SGI 1100 Server

Maintenance a nd Upgrade Guide

007-4047-001

CONTRIBUTORS

Written by Eric Zamost et al

Illustrated by D an Young

Edited by Connie Boltz

Production by Chrystie Danzer

Engineering contributions by David Bertrand, Jagdish Bhavsar, Kunnau Chen, and Charles Skandalis.

COPYRIGHT

© 2001 Silicon Graphics , In c. A ll rights reserved; provided portions m ay be c op y right in third parties, as indicated e lsewhere herein. No

permission is granted to copy, distribute, or create der ivativ e works f r om the content s of thi s elect roni c docume ntati on in any manner, in whole

or in part, without the prior written permission of Silicon Graphics, Inc.

LIMITED RIGHTS LEGEND

The electronic (soft ware) version of thi s document was developed at private expense; if acquir ed under an agreement w ith the USA go vernment

or any contractor thereto, it is acquired as "co mmercial computer s oftware" subject to the p rovisions of its applicable license agreement, as

specified in (a) 48 CFR 12.212 of the FAR; or, if acquired for Dep artment of Defense units, (b) 48 CFR 227-7202 of the DoD FAR Supplement; or

sections succeeding thereto. Con t rac t or/manufacturer is Silicon Graph ic s, In c. , 1600 Amphitheatre Pkwy 2E, Mountain View, CA 94043-1351.

TRADEMARKS AND ATTRIBUTIONS

Silicon Graphics is a registered trademark and SGI and the SGI logo are trademar ks of S ili con Graphics, Inc. Linux is a registered trade m ark of

Linus Torvalds. MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Cor p oration.

Cover Design By S a rah Bolles, Sarah Bolles Design, and Dany Galgani, SGI Technical Publicatio n s .

Record of Revision

Version Description

001 January, 2001

Initial Revision

007-4047-001 iii

Contents

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Tables . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

About Th is Guide. . . . . . . . . . . . . . . . . . . . . . . xv

Obtaining Publications . . . . . . . . . . . . . . . . . . . . . xv

Reader Comments. . . . . . . . . . . . . . . . . . . . . . . xv

1. Chassis Description . . . . . . . . . . . . . . . . . . . . . . 1

Processors . . . . . . . . . . . . . . . . . . . . . . . . . 2

Memory. . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Chipsets . . . . . . . . . . . . . . . . . . . . . . . 3

