SGI® Rackable™ C1110-RP6

System User Guide

007-5843-002

COPYRIGHT

© 2012, 2013 Silicon Graphics International Corp. All rights reserved; provided portions may be copyright in third parties, as indicated elsewhere herein. No

permission is granted to copy , distribute, or create derivative works from the contents of this electronic documentation in any manner, in whole or in part,

without the prior written permission of SGI.

LIMITED RIGHTS LEGEND

The electronic (software) version of this document was developed at private expense; if acquired under an agreement with the USA government or any

contractor thereto, it is acquired as "commercial computer software" subject to the provisions of its applicable license agreement, as specified in (a) 48 CFR

12.212 of the FAR; or, if acquired for Department of Defense units, (b) 48 CFR 227-7202 of the DoD FAR Supplement; or sections succeeding thereto.

Contractor/manufacturer is Silicon Graphics, International, Inc., 46600 Landing Parkway, Freemont, CA 94538.

TRADEMARKS AND ATTRIBUTIONS

Silicon Graphics, SGI, the SGI logo, Rackable, and Supportfolio are trademarks or registered trademarks of Silicon Graphics International Corp. or its

subsidiaries in the United States and other countries.

Intel, Intel QuickPath Interconnect (QPI) and Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and

other countries.

Infiniband is a trademark of the InfiniBand Trade Association.

Linux is a registered trademark of Linus Torvalds.

Novell is a registered trademark of Novell Inc., in the United States and other countries.

PCIe and PCI-X are registered trademarks of PCI SIG.

Red Hat and Red Hat Enterprise LINUX are registered trademarks of Red Hat Inc.

TYAN is a registered trademark of MiTAC International Corporation.

UNIX is a registered trademark in the United States and other countries, licensed exclusively through X/Open Company, Ltd.

All other trademarks mentioned herein are the property of their respective owners.

Record of Revision

Version Description

001 October 2012

Original publication

002 September 2013

Added support for Intel

miscellaneous front matter changes.

®

Xeon® E5-2600 and E5-2600v2 Series processors plus

:

007-5843-002 iii

Contents

Record of Revision . . . . . . . . . . . . . . . . . . . . . . . iii

About This Guide . . . . . . . . . . . . . . . . . . . . . . . ix

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . ix

Related Publications. . . . . . . . . . . . . . . . . . . . . . . x

Product Support . . . . . . . . . . . . . . . . . . . . . . . . xi

Reader Comments . . . . . . . . . . . . . . . . . . . . . . . xi

1 Introduction and Overview . . . . . . . . . . . . . . . . . . . . 1

ESD and Safety Precautions. . . . . . . . . . . . . . . . . . . . . 1

System Overview . . . . . . . . . . . . . . . . . . . . . . . 2

Serverboard Features . . . . . . . . . . . . . . . . . . . . . 3

Processors . . . . . . . . . . . . . . . . . . . . . . . 3

Quick Path Interconnect (QPI). . . . . . . . . . . . . . . . . . 3

Memory . . . . . . . . . . . . . . . . . . . . . . . 4

Serial ATA/SAS . . . . . . . . . . . . . . . . . . . . . 4

PCI Expansion Slots . . . . . . . . . . . . . . . . . . . . 4

On-board Controllers/Ports . . . . . . . . . . . . . . . . . . 4

IPMI . . . . . . . . . . . . . . . . . . . . . . . . . 5

Other Features . . . . . . . . . . . . . . . . . . . . . . . 5

BMC Features . . . . . . . . . . . . . . . . . . . . . . . 5

PCIe Sub-system . . . . . . . . . . . . . . . . . . . . . . 6

Server Chassis Features . . . . . . . . . . . . . . . . . . . . . . 7

System Power . . . . . . . . . . . . . . . . . . . . . . . 7

Disk Drive Subsystem . . . . . . . . . . . . . . . . . . . . . 7

Control Panel . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling System. . . . . . . . . . . . . . . . . . . . . . . 8

007-5843-002 v

Contents

2 System Operation . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking the System and Choosing an Operating Location . . . . . . . . . . . . 9

Preparing for Setup . . . . . . . . . . . . . . . . . . . . . . 9

Choosing a Setup Location . . . . . . . . . . . . . . . . . . . 9

Rack Precautions . . . . . . . . . . . . . . . . . . . . . . 10

Server Precautions . . . . . . . . . . . . . . . . . . . . . . 10

Rack Mounting Considerations . . . . . . . . . . . . . . . . . . . 11

Ambient Operating Temperature . . . . . . . . . . . . . . . . . 11

Reduced Airflow . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Loading . . . . . . . . . . . . . . . . . . . . 11

Circuit Overloading. . . . . . . . . . . . . . . . . . . . . 11

Reliable Ground . . . . . . . . . . . . . . . . . . . . . 11

System Warnings and Precautions . . . . . . . . . . . . . . . . . . . 12

Installing the System into a Rack . . . . . . . . . . . . . . . . . . . 13

Identifying the Sections of the Rack Rails . . . . . . . . . . . . . . . . 13

Installing the Inner Rails . . . . . . . . . . . . . . . . . . . . 14

Installing the Outer Rails . . . . . . . . . . . . . . . . . . . . 14

Locking Tabs . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the Server into the Rack . . . . . . . . . . . . . . . . . . 16

Installing the Server into a Telco Rack . . . . . . . . . . . . . . . . . 17

Server Access After Rack Installation . . . . . . . . . . . . . . . . . 17

Remove/Replace the Chassis Top Covers . . . . . . . . . . . . . . . 18

Checking the Components and Setup Before Power On . . . . . . . . . . . . 20

Checking the Hard Disk Drives . . . . . . . . . . . . . . . . . . . 20

Checking the Airflow . . . . . . . . . . . . . . . . . . . . . 20

Providing Power. . . . . . . . . . . . . . . . . . . . . . . 20

vi 007-5843-002

Contents

3 System Interfaces Overview . . . . . . . . . . . . . . . . . . . . 23

System Interface Overview . . . . . . . . . . . . . . . . . . . . . 23

Control Panel Buttons . . . . . . . . . . . . . . . . . . . . . 24

Control Panel LEDs . . . . . . . . . . . . . . . . . . . . . 24

HDD . . . . . . . . . . . . . . . . . . . . . . . . 25

Power . . . . . . . . . . . . . . . . . . . . . . . . 25

Universal Information LED . . . . . . . . . . . . . . . . . . 25

Disk Drive Carrier LEDs . . . . . . . . . . . . . . . . . . . . 25

4 Internal Component Replacement and Upgrades . . . . . . . . . . . . . . 27

General Precautions . . . . . . . . . . . . . . . . . . . . . . . 27

Installing System DIMM Memory . . . . . . . . . . . . . . . . . . . 27

Installing Memory DIMMs. . . . . . . . . . . . . . . . . . . . 29

Adding PCIe Cards . . . . . . . . . . . . . . . . . . . . . . . 30

System Fans. . . . . . . . . . . . . . . . . . . . . . . . 31

System Fan Failure. . . . . . . . . . . . . . . . . . . . . 31

Drive Bay Installation/Removal . . . . . . . . . . . . . . . . . . 31

Disk Drive Removal and Installation . . . . . . . . . . . . . . . . . . 31

Mounting a Drive in a Carrier . . . . . . . . . . . . . . . . . . . 32

Installing/Removing Hot-swap Drives . . . . . . . . . . . . . . . . . 32

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 34

Power Supply Failure . . . . . . . . . . . . . . . . . . . . . 35

Removing the 650-Watt Redundant Power Supply . . . . . . . . . . . . . 35

Installing a New 650-Watt Redundant Power Supply . . . . . . . . . . . . . 37

Removing the 450-Watt Non-Redundant Power Supply . . . . . . . . . . . . 38

Installing the 450-Watt Non-Redundant Power Supply . . . . . . . . . . . . 40

007-5843-002 vii

Contents

A System Specifications . . . . . . . . . . . . . . . . . . . . . . 41

Processors . . . . . . . . . . . . . . . . . . . . . . . . . 41

I/O Chipset . . . . . . . . . . . . . . . . . . . . . . . . . 41

BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Memory Capacity . . . . . . . . . . . . . . . . . . . . . . . 41

Disk Drive Controller . . . . . . . . . . . . . . . . . . . . . . 42

Drive Bays . . . . . . . . . . . . . . . . . . . . . . . . . 42

Expansion Slots . . . . . . . . . . . . . . . . . . . . . . . . 42

Serverboard . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 43

System Cooling . . . . . . . . . . . . . . . . . . . . . . . . 43

System Input Requirements . . . . . . . . . . . . . . . . . . . . . 43

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . 43

Environmental Specifications . . . . . . . . . . . . . . . . . . . . 44

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . 45

viii 007-5843-002

Audience

. About This Guide

This guide provides an overview of the SGI® Rackable™ C1110-RP6 servers along with

instructions for system installation and general operation. The appendices include technical

specifications and safety practices.

This guide is written for owners, installers, system administrators, and users of C1110-RP6

servers. It is written with the assumption that the reader has a good working knowledge of

computers and computer systems.

