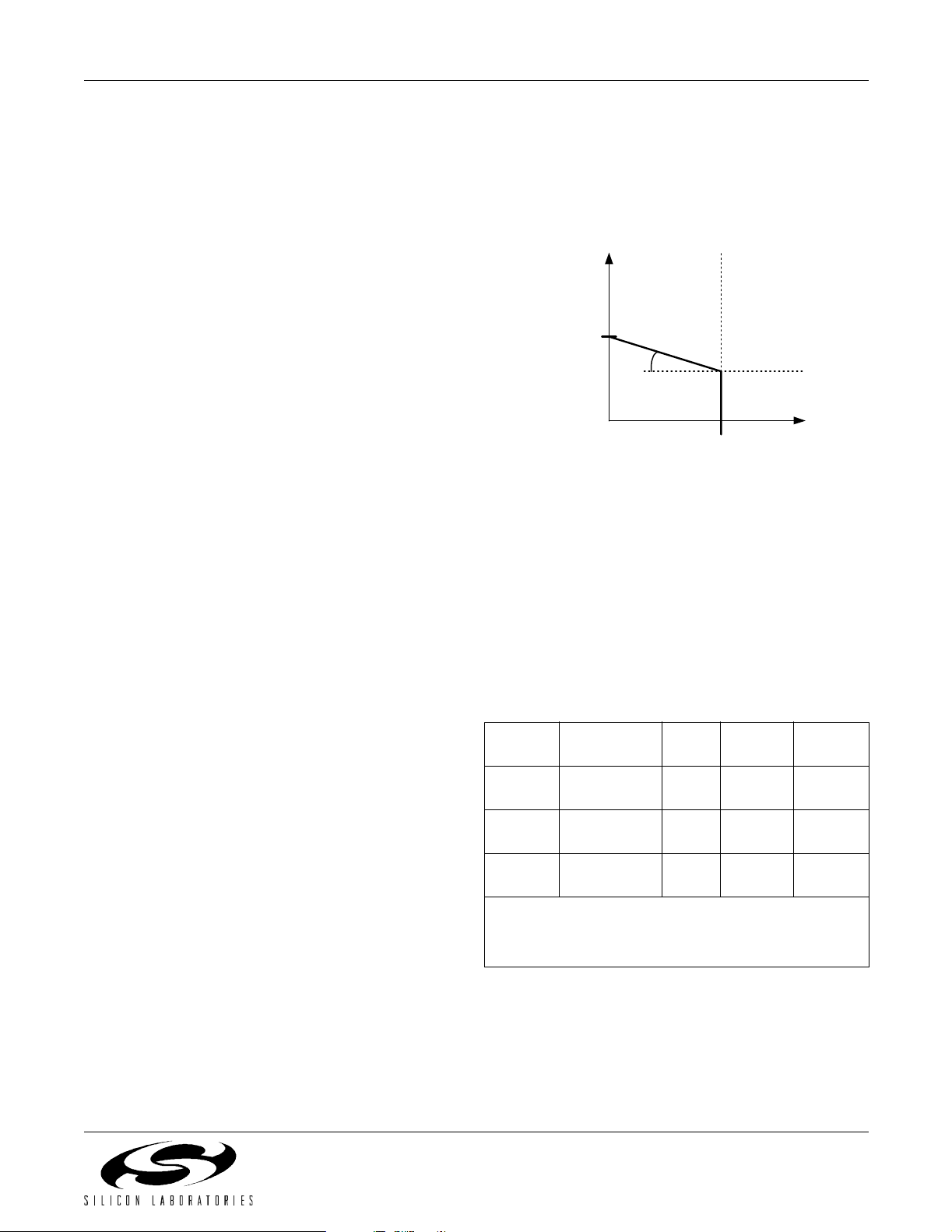

Figure 14. Simplified DC Current/Voltage

Linefeed Characteristic

The TIP-to-R ING v oltage (VOC) is offset from ground by

a programmable voltage (V

) to provide voltage

CM

headroom to the posit ive-most terminal (TIP in forward

polarity states and RING in reverse polarity states) for

carrying audio signals. Table 20 summarizes the

parameters to be initialized before entering an active

state.

Table 20. Programmable Ranges of DC

Linefeed Character i stics

Parameter Programmable

I

LIM

V

OC

V

CM

*Note: The ProSLIC uses registers that are both directly

and indirectly mapped. A “direct” regist er is one that

is mapped directly.

