Silca Delta 2000 SA Operating Manual

Operating manual

D413861XA

vers.

2.0

®

© 1998 SILCA S.p.A - Vittorio Veneto

This manual has been drawn up by SILCA S.p.A.

All rights reserved. No part of this publication may be reproduced or used in any form or by any means (photocopying,

microfilm or other) without the written permission of SILCA S.p.A.

First published in october 1998

Printed in Vittorio Veneto

by SILCA S.p.A.

via Podgora, 20 (Z.I.)

31029 VITTORIO VENETO (TV) - Italy

(*) Supplied with 230V machines, on request for other voltages.

(**) Waste" is any substance or object deriving from human activity or natural cycles, thrown away or to be thrown

away .

Operating manual - English DELTA 2000 SA

INDEX

1 TRANSPORT .................................................................................................. 3

1.1 Packing ................................................................................................ 3

1.2 Transport ............................................................................................. 3

1.3 Unpacking ............................................................................................ 3

1.4 Machine handling ................................................................................. 3

2 WORKING PARTS ......................................................................................... 4

3 MACHINE DESCRIPITON .............................................................................. 5

3.1 Technical data ..................................................................................... 6

3.2 Electrical circuit .................................................................................... 7

4 ACCESSORIES PROVIDED .......................................................................... 8

5 MACHINE INSTALLATION and PREPARATION ......................................... 9

5.1 Checking for damage ........................................................................... 9

5.2 Environmental conditions ..................................................................... 9

5.3 Positioning ........................................................................................... 9

5.4 Description of work station ................................................................. 10

5.5 Separate parts ................................................................................... 10

5.6 Connection to the mains .................................................................... 10

6 REGULATION and USE of the MACHINE .................................................. 11

6.1 Checking And Setting ........................................................................ 11

6.2 Calibration .......................................................................................... 11

6.3 Cutting operations .............................................................................. 12

6.4 Key cutting ......................................................................................... 12

7 MAINTENANCE ............................................................................................ 15

7.1 Cutting tool replacement .................................................................... 15

7.2 Brush replacement ............................................................................. 15

7.3 Tracer point replacement ................................................................... 16

7.4 Regulating carriage depth .................................................................. 16

7.5 Replacing the fuses ........................................................................... 17

8 WASTE DISPOSAL ...................................................................................... 18

9 ASSISTANCE ............................................................................................... 19

9.1 How to request service ...................................................................... 19

Copyright Silca 1998 -1

Operating manual - English DELTA 2000 SA

GUIDE TO THE MANUAL

This manual has been produced to serve as a guide for users of the DELTA 2000 SA key-cutting

machine. Read it carefully; it is essential if you wish to operate your machine safely and efficiently.

CONSULTATION

The contents of the manual are divided into sections relating to: chapter

- Transport and handling......................................................................................................................1

- Description of machine and safety devices ............................................................................. 2-3-4-5

- Proper use of the machine..............................................................................................................5-6

- Maintenance ......................................................................................................................................7