007-5843-002 ix

About This Guide

Related Publications

Depending on your choice of system components and operating system, the following SGI

documents may be relevant to your server:

• SGI Foundation Software release notes

• SGI Performance Suite release notes

• SGI InfiniteStorage series documentation

• Man pages

You can obtain SGI documentation, release notes, or man pages in the following ways:

• Refer to the SGI Technical Publications Library at http://docs.sgi.com. Various formats are

• Refer to the SGI Supportfolio™ webpage for release notes and other documents whose

Note: For information on your motherboard and related system components, see the

documentation provided by the manufacturer/supplier.

available. This library contains the most recent set of books and man pages.

access require a support contract. See “Product Support” on page xi.

x 007-5843-002

Product Support

About This Guide

SGI provides a comprehensive product support and maintenance program for its products. SGI

also offers services to implement and integrate Linux applications in your environment.

• Refer to http://www.sgi.com/support/

• If you are in North America, contact the Technical Assistance Center at

+1 800 800 4SGI or contact your authorized service provider.

• If you are outside North America, contact the SGI subsidiary or authorized distributor in

your country.

Be sure to have the following information before you call Technical Support:

• Product serial number

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

• Motherboard BIOS revision

Reader Comments

If you have comments about the technical accuracy, content, or organization of this document,

contact SGI. Be sure to include the title and document number of the manual with your comments.

(Online, the document number is located in the front matter of the manual. In printed manuals, the

document number is located at the bottom of each page.)

You can contact SGI in any of the following ways:

• Send e-mail to the following address: techpubs@sgi.com

• Contact your customer service representative and ask that an incident be filed in the SGI

incident tracking system:

http://www.sgi.com/support/supportcenters.html

SGI values your comments and will respond to them promptly.

007-5843-002 xi

Chapter 1

1. Introduction and Overview

This chapter provides an overview of your server’s main features.

Operating precautions are provided in this chapter, followed by a general overview of the product.

Before operating your system, familiarize yourself with the safety information that follow s:

ESD and Safety Precautions

Caution: Observe all ESD precautions. Failure to do so can result in damage to the equipment.

W ear an approved grounding wrist strap when you handle any ESD-sensitive device to eliminate

possible ESD damage to equipment. Connect the wrist strap cord directly to earth ground.

Warning: Before operating or servicing any part of this product, read the safety

precautions.

Danger: Keep fingers and conductive tools away from high-voltage areas. Failure to

follow these precautions will result in serious injury or death. The high-voltage areas of the

system are indicated with high-voltage warning labels.

Caution: Power off the system only after the system software has been shut down in an orderly

!

007-5843-002 1

manner. If you power off the system before you halt the operating system, data may be corrupted.

1: Introduction and Overview

System Overview

Warning: If a lithium battery is installed in your system as a soldered part, only qualified

SGI service personnel should replace this lithium battery. For a battery of another type,

replace it only with the same type or an equivalent type recommended by the battery

manufacturer, or an explosion could occur. Discard used batteries according to the

manufacturer’s instructions.

The SGI® Rackable™ C11 10-RP6 system is a compute-optimized server comprised of two main

subsystems: the 1U chassis and a serverboard (motherboard). Check with your sales or service

representative before loading any operating system on your server not provided by the SGI factory

or service organization.

Various hardware components may be included as part of your SGI Rackable C1110-RP6 system

configuration as listed below:

• Serverboard with:

–Two Intel

®

Xeon® E5-2600 or E5-2600v2 Series processors in LGA2011 sockets

– Intel C602 chipset and Quick Path Interconnect system bus support the processors

– Sixteen DDR3 memory DIMM slots

– T wo external Gen3 x16 PCIe slots (one full-height and one low-profile)

• Two disk drive configurations include:

– Four 3.5-inch hard disk drives plus DVD option drive

– Ten 2.5-inch hard disk drives (no DVD option available)

• Seven 4-cm counter-rotating cooling fans for the serverboard

• One 450 Watt auto-ranging power supply (with single power connector)

• Optional 650 Watt redundant auto-ranging power supply (with dual power connectors)

Note: The TYAN S7056 serverboard is the standard C1110-RP6 motherboard offering.

Other customized offerings may be available for specific system or clustering needs. Check

with your SGI sales or service representative for additional information.

