Silicon Graphics® Tezro™ Visual Workstation

Hardware User’s Guide: Tower Configuration

Document Number 007-4564-001

CONTRIBUTORS

Written by Matt Hoy

Production by Glen Traefald

Illustrated by Dan Young

Edited by Susan Wilkening

Engineering contributions by Charles Alexander, Steve Ewing, Brad Juskiewicz, Charlie Skandalis, Bruce Shifrin, Lyle Stoll, and MichaelWright.

COPYRIGHT

© 2003, Silicon Graphics, Inc. All rights reserved; provided portions may be copyright in third parties, as indicated elsewhere herein. No

permission is granted to copy, distribute, or create derivative works from the contents of this electronic documentation is any manner, in whole

or in part, without the prior written permission of Silicon Graphics, Inc.

LIMITED RIGHTS LEGEND

The electronic (software) version of this document was developed at private expense; if acquired under an agreement with the USA government

or any contractor thereto, it is acquired as "commercial computer software" subject to the provisions of its applicable license agreement, as

specified in (a) 48 CFR 12.212 of the FAR; or, if acquired for Department of Defense units, (b) 48 CFR 227-7202 of the DoD FAR Supplement;

or sections succeeding thereto. Contractor/manufacturer is Silicon Graphics, Inc., 1600 Amphitheatre Pkwy 2E, Mountain View, CA

94043-1351, USA.

TRADEMARKS AND ATTRIBUTIONS

Silicon Graphics, SGI, the SGI logo, IRIX, O2, Octane, Onyx, Onyx2, and Origin are registered trademarks, and O2+, Octane2, Stereo View,

Supportfolio, Tezro, and VPro are trademarks of Silicon Graphics, Inc., in the United States and/or other countries worldwide.

Macintosh is a registered trademark of Apple Computer, Inc. Magellan Spaceball is a trademark of the Logitech group. MIPS is a registered

trademark and R16000 is a trademark of MIPS Technologies, Inc., used under license by Silicon Graphics, Inc. in the United States and/or other

countries worldwide.

For regulatory and compliance information, see Appendix B, “Regulatory Information.”

Cover design by Sarah Bolles, Sarah Bolles Design, and Dany Galgani, SGI Technical Publications

Record of Revision

Version Description

001 July 2003

Original Publication

007-4564-001 iii

Contents

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . xi

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . xv

About This Guide. . . . . . . . . . . . . . . . . . . . . . xvii

Chapter Descriptions . . . . . . . . . . . . . . . . . . . . . xvii

Related Publications . . . . . . . . . . . . . . . . . . . . . xviii

Obtaining Publications . . . . . . . . . . . . . . . . . . . . xviii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . xix

