Page 1

AN633

PROGRAMMING GUIDE FOR EZRADIOPRO® Si4X6X DEVICES

1. Introduction

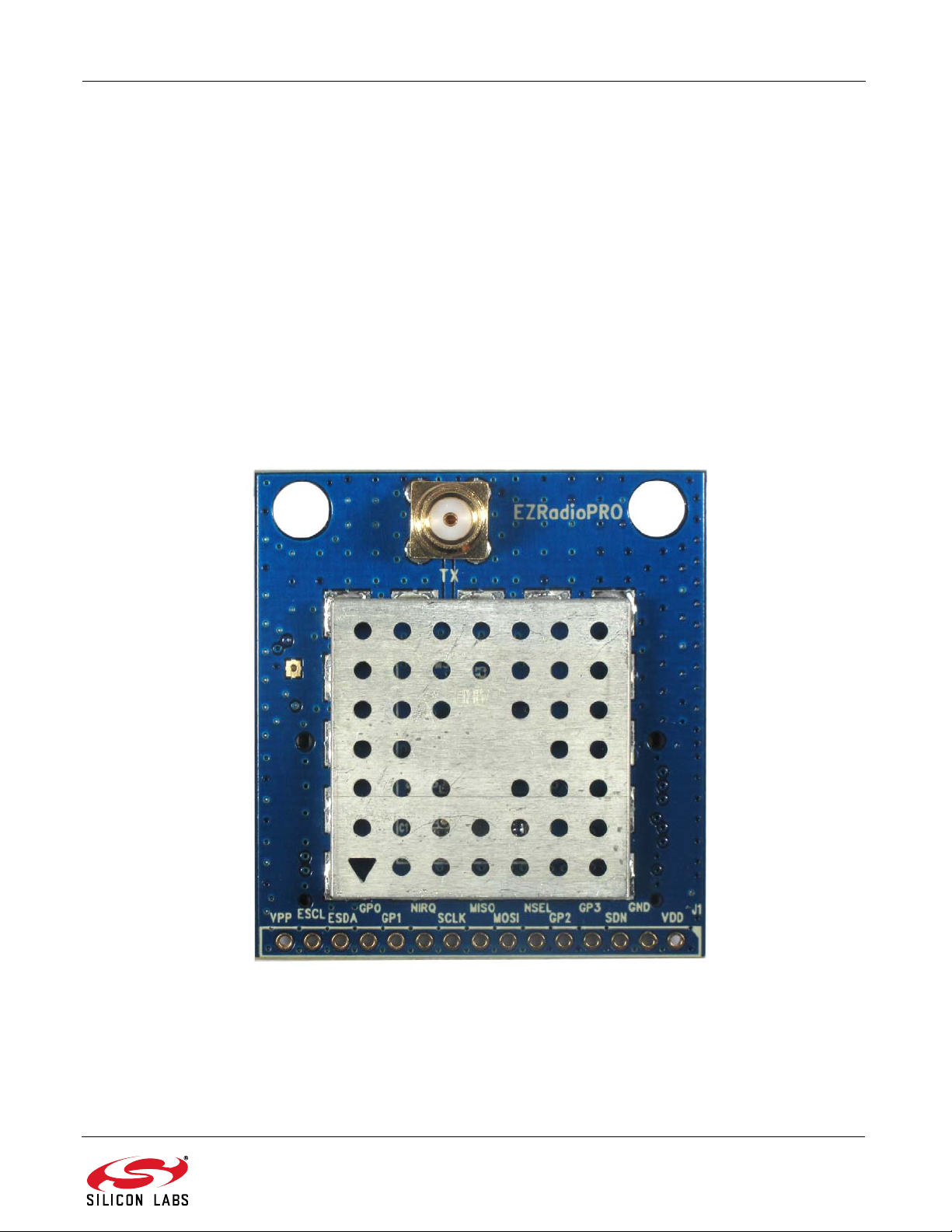

This document is intended to serve as a guide for application development with EZRadioPRO® radio ICs. It

introduces the major parts of the hardware platform, such as the RF Pico board, which contains the radio and the

necessary RF components required to operate the device according to a desired regulatory standard. It also

introduces the 8-bit wireless motherboard (WMB), which is required to control the radio, evaluate the RF

parameters, and develop custom application programs. Besides the hardware, it also describes the application

programming interface (API) that makes it possible for the WMB and RF pico board to communicate with each

other. Using the software tools provided by Silicon Labs and following this programming guide will make software

development as easy as possible, as these items will assist you in configuring the radio effectively. Additionally, the

first boot of the radio and the whole configuration process are clearly described so that software developers can

primarily concentrate on their own applications without experiencing time-consuming configuration problems.

Several example projects are also provided as good starting points for real applications. A layered software

approach is followed in all the source codes. The software modules are logically separated, and they focus on their

own specific tasks. The document refers to the corresponding data sheets, manuals, and application notes.

2. Supported Radio Types

This document provides programming guidance for the following EZRadioPRO RF ICs:

Si4060 Transmitter

Si4063 Transmitter

Si4362 Receiver

Si4438 Transceiver

Si4460 Transceiver

Si4461 Transceiver

Si4463 Transceiver

Si4464 Transceiver

Si4467 Transceiver

Si4468 Transceiver

Rev. 0.8 4/20 Copyright © 2020 by Silicon Laboratories AN633

Page 2

AN633

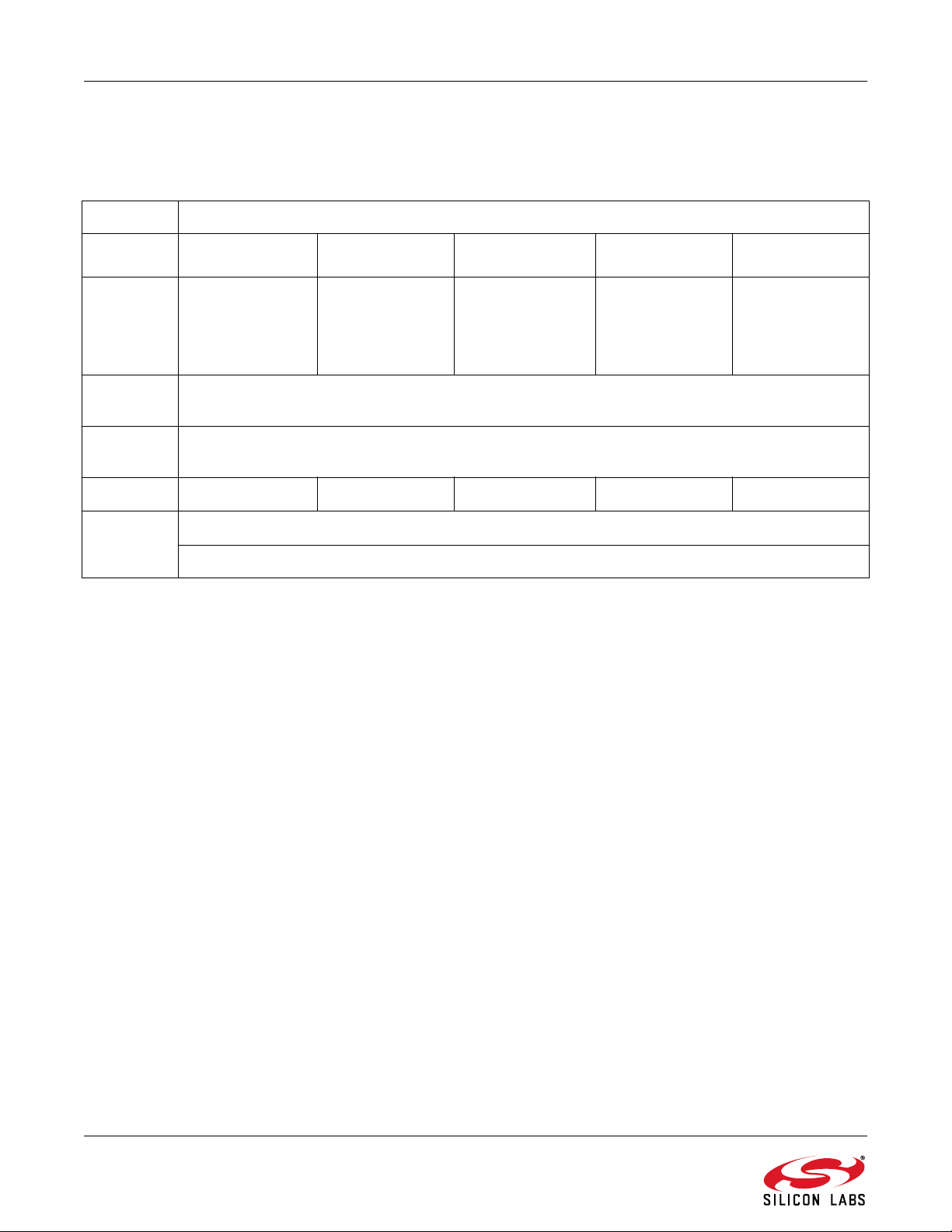

3. Development Kits

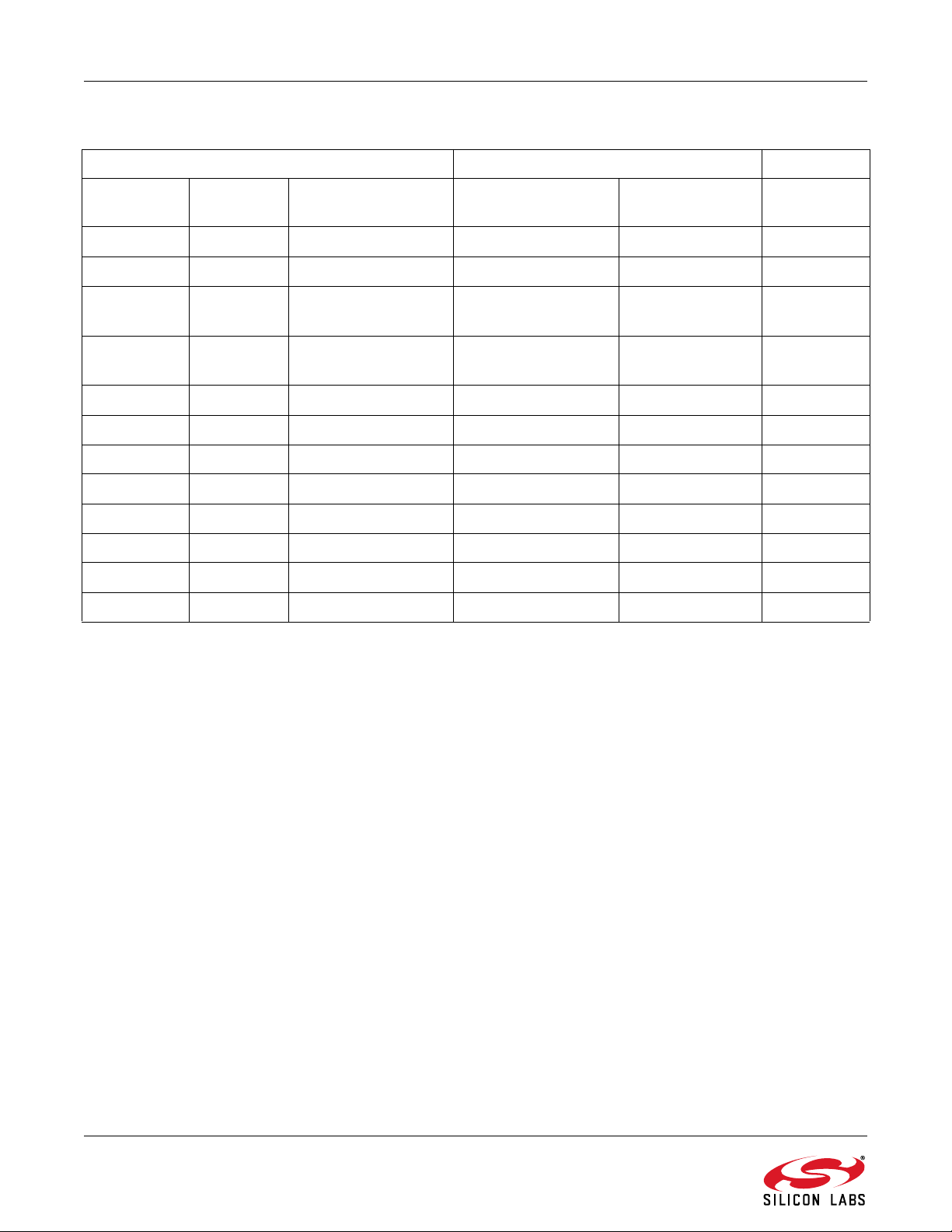

The EZRadioPRO development kits contain two complete RF nodes of different radio ICs. See Table 1.

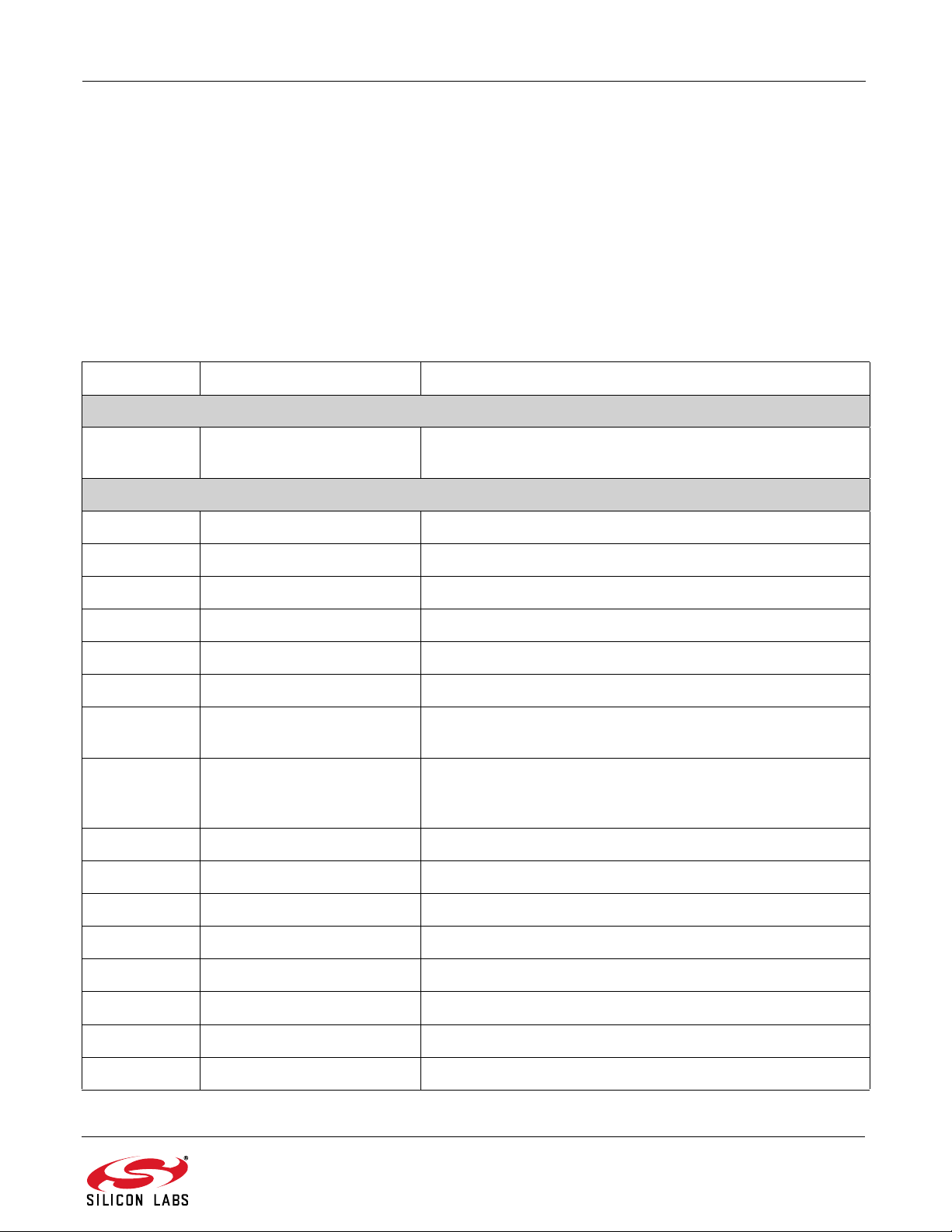

Table 1. EZRadioPRO Development Kit Content

Description Part Number

Dev Kit 4060-868-PDK 4063-915-PDK 4461-868-PDK 4438-490-PDK 4463-915-PDK

RF Pico

Board

Mother-

board

MCU Pico

Board

Antenna 868 MHz 915 MHz 868 MHz 490 MHz 915 MHz

Others 2 pcs USB Cable

4060-PCE10B868

(1 pc)

4362-PRXB868

(1 pc)

4063-PCE20B915

(1 pc)

4362-PRXB915

(1 pc)

4461-PCE14D868

(2 pcs)

2 pcs MSC-WMB93X

2 pcs UPPI-930-RF

Kit user’s guide

4438-PCE20D490

(2pcs)

4463-PCE20C915

(2pcs)

2 Rev. 0.8

Page 3

AN633

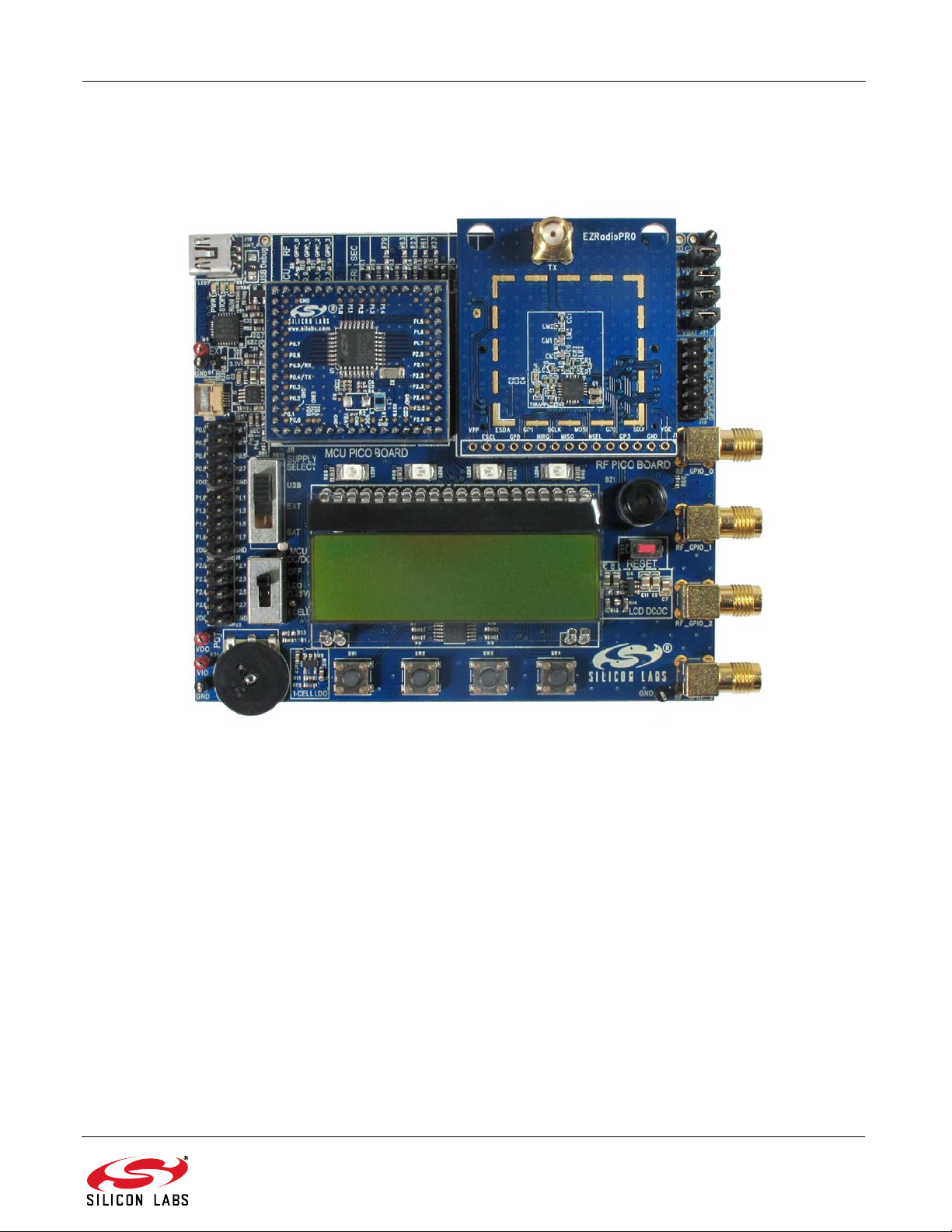

4. The Wireless Motherboard Hardware Platform

The wireless motherboard platform is a demo, evaluation, and development platform for EZRadioPRO radio ICs. It

consists of a wireless motherboard and interchangeable MCU and RF pico boards.