2 007-5843-002

Serverboard Features

System Overview

Figure 1-1 Four-Drive C1110-RP6 System Chassis Front View Example

Figure 1-2 Ten-Drive C1110-RP6 System Chassis Front View Example

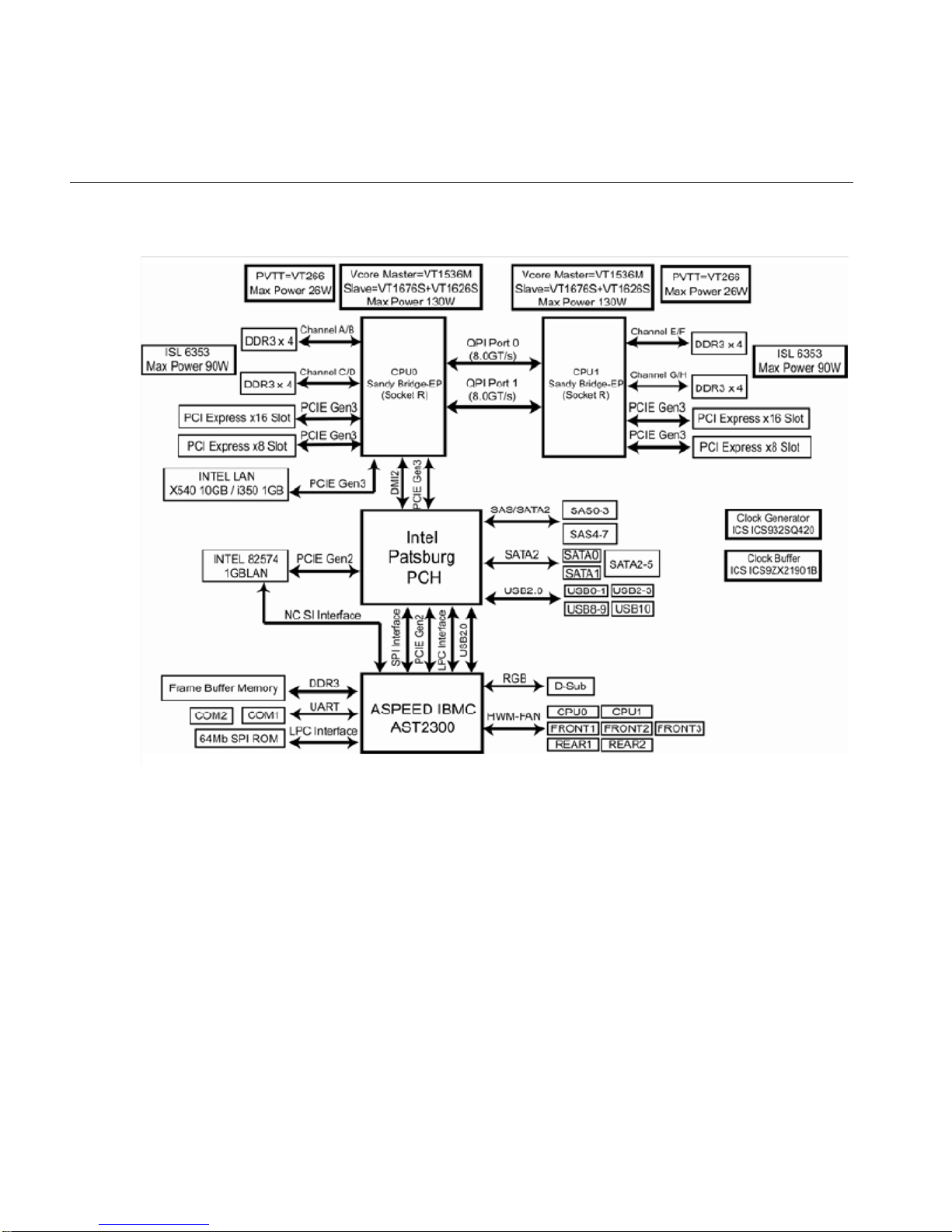

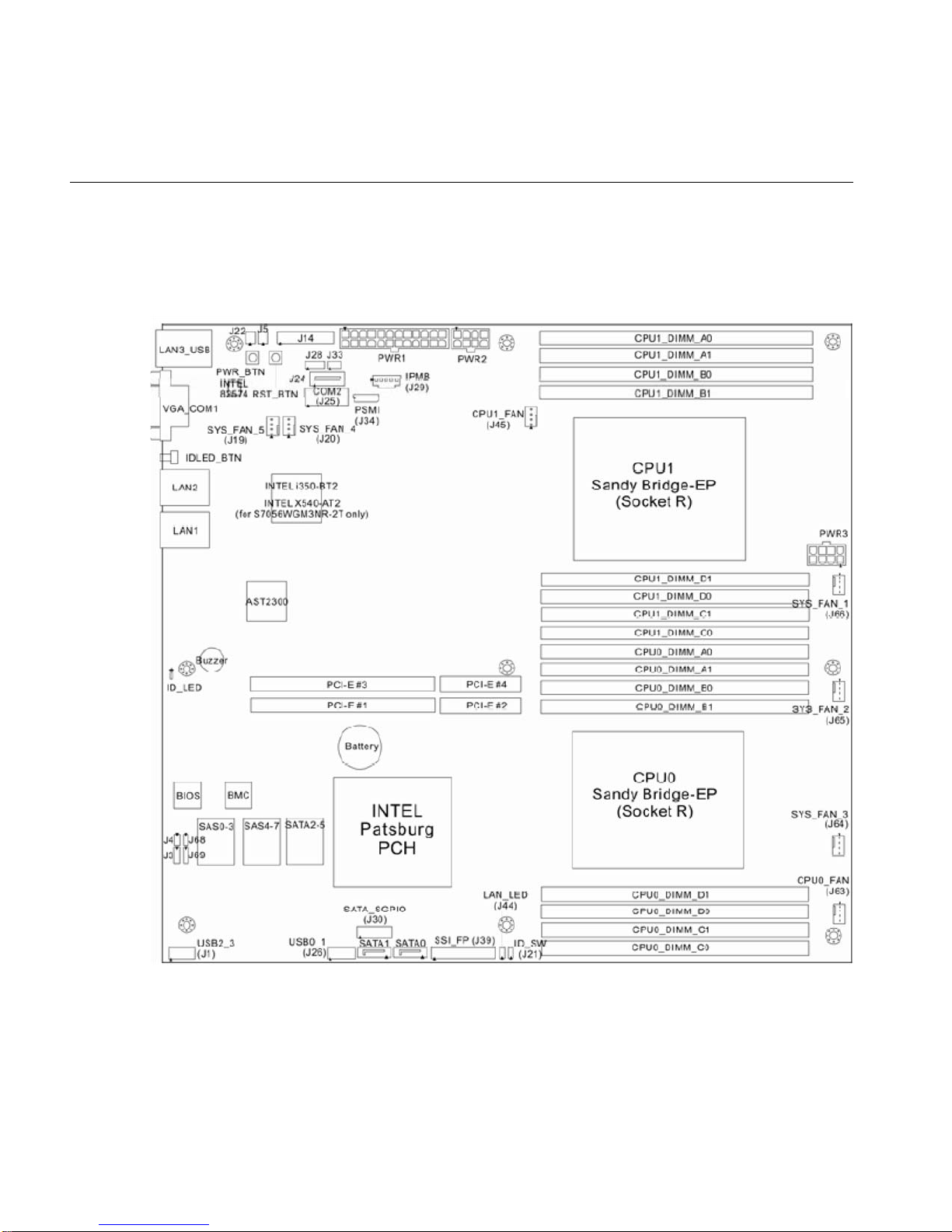

The SGI Rackable C1110-RP6 system has a dual processor serverboard based on the Intel C602

chipset. The following subsections describe the main features of the serverboard. See Figure 1-3

on page 6 for a functional block diagram of the serverboard.

Processors

Each serverboard supports two Intel Xeon series processors. Each processor sits in an LGA2011

socket and is interconnected via Intel QPI link support, see the next subsection for more

information on the QPI bus. Four-core, six-core and eight-core processors are available.

The exact type of processors provided with your system depends on the specific configuration you

ordered. Check with your SGI sales or service representative for information on processor

upgrades.

Quick Path Interconnect (QPI)

Separate QPI link pairs connect the two processors in an 8.0-GT/s network on the serverboard.

Each QPI comprises two 20-lane point-to-point data links, one in each direction (full duplex), with

a separate clock pair in each direction, for a total of 42 signals. Each signal is a differential pair,

so the total number of pins is 84. The 20 data lanes are divided onto four “quadrants” of 5 lanes

each. The basic unit of transfer is the 80-bit “flit”, which is transferred in two clock cycles (four

007-5843-002 3

1: Introduction and Overview

Memory

Serial ATA/SAS

20 bit transfers, two per clock.) The 80-bit “flit” has 8 bits for error detection, 8 bits for “link-layer

header” and 64 bits for “data”. QPI bandwidths are advertised by computing the transfer of 64 bits

(8 bytes) of data every two clock cycles in each direction

The SGI Rackable C1110-RP6 system has 16 DIMM slots that support registered ECC

DDR3-1600/1333/1066/800 SDRAM. Memory DIMMs of the same size and speed are highly

recommended for best overall system performance. A minimum of two DIMMs are required for

the server to be functional. For best memory performance, install DIMMs in multiples of eight.

See “Installing System DIMM Memory” in Chapter 4, for more details on installing memory.

A Serial ATA controller is integrated into the system serverboard to provide a SATA subsystem

with transfer rates up to 6 Gb/second. The optionally hot-swappable SATA drives are connected

to a backplane that provides power, bus termination and configuration settings. Optional SAS or

SAT A RAID 0, 1, 5, 6 and 10 are supported (RAID 5 and 6 require optional hardware). Note that

RAID functionality is required for hot-swap capability.

Note: Your operating system must support RAID functionality in order to use RAIDed drives.

The Intel C600 chipset provides BIOS-assisted software RAID only, not hardware RAID.

Hardware RAID support is available as an optional configuration.

Contact your SGI sales or service provider to order a specific RAID upgrade if your system was

not ordered with that option.

PCI Expansion Slots

The serverboard has two external PCI-Express Gen3 x16 slots.One slot is a low-profile form

factor, the other is a (half-length) full-height PCIe slot.

On-board Controllers/Ports

The rear-mounted I/O ports include one COM port, a VGA (monitor) port, two USB 2.0 ports, and

three Gigabit Ethernet ports (LAN3 is a shared IPMI port). A special serial port is included for

system management.

4 007-5843-002

IPMI

Other Features

BMC Features

System Overview

The IPMI (Intelligent Platform Management Interface) is a hardware-level interface specification

that provides remote access, monitoring and administration for the SGI Rackable C1110-RP6

system. IPMI allows server administrators to view a server’s hardware status remotely , receive an

alarm automatically if a failure occurs, and power cycle a system that is non-responsive.

Other on-board features that promote system health include voltage monitors, auto-switching

voltage regulators, chassis and CPU overheat sensors, virus protection and BIOS rescue.

The baseboard management controller (BMC) has the following features:

• The platform management subsystem uses the BMC to communicate with buses, sensors,

system BIOS, and server management firmware via the Server Management Bus (SMBUS)

• Enables serial-over-LAN (SOL) functionality via serial port B only

• Supports serial-console redirection in BIOS

• The BMC LAN may be configured in BIOS or via ipmitool.

• The ipmitool command is used to communicate with the BMC via an SOL session or by

using the web-based BMC interface.

007-5843-002 5

1: Introduction and Overview

Figure 1-3 Functional Block Diagram of SGI Rackable C1110-RP6 System Server Board

PCIe Sub-system

The primary I/O bus for the serverboard is PCI Express.

6 007-5843-002

Server Chassis Features

The following sections provide a general outline of the main features of the 1U system chassis.

Figure 1-4 shows an example of the rear panel features of the SGI Rackable C1110-RP6 system.

VGA Port

IPMI

LAN/LAN3

Server Chassis Features

Low-profile x16 PCIe Slot

Full-height x16 PCIe slot

System Power

Disk Drive Subsystem

USB

Ports

COM

Figure 1-4 SGI Rackable C1110-RP6 System Rear Panel and I/O Ports

LAN2

LAN1

Port

UID LED

button

Power

Serial Port

HDD

activity

Your SGI Rackable C1110-RP6 system uses a single-cord high-efficiency 450-Watt cold-swap

power supply (shown on the left side of Figure 1-4). Optionally, a dual-cord 650-Watt redundant

power supply is available. Both types of supply are 80+ Gold rated.

The AC power supply cord(s) should always be removed from the system before servicing or

replacing the power supply.

The SGI Rackable C1110-RP6 system chassis includes four 3.5-inch drive bays or ten 2.5-inch

drive bays. These drives can be JBOD disks, or software RAID, or BIOS-assisted software RAID,

or optional hardware RAID disks. An optional SAS disk controller is also supported.

RAID support levels are as follows:

007-5843-002 7

1: Introduction and Overview

Control Panel

• Hardware RAID 0, 1, 10, 5 and 6 (with optional SAS HBA or Megaraid card)

• BIOS-assisted softwa re RAID 0, 1 and 10 when configured as a standalone server

• Linux software RAID 0 and 1 when configured as a compute node

Note: A cluster head node will only support hardware RAID options.

