Page 1

Sigtronics Emergency Apparatus Intercom System (EAI)

INSTALLATION AND OPERATING INSTRUCTIONS

Models EAI-S4, EAI-S6, EAI-D4, and EAI-D6

INTRODUCTION

ATTENTION INSTALLER: To assure a trouble free Installation, please read these entire instructions through once

before beginning.

The Sigtronics EAI system, when used with Sigtronics noise

attenuating headsets provides the emergency apparatus

crew with clear, hands free, voice actuated (VOX) intercom.

The system also allows full radio monitoring at all headset

positions as well as radio transmit capability from selected

headsets via Push-To-Talk (PTT) switches.

Applications: The unit is designed for fire apparatus, rescue

and ambulance vehicles, marine emergency equipment, airport ground vehicles, and mobile emergency command

centers.

igtronics

S

Made in the U.S.A.

®

Specialists in “SOUND” Management

178 East Arrow Highway, San Dimas, CA 91773 ( 909 ) 305-9399

Voice Activated Intercom (VOX) feature allows “hands free”

communication between headsets connected to the EAI unit.

Start speaking and the intercom turns on instantly to relay

your message clearly to the other headsets. Stop talking and

it turns off to reduce background noise.

Up to Four Headset Positions can be connected to the

EAI unit. More headset positions can be achieved by wiring

additional jacks in parallel. Only one headset, however, can

be plugged into paralleled jacks at one time. This paralleled

jack scheme is most commonly used on pumper trucks at the

pump panel. In this case, the driver plugs his headset into the

engineer’s jack while driving. He then unplugs and plugs into

the pump panel when he arrives on scene.

Headphone Output: The EAI system is designed to easily

drive six or more 300 to 1000 ohm headsets.

Page 2

Noise attenuating, full cushion headsets, such as the

Sigtronics SE-2, or SE-40 are recommended for best results.

The EAI system incorporates an automatic headphone limiting circuit to eliminate the possibility of painful spurious

radio or noise spikes from getting to the headsets and into

your ears.

Universal Radio Interface design to accommodate virtually

any type of communication radio.

Mike Output: Designed to be fully compatible with virtually

all mobile radios used on emergency vehicles. An adjustment

for transmit microphone level is provided to perfectly match

the EAI system to your particular radio. For applications where

a very high transmit microphone level is required (some Midland and Wilson radios), an inexpensive plug in Mic Level

Amplifier module is available.

Automatic Sidetone Generation allows everyone on the

vehicle to hear both sides of the radio conversations.

Excellent RF Immunity guarantees clean, clear, radio communications.

Standardized for use with Sigtronics single plug headsets

(ie. SE-2, SE-40, SE-41).

Model Differences: The EAI-S4 is used in applications requiring up to four persons at one time on intercom and using a

single vehicle radio. The EAI-S6 is identical to the EAI-S4 but

can intercom up to six people at one time. The EAI-D4 is used

in applications requiring four intercom positions and the use

of two separate radios. Similarly, the EAI-D6 is a six place intercom with two radio capability.

CONTROL FUNCTIONS

ON / OFF — Power Switch — In “ON” position; supplies

power to all EAI circuits. In “OFF” position; disables all unit

functions except radio receive.

VOL — Intercom Volume — Adjusts intercom volume level.

Does not affect radio volume.

SQ — Intercom Squelch - Adjusts VOX operation of the intercom for variations in background noise levels.

RADIO 1 / RADIO 2 (TALK) — Transmit Select (EAI-D4 and

D6 units only) — Used to select which radio to talk on -Radio

1 or Radio 2.

AUTO / BOTH (LISTEN) — Receive Select (EAI-D4 and D6

units only) — Used to select which radio is heard. In “BOTH”

position, you hear both Radio 1 and the Radio 2. In “AUTO”

position, only the radio selected by the RADIO 1 / RADIO 2

switch is heard.

RADIO TRANSMIT MIC LEVEL — Sets the transmit mic audio

level for the radio(s).

EAI INSTALLATION

Standard Equipment Included

Besides the Intercom unit and the Radio Adapter unit, each

EAI system comes complete with the following:

EAI-S4/D4 EAI-S6/D6

Intercom Drill Template 1 1

Intercom Panel 1 1

(printed on both sides)

Intercom Control Knobs 2 2

Intercom Switch Nut 1 1

Intercom Panel Screws 2 2

Headset Jack Box 6 6

Headset Jack Box Cover

with Pre-mounted Headset Jack 4 6

with Pre-mounted Headset Jack

& Splash Cover 1 1

with Pre-mounted PTT Switch 1 1

PTT Switch with Hardware

(loose, not in boxes) 2 2

Jack Box Cover Screws 12 16

Jack Box Mounting Screws 12 16

Wire Grommets 6 8

Jack Insulator Washer, Flat 5 7

Jack Insulator Washer, Shoulder 5 7

Radio Adapter Mounting Screws 4 4

Radio Adapter Mounting Nuts 4 4

Male Connector Housing 1 1

Male Crimp Pins 13 15

Female Connector Housing 1 1

Female Crimp Pins 13 15

4 ft. Headset Jack

& PTT Switch Cable 1 1

4 ft. Radio 1/ Power

Interface Cable 1 1

4 conductor hook-up wire 1 Roll 1 Roll

4 ft. Radio 2 Interface Cable 1* 1*

Radio Select Switch Cable 1* 1*

Radio Select Panel 1* 1*

* Supplied with Dual Radio EAI-D4 and EAI-D6 units only.

INSTALLATION OVERVIEW

Sigtronics has simplified the installation process, to assure

perfect operation. Refer to the EAI Wiring Diagram (for EAIS4 or EAI-S6 see Figure 4 on page 6 for EAI-D4 or EAI-D6 see

Figure 5 on page 7). If you have any installation questions or

problems that are not addressed in this manual, feel free to

call our installation hot line number located on the last page

of this manual.

Installation of the Sigtronics EAI System is a five step process:

I. Mount the intercom unit. (Intercom Chassis Installation)

II. Install the Radio Adapter unit. (Radio Adapter Chassis

Installation)

Ill. Install the headset jacks and PTT switches. (Headset Jack

and PTT Switch Installation)

IV. Wire the jacks and PTT switches. (Headset Jack and PTT

Switch Wiring)

V. Wire the radio(s). (Radio Hook Up)

2

Page 3

I. INTERCOM CHASSIS INSTALLATION

Intercom Placement:

There are a few factors to consider when selecting a mounting location for the EAI Intercom chassis unit:

1. The unit should be placed in such a way that its controls

can be easily seen and operated. Most commonly, this will

be near the vehicle’s communication radio controls.

2. The Intercom unit is primarily designed to be panel or dash

mounted. Above and below dash mounting, however, can

be accomplished by fabricating an inexpensive bracket.

3. The intercom unit has been designed to mount either

horizontally or vertically. The printed panel is reversible

for this purpose.

4. The location selected requires a minimum front panel area

of 2 1/2˝ by 1 1/16˝.

5. The intercom unit normally mounts though the panel or

dash. The maximum allowable panel thickness is 5/32 of

an inch. If the panel is thicker than this, the volume and

squelch knobs will not attach on the unit.