TECHNICAL TERMS

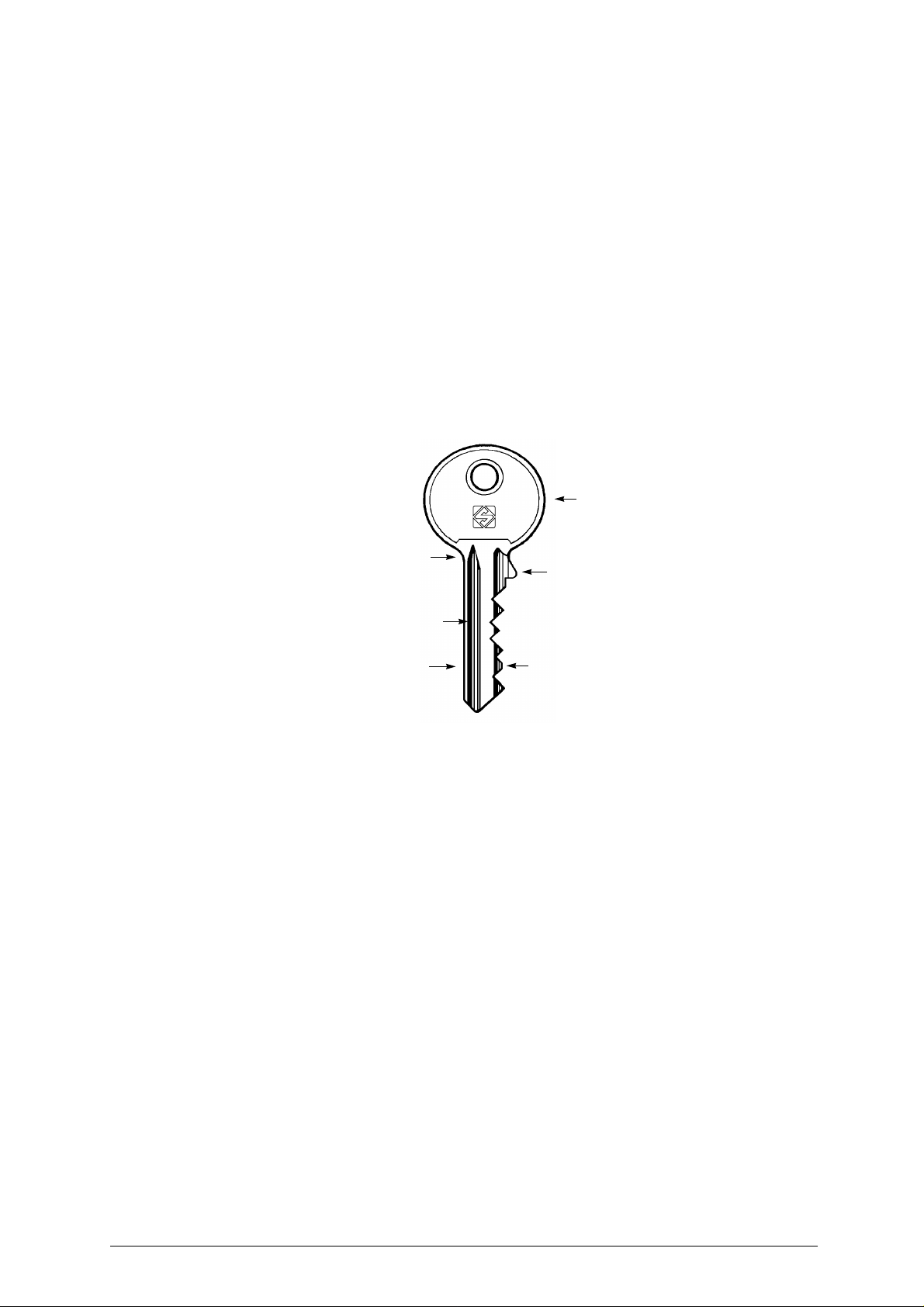

Common technical terms are used in this manual. To assist those with little experience of key cutting,

below is an illustration of the terms used for the different parts of keys:

1

Fig. 1

1) Head

2) Rim

3) Stop

4) Stem

5) Tip

6) Back

7) Cuts

2

3

4

6

5

7

Copyright Silca 1998 1

DELTA 2000 SA Operating manual - English

GENERAL INSTRUCTIONS

The DELTA 2000 SA key-cutting machine has been designed according to the specifications of the

Machine Directives. From the design stage risks for the operator have been eliminated in all areas:

transport, regulation, cutting and maintenance.

The use of protective goggles is compulsory during cutting operations, as indicated on the machine

itself and in this manual.

The material used in the manufacture of this machine and the components employedduring use of the

machine are not dangerous and their use complies with standards.

USE

The DELTA 2000 SA key-cutting machine must be installed and used in the way laid down by the

manufacturer, as illustrated in this manual.

If the machine is used differently or for purposes different from those described in this manual, the

customer will forego any rights he may have over SILCA S.p.A. Furthermore, unforeseen danger to the

operator or any third parties may arise from incorrect use of the machine.