Server Works LE North and South Bridge. . . . . . . . . . . . . . . 3

LAN Subsystem . . . . . . . . . . . . . . . . . . . . . . 3

Video Subsystem . . . . . . . . . . . . . . . . . . . . . . 3

Expansion Slot. . . . . . . . . . . . . . . . . . . . . . . 3

System Block Diagram . . . . . . . . . . . . . . . . . . . . . 4

Chassis Front Controls and Indicators . . . . . . . . . . . . . . . . . 5

Rear Panel I/O Ports and Features . . . . . . . . . . . . . . . . . . 7

Internal Components . . . . . . . . . . . . . . . . . . . . . . 9

Hardware Management Support . . . . . . . . . . . . . . . . . . 11

Power Management . . . . . . . . . . . . . . . . . . . . . . 11

IPMI (Intelligent Platform Management Interface) . . . . . . . . . . . . . 13

Intelligent Platform Management Interface (IPMI) . . . . . . . . . . . . 13

Intelligent Platform Management Bus (IPMB). . . . . . . . . . . . . . 13

Intelligent Chassis Management Bus (ICMB) . . . . . . . . . . . . . . 14

Baseboard Management Controller (BMC) . . . . . . . . . . . . . . 14

007-4047-001 v

Features Summary . . . . . . . . . . . . . . . . . . . . . . . 15

2. Removing and Replacing System Components . . . . . . . . . . . . . . 19

Tools and Supplies Needed . . . . . . . . . . . . . . . . . . . . 20

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . 20

Opening the Chassis . . . . . . . . . . . . . . . . . . . . . . 21

Removing the Chassis Cover. . . . . . . . . . . . . . . . . . . 21

Installing the Chassis Cover . . . . . . . . . . . . . . . . . . . 23

Removing and Installing the Front Panel . . . . . . . . . . . . . . . 24

Replacing the Link Bar and the Riser Card . . . . . . . . . . . . . . . . 25

Removing the Link Bar . . . . . . . . . . . . . . . . . . . . 25

Installing the Link Bar. . . . . . . . . . . . . . . . . . . . . 27

Removing the Riser Card . . . . . . . . . . . . . . . . . . . . 28

Installing the Riser Card . . . . . . . . . . . . . . . . . . . . 29

Installing an Expansion Board . . . . . . . . . . . . . . . . . . . 30

Replacing the Chassis Fan Subsystem . . . . . . . . . . . . . . . . . 32

Removing the Chassis Fan Cage. . . . . . . . . . . . . . . . . . 32

Installing the Chassis Fan Cage . . . . . . . . . . . . . . . . . . 34

Replacing Chassis Fans . . . . . . . . . . . . . . . . . . . . 36

Replacing the Rear Chassis Blowers . . . . . . . . . . . . . . . . . . 37

Removing a Rear Chassis Blower . . . . . . . . . . . . . . . . . 37

Installing a Rear System Blower . . . . . . . . . . . . . . . . . . 39

Replacing the Cable Modules . . . . . . . . . . . . . . . . . . . . 40

Replacing the LED Cable Module . . . . . . . . . . . . . . . . . 40

Replacing the Power Switch Cable Module . . . . . . . . . . . . . . 42

Replacing the USB Daughterboard Cable Module. . . . . . . . . . . . . 45

Replacing the Intrusion Alert Microswitch Cable Module . . . . . . . . . . 48

Replacing Removable-Media Devices . . . . . . . . . . . . . . . . . 51

Removing the Diskette Drive/CD-ROM Drive Module . . . . . . . . . . . 51

Installing the Diskette Drive/CD-ROM Drive Module . . . . . . . . . . . 54

Replacing the Diskette Drive . . . . . . . . . . . . . . . . . . . 56

Replacing the CD-ROM Drive . . . . . . . . . . . . . . . . . . 58

vi 007-4047-001

Replacing a Hard Drive . . . . . . . . . . . . . . . . . . . . . 63

Removing a Hard Drive . . . . . . . . . . . . . . . . . . . . 63

Installing a Hard Disk Drive. . . . . . . . . . . . . . . . . . . 68

Replacing the Power Supply Module . . . . . . . . . . . . . . . . . 71

Removing the Power Supply Module . . . . . . . . . . . . . . . . 71

Installing the Power Supply Module . . . . . . . . . . . . . . . . 76

Removing a Processor. . . . . . . . . . . . . . . . . . . . . . 81

Installing a Processor . . . . . . . . . . . . . . . . . . . . . . 83

Installing a Processor Terminator Board . . . . . . . . . . . . . . . . 86

Removing a DIMM . . . . . . . . . . . . . . . . . . . . . . 87

Installing a DIMM . . . . . . . . . . . . . . . . . . . . . . . 89

Replacing the CMOS Battery. . . . . . . . . . . . . . . . . . . . 91

Replacing the System Board . . . . . . . . . . . . . . . . . . . . 92

3. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 97

Error Beep Definitions . . . . . . . . . . . . . . . . . . . . . 98

Power-On Self-Test (POST) Checkpoints List . . . . . . . . . . . . . . . 99

POST Error Messages . . . . . . . . . . . . . . . . . . . . . .104

Error Message for NMI and Warning Message . . . . . . . . . . . . . .107

IPMI Event Log . . . . . . . . . . . . . . . . . . . . . . .108

Index of Error Symptoms. . . . . . . . . . . . . . . . . . . . .1 14

A. Technical Specifications . . . . . . . . . . . . . . . . . . . . .115

Physical and Environmental Specification . . . . . . . . . . . . . . . .115

Power Consumption . . . . . . . . . . . . . . . . . . . . . 1 16

Thermal Dissipation . . . . . . . . . . . . . . . . . . . . .116

Jumper and Connector Information . . . . . . . . . . . . . . . . . .117

Hardware Specifications and Configurations . . . . . . . . . . . . . . .122

B. Updating the BIOS Firmware . . . . . . . . . . . . . . . . . . .133

BIOS Flashing . . . . . . . . . . . . . . . . . . . . . . . .133

C. Port Pinouts . . . . . . . . . . . . . . . . . . . . . . . .135

PS/2 Keyboard Port . . . . . . . . . . . . . . . . . . . . . . 1 36

PS/2 Mouse Port . . . . . . . . . . . . . . . . . . . . . . .137

VGA Port (DB15 HD) . . . . . . . . . . . . . . . . . . . . . .138

007-4047-001 vii

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . 139

USB Ports . . . . . . . . . . . . . . . . . . . . . . . . 140

Ethernet Ports (RJ45) . . . . . . . . . . . . . . . . . . . . . 141

Index . . . . . . . . . . . . . . . . . . . . . . . . Index-143

viii 007-4047-001

Figures

Figures

Figure 1-1 System Block Diagram. . . . . . . . . . . . . . 4

Figure 1-2 Front Controls and Indicators. . . . . . . . . . . . 5

Figure 1-3 Rear Panel I/O Ports and Features . . . . . . . . . . 7

Figure 1-4 SGI 1100 Server Internal Components . . . . . . . . . 9

Figure 2-1 Removing the Chassis Cover . . . . . . . . . . . . 22

Figure 2-2 Placing the Chassis Cover on the Chassis . . . . . . . . 23

Figure 2-3 Removing the Front Panel. . . . . . . . . . . . . 24

Figure 2-4 Removing the Link Bar . . . . . . . . . . . . . 26

Figure 2-5 Installing the Link Bar . . . . . . . . . . . . . . 27

Figure 2-6 Detaching the Riser Card from the Link Bar . . . . . . . 28

Figure 2-7 Installing the Riser Card on the Link Bar . . . . . . . . 29

Figure 2-8 Removing the Expansion Slot Filler Plate . . . . . . . . 30

Figure 2-9 Inserting the Expansion Card into the Riser Card . . . . . . 31

Figure 2-10 Removing the Chassis Fan Cage . . . . . . . . . . . 33

Figure 2-11 Installing the Chassis Fan Cage . . . . . . . . . . . 35

Figure 2-12 Removing the Chassis Fan . . . . . . . . . . . . 36

Figure 2-13 Location of the Rear System Blower Cable Connectors . . . . 38

Figure 2-14 Rear System Blower Securing Screws . . . . . . . . . 39

Figure 2-15 Location of the LED Cable Connectors . . . . . . . . . 40

Figure 2-16 Installing the LED Cable Module. . . . . . . . . . . 41

Figure 2-17 Location of the Power Switch Cable Connector. . . . . . . 42

Figure 2-18 Removing the Power Switch Cable Module. . . . . . . . 43

Figure 2-19 Installing the Power Switch Cable Module . . . . . . . . 44

Figure 2-20 Location of the USB Daughterboard Cable Connector. . . . . 45

Figure 2-21 Removing the USB Daughterboard Cable Module . . . . . . 46

007-4047-001 ix

Figures

Figure 2-22 Installing the USB Daughterboard Cable Module . . . . . . 47

Figure 2-23 Location of the Intrusion Alert Microswitch Cable Connector. . . 48

Figure 2-24 Removing the Intrusion Alert Microswitch Cable Module. . . . 49

Figure 2-25 Installing the Intrusion Alert Microswitch Cable Module . . . . 50

Figure 2-26 Releasing the Signal Cable Retaining Strap . . . . . . . . 51

Figure 2-27 Disconnecting the Drive Module Signal Cables . . . . . . . 52

Figure 2-28 Removing the Drive Module . . . . . . . . . . . . 53

Figure 2-29 Connecting the Drive Module Signal Cables. . . . . . . . 55

Figure 2-30 Removing the Diskette Drive from the Drive Module . . . . . 56

Figure 2-31 Installing the Diskette Drive into the Drive Module . . . . . 57

Figure 2-32 Removing the CD-ROM Drive Converter Board . . . . . . 58

Figure 2-33 Removing the CD-ROM Drive from the Drive Module. . . . . 59

Figure 2-34 Installing the CD-ROM Drive into the Drive Module . . . . . 60

Figure 2-35 Securing the CD-ROM drive to the Drive Module . . . . . . 61

Figure 2-36 Removing Hard Drive Cables . . . . . . . . . . . . 64

Figure 2-37 Removing Two of Four Hard Disk Drive Screws . . . . . . 65

Figure 2-38 Removing the Hard Disk Drive . . . . . . . . . . . 66

Figure 2-39 Installing the Hard Disk Drive. . . . . . . . . . . . 69

Figure 2-40 Location of the System Board Power Supply Connector . . . . 71

Figure 2-41 Location of the Hard Drive Power Supply Connectors . . . . . 72

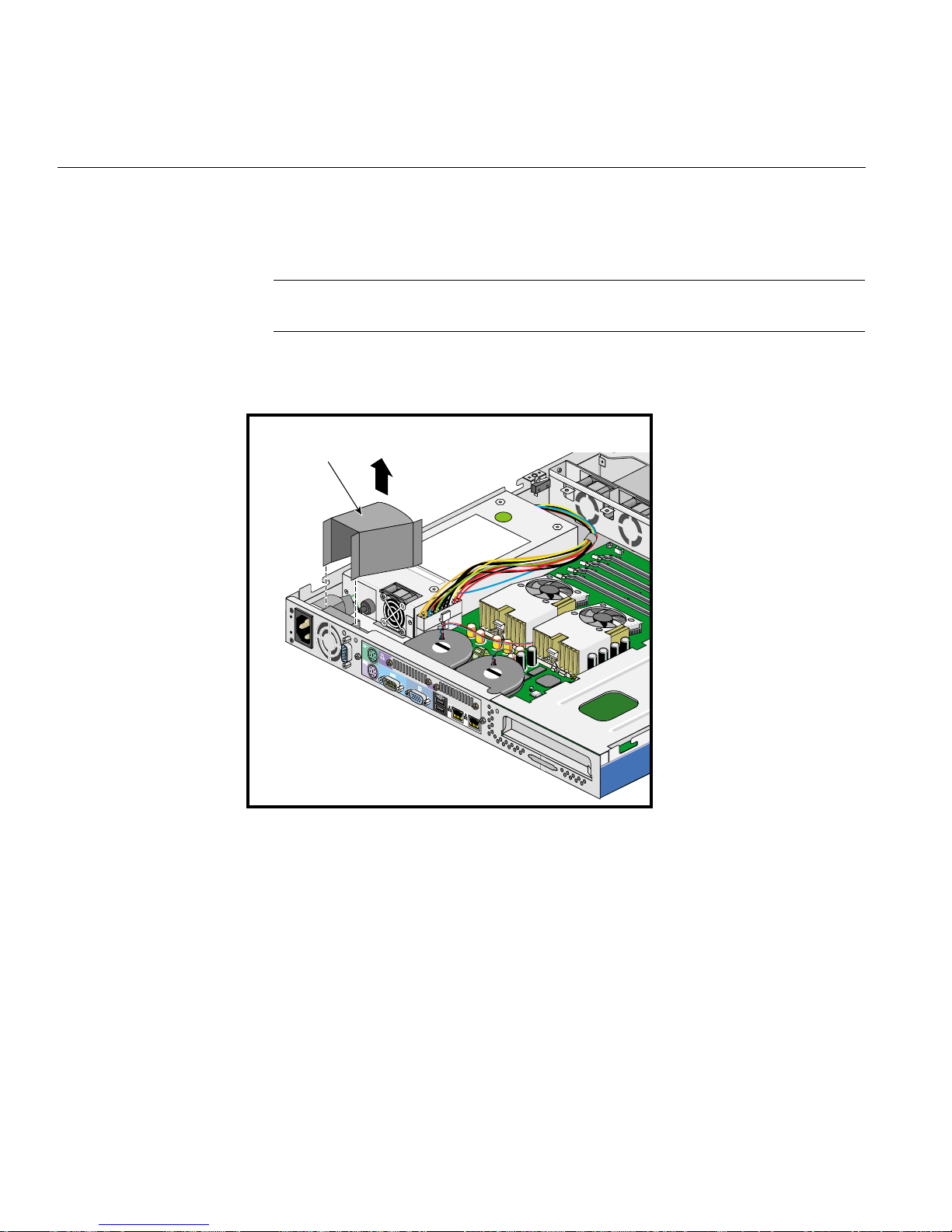

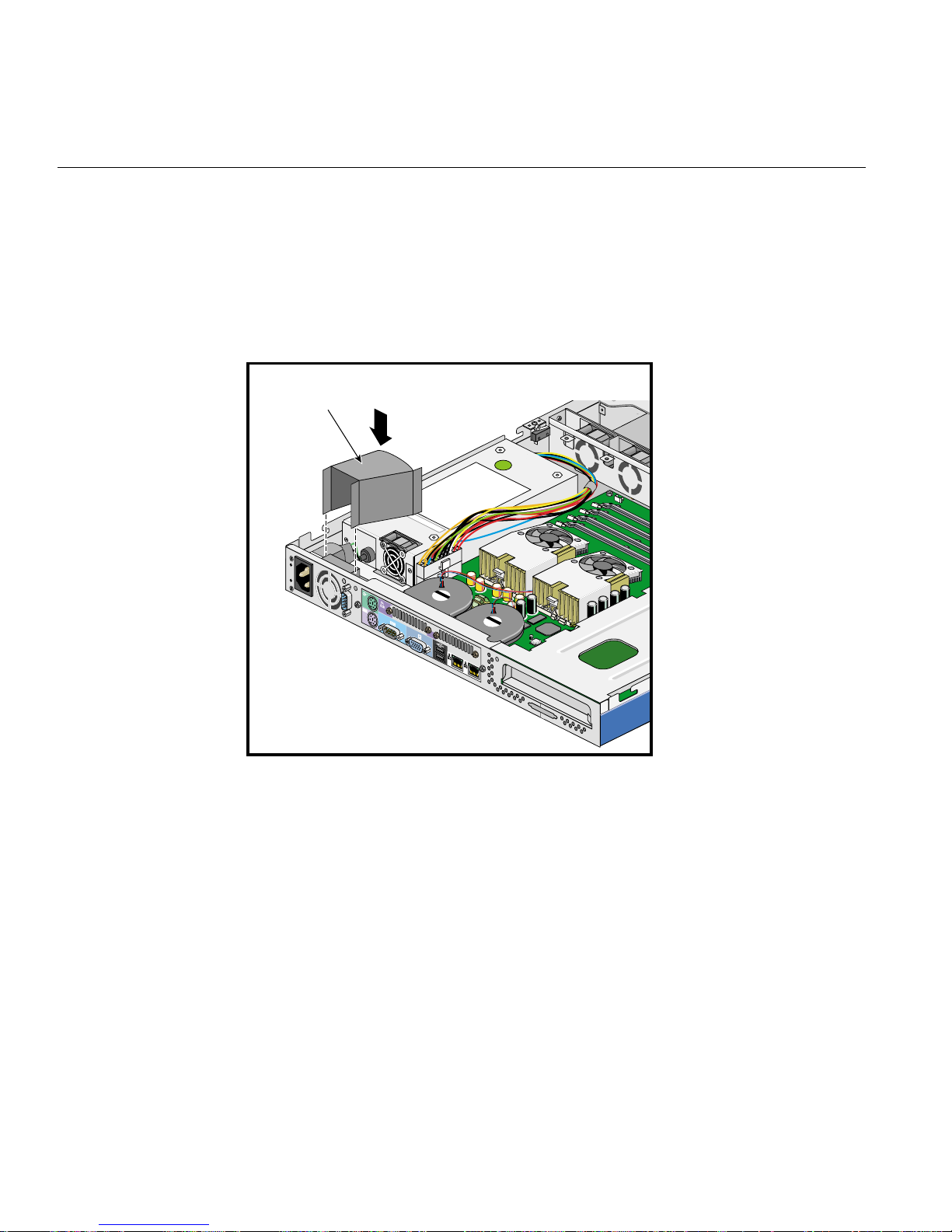

Figure 2-42 Removing the Air Guide Plate. . . . . . . . . . . . 73

Figure 2-43 Removing the Plastic Plenum . . . . . . . . . . . . 74

Figure 2-44 Removing the Power Supply Module. . . . . . . . . . 75

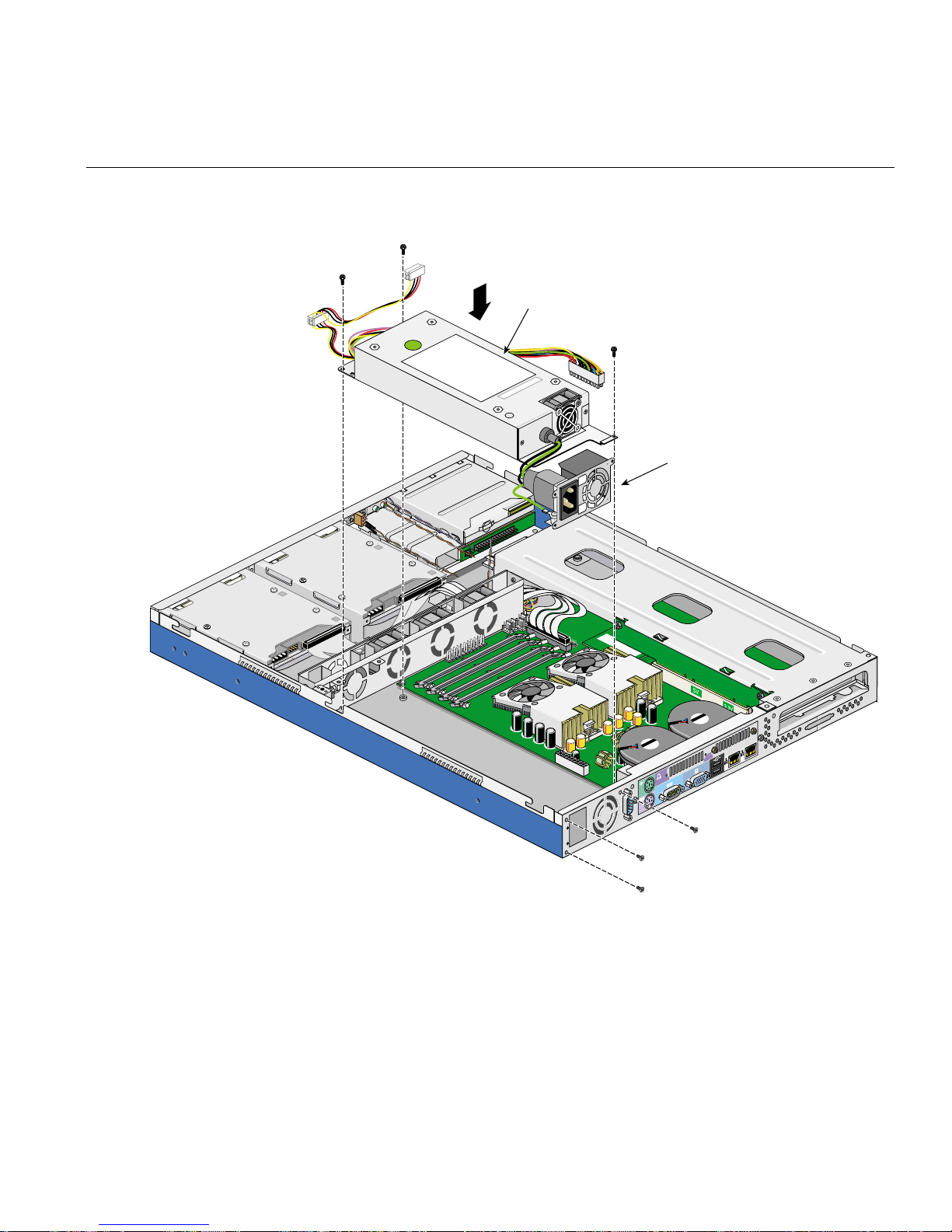

Figure 2-45 Installing the Power Supply Module . . . . . . . . . . 77

Figure 2-46 Installing the Plastic Plenum . . . . . . . . . . . . 78

Figure 2-47 Installing the Metal Air Guide Plate . . . . . . . . . . 79

Figure 2-48 Removing a Processor . . . . . . . . . . . . . . 82

Figure 2-49 Installing the Processor. . . . . . . . . . . . . . 84

Figure 2-50 Location of the Fan/Heatsink Cable Connector . . . . . . . 85

Figure 2-51 Installing a Processor Terminator Board . . . . . . . . . 86

Figure 2-52 Removing a DIMM . . . . . . . . . . . . . . . 88

Figure 2-53 Installing a DIMM . . . . . . . . . . . . . . . 90

Figure 2-54 Replacing the CMOS Battery . . . . . . . . . . . . 91

x 007-4047-001

Figures

Figure 2-55 Removing the System Board . . . . . . . . . . . . 93

Figure 2-56 Installing the System Board . . . . . . . . . . . . 94

Figure 3-1 Threshold Setting Levels . . . . . . . . . . . . .113

Figure A-1 System Board Layout . . . . . . . . . . . . . .117

Figure A-2 CN15 Connector Settings . . . . . . . . . . . . .121

Figure C-1 Keyboard Port Pinout . . . . . . . . . . . . . .136

Figure C-2 Mouse Port Pinout . . . . . . . . . . . . . . .137

Figure C-3 DB15 HD Port Pinout . . . . . . . . . . . . . .138

Figure C-4 Serial Port Pinout . . . . . . . . . . . . . . .139

Figure C-5 USB Port Pinout . . . . . . . . . . . . . . .140

Figure C-6 Ethernet Port Pinout . . . . . . . . . . . . . .141

007-4047-001 xi

Tables

Tables

Table 1-1 Front Controls and Indicators. . . . . . . . . . . . 5

Table 1-2 Rear Panel I/O Ports and Features . . . . . . . . . . 7

Table 1-3 Internal Components . . . . . . . . . . . . . . 9

Table 1-4 Power-Saving Mode Characteristics List . . . . . . . . 11

Table 3-1 Error Beep Definitions . . . . . . . . . . . . . . 98

Table 3-2 POST Checkpoints List . . . . . . . . . . . . . 99

Table 3-3 POST Error Messages . . . . . . . . . . . . . .104

Table 3-4 NMI Error Messages and Warning Messages . . . . . . .107

Table 3-5 IPMI System Event Log . . . . . . . . . . . . .108

Table 3-6 Index of Error Symptoms . . . . . . . . . . . . .1 14

Table A-1 SGI 1100 Server Physical Specification . . . . . . . . .115

Table A-2 System Board Layout . . . . . . . . . . . . . .118

Table A-3 Major Chips on System Board . . . . . . . . . . .122

Table A-4 Processor Specifications . . . . . . . . . . . . .122

Table A-5 BIOS Specifications. . . . . . . . . . . . . . .123

Table A-6 BIOS Hotkey List . . . . . . . . . . . . . . .123

Table A-7 Cache Memory Specifications . . . . . . . . . . . .124

Table A-8 VRM Specifications. . . . . . . . . . . . . . .124

Table A-9 System Memory Specifications . . . . . . . . . . .125

Table A-10 Memory Combinations . . . . . . . . . . . . .125

Table A-11 LAN Interface Specifications . . . . . . . . . . . .126

Table A-12 VGA Interface Specifications . . . . . . . . . . . .126

Table A-13 IDE Interface Specifications . . . . . . . . . . . .126

Table A-14 Diskette Drive Interface Specifications . . . . . . . . .127

Table A-15 Serial Port Specifications . . . . . . . . . . . . .127

007-4047-001 xiii

Tables

Table A-16 Memory Address Map . . . . . . . . . . . . . 128

Table A-17 I/O Address Map . . . . . . . . . . . . . . 128

Table A-18 IRQ Assignment Map . . . . . . . . . . . . . 131

Table A-19 PCI Interrupt Routing 1 . . . . . . . . . . . . 131

Table A-20 PCI Interrupt Routing 2 . . . . . . . . . . . . 132

Table A-21 On-board Device ID & IRQ Map Table . . . . . . . . 132

Table C-1 Keyboard Port Pinout . . . . . . . . . . . . . 136

Table C-2 Mouse Port Pinout . . . . . . . . . . . . . . 137

Table C-3 DB15 HD Port Pinout . . . . . . . . . . . . . 138

Table C-4 Serial Port Pinout . . . . . . . . . . . . . . 139

Table C-5 USB Port Pinout . . . . . . . . . . . . . . . 140

Table C-6 Ethernet Port Pinout . . . . . . . . . . . . . 141

xiv 007-4047-001

About This Guide

This guide contains a detailed description of the SGI 1100 server chassis, and provides

information on removing and installin g system components.

The following topics are covered:

• Chapter 1, “Chassis Description”

• Chapter 2, “Removing and Replacing System Components”

• Chapter 3, “Troubleshooting”

• Appendix A, “Technical Specifications”

• Appendix B, “Updating the BIOS Firmware”

• Appendix C, “P ort Pinouts”

An Index completes this guide.

Obtaining Publications

To obtain SGI documentation, se e the SGI Tec hnical Publications Library at

http://techpubs.sgi.com.

Reader Comments

If you have comments about the technical accuracy, content, or organization of this

document, please contact SGI. Be sure to include the title and document number of the

manual with your comments. (Online, the document number is located in the front

matter of the manual. In printed manuals, the document number is located at the bottom

of each page.)

You can contact SGI in any of the following ways:

007-4047-001 xv

About This Guide

• Send e-mail to the following address:

techpubs@sgi.com

• Use the Feedback option on the Technical Publications Library Web page:

http://techpubs.sgi.com

• Contact your customer service representative and ask that an incident be filed in the

SGI incident tracking system.

• Send mail to the following address:

Technical Publications

SGI

1600 Amphitheatre Pkwy., M/S 535

Mountain View, California 94043-1351

• Send a fax to the attention of “Technical Publications” at +1 650 932 0801.

SGI values your comments and will respond to them promptly.

xvi 007-4047-001

Chapter 1

1. Chassis Description

The SGI 1100 server is a 1U, high-density, rackmountable, PCI bus-based dual-processor

system built on an extended ATX baseboard. It comes with two socket 370 processor

sockets utilizing one or two Intel Pentium III processors integrated with the Server

Works LE north and OSB4 south bridge chipsets. The system board integrates two Intel

82559 10/100 Mbps PCI E the rn et chi ps et s that s u pports WOL (w ak e on LA N) fo r bett er

remote site management.

For expandability , the system includes one 64-bit/66-MHz PCI bus slot and four DIMM

slots that allow memory installation to a maximum of 2 GB using four 512-MB SDRAM

(synchronous DRAM) DIMMs.

For connectivity , the system supports four USB (Universal Serial Bus) connectors, a video

port, two LAN ports, and other standard features such as two serial ports, a diskette

drive interface, and two embedded IDE hard disk interfaces.

The system is fully compatible with Redhat Linux 6.2, Window s NT 4.0, and Windows

2000 Advanced Server OS.

This chapter contains a detailed description of the SGI 1100 server system components.

007-4047-001 1

1: Chassis Description

Processors

Memory

The Pentium III processor implements Dynamic Execution performance, a

multi-transaction system bus, and Intel MMX media enhancement technology. Also, it

offers Streaming SIMD (Single Instruction Multiple Data) extensio ns, which are 70 new

instructions enabling advanced imaging, 3D, streaming audio and video, and speech

recognition applications. The Pentium III processor delivers higher performance than the

previous Pentium processor while maintaining bin ary compatibility with all previous

Intel Architecture processors.

This system board supports 133-MHz GTL+ host bus frequencies for Pentium III

processors running at 800 MHz and above.