Product Support . . . . . . . . . . . . . . . . . . . . . . . xx

Reader Comments . . . . . . . . . . . . . . . . . . . . . . . xx

1. Installation and Operation Procedures . . . . . . . . . . . . . . . . 1

Setting Up the Workstation . . . . . . . . . . . . . . . . . . . . 1

Checking Your Shipment . . . . . . . . . . . . . . . . . . . 2

Lifting the Workstation . . . . . . . . . . . . . . . . . . . . 4

Getting Acquainted . . . . . . . . . . . . . . . . . . . . . 5

Cabling the Workstation . . . . . . . . . . . . . . . . . . . . 8

Using the Workstation . . . . . . . . . . . . . . . . . . . . . 11

Logging In to the Workstation . . . . . . . . . . . . . . . . . . 11

Using the IRIX Interactive Desktop . . . . . . . . . . . . . . . . . 13

Powering Off the Workstation . . . . . . . . . . . . . . . . . . 15

2. System Overview . . . . . . . . . . . . . . . . . . . . . . . 23

System Enclosure . . . . . . . . . . . . . . . . . . . . . . . 24

System Node Board . . . . . . . . . . . . . . . . . . . . . . 26

Processors . . . . . . . . . . . . . . . . . . . . . . . . . 27

Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . 27

Interface Board. . . . . . . . . . . . . . . . . . . . . . . . 29

IO9 Board . . . . . . . . . . . . . . . . . . . . . . . . . 31

007-4564-001 v

Contents

I/O Daughtercard . . . . . . . . . . . . . . . . . . . . . . . 32

Internal Hard Disk Drives . . . . . . . . . . . . . . . . . . . . . 33

DVD-ROM Drive . . . . . . . . . . . . . . . . . . . . . . . 35

Graphics Module . . . . . . . . . . . . . . . . . . . . . . . 35

PCI Buses . . . . . . . . . . . . . . . . . . . . . . . . . 38

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 40

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . 40

Optional Components, Peripherals, and Upgrades. . . . . . . . . . . . . . 42

PCI Boards . . . . . . . . . . . . . . . . . . . . . . . . 42

Memory Upgrades. . . . . . . . . . . . . . . . . . . . . . 43

Processor Upgrades . . . . . . . . . . . . . . . . . . . . . 43

Graphics Options . . . . . . . . . . . . . . . . . . . . . . 43

Storage Upgrades . . . . . . . . . . . . . . . . . . . . . . 44

Displays. . . . . . . . . . . . . . . . . . . . . . . . . 44

Peripherals . . . . . . . . . . . . . . . . . . . . . . . . 44

3. Maintenance and Upgrade Procedures . . . . . . . . . . . . . . . . . 47

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . 48

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . 49

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . 49

Preparing the Workstation for Service . . . . . . . . . . . . . . . . . 49

Powering Off and Disconnecting the Workstation. . . . . . . . . . . . . 50

Removing the Enclosure Panels . . . . . . . . . . . . . . . . . . 51

Installing or Removing Internal Parts . . . . . . . . . . . . . . . . 56

Returning the Workstation to Service . . . . . . . . . . . . . . . . . 57

Installing the Bezel . . . . . . . . . . . . . . . . . . . . . 58

Installing the Side Panels . . . . . . . . . . . . . . . . . . . . 60

Cabling and Powering on the Workstation . . . . . . . . . . . . . . . 61

Installing or Removing a Memory DIMM . . . . . . . . . . . . . . . . 63

Removing a DIMM . . . . . . . . . . . . . . . . . . . . . 64

Installing a DIMM . . . . . . . . . . . . . . . . . . . . . . 65

Verifying Memory Installation . . . . . . . . . . . . . . . . . . 66

vi 007-4564-001

Contents

Installing or Removing Internal Hard Disk Drives . . . . . . . . . . . . . 67

Installing an Internal Hard Disk Drive . . . . . . . . . . . . . . . .67

Removing an Internal Hard Disk Drive . . . . . . . . . . . . . . . 69

Installing or Removing the DVD-ROM Drive . . . . . . . . . . . . . . . 71

Installing the DVD-ROM Drive . . . . . . . . . . . . . . . . . . 71

Removing the DVD-ROM Drive . . . . . . . . . . . . . . . . .74

Replacing the IO9 Board . . . . . . . . . . . . . . . . . . . . . 76

Removing the IO9 Board. . . . . . . . . . . . . . . . . . . . 76

Installing the IO9 Board . . . . . . . . . . . . . . . . . . . . 78

Installing or Removing XIO Boards . . . . . . . . . . . . . . . . . . 81

Installing the XIO Board Support Bracket . . . . . . . . . . . . . . . 81

Installing an XIO Board . . . . . . . . . . . . . . . . . . . . 83

Removing an XIO Board . . . . . . . . . . . . . . . . . . . . 85

Installing or Removing PCI Boards . . . . . . . . . . . . . . . . . . 88

Installing a PCI Board . . . . . . . . . . . . . . . . . . . . 89

Removing a PCI Board . . . . . . . . . . . . . . . . . . . . 92

Installing or Removing External devices . . . . . . . . . . . . . . . . 93

Replacing Cooling System Components . . . . . . . . . . . . . . . . 94

Replacing the Fan Wall . . . . . . . . . . . . . . . . . . . . 94

Replacing the Hard Disk Drive Fan. . . . . . . . . . . . . . . . . 95

Replacing the Rear Fan Assembly . . . . . . . . . . . . . . . . . 98

Replacing Internal Cables. . . . . . . . . . . . . . . . . . . . . 99

Replacing the L1 Display Cable . . . . . . . . . . . . . . . . . .100

Replacing the LED Cable. . . . . . . . . . . . . . . . . . . .103

Replacing the DVD-ROM Drive Cable . . . . . . . . . . . . . . . .105

Replacing Enclosure Components . . . . . . . . . . . . . . . . . .106

Replacing the Enclosure Plastics . . . . . . . . . . . . . . . . .106

Replacing the L1 Display. . . . . . . . . . . . . . . . . . . .108

4. Troubleshooting and Diagnostics . . . . . . . . . . . . . . . . . .113

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . .114

Environmental Fault Monitoring . . . . . . . . . . . . . . . . .114

Bezel LEDs. . . . . . . . . . . . . . . . . . . . . . . .114

007-4564-001 vii

Contents

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 115

Power-on Diagnostics . . . . . . . . . . . . . . . . . . . . 115

Offline Diagnostics . . . . . . . . . . . . . . . . . . . . 117

Online Diagnostics . . . . . . . . . . . . . . . . . . . . 120

A. Technical Specifications and Pinouts . . . . . . . . . . . . . . . . 125

Physical and Environmental Specifications . . . . . . . . . . . . . . . 126

Power Supply Specifications . . . . . . . . . . . . . . . . . . . 128

I/O Port Specifications. . . . . . . . . . . . . . . . . . . . . 128

Ethernet 10-Base-T/100-Base-T Port. . . . . . . . . . . . . . . . 128

Keyboard and Mouse Ports . . . . . . . . . . . . . . . . . . 130

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . 131

Serial Cables and Adapter Specifications . . . . . . . . . . . . . . . 132

Printer/Dumb Terminal Serial Cable . . . . . . . . . . . . . . . 132

PC Modem Serial Cable . . . . . . . . . . . . . . . . . . . 133

Serial Port Adapter Cables . . . . . . . . . . . . . . . . . . 135

VPro Graphics Board I/O Port Specifications . . . . . . . . . . . . . . 137

DVI-I Video Port . . . . . . . . . . . . . . . . . . . . . 137

Stereo View Port . . . . . . . . . . . . . . . . . . . . . 140

Genlock Port . . . . . . . . . . . . . . . . . . . . . . 141

Swap Ready Port . . . . . . . . . . . . . . . . . . . . . 142

B. Regulatory Specifications . . . . . . . . . . . . . . . . . . . 143

CMN Number . . . . . . . . . . . . . . . . . . . . . . . 143

CE Notice and Manufacturer’s Declaration of Conformity . . . . . . . . . . 144

Electromagnetic Emissions . . . . . . . . . . . . . . . . . . . 144

FCC Notice (USA Only) . . . . . . . . . . . . . . . . . . . 144

Industry Canada Notice (Canada Only) . . . . . . . . . . . . . . 145

VCCI Notice (Japan Only) . . . . . . . . . . . . . . . . . . 146

Chinese Class A Regulatory Notice . . . . . . . . . . . . . . . . 146

Korean Class A Regulatory Notice . . . . . . . . . . . . . . . . 146

Shielded Cables. . . . . . . . . . . . . . . . . . . . . . . 146

Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . 147

Laser Compliance Statement . . . . . . . . . . . . . . . . . . . 147

viii 007-4564-001

Contents

Lithium Battery Compliance Statement. . . . . . . . . . . . . . . . .147

Index . . . . . . . . . . . . . . . . . . . . . . . . . .149

007-4564-001 ix

List of Figures

Figure 1-1 Workstation Shipment Contents . . . . . . . . . . . 3

Figure 1-2 Lifting the Workstation . . . . . . . . . . . . . 4

Figure 1-3 Front View of the Workstation . . . . . . . . . . . 6

Figure 1-4 Rear View of the Workstation. . . . . . . . . . . . 7

Figure 1-5 Connecting the Keyboard and Mouse Cables . . . . . . . 8

Figure 1-6 Connecting the Ethernet Cable . . . . . . . . . . . 9

Figure 1-7 Connecting the Monitor Cable . . . . . . . . . . . 10

Figure 1-8 Connecting the Workstation and Monitor Power Cables . . . . 11

Figure 1-9 Powering On the Workstation and Monitor. . . . . . . . 12

Figure 1-10 Login Screen . . . . . . . . . . . . . . . . 12

Figure 1-11 Peripheral Icons. . . . . . . . . . . . . . . . 13

Figure 1-12 Toolchest Menu. . . . . . . . . . . . . . . . 14

Figure 1-13 Console Window . . . . . . . . . . . . . . . 15

Figure 1-14 Powering Off the Workstation . . . . . . . . . . . 16

Figure 1-15 System Shutdown Notifier . . . . . . . . . . . . 16

Figure 1-16 Power Button and Reset Switch . . . . . . . . . . . 17

Figure 1-17 Shutdown Caution Message . . . . . . . . . . . . 18

Figure 1-18 Shutdown System Window . . . . . . . . . . . . 19

Figure 1-19 System Shutdown Notifier . . . . . . . . . . . . 19

Figure 1-20 Restart Notifier . . . . . . . . . . . . . . . . 20

Figure 1-21 System Shutdown Notifier . . . . . . . . . . . . 21

Figure 1-22 Power Off/Restart Notifier . . . . . . . . . . . . 21

Figure 1-23 Restart Notifier . . . . . . . . . . . . . . . . 21

Figure 2-1 System Enclosure Layout (Right-front view) . . . . . . . 24

Figure 2-2 System Enclosure Layout (Left-rear View) . . . . . . . . 25

Figure 2-3 IP53 System Node Board . . . . . . . . . . . . . 26

Figure 2-4 DIMM Sockets and Pairs . . . . . . . . . . . . . 28

007-4564-001 xi

List of Figures

Figure 2-5 Interface Board Connectors . . . . . . . . . . . . 30

Figure 2-6 IO9 Board . . . . . . . . . . . . . . . . . 31

Figure 2-7 I/O Daughtercard . . . . . . . . . . . . . . . 33

Figure 2-8 Hard Disk Drive Sled . . . . . . . . . . . . . . 34

Figure 2-9 Internal Hard Disk Drive Locations . . . . . . . . . . 34

Figure 2-10 Locating the Graphics Module. . . . . . . . . . . . 36

Figure 2-11 VPro Graphics and Dual Channel Display I/O Ports . . . . . 37

Figure 2-12 PCI Buses and Slots . . . . . . . . . . . . . . . 39

Figure 2-13 Power Supply Location. . . . . . . . . . . . . . 40

Figure 2-14 Cooling System Components . . . . . . . . . . . . 41

Figure 3-1 Powering Off the System . . . . . . . . . . . . . 50

Figure 3-2 Moving the Workstation . . . . . . . . . . . . . 51

Figure 3-3 Removing the Enclosure Side Panel . . . . . . . . . . 53

Figure 3-4 Removing the Bezel . . . . . . . . . . . . . . . 55

Figure 3-5 Installing the Bezel . . . . . . . . . . . . . . . 59

Figure 3-6 Replacing the Side Panel . . . . . . . . . . . . . 61

Figure 3-7 Reconnecting the Cables to the Workstation . . . . . . . . 62

Figure 3-8 Removing a DIMM . . . . . . . . . . . . . . . 64

Figure 3-9 Installing a DIMM . . . . . . . . . . . . . . . 65

Figure 3-10 Locating the Notches on a DIMM . . . . . . . . . . . 66

Figure 3-11 Installing an Internal Hard Disk Drive . . . . . . . . . 68

Figure 3-12 Removing an Internal Hard Disk Drive . . . . . . . . . 70

Figure 3-13 Installing the Drive Rails . . . . . . . . . . . . . 72

Figure 3-14 Installing the DVD-ROM Drive. . . . . . . . . . . . 73

Figure 3-15 Removing the DVD-ROM Drive . . . . . . . . . . . 75

Figure 3-16 Disconnecting the Cables and Retention Strap . . . . . . . 77

Figure 3-17 Opening the PCI Gate . . . . . . . . . . . . . . 77

Figure 3-18 Removing the IO9 Board . . . . . . . . . . . . . 78

Figure 3-19 Installing the IO9 Board . . . . . . . . . . . . . 79

Figure 3-20 Connecting the Cables and Retention Strap . . . . . . . . 80

Figure 3-21 Closing the PCI Gate . . . . . . . . . . . . . . 80

Figure 3-22 Installing the XIO Board Support Bracket . . . . . . . . 82

Figure 3-23 Opening the PCI Gate . . . . . . . . . . . . . . 83

xii 007-4564-001

List of Figures

Figure 3-24 Installing an XIO Board . . . . . . . . . . . . . 84

Figure 3-25 Closing the PCI Gate . . . . . . . . . . . . . . 85

Figure 3-26 Opening the PCI Gate . . . . . . . . . . . . . . 86

Figure 3-27 Removing an XIO Board . . . . . . . . . . . . . 87

Figure 3-28 Opening the PCI Gate . . . . . . . . . . . . . . 89

Figure 3-29 Installing the PCI Board . . . . . . . . . . . . . 90

Figure 3-30 Closing the PCI Gate . . . . . . . . . . . . . . 91

Figure 3-31 Opening the PCI Gate . . . . . . . . . . . . . . 92

Figure 3-32 Removing a PCI Board. . . . . . . . . . . . . . 93

Figure 3-33 Replacing the Fan Wall . . . . . . . . . . . . . 95

Figure 3-34 Removing the Hard Disk Drive Fan . . . . . . . . . . 96

Figure 3-35 Installing the Hard Disk Drive Fan . . . . . . . . . . 97

Figure 3-36 Replacing the Rear Fan Assembly . . . . . . . . . . 99

Figure 3-37 Removing the L1 Display Cable . . . . . . . . . . .101

Figure 3-38 Installing the L1 Display Cable . . . . . . . . . . .103

Figure 3-39 Replacing the LED Cable . . . . . . . . . . . . .104

Figure 3-40 Replacing the DVD-ROM Drive Cable . . . . . . . . .106

Figure 3-41 Replacing the Top Plastic . . . . . . . . . . . . .108

Figure 3-42 Removing the L1 Display Board . . . . . . . . . . .110

Figure 3-43 Installing the L1 Display Board . . . . . . . . . . .111

Figure A-1 Ethernet 10-Base-T/100-Base-T Port Pinout and Location. . . .129

Figure A-2 Keyboard and Mouse Port Pinouts and Locations . . . . . .130

Figure A-3 Serial Port Pinouts and Locations. . . . . . . . . . .131

Figure A-4 DVI-I Port Pinout and Location . . . . . . . . . . .137

Figure A-5 StereoView Port Pinout and Location . . . . . . . . .140

Figure A-6 Genlock Port Pinout and Location . . . . . . . . . .141

Figure A-7 Swap Ready Port Pinout and Location . . . . . . . . .142

Figure B-1 VCCI Notice (Japan Only) . . . . . . . . . . . . .146

Figure B-2 Chinese Class A Regulatory Notice . . . . . . . . . .146

Figure B-3 Korean Class A Regulatory Notice . . . . . . . . . .146

007-4564-001 xiii

List of Tables

Table 3-1 Component Access by Enclosure Panel . . . . . . . . . 52

Table 3-2 Customer-replaceable Components and Service Procedures . . . 56

Table 4-1 Bezel LED Signals . . . . . . . . . . . . . . .114

Table 4-2 Time Required to Run Offline Diagnostics . . . . . . . .118

Table 4-3 runalldiags Command-line Options . . . . . . . . .121

Table A-1 Physical Environment Specifications . . . . . . . . .126

Table A-2 Power Supply Specifications . . . . . . . . . . . .128

Table A-3 Ethernet 10-Base-T/100-Base-T Port Pinout . . . . . . . .129

Table A-4 Keyboard and Mouse Port Pinout . . . . . . . . . .130

Table A-5 Serial Port Pinout . . . . . . . . . . . . . . .132

Table A-6 Printer/Dumb Terminal Cable Pinout . . . . . . . . .133

Table A-7 PC Modem Cable Pinout . . . . . . . . . . . . .134

Table A-8 Female DB-9 to Female MiniDIN8 Adapter Cable Pinout . . . .135

Table A-9 Female DB-9 to Female DB-9 Adapter Cable Pinout . . . . .136

Table A-10 DVI-I Video Port Pinout . . . . . . . . . . . . .138

Table A-11 Supported VPro Graphics Board Scan Rates . . . . . . .139

Table A-12 Stereo View Pinout Assignments . . . . . . . . . . .140

Table A-13 Genlock Pinout Assignments . . . . . . . . . . . .141

Table A-14 Swap Ready Pinout Assignments . . . . . . . . . .142

007-4564-001 xv

About This Guide

Welcome to the user’s guide for the Silicon Graphics® Tezro™ visual workstation. Your

new workstation offers VPro graphics and a high-bandwidth architecture in a

convenient free-standing tower chassis. The workstation is available in a variety of

configurations and can be upgraded to meet your future needs.

