SGI® Altix® XE320 System User’s Guide

007-5466-001

COPYRIGHT

© 2008 SGI. All rights reserved; provided portions may be cop yright in third parties, as indicated elsewhere herein. No permission is granted to copy , distribute,

or create derivative works from the contents of this electronic documentation in any manner, in whole or in part, without the prior written permission of SGI.

LIMITED RIGHTS LEGEND

The software described in this document is “commercial computer software” provided with restricted rights (except as to included open/free source) as specified

in the F AR 52.227-19 and/or the DFAR 227.7202, or successive sections. Use beyond license provisions is a violation of worldwide intellectual property laws,

treaties and conventions. This document is provided with limited rights as defined in 52.227-14.

The electronic (software) version of this document was developed at private expense; if acquired under an agreement with the USA government or any

contractor thereto, it is acquired as “commercial computer software” subject to the provisions of its applicable license agreement, as specified in (a) 48 CFR

12.212 of the FAR; or, if acquired for Department of Defense units, (b) 48 CFR 227-7202 of the DoD FAR Supplement; or sections succeeding thereto.

Contractor/manufacturer is SGI, 1140 E. Arques Avenue, Sunnyvale, CA 94085.

TRADEMARKS AND ATTRIBUTIONS

Altix, SGI, and the SGI logo are registered trademarks and SGI ProPack is a trademark of SGI in the United States and/or other countries worldwide.

InfiniBand is a registered trademark of the InfiniBand Trade Association. Intel, Itanium, and Xeon are trademarks or registered trademarks of Intel Corporation

or its subsidiaries in the United States and other countries. Internet Explorer is a registered trademark of Microsoft

Corporation. Java and Java Virtual Machine

are trademarks or registered trademarks of Sun Microsystems, Inc. Linux is a registered trademark of Linus Torvalds, used with permission by SGI. LSI Logic

is a registered trademark of LSI Logic Corporation. Novell and Novell Netware are registered trademarks of Novell Inc. Phoenix and PhoenixBIOS are

registered trademarks of Phoenix Technologies Ltd. Red Hat and all Red Hat-based trademarks are trademarks or registered trademarks of Red Hat, Inc. in the

United States and other countries. SUSE LINUX and the SUSE logo are registered trademarks of Novell, Inc. UNIX is a registered trademark in the

United

States and other countries, licensed exclusively through X/Open Company, Ltd.

All other trademarks mentioned herein are the property of their respective owners.

Adaptec, HostRAID, and the Adaptec logo are registered trademarks of Adaptec Inc.

Record of Revision

Version Description

001 February 2008

Initial publication.

007-5466-001 iii

Contents

Contents

About This Guide . . . . . . . . . . . . . . . . . . . . . . xxiii

Audience. . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Important Information . . . . . . . . . . . . . . . . . . . . . xxiii

Chapter Descriptions . . . . . . . . . . . . . . . . . . . . . xxiv

Related Publications. . . . . . . . . . . . . . . . . . . . . . .xxv

Conventions . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Product Support . . . . . . . . . . . . . . . . . . . . . . . xxvi

Reader Comments . . . . . . . . . . . . . . . . . . . . . . xxvii

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 1

Node Board Features . . . . . . . . . . . . . . . . . . . . . . 4

Processors . . . . . . . . . . . . . . . . . . . . . . . . 4

Memory. . . . . . . . . . . . . . . . . . . . . . . . . 4

Serial ATA (SATA) . . . . . . . . . . . . . . . . . . . . . 4

Serial Attached SCSI (SAS) and RAID Support . . . . . . . . . . . . . . 6

PCIe Expansion Slots . . . . . . . . . . . . . . . . . . . . . 6

Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . 6

Onboard Controllers/Ports . . . . . . . . . . . . . . . . . . . . 6

ATI Graphics Controller . . . . . . . . . . . . . . . . . . . . 6

Other Features . . . . . . . . . . . . . . . . . . . . . . . 6

Server Chassis Features . . . . . . . . . . . . . . . . . . . . . . 7

System Power . . . . . . . . . . . . . . . . . . . . . . . 7

SATA/SAS Backplane/Drives . . . . . . . . . . . . . . . . . . . 7

Control Panel . . . . . . . . . . . . . . . . . . . . . . . 7

Rear I/O Panel . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling System. . . . . . . . . . . . . . . . . . . . . . . 8

007-5466-001 v

Contents

System Security and Pre-Installed Linux Operating Systems . . . . . . . . . . . . 8

2 Server Installation . . . . . . . . . . . . . . . . . . . . . . . 9

Unpack the System . . . . . . . . . . . . . . . . . . . . . . . 9

Prepare for Setup . . . . . . . . . . . . . . . . . . . . . . 9

Choose a Setup Location . . . . . . . . . . . . . . . . . . . . 9

Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . 10

Rack Precautions . . . . . . . . . . . . . . . . . . . . . . 10

Server Precautions . . . . . . . . . . . . . . . . . . . . . . 11

Rack Mounting Considerations . . . . . . . . . . . . . . . . . . . . 11

Ambient Operating Temperature . . . . . . . . . . . . . . . . . . 11

Reduced Airflow . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Loading. . . . . . . . . . . . . . . . . . . . . . 11

Circuit Overloading . . . . . . . . . . . . . . . . . . . . . . 12

Reliable Ground . . . . . . . . . . . . . . . . . . . . . . . 12

Install the System into a Rack . . . . . . . . . . . . . . . . . . . . 12

Identify the Sections of the Rack Rails . . . . . . . . . . . . . . . . . 12

Install the Rails . . . . . . . . . . . . . . . . . . . . . . . 13

Locking Tabs . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Server in a Rack . . . . . . . . . . . . . . . . . . . . 16

Install the Server in a Third-party Rack. . . . . . . . . . . . . . . . . 18

Check the Node Board Setup. . . . . . . . . . . . . . . . . . . . . 21

Access the Inside of the Chassis. . . . . . . . . . . . . . . . . . . 21

Check the CPUs (processors) . . . . . . . . . . . . . . . . . . . 22

Check the System Memory . . . . . . . . . . . . . . . . . . . . 22

Install Expansion PCIe Cards . . . . . . . . . . . . . . . . . . . 23

Check all Cable Connections and Airflow . . . . . . . . . . . . . . . . 23

Check the Drive Bay Setup . . . . . . . . . . . . . . . . . . . . 23

Check the SATA/SAS Drives . . . . . . . . . . . . . . . . . . 23

Check the Airflow . . . . . . . . . . . . . . . . . . . . . 23

Supply Power to the System . . . . . . . . . . . . . . . . . . 23

3 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . 25

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 25

vi 007-5466-001

Contents

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive Carrier Indicators . . . . . . . . . . . . . . . . . . . . 27

4 Advanced Node Board Setup . . . . . . . . . . . . . . . . . . . . 29

Handling the Node Board . . . . . . . . . . . . . . . . . . . . . 29

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . 30

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . 30

Node Board Installation . . . . . . . . . . . . . . . . . . . . . . 31

Connect the Power Cables . . . . . . . . . . . . . . . . . . . . 32

Connecting the Control Panel . . . . . . . . . . . . . . . . . . . 34

I/O Ports . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Processor and Heatsink Installation and Removal . . . . . . . . . . . . . . . 35