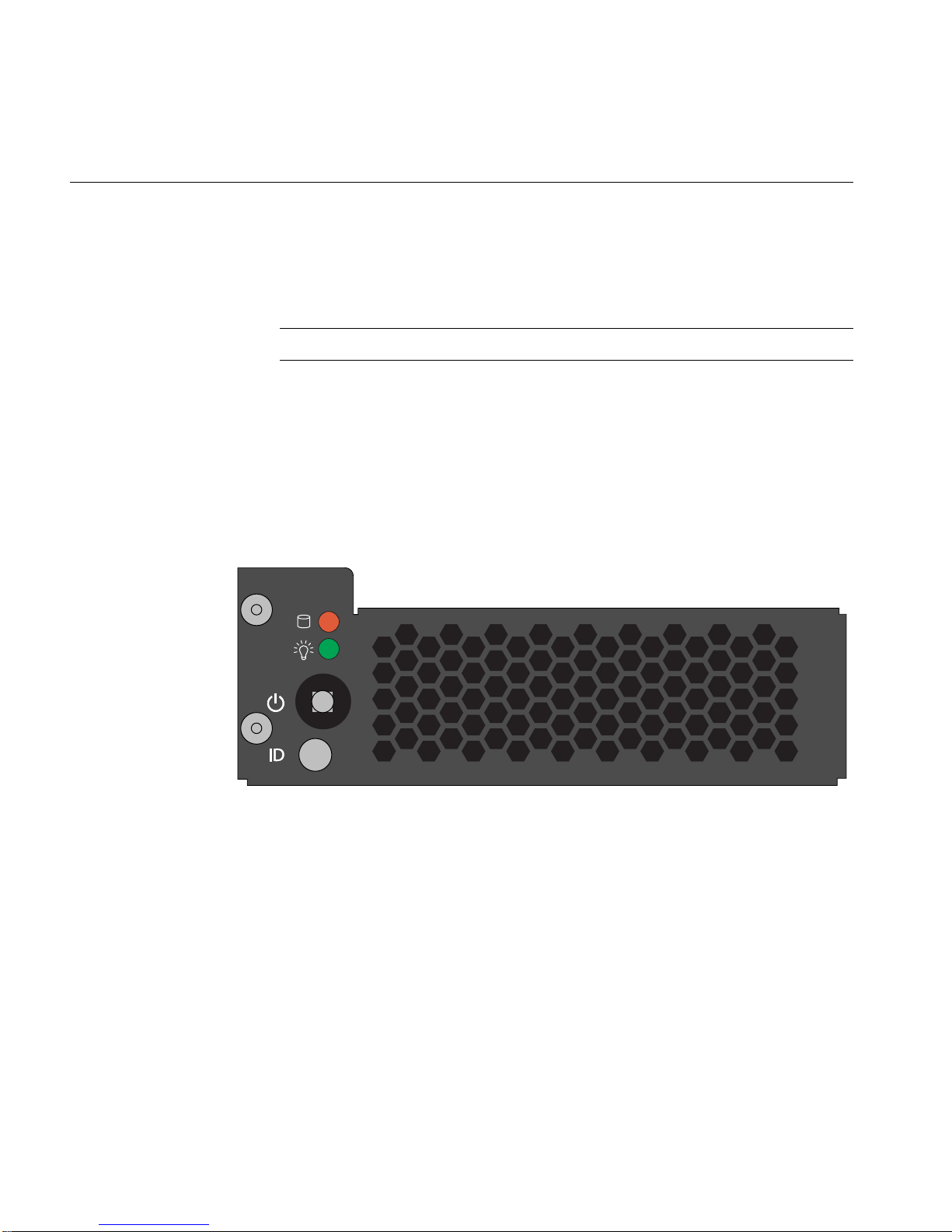

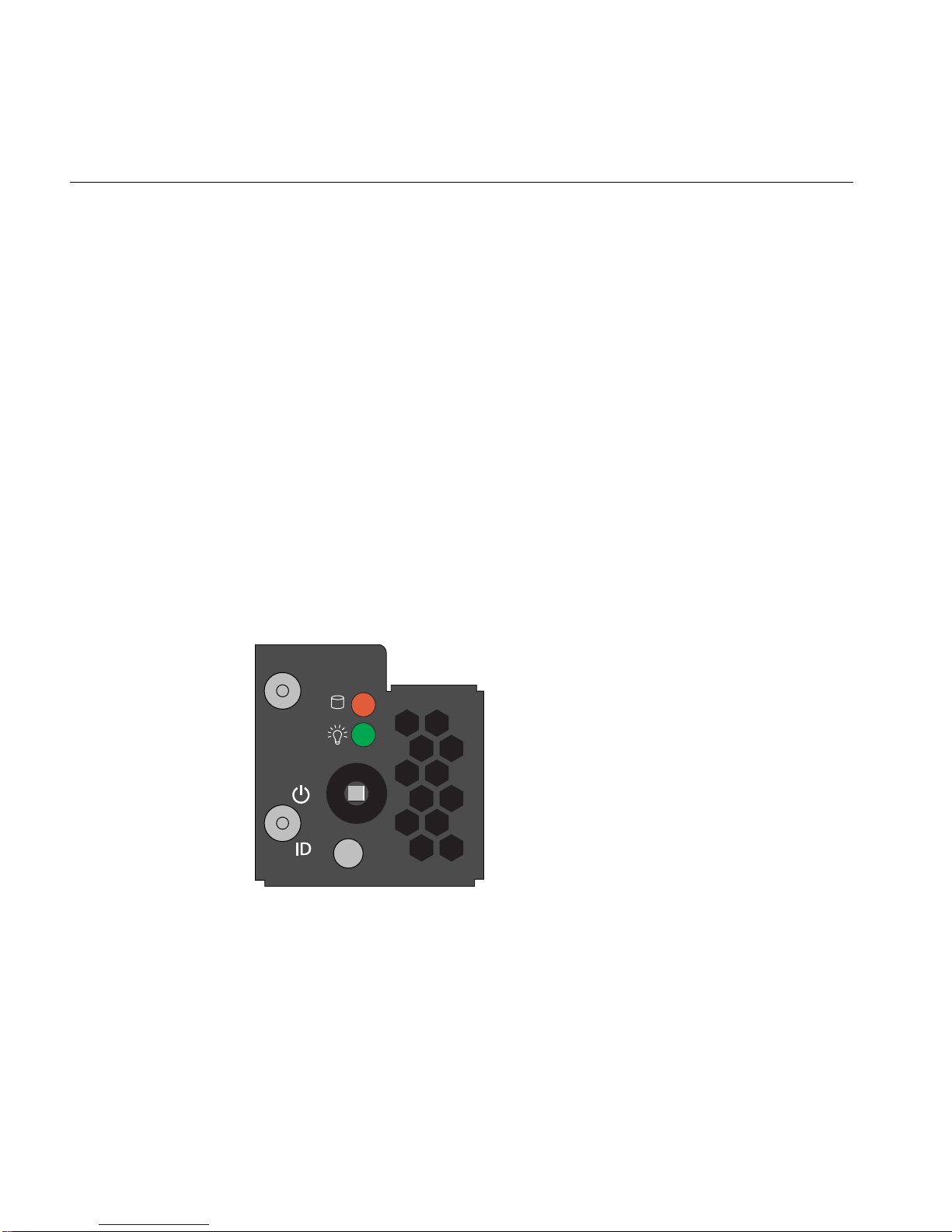

The SGI Rackable C1110-RP6 system control panel provides a system m onitoring and control

interface. The main power button included on the control panel will boot-up or shut down the

system when pressed - it does not remove all power inputs to the system. Remove the power

cord(s) from the system power supply if you need to remove power completely. LEDs on the

control panel (from top to bottom) indicate HDD activity, system power status and system UID.

Figure 1-5 SGI Rackable C110-RP6 Control Panel Example

Cooling System

The server chassis has an innovative cooling design that includes seven 4-cm counter-rotating

pulse width modulated (PWM) fans located in the middle section of the chassis. Additi onal

cooling fans are incorporated into each power supply module. All chassis and power supply fans

operate continuously while the system is on to efficiently cool the processors, memory and other

system components.

8 007-5843-002

Chapter 2

2. System Operation

This chapter describes the basic steps needed to get your SGI Rackable C1 110-RP6 system up and

running. Following these steps in the order given should enable you to have the system operational

within a minimum amount of time.

Unpacking the System and Choosing an Operating Location

You should inspect the box the system was shipped in and note if it was damaged in any way. If

the server itself shows damage you should file a damage claim with the carrier who delivered it.

When you decide on a suitable location for the rack unit that will hold the system, it should be

situated in a clean, dust-free area that is well ventilated. Avoid areas where heat, electrical noise

and electromagnetic fields are generated. You will also need it placed near a grounded power

outlet. Be sure to read the Rack and Server Precautions in the next section.

Preparing for Setup

The box the system was shipped in should include two sets of rail assemblies, two rail mounting

brackets and the mounting screws you will need to install the system into the rack. Follow the steps

in the order given to complete the installation process in a minimum amount of time. Please read

this section in its entirety before you begin the installation procedure outlined in the sections that

follow.

Choosing a Setup Location

Leave enough clearance in front of the rack to enable you to open the front door completely;

approximately 25 inches (63.5 cm) should be sufficient.

Leave approximately 30 inches (76.2 cm) of clearance in the back of the rack to allow for

sufficient airflow and ease in servicing.

007-5843-002 9

2: System Operation

Rack Precautions

This product is for installation only in a Restricted Access Location (dedicated equipment rooms,

service closets and the like).

This product is not suitable for use with visual display work place devices according to the

German Ordinance for Work with Visual Display Units.

The following guidelines help insure your rack systems proper operation:

• Ensure that the leveling jacks on the bottom of the rack are fully extended to the floor with

the full weight of the rack resting on them.

• In single rack installation, stabilizers should be attached to the rack.

• In multiple rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from the rack.

• You should extend only one component at a time - extending two or more simultaneously

may cause the rack to become unstable.

• Always keep the rack's front door and all panels and components on the servers closed when

not servicing to maintain proper cooling.

Server Precautions

Review the electrical and general safety precautions in Chapter 1.

Determine the placement of each component in the rack before you install the rails.

Install the heaviest server components on the bottom of the rack first, and then work up.

For extra protection, use a regulating uninterruptible power supply (UPS) to protect the server

from power surges, voltage spikes and to keep your system operating in case of a power failure.

This is an optional device not provided by SGI with your system.

Allow the hot plug disk drives and power supply modules to cool before touching them. Always

keep the server closed when not servicing to maintain proper cooling.

Make sure all power and data cables are properly connected and not blocking the chassis airflow.