Note: This User's Guide has been translated and is available to download from the SGI

Technical Publications Library at http://docs.sgi.com.

Enter the keywords Tezro visual workstation + <language> to find the version

you need.

This guide shows you how to set up, use, and troubleshoot your system. This guide is

provided for all end-users and SGI technical support staff. Most of the hardware tasks are

relatively simple and require no previous computer knowledge. A few tasks are more

difficult; they are easier to perform if you have some computer hardware experience.

Chapter Descriptions

The following topics are covered in this guide:

• Chapter 1, “Installation and Operation Procedures,” provides instructions for

unpacking and setting up your new workstation. It also explains how to power the

workstation on, log in, access programs, and power off the workstation.

• Chapter 2, “System Overview,” describes the parts of the system and gives an

overview of how they work together. It also provides configuration information and

describes optional components.

• Chapter 3, “Maintenance and Upgrade Procedures,” provides instructions for

installing and removing parts of the workstation. If the part you wish to add or

replace does not appear in this chapter, please contact your SGI service

representative.

007-4564-001 xvii

About This Guide

• Chapter 4, “Troubleshooting and Diagnostics,” explains how to find problems with

• Appendix A, “Technical Specifications and Pinouts,” provides specifications for the

• Appendix B, “Regulatory Specifications,” lists all regulatory information related to

Related Publications

For complete information on installing software, see the online Personal System

Administration Guide. It is located on your desktop in Toolchest > Help > Online Books.

For more advanced information, see the online IRIX Admin: Software Installation &

Licensing Guide. For system administration information, see the SGI_Admin section of

the online bookshelf.

your system and resolve them. It also includes instructions for running the system

diagnostics, which can help you find problems.

size, weight, and power consumption of the system. It also lists environmental

specifications and connector and cable pinouts.

use of the workstation in the United States and other countries and provides a list of

safety instructions to follow when installing, operating, or servicing the system.

It is always a good idea to back up your system. For instructions on backing up your

system, see the online Personal System Administration Guide.

Obtaining Publications

You can obtain SGI documentation, release notes, or man pages in the following ways:

• See the SGI Technical Publications Library at http://docs.sgi.com. Various formats

are available. This library contains the most recent and most comprehensive set of

online books, release notes, man pages, and other information.

• If it is installed on your SGI system, you can use InfoSearch, an online tool that

provides a more limited set of online books, release notes, and man pages. With an

IRIX system, select Help from the Toolchest, and then select InfoSearch. Or you can

type infosearch on a command line.

• You can also view release notes by typing either grelnotes or relnotes on a

command line.

• You can also view man pages by typing man <title> on a command line.

xviii 007-4564-001

About This Guide

SGI systems include a set of IRIX man pages, formatted in the standard UNIX “man

page” style. Important system configuration files and commands are documented on

man pages. These are found online on the internal system disk (or CD-ROM) and are

displayed using the man command. For example, to display the man page for the

Add_disk command, type the following on a command line:

man Add_disk

References in the documentation to these pages include the name of the command and

the section number in which the command is found. For example, “Add_disk(1)” refers

to the Add_disk command and indicates that it is found in section 1 of the IRIX

reference.

For additional information about displaying man pages using the man command, see

man(1).

In addition, the apropos command locates man pages basedon keywords. For example,

to display a list of man pages that describe disks, type the following on a command line:

apropos disk

Conventions

For information about setting up and using apropos, see apropos(1) and

makewhatis(1M).

The following conventions are used throughout this publication:

Convention Meaning

Command This fixed-space font denotes literal items such as commands, files,

routines, path names,signals, messages, and programming language

structures.

variable Italic typeface denotes variable entries and words or concepts being

defined. Italic typeface also is used for book titles.

user input This fixed-space font denotes literal items that the user enters in

interactive sessions. (Output is shown in nonbold, fixed-space font.)

[ ] Brackets enclose optional portions of a command or directive line.

... Ellipses indicate that a preceding element can be repeated.

007-4564-001 xix

About This Guide

Product Support

man page(x) Man page section identifiers appear in parentheses after man page

names.

GUI element This font denotes the names of graphical user interface (GUI)

elements such as windows, screens, dialog boxes, menus, toolbars,

icons, buttons, boxes, fields, and lists.

SGI provides a comprehensive product support and maintenance program for its

products, as follows:

• If you are in North America, contact the Technical Assistance Center at

+1 800 800 4SGI or contact your authorized service provider.

• If you are outside North America, contact the SGI subsidiary or authorized

distributor in your country.

Reader Comments

If you have comments about the technical accuracy, content, or organization of this

document, contact SGI. Be sure to include the title and document number of the manual

with your comments. (Online, the document number is located in the front matter of the

manual. In printed manuals, the document number is located at the bottom of each

page.)

You can contact SGI in any of the following ways:

• Send e-mail to the following address:

techpubs@sgi.com

• Use the Feedback option on the Technical Publications Library webpage:

http://docs.sgi.com

• Contact your customer service representative and ask that an incident be filed in the

SGI incident tracking system.

xx 007-4564-001

About This Guide

• Send mail to the following address:

Technical Publications

SGI

1600 Amphitheatre Parkway., M/S 535

Mountain View, CA 94043-1351

• Send a fax to the attention of “Technical Publications” at +1 650 932 0801.

SGI values your comments and will respond to them promptly.

007-4564-001 xxi

Chapter 1

1. Installation and Operation Procedures

This chapter shows you how to set up and use your Silicon Graphics® Tezro™ visual

workstation in the following sections:

• “Setting Up the Workstation” on page 1

• “Using the Workstation” on page 11

Setting Up the Workstation

This section covers the following topics:

• “Checking Your Shipment” on page 2

• “Lifting the Workstation” on page 4

• “Getting Acquainted” on page 5

• “Cabling the Workstation” on page 8

007-4564-001 1

1: Installation and Operation Procedures

Checking Your Shipment

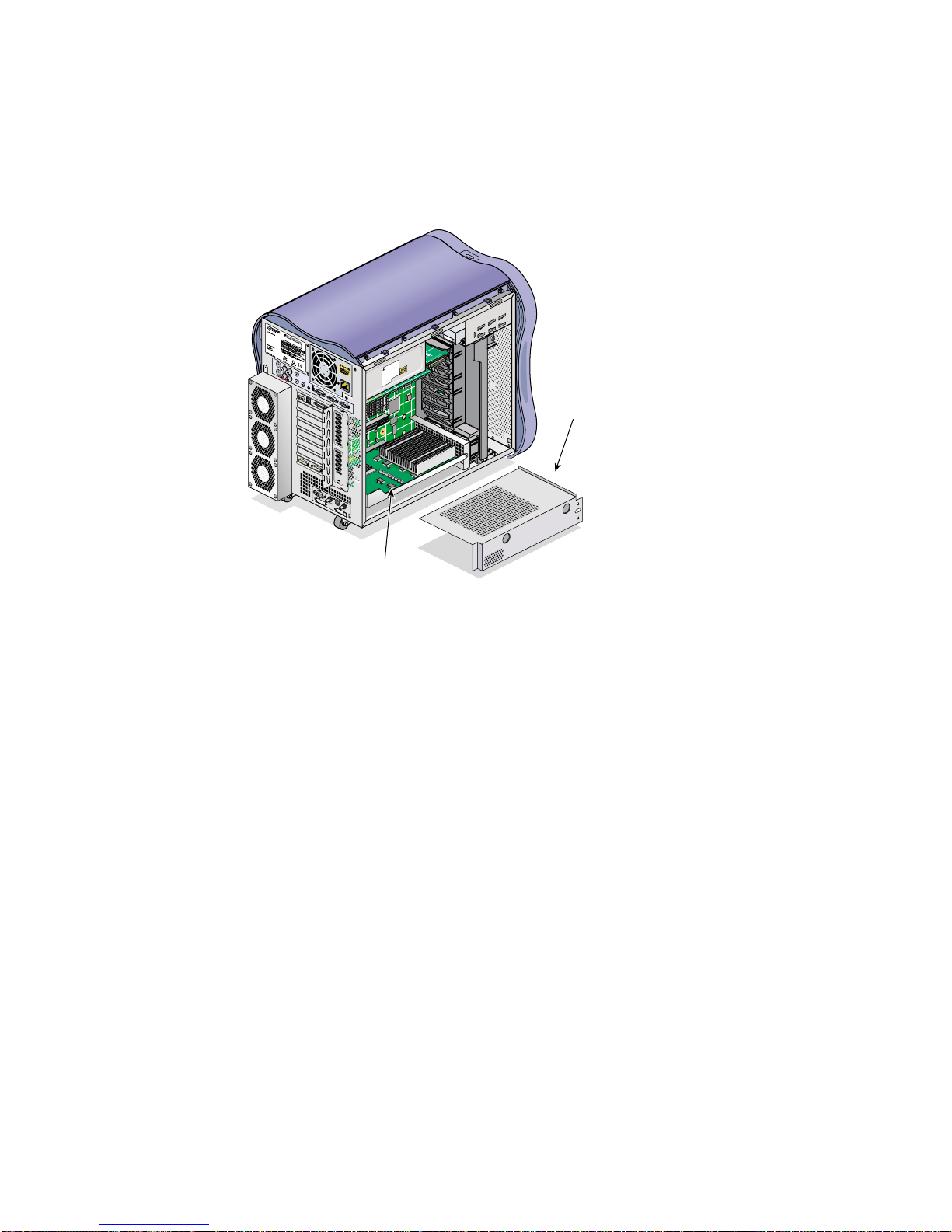

Figure 1-1 shows the basic components that ship with your workstation. If parts of your

shipment are damaged or missing, contact your support provider.

