Usermanual Motors 902x_903x Page 1

Motor Silent Gliss 9020, 9021, 9022, 9023

Motor Silent Gliss 9030, 9031, 9032, 9033

User Manual March 2008

Page 2

Usermanual Motors 902x_903x

Copyright April 2007 by Silent Gliss International Ltd., 3073 Gümligen/Berne (Switzerland)

Realised by Silent Gliss International, Group Headquarters

Printed in Switzerland

Usermanual Motors 902x_903x Page 3

1

2

3

4

5

6

7

8

9

10

4

4

5

5

6

11

17

18

20

20

Introduction and Product Overview

Intended Application

Safety Instructions

Technical Specications

Connection and Operating Equipment

Programming and operating of SG 9020/9021

and SG 9030/9031 motors

Programming and operating of SG 9022/9023

and SG 9032/9033

Group Control

Troubleshooting

Declaration of Conformity

Table of Contents

Please read chapters „Intended application“ and „Safety Instructions“

before installing or connecting. Non-observance as well as opening

and manipulation of the motor will result in voiding of the Silent Gliss

liability and warranty.

Page 4

Usermanual Motors 902x_903x

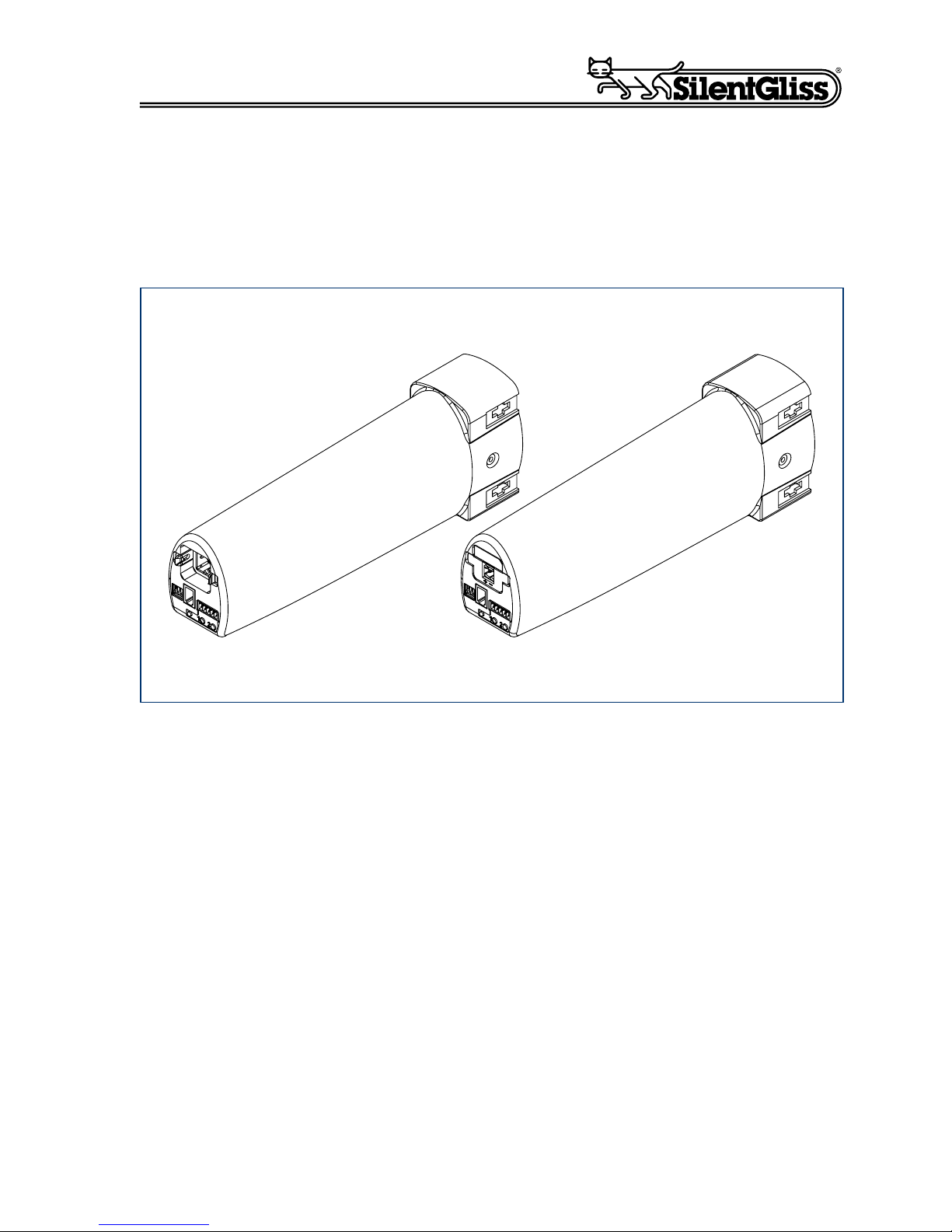

1 Introduction and Product Overview

This User Manual describes the setting up and programming of the

different motor types, which are used in connection with the Silent

Gliss Electrical Curtain Track System SG 5400 and SG 5420 as well as

with the Radio Remote Control System SG 9940. Please refer to the

separate tting instructions and wiring diagrams for the installation of

the Systems SG 5400 and 5420.

