Signode SCM-12, SCM-58, SCM-34 Operation, Parts And Safety Manual

SCM-12/58/34

MANUAL COMBINATION STRAPPING TOOL

2

READ THESE INSTRUCTIONS CAREFULLY.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN SEVERE PERSONAL INJURY.

GENERAL SAFETY CONSIDERATIONS

1.

STRAP BREAKAGE HAZARD.

Improper operation of the tool or sharp corners on the load can result in

strap breakage during tensioning, which could result in the following:

A sudden loss of balance causing you to fall.

Both tool and strap flying violently towards your face.

Failure to place the strap properly around the load or an unstable or shifted load could result

in a sudden loss of strap tension during tensioning. This could result in a sudden loss of

balance causing you to fall.

Read the tool's operating instructions. If the load corners are sharp use edge protectors.

Place the strap correctly around a properly positioned load.

Positioning yourself in-line with the strap, during tensioning and sealing, can result in

severe personal injury from flying strap or tool. When tensioning or sealing, position

yourself to one side of the strap and keep all bystanders away.

2.

TRAINING.

This tool must not be used by persons not properly trained in its use. Be certain that you

receive proper training from your employer. If you have any questions contact your Signode

Representative.

3.

EYE INJURY HAZARD.

Failure to wear safety glasses with side shields can result in severe eye injury

or blindness. Always wear safety glasses with side shields which conform to

ANSI Standard Z87.1 or EN 166.

4.

FALL HAZARD.

Maintaining improper footing and/or balance when operating the tool can cause you to fall. Do

not use the tool when you are in an awkward position.

5.

CUT HAZARD.

Handling strap or sharp parts could result in cut hands or fingers. Wear protective

gloves.

6.

TOOL CARE.

Take good care of the tool. Inspect and clean it daily, lubricate it weekly and adjust

when necessary. Replace any worn or broken parts.

7.

WORK AREA.

Keep work areas uncluttered and well lighted.

3

8.

OPERATING SEQUENCE.

Use the correct Signode products for your application. If you need help contact your Signode

Representative. Before using this sealless tool, read the Operation and Safety Instructions

contained in this manual.

9.