10 007-5843-002

Rack Mounting Considerations

Use the guidelines in the following subsections to properly install, use and maintain a server in a

rack.

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of the rack

environment may be greater than the ambient temperature of the room. Therefore, consideration

should be given to installing the equipment in an environment compatible with the manufacturer’s

maximum rated ambient temperature (Tmra).

Reduced Airflow

Equipment should be mounted into a rack so that the amount of airflow required for safe operation

is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not arise due to

uneven mechanical loading.

Unpacking the System and Choosing an Operating Location

Circuit Overloading

Consideration should be given to the connection of the equipment to the power supply circuitry

and the effect that any possible overloading of circuits might have on over-current protection and

power supply wiring. Appropriate consideration of equipment nameplate ratings should be used

when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself should be

grounded. Particular attention should be given to power supply connections other than the direct

connections to the branch circuit (i.e. the use of power strips, etc.).

007-5843-002 11

2: System Operation

System Warnings and Precautions

!

!

!

!

!

Warning: The SGI Rackable C1110-RP6 server weighs up to ~30 lbs (~13.6 kg). Always

use proper lifting techniques when you move the server. Always get the assistance of another

qualified person when you install the sever in a location above your shoulders. Failure to do

so may result in serious personal injury or damage to the equipment.

Warning: Extend the leveling jacks on the bottom of the rack to the floor with the full

weight of the rack resting on them. Failure to do so can result in serious injury or death.

Warning: Attach stabilizers to the rack in single rack installations. Failure to do so can

result in serious injury or death. Couple racks together in multiple rack installations.

Failure to do so can result in serious injury or death.

Warning: Be s ure the rack is stable befor e extending a component fr om the rack. Failur e

to do so can result in serious injury or death.

Warning: Extend only one rack component at a time. Extending tw o or more component s

simultaneously may cause the rack to tip over and result in serious injury or death.

Slide/Rail Equipment Usage Caution

12 007-5843-002

Installing the System into a Rack

This section provides information on installing the SGI Rackable C1110-RP6 system into a rack

unit with the rack rails provided. If the system has already been mounted into a rack, you can skip

ahead to the next section. There are a variety of rack units on the market, which may mean the

assembly procedure will differ slightly. You should also refer to the installation instructions that

came with the rack unit you are using.

Identifying the Sections of the Rack Rails

You should have received two rack rail assemblies in the rack mounting kit. Each assembly

consists of two sections: an inner fixed chassis rail that secures directly to the server chassis and

an outer fixed rack rail that secures directly to the rack itself (see Figure 2-1). Two pairs of short

brackets to be used on the front side of the outer rails are also included.

Installing the System into a Rack

Figure 2-1 SGI Rackable C1110-RP6 System Rack Rails Example

007-5843-002 13

2: System Operation

Installing the Inner Rails

Both the left and right side inner rails should have been pre-attached to the chassis as shown in the

example in Figure 2-2. Proceed to the next subsection for information on installing the outer rails

into a rack.

Figure 2-2 Chassis Attachment to Inner Rack Rails Example

Installing the Outer Rails

Begin by measuring the distance from the front rail to the rear rail of the rack. Attach a short

bracket to the front side of the right outer rail and a long bracket to the rear side of the right outer

rail. Adjust both the short and long brackets to the proper distance so that the rail can fit snugly

into the rack.

Secure the short bracket to the front side of the outer rail with two M4 screws and the long bracket

to the rear side of the outer rail with three M4 screws. Repeat these steps for the left outer rail, see

Figure 2-3 on page 15 for an example.

14 007-5843-002

Installing the System into a Rack

Figure 2-3 Outer Rail Attachment to Rack Example

Locking Tabs

Both chassis rails have a locking tab, which serves two functions. The first is to lock the server

into place when installed and pushed fully into the rack, which is its normal position. Secondly,

these tabs also lock the server in place when fully extended from the rack. This prevents the server

from coming completely out of the rack when you pull it out for servicing.

007-5843-002 15

2: System Operation

Installing the Server into the Rac k

Y ou should now have rails attached to both the chassis and the rack unit. The next step is to install

the server into the rack. Do this by lining up the rear of the chassis rails with the front of the rack

rails. Slide the chassis rails into the rack rails, keeping the pressure even on both sides (you may

have to depress the locking tabs when inserting the unit). See Figure 2-4 for an example. When

the server has been pushed completely into the rack, you should hear the locking tabs "click" into

place.

Figure 2-4 Sliding the System into a Rack

16 007-5843-002

Installing the Server into a Telco Rack

T o install the server into a T elc o type rack, use two L-shaped brackets on either side of the chassis

(four total). First, determine how far the server will extend out the front of the rack. Larger chassis

should be positioned to balance the weight between front and back. If a bezel is included on your

server, remove it. Then attach the two front brackets to each side of the chassis, then the two rear

brackets positioned with just enough space to accommodate the width of the rack. Finish by

sliding the chassis into the rack and tightening the brackets to the rack.

Server Access After Rack Installation

After you install the unit in the rack, you may need to open the top cover (see Figure 2-5 on

page 18) to access the serverboard or confirm that all components are properly installed and all

the connections have been made.

Grasp the two handles on either side and pull the system straight out until it locks (you should hear

a "click"). If you need to remove the server completely: disconnect all cables at the rear, depress

the locking rail-tabs on either side of the server and slide it completely off the outer rack rail

assembly. The server is heavy when fully loaded, use two people for this process if possible.

Installing the System into a Rack

007-5843-002 17

2: System Operation

Figure 2-5 Top View of Server

Remove/Replace the Chassis Top Covers

Use the following information to remove the chassis top cover over the serverboard:

1. Using a Phillips-head screwdriver, remove the two screws that secure the motherboard top

covers to the chassis.

2. Place your thumbs in the top-cover recess “button” and push the rear section of the top cover

away from you (toward the rear of the chassis) and lift it upward, see Figure 2-6 on page 19.

3. Lift the top cover from the chassis to gain full access to the serverboard, DIMMs, fans,

power supply and PCIe cards.

4. Reverse the process to reinstall the rear top cover section.

18 007-5843-002

Installing the System into a Rack

Figure 2-6 Server T op Covers Removal Example

Use the following steps to remove the (front) chassis top cover over the system drives:

1. Use your thumbs in the top-cover recess “button” to push the front section of the top cover

towards the front of the system and lift upward.

2. Lift the front cover section up and away from the server chassis to access the drive assembly

and backplane interconnects.

3. Reverse the process steps to reinstall the front section of the chassis top cover.

Important: Always replace both top covers when operating the server to ensure thermal

stability.

007-5843-002 19

2: System Operation

Checking the Components and Setup Before Power On

If any internal modifications have been made to the server prior to installation in the rack, you may

wish to recheck the server’s interior.

You should have two processors already installed on the serverboard. Each processor needs its

own heatsink.

Your server comes with system memory already installed. Make sure all DIMMs are fully seated

in their slots. For details on adding system memory, see “Installing System DIMM Memory” on

page 27.

Make sure all power and data cables are properly connected and not blocking the chassis airflow.

Checking the Hard Disk Drives

The system disk drives are accessible from the front of the server and can be installed and removed

from the front of the chassis without removing the top chassis cover.

Depending upon your system's configuration, your system will have one or more drives already

installed.

Checking the Airflow

Airflow through the server is provided by an air shroud and seven 4-cm counter-rotating cooling

fans for the node board and other internal components of the chassis. The system component

layout was carefully designed to direct sufficient cooling airflow to the components that generate

the most heat. Each power supply has it’s own built-in cooling fan assembly.

Note that all power and data cables should be routed in such a way that they do not block the

airflow generated by the fans.

Providing Power

Plug the power cord(s) from the server power supply unit into a rack power distribution unit

(PDU) or high-quality power strip that offers protection from electrical noise and power surges.

20 007-5843-002

Installing the System into a Rack

For higher availability it is recommended that you use an optional uninterruptible power supply

(UPS) with the server.

Note: The blue LED indicates unit identification (UID) when activated by an IPMI tool command

or using the button on the rear of the chassis.

See Chapter 3 for a complete overview of the front control panel LED and button functions.

Figure 2-7 Server Front Control Panel Example

007-5843-002 21

Chapter 3

3. System Interfaces Overview

This chapter provides an overview of the standard and optional interfaces available on your SGI

Rackable C11 10-RP6 system. The major components of the system are described and illustrated.

System Interface Overview

Figure 3-1 shows an example of the system rear interconnects. Each system can be configured

slightly differently in regards to PCIe options, drives and power supplies. Note that the example

shown uses the 650-Watt redundant power supply.