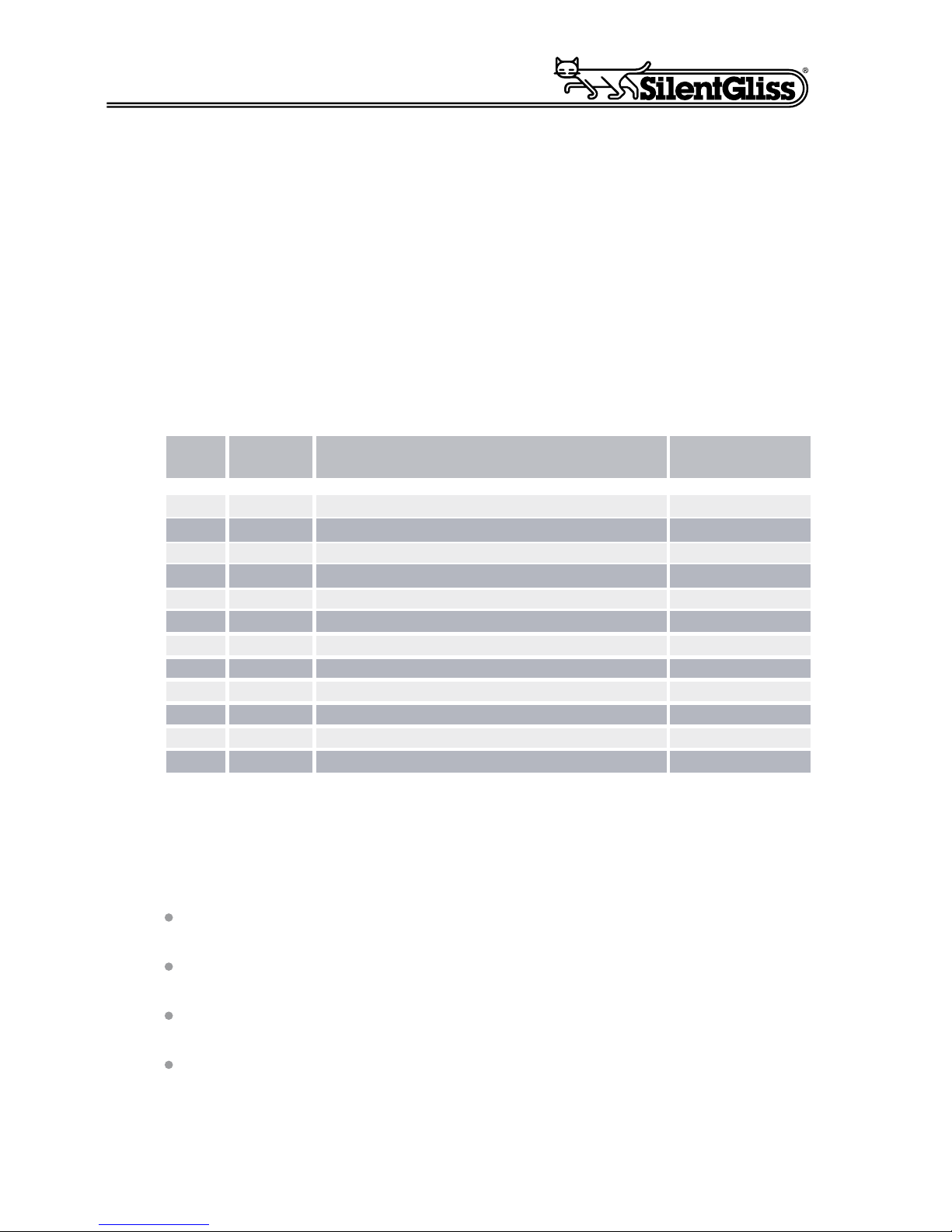

This User Manual applies to following Silent Gliss motor variations:

2 Intended Application

The motors mentioned in Chapter 1 may only be used in combination

with the designated Silent Gliss Systems.

The motor is solely designed for indoor use. Application in wet areas

like bathrooms, indoor swimming-pools, saunas etc. is not permitted.

Please note that Radio Control Systems are not permitted in certain

locations such as Hospitals and Airports.

Please ensure that other equipment is not being controlled by radio

equipment using the same frequency.

9020

9021

9021

9022

9023

SG Nr.

9023

9030

9031

9031

9032

9033

9033

ERP Nr.

100902000

100902101

100902102

100902200

100902301

100902302

100903000

100903101

100903102

100903200

100903301

100903302

Long description

Motor 90-250V AC*

Motor 90-250V AC*,radio 868MHz

Motor 90-250V AC*,radio 915MHz

Motor 90-250V AC*,manual override

Motor 90-250V AC*,radio 868MHz, manual override

Motor 90-250V AC*,radio 915MHz, manual override

Motor 24V DC

Motor 24V DC, radio 868MHz

Motor 24V DC, radio 915MHz

Motor 24V DC, manual override

Motor 24V DC, radio 868MHz, manual override

Motor

*260V AC CB

24V DC, radio 915MHz, manual override

Short description

on motor

9020.000.00

9021.868.00

9021.915.00

9022.000.MO

9023.868.MO

9023.915.MO

9030.000.00

9031.868.00

9031.915.00

9032.000.MO

9033.868.MO

9033.915.MO

Usermanual Motors 902x_903x Page 5

3 Safety Instructions

The Motor may be used only in dry rooms.

The Motor may not be used in explosive areas.

The Motor is not intended for use by young childrens or inrm

persons without supervision.

Only original Silent Gliss parts may be used.