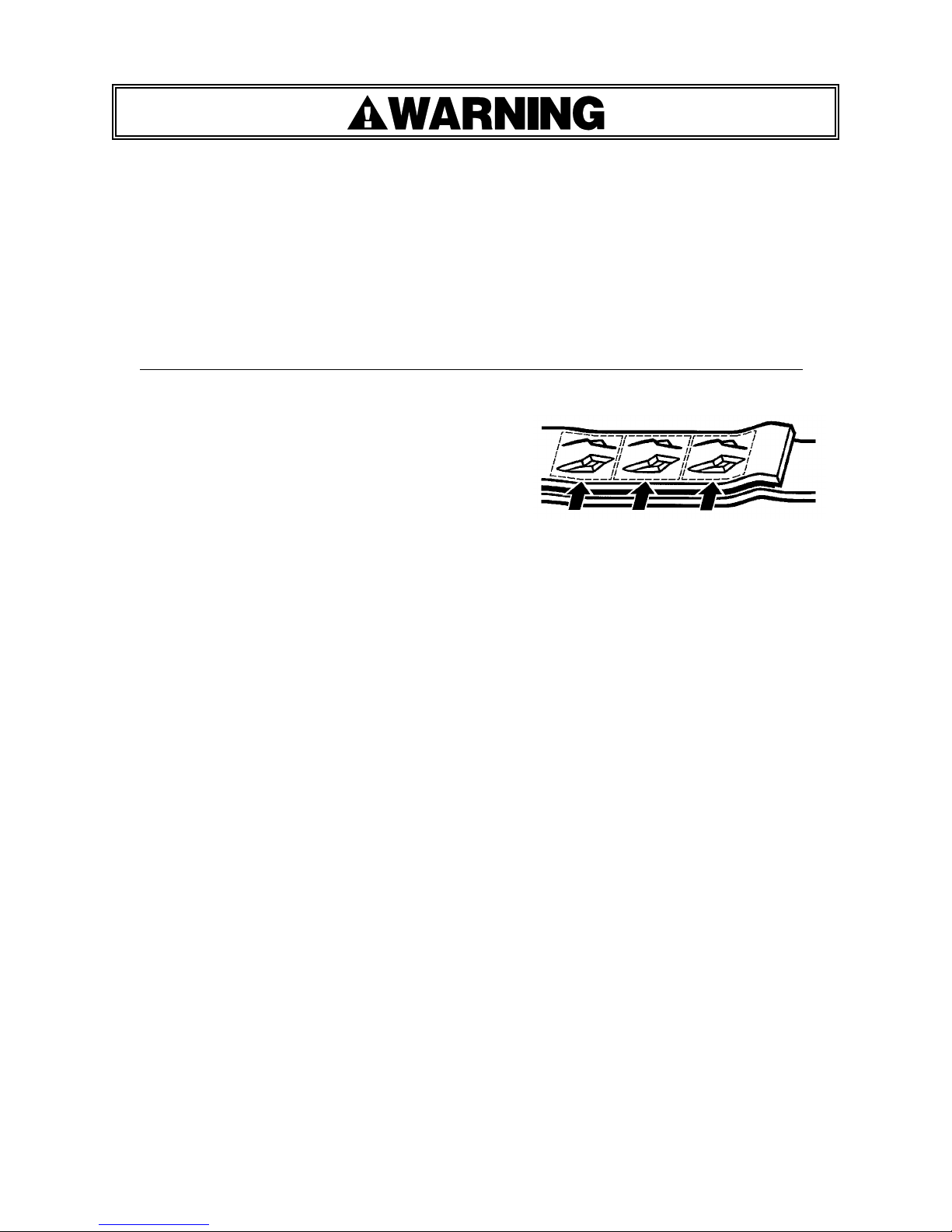

JOINT FORMATION

Sealless joints are formed when overlapping straps are punched simultaneously creating

interlocking keys. However, the integrity of the joint is obtained when the keys punched in the

upper strap move in relation to the keys on the bottom strap, allowing the straps to interlock.

The movement necessary to create the interlock comes from the strap tension release where

the top strap moves one direction and the bottom strap moves in the other direction.

Therefore, never attempt to make a sealless joint without having the straps under tension.

This tool is a punch type sealer. A properly formed joint will appear as shown in the

illustration. If the joint does not appear as shown,

then the operator must proceed as follows:

A.

Ensure that the tool's operating instructions are

being followed before applying another strap.

B.

Ensure that tension has been applied to the

straps before the sealer handle is activated.

Tension is necessary to ensure that the keys fully interlock.

C.

After confirming the above cut the strap off and apply another.

If the joint still does not appear as shown, then inspect the tool for worn and/or damaged

parts. Replace tool parts as needed. NEVER HANDLE OR SHIP ANY LOAD WITH

IMPROPERLY FORMED JOINTS. Misformed joints may not secure the load and could cause

serious injury.

Always tuck the strap end back into the dispenser when not in use.

10.

CUTTING TENSIONED STRAP

Using claw hammers, crowbars, chisels, axes or similar tools can cause tensioned strap to fly

apart with hazardous force. Use only Signode cutters designed for cutting strap such as the

Model CU-30. Read the instructions in the cutter's manual for proper procedure in cutting

strap. Before using any Signode product read its Operation and Safety Manual.

4

Signode

tools

and machines

are designed

and warranted

to

work

toget

her

with

Signode strapping and seals. Use of non-

Signode

strap,

seals

and/or

manufactured

or specified

repla

c

ement

parts

may result

in strap

breakage

or

joint

separation

while

applying

strapping

to a

load

or

during

normal shipping

and handling. This could

result in severe personal injury.

TABLE OF CONTENTS

Page

General Safety Instructions

2

Introduction

4

Specifications

5

Major Components

5

Operating Instructions

6

Strap Joint Formation & Appearance

8

Adjustments

9

Parts List

10

Troubleshooting

13

Changing Strap Sizes

16

Tool Options

18

Declaration Of Conformity

19

INTRODUCTION

The SCM is a light weight, manually operated hand tool intended for use with Apex and Magnus

strapping. The tool is easy to load, tension and seal.

Once the strap has been placed around the package, the operator puts both layers of strap into

the tool, lowers the feed wheel, removes any strap slack and tensions the strap. The keyed

sealless joint is then created and the strap is cut free of the supply.

This manual provides the information necessary for the operation of the SCM hand tool and lists

all of the parts in the event maintenance is needed. Therefore, it is valuable and should be saved.

Extra care should be taken in performing maintenance on the SCM since fasteners and other small

components used on this tool are a combination of SAE and metric sizes.