Figure 1. 8-bit Wireless Motherboard Platform

Rev. 0.8 3

Page 4

AN633

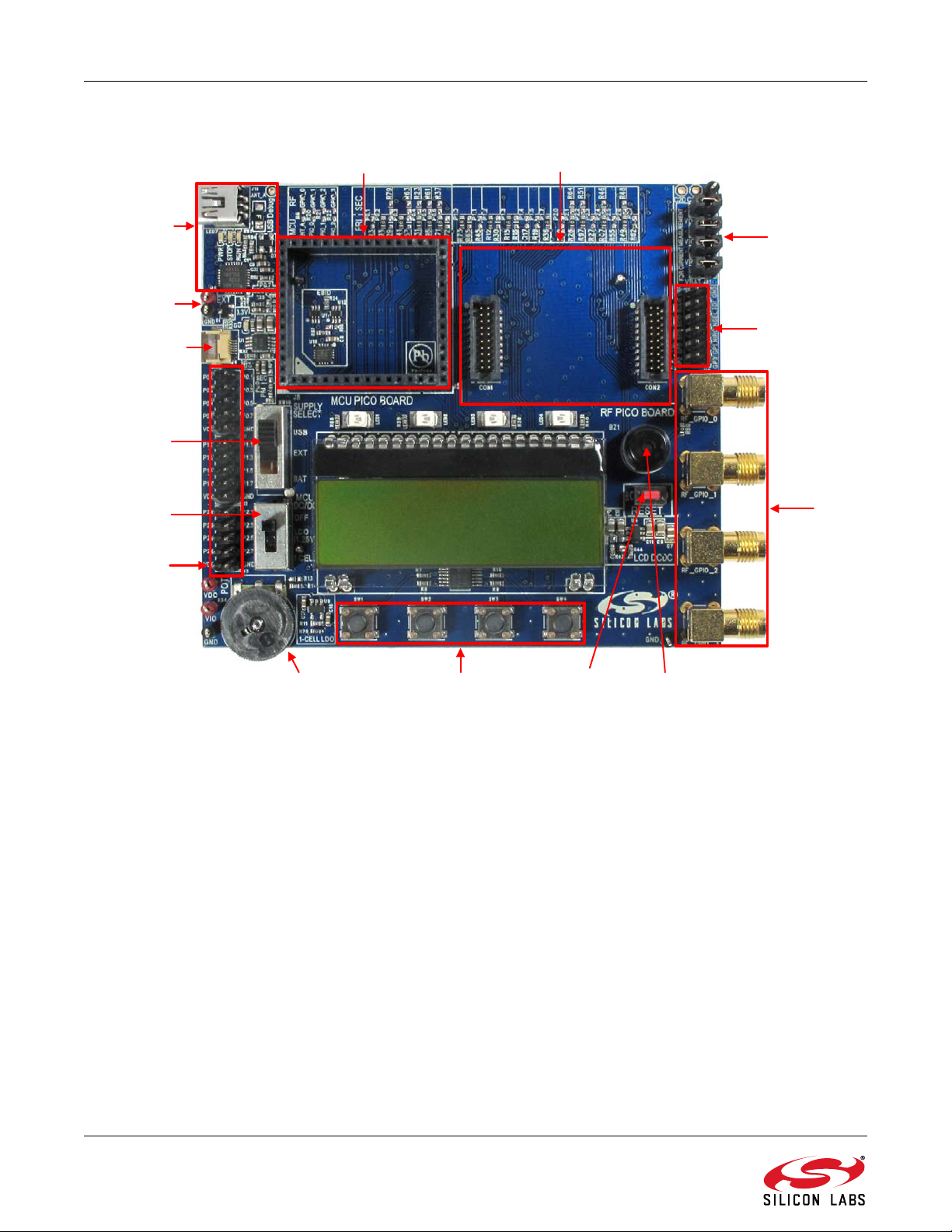

MCU Pico Board RF Pico Board

Current

Measurement

Pins

Radio

Test

Pins

Radio GPIO

Connectors

BuzzerReset ButtonPush ButtonsPotentiometer

MCU DC/DC

Converter

Switch

MCU Test

Pins

Power

Supply

Switch

Sensor

Module

Connector

External

Power

Supply

Connection

USB

Communication

and Debug

Interface

4.1. The Wireless Motherboard

The wireless motherboard contains four pushbuttons, four LEDs, and a buzzer as simple user interfaces. A

graphical LCD displays menu items for range testing purposes and a potentiometer demonstrates analog

capabilities of the MCU. A switch supports the power options of the MCU's built-in dc/dc converter. Using the

current measurement jumpers, current consumption can be measured separately either for the MCU, the radio, or

the peripherals. The motherboard contains test pins for all I/O pins of the MCU and for all digital pins of the radio. In

addition, there are SMA connectors for the GPIOs of the radio for test equipment connection. A USB

communication interface as well as a built-in Silicon Labs USB-to-C2 debug adapter are integrated onto the board

so that the wireless motherboard (WMB) can be directly connected via USB to the PC for downloading and

debugging code on the MCU.

An interface connection towards sensor modules can also be found. The MCU is also connected to the RF pico

board through a connector pair.

Figure 2. Wireless Motherboard

4 Rev. 0.8

Page 5

AN633

4.2. Power Scheme

The power source of the platform can be selected with the power supply selector switch “SUPPLY SELECT” on the

WMB board. If this switch is in the “USB” position, supply voltage is provided by the PC that is connected to the

“J16” mini USB connector. If this switch is in the “BAT” position, the supply voltage is provided by two AA batteries

in the battery holder on the bottom side of the board. If the “SUPPLY SELECT” switch is in the “EXT” position,

supply voltage is provided by an external power source through the “TP7” and “TP9” points.

Using the “MCU dc/dc” switch, the internal dc/dc converter of the C88051F930 MCU on the MCU pico board can

be activated if the connected pico board supports this function. If the switch is in the “OFF” position, the MCU's

dc/dc converter is inactive and the supply voltage is only determined by the state of the “SUPPLY SELECT” switch.

Positioning the switch to either the “LDO (1.25 V)” or “1 CELL” position will turn on the MCU's dc/dc converter by

connecting 1.25–1.5 V supply voltage to the VBAT pin and removing external power from the VDC pin. The MCU

will provide 1.9 V in default setting on its VDC pin to all the other connected loads. Since this current is limited, it

may be necessary to disconnect or disable some loading part of the board. For further details, see the MCU data

sheet and the board schematic. The board schematic can be found in the EZRadioPRO Development Kit User's

Guide. A complete CAD design pack of the board is also available at www.silabs.com.

4.3. RF Pico Board

Figure 3. RF Pico Board Front Side

The RF pico board is a radio module that contains an EZRadioPRO radio IC, matching network and an SMA

connector on the top side. These components apart from the antenna connector are covered by a metal shield for

noise reduction. The digital signals of the radio (SCLK, SDI, SDO, NSEL, SCL, SDA, VDD and GND) can be

accessed on test points at the edge of the board. The boards also have a factory loaded board identification

memory (EBID) on the bottom side that contains data that describes the board properties. Via the unified RF pico

connector pair on the bottom side of the board, any RF pico board can be connected to the WMB.

Rev. 0.8 5

Page 6

AN633

Si446x, Si4362, Si406x, Si4438 WMB C8051F930

Table 2. Connections between the WMB Board and the RF Pico Board

Pin Number Pin Name Pin Function RF Pico board J1

connector

EP,18 GND Ground 2 1,2,19,20 GND

8 VDD Voltage Supply input 1 17,18 VDD

11 NIRQ Interrupt output

active low

1 SDN Shutdown input

active high

15 NSEL SPI select input 6 6 P1.4

12 SCLK SPI clock input 9 5 P1.0

14 SDI SPI data input 7 3 P1.2

13 SDO SPI data output 8 4 P1.1

9 GPIO_0 General Purpose I/O 12 11 P2.6 (2nd)

10 GPIO_1 General Purpose I/O 11 12 P1.3

19 GPIO_2 General Purpose I/O 5 13 P2.5

20 GPIO_3 General Purpose I/O 4 14 P2.4

10 7 P0.1

38P2.3

WMB Con2

connector

Pin Name

6 Rev. 0.8

Page 7

AN633

A schematic of an RF Pico Board can be found in the EZRadioPRO Development Kit User's Guide. A complete

CAD design pack of all boards is also available at www.silabs.com.

4.4. Setting up and Connecting the WMB to the PC

Steps for connecting the platform to the PC:

1. Connect an RF Pico Board to the WMB board through the CON1 and CON2 connectors.

2. Insert a UPPI-930-RF MCU pico board in the connectors J5, J6, J7, J8 on the WMB. The dotted corner of

the C8051F930 MCU has to point to the triangle symbol on the WMB.

3. Connect an antenna to the SMA connector on the RF Pico Board.

4. Select the desired power source with the SUPPLY SELECT switch.

5. Ensure that all the CURRENT MEASUREMENT jumpers are in place.

6. Connect the WMB board to a USB port of the PC.

7. Wait for Windows to install the driver of the debug interface if necessary.

Rev. 0.8 7

Page 8

AN633

5. Software Development Tools

5.1. Wireless Development Suite

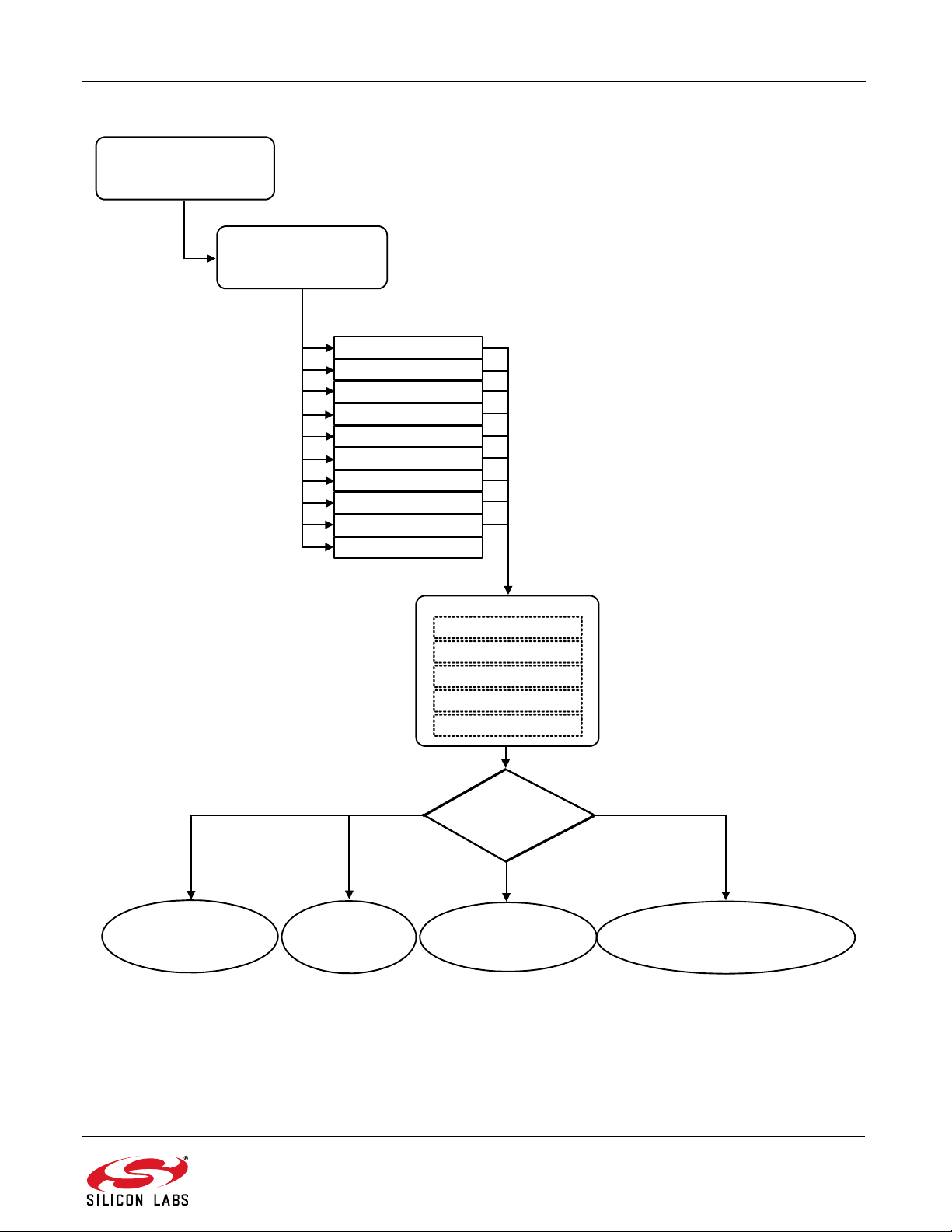

Silicon Labs provides two software tools to help with EZRadioPRO software development: the wireless

development suite (WDS) and the Silicon Labs integrated development environment (IDE). Both software tools are

available at www.silabs.com. The recommended starting point for Si406x, Si4362, Si446x, and Si4438

development is the WDS software tool. After connecting one of the hardware platforms to the PC, WDS is able to

identify the connected boards by reading the EBID memories of the boards. The EZConfigPRO Setup GUI is part

of the WDS program. This setup interface provides an easy path to quickly selecting and loading the desired

configuration for the Si406x, Si4362, Si446x, and Si4438 device. The EZConfigPRO Setup allows four different

methods for device setup. After the desired configuration is selected, the program gives the option to configure

directly the EZRadioPRO chip of the connected hardware, or to modify a selected example code with the

configuration and download it to the connected hardware. It is possible to export and save the example projects

and radio configuration file (radio_config.h) from the WDS. Using the header file generated by the WDS is highly

recommended. Manual editing in the header file may cause problems and prevent the radio from working correctly.

For more complete information on WDS and EZConfigPRO usage, refer to the WDS User's Guide. Figure 4 is a

summary of the WDS configuration workflow.

8 Rev. 0.8

Page 9

AN633

Unmodulated Carrier

Pseudo Random Transmission

Direct Transmission (sync)

Direct Reception (sync/async)

Standard Packet Transmission

Standard Packet Transmission

Standard Packet Reception

Custom Packet Transmission

Custom Packet Reception

Empty Project

Select active project

Open

Radio Configuration Application

in WDS

Frequency and Power

RF Parameters

Packet

Interrupt

GPIO, Fast Response Registers

Configure Active Project

Select Action

Save batch file

to use with Register Setting

Panel

Configure

and Evaluate

Setup

Download customized project

to the device

Generate project source

1. Deploy Silabs IDE project

2. Preview RF configuration header file

3. Save RF configuration header file

For more details about the selectable actions, refer to the WDS User Guide for EZRadioPRO devices.

Figure 4. Device Configuration Options

Rev. 0.8 9

Page 10

AN633

5.2. Silicon Labs IDE

The Silicon Laboratories integrated development environment (IDE) is a standard tool for program development for

any Silicon Labs 8-bit MCUs, including the C8051F930 that is used on the hardware platforms described in this

document. The Silicon Laboratories IDE integrates a project manager, a source-code editor, source-level

debugger, and an in-system flash programmer. The IDE interfaces to third party development tool chains to provide

system designers a complete embedded software development environment. The Keil Demonstration Toolset

includes a compiler, linker, and assembler and easily integrates into the IDE.

Workflow for downloading and running a project:

1. Connect the hardware platform to the PC according to the description of the used platform.

2. Start Silicon Labs IDE (IDE 4.40 or higher required) on your computer.

3. Select ProjectOpen Project... to open a previously saved project.

4. Before connecting to the target device, several connection options may need to be set. Open the

Connection Options window by selecting OptionsConnection Options... in the IDE menu.

5. Select USB Debug Adapter in the "Serial Adapter" section.

6. If more than one adapter is connected, choose the appropriate serial number from the drop-down list.

7. Check “Power target after disconnect" if the target board is currently being powered by the USB Debug

Adapter. The board will remain powered after a software disconnect by the IDE.

8. Next, the correct "Debug Interface" must be selected. Check the C2 Debug Interface.

9. Once all the selections are made, click the OK button to close the window.

10. Click the Connect button in the toolbar or select DebugConnect from the menu to connect to the MCU

of the platform.