Range

20 to 41 mA 20 mA ILIM[2:0] Direct

0 to 94.5 V 48 V VOC[5:0] Direct

0 to 94.5 V 3 V VCM[5:0] Direct

Default

Value

Register

Bits

Location*

Register 71

Register 72

Register 73

DC Feed Characteristics

The ProSLIC has pro grammable constant v oltage and

constant current zones as depicted in Fig ure 14. Open

circuit TIP-to-RING voltage (V

) defines the c onstant

OC

voltage zone and is programmable from 0 V to 94.5 V in

Preliminary Rev. 1.11 21

Si3210/Si3211/Si3212

Linefeed Architecture

The ProSLIC is a low-voltage CMOS d evice that uses

low-cost external components to control the high

voltages required for subscriber line interfaces.

Figure 15 is a simplified illustration of the linefeed

control loop circuit for TIP or RING and the external

components used.

The ProSLIC uses both voltage and c urrent sensing to

control TIP and RING. DC and AC line voltage s on TIP

and RING are measured through sense resistors R

DC

and RAC, respectively. The ProSLIC uses linefeed

transistors Q

and QN to drive TIP and RING. Q

P

DN

isolates the high-voltage base of QN from the ProSLIC.

The ProSLIC measures voltage at various nodes in

order to monitor the linefeed current. R

provide access to these measuring points. The

R

BAT

, RSE, and

DC

sense circuitry is calibrated on-chip to guarantee

measurement accuracy with standard external

component tolerances. See "Linefeed Calibration" on

pa ge 26 for det ails.

Linefeed Operation States

The ProSLIC linefeed has eight states of operatio n as

shown in Table 21. The state of operation is controlled

using the Linefeed Control register ( direc t Regis ter 64).

The open state turns off all currents into the external

bipolar transistors and can be used in the presence of

fault conditions on the line and to generate Open Switch

Intervals (OSIs). TIP and RING a re effectivel y tri-stated

with a dc output impedance of about 150 k

Ω. The

ProSLIC can also automat ic ally ent er the open state if it

detects excessive power being consumed in the

external bipolar transist ors. See "Power Monitoring and

Line Fault Detection" on page 24 for more details.

In the forward active and reverse ac tive states, linef eed

circuitry is on and the audio s ignal paths are powered

down.

In the forward and revers e on-hoo k transmis sion s tates

audio signal paths are powered up to provide data

transmission during an on-hook loop condition.

The TIP Open state turns off all control cur rents to the

external bipolar devices connec ted to TIP and provides

an active linefeed on RING for ground start operation.

The RING Open state provides similar operation with

the RING drivers off and TIP active.

The ringing state drives programmable ringing

waveforms onto the line.

Loop Voltage and Current Monitoring

The ProSLIC continuo usly monitors the TIP and RING

voltages and external BJT currents. These values are

available in regis ters 78–89. Table 22 o n page 24 lis ts

the values that are measured and their associated

registers. An internal A/D converter samples the

measured voltages and currents from the analo g sense

circuitry and translates them into the digital domain. The

A/D updates the samples at an 800 Hz rate. Two

derived values are also reported—loop voltage and loop

current. The loop v olta ge, V

TIP–VRING

, is reported as a

1-bit sign, 6-bit magnitude format. For ground start

operation the reported value is t he RING voltage. The

loop current, (I

– IQ2 + IQ5 –IQ6)/2, is reported i n a 1-

Q1

bit sign, 6-bit magnit ude format. In RING op en and TIP

open states the loop cu rrent is report ed as (I

–IQ6).

(I

Q5

– IQ2) +

Q1

22 Preliminary Rev. 1.11

Aud i o

Codec

Si3210/Si3211/Si3212

Monitor A/D

TIP or

RING

A/D

A/D

DSP

D/AD/A

SLIC DAC

AC

Control

R

C

AC

AC

AC Sense

AC

Control

Loop

R

BP

On-ChipExternal Components

Σ

Q

Q

DN

P

Q

N

R

E

DC

Control

Loop

DC

Control

DC Sense

R

DC

Battery Sense

Emitter Sense

R

SE

R

BAT

V

BAT

Figure 15. Simplified ProSLIC Linefeed Architecture for TIP and RING Leads (One Shown)

Table 21. ProSLIC Linefeed Operations

LF[2:0]* Linefeed State Description

000 Open TIP and RING tri-stated.

001 For ward Active V

010 Forward On-Hook Transmission V

011 TIP Open TIP tri-state d, RING active; used for ground s tart.

100 Ringing Ringing waveform applied to TIP and RING.

101 Reverse Active V

110 Reverse On-Hook Transmission V

1 11 Ring Open RING tri-stated, TIP active.

Note: The Linefeed register (LF) is locat ed in direct Register 64.

TIP

TIP

RING

RING

> V

> V

> V

> V

.

RING

; audio signal paths powered on.

