Operating Manual

Original Instructions

D439848XA

vers. 4

EN

(c) 2012 SILCA S.p.a. – Vittorio Veneto

This manual has been drawn up by SILCA S.p.a.

All rights reserved. No part of this publication can be reproduced or circulated by any means whatsoever (photocopies, microlm or other) without

the consent of SILCA S.p.a.

Edition: June 2012

Printed at Vittorio Veneto

by SILCA S.p.a.

Via Podgora, 20 (Z.I.)

31029 VITTORIO VENETO (TV) – Italy

The Manufacturer declines any responsibility for possible inaccuracies in this document due to printing or transcription errors. The Manufacturer

reserves the right to alter the information without prior notice, except when they affect safety. This document or any of its parts cannot be copied,

altered or reproduced without written authorization from the Manufacturer. Keep the manual and look after it for the entire life cycle of the machine.

The information has been drawn up by the manufacturer in his own language (Italian) to provide users with the necessary indications to use the

key-cutting machine independently, economically and safely.

IMPORTANT NOTE: in compliance with current regulations relating to industrial property, we hereby state that the trade-marks or trade names

mentioned in our documentation are the exclusive property of authorized manufacturers of locks and users.

Said trade-marks or trade names are nominated only for the purposes of information so that any lock for which our keys are made can be rapidly

identied.

INDICE

USE OF THE MANUAL .......................................................................................................................1

GLOSSARY SYMBOLS-TERMINOLOGY ........................................................................................... 2

GENERAL WARNINGS ....................................................................................................................... 4

1 MACHINE DESCRIPTION ....................................................................................................................5

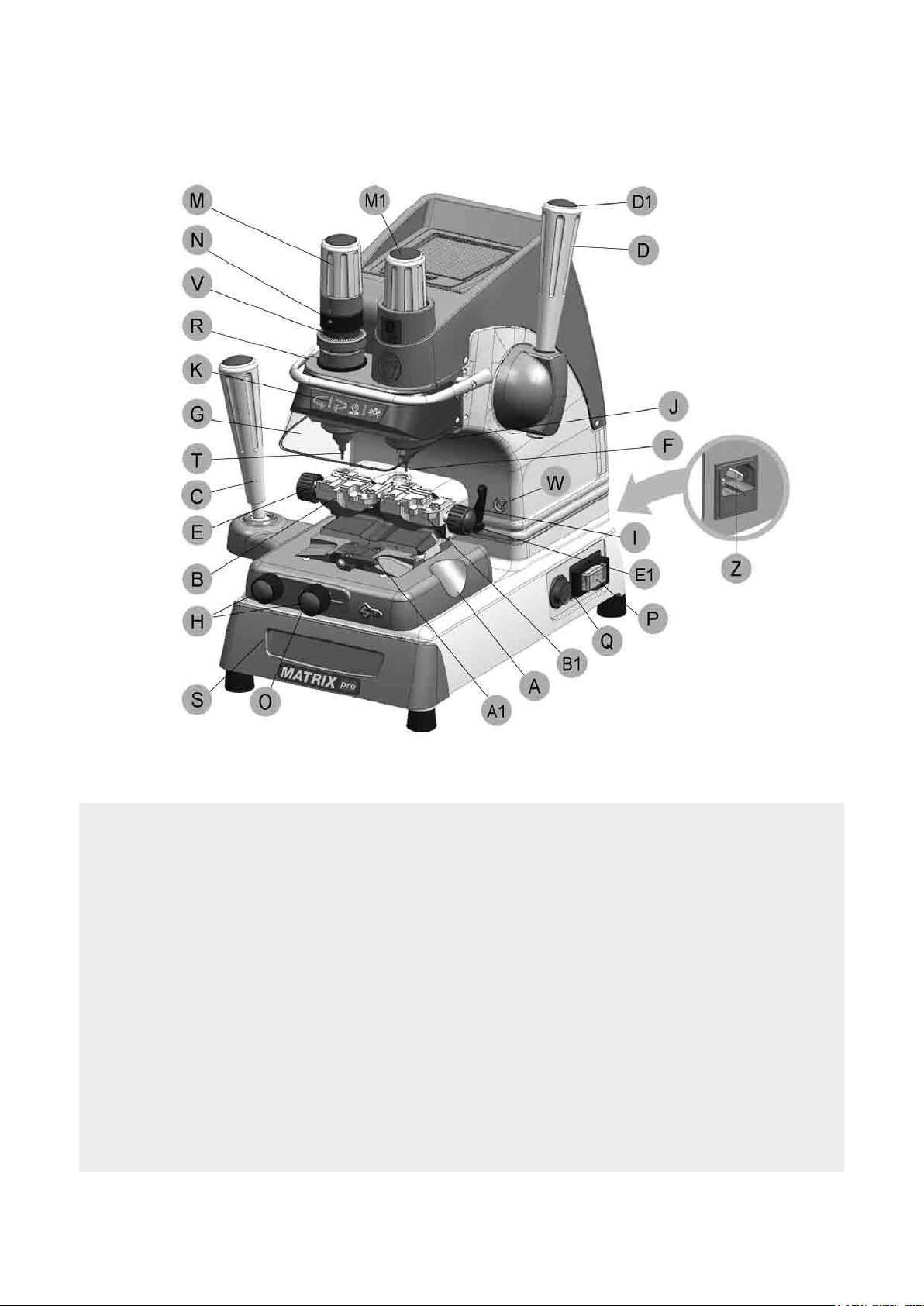

2 WORKING PARTS - Matrix PRO ..........................................................................................................6

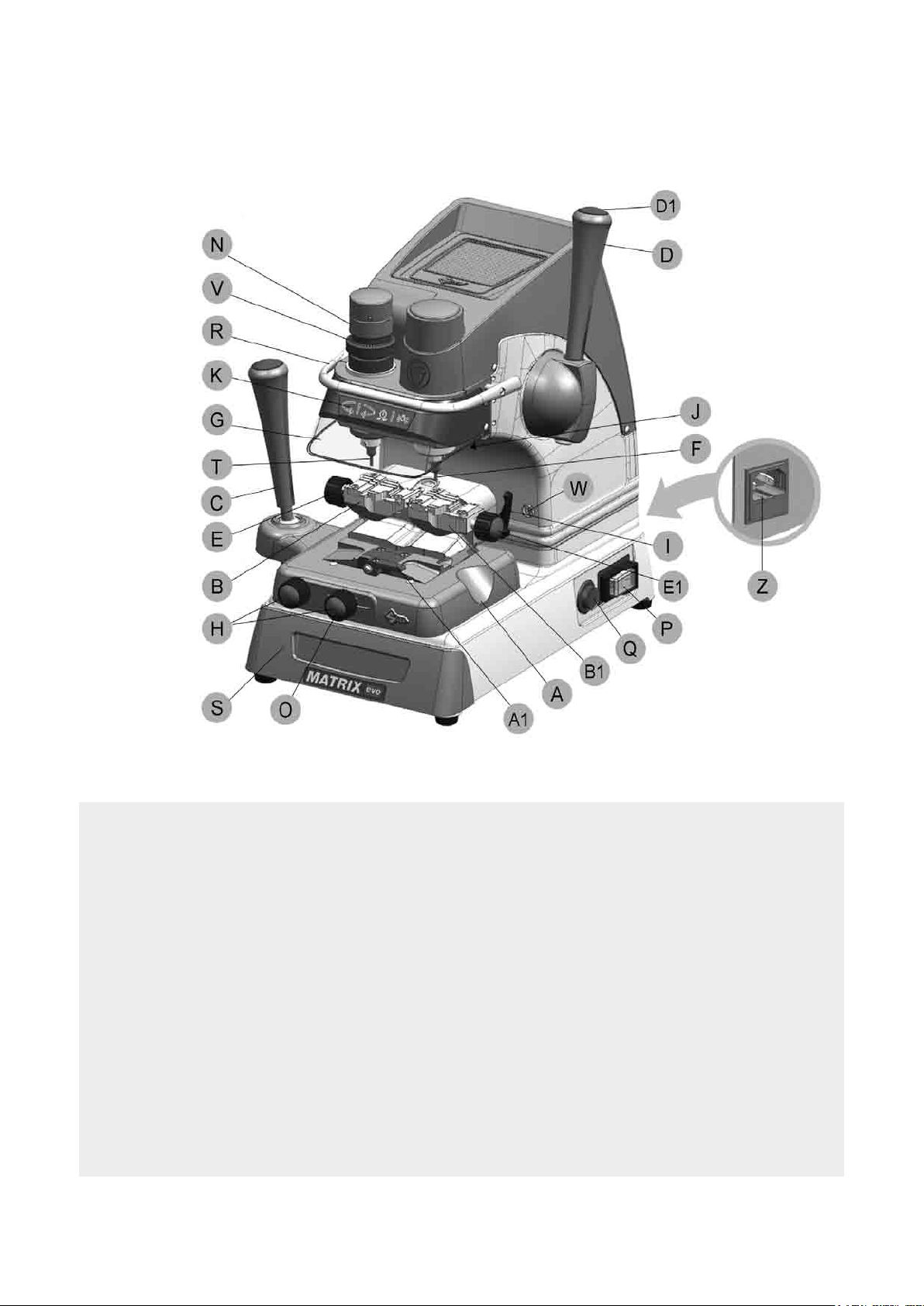

3 WORKING PARTS - Matrix EVO ..........................................................................................................7

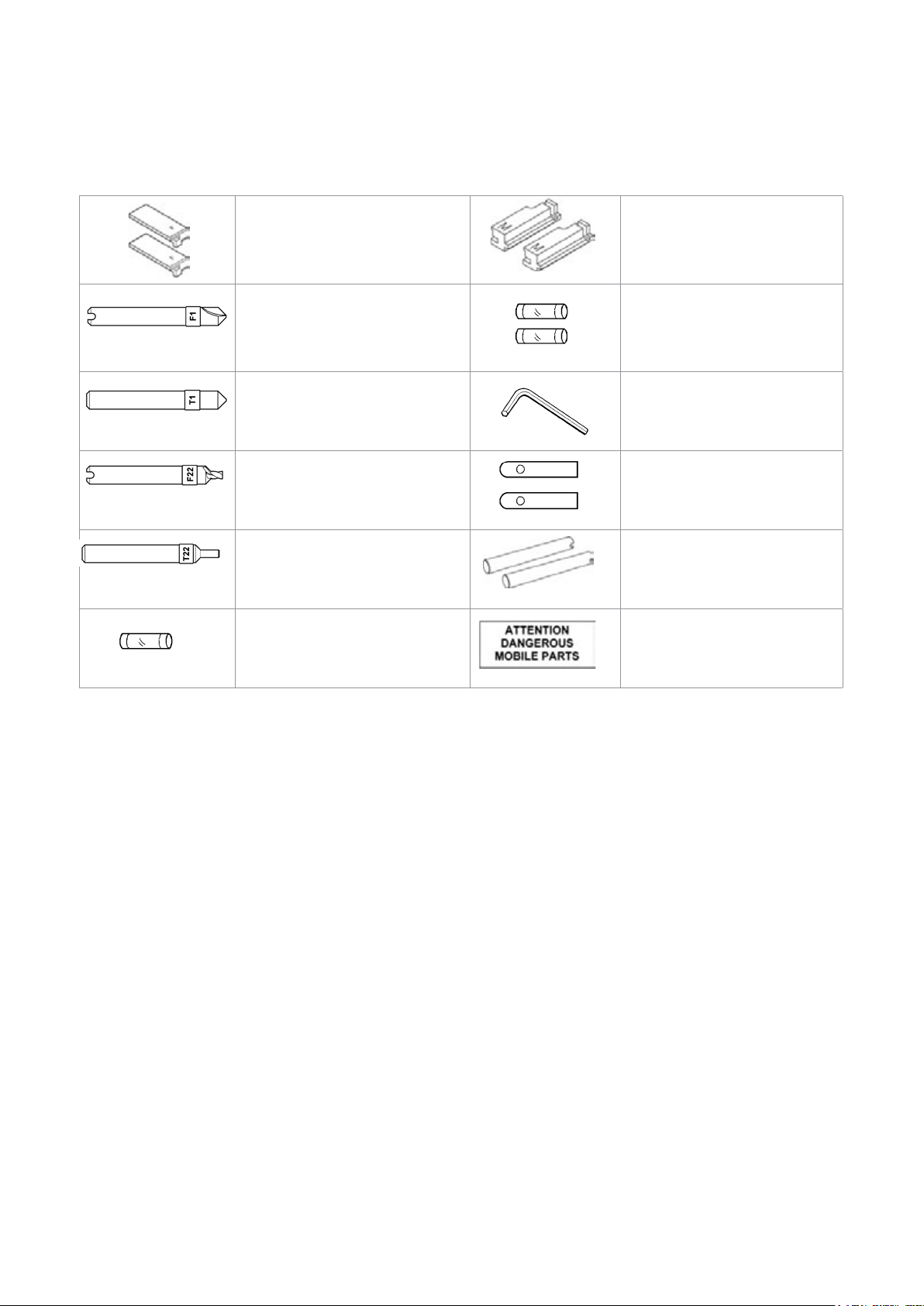

4 ACCESSORIES PROVIDED ................................................................................................................8

4.1 Technical data ...................................................................................................................................8