11. Erase the flash of the MCU in the DebugDownload object codeErase all code space menu item.

12. Download the desired HEX file either by hitting the Download code (Alt+D) toolbar button or from the

DebugDownload object code menu item.

13. Hit the Disconnect toolbar button or invoke the DebugDisconnect menu item to release the device

from halt and to let it run.

5.3. Toolstick Terminal

The ToolStick Terminal program provides the standard terminal interface to the target microcontroller’s UART.

However, instead of requiring the usual RS-232 and COM port connection, ToolStick Terminal uses the USB

interface of the ToolStick Base Adapter to provide the same functionality. The firmware on the target microcontroller

does not need to be customized to sue the UART and communicate with ToolStick Terminal. The firmware on the

microcontroller should write to the UART as it would in any standard application and all of the translation is handled

by the ToolStick Base Adapter. The ToolStick Base Adapter is integrated on the WMB and is also part of the

RFStick platform as a separate device.

The ToolStick Terminal program is part of the Silicon Labs IDE and is also available as a separate application. Both

can be installed as part of the Silicon Labs 8-bit Microcontroller Studio from

http://www.silabs.com/products/mcu/Pages/8-bit-microcontroller-software.aspx.

The IDE and its built-in Toolstick Terminal can communicate with the target MCU simultaneously on the C2

interface and on the UART respectively.

To u s e t he Too lS ti c k Te rm i na l i n the IDE (above v4.60.00) follow these steps:

1. Open the Silabs IDE from the Start Programs Silicon Laboratories menu.

2. Go to the Options Connection Options menu and select the desired ToolStick Base Adapter from the

drop down list.

3. Click on the Connect button to connect the IDE to the target MCU via the C2 interface.

4. From the Tools menu start the ToolStick Terminal. In the top left-hand corner of the Terminal application, go

to the ToolStick Settings menu and set the communications parameters. Now the ToolStick Te rm i na l i s

ready for use. In the Receive Data window, text indicating the received characters will appear.

10 Rev. 0.8

Page 11

AN633

In addition to the standard two UART pins (TX and RX), there are two GPIO/UART handshaking pins on the

ToolStick Base Adapter. On both the WMB and RFStick platforms GPIO0 is used for the internal purpose of the

WDS to select between the C2 interface of the target MCU and the EBID MCU. GPIO1 is not connected. Although

the separate ToolStick Terminal application provides the functionality to control these GPIOs, default settings for

GPIO0 should not be changed.

5.4. Prerequisites for Code Development

All the sample projects have a unified structure and common driver set. This section provides a brief introduction of

the structure of the example software projects. The settings in the sample project files assume that some Silicon

Labs or third party software tools are already installed on the PC where the sample project is going to be compiled.

The tools that need to be installed depends on the functionality to be used. The following list contains a complete

set of such programs:

Silicon Laboratories IDE—Used to open the preconfigured project files and manage the build process.

Keil C51 v9.0+ or SDCC v3.0+—Compilers to use with the Silicon Laboratories IDE to manage build

process.

Silicon Labs Flash Programming Utility (optional)—Needed only if programming outside the Silicon Labs

IDE is necessary.

Make (optional)—This tool is needed in case another compiler is used or the build process takes place

outside of the SiLabs IDE. "Makefile" can be generated with the wsp2make.exe utility. It is only

recommended for advanced users since it may need manual editing.

5.5. Supported Compilers

The projects come with one Silicon Labs IDE project file which is prepared to use the Keil C51 toolchain. An

evaluation version of the Keil toolchain can be downloaded from the Keil website at http://www.keil.com. The Keil

free evaluation version can be unlocked to become a full version with no code placement limitation. Visit the Silicon

Labs website at http://www.silabs.com/products/mcu/Pages/8-bit-microcontroller-software.aspx#keil-pk51 to get

the full license. The project files in examples assume that the Keil tool chain is installed to the C:\Keil directory. The

location of the Keil tool chain can be easily changed in the Silabs IDE in the Project Tool Chain Integration menu.

However, the sample projects can be complied not only with the two mentioned compilers, but with almost any

ANSI C compiler for 8051 architecture with little or no modifications. Each project already contains a "Makefile" in

order to provide an easy and convenient way to compile the code outside the Silicon Labs IDE with the tool chain

of choice. Each sample project described in this document contains a compiled version of the source code in Intel

hex format that is widely supported by a variety of programming and debugging tools. The compiled file in the

projects has been generated using the Silicon Labs IDE and the Keil C51 tool chain. AN104: Integrating Keil 8051

Tools into the Silicon Labs IDE covers toolchain integration and license management in more detail.

Rev. 0.8 11

Page 12

AN633

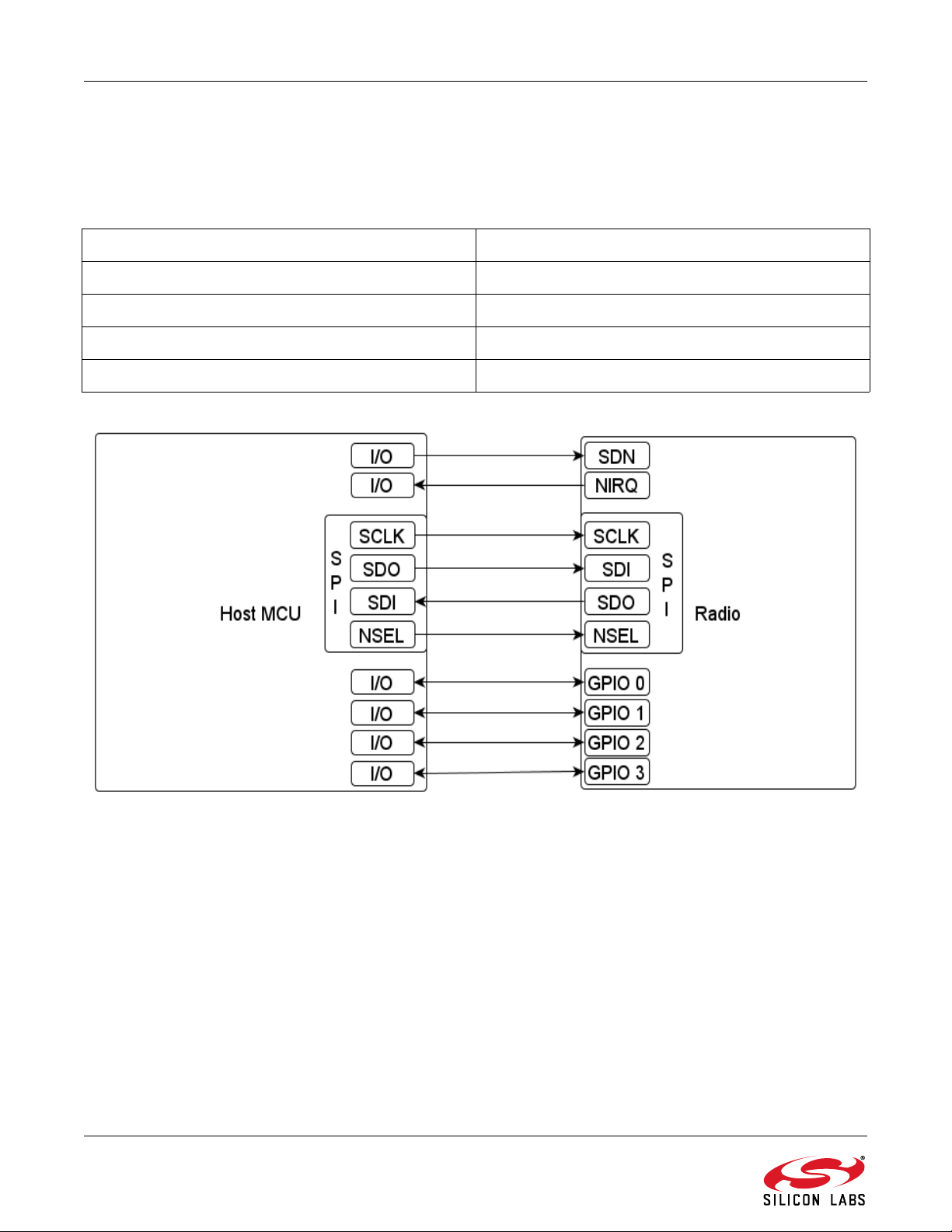

6. Radio Hardware Interface

The EZRadioPRO devices can be controlled by the host MCU over an SPI bus and six additional signals. The user

has access to the radio's API via the SPI bus.

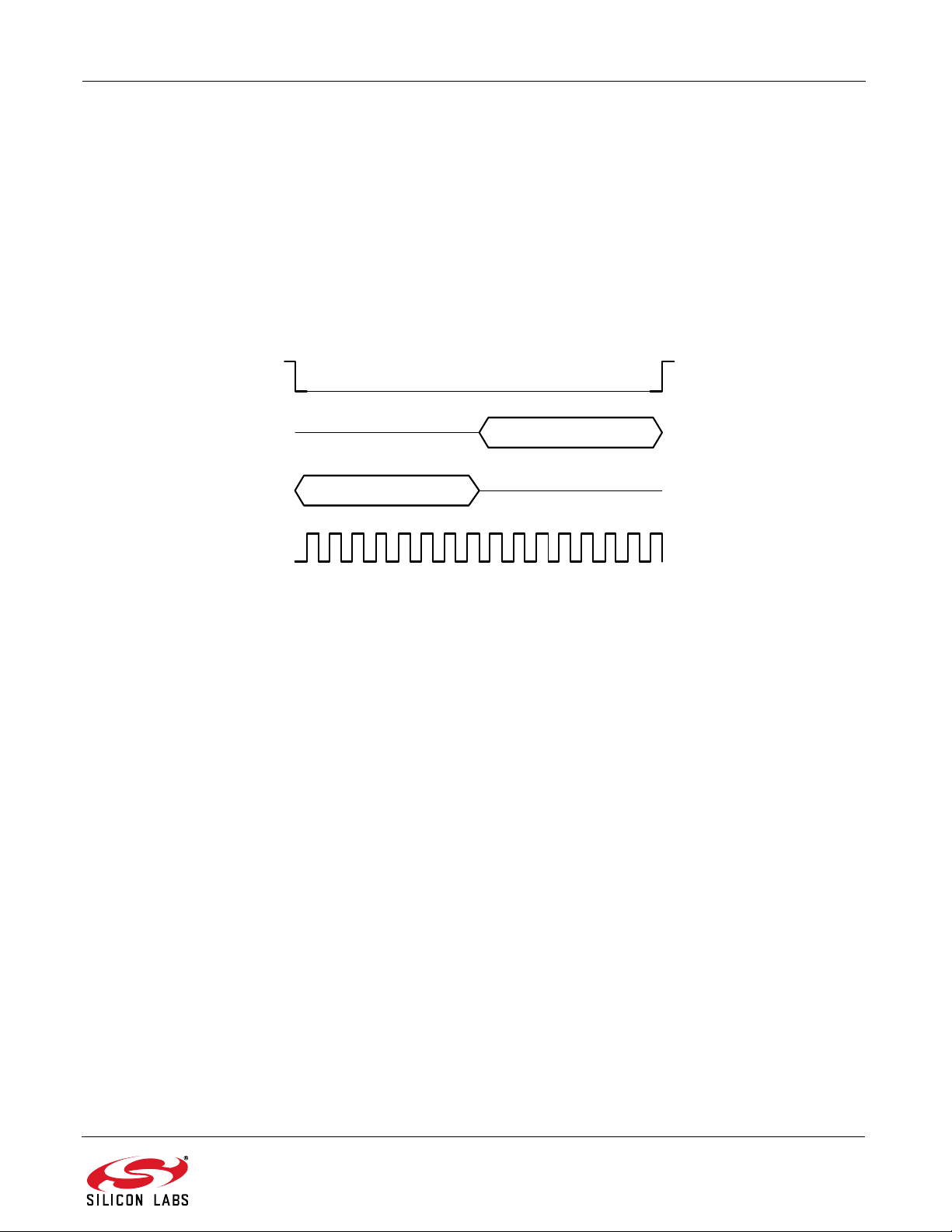

Table 3. Serial Peripheral Interface Signals

Signal Description

SCLK serial clock output from master

SDI master output, slave input

SDO master input, slave output

NSEL slave select, active low

Figure 5. Connections between the Host MCU and the Radio

The high state of the shutdown (SDN) pin is used to completely disable the radio and put the device into the lowest

power consumption state. The radio has an interrupt output pin (NIRQ) which can be used to promptly notify the

host MCU of multiple events. The NIRQ pin is active low, and goes back to high if the pending interrupt flag is

cleared by reading the appropriate interrupt pending registers.

12 Rev. 0.8

Page 13

AN633

7. Application Programming Interface

The programming interface allows the user to do the following:

Send commands to the radio.

Read status information.

Set and get radio parameters.

Handle the Transmit and Receive FIFOs.

The API commands are listed in Table 4. The following sections describe the SPI transactions of sending

commands and getting information from the chip.

Table 4. Command Summary

Command ID Name Description

BOOT_COMMANDS

0x02 POWER_UP Command to power-up the device and select the operational

mode and functionality.

COMMON_COMMANDS

0x00 NOP No operation command.

0x01 PART_INFO Reports basic information about the device.

0x10 FUNC_INFO Returns the Function revision information of the device.

0x11 SET_PROPERTY Sets the value of one or more properties.

0x12 GET_PROPERTY Retrieves the value of one or more properties.

0x13 GPIO_PIN_CFG Configures the GPIO pins.

0x15 FIFO_INFO Access the current byte counts in the TX and RX FIFOs and pro-

vide for resetting the FIFOs.

0x20 GET_INT_STATUS Returns the interrupt status of ALL the possible interrupt events

(both STATUS and PENDING). Optionally, it may be used to

clear latched (PENDING) interrupt events.

0x33 REQUEST_DEVICE_STATE Request current device state and channel.

0x34 CHANGE_STATE Manually switch the chip to a desired operating state.

0x38 OFFLINE_RECAL Recalibrates due to temperature change.

0x44 READ_CMD_BUFF Used to read CTS and the command response.

0x50 FRR_A_READ Reads the fast response registers (FRR) starting with FRR_A.

0x51 FRR_B_READ Reads the fast response registers (FRR) starting with FRR_B.

0x53 FRR_C_READ Reads the fast response registers (FRR) starting with FRR_C.

0x57 FRR_D_READ Reads the fast response registers (FRR) starting with FRR_D.

Rev. 0.8 13

Page 14

AN633

Table 4. Command Summary (Continued)

Command ID Name Description

IR_CAL_COMMANDS

0x17 IRCAL Image rejection calibration.

0x19 IRCAL_MANUAL Image rejection calibration.

TX_COMMANDS

0x31 START_TX Switches to TX state and starts transmission of a packet.

0x37 TX_HOP Hop to a new frequency while in TX.

0x66 WRITE_TX_FIFO Writes data byte(s) to the TX FIFO.

RX_COMMANDS

0x16 PACKET_INFO Returns information about the length of the variable field in the

last packet received and (optionally) overrides field length.

0x22 GET_MODEM_STATUS Returns the interrupt status of the Modem Interrupt Group (both

STATUS and PENDING). Optionally, it may be used to clear

latched (PENDING) interrupt events.

0x32 START_RX Switches to RX state and starts reception of a packet.

0x36 RX_HOP Manually hop to a new frequency while in RX mode.

0x77 READ_RX_FIFO Reads data byte(s) from the RX FIFO.

ADVANCED_COMMANDS

0x14 GET_ADC_READING Performs conversions using the Auxiliary ADC and returns the

results of those conversions.

0x21 GET_PH_STATUS Returns the interrupt status of the Packet Handler Interrupt

Group (both STATUS and PENDING). Optionally, it may be

used to clear latched (PENDING) interrupt events.

0x23 GET_CHIP_STATUS Returns the interrupt status of the Chip Interrupt Group (both

STATUS and PENDING). Optionally, it may be used to clear

latched (PENDING) interrupt events.

The following sections describe the SPI transactions of sending commands and getting information from the chip.

7.1. Sending Command to Radio

The behavior of the radio can be changed by sending API commands to the radio (e.g., changing the power states,

start packet transmission, etc.). The radio can be configured through several so called "properties". The properties

hold radio configuration settings, such as interrupt settings, modem parameters, packet handler settings, etc. The

properties can be set and read via API commands. For most of the commands the host MCU does not expect any

response from the radio chip. Other commands are used to read back a property from the chip such as checking

the interrupt status flags, reading the transmit/receive FIFOs.

After the radio receives a command, it processes the request. During this time, the radio is not capable of receiving

a new command. The host MCU has to poll the radio and identify when the next command can be sent. The clear

14 Rev. 0.8

Page 15

AN633

0x44

NSEL

SDO

SDI

SCK

CT S

to send (CTS) signal shows the actual status of the command buffer of the radio. It can be monitored over the SPI

or on GPIOs, or the chip can generate an interrupt if it is ready to receive the next command. These three options

are detailed below.

7.2. Checking the Radio is Ready to Receive Command

7.2.1. Software Polling Method

To ensure the radio is ready to receive the next command, the host MCU has to pull down the NSEL pin to monitor

the status of CTS over the SPI port. The 0x44 command ID has to be sent and eight clock pulses have to be

generated on the SCLK pin. During the additional eight clock cycles, the radio clocks out the CTS as a byte on the

SDO pin. When completed, the NSEL should be pulled back to high. If the CTS byte is 0xFF, it means that the radio

processed the last command successfully and is ready to receive the next command; in any other case, the CTS

read procedure has to be repeated from the beginning as long as the CTS byte is not 0xFF.