The four DIMM sockets on board allow memory upgrade to a maximum of 2 GB using

four 512-MB SDRAM (Synchronous DRAM) DIMMs. (The DIMM sockets also allow

1024 MB for a maximum upgrade of 4 GB in future models.) For data integrity, the

default setting of the ECC (error-correcting code) function of the memory system in BIOS

is enabled.

Note: Only 3.3-volt SDRAM DIMMs should be used. 5-volt memory devices are not

supported.

The system board supports 133-MHz registered SDRAM; 66-MHz SDRAM is not

supported.

2 007-4047-001

System Chipsets

Server Works LE North and South Bridge

The Server W orks LE north chipset incorporated as a north bridge is in charge of the host

bus interfacing and memory bus control. The memory bus control supports PC-133

SDRAM registered ECC DIMMs up to a total of 4 GB. The north bridge provides one

64-bit PCI bus running at 66 MHz.

The south bridge subset provides the legacy ISA interface, USB port, AT A33, and System

Management Bus (SMB). The BMC (Bas eboard Mana gement Control) w as embedded on

the motherboard and connected with the south bridge to provide the ASM and RDM

functions and industry standard IPMI protocol.

LAN Subsystem

Another cost-effective feature for network solution is the integration of Intel’s 82559

10/100 Mbps Fast Ethernet controller which supports Advanced Configura tion and

Power Interface (ACPI) 1.20A-based power mana gement, wake on Magic Packet, wake

on interesting packet, advanced SMB-based mana geability, Wired for Management

(WfM) 2.0 compliance, IP checksum assist, PCI 2.2 compliance, and PC 98 and PC 99

compliance.

System Chipsets

Video Subsystem

The A TI Rage XL harbors 2D and 3D display capabilities that bring life to any multimedia

and work applications. It also supports hardware DVD decoding. With r emarkable color

depths and high resolutions of up to 1600x1200, it enhances every visual experience on

your system.

The on-board ATI Rage XL chipset comes with 4 MB of video memory.

Expansion Slo t

The system board has one 64-bit/66-MHz PCI bus slot with a riser card.

007-4047-001 3

1: Chassis Description

System Block Diagr am

Figure 1-1 shows a block diagram of the SGI 1100 system board components.

Socket

Coppermine

Front Side Bus @ 133MHz

Secondary

PCI Bus

(64b/66MHz)

PC Bus

RDM VGA

USB

E-IDE

Ultra 33

CNB30LE

Host Bridge

OSB4

PCI-ISA bridge

Up to 1.0 GB/s

Primary PCI Bus (32b/33MHz)

ISA Bus

Socket

Coppermine

133MHz

Memory

Bandwidth

Intel

82559

LAN

Up to

2 GB SDRAM

Intel

82559

LAN

Figure 1-1 System Block Diagram

4 007-4047-001

BIOS

Super I/O

(SMC)

Chassis Front Controls and Indicators

This section describes the front controls and indicators of the SGI 1100 server, as shown

in Figure 1-2.

Figure 1-2 Front Controls and Indic ator s

Table 1-1 describes the front controls and indicators that are indicated in Figure 1-2.

Table 1-1 Front Controls and Indic ator s

Chassis Front Controls and Indicators

No. Item

1 Slim-type floppy disk drive LED

2 Slim-type floppy disk drive

3 Slim-type floppy disk drive eject button

4 Event LED

5 Hard disk drive access LED

6 Power LED

7 LAN 2 access LED

8 LAN 1 access LED

9 Power button

10 Metal handle

11 USB ports (2 ports)

007-4047-001 5

1: Chassis Description

Table 1-1 (continued) Front Controls and Indicators

No. Item

12 Slim-type CD-ROM drive emergency eject hole

13 Slim-type CD-ROM drive eject button

14 Slim-type CD-ROM drive LED

The general event LED indicates the following occurrences:

• Temperature, voltage, system fan, or fuse events.

• CPU IERR and Thermtrip error.

• System fan or power supply unplug .

• Removal of top cover.

• Uncorrectable memory error (multiple ECC errors).

• PCI PERR or SERR error.

If all of the preceding events recover, the Baseboard Management Controller (BMC)

should turn off the LED.

Note: The BMC will not turn on the general event LED for BIOS POST, PCI hot plug, and

correctable memory error events.

6 007-4047-001

Rear Panel I/O Ports and Features

This section describes the rear panel I/O ports and other features, as shown in Figure 1-3.

Figure 1-3 Rear Panel I/O Ports and Features

Table 1-2 describes the rear panel I/O ports and featur es th at a re indicated in F i gure 1-3.

Table 1-2 Rear Panel I/O Ports and Features

Rear Panel I/O Ports and Features

No. Item

1 AC power input

2 Ventilation

3Serial port 2

4 PS/2 mouse port

5 Ventilation

6 Ventilation

7Add-on card bracket

8 LAN 2 port (RJ-45)

9 LAN 1 port (RJ-45)

10 USB ports (2 ports)

11 VGA port

007-4047-001 7

1: Chassis Description

Table 1-2 (continued) Rear Panel I/O Ports and Features

No. Item

12 Serial port 1

13 PS/2 keyboard port

8 007-4047-001

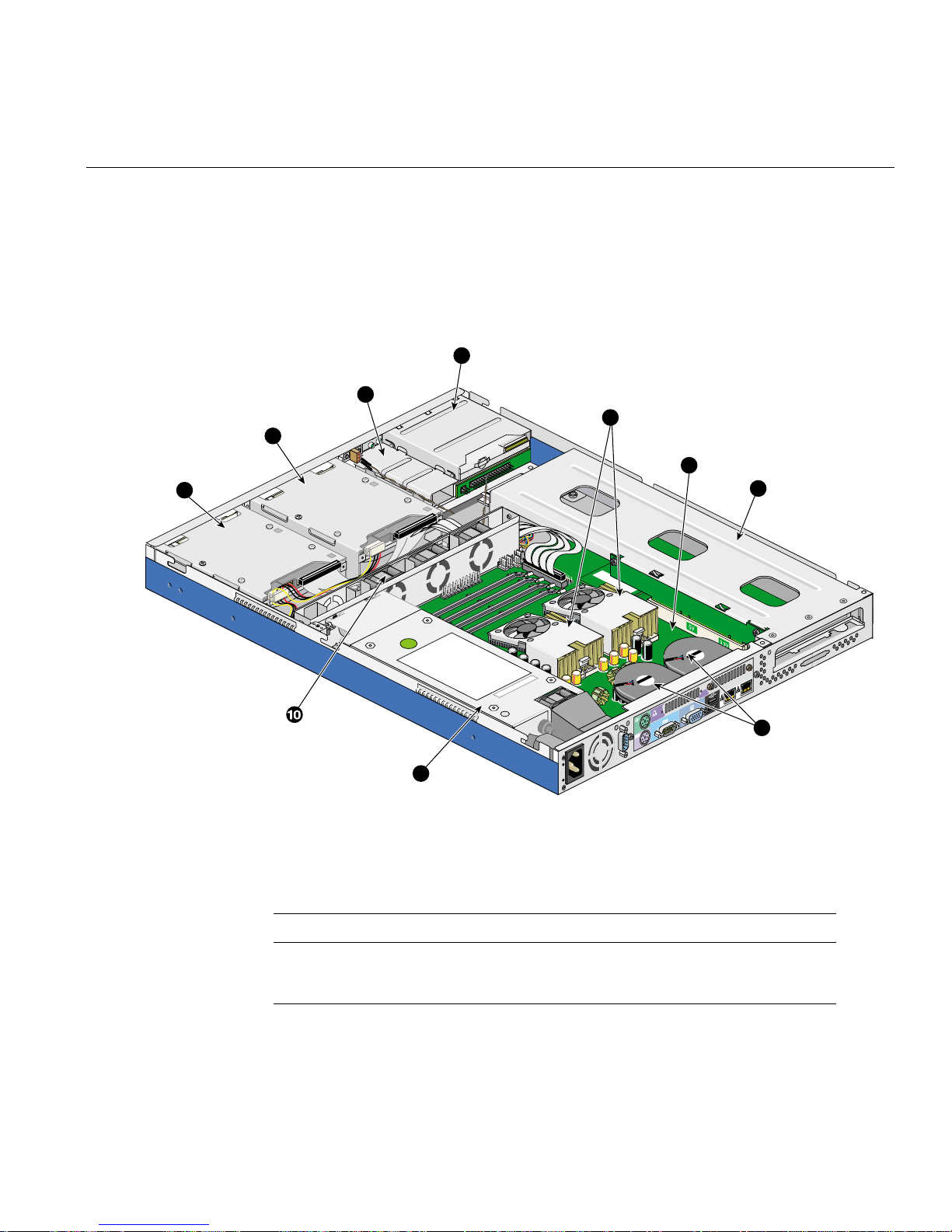

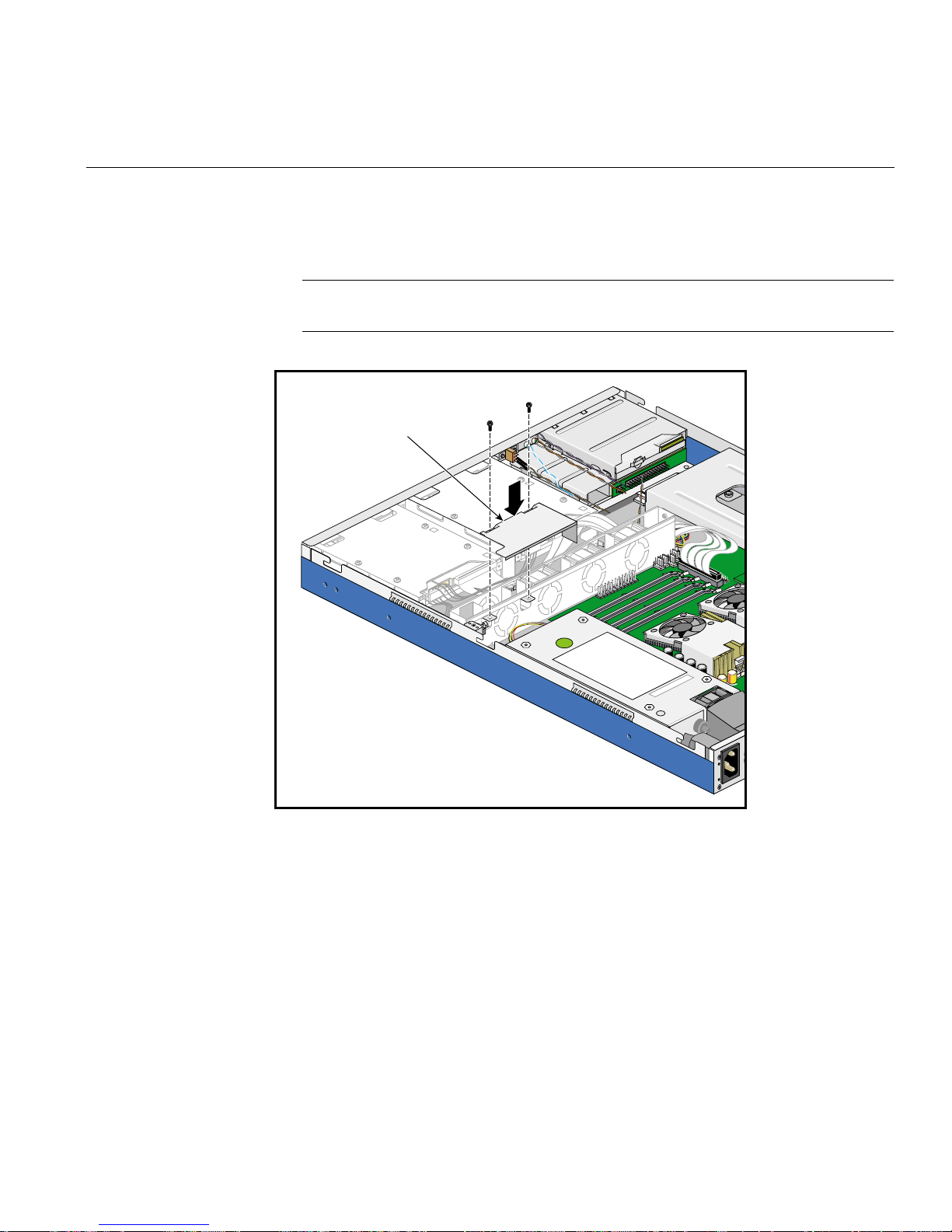

Internal Components

This section describes the location of the main components inside the SGI 1100 server, as

shown in Figure 1-4.

2

1

Internal Components

4

3

5

6

7

8

9

Figure 1-4 SGI 1100 Server Internal Components

Table 1 -3 describes the internal components that are indicated in Figure 1-4.

Table 1-3 Internal Components

No. Item

1 IDE hard disk drive bay

2 IDE hard disk drive bay

007-4047-001 9

1: Chassis Description

Table 1-3 (continued) Internal Components

No. Item

3 Slim-type CD-ROM drive

4 Slim-type floppy disk drive

5 CPUs and fan/heatsinks

6System board

7 PCI expansion card slot and link bar

8 Rear blowers

9 Power supply

10 Housing fans

10 007-4047-001

Hardware Management Support

The system supports the power-management function that conforms to the

power-saving standards of the U.S. Environmental Protection Agency (EP A) Energy Star

program. It also offers Plug-and-Play, which helps users avoid configuration problems

and thus makes the system more user-friendly.

Power Management

T able 1-4 lists the power-saving modes and their respective characteristics. These power

management features are only available if the operating system running on the system

supports them

Table 1-4 Power-Saving Mode Char ac t eristics List

Power-saving mode Characteristics

Device standby mode Independent power management timer for HDD devices (0-15

Hardware Management Support

minutes, time step = 1 mi nute)

Hard disk drive goes into STANDBY mode (for ATA standard

interface)

Disable V-sync to control the VESA DPMS monitor

Resume method: device acti vated (keyboard for DOS, keyboard

and mouse for Windows)

Resume recovery time: 3-5 seconds

007-4047-001 11

1: Chassis Description

Table 1-4 (continued) Power-Saving Mode Characteristics List

Power-saving mode Characteristics

Global standby mode Global power management timer (1-60 minutes)

Hard disk drive goes into STANDBY mode (for ATA standard

interface)

Disable H-sync and V-sync signals to control the VESA DPMS

monitor

Resume recovery time: 7-10 seconds

System suspend mode Independent power management timer (1-60 minutes) or pushing

external switch button

CPU goes into SMM (system management mode)

CPU asserts STPCLK# and goes into the stop grant state

LED on the panel flashes in amber color

Hard disk drive goes into SLEEP mode (for ATA standard

interface)

Disable H-sync and V-sync signals to control the VESA DPMS

monitor

Return to original state by pushing external switch button.

12 007-4047-001

IPMI (Intelligent Platform Management Interface)

IPMI (Intelligent Platform Management Interface)

IPMI is an open standard hardware manageability interface specification. It provides an

architecture that defines how unique devices can all communicate with the CPU in a

standard way.

With IPMI, the CPU only communicates one event to the IPMI event log. The CPU only

“asks” what has changed since the last time it asked. Every device communicates

directly, through IPMI, to the event log, which is used to record, in a consistent way, all

status events for the unique device. This simplifies the agent-handling routine. The

system only needs a single agent, and it does not need to be changed when you change

from five devices to manage, for example, to six. And the system does not need to change

the way the CPU checks the event log when a new device is added to the system; it

always checks in the same way, whether there is one device or 100 devices. With IPMI,

use of the CPU is minimized, so overall system performance improves.

The following are the four elements of IPMI, each of which is described in the sections

that follow:

• Intelligent Platform Management Interface

• Intelligent Platform Management Bus

• Intelligent Chassis Management Bus

• Baseboard Management Controller

Intelligent Platform Management Interface (IPMI)

IPMI is the specification for the management controller command sets, including

command sets for sensors, event logs, and sensor data record access. It is also the

specification for the data formats, including sens or d ata records, event log entries, and

FRU inventory information. IPMI is also the name used for the overall standardization

effort.