RING

.

TIP

; audio signal paths powered on.

TIP

Preliminary Rev. 1.11 23

Si3210/Si3211/Si3212

4096

P

h

Table 22. Measure d Re al ti me Linefe ed Interfa ce Charac ter i stics

Parameter Measurement

Loop Voltage Sense (V

TIP

– V

Range

) –94.5 to +94.5 V 1.5 V L V SP,

RING

Resolution Register

Bits

Location*

Direct Register 78

LVS[6:0]

Loop Current Sense –80 to +80 mA 1.27 mA LCSP,

Direct Register 79

LCS[5:0]

TIP Voltage Sense 0 to –95.88 V 0.376 V VTIP[7:0] Direct Register 80

RING Voltage Sense 0 to –95.88 V 0.376 V VRING[7:0] Direct Register 81

Battery Voltage Sense 1 (V

Battery Voltage Sense 2 (V

) 0 to –95.88 V 0.376 V VBATS1[7:0] Direct Register 82

BAT

) 0 to –95.88 V 0.376 V VBATS2[7:0] Direct Register 83

BAT

Transistor 1 Current Sense 0 to 81.35 mA 0. 319 m A IQ1[7: 0] Direct Register 84

Transistor 2 Current Sense 0 to 81.35 mA 0. 319 m A IQ2[7: 0] Direct Register 85

Transistor 3 Current Sense 0 to 9.59 mA 37.6

Transistor 4 Current Sense 0 to 9.59 mA 37.6

µA IQ3[7:0] Di r ect Regist er 86

µA IQ4[7:0] Di r ect Regist er 87

Transistor 5 Current Sense 0 to 80.58 mA 0. 316 m A IQ5[7: 0] Direct Register 88

Transistor 6 Current Sense 0 to 80.58 mA 0. 316 m A IQ6[7: 0] Direct Register 89

*Note: The ProSLIC uses registers that are both directly and i ndi rectly mapped. A “direct” regi ster is one that is mapped

directly.

Power Monitoring and Li ne Fa u lt D et ec ti on

In addition to reporting voltages and currents, the

ProSLIC continuously monit ors the power dissipated in

the type of fault condition present on the line .

The value of each thermal low-pass filter pole is set

according to the equation:

each external bipolar t ransistor. Realtime output power

of any one of the six linefeed transistors c an be read by

setting the Power Monitor Pointe r (direct Regis ter 76) to

point to the des ir ed t r ansis tor and then reading the Line

Power Output Monitor (direct Register 77).

The realtime power measurem ents are low- pass filter ed

and compared to a maximum power threshold.

Maximum power thresholds and filter time constants are

software programmable and should be set for each

transistor pair based on the characteristics of the

transistors used. Table 23 describes the registers

associated with this function. If the power in any

---------------- -

800 τ⋅

where

thermal LPF register

τ is the thermal time constant of the transistor

package, 4096 is the full range of the 12-bit register, and

800 is the sample rate in hertz. Ge ner ally

for SOT223 packages and

τ = 0.16 seconds f or SO T23,

but check with the manufacturer for the package

thermal con stant of a specif ic device. F or example, t he

power alarm threshol d and low-pass filt er values fo r Q5

and Q6 using a SOT223 package transistor are

computed as follows:

3

2

⋅=

τ = 3 seconds

external transisto r exceeds the programm ed threshold,

a power alarm event is tri ggered. The ProSLIC sets the

Power Alarm register bit, generates an interrupt (if

enabled), and automatically enters the Open state (if

AOPN = 1). This feature protects the external

transistors from fault con ditions and , com bined wit h the

loop voltage and current m onitors, allows diagnosis of

MAX

PPT56

-------------------------------

====

Resolution

Thus, indirect Register 34 should be set to 150Dh.

Note: The power monitor resolution for Q3 and Q4 is differen t

from that of Q1, Q2, Q5, and Q6.

7

1.28

------------------

2

⋅

0.0304

7

2

⋅ 5389 150D

24 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

Table 23. Associated Power Monitoring and Power Fault Registers

Parameter Description/

Range

Power Monit o r Po i nter 0 to 5 points to Q 1

to Q6, respe ctively

Line Power Monitor Output 0 to 7.8 W for Q1,

Q2, Q5, Q6

0 to 0.9 W for Q3,

Q4

Power Alarm Threshold, Q1 & Q2 0 to 7.8 W 30.4 mW PPT12[7:0] Indirect Register 32

Power Alarm Threshold, Q3 & Q4 0 to 0.9 W 3.62 mW PPT34[7:0] Indirect Register 33

Power Alarm Threshold, Q5 & Q6 0 to 7.8 W 30.4 mW PPT56[7:0] Indirect Register 34