Install a Processor . . . . . . . . . . . . . . . . . . . . . . 36

Install a Heatsink . . . . . . . . . . . . . . . . . . . . . . 40

Remove the Heatsink . . . . . . . . . . . . . . . . . . . . . 41

Replace the Thermal Interface Material . . . . . . . . . . . . . . . . 42

Removing TIM from a Processor . . . . . . . . . . . . . . . . . 42

Removing TIM from a Heatsink . . . . . . . . . . . . . . . . . 46

Remove the Processor . . . . . . . . . . . . . . . . . . . . . 48

Install Memory . . . . . . . . . . . . . . . . . . . . . . . . 50

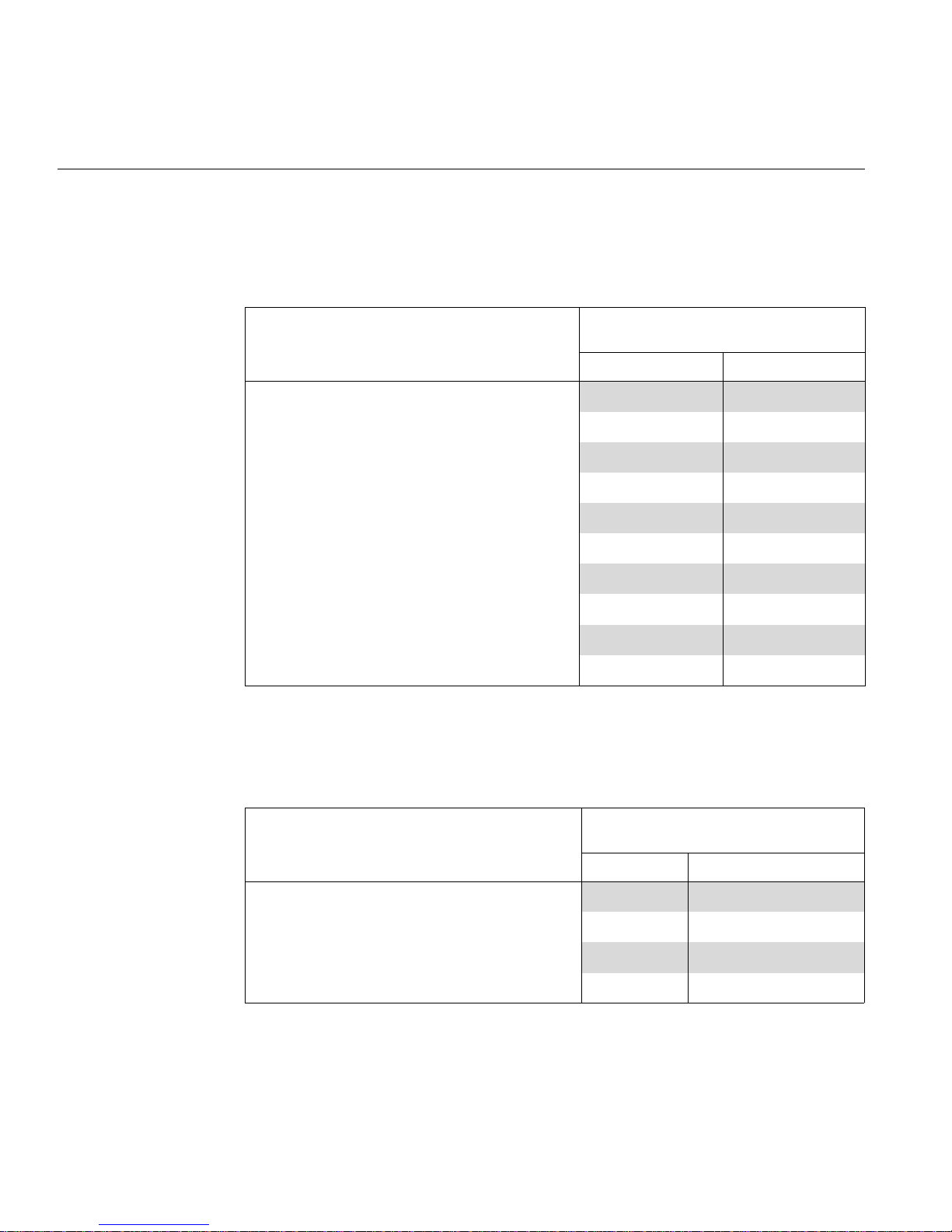

Memory Layout. . . . . . . . . . . . . . . . . . . . . . . 50

Constraints for DIMM Pairs . . . . . . . . . . . . . . . . . . . 51

Performance Optimization . . . . . . . . . . . . . . . . . . . . 52

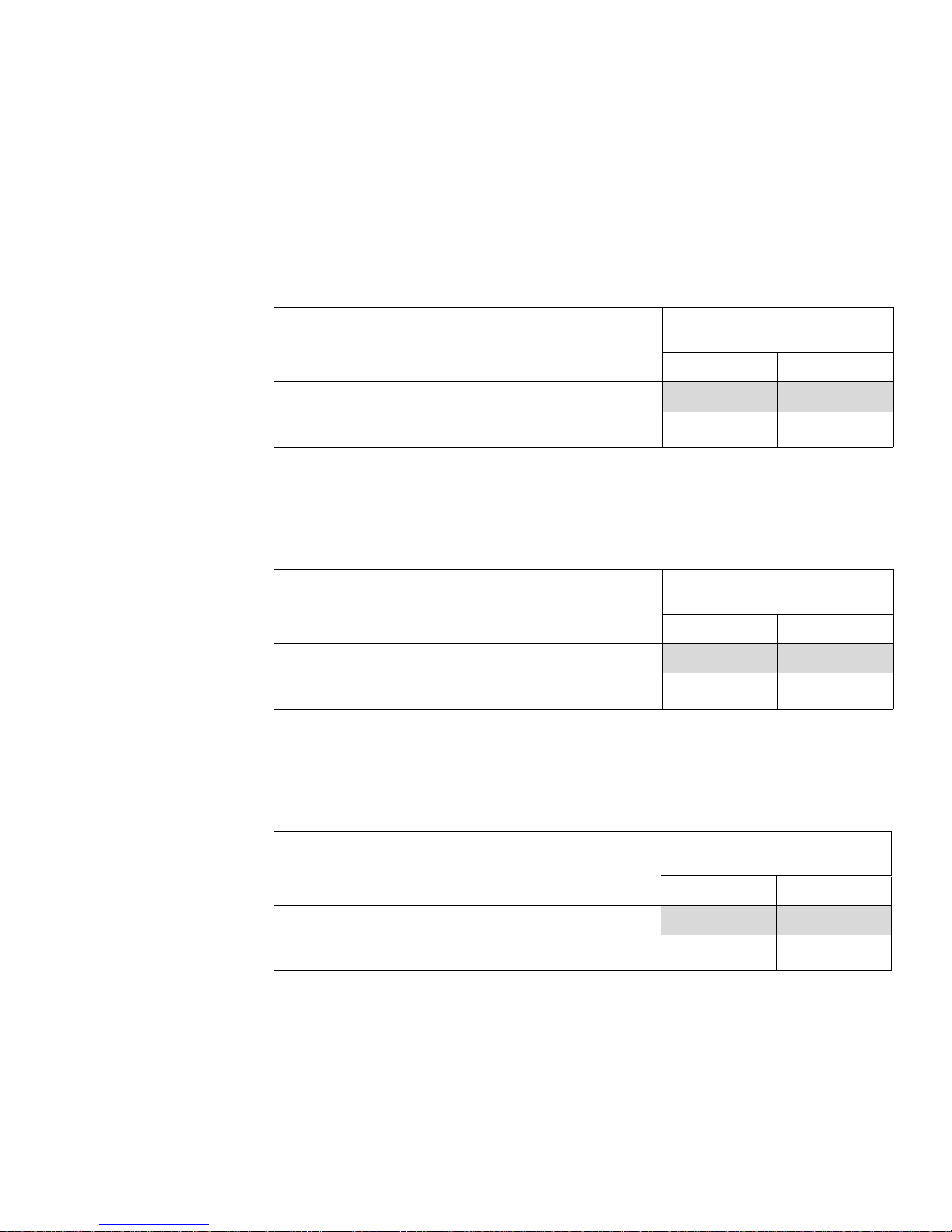

Memory Sparing Mode . . . . . . . . . . . . . . . . . . . . . 53

Memory Mirroring Mode . . . . . . . . . . . . . . . . . . . . 53

Mirroring Mode Upgrade . . . . . . . . . . . . . . . . . . . . 54

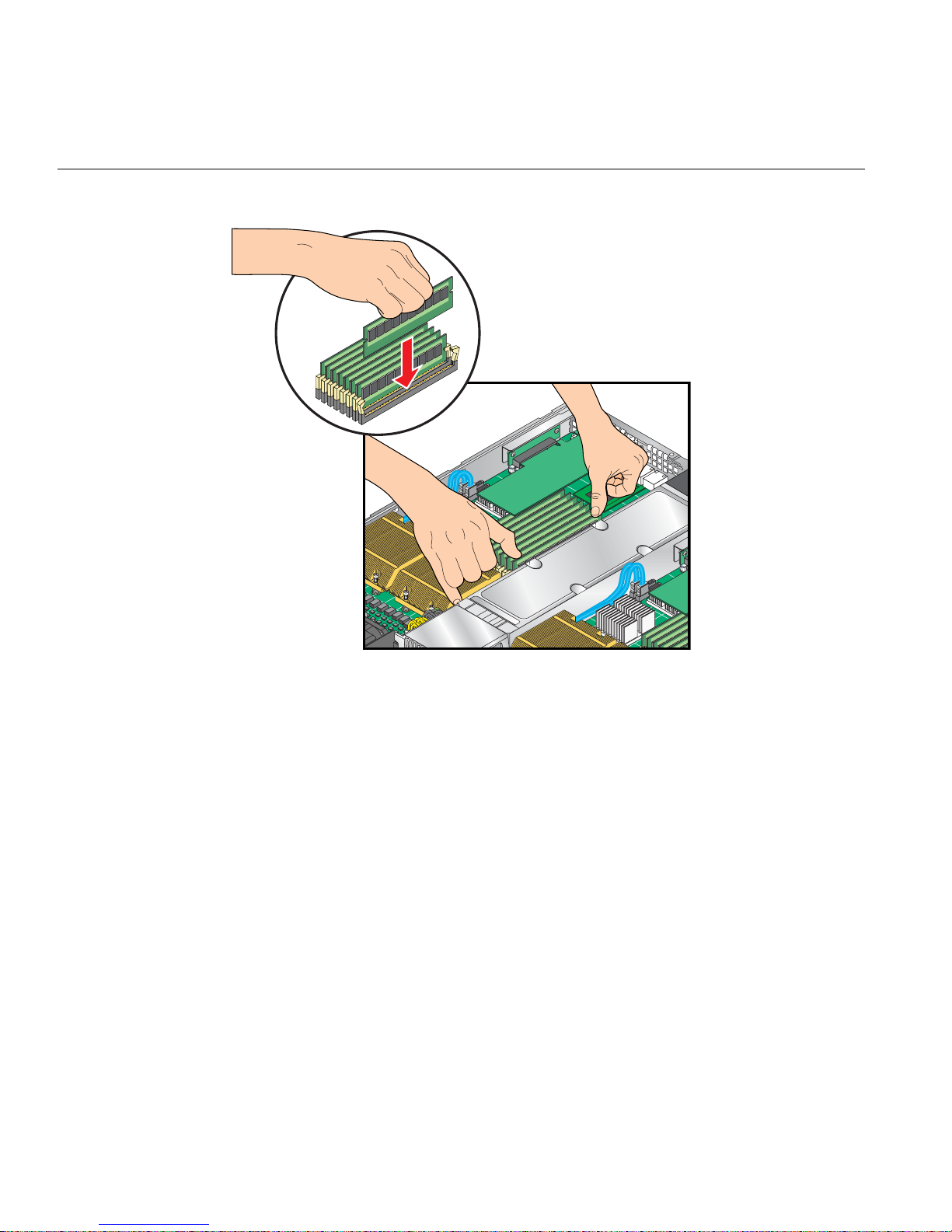

Install DIMMs . . . . . . . . . . . . . . . . . . . . . . . 54

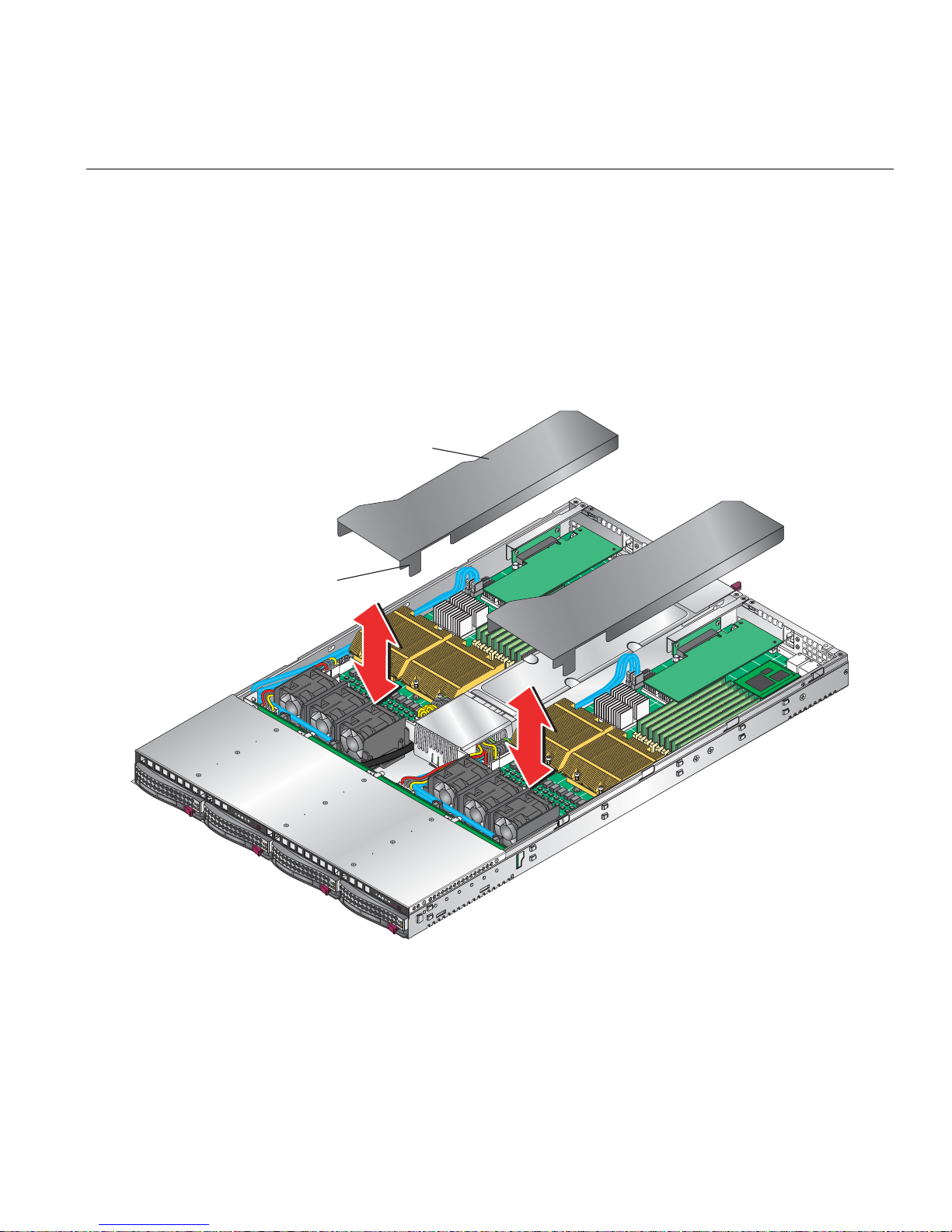

Install or Remove the Air Shroud . . . . . . . . . . . . . . . . . . . 57

Node Board Component Locations . . . . . . . . . . . . . . . . . . . 58

Add PCIe Expansion Cards . . . . . . . . . . . . . . . . . . . . . 59

Install a PCIe Expansion Card . . . . . . . . . . . . . . . . . . . 59

Node Board Jumpers and Connectors . . . . . . . . . . . . . . . . . . 61

Node Board Connector Pin Definitions . . . . . . . . . . . . . . . . . . 63

ATX Power Connector Pin Definitions . . . . . . . . . . . . . . . . 64

007-5466-001 vii

Contents

Auxiliary Power Connector Pin Definitions (JP10). . . . . . . . . . . . . . 64

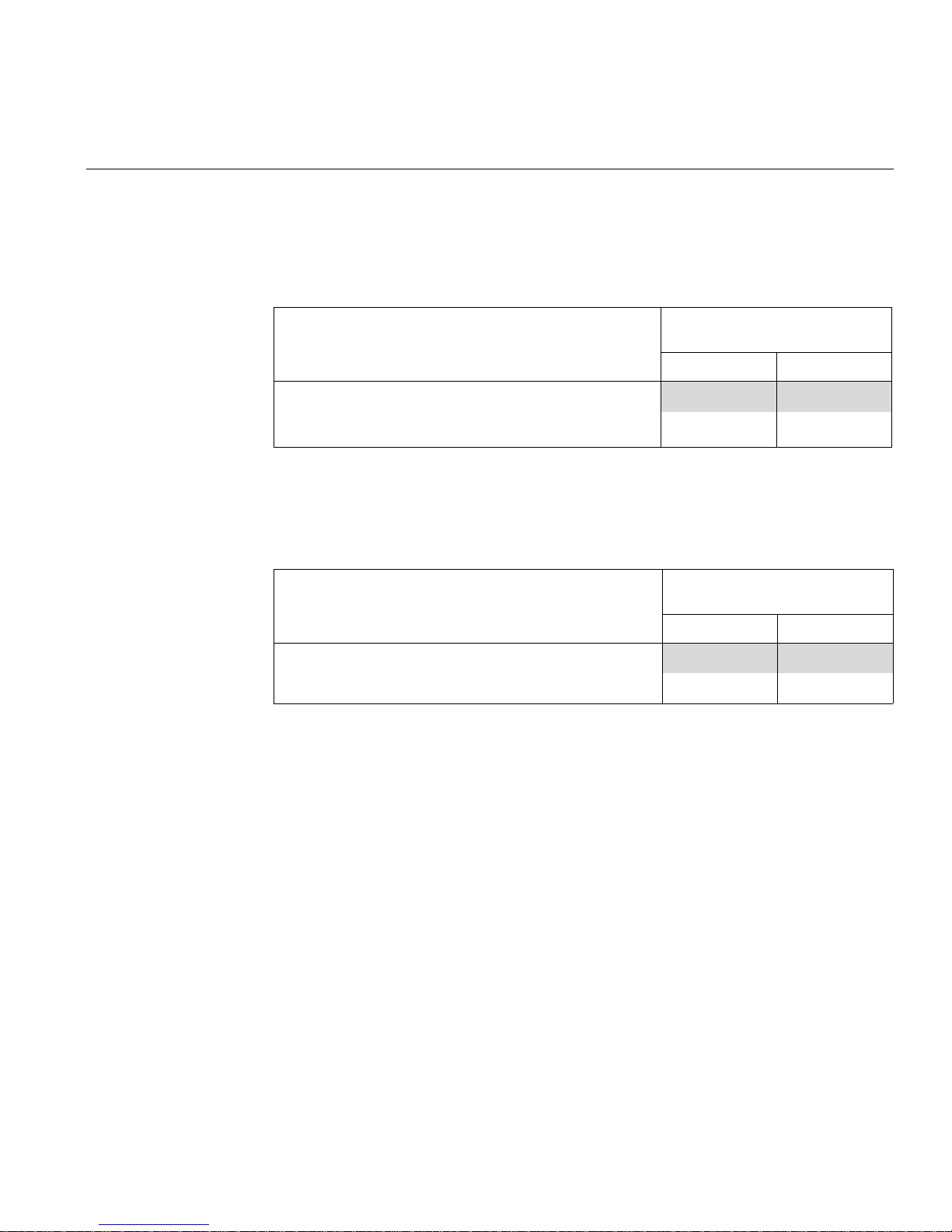

PW_ON Switch Pin Definitions (JF1) . . . . . . . . . . . . . . . . . 65

Reset Switch Pin Definitions (JF1) . . . . . . . . . . . . . . . . . . 65

Overheat/Fan Pin Definitions (JF1) . . . . . . . . . . . . . . . . . . 65

NIC2 LED Pin Definitions (JF1) . . . . . . . . . . . . . . . . . . 66

NIC1 LED Pin Definitions (JF1) . . . . . . . . . . . . . . . . . . 66

HDD LED Pin Definitions (JF1) . . . . . . . . . . . . . . . . . . 66

Power On LED Pin Definitions (JF1) . . . . . . . . . . . . . . . . . 67

NMI Switch Pin Definitions (JF1) . . . . . . . . . . . . . . . . . . 67

Fan Connector Pin Definitions (Fan1/2 - Fan7/8) . . . . . . . . . . . . . . 68

Chassis Intrusion Connector Pin Definitions (JL1) . . . . . . . . . . . . . . 68

USB Connector Pin Definitions (USB0/USB1). . . . . . . . . . . . . . . 69

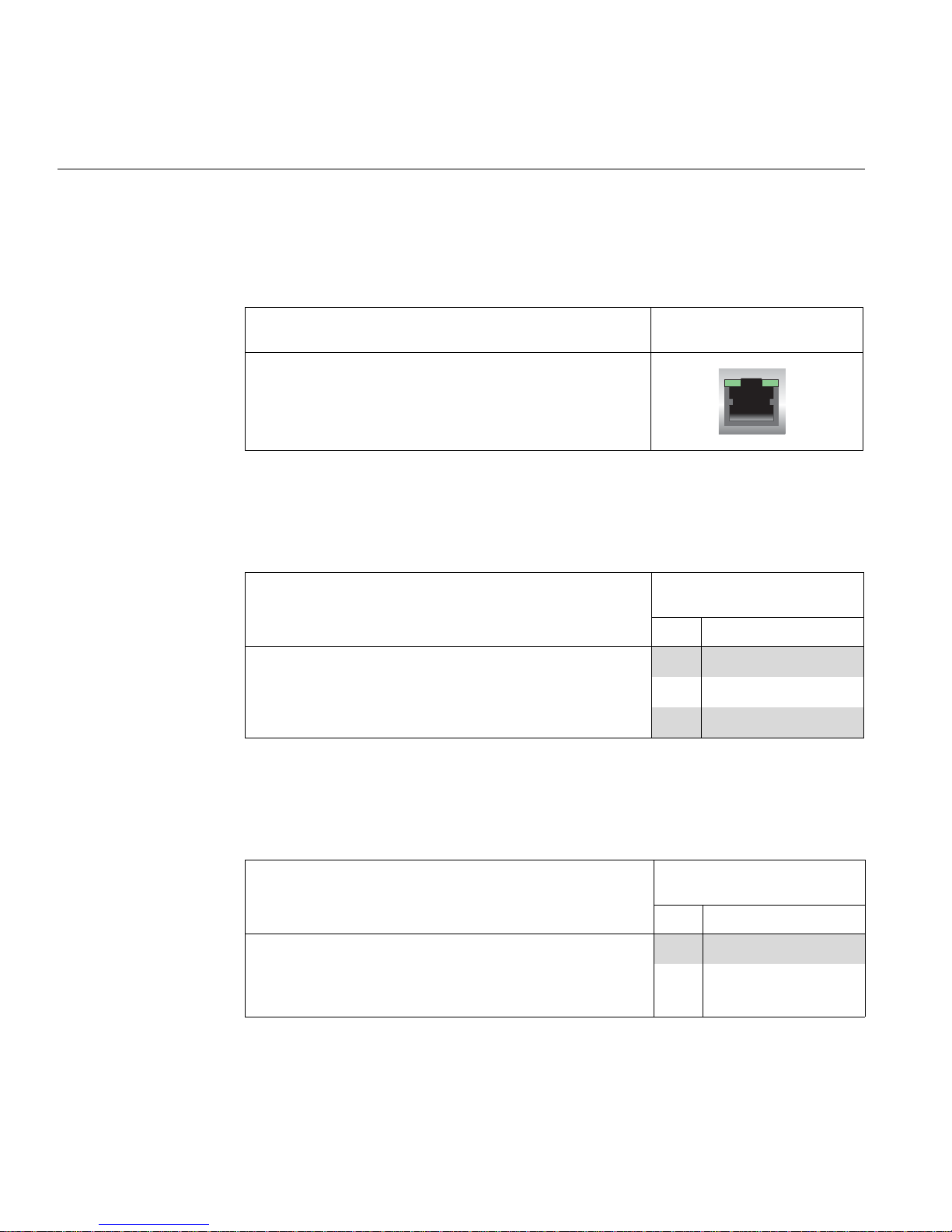

Ethernet Port (LAN1/LAN2) . . . . . . . . . . . . . . . . . . . 70

Wake on LAN Connector Pin Definitions (JWOL). . . . . . . . . . . . . . 70

Wake on Ring Connector Pin Definitions (JWOR) . . . . . . . . . . . . . . 70

Serial Port Pin Definitions (COM2). . . . . . . . . . . . . . . . . . 71

Serial General Purpose I/O Connector Pin Definitions (SGPIO) . . . . . . . . . . 71

System Management Bus Power Connector Pin Definitions (J17) . . . . . . . . . . 72