Negligence in the use of the machine or failure on the part of the operator to observe the instructions

given in this manual are not covered by the guarantee and the manufacturer declines all responsibility

in such cases.

It is therefore indispensable to read the operating manual carefully in order to make the best use

of the DELTA 2000 SA key-cutting machine and benefit from its potential.

FURTHER RISKS

There are no further risks arising from the use of the DELTA 2000 SA key-cutting machine.

PROTECTION AND SAFETY PRECAUTIONS FOR THE OPERATOR

The DELTA 2000 SA key-cutting machine is built entirely to standards. The operations for which it has

been designed are easily carried out at no risk to the operator.

The adoption of general safety precautions (use of protective goggles) and observation of the

instructions provided by the manufacturer in this manual eliminate all human error, unless deliberate.

The DELTA 2000 SA key-cuttingmachine is designed with features which make it completely safe in all

its parts.

• Power supply

The key-cutting machine must be supplied with electricity by means of a safety device (*). The plug

must be earthed.

• Start-up

The machine is started up by means of:

1) the START button on the safety device (*);

2) the ON switch, situated on the machine, which activ ates the machine motor.

• Maintenance

The operations to regulate, service, repair and clean the machine have been devised in the simplest

and safest way possible. There is no danger of removable parts being replaced wrongly or unsafely.