Thermal LPF Pole, Q1 & Q2 see equation above NQ12[7:0] Indirect Register 37

Thermal LPF Pole, Q3 & Q4 see equation above NQ34[7:0] Indirect Register 38

Thermal LPF Pole, Q5 & Q6 see equation above NQ56[7:0] Indirect Register 39

Power Alarm Interrupt Pending Bits 2 to 7 corre-

spond to Q1 to Q6,

respectively

Resolution Register

Bits

n/a PW RM P[2: 0] Direct Register 76

30.4 mW

3.62 mW

n/a QnAP[n+1],

PWROM[7:0] Direct Regis t er 77

where n =1

to 6

Location*

Direct Register 19

Power Alarm Interrupt Enable Bits 2 to 7 corre-

spond to Q1 to Q6,

respectively

Power Alarm

Automatic/Manual Detect

*Note: The ProSLIC uses registers that are both directly and i ndi rectly mapped. A “direct” regi ster is one that is mapped

directly. An “indirect” register i s one that is accessed using the indirect access regist ers (direct registe rs 28 th rough

31).

0 = manual mode

1 = enter open state

upon power alarm

n/a QnAE[n+1],

where n = 1

to 6

n/a A OP N Direct Register 67

Direct Register 22

Preliminary Rev. 1.11 25

Si3210/Si3211/Si3212

LCS

LVS

Input

Signal

Processor

LCVELFS

ISP_ OU T

Digital

LPF

NCLR

HYSTEN

Loop Closure

Threshold

LCRTLLCRT

Figure 16. Loop Closure Detection

Loop Closure Detection

A loop closure event signals that the terminal equipment

has gone off-hook durin g on-hook transmission or onhook active states. The ProSLIC perform s loop closure

detection digitally using its on-chip monitor A/D

converter. The functional bloc ks required to implement

loop closure detection are shown in Figure 16. The

primary input to the system is the Loop Current S ense

value provided in the LCS register (direct Register 79).

The LCS value is processed in the Input Signal

Processor when the ProSLIC is in the on-hook

transmission or on-hook active linefeed state, as

indicated by the Linefeed Shadow register, LFS[2:0]

(direct Register 64). The data then feeds into a

programmable digital low-pass filter, which removes

unwanted ac signal components before threshold

detection.

The output of the low-pass filter is compared to a

programmable threshold, LCRT (indirect register 28).

The threshold comparator output feeds a programmable

debouncing filter. The output of the debouncing filter

remains in its pres ent state unles s the input remains in

the opposite state for the entire period of time

programmed by the loop closure debounce interval,

LCDI (direct Regist er 69). I f the debounce interval has

been satisfied, th e LCR bit will be se t to indicate that a

valid loop closure has oc c urr ed. A loop closure interru pt

is generated if enabled by the LCIE bit (direct

Register 22). Table 24 lists the registers that must be

written or monitored to correctly detect a loop closure

condition.

Loop Closu r e Threshold H y st ere sis

Silicon revisions C and higher support the addition of

programmable hyste resis to the loop closu re threshold,

which can be enabled by setting HYSTEN = 1 (direct

Register 108, b it 0). The hyst eresis is defined b y LCRT

(indirect Register 28) and LCRTL (indirect Regi ster 43),

+

Debo un ce

Filter

–

LCDI

LCR

Interrupt

Logic

LCIE

LCIP

which set the upper and lower bounds, res pec tive ly.

Voltage-Based Loop Closure Detection

Silicon revisions C and highe r also support an optional

voltage-based loop closure detection mode, which is

enabled by setting LCVE = 1 (direct Register 108,

bit 2). In this mode t he loop voltage is co mpared to the

loop closure threshold register (LCRT) which represents

a minimum voltage threshold instead of a maximum

current threshold. If hysteresis is also enabled, then

LCRT represents the upper voltage boundary and

LCRTL represents the lower voltage boundary for

hysteresis. Although voltage-based loop closure

detection is an option, the default current-based loop

closure detection is recommended.

Table 24. Register Set for Loop

Closure Detection

Parameter R egi ster Location

Loop Closure

Interrupt Pending

Loop Closure

Interrupt Enable

Loop Closure Threshold LCRT[5:0] Indir ect Reg. 28

Loop Closure

Threshold—Lower

Loop Closure Filter

Coefficient

Loop Closure Detect

Status (monitor only)

Loop Closure Detect

Debounce Interval

Hysteresis Enable HYSTEN Direct Reg. 108

Voltage-Based Loop

Closure

Linefeed Calibra t i on

LCIP Direct Reg. 19

LCIE Direct Reg. 22

LCRTL[5:0] Indirect Reg. 43

NCLR[12:0] Indirect Reg. 35

LCR Direct Reg. 68

LCDI[6:0] Direct Reg. 69

LCVE Direct Reg. 108

26 Preliminary Rev. 1.11

Si3210/Si3211/Si3212

An internal calibration algorithm corrects for internal and

external component errors. The calibration is initiated by

setting the CAL bit in direct Register 96. Upon

completion of the calibration cycle, this bit is

automatically reset.