2 007-4564-001

Workstation

Setting Up the Workstation

Mouse

Wrist strap

Power cables - 10 ft. each

CDs

Figure 1-1 Workstation Shipment Contents

Keyboard

Monitor

Monitor cable - 3 meters

007-4564-001 3

1: Installation and Operation Procedures

Lifting the Workstation

The base workstation configuration weighs 60 lb. (27 kg). SGI highly recommends that

two people lift the unit when it must be moved. Lift the unit by placing your hands under

the bottom edges of the chassis, as shown in Figure 1-2.

Figure 1-2 Lifting the Workstation

4 007-4564-001

Getting Acquainted

Setting Up the Workstation

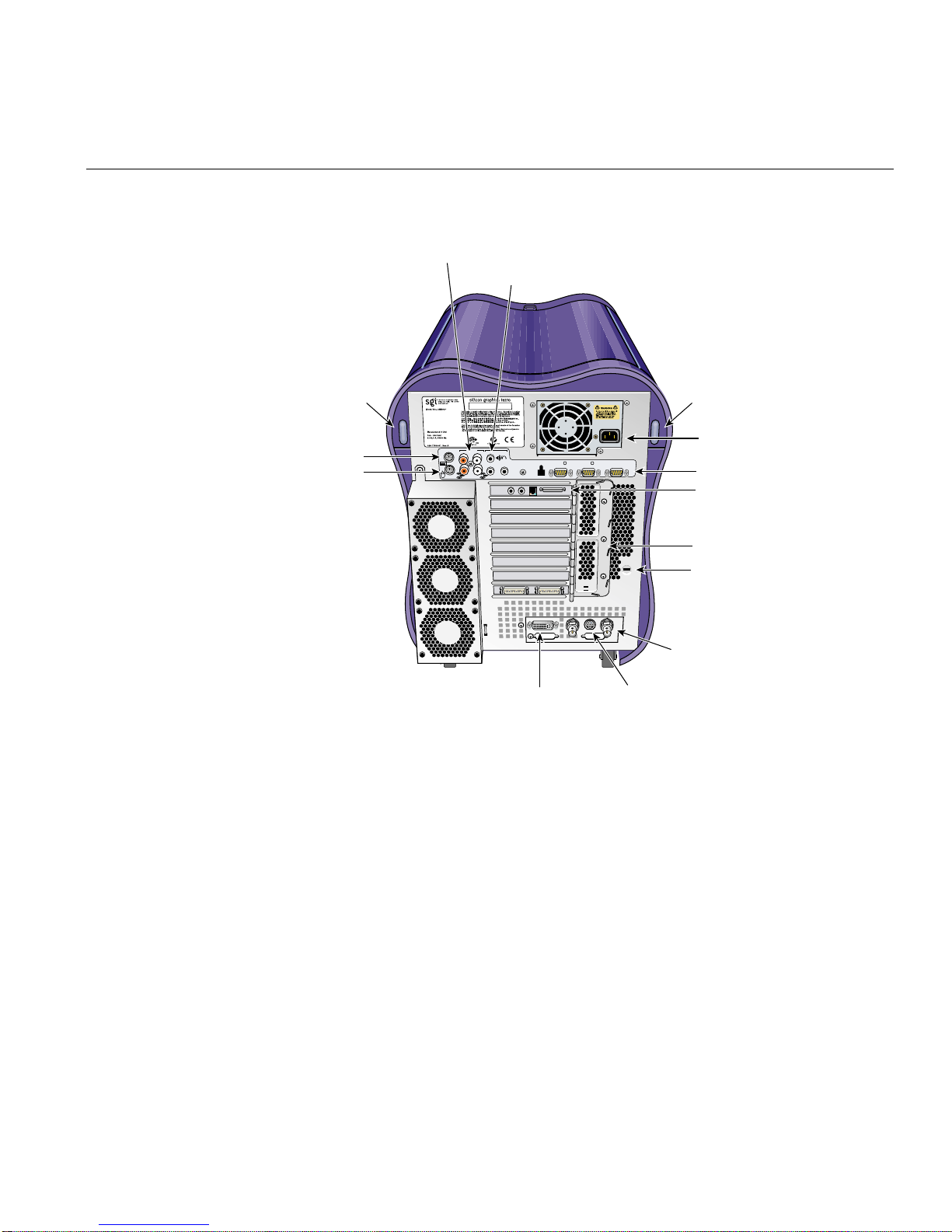

To become familiar with your workstation, refer to the following figures:

• Figure 1-3, which shows the front view of the workstation.

• Figure 1-4, which shows the rear view of the workstation.

After you have set up your workstation and logged in, refer to the following resources

for more information:

• From the Toolchest, select System > System Manager for information on the

workstation’s hardware and software.

• From the Toolchest, select System > System Manager > About This System to

learn about your system’s serial number, IP address, operating system, and more.

007-4564-001 5

1: Installation and Operation Procedures

Status LEDs

Door release

Door

DVD ROM drive

L1 display

SCSI drives

Reset switch

Power on/off

button

Figure 1-3 Front View of the Workstation

6 007-4564-001

Line in and Line out (left)

Line in and Line out (right)

Audio jacks

Setting Up the Workstation

Side panel

release button

LINE

MIC

Keyboard

Mouse

L

+12VDC

L1 PORT IOIOI 1

1.0A

R

IN OUT

DVI-I video

Figure 1-4 Rear View of the Workstation

IOIOI 2

CONSOLE

Stereo View

Side panel

release button

AC power connector

CONSOLE port

IO9 PCI card

PCI gate

Kensington

lock slot

Genlock

007-4564-001 7

1: Installation and Operation Procedures

Cabling the Workstation

To set up the workstation, follow these steps:

1. Connect the keyboard and mouse cables, as shown in Figure 1-5.

Keyboard connector

Mouse connector

R

R

Figure 1-5 Connecting the Keyboard and Mouse Cables

8 007-4564-001

Setting Up the Workstation

2. Connect the Ethernet cable to the Ethernet port on the IO9 card, as shown in

Figure 1-6.

Ethernet connector

R

R

Figure 1-6 Connecting the Ethernet Cable

3. Connect the monitor cable, as follows (see Figure 1-7):

• Connect the monitor-to-graphics cable to the monitor.

• Connect the monitor-to-graphics cable to the DVI-I video connector on the back

of your workstation.

007-4564-001 9

1: Installation and Operation Procedures

Note: The workstation can be connected to a variety of monitors. Your monitor and

monitor cable may differ from those shown. If your monitor has multiple inputs,

ensure that the source switch is set to the correct input port.

R

R

Monitor cable

Figure 1-7 Connecting the Monitor Cable

4. Connect the power cables to your workstation and monitor. Then plug them into

approved electrical outlets (see Figure 1-8).

10 007-4564-001

R

R

A

C

IN

Figure 1-8 Connecting the Workstation and Monitor Power Cables

Using the Workstation

You have finished setting up your workstation. Proceed to the next section.

Using the Workstation

This section provides information about using your Silicon Graphics Tezro visual

workstation. The topics covered include:

• “Logging In to the Workstation” on page 11

• “Using the IRIX Interactive Desktop” on page 13

• “Powering Off the Workstation” on page 15

• “Restarting from the Toolchest” on page 19

Logging In to the Workstation

Press the power buttons on your monitor and workstation as shown in Figure 1-9.

007-4564-001 11

1: Installation and Operation Procedures

Figure 1-9 Powering On the Workstation and Monitor

A green LED flashing below the L1 display on the front of the workstation indicates that

the system is booting. The monitor may remain blank for a few moments.

If your system is booting for the first time, you will see a login screen similar to the

example shown in Figure 1-10.

:

e

m

a

n

n

i

g

o

L

Figure 1-10 Login Screen

12 007-4564-001

If you have a login account, double-click the icon with your login name. If you do not

have a login account, double-click EZsetup and then follow the instructions for creating

a personal login account and setting up the networking software. Then you can begin

using the IRIX interactive desktop to create a personal work area and communicate with

other users on your network.

Using the IRIX Interactive Desktop

After you have logged in, you are ready to use the IRIX Interactive Desktop. By default,

several icons appear on your desktop: a folder icon representing your home directory, a

dumpster icon, and icons forany peripherals you installed, examples of which are shown

in Figure 1-11.

The peripheral icons show the current state of the respective devices. For example, if you

insert a music CD into the DVD-ROM drive, the icon changes. When you double-click

the icon, it opens CD Player, a utility that allows you to play music from a compact disc.

Using the Workstation

Figure 1-11 Peripheral Icons

The Toolchest, located at the top left corner of your screen, provides access to system

functions, applications, hardware and software information, and documentation, as

shown in Figure 1-12.

Note: For a complete description of the Toolchest, select Help > InfoSearch from the

Toolchest, and type Desktop Users Guide.

007-4564-001 13

1: Installation and Operation Procedures

Figure 1-12 Toolchest Menu

System Manager

From the Toolchest, select System > System Manager to display the System Manager,

which shows your workstation’s hardware and software information.

Online Documentation

From the Toolchest, select Help to display the library of online documentation. If your

workstation is turned off and you cannot access online documentation, this printed

guide contains all the information you need. You can also access this guide and most

manuals, man pages, and release notes in the SGI Technical Publications Library at

http://docs.sgi.com, and through InfoSearch, as described in the next section.

InfoSearch

From the Toolchest, select Help > InfoSearch and type the name of the desired book or

topic to searchonline books, man pages, and release notes thatcover end-user, developer,

and system administrator information.