Intelligent Platform Management Bus (IPMB)

IPMB is the I2C-based, multi-master bus used fo r intra -ch assis communication with

“satellite” management controllers. Here sensor devices and cards with IPMI bus access

can be added to the IPMI standard.

007-4047-001 13

1: Chassis Description

Intelligent Chassis Management Bus (ICMB)

ICMB is the RS-485-based inter-chassis management bus, based on IPMB. It is used for

common chassis and emergency management functions, including power and rese t

control, chassis status, events, and FRU inventory.

Baseboard Management Controller (BMC)

BMC is used to monitor baseboard temperatures and voltages , and to manage the system

event log and non-volatile storage for sensor data records. It provides a system software

interface to the IPMB.

14 007-4047-001

Features Summary

The system has the following major components:

• Processor

• Chipset

• LAN controller

• Memory

Features Summary

Supports dual Pentium III processors installed in a socket 370 running a 133-MHz

Front Side Bus (FSB).

ServerWorks ServerSet III LE chipset consists of CNB30LE (Champ North Bridge)

and OSB4 (Open South Bridge) is in charge of the host interfacing, memory system

control, PCI interfacing, and data steering.

Two o n-boa rd Intel 82559 10/ 100-Mb/s PCI LAN controllers.

The CNB30LE champ north bridge consists of a system memory controller

integrated with four DIMM so ckets that supp o rt 128-, 512- an d 1024-MB (in the

future) registered ECC SDRAM DIMMs with a maximum memory upgrade of 4 GB

(1024 MB x 4 DIMM modules).

• Cache

256-KB second-level write-back PipeLined-Burst SRAM supported cache on

Pentium III processor.

• Video

On board PCI VGA controller (ATI Rage XL) with 4-MB SDRAM graphics memory

support.

•BIOS

– 512-KB Flash ROM built-in 28SF040A-90 for system and IPMI BIOS.

– Y2K NSTL-compliant.

• Real-time clock (RTC)

– 256-byte battery-backed CMOS RAM.

– Built-in SMC FDC37B787 super I/O controller.

– System clock/calendar with battery backup.

• Power supply

Standard 200W power supply.

007-4047-001 15

1: Chassis Description

• Memory interface

Four DIMM sockets support four PC 133 registered ECC SDRAM modules.

• IDE interface

– E-IDE controller built-in RCC OSB4 (Open South Bridge).

– PCI bus master dual-channel E-IDE interface.

– Provides up to four IDE devices.

– Supports PIO mode 4 transfers up to 16.7 MB/sec, DMA mode 2, and Ultra

DMA33 (33 MB/sec) mode.

• Diskette drive interface

– Compatible with IBM PC AT disk drive system.

– 16-byte data FIFO.

– Data rate and drive control register.

– DMA enable logic.

– 480 addresses, up to eight IRQs, and seven DMA Options.

– Supports 3.5-inch diskette drives.

– Supports 360K-, 720K-, 1.2M-, 1.44M-, 2.88M-byte format, and 250K-, 300K-,

500K-, 1M-, or 2M-bps data transfer rate.

– Supports 3-mode diskette drive.

• PCI Slots

One 64-bit/66-MHz PCI 2.2-compliant PCI slot with a PCI riser card.

• BMC interface

Two 24-pin BMC (Baseboard Management Controller) interfaces.

• I/O APIC device for SMP interrupt support.

• Server management controller chipset.

• Serial port

Two high-speed NS16C550-compatible UART with send/receive 16-byte FIFO

serial ports.

• USB port

Four USB ports support Universal HCI specification for USB 1.0.

• PS/2 keyboard and mouse port

16 007-4047-001

• One external monitor port

• LAN connector

Two RJ-45 jacks for 10BaseT or 100BaseTX LAN connectors.

Features Summary

007-4047-001 17

Chapter 2

2. Removing and Replacing System Components

This chapter contains step-by-step procedures on how to disassemble the SGI 1100 server

system for maintenance and troubleshooting.

Caution: The procedures contained in this chapter should be performed by a qualified

service technician. Do not perform the procedures described in the following sections

unless you are a qualified technician.

The following sections are covered:

•“Tools and Supplies Needed” on page 20.

•“ESD Precautions” on page 20

•“Opening the Chassis” on page 21.

•“Replacing the Link Bar and the Riser Card” on page 25

•“Installing an Expansion Board” on page 30.

•“Replacing the Chassis Fan Subsystem” on page 32.

•“Replacing the Rear Chassis Blowers” on page 37.

•“Replacing the Cable Modules” on page 40.

•“Replacing Removable-Me d ia Devices” on page 51.

•“Replacing a Hard Drive” on page 63.

•“Replacing the Power Supply Module” on page 71.

•“Removing a Proces sor” on page 81.

•“Removing a DIMM” on page 87 .

•“Replacing the CMOS Battery” on page 91.

•“Replacing the System Board” on page 92.

007-4047-001 19

2: Removing and Re placing System Components

Tools and Supplies Needed

To di sassemble the computer, you need the following tools and supplies:

• Wrist grounding strap and conductive mat for preventing electrostatic discharge

• Phillips screwdrivers

Note: The screws for the different components vary in size. During the disassembly

process, group the screws with the corresponding components to avoid mismatches

when putting back the components.

ESD Precautions

Before proceeding with the disassembly procedure, make sure that you do the following:

1. Turn off the power to the system and all peripherals.

2. Unplug the AC adapter and all power and signal cables from the system.

3. Do not remove a component from its ant i static packaging until you are ready to

install it.

4. Wear a wrist grounding strap before handling electronic components. Wrist

grounding straps are available at most electronic component stores.

20 007-4047-001

Opening the Chassis

This section covers the removal and installation of the chassis cover and the front panel.

Note: A microswitch is located under the chassis cover. It detects wheth er the cover is

removed or installed.

Removing the Chassis Cover

Follow these steps to remove the chassis cover:

1. Turn off the power to the system unit and unplug all external cables.

2. Place the system unit on a flat, steady surface.

3. Release the two screw knobs at the rear of the chassis, as shown in Figure 2-1.

Opening the Chassis

007-4047-001 21

2: Removing and Re placing System Components

Figure 2-1 Removing the Chassis Cover

4. Slide the chassis cover towards the rear of the chassis about 1 inch (2.5 cm), as

shown in Figure 2-1.

5. Lift the cover away from the chassis.

22 007-4047-001

Installing the Chassis Cover

Follow these steps to install the chassis cover:

1. Place the system unit on a flat, steady surface.

2. Place the chassis cover on the chassis, so as to insert each of the six retaining pins

into their slots as shown in Figure 2- 2.

Opening the Chassis

Figure 2-2 Placing the Chassis Cover on the Chassis

007-4047-001 23

2: Removing and Re placing System Components

3. Ensure that all six retaining pins are fully engaged into their slots, and then slide the

chassis cover toward the front of the system, as shown in Figure 2-2.

4. Tighten the two screw knobs to secure the chassis cover into place.

Removing and Installing t he Front Panel

To remove the front panel, release the three screws and pull the front panel away from

the chassis as shown in Figure 2-3.

To instal l the f ront panel, tighten the 3 screws to secure the front panel to the chassis.

Figure 2-3 Removing the Front Panel

24 007-4047-001

Replacing the Link Bar and the Riser Card

This section covers the removal and installation of th e link bar and the riser card.

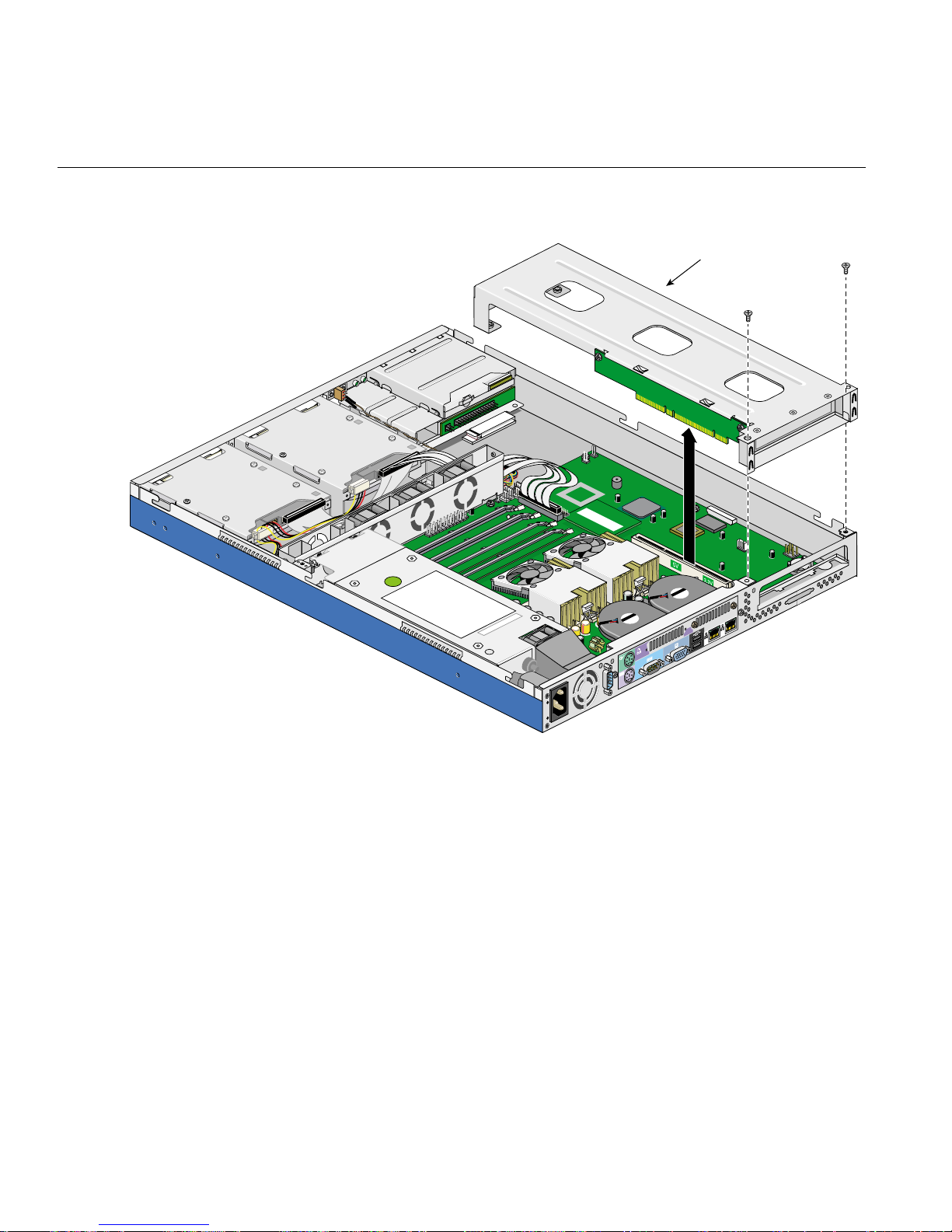

Removing the Link Bar

Follow these steps to remove the link bar:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Remove two screws from the rear panel and pull the link bar away from the chassis

as shown in Figure 2-4.