5

SPECIFICATIONS

TOOL MODEL

STRAP

TYPE

WIDTH

THICKNESS

SCM-12

P/N 424350

Apex

&

Magnus

1/2" (12.7mm)

0.015 - 0.025"

(0.38 - 0.64mm)

SCM-58

P/N 424358

5/8" (15.9mm)

SCM-34

P/N 424334

3/4" (19.1mm)

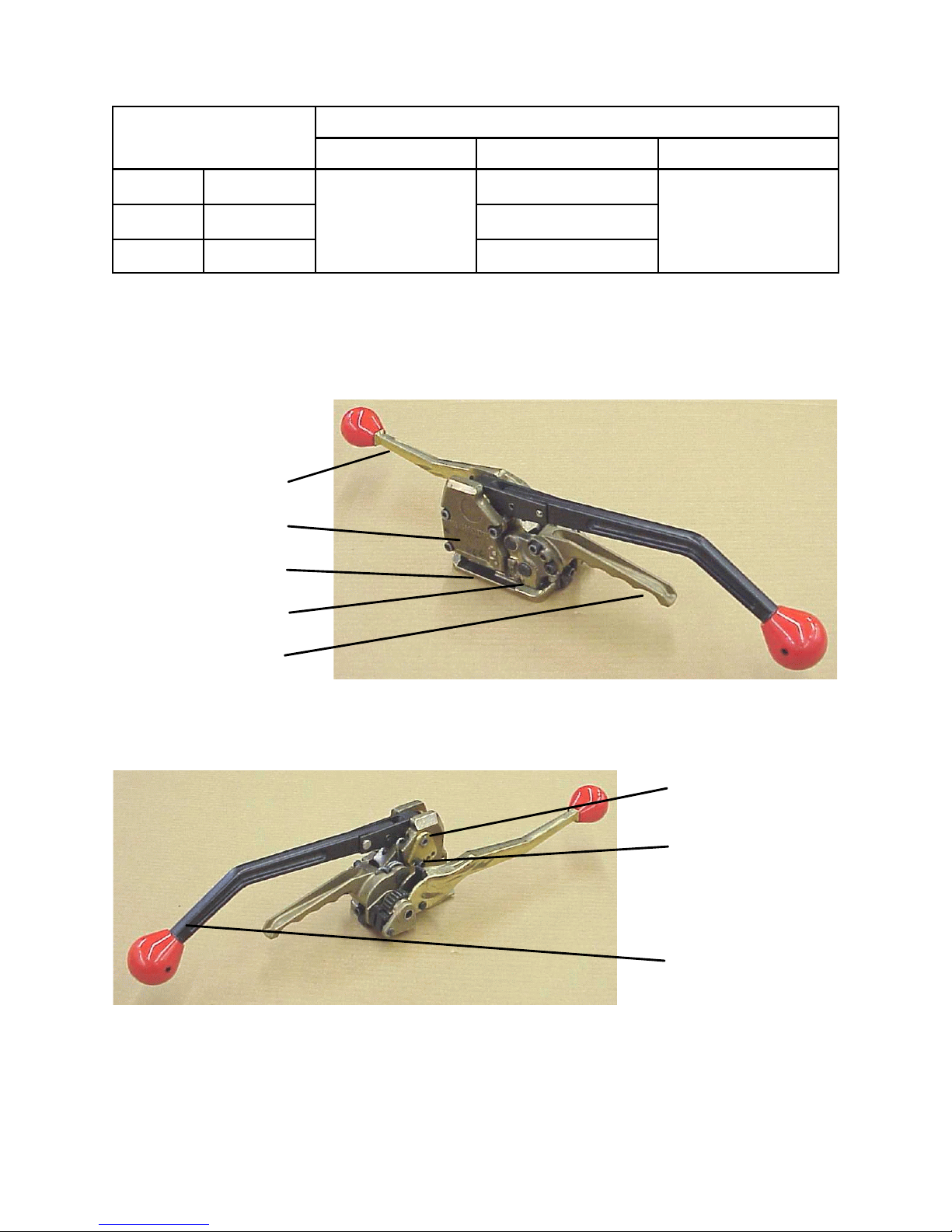

MAJOR COMPONENTS

TENSION HANDLE

SEALER COVER

BASE

FEEDWHEEL COVER

FEEDWHEEL

SUPPORT HANDLE

CUTTER ADJUSTMENT

TENSION RELEASE

SEALER HANDLE

6

OPERATING INSTRUCTIONS

Wear safety glasses. Stand to one side of the strap while tensioning.

Make sure all bystanders are clear before proceeding.