System Interface Overview

VGA Port

IPMI

LAN/LAN3

USB

Ports

COM

Port

UID LED

Low-profile x16 PCIe Slot

LAN2

LAN1

button

Full-height x16 PCIe slot

Serial Port

HDD

activity

Power

Figure 3-1 Server Rear Connectors Example

007-5843-002 23

3: System Interfaces Overview

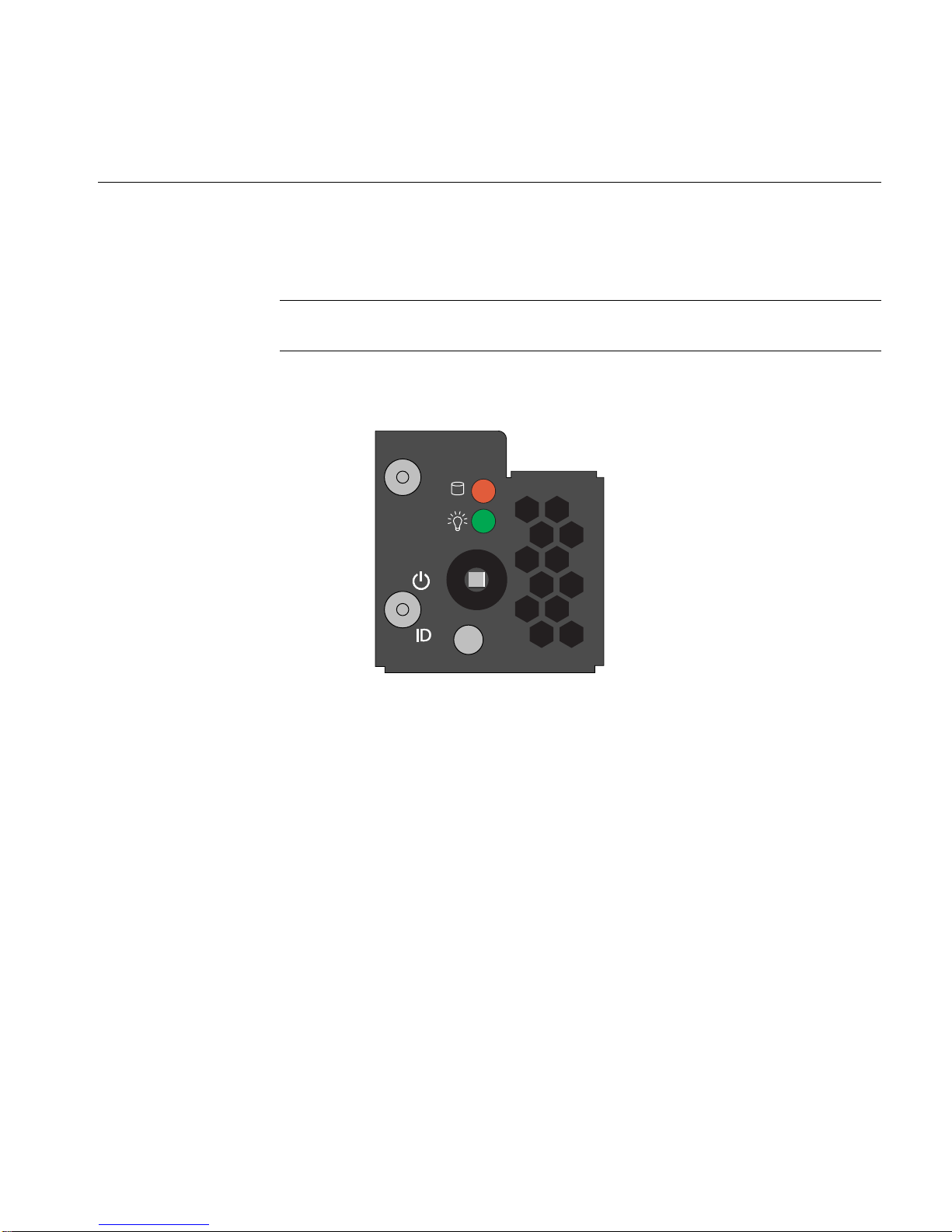

Control Panel Buttons

Control Panel LEDs

There are several LEDs on the front control panel as well as others on the disk drive carriers to

keep you constantly informed of the overall status of the system as well as the activity and health

of specific components. There is also a system power button on each control panel. This chapter

explains the meanings of all LED indicators and the appropriate response you may need to take.

There is only one push-button located on the front control panel of the C1110-RP6 server:

Power - This is the main power button, which is used to apply or turn off the main system power

supply. Pressing this button removes the main power but keeps standby power supplied to the

serverboard, see Figure 3 -2 on page 24.

The control panel located on the front of the server chassis has three LEDs. Each LED provides

you with critical information related to the serverboard. This section explains what each LED

indicates when illuminated and any corrective action you may need to take.

Figure 3-2 Serverboard Control Panel Example

The ten-drive version of the server has its control panel on the left-front section of the chassis front

panel. The four-drive version of the server has the control panel in the upper right front area.

24 007-5843-002

HDD

Power

Universal Information LED

System Interface Overview

Channel activity for the hard disk drive array. This light indicates disk drive activity on the server

when flashing.

The LED indicates power is being supplied to the system's power supply unit. This LED should

normally be illuminated when the system is operating.

This LED will light blue when used for Unit Identifier (UID), see Figure 3-2 on page 24.

Universal Information LED States

State Indication

Solid blue Local (rear) UID button depressed

Blinking blue IPMI-activated UID

This LED will remain flashing or on until manually deactivated via the rear button or software

command.

Note: Deactivating the UID (blue indicator) LED must be performed in the same way it was

activated. If the UID LED was activated via IPMI, you can only turn the LED off via IPMI and

not with the UID button on the rear of the system.

Disk Drive Carrier LEDs

Each disk drive carrier has two LEDs.

• Green: Each drive carrier has a green LED. When illuminated, this green LED (on the front

of the drive carrier) indicates drive activity . A connection to the drive backplane enables this

LED to blink on and off when that particular drive is being accessed. See Chapter 4 for

instructions on replacing hard disk drives.

007-5843-002 25

3: System Interfaces Overview

• Red: The red LED lights to indicate a disk drive failure. If one of the drives fails, you should

also be notified by your system management software. Please refer to Chapter 4 for

instructions on replacing failed internal disk drives.

26 007-5843-002

Chapter 4

4. Internal Component Replacement and Upgrades

This chapter describes basic component replacement and upgrades for the SGI Rackable

C1110-RP6 system.

General Precautions

Care must be taken to assure that the chassis cover is in place when the server is operating to assure

proper cooling. Out of warranty damage to the system can occur if this practice is not strictly

followed.

Caution: Electrostatic Discharge (ESD) can damage electronic components. To prevent damage

to any printed circuit boards (PCBs), it is important to handle them very carefully. The following

measures are generally sufficient to protect your equipment from ESD discharge.

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing any board from its antistatic bag.

• Handle a board by its edges only; do not touch its components, peripheral chips, memory

modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

Installing System DIMM Memory

Exercise extreme care when installing or removing DIMM modules to prevent electrostatic or any

other possible damage. Figure 4-1 on page 28 shows the CPU and DIMM locations.

The serverboard has sixteen 240-pin DIMM slots that can support up to 256 GB of registered ECC

DDR3-1600/1333/1066 SDRAM.

007-5843-002 27

4: Internal Component Replacement and Upgrades

Each processor on the serverboard has a memory controller that supports four DDR3 memory

channels (two DIMMs per channel). For best memory performance, install DIMMs in multiples

of eight.

Figure 4-1 Serverboard DIMM Slot Locations and Designations Example

28 007-5843-002

Note: Check with your SGI sales or service representative for approved replacement or upgrade

DIMM memory modules.

Installing Memory DIMMs

Insert each memory DIMM vertically into a slot using the information and illustrations in this

section. Pay attention to the notch along the bottom of the DIMM to prevent inserting it

incorrectly.

To install a DIMM: Insert the DIMM vertically and gently press down until it snaps into place.

Pay attention to the alignment notch at the bottom.

Repeat for all DIMMs.

To remove a DIMM: Use your thumbs to gently push the release tabs near both ends of the

memory module. This should release it from the slot.

Installing System DIMM Memory

Figure 4-2 DIMM Installation Example

Note the following operational points regarding DIMM usage in the C1110-RP6 server:

• Each processor supports four DDR3 memory channels.

• Each memory channel can support two maximum speed (1600 MT/s) DIMMs per channel.

• Mixing DIMMs with different speeds on a channel causes a default to the lowest speed.

• A 32 GB DIMM is the maximum approved DIMM capacity for the C1110-RP6.

007-5843-002 29

4: Internal Component Replacement and Upgrades

Adding PCIe Cards

The server includes two pre-installed riser cards designed specifically for use in the 1U rackmount

server chassis. One riser card supports a full-height half-depth PCI Express (PCIe) x16 card and

the other supports a low-profile x16 card inside the chassis.

A riser card has already been pre-installed into each serverboard.

Important: The PCIe cards cannot be “hot installed”.

Perform the following steps to add or replace a PCIe add-on card:

1. Power down the server.

2. Grasp the two handles on either side and pull the unit straight out of the rack until it locks

(you will hear a "click").

3. The top cover of the chassis is secured with two screws: remove them with a Phillips type

screwdriver, then place both thumbs in the indentation and push the cover back until it slides

off.

4. Lift the rear section of the top cover from the chassis to gain full access to the inside of the

server.

5. Remove the two PCIe carrier retention screws from the rear of the chassis.

6. Carefully unseat and remove the carrier and set it on a static-free surface.

7. Install the PCIe add-on (or replacement) card in the carrier.

8. Reinstall the PCIe carrier, replace the cover and return the server to operation.

30 007-5843-002

System Fans

The main serverboard is cooled by a set of seven 4-cm high-performance PWM fans. Fan speed

is constant unless modified via a setting in BIOS. Each power supply also has its own dedicated

cooling fan (one or two depending on supply type).