Replacing the Link Bar and the Riser Card

007-4047-001 25

2: Removing and Re placing System Components

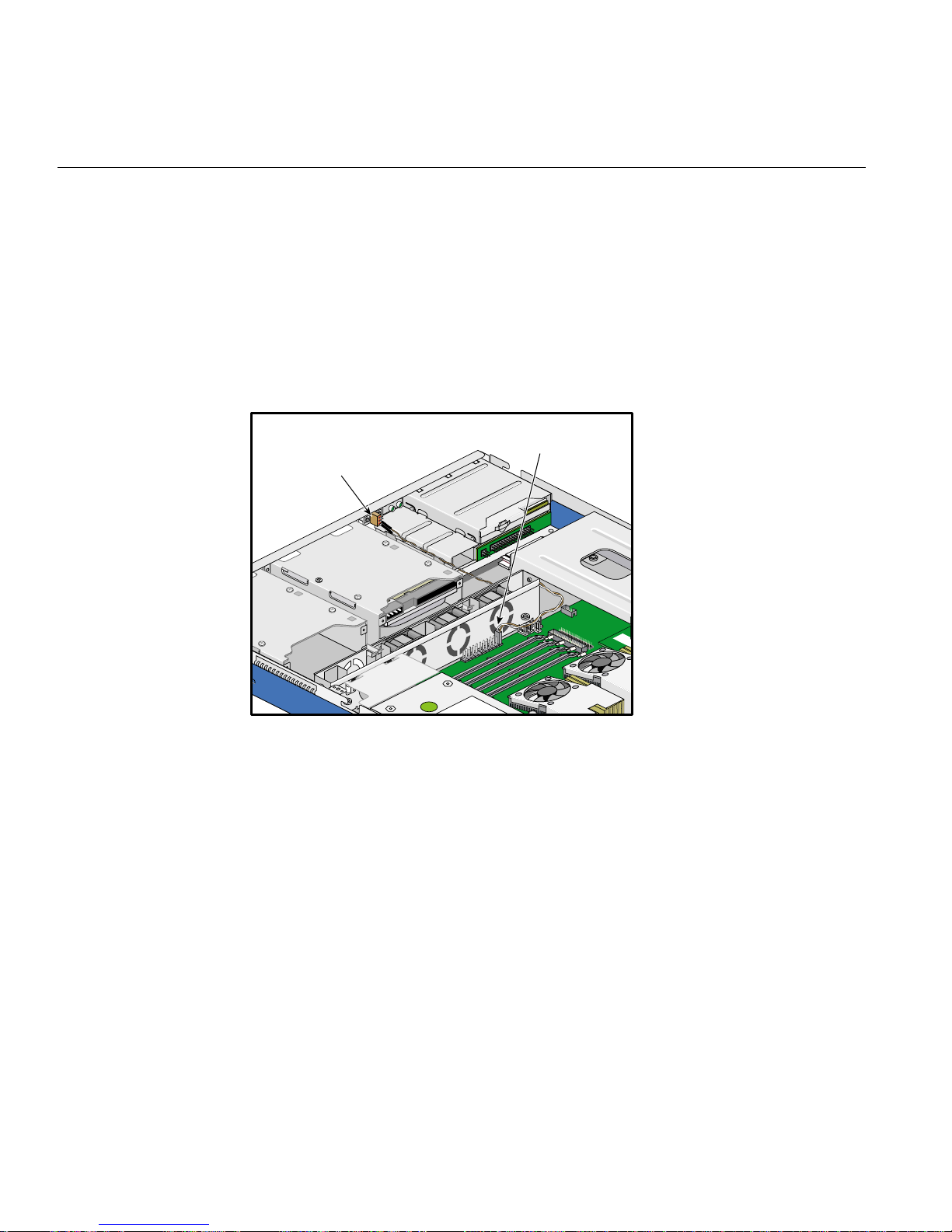

Link bar

Figure 2-4 Removing the Link Bar

26 007-4047-001

Installing the Link Bar

Replacing the Link Bar and the Riser Card

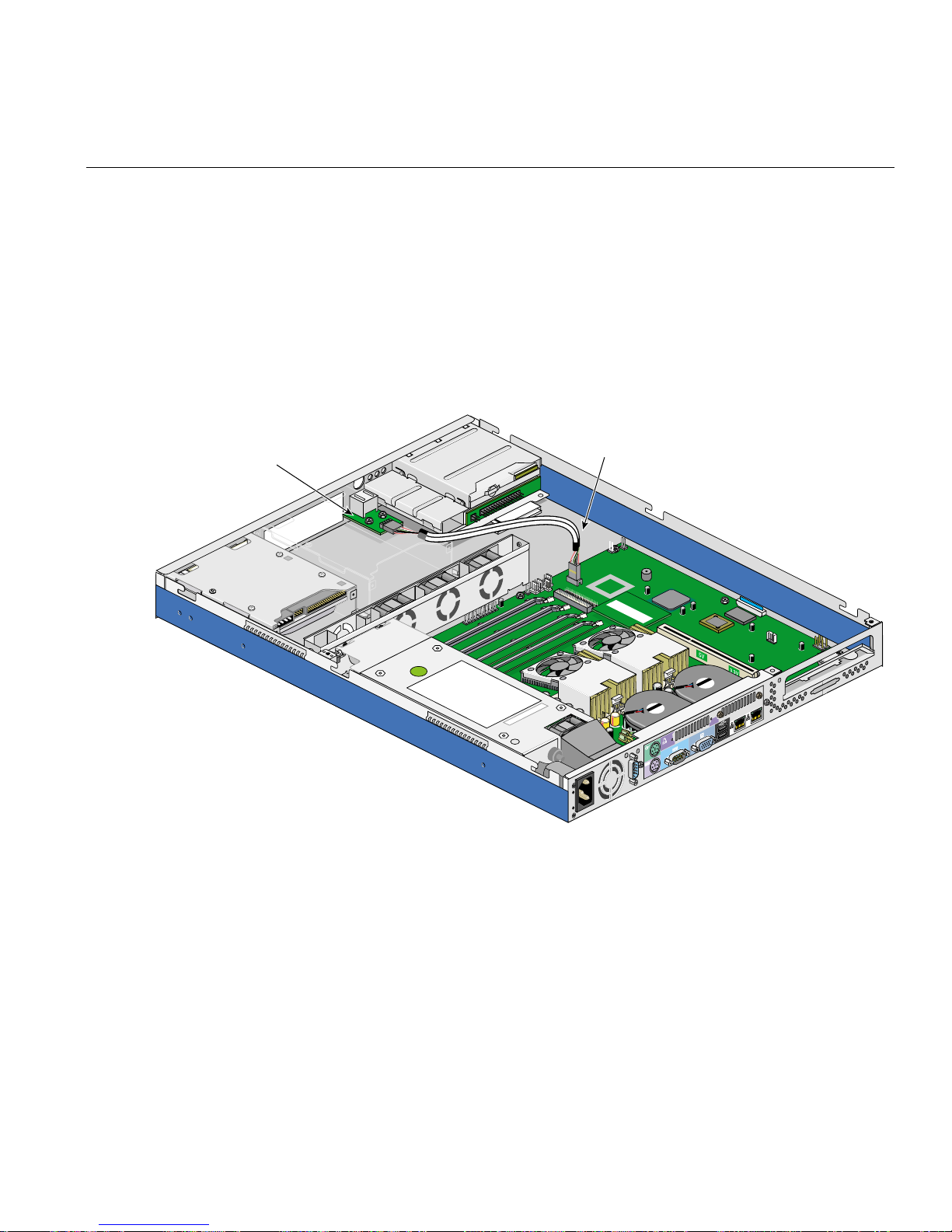

Follow these steps to install the link bar:

1. Insert the link bar into its slot by pushing the assembly straight into the PCI slot

until it is properly seated, as shown in Figure 2-5.

2. Tighten two screws to the rear panel as shown in Figure 2-5.

Link bar

Figure 2-5 Installing the Link Bar

3. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 27

2: Removing and Re placing System Components

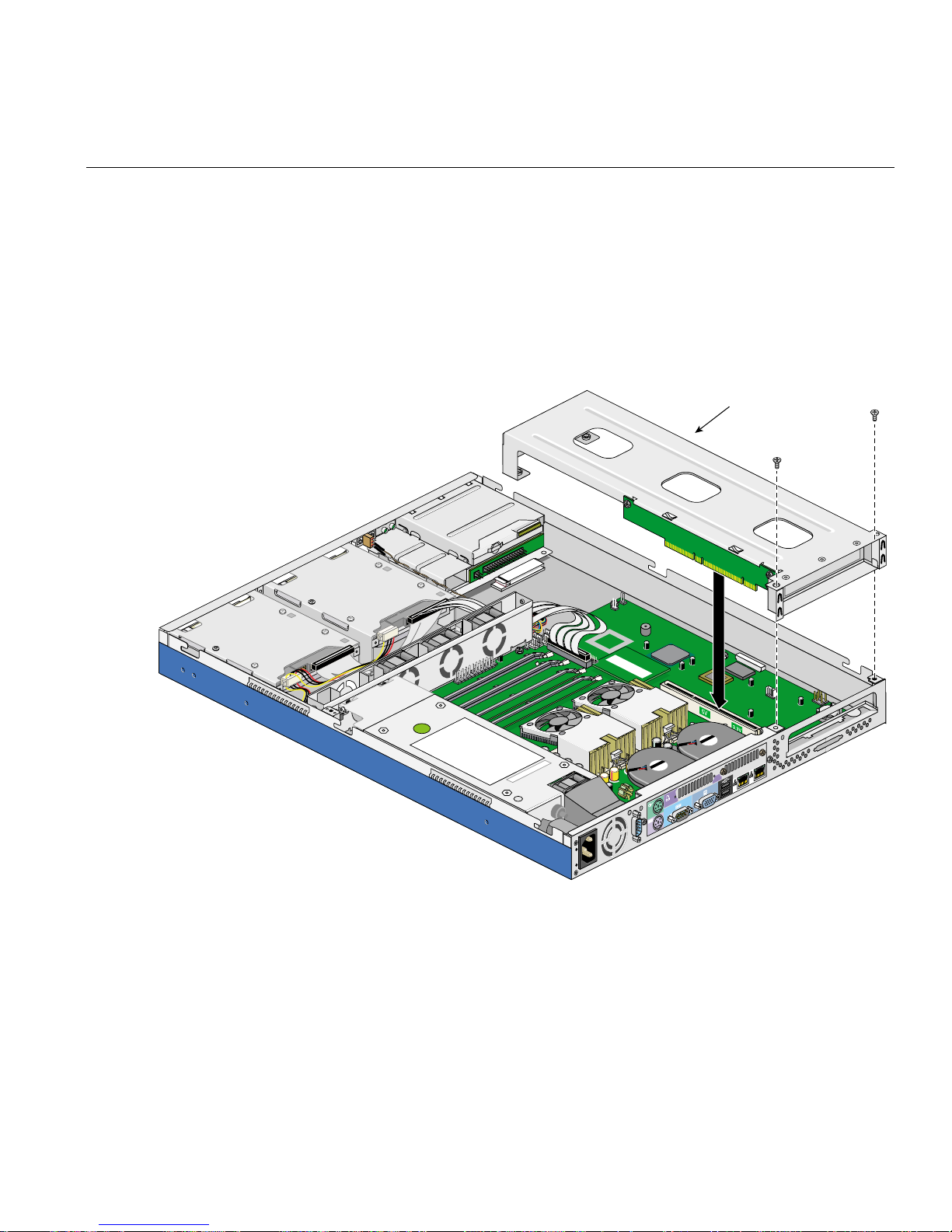

Removing the Riser Card

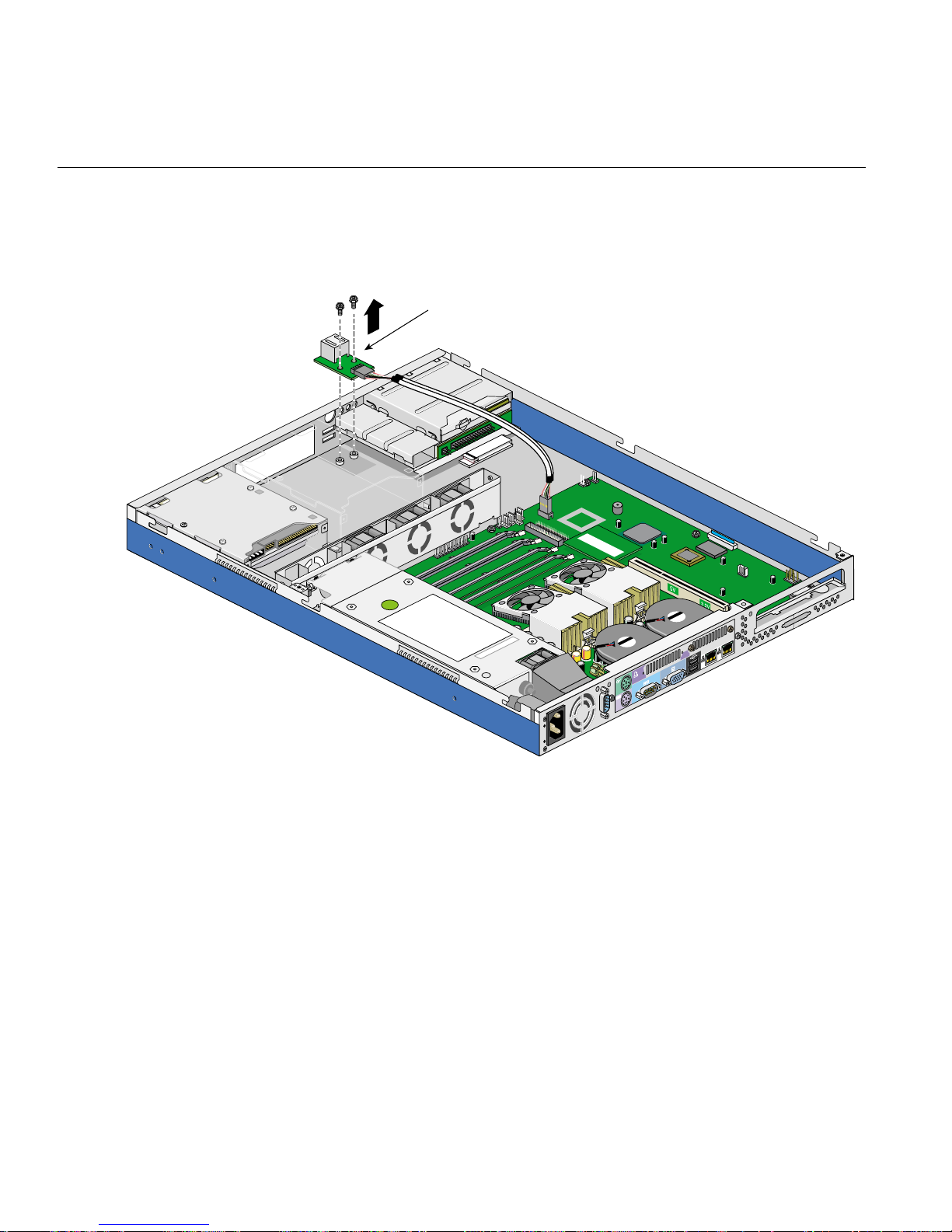

Follow these steps to remove the riser card from the link bar:

