Signode Tension-Weld BTS-16, Tension-Weld BTS-19, Tension-Weld BTS-25, Tension-Weld BTS-32 Operation, Parts And Safety Manual

BTS-16/19/25/32

ENSION-WELD® STRAPPING TOOL

T

NOTE: Fully charge battery before first use of tool.

READ THESE INSTRUCTIONS CAREFULLY. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN

S

EVERE PERSONAL INJURY.

GENERAL SAFETY CONSIDERATIONS

1. STRAP BREAKAGE HAZARD

Improper operation of the tool or sharp corners on the load can result in strap breakage during

tensioning, which could result in the following:

! A sudden loss of balance causing you to fall.

! Both tool and strap flying violently towards your face.

Failure to place the strap properly around the load or an unstable or shifted load could result in a

sudden loss of strap tension during tensioning. This could result in a sudden loss of balance causing

you to fall.

Read the tool's operating instructions. If the load corners are sharp use edge protectors. Place the

strap correctly around a properly positioned load.

! Positioning yourself in-line with the strap, during tensioning and sealing, can result in severe

personal injury from flying strap or tool. When tensioning or sealing, position yourself to one side

of the strap and keep all bystanders away.

! Using strap not recommended for this tensioner can result in strap breakage during tensioning.

Use the correct Signode products for your application.

2. TRAINING

This tool must not be used by persons not properly trained in its use. Be certain that you receive

proper training from your employer. If you have any questions contact your Signode Representative.

3. EYE INJURY HAZARD

Failure to wear safety glasses with side shields can result in severe eye injury or

blindness. Always wear safety glasses with side shields which conform to ANSI Standard

Z87.1 or EN 166.

4. FALL HAZARD

Maintaining improper footing and/or balance when operating the tool can cause you to fall. Do not use

the tool when you are in an awkward position.

5. CUT HAZARD

Handling strap or sharp parts could result in cut hands or fingers. Wear protective gloves.

6. TOOL CARE

Take good care of the tool. Inspect and clean it daily, lubricate it weekly and adjust when

necessary. Replace any worn or broken parts.

7. WORK AREA

Keep work areas uncluttered and well lighted.

Several types of strap can be used with this tool. Use the correct Signode products for your application. If

you need help contact your Signode Representative.

CUTTING TENSIONED STRAP

Use only cutters designed for cutting strap; never use claw hammers, crowbars, chisels, axes or similar

tools. Such tools will cause the strap to fly apart with hazardous force. Before using any Signode product,

read its Operation and Safety Manual.

2

SAFETY PROCEDURES FOR ELECTRIC TOOLS

1

. GUARD AGAINST ELECTRIC SHOCK

2. CONSIDER WORK AREA ENVIRONMENT

!!!! T

ry not to operate tool in damp or wet locations.

!!!! Prevent body contact with grounded surfaces, such as pipes, radiators, ranges, refrigerator

enclosures.

!!!! When tool is used outdoors, use only extension cords intended for outdoors and so marked.

!!!! Wear rubber gloves and non-skid footwear when working outdoors.

!!!! Do not expose power tools directly to rain.

!!!! Never operate tool in presence of gases or flammable liquids.

3. Never allow visitors to contact tool or extension cords. All visitors should be kept away from work

area.

4. DO NOT ABUSE TOOL

!!!! K

eep handle dry, clean and free from oil and grease.

!!!! Never carry tool by cord or yank it to disconnect from receptacle.

!!!! Always keep cord from heat, oil and sharp edges.

!!!! Always store idle tool in dry, high or locked-up place.

!!!! Always disconnect tool when not in use or before servicing.

!!!! To avoid unintentional starting, never carry plugged-in tool with finger on switch. Be sure switch

is off when plugging in.

5. MAINTAIN TOOL WITH CARE

Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check

for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other

condition that may affect its operation. A guard or other part that is damaged should be properly

repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this

instruction manual. Have defective switches replaced by authorized service center. Do not use tool if

switch does not turn it on and off.

!!!! W

hen servicing double insulated tool, use identical replacement parts.

!!!! Keep tool clean for better and safer performance.

!!!! Inspect tool cord periodically and, if damaged, have repaired by authorized service facility.

!!!! Inspect extension cord periodically and replace if damaged.

SAFETY PROCEDURES FOR TOOL OPERATION

Before using this tool, read its Operation and Safety instructions. This tool is a Tension Weld® type sealer.

A properly made joint will appear as shown in the illustration. If the joint does not appear as shown, then

the operator must proceed as follows:

A. Ensure that the tools operating instructions are

being followed before applying another strap.

B. Cut the strap off and apply another.

If the joint still does not appear as shown, then inspect the tool for worn and/or damaged parts. Replace

tool parts as needed. NEVER HANDLE OR SHIP ANY LOAD WITH IMPROPERLY FORMED JOINTS.

Misformed joints may not secure the load and could cause serious injury. Tuck strap end back into the

dispenser when not in use.