It is recommended that a calibration be executed

following system power-up. Upon release of the chip

reset, the Si3210 will be in the open state. After

powering up the dc-dc converter and allowing it to settle

for time (t

) the calibration can be initiated.

settle

Additional calibrations may be performed, but only one

calibration should be necessary as long as t he system

remains powered up.

During calibration, V

BAT

, and V

TIP

voltages are

RING

, V

controlled by the calibration engine to provide the

correct external voltage conditions for the algorithm.

Calibration should be performed in the on-hook state.

RING or TIP must not be connected to ground during

the calibration.

Battery Voltage Generation and Switching

The ProSLIC supports two modes of battery supply

operation. First, the Si3210 integrates a dc-dc converter

controller that dynamically regulates a single output

voltage. This mode eliminates t he need to suppl y large

external battery voltages. Instead, it converts a single

positive input voltage into the real-t ime battery voltage

needed for any given state according to programmed

linefeed parameters. Second, the Si3211 and Si3212

support switching between high and low battery voltage

supplies, as would a traditional monolithic SLIC.

For single to low channel count applications, the Si3210

proves to be an economical choice, as the dc-dc

converter eliminate s the need to design and build highvoltage power supplies. For higher channel count

applications whe re cent ralized batt ery voltag e supp ly is

economical, or for modular legacy systems where

battery voltage is already available, the Si3211 and

Si3212 are recommended.

DC-DC Converter General Description

(Si3210/Si3210M Only)

The dc-dc converter dynamically generates the large

negative voltages required to operate the linefeed

interface. The Si3210 ac ts as the controller for a buckboost dc-dc converter that converts a positive dc

voltage into the desired negative battery voltage. In

addition to eliminating external power supplies, this

allows the Si3210 to dynamically control the battery

voltage to the minimum r equired for any given mode of

operation.

Two different dc-dc circuit options are offered: a BJT/

inductor version and a MOSFET/transformer version.

Due to the differences on the drivi ng circuits, there are

two different versions of the Si3210. The Si3210

supports the BJT/inductor circuit option, and the

Si3210M version supports the MOSFET solution. The

only difference bet ween the two versions is the polarity

of the DCFF pin with respect to the DCDRV pin. For the

Si3210, DCDRV and DCFF are opposite polarity. For

the Si3210M, DCDRV and DCFF are the sam e polarity.

Table 25 summarizes these differences.

Table 25. Si3210 and Si3210M Differences

Device DCFF Signal

Polarity

Si3210

= DCDRV

Si3210M = DCDRV 1

Notes:

1.

DCFF signal polarity wit h respect to DCDRV signal.

2. Di rect Register 93, bit 5; This is a read-only bit.

Extensive design guidance on each of these circuits can

be obtained from Application Note 45 (AN45) and from

an interactive dc-dc converter design spreadsheet. Both

of these documents are available on the Silicon

Laboratories website (www.silabs.com).

BJT/Inductor Circuit Option Using Si3210

The BJT/Inductor circuit option, as defined in Figure 9,

offers a flexible, low-cost solution. Depending on

selected L1 inductance value and the switching

frequency, the input voltage (V

) can range from 5 V to

DC

30 V. By nature of a dc-dc converter ’s operation, peak

and average input currents can become large with small

input voltages. Consider this when selecting the

appropriate i nput voltage and pow er rating for the V

power supply.

For this solution, a PNP power BJT (Q7) switch es the

current flow through low E SR inductor L1. The Si3210

uses the DCD RV and DCFF pins to switch Q7 o n and

off. DCDRV controls Q7 t hrough NPN BJT Q8. DCFF is

ac coupled to Q7 through capacitor C10 to assist R16 in

turning off Q7. Therefore, DCFF must have opposite

polarity to DCDRV, and the Si321 0 (not Si321 0M) must

be used.