1. Remove the link bar as described in “Removing the Link Bar” on page 25.

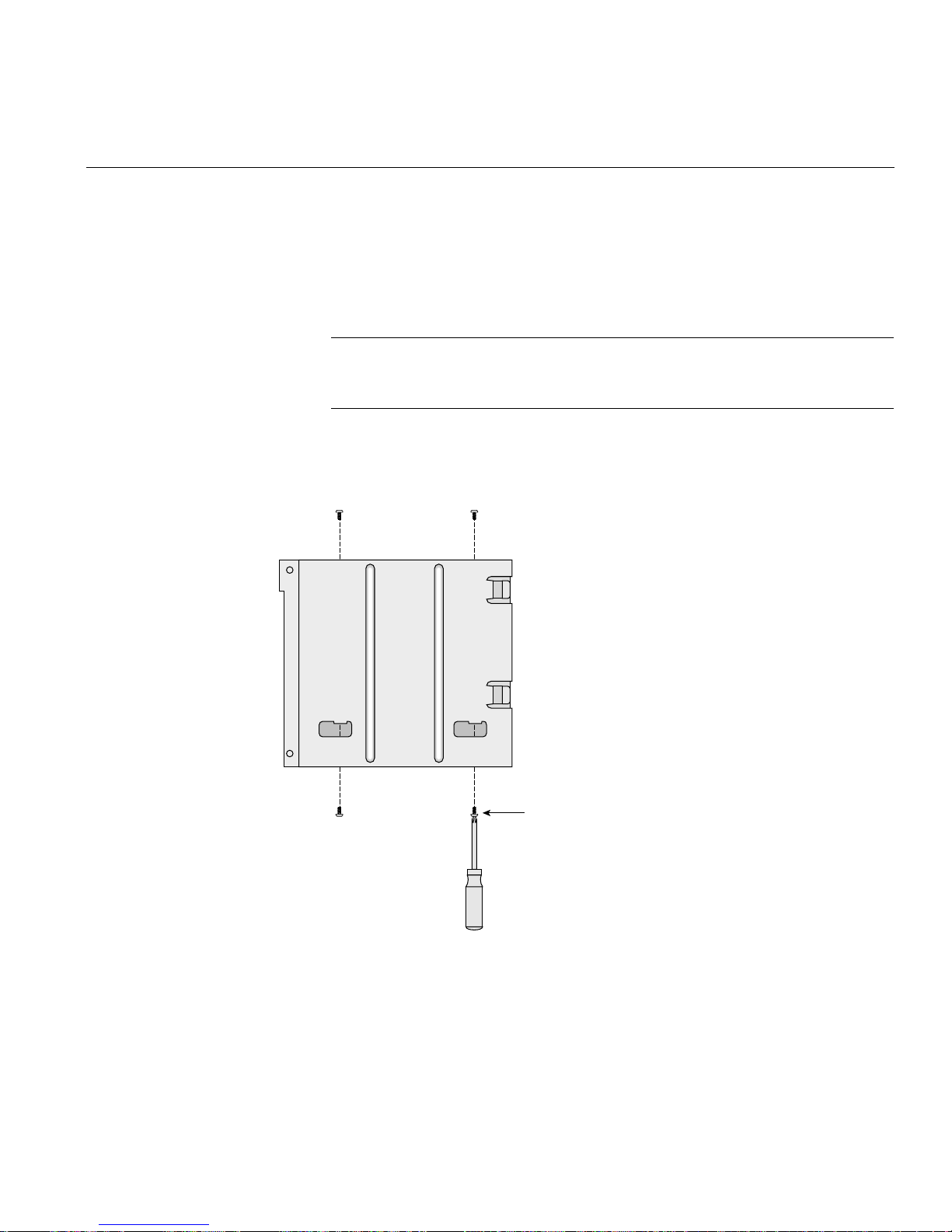

2. Remove three screws as shown in Figure 2-6.

Figure 2-6 Detaching the Riser Card from the Link Bar

3. Separate the riser card from the link bar.

28 007-4047-001

Installing the Riser Card

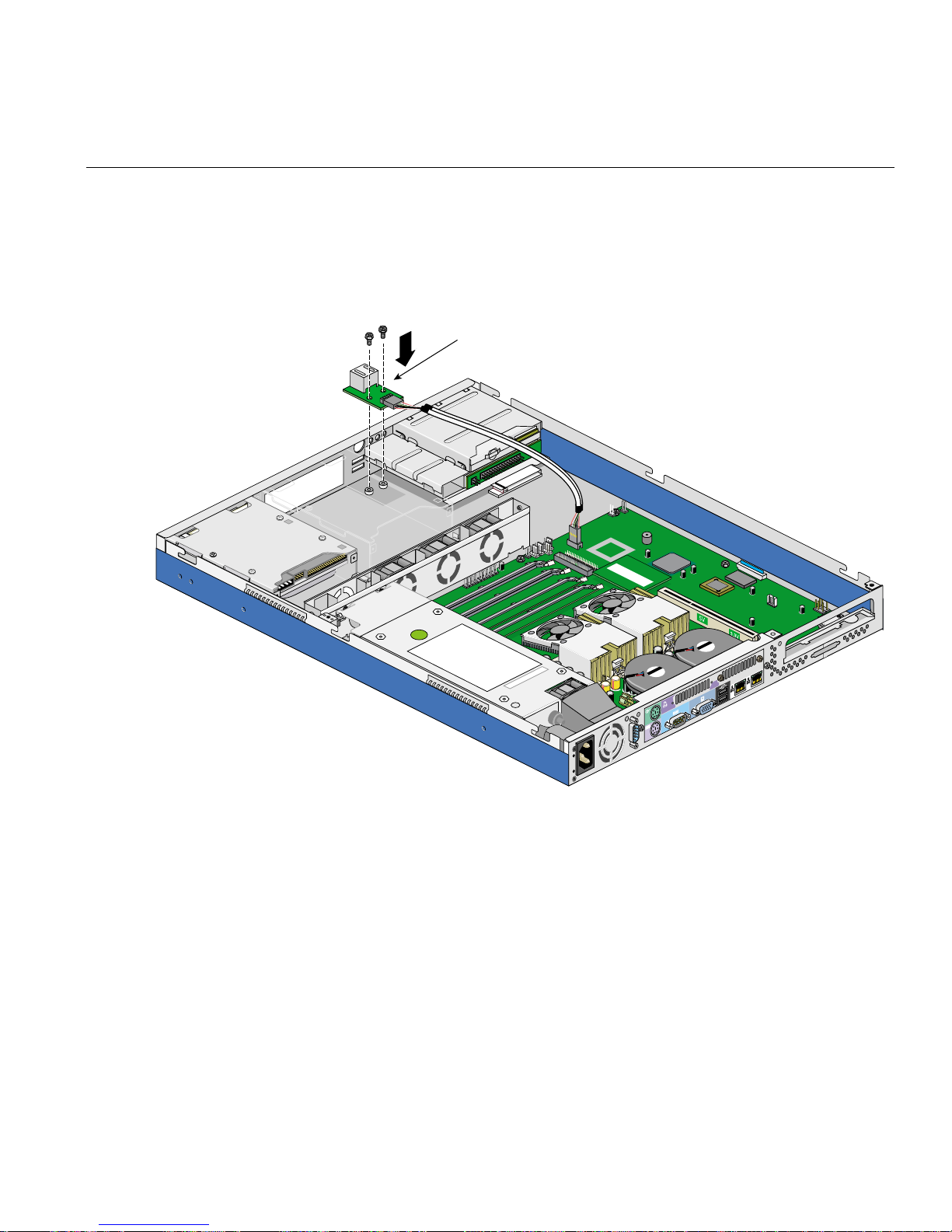

Follow these steps to install the riser card onto the link bar:

1. Place the riser card on the link bar as shown in Figure 2-7.

2. Tighten three screws to secure the riser card to the link bar.

Replacing the Link Bar and the Riser Card

Figure 2-7 Installing the Riser Card on the Link Bar

007-4047-001 29

2: Removing and Re placing System Components

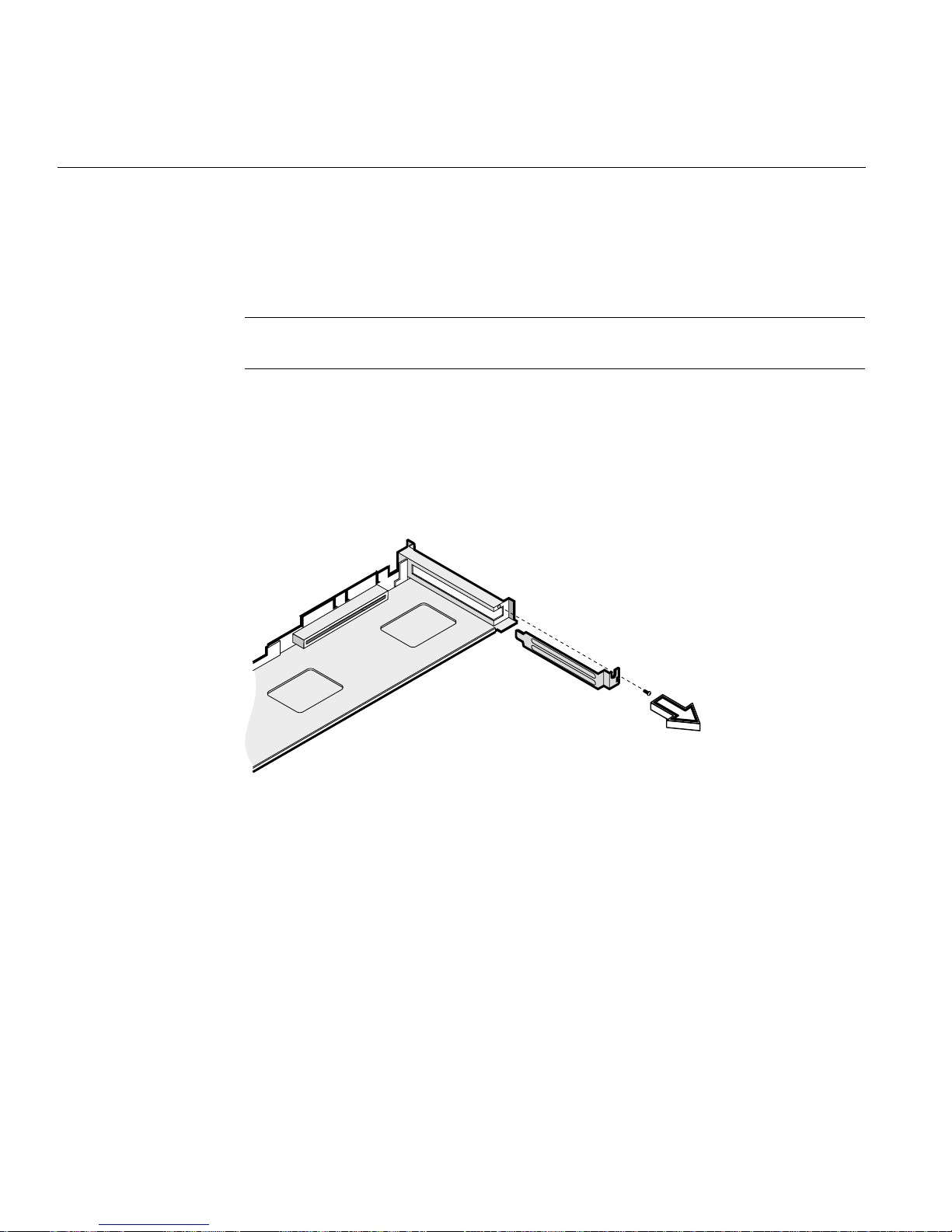

Installing an Expansion Board

Follow these steps to install an expansion board:

Note: The SGI 1100 server system supports only 3.3V or universal PCI cards. 5V PCI

cards are not supported.

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Remove the link bar as described in “Removing the Link Bar” on page 25.

3. Remove the expansion slot filler plate as shown in Figure 2-8. Save the screw for

later use.

Figure 2-8 Removing the Expansion Slot Filler Plate

4. Insert the expansion card into the riser card PCI slot by pushing the expansion

board until it is properly seated. Then secure the expansion board to the metal

bracket with a screw, as shown in Figure 2-9.

30 007-4047-001

Installing an Expansion Boa rd

Figure 2-9 Inserting the Expansion Card into the Riser Card

5. Install the link bar assembly into its slot as described in “Installing the Link Bar” on

page 27.

6. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 31

2: Removing and Re placing System Components

Replacing the Chassis Fan Subsystem

This section covers the removal and installatio n of the chassis fan cage and chassis fans.

Removing the Chassis Fan Cage

Follow these steps to remove the chassis fan cage:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Disconnect the three fan connectors from the system board as shown in Fi gure 2-10.

3. Remove two screws and pull the chassis fan cage up, as shown in Figure 2-10.

32 007-4047-001

Replacing the Chassis Fan Subsystem

Figure 2-10 Removing the Chassis Fan Cage

007-4047-001 33

2: Removing and Re placing System Components

Installing the Chassis Fan Cage

Follow these steps to install the chassis fan cage:

1. Place the chassis fan cage into the chassis.

Note: Ensure that no cables are pinched between the chassis fan and the chassis during

the installation of the chassis fan cage.

2. Tighten two screws to secure the fan cage to the chassis.

3. Connect the three fan connectors to the system board connectors CN19, CN20, and

CN28, as shown in Figure 2-11.

34 007-4047-001

Replacing the Chassis Fan Subsystem

Figure 2-11 Installing the Chassis Fan Cage

4. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 35

2: Removing and Re placing System Components

Replacing Chassis Fans

To remove a chassis fan, gently pull up the chassis fan from the fan cage, as shown in

Figure 2-12.

Figure 2-12 Removing the Chassis Fan

To install a chassis fan, insert the chassis fan into the chassis fan cage.

Note: Ensure th at th e fan you ar e insta llin g is pr ope rly or iente d so as to blow air towar d

the rear of the chassis.

36 007-4047-001

Replacing the Rear Chassis Blowers

This section covers the removal and installation of th e rear chassis blowers.

Removing a Rear Chassis Blower

Follow these steps to remove the rear chassis blowers:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Release two screws to remove the blower as shown in Figure 2-14.

3. Disconnect the blower cables from the connectors on the system board. See

Figure 2-13 for the location of the rear chassis blower cable connectors.

Replacing the Rear Chassis Blowers

007-4047-001 37

2: Removing and Re placing System Components

Cable connection

for right blower

Right blower

Left blower

Figure 2-13 Location of the Rear System Blower Cable Connectors

38 007-4047-001

Cable connection

for left blower

Rear blower

securing screws

Replacing the Rear Chassis Blowers

Figure 2-14 Rear System Blo w e r Sec u ring Screws

Installing a Rear System Blower

Follow theses steps to install each of the rear chassis blowers:

1. Place the blower on its opening on the rear panel as shown in Figure 2-14

2. Connect the rear chassis blower cable to its connector on the system board. The left

blower (the one closest to the power supply) plugs into connector CN13 (which is

underneath the right blower). The right blower plugs into connector CN23 (which is

near the front of the system board). See Figure 2-13 for the locations of the rear

chassis blower cable connectors.

3. Tighten two screws to secure the blower in place.

4. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 39

2: Removing and Re placing System Components

Replacing the Cable Modules

This section covers the removal and installation of th e cable modules.

Replacing the LED Cable Module

Follow these steps to remove the LED cable module:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Disconnect all the LED cable connectors from the system board. See Figure 2-15 for

the location of the LED cable connectors.

LED module

LED module

connectors

LED module

connectors

Figure 2-15 Location of the LED Cable Connectors

40 007-4047-001

Replacing the Cable Modules

3. Remove one screw from the LED cable module as shown in Figure2-16.

4. Remove the LED cable module from the system.

Follow these steps to install the LED cable module:

1. Set the LED cable module in place and secure it with one screw as sh own in

Figure 2-16.

LED cable

module

Figure 2-16 Installing the LED Cable Module

2. Connect all the LED cable connectors to the system board. See Figure 2-15 for the

location of the LED cable connectors.

3. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 41

2: Removing and Re placing System Components

Replacing the Power Switch Cable Module

Follow these steps to remove the power switch cable module:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Disconnect the power switch cable connector from the system board. See

Figure 2-17 for the location of the power switch cable connector.

Power switch

module

Power switch

connector

Figure 2-17 Location of the Power Switch Cable Connector

3. Remove two screws from the power switch cable module as sh own in Figure 2-18.

42 007-4047-001

Power switch

module

Figure 2-18 Removing the Power Switch Cable Module

Replacing the Cable Modules

4. Remove the power switch cable module from the system.

007-4047-001 43

2: Removing and Re placing System Components

Follow these steps to install the power switch cable module:

1. Set the power switch cable module in place and secure it with two screws as shown

in Figure 2-19.

Power switch

module

Figure 2-19 Installing the Power Switch Cable Module

2. Connect the power switch cable connector to the system board connector CN15,

pins 1 and 2. See Figure 2-17 for the location of the power switch cable connector.

3. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

44 007-4047-001

Replacing the USB Daughterboard Cable Module

Follow these steps to remove the USB daughterboard cable module:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Disconnect the USB daughterboard cable connector from the system board. See

Figure 2-20 for the location of the USB daughterboard cable connector.

USB daughterboard

Replacing the Cable Modules

USB daughterboard

cable connector

Figure 2-20 Location of the USB Daughterboard Cable Connector

007-4047-001 45

2: Removing and Re placing System Components

3. Remove two screws from the USB daughterboard cable module as shown in

Figure 2-21.

USB daughterboard

Figure 2-21 Removing the USB Daughterboard Cable Module

4. Remove the USB daughterboard cable module from the system.

46 007-4047-001

Replacing the Cable Modules

Follow these steps to install the USB daughterboard cable module:

1. Set the USB daughterboard cable module in place and secure it with two screws as

shown in Figure 2-22.

USB daughterboard

Figure 2-22 Installing the USB Daughterboard Cable Module

2. Connect the USB daughterboard cable connector to the system board connector

CN30. See Figure 2-20 for the location of the USB daughterboard cable connector.

3. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 47

2: Removing and Re placing System Components

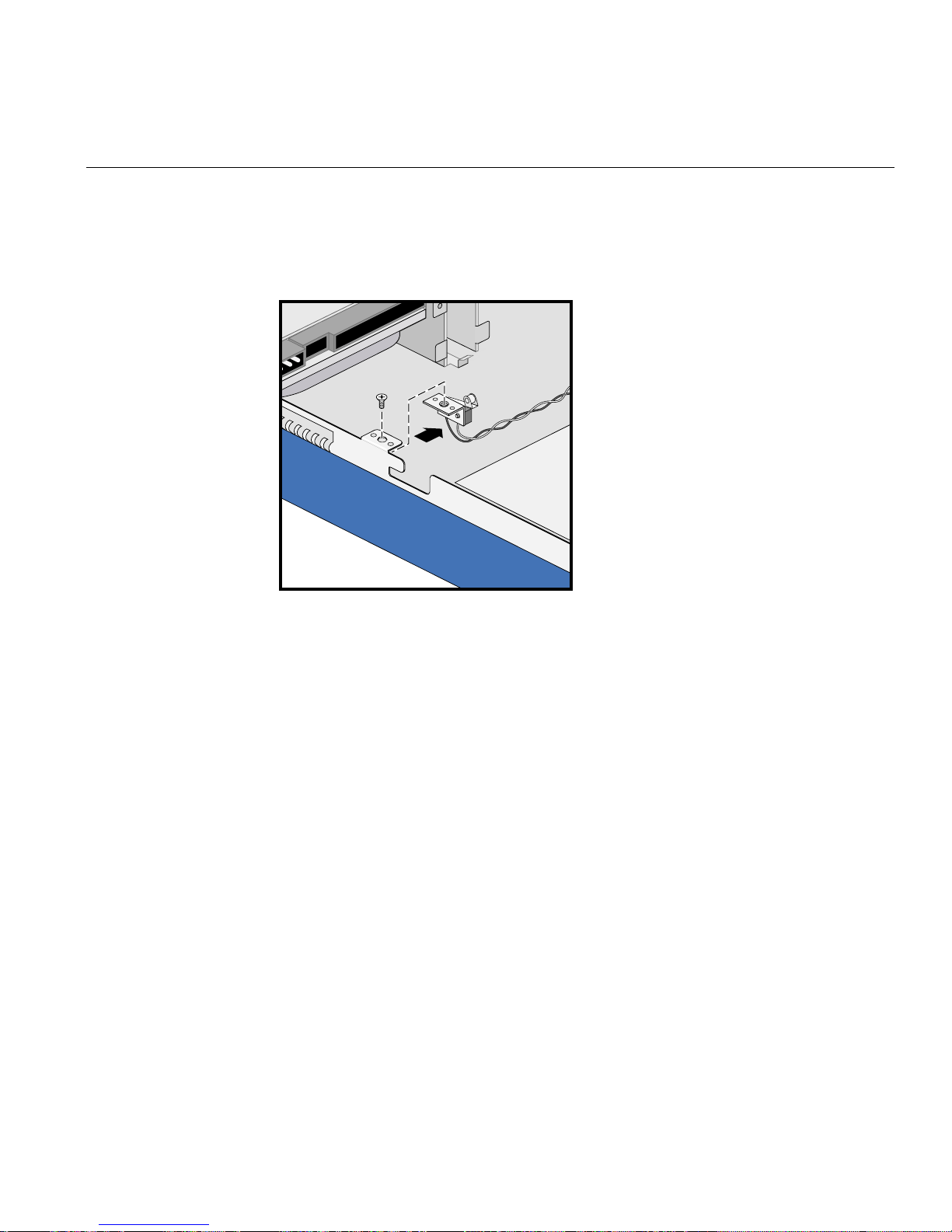

Replacing th e Intrusion Alert Microswitch Cable Module

Follow these steps to remove the intrusion alert microswitch cable module:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Disconnect the intrusion alert microswitch cable connector from the system board.