System Management Bus Connector Pin Definitions (J18). . . . . . . . . . . . 72

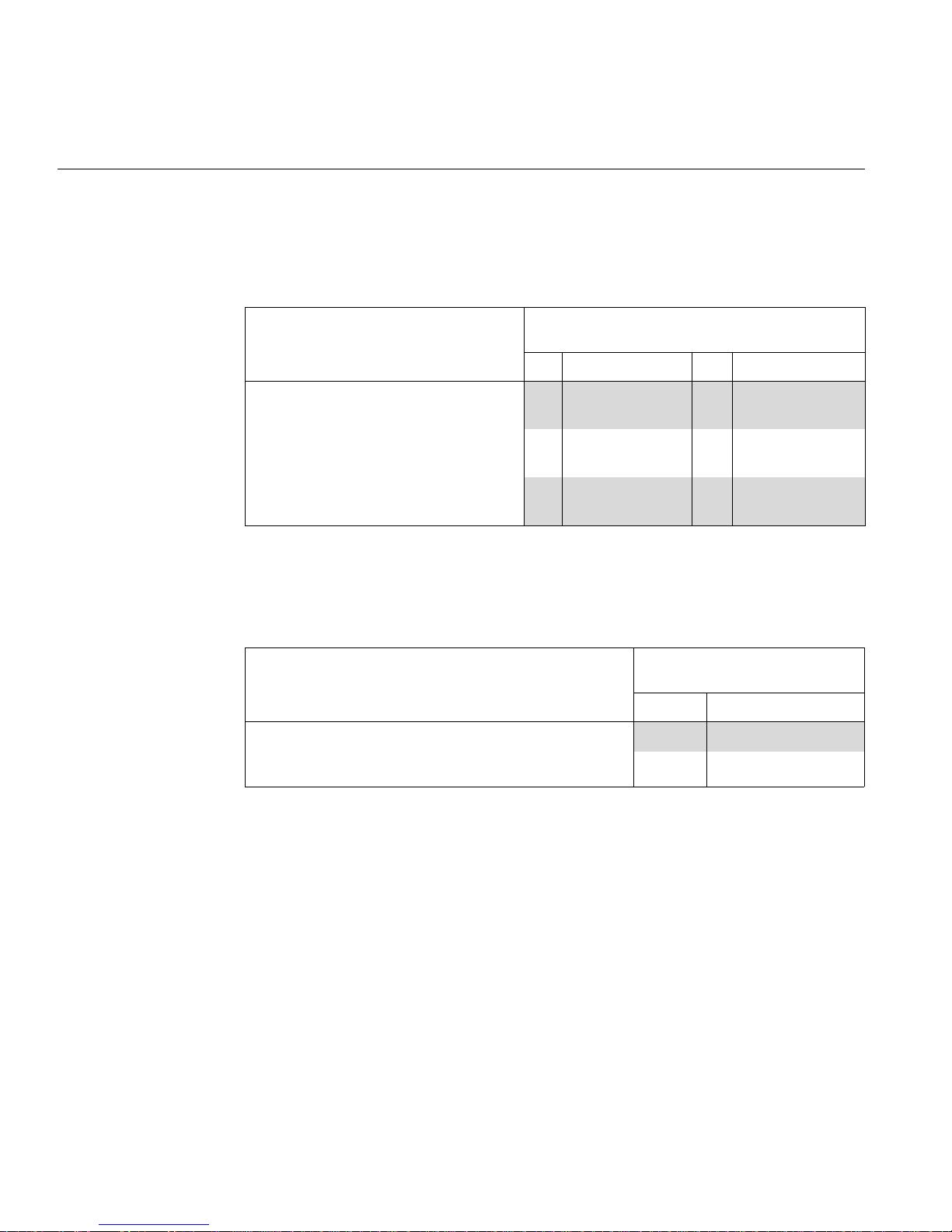

Node Board Jumper Settings. . . . . . . . . . . . . . . . . . . . . 73

Explanation of Jumper Settings . . . . . . . . . . . . . . . . . . . 74

CMOS Memory Clear (JBT1) . . . . . . . . . . . . . . . . . . . 75

VGA Jumper Settings (JPG1) . . . . . . . . . . . . . . . . . . . 76

I2C to PCIe Slot Jumper Settings (JPI2C1/JPI2C2). . . . . . . . . . . . . . 76

LAN1/LAN2 Jumper Settings (JPL1/JPL2). . . . . . . . . . . . . . . . 77

Watch Dog Timer Jumper Settings (JWD) . . . . . . . . . . . . . . . . 78

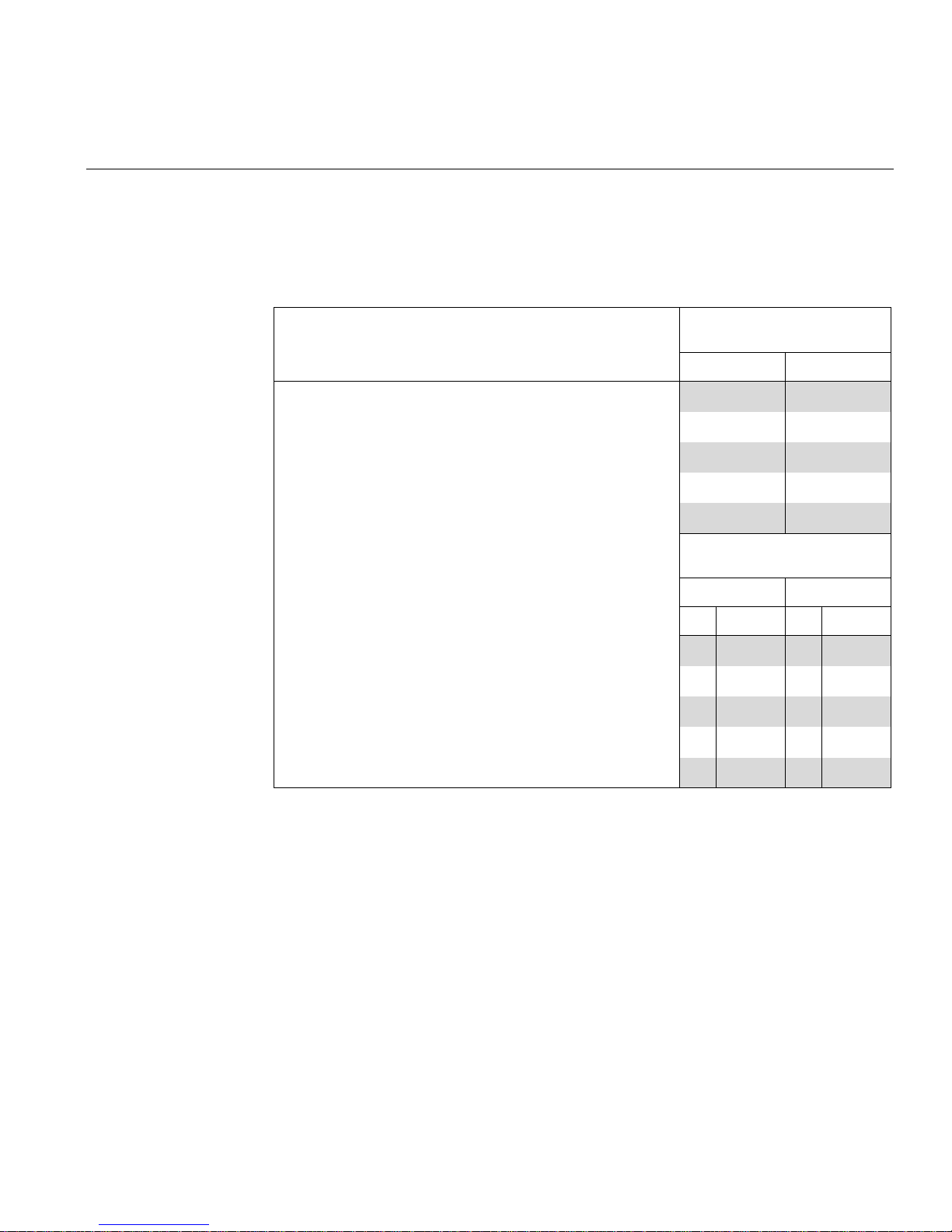

Node Board LED Descriptions . . . . . . . . . . . . . . . . . . . . 79

LAN1 and LAN2 (Ethernet Ports) . . . . . . . . . . . . . . . . . . 79

Power LED (LE1) . . . . . . . . . . . . . . . . . . . . . . 79

InfiniBand Link/Activity LEDs (LE2/LE3). . . . . . . . . . . . . . . . 81

5 Advanced Chassis Setup . . . . . . . . . . . . . . . . . . . . . 83

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . 83

Chassis Components . . . . . . . . . . . . . . . . . . . . . . . 84

viii 007-5466-001

Contents

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . 85

Part Numbers and Marketing Codes. . . . . . . . . . . . . . . . . . . 86

System Fans . . . . . . . . . . . . . . . . . . . . . . . . . 87

System Fan Failure . . . . . . . . . . . . . . . . . . . . . . . 87

Disk Drive Replacement. . . . . . . . . . . . . . . . . . . . . . 87

Disk Drive Installation . . . . . . . . . . . . . . . . . . . . . 88

Mounting a Drive in a Drive Carrier . . . . . . . . . . . . . . . . 88

Drive Replacement. . . . . . . . . . . . . . . . . . . . . 89

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 90

Power Supply Failure . . . . . . . . . . . . . . . . . . . . . 90

Power Supply Replacement . . . . . . . . . . . . . . . . . . . 90

6 BIOS Settings . . . . . . . . . . . . . . . . . . . . . . . . 93

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . 93

System BIOS . . . . . . . . . . . . . . . . . . . . . . . .102

How To Change the Configuration Data . . . . . . . . . . . . . . . .102

Starting the Setup Utility . . . . . . . . . . . . . . . . . . . .102

Running Setup . . . . . . . . . . . . . . . . . . . . . . . .103

Main BIOS Setup . . . . . . . . . . . . . . . . . . . . . . .1 04

Main Setup Features . . . . . . . . . . . . . . . . . . . . .105

System Time . . . . . . . . . . . . . . . . . . . . . .105

System Date . . . . . . . . . . . . . . . . . . . . . .105

BIOS Date . . . . . . . . . . . . . . . . . . . . . . .105

Serial ATA Ports . . . . . . . . . . . . . . . . . . . . .106

Type . . . . . . . . . . . . . . . . . . . . . . . .106

Multi-Sector Transfers. . . . . . . . . . . . . . . . . . . .107

LBA Mode Control . . . . . . . . . . . . . . . . . . . .107

32 Bit I/O . . . . . . . . . . . . . . . . . . . . . . .107

Transfer Mode . . . . . . . . . . . . . . . . . . . . . .107

Ultra DMA Mode . . . . . . . . . . . . . . . . . . . . .107

Native Mode Operation . . . . . . . . . . . . . . . . . . .107

SATA Controller Mode . . . . . . . . . . . . . . . . . . .107

Serial ATA (SATA) RAID Enable . . . . . . . . . . . . . . . .108

ICH RAID Code Base (Available when SATA RAID is Enabled) . . . . . . . .108

007-5466-001 ix

Contents

SATA AHCI (Available when SATA RAID is Disabled) . . . . . . . . . . 108

System Memory . . . . . . . . . . . . . . . . . . . . 108

Extended Memory . . . . . . . . . . . . . . . . . . . . 108

Advanced Setup . . . . . . . . . . . . . . . . . . . . . . . 109

Boot Features . . . . . . . . . . . . . . . . . . . . . . 109

QuickBoot Mode . . . . . . . . . . . . . . . . . . . . 109

QuietBoot Mode . . . . . . . . . . . . . . . . . . . . 109

POST Errors . . . . . . . . . . . . . . . . . . . . . 110

ACPI Mode . . . . . . . . . . . . . . . . . . . . . . 110

Power Button Behavior. . . . . . . . . . . . . . . . . . . 110

Resume On Modem Ring . . . . . . . . . . . . . . . . . . 110

Power Loss Control. . . . . . . . . . . . . . . . . . . . 110

Watch Dog . . . . . . . . . . . . . . . . . . . . . . 110

Summary Screen . . . . . . . . . . . . . . . . . . . . 110

Memory Cache . . . . . . . . . . . . . . . . . . . . . . 111

Cache System BIOS Area . . . . . . . . . . . . . . . . . . 111

Cache Base 0-512K. . . . . . . . . . . . . . . . . . . . 111

Cache Base 512K-640K . . . . . . . . . . . . . . . . . . 111

Cache Extended Memory . . . . . . . . . . . . . . . . . . 111

PCIe Configuration . . . . . . . . . . . . . . . . . . . . . 112

Onboard GLAN1/Onboard GLAN2 (Gigabit- LAN) OPROM Configure. . . . . . 112

Default Primary Video Adapter . . . . . . . . . . . . . . . . 112

Emulated IRQ Solutions . . . . . . . . . . . . . . . . . . 112

PCIe I/O Performance . . . . . . . . . . . . . . . . . . . 112

PCIe Parity Error Forwarding . . . . . . . . . . . . . . . . . 112

ROM Scan Ordering . . . . . . . . . . . . . . . . . . . 112

Reset Configuration Data . . . . . . . . . . . . . . . . . . 113

Slot1 PCIe x8 . . . . . . . . . . . . . . . . . . . . . . 113

Option ROM Scan . . . . . . . . . . . . . . . . . . . . 113

Enable Master . . . . . . . . . . . . . . . . . . . . . 113

Latency Timer . . . . . . . . . . . . . . . . . . . . . 113

Large Disk Access Mode . . . . . . . . . . . . . . . . . . 113

Advanced Chipset Control . . . . . . . . . . . . . . . . . . . 113

x 007-5466-001

Contents

SERR Signal Condition . . . . . . . . . . . . . . . . . . .114

4GB PCIe Hole Granularity . . . . . . . . . . . . . . . . . .114

Memory Branch Mode. . . . . . . . . . . . . . . . . . . . 114

Branch 0/1 Rank Interleaving . . . . . . . . . . . . . . . . . .114

Branch 0/1 Rank Sparing . . . . . . . . . . . . . . . . . . .114

Enhanced x8 Detection . . . . . . . . . . . . . . . . . . .114

High Bandwidth FSB . . . . . . . . . . . . . . . . . . . .1 15

High Temperature DRAM Operation . . . . . . . . . . . . . . . .115

AMB Thermal Sensor . . . . . . . . . . . . . . . . . . . .115

Thermal Throttle . . . . . . . . . . . . . . . . . . . . .115

Global Activation Throttle. . . . . . . . . . . . . . . . . . .115

Snoop Filter . . . . . . . . . . . . . . . . . . . . . .115

Crystal Beach Features. . . . . . . . . . . . . . . . . . . .116

Route Port 80h Cycles to . . . . . . . . . . . . . . . . . . .116

Clock Spectrum Feature . . . . . . . . . . . . . . . . . . .116

High Precision Event Timer . . . . . . . . . . . . . . . . . .1 16

USB Function . . . . . . . . . . . . . . . . . . . . . .116

Legacy USB Support . . . . . . . . . . . . . . . . . . . .116

Advanced Processor Options . . . . . . . . . . . . . . . . . . .117

CPU Speed. . . . . . . . . . . . . . . . . . . . . . .117

Frequency Ratio . . . . . . . . . . . . . . . . . . . . .117

Core-Multi-Processing. . . . . . . . . . . . . . . . . . . . 1 17

Machine Checking . . . . . . . . . . . . . . . . . . . . .117

Thermal Management 2 . . . . . . . . . . . . . . . . . . .117

C1 Enhanced Mode . . . . . . . . . . . . . . . . . . . .117

Execute Disable Bit . . . . . . . . . . . . . . . . . . . .118

Adjacent Cache Line Prefetch . . . . . . . . . . . . . . . . . .118

Hardware Prefetch . . . . . . . . . . . . . . . . . . . . .118

Direct Cache Access . . . . . . . . . . . . . . . . . . . .118

DCA Delay Clocks. . . . . . . . . . . . . . . . . . . . .118

Intel Virtualization Technology . . . . . . . . . . . . . . . . .118

Intel EIST Support. . . . . . . . . . . . . . . . . . . . .119

I/O Device Configuration . . . . . . . . . . . . . . . . . . . .119

007-5466-001 xi

Contents

Serial Port A . . . . . . . . . . . . . . . . . . . . . 119

Serial Port B . . . . . . . . . . . . . . . . . . . . . 119

DMI Event Logging . . . . . . . . . . . . . . . . . . . . . 120

Event Log Validity . . . . . . . . . . . . . . . . . . . . 120

Event Log Capacity. . . . . . . . . . . . . . . . . . . . 120

View DMI Event Log . . . . . . . . . . . . . . . . . . . 120

Event Logging . . . . . . . . . . . . . . . . . . . . . 120

ECC Event Logging . . . . . . . . . . . . . . . . . . . 120

Mark DMI Events as Read . . . . . . . . . . . . . . . . . . 120

Clear All DMI Event Logs . . . . . . . . . . . . . . . . . . 120

Console Redirection . . . . . . . . . . . . . . . . . . . . . 120

COM Port Address . . . . . . . . . . . . . . . . . . . . 121

BAUD Rate. . . . . . . . . . . . . . . . . . . . . . 121

Console Type . . . . . . . . . . . . . . . . . . . . . 121

Flow Control . . . . . . . . . . . . . . . . . . . . . 121

Console Connection . . . . . . . . . . . . . . . . . . . 121

Continue CR after POST . . . . . . . . . . . . . . . . . . 121

Hardware Monitor . . . . . . . . . . . . . . . . . . . . . 121

CPU Temperature Threshold . . . . . . . . . . . . . . . . . 122

Fan Speed Control Modes . . . . . . . . . . . . . . . . . . 122

Voltage Monitoring. . . . . . . . . . . . . . . . . . . . 122

IPMI . . . . . . . . . . . . . . . . . . . . . . . . . 123

IPMI Specification Version. . . . . . . . . . . . . . . . . . 123

Firmware Version . . . . . . . . . . . . . . . . . . . . 123

System Event Logging . . . . . . . . . . . . . . . . . . . 123

Clear System Event Logging . . . . . . . . . . . . . . . . . 124

Existing Event Log Number . . . . . . . . . . . . . . . . . 124

Event Log Control . . . . . . . . . . . . . . . . . . . . 124

System Event Log/System Event Log (List Mode) . . . . . . . . . . . 125

Realtime Sensor Data . . . . . . . . . . . . . . . . . . . 126

Security . . . . . . . . . . . . . . . . . . . . . . . . . 127

Supervisor Password Is . . . . . . . . . . . . . . . . . . . . 127

User Password Is . . . . . . . . . . . . . . . . . . . . . 127

xii 007-5466-001

Contents

Set Supervisor Password . . . . . . . . . . . . . . . . . . . .128

Set User Password . . . . . . . . . . . . . . . . . . . . . .128

Password on Boot . . . . . . . . . . . . . . . . . . . . . .128

Boot . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Boot Priority Order/Excluded from Boot Orders . . . . . . . . . . . . . .129

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Exit Saving Changes . . . . . . . . . . . . . . . . . . . . .131

Exit Discarding Changes . . . . . . . . . . . . . . . . . . . .131

Load Setup Defaults . . . . . . . . . . . . . . . . . . . . .131

Discard Changes . . . . . . . . . . . . . . . . . . . . . .131

Save Changes . . . . . . . . . . . . . . . . . . . . . . .131

A BIOS Power-on Self Test . . . . . . . . . . . . . . . . . . . . .133

BIOS POST Messages . . . . . . . . . . . . . . . . . . . . . .133

BIOS POST Codes . . . . . . . . . . . . . . . . . . . . . . .139

Recoverable POST Errors . . . . . . . . . . . . . . . . . . . .139

Terminal POST Errors . . . . . . . . . . . . . . . . . . . . .139

B IPMI 2.0 Management Utility . . . . . . . . . . . . . . . . . . . .147

Network Connection. . . . . . . . . . . . . . . . . . . . . . .149

Functions Listed on the Home Page. . . . . . . . . . . . . . . . . . .150

Remote Control . . . . . . . . . . . . . . . . . . . . . . . .152

KVM Console . . . . . . . . . . . . . . . . . . . . . . .152

Remote Power . . . . . . . . . . . . . . . . . . . . . . .153

Virtual Media . . . . . . . . . . . . . . . . . . . . . . . .153

CD-ROM Image . . . . . . . . . . . . . . . . . . . . . .154

Drive Redirection . . . . . . . . . . . . . . . . . . . . . .156

Virtual Media Options . . . . . . . . . . . . . . . . . . . . .158

System Health . . . . . . . . . . . . . . . . . . . . . . . .160

Chassis Control . . . . . . . . . . . . . . . . . . . . . . .1 60

Monitor Sensors . . . . . . . . . . . . . . . . . . . . . .162

System Event Log . . . . . . . . . . . . . . . . . . . . . .164

Alert Settings . . . . . . . . . . . . . . . . . . . . . . .165

User Management . . . . . . . . . . . . . . . . . . . . . . .166

007-5466-001 xiii

Contents

Change Password . . . . . . . . . . . . . . . . . . . . . 166

Users and Groups . . . . . . . . . . . . . . . . . . . . . 167

Permissions . . . . . . . . . . . . . . . . . . . . . . . 168

KVM Settings . . . . . . . . . . . . . . . . . . . . . . . 169

User Console . . . . . . . . . . . . . . . . . . . . . . 169

Keyboard/Mouse . . . . . . . . . . . . . . . . . . . . . 172

Device Settings . . . . . . . . . . . . . . . . . . . . . . . 174

Network . . . . . . . . . . . . . . . . . . . . . . . . 174

Dynamic DNS . . . . . . . . . . . . . . . . . . . . . . 176

Security . . . . . . . . . . . . . . . . . . . . . . . . 177

Certificate . . . . . . . . . . . . . . . . . . . . . . . 180

Date and Time . . . . . . . . . . . . . . . . . . . . . . 182

Event Log . . . . . . . . . . . . . . . . . . . . . . . 184

SNMP Settings . . . . . . . . . . . . . . . . . . . . . . 186

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 187

Device Information . . . . . . . . . . . . . . . . . . . . . 187

Event Log . . . . . . . . . . . . . . . . . . . . . . . 189

Update Firmware . . . . . . . . . . . . . . . . . . . . . 190

Unit Reset . . . . . . . . . . . . . . . . . . . . . . . 190

Remote Console Main Page . . . . . . . . . . . . . . . . . . . . 192

Remote Console Options . . . . . . . . . . . . . . . . . . . 193

Log Out . . . . . . . . . . . . . . . . . . . . . . . . . 194

C Regulatory Specifications and Safety Information . . . . . . . . . . . . . 195

Manufacturer’s Regulatory Declarations. . . . . . . . . . . . . . . . . 195

Server Model Number . . . . . . . . . . . . . . . . . . . . 195

CE Notice and Manufacturer's Declaration of Conformity . . . . . . . . . . . 195

Electromagnetic Emissions . . . . . . . . . . . . . . . . . . . 196

FCC Notice (USA Only) . . . . . . . . . . . . . . . . . . 196

Industry Canada Notice (Canada Only) . . . . . . . . . . . . . . 197

VCCI Class A Notice (Japan Only) . . . . . . . . . . . . . . . 197

Shielded Cables . . . . . . . . . . . . . . . . . . . . . . 197

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . 197

xiv 007-5466-001

Contents

D System Specifications . . . . . . . . . . . . . . . . . . . . . .199

E System Safety . . . . . . . . . . . . . . . . . . . . . . . .203

Electrical Safety Precautions . . . . . . . . . . . . . . . . . . . .203

Node Board Battery. . . . . . . . . . . . . . . . . . . . . .204

General Safety Precautions . . . . . . . . . . . . . . . . . . . . .205

ESD Safety Precautions . . . . . . . . . . . . . . . . . . . . . .206

Operating Precautions . . . . . . . . . . . . . . . . . . . . . .206

F Upgrading for SAS/SATA RAID Support . . . . . . . . . . . . . . . .207

Installing the HBAs . . . . . . . . . . . . . . . . . . . . . . . 2 07

Creating RAID Volumes . . . . . . . . . . . . . . . . . . . . .209

G Upgrading BIOS . . . . . . . . . . . . . . . . . . . . . . .211

Requirements . . . . . . . . . . . . . . . . . . . . . . . .211

Setting up the Virtual Media Boot Feature . . . . . . . . . . . . . . . . .212

Booting the Virtual Media DOS Image . . . . . . . . . . . . . . . . . .213

I Index . . . . . . . . . . . . . . . . . . . . . . . . . .215

007-5466-001 xv

Figures

Figures

Figure 1-1 SGI Altix XE320 Server . . . . . . . . . . . . . . 1

Figure 1-2 Chassis Components . . . . . . . . . . . . . . . 3

Figure 1-3 Node Board Block Diagram . . . . . . . . . . . . . 5

Figure 2-1 Identify Sections of the Rack Rails (right side rail shown) . . . . . 13