6. The depth required behind panel is 4 3/16˝, plus cable

access. Verify that the rear of intercom unit and cable will

not interfere with the normal operation of any vehicle

controls or the operation of vehicle compartment doors.

7. The Radio Adapter part of the EAI system plugs into the

intercom unit. Therefore, they are usually mounted near

each other. If necessary, however, an extension between

the two units can be fabricated. Connectors for this are

included with the system.

8. For dual radio systems (EAI-D4 or EAI-D6), allow for an additional panel space of 1˝ x 1-1/2˝ near the Intercom unit for

the radio selection switches.

Panel Preparation:

1. Once the location is selected, remove the protective paper

from the back of the adhesive drill template. Then stick it

down on the vehicle dash or panel in the selected area.

2. Center punch each hole at the cross lines. (The five holes

are in straight line and equally spaced 0.4˝ apart).

3. Drill 1/8˝ pilot hole at all five places.

4. Enlarge ON / OFF switch hole to 1/4˝ and the volume and

squelch control holes to 3/8˝ per template.

Mounting Intercom Unit: See Figure 1

VEH I CL E

PAN E L

DO N OT RE M OV E

THE S E N UTS

INT E RCOM

INT E RCOM

PAN E L

SWI TCH

NUT

FIGURE 1

KNO B

4– 40 S CR EW S

KNO B

1. Remove the nut from the Intercom unit ON / OFF switch.

2. Remove the two small black Phillips head screws (#4-40)

located on either side of the ON / OFF switch.

3. Remove both knobs from the Volume and Squelch controls

using a standard .050˝ Allen wrench. CAUTION: DO NOT

REMOVE the nuts from the Volume and Squelch controls.

4. Insert the Intercom unit from the rear of panel. Arrows on

the top and side of the intercom unit chassis indicate which

way is up. One for horizontal mounting and the other for

vertical.

5. Install the printed Intercom panel and lightly thread on

the ON / OFF switch nut. The nuts on Volume and Squelch

controls should fit inside the drilled 3/8˝ diameter holes.

6. Reinstall and tighten the two small black screws through

the holes in intercom panel. Tighten ON / OFF switch nut.

7. Turn both Volume and Squelch controls fully clockwise.

Reinstall the knobs on Volume and Squelch control shafts.

Without moving the control shafts, align the white line on

the knobs to the five o’clock position. Tighten with the

Allen wrench.

II. RADIO ADAPTER CHASSIS INSTALLATION

Placement:

The Radio Adapter part of the EAI system is designed to

be remote mounted (behind the dash) with four screws

mounted through the grommets on the back of the chassis. Because the Adapter connects to the radio(s), select a

mounting location near the emergency radio controls. Also,

if space allows, mounting this Adapter within a few inches of

the Intercom unit allows connectors P1 and J1 to be mated

directly. An extension can be fabricated if necessary to connect the two together.

Make sure that the transmit mic level adjustment hole(s) on

the side of the Radio Adapter chassis can be easily accessed

for adjustment with the Adapter in place. As usual, with the

Adapter in place, it or its cables should not interfere with the

normal operation of the vehicle.

Mounting Radio Adapter Chassis:

1. Remove the four corner panel screws (the smaller ones)

from the top of the Adapter unit. Remove the unit from

the chassis.

2. Set the Adapter chassis in the intended mounting place.

Using a small point pen or marker, mark the hole pattern

through the four grommets located on the bottom of the

Adapter chassis.

3. Drill four holes using a 5/32 inch drill (clearance for a 6-32

screw).

4. Secure the Adapter chassis to the vehicle using the four

screws and locking nuts supplied. Be sure to install the

screws with the screw heads inside the Adapter chassis.

This should assure that these mounting screws will not

touch the Adapter circuit board when in place. Do not

tighten the nuts and screws so tight as to excessively crush

the grommets.

3

Page 4

5. Replace the Adapter circuit back into the chassis. Make sure

that the transmit mic level adjustment(s) lines up with the

hole(s) in the Adapter chassis. Be sure not to pinch any

wires under the panel. Replace the 4 corner panel screws

and tighten.

6. Plug the Intercom unit plug P1 into the mating connector

J1 on the Radio Adapter unit.

If you are installing an EAI-D4 or EAI-D6 continue on with

the following. Otherwise, for a EAI-S4 or EAI-S6 skip down to

“Headset Jack and PTT Switch Installation” below.

Dual Radio Select Switch Cable Installation (EAI-D4 or EAID6):

The dual radio units have an additional switch cable that

allows radio selection. The switches on this cable are designed

to be panel or dash mounted. The other end of this four foot

cable plugs into the Radio Adapter unit.

1. Select a location for the RADIO 1/ RADIO 2 select switches

near the Intercom unit.

2. Use the printed RADIO 1/ RADIO 2 switch panel as a template to mark the two switch holes. Drill both holes using

a standard 1/4’ drill.

3. Remove the switch nuts and mount the switches from

the back of the panel or dash with the key slots down. The

smaller of the two switches is the AUTO / BOTH switch and

it mounts on the right.

4. Install the printed switch panel, thread on the switch nuts

and tighten.

5. Plug the switch cable plug P5 into the Radio Adapter J5

connector.

6. Secure the switch cable to the vehicle with suitable ties.

Again, make sure that the cable does not interfere with

anything on the vehicle.

Ill. HEADSET JACK AND PTT SWITCH INSTALLATION

Headset Jack Placement:

It is assumed that it has already been determined which

positions on the vehicle will have headsets. At this stage, it is

helpful to have a headset handy to physically gauge the best

place for the jack. There are several things to consider when

selecting a place to mount the headset jacks:

1. In general, for headset positions inside the vehicle, the

jacks should be placed towards the middle between the

user’s positions. They should also be placed up above and

towards the back of the user’s head. This will assure that

the headset cord will not hang between the user and the

vehicle door.

2. The headset jack should be out of the way so that the

headset plug can’t be hit during use or when entering or

exiting the vehicle.

3. The jack position should also take into account how the

headset cord will hang when the headset is in use. The cord

should hang out of the way and should not interfere with

vehicle controls.

4. Verify that the jack placement and headset cable do not

interfere with the normal operation of vehicle doors or

compartments.

