USER MANUAL

SA12

email support@signwarehouse.com

© SignWarehouse Inc

2614 Texoma Drive

Denison, TX 75020

ph: 800-899-5655

Technical support contacts:

Phone: 800-966-1783

1

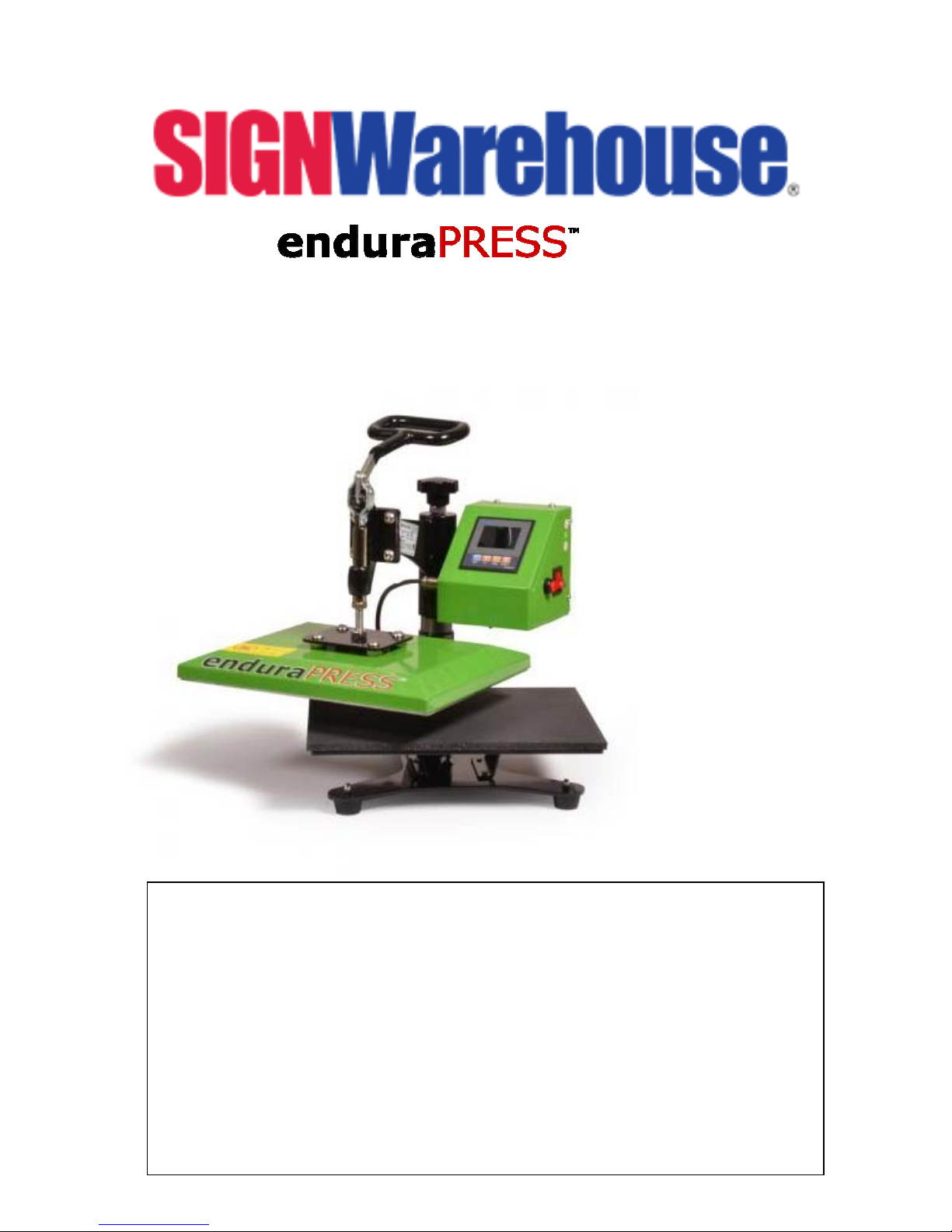

Main Handle

Teflon Coated Heating Platen

Silicon Pad

Components

Pressure Knob

LCD Control Panel

Power Switch

Base

Specifications:

Model NO: ENDURAPRESS SA12

Volta ge: 110V/60Hz

Power: 1.4kW,

Control Panel: LCD Control Panel

Time Range: 0~999sec.