Figure 2-2 Rail Assembly . . . . . . . . . . . . . . . . 13

Figure 2-3 Attaching the Inner Bracket . . . . . . . . . . . . . 14

Figure 2-4 Attaching the Rail to the Front of the Rack (View from Front of Rack) . 15

Figure 2-5 Attaching the Rail to the Rear of the Rack (View from Rear of Rack) . . 15

Figure 2-6 Install the Server in a Rack . . . . . . . . . . . . . 17

Figure 2-7 Install the Server in a Third-party Rack (1) . . . . . . . . . 18

Figure 2-10 Remove the Top Cover . . . . . . . . . . . . . . 22

Figure 3-1 Front Panel Controls and Indicators . . . . . . . . . . . 26

Figure 4-1 Remove the Top Cover . . . . . . . . . . . . . . 31

Figure 4-2 Node Board Installation . . . . . . . . . . . . . . 33

Figure 4-3 Control Panel Connector (JF1) Pin Definitions . . . . . . . . 34

Figure 4-4 I/O Port Locations . . . . . . . . . . . . . . . 35

Figure 4-5 Install a CPU Heatsink . . . . . . . . . . . . . . 41

Figure 4-6 Minimum Population for Dual-Channel Mode with Identical FBDIMMs . 51

Figure 4-7 Standard DIMM Population for Sparing or Mirroring . . . . . . 53

Figure 4-8 Install DIMMs . . . . . . . . . . . . . . . . 55

Figure 4-9 Replace DIMMs . . . . . . . . . . . . . . . . 56

Figure 4-10 Install Air Shrouds . . . . . . . . . . . . . . . 57

Figure 4-11 Node Board Component Locations . . . . . . . . . . . 58

Figure 4-12 Install a PCI Card . . . . . . . . . . . . . . . 60

Figure 4-13 Explanation of Jumper Pins . . . . . . . . . . . . . 74

Figure 4-14 CMOS Memory Jumper Location (JBT1) . . . . . . . . . 75

007-5466-001 xvii

Figures

Figure 4-15 LAN 1 and LAN 2 Jumper Locations (JPL1/JPL2) . . . . . . . 77

Figure 4-16 Watch Dog Timer Jumper Location (JWD) . . . . . . . . . 78

Figure 4-17 InfiniBand Link LED Location (LE1) . . . . . . . . . . 80

Figure 4-18 InfiniBand Link LED Location (LE2) . . . . . . . . . . 81

Figure 5-1 Chassis Front View . . . . . . . . . . . . . . . 84

Figure 5-2 Chassis Rear View . . . . . . . . . . . . . . . 84

Figure 5-3 JF1 Connector Location . . . . . . . . . . . . . . 85

Figure 5-4 Disk Drive Carrier . . . . . . . . . . . . . . . 88

Figure 5-5 Drive Removal . . . . . . . . . . . . . . . . 89

Figure 5-6 Power Supply Replacement . . . . . . . . . . . . . 91

Figure 6-1 Main BIOS Setup Menu . . . . . . . . . . . . . 104

Figure B-1 BMC Remote Console . . . . . . . . . . . . . 150

Figure B-2 Remote Console Screen . . . . . . . . . . . . . 152

Figure B-3 CD-ROM Image . . . . . . . . . . . . . . . 154

Figure B-4 Drive Redirection . . . . . . . . . . . . . . . 156

Figure B-5 Virtual Media Options . . . . . . . . . . . . . 158

Figure B-6 Chassis Control . . . . . . . . . . . . . . . 160

Figure B-7 Monitor Sensors . . . . . . . . . . . . . . . 162

Figure B-8 System Event Log. . . . . . . . . . . . . . . 164

Figure B-9 Alert Settings . . . . . . . . . . . . . . . . 165

Figure B-10 User Console Settings. . . . . . . . . . . . . . 170

Figure B-11 Keyboard/Mouse Settings . . . . . . . . . . . . . 172

Figure B-12 Network Settings . . . . . . . . . . . . . . . 174

Figure B-13 Dynamic DNS Settings . . . . . . . . . . . . . 176

Figure B-14 Security Settings . . . . . . . . . . . . . . . 178

Figure B-15 Certificate Settings . . . . . . . . . . . . . . 180

Figure B-16 Date and Time Settings . . . . . . . . . . . . . 182

Figure B-17 Event Log . . . . . . . . . . . . . . . . . 184

Figure B-18 SNMP Settings . . . . . . . . . . . . . . . 186

Figure B-19 Device Information . . . . . . . . . . . . . . 188

Figure B-20 Event Log . . . . . . . . . . . . . . . . . 189

Figure B-21 Update Firmware . . . . . . . . . . . . . . . 190

Figure B-22 Unit Reset . . . . . . . . . . . . . . . . . 191

xviii 007-5466-001

Figures

Figure B-23 Remove Console Screen . . . . . . . . . . . . . .192

Figure B-24 Remote Console Options. . . . . . . . . . . . . .193

Figure E-1 Install the Battery. . . . . . . . . . . . . . . .204

007-5466-001 xix

Tables

Tables

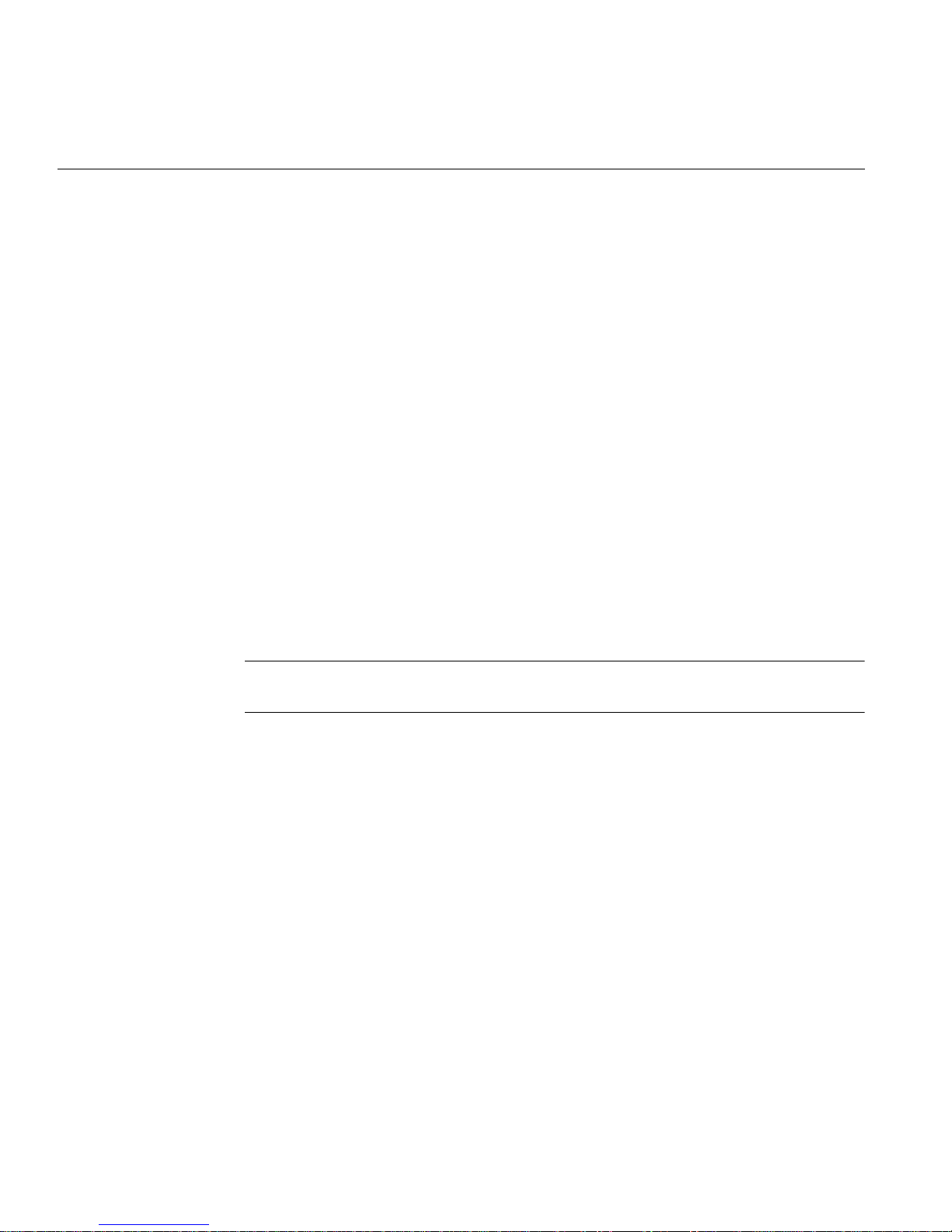

Table 4-1 Recommended DIMM Configurations . . . . . . . . . . 52

Table 4-2 DIMM Configurations . . . . . . . . . . . . . . 55

Table 4-3 Node Board Default Jumper Settings . . . . . . . . . . 61

Table 4-4 Node Board Connector Descriptions. . . . . . . . . . . 61

Table 4-5 Node Board LED Descriptions . . . . . . . . . . . . 62

Table 4-6 Node Board Connector Pin Definitions . . . . . . . . . . 63

Table 4-7 ATX Power Connector Pin Definitions . . . . . . . . . . 64

Table 4-8 Auxiliary Power Connector Pin Definitions (JP10) . . . . . . . 64

Table 4-9 PW_ON Switch Pin Definitions (JF1) . . . . . . . . . . 65

Table 4-10 Reset Switch Pin Definitions (JF1) . . . . . . . . . . . 65

Table 4-11 Overheat/Fan Fail LED Pin Definitions (JF1) . . . . . . . . 65

Table 4-12 NIC2 LED Pin Definitions (JF1). . . . . . . . . . . . 66

Table 4-13 NIC1 LED Pin Definitions . . . . . . . . . . . . . 66

Table 4-14 HDD LED Pin Definitions (JF1). . . . . . . . . . . . 66

Table 4-15 Power On LED Pin Definitions (JF1) . . . . . . . . . . 67

Table 4-16 NMI Button Pin Definitions (JF1) . . . . . . . . . . . 67

Table 4-17 Fan Header Pin Definitions (Fan1/2 - Fan7/8) . . . . . . . . 68

Table 4-18 Chassis Intrusion Pin Definitions (JL1) . . . . . . . . . . 68

Table 4-19 Universal Serial Bus (USB) Pin Definitions . . . . . . . . . 69

Table 4-20 Ethernet Ports (LAN1/LAN2) . . . . . . . . . . . . 70

Table 4-21 Wake on LAN Connector Pin Definitions (JWOL) . . . . . . . 70

Table 4-22 Wake on Ring Connector Pin Definitions . . . . . . . . . 70

Table 4-23 Serial Port Pin Definitions (COM2) . . . . . . . . . . . 71

Table 4-24 Serial General Purpose I/O Connector Pin Definitions (SGPIO) . . . 71

Table 4-25 SMB Power Connector Pin Definitions (J17) . . . . . . . . 72

007-5466-001 xxi

Tables

Table 4-26 SMB Header Pin Definitions (J18) . . . . . . . . . . . 72

Table 4-27 Node Board Jumper Descriptions. . . . . . . . . . . . 73

Table 4-28 VGA Jumper Settings (JPG1). . . . . . . . . . . . . 76

Table 4-29 I2C to PCIe Slot Jumper Settings. . . . . . . . . . . . 76

Table 4-30 LAN1/LAN2 Jumper Settings (JPL1/JPL2) . . . . . . . . . 77

Table 4-31 Watch Dog Timer Jumper Settings (JWD) . . . . . . . . . 78

Table 4-32 LAN1 and LAN 2 LED Descriptions. . . . . . . . . . . 79

Table 4-33 Power LED Description (LE1) . . . . . . . . . . . . 79

Table 4-34 InfiniBand Link/Activity LED Descriptions (LE2/LE3) . . . . . . 81

Table 5-1 Part Numbers and Marketing Codes . . . . . . . . . . . 86

Table 6-1 BIOS Default Settings . . . . . . . . . . . . . . 93

Table A-1 BIOS Post Codes . . . . . . . . . . . . . . . 139

Table B-1 Health Monitoring Sensors . . . . . . . . . . . . 163

Table D-1 SGI Altix XE320 System Specifications . . . . . . . . . 199

xxii 007-5466-001

About This Guide

This guide provides an overview of the installation, architecture, general operation, and

descriptions of the major components in the SGI

troubleshooting and maintenance information, BIOS information, and important safety and

regulatory specifications.

Audience

This guide is written for owners, installers, system administrators, and users of SGI Altix XE320

computer systems. It is written with the assumption that the reader has a good working knowledge

of computers and computer systems.

Important Information

W arning: To avoid problems that could void your warranty, your SGI or other appr oved

system support engineer (SSE) should perform any replacement of parts or service of your

SGI

Altix XE320 system not covered in the following list of items that you can perform

yourself:

• Install the server into system rack(s).

®

Altix® XE320. It also provides basic

• Replace the power supply, power distribution board, or fans in the server chassis.

• Replace disk drives or SATA backplane in the server chassis.

• Replace processors, memory, or processor heatsinks on the node board.

• Add or replace PCIe cards or the baseboard management controller (BMC)

• Replace cables

007-5466-001 xxiii

Chapter Descriptions

The following topics are covered in this guide:

• Chapter 1, “Introduction,” provides a checklist of the main components included with the

• Chapter 2, “Server Installation,” describes the steps necessary to install the system into a

• Chapter 3, “Controls and Indicators,” provides details on the system interface, which

• Chapter 4, “Advanced Node Board Setup,” provides detailed informati on on the 1U

• Chapter 5, “Advanced Chassis Setup,” provides detailed information about the components

• Chapter 6, “BIOS Settings,” includes an introduction to BIOS and provides detailed

• Appendix A, “BIOS Power-on Self T est,” provides information about BIOS POST self-test

• Appendix B, “IPMI 2.0 Management Utility,” provides information about how to start the

system and describes the main features of the SGI Altix XE320 and its node boards.

rack and check out the server configuration prior to powering up the system. If your server

was ordered without the processor and memory components, this chapter will refer you to

the appropriate sections of the manual for their installation.

includes the functions and information provided by the control panel on the chassis, as well

as other LEDs located throughout the system.

rackmount server chassis. Follow the procedures in this chapter when you install, remove, or

reconfigure SAS/SATA or peripheral drives and when you replace system power supply

units and cooling fans.

inside the server chassis, such as the node board connectors and jumper settings, disk drive

information, and power supply replacement.

information on running the CMOS Setup Utility.

messages and codes.

baseboard management controller (BMC) intelligent platform management interface (IPMI

2.0 management utility).

• Appendix C, “Regulatory Specifications and Safety Information,” lists regulatory

information that may be important to the operation of your system.

• Appendix D, “System Specifications,” provides physical, environmental, and power

specifications for your system.

• Appendix E, “System Safety,” provides a general overview of safety precautions that

should be followed when installing and servicing the SGI Altix XE320.

• Appendix F, “Upgrading for SAS/SATA RAID Support,” describes how to upgrade your

server to use SAS hard drives as well as SATA hard drives by using model LSISAS3444E

HBAs. This HBA option also can provide support for RAID 0, RAID 1, or JBOD.

xxiv 007-5466-001

• Appendix G, “Upgrading BIOS,” gives an overview of the various methods for upgrading

Related Publications

The following SGI and LSI documents are relevant to the SGI Altix XE320 server:

• SGI Altix XE1300 Cluster Quick Reference Guide, publication number 007-4979-00x

• SGI ProPack 5 for Linux Start Here, publication number 007-4837-00x

• SGI InfiniteStorage series documentation

• PCI Express to 3.0 Gbit/s Serial Attached SCSI (SAS) Host Bus Adapters User’s Guide,

• Integrated RAID for SAS User’s Guide, publication number 860-0477-001

• Man pages (online)

You can obtain SGI documentation (as well as the pertinent LSI books), release notes, or man

pages in the following ways:

:

BIOS and the details for upgrading clusters via the BMC web interface.

publication number 860-0477-001

• Refer to the SGI Technical Publications Library at http://docs.sgi.com. Various formats are

available. This library contains the most recent and most comprehensive set of online books,

release notes, man pages, and other information.

• You can also view man pages by typing man <title> on a command line.

SGI systems include a set of Linux® man pages, formatted in the standard UNIX® “man page”

style. Important system configuration files and commands are documented on man pages. These

are found online on the internal system disk (or DVD-ROM) and are displayed using the man

command. For example, to display the man page for the xscsidisktest command, type the

following on a command line:

man xscsidisktest

For additional information about displaying man pages using the man command, see man(1).