The installation, inspection and troubleshooting of the drive mecha-

nism may only be performed by qualied specialists. Please consider

the country specic regulations in regards of connection of the motors

to the mains.

The proper operation of the motor in combination with the Electric

Curtain Track Systems is only guaranteed with professional installati-

on, xing, as well as sufcient electric power supply.

Cleaning of the motor may only be performed if the motor is discon-

nected from the mains voltage.

The motor must not be used if cables, plugs, or the motor are

damaged.

Please ensure the specication detailed below and in the declaration

of conformity (page 20) conform with the necessary regulations in the

intended country of use and the radio frequency is approved for that

country.

4 Technical Specications

Technical data for motors only. For the technical data for the entire

curtain track system refer to the corresponding Assembling- / Fitting

Instruction.

9020-9023 9030-9033

Voltage Supply

Frequency

Current

Frequency of radio control

(only for 9021/9023/9031/9033)

90 - 250V AC**

50 - 6 0 Hz

0.5 - 1 A

868 or 915 MHz*

24 V DC

--

2.5 A

868 or 915 MHz*

Speed

Noise level

Dimension

Max. drapery weight

Weight

110 rpm

< 45 dBA (30cm)

240 x 90 x 60mm

1kg

110 rpm

< 45 dBA (30cm)

240 x 90 x 60mm

1kg

44kg / 97lbs 44kg / 97lbs

Page 6

Usermanual Motors 902x_903x

5 Connection and Operating Equipment

5.1 Overview

The Motor is available in two power supply options; 90 – 250V

AC/260V AC CB as well as 24V DC. The power plugs are designed

differently and cannot be mixed up. The remaining ports and indicators

are identical on both motors.

