Page 1

1

Read all instructions carefully before operating your Marker 2000.

Quick Start Guide

Marker 2000

1. Preparation

a. After removing machine from the box,

make sure that all packing has been

removed. There is a gauging template

secured in the vice jaws, make sure that it

is removed for normal marking.

b. All references with a letter in parentheses

(X) refer to the illustration on page three

of this guide.

c. Attach your IBM compatible keyboard to

the back of the Marker 2000 in keyboard

outlet (M). The adapter provided may

need to be connected to your keyboard

cord prior to attachment to the machine

depending on your keyboard style.

d. Attach power cord to machine and plug

into 110VAC circuit. The on/off rocker

main switch (I) is located on the back

right hand side of the machine. Turn

machine on.

2. Press <F5> (Set Up)

Press <F10>

Press 2 (for English)

Press <ESC>

3. Press <F2> on the keyboard (Marking).

4. Press <F3> on the keyboard (New Model). For

advanced Marking features see operations manual.

5. Clamp item to be marked with the key locking

jaw (G) located on the clamp slide (E). The

clamp should

be in the out

(extended or

tracking)

position (See

Fig. 1). The

top (head) of

the item must

be placed

against the

stop (See Fig.

4). Larger

objects may

require repositioning of the top clamp slide by

means of slide locking knob (F). If there is a

groove (mill) in the item being marked, position the clamping jaw by loosening the jaw

locking knob (G1). Place the back of the key

(opposite blade) against the left or right hand

stop depending on the side being marked.

Center the item if it does not have a groove.

Position the key-locking jaw (G) and then

tighten the jaw locking knob (G1) to lock the

settings in place (See Fig 2).