In addition, the apropos command locates man pages based on keywords. For examp le, to

display a list of man pages that describe disks, type the following on a command line:

apropos disk

For information about setting up and using apropos, see apropos(1).

007-5466-001 xxv

Conventions

The following conventions are used throughout this document:

Convention Meaning

Command This fixed-space font denotes literal items such as commands, files,

routines, path names, signals, messages, and programming language

structures.

variable The italic typeface denotes variable entries and words or concepts being

defined. Italic typeface is also used for book titles.

user input This bold fixed-space font denotes literal items that the user enters in

interactive sessions. Output is shown in nonbold, fixed-space font.

[ ] Brackets enclose optional portions of a command or directive line.

... Ellipses indicate that a preceding element can be repeated.

man page(x) Man page section identifiers appear in parentheses after man page nam es.

GUI element This font denotes the names of graphical user interface (GUI) elements such

as windows, screens, dialog boxes, menus, toolbars, icons, buttons, boxes,

fields, and lists.

Product Support

SGI provides a comprehensive product support and maintenance program for its products. SG I

also offers services to implement and integrate Linux applications in your environment.

• Refer to http://www.sgi.com/support/

• If you are in North America, contact the Technical Assistance Center at

+1 800 800 4SGI or contact your authorized service provider.

• If you are outside North America, contact the SGI subsidiary or authorized distributor in

your country.

xxvi 007-5466-001

Reader Comments

:

If you have comments about the technical accuracy, content, or organization of this document,

contact SGI. Be sure to include the title and document number of the manual with your comments.

(Online, the document number is located in the front matter of the manual. In printed manuals, the

document number is located at the bottom of each page.)

You can contact SGI in any of the following ways:

• Send e-mail to the following address: techpubs@sgi.com

• Contact your customer service representative and ask that an incident be filed in the SGI

incident tracking system.

• Send mail to the following address:

SGI

Technical Publications

1140 East Arques Avenue

Sunnyvale, CA 94085–4602

SGI values your comments and will respond to them promp tly.

007-5466-001 xxvii

Chapter 1

1. Introduction

The SGI Altix XE320 server is a 1U rackmount server (refer to Figure 1-1) that contains two node

boards in a single chassis. Each node supports two Intel® Xeon® dual- or quad-core processors.

2

1

2

sgi

1

Figure 1-1 SGI Altix XE320 Server

007-5466-001 1

1: Introduction

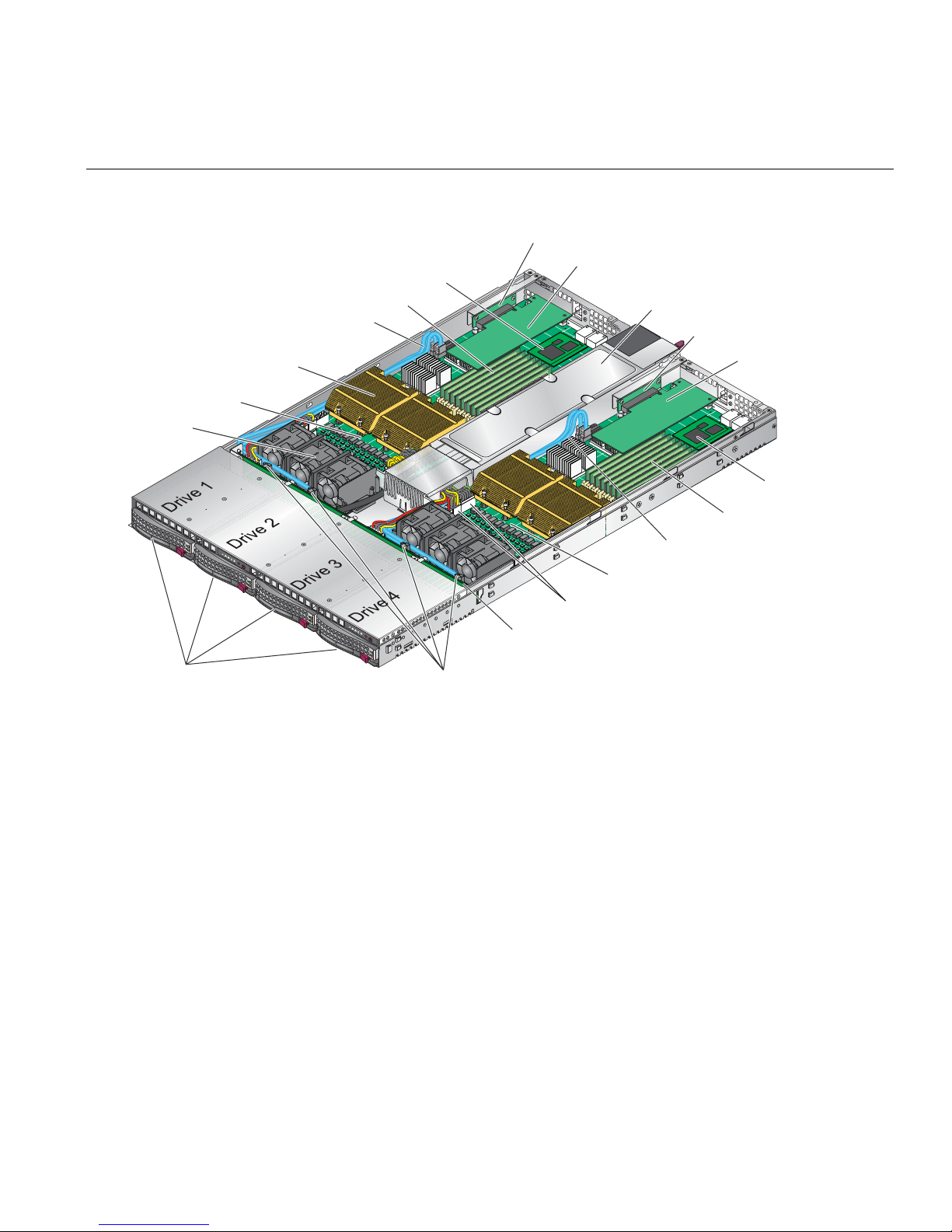

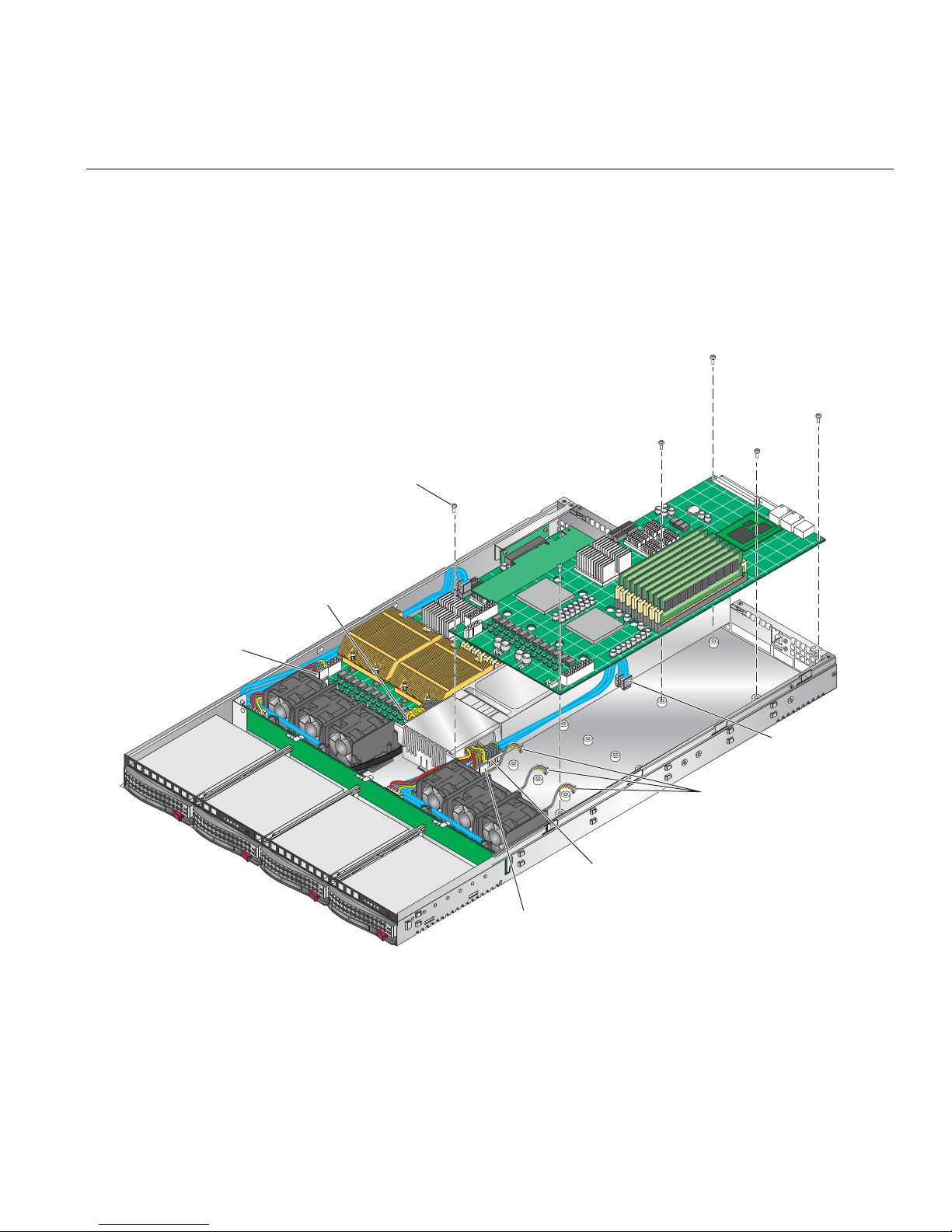

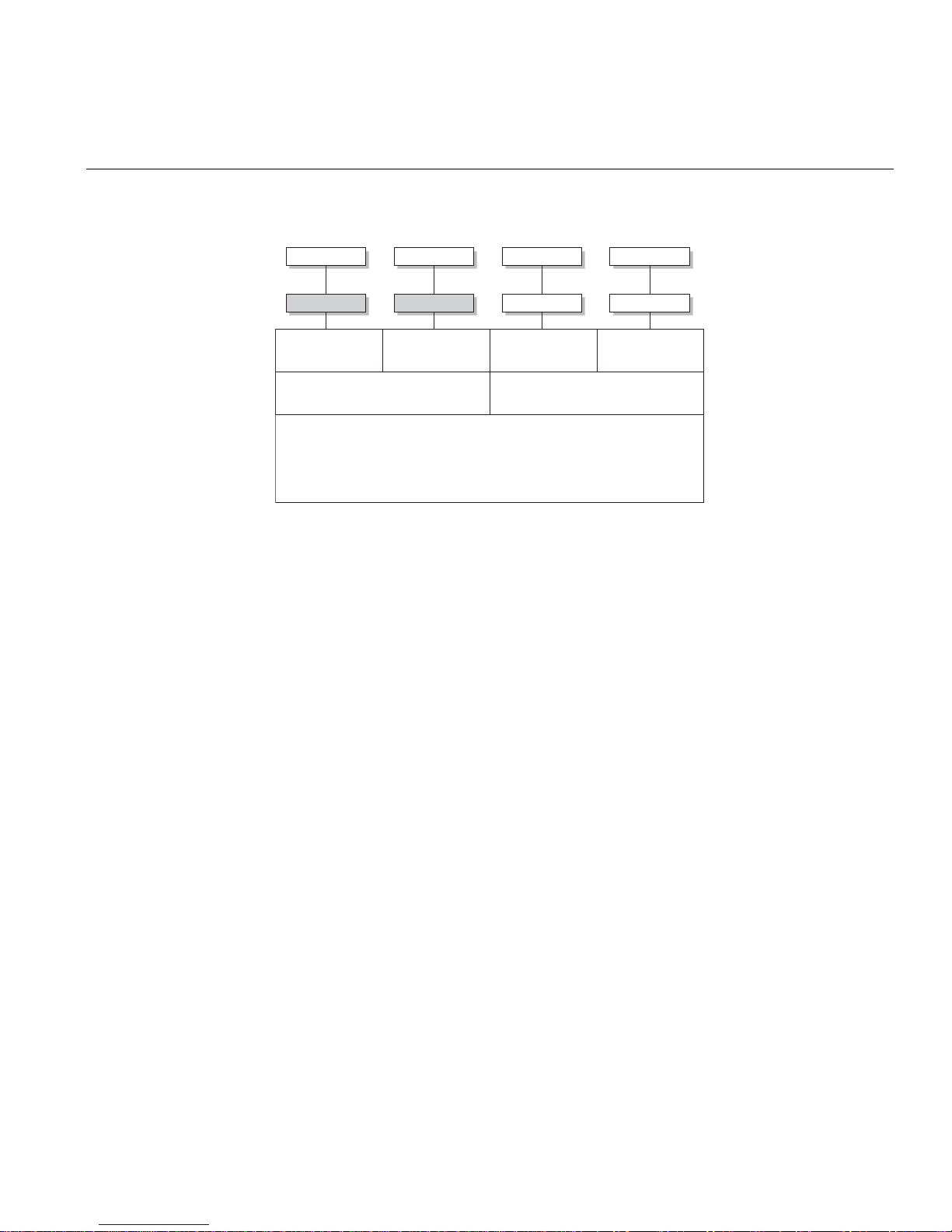

In addition to the node and chassis, the following hardware components are included (refer to

Figure 1-2):

• One or two dual-core or quad-core processors per node board

• Two processor heatsinks per node board

• Four hard drive carriers (two per node)

• One internal SATA backplane

• One SATA cable set

• Two PCI-Express 2.0 x16 riser cards (one per node)

• Two IPMI 2.0 baseboard management cards (BMCs), one per node

• Six 4-cm high-performance fans (three per node)

• Two air shrouds (one per node)

• Rackmount hardware with screws

– Two rack rail assemblies

– Six brackets for mounting the rack rails in a rack/telco rack

2 007-5466-001

Intel Xeon

processor heatsink

Node board 1

Fans

IPMI 2.0 BMC

SATA disk drive cables

DIMMs

PCIe riser card

PCIe card

Power supply

PCIe riser card

PCIe card

IPMI 2.0 BMC

DIMMs

21

SATA disk drives

2

1

SATA connections

Figure 1-2 Chassis Components

SATA disk drive cables

Node board 2

Node board 2 power connectors

SATA backplane

007-5466-001 3

1: Introduction

Node Board Features

At the heart of the SGI Altix XE320 lies two dual-processor node boards, which are based on the

Intel 5400P chipset (refer to

Note: The features on each node board are doubled for the server (refer to Appendix D, “System

Specifications”).

Processors

Each node board supports two Intel Xeon dual- or quad-core processors.

Memory

Each node board has eight 240-pin DIMM sockets (refer to Figure 1-2) that can support up to 64

GB of ECC fully buffered DIMM (FBDIMM) DDR2-800/667 SDRAM. Memory can be installed

in both interleaved (dual-channel) and non-interleaved (single-channel) configurations. All

memory modules used to populate the system should be the same size, type, and speed.

Figure 1-3). Below are the main features of the node board.

The node board memory controller supports memory mirroring to prevent data loss in case of

DIMM failure. The system maintains two copies of all the data in memory; therefore, a mirrored

system uses only half of the installed DIMMs. If a DIMM fails, the system recovers the second

copy of data from the mirrored DIMM in the opposite channel. If both the primary and the

mirrored copy of the data become corrupt, the system will fail. Configure memory mirroring with

the Memory Branch Mode BIOS setting (refer to

“Memory Branch Mode” on page 114.

Serial ATA (SATA)

The southbridge (ESB2 chip) of the 5400P chipset includes a SATA controller for 3-Gb/s SATA

drives. The hot-swappable SATA drives are connected to a backplane (refer to

provides power, bus termination, and configuration settings.

4 007-5466-001

Figure 1-2) that

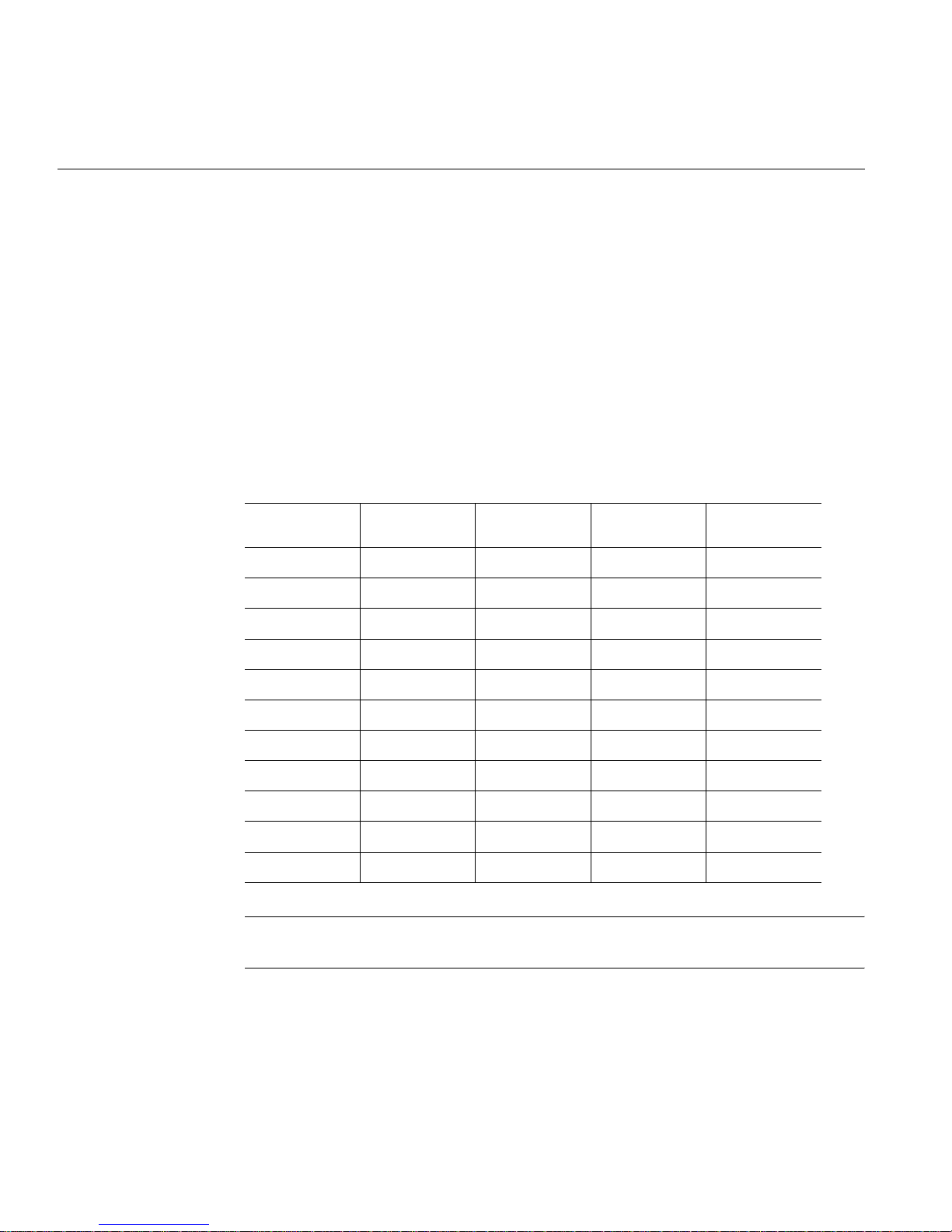

Node Board Features

VGA

CONN

MT25204

VGA

ES1000

PCI-EXP x16

PCI-E SLOT

PCI-EXP x8

PCI 33MHz

PROCESSOR#2

1333/1600

MT/S

KUMERAN

Intel 5400

MCH

PCIE x4

ESB2

PROCESSOR#1

1333/1600

MT/S

FBD CHNL0

FBD CHNL1

FBD CHNL2

FBD CHNL3

PCIE x4

LPC

3.0 Gb/S

USB 2.0

FBD DIMM

SATA

USB

FBD DIMM

FBD DIMM

FBD DIMM

RJ45

RJ45

Figure 1-3 Node Board Block Diagram

007-5466-001 5

GB LAN

GILGAL

SIO

W83627

HF

MS

KB

FWH

COM2

1: Introduction

Serial Attached SCSI (SAS) and RAID Support

Appendix F, “Upgrading for SAS/SATA RAID Support,” describes how to upgrade your server

to use SAS hard drives as well as SATA hard drives by using model LSISAS3444E HBAs. This

HBA option also can provide support for RAID 0, RAID 1, or JBOD.