3

TABLE OF CONTENTS

Pa

ge

Page

General Safety Instructions 2

Specifications 4

Major Components 5

Battery Information 5

Operating Instructions 7

Weld Time Adjustments 9

Parts List 10

Troubleshooting 12

Tool Maintenance 13

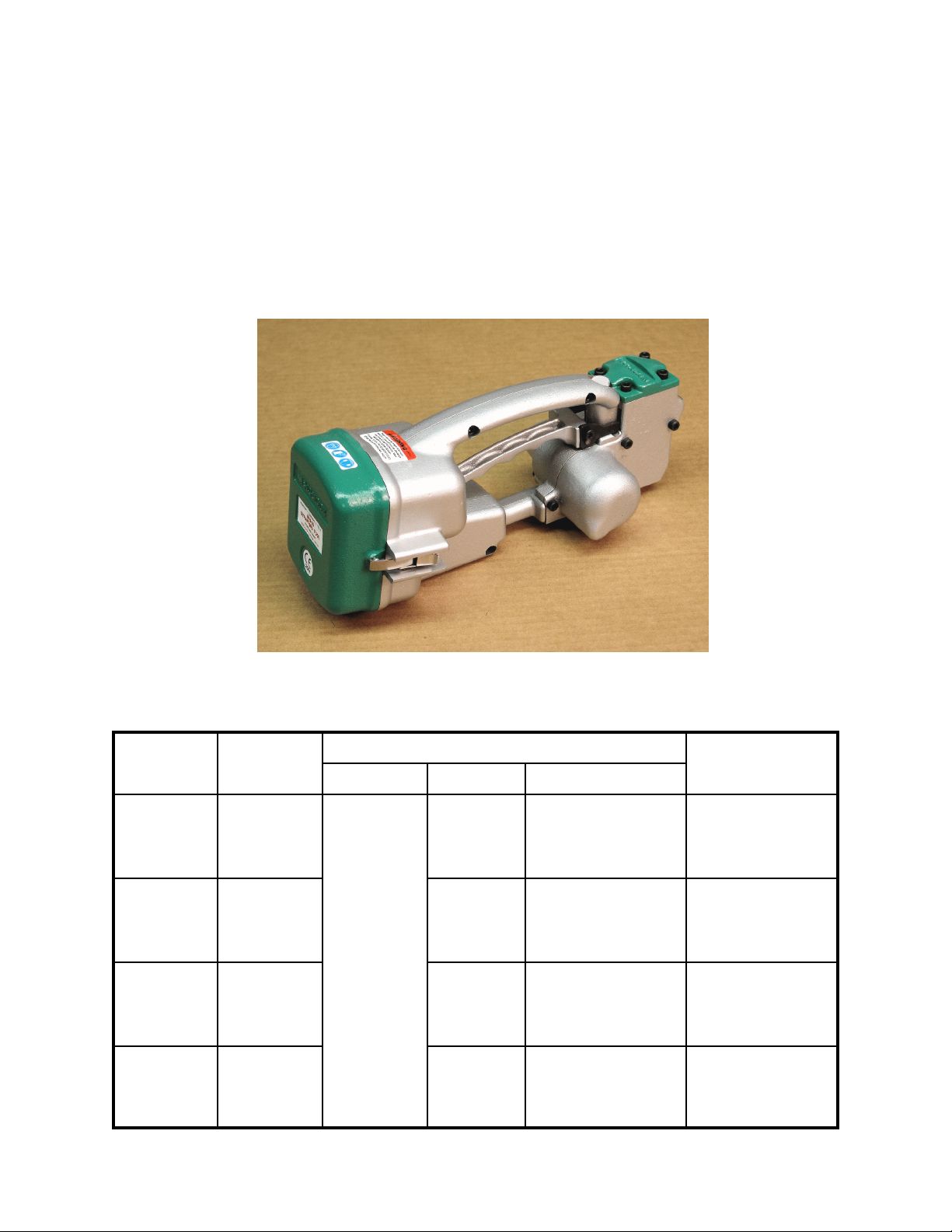

SPECIFICATIONS

MODEL

(110 Volt)

BTS-16

(426500)

BTS-19

(426501)

BTS-25

(426502)

BTS-32

(427140)

MODEL

(220 Volt)

BTS-16

(429516)

BTS-19

(429519)

BTS-25

(429525)

BTS-32

(429532)

STRAP

TYPE WIDTH THICKNESS

16mm

(.629")

19mm

(.748")

High

Strength

Tenax

25mm

(1.000")

32mm

(1.250")

0.030" to 0.044"

(0.76-1.11mm)

0.045" to 0.055"

(1.14-1.40mm)

0.045" to 0.055"

(1.14-1.40mm)

0.040" to 0.050"

(1.00-1.30mm)