The Console Window

The small box next to the Toolchest is the Console window, as shown in Figure 1-13. It

appears as a small box because it is minimized. You can open it to its full size by clicking

it. Many system status and error messages appear in this window.

14 007-4564-001

Figure 1-13 Console Window

If you click in the Console window, an IRIX shell appears, where you can type IRIX

commands. For information on IRIX commands, select Help > Online Books. This will

launch the InfoSearch tool, which allows you to read documentation stored on your

workstation. Enter "Desktop User's Guide" in the Keyword search box. IRIX

commands are covered in Appendix A.

Powering Off the Workstation

Using the Workstation

You can shut down and power off your workstation in either of two ways, which are

explained in the following sections:

• “Powering Off with the Power Button” on page 15

• “Powering Off from the Toolchest” on page 17

Powering Off with the Power Button

To power off your workstation with the power button, follow these steps:

1. Open the door on the front of your workstation.

2. Press the power button, as shown in Figure 1-14.

007-4564-001 15

1: Installation and Operation Procedures

Figure 1-14 Powering Off the Workstation

Within a few seconds, a shutdown notifier appears, as shown in Figure 1-15. Within

a minute, the system powers off automatically.

Figure 1-15 System Shutdown Notifier

3. Turn off your monitor by pressing the monitor power button.

If your system does not power off and you do not see any activity for several

minutes, press the power button again.

Note: If you press the power button a second time, the system should power off

immediately, but this method does not perform a clean shutdown. Avoid using this

method unless the system does not respond for several minutes after you first press

the power button.

If pressing the power button a second time does not work, use a pen to press the

reset switch, shown in Figure 1-16. If the system still fails to power off, unplug the

power cable from the rear of your workstation and contact your service provider.

16 007-4564-001

Figure 1-16 Power Button and Reset Switch

Powering Off from the Toolchest

Using the Workstation

Reset switch

Power on/off

button

If you have root level access to the workstation, you can shut down your system from the

Toolchest. as follows:

1. From the Toolchest, select System > System Shutdown.

After a few seconds, a shutdown caution message appears, as shown in Figure 1-17.

007-4564-001 17

1: Installation and Operation Procedures

Figure 1-17 Shutdown Caution Message

2. Click the Power off the system check box.

The Shut Down System window appears. At this point, you can shut down and

power off the system or configure it to restart at a designated time, as shown in

Figure 1-18.

18 007-4564-001

Using the Workstation

Figure 1-18 Shutdown System Window

3. Click OK to shut down and power off the system.

The shutdown notifier appears, as shown in Figure 1-19. After a few seconds, the

system powers off.

Figure 1-19 System Shutdown Notifier

Restarting from the Toolchest

If you have root level access to the workstation, you can restart the system from the

Toolchest.

1. From the Toolchest, select System > Restart.

After a few seconds the restart notifier appears, as shown in Figure 1-20.

007-4564-001 19

1: Installation and Operation Procedures

Figure 1-20 Restart Notifier

20 007-4564-001

Using the Workstation

2. Click OK in the restart notifier.

The shutdown notifier appears, as shown in Figure 1-21.

Figure 1-21 System Shutdown Notifier

After a brief delay, the power off/restart notifier appears, as shown in Figure 1-22.

Figure 1-22 Power Off/Restart Notifier

3. Click Restart.

The restart notifier informs you that the system is coming up (restarting), as shown in

Figure 1-23.

Figure 1-23 Restart Notifier

007-4564-001 21

Chapter 2

2. System Overview

The Silicon Graphics® Tezro™ visual workstation is a high-power, high-performance

system. It features VPro™ graphics, 64-bit MIPS processors, and a high-bandwidth

architecture in a convenient free-standing tower chassis. This chapter provides general

information about the components of the workstation in the following sections:

• “System Enclosure” on page 24

• “System Node Board” on page 26

• “Processors” on page 27

• “Memory DIMMs” on page 27

• “Interface Board” on page 29

• “IO9 Board” on page 31

• “I/O Daughtercard” on page 32

• “Internal Hard Disk Drives” on page 33

• “DVD-ROM Drive” on page 35

• “Graphics Module” on page 35

• “PCI Buses” on page 38

• “Power Supply” on page 40

• “Cooling System” on page 40

• “Optional Components, Peripherals, and Upgrades” on page 42

007-4564-001 23

2: System Overview

System Enclosure

The Silicon Graphics Tezro visual workstation is installed in the system enclosure as

shown in Figure 2-1 and Figure 2-2. The enclosure provides structure and protection for

the internal components.

SCSI drive housing

IP53 processors

SCSI backplane

I/O daughtercard

SCSI drive fan

DIMMs

Airflow baffle

Figure 2-1 System Enclosure Layout (Right-front view)

24 007-4564-001

Power supply

R

R

R

R

R

R

Graphics module

System Enclosure

IO9 board

DVD drive housing

Interface

board

R

Fan wall

Digital media

XIO option board

Figure 2-2 System Enclosure Layout (Left-rear View)

007-4564-001 25

2: System Overview

System Node Board

The workstation is powered by an IP53 system node board (see Figure 2-3). The system

node board provides a mounting point and connectivity for the processor(s) and

memory DIMMs. The node board connects to the interface board via two connectors on

its underside.

Interface board

Figure 2-3 IP53 System Node Board

26 007-4564-001

DIMMs

Processors (under cover)

IP53 node board

Processors

Memory DIMMs

Processors

The workstation is available with 1, 2, or 4 R16000 MIPS processors. These processors are

available in several different clock speeds. Each processor has a total of 64 KB onboard

cache memory and 4-MB of external cache memory. The processors are mounted on the

system node board under a protective cover.

The workstation is configured with a minimum of 512 MB of memory and a maximum

of 8 GB of memory. Your system uses double data rate synchronous dynamic

random-access memory (DDR SDRAM). The DIMMs used in your workstation are

compatible with the DIMMs used in Origin 300, Origin 3000, and Onyx 3000 systems.

The DIMMs used in your workstation are not compatible with the DIMMs used in

Octane, Octane2, O2, O2+, Origin 200, Origin 2000, or Onyx2 systems.

The memory DIMMS are installed in eight DIMM slots on the system node board. The

DIMM slots are numbered 0 through 7 (see Figure 2-4). The slots are grouped into four

pairs of two DIMMs. The DIMM pairs are numbered as follows:

• DIMM pair 1: slots 0 and 1

• DIMM pair 2: slots 2 and 3

• DIMM pair 3: slots 4 and 5

• DIMM pair 4: slots 6 and 7

007-4564-001 27

2: System Overview

DIMM slot 7 DIMM Pair 4

DIMM slot 5 DIMM Pair 3

DIMM slot 3 DIMM Pair 2

DIMM slot 1 DIMM Pair 1

2.5-V VRM

1.5-V VRM

1.1-V to 1.8-V VRM

DIMM slot 6 DIMM Pair 4

DIMM slot 4 DIMM Pair 3

DIMM slot 2 DIMM Pair 2

DIMM slot 0 DIMM Pair 1

DIMM slot 7 DIMM Pair 4

DIMM slot 5 DIMM Pair 3

DIMM slot 3 DIMM Pair 2

DIMM slot 1 DIMM Pair 1

DIMM slot 6 DIMM Pair 4

DIMM slot 4 DIMM Pair 3

DIMM slot 2 DIMM Pair 2

DIMM slot 0 DIMM Pair 1

Figure 2-4 DIMM Sockets and Pairs

The following configuration rules apply to the memory banks and DIMMs in your

system:

• DIMM pair 1 must be present.

• DIMMs in the same DIMM pair must be the same density. For example, if DIMM 0

is 512 MB, then DIMM 1 must be 512 MB.

• DIMMs must be installed in pairs.

• The minimum amount of memory that should be installed in a 1-processor

workstation is 512 MB; the minimum for a 2- or 4-processor workstation is 1 GB.

For information on removing or installing memory DIMMs, see “Installing or Removing

a Memory DIMM” on page 63.

28 007-4564-001

Interface Board

Interface Board

The interface board connects the processors and memory mounted on the node board to

the graphics and I/O components of the system. It also provides card slots for the PCI

and graphics boards and distributes power to the system components. The interface

board has the following connectors (see Figure 2-5):

• XIO Slot connectors

There are two XIO slots: one for the VPro graphics board, and one for the

DMediaPro DM3-to-VBOB board

• PCI Slot connectors

There are eight PCI-X slots divided into three buses. For more information on the

PCI slots and buses, see “PCI Buses” on page 38.

The interface board also supplies connectivity and power to many of the system

components through the following connectors (see Figure 2-5):

• L1 display connector

• LED connector

• Power input connectors

• Fan wall connector

Note: Figure 2-5 depicts the interface board in a 2- or 4-processor workstation. The

interface board in a 1-processor workstation has 4 PCI-X slots (3 available) and 1 XIO slot.

007-4564-001 29

2: System Overview

PCI slots

Power input

connector

LED

connector

L1 display

connector

Fan wall

connector

XIO slot

for optional XIO

boards

XIO slot for

VPro graphics board

Figure 2-5 Interface Board Connectors

30 007-4564-001

IO9 Board

IO9 Board

The IO9 board is the full-length PCI board that is installed in PCI bus 1, slot 1. It provides

the following I/O connectors and interfaces for the workstation (see Figure 2-6):

• An internal IDE connector for the internal DVD-ROM drive

• An internal SCSI connector for the hard disk drives

• An external SCSI connector for optional external drives

• Real time interrupt in and out (RTI input and RTI output) connectors

• A 10/100BaseT Ethernet connector (RJ45)

The IO9 board also contains the non-volatile RAM and time-of-day clock for the system.

For technical specifications and pinouts of these connectors, see Appendix A, “Technical

Specifications and Pinouts”.