The following main overview of the ports and indicators may be used

for both motors. The subsequent chapters deal in detail with the functions, allocations and setting of the ports and indicators.

9020-9023 9030-9033

Voltage Supply

Frequency

Current

Frequency of radio control

(only for 9021/9023/9031/9033)

90 - 250V AC**

50 - 6 0 Hz

0.5 - 1 A

868 or 915 MHz*

24 V DC

--

2.5 A

868 or 915 MHz*

Speed

Noise level

Dimension

Max. drapery weight

Weight

110 rpm

< 45 dBA (30cm)

240 x 90 x 60mm

1kg

110 rpm

< 45 dBA (30cm)

240 x 90 x 60mm

1kg

44kg / 97lbs 44kg / 97lbs

Temperature ranges:

For operation

Storage

Safety class

*(depending

**260V AC CB

on regulation of respective country)

0 C to + 60 C

-20 C to + 70 C

IP40

0 C to + 60 C

-20 C to + 70 C

IP40

2 1

2 1

Programming Buttons

Power Plug

LED

Low Voltage Switch

Connections

DIP Switch

Special Function Socket

SG 9020 - 9023

(90-250V AC/

260V AC CB)

SG 9030 - 9033

(24V DC)

Usermanual Motors 902x_903x Page 7

5.2 Special Function Socket

Used in connection with the Manual Override version for the motors

SG 9022 / 9023 / 9032 / 9033.

5.3 Low Voltage Switch Connections

Used for control by low voltage, group control or for the connection

of the programming cable.

5.4 Programming Buttons

Used for the programming of the endstops as well as for the

intermediate positions (scenes).

The numbers of the buttons are marked on housing of the motors.

The right button is nr. 1, the left nr. 2.

DenotationPin

1

2

3

4

GND

Endstop 1

Endstop 2

VCC

123

4

DenotationPin

1

2

3

4

5

Common

Open - Single

Close - Single

Open - Group

Close - Group

5

4

3

2

1

Programming

buttons

Page 8

Usermanual Motors 902x_903x

5.5 LED

Flashes or is illuminated in the programming mode.

5.6 Mains Connection and Wiring of

SG 9020 – 9023 (90 – 250V AC/260V AC CB)

Wiring: The motors SG 9020 – 9023 can be wired for non permanent

power as well as for permanent power. The wiring is to be employed as

required by local codes. The wiring diagrams are as follows:

Note!

The earth wire has to be wired according to the international wiring

standards for buildings by reason of a proper grounding. The used

switch must be equiped with a neutral terminal.

LED

DenotationPin

1

2

3

4

Neutral

Phase (rotating direction left)

Phase (rotating direction right)

PE,

Parallel jacketed

thermoplastic cable,

300V with third

conductor for

grounding. (PVC)

Minimum lenght 72.04" (1.83m)

1

Contact H-A 3TGV 10426400

Contact H-A 3BS 10421000

2

3

1

2

3

Phase

Neutra

l

1

2

3

Phase

Neutra

l

Low Voltage switched

(requires permanent mains supply)

Mains Switched (90-260VAC)

Usermanual Motors 902x_903x Page 9

5.7 Mains Connection and Wiring of

SG 9030 - 9033 (24V DC)

Wiring: The motors SG 9030 - 9033 are always connected with permanent power.

5.8 DIP - Switch Settings of SG 9020 - 9023

(90 - 250V AC/260V AC CB)

and SG 9030 - 9033 (24V DC)

The DIP Switches are used to set the motor depending on the wiring

and the required operation mode. Following table shows the

possibilities.

+

-

ON

1 2 3

ON

1 2 3

DIP Switch Position

"off-off-off"

DIP Switch Position

"on-on-on"

Page 10

Usermanual Motors 902x_903x

ON

1 2 3

Controlled by switched mains

Non Latching Switch: the motor will latch immediately it receives a

momentary signal and continue to the pre set end position.

To stop the motor while it is running apply a short signal in the

opposite direction.