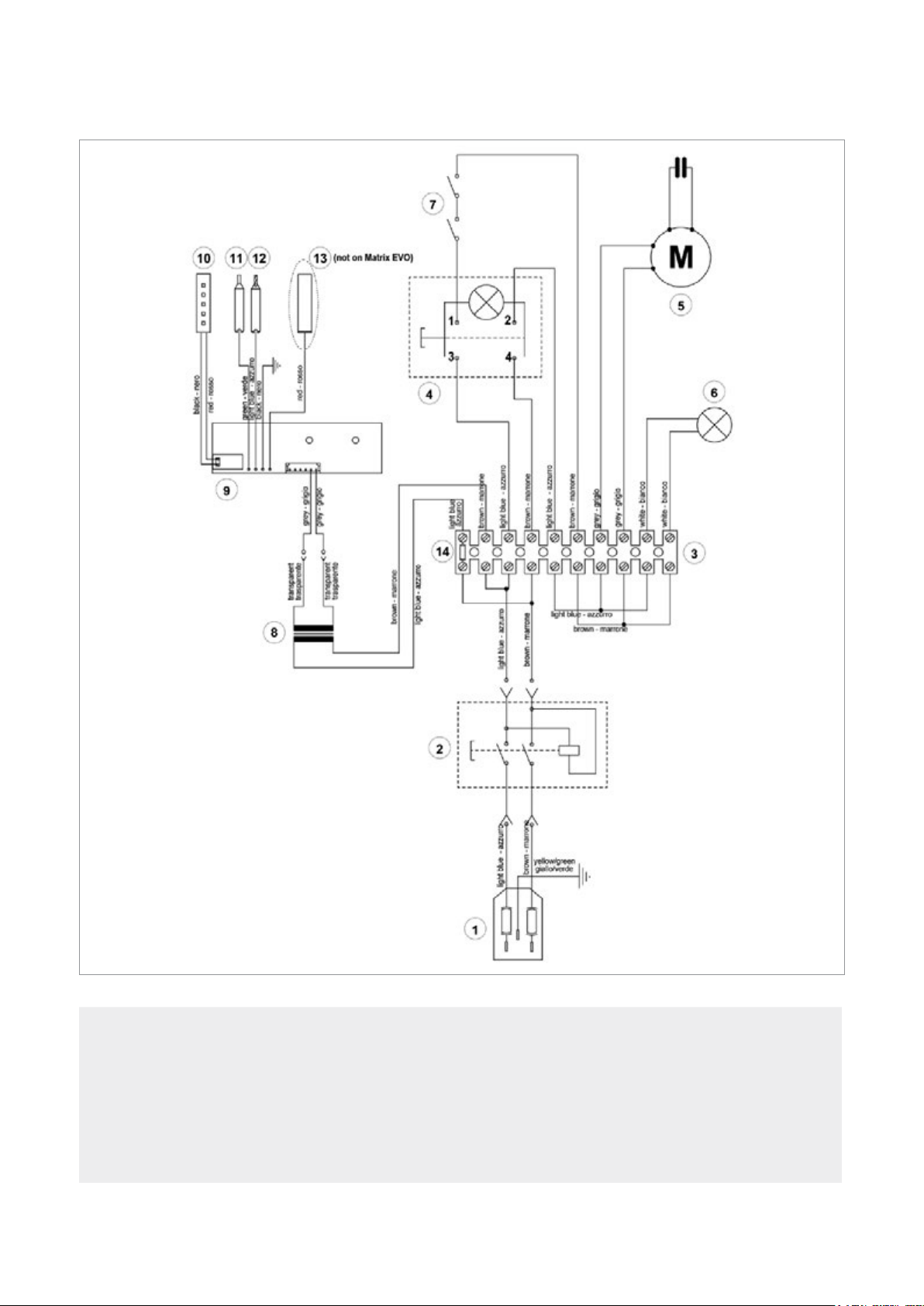

5 ELECTRIC DIAGRAM .........................................................................................................................9

6 HANDLING .........................................................................................................................................10

6.1 Packing ........................................................................................................................................... 10

6.2 Transport ........................................................................................................................................10

6.3 Unpacking.......................................................................................................................................10

6.4 Handling the machine ..................................................................................................................... 10

7 MACHINE INSTALLATION AND PREPARATION ..............................................................................11

7.1 Checking for damage ..................................................................................................................... 11

7.2 Environmental conditions ............................................................................................................... 11

7.3 Positioning ...................................................................................................................................... 11

7.4 Safety devices ................................................................................................................................ 11

7.5 Work station description .................................................................................................................12

7.6 Starting the key-cutting machine .................................................................................................... 13

7.6.1 Starting the motor .......................................................................................................................... 13

7.6.2 Cutter motor on warning light ........................................................................................................ 13

7.6.3 Led lamp (matrix pro version) ........................................................................................................ 13

7.6.4 Led lamp (matrix evo version) ....................................................................................................... 13

8 MACHINE CALIBRATION AND REGULATION ..................................................................................14

8.1 Fitting and removing tools ..............................................................................................................14

8.2 Micrometer gauge...........................................................................................................................15

8.3 Calibration / tool alignment ............................................................................................................. 16

8.4 Tracer point spring ..........................................................................................................................17

8.5 Carriage spring for laser keys.........................................................................................................18

8.6 Clamps ...........................................................................................................................................20

8.6.1 The clamp unit has several seats dedicated to the positioning of different types of keys: ............ 21

9 CUTTING ............................................................................................................................................25

9.1 Fitting keys .....................................................................................................................................25

9.2 Key stop..........................................................................................................................................25

9.3 Cutting dimple keys ......................................................................................................................26

9.3.1 Back cuts ..................................................................................................................................... 26

9.3.2 Inclined cuts................................................................................................................................... 27

9.4 Cutting laser type keys ..................................................................................................................28

9.4.1 Cutting laser keys with narrow stems ............................................................................................ 29

9.5 Cutting chet type keys (h prole) .................................................................................................. 30

9.6 Cutting tubular keys (MATRIX PRO version) ..................................................................................31

10 MAINTENANCE ..................................................................................................................................32

10.1 Tightening and replacing the belt ...................................................................................................32

10.2

Removing

Replacing

10.3

10.4

Replacing

Replacing

10.5

10.6 Adjusting/replacing the vertical carriage spring .............................................................................. 35

10.7

Checking a

Replacing

10.8

10.9

Replacing

Replacing

10.10

10.11 Replacing the transformer ..............................................................................................................38

10.12

Replacing

Aligning/ca

10.13

10.13.1 Control alignment left-hand stationary jaws............................................................................... 40

10.13.2 Control alignment right-hand stationary jaws ............................................................................ 41

10.14 Replacing the jaws .........................................................................................................................42

10.14.1 Replacing the left-hand stationary jaws ..................................................................................... 42

10.14.2 Replacing right-hand stationary jaws......................................................................................... 42

10.14.3 Replacing left-hand clamp mobile jaw ....................................................................................... 43

10.14.4 Replacing right-hand mobile clamp jaw ..................................................................................... 43

the upper front unit ........................................................................................................33

the rollbar.......................................................................................................................33

the transparent safety shield

the lamp

nd replacing fuses ........................................................................................................36

the calibration key pad electronic circuit board..............................................................37

the condenser

the motor

switches: master and motor on......................................................................................39

librating the clamp ......................................................................................................... 40

....

..................................................................................................................... 34

............................................................................................................ 37

....

...

....................................................................................................................38

......................................................................................34

...

11 DISPOSAL ..........................................................................................................................................44

12 AFTER-SALES SER

12.1 How to apply for after-sales service ...............................................................................................45

VICE

............................................................................................................45

......

Operating Manual Matrix

USE OF THE MANUAL

This manual has been drawn up by the Manufacturer and is an integral part of the machine literature.

The manual gives information it is obligatory for the operator to know and which makes it possible to use the

machine safely.

User’s Manual

This user’s manual is provided because it is essential for proper use and maintenance of the machine.

The manual must be kept carefully throughout the life of the machine, including the decommissioning stage. Keep

in a dry place close to the machine where it is always to hand for the operator.

IT IS OBLIGATORY to read the manual carefully before using the machine.

Readers’ characteristics

This manual must be read and its contents acquired by those who will use it.

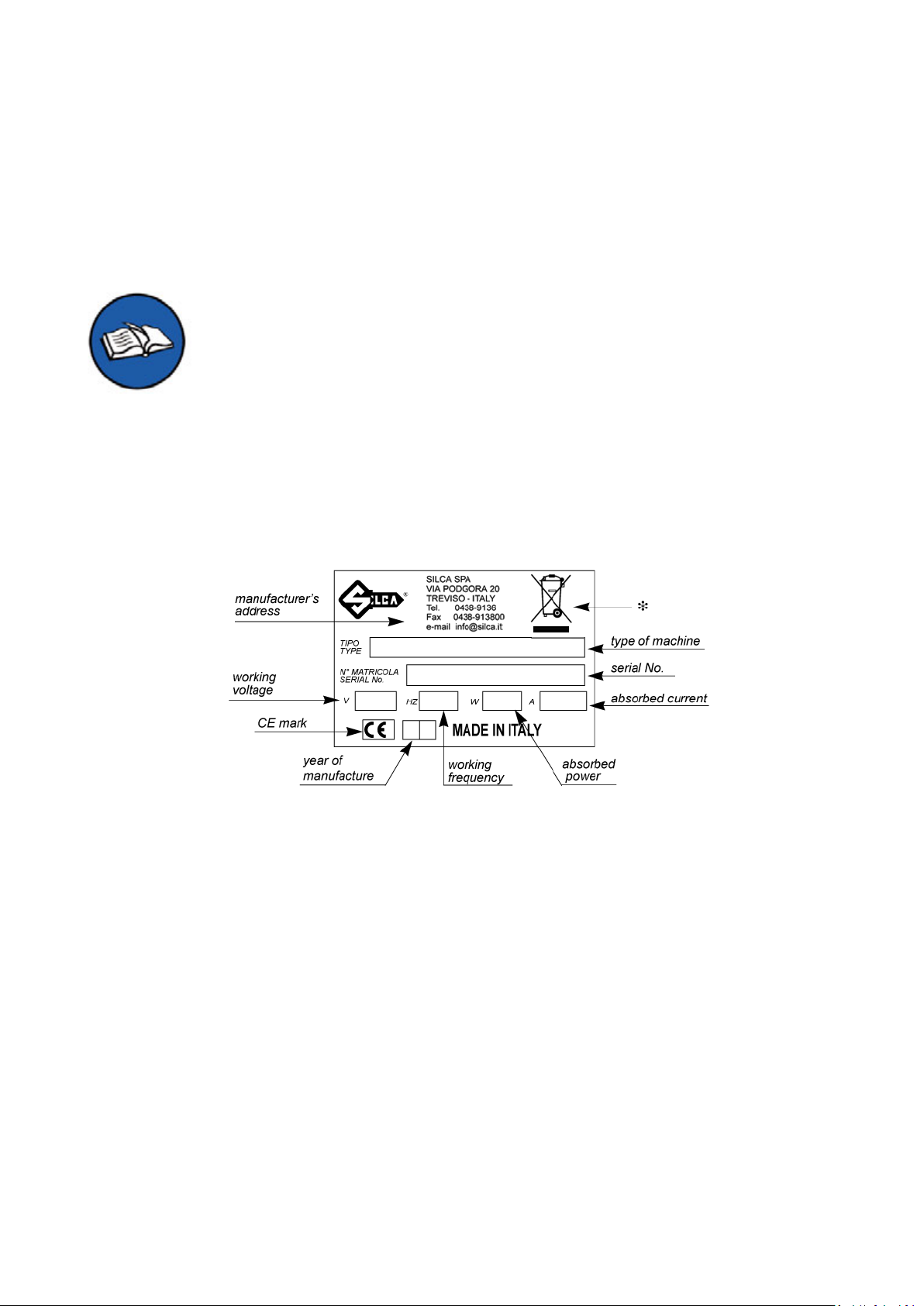

Manufacturer’s ID

MATRIX has an ID plate located on the back of the machine, showing the serial number.

Fig. 1

(*) See Ch. 11 DISPOSAL.

How to apply for after-sales service

Silca provides purchasers of MATRIX with After-Sales Service.

For the total safety of the operator and machine, any operation not described in the manual must be carried out

by the manufacturer or in the special Service Centres recommended by Silca.

At the end of the manual there is a list of manufacturers’ and authorized Service Centre addresses.

The warranty card attached to the machine covers free repairs or replacement of faulty parts for 24 months from

the date of purchase*. All operations must be agreed by the user with Silca or the Service Centre.

* Damage caused by negligence or wrong use of the machine by the user will null the warranty.

Copyright Silca 2012 1

Operating Manual Matrix

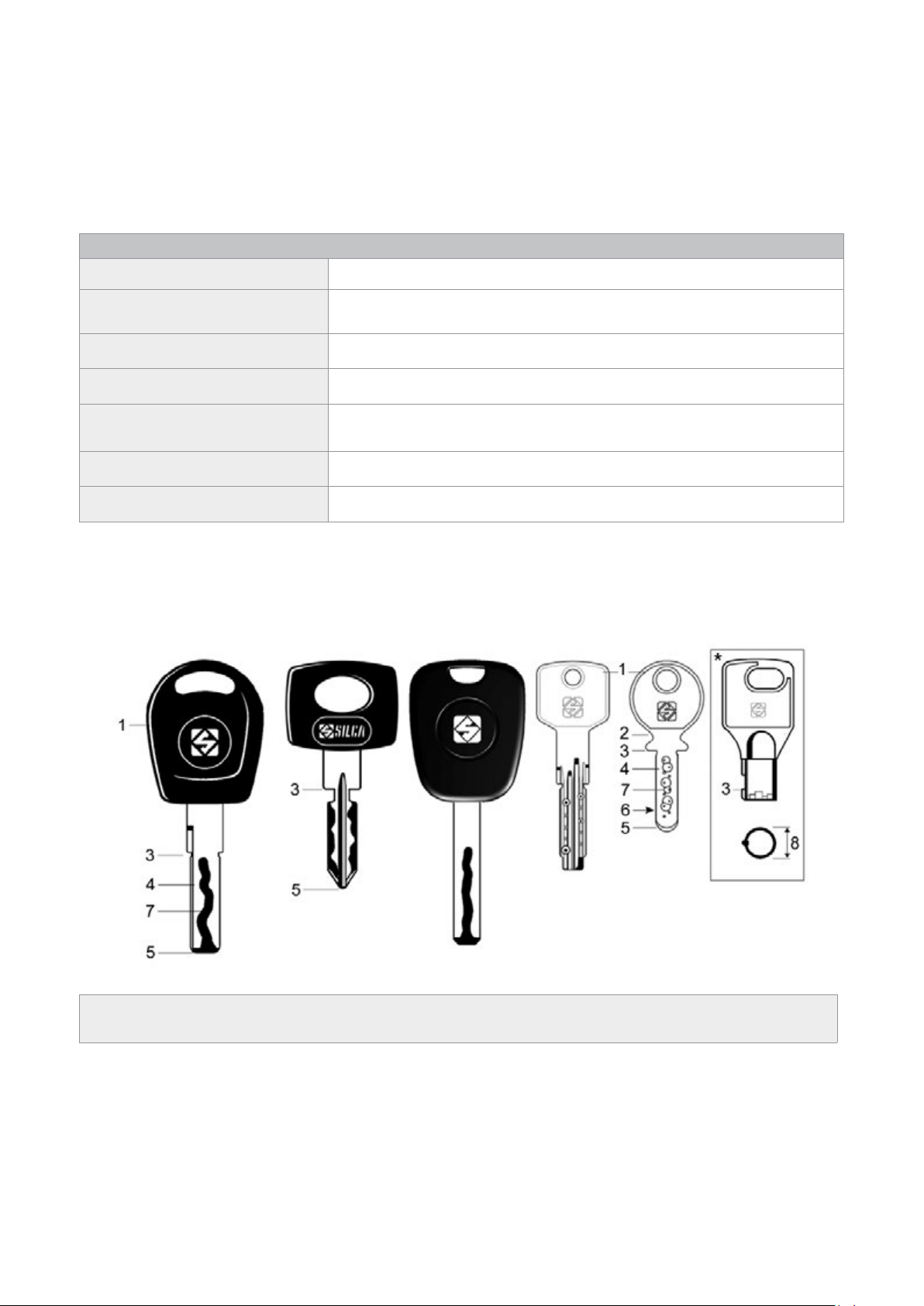

GLOSSARY SYMBOLS-TERMINOLOGY

To facilitate reading, a glossary is given below of commonly used symbols and terms connected to keys and the

key-cutting machine.