IO9 board

10/100BaseT

Ethernet

Figure 2-6 IO9 Board

007-4564-001 31

External SCSI

connector

RTI out

RTI in

Internal IDE connector

for DVD-ROM drive

Internal SCSI connector

for hard drives

2: System Overview

I/O Daughtercard

The I/O daughtercard is the long narrow board that is mounted on the rear of the

enclosure just below the power supply. This card acts as an extension of the IO9 board; it

provides the following connectors (see Figure 2-7):

• Two PS2 ports for keyboard and mouse

• Four RCA audio jacks (2 inputs, 2 outputs)

• Power port for external speakers (2.5 mm jack)

• Two 3.5 mm stereo audio jacks (one input, one output)

• Two serial ports (DB9)

• One L1 diagnostic port (USB-B)

• One console port (DB9)

32 007-4564-001

Internal Hard Disk Drives

Figure 2-7 I/O Daughtercard

For technical specifications and pinout of these connectors, refer to Appendix A,

“Technical Specifications and Pinouts”.

Internal Hard Disk Drives

LINE

L

R

IN OUT

MIC

+12VDC

1.0A

L1 PORT IOIOI 1

IOIOI 2

CONSOLE

The Silicon Graphics Tezro visual workstation supports one or two internal SCSI hard

disk drives. These drives provide the unit with large amounts of storage and quick access

times.

The hard disk drives in the workstation are sled mounted (see Figure 2-8). The drive

sleds provide a safe and easy way to install and remove the drives. The drive sleds also

007-4564-001 33

2: System Overview

provides a positive, locking connection to the SCSI backplane, which connects the disk

drives to the IO9 board (see Figure 2-9).

Figure 2-8 Hard Disk Drive Sled

DVD-ROM drive

Disk 2

Disk 1

IO9 board

IDE connector

SCSI connector

Figure 2-9 Internal Hard Disk Drive Locations

34 007-4564-001

DVD-ROM Drive

DVD-ROM Drive

The disks are numbered 1 and 2, with 1 being the bottom disk and 2 being the top. The

SCSI ID number of each disk must correspond with these drive numbers. Disk 1 is the

system disk, which has the IRIX operating system installed on it. Your workstation will

not function without the system disk.

For information on removing or installing an internal hard disk drive, refer to “Installing

or Removing Internal Hard Disk Drives” on page 67.

Your workstation supports an optional internal DVD-ROM drive.

The drive is installed in the 5.25-in. drive bay, as shown in Figure 2-9.

For information about installing and removing the DVD-ROM drive, refer to “Installing

or Removing the DVD-ROM Drive” on page 71.

Graphics Module

The graphics module is located near the bottom of your workstation, as shown in

Figure 2-10. It is made up of a metal cover, the VPro graphics boardand the optional Dual

Channel Display daughterboard. The metal shell protects the graphics board and

optional daughterboard and shields them from electrical interference.

The VPro graphics board has the following features:

• 128 MB of onboard SDRAM

• Analog RGB and TMDS video on a single DVI-I monitor port

• Additional ports for Swap Ready, Stereo View, and Genlock signals

The optional Dual Channel Display (DCD-2) daughterboard supplies two additional

DVI-I monitor ports. The daughterboard connects to the underside of the VPro graphics

board and allows you to display data across two monitors at once. For more information

about the optional Dual Channel Display daughterboard, contact your SGI sales

representative.

007-4564-001 35

2: System Overview

R

R

R

R

R

R

Graphics module

Figure 2-10 Locating the Graphics Module

Cover

Figure 2-11 shows the I/O ports of the VPro graphics board and optional Dual Channel

Display daughterboard.

36 007-4564-001

Graphics Module

Stereo View

L

R

L

Genlock

DVI-I video

Swap Ready

DCD right

DCD left

Figure 2-11 VPro Graphics and Dual Channel Display I/O Ports

For more information on the VPro graphics board and Dual Channel Display (DCD-2)

I/O ports, refer to “VPro Graphics Board I/O Port Specifications” in Appendix A.

007-4564-001 37

2: System Overview

PCI Buses

The 2- and 4-processor workstations have eight 64-bit, 3.3-V PCI-X slots which are

divided into four buses. The1-processor workstation has four 64-bit, 3.3-V PCI-X slots

which are divided into two buses. The IO9 board always occupies bus 1, slot 1, leaving

the remaining slots available for other boards. Each bus can support card speeds of up to

100 MHz. The slots are divided into buses, as shown in Figure 2-12.

Note: Figure 2-12 shows a 2- or 4-processor workstation. Buses 3 and 4 are not present

in 1 processor workstations.

• PCI Bus 1 has one slot, which always contains the IO9 board.

• PCI Bus 2 has three slots.

• PCI Buses 3 and 4 each have two slots.

• Bus 4, slot 2 shares a chassis opening with the second XIO slot. If you intend to

install a second XIO board, such as the DM3 Digital Media board, you cannot install

a PCI board in this slot.

Follow these rules when installing PCI and PCI-X boards on the PCI-X buses:

• Avoid placing high and low speed cards one the same bus. This forces the high

speed card to run at the same speed as the slower card. For example, placing a

100-MHz board on the same bus as a 33-MHz board forces the 100-MHz board to

run at the slower speed.

• Avoid placing storage and network boards on the same bus. These types of boards

use large amounts of bandwidth, and placing both types on the same bus can cause

the system to exceed the bandwidth of the bus.

• Spread the PCI boards across the buses as evenly as possible. For example, if you

have three PCI boards and three available PCI buses, install one board on each bus.

If you must install more than one board on a bus, group the boards by speed.

38 007-4564-001

PCI bus 1 slot 1

PCI bus 2 slot 1

PCI bus 2 slot 2

PCI bus 2 slot 3

PCI bus 3 slot 1

PCI bus 3 slot 2

PCI bus 4 slot 1

PCI bus 4 slot 2

PCI Buses

Figure 2-12 PCI Buses and Slots

For a list of available PCI boards see “PCI Boards” on page 42 or contact your SGI sales

representative.

007-4564-001 39

2: System Overview

Power Supply

The power supply for the workstation is located in the top rear quadrant of the chassis,

as shown in Figure 2-13.

Power supply

R

R

R

R

R

R

R

Figure 2-13 Power Supply Location

The power supply provides up to 550 watts of power to the node and interface boards,

internal hard disk drives, DVD-ROM drive, and other optional components installed in

the enclosure. For detailed information about the power supply specifications, refer to

Appendix A, “Technical Specifications and Pinouts”.

Cooling System

The workstation uses a total of eight fans to cool the internal components. The following

components make up the cooling system (see Figure 2-14):

• Fan Wall

The fan wall is a plastic housing that contains two 60-mm (2.4-in.) fans and two

80-mm (3.1-in.) fans. These fans provide cooling for the interface board, PCI boards,

and the graphics module.

40 007-4564-001

Cooling System

• Disk Drive Fan

The disk drive fan is an 80-mm fan that mounts directly behind the disk drives.

• Rear Fan Assembly

The rear fan assembly is made up of a sheet metal enclosure and three 80-mm fans.

These fans provide cooling for the system node board and memory DIMMs. The

rear fan assembly is mounted to the rear of the enclosure with hooks and a screw.

Note: The power supply is cooled by its own internal fan.

Disk drive fan

Power supply fan

Fan wall

Rear fan assembly

Figure 2-14 Cooling System Components

007-4564-001 41

2: System Overview

Optional Components, Peripherals, and Upgrades

Various optional components, peripherals, and upgrades are available for your

workstation. The following sections describe some of these options:

• “PCI Boards” on page 42

• “Memory Upgrades” on page 43

• “Processor Upgrades” on page 43

• “Graphics Options” on page 43

• “Storage Upgrades” on page 44

• “Displays” on page 44

• “Peripherals” on page 44

For more information about upgrading your system contact your SGI sales

representative.

PCI Boards

A wide variety of PCI options are available for you workstation, including networking,

audio, and video boards. The following boards a sample of the available options:

• Dual port Ultra3 SCSI LVD or single-ended SCSI adapter

• Single-port 1-gigabit Fibre Channel board with optical or copper connector

• Single- and dual-port 2-gigabit Fibre Channel boards with optical connectors

• 33- and 64-MHz, 64-bit single port ATM boards

• 1-port copper gigabit Ethernet adapter

• 1-port 1000Base-SX gigabit Ethernet adapter

• 8-channel Digital Audio I/O board

• DMedia DM3-to-VBOB board (2-or 4-processor workstations only)

For a complete list of available boards, contact your sales representative.

42 007-4564-001

Memory Upgrades

Processor Upgrades

Optional Components, Peripherals, and Upgrades

The following memory upgrades are available for the workstation:

• 512-MB DIMM pair (1-processor workstations only)

• 1-GB DIMM pair

• 2-GB DIMM pair

Note: The workstation supports a maximum of eight memory DIMMs totalling 8 GB.

Memory DIMMs must be installed in pairs of the same size.

The workstation is available with 1, 2, or 4 processors. The processors are available with

several different clock speeds. Processor upgrades are accomplished by replacing the

entire system node board. 2-processor workstations can be upgraded to 4-processor

workstations by replacing the node board.

Note: 1-processor workstations cannot be upgraded with 2- or 4-processor node boards.

Graphics Options

A varietyof graphics options are available for you workstation. The following boards are

a sample of the available options:

• Dual-Channel Display (DCD-2) daughterboard

This board attaches to the VPro graphics board and allows data to be displayed

across two monitors. It has two DVI-I video ports.

• DMediaPro DM5 HD & SD Graphics to Video Output Option

This board allows direct output from graphics to video. The board is available with

or without the video break-out box (VBOB) option.

• DMediaPro DM3 HD & SD Graphics Video I/O XIO

This board allows direct input and output between graphics and video. The video

break-out box (VBOB) is included with this board.

007-4564-001 43

2: System Overview

Storage Upgrades

For a complete list of available graphics options, contact your sales representative.

The following storage upgrades are available for the workstation:

• 18-GB internal Ultra SCSI hard disk drive, 15000 RPM

• 73-GB internal Ultra SCSI hard disk drive, 10000 RPM

• External SCSI DAT drive

• Internal DVD-ROM drive

The workstation can also be connected to a storage array, such as the SGI Total

Performance 9100, SGI Total Performance 9300, or SGI Total Performance 9400. These

disk arrays offer large storage capacities in both RAID and JBOD configurations.