See Figure 2-23 for the location of the intrusion alert microswitch cable connector.

Microswitch cable

connector

Microswitch

Figure 2-23 Location of the Intrusion Alert Microswitch Cable Connector

48 007-4047-001

Replacing the Cable Modules

3. Remove the screw from the intrusion alert microswitch cable module as shown in

Figure 2-24.

Figure 2-24 Removing the In tr u sion Alert Micr o switch Cable Module

4. Remove the intrusion alert microswitch cable module from the system as shown in

Figure 2-24.

007-4047-001 49

2: Removing and Re placing System Components

Follow these steps to install the intrusion alert microswitch cable module:

1. Set the intrusion alert microswitch cable module in place and secure it with one

screw as shown in Figure 2-25.

Figure 2-25 Installing the Intrusion Alert Microswitch Cable Module

2. Connect the intrusion alert microswitch cable connector to the system board

connector CN15, pins 19 and 20. See Figure 2-23 for the location of intrusion alert

microswitch cable connector.

3. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

50 007-4047-001

Replacing Removable-Media Devices

This section covers the removal and installation of the removable-media devices.

Removing the Diskette Drive/CD-ROM Drive Module

Follow these steps to remove the diskette drive/CD-ROM drive module:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Remove the link bar, as described in “Removing the Link Bar” on page 25.

3. Release the signal cable retaining strap, as shown in Figure 2-26.

Retaining strap

Replacing Removable-Media Devices

Figure 2-26 Releasing the Signal Cable Retaining Strap

4. Disconnect the CD-ROM drive signal cable from the CD-ROM drive connector as

shown in Figure 2-27.

007-4047-001 51

2: Removing and Re placing System Components

Note: The CD-ROM drive signal cable is not a standard IDE cable. Instead, the

CD-ROM drive uses a signal cable with 50 conductors, some of which supply power.

5. Disconnect the diskette drive signal cable from the diskette drive connector. To do

so, lift the connector retaining latch and then pull the signal ca ble out of the

connector as shown in Figure 2-27.

Note: If you need to replace the diskette drive signal cable, follow the same

procedure to remove the diskette drive signal cable from the connector on the system

board.

Note: The diskette drive signal cable is not a standard floppy drive cable. Instead,

the diskette drive uses a signal cable with 26 conductors, some of which supply

power.

Figure 2-27 Disconnecting the Drive Module Signal Cables

52 007-4047-001

Replacing Removable-Media Devices

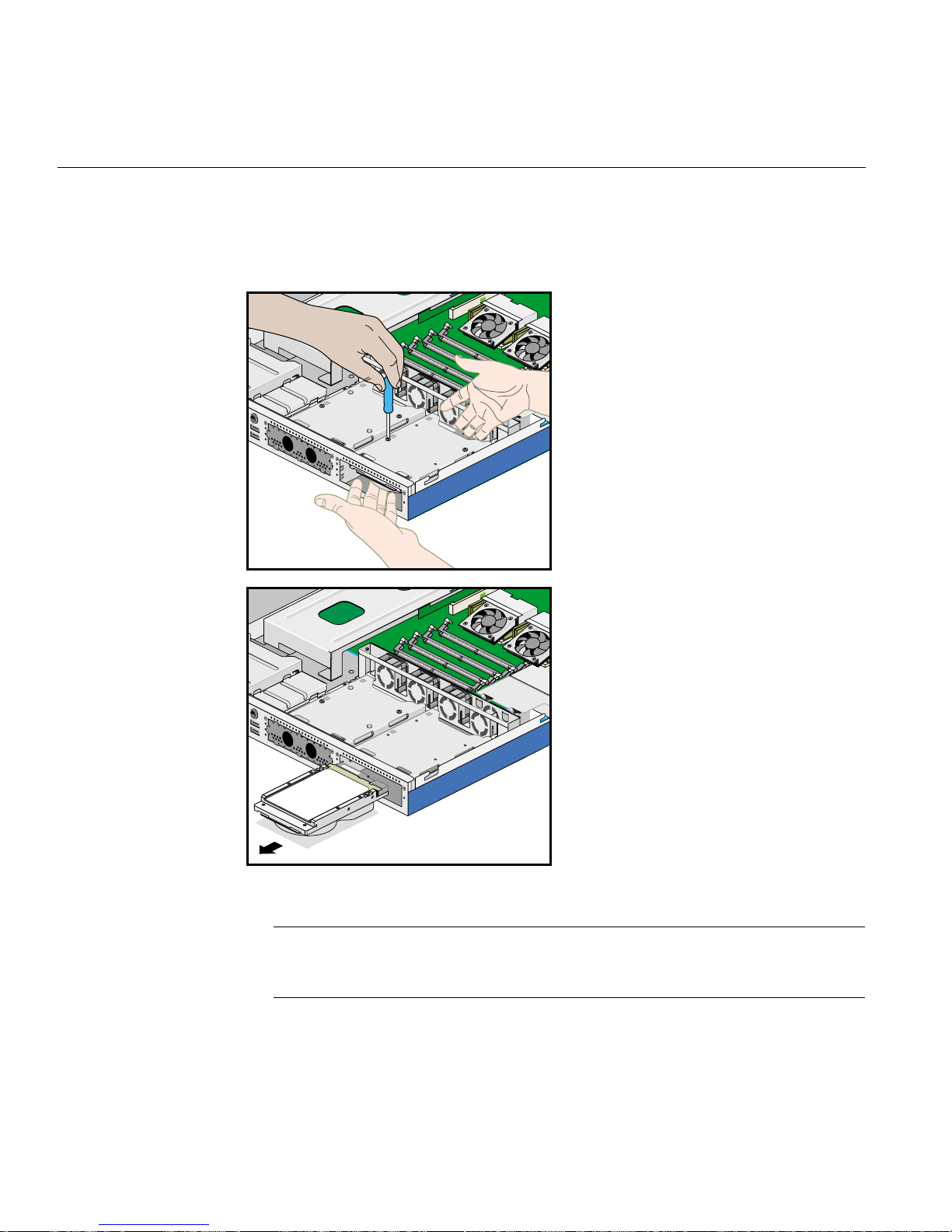

6. Remove two screws that hold the drive module to the chassis as shown in

Figure 2-28.

7. Gently slide the drive module back, and then lift it out of the chassis as shown in

Figure 2-28.

Figure 2-28 Removing the Drive Module

007-4047-001 53

2: Removing and Re placing System Components

Installing the Diskette Drive/CD-ROM Drive Module

Follow these steps to install the diskette drive/CD-ROM drive module:

1. Insert the drive module into its chassis.

2. Tighten the two screws to secure the drive module to the chassis as shown in

Figure 2-29.

3. Connect the CD-ROM drive signal cable to the CD-ROM drive connector as shown

in Figure 2-29.

Note: The CD-ROM drive signal cable is not a standard IDE cable. Instead, the

CD-ROM drive uses a signal cable with 50 conductors, some of which supply power.

4. Connect the diskette drive signal cable to the diskette drive connector. To do so,

follow these steps:

– Lift the connector retaining latch.

– Carefully insert the signal cable into the diskette drive connector.

– Push the retaining latch in on both sides of the connector, using a small

flat-head screwdriver. See Figure 2-29 for an illustration of the procedure.

Note: Follow the same procedure to connect the diskette drive signal cable to the

connector on the system board.

Note: The diskette drive signal cable is not a standard floppy drive cable. Instead,

the diskette drive uses a signal cable with 26 conductors, some of which supply

power.

54 007-4047-001

Replacing Removable-Media Devices

Raise retaining latch

Insert cable

Lower retaining latch

123

CD-ROM drive

data cable connector

Diskette drive

data cable

Figure 2-29 Connecting the Drive Module Signal Cables

5. Secure the signal cable retaining strap.

6. Install the link bar, as described in “Installing the Link Bar” on page 27.

7. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 55

2: Removing and Re placing System Components

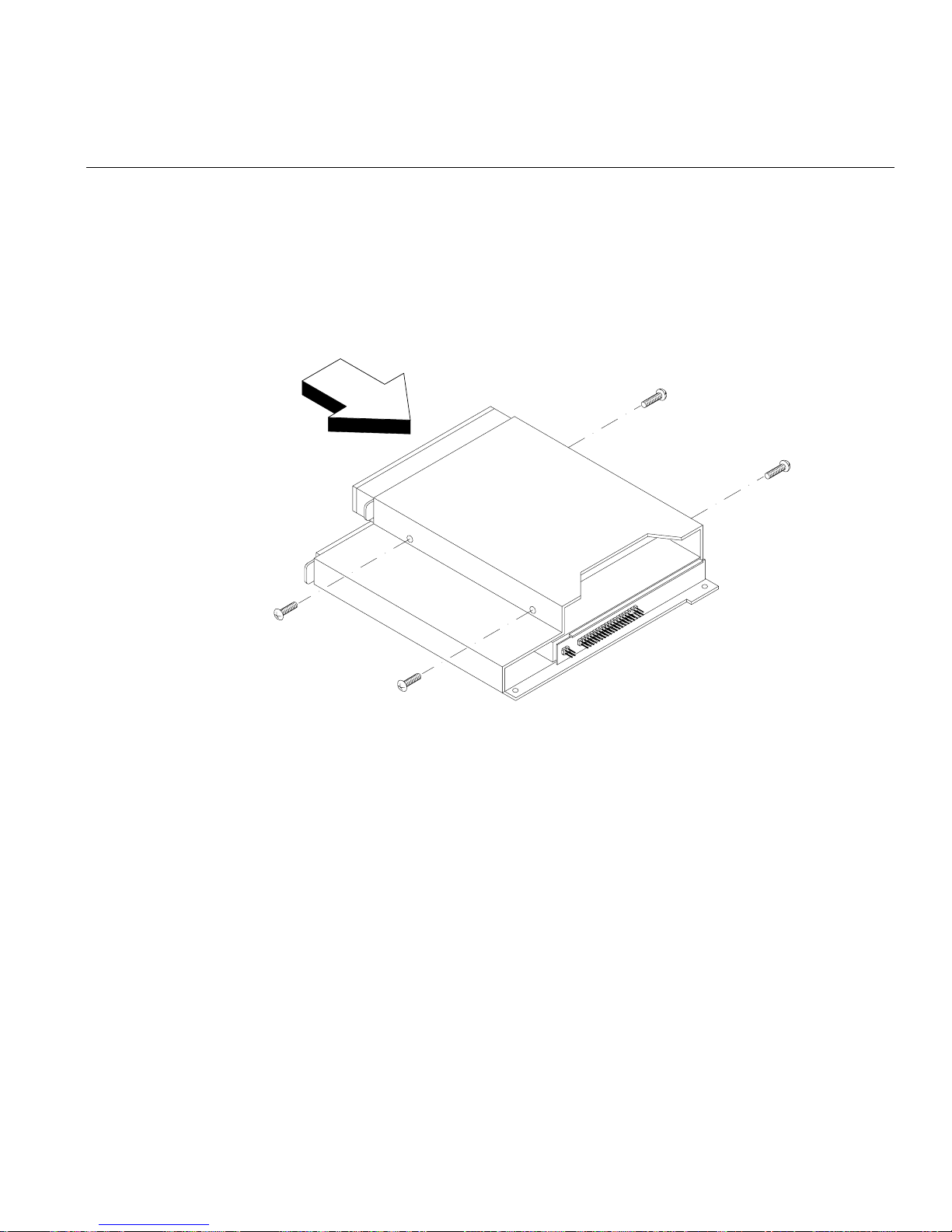

Replacing the Diskette Drive

Follow these steps to remove the diskette drive:

1. Remove the diskette drive module as described in “Removing the Diskette

Drive/CD-ROM Drive Module” on page 51.

2. Remove four screws, two on each side of the disk drive module, as shown in

Figure 2-30.

3. Gently pull the drive out of the dr ive module as shown in Figure 2-30.

Figure 2-30 Removing the Diskette Drive from the Drive Module

56 007-4047-001

Replacing Removable-Media Devices

Follow these steps to install the diskette drive:

1. Slide the diskette drive into the drive module as shown in Figure 2-31.

2. Tighten four screws, two on each side of the disk drive module, as shown in

Figure 2-31.

Figure 2-31 Installing the Diskette Drive into the Drive Module

3. Install the diskette drive module as described in “Installing the Diskette

Drive/CD-ROM Drive Module” on page 54.

007-4047-001 57

2: Removing and Re placing System Components

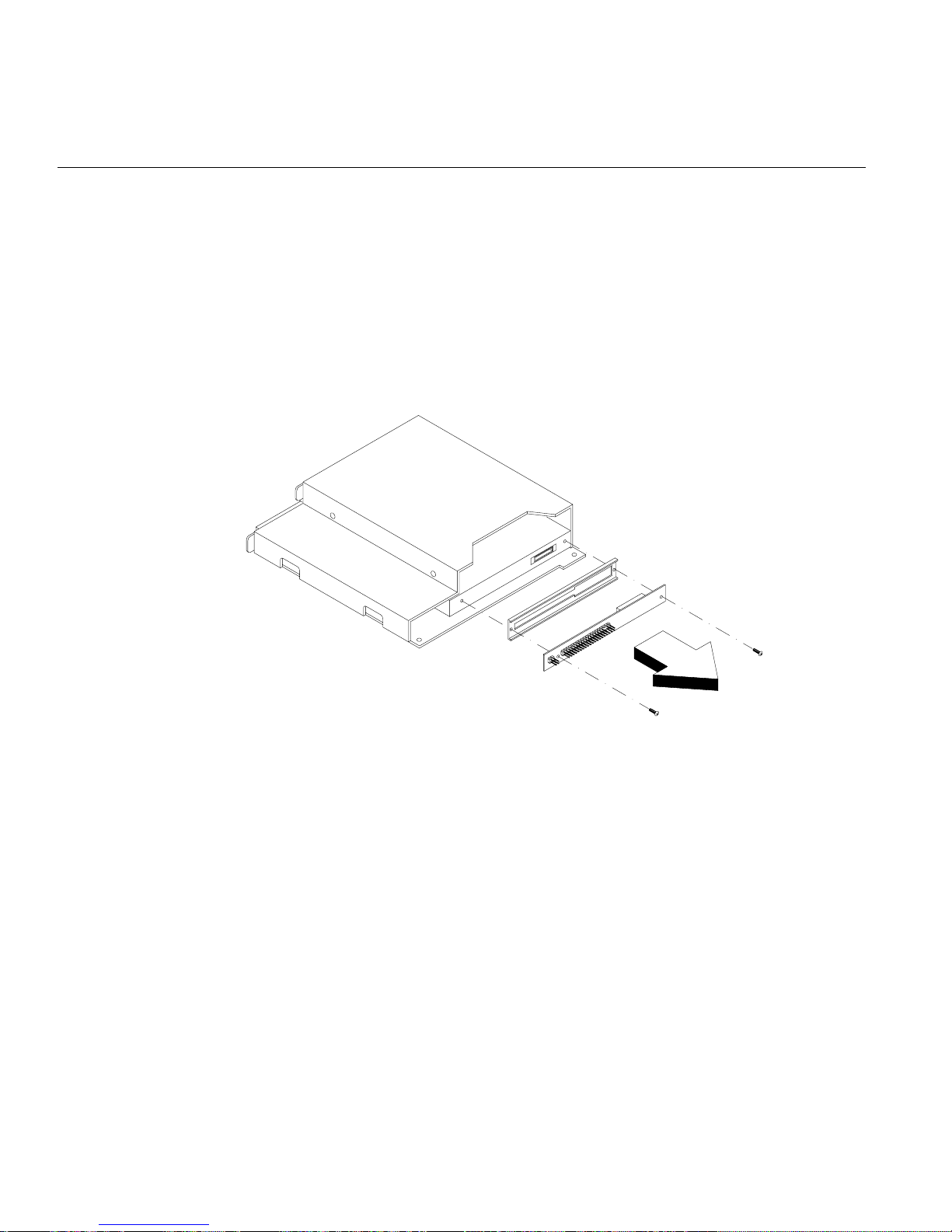

Replacing the CD-ROM Drive

Follow these steps to remove the CD-ROM drive:

1. Remove the diskette drive module as described in “Removing the Diskette

Drive/CD-ROM Drive Module” on page 51.