Temp. Range: 0~480°F

Maximum material width: 1"

Packaging: Corrugated Paper Carton

Gross Weight: 75LBS (16”x20”),

2

OPERATING INSTRUCTIONS

READ BEFORE USING

1. Check the voltage before using it. The correct voltage is 110-120V/60Hz

2. Turn off the machine when not in use, and remove the power plug from scoket.

3. Grasp the handle firmly when opening.

4. Keep children away from the machine.

5. Do not touch the heating platen and platen cover after pressing whilst in operation

6. Do not attempt to press products that are not intended for normal heat transfer

7. Do not set the temperature any higher than 480F as it may cause over heat and stop

working.

8. HPN heat press carries a ground line by default, please make sure the scoket gets a

ground line protector.

3

Control Panel Operation

Touch Screen Control Panel.

Touch "Set" to activate menu.

Set button

Touch up or down arrow to adjust

temperture.

Page 1:

Tem pe ra ture

Page 2: Time

Touch up or down arrow to

adjust press cycle time.

Page 3: Celsius or Fahrenheit.

Touch up or down arrow to change temp

display from Farhenheit to Celsius.

Page 4: Temperature Calibration.

Touch up or down arrow to adjust displayed temperature reading to match

actual (measured) heat platen temperature. For instance, if display reads

200° and actual temperature is 210°, set +10 here using up arrow.

Page 5: Pre-Alarm Setting.

Touch up or down arrow to set off the end-of-cylcle alarm before the end of

cycle. This feature is helpful for hot peel applications requiring immediate

action at the end of the cycle. The pre-alarm gives you time to prepare.

Touch "Set"again to leave the menu and begin work.

4

Heat Transfer Application Guidelines

* These are general guidelines. For specific time and temperature settings for specific films and/or transfer

papers, please refer to the instructions for that particular product.

TRANSFERS PRINTER MARK TEMP. TIME PRESSURE

Sub. Paper

Ricoh, Epson

Polyester 400°F 25~30sec. 30Psi

Light Color 365°F 15sec. 30Psi

Ink Tran. Paper Inkjet Printer

Dark Color 330°F 25sec. 30Psi

Laser Tran.Paper** Laser Printer Light Color 345°F 30sec. 30Psi

Laser Printer Dark Color 260 - 320°F 35 - 120 sec. 25Psi

Transfer Vinyls Cutting Plotter / 300~320°F 8~10sec. 30Psi

Plastisol Tranfer / / 335°F 12sec. 50Psi

5

Troubleshooting Tips

Q. Why isn't my heat transfer vinyl sticking to the fabric?

A. This can be caused by three things. Insuficient pressure, or temperature, or time.

Time: Some heat transfer films need a few seconds to cool before you remove the liner. Try a warm

or cold peel first.

Temperature: If that doesn't work, check to make sure you are using the recommended time and

temperature settings. If you are, your press may not be putting out the correct amount of heat. Use a

Geo Knight IR thermometer to check the actual temperature of the platen. If it is more than 5°

different from the LCD display (PV), adjust it using step four in the control panel (see page 4).

Pressure: If the temperature is correct, adjust the pressure. Some films require more pressure to

bond the adhesive to the fabric. There should be some resistance when you close the press. If you

have verified all of these and the film doesn't stick, contact SIGNWarehouse customer service or

Technical Support for further assistance.

Q. Why does my sublimated transfer look washed out?

A. This is usually caused by insufficient temperature. Sublimation works best at or near 400°F. If

your transfer is faded, check the output of the heat platen with a contact thermometer and make sure

the output matches the displayed temperature. If not, adjust as directed above. Then repress at 390 -

400°F.

Q. Why are my transfers are sticking to the heating element of the upper platen?

A. If T-shirt vinyl is sticking to the heating element, you have it upside down. Remove any adhesive

residue, flip it over and try again. If an inkjet or laser transfer is sticking to the heating element, it's

because the heat is affectign the ink. Cover it with a Teflon sheet or sheet of silicone Kraft paper to

prevent this. Using a Teflon sheet or Kraft peaper is recommended for almost all heat transfer

applications.

Q. Why is it so hard to peel the liner when I'm done pressing the paper?

A. A hot or warm peel film may become hard to peel if allowed to cool. Always peel the film or

transfer paper in accordance with the product's recommendations.

6

Wiring Schematic

6. WARRANTY

Thank you for choosing our products, you are entitled to one year free warranty service

for our products. All exceeds warranty period we will still provide technical supports

and maintenance guidance.

For further assistance, please contact SignWarehouse technical support:

7

• Toll Free Phone: 800-966-1783. • email: techsupport@signwarehouse.com

8

Loading...

Loading...