5. In vehicles with intercom headset positions installed in

open jump seat locations, the combination of wind, road,

and engine noise, picked up by these jump seat headsets,

can in some cases produce excessive background noise

in the intercom system. Additionally, wide variations in

engine noise (from idle to high RPM) can falsely trigger the

intercom VOX (voice activated) feature. This is especially

true for older vehicles with open jump seats located right

next to the vehicle engine. There are two solutions for this

situation. The first one is the recommended one:

a) Order an additional Push-To-Talk (PTT ) switch (and

mounting box if needed) for each open jump seat

position. These switches can be conveniently mounted

at each jump seat location and wired so that the jump

seat headset microphone is disabled until the switch is

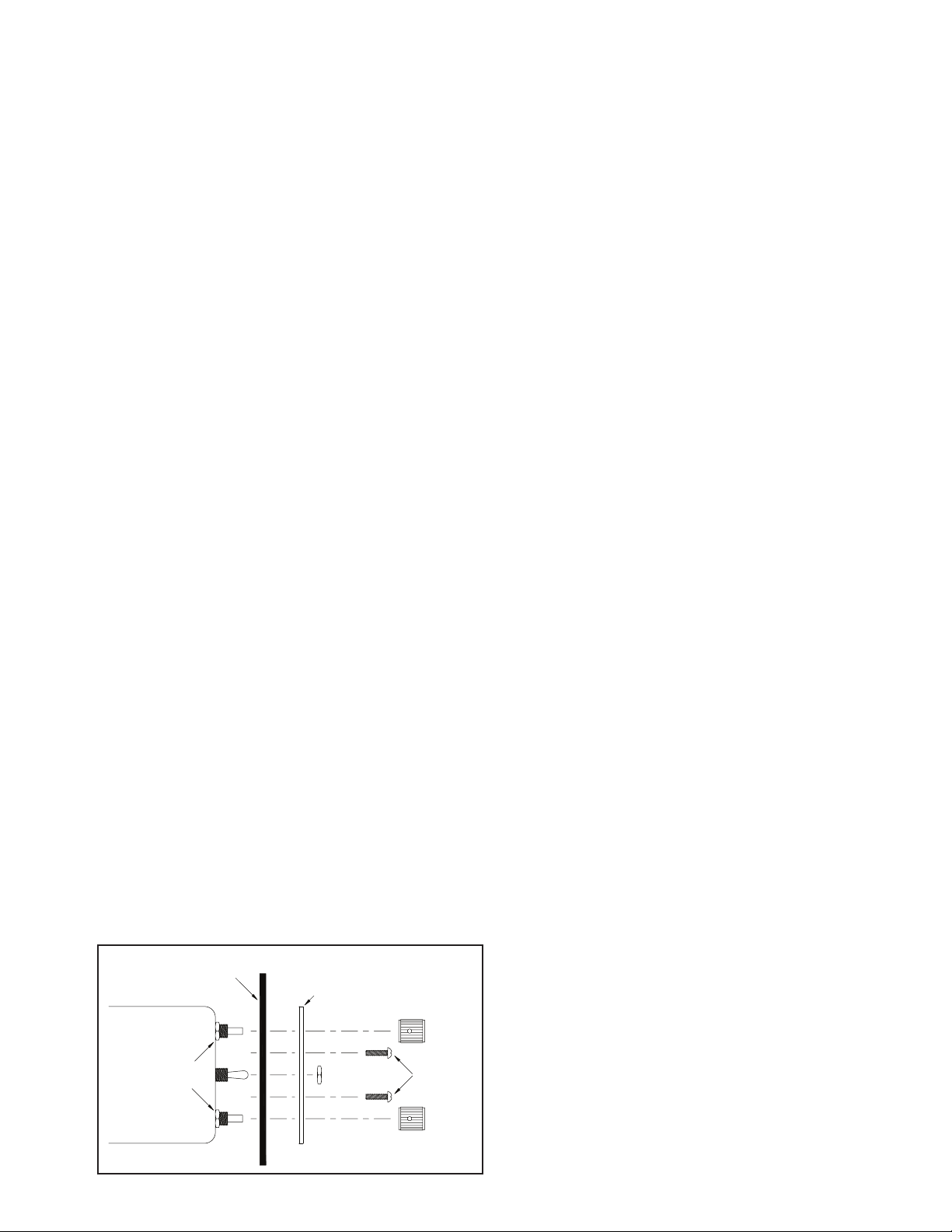

pressed. See Figure 2 below. The firefighter then uses the

PIT button to talk on the intercom instead of the VOX

(voice activated) intercom feature. PTT buttons wired in

this way only activate the intercom. They do not let the

FIGURE 2

TAN

INTERCOM PTT SWITCH

OPEN JUMP SEAT WIRING DIAGRAM

jump seat locations talk on the vehicle radio(s).

b) Order Sigtronics headsets (Models SE-2P, SE-40P, or SE-

41P) with the intercom PTT switch already mounted on

the ear cup for the open jump seat positions. The fire

fighter then uses the PIT button on his headset ear cup

to talk on the intercom instead of the VOX feature. The

advantage of this method is that it eliminates having to

mount and wire in additional PIT buttons for the jump

seats. Note, however, most departments prefer to have

all the headsets on the vehicle(s) the same so that any

headset can be used in any position. The headsets with

intercom PTT switches on them cannot easily be used

in a position that has radio trans-mit capability such as

the driver or officer position.

Sigtronics provides two ways to mount the headset jacks for

the EAI unit:

1. Mount the jacks in the supplied blue jack boxes.

Advantages:

a) Little or no “behind the panel” space required.

b) No vehicle panel thickness limitation.

c) Smaller holes are required to be drilled — a real advan-

tage on vehicles with thick metal panels.

d) Complete electrical isolation of the jacks from the

vehicles chassis, because the jack box is fabricated out

of non-conductive high impact plastic.

TIPRING

BARREL

HEADSET JACK

BLUE

BLACK

4

Page 5

2. Mount the jacks directly on the vehicle with a “through the

panel” mounting scheme. Advantages:

a) Smaller space requirement. (Only slightly larger than the

jack itself).

b) Only one hole to drill per jack (1/2 inch).

c) Most of jack is behind panel and out of the way.

Sigtronics recommends that you use the jack box mounting

method, but either approach can be used as well as a combination of both.

If required, additional headset jacks, PTT switches, mounting

boxes, and hardware are available through your Sigtronics

dealer.

Splash Cover:

If a jack is to be mounted outside the vehicle (ie. on or near

a fire engines pump panel), a splash cover should be used

to keep excess moisture out of the jack when it is not in use.

Every EAI system comes with one such splash cover already

pre-mounted on a jack in a mounting box. On other positions,

where the headset is always plugged in, a splash cover is not

required.

Jack Box Mounting:

For most installations the wiring for the headset jack will

come out the back of the jack box. Four holes are provided in

the back of the box for mounting and headset jack wiring.

Place the jack box on the mounting surface and mark and

drill the corresponding holes into the vehicle. Use a 1/8 inch

drill for mounting holes, a 1/4 inch drill for the headset jack

wiring. Mount the jack box to the vehicle with the provided

#10 screws. The screws require a 5/16 inch hex driver.

Alternately, the headset jack wire can come out of the side of

the jack box if desired. You will have to drill the hole where

required. Use a 1/4 inch drill. Rubber wire grommets are provided for the wire going through the jack box hole.

SHOULDER

INSULATING

WASHER

TIP

BARREL

RING

HEADSET JACK

FLAT

INSULATING

WASHER

VEHICLE

PANEL

FLAT

METAL

WASHER

NUT – OR – SPLASH COVER AND NUT

FIGURE 3

Through the Panel Mounting:

For direct mounting of headset jacks on the vehicle panel you

will need to remove the jack from the jack box cover with a

1/2 inch wrench. For normal jack mounting (no splash cover),

the maximum panel thickness is 0.10 inches or a little less

than 1/8 of an inch. If you need the splash cover (optional), the

maximum panel thickness is 0.062 inches or 1/16 of an inch.