PCIe Expansion Slots

Each node board supports one PCI-Express 2.0 x16 slot. Two PCIe slots are available in the server

chassis.

Ethernet Ports

T wo Intel 82563EB network controllers are integrated into the 5400P chipset on each of the node

boards to support a total of four Gigabit LAN ports (100/1000

output).

Base-T/1000 BaseTX, RJ45

Onboard Controllers/Ports

Each node board I/O panel ports includes one COM port, a VGA port, two USB ports, two Gigabit

Ethernet LAN (NIC) ports, and one optional InfiniBand

®

port.

ATI Graphics Controller

The SGI Altix XE320 features an integrated ATI video controller based on the ES1000 graphics

chip. The ES1000 was designed specifically for servers, featuring low-power consumption, high

reliability, and superior longevity.

Other Features

Other onboard features that enable reliable service include voltage monitors, a chassis intrusion

header, auto-switching voltage regulators, chassis and CPU overheat sensors, virus protection,

and BIOS rescue.

6 007-5466-001

Server Chassis Features

This section describes the main features of the SGI Altix XE320 1U chassis. Refer to Chapter 5,

“Advanced Chassis Setup.” for more detailed information.

Note: For more detail on the chassis, refer to Chapter 5, “Advanced Chassis Setup.”

System Power

A single power supply (refer to Figure 1-2) provides the power for both node boards. Each node

board however, can be shut down independently of the other with the power button on its own

control panel.

Although they share a common power supply, the I2C signals used for power supply monitoring

are received by the node board 1 only. (When viewed from the front of the chassis, the node board

on the left is node board 1 and the node board on the right is the node board 2.)

Server Chassis Features

SATA/SAS Backplane/Drives

As a system, the SGI Altix XE320 supports four SA TA/SAS disk drives (refer to Figure 1-2). The

SA TA/SAS backplane is divided into two sections. A single power connector is used for the entire

backplane, but other functions, such as circuit board over-temperature monitoring, apply to both

sections. Each pair of disk drives is logically connected to its own node board. Consequently, the

RAID configuration is limited to a two-drive scheme (RAID 1 or RAID 0). The RAID

configuration cannot be set up across all four drives.

Control Panel

The chassis features two independent control panels associated with each node board in the

chassis. Each control panel has LEDs to indicate power on, network activity, hard disk drive

activity, and system overheat conditions. Each control panel also includes a main power button

and a system reset button.

007-5466-001 7

Rear I/O Panel

The I/O panel provides slots for two low-profile PCI-Express 2.0 x16 expansion cards, two COM

ports, four USB ports, two VGA ports, and four Gb Ethernet ports. The server also provides two

InfiniBand ports.

Cooling System

The server chassis has an innovative cooling design that features two sets of triple (for a total of

six) 4-cm high-performance fans. A fan speed control setting in BIOS allows fan speed to be

determined by system temperature.

System Security and Pre-Installed Linux Operating Systems

If your server was shipped with a pre-installed Linux® operating system, the password for root

was set to sgisgi for your convenience. You should change this password at your earliest

opportunity. Consult your Linux documentation for the procedure.

Chapter 2

2. Server Installation

This chapter provides a quick setup checklist to get the SGI Altix XE320 operational.

Unpack the System

Inspect the shipping container that the SGI Altix XE320 was shipped in and note if it was damaged

in any way. If the server shows damage, file a damage claim with the carrier who delivered it.

Decide on a suitable location for the rack that supports the weight, power requirements, and

environmental requirements of the SGI Altix XE320 server. It should be situated in a clean,

dust-free environment that is well ventilated. Avoid areas where heat, electrical noise, and

electromagnetic fields are generated. Place the server rack near a grounded power outlet. Refer to

“Warnings and Precautions” on page 10.

Prepare for Setup

The shipping container should include two sets of rail assemblies, two rail mounting brackets and

the mounting screws that you will use to install the system into a rack.

Read this section in its entirety before you begin the installation procedure.

Choose a Setup Location

• Leave enough clearance in front of the rack to enable you to open the front door completely,

approximately 25 in. (65 cm).

• Leave approximately 30 in. (76 cm) of clearance in the back of the rack to allow for

sufficient airflow and ease in servicing.

007-5466-001 9

2: Server Installation

Warnings and Precautions

Rack Precautions

Warning: The SGI Altix XE320 server weighs 40 lb (18 kg). Always use proper lifting

techniques when your move the server . Always get the assistance of another qualified person

when you install the sever in a location above your shoulders. Failure to do so may r esult in

serious personal injury or damage to the equipment.

Warning: Extend the leveling jacks on the bottom of the rack to the floor with the full

weight of the rack resting on them. Failure to do so can result in serious injury or death.

Warning: Attach stabilizers to the rack in single rack installations. Failure to do so can

result in serious injury or death.

W arning: Couple racks together in multiple rack installations. Failure to do so can result

in serious injury or death.

W arning: Be sure the rack is stable befor e extending a component fr om the rack. Failur e

to do so can result in serious injury or death.

Warning: Extend only one component at a time. Extending two or more components

simultaneously may cause the rack to tip over and result in serious injury or death.

10 007-5466-001

Server Precautions

• Review the electrical and general safety precautions in Appendix E, “System Safety.”

• Determine the placement of each component in the rack before you install the rails.

• Install the heaviest server components in the bottom of the rack first, and then work up.

• Use a regulating uninterruptible power supply (UPS) to protect the server from power surges

and voltage spikes and to keep your system operating in case of a power failure.

• Allow the hot plug SATA drives and power supply modules to cool before touching them.

• Always keep the rack’s front door and all panels and components on the servers closed when

not servicing to maintain proper cooling.

Rack Mounting Considerations

Ambient Operating Temperature

Rack Mounting Considerations

Reduced Airflow

Mechanical Loading

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of the rack

environment may be greater than the ambient temperature of the room. Therefore, consideration

should be given to installing the equipment in an environment compatible with the manufacturer’s

maximum rated ambient temperature (

Specifications” for information.

Equipment should be mounted into a rack so that the amount of airflow required for safe operation

is not compromised.

Equipment should be mounted into a rack so that a hazardous condition does not arise due to

uneven mechanical loading.

35º C or 95º F). Refer to Appendix D, “System

007-5466-001 11

2: Server Installation

Circuit Overloading

Consideration should be given to the connection of the equipment to the power supply circuitry

and the effect that any possible overloading of circuits might have on overcurrent protection and

power supply wiring. Appropriate consideration of equipment nameplat e ratings should be used

when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself should be

grounded. Particular attention should be given to power supply connections other than the direct

connections to the branch circuit (i.e. the use of power strips, etc.).

Install the System into a Rack

This section provides information on installing the SGI Altix XE320 into a rack unit with the rack

rails provided. If the system has already been mounted into a rack, refer to

Setup” on page 21. There are a variety of rack units on the market, which may mean the assembly

procedure will differ slightly . You should also refer to the installation instructions that came with

the rack unit you are using.

“Check the Node Board

Identify the Sections of the Rack Rails

You should have received two rack rail assemblies in the rack mounting kit. Each assembly

consists of two sections: an inner fixed chassis rail that secures directly to the server chassis and

an outer fixed rack rail that secures directly to the rack itself (refer to

short brackets to be used on the front side of the outer rails are also included.

12 007-5466-001

Figure 2-1). Two pairs of

Install the Rails

I

Install the System into a Rack

Perform the following procedure to install the inner rails:

1. If the left and right side inner rails (refer to Figure 2-1) have not been pre-attached to the

chassis, attach them.

Outer rail (attaches to rack)

nner rail (pre-installed)

Locking tab

Figure 2-1 Identify Sections of the Rack Rails (right side rail shown)

2. Assemble one of the rails that attaches to the rack. (Refer to Figure 2-2.)

Figure 2-2 Rail Assembly

007-5466-001 13

2: Server Installation

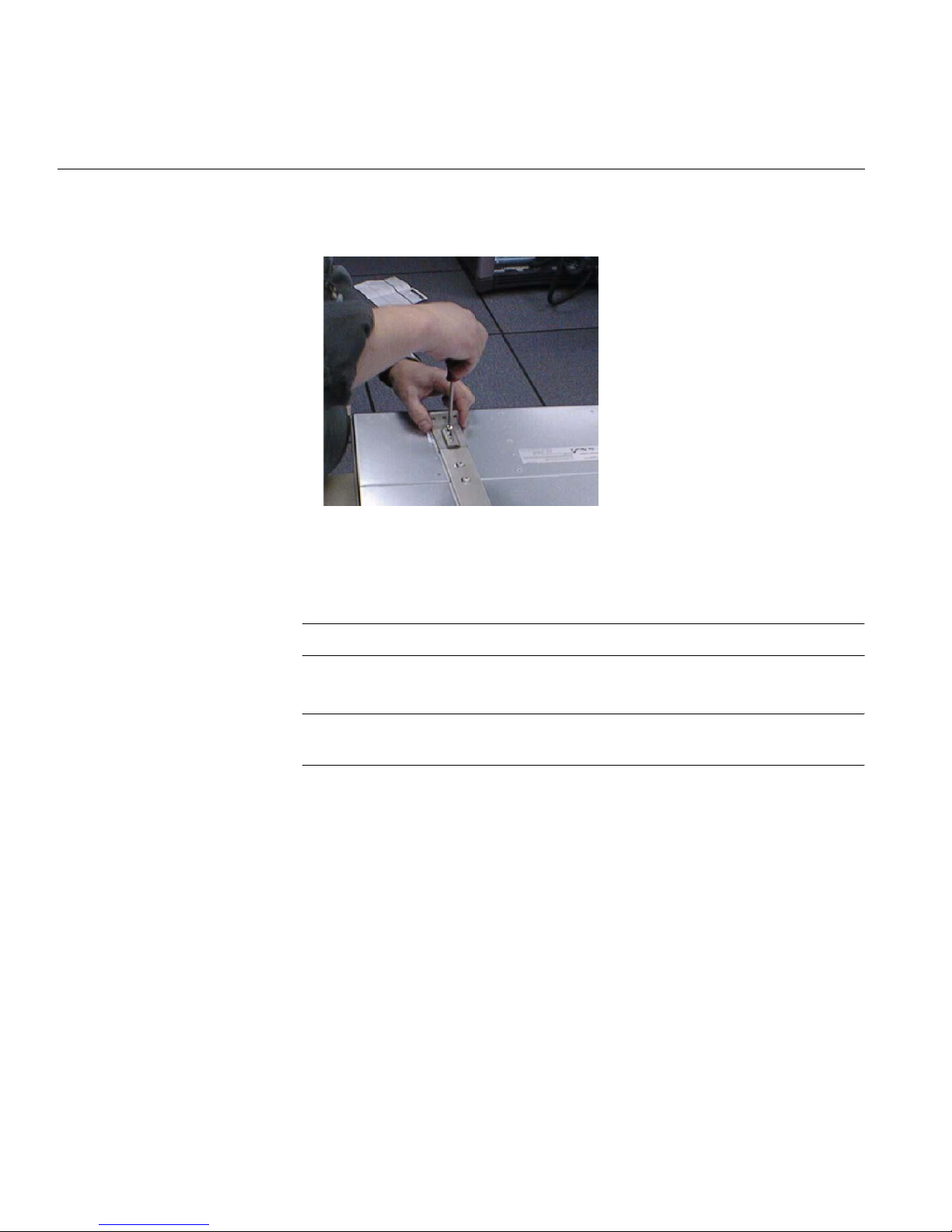

3. Install two screws to attach the inner bracket to the front of the rail. (Refer to Figure 2-3.)

Figure 2-3 Attaching the Inner Bracket

4. Attach the rail to the front of the rack chassis (refer to Figure 2-4):

a. Slide the front brackets over the appropriate holes in the rack frame.

Note: The frame of the rack fits between the two brackets on front of the rail.

b. Install the upper and lower screws to attach the rail to the rack.

Note: The middle hole remains empty. You will install a screw into this hole to secure

the server to the front of the rack.

14 007-5466-001

The sheet metal

from the rack

frame fits

between the two

brackets on the

front of the rail.

Install the System into a Rack

Attach these two screws.

Figure 2-4 Attaching the Rail to the Front of the Rack (View from Front of Rack)

5. Attach the rail to the rear of the chassis (refer to Figure 2-5):

a. Slide two clips (rail nu ts) over the appropriate holes in the rack frame.

b. Position the rail over the rack chassis (in front of the rail clips/nuts) and align to the

proper position.

c. Install two screws through the holes in the rail. The screws fasten into the two rail

clips/nuts that you previously installed.

6. Repeat Steps 1 through 5 to install the other rail in the rack.

Slide two rail

clips/nuts over

the rack frame.

Then, position

the rail and

attach it with two

screws.

The screws

fasten into the

rail clips/nuts.

Figure 2-5 Attaching the Rail to the Rear of the Rack (View from Rear of Rack)

007-5466-001 15

2: Server Installation

Locking Tabs

Both chassis rails have a locking tab (refer to Figure 2-1), which serves two functions: the first is

to lock the server into place when it is installed in the rack; the second is to lock the server in place

when it is fully extended from the rack. The locking tab prevents the server from being removed

from the rack accidentally when you pull it out for service.

Install the Server in a Rack

Warning: The SGI Altix XE320 server weighs 40 lb (18 kg). Always use proper lifting

techniques when your move the server . Always get the assistance of another qualified person

when you install the sever in a location above your shoulders. Failure to do so may r esult in

serious personal injury or damage to the equipment.

You should now have rails attached to both the server chassis and the rack unit. The next step is

to install the server into the rack (refer to

1. Line up the rear of the chassis rails with the front of the rack rails.

Figure 2-6).

2. Slide the server chassis rails into the rack rails, keeping the pressure even on both sides (you

may have to depress the locking tabs when inserting).

3. When the server has been pushed completely into the rack, you should hear the locking tabs

“click.”

4. Install and tighten two screws to secure the server to the rack.

16 007-5466-001

Install the System into a Rack

Figure 2-6 Install the Server in a Rack

007-5466-001 17

2: Server Installation

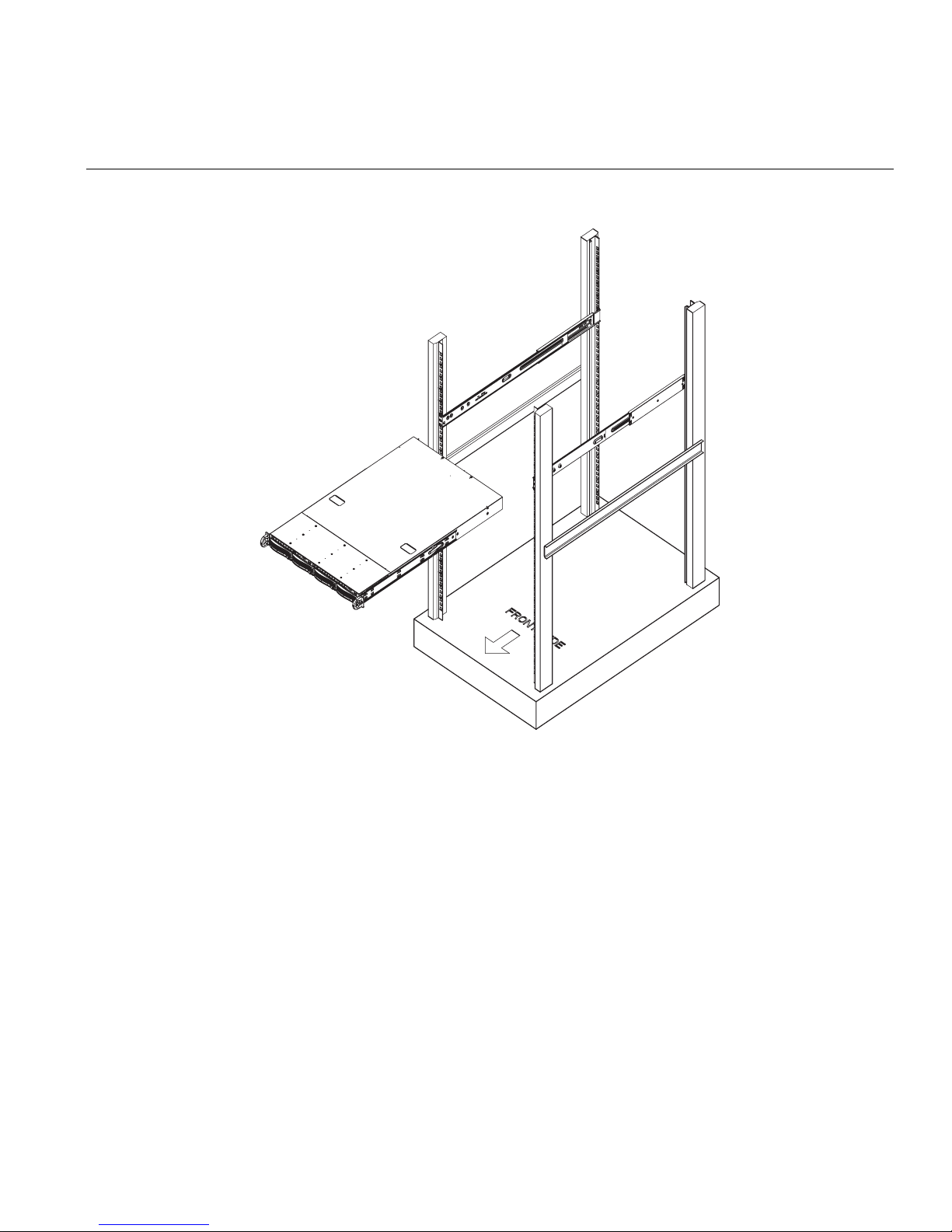

Install the Server in a Third-party Rack

Warning: The SGI Altix XE320 server weighs 40 lb (18 kg). Always use proper lifting

techniques when your move the server . Always get the assistance of another qualified person

when you install the sever in a location above your shoulders. Failure to do so may r esult in

serious personal injury or damage to the equipment.