In addition to the items listed above, there are a variety of other storage solutions

available from SGI. For more, information, contact your SGI sales representative.

Displays

The following displays are available with the workstation:

• 21-in. SGI CRT monitor

• 24-in. SGI CRT monitor (wide-aspect-ratio)

• Silicon Graphics F180 (18.1-in. flat panel monitor)

• Silicon Graphics F220 (22-in. wide-aspect-ratio flat panel monitor)

Peripherals

The following peripherals are available with the workstation:

• 3-button mouse

• beeping keyboard

• Speakers

• Magellan Spaceball programmable trackball

44 007-4564-001

Optional Components, Peripherals, and Upgrades

For a complete list of available components, contact your SGI sales representative or see

the following webpage:

http://www.sgi.com/peripherals/workstation/

007-4564-001 45

Chapter 3

3. Maintenance and Upgrade Procedures

This chapter provides safety information and instructions for adding or removing

components from your Silicon Graphics® Tezro™ visual workstation. These topics are

covered in the following sections:

• “Safety Instructions” on page 48

• “Ordering Parts” on page 49

• “Required Tools” on page 49

• “Preparing the Workstation for Service” on page 49

• “Returning the Workstation to Service” on page 57

• “Installing or Removing a Memory DIMM” on page 63

• “Installing or Removing Internal Hard Disk Drives” on page 67

• “Installing or Removing the DVD-ROM Drive” on page 71

• “Replacing the IO9 Board” on page 76

• “Installing or Removing XIO Boards” on page 81

• “Installing or Removing PCI Boards” on page 88

• “Installing or Removing External devices” on page 93

• “Replacing Cooling System Components” on page 94

• “Replacing Internal Cables” on page 99

• “Replacing Enclosure Components” on page 106

Caution: For your own safety and to avoid damage to your equipment, do not attempt

to install or remove components that are not listed in this chapter.

007-4564-001 47

3: Maintenance and Upgrade Procedures

Safety Instructions

Read and follow these instructions carefully before servicing your workstation.

1. Follow all warnings and instructions marked on the system and noted in this and

other documentation included with this system.

2. Unplug the system from the wall outlet before cleaning. Do not use liquid cleaners

or aerosol cleaners. Use a damp cloth for cleaning.

3. Do not use the workstation near water.

4. Do not place the system on an unstable cart, stand, or table. It may fall, causing

serious damage to the system.

5. Slots and openings on the workstation are provided for ventilation. To ensure

reliable operation of the system and to protect it from overheating, these openings

must not be blocked or covered. This system should never be placed near or over a

radiator or heat register, or in a built-in installation, unless proper ventilation is

provided.

6. This system should be operated from the type of power indicated on the marking

label. If you are not sure of the type of power available, consult your dealer or local

power company.

7. Do not allow anything to rest on the power cord. Do not locate this system where

people will walk on the cord.

8. Never push objects of any kind into this system through cabinet slots as they may

touch dangerous voltage points or short out parts, which could result in a fire or

electric shock. Never spill liquid of any kind on the system.

9. Do not attempt to service this system yourself except as noted in this guide.

Opening or removing covers of node and switch internal components may expose

you to dangerous voltage points or other risks. Refer all servicing to qualified

service personnel.

10. Unplug this system from the wall outlet and refer servicing to qualified service

personnel under the following conditions:

• When the power cord or plug is damaged or frayed.

• If liquid has been spilled into the system.

• If the system has been exposed to rain or water.

• If the system does not operate normally when the operating instructions are

followed. Adjust only those controls that are covered by the operating

48 007-4564-001

Ordering Parts

Ordering Parts

instructions since improper adjustment of other controls may result in damage

and will often require extensive work by a qualified technician to restore the

system to normal condition.

• If the system has been dropped or the cabinet has been damaged.

• If the system exhibits a distinct change in performance, indicating a need for

service.

11. Use only the proper type of power supply cord set (provided with the system) for

this unit.

12. Only qualified service personnel should replace the soldered lithium battery(s) in

the workstation. Please see “Lithium Battery Compliance Statement” on page 147

for more information.

Replacement parts are available directly from your local service provider. Contact the

SGI support office for more information.

Required Tools

All of the procedures in this chapter can be performed with the following tools:

• Wrist grounding strap

• T15 Torx driver

• Small flat-blade screwdriver

• Small phillips-blade screwdriver

Preparing the Workstation for Service

This section shows you how to open the workstation for service and protect the

components from static damage. The following topics are covered:

• “Powering Off and Disconnecting the Workstation” on page 50

• “Removing the Enclosure Panels” on page 51

007-4564-001 49

3: Maintenance and Upgrade Procedures

• “Installing or Removing Internal Parts” on page 56

Powering Off and Disconnecting the Workstation

Follow these steps to power off and remove cables from your workstation:

1. If you are logged in to the workstation, log out. Then, press the power buttons to

power off your workstation and monitor (see Figure 3-1).

Figure 3-1 Powering Off the System

2. Disconnect all of the cables from the rear of the workstation. Be sure to note where

each cable is connected, so that you can reconnect them correctly when you have

finished servicing the system.

Note: You do not need to disconnect the cables or move the workstation for some

procedures. Refer to the individual procedures for detailed instructions on preparing the

system.

3. Move the workstation to a sturdy, flat surface. Always use two people to move the

workstation (see Figure 3-2).

50 007-4564-001

Preparing the Workstation for Service

Figure 3-2 Moving the Workstation

Removing the Enclosure Panels

This section shows you how to open the enclosure in the following sections.

• “Determining Which Enclosure Panels to Remove” on page 52

• “Removing the Left or Right Side Panel” on page 52

• “Removing the Enclosure Bezel” on page 54

007-4564-001 51

3: Maintenance and Upgrade Procedures

Determining Which Enclosure Panels to Remove

To determine which side(s) of the enclosure you need to remove to access specific

components, see Table 3-1. If a part appears in two columns, you must remove both

panels in order to access that component.

Note: Table 3-1 assumes that you are looking at the front of the workstation.

Table 3-1 Component Access by Enclosure Panel

Right Side Panel Left Side Panel Front Side Panel (Bezel)

Memory DIMMS

Hard Disk Drive Fan

Rear Fan Assembly

After you have determined which side(s) of the enclosure you need to open, proceed to

the appropriate section.

Removing the Left or Right Side Panel

Follow these steps to open the left or right side of the enclosure:

1. Press the panel release button on the rear of the enclosure. Then swing the top edge

of the panel away from the enclosure (see Figure 3-3).

2. Lift the panel until the hooks on the bottom edge clear the lip on the base of the

enclosure. Then swing the bottom edge of the panel away from the enclosure and

place it in a safe location (see Figure 3-3).

IO9 board

XIO boards

L1 display cable

LED cable

PCI boards

DVD-ROM drive

Fan wall

L1 display

L1 display cable

LED cable

52 007-4564-001

Panel

release

button

Preparing the Workstation for Service

Panel

release

L

button

L

Figure 3-3 Removing the Enclosure Side Panel

If you only need to remove the left or right side panel, proceed to “Installing or

Removing Internal Parts” on page 56. If you need to remove the bezel of the workstation,

proceed to the next section.

007-4564-001 53

L

Hooks

3: Maintenance and Upgrade Procedures

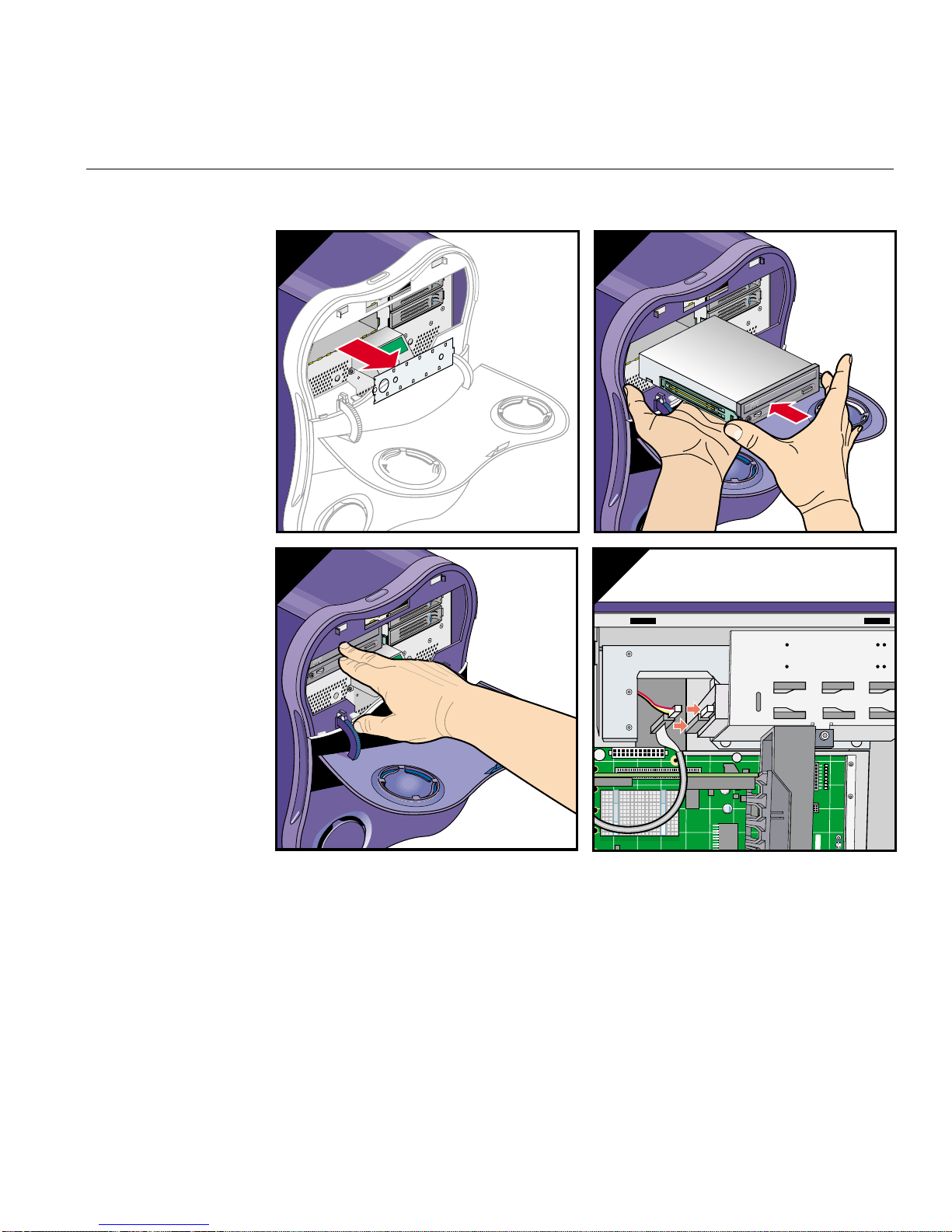

Removing the Enclosure Bezel

The front of the enclosure is covered by a decorative plastic bezel. The bezel is made up

of two pieces: the bezel frame and the drive shroud. The bezel frame covers the front of

the enclosure. The drive shroud mounts inside the bezel frame and covers the area

adjacent to the DVD-ROM drive and hard disk drives.