NOTE: Longer headset jacks that can accommodate thicker

panels are available from your Sigtronics dealer (order part

number 100418 - maximum panel thickness 0.155˝ with

splash cover and 0195˝ without).

Mounting on the panel requires that you insert the jack

from the back of the panel. Test jack(s) for clearance and fit.

Leave room behind - the jack expands when headset plug is

inserted. Make sure the back of the jack does not interfere

with any moving parts of the vehicle.

Drill a 1/2 inch hole in the panel. Install jack with mounting

washers and nut as in Figure 3. Both jack insulating washers

must be used. Jack has to be insulated from mounting spot

to minimize electrical noise getting into intercom system. No

need to tighten the jack now. You may have to remove the

jack to connect the wires.

PTT Switch Installation:

In order for the officers to transmit on their selected radios,

they will each need a Push-To-Talk (PU) switch.

The PTT switches should be placed within easy reach of the

users. It is also helpful if they can be easily seen by the users.

The maximum panel thickness that can accommodate the

switches is 3/16 of an inch. The PTT switches are mounted

through the panel from the front. They can also be mounted

in a jack box.

In the selected spot, drill a 5/8 inch hole. Mount the switch

into the hole but only loosely install the provided lock washer

and nut from the back. The PTT switch will likely have to be

removed to connect the wires later.

IV. HEADSET JACK AND PTT SWITCH WIRING

The wiring of the headset jacks and PTTs is straight forward.

In general, the 4 ft.. Headset Jack and PTT Switch Cable gets

wired to the four conductor Hook-up Wire (gray) and then the

Hook-up wire connects to the jacks and the PTT switches. For

the EAI-S4 and D4 models, this cable has a 12 pin connector

with 8 wires. For the EAI-S6 and D6, there is a 15 pin connector

and 10 wires. Before going on, plug in J2 of the cable into P2

on the Radio Adapter unit.

Flexible four conductor hook-up wire is provided with each

system to connect each headset jack and PTT switch to

the EAI unit’s Headset Jack and PTT Switch Cable. Enough

wire is provided for a typical vehicle installation. If required,

additional hook-up wire can be purchased through your

Sigtronics dealer.

Each headset jack requires three wires. Each PTT switch

requires two. If an officer’s PTT switch and headset jack are

mounted near each other, only four wires are needed. Refer

to the EAI Wiring Diagram (for EAI-S4 or EAI-S6 see Figure 4

on page 6 for EAI-D4 or EAI-D6 see Figure 5 on page 7) for the

exact wiring information.

The connections between the Headset Jack and PTT Switch

Cable and the hook-up wire should be soldered and insulated

for reliability. Do not use crimp type splices. They can become

intermittent over time. Use a good quality electrical tape, or

better yet, use heat shrink tubing to cover the soldered

connections. The connections to the headset jacks and PTT

switches will also have to be soldered. See Figure 3 on page

5 for jack terminal identification.

5

Page 6

SPEAKER HI (2) VIOLET NOTE 1

SPEAKER LO (3) VIOLET NOTE 1

1234

PTT HI (5) WHITE NOTE 2

RADIO

CHASSIS GROUND (8) GREEN

+12 / +24 FUSE

VOLTS DC (7) RED

NOTES:

1. CONNEC T EITHER VIOLE T WIRE TO TH E RADIO SPE AKER HI OUTPUT. CONNECT THE

REMAINING VIOLET WIRE TO SPEAKER LO.

2. CONNEC T EITHER WHITE WIRE TO THE RADIO PUSH -TO-TALK ( PTT) KEY LINE INPUT.

CONNEC T THE REMAINING WHITE WIRE TO THE PT T KEY LIN E RETURN (PTT LO ).

3. IF NEEDED, AN EXTENSIO N CABLE MAY BE FABRICATED AND INSERT ED BETWEEN

P1 AND J1. PINS AND CONNEC TORS HAVE BEEN SUPPLI ED.

4. FOR EAI-S6 UNITS CONNECT PIN 13 (TAN ) TO CREW #3 HEADSET JACK RING TERMINAL

AND PIN 14 (TAN) TO CRE W #4 JACK RING TERMINAL . CONNECT BLUE AND BLACK

WIRES TO CREW #3 AND # 4 AS ON OTHER JACKS.

PTT LO (6) WHITE NOTE 2

MIC HI (1) BROWN

MIC LO (4) BLACK

(1 AMP)

SQ

VOL

ON

Intercom

NOTE 3

P1 J1

INTERCOM

UNIT

J3

P3

Radio Transmit

Mic Level

RADIO ADAPTER

UNIT

NOTE 4

J2

P2

EAI-S4 / S6 ( SINGLE RADIO ) WIRING DIAGRAM

(2) WHITE / RED

(1) WHITE / BLACK

(8) TAN

(4) BLACK

(3) BLUE

(9) TAN

(10) WHITE / BLUE

(11) WHITE / ORANGE

(10) WHITE / BLUE

(11) WHITE / ORANGE

PTT SWITCH

TIPRING

BARREL

HEADSET JACK

CAPTAIN

PTT SWITCH

TIPRING

BARREL

HEADSET JACK

DRIVER

FIGURE 4

TIPRING

BARREL

HEADSET JACK

CREW # 1

TIPRING

BARREL

HEADSET JACK

CREW # 2

PTT SWITCH

TIPRING

BARREL

HEADSET JACK

PUMP PANEL

We also do not recommend using screw type terminal strips

for intercom connections. There have been several instances

where terminal strips introduced high levels of electrical

noise like alternator whine into the intercom system. It is

acceptable however to tie the intercom red and green power

wires to existing vehicle terminal strips.

The best place to run the wiring between the unit and the

jack and PTT switches is out of sight. It should be run behind

vehicle panels and/or up in the headliner. This will reduce the

chance of personnel or equipment catching on or damaging the wiring. Wire routing should take into account normal

vehicle operations. Wires should not interfere with any of the

vehicle’s controls, compartments, or doors. If the vehicle’s cab

tilts up for engine servicing, run wiring along the existing

vehicle wiring bundle. Make sure that wiring does not interfere or restrict the tilting operation. Also, make sure that the

tilting operation will not cut or sever the wiring.

Make sure that the wiring does not rest on sharp edges. Over

time the vehicle’s vibration may cause a sharp edge to cut

into the wire. Use the provided wire grommets wherever

the four conductor wire goes through the hole into a jack

box. Use wire ties or tie wraps to secure and strain relieve

the wire.

At this time do not put the covers on the jack boxes or tighten

up the PTT switches. You will need to verify the correct operation of the system before you close everything up.

Power Connections:

The EAI unit will run on 11-34 VDC, so it automatically adjusts

to 12 or 24 volt vehicles. CAUTION: This EAI unit is designed

for negative ground vehicles only. It can be used on positive

ground vehicles only if a Sigtronics Positive Ground Adapter

is used. Contact your Sigtronics dealer on pricing and availability.