For vertical Blinds only. Use a non latching switch. Short pulses

will rotate the angle of the blind but if the switch is held depressed

for more than 1 second the motor will latch and the blind will run to

the fully open or fully closed position.

Non latching switch: The motor will only run when the signal is

present (switch depressed). Mainly used when the motor is

being controlled from an AV or BMS controller.

As on-off-off but with the manual/electrical option enabled for

use with a 5420 system.

As off-on-off but with the manual/electrical option enabled for

use with a 5420 system.

As on-on-off but with the manual/electrical option enabled for

use with a 5420 system.

Not applicable

off-off-off

on-on-off

off-off-on

on-off-on

off-on-on

on-on-on

Operational Mode

DIP Switch

Position

Controlled by low voltage switching

(requires permanent mains supply)

or Radio

on-off-off

off-on-off

Important:

When changing the DIP-mode please allways plug-off the motor rst!

Usermanual Motors 902x_903x Page 11

6 Programming and Operating of

SG 9020/9021 and SG 9030/9031

Motors

6.1 Main Overview

After installation of a motor onto the designated Curtain Track System,

the end stops – and if required, the intermediate positions can be

programmed. This programming can be carried out in several ways:

by means of the programming buttons on the motor, by means of the

optional available Programming Cable SG 5651 or by means of the

Radio Remote Control System SG 9940.

6.2 Programming by means of Programming Buttons

on Motor or Programming Cable SG 5651

The following table shows the different steps required to program

the nal stops regardless of mains or low voltage switch type. If the

Programming Cable SG 5651 is used to program the end stops, it

is required to plug it into the Low Voltage Switch connection before

programming.

To do Signal

Step

12Check if the DIP switch setting is correct

(Setting according to Chapter 5.8).

Disconnect power supply of the motor for 5

seconds and make sure that the motor will

have permanent power supply when

reconnected. Typically unplug power

lead from motor.

Page 12

Usermanual Motors 902x_903x

6.3 Programming by means of Radio Remote

Control SG 9940

The remote control has to be teached-in with the motor before

the programming of the end positions by means of the Radio Remote Control System can be performed. This can be carried out

with the following steps. Please refer to the user manual which is

enclosed with every delivered remote control.

To do Signal

Step

1

2

3

4

5

6

Check if the DIP switch setting is correct

(Setting according to Chapter 5.8).

Disconnect power supply of the motor for 5

seconds and make sure that the motor will

have permanent power supply when

reconnected. Typically unplug power

lead from motor.

Reconnect to power supply and

simultaneously push programming

button 1 or 2.

Simultaneously press both buttons (1&2)

and hold depressed for > 6 seconds.

After 3 seconds motor will sound and the

light will flash. Do not release the buttons.

Wait until motor sounds and light flashes

for the second time. Motor is then in programming mode for 3 minutes.

Use programming button 1 to drive the

system to the first end stop position.

Then press both buttons simultaneously

for 3 seconds. This end position is

then stored.

Use programming button 2 to drive the

system to the other end stop position.

Then press both buttons simultaneously

for 3 seconds. This end position is

then stored.

Acoustic Signal,

LED blinks

Acoustic Signal

and LED blinks

after 3 and 6 seconds

respectively

Acoustic Signal

and LED blinks 1 x

Acoustic Signal

and LED blinks 1 x

Step

Todo Signal

1 Check if the DIP switch setting is correct

(Setting according to Chapter 5.8).

Usermanual Motors 902x_903x Page 13

To do Signal

Step

1

2

3

4

Check if the DIP switch setting is correct

(Setting according to Chapter 5.8)

Disconnect power supply of the motor for

5 seconds and make sure that the motor

will have permanent power supply

Establish power supply and simultaneously

push programming button 1 or 2 on Motor.

Select the desired chanel by pressing the

select button (only SG 9942)

Acoustic Signal,

LED lights

Chanel LED on transmitter lights on

2 Disconnect power supply of the motor for

5 seconds and make sure that the motor

will have permanent power supply when

reconnected. Typically unplug power lead

from motor.

3 Move the curtain with button 1 or 2 on the

motor about to the middle position of the

two endstops.