MOSFET/Transformer Circuit Option Using Si3210M

The MOSFET/transformer circuit option, as defined in

Figure 11, offers higher power efficiencies across a

larger input voltage range. Depending on the

transformers primary inductor value and the switching

frequency, the input voltage (V

) can range from 3.3 V

DC

to 35 V. Therefore, it is possible to power the entire

ProSLIC solution from a single 3.3 V or 5 V power

supply. By nature of a dc-dc converter’s operation, peak

DCPOL

0

DC

Preliminary Rev. 1.11 27

Si3210/Si3211/Si3212

and average input currents can become large with small

input voltages. Consider this when selecting the

appropriate input voltage and power rating for the V

DC

power supply (number of REN supported).

For this solution, an n-channel power MOSFET (M1)

switches the cur rent flow through a p ower transformer

T1. T1 is specified in Applicat ion Note 45 (AN45), and

includes several taps on the prim ary side to facilitate a

wide range of input voltages. The Si3210M version of

the Si3210 must be used for the application circuit

depicted in Figure 9 because the DCFF pin is used to

drive M1 directly and therefore must be the same

polarity as DCDRV. DCDRV is not used in this circuit

option; connecting DCFF and DCDRV together is not

recommended.

DC-DC Converter Architecture

(Si3210/Si3210M Only)

The control logic for a pulse width modulated (PWM) dcdc converter is incor porated in the S i3210. O utput pins ,

DCDRV and DCFF, are used to switch a bipolar

transistor or MOSFET. The polarity of DCFF is opposite

to that of DCDRV.

The dc-dc converter circuit is powered on when the

DCOF bit in the Power Down Register (direct

Register 14, bit 4) is cleared to 0.

The switching

regulator circuit within the Si3210 is a high

performance, pulse-width modulation controller. The

control pins are driven by the PWM controller logic in

the Si3210. The regulated output voltage (V

BA T

) is

sensed by the SVBAT pin and is used to detect whether

the output voltage is above or below an internal

reference for the desired battery voltage. The dc

monitor pins SDCH and SDCL monitor input current and

voltage to the dc-dc converter external circuitry. If an

overload condition is detected, the PWM controller w ill

turn off the sw itching transistor for the remainder of a

PWM period to prevent damage to external

components. It is important that the proper val ue of R18

be selected to ensure safe operation. Guidance is given

in Application Note 45 (AN45).

The PWM co ntroller o perates at a frequency se t by t he

dc-dc Converter PWM register (direct Register 92).

During a PWM period the outputs of the control pins

DCDRV and DCFF are asserted for a time given by the

read-only PWM Pulse Width register (direct

Register 94).

The dc-dc converter must be off for some time in each

cycle to allow the inductor or trans former to trans fer its

stored energy to the output capacitor, C9. This minimum

off time can be set through the dc-dc Converter

Switching Delay register, (direct Register 93). The

number of 16.384 MHz clock cycles that the controller is

off is equal to DCTOF (bits 0 throug h 4) plus 4. I f the dc

Monitor pins detect an overload condition, the dc-dc

converter interru pts its conversion cycles regardl ess of

the register settings to prevent component damage.

These inputs should be calibrated by writing the DCCAL

bit (bit 7) of the dc-dc Converter Switching Delay

register, direct Register 93, after the dc-dc converter

has been turned on.

Because the Si3210 dynamically regulates its own

battery supply voltage using the dc-dc converter

controller, the battery vo ltage (V

) is offset from the

BAT

negative-most terminal by a programmable voltage

) to allow voltage headroom for carrying audio

(V

OV

signals.

As mentioned previously, the Si3210 dynamically

adjusts V

illus tra te th i s, the be h av ior of V

to suit the particular circuit requirement. To

BAT

in the active state is

BAT

shown in Figure 17. In the active state, the TIP-t o- RING

open circuit voltage is kept at V

voltage region while the regulator output voltage, V

+ VOC + VOV.

V

CM

When the loop cu rrent attempts to exceed I

in the constant

OC

, the dc

LIM

BAT

=

line driver c ircuit ent ers cons tant current mode a llowing

the TIP to RING voltage to track R

. As the TIP

LOOP

terminal is kept at a constant voltage, it is the RING

terminal voltag e that tracks R

| voltage will als o track R

|V

BAT

R

= I

LIM

the VOC/I

continue to track R

+ VCM +VOV. As R

LOOP

mark, the regulator output voltage can

LIM

(TRACK = 1), or the R

LOOP

tracking mechanism is stopped when |V

and, as a result, the

LOOP

. In this state, |V

LOOP

decreases below

LOOP

BAT

| = |V

BAT

LOOP

BATL

(TRACK = 0). The former case is the more common

application and provides the maximum power

dissipation savings. In principle, the regulator output

voltage can go as low as |V

|=VCM+ VOV, offeri ng

BAT

significant powe r savings.