Make sure that the vehicle power is turned off before connecting the EAI power wire. The power for the EAI units comes

in on the red and green wires on the Radio 1/ Power Interface

Cable. It is an eight wire cable with a 9 pin connector. Plug

the 9 pin connector J3 into the mating connector P3 on the

Radio Adapter unit.

Connect the red wire to vehicle power. ( Try not to use a power

buss that also runs electrical motors such as fans or light bars

with rotating lights.) Connect the green wire to the vehicle

chassis ground.

INTERCOM WIRING CHECK OUT

System Setup:

Before you connect the vehicle’s radios, check out the system

operation. Do the following without the vehicle’s engine running:

First plug all headsets into the respective headset jacks.

6

Page 7

SPEAKER HI (2) VIOLET NOTE 1

SPEAKER LO (3) VIOLET NOTE 1

1234

PTT HI (5) WHITE NOTE 2

RADIO 2

RADIO 1

CHASSIS GROUND (8) GREEN

+12 / +24 FUSE

VOLTS DC (7) RED

PTT LO (6) WHITE NOTE 2

MIC HI (1) BROWN

MIC LO (4) BLACK

SPEAKER HI (2) VIOLET NOTE 1

SPEAKER LO (3) VIOLET NOTE 1

1234

PTT HI (5) WHITE NOTE 2

PTT LO (6) WHITE NOTE 2

MIC HI (1) BROWN

MIC LO (4) BLACK

(1 AMP)

SQ

P1 J1

NOTE 3

VOL

ON

Intercom

INTERCOM UNIT

NOTES:

1. CONNEC T EITHER VIOLE T WIRE TO TH E RADIO SPE AKER HI OUTPUT. CONNECT THE

REMAINING V IOLET WIRE TO SPEAKER LO.

2. CONNEC T EITHER WHITE WIRE TO THE RADI O PUSH-TO-TALK (PTT ) KEY LINE INPUT.

CONNEC T THE REMAINING WHIT E WIRE TO THE PT T KEY LINE RETURN ( PTT LO) .

3. IF NEEDED, AN EXTENSION CABLE MAY BE FABRICATED AND INSERT ED BETWEEN

P1 AND J1. PINS AND CON NECTORS HAVE BEEN SUPPLIED.

4. FOR EAI-D6 UNI TS CONNECT PIN 13 (TAN ) TO CREW # 3 HEADSET JACK RING TERMINAL

AND PIN 14 (TAN) TO CREW #4 JACK RING TERMINAL. CONNECT BLUE AND BLACK

WIRES TO CREW #3 AND #4 AS ON OTHER JACKS.

5. MOUNT SWITCHES W ITH BUSHING KEYSLOT DOWN.

RADIO SELECT SWITCHES

TALK

RADIO 1

RADIO 2

J4

P4

J3

P3

Transmit

Mic Level

Radio 1

Radio 2

RADIO ADAPTER UNIT

P5

J5

LISTEN

AUTO

BOTH

NOTE 5

NOTE 4

J2

P2

EAI-D4 / D6 ( DUAL RADIO ) WIRING DIAGRAM

(2) WHITE / RED

(1) WHITE / BLACK

(8) TAN

(4) BLACK

(3) BLUE

(9) TAN

(10) WHITE / BLUE

(11) WHITE / ORANGE

(10) WHITE / BLUE

(11) WHITE / ORANGE

PTT SWITCH

TIPRING

BARREL

HEADSET JACK

CAPTAIN

PTT SWITCH

TIPRING

BARREL

HEADSET JACK

DRIVER

FIGURE 5

TIPRING

BARREL

HEADSET JACK

CREW # 1

TIPRING

BARREL

HEADSET JACK

CREW # 2

PTT SWITCH

TIPRING

BARREL

HEADSET JACK

PUMP PANEL

Put on one of the headsets and position the boom mic close

to the mouth, as is the practice with hand-held microphones.

Voice clarity is best when the mic is about 1/4 inch away and

slightly off center from the lips. Turn the volume control on

the headset, all the way up (clockwise).

On the EAI unit, set both the intercom volume (VOL) control

and squelch (SQ) control to full clockwise position.

Now turn vehicle power on. Then turn the EAI power switch to

“ON”. Verify that you can now hear yourself in your headset.

Verify also that you can hear all the other headsets and that

they can hear you. If everything is OK, skip to the “PTT Test” on

page 8. Otherwise, if something is not working right, see the

following troubleshooting guide to find and fix the problem

before going on with the installation:

No Intercom In Any Of The Headsets:

1. Make sure the EAI power switch and VOLume and SQuelch

controls are set as above.

2. Make sure the vehicle power is on.

3. Check in-line fuse in EAI Radio 1/ Power Interface Cable.

4. Check power connection - red wire.

5. Check ground connection - green wire.

6. Check for short or open on headphone wire (Blue wire on

the Headset Jack and PTT Switch Cable). The problem could

be anywhere along the blue wire connection between the

headset jacks and the EAI unit.

Intercom In Some Headsets But Not In Others:

1. Make sure that EAI switch and controls are set as above.

2. Make sure that neither of the PTT buttons are pressed.

3. Make sure that neither of the PTT wires (white / red or

white / blue) are shorted to ground.

4. Check specific “bad” headset jack wiring for:

a) Microphone wire (jack ring terminal) open or shorted

to ground.

b) Headphone wire (jack tip wire) open or shorted to

ground.

c) Incorrect wiring - wires switched either at the jack or

at the point where the hookup wire connects to the

Headset Jack and PTT Switch Cable.

Loud Squeal In The Headsets All The Time:

1. First make sure all headset plugs are plugged in all the way

and that no part of any headset jack is physically touching

any metal.

2. Check headset jack wiring at all jacks. For example, incorrect wiring such as reversing the jack tip and ring wires will

cause a squeal.

7

Page 8

3. Check for open headset jack barrel connection (black wire).

The open could be anywhere along the black wire connection between the jack and the EAI unit.

4. Check for a microphone line (white / black, white / orange,

or tan wires) shorted to the headphone line (blue wire). The

short could be at one of the headset jacks or in the wiring

between the unit and a jack.

Note that for 2 and 3 above, it will only squeal if a headset

is actually plugged into the specific jack that is wired incorrectly.

PTT Test:

If all above is good, make sure all headsets are plugged into

their respective jacks. Put on the Engineer’s (driver) headset

and position the microphone as usual. Press the Engineer’s

PTT switch. While continuing to hold down the switch, talk

into the mic and verify that you can still hear yourself. Also,

while holding down the PTT switch, verify that none of the

other head set microphones are active. Release the PTT

switch.

Now put on the Captain’s headset, position the microphone,

and press the Captain’s PTT switch. Verify that only Captain’s

head set microphone is active as his switch is held down.

If the system has a jack and PTT wired up at the vehicles pump

panel, unplug the headset from the drivers position and plug

it into the pump panels jack. Press and hold down the pump

panel PTT switch. Verify that only the pump panel headset

microphone is active.

If all works fine, skip down to “Electrical Noise Test” on this

page. If anything does not work as above, you have one of

three possible PTT switch wiring errors:

1. PTT line (white / red or white / blue wires) open or not

connected between a PTT switch and the EAI unit.