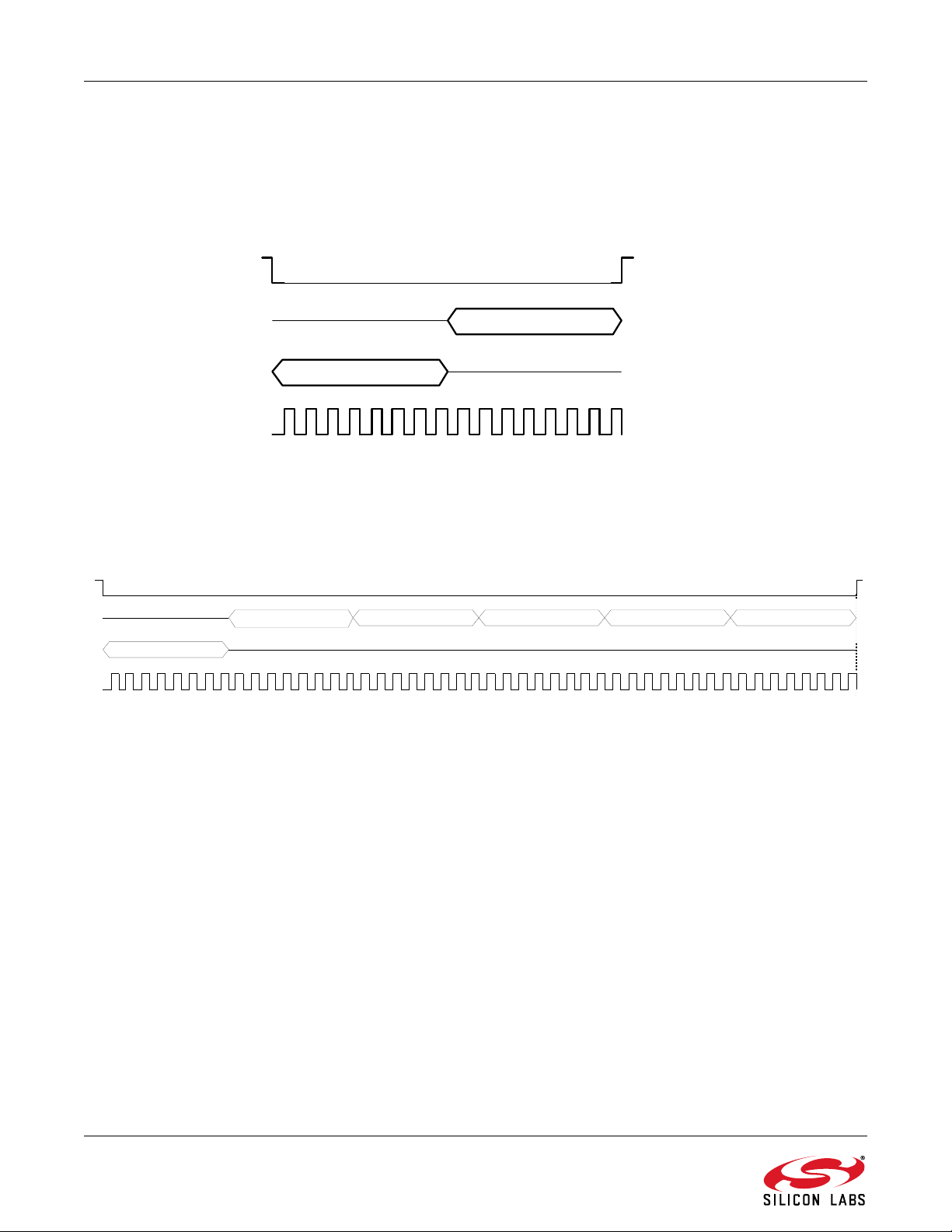

Figure 6. Polling the Radio Availability

Rev. 0.8 15

Page 16

AN633

Sen d Command Read CTS

Re tri eve

Response

CT S V alue

Not

0xFF

0xFF

7.2.2. GPIO Checking Method

Any GPIO can be configured for monitoring the CTS. GPIOs can be configured to go either high or low when the

chip has completed the command. The function of the GPIOs can be changed by the GPIO_PIN_CFG command.

By default, GPIO1 is set as "High when command completed, low otherwise" after Power On Reset. Therefore, this

pin can be used for monitoring the CTS right after Power On Reset to know when the chip is ready to boot up.

7.2.3. NIRQ Interrupt Checking Method

The radio asserts the CHIP_READY interrupt flag if a command is completed. The interrupt flag can be monitored

by either the GET_CHIP_STATUS or the GET_INT_STATUS command. Apart from monitoring the interrupt flags,

the radio may pull down the NIRQ pin if this feature is enabled. If a new command is sent while the CTS is

asserted, then the radio ignores the new command. The Si446x can generate an interrupt to communicate this

error to the MCU by the CMD_ERROR interrupt flag in the CHIP_STATUS group. The interrupt flag has to be read

(by issuing a GET_CHIP_STATUS or GET_INTERRUPT_STATUS command) to clear the pending interrupt and

release the NIRQ pin. No other action is needed to reset the command buffer of the radio, but, after a

CMD_ERROR, the host MCU should repeat the new command after the radio has processed the previous one.

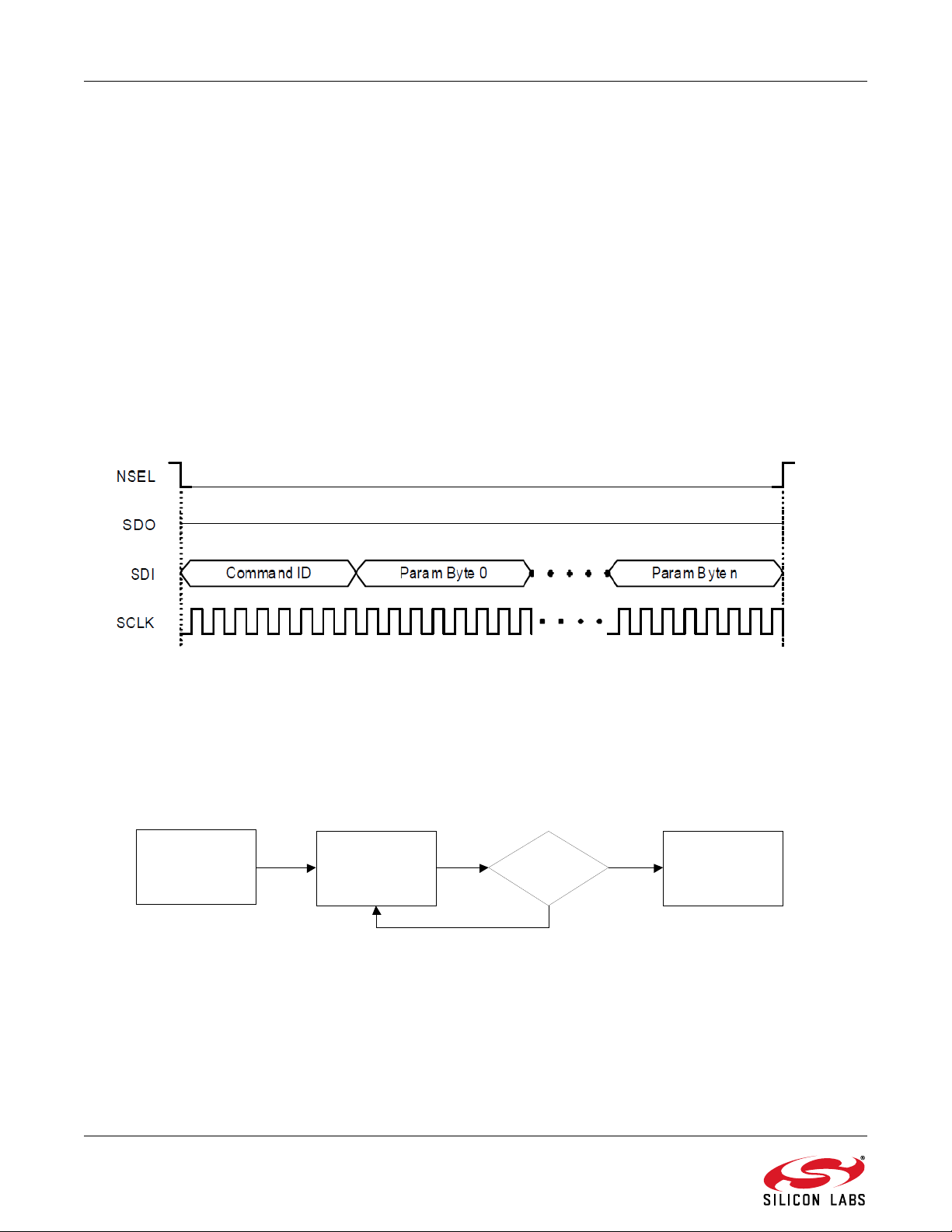

All the commands that are sent to the radio have the same structure. After pulling down the NSEL pin of the radio,

the command ID should be sent first. The commands may have up to 15 input parameters.

Figure 7. Host MCU Sends Command to Radio

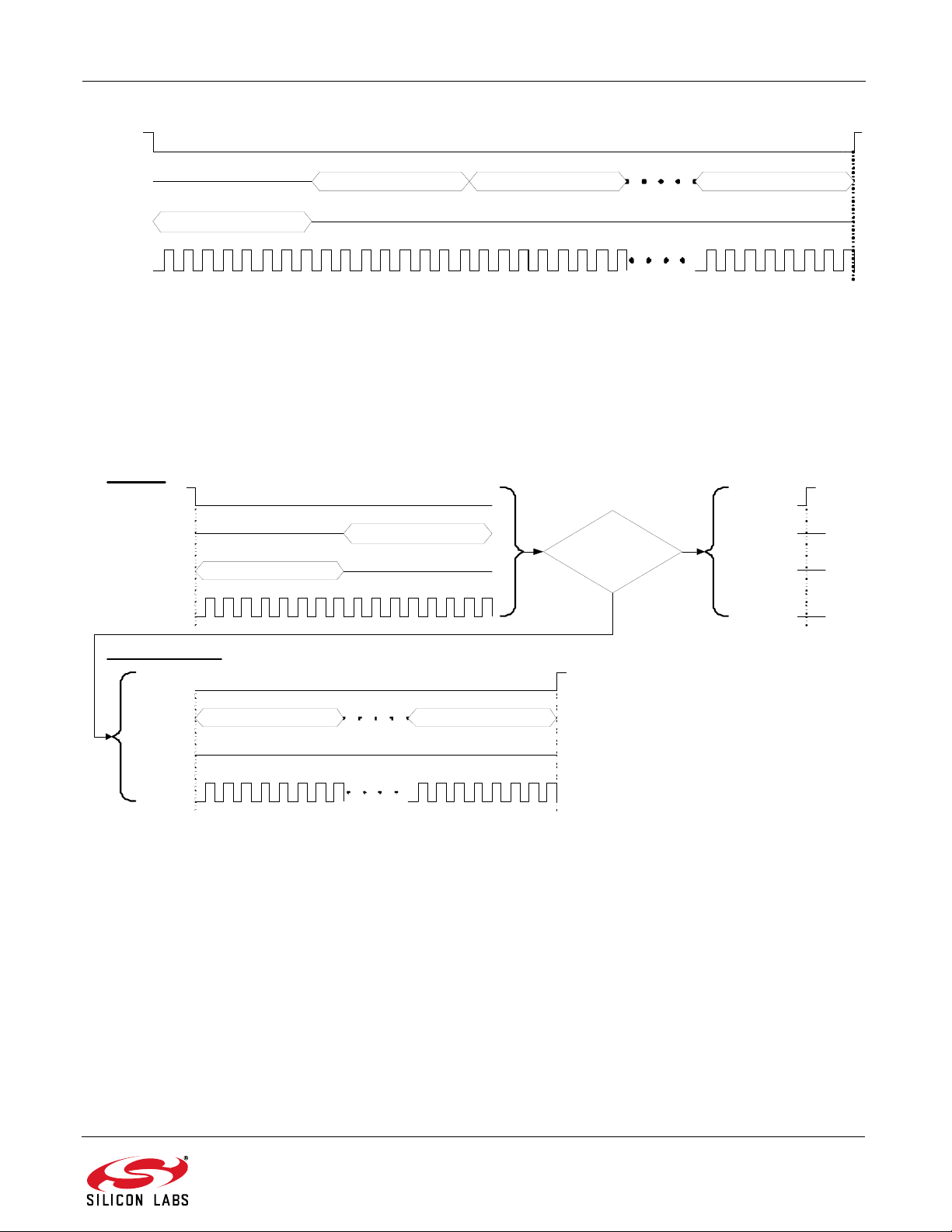

7.3. Getting Response to a Command from the Radio

Reading from the radio requires several steps to be followed. The host MCU should send a command with the

address it requests to read. The radio holds the CTS while it retrieves the requested information. Once the CTS is

set (0xFF), the host MCU can read the answer from the radio.

Figure 8. Read Procedure

If the CTS is polled on the GPIOs, or the radio is configured to provide interrupt if the answer is available, then the

response can be read out from the radio with the following SPI transaction.

16 Rev. 0.8

Page 17

AN633

0x44

NSEL

SDO

SD I

SCLK

CTS = 0xFF Response B yte 0 Re spon se Byte n

0x44

NSEL

SDO

SDI

SCLK

NSEL

SDO

SDI

SCLK

Re ad CTS

Re tr iev ing Re spo nse

CT S

Re spons e By te 0 Resp onse Byte n

CT S V alu e

Not

0xFF

0xF F

NSE L

SDO

SDI

SCLK

Figure 9. Read the Response from Radio

If the CTS is polled over the SPI bus, first the host MCU should pull the NSEL pin low. This action should be

followed by sending out the 0x44 Read command ID and providing an additional eight clock pulses on the SCLK

pin. The radio will provide the CTS byte on its SDO pin during the additional clock pulses. If the CTS byte is 0x00,

then the response is not yet ready and the host MCU should pull up the NSEL pin and repeat the procedure from

the beginning as long as the CTS becomes 0xFF. If CTS is 0xFF, then the host MCU should keep the NSEL pin low

and provide clock cycles on the SCLK pin, as many as the data to be read out requires. The radio will clock out the

requested data on its SDO pin during the additional clock pulses.

Reading the response from the radio can be interrupted earlier. For example, if the host MCU asked for five bytes

of response, it may read fewer bytes in one SPI transaction. As long as a new command is sent, the radio keeps

the response for the last request in the command buffer. The host MCU can read the response several times in a

new SPI transaction. In such a case, the response is always provided from the first byte.

Notes:

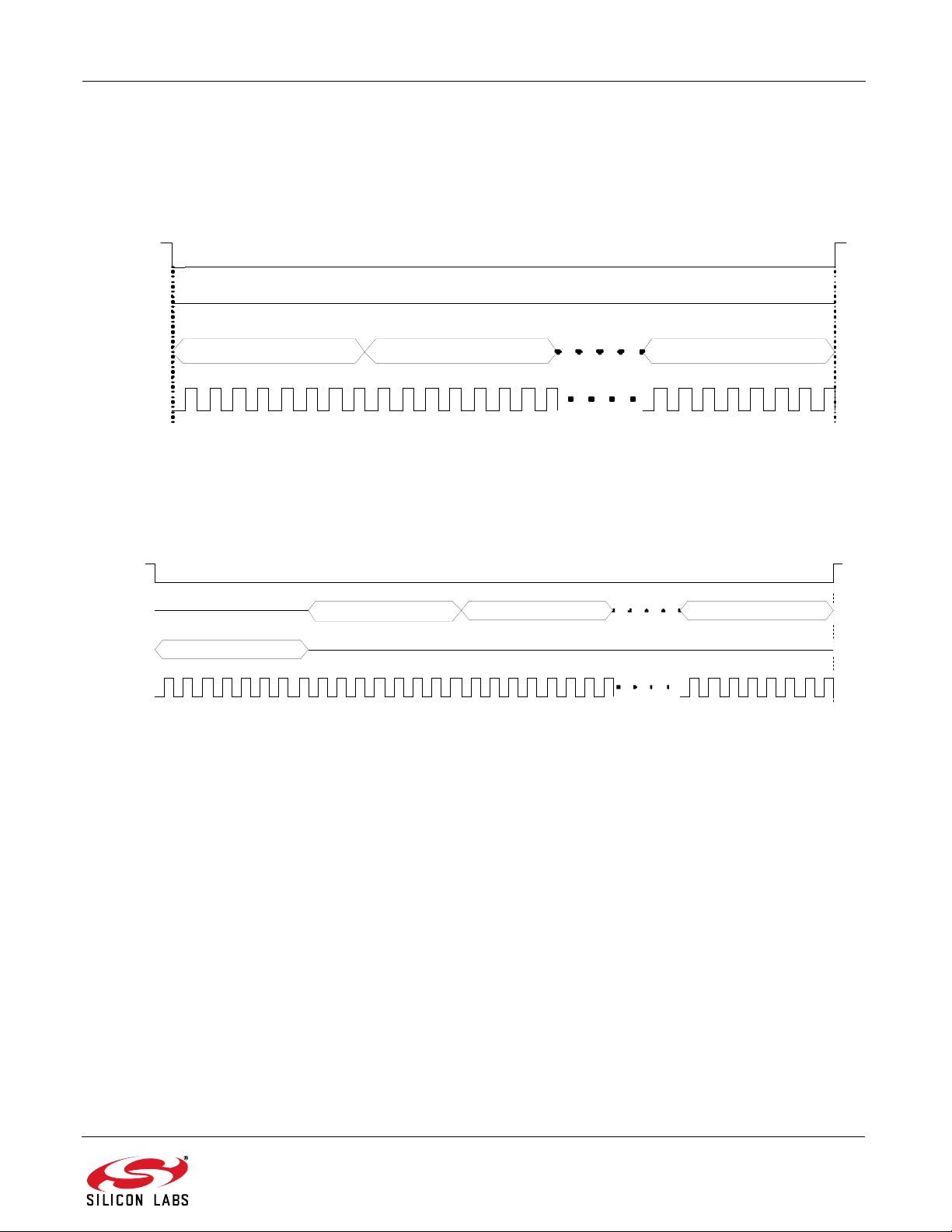

Figure 10. Monitor CTS and Read the Response on the SPI Bus

Up to 16 bytes of response can be read from the radio in one SPI transaction. If more bytes are read, the

radio will provide the same 16 bytes of response in a circular manner.

If the command says that the host MCU expects N bytes of response, but during the read sequence, the

host MCU provides less than N bytes of clock pulses, it causes no issue for the radio. The response buffer

is reset if a new command is issued.

If the command says that the host MCU expects N bytes of response, but during the read sequence, the

host MCU provides more than N bytes of clock pulses, the radio will provide unpredictable bytes after the

first N bytes. The host MCU does not need to reset the SPI interface; it happens automatically if NSEL is

pulled low before the next command is sent.

Rev. 0.8 17

Page 18

AN633

0x51

Fast Response R. B

0x51

Fas t Response R. B Fast Response R. C Fa s t R es po n se R . D Fast Response R. A Fast Response R B

7.4. Using Fast Response Registers

There are several types of status information that can be read out from the radio faster. The FRR_CTL_x_MODE

(where x can be A, B, C or D) properties define what status information is assigned to a given fast response

register (FRR). The actual value of the registers can be read by pulling down the NSEL pin, issuing the proper

command ID, and providing an additional eight clock pulses on the SCLK pin. During these clock pulses, the radio

provides the value of the addressed FRR. The NSEL pin has to be pulled high after finishing the register read.