When TRACK = 0, |V

. The RING t erminal voltage, howev er, continues

V

BATL

to decrease with decreasing R

| will not decrease below

BAT

. The power

LOOP

dissipation on the NPN bipolar transistor driving the

RING terminal can become large and may require a

higher power rat ing device. The non-trac king mode of

operation is required by specific terminal equipment

which, in order to initiate certain data transmission

modes, goes briefly on-hook to measure the line voltage

to determine whether there is any other off-hook

terminal equipmen t on the same line. TRACK = 0 mode

is desired since the regulator output voltage has long

settling time constants (on the order of tens of

milliseconds) and cannot change ra pidly for TRACK = 1

mode. Therefore, the brief on-hook voltage

measurement would yield approximately the same

voltage as the off-hook line voltage and would cause the

terminal equipment to incorrectly sense another offhook terminal.

|

|

28 Preliminary Rev. 1.11

V

V

V

BATL

T

R

A

C

TRACK=0

Si3210/Si3211/Si3212

OC

I

Constant I Re gi on Consta nt V Region

K

=

1

V

OV

LIM

|V

TIP

V

CM

- V

RING

|

V

OV

R

LOOP

V

TIP

V

OC

V

RING

V

BAT

Figure 17. V

TIP

, V

RING

, and V

in the For ward Acti ve State

BAT

Table 26. Associated Relevant DC-DC Converter Registers

Parameter Range Resolution Register Bit Location

DC-DC Converter Power-off

Control

DC-DC Converter Calibration

Enable/Status

DC-DC Converter PWM Period 0 to 15.564 us 61.035 ns DCN[7:0] Direct Register 92

DC-DC Converter Min. Off Time (0 to 1.892 us ) +

High Battery Voltage—V

Low Battery Voltage—V

V

OV

Note: The ProSLIC uses registers that are both directly and i ndi rectly mapped. A “direct” regi ster is one that is mapped

directly. An “indirect” register is one that i s accessed using the indirect access registers (direct r egisters 28 thr ough 31).

BATH

BATL

n/a n/a DCOF Direct Regist er 14

n/a n/a DCCAL Direct Register 93

61.035 ns DCTOF[4:0] Direct Register 93

4ns

0 to –94.5 V 1.5 V VBATH[5:0] Direct Reg i s ter 74

0 to –94.5 V 1.5 V VBATL[5:0] Direct Regist er 75

0 to –9 V or

0 to –13.5 V

1.5 V VMIND[ 3:0 ]

VOV

Indirect Register 41

Direct Register 66

Preliminary Rev. 1.11 29

Si3210/Si3211/Si3212

DC-DC Converter Enhancements

Silicon revisions C and higher support two

enhancements to the dc-dc converter. The first is a

multi-threshold er ror control algorithm tha t enables the

dc-dc converter to adjust more quickly to voltage

changes. This option is enabled by setting DCSU = 1

(direct Register 108, bit 5). The se cond enhancement is

an audio band filter that removes audio band noise from

the dc-dc co nverter contro l loop. This o ption i s ena bled

by setting DCFIL = 1 (direct Register 108, bit 1).

DC-DC Converter During Ringing

When the ProSLIC enters the ringing state, it requires

voltages well above those used in the acti ve mo de. The

voltage to be generated and regulated by the dc-dc

converter during a ringin g burst is set us ing the VBATH

register (direct Register 74). VBATH can be set between

0 and –94.5 V in 1.5 V steps. To avoid clipping the

ringing signal, V

amplitude. At the end of each ringing burst the dc-dc

converter adjusts back to active state regulation as

described above.

External Battery Switching (Si3211 and Si3212 Only)

The Si3211 and Si3212 support switching between two

battery voltages. The circuit for external battery

switching is defined in Figure 12. Typically a high

voltage battery (e.g., –70 V) is used for on-hook and

ringing states, and a low v oltage battery (e.g., –24 V) is

used for the off-hook condition. The ProSLIC uses an

external transistor to switch bet ween th e two s upplies.

When the ProSLIC changes operating states, it

automatically sw it c hes bat t er y s upplies if the au tom at ic /

manual control bit ABAT (direct Register 67, bit 3) is set.

For example, the ProSLI C will switch from high batte ry

to low battery when it detects an off-hook ev ent t hr ough

either a ring trip or loop closure event. If automatic

battery selection is disabled (ABAT = 0), the battery is

selected by the Batt ery Feed Select bit, BATSL (direct

Register 66, bit 1).

Silicon revisions C and higher support the option to add

a 60 ms debounce period to the battery switching circuit

when transitioning from high batt ery to low batte ry. This

option is enabled by setting SWDB = 1 (direct

Register 108, bit 3). This debounce minimizes battery

transitions in the case of pulse dialing or other quick onhook to off-hook transitions.

must be set larger than the ringing

BATH

Tone Generation

Two digital tone generators are provided in the ProSLIC.