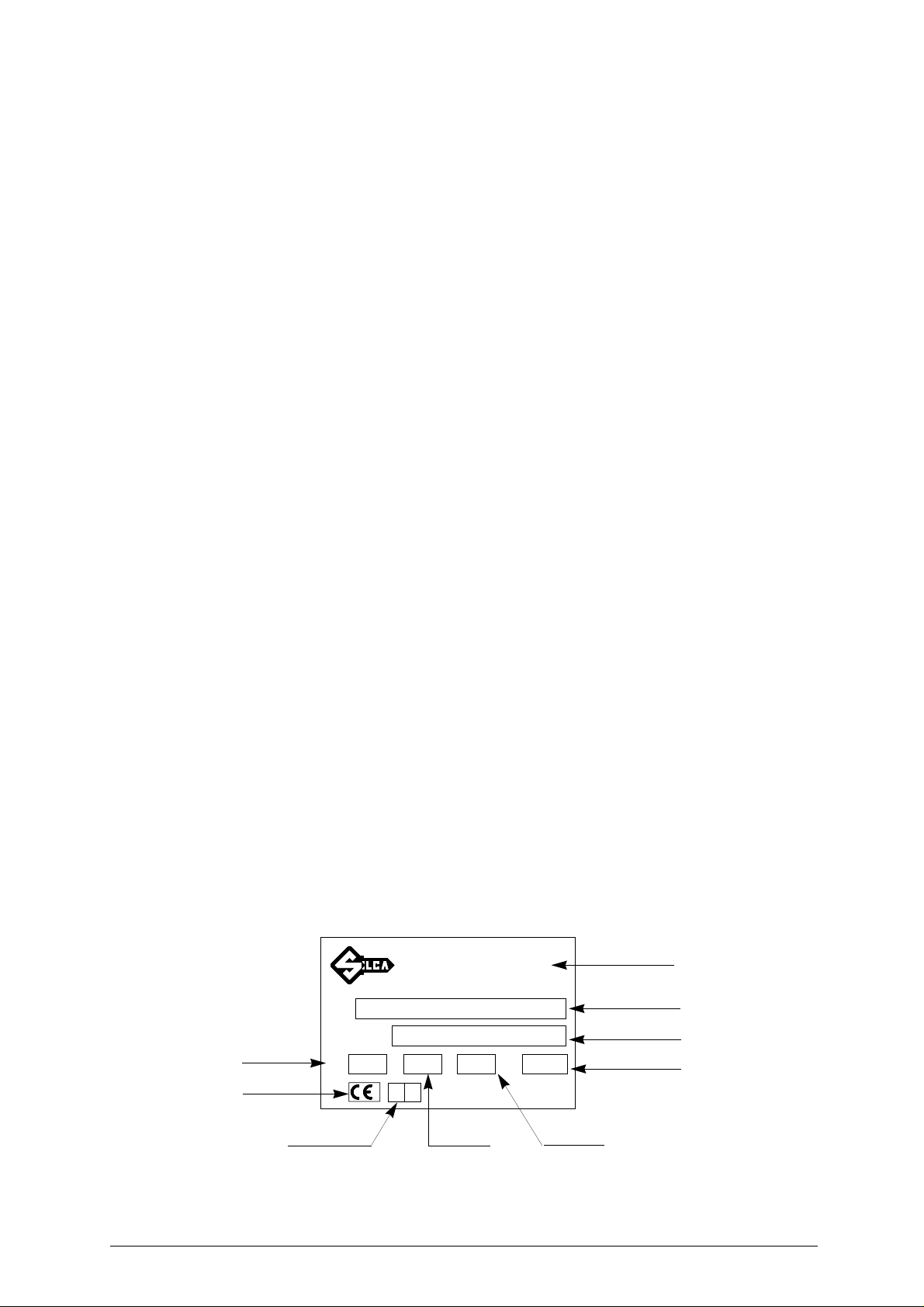

• Machine identification

The DELTA 2000 SA is provided with an identification label which shows the serial number (fig. 2).

ATTENTION: should the machine be left on continuously for over 50 minutes, the cutting tool motor is protected

against overheating and will automatically cut out.

In such cases, proceed as follows:

a) turn off the master switch (E);

b) let the motor cool for at least 2 hours before using the machine again.

Manufacturer’s

identity

Type of machine

Serial No.

Absorbed power

Working

voltage

CE mark

TIPO

TYPE

N˚ MATRICOLA

SERIAL No.

VOLT

SILCA S.p.A. - Via Podgora 20 (Z.I.)

®

31029 VITTORIO VENETO (TV) ITALY

(0438) 9136

☎

Telefax (0438) 913800

Telex 410579 SILCA I

Hz. WATT

A.

Year of

manufacture

Fig. 2

Working

frequency

2 Copyright Silca 1998

Absorbed

current

Operating manual - English DELTA 2000 SA

1 TRANSPORT

The DELTA 2000 SA key-cutting machine is easily transported and is not dangerous to handle.

The packed machine can be carried by one person.

1.1 Packing

The DELTA 2000 SA key-cutting machine comes in a strong

cardboard box, the dimensions of which are shown in fig. 3,

designed to protect the machine and all its parts even when

it is stored for long periods.

Fig. 3

1.2 Transport

It is advisable to use the packing every time the machine is transported, as this will avoid knocks which

could cause damage to the machine, persons or things.

1.3 Unpacking

To remove the machine from the packing box, carefully follow the illustrated instructions below:

Fig. 4

Check the contents of the box, which should comprise:

- 1 DELTA 2000 SA key-cutting machine;

- 1 set of documents, including: operating manual, spare parts list and guarantee;

- 1 chippings tray;

- 1 power cable;

- 1 power supply safety device (*);

- 1 set of accessories.

AB

CD

1.4 Machine handling

When the DELTA 2000 SA key-cutting machine has been unpacked, place it directly on its workbench.

This operation can be carried out by one person, firmly holdingthe base, and no other part, to lift and

carry the machine.