Figure 11. Reading a Single Fast Response Register

It is also possible to read out multiple FRRs in a single SPI transaction. The NSEL pin has to be pulled low, and

one of the FRRs has to be addressed with the proper command ID. Providing an additional 8 x N clock cycles will

clock out an additional N number of FRRs. After the fourth byte is read, the radio will provide the value of the

registers in a circular manner. The reading stops by pulling the NSEL pin high.

Figure 12. Reading More Fast Response Registers in a Single SPI Transaction

Note: If the pending interrupt status register is read through the FRR, the NIRQ pin does not go back to high. The pending

interrupt registers have to be read by a Get response to a command sequence in order to release the NIRQ pin.

18 Rev. 0.8

Page 19

AN633

0x66 Byte 0 Byte n

NSEL

SDO

SDI

SCLK

0x77

NSEL

SD O

SDI

SCL K

Byte 0 By t e 1 Byte n

7.5. Write and Read the FIFOs

There are two 64-byte FIFOs for RX and TX data in the Si4x6x.

To fill data into the transmit FIFO, the host MCU should pull the NSEL pin low and send the 0x66 Transmit FIFO

Write command ID followed by the bytes to be filled into the FIFO. Finally, the host MCU should pull the NSEL pin

high. Up to 64 bytes can be filled into the FIFO during one SPI transaction.

Figure 13. Transmit FIFO Write

If the host MCU needs to read the receive FIFO, it has to pull the NSEL pin low and send the 0x77 Receive FIFO

Read command ID. The MCU should provide as many clock pulses on the SCLK pin as necessary for the radio to

clock out the requested amount of bytes from the FIFO on the SDO pin. Finally, the host MCU should pull up the

NSEL pin.

Figure 14. Receive FIFO Read

If more than 64 bytes are written into the Transmit FIFO, then a FIFO overflow occurs. If more bytes are read from

the Receive FIFO than it holds, then FIFO underflow occurs. In either of these cases, the

FIFO_UNDERFLOW_OVERFLOW_ERROR interrupt flag will be set. The radio can also generate an interrupt on

the NIRQ pin if this flag is enabled. The interrupt flag has to be read, issuing a GET_CHIP_STATUS or

GET_INTERRUPT_STATUS command, to clear the pending interrupt and release the NIRQ pin.

Rev. 0.8 19

Page 20

AN633

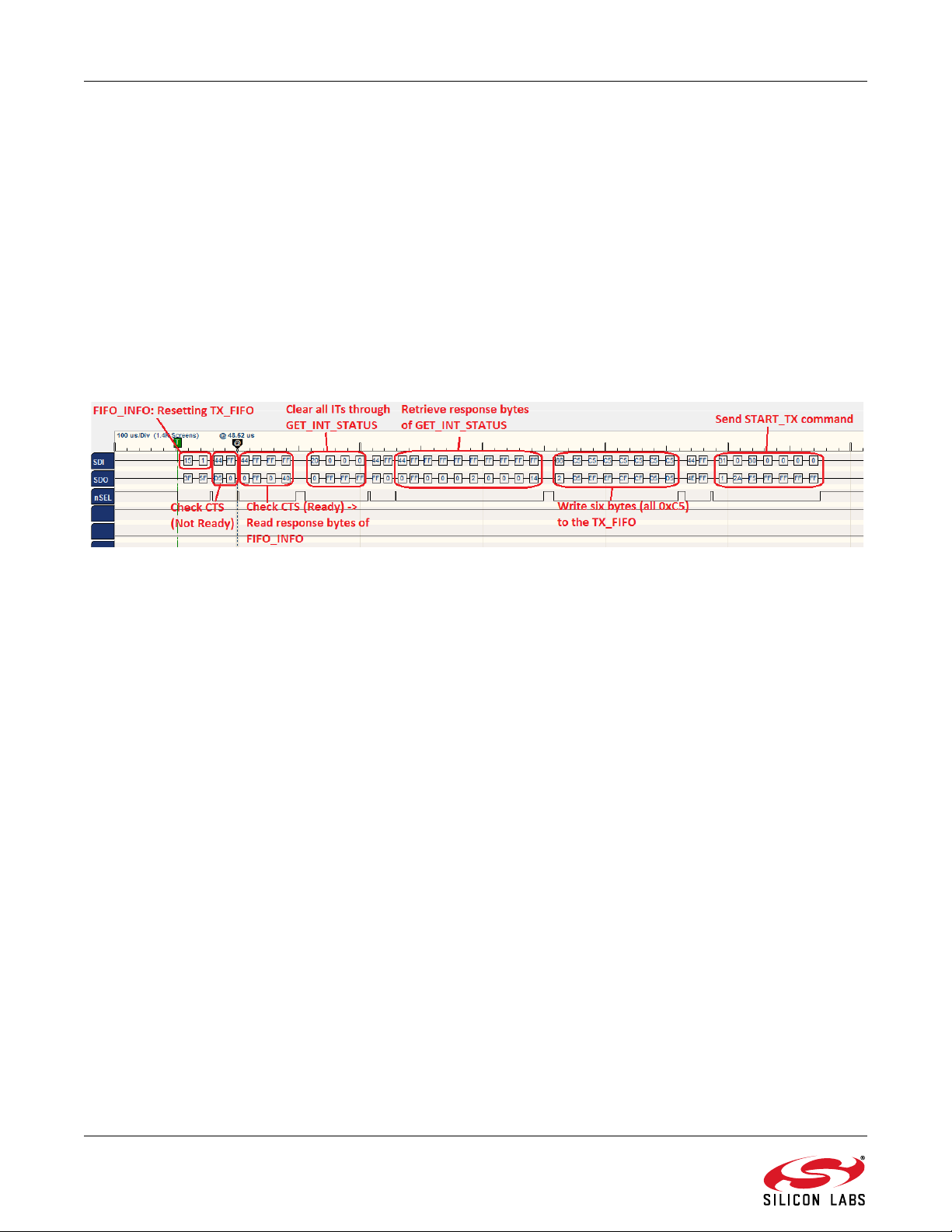

7.6. SPI Communication Capture Example

Figure 15 shows an actual SPI communication capture taken by a logic analyzer. The signals being monitored are

SDI, SDO, and NSEL between the radio IC and the host MCU. The first command being sent is FIFO_INFO

(command ID 0x15) with an input parameter of 0x01, which will reset the TX FIFO. Right after sending the

FIFO_INFO command, the CTS is being monitored (0x44). For the first attempt, it is still busy; the returned value is

NOT 0xFF, so NSEL goes back high. For the second attempt, the CTS value will be 0xFF, meaning that the radio

IC has processed the command (i.e. resetting the TX_FIFO), and it is ready to provide the response bytes of the

FIFO_INFO command. Therefore, NSEL stays low, and two dummy bytes are provided via SDI to read out the two

response bytes through SDO. The response bytes are RX FIFO count and TX FIFO count numbers for the

FIFO_INFO command. The next sequence is sending GET_STATUS command with three input bytes, all zeroes,

to clear all ITs, and then retrieving the response bytes of the command after checking CTS. Once the ITs are

cleared, six bytes are being written to the TX FIFO via WRITE_TX_FIFO command (0x66). Lastly, START_TX

command is being sent to initiate an actual transmission. For more details of the commands described here, please

see the html-based API documentation.

Figure 15. SPI Communications Example

20 Rev. 0.8

Page 21

AN633

8. Radio Initialization

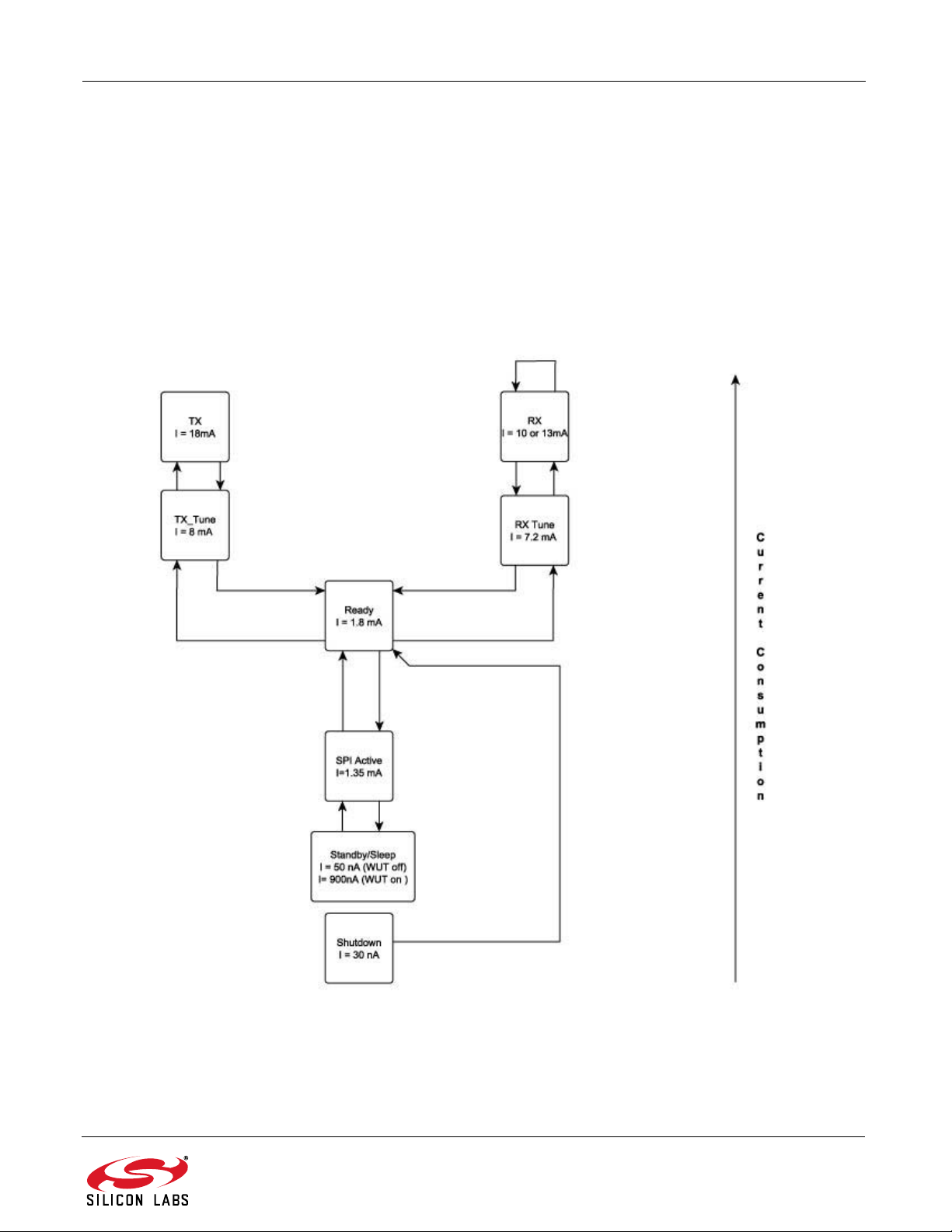

8.1. State Transitions of the EZRadioPRO Devices

Ready state is designed to give a fast transition time to TX or RX state with reasonable current consumption. In this

mode the crystal oscillator remains enabled reducing the time required to switch to TX or RX mode by eliminating

the crystal start-up time. An automatic sequencer will put the chip into RX or TX from any state. It is not necessary

to manually step through the states. Although it is not shown in the diagram, any of the lower power states can be

returned to automatically after RX or TX.

Figure 16. Operational States and Current Consumption

Rev. 0.8 21

Page 22

AN633

Table 5. Switching Times between Radio States

State/Mode Response Time to

TX RX

Shutdown 15ms 15ms

Sleep* 500 µs 500 µs

SPI Active 340 µs 340 µs

Ready 110 µs 120 µs

TX Tune 60 µs 125 µs

RX Tune 120 µs 84 µs

TX 130 µs 132 µs

RX 120 µs 108µs

*Note: While the chip is in sleep state, the NSEL pin has to stay in high state. If the host processor is not able to provide this

during sleep, a pullup resistor can be necessary on the NSEL pin.

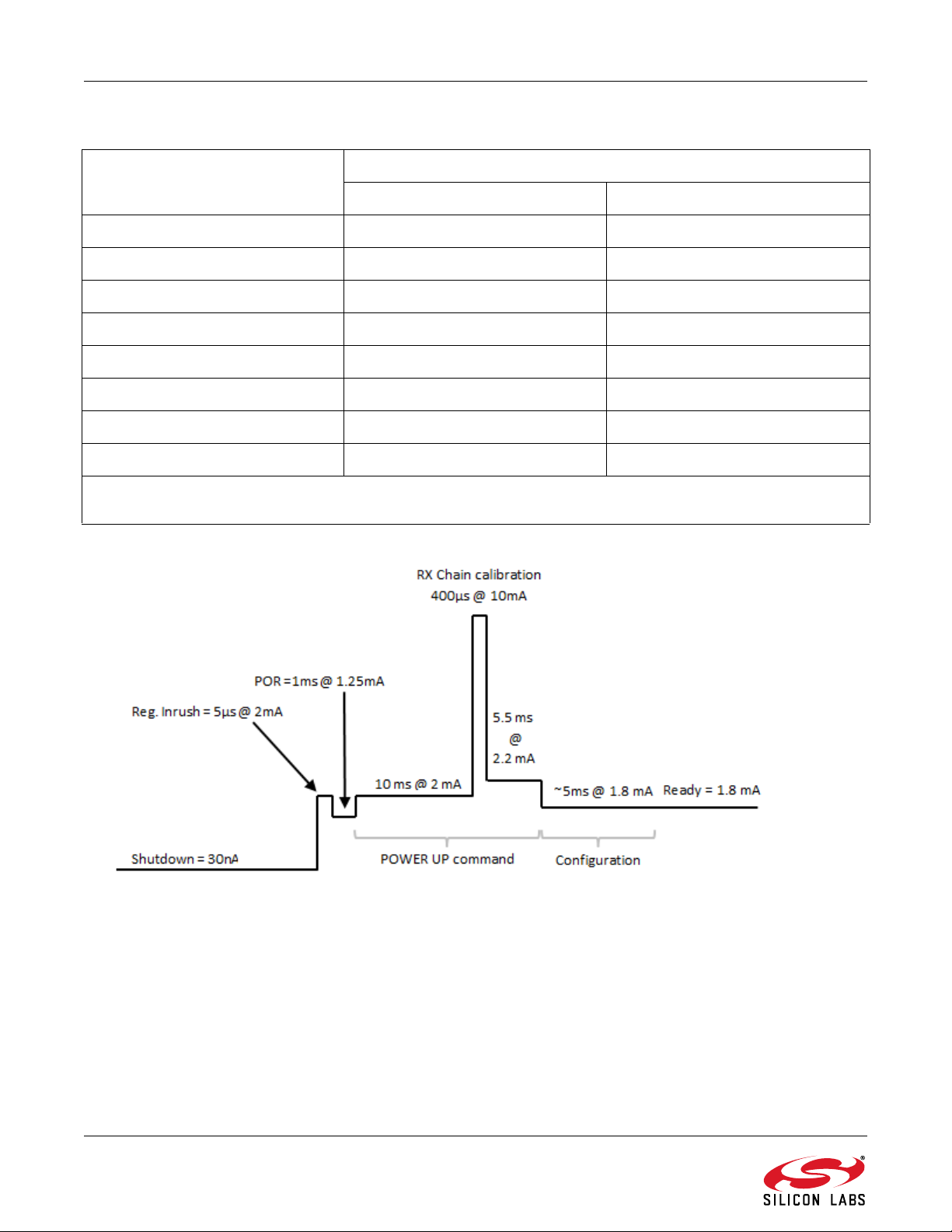

Figure 17. Supply Current versus Time Diagram from Shutdown to RF initialized Ready State