System Fan Failure

Replace any failed fan at your earliest convenience with the same type and model (the system can

continue to run with a failed fan). Remove the top chassis cover while the system is still running

to determine which of the fans has failed. Power down the system before replacing a fan.

Removing the power cord is also recommended as a safety precaution.

Drive Bay Installation/Removal

Hard Disk Drives: Because of their hot-swap capability, you do not need to access the inside of

the chassis or power down the system to install or replace disk drives. Proceed to the next step for

instructions.

Disk Drive Removal and Installation

Note: The operating system you use must have RAID support to enable the optional hot-swap

capability of the SATA/SAS drives.

Use caution when working around the disk drive backplane. Do not touch the backplane with any

metal objects and make sure no cables touch the backplane. Also, regardless of how many drives

are installed, all drive carriers must remain in the chassis to maintain proper airflow.

Disk Drive Removal and Installation

The system disk drives are mounted in drive carriers to simplify their instal lat ion and removal

from the chassis. These carriers also help promote proper airflow for the system. For this reason,

even empty carriers without drives installed must remain in the chassis.

007-5843-002 31

4: Internal Component Replacement and Upgrades

Mounting a Drive in a Carrier

Check with your SGI sales or service representative to obtain new or replacement hard disk drives

for the server.

Install the drive into the carrier with the printed circuit board side facing down so that the

mounting holes align with those in the carrier.

Secure the drive to the carrier with the side screws, similar to the example in Figure 4-3.

Figure 4-3 Drive Carrier Mounting Example

Installing/Removing Hot-swap Drives

To remove a carrier, push the release button located beside the drive LEDs.

Swing the handle fully out and use it to pull the disk assembly straight out of the chassis (see

Figure 4-4 on page 33).

32 007-5843-002

Disk Drive Removal and Installation

Figure 4-4 Server Disk Drive Remove Example

007-5843-002 33

4: Internal Component Replacement and Upgrades

Figure 4-5 Replacing the Drive and Carrier Example

Power Supply

The SGI Rackable C1110-RP6 server power supply is installed at the rear of the system and is

“auto-ranging” (has the capability of operating at 100 - 240 inpu t volts). To shut down the system,

press the main power button on the front of the chassis and then unplug the AC power cord(s).

Note that there are two versions of power supply used with the server as follows:

• A 450-Watt “non-redundant” single-cord power supply

• A 650-Watt redundant dual-cord power supply assembl y

The LED located directly on the front of the power supply has three states:

• Dark - no AC power is available to the supply

• Yellow - AC power available to the supply but the server is not powered on

• Green - AC power is applied and the system is on (front panel power button pushed to On)

34 007-5843-002

Power Supply Failure

If the power supply unit experiences a failure, the system will shut down if it is a 450-Watt

“non-redundant” supply and you will need to replace the power supply unit to return the

C1110-RP6 to operating status. Note that the 450-Watt unit has an On/Off rocker switch; make

sure the switch has not accidentally been turned off before replacing it.

If the power supply is 650-Watt redundant supply that experiences a failure - the server can

continue to operate until a replacement is available. Shutting down the server during replacement

of the “redundant” unit is optional.

Replacement power supply units can be obtained directly from your SGI sales or service

representative or third-party support provider.

If the power supply has failed, the LED located on the front of the power supply should be off

(unlit). Be sure the system power cord is fully plugged in to a power distribution unit that is turned

on before replacing the supply.

Removing the 650-Watt Redundant Power Supply

Power Supply

Use the following steps to remove a failed 650-Watt power supply from the system:

1. Unplug the AC power cord from the failed side of the redundant power supply system.

Caution: The power supply may be hot if the system has been running - make sure the supply

has at least 5 minutes to cool down.

2. Push the release tab on the front of the power supply inward. See Figure 4-6 on page 36.

3. Pull outward on the power supply handle and the unit should disengage from the internal

connector.

4. Extract the supply from the chassis by pulling it outward. Handle it with caution as the unit

may still be hot.

5. Follow the instructions in “Installing a New 650-Watt Redundant Power Supply” on

page 37.

007-5843-002 35

4: Internal Component Replacement and Upgrades

Figure 4-6 650-Watt Redundant Power Supply Removal Example

Figure 4-7 Individual 650-Watt Power Supply

36 007-5843-002

Installing a New 650-Watt Redundant Power Supply

Use the following steps to replace a failed power supply in the server:

1. Replace the failed power supply with the exact same model from SGI or another approved

vendor, contact your SGI sales or service representative for more information.

2. Insert the new unit into the chassis and push it in until seated. This may require some

moderate force but you should hear an audible “click” as the power supply is seated.

3. Reconnect the AC power cord to the supply and press the power button on the front of the

chassis to resupply power to the system if you had shut down the server.

Power Supply

Figure 4-8 650-Watt Redundant Power Supply Replacement Example

007-5843-002 37

4: Internal Component Replacement and Upgrades

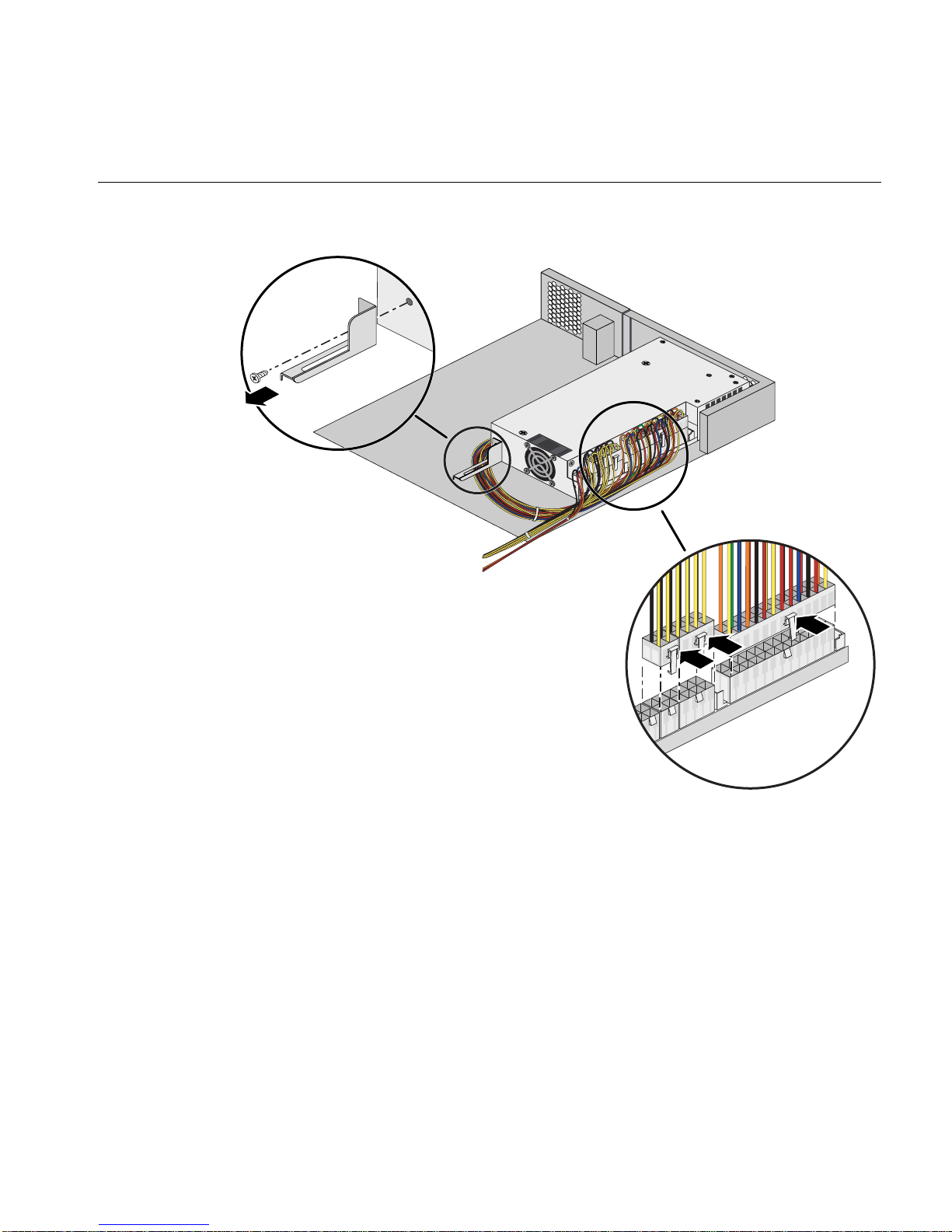

Removing the 450-Watt Non-Redundant Power Supply

If the 450-Watt “non-redundant” power supply fails, you will need to replace it as soon as possible

to restore the server to operational status. See Figure 4-9 for an example view that also shows the

two rear screw locations on the supply.

Figure 4-9 450-Watt (Non-redundant) Power Supply Example

Use the following steps to remove the failed supply:

1. Remove the rear cover portion from the server chassis; see “Remove/Replace the Chassis

Top Covers” on page 18 if you are unfamiliar with the procedure.

2. Verify the power cord is disconnected from the unit, then confirm that the supply is cool

enough to touch.

3. Reach in and undo the small, medium and large power connector cables on the outer side of

the power supply, see Figure 4-10 on page 39. Note their locations for re-installation

purposes.

4. Undo the two Phillips-head screws on the rear of the chassis that hold the 450-Watt supply

rear case in place (shown in Figure 4-9).