These symbols and terms will be used in the manual with reference to this page, but we advise reading the list

before the rest of the manual.

GLOSSARY

Tools cutters and Tracer Points

Clamp unit clamp set: pull-out tilting clamp unit (right and left hand) for positioning

keys

Vertical carriage spindle unit (tracer point and cutter) with relative support (Z axis)

Clamp carriage clamp support perpendicular carriages (X, Y axes)

Safety shield transparent shield to prevent swarf scattering and (partially) protect the

operator

Front vertical carriage cover

Hole dimple cut on the stem or back of the key

TERMINOLOGY

For those inexperienced in the subject of keys and key cutting, below is an illustration of the most frequently used

terms:

1) Head

2) Neck

3) Stop

4) Stem

5) Tip

6) Back

7) Cuts

8) Diameter

(*) Matrix PRO only

Fig. 2

Copyright Silca 20122

Operating Manual Matrix

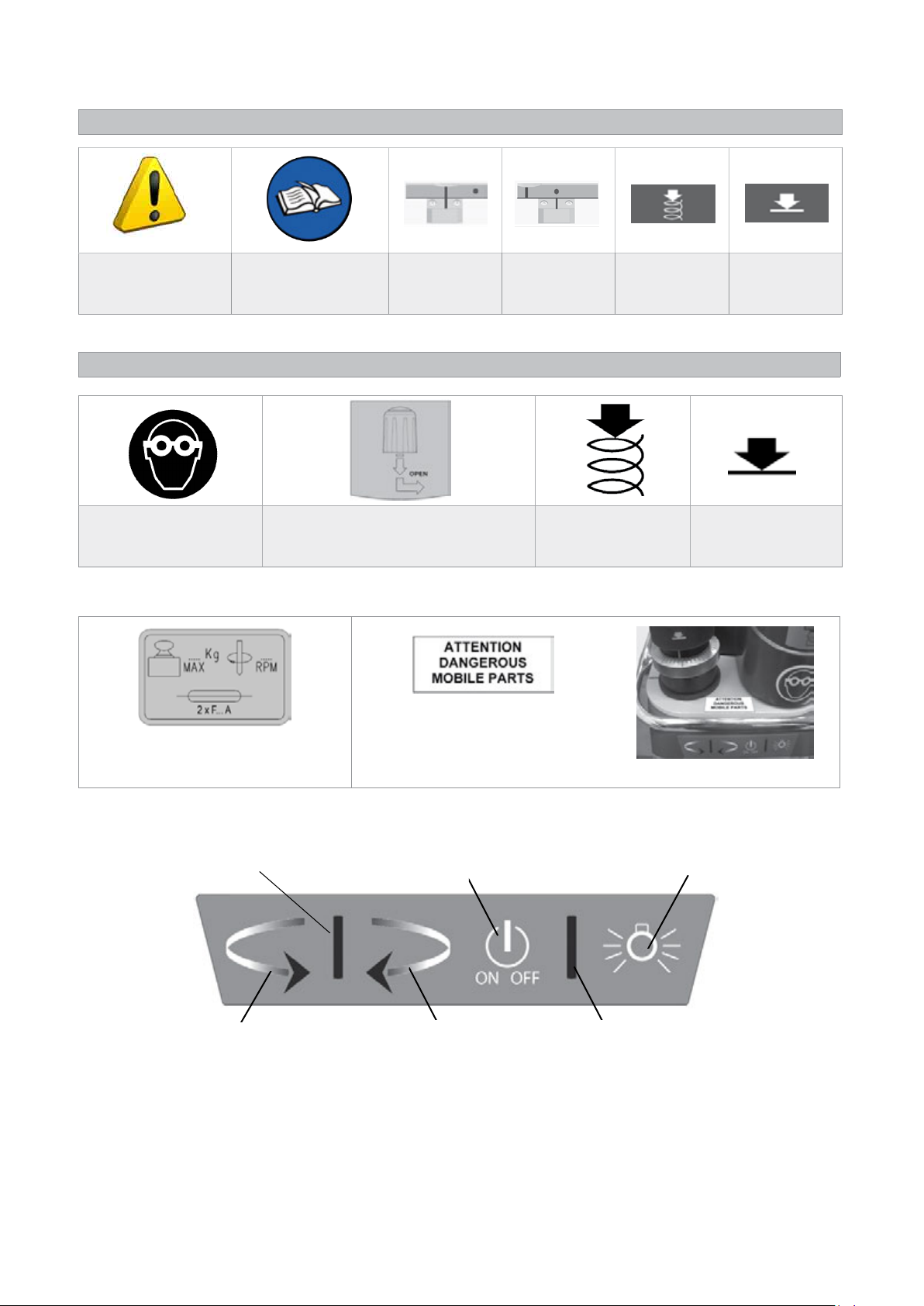

GRAPHICS IN THE USER’S MANUAL

Pay attention Obligation to read

the manual

Position of

clamp carriage

to the left

GRAPHICS ON THE MATRIX KEY-CUTTING MACHINE

Obligatory use of

safety goggles

Cuer release

- Matrix PRO only -

Position of

clamp carriage

to the right

Tracer point spring

Activation of

tracer point

ON

spring

Deactivation

of tracer point

spring

Tracer point spring

OFF

Adhesive labels

Mass - RPM - Fusibles

Fig. 3 Fig. 4

Tool alignment (green)

Tracer point-key contact

Adhesive label

“DANGEROUS MOBILE PARTS”(cap.4)

place the adhesive label

in the way illustrated.

Calibration control ON

Cutter-key contact

switch

Blue LED for machine live

Fig. 5

Lamp switch

Copyright Silca 2012 3

Operating Manual Matrix

GENERAL WARNINGS

MATRIX is designed to the principles of European Standards (CE).

Right from the design stage solutions have been adopted to eliminate hazards for the operator in all the stages

of use: handling, regulation, use and maintenance.

The materials used in manufacture and the components employed in using MATRIX are not dangerous and

ensure that the machine complies to current standards.

Silca S.p.A. has also experimented and applied numerous technical solutions that allow the key-cutting machine

to optimize the quality of the cut keys.

To guarantee maintaining these results over time, please follow the instructions below:

•

Observe the procedures described in this manual;

•

Always use Original Silca Tools as they are designed to make the best of MATRIX and provide quality keycutting;

•

Use Silca key blanks, made with top quality materials;

•

Have the key-cutting machine checked periodically by an authorized Silca After-Sales Service Centre (list at

the end of this manual); always use Silca Original Spare Parts. Beware of imitations!

NORMAL USE

MATRIX is a key-cutting machine and must be installed and used according to the rules and specications

established by the manufacturer.

Any other use different from that indicated in this manual will cause the forfeiture of all customers’ rights to make

claims on Silca S.p.A. and may be an unknown source of hazard for the operator or third parties.

ATTENTION: Negligent use or failure by the operator to observe the instructions

in this manual are not covered by the warranty and the manufacturer declines any

responsibility in such cases.

RESIDUAL RISKS

On the Matrix key-cutting machine there is a residual risk of injury

in the cutter spindle area (cutter rotating) if the vertical axis for laser

cuts is blocked.

Furthermore, the MATRIX key-cutting machine has residual risks

when gaining access to parts in motion (not fully protected) and the

risk of chippings ying into the air during the key copying process.

These residual risks in the product are reported in special warnings

(“ATTENTION MOVING PART HAZARD”) and involve the obligatory

use of personal protective devices (GOGGLES).

Fig. 6

SAFETY REGULATIONS

• Always disconnect the machine when it is not in use or when performing maintenance operations.

• Check the electrical wiring periodically; replace any wires that show signs of wear.

• Always work with dry hands free of grease or oil.

• Never pull hard on the power lead and make sure it does not come into contract with oil, sharp objects

or heat. Never remove the earth wire from the plug. Make sure the earth wire connection is sound.

• Do not use the machine in dangerous environments (wet or damp).

• All visitors, especially children, must stay at a safe distance from the machine and must never come

into contact with the electric wiring.

Copyright Silca 20124

Operating Manual Matrix

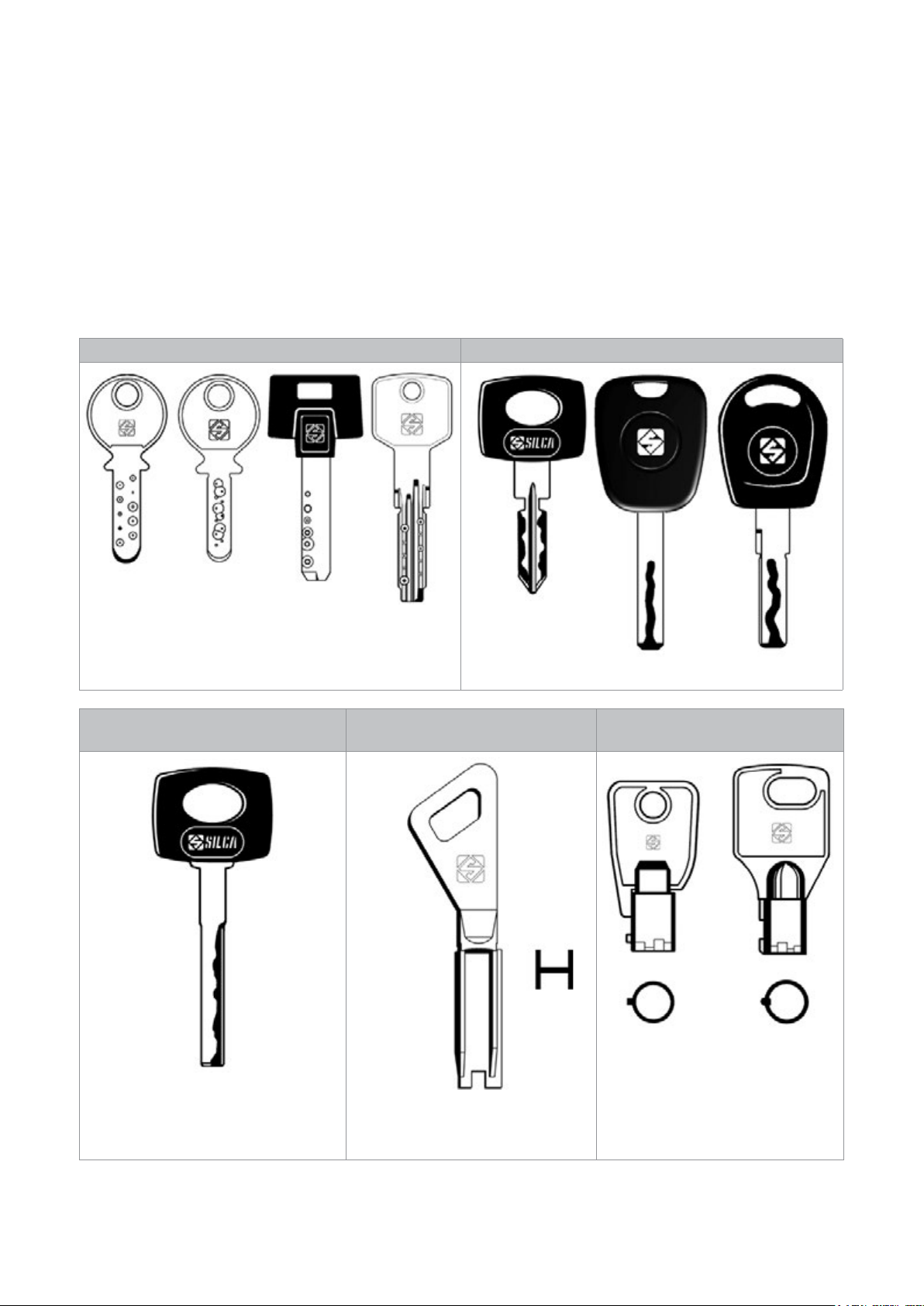

1 MACHINE DESCRIPTION

The MATRIX key-cutting machine gives excellent technical performance of great precision.