22 Rev. 0.8

Page 23

AN633

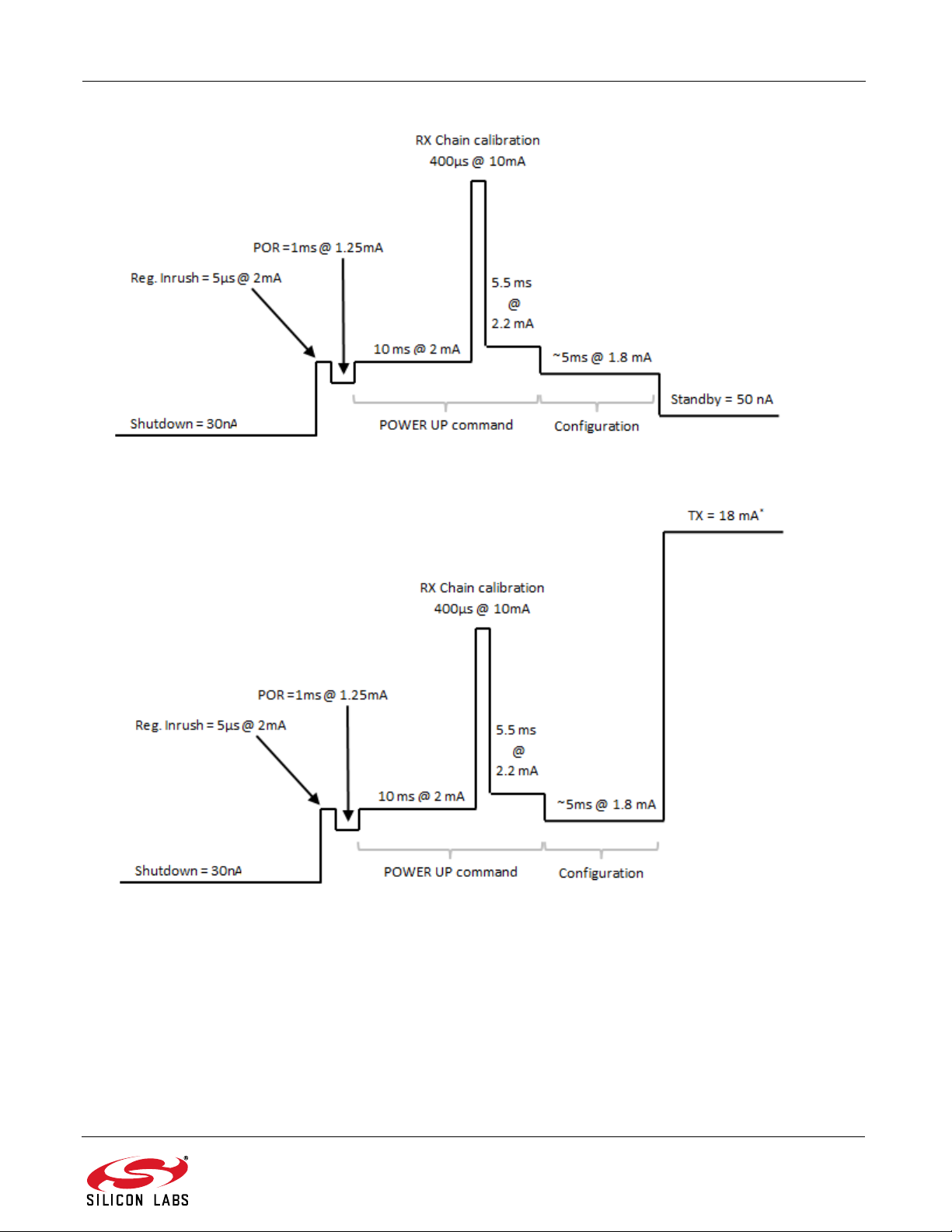

Figure 18. Supply Current versus Time Diagram from Shutdown to Standby State

Figure 19. Supply Current versus Time Diagram from Shutdown to TX State

Rev. 0.8 23

Page 24

AN633

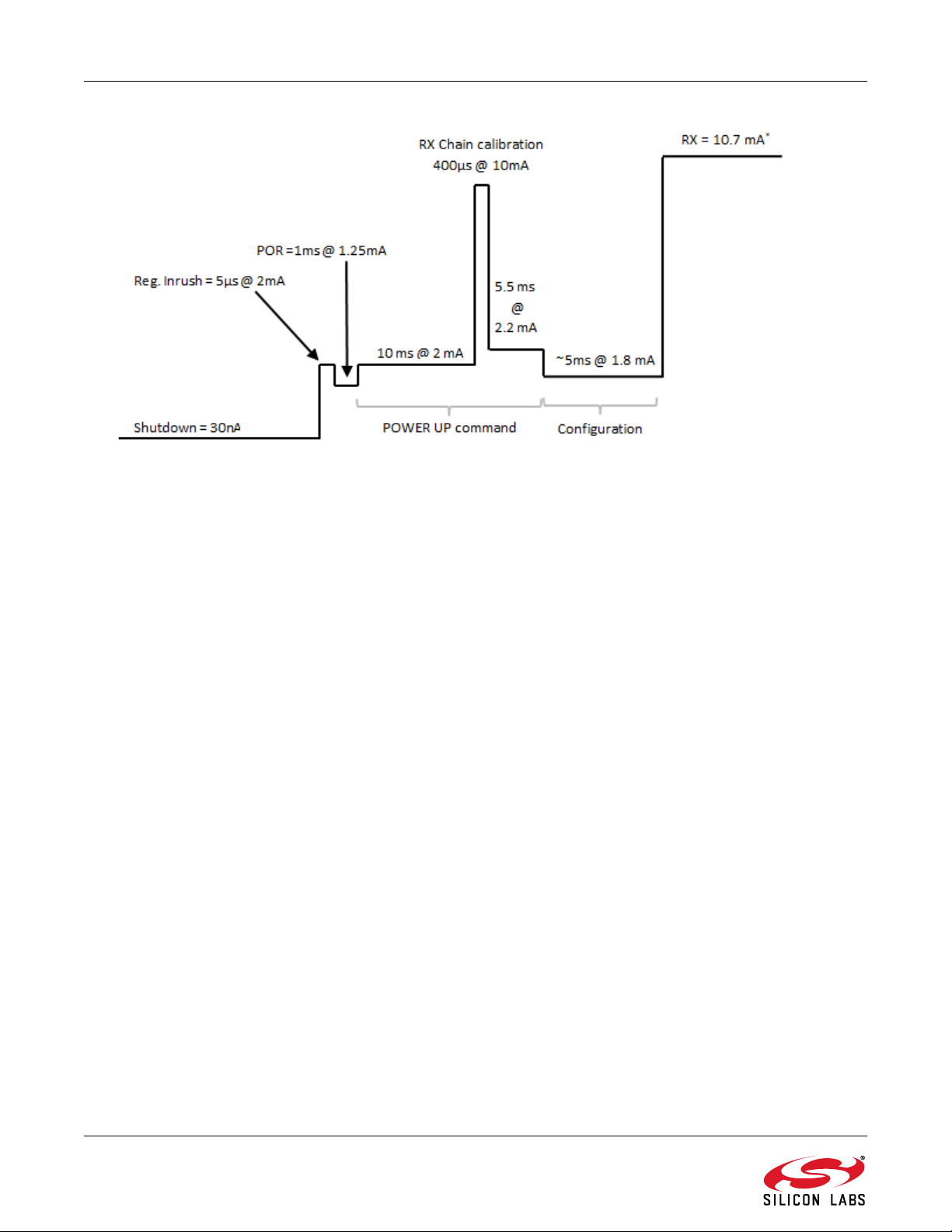

Figure 20. Supply Current versus Time Diagram from Shutdown to RX State

24 Rev. 0.8

Page 25

AN633

Issue POWER_UP

command over SPI

(GPIO1= )

Clear all interrupts

(GPIO1= )

Wait for max. delay of

POR (<6ms)

CTS ready

over SPI?

nIRQ = ?

GPIO1 = ?

N

Y

Optional

Optional

N NN

YY Y

CTS ready

over SPI?

GPIO1 = ?

GPIO1 = ?

Y Y

N N

Optional

Start

2.

Radio Power

On Reset

(POR)

3.

Radio

Boot

1.

Host MCU

Initialization

4.

Radio

Ready

Host MCU applies

SDN pulse

Host MCU

initiates invoking

Radio API

Host MCU clears

Radio interrupts

SDN = 10us

8.2. Radio Chip Waking Up

First, the radio is in the off state. After the SDN pin is pulled low, the radio wakes up and performs a Power on

Reset which takes a maximum of 6 ms (900 µs typical at room temperature) until the chip is ready to receive

commands on the SPI bus. The GPIO1 pin goes high when the radio is ready for receiving SPI commands. During

the reset period, the radio cannot accept any SPI commands. There are two ways to determine if the chip is ready

to receive SPI commands after a reset event. Either use a timer in the host microcontroller to wait or connect the

GPIO1 pin of the radio to the host MCU and poll the status of this pin. During power on reset, it remains low. Once

the reset is finished, the radio sets the GPIO1 to the high state.

Next, the radio device has to be sent to active mode by issuing a "POWER_UP" command via the SPI interface

which takes approximately 15 ms to be completed. It can be monitored in three ways. If the command is completed

either the GPIO1 pin of the radio goes low by issuing the command and the radio sets it to high state or the NIRQ

pin is asserted or the host MCU can monitor CTS over the SPI.

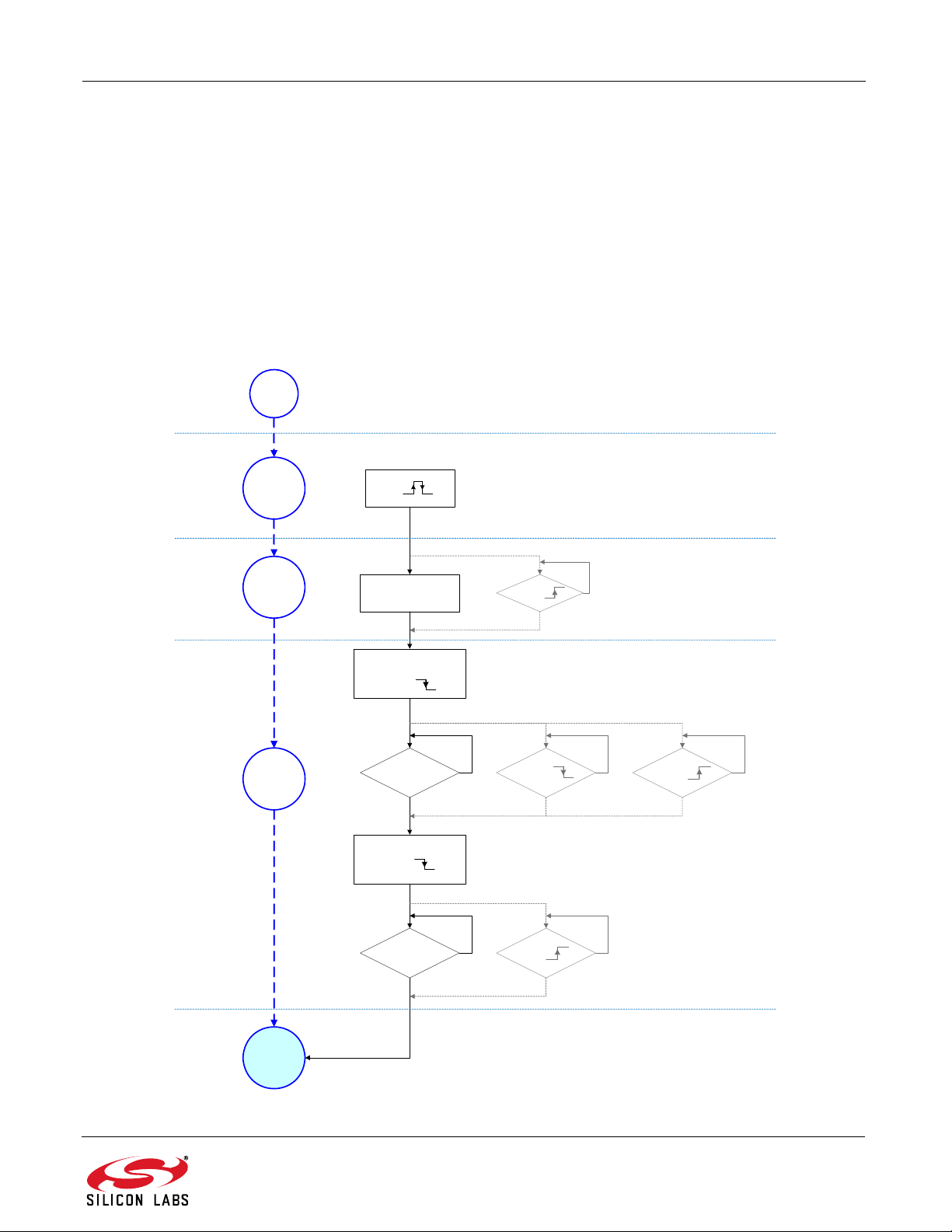

Figure 21. Radio Wake Up Process

Rev. 0.8 25

Page 26

AN633

8.3. Radio Initialization with Generated Radio Configuration File

8.3.1. Radio Initialization with RF Parameters

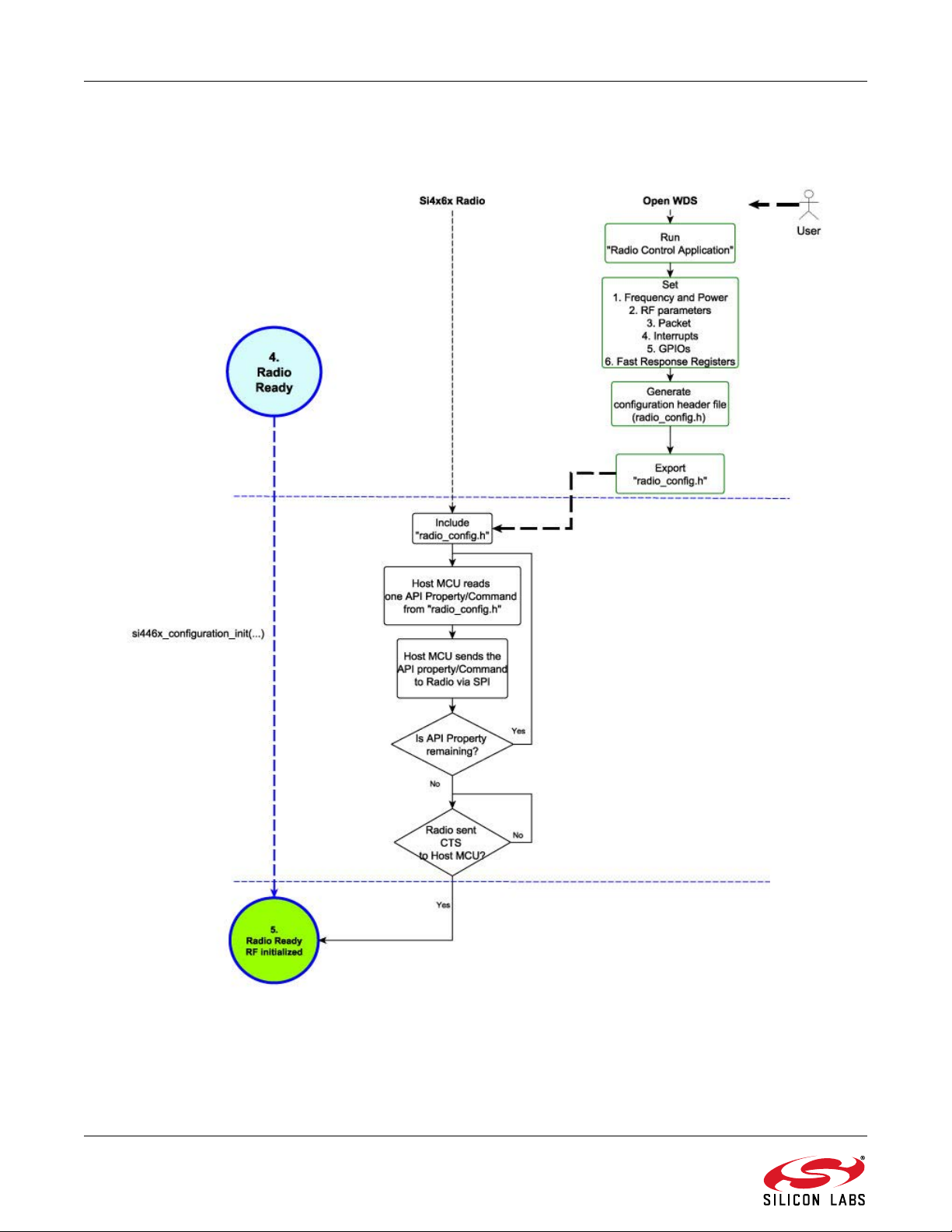

Figure 22. Radio RF Initialization Process

26 Rev. 0.8

Page 27

AN633

The radio parameter configuration process can be accomplished by using the Wireless Development Studio

(WDS). After the required parameters are given to the radio configuration application, the WDS creates the

configuration data based on these parameters. If the Launch IDE option is selected, the WDS generates a

radio_config.h header file that contains the configuration data. This header file contains all the information needed

by the application to configure the radio properly. This information includes the parameters of the RF link such as

the modulation type, channel bandwidth, data rate, center frequency, crystal tolerance, crystal capacitor bank

value, modulation source, CRC calculation and sync word setting. For more complete information on WDS and

EZConfigPRO usage, refer to the WDS User's Guide.

8.3.2. Generated Radio Configuration File

The configuration file is automatically generated by the "Radio Control Application" tool. It is interpreted as a Cheader file called "radio_config.h" and it has four sections. The first two sections are intended for the users and

allow them to see the exact values of the API properties. The last two sections are specifically intended for the

example projects. The structure of the header file is shown in Figure 23.

Figure 23. Radio_config.h File Structure

The "License of the Active Project" section consists of numerous commented lines about the license.

/**

* Copyright 2012 Silicon Laboratories, Inc.

* http://www.silabs.com

*

* @file radio_config.h

*

* H File Description:

* @brief Radio configuration macros and definitions.

*

* Project Name: EZRPRO_Examples

*

* THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

Rev. 0.8 27

Page 28

AN633

* PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT

* HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF

* CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE

* SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE.

*

* This software must be used in accordance with the End User License Agreement.

The "Radio Setup Configuration in Definitions" section is the list of initialization commands that are sent to the radio

over the SPI interface. The structure of one element of the list is shown below. The comment lines describe how

the C definition configures the dedicated API properties. The C define line stands for the initialization command.

/* Set Multiple Properties starting with MODEM_MOD_TYPE

* Starting Location: 0x2000

* Number of properties: 3

* Defaults: 0x02 0x80 0x07

* Descriptions:

* MODEM_MOD_TYPE - Modulation Type.

* Bit[7] : TX_DIRECT_MODE_TYPE : 0

* Bit[6:5] : TX_DIRECT_MODE_GPIO [1:0] : 0

* Bit[4:3] : MOD_SOURCE[1:0] : 0

* Bit[2:0] : MOD_TYPE[2:0]: 3

* MODEM_MAP_CONTROL - Controls bit mapping.

* Bit[7] : enmanch : 0

* Bit[6] : eninv_rxbit : 0

* Bit[5] : envinv_txbit : 0

* Bit[4] : envinv_fd : 0

* Bit[3] : envinv_adcq : 0

* MODEM_DSM_CTRL - DSM control.

* Bit[7] : dsmclk_sel : 0

* Bit[6] : dsm_mode : 0

* Bit[5] : dsmdt_en : 0

* Bit[4] : dsmdttp : 0

* Bit[3] : dsm_rst : 0

* Bit[2] : dsm_lsb : 1

* Bit[1:0] :dsm_order :3

*/

#define RADIO_CONFIGURATION_SET_PROPERTIES_MODEM_MOD_TYPE 0x11, 0x20, 0x03, 0x00, 0x03,

0x00, 0x07

28 Rev. 0.8

Page 29

AN633

Command

ID

Starting Property

(MSB)

Number of

Properties

(N)

Starting

Property (LSB)

Value

1

Value

...

Value

N

Command

ID

Length of

API command

Starting

Property

(MSB)

Number of

Properties

(N)

Starting

Property

(LSB)

Value

1

Value

...

Value

N

The commented lines explain which API property/properties will be overwritten with new value(s). For example,

this definition is responsible for initializing three API properties of the radio at one time, "MODEM_MOD_TYPE",

"MODEM_MAP_CONTROL", and "MODEM_DSM_CTRL". The format of the definition is as follows:

The first byte is the command ID of the "SET_PROPERTY" API command.

The next three bytes are the requirements of the command:

MSB of the starting location of the API property

Number of the immediate adjacent API properties

LSB of the starting location of the API property

Finally, the values of the properties set by the command.