5. Undo the single bracket screw near the fan at the “front” of the supply, shown in

Figure 4 -10. Set all screws carefully aside for use during the re-installation process.

6. Lift the failed unit up and out of the server chassis. See the next subsection for installation of

a new power supply unit.

38 007-5843-002

Power Supply

Figure 4-10 Removing the 450-Watt Non-Redundant Power Supply

007-5843-002 39

4: Internal Component Replacement and Upgrades

Installing the 450-Watt Non-Redundant Power Supply

Use the following steps to install a new 450-Watt power supply into the server:

1. Position the new supply in the chassis so that the rear screw holes are aligned with the holes

in the rear sheetmetal and the front chassis retention bracket.

2. Use the three screws you removed in step 4 of the instructions “Removing the 450-Watt

Non-Redundant Power Supply” on page 38 to secure the unit inside the server. See

Figure 4-11.

3. Reconnect the small, medium and large power cable connectors to the outer side of the

power supply, see Figure 4-10 on page 39.

4. Attach the rear system power cord to the supply and ensure the rocker switch is set to the (|)

on position. The system fans should start up and pushing the power button on the front of the

chassis should boot the system.

5. Replace the top cover and secure it with the two top cover-retention screws. Slide the system

back into the rack as applicable.

Figure 4-11 450-Watt Power Supply Replacement Example

40 007-5843-002

Processors

I/O Chipset

Appendix A

A. System Specifications

This appendix contains technical specification information about your SGI Rackable C1110-RP6

system.

T wo Intel Xeon E5-2600 or E5-2600v2 Series processors

Intel C602 chipset series with IPMI 2.0 compliant BMC

BIOS

8-MB SMBIOS 2.3 Flash ROM

Memory Capacity

Sixteen DIMM sockets supporting registered ECC DDR3-1600/1333/1066/800 SDRAM or

unbuffered ECC/non-ECC DDR3-1600/1333/1066/800 MHz SDRAM

Memory DIMM voltage is 1.5V or 1.35V

007-5843-002 41

A: System Specifications

Disk Drive Controller

On-chip SATA controller for 3 Gb/s SATA (BIOS-assi sted software RAID 0, 1 and 10 support

available) or two SATA connectors running at 6.0 Gb/s.

Drive Bays

Four hot-swap capable 3.5-in drive bays that house standard SA T A drives or ten hot-swap capable

2.5-in SATA drive bays. Optional SAS drive configurations are available using an HBA - no te

that only RAID 0 and 1 are supported with the SAS option.

Expansion Slots

The server’s expansion slots include the following:

• One PCI-Express x16 Gen 3 full-height half-depth external slot

• One PCI-Express x16 Gen 3 low-profile external slot

Serverboard

Proprietary serverboard design and size.

Dimensions: 12.0" x 13.0" (305 x 330 mm)

Chassis

1U rackmount

Dimensions: (WxHxD) 17.2 x 1.7 x 28.2 in. (437 x 43 x 716 mm)

42 007-5843-002

Weight

Gross weight (approximate): 30 lbs. (13.6 kg.)

System Cooling

Seven 4-cm counter-rotating cooling fans plus individual power supply fans provide system

cooling.

System Input Requirements

AC Input Voltage: 100-240 VAC (auto ranging)

Rated Input Current to base (450W) supply: 5.5A (100-127V) to 2.7A (200-240V)

Rated Input Frequency: 50-60 Hz

Weight

Power Supply

Rated Output Power:

Base 450-Watt supply Rated Output Voltages: +12V, (30A max) +5V, (38A max) +3.3V, (10A

max) -12V, (0.5A max)

007-5843-002 43

A: System Specifications

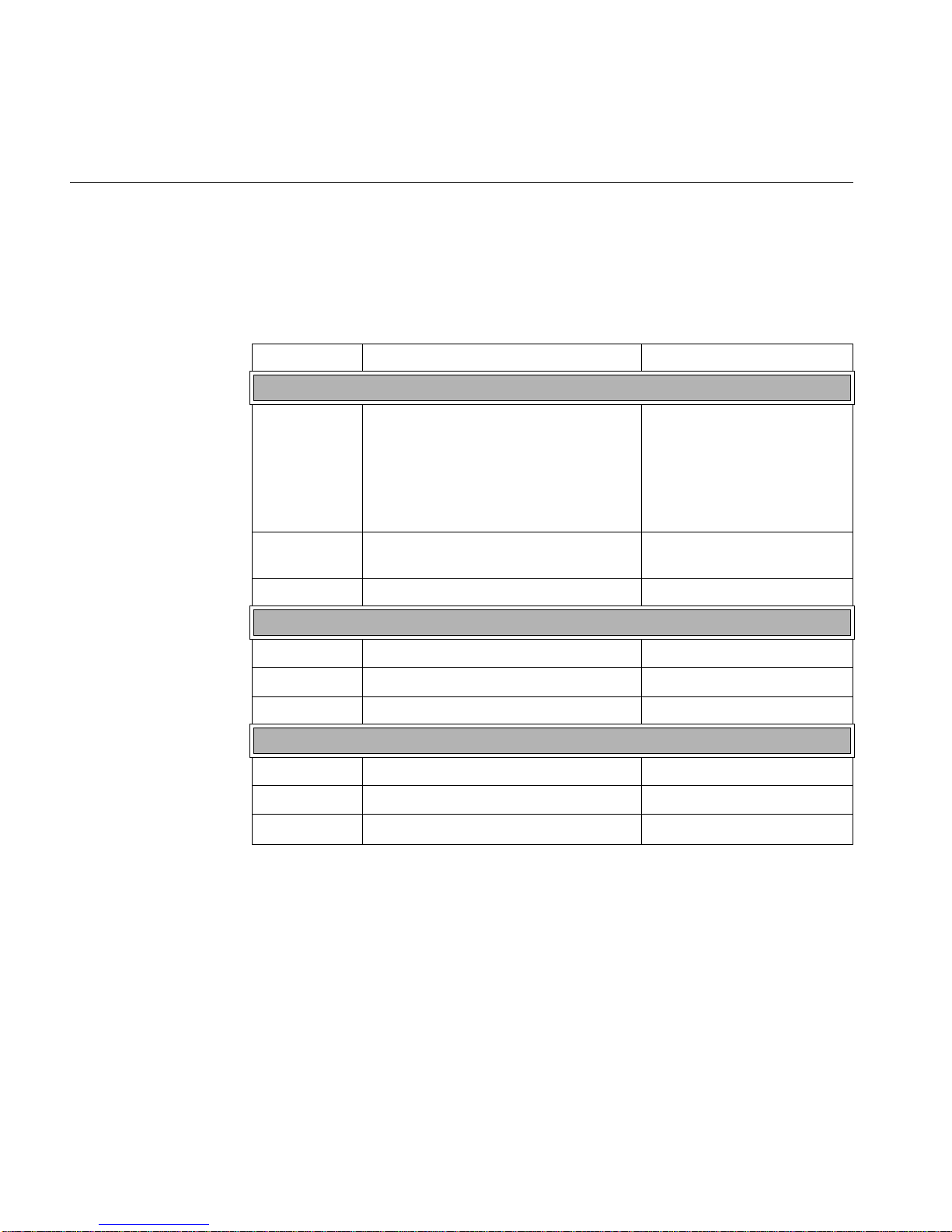

Environmental Specifications

Table A-1 lists allowable ranges for temperature, humidity, and altitude for the server.

Table A-1 Temperature, Humidity, and Altitude Specifications

Attribute Specification Rate of Change Constraints

While Product Operating

Temperature – Up to 1500m (5000ft)

+5

ºC (41ºF) to +35ºC (95ºF)

– 1525m (5000ft) to 3050m (10,000ft)

Reduce max temperature (35

305m (1000ft) of altitude above 1525m

(5000ft).

Humidity 20% to 80% Non-condensing Maximum: 10% relative

Altitude 3050m (10,000ft)

While Product Power Off

Temperature +5

Humidity 8% to 80% Non-condensing

Altitude 3050m (10,000ft)

While Product Packaged for Shipping

Temperature -40

Humidity 8% to 80% Non-condensing

Altitude 12,200m (40,000ft)

ºC (41ºF) to +45ºC (113ºF) Maximum: 20ºC/hour (36ºF/hour)

ºC (-40ºF) to +60ºC (140ºF) Maximum: 20ºC/hour (36ºF/hour)

ºC) by 1ºC per

Maximum: 10

humidity/hour

ºC/hour (18ºF/hour)

44 007-5843-002

Regulatory Compliance

Electromagnetic Emissions: FCC Class A, EN 55022 Class A, EN 61000-3-2/-3-3, CISPR 22

Class A

Electromagnetic Immunity: EN 55024/CISPR 24, (EN 61000-4-2, EN 61000- 4-3, EN 61000-4-4,

EN 61000-4-5, EN 61000-4-6, EN 61000-4-8, EN 61000-4-11)

Safety: CSA/EN/IEC/UL 60950-1 Compliant, UL or CSA Listed (USA and

Canada), CE Marking (Europe)

California Best Management Practices Regulations for Perchlorate Materials:

This Perchlorate warning applies only to products containing CR (Manganese

Dioxide) Lithium coin cells. "Perchlorate Material-special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate"

Regulatory Compliance

007-5843-002 45

Loading...

Loading...