4 Select the desired chanel by pressing the

select button (only SG 9942)

Chanel LED on

trans-mitter lights on

5 Position yourself in front of the motor

with the remote control in your hand, and

open the front cover of the device and

press button „P“.

Curtain moves

independently

approx. 2 minutes

open and close

6 To dene the allocation of the buttons

press rst button on the transmitter as

soon as the curtain begins to move in the

rst direction.

The curtain will

come to a briey

hold

7 As soon as the curtain begins to move

again, press the second button on the

handheld transmitter. The transmitter has

been succesfully programmed.

The curtain will

come to a stop

Adjusting the endpositions

Page 14

Usermanual Motors 902x_903x

6.4 Programming and Accessing of intermediate

Positions

Two intermediate positions can be set for the Electric Curtain

Track System with low voltage switching. The programming of

the intermediate positions doesn’t have to be carried out in the

programming mode. It can be carried out in operational mode.

Programming with Low Voltage Control:

To do Signal

Step

1

2

3

4

5

6

Check if the DIP switch setting is correct

(Setting according to Chapter 5.8)

Disconnect power supply of the motor for

5 seconds and make sure that the motor

will have permanent power supply

Establish power supply and simultaneously

push programming button 1 or 2 on Motor.

Select the desired chanel by pressing the

select button (only SG 9942)

Push simultaneously programming button

1 and 2, >6 seconds. The motor is now

able to be programmed for 3 minutes

Move to first end position with programming

button 1. Subsequently, push both programming buttons simultaneously for 3 seconds.

The first end position is now saved

Acoustic Signal,

LED lights

Chanel LED on trans-

mitter lights on

Acoustic Signal and

LED blinks after 3 and

6 seconds respectively

Acoustic Signal and

LED blinks 1 x

7 Move to the second end position with pro-

gramming button 2. Subsequently, push

both programming buttons simultaneously

for 3 seconds. The second end position is

now saved

Acoustic Signal and

LED blinks 1 x

To do Signal

Step

12Use button 1 to move the system to the

required scene position 1. When you reach

the required position press button 2 twice

while still holding down button 1

Use button 2 to move the system to the

required scene position 2. When you reach

the required position press button 1 twice

while still holding down button 2. The

intermediate positions are now adjusted.

Acoustic Signal and

LED blinks 1 x

Acoustic Signal and

LED blinks 1 x

Usermanual Motors 902x_903x Page 15

Programming with Remote Control:

Recalling the intermidiate positions: The curtain automatically moves to

the programmed positions by briey pressing 2 times the buttons which

are assigned to the intermediate positions.

6.5 Resetting of Motor to Factory Status

To do Signal

Step

12Press button 1 permanently and move the

curtain to the desired intermediate position

1. Arrived at the first intermediate position,

press button STOP simultaneously.

Press button 2 permanently and move the

curtain to the desired intermediate position

2. Arrived at the first intermediate position,

press button STOP simultaneously.

Acoustic Signal and

LED blinks 1 x

Acoustic Signal and

LED blinks 1 x

To do Signal

Step

12Disconnect power supply of the motor for 5

seconds and make sure that the motor will

have permanent power supply when

reconnected. Typically unplug power

lead from motor.

Reconnect to power supply and

simultaneously push programming

button 1 or 2.

Acoustic Signal,

LED blinks

3 Simultaneously press both buttons (1&2)

and hold depressed for > 6 seconds.

After 3 seconds motor will sound and the

light will flash. Do not release the buttons.

Wait until motor sounds and light flashes

for the second time.

Acoustic Signal

and LED blinks

after 3 and 6 seconds

respectively

Page 16

Usermanual Motors 902x_903x

6.6 Deleting transmitters 9940 to motors

SG 9021/9023 and SG 9031/9033

Transmitter 9941 (1-Channel)

Transmitter 9942 (5+1-Channel)

To do Signal

Step

1

2

3

Make shure that the motor has permanent

power.

Open the front cover on the device and

press the following buttons simultaneously:

- Programming button P

- STOP button

Keep these two buttons pressed until the

LED goes out briefly.

LED turns off short

1 Make shure that the motor has perma-

nent power.