The standard clamp on MATRIX is used to cut the following types of keys:

• keyswithatorinclineddimplecuts

• keys with laser type cuts

• laser keys with a narrow stem (Mercedes)

• Fichettypekeys(Hprole)(seenote)

• tubular keys (Matrix PRO only)

KEYS WITH DIMPLE CUTS KEYS WITH LASER TYPE CUTS

LASER KEYS WITH A

NARROW STEM (MERCEDES)

with “M” adapter

STANDARD on vers.120V

OPTIONAL on vers.230V

FICHET type KEYS

(Hprole)

with “F” adapter

STANDARD on vers.230V

OPTIONAL on vers.120V

TUBULAR KEYS

Ø min. 4 mm

Ø max.12 mm

STANDARD on Matrix PRO only

Copyright Silca 2012 5

Operating Manual Matrix

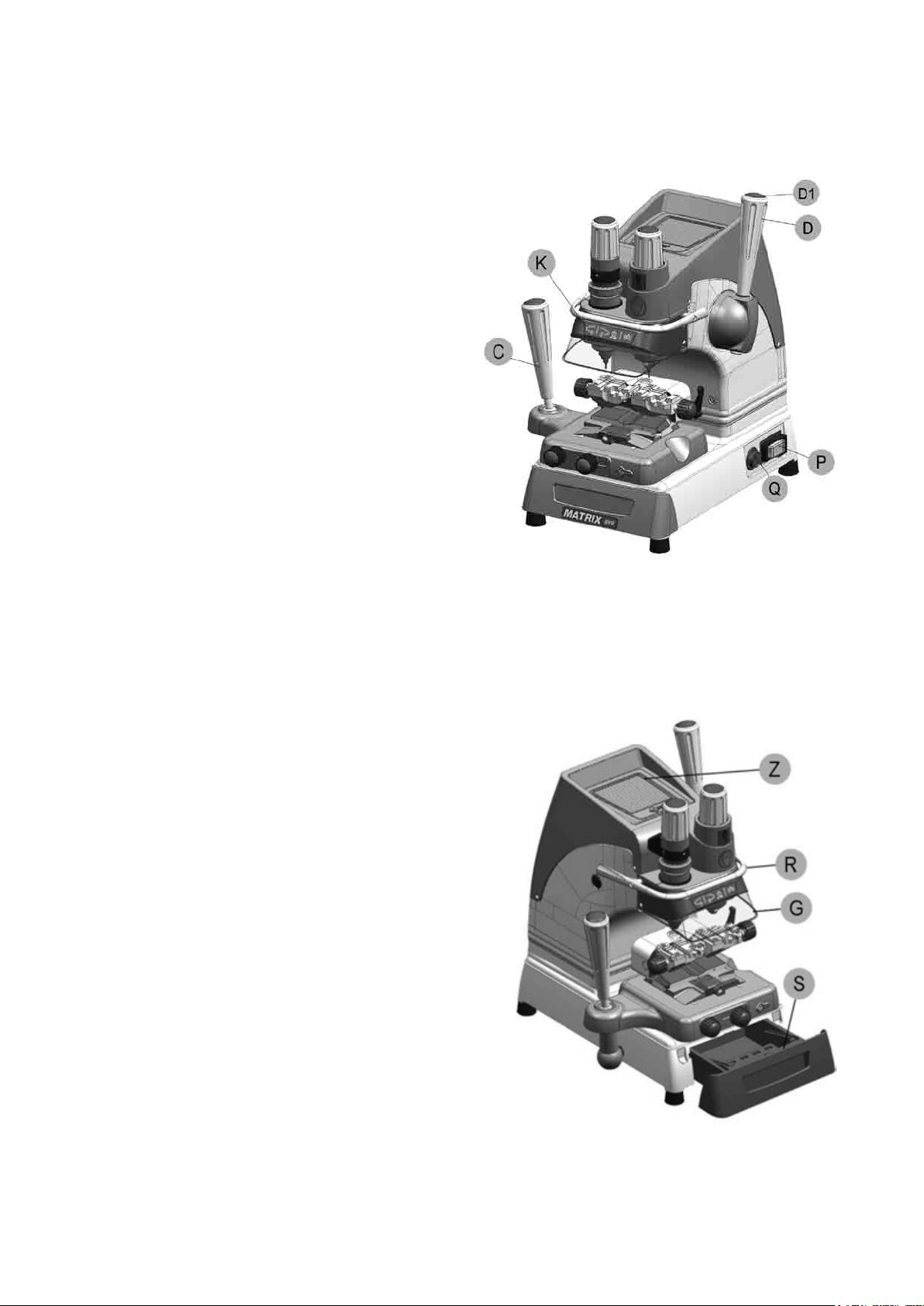

2 WORKING PARTS - MATRIX PRO

Fig. 7

A - clamp carriage (X-Y axes)

A1- clamp locking lever

B - left-hand tilting clamp

B1- right-hand tilting clamp

C - clamp carriage lever (X-Y axes)

D - vertical carriage lever (Z axis)

D1- lever release and motor start button

E - left-hand clamp knob

E1- right-hand clamp knob

F - cutter

G - transparent safety shield

H - clamp carriage locking knob

I - clamp tilt locking lever

J - lamp

K - calibration unit key pad

M - tracer point locking knob

M1- cutter locking knob

N - tracer point spring cam

O - carriage spring knob

P - ON/OFF switch

Q- motor ON switch

R - rollbar

S - tool box

T - tracer point

V - tracer point regulation micrometric ring

W- motor ON warning light

Z - power socket

Copyright Silca 20126

Operating Manual Matrix

3 WORKING PARTS - MATRIX EVO

A - clamp carriage (X-Y axes)

A1- clamp locking lever

B - left-hand tilting clamp

B1- right-hand tilting clamp

C - clamp carriage lever (X-Y axes)

D - vertical carriage lever (Z axis)

D1- lever release and motor ON button

E - left-hand clamp knob

E1- right-hand clamp knob

F - cutter

G - transparent safety shield

H - clamp carriage locking knob

I - clamp tilt locking lever

J - lamp

K - calibration unit key pad

Fig. 8

N - tracer point spring cam

O - carriage spring knob

P - ON/OFF switch

Q - motor ON switch

R - rollbar

S - tool box

T - tracer point

V - tracer point regulation micrometric ring

W - motor ON warning light

Z - power socket

Copyright Silca 2012 7

Operating Manual Matrix

4 ACCESSORIES PROVIDED

MATRIX comes with a series of accessories for use and maintenance (tools, hex wrenches, fuses, etc.) provided

in a special holder:

FICHET adapter “F”

D910534ZR

(STANDARD on vers.230V)

F1 cutter fuse 2 pcs

T1 tracer point

F22 cutter Steel bar

T22 tracer point Calibration pins

fuse 1 pc

500 mA - rapid

MERCEDES adapter “M”

D910533ZR

(STANDARD on vers.120V)

2,5 Amp - rapid (230V)

6,3 Amp - rapid (120V/100V)

2.5 mm hex wrench

Adhesive label

“DANGEROUS

MOBILE PARTS”

4.1 TECHNICAL DATA

Power supply: 230V-50/60Hz - 0,75 Amp. - 170 Watt

100V/120V - 50/60Hz - 2,3 Amp. - 220 Watt

Cutter motor: single phase 1 speed motor 230V - 50/60 Hz

Cutters: Super speed steel

Tool speed: 6000 rpm (for cutters in super speed steel)

Movements: on 3 axes by ball guides

Clamps: tilting with interchangeable plates

Runs: X axis: 40 mm Y axis: 50 mm Z axis: 30 mm

Dimensions: width: 310 mm (maximum lever operating space 400 mm)

depth: 400 mm height: 470 mm

Illumination: LED lamp

Mass: Kg. 24,6

Noise rating: Lp (A) = 70,5 dB (A) brass dimple keys

Lp (A) = 75,9 dB(A) brass keys with laser cuts

Lp (A) = 76,6 dB(A) steel keys with laser cuts

Copyright Silca 20128

Operating Manual Matrix

5 ELECTRIC DIAGRAM

Fig. 9

1) Fuses: 2,5 Amp (230V) - 6,3 Amp (100V/120V)

2) Safety switch

3) Terminal board

4) Motor ON/OFF switch

5) Motor 6,3mF (230V) - 14 mF(100V/120V)

6) Motor warning light (LED)

7) Motor safety microswitch

Copyright Silca 2012 9

8) Transformer

9) LED circuit

10) LED lamp

11) Tracer point contact

12) Cutter contact

13) Antenna (not on Matrix EVO)

14) Fuse 500 mA - rapid

Operating Manual Matrix

6 HANDLING

The MATRIX key-cutting machine is easy to handle and there are no special hazards involved in moving it.

The packed machine can by carried manually by one person.

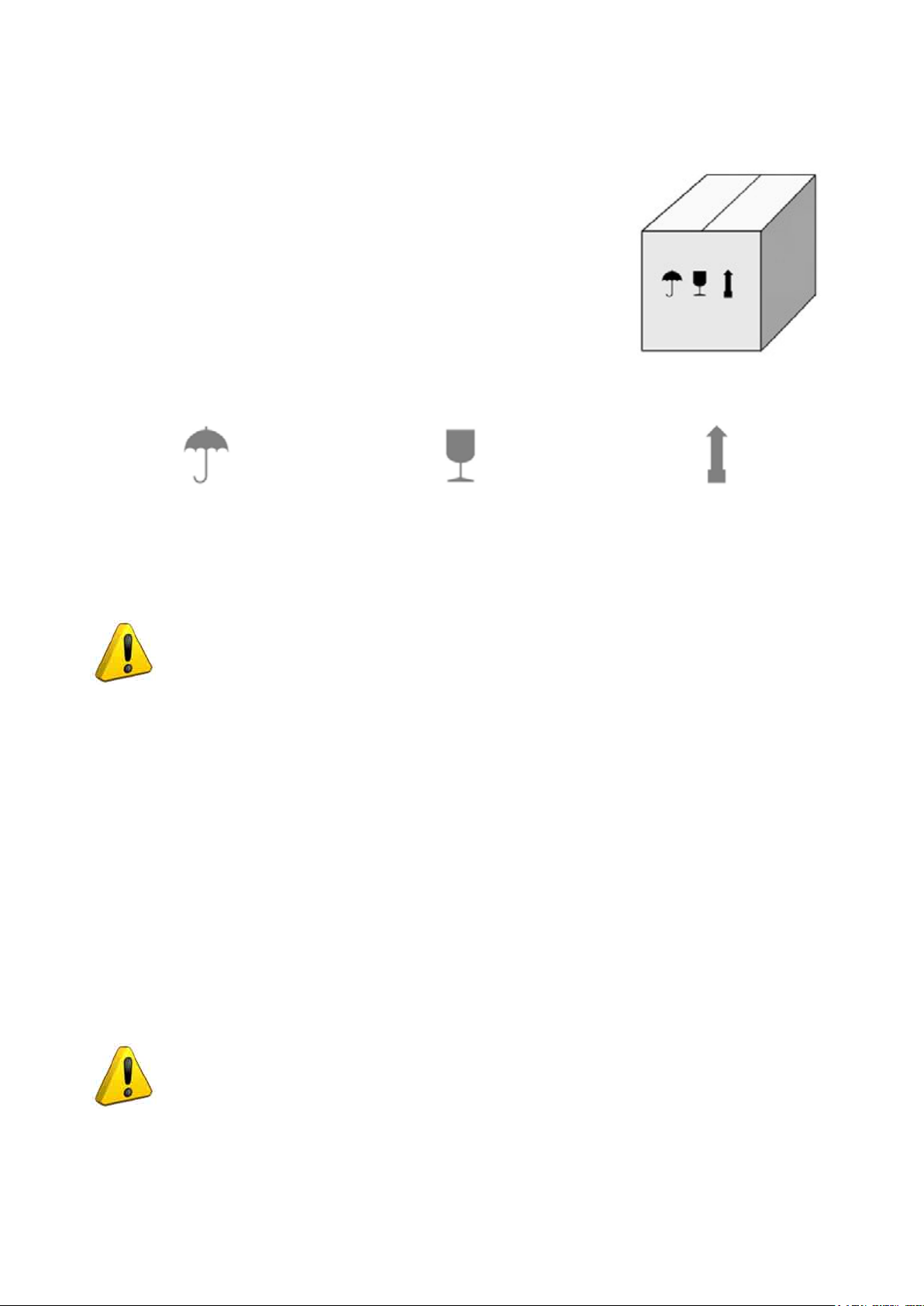

6.1 PACKING

The packing for the MATRIX key-cutting machine ensures safe handling of

the machine and all its components.

Packing comprises expanded plastic material wrapped around the machine.

The robust cardboard box in which it is placed and the nylon wrapping protect

the machine even when stored for a long period.

Fig. 10

Keep dry Handle with care Up

6.2 TRANSPORT

The symbols on the outside of the cardboard box give indications for transport.

ATTENTION: keep the packing for future machine transfers.

6.3 UNPACKING

To remove the machine from its packing:

1) Cut the strapping with scissors and remove.

2) Open the box carefully without damaging it.

3) Free the machine from the protective shells.

4) Check the contents of the packing, comprising:

-

MATRIX key-cutting machine.

-

Documentation comprising: user’s manual, spare parts sheet, specialist guide and warranty.

-

Power lead.

-

Tool holder.

6.4 HANDLING THE MACHINE

Once removed from its packing place MATRIX directly on the work bench; one person can easily perform this

operation.

ATTENTION: lift the machine by holding onto the base. Never lift the machine by gripping

the clamps, levers or other parts.

Copyright Silca 201210

Operating Manual Matrix

7 MACHINE INSTALLATION AND PREPARATION

Installation is the customer’s task and does not require any special skills.

The key-cutting machine is supplied ready for use and does not need calibration except for the tools to be used;

however, the operator is required to make certain checks and prepare the machine for use.

7.1 CHECKING FOR DAMAGE

MATRIX is a solid compact machine and will not break if handling, unpacking and installation are carried out to

the instructions in this manual. However, it is good practice to check that the machine has not been damaged.

7.2 ENVIRONMENTAL CONDITIONS

To make the most of the key-cutting machine, bear in mind the following environmental parameters: it is advisable

for the area to be dry with good air circulation.