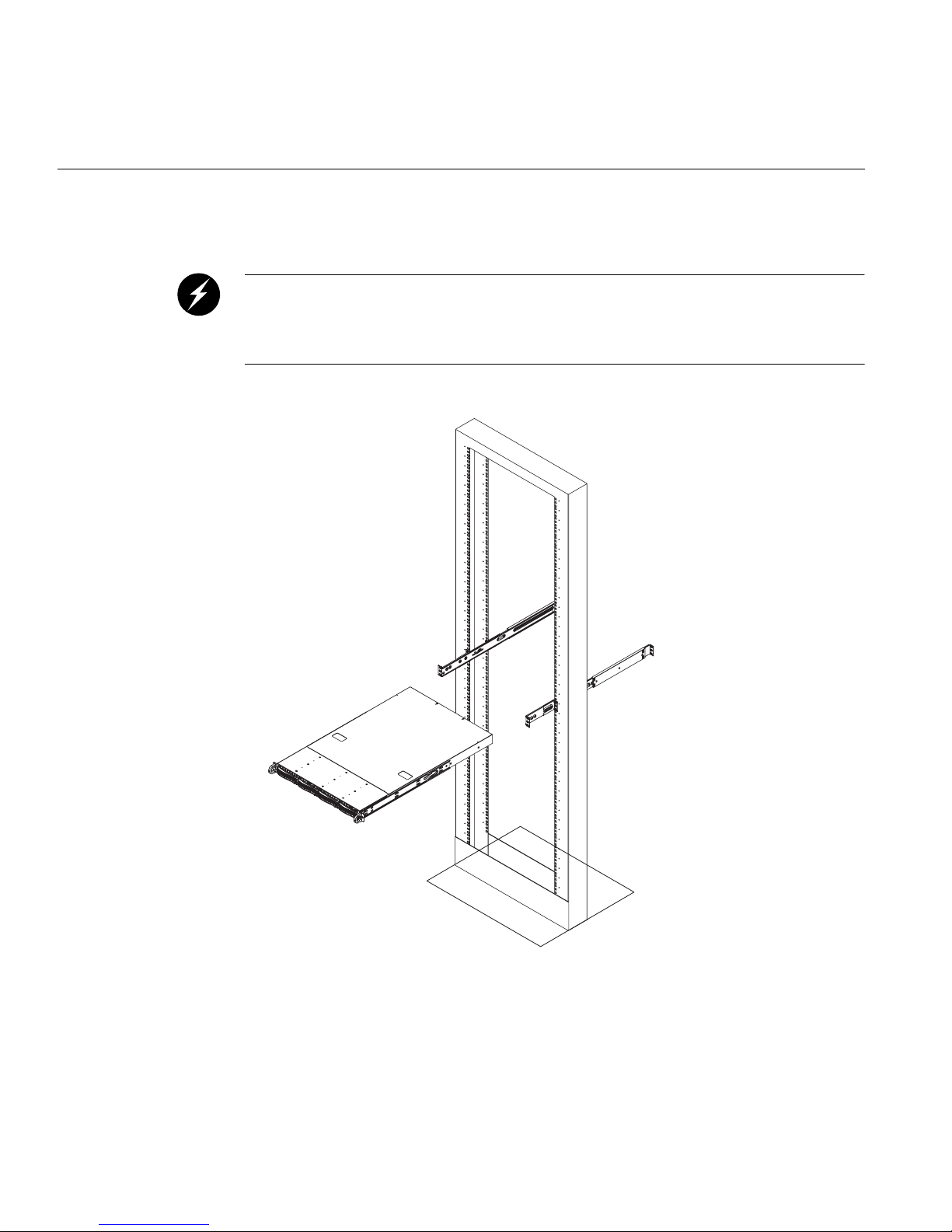

1. Slide the server onto the outer rack rails (refer to Figure 2-7).

Figure 2-7 Install the Server in a Third-party Rack (1)

18 007-5466-001

Install the System into a Rack

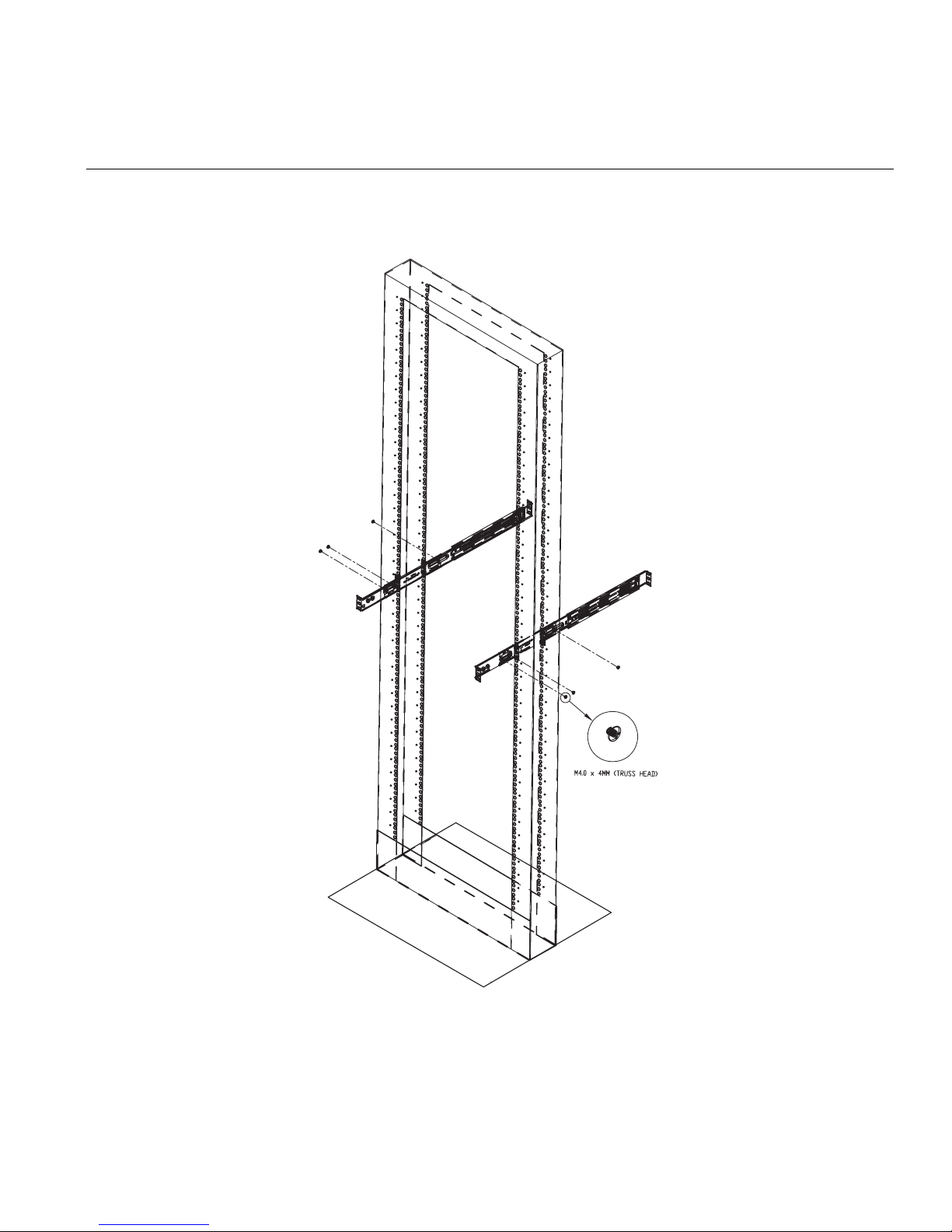

2. Using three screws each, attach the outer rail assembly onto the right angle brackets.

Figure 2-8 Install the Server in a Third-party Rack (2)

007-5466-001 19

2: Server Installation

3. Install the right angle brackets onto the two-post rack, using two screws on each end.

Figure 2-9 Install the Server in a Third-party Rack (3)

20 007-5466-001

Check the Node Board Setup

Use the following sections to open the top cover and check that each node board is properly

installed and all the connections have been made.

Access the Inside of the Chassis

Refer to Figure 2-10 when using the following procedure.

1. Remove the screws that secure the system to the rack.

2. Grasp the two handles on either side and pull the system straight out until it locks (you will

hear a “click”).

3. Press the locking tabs to release the system from the rack and place it on a stable ESD-safe

work surface.

4. Remove the rack rails from the chassis so that you can gain access to the top cover screws.

5. Remove the four screws (two on the sides and two on the top) that secure the top cover to the

chassis.

Check the Node Board Setup

6. Place your thumbs in the two rectangular recesses and push the cover away from you

(toward the rear of the chassis) until it stops.

7. Lift the top cover from the chassis to gain access to the inside of the server.

Note: T o remove the system from the rack completely , depress the locking tabs in the chassis

rails (push the right-side tab down and the left-side tab up) to continue to pull the system out

past the locked position.

007-5466-001 21

2: Server Installation

2

1

2

1

Figure 2-10 Remove the Top Cover

Check the CPUs (processors)

You may have one or two processors installed on each node board. Each processor needs its own

heatsink. Refer to

Chapter 4, “Advanced Node Board Setup,” for instructions on how to install

processors and heatsinks.

Check the System Memory

Yo ur server system is shipped with system memory installed. Make sure all DIMMs are fully

seated in their slots. For details on adding system memory, refer to

22 007-5466-001

Chapter 4.

Install Expansion PCIe Cards

Y ou can install two expansion PCIe cards in the system. Refer to Chapter 4 for details on installing

PCIe expansion cards.

Check all Cable Connections and Airflow

Make sure all power and data cables are properly connected and not blocking the chassis airflow.

Refer to

Chapter 4 for details on cable connections.

Check the Drive Bay Setup

Next, you should check to make sure the SA TA/SAS drives and SA TA/SAS backplane have been

properly installed and all connections have been made.

Check the SATA/SAS Drives

Check the Node Board Setup

Depending upon your system configuration, your system may have one or more drives installed.

For detailed information about how to install SATA/SAS drives, refer to

Chassis Setup.”

Check the Airflow

Airflow is provided by six sets of 4-cm fans (each set of fans consists of two fans that are mounted

back to back). The system component layout was carefully designed to direct sufficient airflow to

cool the components that generate the most heat. Note that all power and data cables have been

routed in such a way that they do not block the airflow generated by the fans. An air shroud is also

installed to focus the airflow to areas where the most heat is generated.

Supply Power to the System

If necessary , install the system in a rack (refer to “Install the System into a Rack” on page 12), and

connect the power cord from the power supply module into a power strip or power distribution

unit (PDU). The PDU offers protection from electrical noise and power surges. SGI also

recommends that you use an uninterruptible power supply (UPS) source.

Chapter 5, “Advanced

007-5466-001 23

Chapter 3

3. Controls and Indicators

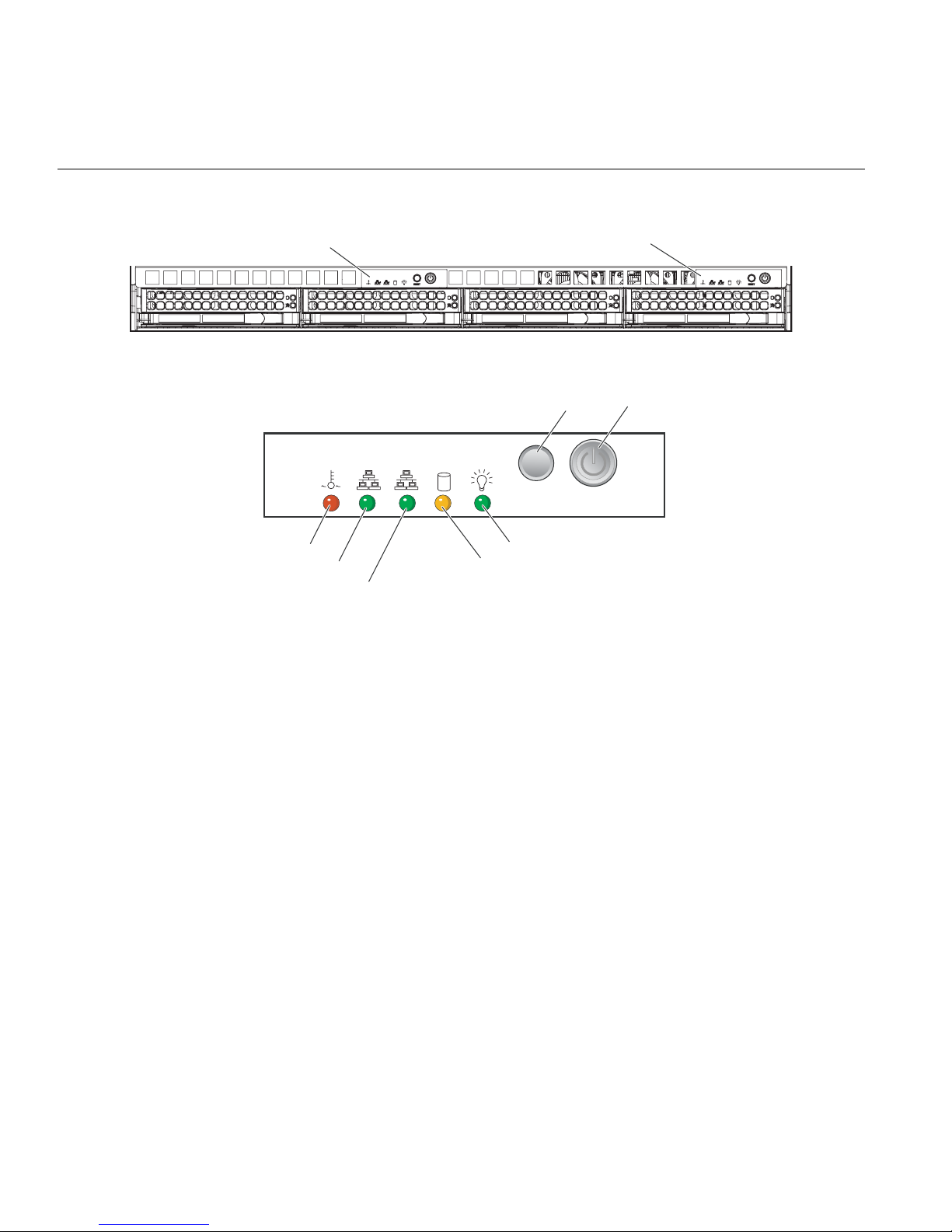

This chapter describes the functions of the controls and indicators (light emitting diodes, or LEDs)

on the SGI Altix XE320 server. There are several LEDs on the two control panels (refer to

Figure 3-1) as well as others on the drive carriers that inform you of the overall system status, as

well as the activity and status of specific components. There are also two switches (buttons) on

each control panel.

Note: The server has two control panels, one for each node board installed in the system. This

allows each node board to be controlled independently of the other.

Controls

There are two push-button switches located on each control panel: a reset switch and a power

on/off switch (refer to

• RESET: Press the reset button to reboot only the node board controlled by that control panel.

• POWER: Press power button to apply or remove power only to the node board controlled by

that control panel. Pressing this button removes the main power but keeps standby power

supplied to the node board.

Figure 3-1).

007-5466-001 25

3: Controls and Indicators

Indicators

Control panel: Node board 1

Overheat/Fan fail LED

NIC 2 activity LED

NIC 1 activity LED

Figure 3-1 Front Panel Controls and Indicators

21

Control panel: Node board 2

PowerRESET

RESET

Power LED

HDD activity LED

Each control panel is located on the front of the SGI Altix XE320 system and has five LED

indicators (refer to

Figure 3-1). Each LED provides you with critical information related to its own

specific node board.

The following items explain the node board LED indicators and the corrective action that you

should take when the LED illuminates:

• Overheat/Fan fail: When the Overheat/Fan Fail LED flashes, it indicates that a fan has

failed. When the Overheat/Fan Fail LED is on continuously, it indicates that an overheat

condition has occurred, which may be caused by cables obstructing the airflow in the system

or the ambient room temperature being too warm.

26 007-5466-001

• NIC2: Indicates network activity on LAN2 when flashing.

• NIC1: Indicates network activity on LAN1 when flashing.

• HDD: Channel activity for the hard disk drive (HDD). This light indicates drive activity on

• Power: Indicates power is being supplied to the system’s power supply unit. This LED

Drive Carrier Indicators

Indicators

Note: Check the routing of the cables and make sure all fans are present and operating

normally. Check that the chassis covers are installed properly.

Verify that the processor heatsinks are installed properly (refer to Chapter 4). Verify that the

overhead/fan fail LED remains flashing. It will remain flashing as long as the overheated or

fan fail condition exists.

the node board when flashing.

should normally be illuminated when the system is operating.

Each drive carrier has two LED indicators.

• Green

• When illuminated, the green LED on the front of the drive carrier indicates drive

activity. A connection to the SATA backplane enables this LED to blink on and off

when that particular drive is being accessed.

• Red

• The red LED indicates two states. When blinking, it indicates the drive is rebuilding.

When solid, it indicates a drive failure.