RECOMMENDED

TENSIONER

Signode PT-16

Signode PT-19

Signode PT-25

Signode PT-32

4

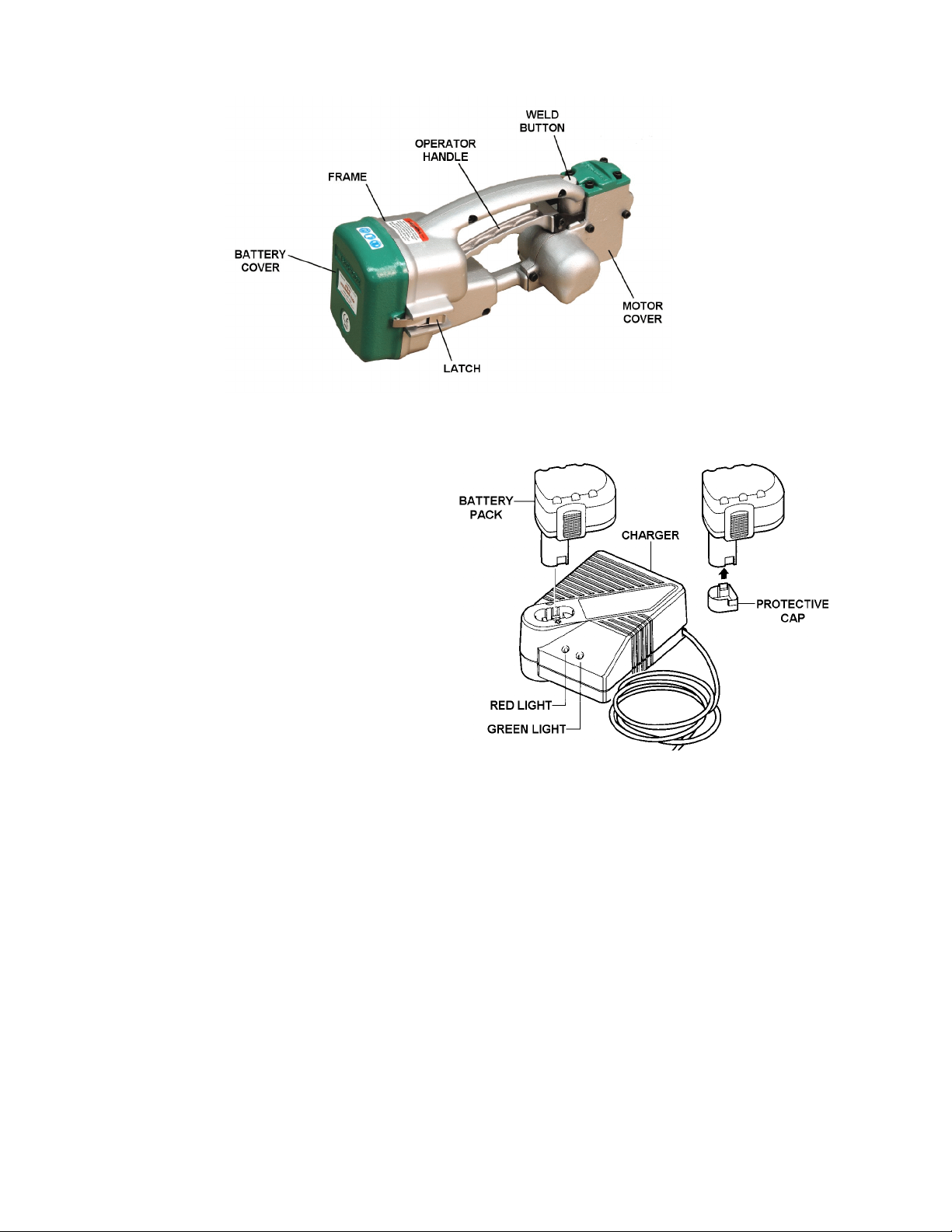

MAJOR COMPONENTS

B

ATTERY INFORMATION

Before attempting to us this tool make sure the

batteries are properly charged. A discharged

battery may result in a poor weld or no weld

condition.

1. The battery pack accepts only about 80% of

its maximum capacity with its first few

charge cycles. However, after the first few

charge cycles, the battery will charge to full

capacity.

2. The charger was designed to fast charge the

battery only when the battery temperature is

between 40/F (4/C) and 105/F (41 OC).

3. A substantial drop in operating time per charge may mean that the battery pack is nearing the end of

its life and should be replaced.

4. If you anticipate long periods (i.e. a month or more) of non-use of your tool, it is best to run your tool

down until it is fully discharged before storing your battery pack. After a long period of storage, the

capacity at first recharge will be lower. Normal capacity will be restored in two or three

charge/discharge cycles. Remember to unplug charger during storage period.

5. If battery does not charge properly:

A. Check for voltage at outlet by plugging in some other electrical device.

B. Check to see if outlet is connected to a light switch which turns power "off"when lights are turned

off.

C. Check battery pack terminals for dirt. Clean with cotton swab and alcohol if necessary.

5

Loading...

Loading...