The optimum environmental conditions for machine operation are:

-

temperature 10° C to 40° C;

-

relative humidity: approx. 60%.

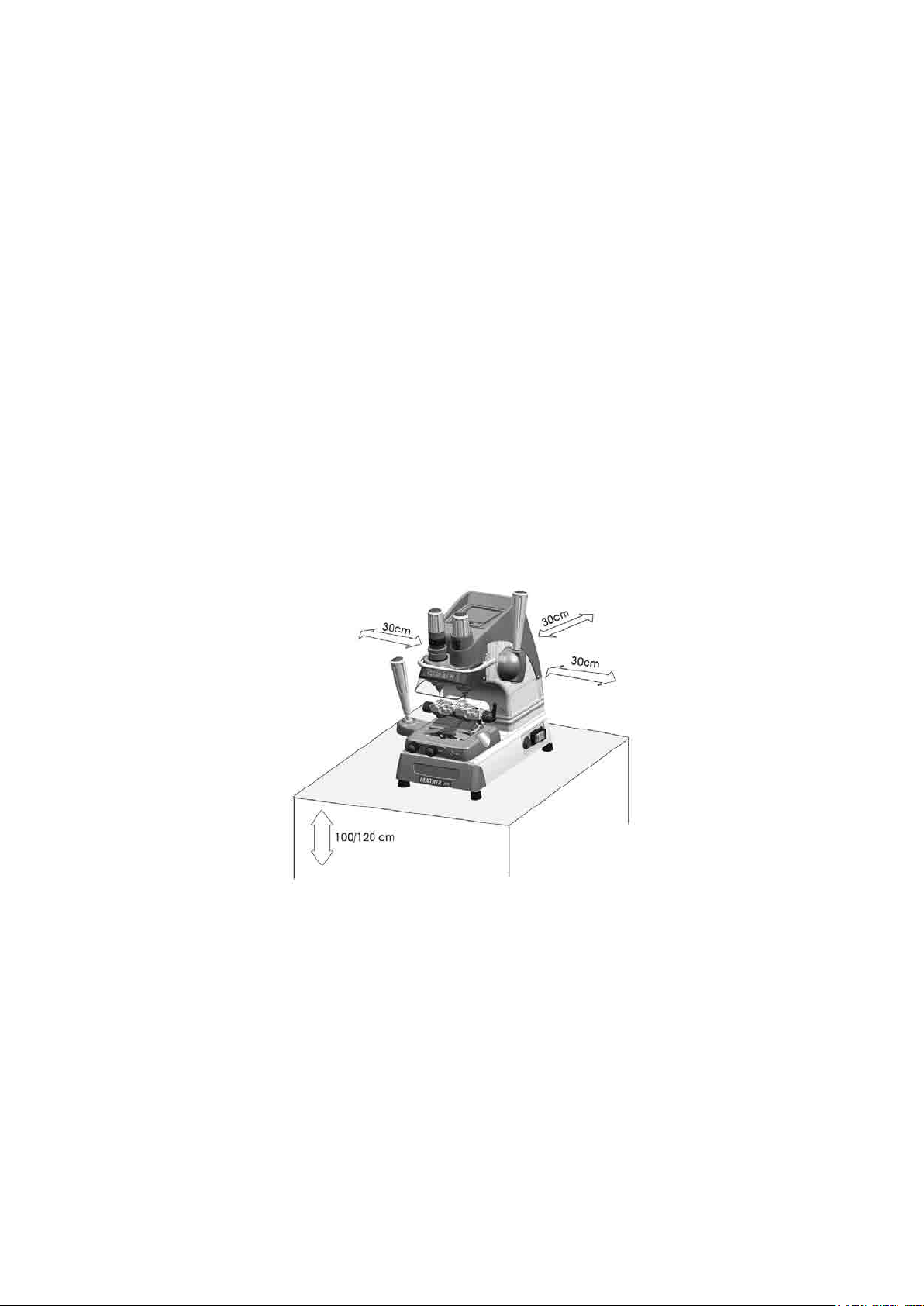

7.3 POSITIONING

1) Place the key-cutting machine on a solid horizontal work bench suitable for the weight of the machine (24,6

Kg). The work bench should be approximately 100-120 cm high to facilitate access to the working parts. We

recommend leaving at least 30 cm clearance behind and around the machine to ensure good ventilation and

facilitate handling (Fig. 11).

2) Make sure machine voltage is suitable for the mains supply and that the latter is earthed with a differential

switch.

3) Connect the power lead to the machine.

Fig. 11

7.4 SAFETY DEVICES

• ON/OFF master switch (P)

The master switch (P) is electromagnetic and turns the machine off automatically when power fails. When power

returns the switch must be reset manually to provide the machine with voltage.

• Push button (D1) to release the lever and start the motor

When push button (D1) is not activated there is no risk of involuntarily or accidentally moving the lever (D) and

preventing the motor from starting.

• Warning light (W) cutter motor on

The right-hand front part of the machine (behind the clamp unit) has a warning light (W). The warning light ashes

when the cutter motor is on.

Copyright Silca 2012 11

Operating Manual Matrix

7.5 WORK STATION DESCRIPTION

The machine is operated by a single person using the following controls:

• ON/OFF master switch (P) located on the righthand side of the machine.

• Motor ON/OFF switch (Q).

• Vertical carriage lever (D) with push button (D1) to

release the lever and start the motor.

• Clamp unit

• Lever (left-hand) (C)

• Key pad (calibration and illumination) (K)

Fig. 12

• ORGANIZER SHELF (Z)

The top part of the cover incorporates an area for the operator to use as a place for things such as key blanks or

cut keys. It is advisable not to put too many things in this area, as they could accidentally fall off.

• ROLLBAR (R)

The purpose of this special bar is to assist the operator

during key cutting. It is used as a rest for the left hand when

moving the clamp carriage (centering cuts on dimple keys or

cutting path for laser keys). It ensures smooth synchronised

carriage movements during cutting operations.

• TRANSPARENT SAFETY SHIELD (G)

Special plexiglass shield to limit the dispersal of swarf.

• TOOL BOX (S)

In the bottom part of the machine front, under the clamp

unit carriage, there is a tool box with an open part to use as

a handle for pulling out the box. Inside it has 20 spaces for

holding tracer points and cutters, and a larger area for other

small tools and/or keys.

Fig. 13

Copyright Silca 201212

Operating Manual Matrix

7.6 STARTING THE KEY-CUTTING MACHINE

1) Connect the power lead.

2) Turn on the key-cutting machine with the master switch (P). A beep sounds and for a second all the warning

lights (leds) on the key pad/control board (K) light up simultaneously on the machine front (blue vertical bar –

green vertical bar -2 red arrows) (Fig. 5).

3) When the beep stops only the blue warning light stays on to indicate that the machine is live.

Note: if the conditions described above do not occur, see chap. 10.7.

7.6.1 STARTING THE MOTOR

With the machine connected and on:

1) press the luminous switch (Q) to power the motor.(Fig. 12).

2) Press the push button (D1) on the vertical axis lever (D) and lower the lever.

ATTENTION: if the motor does not start and the lever (D) will not move, check that the

lever is fully tightened.

Aashingwarninglight(W)signalsthatthemotorison(Ch.7.6.2).Attention:cutterinmotion!

3) To turn off the motor release the lever (D) or turn off one of the 2 switches (P) or (Q).

7.6.2 CUTTER MOTOR ON WARNING LIGHT

There is a warning light (W) on the right-hand part of the machine front (behind the

clamps unit) (Fig. 14). When the cutter motor is on the warning light ashes.

7.6.3 LED LAMP (MATRIX PRO VERSION)

When the key-cutting machine is turned on the lamp is off.

To turn on the lamp simply take a hand up to the clamp or

spindle area.

The light goes on atuomatically due to a proximity sensor

inside the front part..

This function can be disabled by the operator:

Turning on:

-

lightly touch the lamp button (J1) to keep the light on.

Turning off:

-

lightly touch the lamp button (J1) again; after a few seconds

initial conditions are automatically reset.

Note: every time the machine is turned on the initial

illumination function is reset (turning on by proximity

sensor).

Fig. 14

7.6.4 LED LAMP (MATRIX EVO VERSION)

When the key-cutting machine is turned on the lamp is off.

Lightly touch the button (J1) to turn the lamp on or off.

Copyright Silca 2012 13

Fig. 15

Operating Manual Matrix

8 MACHINE CALIBRATION AND REGULATION

Before carrying out cutting operations the clamps and tools must be regulated. The spring devices on the machine

to facilitate cutting operations for the operator are activated or deactivated according to the type of key to be cut:

• vertical spring for the tracer point used for dimple keys (ch.8.4)

• cross spring for the carriage used for laser keys (ch.8.5)

8.1 FITTING AND REMOVING TOOLS

ATTENTION: carry out this operation with the cutter motor off.

Lever (D) fully raised.

Clamp carriage lever (C) fully down.

Fig. 16

Matrix PRO version

Tracer point

Fitting:

-

insert the tracer point all the way into its spindle,

with numbered ring towards the clamp.

-

Hold the tracer point in this position and turn the

upper knob (M) clockwise to lock.

Removing:

-

turn the knob (M) anti-clockwise to open the selfcentering gripper and remove the tool. Rotate the

knob without exerting pressure until it clicks.

Cutter

Fitting:

-

insert the cutter all the way into its spindle, with

numbered ring towards the clamp.

-

Turn the tool to t it into its seat (anti-rotation

system).

-

Hold the cutter in this position and turn the knob

(M1) clockwise to lock. Do not exert pressure to

turn the knob slightly (M1).

Removing:

-

press knob (M1) lightly downwards and turn anticlockwise to open the self-centering gripper and

remove the tool. Do not exert pressure to turn the

knob slightly (M1).

Fig. 17

Copyright Silca 201214

Operating Manual Matrix

Matrix EVO version

Tracer point

Fitting:

-

insert the tracer point all the way into the spindle with the numbered ring

towards the clamp.

-

hold the tool in this position and tighten the grub screw (G3) with the hex

wrench provided.

Removing:

-

loosen the grub screw (G3) with the hex wrench and remove the tool.

Fig. 18

Cutter

Fitting:

-

insert the cutter into the spindle with the numbered ring towards the clamp.

-

hold the tool in this position and tighten the grub screw (G4) with the hex wrench.

Removing:

-

loosen the grub screw (G4) with the hex wrench and remove the tool.

8.2 MICROMETER GAUGE

The micrometer gauge is used for tool alignment and also for adjusting small

variations in depths often necessary on worn keys.

After tool alignment (green bar) the depth of cuts can be reduced or increased

by turning the micrometer gauge (V) to the left or right.

Each line on the gauge corresponds to an increase of 0.02 mm.

Fig. 19

• Turn the gauge clockwise to make cuts less

deep.

Copyright Silca 2012 15

• Turn the gauge anti-clockwise to make cuts

deeper.

Operating Manual Matrix

8.3 CALIBRATION / TOOL ALIGNMENT

Carry out this operation with the key-cutting machine on.

ATTENTION: check that the motor start switch (Q) is off.

1) Check that the clamps are in the horizontal position (ref. 0) (Ch.8.6).

2) Turn the cam (N) clockwise all the way to disable the tracer point spring (Ch.8.4).

3) Fit and secure the two tools (tracer point and cutter) in their respective spindles.

4) Press the button (K1) on the front of the machine to enable the key pad/control board.

Tool alignment (green)

Tracer point -

key

contact

Cutter - key contact

Fig. 20

5) Press the lever (D) release button (D1), lower the vertical carriage and take the tools into contact with the clamp

surface (seat of the key)(Fig. 21) There are three possibilities:

• Central green bar illuminated - Green arrows illuminated - CALIBRATION OK

In this case both tools are in contact with the keys and aligned.

Note: from this position it is advisable to turn the gauge (V) clockwise by a couple of clicks.

• Left-hand red arrow illuminated - Tracer point side

In this case only the tracer point is in contact with the key.

Hold the vertical carriage down and turn the gauge (V) anti-clockwise in the direction of the illuminated arrow.

Calibration is complete as soon as the green vertical bar illuminates together with the two green arrows.

• Right-hand red arrow illuminated - Cutter side

In this case only the cutter is in contact with the key.

Hold the vertical carriage down and turn the gauge (V) clockwise in the direction of the illuminated arrow so that

the red light on the left-hand arrow goes on. From this position hold down rmly the right-hand lever and turn the

gauge (V) one click at a time. Calibration is complete as soon as the green vertical bar illuminates together with

the two green arrows.

ATTENTION: at the end of calibration press the button (K1) to disable the key pad/control

board.

6) Now it’s possible to proceed with duplication.

Copyright Silca 201216

Operating Manual Matrix

8.4 TRACER POINT SPRING

Fig. 21

The machine comes with a rapid system for enabling or

disabling the tracer point spring.

• To enable the tracer point spring function.

Turn/push the cam (N) all the way anti-clockwise.

• To disable the tracer point spring function.

Turn/push the cam (N) all the way clockwise.

Enable the tracer point spring:

-

to cut dimple and tubular keys.

Disable the tracer point spring:

-

for calibration operations.

-

to cut keys with laser cuts and vehicle keys in

general.

Fig. 22

Copyright Silca 2012 17

Operating Manual Matrix

8.5 CARRIAGE SPRING FOR LASER KEYS

The MATRIX key-cutting machine comes with a spring system on the clamp carriage to control the range of

movement, considerably facilitating the cutting of laser keys. The spring function for laser keys is activated by

means of the knob (O) (Fig. 23) and causes pressure on the tool sides along the cutting track when making cuts;

this method allows the operator to trace cuts manually without pressing crosswise with the lever (C). Fig. 24, Fig.

25 and Fig. 26 illustrate the three examples of use of the spring system:

• CENTRAL cuts

• RIGHT-HAND cuts

• LEFT-HAND cuts

CENTRAL cuts

Fig. 23

Fig. 24

Copyright Silca 201218

Operating Manual Matrix

RIGHT-HAND cuts

Fig. 25

LEFT-HAND cuts

D910533ZR

OPTIONAL on vers.230V

STANDARD on vers.120V

Fig. 26

REGULATING CARRIAGE SPRING for LASER KEYS

With the motor power switch (Q) off, loosen the knob (O) slightly (Fig. 23).