• If a drive fails, you should be notified by your system management software. Refer to

Chapter 5 for instructions about how to replace a failed disk drive.

007-5466-001 27

Chapter 4

4. Advanced Node Board Setup

This chapter includes procedures to install a node board into the SGI Altix XE320 chassis, connect

the data and power cables, and install expansion cards. All node board jumpers and connections

are also discussed.

A layout and quick reference chart is included in this chapter for your reference.

Note: Some software products are protected with software license keys derived fr om the

Access Control (MAC) ethernet address. When you replace a node board, the

Media

MAC ethernet address changes. If you are using such a product, you must request a new

license key after replacing the node board. Contact your local customer support office:

http://www.sgi.com/support/supportcenters.html

!

Caution: Install the chassis cover after you have completed accessing the components inside the

server to maintain proper airflow and cooling for the system.

Handling the Node Board

!

007-5466-001 29

Caution: Electrostatic discharge (ESD) can damage electrostatic-sensitive devices inside the SGI

Altix XE320 server. Use the ESD precautions described below when you handle printed circuit

boards or other components in the system. To prevent the node board from bending, keep one hand

under the center of the board to support it when handling it. The following measures are generally

sufficient to protect your equipment from electric static discharge.

4: Advanced Node Board Setup

ESD Precautions

Unpacking

• Use a grounded wrist strap designed to prevent electrostatic discharge.

• Touch a grounded metal object before removing any board from its antistatic bag.

• Handle each printed circuit board (PCB) by the edges; do not touch the components,

peripheral chips, memory modules, or gold contacts on the PCB.

• When handling chips or modules, avoid touching the pins.

• Place the node board, expansion PCI cards, or other boards and components into antistatic

bags when not in use.

• Make sure your computer chassis provides a conductive path between the power supply, the

case, the mounting fasteners, and the node board to chassis ground.

!

Caution: The node board is shipped in antistatic packaging to avoid electrostatic discharge

damage. Be sure to use ESD precautions when you unpack replacement components for the SGI

Altix XE320 server. Failure to do so can result in damage to the equipment.

30 007-5466-001

Node Board Installation

This section explains how to mount the node board into the SGI Altix XE320 chassis. To remove

the node board, follow this procedure in reverse order.

1. Access the inside of the system (refer to Figure 4-1):

a. Remove the rack rails so that you can gain access to the top cover screws.

b. The top cover of the chassis is secured with four screws: two at the top rear of the cover

Note: If already installed in a rack, you must first release the retention screws that secure the

unit to the rack. Then grasp the two handles on either side and pull the unit straight out until

the rails lock into place.)

Node Board Installation

and one on each side lip, also near the back. Remove all four screws, then place both

thumbs in the indentations and push the cover back until it slides off. You can then lift

the top cover from the chassis to gain full access to the inside of the server.

2

1

Figure 4-1 Remove the Top Cover

007-5466-001 31

2

1

4: Advanced Node Board Setup

2. Check compatibility of node board ports and I/O shield:

Note: Make sure that the I/O ports on the node boards align properly with their respective

holes in the I/O shield on the back of the SGI Altix XE320 chassis.

3. Remove the PCI card riser card and bracket.

4. Mount the node board onto the node board tray:

a. Carefully mount the node boards by aligning the board holes with the raised metal

standoffs that are visible in the chassis (refer to

Figure 4-2).

b. Install the six screws into the mounting holes on the node board that line up with the

5. Install the PCI riser card and bracket.

Connect the Power Cables

A node board has two 20-pin ATX power supply connectors (refer to Figure 4-2) that can be

connected to the AT X power supply. Only one of these connectors is used when the node board

is installed in the chassis. Each node board also provide a 4-pin auxiliary power connector used to

connect disk drive power to the SATA backplane.

For the node board 1 (installed on the left side of the chassis):

1. Connect the power cable to the primary ATX power header on the right side of the nod e

board.

2. Connect the auxiliary power cable to the power connector on left side of the SATA

backplane.

!

standoffs and tighten until snug. The metal screws provide an electrical contact to the

node board ground to provide a continuous ground for the system.

Caution: Do not overtighten the screws in step b. Overtightening the screws

will damage the equipment.

32 007-5466-001

Node Board Installation

for SATA backplane

N

a

f

rs

For node board 2 (installed on the right side of the chassis):

1. Connect the power cable to the secondary ATX power header on the left side of the node

board.

2. Connect the auxiliary power cable to the power connector on right side of the SATA

backplane.

5 screws

Node board 1

power connector

ode board 1

uxiliary power connector

or SATA backplane

SATA connecto

Fan connectors

2

1

Node board 2

2

1

Node board 2

auxiliary power connector

power connector

Figure 4-2 Node Board Installation

007-5466-001 33

4: Advanced Node Board Setup

Connecting the Control Panel

The JF1 connector (refer to Figure 4-3) contains header pins for various front control panel

connectors, switches, and LED indicators.

All of the JF1 connector wires are bundled into a single ribbon cable to simplify this connection.

Make sure the red wire plugs into pin 1 as marked on the board. The other end connects to the

control panel PCB, located just behind the system status LEDs on the chassis.

20 19

Ground

x (Key)

Power On LED

IDE/SATA LED

NIC1 LED

NIC2 LED

OH/Fan Fail LED

Reserved

Ground

Ground

2 1

Figure 4-3 Control Panel Connector (JF1) Pin Definitions

NMI

x (Key)

Vcc 5V Stby

Vcc 3V

Vcc 3V Stby

Vcc 3V Stby

Vcc 3V

Reserved

Reset (Button)

Power (Button)

34 007-5466-001

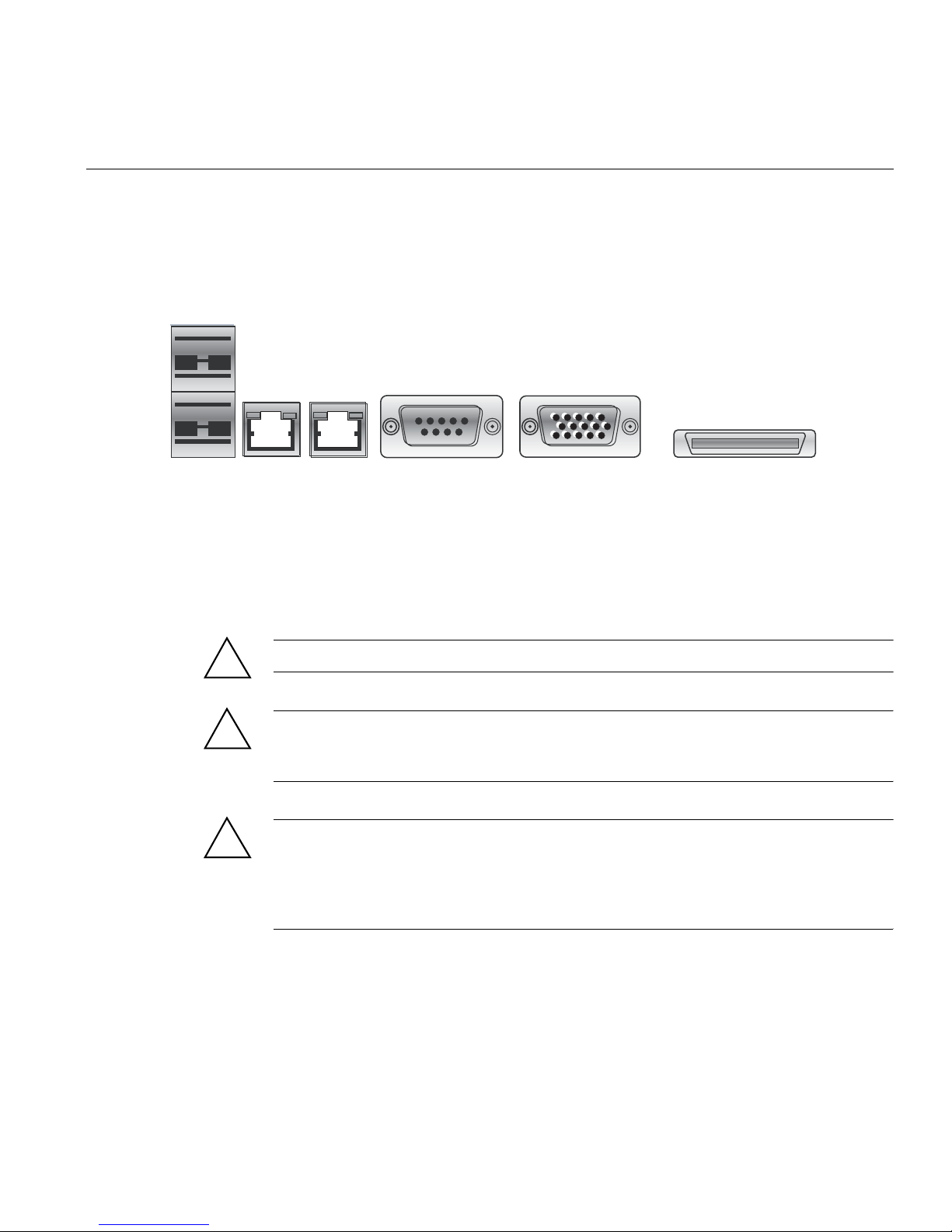

I/O Ports

U

I/O Ports

The I/O ports are color coded. Figure 4-4 shows the color and location of the various I/O ports on

the I/O panel.

SB 0/1 Ports

LAN 1 LAN 2

Figure 4-4 I/O Port Locations

COM2 Port

(Turquiose)

VGA Port

(Blue)

Processor and Heatsink Installation and Removal

!

Caution: When handling the processor, avoid placing direct pressure on the label area of the fan.

!

!

Caution: Do not place the node board on a conductive surface. A conductive surface can damage

the BIOS battery and prevent the system from booting. Always place the node board on an

ESD-safe worksurface.

Caution: Always disconnect the power before adding, removing or changing any hardware

components. Make sure that you install the processor into the CPU socket before you install the

heatsink and fan. The node board can support either one or two processors. If installing one

processor only, install it into CPU socket 2. The DIMMs run significantly cooler using socket 2

rather than socket 1.

InfiniBand Port

007-5466-001 35

4: Advanced Node Board Setup

Install a Processor

Note: SGI’s replacement Xeon CPU package contains a heatsink assembly. Make sure that the

black pick-and-place (PnP) cap is in place; otherwise, contact the SGI immediately.

Important!: When you install only a single CPU on each node board, install the single CPU in

socket 2 (refer to

Figure 4-11 on page 58) on both node boards. Install the air shroud in accordance

with “Install or Remove the Air Shroud” on page 57.

Note: A black pick-and-place (PnP) cap is attached to the load plate to protect the CPU socket.

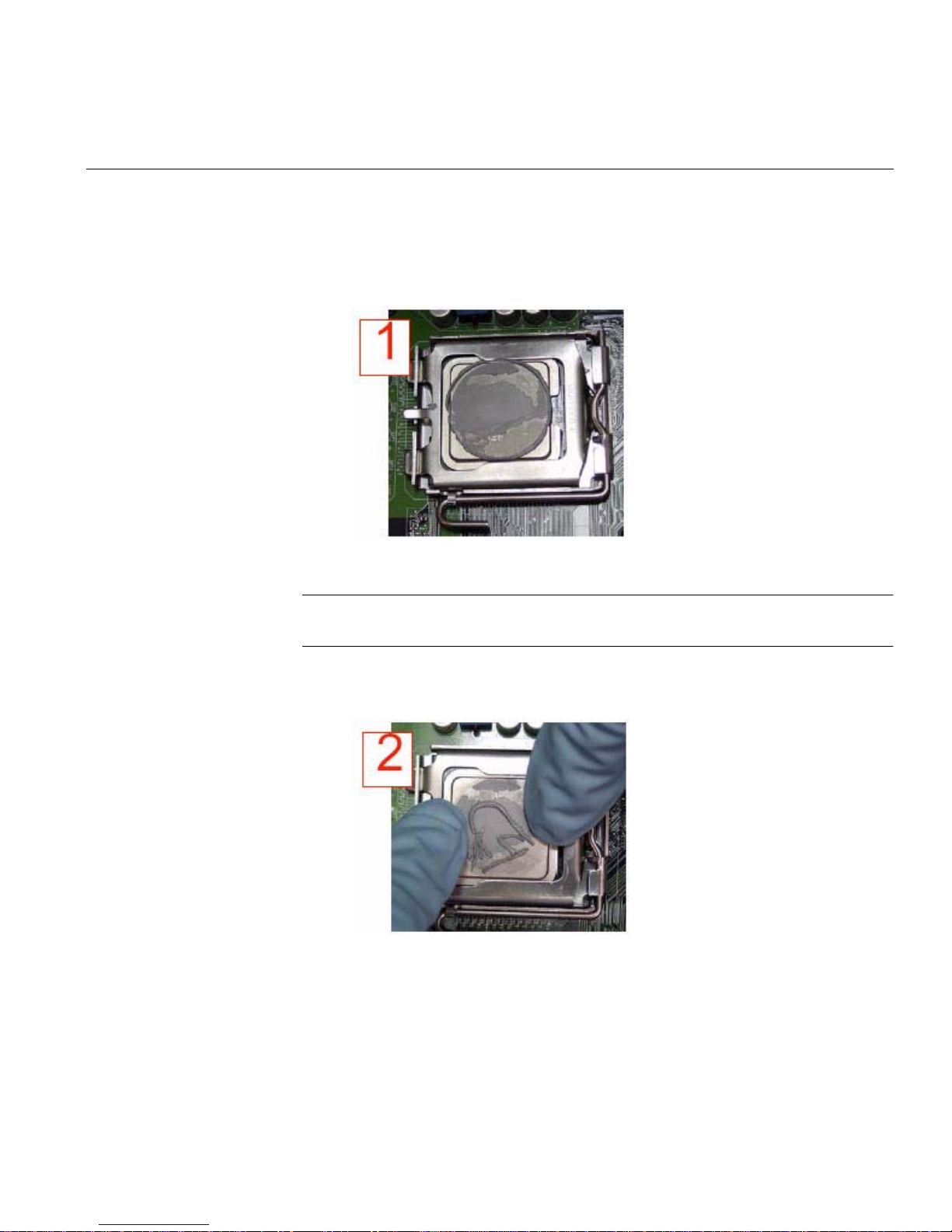

1. Press the load lever down and away from the retention clasp to release the load plate from its

locked position.

Load Lever

PnP cap

36 007-5466-001

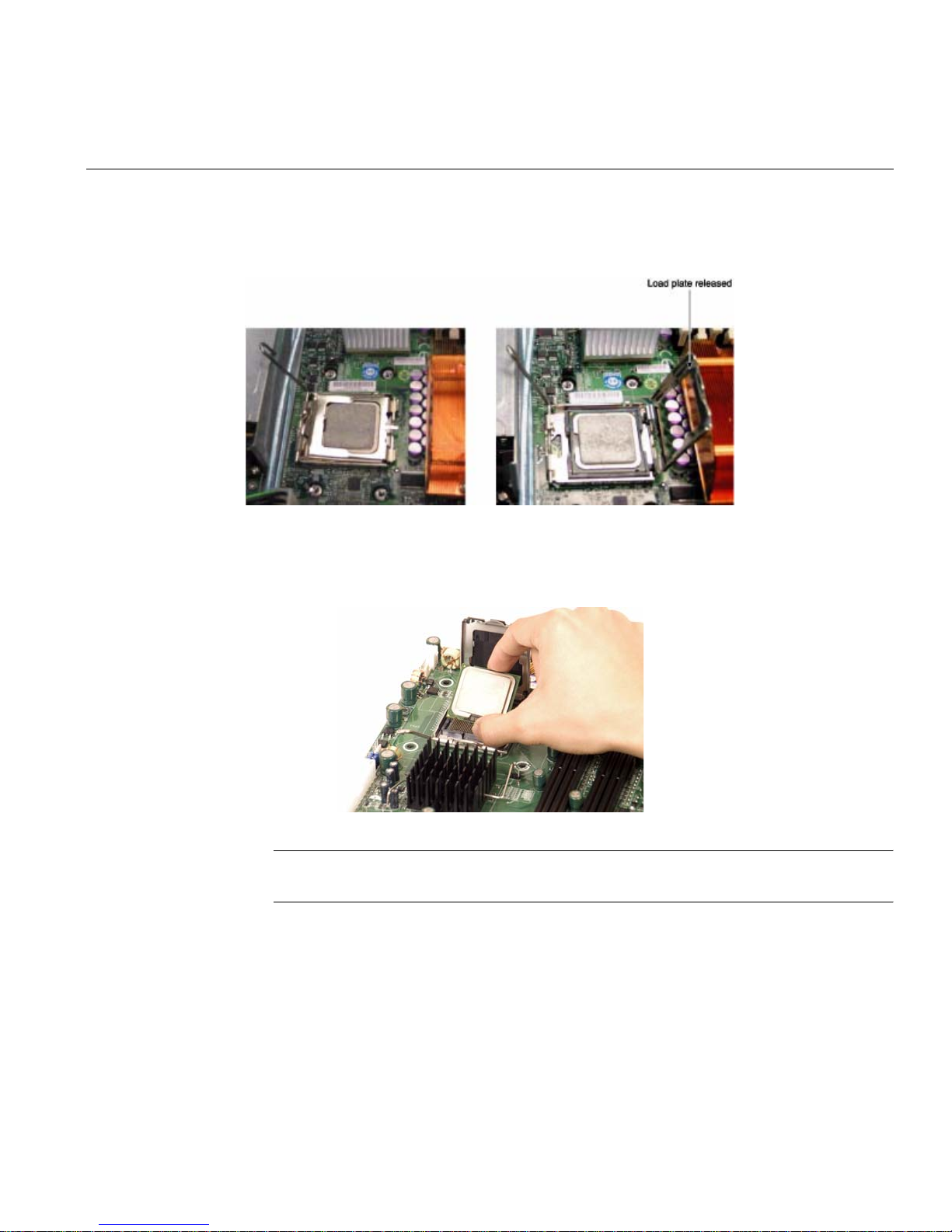

2. Gently lift the load lever to open the load plate.

Load plate

released

Processor and Heatsink Installation and Removal

3. Use your thumb and your index finger to hold the CPU at opposite sides.

007-5466-001 37

4: Advanced Node Board Setup

4. Align pin 1 of the CPU (the corner marked with a triangle) with the notched corner of the

CPU socket.

Caution: In step 5, do not drop the CPU on the socket. Do not move the CPU

!

horizontally or vertically, and do not rub the CPU against any surface or any of the