Figure 24. Structure of “SET_PROPERTY” API Command

The "Radio Setup Configuration" section is intended only for the example project. This part only has a C-like

structure, called "Radio_Setup_Configuration_Array", that contains the previously mentioned definitions with the

modification that the first element is the length of the API command. The format of the definition remains almost the

same but the length field is added. The importance of the extended structure is to build the appropriate format of

the input parameter for the 'Si446x_configuration_init(…)' function. The format of a line from the array is as follows:

Figure 25. One Element of the Radio Setup Configuration Section

The "Specific Configuration of the Example Project" section is intended for the example project. It contains some

specific definitions for the example application such as which channel is selected either for the transmission or for

the reception. The content of the custom packet is initialized in this section. It also contains WDS calculator-related

information in the commented lines.

/**

* crys_freq xtaltol ifmode hipfm_Ch_Fil OSRtune chfil_sw_AFC ant_div pm_pattern

* 30000000 20 2 1 0 0 0 0

*

* mod_type Rsymb(sps) Fdev(Hz) OOK_BW(Hz) Manchester afc_en Rb_error Chip_Version

* 1 40000 83333.3 350000 0 0 0 2

*

* fc(MHz) API_TC fhst hi_pfm_cp BER_mode raw_demod dsource hi_pfm_div

* 915 27 0 0 0 0 0 1

**/

#define CUSTOM_PACKET_TX_CONTENT {SiliconLabs}

#define CUSTOM_PACKET_RX_CONTENT {SiliconLabs}

#define CUSTOM_CHANNEL_NUMBER_TX 0

#define CUSTOM_CHANNEL_NUMBER_RX 0

Rev. 0.8 29

Page 30

AN633

9. Example Projects and Software Layers

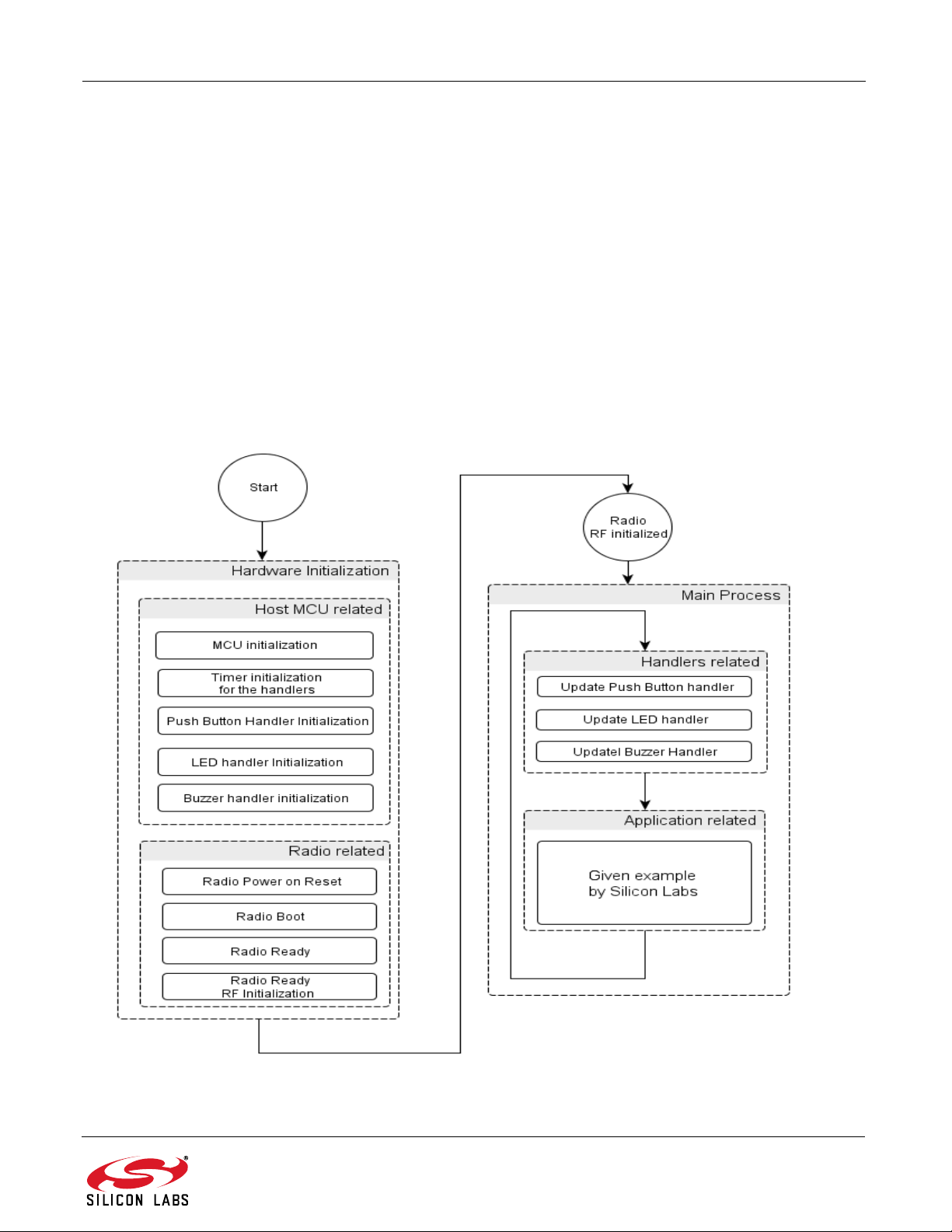

9.1. Software Layers

In all of the sample projects, the layered software approach is followed. There is a distinct scope for each software

module, and all modules can communicate through each other's API functions. The software modules are

separated and focused to cover one specific task. Figure 26 shows the software layers and its relations.

Figure 26. Software Layers of the Example Codes

9.2. Radio Initialization in the Software Layers Perspective

Using the software layer approach, the example project can be understood easily. Each and every layer has its

own responsibility. If the upper layer, e.g. the “Application”, wants to configure the hardware platform including the

host microcontroller and also the radio chip, it simply calls the hardware initial routine. The radio chip initialization is

started with a power on reset. The radio module sends a request to the si446x radio driver to reset the chip.

Thereafter, the driver forwards the request to the hardware abstraction layer that pulls down the SDN pin to

perform the power on reset. After the POR, the host MCU needs to send all the API properties to the radio via SPI

interface that means the “radio setup configuration” of the radio_config.h header file needs to be processed line by

line. The whole process of sending one API property and checking whether the radio is ready to receive the next

property is a repetitive task is represented by a configuration loop. Finally, host MCU clears all the pending

interrupts of the radio that is initialized to ready in RF perspective.

30 Rev. 0.8

Page 31

AN633

Figure 27. Function Calls During the Radio Initialization

9.3. Directory Structure of the Example Project

All sample source code has a common directory structure with separated source and project files to ease the

understanding of the individual modules. For every sample project, the following directories and files can be found

in the main directory:

bin—Contains the SiLabs project files for Keil and SDCC compilers and the Makefile if the make tool is

used instead.

doc—Doxygen-generated documentation based on comments inside the source files in html format.

out—The outputs of the compilation process are sent to this folder. After successful compilation, this

directory contains files such as the hex file, the linker output, and the OMF file.

src—Directories containing the source files.

1. application

2. drivers

Doxyfile—This file contains the Doxygen documentation generator settings.

Rev. 0.8 31

Page 32

AN633

Cleanup.bat—Batch file used to delete all files generated during build process.

Figure 28. Directory Structure of the Example Project

The individual software modules are separated into several source files. The sample projects contain one header

file (bsp.h) that is included in the source files and collects the individual headers that need to be included. Under

“src” folder, the “application” folder contains application-related sources. Common modules (e.g., handlers, drivers)

are located under the “driver” directory.

9.4. Common Software Modules

In the modules hierarchy, the common software modules (CSM) are located between the application and the

hardware layers. The CSM is a set of interfaces that provide possible options for controlling various peripherals on

modular HW platforms. Registers can be initialized with pre-configured settings and peripherals can be enabled to

start/stop their own processing. The major tasks of these software modules are to initialize the hardware elements

and control its behaviors. The principle of their installation is to provide a façade for the upper layers. Functionally,

the User Application at the top of the hierarchy can be independent of the hardware and its logical operation can

remain unchanged even if the hardware has been modified later. It can be adapted to any device without

encountering difficulties. All the modules in the following subsections except the human-machine interface module

are primarily responsible for handling the dedicated internal peripherals such as the IO, timers, SPI, and PCA. The

HMI holds the peripherals together so it gives a higher abstraction level to the User Application in the form of

handlers.

32 Rev. 0.8

Page 33

9.4.1. Common Software Modules Location

AN633

Figure 29. Location of the Common Software Modules

9.4.2. Input/Output Control Module

The Input/Output (I/O) control-related source files, called control_IO.h and control_IO.c, are located in the

/src/drivers/ folder. The module handles the port initializations for the physical HW platform such as LEDs, pushbuttons, or buzzer. For example, the module can set the state of the LEDs and read the status of the selected

push-buttons.

Function Name: void vCio_InitIO(void)

Description: This function is used to initialize specific IO port for LED and PB.

Return Value: None

Note: It has to be called from the initialization section.

Function Name:

Description:

Input Parameter(s):

Return Value:

Function Name: void vCio_ClearLed(uint8_t biLedNum)

Description: This function is used to switch the selected LED off.

Input Parameter(s): biLedNum : Number of the LED to be switched off (1-4).

Return Value: None

void vCio_SetLed(uint8_t biLedNum)

This function is used to switch the selected LED on.

biLedNum : Number of the LED to be switched on (1-4).

None

Function Name: BIT gCio_GetPB(uint8_t biPbNum)

Description: This function is used to read the status of the selected push-button.

Input Parameter(s): biPbNum : Number of the push-button to be switched on (1-4).

Return Value: State of the selected PB.

Rev. 0.8 33

Page 34

AN633

9.4.3. Timer Peripheral Module

The timer-related source files, called timer.h and timer.c, are located in the /src/drivers/ folder. This module handles

two 16-bit timers, timer2 and timer3. The most accurate timing interval can be calculated from the frequency of the

system clock, which is generally 24.5 MHz. External clock sources can be selected as timer input and the required

timing frequency can be adjusted thoroughly with several different prescalers. In general, the timer files are set to a

frequency of 1 kHz (1 ms). By using the timer with 1 ms settings, timeouts that are a multiple of 1 ms can be easily

implemented. Timer-related operations provide options to start or stop counting. Additionally, interrupts can be

generated when the low byte of the timer overflows. Timers can also be checked for expiration.

Function Name:

Description:

Input Parameter(s):

Return Value:

Function Name: BIT gTmr_Tmr2Expired(void)

Description: This function is used to check if Timer 2 is expired.

Return Value: True if timer is expired (also stops the timer).

Note: Function clears the IT status flag as well.

Function Name:

Description: This function is used to start Timer 3 in the specified mode.

Input Parameter(s):

Return Value: None

void vTmr_StartTmr2(uint8_t biPrescaler, uint16_t wiPeriod, uint8_t biItEnable,

uint8_t biExtClkSel)

This function is used to start Timer 2 in the specified mode.

biPrescaler : Prescaler value of timer .

(use predefined constants: bTmr_Tmr2One_c, bTmr_Tmr2Both_c)

wwiPeriod : The duration of the timing.

biItEnable : Enables timer IT if TRUE, disables it if FALSE.

biExtClkSel External clock select.

(use predefined constants: bTmr_TxXCLK_00_c etc.)

None.

void vTmr_StartTmr3(uint8_t biPrescaler, uint16_t wiPeriod, uint8_t biItEnable,

uint8_t biExtClkSel)

biPrescaler : Prescaler value of timer.

(use predefined constants: bTmr_Tmr3One_c, bTmr_Tmr3Both_c)

wwiPeriod : The duration of the timing.

biItEnable : Enables timer IT if TRUE, disables it if FALSE.

biExtClkSel : External clock select.

(use predefined constants: bTmr_TxXCLK_00_c etc.)

Function Name: BIT gTmr_Tmr3Expired(void)

Description: This function is used to check if Timer 3 is expired.

Return Value: True if timer is expired (also stops the timer).

Note: Function clears the IT status flag as well.

34 Rev. 0.8

Page 35

AN633

9.4.4. Programmable Counter Array Module

The programmable counter array (PCA)-related source files, called pca.h and pca.c, are located in the /src/driver/

folder. This module initializes the PCA, which creates beeping sounds from the buzzer. The time-base source of

the PCA can be selected. Interrupts can be generated when the lower byte of the counter overflows. PWM-mod

cycle length also can be selected to modify the frequency of the tweeting sound.

Function Name:

Description:

Input Parameter(s):

Return Value

9.4.5. Serial Peripheral Interface Module

The serial peripheral interface (SPI)-related source files, called spi.h and spi.c, are located in the /src/driver/ folder.

This module is the most essential because it enables a connection to the radio via the SPI bus. The radio can be

controlled by its built-in application programming interface. Communication with the radio is based on sending

commands to the API and receiving responses from the API. To enable the SPI interface, the SPI port must be

enabled and associated to the crossbar. The directions of the SCK, MISO, and MOSI ports have to be configured

properly on the IO port. Finally, the default states of the pins have to be set correctly. Since several devices can be

connected to the same SPI bus, the NSEL pin of the selected device is activated during communication. Because

the commands to be sent to the API are sequences of bytes, the module has to be able to send and receive

continuous byte stream. There are some cases when either reading a single byte directly from the MISO or writing

specified number of bits directly to the MOSI is necessary. In order to cover these kinds of cases, bitbang

read/write methods have been also implemented.

Function Name: uint8_t bSpi_ReadWriteSpi0(uint8_t biDataIn)

Description: This function is used to read/write one byte from/to SPI0.

Input Parameter(s): biDataIn : Data to be sent.

Return Value: Read value of the SPI port after writing on it.

void vPca_InitPcaTmr(uint8_t biPulseSelect, uint8_t biPcaTmrItEnable, uint8_t

biCycleLengthSelect)

This function is used to start Timer 2 in the specified mode.

biPulseSelect Selects time-base source of PCA .

(use predefined constants: bPca_PcaCps_000_c etc.)

biPcaTmrItEnable : Enables PCA timer IT if TRUE, disables it if FALSE.

biCycleLengthSelect :PWM-mode cycle length select

(use predefined constants: bPca_PwmClsel_00_c, etc.).

None

Function Name:

Description:

Input Parameter(s):

Return Value:

Function Name:

Description:

Input Parameter(s):

Return Value:

uint8_t bSpi_ReadWriteSpi1(uint8_t biDataIn)

This function is used to read/write one byte from/to SPI1.

biDataIn : Data to be sent.

Read value of the SPI port after writing on it.

void vSpi_WriteDataSpi0(uint8_t biDataInLength, uint8_t *pabiDataIn)

This function is used to send data over SPI0 no response expected.

biDataInLength : The length of the data.

*pabiDataIn : Pointer to the first element of the data.

None

Rev. 0.8 35

Page 36

AN633

Function Name: void vSpi_WriteDataSpi1(uint8_t biDataInLength, uint8_t *pabiDataIn)

Description: This function is used to send data over SPI1 no response expected.

Input Parameter(s): biDataInLength : The length of the data.

*pabiDataIn : Pointer to the first element of the data.

Return Value: None

Function Name:

Description:

Input Parameter(s):

Output Parameters(s):

Return Value:

Function Name:

Description:

Input Parameter(s):

Output Parameters(s):

Return Value:

Function Name:

Description:

Return Value:

Function Name:

Description:

Return Value:

Function Name:

Description:

Return Value:

void vSpi_ReadDataSpi0(uint8_t biDataOutLength, uint8_t *paboDataOut)

This function is used to read data from SPI0.

biDataOutLength :The length of the data.

*paboDataOut : Pointer to the first element of the response.

None

void vSpi_ReadDataSpi1(uint8_t biDataOutLength, uint8_t *paboDataOut)

This function is used to read data from SPI1.

biDataOutLength : The length of the data.

*paboDataOut : Pointer to the first element of the response.

None

void vSpi_EnableSpi0(void)

This function is used to enable SPI0 and associate to XBAR.

None

void vSpi_EnableSpi1(void)

This function is used to enable SPI1 and associate to XBAR.

None

void vSpi_DisableSpi0(void)

This function is used to disable SPI0 and disconnect from XBAR.

None

Function Name:

Description:

Return Value:

Function Name:

Description:

Input Parameter(s):

Return Value:

36 Rev. 0.8

void vSpi_DisableSpi1(void)

This function is used to disable SPI1 and disconnect from XBAR.

None

void vSpi_ClearNselSpi0(uint8_t biSelectDevice)

This function is used to pull down nSEL of the selected device on SPI0.

biSelectDevice Selected device

None

Page 37

Function Name: void vSpi_ClearNselSpi1(uint8_t biSelectDevice)

Description: This function is used to pull down nSEL of the selected device on SPI1.

Input Parameter(s): biSelectDevice Selected device

0 - DUT

2 - EEPROM

3 - MCU2

Return Value: None

Function Name: void vSpi_SetNselSpi0(uint8_t biSelectDevice)

Description: This function is used to pull up nSEL of the selected device on SPI0.

Input Parameter(s): biSelectDevice : Selected device

Return Value: None

Function Name: void vSpi_SetNselSpi1(uint8_t biSelectDevice)

Description: This function is used to pull up nSEL of the selected device on SPI1.

Input Parameter(s): biSelectDevice: Selected device

0 - DUT

2 - EEPROM

3 - MCU2

Return Value: None

AN633

Function Name: uint8_t bSpi_ReadByteBitbangSpi0(void)

Description: This function is used to read one byte from SPI0 using bitbang method.

Return Value: Read byte

Function Name: uint8_t bSpi_ReadByteBitbangSpi1(void)

Description: This function is used to read one byte from SPI1 using bitbang method.

Return Value: Read byte

Function Name: void vSpi_WriteBitsBitbangSpi0(uint8_t biDataIn, uint8_t biNumOfBits)

Description: This function is used to write specified number of bits to SPI0 using bitbang method.

Input Parameter(s): biDataIn : Input byte of data bits

Output Parameters(s): biNumOfBits : Number of bits to be written to SPI

Return Value: None

Function Name: void vSpi_WriteBitsBitbangSpi1(uint8_t biDataIn, uint8_t biNumOfBits)

Description: This function is used to write specified number of bits to SPI1 using bitbang

method.

Input Parameter(s): biDataIn : Input byte of data bits

Output Parameters(s): biNumOfBits : Number of bits to be written to SPI.

Return Value: None

Rev. 0.8 37

Page 38

AN633

9.4.6. Human Machine Interface Module

The human machine interface (HMI)-related source files, called hmi.h and hmi.c, are located in the /src/driver/

folder. In order to use this module, the required handlers need to be initialized at the very beginning of the program.