2. Open or missing return line (black wire) to a PTT switch.

3. Reversed PTT lines. The Engineers PTT line connected to

the Captain’s PTT switch and visa versa.

Electrical Noise Test:

The last thing to do before the radios are hooked up to the

unit is a simple noise test to verify system wiring as well as

vehicle electrical system integrity.

1. Unplug all intercom headsets except for the drivers.

2. Make sure all the EAI panel controls and switches are set

as in “System Setup” on page 6.

3. Start the vehicles engine and let it idle a bit. This is a stationary test - the vehicle should not be moving and should be

in “PARK” or “NEUTRAL” with brakes set.

4. Close all vehicle windows and doors to eliminate as much

background noise as possible.

5. Turn on as much vehicle electrical equipment as possible.

This usually means all lights and strobes. Do not turn on

sirens or horns.

6. Put on the driver’s headset, position the mic, and make sure

the headset volume control is set to maximum.

7. With the vehicle still in “PARK” or “NEUTRAL” and brakes set,

slowly increase the vehicle engine rpm from idle to about

1500 RPM and back again. While doing this, listen for any

whine or hum in the headsets. Except for some possible

engine background noise being picked up from the headset microphone you should not hear any “Electrical” whine

or hum in the headset.

8. Shut off the vehicle engine as well as the lights, strobes,

etc. If, while the engine was running, there was no electrical

noise, skip down to “Radio Hook Up” on page 9. If you did

hear electrical noise, use the following to track down the

problem:

Turn the vehicle power off and disconnect the EAI ground

connection (green wire) from ground. Turn on the vehicle

power (engine off ), put on the driver’s headset and see if

the intercom part of the EAI unit is working.

If You Can Hear Yourself In The Headset:

1. Then the EAI intercom return wire (black) is incorrectly

grounded to the vehicle chassis. Look for:

a) A headset jack barrel touching the vehicle chassis. Most

common when a headset jack is mounted directly into

the vehicle’s panel without using the supplied insulating washers or incorrectly installing the washers.

b) The black wire pinched or cut and shorting to the vehi-

cle chassis. This can be anywhere along the intercom

wiring as the black wire goes to all head set jacks and

PTT switches.

2. Once the problem has been found and fixed, again make

sure that the intercom now does not work with the green

wire disconnected. You could have the black wire grounded

in more than one spot.

3. The next step is to reconnect the green wire and do the

electrical noise test again to assure that you have fixed all

possible noise problems.

If You Cannot Hear Yourself In The Headset:

The intercom wiring is correct, but excessive electrical noise

from the vehicle’s power system is affecting the EAI unit

operation. This noise is getting into the unit on the EAI power

wires (red and green). There are basically two types of power

line electrical noise sources:

1. Noise generated directly by the vehicle’s electrical/charging

system - most commonly known as alternator whine. This

is only present when the vehicle’s engine is running and

recognized by the fact that the pitch or frequency of the

whine changes directly with the change in engine rpm.

(Higher frequency at higher engine rpm’s and lower frequency at lower rpm’s.)

The preferred way to solve this type of problem is to have

the vehicle’s electrical / charging system serviced. The most

common cause of this type of noise is bad diodes in the

vehicle’s alternator. Other possible causes are: bad vehicle

voltage regulator; bad alternator or battery cable connections; missing or bad engine or alternator grounding

straps.

If servicing the vehicle’s charging system is impracti-

cal, installing a good alternator whine power line filter

8

Page 9

between the vehicle power and the EAI red wire will usually accomplish the same thing. Do not use the type of filter

that installs on or near the alternator. NOTE: This solution

should not be considered a permanent fix. Vehicle charging

system problems of this type will eventually cause other

equipment failure as well as shorten the life of the vehicle’s

batteries.

2. The other type of noise is that generated by equipment

that uses the vehicle’s power. This type of noise is usually

constant and does not vary with engine rpm. It does, however, go away completely if the offending equipment is

shut off or disconnected. Electrical motors in fans or light

bars with rotating lights are two common examples.

Several things can be done to rectify this type of electrical

noise:

a) Find a better (less noisy) vehicle power source for the EAI

unit. Move the EAI red wire to another power buss. Try

not to use a power buss that also runs electrical motors

such as fans or light bars with rotating lights.

b) Move the EAI ground connection (green wire) to

another ground point on the vehicle.

c) Install an electrical noise filter on the power line going

to the equipment causing the noise. Contact the company that makes the offending equipment for a recommendation on the type of filter to use.

If something does not work as described, go back over the

wiring and correct before going on. If all is well, you can

tighten all headset jacks and secure all jack box covers

with the supplied hardware. Also, tighten and secure all PTT

switches. On the EAI unit, turn down the intercom VOLume

control to approximately 1/3 position.

V. RADIO HOOK UP

The connection of the EAI unit to the vehicle’s radio(s) should

be done by someone familiar with the radio(s) such as your

radio installer. Refer to the EAI Wiring Diagram -Figure 4 on

page 6 for EAI-S4 or EAI-S6 units or for EAI-D4 or EAI-D6 see

Figure 5 on page 7. Only the radio functions are shown for

the radio end of the EAI Radio Interface Cable. Because the

connector(s) used by radio manufacturers varies widely, you

will have to consult the radio manual or manufacturer for

the connector(s) and pin assignments used. Sigtronics has

extensive radio interface experience and can assist with any

question you might have concerning this or any other aspect

of the EAI system. See our installation hot line number located

on the last page of this manual.

Using the radio manuals and the EAI Wiring Diagram, identify the correct signal wires or connector pins to attach the

respective EAI wires. For most radios, these connections are at

the back of the radio or radio control head. For some radios,

the only place to connect the MIC HI and LO and PTT HI and

LO wires is to the hand-held microphone connector.* It is best

to wire in such a way that the radio hand microphone can

still be used as normal. Make sure that you do not physically

tie the EAI MIC LO and SPEAKER LO wires to the same pin on

the radio, even if they are tied together inside the radio. As

in the headset wiring, the connections between the EAI and

radios should be soldered and insulated for reliability. Do not

use crimp type splices.

Use a good quality electrical tape or heat shrink tubing to

cover the soldered connections.

* For the more popular radios of this type Sigtronics manufactures plug in “Y” adapters to make these connections easy.

Contact your Sigtronics dealer for pricing and availability.

For dual radio units (EAI-D4 or EAI-D6), hook up Radio 1 first

and test before moving on to Radio 2.

Connect the six wires from the Radio 1 / Power Interface

Cable to the appropriate connections on the vehicle’s radio.

Once that is done you will need to adjust the Radio 1 Transmit

Mic Level.

Radio transmit mic level adjustment for the radio (or both

radios for EAI-D4 and EAI-D6) is provided through a hole (or

holes) on the side of the Radio Adapter unit. The adjustment(s)

sets the microphone audio level going to the radio(s) during

transmit. The radio transmit mic level adjustment(s) will need

to be initially set to your particular radio(s). The level(s) once

set, should never need adjustment again unless the type of

radio(s) used are changed. The following simple procedures

take you through the adjustment of the mic level(s).