• Central cuts:

Take the tools above the keys centred over the key stem (Fig. 24).

• Right-hand cuts:

Take the tools above the keys to the left of the key stem (Fig. 25).

• Left-hand cuts:

Take the tools above the keys to the right of the key stem (Fig. 26).

-

Lock the knob (O) and proceed with cutting.

Copyright Silca 2012 19

Operating Manual Matrix

8.6 CLAMPS

The machine comes with a set of tilting clamps (0 +- 45°). The clamp unit can be pulled out and placed into the

guides according to the operator’s needs. The clamp unit has two positioning notches according to the type of

jaws to be used for cutting (Fig. 27 and Fig. 28).

1) Turn the lever (A1) anti-clockwise to move the clamp sideways and/or remove it. Turn the lever (A1) clockwise

to lock the clamp in place.

Fig. 27 Fig. 28

2) Loosen the handle (I) in order to turn/incline the clamp for the cutting angle required. The angle is shown on the

central body (B2). The values of 0°, 15°, 30° and 45° are visible, whereas to see the others the reference lines

must be used. Each line corresponds to 5°.

Each clamp (right or left hand) comprises 3 jaws.

-

Standard stationary jaw (located on left)

-

Mobile central jaw

-

Right-hand stationary jaw

NOTE: Carefully clean the clamp before and/or after cutting a key.

Fig. 29 - Matrix PRO clamps

Copyright Silca 201220

Operating Manual Matrix

Fig. 30- Matrix EVO clamps

Fig. 31

8.6.1 THE CLAMP UNIT HAS SEVERAL SEATS DEDICATED TO THE POSITIONING OF DIFFERENT TYPES OF KEYS:

• keys with dimple cuts and laser keys

• laser keys with a narrow stem (Mercedes)

• FichetkeyswithHprole

• Cisa/Abus/Bricard(withCS62-CS70...proles)keys

• vehiclekeyswithHU66proles

• tubular keys (Matrix Pro version only).

Copyright Silca 2012 21

Operating Manual Matrix

KEYS WITH DIMPLE CUTS AND LASER KEYS

Fig. 32 Fig. 33

Use the left-hand part of the clamp for keys with head stop (stop 0) or tip stop (Stop 1 - Stop 2 - Stop 3).

Copyright Silca 201222

Fig. 34

Operating Manual Matrix

FICHET KEYS WITH H PROFILE

D910534ZR

STANDARD on vers.230V

OPTIONAL on vers.120V

Use the left-hand part of the clamp and the F adapter.

Fig. 35

LASER KEYS WITH A NARROW STEM (MERCEDES)

D910534ZR

STANDARD on vers.120V

OPTIONAL on vers.230V

Use the left-hand part of the clamp and the M adapter.

Fig. 36

KEYSWITHDIMPLECUTSCISA/ABUS/BRICARD(withCS62-CS70-BD13...prole)

Use the bottom right-hand part of the clamp for cuts on the stem.

Fig. 37

Copyright Silca 2012 23

Operating Manual Matrix

LASER KEYS WITH HU66 PROFILE

Use the top right-hand part of the clamp.

Fig. 38

TUBULAR KEYS (MATRIX PRO VERSION ONLY)

Use the special seat in the front right-hand part of the clamp.

Fig. 39

For other types of keys consult the Specialist Guide for the key-cutting machine in use.

Copyright Silca 201224

Operating Manual Matrix

9 CUTTING

ATTENTION: Please see the following warnings to ensure completely safe cutting

operations:

• Always work with dry hands.

• Check that the machine is earthed.

• Wear the safety goggles even when the machine has a safety shield.

• Start the motor only after completing the following operations:

-

tting keys into the clamps

-

tting and calibrating tools.

• Keep your hands out of the way of the cutter in motion.

• For each cutting operation make sure the clamp is in the horizontal position (reference notch 0) except

when keys need inclined cuts.

• Cut the key only if calibration has taken place:

-

insert the necessary tools

-

turn on the key-cutting machine

-

disable the tracer point spring

-

proceed with calibration

9.1 FITTING KEYS

1) Take the clamp carriage towards the operator until you feel the limit switch click.

2) Insert the original key into the left-hand clamp and the key to be cut into the right-hand clamp, taking care to:

-

type of stop on key (Ch. 8.6.1)

-

choice of key seat (Ch.8.6.1).

-

secure the keys with the knobs (E) (E1).

9.2 KEY STOP

The notches 0-1-2-3 on the clamp are used according to the type of key stop:

-

0: for keys with back stop (towards head - Fig. 40).

-

1-2-3: for keys with tip stop (Fig. 41)

Choice of stops 1 - 2 - 3 is determined by the length of the key stem.

ATTENTION: the cutting path must always lie within the clamp surface.

Fig. 40 Fig. 41

Copyright Silca 2012 25

Operating Manual Matrix

After tting the keys into the clamps, follow the instructions for the type of key to be cut (9.3 Cutting dimple keys;

9.4 CUTTING laser TYPE keys; 9.5 Cutting FICHET type keys (H prole); 9.6 CUTTING tubular keys (MATRIX

PRO version)).

9.3 CUTTING DIMPLE KEYS

1) Enable the tracer point spring (Ch.8.4).

2) Press the motor on switch (Q).

3) Insert the two keys into their clamps.

4) Take care when positioning the keys:

-

Stop 0 for keys with stops.

-

Stop 1 / 2 / 3 for keys without stops, using the bar provided for tip stop.

5) Attention: if the bar is used, remove it before making the cuts.

6) Grip the levers (C) and (D).

7) Press the button (D1) and lower the vertical carriage to start the motor.

8) Hold the carriage with the left-hand lever (C), lower the tool unit by means of the right-hand lever (D) until the

tracer point tip centres one of the holes. Continue to lower the lever (using the tracer point spring function) to

reach the cutting depth.

9) Repeat this operation for each hole on the key.

10) End cutting on the rst side, release the lever (D) to stop the motor.

11) Remove the cut key only and place it on the second side (the key has the same cuts on both sides).

12) Proceed with cutting side 2.

Fig. 42

9.3.1 BACK CUTS

If there are cuts on the back of the key, stand it upright on the bottom of the

clamp (Fig. 43).

Copyright Silca 201226

Fig. 43

Operating Manual Matrix

9.3.2 INCLINED CUTS

Proceed as follows for keys with inclined cuts:

1) Loosen the handle (I) to free the clamps and incline them to the chosen angle (see index (B2) on graduated

drum) (Fig. 44).

2) Lock the clamps in place with the handle (I).

3) Make the cuts.

Fig. 44

Fig. 45

Fig. 46

Copyright Silca 2012 27

Operating Manual Matrix

9.4 CUTTING LASER TYPE KEYS

1) Disable the tracer point spring (Ch.8.4).

2) Turn on the motor with the switch (Q).

3) Insert the two keys into their clamps.

4) Take care when positioning the keys:

-

Stop 0 for keys with stops (Ch. 9.2).

-

Stop 1 / 2 / 3 for keys without stops, using the bar provided for tip stop (Ch. 9.2).

5) Attention: if the bar is used, remove it before making the cuts.

6) Adjust carriage spring for laser keys (Ch.8.5) - Optional.

7) Grip the levers (C) and (D).

8) Press the button (D1) and lower the vertical carriage to start the motor.

9) Keep the clamp carriage still with the left-hand lever (C) and lower the tool unit by means of the right-hand lever

(D) until the tracer point reaches the cutting depth.

10) Without exerting pressure, turn the lever (D) clockwise to lock the height reached.

11) Move the lever (C) to trace all the cuts on the key with the tracer point.

• For right-hand cuts it is advisable to make the cuts by moving the tracer point from the head to the tip.

• For left-hand cuts it is advisable to make the cuts by moving the tracer point from the tip to the head.

12) When side 1 has been cut, turn off the motor with the switch (Q).

13) Remove the key blank only and turn it 180° to cut side 2. The key has the same cuts on both sides.

14) Start the motor with the switch (Q) and make the cuts.

Copyright Silca 201228

Fig. 47

Operating Manual Matrix

9.4.1 CUTTING LASER KEYS WITH NARROW STEMS

Another function of the clamp is to cut laser keys with narrow stems by tting the

adapter M (standard on 120V version, optional on 230V version).

Follow the instructions below:

1) open the clamps by loosening the knobs (E) (E1).

Silca ref. HU41P, HU64P, HU64T - HU81T:

2) t the adapter onto the left-hand clamp and align the groove with the one on the clamp for “Stop 2” (Fig. 49).

Silca ref. HU55P:

3) t the adapter onto the left-hand clamp and align the groove with the one on the clamp for “Stop 3” (Fig. 50).

4) slide the stop bar into the groove.

5) insert the key and take it right up against the bar.

6) secure adapter and key by tightening the knob (E).

7) remove the bar and repeat the same operation on the right-hand clamp.

Cutting:

8) disable the tracer point spring (cap.8.4).

9) grip the levers (C) and (D).

10) press the button (D1) and lower the vertical carriage to start the motor.

11) hold the clamp carriage still with the left-hand lever (C) and lower the tool unit with the right-hand lever (D) until

the tracer point touches the depth of the cut.

12) without exerting pressure, turn the lever (D) clockwise to block the height.

13) move the lever (C) to trace all the cuts on the key with the tracer point.

• For left-hand cuts we advise tracing the cuts by taking the tracer point from the tip to the head.

14) when the rst side has been cut, turn off the motor with switch (Q).

15) remove the key blank only and turn 180° to cut the second side. The key has the same cuts on both sides.

16) re-start the motor with switch (Q) and proceed with cutting.

STANDARD on vers.120V

OPTIONAL on vers. 230V

Fig. 48

D910533ZR

HU41P - HU64P - HU64T - HU81T HU55P

Fig. 49 Fig. 50

Copyright Silca 2012 29

Operating Manual Matrix

9.5 CUTTING FICHET TYPE KEYS (H PROFILE)

1) Open the clamps slightly by loosening the knobs (E) (E1).

2) Fit the adapters and take them up against the clamps (Fig. 51).

3) Insert the keys taking the stop up against the adapter (Fig. 52).

4) Secure adapters and keys by tightening the knobs (E) (E1).

Check that the motor ON switch (Q) is OFF.

5) Disable the tracer point spring (Ch. 8.4).

6) Adjust the spring for the laser key carriage (Ch.8.5 - central cuts) Optional.

7) Grip the levers (C) and (D).

8) Press the button (D1) and lower the vertical carriage.

9) Keep the clamp carriage still with the left-hand lever (C); lower the tool unit with the righthand lever (D), stopping before coming into contact with the clamp (close to the key).

10) Without exerting pressure, turn the lever (D) clockwise to lock the height reached (Fig.

53).

11) Start the motor with the switch (Q).

12) Move the lever (C) to trace all the cuts on the key with the tracer point.

Note:

• For right-hand cuts it is advisable to make the cuts by moving the tracer point from the head to the tip.

• For left-hand cuts it is advisable to make the cuts by moving the tracer point from the tip to the head.

13) When side 1 has been cut, turn off the motor with the switch (Q).

14) Remove both keys, turn 180 and t them into their clamps/adapters again. Start the motor with the switch (Q)

and make the cuts.

D910534ZR

STANDARD on vers.230V

OPTIONAL on vers.120V

Fig. 51

Fig. 52 Fig. 53

Copyright Silca 201230

Operating Manual Matrix

9.6 CUTTING TUBULAR KEYS (MATRIX PRO VERSION)

Check that the motor ON switch (Q) is OFF.

1) Insert the tools into their spindles.

2) Fit the keys into their seats on the clamps (original key in the left-hand clamp and key blank in the right-hand

clamp).

3) Take care when positioning the keys, the stop goes up against the jaws aligned with the notch.

4) Enable the tracer point spring function.

5) Turn on the motor.

6) Prip the levers (C) and (D).

7) press the button (D1) and lower the vertical carriage to start the motor.

8) Hold the carriage with the left-hand lever (C), lower the vertical carriage with the right-hand lever (D) until the

tracer point centres on one of the cuts in the key and continue to lower (using the tracer point spring function)

to reach cutting depth.

9) Move the lever (C) slightly to complete each single cut.

10) Repeat this operation for each cut on the key.

Fig. 54

Copyright Silca 2012 31

Operating Manual Matrix

10 MAINTENANCE

ATTENTION: when repairing or replacing parts the “CE” label is guaranteed only if

original spare parts provided by the manufacturer are used.

The MATRIX key-cutting machine does not need special maintenance, but it is good practice to check and if

necessary replace parts subject to wear: belts, lamp and vertical carriage spring.

Replacement operations are simple and can be performed by the operator.

CLEANING: it is advisable to keep the carriage and clamps clean by regularly brushing away the swarf deriving

from cutting operations.

ATTENTION:DONOTUSECOMPRESSEDAIR!

ATTENTION:tomaintainmachineefciencywerecommendusingprotectiveoilsuchas

WD40 or similar to apply to the burnished mechanical parts. This will prevent oxidation

of the parts in question (clamps, guides, carriages...). Make sure the oil does not come

into contact with the electronic parts.

Before performing any type of maintenance (checks or replacements) read the warnings below:

• do not perform any maintenance operations with the machine on.

• always disconnect the power lead.

• follow the instructions in the manual carefully.

• use original spare parts.