The status of the various hardware components must be checked in order to have a common cyclic mechanism. In

addition, it is vital that a 1 ms interrupt-based cycle run in the background to serve the different handlers. Using the

LED handler, states of LEDs can be set and cleared either separately or together.

Using the button handler, statuses of the push-buttons can be read. If multiple button events happen

simultaneously, they can be stored to be handled later. The last pushed button event is always available first

amongst the un-handled events. Using the buzzer related sub-interface, the state of buzzer can be changed to the

required one.

Function Name: void vHmi_InitLedHandler(void)

Description: This function is used to initialize the Led handler.

Return value: None

Note: Must be called from the initialization section.

Re-initialization of LED Handler supported by the extended HMI driver.

Function Name: void vHmi_ChangeLedState(eHmi_Leds qiLed, eHmi_LedStates qiLedState)

Description: This function is used to change state of selected Led.

Input Parameter(s): qiLed : Led to change its state

qiLedState : New state of qiLed

Return Value: None

Function Name: void vHmi_ChangeAllLedState(eHmi_LedStates qiLedState)

Description: This function is used to change state of all Leds.

Input Parameter(s): qiLedState : New state of all the Leds

Return Value: None

Function Name: void vHmi_ClearAllLeds(void)

Description: This function is used to force all Leds to off immediately.

Return Value: None

Function Name: void vHmi_LedHandler(void)

Description: This function is used to handle Led management.

Return Value: None

Function Name: void vHmi_InitPbHandler(void)

Description: This function is used to initialize push-button handler.

Return Value: None

Note: It has to be called from the initialization section.

Re-initialization of LED Handler supported by the extended HMI driver.

38 Rev. 0.8

Page 39

AN633

Function Name: BIT gHmi_PbIsPushed(uint8_t *boPbPushTrack, uint16_t *woPbPushTime)

Description: This function is used to check if any of the push-buttons are pushed.

Output Parameters(s): *boPbPushTrack : Read value of pushed button.

*woPbPushTime : Push time of pushed button.

Return Value: Pushed state of push-buttons

Function Name: bool gHmi_IsPbUnHandled(void)

Description: This function is used to check if there is unhandled push-buttons event.

Return Value: True if there is unhandled push-button event.

Function Name:

Description:

Output parameters(s):

Return Value:

Function Name:

Description:

Return Value:

Function Name:

Description:

Return Value:

Function Name:

Description:

Return Value:

Function Name:

Description:

Return Value:

uint8_t bHmi_PbGetLastButton(uint16_t *woPbPushTime)

This function is used to read last pushed button(s), push track holder is erased if

button(s) was already released.

*woPbPushTime : Push time of pushed button.

Push track holder of last pushed button(s)

void vHmi_PbHandler(void)

This function is used to handle push-button management.

None

void vHmi_ShowPbOnLeds(void)

This function is used to show the actual state of the push-buttons on the Leds.

None

bool gHmi_SwStateHandler(void)

This function is used to handle switch state change.

True if state of switches has changed

uint8_t bHmi_GetSwState(void)

This function is used to handle give the state

State

Function Name:

Description:

Return Value:

Note:

Function Name:

Description:

Input Parameter(s):

Return Value:

void vHmi_InitBuzzer(void)

This function is used to initialize the buzzer operation.

None

It has to be called from the initialization section.

void vHmi_ChangeBuzzState(eHmi_BuzzStates qiBuzzState)

This function is used to change the state the buzzer.

qiBuzzState : New state of the buzzer

None

Rev. 0.8 39

Page 40

AN633

Function Name:

Description:

9.4.7. UART interface Module

The UART related source files, called uart.h and uart.c, are located in the /src/driver/ folder. In order to use this

module, the functionality needs to be initialized at the very beginning of the program.

Bytes can be sent and received as well and the functionality uses the uart interrupt service routine.

Function Name: uint8_t Comm_IF_RecvUART(uint8_t * byte)

Description: This function is used to receive bytes from UART.

Output Parameters(s): *byte Pointer to the first element of the incoming data.

Return Value: True if there is an incoming data otherwise FALSE.

Function Name: uint8_t Comm_IF_SendUART(uint8_t byte)

Description: This function is used to send bytes through UART.

Input Parameters(s): byte : data to be sent

Return Value: True if sending data completed successfully otherwise FALSE.

Function Name: void Comm_IF_EnableUART(void)

Description: Enable and set the UART0 peripheral

Return Value: None

void vHmi_BuzzHandler(void)

This function is used to handle buzzer management.

40 Rev. 0.8

Page 41

AN633

9.4.8. Size Optimization of the Common Software Modules

To optimize the code size of the common software modules and consequently the example source codes, software

switches must be introduced in almost every module. By enabling these switches, new functions can be added to

the whole project to compile. If the switch is not defined at the beginning of the bsp.h header file, then only the

basic features can be used, which is barely sufficient for most of the example codes.

The rest of the module’s features can be added to the project by defining the following switches:

TIMER_DRIVER_EXTENDED_SUPPORT

SPI_DRIVER_EXTENDED_SUPPORT

HMI_DRIVER_EXTENDED_SUPPORT

UART_DRIVER_EXTENDED_SUPPORT

The control_IO and PCA modules are quite simple, so there is no need to use driver extension in these cases.

Figure 30. Usage of Software Switches

Table 6 shows which module can support the driver expansion feature:

Table 6. Size Optimization Possibilities for Common Software Modules

Common Software Module Software Switch

Minimal Driver Extended Driver

Control IO default Not supported

Timer default TIMER_DRIVER_EXTENDED_

PCA default Not supported

SPI default SPI_DRIVER_EXTENDED_SUPPORT

HMI default HMI_DRIVER_EXTENDED_SUPPORT

UART default UART_DRIVER_EXTENDED_

SUPPORT

SUPPORT

Rev. 0.8 41

Page 42

AN633

Table 7 shows the comparison between the modules’ sizes:

Table 7. Size Comparison of Common Software Modules

Common Software

Module

Minimal Driver Extended Driver

Control I/O 60 Not supported —

Timer 60 146 58

PCA 29 Not supported —

SPI127 252 49

HMI 698 1295 46

UART 49 246 80

Module Code Size [Byte] Size Optimization

[%]

42 Rev. 0.8

Page 43

AN633

9.5. Radio Driver

The radio driver module resides in a low-level driver software layer. It is intended to provide a user-friendly and

easy-to-use API to the radio functionality. It contains API functions and macro definitions for all radio commands.

Constants can be found in the "EZRadioPRO API Documentation" zipped html file at http://www.silabs.com/

products/wireless/EZRadioPRO/Pages/Si446x.aspx. Including this driver module into the software project makes

the control of the radio chip easier than ever before through its comprehensive public API functions. The driver

handles all the SPI communication with the chip, including the check for the CTS signal, and automatically reads

the response from the chip. Thanks to the layered approach, it can be easily ported to other architectures and

platforms, as it depends only on the Hardware Application Layer. This means it is enough to port the HAL for a

given architecture in order to get the radio driver work. As introduced in the other drivers, the radio driver also can

be compiled with different support types (Minimal, Extended or Full). Depending on which support type defined, the

radio driver provides different level of API coverage. This way it provides a convenient way of managing the

compile firmware size depending on the API functions usage and excludes the unused and, therefore,

unnecessary functions.

9.5.1. Radio Driver Location

Figure 31. Location of the Radio Driver

Rev. 0.8 43

Page 44

AN633

9.5.2. Size Optimization of the Radio Driver

In order to optimize the code size of the common software modules and consequently the example project as well,

software switches must be introduced in the radio driver. By activating the switches, new functions can be added to

the radio driver. There are three ways of using it. If any of the radio driver switches is not defined at the beginning

of the bsp.h header file, then only the basic features are used. It is sufficient for all example projects to work. The

rest of the features can be added to the driver in two levels with the following switches:

RADIO_DRIVER_EXTENDED_SUPPORT

RADIO_DRIVER_FULL_SUPPORT

Table 8. Size Optimization Possibilities for Radio Driver

Software Switch

Driver Minimal Driver Extended Driver Full Driver

Radio default RADIO_DRIVER_

EXTENDED_SUPPORT

RADIO_DRIVER_

FULL_SUPPORT

Table 9. Size Comparison of Radio Driver

Module size [byte]

Driver Minimal Driver Extended Driver Full Driver

Radio 922 1094 1490

44 Rev. 0.8

Page 45

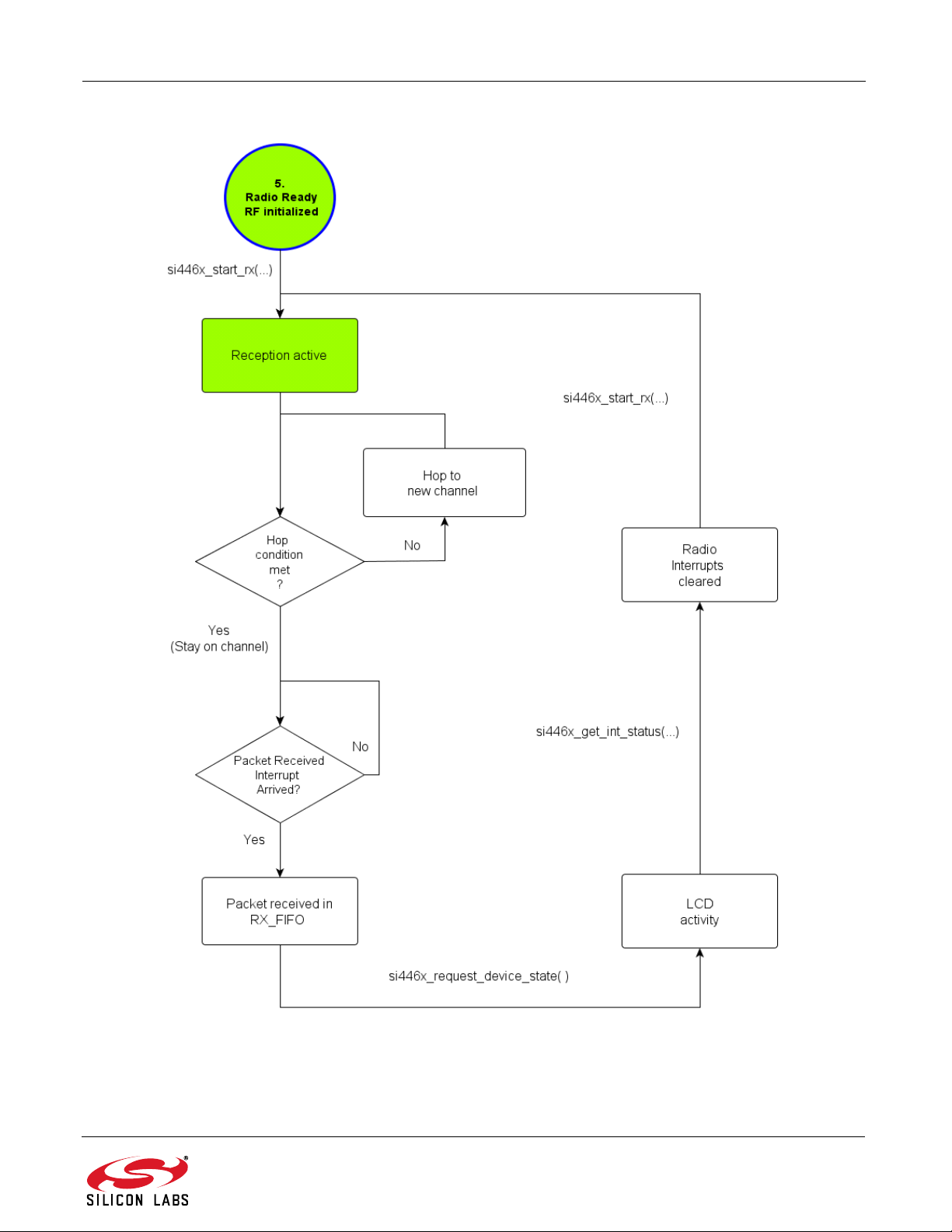

si446x_reset(...)

si446x_power_up(...)

si446x_configuration_init(...)

si446x_part_info(...)

si446x_start_tx(...)

si446x_start_rx(...)

si446x_get_int_status(...)

si446x_gpio_pin_cfg(...)

si446x_set_property(...)

si446x_change_state(...)

Default – No switch

Minimal Radio Driver

si446x_reset(...)

si446x_power_up(...)

si446x_configuration_init(...)

si446x_part_info(...)

si446x_start_tx(...)

si446x_start_rx(...)

si446x_get_int_status(...)

si446x_gpio_pin_cfg(...)

si446x_set_property(...)

si446x_change_state(...)

-------------------------------------si446x_nop(...)

si446x_fifo_info(...)

si446x_write_tx_fifo(...)

si446x_read_rx_fifo(...)

si446x_get_property(...)

-------------------------------------si446x_func_info(...)

si446x_frr_a_read(...)

si446x_frr_b_read(...)

si446x_frr_c_read(...)

si446x_frr_d_read(...)

si446x_get_adc_reading(...)

si446x_get_packet_info(...)

si446x_get_ph_status(...)

si446x_get_modem_status(...)

si446x_get_chip_status(...)

si446x_ircal_manual(...)

si446x_protocol_cfg(...)

si446x_request_device_state(...)

si446x_tx_hop(...)

si446x_rx_hop(...)

si446x_start_tx_fast( )

si446x_start_rx_fast( )

si446x_get_int_status_fast_clear( )

si446x_get_int_status_fast_clear_read( )

si446x_gpio_pin_cfg_fast( )

si446x_get_ph_status_fast_clear( )

si446x_get_ph_status_fast_clear_read( )

si446x_get_modem_status_fast_clear( )

si446x_get_modem_status_fast_clear_read( )

si446x_get_chip_status_fast_clear( )

si446x_get_chip_status_fast_clear_read( )

si446x_fifo_info_fast_reset(...)

si446x_fifo_info_fast_read(...)

RADIO_DRIVER_EXTENDED_SUPPORT

RADIO_DRIVER_FULL_SUPPORT

Full Radio Driver

si446x_reset(...)

si446x_power_up(...)

si446x_configuration_init(...)

si446x_part_info(...)

si446x_start_tx(...)

si446x_start_rx(...)

si446x_get_int_status(...)

si446x_gpio_pin_cfg(...)

si446x_set_property(...)

si446x_change_state(...)

-------------------------------------si446x_nop(...)

si446x_fifo_info(...)

si446x_write_tx_fifo(...)

si446x_read_rx_fifo(...)

si446x_get_property(...)

RADIO_DRIVER_EXTENDED_SUPPORT

Extended Radio Driver

AN633

Figure 32. Usage of Radio Driver Switches

Rev. 0.8 45

Page 46

AN633

9.5.3. Minimal Radio Driver

Function Name: void si446x_reset(void);

Description: This functions is used to reset the si446x radio by applying shutdown and releasing

it. After this function si446x_boot should be called. You can check if POR has completed by waiting 4 ms or by polling GPIO 0, 2, or 3. When these GPIOs are high, it

is safe to call si446x_boot.

Return Value: None

Function Name: void si446x_power_up(uint8_t BOOT_OPTIONS, uint8_t XTAL_OPTIONS,

uint32_t XO_FREQ);

Description: This function is used to initialize after power-up the radio chip.

Input Parameter(s): BOOT_OPTIONS : Patch mode selector

XTAL_OPTIONS : Select if TCXO is in use

XO_FREQ :Frequency of TCXO or external crystal oscillator in Hz

Return Value: None

Note: Before this function si446x_reset should be called.

Function Name: uint8_t si446x_configuration_init(const uint8_t* pSetPropCmd

Description: This function is used to load all properties with a list of NULL terminated set property

commands.

Input Parameter(s): *pSetPropCmd : First element of the list to be loaded

Return Value: SI446X_COMMAND_ERROR : the list of commands is wrong

SI446X_CTS_TIMEOUT : If a CTS error occurs

SI446X_SUCCESS : If loading is successful

Note: Before this function si446x_reset should be called.

Function Name: void si446x_part_info(void);

Description: This function sends the PART_INFO command to the radio and receives the answer

Si446xCmd union.

Return Value: None

Function Name: void si446x_start_tx(uint8_t CHANNEL, uint8_t CONDITION, uint16_t TX_LEN);

Description: Sends START_TX command to the radio.

Input Parameter(s): CHANNEL : Channel number.

CONDITION : Start TX condition.

TX_LEN : Payload length (exclude the PH generated CRC).

Return Value: None

Function Name: void si446x_start_rx(uint8_t CHANNEL, uint8_t CONDITION, uint16_t RX_LEN,

uint8_t NEXT_STATE1, uint8_t NEXT_STATE2, uint8_t NEXT_STATE3);

Description: Sends START_RX command to the radio.

46 Rev. 0.8

Page 47

AN633

Input Parameter(s): CHANNEL : Channel number.

CONDITION : Start RX condition.

RX_LEN : Payload length (exclude the PH generated CRC).

NEXT_STATE1 : Next state when Preamble Timeout occurs.

NEXT_STATE2 : Next state when a valid packet received.

NEXT_STATE3 : Next state when invalid packet received (e.g., CRC error).

Return Value: None

Function Name: void si446x_get_int_status(uint8_t PH_CLR_PEND,uint8_t MODEM_CLR_PEND,

uint8_t CHIP_CLR_PEND);

Description: Get the Interrupt status/pending flags form the radio and clear flags if requested.

Input Parameter(s): PH_CLR_PEND : Packet Handler pending flags clear.

MODEM_CLR_PEND : Modem Status pending flags clear.

CHIP_CLR_PEND : Chip State pending flags clear.

Return Value: None

Function Name: void si446x_gpio_pin_cfg(uint8_t GPIO0, uint8_t GPIO1, uint8_t GPIO2, uint8_t

GPIO3, uint8_t NIRQ, uint8_t SDO, uint8_t GEN_CONFIG);

Description: Send GPIO pin config command to the radio and reads the answer into Si446xCmd

union.

Input Parameter(s): GPIO0 : GPIO0 configuration.

GPIO1 : GPIO1 configuration.

GPIO2 : GPIO2 configuration.

GPIO3 : GPIO3 configuration.

NIRQ : NIRQ configuration.

SDO : SDO configuration.

GEN_CONFIG : General pin configuration.

Return Value: None

Function Name: void si446x_set_property( uint8_t GROUP, uint8_t NUM_PROPS, uint8_t

START_PROP, ... );

Description: Send SET_PROPERTY command to the radio.

Input Parameter(s): GROUP : Property group.