They allow the gener ation of a wide variety of single or

dual tone frequency and amplitude combinations and

spare the user the effort of generating the required

POTS signaling tones on the PCM highway. DTMF, FSK

(caller ID), call progress, and other tones can all be

generated on -chip. The tones can be sent t o either t he

receive or transmit paths (see Figure 23 on page 40).

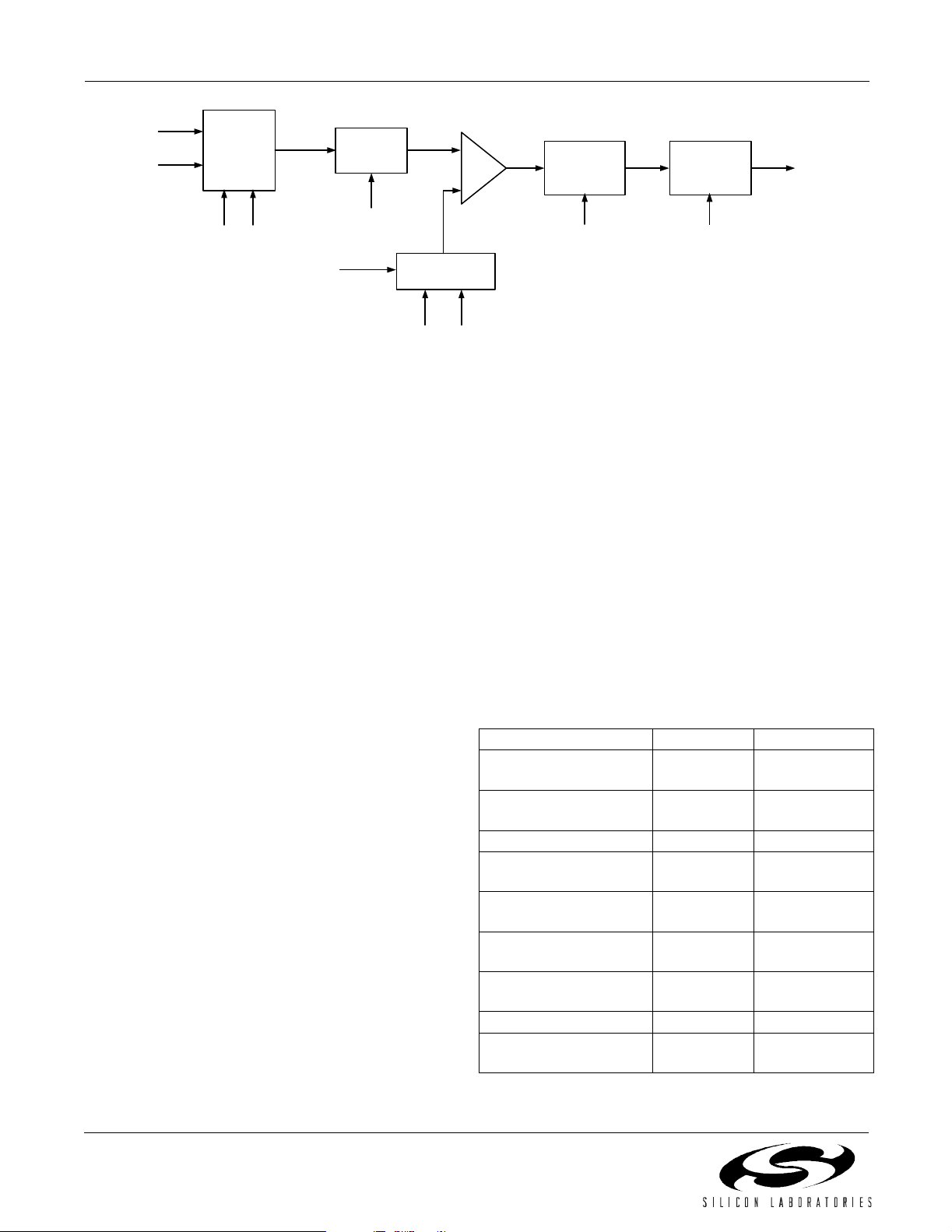

Tone Generator Architecture

A simplified dia gram of the tone gener ator architecture

is shown in Figure 18. The oscillator, active/inactive

timers, interrupt block, and signal routing block are

connected to give the user flexibility in creating audio

signals. Control and status register bits are placed in the

figure to indicate their association with the tone

generator architect ur e. These r egisters are described in

more detail in Table 27.

30 Preliminary Rev. 1.11

Loading...

Loading...