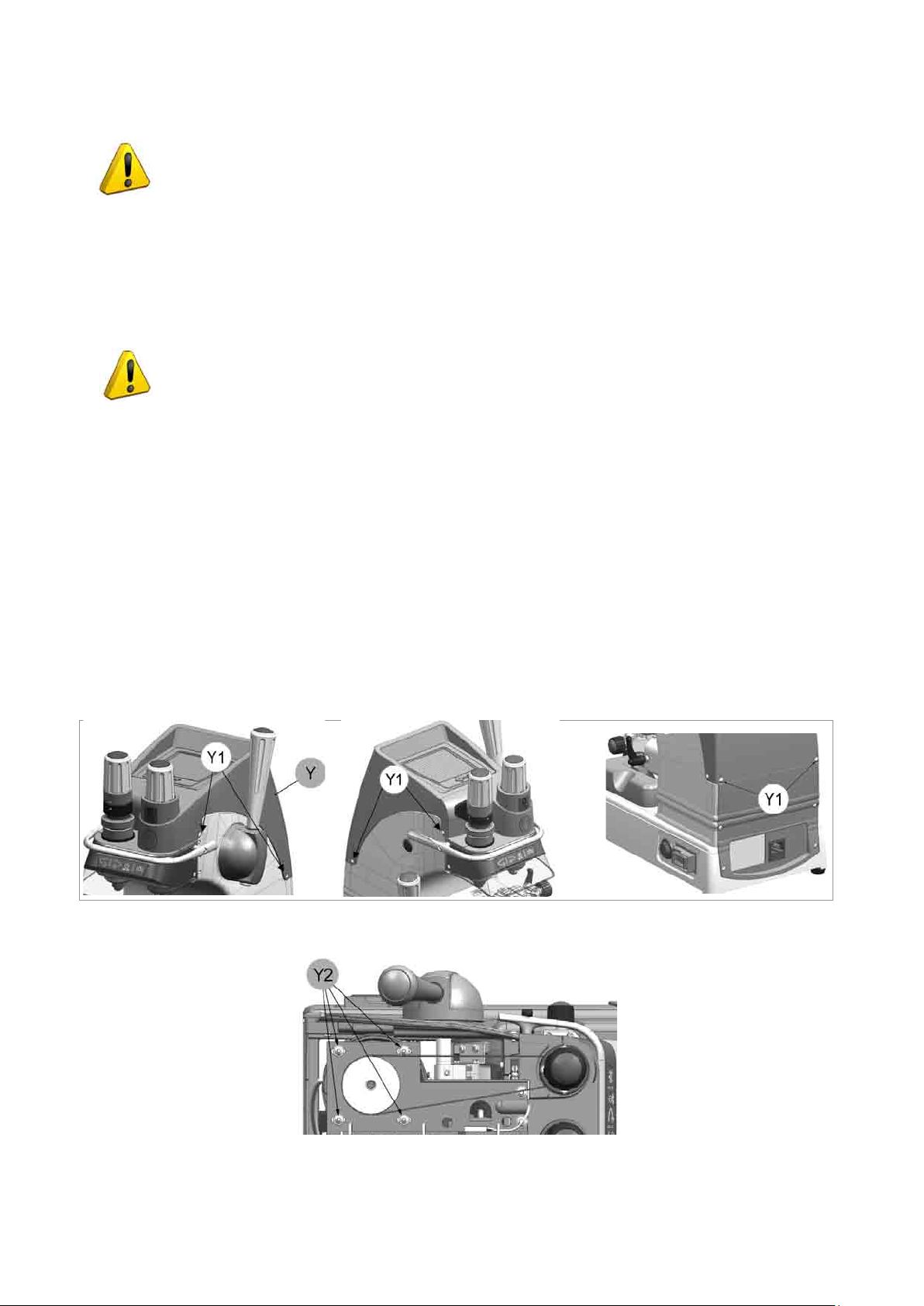

10.1 TIGHTENING AND REPLACING THE BELT

If vibrations occur on the top part of the key-cutting machine, check the state and tightness of the belt in the way

described:

1) Turn off the master switch and disconnect the power lead.

2) Loosen the 6 screws (Y1) and remove the top safety guard (Y).

3) Loosen (without removing) the 4 allen screws (Y2) securing the motor (Fig. 56).

Fig. 55

Copyright Silca 201232

Fig. 56

Operating Manual Matrix

Tightening:

• Increase belt tension by pushing the motor towards the back of the machine.

Replacing:

1) Loosen the 2 screws (V2). (Matrix PRO only).

2) Remove the knob unit by pulling towards the back of the machine (Matrix PRO version only).

3) Loosen the belt by pushing the motor gently towards the tracer point and cutter.

4) Remove the belt and replace.

5) Tighten by pushing the motor towards the back of the machine.

• secure the motor by tightening the 4 allen screws (Y2).

• re-position the knob unit and secure with the 2 screws (V2) (Matrix PRO only).

• replace the top safety guard (Y) and secure with the 6 screws (Y1).

Fig. 57 Fig. 58

10.2 REMOVING THE UPPER FRONT UNIT

1) Switch the machine off and disconnect the power lead.

2) Remove the 2 screws (R1) securing the rollbar (Fig. 59).

3) Loosen the 4 screws (K2) securing the upper front unit (K5) and remove.

10.3 REPLACING THE ROLLBAR

1) Remove the upper front unit (K1) (Ch. 10.2).

2) Loosen the 3 screws (R3) and remove the rollbar (R) (Fig. 60).

3) Fit the new rollbar and secure with the 3 screws (R3).

4) Replace the upper front unit on the machine and secure with the 4 screws (K2).

5) Secure the rollbar with the 2 screws (R1).

Copyright Silca 2012 33

Operating Manual Matrix

10.4 REPLACING THE TRANSPARENT SAFETY SHIELD

1) Remove the upper front unit (Ch.10.2).

2) Use a screwdriver to detach the shield from the upper front unit.

3) Attach the new shield to the upper front unit.

4) Replace the cover on the machine and secure with the 4 screws (K2).

5) Secure the rollbar with the 2 screws (R1).

Fig. 59 Fig. 60

10.5 REPLACING THE LAMP

Follow the instructions below to replace the lamp:

1) Remove the upper front unit (Ch. 10.2).

2) Disconnect the connector (J4) (Fig. 61).

3) Loosen and remove the 2 screws (J1) securing the lamp glass (Fig. 62).

4) Loosen and remove the 2 screws (J3) securing the LED board.

5) Pull the LED lamp downwards.

6) Fit the new LED board so that the wire passes over the top and connect the connector to the board.

7) Secure the new board with the 2 screws (J3).

8) Secure the lamp glass with the 2 screws (J1).

9) Connect the connector (J4).

10) Replace the upper front unit on the machine and secure with the 4 screws (K2).

11) Secure the rollbar with the 2 screws (R1).

Fig. 61 Fig. 62

Copyright Silca 201234

Operating Manual Matrix

10.6 ADJUSTING/REPLACING THE VERTICAL CARRIAGE SPRING

If the vertical carriage (Z axis) seems loose it is advisable to adjust the spring and replace if necessary. Proceed

as follows:

1) Switch off the machine and disconnect the power lead.

2) Remove the 6 screws (Y1) to detach the top safety guard (Y) (Fig. 55).

3) Loosen the 4 screws (Y3) and remove the rear panel (Fig. 63).

4) Turn the machine so that its back faces the operator.

to increase spring tightness:

-

perform operations 1 and 2 shown in Fig. 65.

to decrease spring tightness:

-

perform operations 1 and 2 shown in Fig. 66.

5) Replace the safety guard (Y) and secure with the 6 screws (Y1) (Fig. 51).

To replace the spring:

-

follow the instructions in points 1. 2. 3.

-

replace the spring and adjust tightness.

Fig. 63

Fig. 64 Fig. 65 Fig. 66

Copyright Silca 2012 35

Operating Manual Matrix

10.7 CHECKING AND REPLACING FUSES

Fuses should be checked with an instrument for measuring continuity (tester, ohmeter, multimeter, etc.) as they

may appear normal to the eye even when electrically damaged. Each fuse must be replaced with one of the same

value (Amperes) and type (rapid or delayed), as shown in the manual. The MATRIX key-cutting machine has:

2 fuses:

2,5 Amperes rapid on the 230 Volt key-cutting machine.

6,3 Amperes rapid on the 100/120 Volt key-cutting machine

located in the mains socket, they protect the machine from voltage

variations and possible short circuits.

If the machine does not go on when the switch is activated, it is

advisable to check the fuses in the way described:

1) Turn off the machine with switch (P) and disconnect the power

lead.

2) Use a screwdriver to remove the fuses.

Fig. 67

1 fuse:

500 mA rapid

situated on the terminal board, it protects the calibration keypad circuit board from possible short circuiting. Check

the fuse when the blue LED does not illuminate with the machine on (circuit board not powered).

Follow the instructions below:

1) Turn off switch (P) and detach the power lead.

2) Place the key-cutting machine on its back and loosen the 4 screws (P4) to remove the bottom safety plate (Fig.

75).

1) Take the fuse out of its seat (V3) (Fig. 68 and Fig. 69).

2) Replace and secure the bottom safety plate with the 4 screws (P4).

3) Return the key-cutting machine to its proper position.

Fig. 68 Fig. 69

Copyright Silca 201236

Operating Manual Matrix

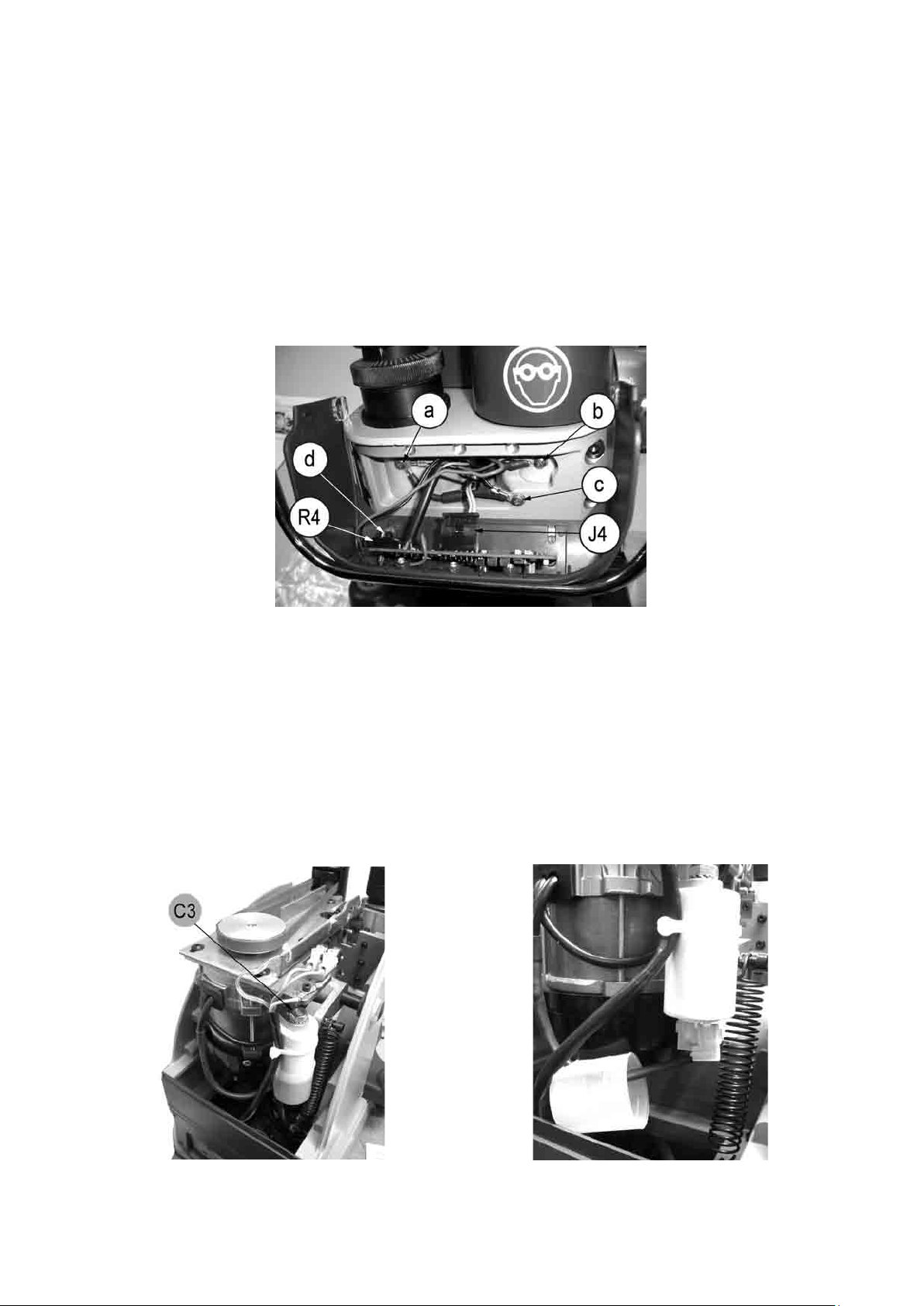

10.8 REPLACING THE CALIBRATION KEY PAD ELECTRONIC CIRCUIT BOARD

If the key pad (K) is not working properly replace the electronic circuit board inside it as described below:

1) Remove the upper front unit (Ch. 10.2).

2) Detach the connectors (J4 and (R4) (Fig. 70).

3) Remove the 4 screws (a) (b) (c) (d) paying attention to the position of the wires.

4) Remove the 2 screws (K4) xing the circuit board.

5) Replace the circuit board, secure with the 2 screws and re-connect the 2 connectors (J4) and (R4) and the 4

wires with screws (a) (b) (c) (d).

6) Replace the upper front unit on the machine and secure with the 4 screws (Ch. 10.2).

7) Secure the rollbar with the 2 screws (R1) (Ch. 10.3).

Fig. 70

10.9 REPLACING THE CONDENSER

1) Disconnect the key-cutting machine from the mains.

2) Loosen the 6 screws (Y1) and remove the top cover (Fig. 55).

3) Move the protective cap on the condenser (Fig. 72).

4) Disconnect the connectors from the condenser, paying attention to their position.

5) Loosen the condenser xing nut (C3).

6) Connect the connectors to the new condenser and replace the protective cap.

7) Secure the condenser with the nut (C3).

8) Replace the top cover and tighten the 6 screws (Y1).

Fig. 71 Fig. 72

Copyright Silca 2012 37

Operating Manual Matrix

10.10 REPLACING THE MOTOR

1) Disconnect the key-cutting machine from the mains.