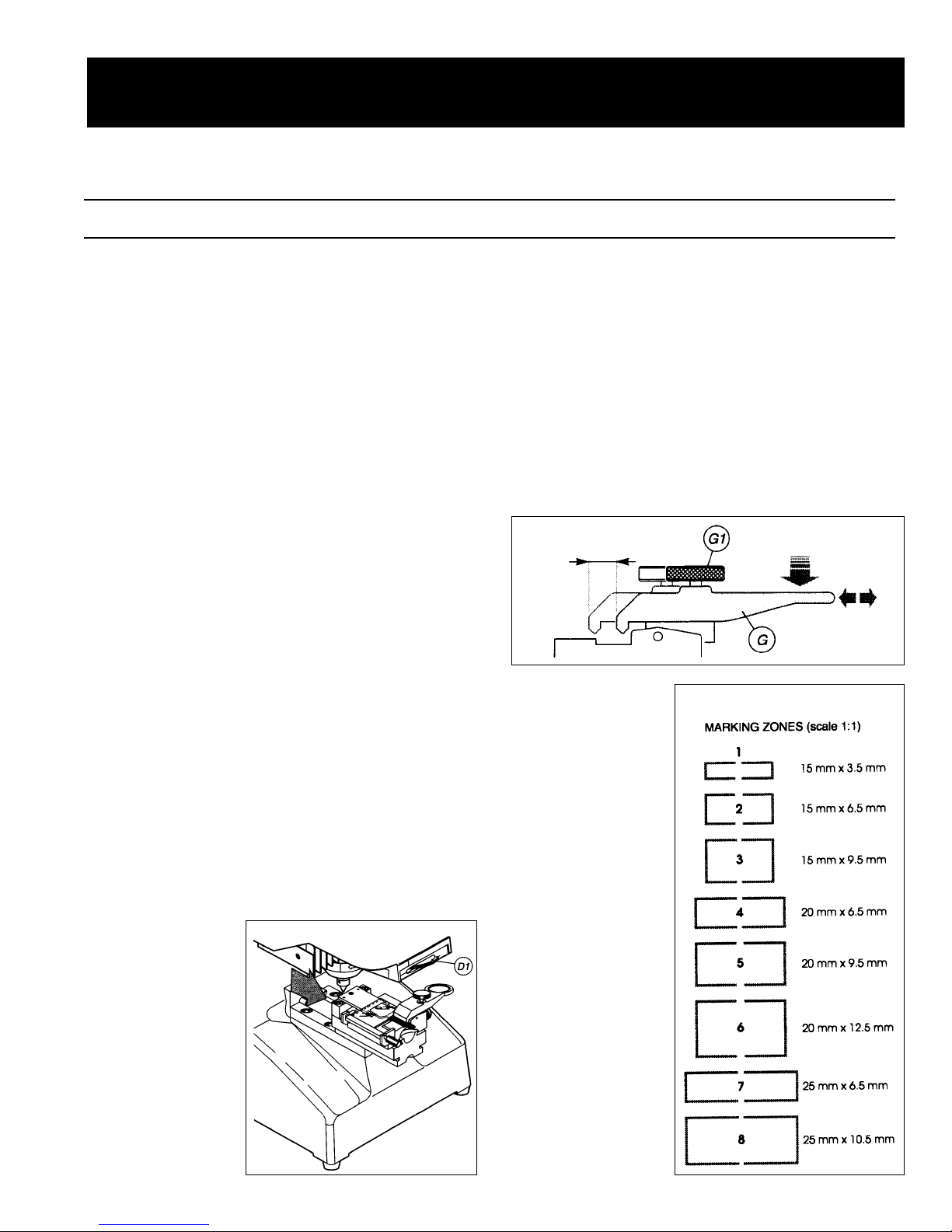

6. Select <F8> for

Tracking.

Make sure that

the slide clamp

assembly is in

the out, or

tracking, position. Turn the

clear plastic

slide (P) over

the jaw. A red

colored laser

light now outlines the area

where marking

will occur.

Move the

marking zone

to the desired

location on

the object to

be marked by

means of the

arrow keys

Fig. 2

Fig. 3

Fig. 1

Page 2

located on your keyboard. Select a marking

zone from the eight available on the tracking

disk (D1) Rotating this disk will display the

different images available (See Fig. 3). At this

time, ensure the number of the zone selected

(See Fig. 4) is displayed on the tracking information screen of the Marker 2000 display.

The + and - keys on the keyboard change the

selection. When correct, press <F10>.

7. Press <F7> for text entry and four lines are

displayed. By pressing enter after keying in

the desired information you can move down a

line. When you have completed the text press

<F10>.

8. T urn the clear plastic slide back off the jaw. If

the information displayed is correct push the

jaw back to the in (Marking) position (See

Fig. 5) until it

locks in place.

Press <F10>

for Marking. If

a problem

occurs during

marking,

action may be

halted by

pressing the

<ESC> key.

9. After the job is

completed,

select the <ESC> button to set up the next task.

If you wish to save the original information

select “Y” for yes and this file will be saved

under the name you select. <Press F10>. This

file name is then listed under “Local Marking”.

To access this file at a later time, select <F2>

(List of Models). At the screen display listing

all models, pressing <ESC> will allow you to

start a new job. If you select “N” for No, you

will be at Step 4 of this guide.

10.Refer to the Troubleshooting section on page

four of this guide if problems are experienced.

If the problem is not listed, check the operations manual or contact technical support at

Ilco Unican.