Copyright Silca 1998 3

DELTA 2000 SA Operating manual - English

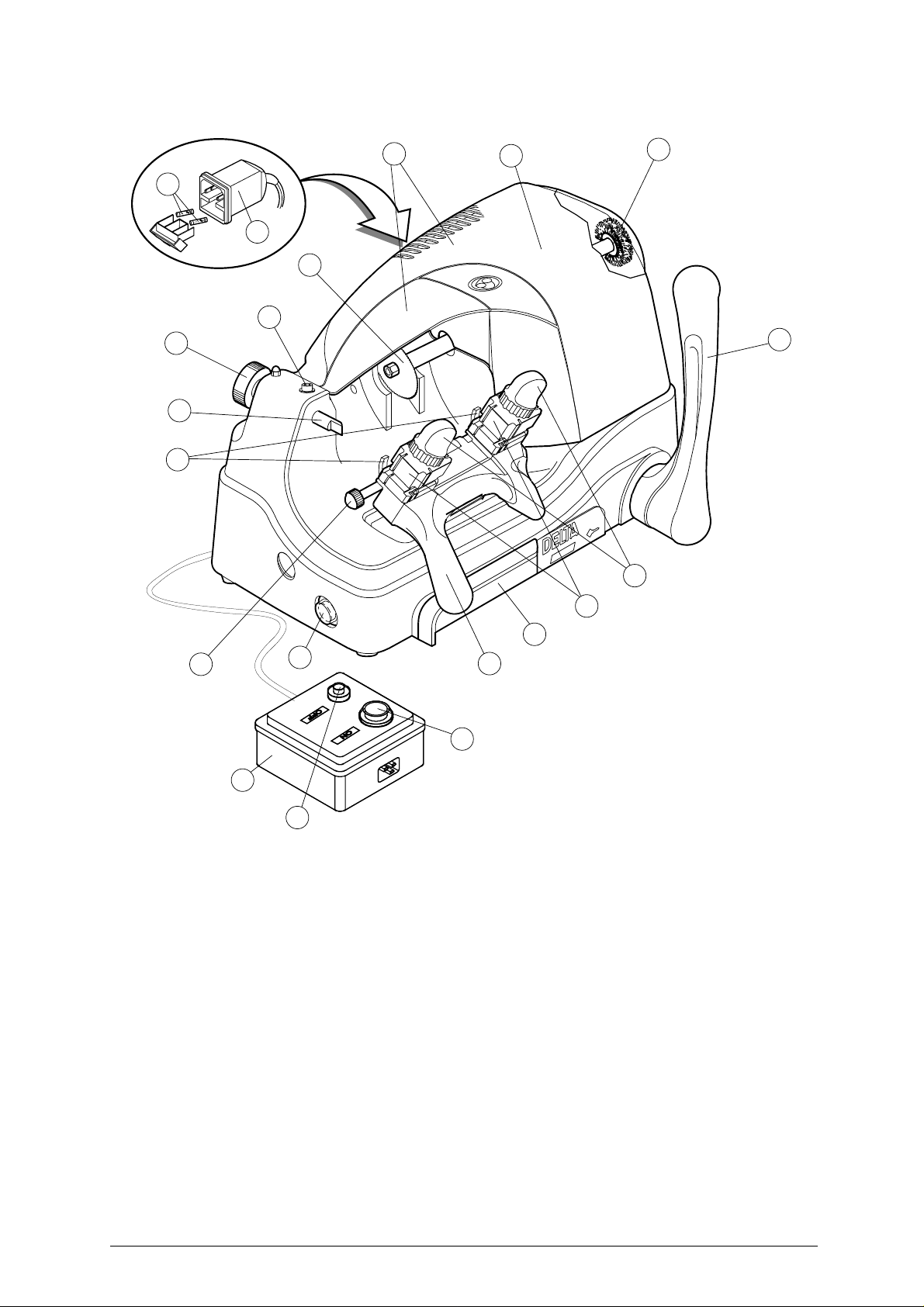

2 WORKING PARTS

L

P

Q

K

J

I

H

G

M

N

O

A

Fig. 5

F

R

A - clamp knobs

B - clamps

C - chippings tray

D - carriage lever handle

E - motor/brush start button

F - gauge knob

G - gauges

H - tracer point

I - adjusting nut

J - tracer point locking screw

K - cutting tool

L - cover

M- motor

N - brush

O - carriage movement lever

P - fuses

Q - supply socket

R - Safety device (*)

S - START button

T - STOP button

E

T

B

C

D

S

4 Copyright Silca 1998

Loading...

Loading...