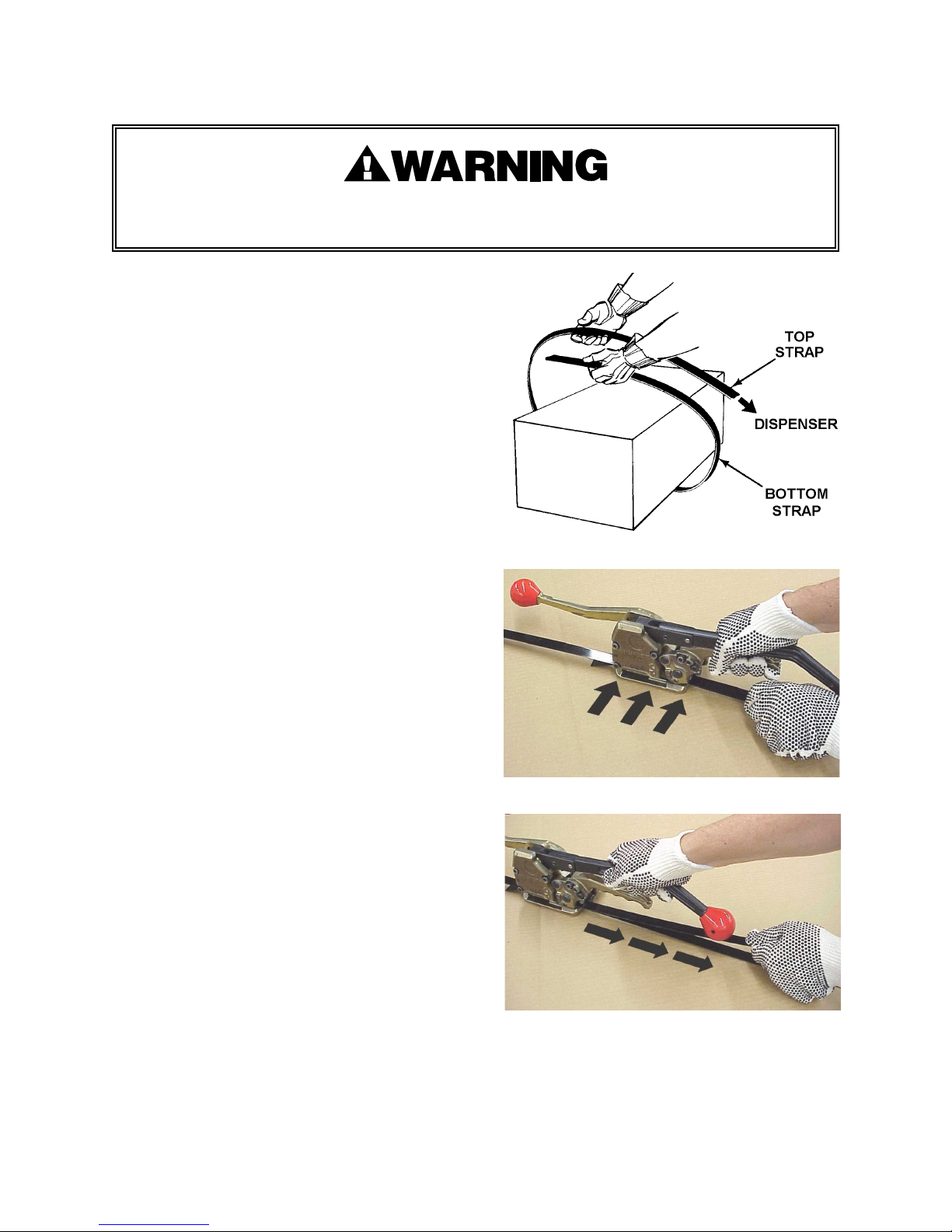

1.

STRAP PREPARATION.

Encircle the package with strap by passing the

loose end over the top and bringing it back

around. This will result in a top strap and a

bottom strap.

2.

TOP AND BOTTOM STRAP INSERTION. Squeeze

the sealer handle and the feedwheel support

handle together with the right hand. With the left

hand, align the top and bottom straps. Then,

with a sideways motion, insert them into the tool,

making sure both straps are fully seated in and

against the front and back strap guides. Note

that both straps must be placed between the

feed wheel and the clutch plug. Make sure the

lead end of the bottom strap extends about 1" to

1 1/2" (25 - 40mm) beyond the front of the tool.

3.

REMOVING SLACK STRAP. After the straps

have been inserted into the tool, release the

feedwheel support handle. With the left hand,

grasp the top strap and pull back on it to

remove slack strap. Pull it snug around the

package. The feed wheel will rotate as the strap

is being pulled back.

Loading...

Loading...