2. Remove two screws to detach the IDE converter board and the plastic plate as

shown in Figure 2-32.

Figure 2-32 Removing the CD-ROM Drive Converter Board

3. Remove four screws, two on each side of the drive module, as shown in Figure 2-33.

4. Gently pull the drive out of the dr ive module as shown in Figure 2-33.

58 007-4047-001

Replacing Removable-Media Devices

Figure 2-33 Removing the CD-ROM Drive from the Drive Module

007-4047-001 59

2: Removing and Re placing System Components

Follow these steps to install the CD-ROM drive:

1. Remove the drive module from the chassis as described in “Removing the Diskette

Drive/CD-ROM Drive Module” on page 51.

2. Insert the CD-ROM drive into the drive module as shown in Figure 2-34.

3. Tighten the two screws located on the side of the drive module that is in contact

with the side of the chassis, as shown in Figure 2-34.

Figure 2-34 Installing the CD-ROM Drive into the Drive Module

60 007-4047-001

Replacing Removable-Media Devices

4. Follow these steps to tighten the two s crews on the oth e r side of the drive module:

– Hold the drive module vertically with the two empty screw holes poin ting

down as shown in Figure 2-35.

– Place a screw on the tip of a small Phillips screwdriver as s hown in Figure 2-35.

Note: If the type of Phillips screwdriver you are using does not allow a screw to

stay balanced on the tip of the screwdriver, see step 5 for an alternative

procedure.

– Pass the screw through the drive module opening and tigh ten the screw.

– Repeat this procedure for the other screw.

Figure 2-35 Securing the CD-ROM drive to the Drive Module

007-4047-001 61

Screw balanced

on tip of screwdriver

2: Removing and Re placing System Components

5. If the type of Phillips screwdriver you are using does not allow you to perform the

procedure shown in step 4, follow these alternative steps:

– Using needle-nose pliers, hold one of the screws through the hole in the drive

module.

– With your other hand, tighten the screw with a small Phillips screwdriver.

– Repeat this procedure for the other screw.

6. Install the diskette drive module as described in “Installing the Diskette

Drive/CD-ROM Drive Module” on page 54.

7. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

62 007-4047-001

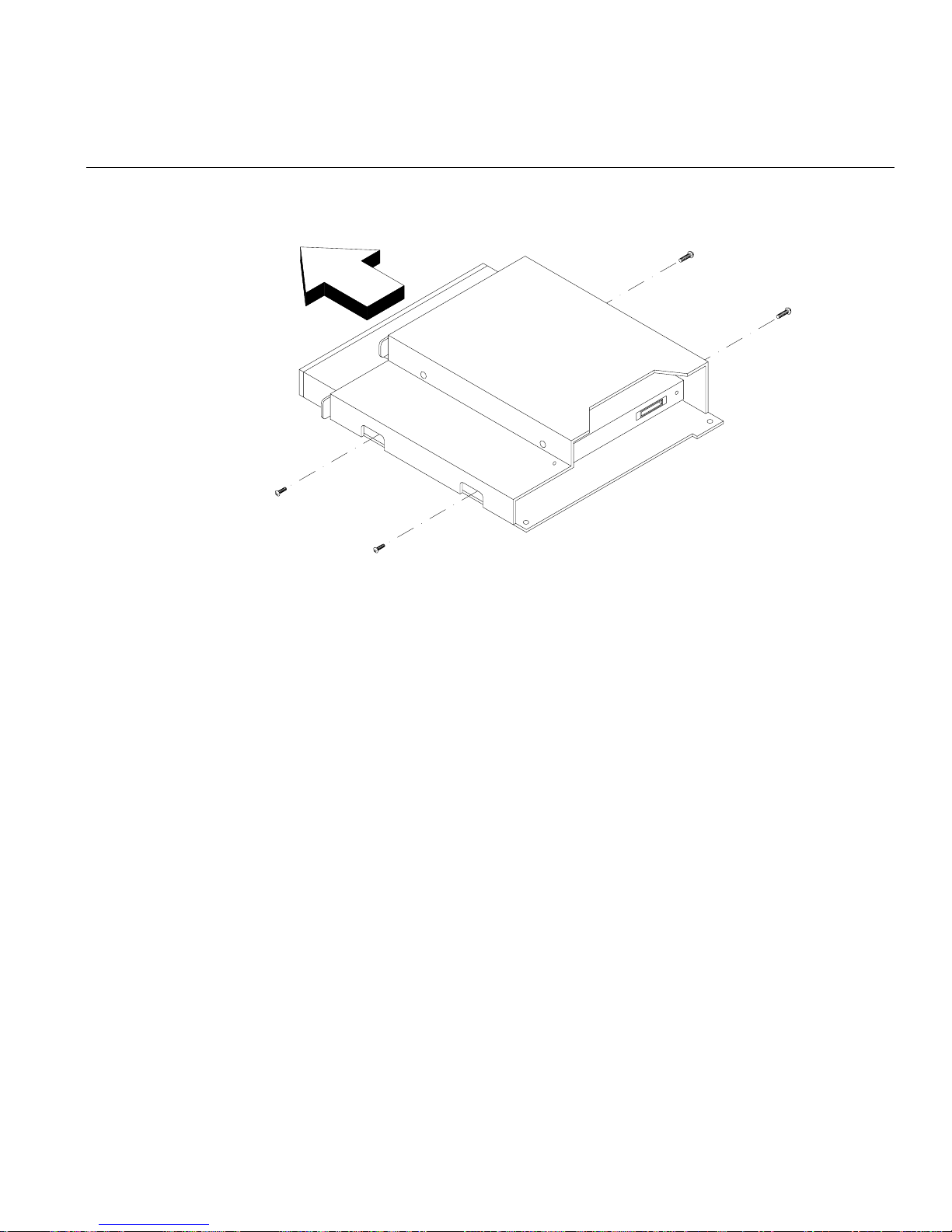

Replacing a Hard Drive

This section covers the removal and installation of a hard drive.

Note: It is recommended that two people be available for some of the hard drive

replacement steps.

Removing a Hard Drive

Follow these steps to remove a hard drive:

1. Remove the chassis cover and the front panel as described in “Opening the Chassis”

on page 21.

2. Remove the EMI filler panel from in front of the hard drive by p ulling it straight

away from the chassis.

Replacing a Hard Drive

007-4047-001 63

2: Removing and Re placing System Components

3. Disconnect the power cable and the data cable from the back of the hard drive as

shown in Figure 2-36.

Data cables

Power

connectors

Figure 2-36 Removing Hard Drive Cables

64 007-4047-001

Replacing a Hard Drive

4. Remove two of the four screws that attach the hard drive to the chassis as shown in

Figure 2-37. The first two screws that you remove should be diagonally-l ocated.

5V

Figure 2-37 Removing Two of Four Hard Disk Drive Screws

007-4047-001 65

2: Removing and Re placing System Components

5. While another person hold s the hard drive in place, remove the remaining two

screws, as shown in Figure 2-38.

5V

5V

Figure 2-38 Removing the Hard Disk Drive

Note: If the drive is not held in place when the last 2 screws are r emoved, it will fall.

In order to avoid damage to the hard drive, and if there is no other person available

to help with this task, place a soft object under the drive to absorb the shock.

66 007-4047-001

Replacing a Hard Drive

6. Pull the drive out of the chassis.

7. Insert the EMI filler panel into the chassis if no other drive is to be installed.

Note: Ensure that the arrow on the EMI filler panel points up.

8. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 67

2: Removing and Re placing System Components

Installing a Hard Disk Drive

Follow these steps to install a hard drive:

1. Remove the chassis cover and the front panel as described in “Opening the Chassis”

on page 21.

2. Remove the EMI filler panel by pulling it awa y f rom the chassis.

3. Ensure that the master/slave jumper on the hard drive is set correctly.

4. Place the hard drive (with the screw holes and connectors facing up) in the chassis.

5. While another person holds the hard drive up against the frame, tigh ten two

diagonally-located screws to secure the drive in place, as shown in Figure 2-39.

68 007-4047-001

Replacing a Hard Drive

5V

5V

Figure 2-39 Installing the Hard Disk Drive

Note: If there is no other person available to help with this task, place an object

under the hard drive to allow you to tighten the first two screws.

6. Tighten the remaining two screws.

7. Connect the power cable and the data cable to the back of the hard drive.

007-4047-001 69

2: Removing and Re placing System Components

8. Insert the EMI filler panel into the chassis.

Note: Ensure that the arrow on the EMI filler panel points up.

9. Install the chassis cover as described in “Installing the Chassis Cover” on page 23

and the front panel as described in “Removing and Installing the Front Pan e l” on

page 24.

70 007-4047-001

Replacing the Pow er Su pply Module

This section covers the removal and installation of th e power supply module:

Removing the Power Supply Module

Follow these steps to remove the power supply module:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Remove the intrusion alert microswitch module as described in “Replacing the

Intrusion Alert Microswitch Cable Module” on page 48.

3. Disconnect the power supply cable from the system board. See Figure 2-40 for the

location of the system board power supply connector.

Power supply

connector

Power

supply

Replacing the Power Supply Module

Figure 2-40 Location of the System Board Power Supply Connector

007-4047-001 71

2: Removing and Re placing System Components

4. Disconnect the power supply cable from the hard drives. See Figure 2-41 for the

location of the hard drive power supply connectors.

Power

connectors

Figure 2-41 Location of the Hard Drive Power Supply Connectors

72 007-4047-001

Replacing the Power Supply Module

5. Remove the metal air guide plate by releasing the two s c rews as shown in

Figure 2-42.

Air guide plate

Figure 2-42 Removing the Air Guide Plate

007-4047-001 73

2: Removing and Re placing System Components

6. Remove the plastic plenum by separating it from the power supply module and

gently detaching it from the power socket module, as shown in Figure 2- 43.

Note: The plastic plenum adheres to the sides of the power socket module. Proceed

with care to free the plenum from the power socket module.

Plenum

Figure 2-43 Removing the Plastic Plenum

74 007-4047-001

Replacing the Power Supply Module

7. Remove the three screws from the power supply module as shown in Figure 2-44 .

Power supply

module

Power socket

assembly

Figure 2-44 Removing the Power Supply Module

007-4047-001 75

2: Removing and Re placing System Components

8. Remove three screws to release the power socket module as shown in Figure 2-44.

9. Lift up the power supply module from the chassis as shown in Figure 2-44.

Installing the Power Supply Module

Follow these steps to install the powe r supply module:

1. Place the power supply module in the chassis as shown in Figure 2-45.

2. Tighten three screws to attach the power supply socket module to the rear panel as

shown in Figure 2-45.

76 007-4047-001

Power supply

module

Replacing the Power Supply Module

Power socket

assembly

Figure 2-45 Installing the Power Supply Module

007-4047-001 77

2: Removing and Re placing System Components

3. Follow these steps to install the plastic plenum:

– Align the narrow part of the plastic plenum with the air vent on the power

supply socket module, using the adhesive sides of the plenum to stick it into

position, as shown in Figure 2-46.

– Align the wide part of the plenum with the power supply fan opening.

Plenum

Figure 2-46 Installing the Plastic Plenum

4. Tighten three screws to secure the power supply module to the chassis as shown in

Figure 2-45.

78 007-4047-001

Replacing the Power Supply Module

5. Install the metal air guide plate and secure it with two screws as shown in

Figure 2-47.

Note: Ensure that all cables fit within the metal air guide plate opening, so that no

cables are stuck between the air guide plate and the chassis.

Air guide plate

Figure 2-47 Installing the Metal Air Guide Plate

007-4047-001 79

2: Removing and Re placing System Components

6. Connect the power supply cable to the system board. See Figure 2-40 on page 71 for

the location of the system board power supply connector.

7. Connect the power supply cable to the hard drives. See Figure 2-41 on page 72 for

the location of the hard drive power supply connectors.

8. Install the intrusion alert microswitch module as described in “Replacing the

Intrusion Alert Microswitch Cable Module” on page 48.

9. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

80 007-4047-001

Removing a Processor

Follow these steps to remove a processor:

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Disconnect the fan/heatsink cables from the system board.

3. Follow these steps to remove the fan/heatsink assembly from the processor:

– Disconnect the fan/heatsink cable from the system board. See Figure 2-50 for

– Push on the releasing tab to unhook the metal bracket that is facing the rear of

– Lift the fan/heatsink assembly and unhook the other metal bracket. See step C

– Remove the fan/heatsink assembly from the processor.

Note: Avoid touching the thermal conductive grease on the bottom of the

fan/heatsink and the top of the processor.

Removing a Processor

the location of the cable connection.

the system. See steps A and B in Figure 2-48.

in Figure 2-48.

4. Pull up the socket lever (see step D in Figure 2-48). The processor pins will be

automatically released from the socket holes.

5. Lift the processor from the socket as shown in Figure2-48.

Caution: Do not touch the pins on the processor, so as to ensure long-term reliable

contact.

6. If you will now be using the system as a single-CPU system, this processor must be

replaced with a terminator board. See “Installing a Processor Terminator Board” on

page 86.

7. Install the chassis cover as described in “Installing the Chassis Cover” on page 23.

007-4047-001 81

2: Removing and Re placing System Components

A

B

C

D

Figure 2-48 Removing a Processor

82 007-4047-001

Installing a Processor

Follow these steps to install a processor:

Warning: B oth CPUs must be the same speed and cache size. Do not install CPUs

with different speeds or cache sizes; this would cause your system to malfunction.

1. Remove the chassis cover as described in “Removing the Chassis Cover” on

page 21.

2. Pull up the socket lever.

3. Remove the terminator board, if present.

4. Insert the processor, making sure that pin 1 (indicated by a triangle at the corner of

the processor) connects to hole 1 of the socket, as shown in Figure 2-49.

Caution: Do not touch the pins on the processor, so as to ensure long-term reliable

contact.

Installing a Processor

5. Pull down the socket lever to lock the processor into the socket. See step B in

Figure 2-49.

007-4047-001 83

2: Removing and Re placing System Components

C

A

B

Figure 2-49 Installing the Processor

E

D

F

6. Follow these procedures to attach the heatsink/fan assem b ly to the processor:

Note: Avoid touching the thermal conductive grease on the bottom of the

fan/heatsink and the top of the processor.

– Spread a small amount of thermal conductive grease on the top center of the

processor.

– Tilt the heatsink/fan assembly on the processor so as to be able to hook the

metal bracket that is facing the front of the chassis over the retaining hook on

the CPU socket. See step D in Figure 2-49.

– Place the heatsink/fan assembly flat on the processor.

– Push the releasing tab to latch the other metal bracket over the retaining hook

on the CPU socket. See steps E and F in Figure 2 -49 .

84 007-4047-001

Loading...

Loading...