2a Deleting of a specied channel

Select the channel to be deleted. Then

open the front cover and press the following buttons simultaneously:

Programming button P + STOP button

2b Keep all of these buttons pressed until

the LED ashes off short

LED ashes off

short

3a Deleting of all channels

Select all Channel. Open the front cover

and press the following buttons simul-

taneously: Programming button P + UP

button + STOP button + DOWN button

3b Keep all of these buttons pressed until

the LED ash off 3 x

LED ash off 3 x

Usermanual Motors 902x_903x Page 17

7 Programming and Operating of

SG 9022/9023 and SG 9032/9033

These motors and Electric Curtain Track Systems are equipped with

a Manual Override function, i.e. the curtain can be moved by hand if

the motor is turned off. This function is only applicable with a low voltage switching.. In addition, no intermediate position can be programmed.

The programming occurs through following steps

To do Signal

Step

1

2

3

Check if the DIP switch setting is correct

(Setting according to Chapter 5.8).

Disconnect power supply of the motor for 5

seconds and make sure that the motor will

have permanent power supply when

reconnected. Typically unplug power

lead from motor.

Pull the curtain to about the middle position

between the two end positions.

5

6

7

Reconnect to power supply and

simultaneously push programming

button 1 or 2.

Move the curtain to one end position.

Motor is programmed.

Acoustic Signal,

LED lights

Motor stops

automatically

4 Simultaneously press both buttons (1&2)

and hold depressed for > 6 seconds.

After 3 seconds motor will sound and the

light will flash. Do not release the buttons.

Wait until motor sounds and light flashes

for the second time. Motor is then in programming mode for 3 minutes.

Acoustic Signal

and LED blinks

after 3 and 6 seconds

respectively

Page 18

Usermanual Motors 902x_903x

8 Group Control of Motors

8.1 Group Control via Mains

Motors can be connected in parallel when mains switching. 3 motors

maximum are recommended. If quantities above 3 motors in parallel

are required, a qualied electrician must be consulted to ensure that

the supply, wiring and switching is suitable for the electrical load.

For motors to all run in the same direction on command attention must

be paid to ensure that the connections to all motors are identical. If

a motor is specically required to operate in the reverse direction on

command the connections to pins 2 & 3 should be reversed on that

specic motor.

2 1 2 1

Group

Switch

Phase Neutral

2 3

1

2 3

1

Usermanual Motors 902x_903x Page 19

8.2 Group Control via Low Voltage Inputs (max. 15)

If a motor is required to run in the opposite direction to others wired

within the same group connections 2 & 3 at the low voltage switch

connection should be reversed on that specic motor.

8.3 Group Control via Radio Remote Control

SG 9940

For the programming of the group control by means of the radio remote

control system SG 9940 please refer to the user manual which is enclosed in every delivered hand remote control device.

2 1 2 1

Group

switch

Phase

Single

switch

motor 2

Neutral

2 3

1

Phase NOTE: No protection

relays are required

Neutral

2 3

1

5 4 3 2 1 5 4 3 2 1

Single

switch

motor 1

Page 20

Usermanual Motors 902x_903x

9 Troubleshooting

... the motor doesn’t move?

Check if motor is correctly supplied with power according to the

wiring diagram and if the DIP switches are in the right position.

... the motor doesn’t move after saving the rst end stop?

Disconnect power supply. Start limit setting process again ensuring

that button 1 is used rst to drive the system to its rst limit position.

... the motor turns in the wrong direction with low voltage switching

(permanent power supply)

Exchange cable of Pin 2 with Pin 3 at the low voltage switch

terminal connection.

... the motor SG 9020 turns in the wrong direction with mains

switched connection?

Exchange cable of Pin 2 and 3 on mains plug.

... some motors 9020 / 9022 turn in the wrong direction when

connected for simultaneous operation using mains switching.

Check if Pin 2 and Pin 3 on each motor are connected identically.

10 Declaration of Conformity

Micro- Motor AG conrms herewith that this product complies with

the relevant harmonised regulations of the 73 / 23 / EEC + 89 / 336 /

EEC + 93 / 68 / EEC directives. The declaration of conformity can be

ordered at: info@micromotor.ch .

Loading...

Loading...