SPECIAL MARKING

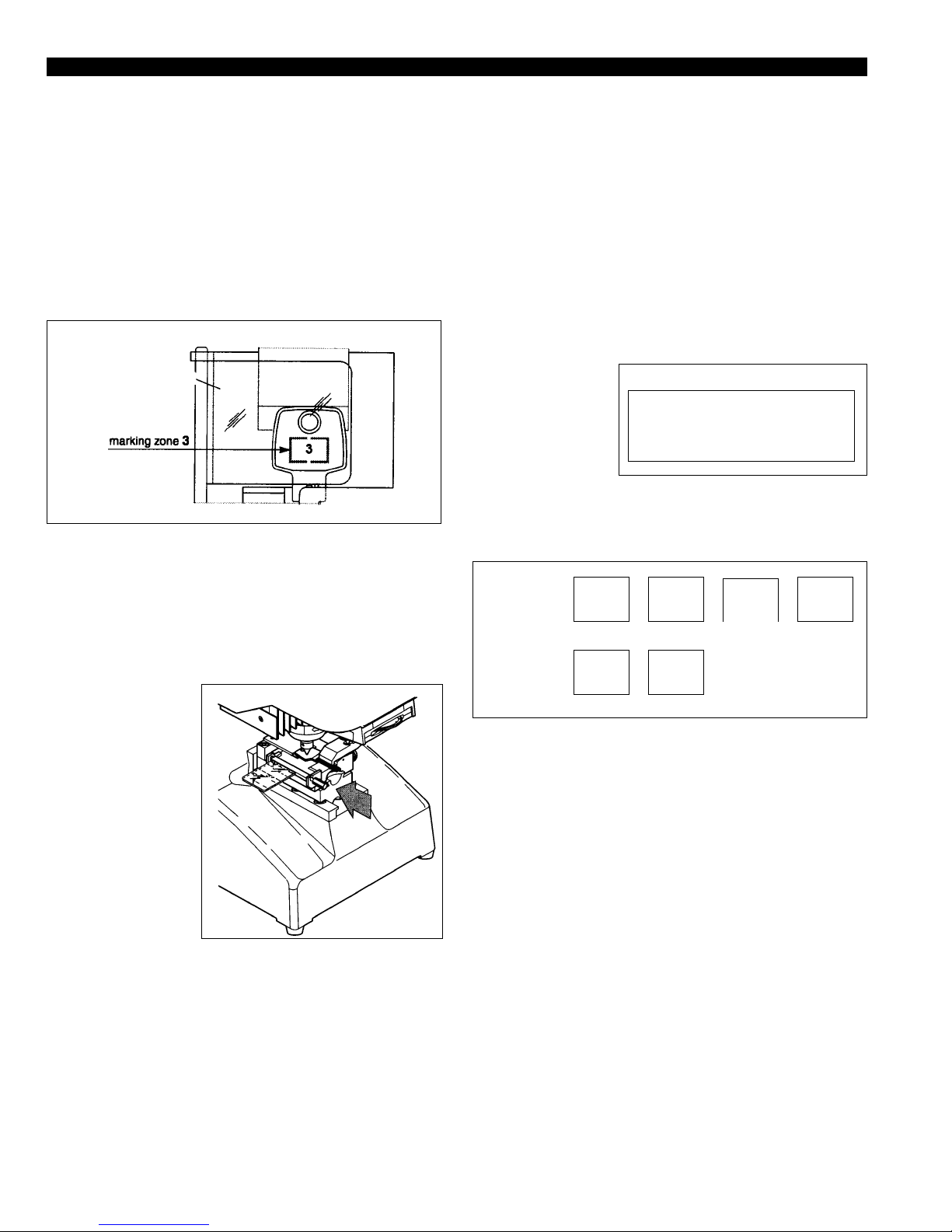

You may change either direction or orientation of

your marking. At the marking information screen

(See Fig. 6) press the tab key on your keyboard

until you reach

the selection you

wish to change.

Press the space

more for the

desired direction

or orientation. Options available are illustrated

in Fig. 7.

When selections have been made, continue at

Step 5 of this guide.

2

Fig. 5

Fig. 4

Slide = 3

Side = LH

Dire. = Hor

Pcs. = 1 of 1

Clamp = C1

Orie. = 0

AutoF - [x]

Fig. 6

SILCA

SILCA

SILCA

SILCA

SILCA

S

I

L

C

A

0 90 180 270

HORIZONTAL VERTICAL

direction:

orientation

Fig. 7

Page 3

3

A marking punch

B display

C marking depth regulation ring

D tracking device

D1 tracking disk

E clamp slide

F slide locking knob

G key locking jaw

G1 jaw locking knob

H head unit

I master switch

L feeder outlet

M keyboard outlet

N serial port

O clamp sensor

P glass slide diffuser

P1 glass slide diffuser knob

Page 4

4

1. Marking depth is too shallow or deep

Cause: Marking punch ring is not adjust-

ed properly.

Solution: Change setting (See figure 8 ).

Clockwise will decrease and

counter clockwise will increase

the punching pressure.

2. Text is marked in an area not selected with

the dial.

Cause: The data registered on the infor-

mation screen regarding slide

number is different than the box

selected from the dial.

Solution: Check the box selected on the dial

and verify the same slide number

is selected on the information

screen. If not change this slide

number with the + or - key.

3. When marking, the

object moves from the

original position, the

object is not being held

tightly, the object will

not fit in the clamp correctly.

Cause: The object is

not being held

correctly .

Solution: Ensure that

the lateral

adjustment

clamp is

positioned properly. If not,

loosen the locking knob and

adjust accordingly (See Fig. 9).

Also check that the vertical jaw

slide is in the correct position.

For more clearance loosen the

knob (F) and reposition (See Fig.

10). Make sure knob (F) is tight

before marking.

4. Unreadable text

Cause: Autoformat is not selected.

Solution: Check to see if the Autoformat

option located on the general

information screen is selected

(Marked with an X). If not, select

it to ensure that scaling will occur .

5. When preparing to Mark object, the display

reads, “Marking in Progress, Clamp out of

position”.

Cause: Clamp is in the forward (tracking

position).

Solution: Push clamp to the back (marking

position).

Troubleshooting Guide

Fig. 8

Fig. 9

Fig. 10

USA: 400 Jeffreys Rd., P.O. Box 2627, Rocky Mount, NC 27802-2627 • Tel.: (252) 446-3321 • FAX: (252) 446-4702

Canada: 7301 Decarie Blvd., Montreal, Que. H4P 2G7 • Tel.: (514) 735-5411 • FAX: (514) 735-8707

Form No. 2442/E/997-X

Loading...

Loading...