Follow these steps to remove the bezel from the front of the enclosure:

1. Open the door on the front of the bezel.Use a small flat-bladed screwdriver to press

down in the two slots at the top of the drive shroud.

2. Tilt the top of the drive shroud toward you. Then lift the shroud off of the three tabs

that are supporting it and place it in a secure location.

3. Remove the five screws that were covered by the drive shroud. Place these screws in

a secure location.

4. Tilt the top of the bezel frame toward you. Then reach behind the bezel frame and

disconnect the LED cable by squeezing the spring clips on the LED cable connector

and gently pulling. Lift the bezel off of the enclosure and place it in a secure

location.

54 007-4564-001

Slots

Preparing the Workstation for Service

BA

C

Figure 3-4 Removing the Bezel

D

Proceed to the next section to install or remove internal components.

Cable

connector

007-4564-001 55

3: Maintenance and Upgrade Procedures

Installing or Removing Internal Parts

Warning: The heat sinks on the interface board getvery hot. Wait5 minutes after

powering off your workstation before you touch any internal components.

Touching the heat sinks could result in burns if a cooling-off period is not

observed.

Caution: The components inside your workstation are extremely sensitive to static

electricity. Always wear the wrist strap when you work with parts inside your

workstation. Follow these steps to use the wrist strap:

1. Unroll the first two folds of the strap.

2. Wrap the exposed adhesive side firmly around your wrist, unroll the rest of the

strap, and then peel the liner from the copper foil at the opposite end.

3. Attach the copper foil to an exposed electrical ground, such as a metal part of the

chassis.

After you attach the wrist strap, you can install or remove internal parts of the

workstation. Table 3-2 contains a list of all of the internal components that you can install

or remove and the procedure associated with each one.

Caution: Do not attempt to install or remove components that are not listed in Table 3-2.

Components not listed in Table 3-2 must be installed or removed by a qualified SGI field

engineer.

Table 3-2 Customer-replaceable Components and Service Procedures

Component Procedure

Memory DIMMs “Installing or Removing a Memory DIMM” on page 63

Internal hard disk drives “Installing or Removing Internal Hard Disk Drives” on

page 67

DVD-ROM Drive “Installing or Removing the DVD-ROM Drive” on page 71

56 007-4564-001

Returning the Workstation to Service

Table 3-2 Customer-replaceable Components and Service Procedures (continued)

Component Procedure

PCI and XIO Boards:

IO9 board

XIO boards

PCI boards

Fans:

Fan wall

Hard disk drive fan

Rear fan assembly

Internal Cables:

L1 display cable

LED cable

DVD-ROM drive cable

Enclosure Components:

Enclosure Bezel Assembly

Enclosure Side Plastics

Enclosure Top Plastics

L1 Controller Display

“Replacing the IO9 Board” on page 76

“Installing or Removing XIO Boards” on page 81

“Installing or Removing PCI Boards” on page 88

“Replacing the Fan Wall” on page 94

“Replacing the Hard Disk Drive Fan” on page 95

“Replacing the Rear Fan Assembly” on page 98

“Replacing the L1 Display Cable” on page 100

“Replacing the LED Cable” on page 103

“Replacing the DVD-ROM Drive Cable” on page 105

“Replacing the Bezel Assembly” on page 107

“Replacing the Side Plastics” on page 107

“Replacing the Top Plastics” on page 107

“Replacing the L1 Display” on page 108

When you are finished installing or removing internal components, proceed to the next

section.

Returning the Workstation to Service

The following sections contain instructions for returning the workstation to service:

• “Installing the Bezel” on page 58

• “Installing the Side Panels” on page 60

• “Cabling and Powering on the Workstation” on page 61

007-4564-001 57

3: Maintenance and Upgrade Procedures

Installing the Bezel

Follow these instructions to install the bezel.

1. Align the tabs on the lower portion of the bezel with the holes in the enclosure.

Insert the tabs into the holes and press the bezel against the enclosure to ensure that

it is properly seated.

2. Lift the bezel slightly to align the screw holes with the mounting holes in the

enclosure. Then install the five screws that secure the bezel to the enclosure.

3. Align the three tabs on the lower edge of the drive shroud with the corresponding

holes on the face of the enclosure. Then swing upper edge of the drive shroud

toward the enclosure and press the two tabs on the upper edge into their holes.

Press the shroud against the enclosure to ensure that it is properly seated.

58 007-4564-001

Returning the Workstation to Service

A

C

B

D

Figure 3-5 Installing the Bezel

007-4564-001 59

3: Maintenance and Upgrade Procedures

Installing the Side Panels

Follow these steps to install a side panel (see Figure 3-6):

1. Align the hooks on bottom edge of the side panel over the lip on the bottom edge of

the enclosure.

2. Swing the side of the panel up. Press the top edge of the panel against the enclosure

to ensure that it is properly seated.

60 007-4564-001

Returning the Workstation to Service

Tabs

L

Figure 3-6 Replacing the Side Panel

Cabling and Powering on the Workstation

Follow these steps to cable and power on the workstation.

007-4564-001 61

L

L

3: Maintenance and Upgrade Procedures

1. Reconnect all of the system cables to the rear of the enclosure (see Figure 3-7).

R

R

Figure 3-7 Reconnecting the Cables to the Workstation

2. Press the power buttons on your workstation and monitor.

3. If your workstation does not boot correctly, see Chapter 4, “Troubleshooting and

Diagnostics.”

This completes the procedure for returning the workstation to service.

62 007-4564-001

Installing or Removing a Memory DIMM

The Silicon Graphics® Tezro™ visual workstation is configured with a minimum of 512

MB of memory and a maximum of 8 GB of memory. The memory is contained in dual

in-line memory modules (DIMMs) which are installed in eight DIMM sockets on the

system node board. The sockets are divided into four DIMM pairs. The instructions in

the following sections assume that you know the correct slots in which to install the

memory DIMMs. For information about DIMM configurations and placement rules,

refer to “Memory DIMMs” in Chapter 2.

Note: If you have not already done so, remove the right side of the enclosure to access

the DIMMS. Refer to “Preparing the Workstation for Service” on page 49.

Instructions are provided in the following sections:

• “Removing a DIMM” on page 64

• “Installing a DIMM” on page 65

Installing or Removing a Memory DIMM

• “Verifying Memory Installation” on page 66

007-4564-001 63

3: Maintenance and Upgrade Procedures

Removing a DIMM

To remove a DIMM, follow these steps:

1. Locate the DIMM that you want to remove.

2. Pull up on the latches at the end of the DIMM socket (see Figure 3-8). The DIMM

will partially eject from the socket.

3. Lift the DIMM up and out of the enclosure.

4. Place the DIMM in an antistatic bag and store it in a secure location.

Note: Both sockets in a DIMM bank must be either empty or populated. If you

remove one DIMM and do not plan to replace it immediately, also remove the other

DIMM in the bank and replace it when you install a new DIMM.

Figure 3-8 Removing a DIMM

5. Install a new DIMM or return the system to service, as follows:

• To replace the DIMM immediately, proceed to the next section, “Installing a

DIMM” on page 65.

• To return the system to service, see “Returning the Workstation to Service” on

page 57.

64 007-4564-001

Installing a DIMM

Installing or Removing a Memory DIMM

Note: The workstation will not function if there are no memory DIMMs installed. Two

memory DIMMs of equal size must be installed in DIMM pair number 1.

To install a DIMM, follow these steps:

Caution: DIMMs are sensitive to static electricity. Be sure to wear the anti-static wrist

strap while you complete these steps.

1. Rotate the ejector latches on each end of the socket so that they stick straight out, as

shown in Figure 3-9.

Figure 3-9 Installing a DIMM

2. Align the DIMM with the socket. Make sure that the notches on the bottom of the

DIMM align with the protrusions in the bottom of the socket (see Figure 3-10).

007-4564-001 65

3: Maintenance and Upgrade Procedures

Figure 3-10 Locating the Notches on a DIMM

3. Seat the DIMM in the socket and press down. If you have seated the DIMM

correctly, the ejector latches will swing up and click into place in the notches on the

ends of the DIMM.

4. If necessary, repeat steps 1 through 3 to install a second DIMM.

5. Ensure that both sockets in the DIMM bank are full. DIMMs must be installed in

pairs.

Notches

This completes the memory DIMM installation. To return the workstation to service, see

“Returning the Workstation to Service” on page 57. After you have returned the system

to service, you may verify that the memory you installed is working correctly by

following the steps in the next section.

Verifying Memory Installation

To verify the memory installation, follow these steps:

1. After you power on the system, select System Manager > Hardware and Devices >

About This System from the Toolchest and check the amount of memory displayed

for Main Memory. The displayed memory should equal the original amount of

memory minus any memory you removed, plus the amount of memory you

installed.

2. If the amount of memory is incorrect, power off the system and check the following:

• Check the angle of the DIMMs. They should be upright and completely seated.

• Ensure that each bank is populated with two DIMMs, and that they are the

same size. You must have an even number of DIMMs installed.