Radio Transmit Mic Level Adjustment can be made with

a small, flat blade screwdriver. Clockwise rotation increases

the output level to the radio. Counter-clockwise rotation

decreases it. The basic adjustment concept is simple. You

will be setting the level and clarity of outgoing radio transmissions through the EAI unit headsets, to match or exceed

that of transmissions using the radio’s standard hand microphone. To do this, you will need to transmit and receive on the

vehicle’s radio to a remote station. Arrange to have someone

nearby with a radio compatible to the radio you are using

with the EAI. Then

1. Set the EAI ON / OFF switch to the “ON” position. Plug a

headset into the Captain’s jack. Make sure that the volume

control on the headset is turned up to full. It is not necessary to connect the other headsets (or Radio 2 on EAI-D4 or

EAI-D6 units) for this adjustment. On dual radio units (EAID4 or EAI-D6), set RADIO 1/ RADIO 2 switch to “RADIO 1”

and the AUTO / BOTH switch to “AUTO”.

2. Set the headset aside for a moment. With the radio’s hand

mic, transmit as normal, to the remote station. Transmit

long enough so that the receiving station can get “calibrated” to your transmission (voice) level.

3. Put on the Captain’s headset and position the headset

microphone as normal. Verify radio reception. If OK, use

Captain’s PTT to transmit to your receiving party. If receiving station reports weak transmission, use the screwdriver

to turn the RADIO TRANSMIT MIC LEVEL clockwise a small

amount. If they report garbled, broken, or noisy transmissions, turn the RADIO TRANSMIT MIC LEVEL counterclockwise a small amount. Repeat as necessary until the

receiving party reports that transmissions through the EAI

sound as good or better then when using the radio hand

microphone. That’s all there is to it!

Once the mic level is set also check radio operation with the

9

Page 10

vehicles engine running. If radio reception and transmission

through the EAI unit is fine, for EAI-S4 or EAI-S6 units this com-

pletes the installation. Skip down to the “System Operation”

section on page 11. If everything is OK for EAI-D4 or EAI-D6

units skip down to the “Radio 2 Hook Up” section on page

11. If something does not work correctly, check the following

trouble shooting guide:

RADIO TROUBLESHOOTING GUIDE

NOTE: For dual radio units (EAI-D4 or EAI-D6) it is far easier to

troubleshoot with only one radio connected to the Sigtronics

at a time.

First determine if the trouble occurs with the vehicle engine

running.

Vehicle Engine Off:

1. Can’t hear radio in headset:

a) Turn up radio volume at the radio as normal. Make sure

however, you are not picking up the radio through the

headset mics by briefly turning down (counter-clockwise) the intercom VOLume control all the way.

b) Check violet wire (SPEAKER HI and LO) connections from

the EAI to the radio.

c) For EAI-D4 or EAI-D6 units, make sure that RADIO 1/

RADIO 2 switch is set to the radio you want to hear.

d) Some radios do not have sufficient speaker audio to be

heard on a standard EAI system. For such radios a minor

modification can be done to the Radio Adapter unit to

increase the level (by approximately 300%). Refer to

Figure 6 below. Using small piece of hook up wire and

a soldering iron, jumper across the pads as indicated on

the solder side of the Radio Adapter unit circuit board.

For EAI-S4 or EAI-S6 units jumper across the “A” pads. To

increase the audio for RADIO 1 of a EAI-D4 or EAI-D6

unit, also jumper across the “A” pads. To increase the

audio of RADIO 2 on a EAI-D4 or EAI-D6, jumper across

the “B” pads.

FIGURE 6

A

2. Can’t talk to dispatch (transmit) on radio through the head

set:

a) Check the connections between EAI Radio Adapter unit

and the radio. Both white wires (PTT HI and LO) and the

Brown and Black wires (MIC HI and LO).

b) Check the Radio Transmit Mic Level adjustment.

c) If the EAI is connected to a Midland radio a Sigtronics

Mic Level Amplifier might be required to boost the

transmit level. Contact your Sigtronics dealer for details.

B

d) For EAI-D4 or EAI-D6 units, make sure the RADIO 1/

RADIO 2 switch is set to the radio you want to transmit

on.

Vehicle Engine On:

1. Electrical noise (alternator whine) in headsets when receiving on radio, or

Dispatch reports that they hear electrical noise (alternator

whine) when transmitting from vehicle through the headsets.

First make sure that the problem is only related to the radio

hook up. Make sure that you did the “Electrical Noise Test”

for the intercom (without the radios connected) on page 8

and fixed any problems there before you go further. If OK

then:

Check all six radio interface wires between the EAI unit and

the radio - MIC HI, MIC LO, PTT HI, PTT LO, SPEAKER HI, and

LO. Make sure that you have the correct pin numbers for

the radio you are hooking to. Make sure that MIC LO and

SPEAKER LO are not physically tied to the same pin on the

radio; even if they are tied together inside the radio.

If the wiring is OK, then noise is coming from radio.

Possible bad radio wiring, (Check radio power and ground-

connections for loose or corroded connections) or

Excessive noise is generated directly by the vehicle’s electri-

cal / charging system – most commonly known as alternator whine. This is only present when the vehicle’s engine

is running and recognized by the fact that the pitch or

frequency of the whine changes directly with the change

in engine rpm.

The preferred way to solve this type of problem is to have

the vehicle’s electrical / charging system serviced. The most

common cause of this type of noise is bad diodes in the

vehicles alternator. Other possible causes are: bad vehicle

voltage regulator; bad alternator or battery cable connections; missing or bad engine or alternator grounding

straps.

If servicing the vehicle’s charging system is impractical,

installing a good alternator whine power line filter in-line

with the radio power wire(s) will usually accomplish the

same thing. All radio power wires will have to be filtered.

Some radios have more than one wire that hooks to vehicle

power. Contact the radio manufacturer for a recommendation on the best filter for the particular radio. NOTE: This

solution should not be considered a permanent fix. Vehicle

charging system problems of this type will eventually

cause other equipment failure as well as shorten the life

of the vehicle’s batteries.

2. Dispatch says too much background noise or unclear or

weak transmissions.

a) Check to see if a radio hand mic on the vehicle is also

active or ‘live” when transmitting through the EAI unit.

Check this while not wearing a headset and by talking

directly into the radio hand mic and pressing either EAI

PTT switches. Do not press the PTT button on the hand

mic itself. If dispatch can hear you loud and clear, then

10

Page 11

the background noise pick up is coming from this active

hand mic. If you have this type of hand mic then it is best

to contact the radio manufacturer for instructions on a

possible microphone modifica-tion to fix the problem.

Some radio manufacturers can supply a compatible

microphone that does not have this problem.

b) Adjust the EAI Radio Transmit Mic Level Adjustment. If

the mic level is set too low, you will get reports of weak

transmissions. If the mic level is too high, you will get

reports of noisy or garbled transmissions. See “Radio

Transmit Mic Level Adjustment” on page 9.

Radio 2 Hook Up:

Plug in J4 of the Radio 2 Interface Cable into P4 of the Radio

Adapter unit. (This cable has a six pin connector.) Using the

radio manual and Figure 5 on page 7, connect the six wires

to the appropriate connections on the vehicle’s radio. Once

that is done you will need to adjust the Radio 2 Transmit Mic

Level.