2) Loosen the 6 screws (Y1) and remove the top cover (Fig. 55).

3) Loosen the 2 screws (W1) xing the motor wires to the terminal board and the screw on the earth wire (W2).

4) Loosen the 4 screws (Y2) securing the motor.

5) Remove the motor pulley belt.

6) Loosen the grub screw (P2) securing the motor pulley and pull upwards to remove (Fig. 74).

7) Grip the motor with one hand and use the other to loosen and remove the 4 screws (Y2).

8) Pull the motor out from back of the machine.

Fig. 73 Fig. 74

10.11 REPLACING THE TRANSFORMER

1) Disconnect the power lead from the machine.

2) Turn the key-cutting machine on its back and loosen the 4 screws (P4) to remove the bottom safety guard (Fig.

75).

3) Loosen the 2 screws (Z2) xing the low voltage (transparent) cables (20V) (Fig. 76).

4) Loosen the 2 screws (Z3) xing the mains supply wires (a wire in position 0 and a wire corresponding to the

voltage being used).

5) Loosen the 4 screws (T3) securing the transformer and remove.

6) Install and secure the new transformer with the 4 screws (T3).

7) Use the screws (Z2) to x the 2 transparent low voltage cables in the 12 Volt connectors on the transformer.

8) Secure the 2 mains supply wires to the connectors on the transformer (a wire in position 0 and one

corresponding to the voltage being used), with their screws (Z3).

Take care that the position is correct according to the voltage

9) Replace and secure the bottom safety guard with the 4 screws (P4).

10) Return the key-cutting machine to the upright position.

(Fig. 76)

.

Copyright Silca 201238

Operating Manual Matrix

Fig. 75 Fig. 76

10.12 REPLACING SWITCHES: MASTER AND MOTOR ON

1) Disconnect the power lead from the machine.

2) Turn the key-cutting machine onto its back and loosen the 4 screws (P4) to remove the bottom safety guard

(Fig. 75).

3) Disconnect the wires from the switch to be replaced, paying attention to their position.

4) Press the xing “tabs” on the switch so that it can be pulled out.

5) Insert the new switch into the special seat.

6) Reconnect the connectors.

7) Replace and secure the bottom safety guard with the 4 screws (P4).

8) Return the key-cutting machine to the upright position.

Fig. 77 Fig. 78

Copyright Silca 2012 39

Operating Manual Matrix

10.13 ALIGNING/CALIBRATING THE CLAMP

The key-cutting machine comes from Silca with the clamp perfectly aligned. Alignment is necessary only if:

-

a jaw falls from the clamp and has to be replaced

-

caduta accidentale del morsetto

1) Make sure the motor ON switch is OFF.

2) Fit and secure the 2 calibrating pins (provided) to the 2 spindles as if they were tools. N.B.: the at part (with

greater diameter) must be visible (towards the clamp).

3) Turn on the key-cutting machine with the master switch (P).

4) Enable the key pad /calibration control board with key (K1).

5) Disable the tracer point spring (Ch. 8.4).

6) Place the clamp set on the right or left hand notch, according to the control to be performed.

Fig. 79 Fig. 80

10.13.1 CONTROL ALIGNMENT LEFT-HAND STATIONARY JAWS

1) Lower the vertical carriage with the lever (D (Fig. 80).

2) Align the 2 pins on the key surface (Ch.8.3).

3) When the pins are aligned, raise them slightly with the lever (D) so that they are not in contact with the key

surface.

4) Turn the lever (D) clockwise to lock the height of the vertical carriage.

5) Move the clamp carriage with the lever (C) and take the pins into contact with several points on the left-hand

jaw (also on the side of Stop 0). If the calibration board shows a green light the left-hand jaws are aligned.

6) If not, loosen the 2 screws (B3) and regulate the jaw (if necessary, loosen the 2 nuts (B4) and regulate the 2

grub screws B5) until the condition described above is achieved.

Copyright Silca 201240

Fig. 81

Operating Manual Matrix

Fig. 82

10.13.2 CONTROL ALIGNMENT RIGHT-HAND STATIONARY JAWS

1) Lower the vertical carriage with the lever (D).

2) Align the 2 pins (Ch.8.3) on the key surface (seat for CS62 keys).

3) When the pins are aligned, raise them slightly with the lever (D) so that they are a few mm below the top

surface of the clamp. Turn the lever (D) clockwise to lock the height of the vertical carriage.

4) Move the clamp carriage with the lever (C) and take the pins into contact with several points on the right-hand

jaw. If the calibration board shows a green light the right-hand jaws are aligned.

5) If not, loosen the 2 screws (H3) and regulate the jaw (if necessary, loosen the 2 nuts (H4) and regulate the 2

grub screws (H5) until the condition described above is achieved.

Fig. 83

Fig. 84

Copyright Silca 2012 41

Operating Manual Matrix

10.14 REPLACING THE JAWS

Make sure the motor ON switch is OFF

10.14.1 REPLACING THE LEFT-HAND STATIONARY JAWS

1) Loosen the 2 screws (B3) and remove the jaw.

2) Fit the new jaw up against the left-hand side and align also from the front (Fig. 86).

3) Tighten the 2 screws (B3) without exerting pressure.

4) Check alignment (Ch. 10.13.1) and then fully tighten the 2 screws (B3).

Fig. 85 Fig. 86

10.14.2 REPLACING RIGHT-HAND STATIONARY JAWS

1) Loosen the 2 screws (H3) and remove the jaw.

2) Carefully clean the seat and t the new jaw up against the right-hand side and align also from the front(Fig. 88).

3) Tighten the 2 screws (H3) without exerting pressure.

4) Check alignment (Ch. 10.13.2) and then fully tighten the 2 screws (H3).

Fig. 87 Fig. 88

Copyright Silca 201242

Operating Manual Matrix

10.14.3 REPLACING LEFT-HAND CLAMP MOBILE JAW

1) Loosen the 2 screws (B3) and remove the stationary jaw (Ch.10.14.1).

2) Remove the knob (E) stop plate (S4) (Fig. 89).

3) Fully unscrew the knob (E).

4) Remove the mobile jaw and clean the clamp.

5) Fit the new jaw, screw in the knob and replace the plate (S4).

6) Fit the stationary jaw up against the left-hand side and align also from the front (Fig. 86).

7) Tighten the 2 screws (B3) without exerting pressure.

8) Check alignment (Ch. 10.13.1) and then fully tighten the 2 screws (B3).

Fig. 89 Fig. 90

10.14.4 REPLACING RIGHT-HAND MOBILE CLAMP JAW

1) Loosen the 2 screws (H3) and remove the stationary jaw (Ch.10.14.2).

2) Remove the knob (E1) stop plate (U4).

3) Fully unscrew the knob (E1).

4) Remove the mobile jaw and clean the clamp.

5) Fit the new jaw, screw in the knob and replace the plate (U4).

6) Fit the stationary jaw up against the right-hand side and align also from the front.

7) Tighten the 2 screws (H3) without exerting pressure.

8) Check alignment (Ch.10.13.2) and then fully tighten the 2 screws (H3).

Fig. 91 Fig. 92

Copyright Silca 2012 43

Operating Manual Matrix

11 DISPOSAL

For correct disposal please refer to current standards.

INFORMATION FOR USERS OF PROFESSIONAL EQUIPMENT

From “Actuation of Directive 2012/19/EU regarding Waste Electrical and Electronic Equipment (WEEE)”

The symbol of a crossed waste bin found on equipment or its packing indicates that at the end of the product’s

useful life it must be collected separately from other waste so that it can be properly treated and recycled.

In particular, separate collection of this professional equipment when no longer in use is organised and managed:

a) directly by the user when the equipment was placed on the market before 31 December 2010 and the

user personally decides to eliminate it without replacing it with new equivalent equipment designed for the

same use;

b) by the manufacturer, that is to say the subject which was the fi rst to introduce and market new equipment

that replaces previous equipment, when the user decides to eliminate equipment placed on the market

before 31 December 2010 at the end of its useful life and replace it with an equivalent product designed

for the same use. In this latter case the user may ask the manufacturer to collect the existing equipment;

c) by the manufacturer, that is to say the subject which was the fi rst to introduce and market new equipment

that replaces previous equipment, if it was placed on the market after 31 December 2010;

Suitable separate collection for the purpose of forwarding discarded equipment for recycling, treatment or disposal

in an environmentally friendly way helps to avoid possible negative effects on the environment and human health

and encourages re-use and/or recycling of the materials making up the equipment.

The sanctions currently provided for by law shall apply to users who dispose of products in unauthorised ways.

Copyright Silca 201244

Operating Manual Matrix

12 AFTER-SALES SERVICE

Silca provides full service to purchasers of the MATRIX machine. To ensure total safety for the operator and the

machine, any operations not specied in this manual shall be carried out by the manufacturer or in the special

Service Centres recommended by Silca.

On the back cover of the manual there is a list of the manufacturer’s addresses; the following page lists the

addresses of specialized Service Centres.

12.1 HOW TO APPLY FOR AFTER-SALES SERVICE

The warranty attached to the MATRIX machine guarantees free repairs or replacement of faulty parts within 24

months of purchase. Any other operation shall be agreed by the user with Silca or its Service Centres.

Copyright Silca 2012 45

VITTORIO VENETO 13/01/2012

CE DECLARATION OF MACHINE COMPLIANCE

SILCA S.p.A. - VIA PODGORA 20 ( Z.I.)

31029 VITTORIO VENETO (TV) - (ITALY)

TEL. 0438 9136 - FAX. 0438 913800

Declares under its own responsibility that the Key-cutting machine model

MATRIX PRO

complies with the requirements of the following European Directives:

European Union DIRECTIVE 2006/42/CE (Machines)

and with the EN 12100 Standards

European Union DIRECTIVE 2004/108/CE

and with the EN 55022 ; EN 55024 ; EN 61000-3-2 ; EN 61000-3-3 Standards

European Union DIRECTIVE 2006/95/CE

and with the EN 60950-1 ; EN 62233 Standards

Claudio Tomasella of the Silca S.p.A. Research & Development Division is authorized

to create a Technical File.

Operations Director

(Electromagnetic Compatibility)

(Low Voltage) | 12 |

VITTORIO VENETO 13/01/2012

CE DECLARATION OF MACHINE COMPLIANCE

SILCA S.p.A. - VIA PODGORA 20 ( Z.I.)

31029 VITTORIO VENETO (TV) - (ITALY)

TEL. 0438 9136 - FAX. 0438 913800

Declares under its own responsibility that the Key-cutting machine model

MATRIX EVO

complies with the requirements of the following European Directives:

European Union DIRECTIVE 2006/42/CE (Machines)

and with the EN 12100 Standards

European Union DIRECTIVE 2004/108/CE

and with the EN 55022 ; EN 55024 ; EN 61000-3-2 ; EN 61000-3-3 Standards

(Electromagnetic Compatibility)

European Union DIRECTIVE 2006/95/CE

and with the EN 60950-1 ; EN 62233 Standards

Claudio Tomasella of the Silca S.p.A. Research & Development Division is authorized

to create a Technical File.

Operations Director

(Low Voltage) | 12 |

SILCA S.p.A.

Via Podgora, 20 (Z.I.)

31029 VITTORIO VENETO (TV)

Phone: +39 0438 9136

Fax +39 0438 913800

E-mail: silca@silca.it

www.silca.biz

United Kingdom

SILCA Ltd.

Unit 6 Lloyds Court - Manor Royal

CRAWLEY RH10 9QU

Phone: +44 1293 531134

Fax +44 1293 531108

E-mail: sales@silcaltd.co.uk

www.silcaltd.co.uk

France

SILCA S.A.S.

12, Rue de Rouen

Z.I. de Limay - Porcheville

78440 PORCHEVILLE

Phone: +33 1 30983500

Fax +33 1 30983501

E-mail: info@silca.fr

www.silca.fr

Germany

SILCA GmbH

Siemensstrasse, 33

42551 VELBERT

Phone: +49 2051 2710

Fax +49 2051 271172

E-mail: info@silca.de

www.silca.de

India

MINDA SILCA Engineering Ltd.

Plot no.37, Toy City,

GREATER NOIDA (U.P.) - 201308

Phone: +91 9871397630/31

Fax: +91 120 2351301

E-mail: info@mindasilca.in

www.mindasilca.in

North America

U.S.A., Canada, Caribbean Islands

KABA Ilco Corp.

400 Jeffreys Road

Rocky Mount, NC 27804 USA

Phone: 1 800 334 1381 / 1 252 446 3321

Fax: 1 252 446 4702

E-mail: info@irm.kaba.com

www.ilco.us

Central America

Mexico, Guatemala, Belize, El Salvador,

Honduras, Nicaragua, Costa Rica, Panama

Corporación Cerraiera Alba S.A. de C.V.

Prolongaci

Col.Los reyes, Tultitlán, Estado de México C.P. 54915

ón avenida independencia 14, Bodega 5,

E-mail: informacion-mexico@kaba.com

Kaba Mexico

Phone: 01 55 5366 7200

www.kabamexico.com

Spain

SILCA KEY SYSTEMS S.A.

C/Santander 73A

08020 BARCELONA

Phone: +34 93 4981400

Fax +34 93 2788004

E-mail: silca@silca.es

www.silca.es

Netherlands

H. CILLEKENS B.V.

Metaalweg, 4

6045 JB ROERMOND

Phone: +31 475 325147

Fax +31 475 323640

E-mail: info@hcillekens.nl

www.hcillekens.nl

Brazil

KABA DO BRASIL Ltda

Rua Guilherme Asbahr Neto, 510

São Paulo, SP 04646-001

Phone: +55 11 55454520 / 29

E-mail: silca@kabadobrasil.com.br

www.silcachaves.com.br

Colombia

SILCA SOUTH AMERICA S.A.

Km 1.5 Via Briceño-Zipaquira

Parque Ind. Trafalgar Bodega 3

Tocancipa-Cundinamarca

Phone: +57 1 7366480

Fax +57 1 7366490

www.fl exonsilca.co

Loading...

Loading...