The Radio 2 Transmit Mic Level Adjustment is the right one

of the two located on the Radio Adapter unit. The adjustment

procedure is very similar to that of the Radio 1 Transmit Mic

Level adjustment. Arrange to have someone nearby with a

radio compatible with your Radio 2. Then, proceed as follows:

1. Set the EAI ON / OFF switch to the “ON” position. Again,

Plug in a headset into Captain’s jack. Make sure that the

volume control on the headset is turned up to full. (Radio

1 and the other headsets are not needed for this adjustment.) Set the RADIO 1/ RADIO 2 switch to “RADIO 2”

and the AUTO / BOTH switch to “AUTO”.

2. Set the headset aside for a moment. With the radio’s hand

mic, transmit as normal, to the remote station. Transmit

long enough so that the receiving station can get “calibrated” to your transmission (voice) level.

3. Put on the Captain’s headset and position the headset

microphone as normal. Verify Radio 2 reception. If OK, use

Captain’s PTT to transmit to your receiving party. If receiving station reports weak transmission, use the screwdriver

to turn the RADIO 2 TRANSMIT MIC LEVEL clockwise a

small amount. If they report garbled, broken, or noisy transmissions, turn the RADIO 2 TRANSMIT MIC LEVEL counterclockwise a small amount. Repeat as necessary until the

receiving party reports that transmissions through the EAI

sound as good or better then when using the radio hand

microphone.

If Radio 2 does not operate as it should, use the “Radio Trouble

shooting Guide” on page 10 to find and fix the problem. This

completes the EAI installation.

SYSTEM OPERATION

The following describes how to use the EAI System as well as

adjust the EAI controls. It also explains exactly how the EAI

unit operates. This will allow you to easily set all unit functions to your specific needs. If you are not familiar with the

EAI operation, perform the next few steps while the vehicle

is not in motion.

HEADSETS

Put on the headset(s) and position the boom mike close to

the mouth, as is the practice with a hand-held mike. For best

voice clarity, the headset microphone must be positioned to

one side of the mouth and 1/4 inch from the lips. Turn the

volume control on the headset ear cup to maximum. Turn

down for individual hearing needs if necessary only after

intercom and radio volumes have been set correctly. (see

below)

Intercom operation and adjustment can be performed by

the following procedure:

1. Set the ON / OFF switch to the “ON” position.

2. Turn the intercom SQuelch control to the maximum

clockwise position. For best system performance set the

intercom VOLume control as low as possible. On most

systems this will be approximately between 1/4 to 1/3

open. Note: the intercom volume control only adjusts the

volume of conversation between the headsets inside the

vehicle. It does not affect the level at which you hear the

dispatch radio. (see Radio Volume below) You should now

hear yourself and others on the intercom.

3. To adjust the Intercom SQuelch for voice activated operation (VOX), it is helpful to have some background noise

(truck engine or ...). Turn intercom SQuelch control all the

way counter-clockwise. Now, without speaking, rotate the

SQuelch control clockwise until you hear the background

noise in your headset. Next, rotate it counterclockwise in

small amounts until the background noise disappears.

Finally, make small adjustments until your voice triggers

the unit at comfortable speaking levels. This procedure

is necessary because the squelch is a “Fast-on, Slow-off’

system.

When you speak, your voice will be heard in the headsets

but the sound will cut off about a second after you stop

speaking. Minor readjustment of the Squelch may be necessary if the background noise level changes significantly

(engine idling to cruise power with siren on).

RADIO OPERATION

With the EAI System, your radio(s) are heard through the

headsets as well. Adjust the volume level of the dispatch

radio(s) in the headsets with the volume control on the

radio as normal. Note that the radio volume does not effect

the intercom volume and visa versa.

Transmitting (talking to dispatch) from the selected headset

positions is possible on a one-at-a-time basis. For a typical EAI

installation the Captain or Engineer positions can transmit

at any time simply by pressing their PTT switch. The Crew

positions cannot transmit on the radios. When one position

transmits, several things take place automatically:

• All headset microphones, except for the transmitting position, are muted.

• The selected radio is put into transmit mode.

• The headset microphone audio (your voice) is sent to the

selected radio.

11

Page 12

• Sidetone is generated and sent to your headphones.*

* Sidetone is a portion of the transmitted voice signal sent

back into your headset so that you can hear what you are

saying while transmitting. The intercom VOLume control

adjusts the volume level of the sidetone that you hear in

your headset. The other headsets will also hear the transmission sidetone. Of course, when the PTT switch is released,

(stop transmitting) all functions return to normal, instantly

and automatically.

For Dual Radio Units - EAI-D4 and EAI-D6:

The operation of the dual radio EAI units are identical to

that of the single radio units except for the addition of radio

selection:

Radio Selection of both Radio 1 and Radio 2 radios are provided by two switches.

1. RADIO 1/ RADIO 2 (TALK) determines the radio you wish

to transmit on.

2. AUTO / BOTH (LISTEN) selects which radio(s) you receive

or hear in your headset.

a) “ AUTO” position allows you to hear the radio that the

RADIO 1 / RADIO 2 switch is set to.

b) “ BOTH” position permits you to hear both the radios at

the same time.

EAI Specifications

Input Voltage: . . . . . . . . . . . . . . .11 - 34 VDC

Nominal Current: . . . . . . . . . . . 0.06 Amps

Maximum Current: . . . . . . . . . 0.10 Amps

Intercom Unit Size: . . . . . . . . . 2.5 x 1.06 x 4.2 inches

Radio Adapter Unit Size: . . 4 x 2.9 x 2 inches

Weight: . . . . . . . . . . . . . . . . . . . . . . . .12 oz. (not including cables and hardware)

TWO YEAR WARR ANTY

Ever y Sig tronics product has bee n carefully inspec ted b efore shipment. We g uarantee to corre ct any defect caused by fau lty

material or wo rkmanship free of charge to the user who origina lly purchased the pro duc t for a perio d of two years from the

original pu rchase date. Our obligati on assumed under this guarantee is limited to the replacin g of any par t or pa rts which

prove to our s atisfaction, upon examination to have b een defective, and which h ave not been mis used or carelessly handled.

The com plete unit m ust be retur ned to our factory, transporta tion c harges prepaid. We rese rve the ri ght to decli ne responsibi lit y where r epairs or replace ments have been made or attemp ted by others. N o other guarantee, written or verbal, on our

product s is author ized by us.

Repairs required due to abuse, misuse, damage o r normal ser vice beyond the warranty pe rio d will be subj ect to normal ser vice charges.

To expedite factory s ervice work, contact Sigtronics Service Departm ent an d explain the problem . All corres pondence relative to service work shou ld inclu de model and ser ial number. Frequently p roblems can be resolved by phon e. The Sigtronics

numb er is located below.

Sigtronics Installation Hot Line Number:

igtronics

S

1-800-367-0977 ext. 8

M-F 8:00 am to 4:30 pm Pacific Time

www.sigtronics.com

®

10-7-2010 EAI_INST_Rev_G.pdf

12

Loading...

Loading...